Page 1

HGL- 1, 2 & 3 BS, TS

®

Bottom / Top Mount

Low Temperature

Remote and Self Contained

Glass Door Merchandisers

HGL-2BS

Operation Manual

IMPORTANT

Keep in store for future reference!

HGL-3TS

Installation &

P/N 0515296_E

April 2015

Spanish 0531287

French 0531288

Page 2

Page 3

P/N 0515296_E iii

®

IMPORTANT

KEEP IN STORE FOR FUTURE REFERENCE

Quality that sets industry standards!

12999 St. Charles Rock Road • Bridgeton, MO 63044-2483

®

U.S. & Canada 1-800-922-1919 • Mexico 1-800-522-1900

www.hussmann.com

© 2015 Hussmann Corporation

Page 4

Page 5

P/N 0515296_E TABLE OF CONTENTS v

ANSI DEFINITIONS ................. vi

INSTALLATION

Certification

Hussmann Product Control

Shipping Damage

Location

Self Contained Location

Model Description

Unloading

Exterior Loading

Shipping Skid

Merchandiser Leveling

Leg Installation

Serial Plate Location

Refrigeration Unit Access

Sealing Merchandiser to Floor

........................ 1-1

........... 1-1

................... 1-1

........................... 1-1

.............. 1-2

.................. 1-4

......................... 1-4

.................... 1-4

...................... 1-4

............... 1-5

(Top Mounts Only) ....... 1-5

................. 1-5

............. 1-6

......... 1-6

Air Distribution & Rear Flue Spacer

Shelves

Checklists

............................ 1-6

.......................... 1-7

.... 1-6

Display ............................ 3-2

Start-Up

Sequence of Operation Diagram

Alarms and Codes

Defrost Termination Switch

Manual Defrost

Temperature Adjustment

Sensor to Control Adjustment

Controls and Adjustments

Start Up

Crankcase Pressure Regulator

Receiver

TEV Adjustment

Load Limits

Stocking

Thermometer

Lighting

Door Switches

Door Defrost Heater Thermostat

Alarm Thermostat

........................... 3-2

....... 3-4

................... 3-5

........... 3-5

..................... 3-5

............. 3-6

......... 3-7

............ 3-8

........................... 3-9

......... 3-9

........................... 3-9

................... 3-10

....................... 3-11

.......................... 3-11

...................... 3-12

.......................... 3-12

..................... 3-12

...... 3-12

.................. 3-12

ELECTRICAL / REFRIGERATION

Merchandiser Electrical Data

Field Wiring

........................ 2-1

.......... 2-1

Electrical Connections . . . . . . . . . . . . . . . . 2-1

Electrical Enclosure

Power Switches

Electrical Outlet

Refrigeration (Self Contained)

Refrigeration (Remote)

Line Sizing (Remote)

Koolgas (Remote)

Compressor

........................ 2-3

Condensate Pan

Air Distribution and Rear Flue Spacer

NOTES:

........................... 2-4

.................. 2-1

..................... 2-1

..................... 2-1

......... 2-2

............... 2-2

................. 2-2

................... 2-2

..................... 2-3

.. 2-3

START UP / OPERATION

Safe-NET III User Instructions

User Instructions

.................... 3-1

........ 3-1

MAINTENANCE

Care and Cleaning

Do NOT Use:

Do:

............................... 4-1

Cleaning Stainless Steel Surfaces

Cleaning Coils

Cleaning Condensate Pan

Maintaining Fluorescent Lamps

................... 4-1

...................... 4-1

....... 4-2

...................... 4-2

............. 4-3

........ 4-4

SERVICE

Replacing Fan Motors and Blades

Replacing Thermometer

............... 5-1

Defrost Heater Replacement

Troubleshooting Guide

Lighting Problem / Solution

Replacing Door Parts

Servicing Lighting

Replacement Parts List

............... 5-2

........... 5-4

................ 5-5

................... 5-5

............... 5-6

...... 5-1

.......... 5-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 6

vi

APPENDIX — TECHNICAL DATA

* * * * * * * * * * * * * * * * * * * * * * * * * *

HGL-1BS — Plan View

HGL-2BS & HGL-3BS — Plan View

HGL-1TS — Plan View

HGL-2TS & HGL-3TS — Plan View

HGL Dimensions & Electrical Data

Cross Sections and Refrigeration Data

HGL Wiring Diagrams

.............. A-1

... A-2

............. A-3

.. A-4

... A-5

.. A-6

.............. A-7

REVISION HISTORY

REVISION E — Revised Parts List

REVISION D — Added Checklists Page 1-7; Added

Warning Page 1-3; Cleaning Coils 4-3; Maintaining

Fluorescent Lights 4-4. Checklist 4-5. New Replacement

Parts List, New Wiring Diagrams, New Sensor drawing

3-7, Replacing door parts Page 5-5

REVISION C — JUNE 2013

Replaced wiring diagrams; added new for each model

A-9

ANSI Z535.5 DEFINITIONS

• DANGER – Indicate[s] a hazardous

situation which, if not avoided, will

result in death or serious injury.

• WARNING – Indicate[s] a hazardous

situation which, if not avoided, could

result in death or serious injury.

• CAUTION – Indicate[s] a hazardous

situation which, if not avoided, could

result in minor or moderate injury.

• NOTICE – Not related to personal injury –

Indicates[s] situations, which if not avoided,

could result in damage to equipment.

Updated drawing on Page 3-7

REVISION B — FEBRUARY 2012

Revised to B for Wind Chill purposes

ORIGINAL ISSUE — JANUARY 2011

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 7

P/N 0515296_E 1-1

INSTALLATION

CERTIFICATION

These merchandisers are manufactured to

meet ANSI / National Sanitation Foundation

®

(NSF

) Standard #7 requirements. Proper

installation is required to maintain certification.

Near the serial plate, each case carries a label

identifying the type of application for which

the case was certified.

ANSI/NSF-7 Type I - Display Refrigerator / Freezer

Intended for 75°F / 55% RH Ambient Application

ANSI/NSF-7 Type II - Display Refrigerator / Freezer

Intended for 80°F / 55% RH Ambient Application

ANSI/NSF-7 - Display Refrigerator

Intended for Bulk Produce

HUSSMANN PRODUCT CONTROL

SHIPPING DAMAGE

All equipment should be thoroughly examined

for shipping damage before and during

unloading. This equipment has been carefully

inspected at our factory. Any claim for loss

or damage must be made to the carrier. The

carrier will provide any necessary inspection

reports and/or claim forms.

Apparent Loss or Damage

If there is an obvious loss or damage, it must

be noted on the freight bill or express receipt

and signed by the carrier’s agent; otherwise,

carrier may refuse claim.

Concealed Loss or Damage

When loss or damage is not apparent until

after equipment is uncrated, retain all packing

materials and submit a written response to the

carrier for inspection within 15 days.

The serial number and shipping date of all

equipment is recorded in Hussmann’s files

for warranty and replacement part purposes.

All correspondence pertaining to warranty or

parts ordering must include the serial number

of each piece of equipment involved. This is to

ensure the customer is provided with the correct parts.

Recommended operating ambient

temperature is between

65°F (18°C) and 75°F (23.9°C).

Maximum relative humidity is 55%.

LOCATION

These merchandisers are designed for

displaying products in air conditioned stores

where temperature is maintained at or below

the ANSI / NSF-7 specified level and relative humidity is maintained at or below 55%.

Placing refrigerated merchandisers in direct

sunlight, near hot tables or near other heat

sources could impair their efficiency. Like

other merchandisers, these merchandisers are

sensitive to air disturbances. Air currents

passing around merchandisers will seriously

impair their operation. Do NOT allow air

conditioning, electric fans, open doors or

windows, etc. to create air currents around the

merchandiser.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 8

1-2 InstallatIon

SELF CONTAINED (LOCATION)

Product should always be maintained at proper temperature. This means that from the

time the product is received, through storage,

preparation and display, the temperature of the

product must be controlled to maximize the

life of the product.

Be sure to position self contained

merchandisers properly.

HGL-TS Location

The condensing unit is located at the top of

the HGL-TS. At least 12 inches of clearance

should be allowed at the rear of the cabinet and

at the top of the merchandiser. This clearance is

necessary to provide free air movement to and

from the condenser for maximum operating

efficiency.

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 9

P/N 0515296_E 1-3

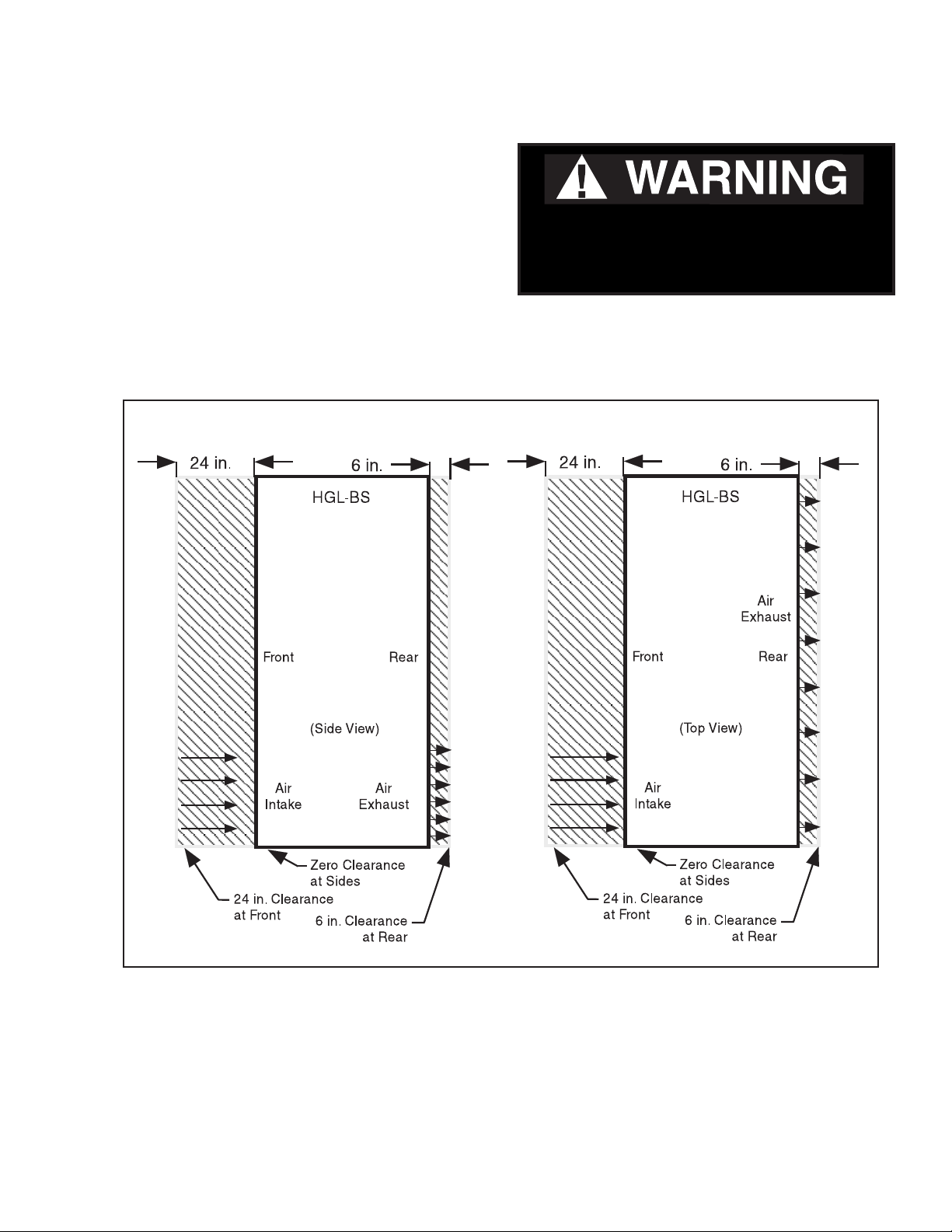

HGL-BS Location

At least 24 inches of clearance should be

maintained in front of HGL-BS merchandisers

and 6 inches of clearance at the rear to provide

the necessary free air movement to and from

Do NOT stand or walk on top of

merchandiser. Do not store items or

ammable materials atop the unit.

the condenser. The condensing unit is located

at the bottom of these merchandisers.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 10

1-4 InstallatIon

MODEL DESCRIPTION

Hussmann HGL-BS/TS models are self-contained,

low temperature, vertical display merchandisers.

