Hussmann HGM-3 BS, HGM-2 BS, HGM-1 TS, HGM-2 TS, HGM-3 TS Installation & Operation Manual

HGM-1, 2 & 3 BS, TS

®

Bottom / Top Mount

Medium Temperature

Remote and Self Contained

Glass Door Merchandisers

HGM-3BS HGM-2TS

IMPORTANT

Keep in store

for future reference!

MANUAL - I/O SELF CONTAINED HGM

Installation &

Operation Manual

P/N 0515297_E

June 2015

Spanish 0531289

French 0531290

P/N 0515297_E iii

AT TENTION

Merchandiser must operate for 24 hours

before loading product!

Regularly check merchandiser temperatures.

Do not break the cold chain. Keep products

in cooler before loading into merchandiser.

These merchandisers are designed

for only pre-fozen products.

IMPORTANT

KEEP IN STORE FOR FUTURE REFERENCE

Quality that sets industry standards!

12999 St. Charles Rock Road • Bridgeton, MO 63044-2483

U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900

www.hussmann.com

© 2015 Hussmann Corporation

TABLE OF CONTENTS v

ANSI DEFINITIONS ................. vi

INSTALLATION

Certification ........................ 1-1

Hussmann Product Control ........... 1-1

Shipping Damage ................... 1-1

Location ........................... 1-1

Self Contained (Location) ............. 1-2

Model Description .................. 1-4

Unloading ......................... 1-4

Exterior Loading .................... 1-4

Shipping Skid ...................... 1-4

Merchandiser Leveling ............... 1-5

Leg Installation ..................... 1-5

Serial Plate Location ................. 1-5

Refrigeration Unit Access ............. 1-6

Sealing Merchandiser to Floor ......... 1-5

Air Distribution & Rear Flue Spacer .... 1-6

Shelves ............................ 1-6

ELECTRICAL / REFRIGERATION

Manual Defrost ..................... 3-6

Temperature Adjustment ............. 3-7

Sensor to Control Configuration ....... 3-8

Lighting ........................... 3-9

LED Lights ........................ 3-9

Door Defrost Heater Thermostat ....... 3-9

Controls and Adjustments ........... 3-10

Refrigerant Control ................. 3-10

Load Limits ....................... 3-11

Stocking .......................... 3-11

NOTES: .......................... 3-12

MAINTENANCE

Care and Cleaning ................... 4-1

Exterior Surfaces .......................... 4-1

Interior Surfaces .......................... 4-1

Do NOT Use: ...................... 4-1

Do: ............................... 4-1

Cleaning Stainless Steel Surfaces ....... 4-2

Cleaning Coils ...................... 4-2

Cleaning Evaporation Pan ............ 4-3

NOTES: ........................... 4-4

Merchandiser Electrical Data .......... 2-1

Field Wiring ........................ 2-1

Electrical Connections . . . . . . . . . . . . . . . . 2-1

Electrical Outlet ..................... 2-1

Refrigeration (Self Contained) .......... 2-1

Line Sizing (Remote Models) .......... 2-2

Oil Traps ................................ 2-2

Pressure Drop ............................ 2-2

Water Outlet and Water Seal .......... 2-2

START UP / OPERATION

Start-Up ........................... 3-1

Operation .......................... 3-1

Power Switch ............................. 3-1

Light Switch ............................. 3-1

Electromechanical Control .................. 3-1

Safe NET III User Instructions ........ 3-2

Start-Up ........................... 3-3

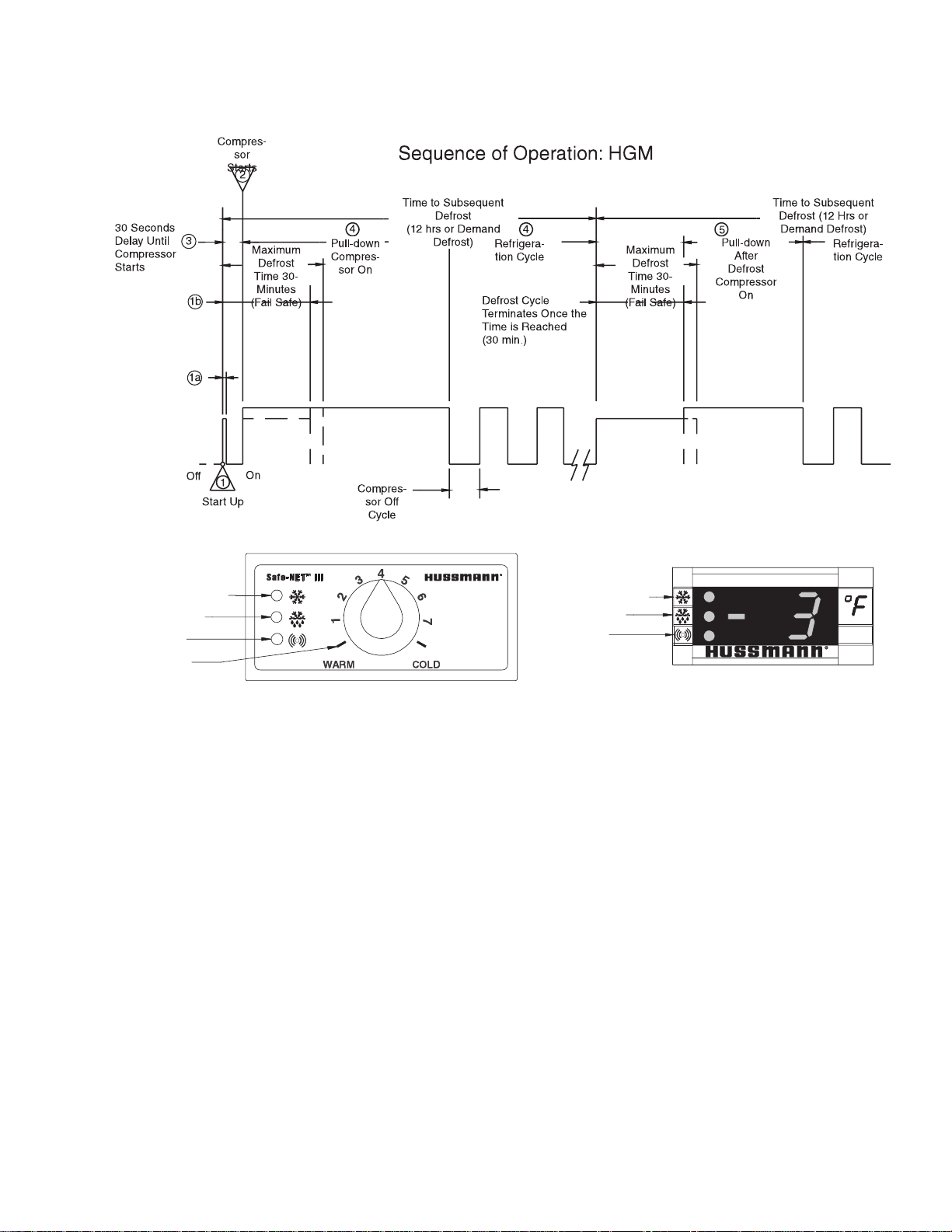

Sequence of Operation ............... 3-5

Temperature Adjustment ............. 3-6

Alarms and Codes ................... 3-6

Defrost Termination Switch ........... 3-6

SERVICE

Replacing Fan Motors and Blades ...... 5-1

Replacing Thermometer .............. 5-1

Trouble Shooting Guide .............. 5-2

Replacing door parts ................. 5-3

Servicing led lighting ................. 5-3

Servicing flourescent lighting ........... 5-3

Replacement parts ................... 5-4

APPENDIX

Part Numbers ..................... A-1

HGM-1BS — Plan View ............. A-2

HGM-2BS & HGM-2BS — Plan View .. A-3

HGM-1TS — Plan View ............. A-4

HGM-2TS — Plan View ............. A-5

HGM-3TS — Plan View ............. A-6

Dimensions & Electrical Data ........ A-7

Cross Sections and Refrigeration Data .. A-8

Wiring Diagram — Remote .......... A-9

WARRANTY

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGM Merchandisers

vi

REVISION HISTORY

REVISION E — Changed value of amps to

12.6, HGM-3BS TS Wiring Diagram, Page

A-10

REVISION D — California Warning, Page

1-2, HGM-2BS location, Page 1-3

REVISION C — Changed NEMA plug, New

Parts List, Updated Wiring Diagrams

