Page 1

2402646

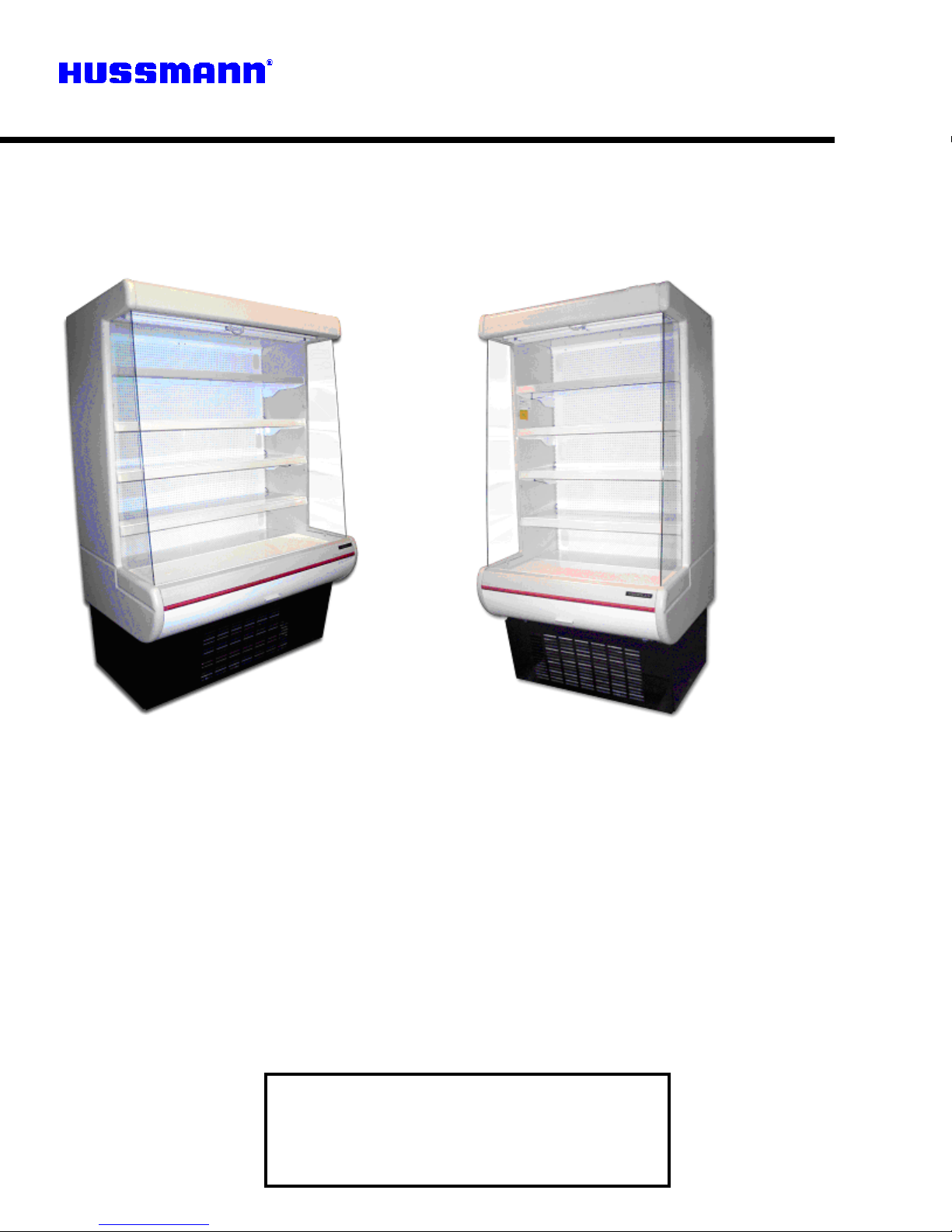

SERIES MD’s

Medium Temperature

Merchandisers

PLEASE READ THIS MANUAL BEFORE USING THE PRODUCT

Installation &

Operation Manual

P/N 2402646A

MD-10, MD-14

Agust 2005

HUSSMANN - CORPORATION

1331 Seamist Drive

Houston TX 77008

Phone (713) 861-9171

Page 2

2402646

TABLE OF CONTENTS PAGE

INTRODUCTION, INSPECTION, LOCATION and CLEARANCE

SKID, LEVELING and SEALING

DRAINS

SERIAL PLATE

AIR DISTRIBUTION and PRODUCT LOADING

POWER REQUIREMENTS

ELECTRICAL BOX, POWER SWITCH, TIME CLOCK

CONNECTIONS

SPECIFICATIONS, DIMENSIONS, BTU CAPACITY

SHELVING, TEMPERATURE CONTROL,

CONDENSING UNIT

THERMOMETER

LIGHTING, LAMP SWITCH, BALLAST

NIGHT COVER, CLEANING EXTERIOR

3

3

3

3

3

3

4

4

4

4

5

5

5

5

CLEANING INTERIOR

REFRIGERATION

LEAK TESTING AND EVACUATION

TROUBLE SHOOTING CHARTS

LIGHTING TROUBLESHOOTING

5

6

6

7

8

REPLACEMENT PARTS INFORMATION 8

WARRANTY. 9

2

Page 3

2402646

INTRODUCTION, INSPECTION, LOCA TION and

CLEARANCE SKID, LEVELING and SEALING and

DRAINS

Hussmann MD model cabinets offer maximum

versatility in the display of medium temperature

prechillded products such as prepared salads,

pizzas, fresh entrees, and dairy products.

INSPECTION

-

Upon receipt of the cabinet, carefully inspect the

crating and equipment for damage. If damage is found,

note on the delivery receipt where and how extensive

the damage before signing.

After removal of the crating, again inspect

the cabinet

for damage. If damage is found, contact the delivering

carrier and request for an inspection and inspection

report be made for the purpose of filing a claim. Save

as much as the crating as possible and move the

cabinet as little as possible until after the inspection.

Once the cabinet has been installed and properly

leveled,

it

should be sealed to the floor as shown in the

following drawing, utilizing a NSF approved material

such as General Electric RTV -102 silicone sealant or

equivalent.

DRAINS

-

Remote draining is not required on self -contained

models. The condensate water from the evaporator

drains out through the bottom of the cabinet, through a

hose trap located to the underside of the condensing

unit area, into an electrically heated condensate pan.

Until the trap gets filled with water; there may be a small

frost accumulation in the evaporator coil area. This frost

should disappear after the trap gets filled with water;

usually after the first defrost. The drains for the

condensate water are located in the front corners of the

evaporator coil area. These drains must be kept clear to

ensure proper drainage of the condensate water.

THIS IS YOUR RESPONSABILITY

LOCATION and CLEARANCE

-

It is very important that careful consideration be given to

the cabinet location in the store where direct sunlight