Design features include: heated glass doors for

fog-free visibility, automatic defrost, efficient

foamed in place non-CFC insulation, cord

connection for self-contained 208-230 volt

application, and balanced refrigeration systems

for energy-saving performance.

HGL- B/T models are low temperature remote

cases. These cases do not have a condensing

unit or condensate pan.

UNLOADING

Unloading from Trailer:

Lever Bar (also known as a Mule, Johnson

Bar, J-bar, Lever Dolly, or Pry Lever)

Move the merchandiser as close as possible to

its permanent location and remove all packaging.

Check for damage before discarding packaging.

Remove all separately packed accessories such

as kits and shelves.

Improper handling may cause damage to the

merchandiser when unloading. To avoid damage:

1. Do not drag the merchandiser out of the

trailer. Use a Johnson bar (mule).

2. Use a forklift or dolly to remove the

merchandiser from the trailer.

EXTERIOR LOADING

Do NOT walk on top of merchandisers or

damage to the merchandisers and serious

personal injury could occur.

merchandisers are not structurally

designed to support external loading

such as the weight of a person. Do not place

heavy objects on the merchandiser.

SHIPPING SKID

Each merchandiser is shipped on a skid to

protect the merchandiser’s base, and to make

positioning the case easier.

Remove the top of the crate and detach walls

from each other. Lift crate from the skid.

Unscrew the case from the skid. The fixture

can now be lifted off the crate skid. Lift only at

base of skid! Remove any braces and/or skids

attached (blanket wrapped merchandiser may

have skids).

DO NOT LAY MERCHANDISER OVER

ON THE FLOOR TO REMOVE SKID.

Once the skid is removed, the merchandiser

must be lifted —NOT PUSHED— to reposition.

To remove the skid, remove screws attaching

skid to the merchandiser.

Check floor where cases are to be set to see if

it is a level area. Determine the highest part of

the floor.

Do NOT remove shipping crate until the

merchandiser is positioned

for installation.

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 11

P/N 0515296_E 1-5

MERCHANDISER LEVELING

Be sure to position merchandisers properly.

Level the merchandiser at corners.

Merchandiser(s) must be installed level to

ensure proper operation of the refrigeration

system and to ensure proper drainage of

defrost water. The merchandiser can be leveled

by shimming under the cabinet base frame, or

by installing optional leg levelers.

The self-closing doors require the cabinet to be

properly leveled. End to end leveling will allow

the door(s) to close with uniform speed and

tightness. A slight pitch from front to rear

is desirable.

should never Be higher than the front.

the Back of merchandiser

LEG INSTALLATION (Top Mounts Only)

Install the NSF approved legs after the case is

near its final location. The legs are packaged

inside the cabinet. Replace the tape and door

blocks.

To install legs:

Raise one end of the cabinet about 8 inches.

Block the merchandiser securely, and install

two legs. The leg mounting plates are factory

installed and contain a

1

/2 x 13 in. tapped hole

to mate with the leg assembly. The procedure

is repeated on the opposite end. Three-door

merchandisers require legs in the center.

The cabinet should now be positioned at its

final location with all legs installed. The

merchandiser is leveled by turning the bottom

section of each leg. End to end leveling will

make the door(s) close with uniform speed and

tightness. A slight pitch from front to rear is

desirable.

SERIAL PLATE LOCATION

The serial plate is located in the upper lefthand corner of the merchandiser’s interior.

The serial plate contains all pertinent information such as model, serial number, amperage

rating, refrigerant type and charge. Do not

remove the serial plate under any circumstance.

Serial Plate

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 12

1-6 InstallatIon

REFRIGERATION UNIT ACCESS

Top Mounts — The top decorative panel is

removed by lifting the panel up and pulling

forward.

Bottom Mounts — The lower front panel may

be removed by removing screw at bottom and

lifting the panel straight upward and over

the tabs on which it is hanging. The panel is

installed by reversing the above procedure.

Then

Lift up and

out to remove

access panel

First

Ensure lower front panel is flat against the

floor when installed to prevent air circulation

problems for self contained merchandisers.

If the condensing unit needs to be serviced, it

can be pulled out to gain access for hard to

reach components like the condenser fans.

To pull out the condensing unit, remove the

two hold down brackets, at the unit base.

Care must be given to the drain line when

re-inserting the condensing unit back into

the case. The drain line must be inside the

defrost water evaporation pan to prevent the

discharge of water on the floor.

SEALING MERCHANDISER TO FLOOR

(Bottom Mounts Only)

If required by local sanitary codes, or if the

customer desires, merchandisers may be sealed

to the floor using a vinyl cove base trim. The

size needed will depend on how much variation there is in the floor, from one end of the

merchandiser to the other. Sealing of the lower

front and rear panels on self contained models may hamper their removal for servicing or

maintenance of the condensing unit.

NOTE: Do not allow trim to cover any intake

or discharge grilles located in the lower front

panel.

AIR DISTRIBUTION & REAR FLUE

SPACER

Air is drawn through the evaporator from

front to rear and is discharged down the back

wall, returning up the face of the glass door to

the return air grille.

NOTE: Rear flue spacer must be in place as

this forms a discharge air flue at the back of

the cabinet.

SHELVES

Each cabinet is provided with four cantilever

shelves per door that are adjustable by 1 inch

increments. The shelves can also be tilted.

Each cabinet had one bottom shelf per door.

These shelves have one-inch legs to allow

proper air flow in the cabinet. Behind the

shelves are wire flues spacers, which allow for

proper air flow. All shelves and flue spacers

are white and epoxy coated for durability and

ease of cleaning.

Shelves should be adjusted to desired operating

height. Do not load product so that it touches

the evaporator coil cover. Do not extend product past the front edge of the shelf. Extending

past the edge will seriously affect internal air

flow through the cabinet. Shelves are UL rated

for a maximum load of 120 lbs.

loaD the shelves.

Do not over-

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 13

P/N 0515296_E 1-7

Form HSCW01 Rev. 30MAY12 P/N 0525209_B

Hussmann Self-Contained Refrigerati on E quipm ent Sta rt Up Check List

***Please note that failure to follow this start-up document may void your factory warranty***

Step Startup Activity Check

1

Locate, read and maintain install/operation manual in a safe place for

future reference.

2 Examine unit. Confirm there is NO damage or concealed damage.

3 Level the unit, side to side and front to rear.

4 Remove all shipping brackets/compressor straps/bolts etc.

5

6

Unit must be run on a dedicated electrical circuit without the use of

an extension cord.

Ensure that the proper electrical requirements for the equipment are

supplied.

7 Verify field electrical connections are tight.

8

Verify all electrical wiring is secured and clear of any sharp edges or

hot lines.

9 Verify the condensate drain line is properly trapped and pitched.

10 Verify all required clearances on the sides and back of unit.

11

Advise owner/operator that merchandiser must operate at temperature for 24 hrs prior to loading

LEGAL DISCLAIMER:

Hussmann shall not be liable for any repair or replacements made without the written consent of Hussmann, or w hen the productis installed or operated in a manner

contrary to the printed instructions covering installation and service which accompanied such product.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Verify there are no air disturbances external to the unit. Heat and air

registers, fans, and doors etc.

with product.

HGL Glass Door Merchandisers

Page 14

1-8 InstallatIon

NOTES:

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 15

P/N 0515296_E 2-1

ELECTRICAL / REFRIGERATION

MERCHANDISER ELECTRICAL DATA

Refer to Appendix A of this manual or the

merchandiser’s serial plate for electrical

information.

FIELD WIRING

Field wiring must be sized for component

amperes stamped on the serial plate. Actual

ampere draw may be less than specified.

ALWAYS CHECK THE SERIAL PLATE FOR

COMPONENT AMPERES

ELECTRICAL CONNECTIONS

All wiring must be in compliance with NEC

and local codes. All electrical connections (for

remote models) are to be made in the electrical

Handy Box located behind the removable base

panel at the left end of the merchandiser when

facing the discharge air louver.

Before any service is performed on this piece

of equipment, make sure the power supply to

the merchandiser is disconnected.

