Hussmann HGL-1BS, HGL-2-TS, HGL-2BS, HGL-1TS, HGL-3BS Installation And Service Instructions Manual

...

January 2006

INSTALLATION & SERVICE

INSTRUCTIONS

FOR

HGL-1, 2 & 3 BOTTOM & TOP MOUNT

REMOTES

First Call for help (US and Canada):

1-800-922-1919

Soporte Tècnico y Asistencia (Mèxico):

01-800-522-1900

For a Service Network Locator and other

Information visit us at

www.hussmann.com

select Worldwide Locations

HUSSMANN - GLOVERSVILLE

P/N OII – HGL Remotes

January 2006

TABLE OF CONTENTS

Page

Introduction 5

Inspection 5

Location 5

Skid 5

Leg Installation (Top Mounts only) 5

Leveling and Sealing (Bottom Mounts only) 6

Top Decorative Panel Removal 6

Shelves 6

Air Distribution and Rear Flue Spacer 6

Electrical Connections 6

Serial Plate Information 7

Start-Up Procedure 7

General Up-Keep, Care & Cleaning, Routine Maintenance

Operation and Maintenance 8

Power Switches 8

Temperature Control 8

Thermometer 9

Electrical Enclosure 9

Defrost Time Clock 10

Defrost Heater Thermostat 10

Defrost Heater Replacement 10

Lighting Door Switches 11

Door and Frame Heaters 11

Expansion Valve Adjustment 11

Alarm Thermostat (Heater Delay) 11

Refrigeration, Leak Testing, and Evacuation 12

Remote Condensing Unit and Compressor 13

Fan Delay Thermostat 13

Head Pressure By-Pass Valve 13

Crankcase Heater 13

Crankcase Pressure Regulator 13

TABLE OF CONTENTS CON’T

Page

Electrical Box 14

Electrical Line Set 14

Refrigeration Line Sets 14

Pumpdown System on the Remote Unit 14

Setting up the Pumpdown System 15

Trouble Shooting Charts 16-19

Electrical Components List 19

Warranty and Parts Information 20

Ordering Replacement Parts 20

Warranty Parts Procedure 20

Compressor Replacement Procedure 21

INSTALLATION CHECK LIST

HGL / HGM / HGS UPRIGHT CABINETS

Level cabinet front to back and left to right. Level doors and adjust torque as needed. On HGL cabinets, it is important this be

done to ensure proper operation of evaporator fan switches.

Is proper voltage supplied to cabinet?

Cut and remove compressor shipping band (HGL only)

Is timer set for correct time of day? Fail-safe at 40 minutes, defrost pins at 10 p.m. and 6 a.m. (HGL only)

Are electrical connections tight and tubing positioned to prevent

rubbing? Is drain hose in water pan and trapped?

Does the condenser fan blade (s) turn freely?

Is the temperature control set per the following specifications?

Control Set At Cabinet Temperature

HGL -18 -13 off -9 on

HGM/HGS +29 to 30 +34 off +40 on

Revised 5/99 lw

sent with the cabinet.

For more details on the above, refer to the Installation Booklet

INTRODUCTION –

Hussmann HGL B/T models are

remote, low temperature, vertical display

merchandisers for ice cream and frozen

foods. Design features include heated

glass doors for fog free visibility, automatic defrost, and efficient foamed in

place non-CFC insulation. These models

are designed for remote installation as

single cases or multiplexed with other

cases.

INSPECTION –

Upon receipt of the cabinet, carefully examine the crating for damage. If

crate is damaged, make a note on the delivery ticket before signing. Carefully remove shipping crate and examine cabinet

for “concealed” damage. If damage is

found, contact the delivery carrier immediately and have his agent prepare an inspection report for the purpose of filing a

claim. This is your responsibility.

LOCATION –

Avoid locating the cabinet where

direct sunlight would shine into the fixture or where drafts from air conditioning grills, fans and open doors could affect its operation.

INSTALLATION and START-UP

–

SKID

–

The skid should be left on the unit

until it is near its final location. The skid

provides protection for both case and

floor. The skid is removed by raising one

end of the case approximately six inches.

BLOCK SECURELY and remove

the two skid bolts on the raised end. The

procedure is repeated on the opposite end.

When the skid bolts are removed, the case

may be slid off the skid.

LEG INSTALLATION – Top Mounts

Only

After the case is near its final location and the skid has been removed, the

NSF approved legs should be installed.

The legs are packaged inside the cabinet.

Replace the tape and door blocks. To install legs, raise one end of the cabinet approximately eight (8) inches, BLOCK SECURELY, and install two legs. The leg

mounting plates are factory installed and

contain a 1/2 x 13 tapped hole to mate

with the leg assembly. The procedure is

repeated on the opposite end. The 3-door

requires legs in the center. With cabinet

legs installed, the cabinet should be positioned in its final location and leveled.

