Hussmann HGM-1BS, HGM-3BS, HGM-2BS, HGM-1TS, HGM-2TS Installation And Service Instructions Manual

...

January 2006

INSTALLATION & SERVICE

INSTRUCTIONS

FOR

HGM-1, 2 & 3 BS,TS SELF-CONTAINED

Medium Temperature Glass Door Merchandiser

First Call for help (US and Canada):

1-800-922-1919

Soporte Tècnico y Asistencia (Mèxico):

01-800-522-1900

For a Service Network Locator and other

Information visit us at

www.hussmann.com

select Worldwide Locations

P/N OII – HGM BS-TS Self-Contained

January 2006

HUSSMANN - GLOVERSVILLE

TABLE OF CONTENTS

Introduction 2

Inspection Upon Receipt – Proper Location and Clearance 2

Skid 2

Leg Installation 2

Leveling and Sealing 3

Condensate Pan 3

Bottom Louvered Panel Removal 3

Top Decorative Panel Removal 3

Shelves 3

Air Distribution and Rear Flue Spacer 3

Serial Plate Information Electrical Connections 4

Electrical, BTU Capacities 4

Initial Start Up and Loading 4

General Upkeep and Cleaning 5

Power Switches, Temperature Controls 5

Thermometer 6

Electrical Enclosure 6

Lighting 6

Refrigeration 7

Leak Testing 7

Evacuation 7

Operational Data and Refrigerant Control 8

Trouble Shooting, and Lights Trouble Shooting 9 & 10

Warranty and Electrical Components Replacement List 11 & 12

Commercial Door Literature 13-16

Page 1

Introduction –

The HGM-BS/TS models are self contained, medium temperature, vertical glass

door merchandisers designed for the display

of dairy products, deli items, beverages, and

wine. Design features include self-closing

glass doors, efficient foamed in place nonCFC insulation, and balanced R-134a refrigeration systems for energy saving performance.

Inspection upon receipt –

Upon receipt of the cabinet, carefully

examine the crating for damage. If crate is

damaged, make a note on the delivery ticket

before signing. Carefully remove shipping

crate and examine cabinet for “concealed”

damage. If damage is found, contact the delivery carrier immediately and have his agent

prepare an inspection report for the purpose

of filing a claim. THIS IS YOUR RESPONSIBILITY.

Proper Location & Clearance –

allowed in front of the case and six (6) inches of

clearance at the rear to provide the necessary

free air movement to and from the condenser.

INITIAL SET-UP Skid –

The skid should be left on the case until it

is near its final location. The skid provides protection for both case and floor. The skid is removed by raising one end of the case approximately six inches. Block securely and remove

the two skid bolts on the raised end. The procedure is repeated on the opposite end. When the

skid bolts are removed, the case may be slid off

the skid.

Leg Installation – Top Mounts only

After the case is near its final location

and the skid has been removed, the NSF approved legs should b e installed. The legs are

packaged inside the cabinet. Replace the tape

and door blocks. To install legs, raise one end of

the cabinet approximately eight (8) inches, block

securely, and install two legs.

Avoid locating the cabinet where direct

sunlight would shine into the fixture or where

drafts from air conditioning grills, fans and

open doors could affect its operation.

Because the condensing unit is located

at the top of the HGM-TS, at least twelve (12)

inches of clearance should be allowed at the

rear of the cabinet and at the top of the case.

This clearance is necessary to provide free air

movement to and from the condenser for

maximum operating efficiency.

Because the condensing unit is located

on the bottom of the HGM-BS, at least twenty

four (24) inches of clearance should be

Page 2

The leg mounting plates are factory installed and contain a ½ x 13 tapped hole to mate

with the leg assembly. The procedure is repeated on the opposite end. The 3-door requires

legs in the center. With cabinet legs installed,

the cabinet should be positioned in its final location and leveled.

The cabinet is leveled by turning the bottom section of each leg. The self-closing doors require

the cabinet to be properly leveled. End to end

leveling will make the door (s) close with uniform speed and tightness. A slight pitch from

front to rear is desirable.

THE CABINET BACK SHOULD

NEVER BE HIGHER THAN THE FRONT.

electrical box to allow the electrical box to

slide out for servicing.

Leveling and Sealing

– Bottom

Mounts only

The case can be leveled by shimming under the cabinet base frame, or be installing optional levelers. The self-closing doors require

the cabinet to be properly leveled. End to end

leveling will make the door (s) close with uniform speed and tightness. A slight pitch from

front to rear is desirable.

Silicone Sealant

Condensate Pan –

Floor

An electrically heated (300w, 115v) condensate pan is provided to evaporate the defrost

water. The heated condensate pan slides onto

the slide plate on the cabinet bottom on TS

cases and has a thermistor. On BS cases the

pan is screwed to the base of the case. The pan

is removable for cleaning. A vinyl drain tube is

provided for connection to the heated condensate pan. The drain must be trapped to guard

against drain line freezing and for good sanitation practice.

Bottom Louvered Panel Removal –

The louvered panel provides access to

the condensing unit and the electrical box.