would shine into the cabinet, and locations where drafts

from air conditioning, open doors, and fans would blow

directly into the cabinet should be avoided.

The MD cabinets have front air intake and rear air

discharge for proper airflow over the condensing unit. A

minimum distance of two feet must be left open in front

of the cabinet so that air intake to the condensing unit is

not obstructed.

In addition, a minimum of five inches clearance behind

the case and eighteen inches above the case is

required to allow for proper discharge air flowing over

the condensing unit.

SKID-

The shipping skid should be left on the cabinet until it is

near its selected location in the store. The skid provides

protection for both the cabinet and floor. The skid can be

removed by backing out the screws that are run through

the front and rear base rails into the skid. Once these

screws are removed, the cabinet may be slid carefully

off the skid.

LEVELING

-

The cabinet must be properly leveled to ensure full

drainage of the water produced during the off and

defrost cycles. Level the cabinet from front to rear and

end-to-end.

SEALING

-

SERIAL PLATE-

The serial plate is located on the interior left hand end. It

contains all pertinent information such as model, cabinet

serial number, refrigerant type and amount etc. The

information on this plate is very helpful when servicing or

ordering replacement parts. This plate should never be

altered or removed for any reason

AIR DISTRIBUTION and PRODUCT LOADING

This cabinet has a forced-air circulation system. Air flows

through the perforations in the back wall over the

product on the shelves, as well as out the baffles located

above the product, across the face of the product and

into the return air grill.

WHEN LOADING THE PRODUCT DO NOT

PLACE IT SO THAT IT EXTENDS OVER THE

SHELF EDGES OR OVER THE RETURN AIR

GRILL. IT IS ALSO IMPORTANT NOT TO

PLACE THE PRODUCT TIGHT AGAINST THE

BACK PANEL. THIS WILL RESTRICT AIR

FROM FLOWING OUT OF THE

PERFORATIONS AND OVER THE PRODUCT.

POWER REQUIREMENTS

-

The MD-10 and MD-14 Comes equipped with a 15A

power cord, Under no circumstances should the

grounding prong on the cords be removed.

It is very important for the safety of both you and your

customer to have each circuit properly grounded. A

qualified electrician should perform all wiring in

accordance with the National Electrical Code and/or all

3

Page 4

2402646

local codes. Separate circuits are recommended for

MODEL Length Width Height

each cabinet in order to prevent product loss due circuit

overloading of malfunction of other equipment, which

may be on the same circuit. For proper operation of the

equipment, voltage measured at the compressor must

not vary more that 5 % from the cabinet serial plate

rating.