The cabinet is leveled by turning

the bottom section of each leg. The selfclosing doors require the cabinet to be

properly leveled. End to end leveling will

make the door (s) close with uniform

speed and tightness. A slight pitch from

front to rear is desirable. THE CABINET BACK SHOULD NEVER BE

HIGHER THAN THE FRONT.

Page 5

LEVELING – SEALING – Bottom

Mounts Only

The case can be leveled by shimming under the cabinet base frame, or by installing optional levelers. The self-closing

doors require the cabinet to be properly

leveled. End to end leveling will make

the doors close with uniform speed and

tightness. A slight pitch from front to

rear is desirable. Once level the case

should be sealed to the floor as shown in

the following drawing, using an NSF approved material such as General Electric

RTV-102 silicone sealer or an equivalent

Silicone Sealant

Floor

BOTTOM LOUVERED PANEL REMOVAL -

The louvered panel provides access to the electrical box. Remove panel

by removing shipping screw (s) at the

bottom and lifting up and pulling forward. Remove shipping screw on electrical box to allow the electrical box to slide

out for servicing.

TOP DECORATIVE PANEL REMOVAL –

The top decorative panel is removed by lifting up and pulling forward.

SHELVES –

Each cabinet is provided with 4cantilever shelves per door that are adjustable on 1-inch increments and are

tiltable. Each cabinet also has one bottom shelf per door. These shelves

have one inch legs to allow proper airflow

in the cabinet. Behind the shelves are

wire flue spacers which also allow for

proper airflow. All shelves and flue spacers are white, epoxy coated for durability

and ease of cleaning. Shelves should be

adjusted to desired operating height.

When loading product into the cabinet,

care should be taken not to load product

so that it touches the evaporator coil

cover, also, do not extend product past the

front edge of the shelf. Extending past the

edge will seriously effect internal air flow

through out the cabinet.

Shelves are UL rated for a maximum load of 123 lbs. DO NOT OVERLOAD SHELVES.

AIR DISTRIBUTION AND REAR FLUE

SPACER –

Air is drawn through the evaporator from front to rear and is discharged

down the back wall, returning up the face

of the glass door to the return air grill.

NOTE: Rear wire grid must be in place

as this forms a discharge air flue at the

back of the cabinet.

ELECTRICAL CONNECTIONS

–

The HGL-2, 3,-T/B require a conduit connections of 208-230 supply voltage. It is very important for safety to you

and your customers to have the cabinet

properly grounded. Conduit connections

are required for positive grounding. The

electrical installation should be done by a

qualified electrician in accordance with

the National Electrical Code and/or local

code

s.

Page 6

NOTE: Connecting this unit to any electrical supply other than specified on the

serial plate will VOID the warranty and

may result in serious damage to the unit.

The cabinet should be supplied with its

own service.

SERIAL PLATE INFORMATION –

The serial plate is located in the

upper left hand corner of the case interior. It has all the pertinent information

needed for proper electrical installation.

The serial plate should not be removed

for any reason.

START UP PROCEDURE -

√

After the wiring has been completed,

set the defrost timer for the correct

time of day, making sure the defrost

pins are secure in the face of the

clock. HGL cabinets are factory set

for 2 defrost periods in 24 hours. (6

a.m. and 10 p.m.)

√

Check the cabinet thoroughly for

loose nuts and bolts and electrical

connections. Inspect the refrigeration lines for any visible damage or

chafing.

√

Replace the electrical box cover.

√

Start the cabinet and allow to pull

down to operating temperature before loading.

BTU CAPACITIES -

RATING TEMP ºF

BTU/HR EVAP COND AMB

1-T/B 3100 -20 110 90

2-T/B 4160 -20 110 90

3-T/B 5900 -20 110 90

ELECTRICAL SPECIFICATIONS

RUN

HZ/PH VOLTS AMPS FUSE WT.

1-T 60/1 208-230 7.9 15AMP 547

2-T 60/1 208-230 8.8 15AMP 755

3-T 60/1 208-230 11.0 15AMP 986

1-B 60/1 208-230 7.9 15AMP 547

2-B 60/1 208-230 8.8 15AMP 816

3-B 60/1 208-230 11.0 15AMP 1065

All cases use R-404A refrigerant. Please

check the serial plate for the specific refrigerant used.

Page 7

GENERAL UP-KEEP, CARE and CLEANING, ROUTINE

MAINTENANCE, and

OPERATION MAINTENANCE

CARE and CLEANING –

To insure good sanitation, appearance, and minimum maintenance, the cabinet should be cleaned and washed regularly as use demands. Clean with mild detergent and warm water. DO NOT USE

AN ABRASIVE CLEANER OR STEEL

WOOL AS THEY WILL MAR THE FINISH.