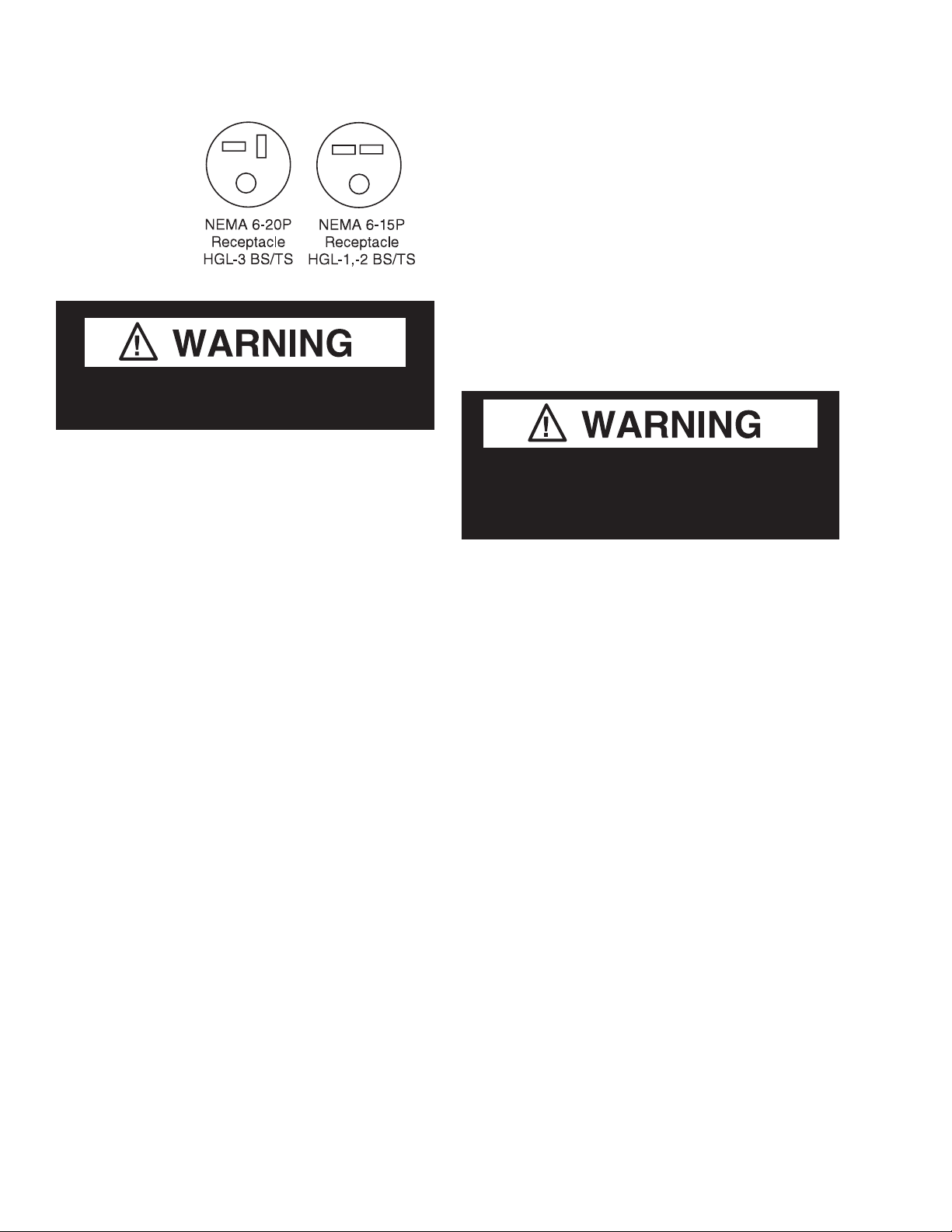

ELECTRICAL OUTLET:

Before the merchandiser is connected to any

wall circuit, use a voltmeter to check that the

outlet is at 100% of the rated voltage. The wall

circuit must be dedicated for the merchandiser. Failure to do so voids the warranty. Do

not use an extension cord. Never plug in more

than one merchandiser per electrical circuit.

• Always use a dedicated circuit with the

amperage stated on the unit.

• Plug into an outlet designed for the plug.

• Do not overload the circuit

• Do not use long or thin extension cords.

Never use adapters.

• If in doubt, call an electrician.

ELECTRICAL ENCLOSURE

Remove the access panel and electrical box

cover to access the electrical enclosure. The

cabinet supply breakers should be disconnected before removing the enclosure cover.

POWER SWITCHES

The power switch is located at the electrical

box, which is behind the top decorative panel

(TS models) or bottom louvered panel (BS

models). The switch will shut off all power to

the merchandiser.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Risk of Electric Shock. If cord or plug

becomes damaged, replace only with

a cord and plug of the same type.

— LOCK OUT / TAG OUT —

To avoid serious injury or death from electrical shock, always disconnect the electrical

power at the main disconnect when servicing

or replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

HGL Merchandisers

Page 16

2-2 ElEctrical / rEfrigEration

Self-contained

models have

factory-installed

power cords

attached at the

electrical box.

Merchandiser must be grounded.

Do not remove the power supply cord ground.

REFRIGERATION

(Self Contained Models)

LINE SIZING

(Remote Models)

Refrigerant line connections are made at the

left end of merchandiser (facing front) beneath

the refrigerated display area. The refrigerant

line connection size is

5

is

/8 in. Refrigerant lines should be sized as

3

/8 in. The suction line

shown on the refrigeration legend that is

furnished for the store or according to

ASHRAE guidelines.

Refrigeration lines are under pressure.

Refrigerant must be recovered before

attempting any connection or repair.

Each self contained model is equipped with

its own condensing unit. The correct type of

refrigerant will be stamped on each merchandiser’s

serial plate. The merchandiser refrigeration piping

is leak tested. The unit is charged with refrigerant,

and shipped from the factory with all service

valves open.

REFRIGERATION

(Remote Models)

Refrigeration temperature is controlled by an

electronic factory-installed thermostat. The

electronic thermostat controls a liquid line

solenoid valve (not provided with the merchandiser).

The thermostat energizes the valve as the temperature rises. A pump down system is recommended for outdoor condensing units.

For refrigerators with other than Koolgas

defrost, the suction and liquid line should be

clamped and/or taped together and insulated

for a minimum of 30 feet from the refrigerator.

KOOLGAS

(Remote Models)

If Koolgas defrost is used, the liquid line will

need to be increased two sizes larger inside the

merchandiser area. This is necessary to ensure

even liquid drainage from all evaporators

during defrost.

Refrigerators with Koolgas defrost

not have their liquid lines and suction lines in

should

contact with each other but are to be separately insulated for a minimum of 30 ft from the

refrigerator. Additional information for the

balance of the refrigerant lines is recommended

and required wherever condensation and dripping

would be objectionable.

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 17

P/N 0515296_E 2-3

CONDENSATE PAN

Oil Traps

P-traps (oil traps) must be installed at the base

of all suction line vertical risers.

Pressure Drop

Keep refrigerant line runs as short as possible

to avoid large pressure drops. Use a minimum

number of elbows. Where elbows are required,

use long radius elbows only.

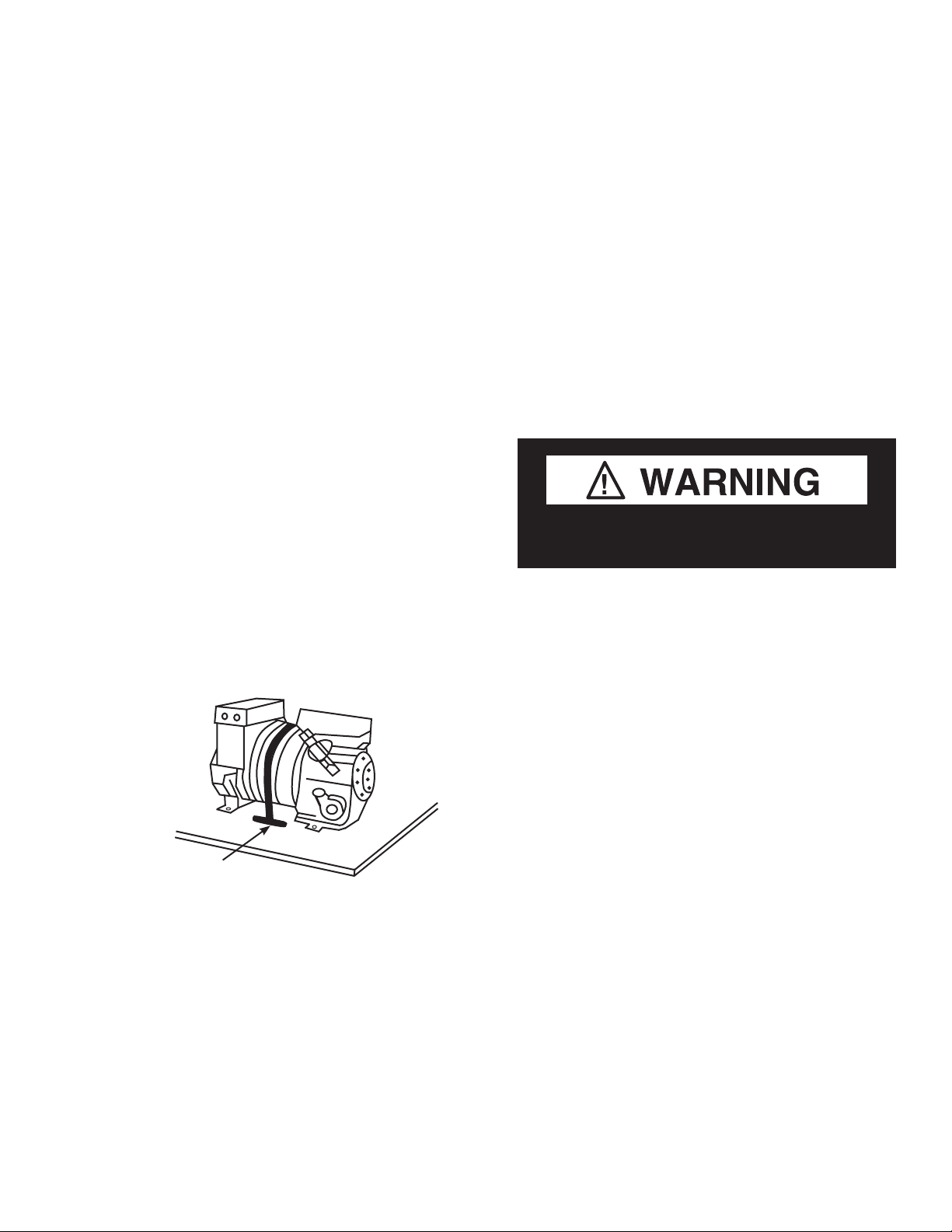

COMPRESSOR

(Self Contained)

The HGL compressor is mounted on vibration

springs. The compressor is banded down during

shipment. This band MUST be cut and removed

to allow the compressor to float freely once

placed into operation. Failure to cut compressor

shipment band may result in excessive noise or

system damage.

An electrically heated (300W, 208-230V)

condensate pan evaporates defrost water. The

heated condensate pan slides onto the slide

plate on the cabinet bottom on both the TS

and BS merchandisers.

The pan is removable for cleaning. A vinyl

drain tube is provided for connection to the

heated condensate pan. The drain must be

trapped to guard against drain line freezing

and as a good sanitation practice.