REVISION B — Changed fonts and replaced

revision level to B for Wind Chill

ORIGINAL ISSUE — JANUARY 2011

* * * * * * * * * * * * * * * * * * * * * * * * * *

ANSI Z535.5 DEFINITIONS

• DANGER – Indicate[s] a hazardous

situation which, if not avoided, will

result in death or serious injury.

• WARNING – Indicate[s] a hazardous

situation which, if not avoided, could

result in death or serious injury.

• CAUTION – Indicate[s] a hazardous

situation which, if not avoided, could

result in minor or moderate injury.

• NOTICE – Not related to personal injury –

Indicates[s] situations, which if not avoided,

could result in damage to equipment.

P/N 0515297_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

P/N 0515297_E 1-1

INSTALLATION

CERTIFICATION

These merchandisers are manufactured to

meet ANSI / National Sanitation Foundation

®

(NSF

) Standard #7 requirements. Proper

installation is required to maintain certification.

Near the serial plate, each case carries a label

identifying the type of application for which

the case was certified.

ANSI/NSF-7 Type I - Display Refrigerator / Freezer

Intended for 75°F / 55% RH Ambient Application

ANSI/NSF-7 Type II - Display Refrigerator / Freezer

Intended for 80°F / 55% RH Ambient Application

ANSI/NSF-7 - Display Refrigerator

Intended for Bulk Produce

HUSSMANN PRODUCT CONTROL

The serial number and shipping date of all

equipment is recorded in Hussmann’s files

for warranty and replacement part purposes.

All correspondence pertaining to warranty or

parts ordering must include the serial number

of each piece of equipment involved. This is

to ensure the customer is provided with the

correct parts.

Apparent Loss or Damage

If there is an obvious loss or damage, it must

be noted on the freight bill or express receipt

and signed by the carrier’s agent; otherwise,

carrier may refuse claim.

Concealed Loss or Damage

When loss or damage is not apparent until

after equipment is uncrated, retain all packing

materials and submit a written response to the

carrier for inspection within 15 days.

LOCATION

These merchandisers are designed for

displaying products in air conditioned stores

where temperature is maintained at or below

the ANSI / NSF-7 specified level and relative

humidity is maintained at or below 55%.

Recommended operating ambient

temperature is between

65°F (18°C) to 75°F (23.9°C).

Maximum relative humidity is 55%.

SHIPPING DAMAGE

All equipment should be thoroughly examined

for shipping damage before and during

unloading. This equipment has been carefully

inspected at our factory. Any claim for loss or

damage must be made to the carrier. The

carrier will provide any necessary inspection

reports and/or claim forms.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Placing refrigerated merchandisers in direct

sunlight, near hot tables or near other heat

sources could impair their efficiency. Like

other merchandisers, these merchandisers are

sensitive to air disturbances. Air currents

passing around merchandisers will seriously

impair their operation. Do NOT allow air

conditioning, electric fans, open doors or

windows, etc. to create air currents around the

merchandiser.

HGM Merchandisers

1-2 InstallatIon

For California Businesses:

This product may contain chemicals known

to the State of California to cause cancer,

birth defects, or other reproductive harm.

This warning is the result of the California State

law known as the California Safe Drinking Water

and Toxic Enforcement Act of 1986, which is

commonly referred to as “Proposition 65.”

SELF CONTAINED (LOCATION)

Product should always be maintained at

proper

temperature. This means that from the time

the product is received, through storage,

preparation and display. The temperature of the

product must be controlled to maximize the life

of the product.

This warning does not mean that Hussmann

products will cause cancer or reproductive

harm, or is in violation of any product-safety

standards or requirements. As claried by the

California State government, Proposition 65

can be considered more of a ‘right to know’ law

than a pure product safety law. When used as

designed, Hussmann believes that our products

are not harmful. We provide the Proposition 65

warning to stay in compliance with California

State law. It is your responsibility to provide

accurate Proposition 65 warning labels to your

customers when necessary. For more information

on Proposition 65, please visit the California

State government website.