ROUTINE MAINTENANCE –

Under normal conditions, after the

cabinet is installed and running, very little

maintenance should be required. However, the following list of housekeeping

practices will assure trouble-free operation.

√ Check drain pan and heater to prevent

accidental overflow.

√ Make sure doors are closing properly

and that the gaskets seal.

√ Make sure all evaporator fan motors

are running. These can be seen

through grill inside cabinet.

OPERATION and MAINTENANCE

POWER SWITCHES -

The power switch is located at the

electrical box which is behind the bottom,

louvered access panel (bottom mount) or

behind the top decorative panel (top

mounts). The switch will shut off all

power.

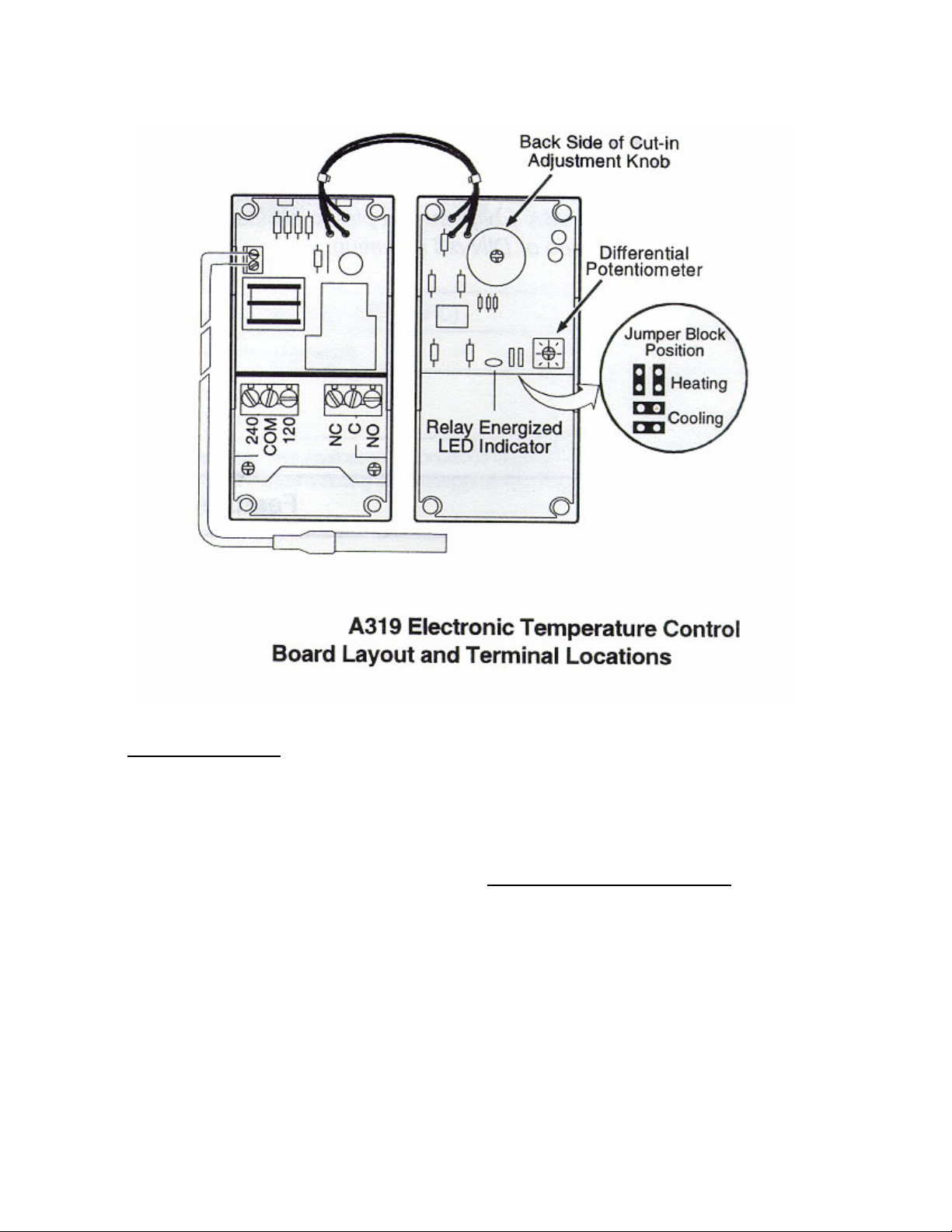

TEMPERATURE CONTROL –

The electronic temperature control is located in the electrical box. The

temperature control does not have an

‘OFF’ position. Adjustments may be

made by turning the knob on the face of

the dial. Turning it clockwise will give

warmer temperatures while counterclockwise will give colder temperatures.