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

Compressor Band

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 18

2-4 ElEctrical / rEfrigEration

NOTES:

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 19

P/N 0515296_E 3-1

START UP / OPERATION

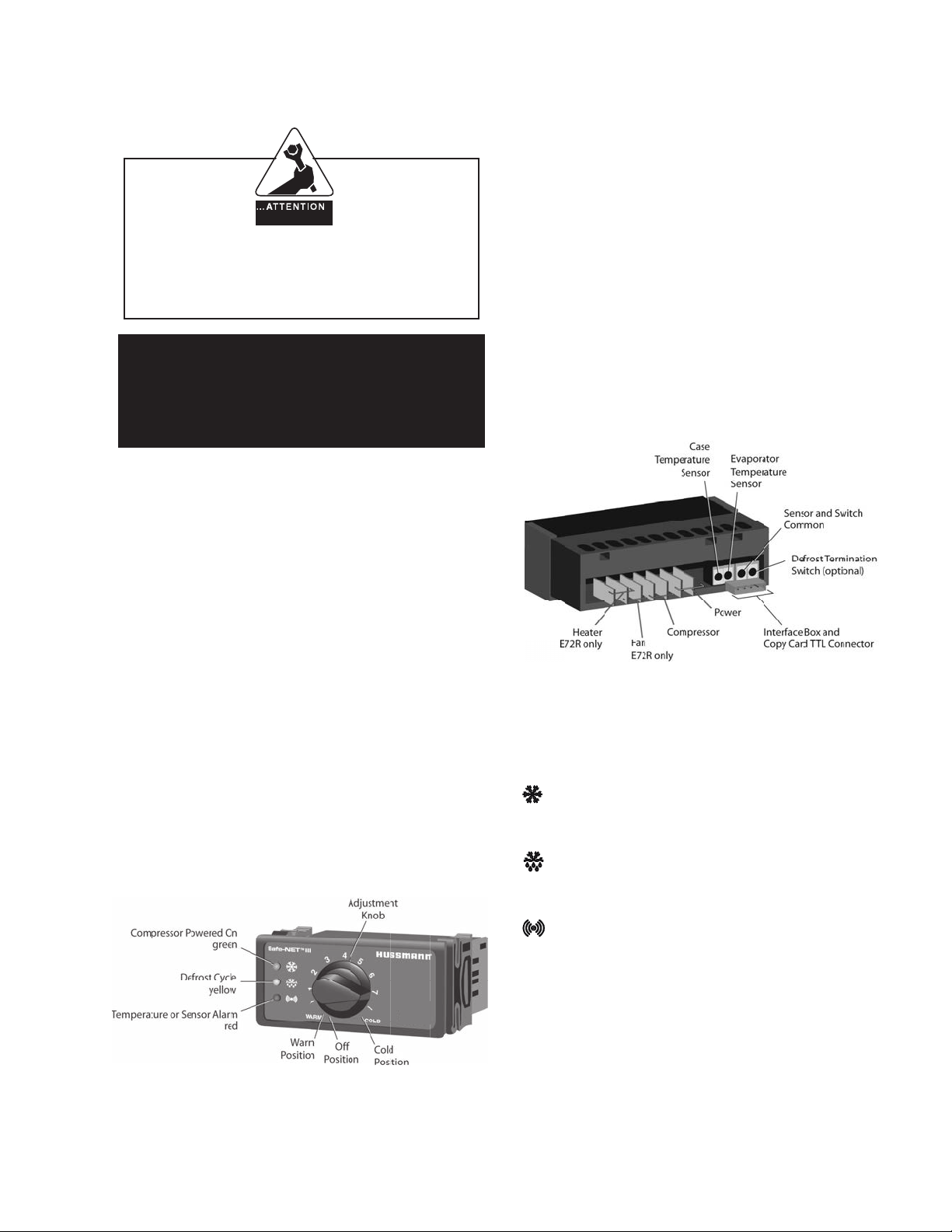

The front of the controller has an adjustment

knob and status LEDs. The back of the

IN STA LLER

controller has connections for sensors and

switched equipment.

It is the contractor’s responsibility to

install merchandiser(s) in accordance with

all local building and health codes.

Safe-NET III™

TEMPERATURE AND DEFROST

CONTROLLER

SAFE-NET III™ USER INSTRUCTIONS

Your refrigerated case uses a Hussmann

Safe-NET™ III temperature and defrost

controller to precisely maintain the temperature and prevent frost buildup on the cooling

coil. LEDs indicate when the compressor or

refrigeration is on, when the case is in a defrost

cycle, if the temperature is outside the desired

range, or if there is a sensor failure.

The Safe-NET III controller includes the

following features and connections.

• Adjustment knob:

Adjusts the temperature setpoint.

Turn adjustment knob to OFF to turn off

refrigeration system. Unplug merchandiser

from power before servicing the unit.

An adjustment knob allows the temperature

to be set within the configured range and can

power off the controller and compressor. Your

controller has been custom-configured to provide the best temperature and defrost control

for your chilled or frozen food.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

• Controller LEDs:

Compressor Powered On LED (green):

Lights while the compressor is running or

the refrigeration valve is open.

Defrost Cycle LED (yellow):

Lights while the refrigeration coil is

defrosting.

Temperature or Sensor Alarm (red):

Lights if the temperature is too warm or

too cold. Flashes if a sensor fails.

HGL Merchandisers

Page 20

3-2 Start up / OperatiOn

START-UP / OPERATION

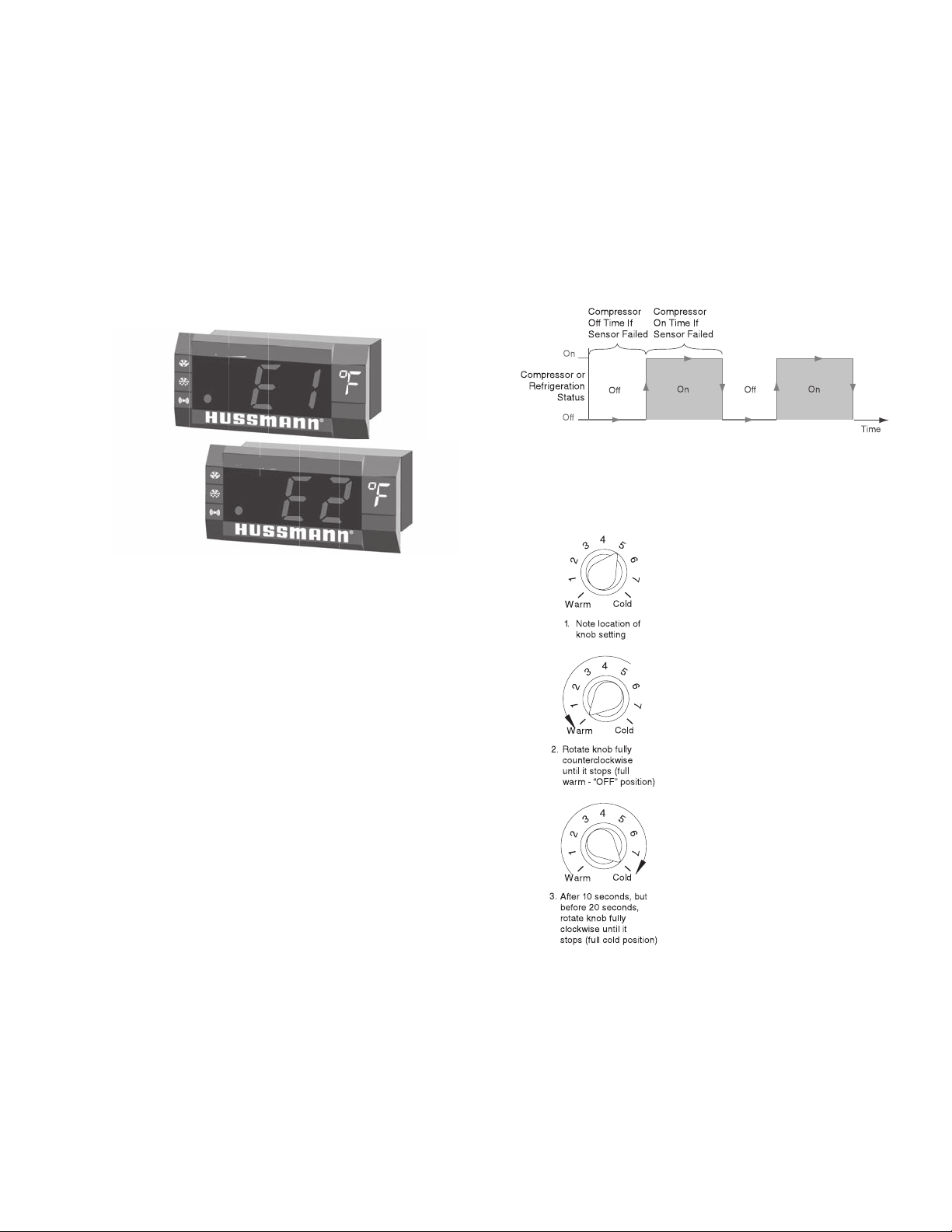

• Rear connections:

– Case temperature sensor:

• Typically senses the temperature

of the air in the case.

Used by the controller to determine when

to power on or power off the compressor

or refrigeration.

– Evaporator temperature sensor:

• Senses the temperature of the

refrigeration coil.

Terminates a defrost cycle when

refrigeration coil ice melts.

– Compressor or refrigeration relay:

• Switches on the compressor or

refrigeration valve for cooling.

The optional evaporator fan remains

ON when the adjustment knob is in the

Off position.

Before applying power to the merchandiser,

remove the front grille.

Locate the compressor (for self contained

models),

compressor in place. This band is only needed

cut the band holding the

for shipment, and must be cut prior to

operation.

Check thermostat knob is at the appropriate

position. See temperature adjustment on

Page 3-6.

Check the check the merchandiser’s cabinet

thoroughly for loose nuts and bolts. Check all

electrical connections. Inspect the refrigerant

lines for any visible damage or chafing.

Replace the front grille.

The following list of housekeeping practices

will assure trouble-free operation:

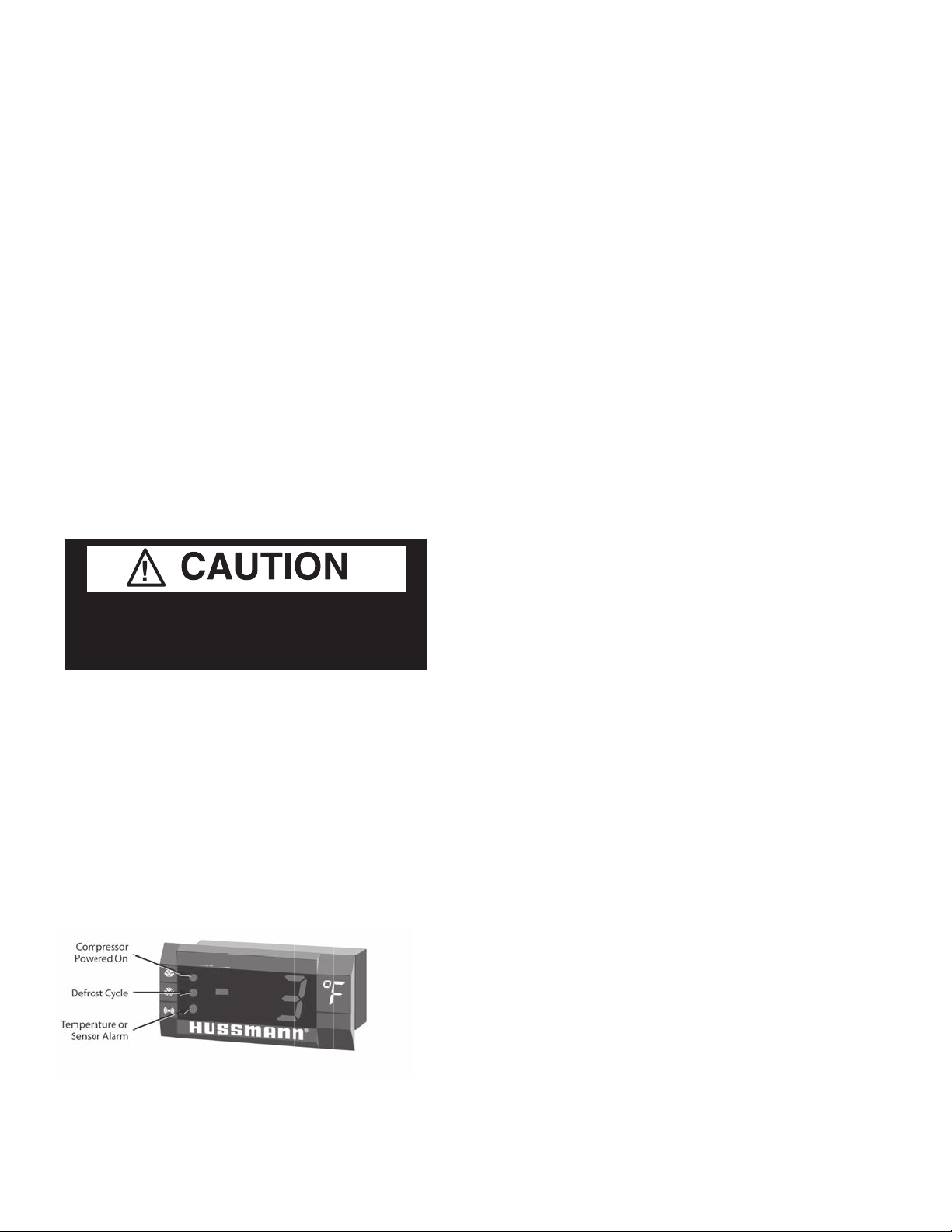

DISPLAY

The display includes three red LEDs and two

digits for temperature, defrost status, and error

codes.