Be sure to position self contained

merchandisers properly.

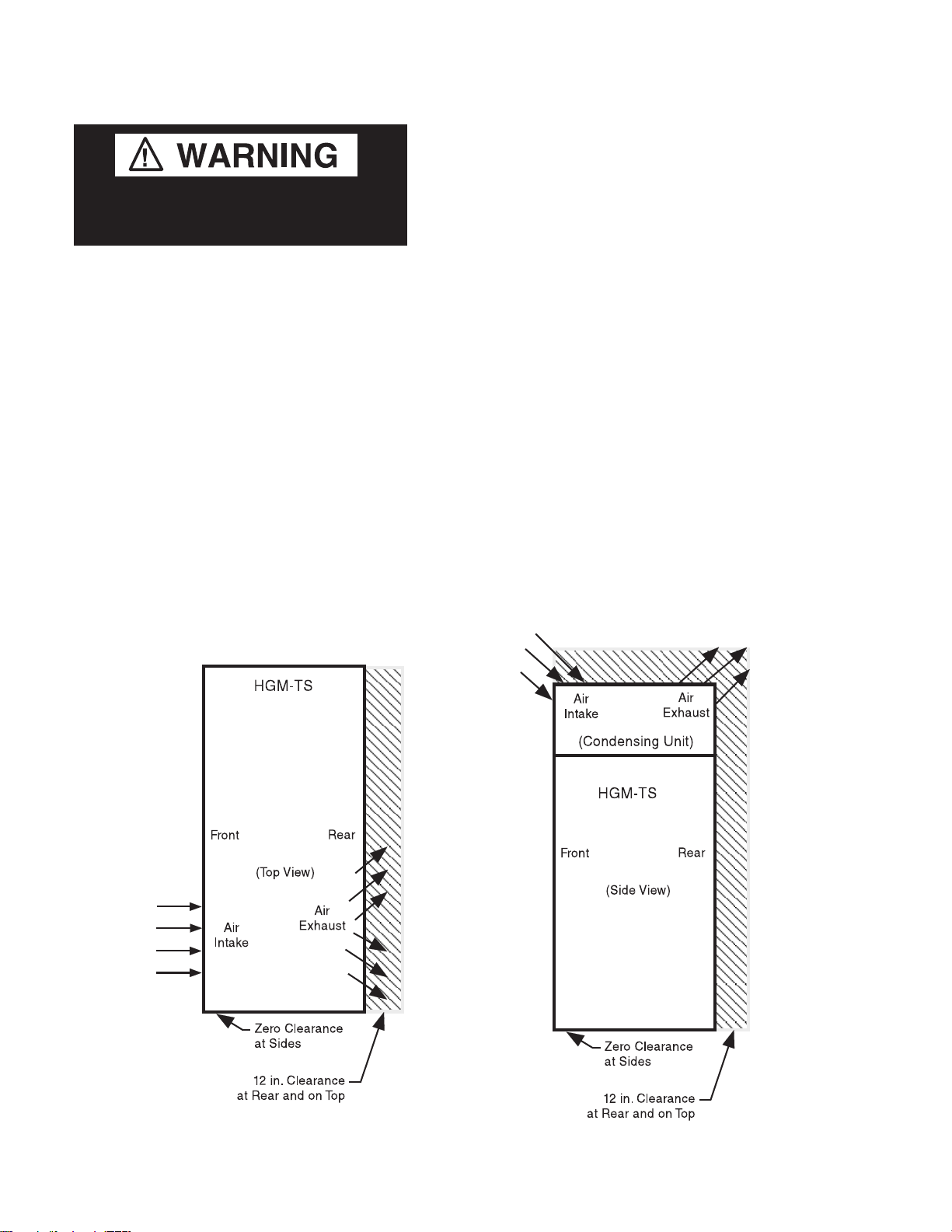

HGM-TS Location

The condensing unit is located at the top of

the HGM-TS. At least 12 inches of clearance

should be allowed at the rear of the cabinet and

at the top of the merchandiser. This clearance is

necessary to provide free air movement to and

from the condensing unit for maximum

operating efficiency.