There is also an adjustable temperature

differential (the difference between the

cut-in temperature and the cut-out temperatures) located on the back of the temperature control cover. When adjusting

the differential, the temperature setting

may also have to be adjusted.

A picture of this Electronic Temperature Control board layout and terminal location is on the next page.

The control has a range of –20ºF to

+100ºF with a differential of 1º to 30º. It

is factory set for approximately –18F with

an 10º differential. The temperature

should be checked with a thermometer

other than the case thermometer after it is

running to insure that the case is running

at the proper temperature for the product.

Page 8

THERMOMETER –

The thermometer is located by

looking through the right hand door onto

the right hand end of the fan plenum.

The thermometer will also warm up

rather rapidly when the case door is held

open for a time such as when the case is

being restocked or a shopper is making a

decision on a product.

After the door is closed it will take some

time for the thermometer to pull back

down to the case temperature. The thermometer and temperature control sense

discharge air temperature which is 5-10º

colder than the case temperature.

ELECTRICAL ENCLOSURE

–

The electrical enclosure contains

the defrost time clock and temperature

control. For servicing convenience, access

is gained by removing the access panel

and electrical box cover.

Page 9

THE CABINET SUPPLY BREAKERS

SHOULD BE DISCONNECTED BEFORE REMOVING THE ENCLOSURE

COVER.

DEFROST TIME CLOCK –

The timer is factory pre-set for two

defrost cycles per day at 6:00 a.m. and

10:00 p.m. with a 40 minute failsafe. The

timer must be adjusted to the proper time

of day when the cabinet is started. The

timer is adjusted by turning the knurled

adjustment knob in the center of the dial

face counter-clockwise until the time indicator corresponds with the correct time of

day. The defrost pins should be checked

for tightness. The timer will require readjusting after a power failure or the

cabinet supply is turned off for extended

periods of time. If an additional defrost is

required due to ambient or cabinet usage

conditions, do not put a defrost during the

middle of the day. Put any additional defrost during the night or a time when the

cabinet has the lowest usage.

Defrost is time initiated and temperature terminated. If cases are multiplexed, the defrost thermostats can be

wired in series so that the cases can be

temperature terminated.

If the thermostat should fail, the

timer is equipped with a failsafe set at 40

minutes that will allow defrost to terminate on time.

DEFROST HEATER THERMOSTAT –

The defrost heater thermostat is

clamped to the evaporator outlet tube. It

is a bi-metal thermostat that is tied in series with the evaporator fans for a delay

and with defrost time clock solenoid to end

defrost when the temperature has been

satisfied. The evaporator fans will not

come on until the thermostat senses 32ºF

and defrost will terminated when the stat

senses 58ºF.

DEFROST HEATER REPLACEMENT

The defrost heaters are firmly embedded in the evaporator and held in place

with spring clips. To remove the heater,

first remove all the spring clips and pull

the defective heater out of the slots in the

evaporator, starting at the wire supply

lead.

The replacement heater should be

firmly seated in the slots by using a small

block of wood and a mallet. After the new

heater is in place, replace all of the spring

retaining clips to assure heater retention.

One lead of the defective heater may be

used to pull the new leads through the

cabinet to the respective terminals as

marked on each lead.

NOTE: Care must be taken to make sure

the drain stub is correctly inserted in the

cabinet drain tube for proper drainage.

Page 10

LIGHTING –

Interior lighting is provided by

electronically powered T-8 lamps located

inside each doorway. The tubes are enclosed in a patented lens system to maintain proper heat around the bulb for

maximum, light intensity and to protect

the product in case of breakage. See the

Anthony “ELS” instructions for lens removal, attached at the back of this booklet.

Each HGL model has a convenient

ON/OFF switch so lights may be turned

off to conserve energy during hours when

the store is closed. The switch is located

inside the cabinet above the left hand

door. This switch only controls the lights.

208-230 volt power must be shut off at the

main power supply source located within

the store prior to starting any service or

maintenance work.

Light ballasts are located in the

mullions of the door frames. See the Anthony ballast removal instructions at the

back of this installation booklet.

DOOR SWITCHES –

The switches at the top of the doorways operate the evaporator fan motors.

These switches stop the fan motors when

the doors are open.