Remove panel by removing the shipping

screw (s) at bottom and lifting up and pulling

forward. Remove shipping screw on

Top Decorative Panel Removal –

The top decorative panel is removed by

lifting up and pulling forward.

Shelves

–

Each cabinet is provided with 4 cantilever shelves per door that are adjustable on 1inch increments and are tiltable. Each cabinet

also has one bottom shelf per door. These

shelves have one-inch legs to allow proper airflow in the cabinet. Behind the shelves are

wire flue spacers which also allow for proper

airflow. All shelves and flue spacers are white,

epoxy coated for durability and ease of cleaning. Shelves should be adjusted to desired operating height.

When loading product, into the cabinet,

care should be taken not to load product so

that it touches the evaporator coil cover. Do

not extend product past the front edge of the

shelf. Extending past the edge will seriously

effect internal air flow through out the cabinet.

Shelves are UL rated for a maximum

load of 123 lbs. DO NOT OVERLOAD

SHELVES.

Air Distribution and

Rear Flue Spacer –

Air is drawn through the evaporator

from front to rear and is discharged down the

back wall, returning up the face of the glass

door to the return air grill. NOTE: Rear flue

Page 3

spacer must be in place as this forms a discharge air flue at the back of the cabinet.

Electrical Connections –

The HGM-1 and 2 cases are supplied

with a supply cord as charted below with a

grounding prong for operation on a 115v power

supply. Do not remove the grounding prong

under any circumstances. The HGM-3 requires

hard wiring to a 30 amp, 115v circuit.

Cord Plug Nema

Model Amperage Designation

HGM-1-BS/TS 15 5 – 15 P

HGM-2-BS/TS 20 5 – 20 P

Serial Plate Information –

The serial plate is located in the upper

left-hand corner of the case interior. It has all

the pertinent information needed for proper

electrical installation. The serial plate should

not be removed for any reason.

NOTE: Connecting this unit to any electrical

supply other than specified on the serial plate

will void the warranty and may result in serious

damage with its own service.

Electrical –

Unit Run Ship

H.P. Hz/Ph Volts Amps Fuse Size Wt.

1-BS 1/3 60/1 115

2-BS 1/2 60/1 115 12.5 20 amp 825

3-BS 3/4 60/1 115 20.5 30 amp 1096

1-TS 1/3 60/1 115

2-TS 1/2 60/1 115 12.5 20 amp 776

3-TS 3/4 60/1 115 20.5 30 amp 1050

BTU Capacities –

Rating Temps ºF

BTU/HR EVAP COND AMB

1-TS/BS 2300 +25 110 90

2-TS/BS 2570 +25 110 90

3-TS/BS 3620 +25 110 90

The HGM cases use R-134a refrigerant. Check the serial plate for the specific refrigerant

charge used.

Page 4

Initial Start-up and Loading –

Check the cabinet thoroughly for loose nuts

and bolts and electrical connections. Inspect the refrigeration lines for any visible

damage or chafing.

Replace the electrical box cover.

Start the cabinet and allow to pull down to

operating temperature before loading.

General Upkeep and Cleaning –

1. To insure good sanitation, appearance, and

minimum maintenance, the cabinet should

be cleaned and washed regularly as sue demands. Clean with mile detergent and

warm water. DO NOT USE AN ABRASIVE CLEANER OR STEEL WOOL AS

THEN WILL MAR THE FINISH.

1. Under normal conditions, after the cabinet

is installed and running, very little maintenance should be required. However, the following list of housekeeping practices will

assure trouble-free operation.

a) Check operation of condenser fan motors.

Fan blades must turn freely.

a) Check drain pan and heater to prevent acci-

dental overflow.

a) Make sure doors are closing properly and

that the gaskets seal.

a) Make sure all evaporator fan motors are

running. These can be seen through grill

inside cabinet.

a) Clean the cabinet with a mild detergent.

this will insure good sanitation, and minimize maintenance. Never use an abrasive as

this could mar the finish.

a) A regular program should be set up for the

cleaning of the fin-and-tube condenser.

Normally, this cleaning is required every 3

to 4 months, but the individual store application may shorten or lengthen this time period. Dust and dirt accumulation can cause

serious efficiency loss.

a) On the BS cases (bottom mounts) access is

gained to the unit area by removing the louvered grille. The unit slides forward to facilitate cleaning and for service. Care

should be taken when pushing the unit back

in place to insure that the pullout coil does

not become kinked or damaged in some

way.

OPERATION AND MAINTENANCE

Power Switches –

The power switch is located at the electrical box which is behind the top decorative

panel (TS models) or bottom louvered panel

(BS models). The switch will shut off al power

to the case.

Temperature Control –

The electrical temperature control is located in

the electrical box. The temperature control

does not have an ‘OFF’ position.

Adjustments may be made by turning

the knob on the face of the dial. Turning it

clockwise will give warmer temperatures while

counter-clockwise will give colder temperatures.

Page 5

There is also and adjustable temperature differential (the difference between the cutin temperature and the cut-out temperature)

located on the back of the temperature control

cover. When adjusting the differential, the temperature setting may also have to be adjusted.

See figure below for internal adjustment locations.