The three display LEDs are red, and their

behavior matches the LEDs on the controller.

• Check operation of condenser fan motors.

Fan blades must turn freely.

• Check drain pan and heater to prevent

accidental overflow.

• Make sure doors are closing properly, and

that gaskets are sealed.

• Make sure all evaporator fan motors are

running. These can be seen through grille

inside of cabinet.

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 21

P/N 0515296_E 3-3

START-UP / OPERATION

1. Plug in the merchandiser.

The OFF Position does not disconnect line

voltage to the case, refrigeration unit, fan,

or heater.

NOTE: The 65°C Version Controller includes

a Parameter Code Number. This number indicates what program has been loaded into the

controller. When the Controller is first powered up, or is turned off and then back on, a

2-digit parameter code number will display for

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

3 seconds. Then the Self Check will Start.

The Safe-NET parameter code is 63.

2. Wait for the self check to complete. During

the self check, each LED flashes for one

second, then all LEDs turn on for two

seconds. If the LEDs do not flash, make

sure the adjustment knob is not in the Off

position.

• After the self check, all LEDs turn off

until the compressor starts. There may be

a delay before the compressor starts. If the

red Temperature or Sensor Alarm LED

stays on after the self check.

• The green Compressor Powered On LED

turns on when the compressor starts.

NOTE: Do NOT load product until AFTER

merchandiser operates for 24 hours and reaches desired operating temperature.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 22

3-4 Start up / OperatiOn

1. Apply power to the merchandiser. Wait for

the self check to complete. During the self

check a 2 digit number will appear for 3 seconds. Then each LED flashed for one second and then all LED’s turn on for two seconds. If the LED’s do not flash, make sure

the adjustment knob is not in the “OFF”

position.

1A. The merchandiser temperature displays at

startup. The initial defrost starts two hours

later. The display will show the temperature at

the start of defrost. This reading will remain

displayed during defrost and until it times out,

even though the refrigeration mode has been

initiated. (The green LED will be lit.)

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

2. The compressor will start after a delay; 30

seconds after the power is applied.

3. The compressor will continue to run until it

reaches its cut-out temperature (Pulldown).

4. The refrigeration cycle will continue for the next

subsequent scheduled 12-hours or demand

defrost.

5. The above process will repeat (steps 3 and 4)

until the power is interrupted.

6. If power stops, the process will start over at

Step 1, and the time to subsequent defrost will

reset.

Page 23

P/N 0515296_E 3-5

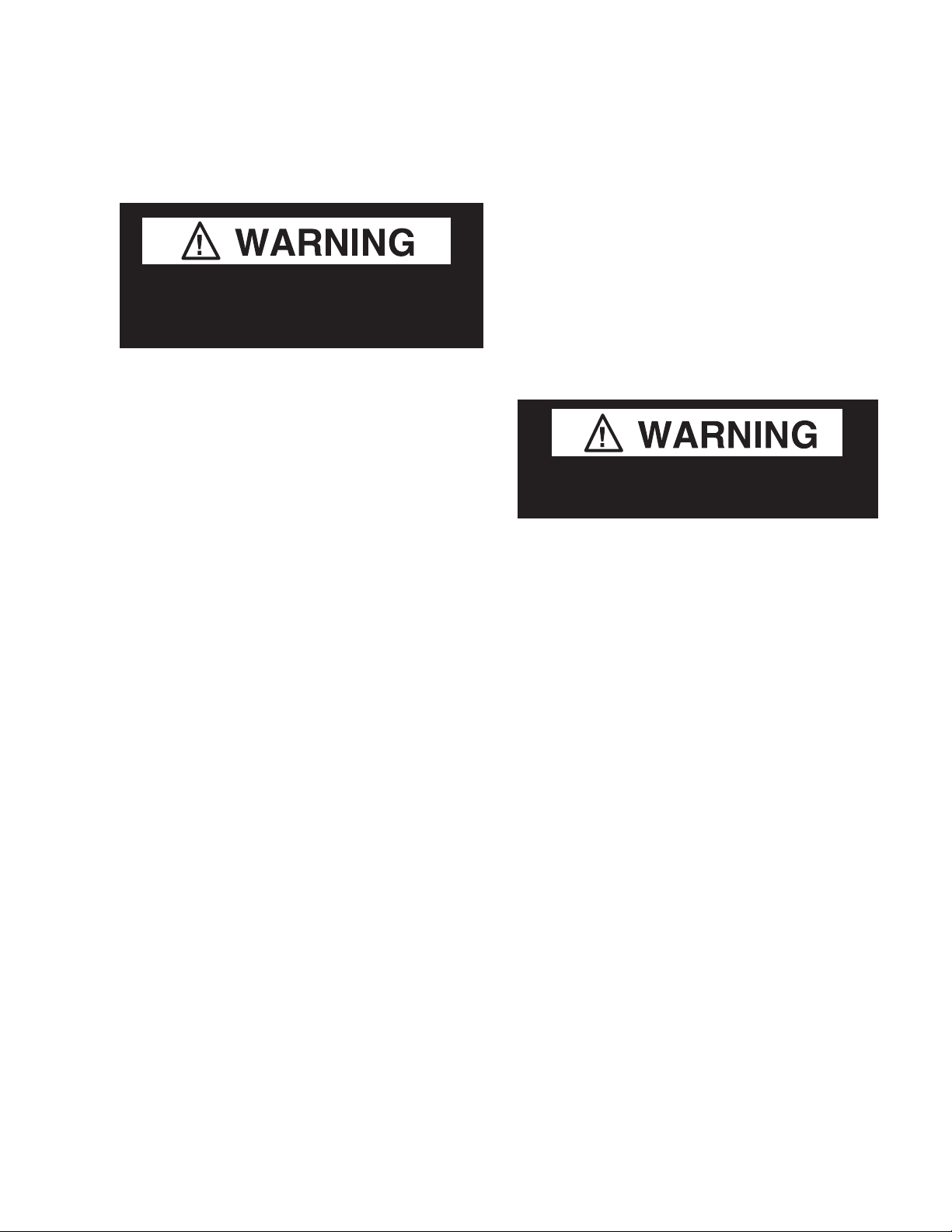

ALARMS AND CODES

Flashing temperature or sensor alarm

led, e1 or e2

If the Temperature or Sensor Alarm LED

(red) on the controller and display is flashing,

a temperature sensor has failed. The display

shows E1 if the case sensor has failed or E2 if

the evaporator sensor has failed.

If the merchandiser sensor fails, refrigeration

will run continuously. Turn off, or repeat a

duty cycle of a few minutes on and a few

minutes off.

DEFROST TERMINATION SWITCH

Merchandisers may use a defrost termination

switch, instead of an evaporator sensor to

terminate a defrost cycle. The defrost

termination switch is temperature activated

and senses the completion of defrost.

MANUAL DEFROST

Note:

This procedure initiates

a manual or forced

defrost.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

IMPORTANT: Return the control knob to

its original setting (Step1) once the manual

defrost has been initiated.

HGL Merchandisers

Page 24

3-6 Start up / OperatiOn

TEMPERATURE ADJUSTMENT

1. Rotate the adjustment knob counter clock-

wise for a hammer setpoint or clockwise for

a colder setpoint.

2. While adjusting the temperature, the display

shows the setpoint (cut out value). A few

seconds after the temperature is set, the

controller reverts to the sensed temperature

in the merchandiser.

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

3. To verify merchandiser settings, perform the

operations below. Output readings should

be within one degree of the temperatures

shown above.

Page 25

P/N 0515296_E 3-7

Sensor to Control Conguration

Sensor Bracket (HGL/HGM)

Thermometer Sensor

(Black Sheath)

(x)

Safe-NET Control Sensor

(Black Sheath)

#8 Black

Sheathed Air

Sensor

#9 Yellow Sheathed

Defrost Sensor

(See page 3-10

for location

of sensor)

#10 White

(Common)

Back of Safe-NET

Control Detail

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

#11

Not Used

HGL Merchandisers

Page 26

3-8 Start up / OperatiOn

1. The Safe-NET III Controller controls refrigeration temperature. This is factory installed in

the control panel. Adjust this control knob to

maintain the discharge air temperature shown.

Measure discharge air temperatures at the

center of the discharge louver.

Defrosts are time initiated and temperature

terminated for self contained and remote,

including Koolgas models. The defrost setting

is factory set as shown above.

To ensure a thorough defrost, defrost must be

terminated by the temperature termination

setting — not by time.

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 27

P/N 0515296_E 3-9

START UP

Follow the Safe-NET III start up procedures

as detailed in Section 3 of this manual.

Each self contained merchandiser has its own

evaporator coil and a pre-set thermostatic

expansion valve (TEV). The TEV has been

factory set at design conditions to provide the

recommended performance.

CRANKCASE PRESSURE REGULATOR

The HGL-1 and HGL-2 merchandisers employ

a crankcase pressure regulator in the suction

line. The CPR is set for 10 psi. The purpose of

the valve is to maintain a low suction pressure

on startup so that the compressor will start

properly. On start-up, the valve will hold the

suction pressure at the desired setting until the

suction pressure drops below the setting, then

the valve will open. If it becomes necessary to

check or reset the setting, the merchandiser

must be warm such as after a defrost cycle or

from an initial warm case condition.

Put a suction compound gauge on the compressor suction valve. Start the compressor.

If the pressure needs to be reduced, turn the

adjustment screw clockwise or counterclockwise to raise the pressure.

RECEIVER

NOTE: All HGL models prior to early 2014

had this receiver. New production early 2014

does not have this receiver.

The receiver should not be confused for a filter-drier

or muffler. The receiver is in the liquid line after

the condenser and just ahead of the filter drier.