Page 11

DOOR FRAME HEATERS –

This cabinet is equipped with both

frame and door heaters. These are thermostatically controlled and will not come

on until the cabinet is at operating temperature. See door mfg. instructions for

heater replacement at the back of this

booklet

ALARM THERMOSTAT (Heater Delay)

The alarm (heater delay) thermostat is located on the top of the inner liner

in the upper right hand corner behind the

evaporator. The thermostat will not turn

the heaters on until it senses 0º and in

turn will turn the heaters off when its

senses +18º F. This is so that unwanted

heat will not be added to the case during

defrost or if the case refrigeration system

fails.

EXPANSION VALVE ADJUSTMENT –

Expansion valve must be adjusted

to fully feed the evaporator. Before attempting to adjust the valve make sure

the evaporator is either clean or only

lightly covered with frost, and that the

cabinet is within 10º of its expected operation temperature. Adjust the expansion

valve as follows:

Attach two sensing probes to the

evaporator, one under the clamp holding

the expansion valve sensing bulb and the

other securely taped to one of the return

bends two thirds of the way through the

evaporator circuit. Some “hunting” of

the expansion valve is normal. The valve

should be adjusted so that during the

hunting the greatest difference between

the two probes is 3º to 5ºF.

Remove valve stem cover and turn

valve stem counter-clockwise to decrease

temperature difference between the

probes. To increase temperature difference of probes, turn the valve stem clockwise. With this adjustment, during a portion of the hunting the temperature differences between the two probes may be

less than 3ºF, or at times as low as 0ºF.

Make adjustments of no more than

one half turn of the valve stem at a time

and wait for at least fifteen minutes before rechecking probe temperature and

making further adjustments. Replace

and tighten cover of the valve stem.

REFRIGERATION –

As stated previously, these cases

can be designed for single or multiplexed

installations. The following is a description of a 'packaged system' which includes the case, a factory-designed condensing unit, electrical line set, and refrigeration line set. These systems come precharged for easy field installation.

If it should become necessary to

leak test the system, please adhere to the

following notice:

NOTICE: BECAUSE OF THE CFC ATMOSPHERIC CONSIDERATIONS

BEING TAKEN TODAY, WE ASK

THAT LEAK TESTING BE DONE WITH

REFRIGERANT 22 MIXED WITH NITROGEN.

IF THE CONDENSING UNIT

NAMEPLATE DESIGNATES A REFRIGERANT OTHER THAN R-22 REMOVE ALL R-22 FROM THE IMMEDIATE AREA TO AVOID CONFUSION

AFTER LEAK TESTING AND EVACUATING THE UNIT. RECHARGE THE

UNIT WITH PROPER REFRIGERANT.

LEAK TESTING –

***** CAUTION*****

The test gas cylinder must be

equipped with a pressure gauge and regulator so that system test pressures do not

exceed maximum allowable limits. Do not

ever use anything other than a R-22 / Nitrogen mixture for leak testing.

Attach a refrigerant test gas cylinder to your service manifold and connect

the manifold to the charging port on the

liquid line valve. Charge an R-22 / Nitrogen mixture into the system, raising the

pressure to the remote unit’s nameplate

for the low side and high side pressures.

Using an electronic detector, carefully

check the entire system for leaks. Take

special care to inspect all brazed and flare

connections.

EVACUATION –

After the system is proven leak

tight, thoroughly evacuate the system according to the following procedure:

Page 12

√

Discharge the refrigerant-nitrogen

mixture, allowing it to blow from the

system as rapidly as possible, into an

empty cylinder. Be sure that all service valves and solenoid valves are

open to allow all of the mixture to be

discharged.

√

Connect a deep-drain vacuum pump

to both the high and low side of the

system. Pull a vacuum on the system

to at least 1500 microns.

√

Break the vacuum by adding refrigerant into the system until the pressure

is above 0 psig. Always charge the refrigerant line into the system through

a new drier in the charging manifold

line. A 16 cubic inch drier is sufficient

for this purpose.

√

Repeat steps 2 and 3 two more times,

the third time evacuating the system

to 500 microns.

REMOTE CONDENSING UNIT -

The remote condensing unit is constructed of weather resistant G-90 galvanized steel for durability. It includes the

compressor, condenser, head pressure bypass valve, receiver (insulated), crankcase

heater, drier, sight glass, condenser fan

motors, fan delay thermostat, dual pressure control, solenoid valve, electrical

box, and quick connects (optional).

COMPRESSOR –

The compressor is mounted on

Page 13

semi-rigid, rubber pads. There are no

mounting springs so the compressor is essence becomes solid mounted. DO NOT

LOOSEN THE MOUNTING BOLTS ON

THE COMPRESSOR.

FAN DELAY THERMOSTAT –

The fan delay thermostat is connected to the left hand fan motor (as you

face the unit from the electrical box side)

and will leave this fan off at ambients below 65ºF to insure proper condensing temperatures.