P/N 0515297_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

P/N 0515297_E 1-3

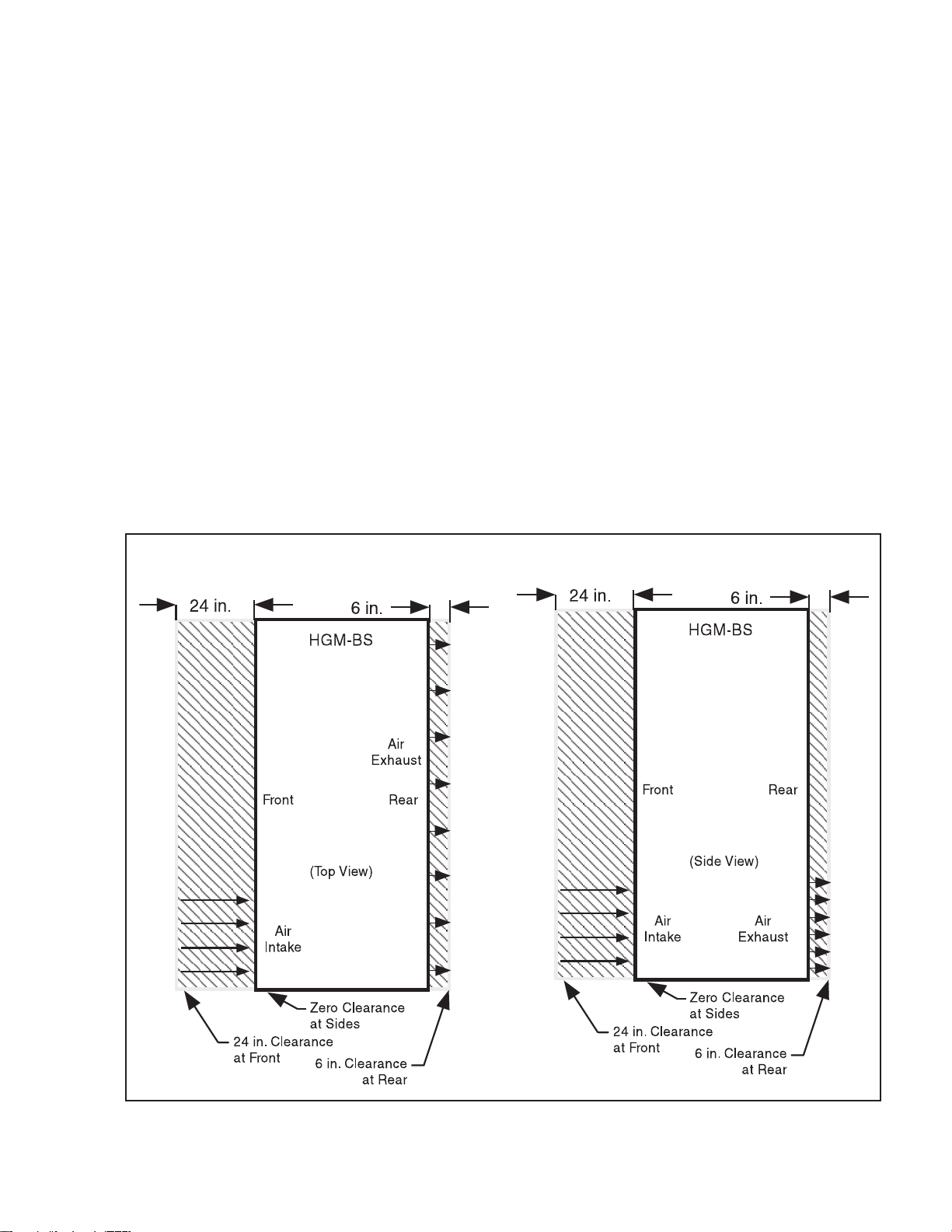

HGM-BS Location

At least 24 inches of clearance should be

maintained in front of HGM-BS merchandisers

and 6 inches of clearance at the rear to provide

the necessary free air movement to and from

the condensing unit. The condensing unit is

located at the bottom of these merchandiser.

HGM-2BS merchandisers require the same

clearance space, but the air flow is different

as shown in the illustration at right. Avoid

installing 1-door merchandisers on the left side

of the case.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGM Merchandisers

1-4 InstallatIon

MODEL DESCRIPTION

The HGM-BS/TS models are self-contained,

medium temperature, vertical glass door

merchandisers designed for the display of dairy

products, deli items and beverages. Design

features include self-closing glass doors,

efficient foamed in place non-CFC insulation

and balanced R-134a refrigeration systems for

energy saving performance.

UNLOADING

Unloading from Trailer:

Lever Bar (also known as a Mule, Johnson

Bar, J-bar, Lever Dolly, or Pry Lever)

Move the merchandiser as close as possible to

its permanent location and remove all packaging.

Check for damage before discarding packaging.

Remove all separately packed accessories such

as kits and shelves.

Improper handling may cause damage to

the merchandiser when unloading. To avoid

damage:

1. Do not drag the merchandiser out of the

trailer. Use a Johnson bar (mule).

2. Use a forklift or dolly to remove the

merchandiser from the trailer.

EXTERIOR LOADING

Do NOT walk on top of merchandisers or

damage to the merchandisers and serious

personal injury could occur.

merchandisers are not structurally

designed to support excessive external

loading such as the weight of a person. Do

not place heavy objects on the merchandiser.

SHIPPING SKID

Each merchandiser is shipped on a skid to

protect the merchandiser’s base, and to make

positioning the case easier.

Remove the top of the crate and detach walls

from each other. Lift crate from the skid.

Unscrew the case from the skid. The fixture

can now be lifted off the crate skid. Lift only at

base of skid! Remove any braces and/or skids

attached (blanket wrapped merchandiser may

have skids).

DO NOT TILT MERCHANDISER ON ITS

SIDE OR END WHEN REMOVING SKID.

Tilting merchandiser could cause damage to

the refrigeration system.

Once the skid is removed, the merchandiser

must be lifted —NOT PUSHED— to reposition.

To remove the skid, remove screws attaching

skid to the merchandiser.

Do not store objects or ammable

materials atop the unit.

Check floor where cases are to be set to see if

it is a level area. Determine the highest part of

the floor.

Unpack door and all packaged accessories.

Do NOT remove shipping crate until the

merchandiser is positioned

for installation.

P/N 0515297_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

P/N 0515297_E 1-5

Drain

(HGL-BS Shown)

MERCHANDISER LEVELING

Be sure to position merchandisers

properly. Level the merchandiser at corners.

Merchandiser(s) must be installed level to

ensure proper operation of the refrigeration

system and to ensure proper drainage of

defrost water. The merchandiser can be leveled

by shimming under the cabinet base frame, or

by installing optional leg levelers.

The self-closing doors require the cabinet to be

properly leveled. End to end leveling will allow

the door(s) to close with uniform speed and

tightness. A slight pitch from front to rear

is desirable.

should never Be higher than the front.

the Back of merchandiser

LEG INSTALLATION (Top Mounts Only)

Install the NSF approved legs after the case is

near its final location. The legs are packaged

inside the cabinet. Replace the tape and door

blocks.

To install legs:

Raise one end of the cabinet about 8 inches.

Block the merchandiser securely, and install

two legs. The leg mounting plates are factory

installed and contain a

1

/2 x 13 in. tapped hole

to mate with the leg assembly. The procedure

is repeated on the opposite end. Three-door

merchandisers require legs in the center.

The cabinet should now be positioned at its

final location with all legs installed. The

merchandiser is leveled by turning the bottom

section of each leg . End to end leveling will

make the door(s) close with uniform speed and

tightness. A slight pitch from front to rear is

desirable.

SERIAL PLATE LOCATION

The serial plate is located in the upper lefthand corner of the merchandiser’s interior.

The serial plate contains all pertinent

information such as model, serial number,

amperage rating, refrigerant type and charge.

Do not remove the serial plate under any

circumstance.

Serial Plate

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGM Merchandisers

1-6 InstallatIon

REFRIGERATION UNIT ACCESS

Top Mounts — The top decorative panel is

removed by lifting the panel up and pulling

forward.

Bottom Mounts — The lower front panel may

be removed by removing screw at bottom and

lifting the panel straight upward and over

the tabs on which it is hanging. The panel is

installed by reversing the above procedure.