The control has a range of –20º F to

+220º F with a differential of 1º to 30º. It is factory set for approximately 29ºF with a 10º differential. The temperature should be checked

with a thermometer other than the case thermometer after it is running to insure that the

case is running at the proper temperature for

the product.

A picture of A319 Electronic Temperature Control and Board Layout is located on

the last page of this booklet.

Thermometer –

The thermometer is located by looking

through the right hand door onto the right

hand end of the fan plenum.

The thermometer will also warm up

rather rapidly when the case door is held open

for a time such as when the case is being restocked or a shopper is making a decision on a

product. After the door is closed it will take

some time for the thermometer to pull back

down to the case temperature. The thermometer and temperature control sense discharge air

temperature which is 5-10º colder than the case

temperature.

The thermometer may be replaced by

removing the two screws securing it to the

evaporator fan grill. Lower the evaporator coil

cover by removing the brass thumb screws

located at each end of the cover, and backing

out the thumb screws located along the front

edge of the cover.

Follow the sensing lead from the thermometer until you locate the sensing element.

Loosen the clamp securing the element and remove the element. Remove the thermometer.

Assemble is the reverse order making sure you

first thread the element through the hole in the

evaporator fan grill. Cleaning of the sensing

element may also be accomplished in this manner.

Electrical Enclosure –

For servicing convenience, access is

gained by removing the access panel and electrical box cover. The cabinet supply breakers

should be disconnected before removing the enclosure cover.