If either high or low voltage condition exists, contact your

electrician or local power company. If service or

maintenance is being performed on the cabinet, make

MD-10 39" 33" 5/8 77"

MD-14 52" 33" 5/8 77"

ELECTRICAL

MODEL Refrg. Run Fuse

MD-10 R-134A 10.3 15

25.50oz.

sure the power supply to the cabinet is off before

proceeding.

MD-14 R-134A 9.5 15

30.25 oz.

ELECTRICAL BOX

-

The electrical box is located behind the front access

MODEL BTU/HR EVAP COND AMB

BTU CAPACITY

panel. Access to this box is gained by removing this

panel.

The box contains the power switch and contactor.

Power to the cabinet should be disconnected before any

service is performed on this box.

MD-10 4635 20 130 75-80

MD-14

6430

20

130

75-80

SHELVING-

The MD models come equipped with four shelves. They

POWER SWITCH

are adjustable on one inch increments. When loading

the shelves with product, they should be loaded so that

The main power switch is located in the electrical box.

This switch controls all power to the case. This switch

must be in the off position before starting any cleaning or

service work on the equipment.

CONNECTIONS

-

Check all electrical and refrigeration connections

thoroughly for tightness. Make sure the refrigeration

tubing is not rubbing or chafing against itself or other

components. Electrical connections should be tight.

Condenser fan motor blades should spin freely without

hitting anything. Install all protective covers, start the

cabinet and allow to pull down to temperature before

loading.

SPECIFICA TIONS - DIMENSIONS

the product does not extend over the front edge of the

shelf. Product loaded over the edge will interfere with air

circulation in the cabinet. It is also desirable to leave a

small space between the rear interior wall and the

product on the shelves to allow air to enter the cabinet

interior through the perforations in the rear wall.

The shelves are rated for 130 pounds each load

capacity. When installing the shelves, first install the

shelf support bracket at the sired height. Place the rear

of the bracket in the desired slot. Raise the front of the

bracket towards the rear of the cabinet. Once the ends

are in the slot, rotate the bracket forward locking it in

place. Place the shelf on the bracket. Load the product.

The shelves are not to be slanted. They must remain in

a horizontal position.

TEMPERATURE CONTROL

-

4

Page 5

2402646

Safe Net

bulb located under the top header. The bulb is sleeved

to maintain proper heat around the bulb for maximum

light intensity and to protect the product in case of

breakage. The bulb can be replaced without removing

shelves or product .To replace the bulb, twist the bulb

and slide the prongs clear of the lamp holder. Remove

the shield from the old bulb and put it on the new bulb.

When placing the bulb back in the holders, make sure

the prongs on the bulb twist and lock into place.

LAMP WITCH -

The lamp switch is located on the right hand end of the

upper header near the lamp. This switch controls the

lamp only. Before replacing a bulb or ballast, make sure

power to the cabinet is disconnected.

BALLAST -

The ballast is located on the top interior of the cabinet

near the center of the cabinet. Access to the ballast is

gained by removing the two screws, (one on each end)

of the lamp fixture. Rotate the fixture down towards the

bottom of the cabinet.

CONDENSING UNIT-

A regular program should be established for cleaning

the fin and tube condenser. Normally this cleaning is

required every 1-2 months, but individual store

conditions may dictate otherwise. A clean condenser

increases cabinet efficiency and extends compressor

life.

NIGHT COVER-

All MD models come equipped with a night cover as a

standard feature .The handle for the cover is located

near the lamp, grasp the handle and pull downward until

enough of the cover has been exposed allowing the

handle to be placed over the retainer located on the

lower panel. In the event a night cover has to be

replaced, follow these steps: disconnect power to the

cabinet. On the top exterior of the cabinet, there is a

perforated metal cover. Remove the cover. Lower the

lamp fixture as if you were replacing the ballast. Lift the

left retainer Pull the night cover toward you and slid to

left. Install the new cover in reverse order. Torn power

back on.

Access to the condenser is gained by removing the

front access panel. Power should be disconnected to

the cabinet before removing this panel. Slide the

condensing unit forward. Clean the surface of the fins

with a vacuum or soft brush. Do not use hard or sharp

objects as damage to the fins and tubing may occur.

Compressed air maybe used. However, proper safety

precautions should be observed. After cleaning,

carefully push the condensing unit back in making slure

not to kink or pinch any tubing or wires. Also make sure

the tubing and wires are not rubbing on any other

components. Make sure all drain hoses are back in the

proper places before replacing front access cover.