Then

Lift up and

out to remove

access panel

First

Ensure lower front panel is flat against the

floor when installed to prevent air circulation

problems for self contained merchandisers.

If the condensing unit needs to be serviced, it

can be pulled out to gain access for hard to

reach components like the condenser fans.

To pull out the condensing unit, remove the

two hold down brackets at the unit base.

Care must be given to the drain line when

replacing the condensing unit into the case.

The drain line must be inside the defrost water

evaporation pan to prevent the discharge of

water on the floor.

SEALING MERCHANDISER TO FLOOR

(Bottom Mounts Only)

If required by local sanitary codes, or if the

customer desires, merchandisers may be sealed

to the floor using a vinyl cove base trim. The

size needed will depend on how much variation

there is in the floor, from one end of the

merchandiser to the other. Sealing of the lower

front and rear panels on self contained models

may hamper their removal for servicing or

maintenance of the condensing unit.

NOTE: Do not allow trim to cover any intake

or discharge grilles located in the lower front

panel.

AIR DISTRIBUTION & REAR FLUE

SPACER

Air is drawn through the evaporator from

front to rear and is discharged down the back

wall, returning up the face of the glass door to

the return air grille.

NOTE: Rear flue spacer must be in place as

this forms a discharge air flue at the back of

the cabinet.

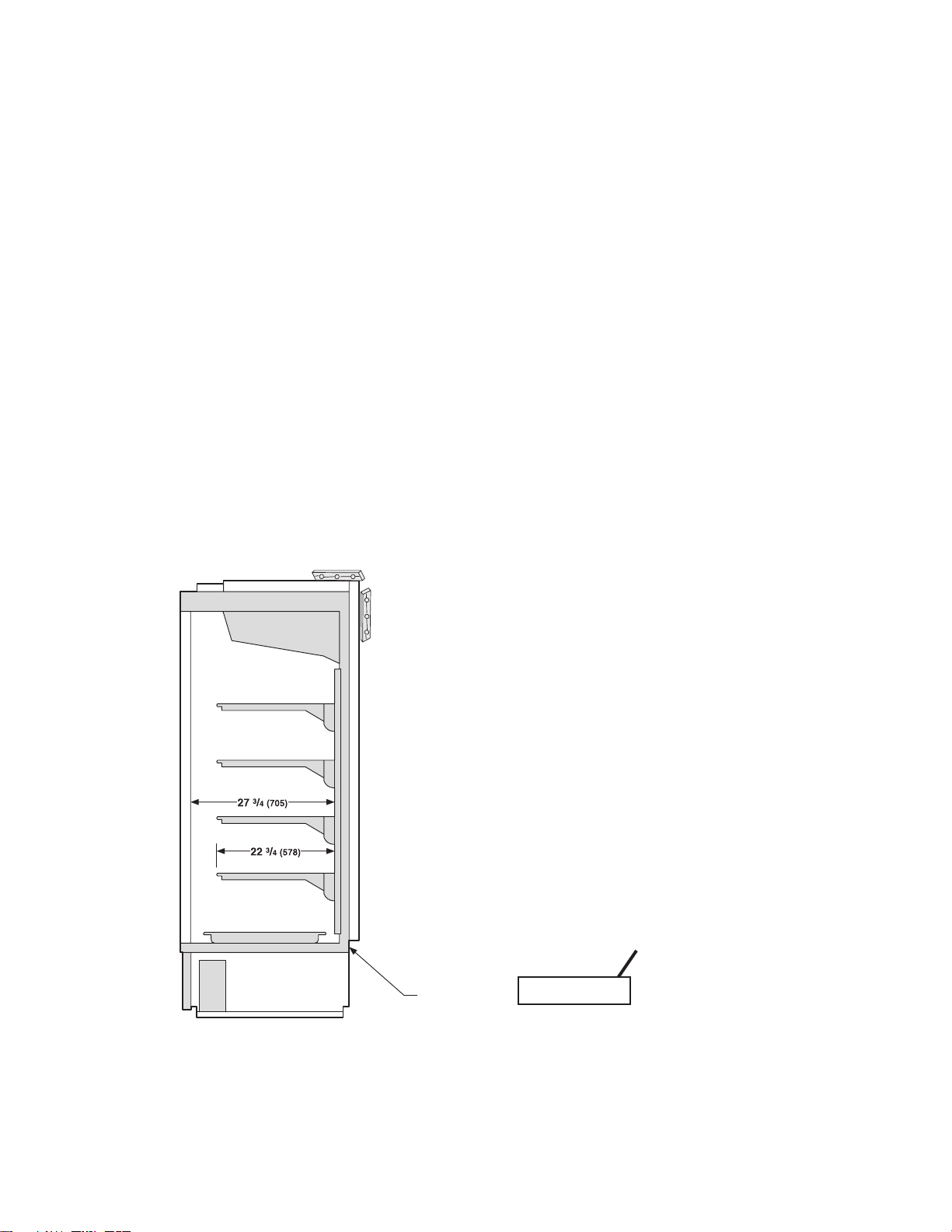

SHELVES

Each cabinet is provided with four cantilever

shelves per door that are adjustable by 1 inch

increments. The shelves can also be tilted.

Each cabinet has one bottom shelf per door.

These shelves have one-inch legs to allow

proper air flow in the cabinet. Behind the

shelves are wire flues spacers, which allow for

proper air flow. All shelves and flue spacers

are white and epoxy coated for durability and

ease of cleaning. Shelves should be adjusted to

desired operating height. Do not load product

so that it touches the evaporator coil cover.

Do not extend product past the front edge of

the shelf. Extending past the edge will seriously

affect internal air flow through the cabinet.

Shelves are UL rated for a maximum load of

120 lbs.

Do not overloaD the shelves.