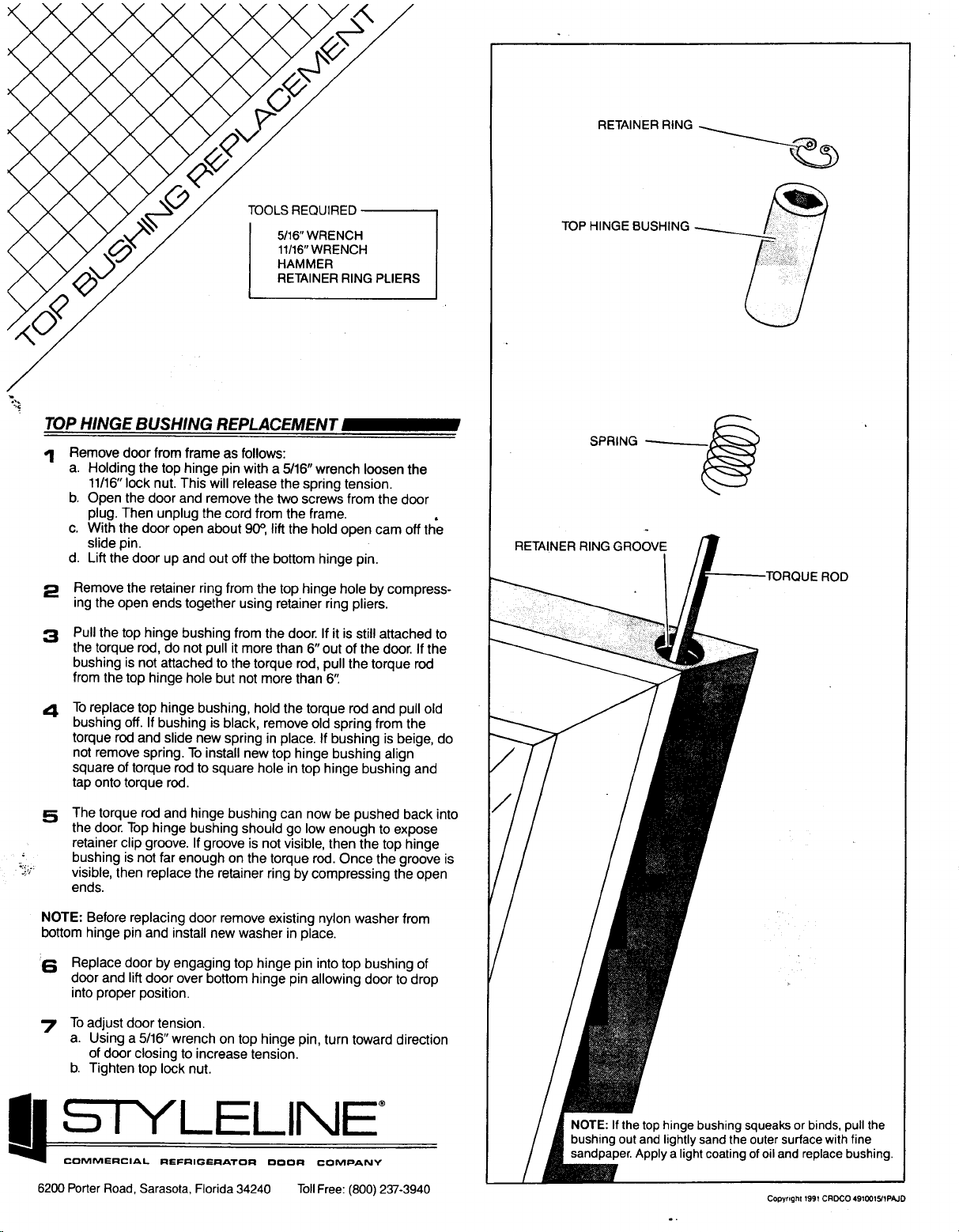

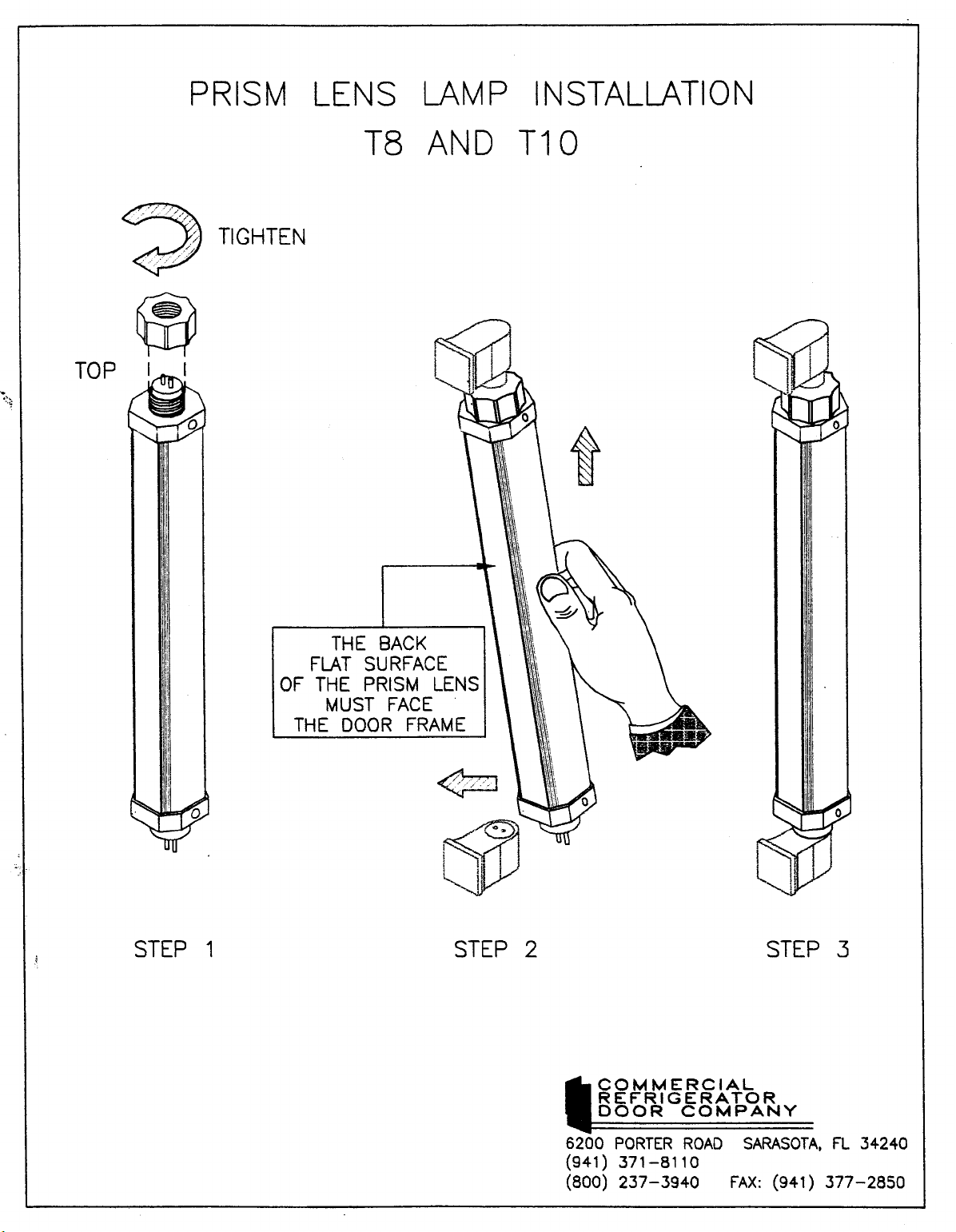

Lighting –

Electronically powered T-8 lamps located inside each doorway provide interior

lighting. The tubes are enclosed in a patented

lens system to maintain proper heat around the

bulb for maximum light intensity and to protect

the product in case of breakage. See the

Commercial instructions for the lens removal,

attached at the back of this booklet.

Each HGM model has a convenient ON/

OFF switch so lights may be turned off to conserve energy during hours when the store is

closed. The switch is located inside the cabinet

above the left hand door. This switch only controls the lights. 115 volt power must be shut off

at the main power supply source located within

the store prior to starting any service or maintenance work.

Page 6

Light ballasts are located on mullions of

the door frames. See the Anthony ballast removal instructions at the back of the booklet.

–

Commercial Doors –

See Door Instructions at

the back of this booklet.

Refrigeration –

As stated previously, these cases are selfcontained with the condensing unit mounted at

the top or bottom. they are equipped with a

hermetic compressor and a capillary tube. The

condenser is of fin and tube construction and

should be periodically cleaned to maintain efficient operation.