THERMOMETER –

The thermometer reading is in C°/ F°, is located next to

discharge in the middle of the case

LIGHTING -

Interior lighting is provided by a cool white fluorescent

CLEANING EXTERIOR When cleaning the exterior of the cabinet, use a soft

cloth or sponge with water and a mild detergent. Do

not use any thing abrasive, as this will mar the finish.

Clean the glass with a glass cleaner of your choice.

CLEANING INTERIOR-

Disconned fue power and remove all product. Allow the

cabinet to warm to room temperature. Remove the front

access panel and monitor the amount of water going

into the condensate pan. It may be necessary to

remove some water so the pan does not overflow. Use

soft cloth or sponge with a mild detergent to clean the

interior. Check the drain to ensure no debris has

become lodged in it during cleaning. Make sure the

drain hose(s) are into the condensate pan, set timer for

correct time of day, install removed covers. Wipe

interior dry and restart cabinet. Allow cabinet to achieve

5

Page 6

2402646

proper operating temperature before reloading product.

REFRIGERATION -

The MD models employ a refrigeration system using a

hermetic compressor, with refrigerant flow being

controlled through the use of a capillary tube. In the

event the capillary tube may become partially or fully

restricted, replace the entire tube. Do not attempt to cut

and/or splice the tube. Capillary tube sizes are:

MD-10 .064 I.D. x 115 inches.

MD-14 .076 I.D. x 118.50 inches.

LEAK TESTING-

The test gas cylinder must be equipped with a pressure

gauge and regulator so that system test pressures do

not exceed maximum allowable limits. Do not ever use

anything other than a R-22/Nitrogen mixture for leak

testing.

Attach a refrigerant test gas cylinder to your service

manifold and connect the manifold to the charging port

on the liquid line valve.

Charge an R-22/Nitrogen mixture into the system,

raising the pressure to the unit's nameplate for the low

side and high side pressures. Using an electronic

detector, carefully check the entire system for leaks.

Take special care to inspect all brazed and flare

connections.

EVACUATION –

After the system is proven leak tight, thoroughly

evacuate the system according to the following

procedure:

Discharge the refrigerant-nitrogen mixture, allowing it to

blow from the system as rapidly as possible, into any

empty cylinder. Be sure that all service valves are open

to allow all of the mixture to be discharged.

Connect a deep-drain vacuum pump to both the high

and low side of the system. Pull a vacuum on the

system to at least 1500 microns.

Break the vacuum by adding refrigerant into the system

until the pressure is above 0 psig. Always charge the

refrigerant line into the system through a new drier in the

charging manifold line. A 16 cubic inch drier is sufficient

for this purpose.

Repeat steps 2 and 3 two more times, the third time

evacuating the system to 500 microns.

6

Page 7

2402646

TROUBLE SHOOTING CHARTS

TROUBLE

PROBABLE CAUSE SOLUTION

Compressor will not start no

noise

Compressor will not start, cuts

out on overload

Warm storage temperature

1. Power disconnected 1. Check service cord or

2. Blown fuse or breaker 2. Replace fuse or reset

3. Defective or broken wiring 3. Repair or replace

4. Defective overload 4. Replace

5. Defective temperature

control

1. Low voltage 1. Check voltages at cabinet,

2. Defective compressor 2. Replace

3. Defective relay 3. Replace

4. Restriction (pinched cap

tube)

5. Restriction (moisture) 5. Leak check, replace drier

6. Condenser blocked with

dust and dirt

7. Defective condenser fan

motor

wiring connection.

breaker

5. Replace

should not be more than 5%

below rating.

4. Repair or replace

evacuate and recharge

6. Clean condenser

7. Replace

Compressor runs

continuously. Product too

warm

Compressor runs

continuously. Product too cold

1. Short of refrigerant 1. Leak check, replace drier

evacuate and recharge

2. Cabinet location too warm 2. Move to cooler location or

correct excessive heat source.

3. Refrigerant overcharge 3. Purge system, evacuate and

recharge.

4. Low voltage, compressor

cycling on overload

1. Short of refrigerant 1. Leak check, replace drier,

2. Inefficient compressor 2. Replace

1. Defective control 1. Replace

2. Short on refrigerant 2. Leak check, replace drier,

4. Check voltage at

compressor should not be

more than 5% below rating

evacuate and recharge

evacuate and recharge.