HEAD PRESSURE BY-PASS VALVE –

The head pressure by-pass valve is

a pre-set, non-adjustable type. Its function

is to divert the refrigerant to the receiver

when the head pressure falls below the setting so that proper head pressure is maintained in the system and liquid is feeding

the thermostatic expansion valve.

CRANKCASE HEATER –

The crankcase heater is located below the compressor on semi-hermetic models and wrapped around on hermetic models. The heater is on at all times.

CRANKCASE PRESSURE REGULATOR –

The remote units designed for the

HGL-1-T/B and HGL-2-T/B employ a

crankcase pressure regulator in the suction

line. The CPR is set for 10 psi on the remote unit for both 1 and 2 door. The purpose of the valve is to maintain a low suction pressure on start-up so that the

compressor will start properly. On startup, the valve will hold the suction pressure at the desired setting until the suction pressure has dropped below the setting, then the valve will open.

If it becomes necessary to check or

reset the valve, the case must be warm

such as after a defrost cycle or from an

initial warm case condition. Put a suction

compound gauge on the compressor suction valve, start the compressor. If the

pressure needs to be reduced turn the adjustment screw clockwise or, counterclockwise to raise the pressure. DO NOT

SET THE VALVE BASED ON THE

NAMEPLATE AMPERAGE RATING

AS THE PRESSURE SETTING WILL

BE TOO HIGH AND THE COMPRESSOR WILL NOT START PROPERLY.

ELECTRICAL BOX –

The electrical box comes pre-wired

except for the electrical line set coming

from the cabinet. Consult the wiring diagram for proper wiring. There is a power

switch in the box for the compressor and

a separate one for the crankcase heater.

ELECTRICAL LINE SET

When the electrical line set is employed, power is brought to the case first

and the line set is installed between the

case and the remote unit. Consult the

wiring diagram for proper wiring.

BOTTOM MOUNT VERSIONS -

The refrigeration line set is

provided with quick-connect connections

on both ends for installation at the case

and the remote unit.

The line set is tagged with the end

that is to be attached at the case. The line

set is tagged with the end that is to be attached at the case end.

Do not over tighten the quick connects as this will damage the seals.

After the quick connects are installed at the case end, the factory supplied

‘insulating boot’ must be sealed with contact cement to prevent air leakage that can

cause ice and water to build up on the case.

Nylon ties are further provided to seal the

ends but should not be used solely to seal

the ends. Do not over tighten the ties.

TOP MOUNT VERSIONS –

The refrigeration line set is provided with quick connects to mount to the

remote condensing unit. The lines are factory installed and sealed at the case end.

Care should be taken when uncoiling the

line set. Do not over tighten the quick connects as this will damage the seals.

PUMPDOWN SYSTEM ON THE

REMOTE UNIT

-

Operation

– The pumpdown system shuts

off the flow of refrigerant in the high side

liquid line when the case cycles off or during a defrost cycle and pumps the refrigerant from the evaporator into the condenser

and receiver.

Page 14

TROUBLE SHOOTING, LIGHTING TROUBLE SHOOTING

WARRANTY and ELECTRONIC LIGHTING

SYSTEM INSTRUCTIONS

TROUBLE SHOOTING CHARTS

TROUBLE PROBABLE CAUSE SOLUTION

Compressor runs continuously, Product too warm

1. Short of refrigerant 1. Leak check. Change

drier. Evacuate and recharge

2. Inefficient compressor 2. Replace

3. Dirty condenser 3. Clean

High head pressure 1. Cabinet location too

1. Relocate cabinet

warm

2. Restricted condenser air

flow

3. Defective condenser fan

2. Clean condenser to remove air flow restriction

3. Replace

motor

4. Air or non-condensable

gases in system

4. Leak check., change

drier, evacuate, and recharge

5. Defective fan delay ther-

5. Replace

mostat

Warm storage temperatures 1. Temperature control not

1. Reset control

set properly

2. Short of refrigerant 2. Leak check, change

drier, evacuate, and recharge.