P/N 0515297_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

P/N 0515297_E 1-7

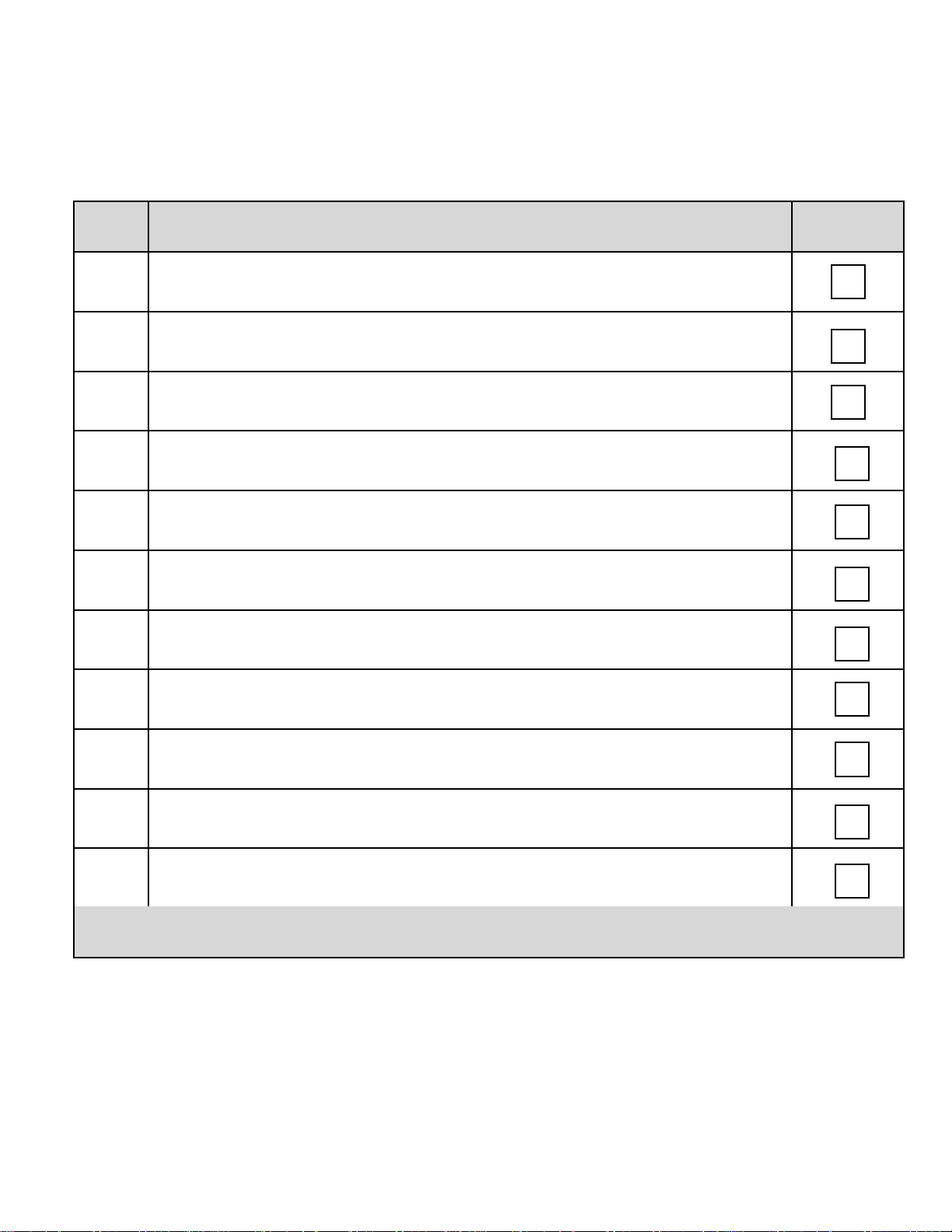

Hussmann Self-Contained Refrigeration Equipment Start Up Check List

***Please note that failure to follow this start-up document may void your factory warranty***

Step Startup Activity Check

1

Locate, read and maintain install/operation manual in a safe place for

future reference.

2 Examine unit. Conrm there is NO damage or concealed damage.

3 Level the unit, side to side and front to rear.

4 Remove all shipping brackets/compressor straps/bolts etc.

5

6

Unit must be run on a dedicated electrical circuit without the use of an

extension cord.

Ensure that the proper electrical requirements for the equipment are

supplied.

7 Verify eld electrical connections are tight.

8

Verify all electrical wiring is secured and clear of any sharp edges or

hot lines.

9 Verify the condensate drain line is properly trapped and pitched.

10 Verify all required clearances on the sides and back of unit.

11

Verify there are no air disturbances external to the unit. Heat and air

registers, fans, and doors etc.

Advise owner/operator that merchandiser must operate at temperature for 24 hrs prior to

loading with product.

Form HSCW01 Rev. 30MAY12 P/N 0525209_B

LEGAL DISCLAIMER:

Hussmann shall not be liable for any repair or replacements made without the written consent of Hussmann, or when the product is installed or operated in a

manner contrary to the printed instructions covering installation and service which accompanied such product.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGM Merchandisers

1-8 InstallatIon

P/N 0515297_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

P/N 0515297_E 2-1

ELECTRICAL / REFRIGERATION

MERCHANDISER ELECTRICAL DATA

Refer to Appendix A of this manual or the

merchandiser’s serial plate for electrical

information.

FIELD WIRING

Field wiring must be sized for component

amperes stamped on the serial plate. Actual

ampere draw may be less than specified.

ALWAYS CHECK THE SERIAL PLATE FOR

COMPONENT AMPERES

ELECTRICAL CONNECTIONS

All wiring must be in compliance with NEC

and local codes. All electrical connections (for

the HGM remote models) are to be made in

the electrical Handy Box located behind the

removable base panel at the right end of the

merchandiser when facing the discharge

honeycomb. The cabinet supply breakers

should be disconnected before removing the

enclosure cover.

The wall circuit must be dedicated for the

merchandiser. Failure to do so voids the

warranty. Do not use an extension cord. Never

plug in more than one merchandiser per

electrical circuit.

• Always use a dedicated circuit with the

amperage stated on the unit.

• Plug into an outlet designed for the plug.

• Do not overload the circuit

• Do not use long or thin extension cords.

Never use adapters.

• If in doubt, call an electrician.