7

Page 8

2402646

TROUBLE SHOOTING LIGHT CHART

PROBLEM SOLUTION

Lights won’t start 1. Check light switch

2. Check continuity to ballast

3. Check to see if bulbs inserted properly in

sockets

4. Check voltage

Lights flicker 1. Allow lamps to warm up

2. Check lamp sleeve for cracks

3. Check sockets for moisture and proper contact

4. Bulb replacement may be necessary

5. Check voltage

6. New bulbs tend to flicker until used

Ballast Hums 1. Check voltage

REPLACEMENT PARTS INFORMATION

2. Replace ballast

IMPORTANT - Please read carefully to assure prompt and accurate service.

ORDERING PARTS REPLACEMENT-

Contact your nearest Hussmann Distributor.

Always specify model and serial number of cabinet.

If correct part number is not know, give a clear description of part itself and its function in the cabinet or remote

unit

Same as first three items in Ordering Replacement Parts Procedure.

Give original installation date of cabinet and, if possible, forward a copy of the original invoice or delivery receipt.

All shipments of in warranty replacement parts will be invoiced from the factory until such time as the defective

part is returned and proved to be defective by our Quality Control Department.

Contact your Hussmann Distributor for instructions on returning in-warranty parts.

Warranty parts must be returned to the factory within 30 days of date of failure to assure proper disposition.

Lack of any of the above information may result in the shipment of the wrong part, or a relay in shipment.

8

Page 9

2402646

SERIES MD’S

LIMITED WARRANTY

This warranty is made to the original purchaser-user and is NOT TRANSFERABLE.

WARRANTIES:

FIRST YEAR:

Hussmann Corporation warrants new Hussmann equipment and all parts there of to be free from defects in material and workmanship at the time of

purchase.

Hussmann's obligation under this warranty shall be limited to repairing or exchanging, at its option, any part or parts, without change F.O.B. factory or nearest authorized

parts depot, which may prove defective within one year from date of original installation (not to exceed fifteen (15) months from date of shipment from the factory), and which

is proven to the satisfaction of Hussmann to be thus defective.

ADITIONAL FOUR YEARS:

Hussmann agrees to repair or replace at its option, Hussmann equipment determined through its inspection to have an inherent foam insulation failure

or refrigerant leak within such insulation area for period of live (5) years from date of factory shipment. In addition, Hussmann agrees to repair or

exchange, at its option, the original Motor Compressor Unit only with a compressor of like or of similar design and capacity if it is shown to the

satisfaction of Hussmann that the Motor Compressor is inoperative due defects in factory workmanship or material under normal use and service as

outlined in Hussmann's "Installation Instructions" which are shipped inside new Hussmann equipment. Hussmann's sole obligation under this warranty

shall be limited to a period not to exceed five (5) years from date of factory shipment. The term "Motor Compressor Unit" does not include electric

controls; such as relays, capacitors, pressure controls, or fan motor assembly, condenser, receiver, etc. The warranty does not include any equipment

to which the Motor Compressor Unit is connected such as cooling coils, temperature controls, refrigerant metering devices, etc.

The warranties to repair or replace above recited, are the only warranties, expressed, implied, or statutory, made by Hussmann with respect to

Hussmann equipment. Hussmann makes no express or implied warranties as to merchantability or fitness for a particular purpose or use.

Hussmann neither assumes, not authorizes any person to assume for it, any other obligation or liability on connection with the sale of said equipment or

any part thereof.

EXCLUSIONS_

1. There is NO warranty against breakage of glass.

2. THIS WARRANTY SHALL NOT APPLY TO LOSS OF FOOD OR CONTENTS OF THIS EQUIPMENT DUE TO FAILURE FOR ANY REASON. 3.

Hussmann Corporation SHALL NOT BE LIABLE:

A) For any repairs or replacements made by buyer without the written consent of Hussmann or when equipment is installed or operated in a manner contrary to the printed

instructions covering installation and service which accompanied.

B) For any damage, delays, or losses, direct or consequential, caused by defects, nor for damage caused by shortages or reduced supply of material, fire, flood, strikes, acts

of God, or circumstances beyond its control.

C) When the failure or defect of the equipment or of any part or parts is incident to ordinary wear, accident (including accident occurring in transit), abuse or misuse; or when

the serial number of the equipment has been removed, defaced, altered, or tampered with.

D) When this equipment is operated on low or improper voltage, or is put to a use other than normally recommended by Hussmann, such as remoting self-contained

equipment.

E) Toward payment of any removal or installation charges of warranted parts and equipment or for transportation charges in connection therewith.

December,1997.

Hussmann Corporation

HUSSMANN-CORPORATION

1331 Seamist Drive

Houston TX 77008

Phone (713)861-9171

9

Loading...

Loading...