Page 15

TROUBLE SHOOTING CON’T

3. Cabinet location too

3. Relocate

warm

4. Too much refrigerant 4. Change drier, evacuate,

and recharge

5. Low voltage. Compres-

5. Check power

sor cycling on overload

6. Condenser dirty 6. Clean

7. Dual pressure control

7. Reset control

not properly

Compressor runs continu-

1. Defective control 1. Replace

ously. Product too cold

2. Control feeder tube not

2. Assure proper contract

in positive contract

3. Short on refrigerant 3. Leak check, change

drier, evacuate, and recharge

Compressor will not start,

no noise

2. Defective or broken wir-

1. Blown fuse or breaker 1. Replace fuse or reset

breaker

2. Repair or replace

ing

3. Defective overload 3. Replace

4. Defective temperature

4. Replace

control

5. Power disconnected 5. Check service cord or

wiring connections

6. Defective dual pressure

6. Replace

control

7. Defective solenoid valve 7. Replace

Page 16

TROUBLE SHOOTING CON’T

Compressor will not start,

1. Low voltage 1. Contact electrician

cuts out on overload

2. Defective compressor 2. Replace

3. Defective relay 3. Replace

4. Restriction or moisture 4. Leak check, replace

drier, evacuate and recharge

5. Inadequate air over con-

5. Clean condenser

denser

6. Defective condenser fan

6. Replace

motor

7. CRO not set properly 7. Reset to 10 psi.

Icing condition in drain pan 1. Low voltage 1. Check voltage at com-

pressor

2. Cabinet not level 2. Check front to rear level-

ing, adjust legs accordingly

3. Defective drain tube

3. Replace

heater

4. Defective drain pan

4. Replace

heater

LIGHTING SYSTEM

Lights won’t start 1. Check light switch

2. Check continuity to ballast

3. Check to see if bulbs are inserted properly into sock-

ets

4. Check voltage

Page 17

LIGHTING SYSTEM

Lights flicker 1. Allow lamps to warm up

2. Check lamp sleeve for cracks

3. Check sockets for moisture and proper contact

4. Bulb replacement may be necessary

5. Check voltage

6. New bulbs tend to flicker until used

Ballast hums 1. Check voltage

2. Replace ballast

ELECTRICAL COMPONENTS

MODEL HGL-1-T/B HGL-2-T/B HGL-3-T/B

Evaporator Fan Morrill SPB5EM2 Same Same

Motor

Light Ballast Huss. #06-S183-1 06-S-183-1 (1) 06-S-183-2 (2)

06-S-183-2 (1)

Fluorescent lamp FO4OW-T8-60” Same Same

Page 18

WARRANTY –

Please read carefully to assure prompt and accurate service

Ordering Replacement Parts –

Contact your nearest Hussmann Distributor.

Always specify model and serial number of cabinet.

If correct part number is not known, give a clear description of part itself and its function

in the cabinet or remote unit.

Warranty Parts Procedure –

Same as items above

Give original installation date of cabinet and, if possible, forward a copy of the original

invoice or delivery receipt.

All shipments of in-warranty replacement parts will be invoiced from the factory until

such time as the defective part is returned and proved to be defective by our Quality Control Department.

Contact your Hussmann Distributor for instructions on returning in-warranty parts.

Warranty parts must be returned to the factory within 30 days of date of failure to assure

proper disposition.

Lack of any of the above information may result in the shipment of the wrong part, or a

delay in shipment.

Page 19

Compressor Replacement Procedure –

Replacement compressors will not be shipped from the Hussmann factory. They may be

obtained from your nearest Copeland Wholesaler.

Your wholesaler will replace, free of charge, any compressor found to be defective

within twelve months of installation, not to exceed twenty months from the date of

manufacture, as determined by the compressor serial number on the compressor serial

plate.

For any defective compressor beyond the twelve or twenty month time period, a salvage

value credit will be given too partially offset the invoice for the replacement.

To obtain reimbursement forward to: Hussmann Corporation

140 East State Street

Gloversville, NY

12078

the following information:

1. The cabinet model and serial number

2. A copy of the wholesaler’s invoice, along with a copy of the salvage value credit.

WIRING DIAGRAMS ARE ATTACHED AT THE BACK OF THIS BOOKLET

Page 20

FRAME HEATERS

DOOR & FRAME HEATERS

BLU

GREY

BRN

ORN

DOOR HEATERS

FAN SWITCH

BRN

BLU

LIGHT SWITCH

LAMP

ORN

ORN

BRN

BRN

BLK

3

WHT

4

8

BALLAST

9

10

1

RED

2

RED

5

BLU

6

BLU

7

LAMP

SENSING

BULB

DEFROST CLOCK

T

1

3

ALARM STAT

4

2

X

N

DEFROST HTRS

DRAIN

TUBE

HTRS

COMM

240 AC 120 NC C NO

BLK

BLK

SENSOR

RED

DRAIN PAN HTRS

BLK

JUMPER

***

***

***

***

***

RED

BLK

BLK

RED

ORN

WHT

RED

BRN

BLK

BLK

BLK

BLK

GRD

BLK

BLK

BLK

***

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

***

***

RED

***

***

ORN

BLK

DEFROST

THERMOSTAT

P

Z

BLK

EVAP FANS

S8

S7

REV EO # REV DATE REV BY

APPROVED BY

ELIMINATED OPTIONAL CONDENSATE PAN HEATER

-

-

-

-

B

06/24/03 JLS

-

PUR

RED

BLK

NOTE:

WIRES NOTED WITH ARE IN

WIRE HARNESS UP BACK OF CASE

S6

RED

BLK

S5

TC2

3

1

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

GRD

TO

CONDENSING

}

UNIT

EO NUMBER

DRAWN BY:

DATE DRAWN :

APPROVED BY:

208-230 V

60 Hz

5224

1 PH

-

JWL

2/23/96

ANTHONY FRAME

***

SCALE

INCHES

SHEET #

1 OF 1

M100-2024R B

HGL-1-B

HGL-1-T

GLOVERSVILLE, NY 12078

WIRING DIAGRAM

SENSING

BULB

DEFROST CLOCK

T

3

1

FRAME HEATERS

4

X

2

DOOR & FRAME HEATERS

ALARM STAT

DEFROST HTRS

N

BLK

BLU

RED

BLK

BLK

DRAIN

TUBE

HTRS

COMM

240 AC 120 NC C NO

DRAIN PAN HTRS

SENSOR

BLK

JUMPER

***

RED

***

***

***

***

BLK

RED

ORN

WHT

RED

BRN

BLK

BLK

BLK

BRN

BLK

GRD

BLK

BLK

BLK

FAN SWITCHES

ORN

DOOR HEATERS

***

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

BRN

***

***

BLU

***

ORN

RED

BLK

***

LIGHT SWITCH

ORN

8

ORN

9

BRN

10

BRN

1

LAMP

DEFROST

THERMOSTAT

P

Z

BLK

EVAP FANS

S8

S7

REV EO # REV DATE REV BY

APPROVED BY

ELIMINATED OPTIONAL CONDENSATE PAN HEATER

-

-

-

-

B

06/24/03 JLS

-

PUR

RED

BLK

BALLAST

S6

S5

BLK

3

WHT

4

RED

2

RED

5

BLU

6

BLU

7

LAMP

OPTIONAL DISCHARGE AIR SENSOR

NOTE:

WIRES NOTED WITH ARE IN

WIRE HARNESS UP BACK OF CASE

RED

BLK

TC2

3

1

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

GRD

TO

CONDENSING

}

UNIT

EO NUMBER

DRAWN BY:

DATE DRAWN :

APPROVED BY:

208-230 V

60 Hz

1 PH

5224

JWL

1/23/95

-

8

BALLAST

9

10

1

ANTHONY FRAME

***

SCALE

INCHES

SHEET #

1 OF 1

BLK

3

WHT

4

RED

2

RED

5

BLU

6

BLU

7

LAMP

HGL-2-B

HGL-2-T

GLOVERSVILLE, NY 12078

WIRING DIAGRAM

M100-2025R B

SENSING

BULB

DEFROST CLOCK

T

1

DOOR & FRAME HEATERS

FRAME HEATERS

3

4

X

2

N

ALARM STAT

BLK

BLU

RED

BLK

DEFROST HTRS

SENSOR

BLK

JUMPER

COMM

240 AC 120 NC C NO

RED

***

***

***

***

***

BRN

GRD

BLK

BLK

DRAIN PAN HTRS

DRAIN

TUBE

HTRS

PUR

RED

ORN

WHT

RED

BRN

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

DOOR

HEATERS

BLK

FAN SWITCHES

ORN

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

***

BRN

***

***

BLU

***

ORN

RED

***

BLK

LIGHT SWITCH

ORN

8

ORN

BRN

BRN

LAMP

P

BALLAST

9

10

1

DEFROST

THERMOSTAT

Z

BLK

EVAP FANS

S5

S7

TC2

PUR

RED

BLK

REV EO # REV DATE REV BY

APPROVED BY

ELIMINATED OPTIONAL CONDENSATE PAN HEATER

-

-

-

-

C

09/22/03 JLS

-

BLK

3

WHT

4

RED

2

RED

5

BLU

6

BLU

7

LAMP

NOTE:

WIRES NOTED WITH ARE IN

WIRE HARNESS UP BACK OF CASE

RED

BLK

3

1

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

GRD

TO

CONDENSING

}

UNIT

EO NUMBER

DRAWN BY:

DATE DRAWN :

APPROVED BY:

208-230 V

60 Hz

1 PH

5263

JWL

2/23/96

-

ORN

8

9

10

1

BALLAST

ORN

BRN

BRN

LAMP

ANTHONY FRAME

SCALE

INCHES

SHEET #

1 OF 1

M100-2026R C

BLK

3

WHT

4

RED

2

RED

5

BLU

6

BLU

7

LAMP

***

HGL-3-B

HGL-3-T

GLOVERSVILLE, NY 12078

WIRING DIAGRAM

Loading...

Loading...