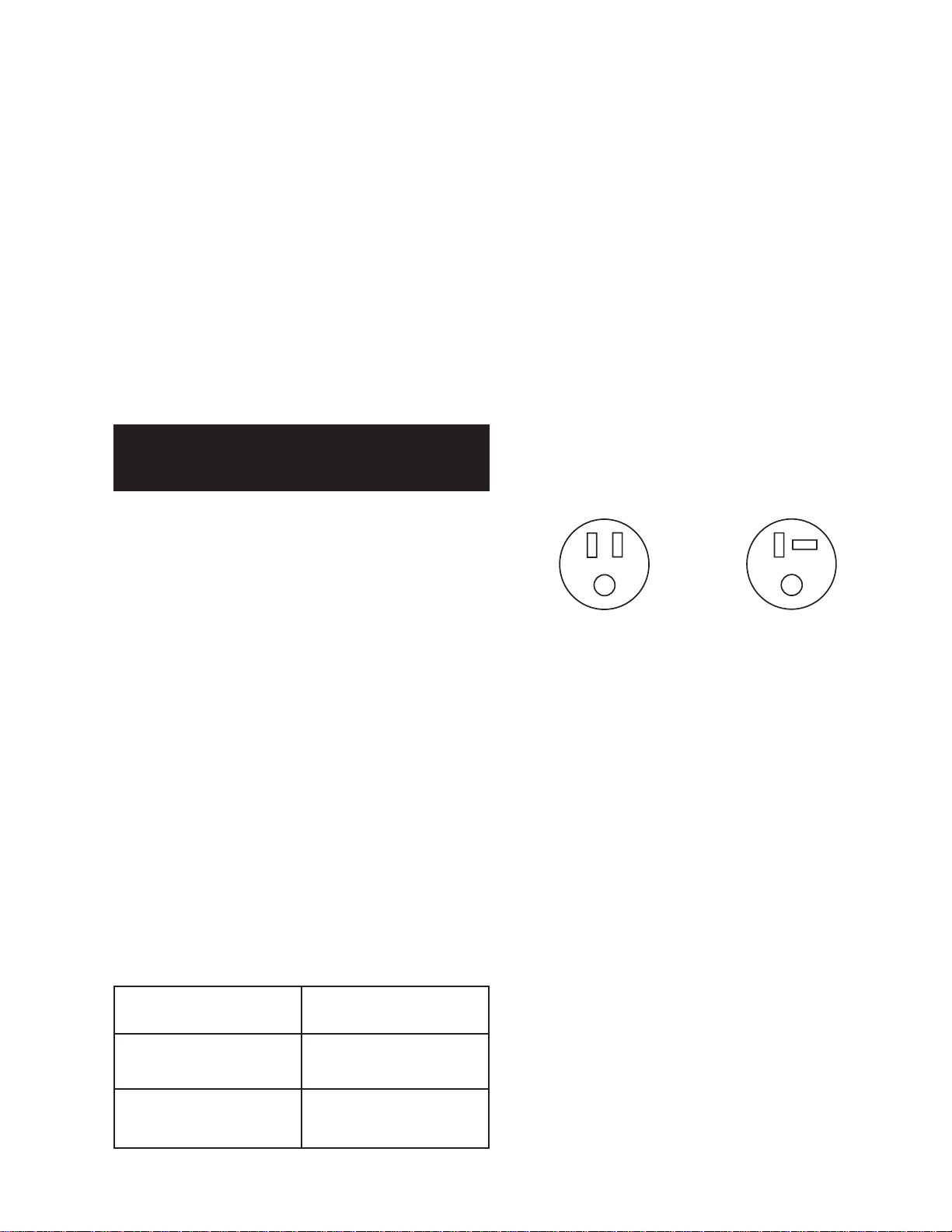

NEMA 5-15P

HGM-1, 2 BS/TS

All HGM models are supplied with a power cord

and grounding prong for operation on a 115V

power supply.

NEMA 5-20P

HGM-3 BS/TS

REFRIGERATION

ELECTRICAL OUTLET:

Before the merchandiser is connected to any

wall circuit, use a voltmeter to check that the

outlet is within the recommended voltage

limits:

Nominal Volts 120V

Minimum Volts 108V

Maximum Volts 132V

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

(Self Contained Models)

Each self contained model is equipped with

its own condensing unit and control panel

located beneath the display area. The correct

type of refrigerant will be stamped on each

merchandiser’s serial plate. The merchandiser refrigeration piping is leak tested. The

unit is charged with refrigerant, and shipped

from the factory with all service valves open.

HGM Merchandisers

2-2 InstallatIon

Risk of Electric Shock. If cord or plug

becomes damaged, replace only with

a cord and plug of the same type.

Refrigeration lines are under pressure.

Refrigerant must be recovered before

attempting any connection or repair.

WATER OUTLET AND WATER SEAL

Merchandiser must be grounded.

Do not remove the power supply cord ground.

LINE SIZING

(Remote Models)

Refrigerant line connections are made at

the right end of merchandiser (facing front)

beneath the refrigerated display area. The

refrigerant line connection size is

suction line is

5

/8 in. Refrigerant lines should

3

/8 in. The

be sized as shown on the refrigeration legend

that is furnished for the store or according to

ASHRAE guidelines.

Oil Traps

P-traps (oil traps) must be installed at the base

of all suction line vertical risers.

Pressure Drop

Keep refrigerant line runs as short as possible

to avoid large pressure drops. Use a minimum

number of elbows. Where elbows are required,

use long radius elbows only.

The cabinet is provided with a factory installed

outlet for defrost water. It runs from the

bottom of the display area to an evaporation

pan near the condenser unit.

The outlet is not connected to the waste water

system for washing out the cabinet. This system

is designed to evaporate normal condensate.

This system should be checked regularly, especially during high relative humidity conditions, to

verify the condensate tube is not blocked, and

that the pan does not accumulate too much

water which could spill out on the floor.

— LOCK OUT / TAG OUT —

To avoid serious injury or death from electrical shock, always disconnect the electrical

power at the main disconnect when servicing

or replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

When brazing pipes, be sure to use the

insulation blanket shipped with the

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

merchandiser to prevent damage to the

metal merchandiser bottom.

P/N 0515297_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

P/N 0515297_E 3-1

START UP / OPERATION

START UP

1. Check the cabinet thoroughly for loose

nuts and bolts and electrical connections.

Inspect the refrigeration lines for any vis

able damage or chafing.