The manufacturer may label the receiver as a

muffler or a drier, but it is in fact, an empty

shell.

IN STA LLER

COMPRESSOR

HGL self contained merchandiser has

a compressor that is banded down for

shipment. This band MUST be cut and

removed to allow the compressor to float

freely once placed into operation.

NOTE: Failure to cut compressor

shipment band may result in excessive

noise or system damage, which is not

covered by warranty.

do not set the valve based on the serial

plate amperage rating as the pressure

setting will be too high, and the compressor

will not start properly.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 28

3-10 Start up / OperatiOn

TEV Adjustment

Expansion valves may be adjusted to fully feed

the evaporator. Before attempting to adjust

valves, make sure the evaporator is clear or only

lightly covered with frost, and the merchandiser

is within 10°F of its expected operating temperature.

TXV Bulb

Sensor probe to

be located at 90°

Sensor attached

(white)

Adjust the valve as Follows:

a. Attach a probe to the suction line near the

expansion valve bulb.

b. Obtain a pressure reading from the factory

installed Schraeder valve. Convert the pressure

reading to a saturated temperature for the

refrigerant.

Temperature (b) minus Temperature (a) is the

superheat. The valve should be adjusted so that

the greatest difference between the two temperatures is 3°F to 5° F.

Make adjustments of no more than

the valve stem at a time and wait for at least

15 minutes before rechecking the probe temperature and making further adjustments.

1

/2 turn of

be located at 90°

Yellow Sensor SS Tip

Sensor probe to

TXV Bulb

Yellow Sensor

SS Tip

HGL 1-door

TXV Bulb

HGL 2-door

See replacement parts list in Section 5 of this

manual for proper TXV replacement. If you

have flare connections on TXV you must

replace with a flare style TXV. Newer models

will have sweat connections.

Sensor probe to

be located at 90°

TXV Bulb

HGL 3-door

TXV Bulb

Yellow Sensor

SS Tip

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 29

P/N 0515296_E 3-11

LOAD LIMITS

Each merchandiser has a load limit decal. Shelf

life of perishables will be short if load limit is

violated.

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

At no time should merchAndisers be

stocked beyond the loAd limits indicAted.

do not block Air louvers.

STOCKING

Product should NOT be placed inside the

merchandisers until merchandisers are at

proper operating temperature.

Allow merchandiser 24 hours to operate before

loading product.

Proper rotation of product during stocking is

necessary to prevent product loss. Always

bring the oldest product to the front and set

the newest to the rear.

air discharge and return Flues must

remain open and Free oF obstruction at

all times to provide proper refrigeration and

air curtain performance. Do not allow product, packages, signs, etc. to block these grilles.

Do not use non-approved shelving, baskets,

display racks, or any accessory that could

hamper air curtain performance.

Do not load

product past

shelves

Do not allow product to be placed outside of

the designated load limits in the illustration.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 30

3-12 Start up / OperatiOn

THERMOMETER

The thermometer is located by looking

through the right hand door onto the right

hand end of the fan grille. The thermometer

will warm up rapidly when the merchandiser

door is held open, or when the merchandiser is

being restocked. After the door is closed it will

take some time for the thermometer to decrease

to optimal temperature. The thermometer and

temperature control senses discharge air

temperature, which is 5º to 10º F colder than

the merchandiser temperature.

LIGHTING

Electronically powered T-8 lamps, located

inside each doorway, provide interior lighting.

The tubes are enclosed in a patented lens system

to maintain proper heat around the bulb for

maximum light intensity. The tubes also protect

the product in case of breakage.

LED LIGHTS

Each HGL model has an ON/OFF switch so

lights may be turned off to conserve energy

during hours when the store is closed. The

switch is located inside the cabinet above the

left-hand door. This switch only controls the

lights. 208-230 V power must be shut off at the

main disconnect, located within the store prior

to starting any service or maintenance work.

For details showing how the LED fixtures are

mounted, see the supplemental document at the

end of this manual.

DOOR SWITCHES

The switches at the top of the doorways operate

the evaporator fan motors. These switches stop

the fan motors when the doors are open.

DOOR DEFROST HEATER THERMOSTAT

Each HGL model has an ON/OFF switch so

lights may be turned off to conserve energy

during hours when the store is closed. The

switch is located inside the cabinet above the

left-hand door. This switch only controls the

lights. 208-230 V power must be shut off at the

main disconnect, located within the store prior

to starting any service or maintenance work.

Light ballasts are accessed from the outside of

the mullion. For details showing how the T8

fixtures are mounted, see the supplemental

document at the end of this manual.

This cabinet is equipped with both frame and

door heaters. These are thermostatically controlled, and will not come on until the cabinet is

at operating temperature.

ALARM THERMOSTAT (heater display)

The alarm (heater display) thermostat is located

on the top of the inner liner in the upper right

hand corner behind the evaporator. The

thermostat will not turn the heaters on until it

senses 0º F, and in turn will turn the heaters

off when it senses +18º F. This is because the

unwanted heat will not be added to the merchandiser during defrost or if the case refrigeration system fails.

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 31

P/N 0515296_E 4-1

MAINTENANCE

CARE AND CLEANING

Long life and satisfactory performance of

any equipment is dependent upon the care it

receives. To ensure long life, proper sanitation

and minimum maintenance costs, these

merchandisers should be thoroughly cleaned,

all debris removed and the interiors washed

down, weekly.

Exterior Surfaces

The exterior surfaces must be cleaned with a

mild detergent and warm water to protect and

maintain their attractive finish.

abrasive cleaNsers or scouriNg pads.

Never use

Interior Surfaces

The interior surfaces may be cleaned with most

domestic detergents, ammonia based cleaners

and sanitizing solutions with no harm to the

surface. Self contained models empty into a

limited capacity condensate pan, which will

overflow if excess water is used in cleaning.

Do:

•Remove the product and all loose debris to

avoid clogging the waste outlet.

•Store product in a refrigerated area such as a

cooler. Remove only as much product as can

be taken to the cooler in a timely manner.

•Disconnect electrical power before cleaning.

•Thoroughly clean all surfaces with soap and

hot water.

pressure hoses to wash the iNterior.

These will desTroy The merchandisers’

sealing causing leaks and poor perfor-

mance.

•Take care to minimize direct contact between

fan motors and cleaning or rinse water.

do Not use steam or high water

Do NOT Use:

•Abrasive cleansers and scouring pads, as these

will mar the finish.

•Coarse paper towels on coated glass.

•Ammonia-based cleaners on acrylic parts.

•Solvent, oil or acidic based cleaners on any

interior surfaces.

•Do not use high pressure water hoses.

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

Do NOT allow cleaning agent or

cloth to contact food product.

•Do NOT flood merchandiser with water.

Never iNtroduce water faster thaN the

waste outlet caN remove it.

self coNtaiNed models empty iNto aN

coNdeNsate paN that will overflow if too

much water is iNtroduced duriNg cleaNiNg.

•Allow merchandisers to dry before resuming

operation.

•After cleaning is completed, turn on power to

the merchandiser.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 32

4-2 Maintenance

CLEANING STAINLESS STEEL SURFACES

Use non-abrasive cleaning materials, and

always polish with grain of the steel. Use warm

water or add a mild detergent to the water and

apply with a cloth. Always wipe rails dry after

wetting.

Use alkaline chlorinated or non-chlorine

containing cleaners such as window cleaners

and mild detergents. Do not use cleaners

containing salts as this may cause pitting and

rusting of the stainless steel finish. Do not use

bleach.

— LOCK OUT / TAG OUT —

To avoid serious injury or death from electrical shock, always disconnect the electrical

power at the main disconnect when servicing

or replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

CLEANING COILS

Condenser coils should be cleaned at least

once per month. Additional cleaning may be

needed depending on the operational environment. A dirty condenser blocks normal airflow

through the coils.

Airflow blockage increases energy consumption and reduces the merchandiser’s ability to

maintain operating temperature.

To clean the coils, use a vacuum cleaner with

a wand attachment and a soft (non-metallic)

brush to remove dirt and debris. Do not bend

coil fins. Always wear gloves and protective

eye wear when cleaning near sharp coil fins

and dust particles.

Do NOT use HOT water on Cold glass Surfaces.

This can cause the glass to shatter and could

result in personal injury. Allow glass fronts, to

warm before applying hot water.

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Unplug merchandiser before servicing. Always

wear gloves and protective eye wear when cleaning

coils.

Page 33

P/N 0515296_E 4-3

NEVER USE SHARP OBJECTS AROUND

COILS. Use a soft brush or vacuum brush to

clean debris from coils. Do not puncture coils!

Do not bend fins. Contact an authorized

service technician if a coil is punctured,

cracked, or otherwise damaged.

ICE in or on the coil indicates the refrigeration and defrost cycle is not operating properly. Contact an authorized service technician

to determine the cause of icing, and to make

adjustments as necessary. To maintain product

integrity, move all product to a cooler until

the unit has returned to normal operating

temperatures.

CLEANING CONDENSATE PAN

(SELF CONTAINED ONLY)

The condensate water outlet for self

contained models empties into a limited

capacity condensate pan.

Debris or dirt accumulation inside the condensate

pan or on the heater coil will reduce the pan’s

evaporation capacity and cause premature heater failure. The condensate pan waste will overflow and spill onto the floor if the heater is not

properly operating.

and poses risk of bodily injury – Always Wear gloves

and protective eye wear when servicing. Turn off

condensate pan heater, and allow pan to cool.

Use only enough water necessary to clean

surface. Water must not drip down the case!

Never use ammonia based cleansers, abrasive

Condensate Pan is Hot!

DO NOT FLOOD!

cleansers, or scouring pads.

Always wear protective eye wear and gloves

when servicing.

Remove accumulated debris from the condensate pan. Wipe down heater coil with a cloth

and warm water. Be sure to remove any dirt,

debris or liquids from the heater coil.

Water introduced during cleaning will cause

the condensate pan to overflow.

Unplug merchandiser before servicing. Always

wear gloves and protective eye wear when cleaning

condensate pan.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 34

4-4 Maintenance

MAINTAINING FLUORESCENT LAMPS

(IF APPLICABLE)

Many of the self-contained cases are equipped

with LEDs. For cases with fluorescent lamps,

follow these directions to ensure long-lasting

life of the lights:

Fluorescent lamps should not be allowed to

run to failure. If a re-lamp schedule is not in

place, the tubes should be inspected for signs

of degradation (blackened ends). Degraded or

failed tubes should be replaced.

Allowing severly degraded lamps to operate

may cause a ballast failure or could expose

the lamp holder to excessive heat. Replacing

degraded bulbs is more cost effective

than replacing ballast and lamp-holders.

Traditional re-lamp programs are 18-to-24

month intervals. In the absence of a re-lamp

program, a yearly inspection of the lighting

system is recommended.

1. Inspect all lamp sockets and plug-receptacle

connections for signs of arching. Replace any

component that shows signs of arching.

2. Make sure all unused receptacles have their

close-off covers securely installed.

3. Make sure proper cleaning procedures are

followed. Lights and fans MUST be turned off

when a case is cleaned and MUST be allowed to

dry before turning power back on.