If it should become necessary to leak test

the system, please adhere following notice:

NOTICE

considerations being taken today, we ask that

leak testing be done with refrigerant 22 mixed

with nitrogen. If the condensing unit nameplate

designates a refrigerant other than R-22 remove all R-22 from the immediate area to avoid

confusion after leak testing and evacuating the

unit. Recharge the unit with proper refrigerant.

Leak Testing

The test gas cylinder must be equipped

– Because of the CFC atmoshperic

- CAUTION

with a pressure gauge and regulators so that

system test pressures do not exceed maximum

allowable limits. Do not ever use anything

other than an R-22/Nitrogen mixture for leak

testing.

Attach a refrigerant test gas cylinder to

your service manifold and connect the manifold

to the charging port on the liquid line valve.

Charge an R-22/Nitrogen mixture into the system, raising the pressure to the remote unit’s

nameplate for the low side and high side pressures. Using the electronic detector, carefully

check the entire system for leaks. Take special

care to inspect all brazed and flare connections.

Evacuation –

After the system is proven leak tight,

thoroughly evacuate the system according to

the following procedure:

Discharge the refrigerant-nitrogen mixture,

allowing it to blow from the system as rapidly as possible, into an empty cylinder. Be

sure that all service valves and solenoid

valves are open to allow all of the mixture to

be discharged.

Connect a deep-drain vacuum pump to both

the high and low side of the system. Pull a

vacuum on the system to at least 1500 micorns.

Break the vacuum by adding refrigerant

into the system until the pressure is above 0

psig. Always charge the refrigerant line into

the system through a new drier in the charging manifold line. A 16 cubic inch drier is

sufficient for this purpose.

Page 7

Repeat steps 2 and 3 two more times, the

third time evacuating the system 500 microns.

Operational Data

–

The following is typical data for HGM

models based on lab tests, and may vary under

field operating conditions.

Ambient Temperatue

Head Pressure (psi) 120-135

Suction Pressure (psi) 9-12

75ºF

Refrigerant Control

Refrigerant flow to the evaporator is controlled through the use of a capillary tube.

Because the suction line capillary tube assembly (sometimes referred to as heat exchanger

or pull-out coil) has no moving parts, it very

rarely if ever, needs servicing. However, should a

leak occur in the system, it is possible that dirt,

dust, or moisture may collect in the capillary tube

causing the system to go into a vacuum. Should

this occur, it is recommended that dry nitrogen

or a dry refrigerant be forced through the system

to clear the blockage.

If attempts to clear the restriction by this

method are unsuccessful, the entire assembly, not

the capillary tube only, should be replaced with a

new factory ordered replacement.

Page 8

TROUBLE SHOOTING

Symptom Probable Cause (s) Possible Solution (s)

Compressor runs continuously

Product too warm

1. Short of refrigerant 1. Leak check, change drier,

evacuate, and recharge

2. Inefficient compressor 2. Replace

3. Dirty condenser 3. Clean

High Head Pressure 1. Cabinet location too warm 1. Relocate cabinet

2. Restricted condenser air flow 2. Clean condenser to remove

air flow restriction

3. Defective condenser fan mo-

3. Replace

tor

Warm storage temperatures 1. Temperature control not set

4. Air or non-condensable gases

in system

4. Leak check, change drier,

evacuate, and recharge

1. Reset control

properly

2. Short of refrigerant 2. Leak check , change drier,

evacuate, and recharge

3. Cabinet location too warm 3. Relocate

4. Too much refrigerant 4. Change drier, evacuate, and

recharge

5. Low voltage. Compressor

5. Check power

cycling on overload

6. Condenser dirty 6. Clean

Compressor runs continuously

1. Defective control 1. Replace

product too cold

Compressor will not start no

2. Short on refrigerant 2. Leak check, change drier,

1. Blown fuse or breaker 1. Replace fuse or reset breaker

noise

2. Defective or broken wiring 2. Repair or replace

3. Defective overload 3. Replace

4. Defective temperature control 4. Replace

5. Power Control 5. Check service cord or wiring

Page 9

evacuate, and recharge

conditions

TROUBLE SHOOTING CON’T

Symptom Probable Cause (s) Possible Solution (s)

Compressor will not start

cuts out on overload

1. Low voltage 1. Contact electrician

2. Defective compressor 2. Replace

3. Defective relay 3. Replace

4. Restriction or moisture 4. Leak check, replace drier,

evacuate and recharge

5. Inadequate air over con-

5. Clean condenser

denser

6. Defective condenser fan

6. Replace

motor

Trouble Shooting Lighting System

Problem Solution

Light’s won’t start 1. Check light switch

2. Check continuity to ballast

3. Check to see if bulbs inserted properly into

socket

4. Check voltage

Light’s flicker 1. Allow lamps to warm up

2. Check lamp shield for cracks

3. Check sockets for moisture and proper

contact

4. Bulb replacement may be necessary

5. Check voltage

6. New bulbs tend to flicker until used

Ballast hums 1. Check voltage

2. Replace ballast

This HGM case was manufactured in Gloversville, New York. Our phone #’s are (518) 7250644 for NY state residents, and toll free 800-753-7790 or outside NY. Any questions not

covered in this manual, please call the factory.