2. Replace the electrical box cover.

3. Start the merchandiser and allow the

merchandiser to pull down to operating

temperature.

The merchandiser must operate for 24 hours

before loading product. Regularly check

temperatures. Do not break the cold chain.

Keep products in cooler before loading

merchandiser. These merchandisers are

designed for pre-chilled product only.

OPERATION

Power Switch

The power switch is located at the electrical

box behind the top, decorative panel (TS models)

or bottom louvered panel (BS models). The

switch will shut off all power to the merchandiser.

Light Switch

Each HGM model has a convenient ON/OFF

switch so lights may be turned off to conserve

energy during hours when the store is closed.

The switch only controls the lights.

Product will be degraded and may spoil if allowed to sit

in a non-refrigerated area.

Under normal conditions, after the cabinet is

installed and running, very little maintenance

should be required. Follow the list of instruction below after initial startup and for periodic

maintenance purposes.

1. Check operation of condenser fan motors.

Fan blades must turn freely.

2. Check drain pan and heater to prevent

accidental overflow.

3. Make sure doors are closing properly and

that the gaskets seal.

4. Make sure all evaporator fan motors are

running. These can be seen through the

grille inside the cabinet.

...ATTENTION

INSTALLER

It is the contractor’s responsibility to install

merchandiser(s) in accordance with all local

building and health codes.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGM Merchandisers

3-2 Start up / OperatiOn

Position

START UP / OPERATION

Safe-NET III™

TEMPERATURE AND DEFROST

CONTROLLER

SAFE-NET III™ USER INSTRUCTIONS

Your refrigerated case uses a Hussmann

Safe-NET™ III temperature and defrost

controller to precisely maintain the temperature and prevent frost buildup on the cooling

coil. LEDs indicate when the compressor or

refrigeration is on, when the case is in a defrost

cycle, if the temperature is outside the desired

range, or if there is a sensor failure.

An adjustment knob allows the temperature

to be set within the configured range and can

power off the controller and compressor. Your

controller has been custom-configured to provide the best temperature and defrost control

for your chilled or frozen food.

The front of the controller has an adjustment

knob and status LEDs. The back of the

controller has connections for sensors and

switched equipment.

Adustment

Knob

Compressor Powered On

green

The Safe-NET III controller includes the

following features and connections.

• Adjustment knob:

Adjusts the temperature setpoint.

Turn adjustment knob to OFF to turn off

refrigeration system. Unplug merchandiser

from power before servicing the unit.

Case

Heater

E72R

Temperature

Fan

E72R only

Sensor

Compressor

Evaporator

Temperature

Sensor

Power

Sensor and Switch

Common

Defrost Termination

Switch (optional)

Interface Box and

Copy Card TTL Connector

• Controller LEDs:

Compressor Powered On LED (green):

Lights while the compressor is running or

the refrigeration valve is open.

Defrost Cycle LED (yellow):

Lights while the refrigeration coil is

defrosting.

Temperature or Sensor Alarm (red):

Lights if the temperature is too warm or

too cold. Flashes if a sensor fails.

Defrost Cycle

yellow

Temperature or Sensor Alarm

red

Warm

Position

Off

Position

Cold

P/N 0515297_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

P/N 0515297_E 3-3

START-UP

• Rear connections:

– Case temperature sensor:

• Typically senses the temperature

of the air in the case.

Used by the controller to determine when

to power on or power off the compressor

or refrigeration.

– Compressor or refrigeration relay:

• Switches on the compressor or

refrigeration valve for cooling.

The optional evaporator fan remains

ON when the adjustment knob is in the

Off position.

Before applying power to the merchandiser,

remove the front grille.

Check thermostat knob is at the appropriate

position. See temperature adjustment on

Page 3-6.

Check the check the merchandiser’s cabinet

thoroughly for loose nuts and bolts. Check all

electrical connections. Inspect the refrigerant

lines for any visible damage or chafing.

Replace the front grille.

The following list of housekeeping practices

will assure trouble-free operation:

• Check operation of condenser fan motors.

Fan blades must turn freely.

DISPLAY

The display includes three red LEDs and two

digits for temperature, defrost status, and error

codes.

The three display LEDs are red, and their

behavior matches the LEDs on the controller.

Compressor

Powered On

Defrost Cycle

Temperature or

Sensor Alarm

• Check drain pan and heater to prevent

accidental overflow.

• Make sure doors are closing properly, and

that gaskets are sealed.

• Make sure all evaporator fan motors are

running. These can be seen through grille

inside of cabinet.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGM Merchandisers

3-4 Start up / OperatiOn

1. Plug in the merchandiser.

The OFF Position does not disconnect line

voltage to the case, refrigeration unit, fan, or

heater.

2. Wait for the self check to complete. During

the self check, each LED flashes for one

second, then all LEDs turn on for two

seconds. If the LEDs do not flash, make

sure the adjustment knob is not in the Off

position.

• After the self check, all LEDs turn off

until the compressor starts. There may be

a delay before the compressor starts. If the

red Temperature or Sensor Alarm LED

stays on after the self check.

• The green Compressor Powered On LED

turns on when the compressor starts.

NOTE: Do NOT load product until AFTER

merchandiser operates for 24 hours and reaches

desired operating temperature.

Safe-NET parameter code is 58.

Product will be degraded and may spoil if allowed to

sit in a non-refrigerated area.

P/N 0515297_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

P/N 0515297_E 3-5

Green

(Refrigeration)

Yellow

(Defrost)

Red

(Alarm)

‘OFF’ Position

1. During the self check a 2 digit number

will appear for 3 seconds. Then each LED

flashed for one second and then all LED’s

turn on for two seconds. If the LED’s do

not flash, make sure the adjustment knob is

not in the “OFF” position.

2. The compressor will start after a delay; 30

seconds after the power is applied.

3. The compressor will continue to run until it

reaches its cut-out temperature (pull down).

Green

(Refrigeration)

Yellow

(Defrost)

Red

(Alarm)

4. The refrigeration cycle will continue until the

next scheduled defrost (12 hours).

5. The above process will repeat (steps 3 and 4)

until the power is interrupted.

6. If power stops, the process will start over at

Step 1, and the time to subsequent defrost will

reset.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGM Merchandisers

Loading...

Loading...