4. Do not use a pressure nozzle to clean inside

of case.

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 35

P/N 0515296_E 4-5

Record starting date

Store Address

Unit Model Number

Unit Serial Number

Contractor/Technician

Check in with store manager, record any complaints or issues

x

Lookunitoverforanydamage, vibrationsor abnormalnoise.

x

x

Confirm refrigerant lines properly are secured and not touching

or rubbing other lines, wires or frame work.

x

x

Confirm fan blade/s are tight and not r ubbing or hitting.

x

x

x

x

Check all electrical wiring make sure it is secured and not on

any sharp edges or hot lines.

x

registers,fans, and doors etc.

x

x

base cleaner. Rinse off any cleaner residue.

x

base cleaner. Rinseoff any cleaner residue.

x

Clean condenser coil/s and fan blade/s. Do not use an acid base

Cleaner. Rinseoff any cleaner residue.

x

Clean condensate drain pan and drain line.

x

x

x

x

Record condenser air inlet temperature

x

x

x

x

x

x

Record defrost heater voltage and am p d r a w.

x

Record anti-sweat heater voltage and amp draw.

x

x

Record unit discharge air temperature.

x

x

x

x

Manual for proper controller operation.

x

x

x

x

Self-Contained Refrigeration Equipment Maintenance Check List

* * * * * Warranty does not cover issues caused by improper installation or lack of basic preventative maintenance. * * * * *

Store Name and Number

Technician

PMdate

PMactivity-For visual inspection items,denote"okor

complete" inthe column to rightwhen PM has been

performed. For measured data requested, recorddata

requested in the appropriate column to the right)

they have with unit.

Verify unit is level side to side and front to rear.

Verify fan motors and motor mounts are tight.

Make sure all electrical connections, factory and field, are tight.

Verify ele ctric al connections at lamps arethey secure and dry.

Check for and replace any frayed or chaffed wiring.

Check for ai r disturbances externallto the unit. Heat and air

Check for water leaks.

Clean evaporator coil/s and fan blade/s. Do not use an acid

Clean discharge air honeycom b s or grilles. Do not use an acid

Verify condensate drain lines are clear and functioning.

Record voltage reading at unit with unit off?

Verify condenser and evaporator fans are working.

Quarterly

Semi-

Annually

Ql

Q2

Q3 Q4

Ql

Q2

Q3 Q4

Record condenser air outlet temperature

Is condenser air inlet or air exhaust restricted or recirculating?

Verify t here are no visual oil or refrigerant leaks.

Record voltage reading with unit running.

Record compressor amp draw.

Record case product temperature.

Record unit return air temperature.

Record ambient conditions around unit (wet Bulb temperature

and dry bulb temperature).

Check product loading, do not load beyond the units load limits.

Verify clearances on sides/back of u nit .

Check unit controller for proper operation. See controller or 1/0

Confirm door switches function.

Verify unit doors and lids work and are sealed correctly.

Verify that all the panels, shields and covers are in place.

Technician Notes:

Form HSCW03 Rev-29 OCTOBER13

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

x

P/N 0525210_C

HGL Glass Door Merchandisers

Page 36

4-6 Maintenance

NOTE:

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-522-1900 • www.hussmann.com

Page 37

P/N 0515296_E 5-1

SERVICE

REPLACING FAN MOTORS AND

BLADES

Should it ever be necessary to service or

replace the fan motors or blades be certain

that the fan blades are reinstalled correctly.

The blades musT be insTalled wiTh

raised embossing (parT number on plasTic

blades) posiTioned as indicaTed on The

parTs lisT.

For access to these fans:

1. Remove product and place in a refrigerated

area. Turn off power to the merchandiser.

2. Remove two thumb screws that secure the

return air grille / coil cover.

3. Remove return air grille.

4. Remove fan assembly.

5. Replace fan motor and blade.

6. Reconnect fan to wiring harness.

9. Verify that motor is working and blade is

turning in the correct direction.

REPLACING THERMOMETER

The thermometer may be replaced by removing the two screws holding it to the evaporator

fan grille. Lower the evaporator coil cover by

removing the brass screws located at the two

front corners of the cover. Remove the screws

along the front edge of the cover holding it to

the grille. Follow the sensing lead to the center rear of the evaporator coil. Loosen the clip

holding it to the bracket, and slide the end of

the lead out.

When installing the new thermometer be sure

to run the lead of the new thermometer through

the hole in the fan grille first. Finish assembly in

reverse order. The same procedures should be

followed when cleaning the end of the sensing

lead.

7. Replace return air grille, and fasten air

grille to coil cover.

8. Turn on power.

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

— LOCK OUT / TAG OUT —

To avoid serious injury or death from electrical shock, always disconnect the electrical

power at the main disconnect when servicing

or replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

DEFROST HEATER REPLACEMENT

The defrost heaters are firmly embedded in the

evaporator and held in place with spring clips.

To remove the heater: first remove all spring

clips and pull the defective heater out of the

slots in the evaporator, starting at the wire supply

lead.

The replacement heater should be firmly

seated in the slots by using a small block of

wood and a mallet. After the new heater is in

place, replace all the spring retaining clips to

assure heater retention. One lead of the defective heater may be used to pull the new leads

through the cabinet to the respective terminals

as marked on each lead.

NOTE: Care must be taken to ensure the drain

stub is correctly inserted in the cabinet drain

tube for proper drainage.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 38

5-2 Service

TROUBLESHOOTING GUIDE

PROBLEM

Compressor runs continuously

product too warm

High head pressure

PROBABLE CAUSE

1. Short of refrigerant

2. Inefficient compressor

3. Dirty condenser

1. Cabinet location too warm

2. Restricted condenser air

flow

3. Defective condenser fan

motor

4. Air or non-condensable gases

in system

SOLUTION

1. Leak check, change drier,

evacuate, and recharge

2. Replace

3. Clean

1. Relocate cabinet

2. Clean condenser to remove

air flow restriction

3. Replace

4. Leak check, change drier,

evacuate and recharge

Warm storage temperature

Compressor runs continuously

product too cold

1. Temperature control not

set properly

2. Short of refrigerant

3. Cabinet location too warm

4. Too much refrigerant

5. Low voltage, compressor

cycling on overload

6. Condenser dirty

1. Defective control

2. Control feeler not in tube

properly

3. Short on refrigerant

1. Reset control.

2. Leak check, replace drier

evacuate and recharge

3. Relocate

4. Change drier evacuate

and recharge

5. Check power

6. Clean

1. Replace

2. Assure proper length in

tube

3. Leak check change drier,

evacuate and recharge

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 39

P/N 0515296_E 5-3

PROBLEM

Compressor runs continuously

product too cold

Compressor will not start

no noise

PROBABLE CAUSE

1. Defective control

2. Control feeler not in tube

properly

3. Short on refrigerant

1. Blown fuse or breaker

2. Defective or broken wiring

3. Defective overload

4. Defective temperature control

5. Power disconnected

SOLUTION

1. Replace

2. Assure proper length in

tube

3. Leak check change drier,

evacuate and recharge

1. Replace fuse or reset

breaker

2. Repair or replace

3. Replace

4. Replace

5. Check service cords or

wiring connections

Compressor will not start

cuts out on overload

1. Low voltage

2. Defective compressor

3. Defective relay

4. Restriction or moisture

5. Inadequate air over

condenser

6. Defective condenser fan

motor

7. CRO not set properly

1. Contact electrician

2. Replace

3. Replace

4. Leak check, replace drier,

evacuate and recharge

5. Clean condenser

6. Replace

7. Reset to 10 psi.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 40

5-4 Service

PROBLEM

Icing condition in drain pan

PROBLEM

PROBABLE CAUSE

1. Low voltage

2. Cabinet not level

3. Defective drain tube heater

4. Defective drain pan heater

LIGHTING PROBLEM / SOLUTION

1. Check light switch

2. Check continuity to ballast

SOLUTION

1. Check voltage at compressor

2. Check front to rear leveling,

adjust legs accordingly

3. Replace

4. Replace

SOLUTION

Lights won’t start

Lights flicker

Ballast hums

3. Check to see if bulbs are inserted properly

in sockets

4. Check voltage

1. Allow lamps to warm up

2. Check sleeve for cracks

3. Check sockets for moisture

and proper contact

4. Bulb replacement may be necessary

5. Check voltage

6. New bulbs tend to flicker until used

1. Check voltage

2. Replace ballast

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 41

P/N 0515296_E 5-5

REPLACING DOOR PARTS

Hussmann provides replacement doors. See door

parts listed on the next page, and contact your

Hussmann representative to place an order for

replacement doors. Door frame assemblies,

LEDs, powersupplys, lamps, ballasts, door

handles and hold open slides must be ordered

direct from the door manufacturer. Refer to the

supplemental manuals from Anthony. Refer

to specic warranty supplied with the door.

The manufacturers have a warranty against

moisture penetration, a warranty against tempered glass breakage, and a warranty on ballasts.

Lamps are not covered by Hussmann or the door

manufacturer.

Anthony® door and frame service instructions are

available at the end of this manual and online at

the door manufacturer’s website:

www.anthonyintl.com The names of the instruc-

tion manuals for the doors are listed below:

99-16105-S001_B 101B, 210X, ELM, 101X

Frame Installation and Service Manual

OR

99-16105-I001_E 101B, 210X, ELM, VSTB

Installation Manual

Anthony®

Phone: 1(800) 772-0900

SERVICING LED LIGHTING

Refer to door manufacturer’s manual for information about servicing of LED lamps at the

end of this manual. Additional manuals are

available on the Anthony® website:

www.anthonyintl.com to download LED and

powersupply replacement instructions. The

names of the instruction manuals for the lights

are listed below:

99-19830-I001_C OptiMax Pro 24 Installation Instructions

99-18901-I001_B OptiMax Pro Retrot Instructions

SERVICING FLUORESCENT LIGHTING

Refer to door manufacturer’s manual at the end

of this manual for information about servicing

uorescent lamps. Please visit: www.anthony-

intl.com to download LED and powersupply

replacement instructions. The names of the

instruction manuals for the lights are listed

below:

99-20367-I001_C ELS Ballast Replacement

99-20374-I001_C ELS T-8 Lamp Replacement

2 and 3-door power supply

or ballast location - inside

center mullions

1-door power supply

or ballast location behind upper frame

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Glass Door Merchandisers

Page 42

5-6 Service

Replacement Parts List HGL BS/TS & HGL B/T

Standard Parts Part Number HGL1BS HGL2BS HGL3BS HGL1TS HGL2TS HGL3TS

Evaporator Fan Motor 21S061 X X X X X X

Evaporator Fan Blade 0519568 X X X X X X

Evaporator Fan Harness 19S512 X X X X

Evaporator Fan Harness 19S793 X X

Defrost Sensor (Yellow) 4000MM 0510532 X X X X X X

Air Sensor (Black) 4000MM 0510533 X X X X X X

Safe-Net III Controller 65C 0524131 X X X X X X

Safe-Net III Display (F°) 65C 1H59052001 X X X X X X

Safe-Net III Display Interface Cable 0509783 X X X X X X

Safe-Net IIIControl Harness 0513058 X X X X X X

Compressor Relay 1804241 X X X X X X

Defrost Relay 1804241 X X X X X X

Power Switch 03S422 X X

Power Switch 03S286 X X X X

Alarm Thermostat 03S197 X X X X X X

Fan/Defrost Thermostat 03S219 X X X X X X

Solar Thermometer 05S528 X X X X X X

Cantilever Shelf (White) 22S268 X X X X X X

Bottom Shelf (White) 1 per door 22S128 X X X X X X

Wire Rear Flue Spacer (1 per door) 22S121 X X X X X X

Legs Adjustable 6” (TS Only) 35S032 X X X

Power Cord (6-15P) 0508528 X X X X

Power Cord (6-20P) 1804385 X X

Refrigeration Part Number HGL1BS HGL2BS HGL3BS HGL1TS HGL2TS HGL3TS

Compressor (Copeland KAAB-007E-CAV) 02S573 X X

Compressor (Copeland KALB-010E-CAV) 02S445 X X

Compressor (Copeland KALB-015E-CAV) 02S446 X X

Condenser 25S040 X X X X

Condenser 25S039 X X

Condenser Fan Motor 21S071 X X X X X X

Condenser Fan Blade 21S015 X X X X

Condenser Fan Blade 21S017 X X

Condenser Fan Motor Bracket 21S007 X X X X X X

Evaporator Coil 26S120 X X

Evaporator Coil 26S085 X X

Evaporator Coil 26S086 X X

TXV (Sweat)R404A EFS- 1/4Z ADJ-

52.5PSI

TXV (Sweat) R404A EFS-1/2-ZP35 ADJ

STD

TXV (Flare) Sporlan FS-1/4 Z 17S444 X X X X

TXV (Flare) Sporlan FR or FS-1/2 ZP35 17S115 X X

Filter Drier (Sporlan C-082S) 17S365 X X X X X X

CPR (Sporlan CRO-4) 17s114 X X X

CPR (Sporlan CRO-6) 17S137 X

0540080 X X X X

0540081 X X

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 43

P/N 0515296_E 5-7

Replacement Parts List HGL BS/TS & HGL B/T

Heaters Part Number HGL1BS HGL2BS HGL3BS HGL1TS HGL2TS HGL3TS

Defrost 19S7911 X X

Defrost 19S7912 X X

Defrost (Terminals 33 & 7) 19S7913 X X

Defrost (Terminals 31 & 9) 19S7914 X X

Drain Tube Heater 19S8011 X X

Drain Tube Heater 19S8012 X X

Drain Tube Heater 19S8013 X X

Evaporator Pan Heater 19S704 X X

Evaporator Pan Heater 19S598 X X

Evaporator Pan Heater 19S705 X X

Condensate Pan Heater 19S631 X X X X X

Condensate Pan & Heater 35S050 X

Condensate Pan (Less Heater) 930890 X X X X X

Condensate Pan Compleate w/ Heater 951001 X X

Condensate Pan Compleate w/ Heater 951441 X X X

Sheel Metal Replacement Parts Painted Part Number HGL1BS HGL2BS HGL3BS HGL1TS HGL2TS HGL3TS

Front Louvered Access Panel w/SNIII KO 950851 X

Front Louvered Access Panel w/SNIII KO 950852 X

Front Louvered Access Panel w/SNIII KO 950853 X

Front Access Panel w/ SNIII KO 953451 X

Front Access Panel w/ SNIII KO 953452 X

Front Access Panel w/ SNIII KO 953453 X

Evaporator Drain Pan Cover 950771 X X

Evaporator Drain Pan Cover 950772 X X

Evaporator Drain Pan Cover 950773 X X

Front Evaporator Grille 954101 X X

Front Evaporator Grille 954102 X X

Front Evaporator Grille 954103 X X

All these part numbers above are painted assemblies

Door Replacement Parts Part Number HGL1BS HGL2BS HGL3BS HGL1TS HGL2TS HGL3TS

Door Polished Silver Low Temp (Anthony) Std. 29S7931

Door Black, Low Temp (Anthony) Option 29S7933

Door Polisher Silver Low Temp (Anthony) LED 0544034

Door Black, Low Temp (Anthony) LED 0543852

Frame Heater AS Control (10A) Remote only 1803409

X

X

X

X

X X X

X

X

X

X

X

X

X

X

X

X

X

X

X X X

X

X

X

X

X

X

X

X

Serial Plate

Location

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Hussmann

Part Number

Anthony

Work Order Number

HGL Glass Door Merchandisers

Page 44

Page 45

Appendix A — TechnicAl dATA A-1

HGL-1BS — Plan View

Dimensions shown as inches and (mm).

ELECTRIC CONDENSATE PAN

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 46

A-2 Appendix A — TechnicAl dATA

HGL-2BS & HGL-3BS — Plan View

Dimensions shown as inches and (mm).

ELECTRIC CONDENSATE PAN

Dimensions shown as inches and (mm).

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 47

P/N 0515296_E A-3

HGL-1TS — Plan View

Dimensions shown as inches and (mm).

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 48

A-4 Appendix A — TechnicAl dATA

HGL-2TS — Plan View

Dimensions shown as inches and (mm).

HGL-3TS — Plan View

Dimensions shown as inches and (mm).

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 49

P/N 0515296_E A-5

HGL — Dimensions

HGL — Electrical Data

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 50

A-6 Appendix A — TechnicAl dATA

Dimensions shown as inches and (mm).

HGL-BS

HGL-TS

Models

HGL1BS

HGL2BS

HGL3BS

REFRIGERATION DATA

HGL

Thermostat

Setting CI/CO (°F)

Position #1 5 / -18

Position #7 -5 / -28

Compressor (hp)

HGL-1

3

/4

HGL-2 1

HGL-3 1

1

/2

Condensing Unit

Capacity

(Btu/hr at std. rating

conditions)

HGL-1 1870

HGL-2 2300

HGL-3 4270

(at 10º F evaporation and

110º F condensing temperature)

DEFROST DATA

HGL

Frequency (hr) 8

Defrost termination

temperature

Failsafe 50 minutes

PHYSICAL DATA

Refrigerant Charge R404A

HGL-1 35.3 oz (1) kg

HGL-2 37.9 oz (1.074) kg

HGL-3 56 oz (1.587) kg

Note: This data is based on store temperature

and humidity that does not exceed 75°F and

55% R.H. unless otherwise stated. Schedule

defrost at night while lights are off.

P/N 0515296_E U.S. & Canada 1-800-922-1919 • Mexico 1-800-890-2900 • www.hussmann.com

Page 51

P/N 0515296_E A-7

COMPRESSOR

-DOTTED

REVERSIBLE MOTOR

PARA

REVERSIBLE

HGL 1 BS/TS with Safe-NET III

HGL 2 BS/TS with Safe-NET III

1H16704002

DISPLAY

KEY

LINK

PROG

HACCP

SERIAL

2 M

B / Y

BL / W

SWITCH

B / Y

BL / W

ANTHONY DOORS & FRAMES

SWITCH

DOORS AND FRAME HEATERS

R

BK

BK

B

R

BL

B

O

12

11

14 O13

BALLAST

3

4

BK

BK

W / BL

W / BL

BK

10

R

9

LED LIGHTING (OPTIONAL KIT)

BL / W

B / Y

RS

DOOR

HEATE

F

0517376

WIRING DIAGRAM W/

SN III HGL1BS/TS

END LED

BK

BK

BK

POWER SUPPLY

R

END LED

END LAMP

END LAMP

T8 FLUORESCENT LIGHTING

GR

B

GRN

BL

R

ALARM STAT

BR

LL

UU

GR

BL

B

TEMP

DEFROST

THERMOST

AT SENSOR

AIR TEMP

THERMOST

AT SENSOR

o

FAN SWITCH

o

Y

BK

BK

A

YELLOW SHEATH

BLACK SHEATH

R

THERMO

W

2

LINE 2

1

3

BK

DEFROST HEATERS

UU

LL

6

4

5

BK

WILL NOT BE USED

* NOTE: RED TERMINAL

B

Z

DOOR / FRAME

8

10

7

9

BK

DRAIN

HP

PAN HTR

HTR

TUBE

DRAIN

12

LINE 1

11

EVAPORATOR FANS

B

24

23

7

6

5

SAFENET III CONTROL

4

3

2

1

CONDENSATE

BK

6

2

4

LINE 2

5

1

3

B

26

25

LINE 1

LINE 2

COMP

PHASE

FAN

PHASE

HEATER

PAN HEATER

BK

BK

BK

8

12

10

LINE 1

7

9

11

HEATER

W

BK

BK

8 9 10 11

BK

POWER

PLUG

26

24

12

10

8

6

4

2

LINE 1

7

5

LINE 2

1

NEMA

1PH

60Hz

POWER

SUPPLY

25

23

11

9

3

ELECTRIC BOX

C

RELAY

0 1

W

BL

BK

Y

BK

B

W

BK

Y

THERMO DISC

R

Y

26

24

25

23

BK

KIT (ONLY)

LINE IS FOR THE

KIT DE MOTOR

-LINEA PUNTEADA ES SOLO

B

R

W

R

R

CONDENS ER

FAN

MOTORS

REVERSIBLE

BK

(OPTIONAL KIT)

6-15P

GRD

208-230V

BK

S1

SWITCH

S3

BK

HEATERS

W

B

GRN

2

3

1

C

R

4

R

S4

S6

8

PLUG END

15 AMP, 250 V

BK

6

2

R

R

R

S

DETAIL

BK

P

BK

L2

2

1

BL

R

RELAY

L1

BL

0 1

.

COMP

WARNING

BK

R

R

8

6

2

4

R

R

All components must have mechanical ground, and the merchandiser must be grounded.

R = Red Y = Yellow G = Green BL = Blue BK = Black W = White B = Brown O = Orange GR = Gray P = Purple

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

HGL Merchandisers

Page 52

A-8 Appendix A — Wiring diAgrAm

R = Red Y = Yellow G = Green BL = Blue BK = Black W = White B = Brown O = Orange GR = Gray P = Purple

COMPRESSOR

REVERSIBLE MOTOR

REVERSIBLE

ANTHONY DOORS & FRAMES

HGL 3 BS/TS with Safe-NET III

BK

BK

W / BL

W / BL

W / BL

W / BL

R

BK

BK

BL / W

SWITCH

RRBL

121110

BK

BL

9

B / Y

BK

END LED

BK

BK

POWER SUPPLY

R

BK

POWER SUPPLY

R

BK

CENTRAL LED

BK

THERMOST

AT SENSOR

END LED

LED LIGHTING (OPTIONAL KIT)

THERMOST

AT SENSOR

CENTRAL LAMP

BALLAST

4

3

GR

HEATERS

BR

END LAMP

END LAMP

BL

T8 FLUORESCENT LIGHTING

GR

BR

BL

GRN

R

BR

LL

UU

ALARM STAT

FAN SWITCHES

BK

BK

ANTHONY DOORS & FRAMES

O

B

O

13

14

B / Y

BL / W

3

SWITCH

BL

R