Page 10

WARRANTY PARTS PROCEDURE, COMPRESSOR REPLACEMENT,

AND

ELECTRICAL COMPONENTS REPLACEMENT LIST

Ordering Replacement Parts –

Contact your nearest Hussmann Distributor

Always specify model and serial number of cabinet

If correct part number is not know, give a clear description of part itself and its func-

tion in the cabinet or remote unit.

Warranty Parts Procedure

Same as above

Give original installation date of cabinet and, if possible, forward a copy of the original

invoice or delivery receipt.

All shipments of in-warranty replacement parts will be invoiced from the factory until

such time as the defective part is returned and proved to be defective by our Quality

control Department.

Contact your Hussmann Distributor for instructions on returning in-warranty parts.

In case of a compressor failure, see next section.

Warranty parts must be returned to the factory within 30 days of date of failure to as-

sure proper disposition.

Lack of any of the above information may result in the shipment of the wrong part, or

a delay in shipment.

Compressor Replacement Procedure

–

Replacement compressors will not be shipped from the Hussmann Factory. They may

be obtained from your nearest Wholesaler.

Your wholesaler will replace, free of charge, any compressor found to be defective

within twelve months of installation, not to exceed twenty months from the date of

manufacture, as determined by the compressor serial number on the serial plate.

Page 11

To obtain reimbursement forward to: Hussmann Corporation

140 East State Street

Gloversville, NY

12078

the following information:

1. The cabinet model and serial number

2. A copy of the wholesaler’s invoice, along with tag from old compressor.

Electrical Components Replacement List

Model HGM-1-TS/BS HGM-2-TS/BS HGM-3-TS/BS

Compressor Tecum. AE44484 Tecum. AKYY60Y Cope. RSL4CIE-IAA

Cond. Fan Mtr. EMS ESPL25EM1 EMS ESPL25EM1

Evap Fan Mtr Bomax 310-5734 same same

Light Ballast Huss. # 6-S-166 same same

Fluores. Lamp F040W-T8-60" same same

Page 12

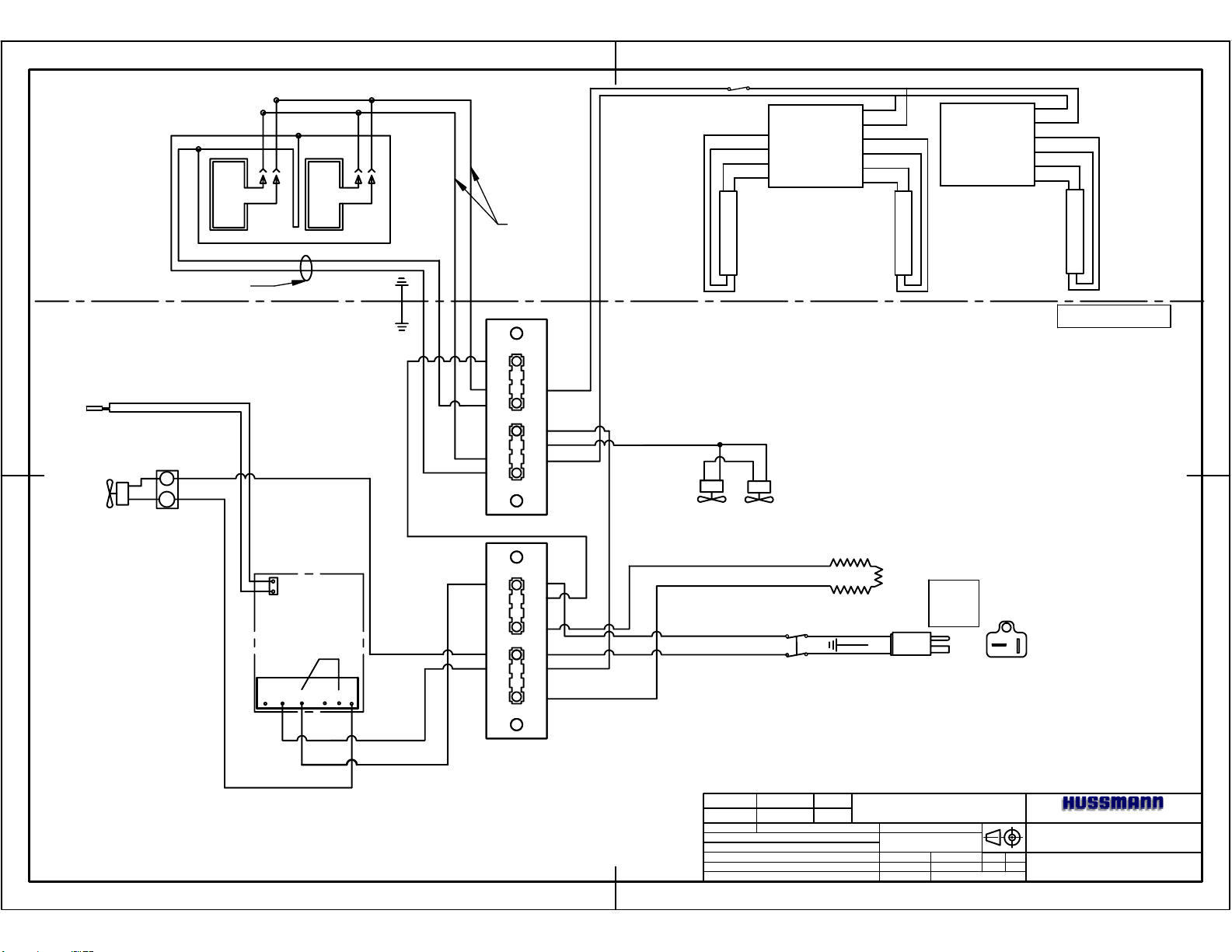

DOOR & FRAME HEATERS

FRAME HEATERS

BLK

WHT

BLK

WHT

DOOR HEATERS

BLU

BLU/WHT

LIGHT SWITCH

LAMP

ORN

ORN

BRN

BRN

BLK

3

WHT

4

8

BALLAST

9

10

1

RED

2

RED

5

BLU

6

BLU

7

LAMP

SENSING

BULB

2

1

COMPRESSOR

WHT

SENSOR

BLK

JUMPER

COMM

240 AC 120 NC C NO

WHT

BLK

PUR

GRD

3-S-226

1 2

3 4

5 6

7 8

9 10

11 12

23 24

25 26

ELEC-TRON

3-S-226

1 2

3 4

5 6

7 8

9 10

11 12

23 24

25 26

ELEC-TRON

BLK

EVAP FANS

BLK

BLK

BLK

WHT

S3

S4

REV EO # REV DATE REV BY

APPROVED BY

-

-

-

-

-

-

--

-

CONDENSATE PAN HEATER

BLK

S1

GRD

WHT

S2

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

EO NUMBER

DRAWN BY:

DATE DRAWN :

APPROVED BY:

115 V

60 Hz

15 AMP

POWER PLUG

-

-

1 PH

JWL

1/29/96

ANTHONY FRAME

HGM-1-BS

SCALE

INCHES

SHEET #

1 OF 1

PLUG

END

DETAIL

GLOVERSVILLE, NY 12078

WIRING DIAGRAM

M100-2021

DOOR AND FRAME HEATERS

LIGHT

SWITCH

BLU

BLU/WHT

ANTHONY T8 ELECTRONIC LIGHTING

SENSING

BULB

CONDENSOR

FANS

1

C

COMPRESSOR

FRAME HEATERS

WHT

PUR

BLK

WHT

WHT

GRN

DOOR

HEATERS

BLK

WHT

BLK

WHT

BLK

1 2

3 4

5 6

7 8

9 10

11 12

23 24

25 26

BLU

BLU

BLK

3

WHT

ORN

8

BALLAST

ORN

9

ORN/BLK

10

ORN/BLK

BLU/WHT

BLU/WHT

1

LAMP

4

RED

2

RED

5

BLU

BLU

LAMP

ORN/BLK

ORN/BLK

LAMP

ORN

ORN

8

9

10

1

BALLAST

BLK

3

WHT

4

RED

2

RED

5

BLU

66

BLU

77

LAMP

ANTHONY FRAME

BLK

EVAPORATOR FANS

BLK

SENSOR

1 2

3 4

5 6

BLK

COMM

120

240

AC

NOCNC

PUR

WHT

BLK

7 8

9 10

11 12

23 24

25 26

BLK

WHT

S4

BLK

S3

REV EO # REV DATE REV BY

-

APPROVED BY

-

-

-

-

-

WHT

S2

GRN

BLK

S1

--

-

1 PH

60 Hz

115 V

25 AMP

CONDENSATE

PAN

HEATER

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

EO NUMBER

DRAWN BY:

DATE DRAWN :

APPROVED BY:

-

JLS

SCALE

INCHES

SHEET #

12/01/03

-

1 OF 1

HGM-3-BS

GLOVERSVILLE, NY 12078

WIRING DIAGRAM

M100-2023

DOOR AND FRAME HEATERS

LIGHT

SWITCH

BLU

BLU/WHT

ANTHONY T8 ELECTRONIC LIGHTING

SENSING

BULB

CONDENSOR

FANS

1

C

COMPRESSOR

FRAME HEATERS

WHT

PUR

BLK

WHT

WHT

GRN

DOOR

HEATERS

BLK

BLK

WHT

ORN/BLK

ORN/BLK

ORN

ORN

8

9

10

1

BALLAST

BLK

3

WHT

4

RED

2

RED

5

BLU

6

BLU

7

BALLAST

BLK

3

WHT

4

RED

2

RED

5

BLU

6

BLU

7

BLU

BLU/WHT

LAMP

BLK

WHT

BLU

BLU/WHT

LAMP

LAMP

DOOR FRAME

1 2

3 4

5 6

7 8

9 10

11 12

23 24

25 26

BLK

EVAPORATOR FANS

SENSOR

BLK

BLK

CONDENSATE

PAN HEATER

BLK

COMM

120

240

AC

BLK

WHT

PUR

NOCNC

WHT

BLK

S4

S3

WHT

S2

BLK

S1

REV EO # REV DATE REV BY

-

APPROVED BY

-

-

-

-

-

-

1 PH

60 Hz

115 V

GRN

25 AMP

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

--

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

EO NUMBER

DRAWN BY:

DATE DRAWN :

APPROVED BY:

HGM-2-TS

GLOVERSVILLE, NY 12078

-

JLS

SCALE

INCHES

SHEET #

12/01/03

-

1 OF 1

WIRING DIAGRAM

M100-2028

SENSING

BULB

FRAME HEATERS

2

1

COMPRESSOR

DOOR & FRAME HEATERS

BLK

WHT

WHT

SENSOR

BLK

JUMPER

COMM

240 AC 120 NC C NO

WHT

BLK

PUR

GRD

DOOR HEATERS

BLU

BLU/WHT

LIGHT SWITCH

ORN

ORN

BRN

BRN

8

9

10

1

ANTHONY T8 ELECTRONIC LIGHTING

BLK

3

WHT

4

BALLAST

RED

2

RED

5

BLU

6

BLU

7

LAMP

BLK

3

WHT

4

8

BALLAST

9

10

1

RED

2

RED

5

BLU

6

BLU

7

LAMP

LAMP

BLK

WHT

BLK

WHT

ANTHONY FRAME

3-S-226

1 2

3 4

5 6

7 8

9 10

11 12

23 24

25 26

ELEC-TRON

EVAP FANS

BLK

3-S-226

1 2

3 4

5 6

7 8

9 10

11 12

23 24

25 26

BLK

WHT

BLK

CONDENSATE PAN HEATER

S1

S3

S4

S2

BLK

GRD

WHT

20 AMP

POWER PLUG

115 V

60 Hz

1 PH

PLUG

END

DETAIL

ELEC-TRON

HGM-2-BS

REV EO # REV DATE REV BY

APPROVED BY

-

-

-

-

-

-

--

-

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

EO NUMBER

DRAWN BY:

DATE DRAWN :

APPROVED BY:

-

JWL

SCALE

INCHES

SHEET #

1/29/96

-

1 OF 1

GLOVERSVILLE, NY 12078

WIRING DIAGRAM

M100-2022

DOOR & FRAME HEATERS

LIGHT SWITCH

BLU

BLU/WHT

BRN/BLK

BRN/BLK

ANTHONY T8 ELECTRONIC LIGHT ING

BLK

3

WHT

ORN

8

BALLAST

ORN

9

10

1

4

RED

2

RED

5

RED

6

RED

7

FRAME HEATERS

SENSING

BULB

COMPRESSOR

COND

FAN

LAMP

ANTHONY FRAME

BLK

WHT

DOOR

HEATERS

BLK

WHT

BLK

WHT

LAMP

3-S-226

1 2

3 4

5 6

7 8

2

1

WHT

9 10

11 12

23 24

25 26

BLK

ELEC-TRON

EVAP

FANS

BLK

SENSOR

BLK

CONDENSATE

PAN

HEATER

BLK

COMM

240 AC 120 NC C NO

PUR

WHT

BLK

S2

S4

S3

S1

WHT

BLK

REV EO # REV DATE REV BY

APPROVED BY

-

-

-

-

-

115 V

60 Hz

1 PH

GRD

PLUG END

DETAIL

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

-

-

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

--

EO NUMBER

-

DRAWN BY:

DATE DRAWN:

APPROVED BY

JHB

12/1/98

-

UNIT

SHEET #

INCHES

1 OF 1

HGM-1-TS

GLOVERSVILLE, NY 12078

WIRING DIAGRAM

M100-2027

DOOR & FRAME HEATERS

LIGHT SWITCH

ANTHONY T8 ELECTRONIC LIGHT ING

FRAME HEATERS

SENSING

BULB

COMPRESSOR

COND

FANS

BLK

WHT

BLK

3

WHT

ORN

8

BALLAST

ORN

9

BRN/BLK

BLU

BLU/WHT

DOOR

HEATERS

BLK

WHT

BLK

WHT

BRN/BLK

LAMP

10

1

4

RED

2

RED

5

RED

6

RED

7

LAMP

BRN/BLK

BRN/BLK

LAMP

ORN

8

BALLAST

ORN

9

10

1

BLK

3

WHT

4

RED

2

RED

5

RED

6

RED

7

LAMP

ANTHONY FRAME

3-S-226

1 2

3 4

5 6

7 8

2

1

WHT

9 10

11 12

23 24

25 26

BLK

ELEC-TRON

EVAP

FANS

SENSOR

BLK

COMM

240 AC 120 NC C NO

PUR

WHT

BLK

BLK

BLK

CONDENSATE

HEATER

S2

S4

S3

S1

WHT

BLK

REV EO # REV DATE REV BY

APPROVED BY

-

-

-

-

-

PAN

-

GRD

115 V

60 Hz

1 PH

PLUG END

DETAIL

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

-

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

--

EO NUMBER

-

DRAWN BY:

DATE DRAWN:

APPROVED BY

JHB

12/1/98

-

UNIT

SHEET #

WIRING DIAGRAM

INCHES

1 OF 1

HGM-3-TS

GLOVERSVILLE, NY 12078

M100-2029

Loading...

Loading...