Page 1

Manual

Installation

& Operation

REV. 0508

/CHINO

HEDN (02,03,04,05), HED COMBO, HEDW05

HEDN HOT END DISPLAY

HEDN (02,03,04,05) HED COMBO HEDW05

HED HOT CASE FAMILY

P/N IGHT-HEDN, HEDN COMBO, HEDW-0508

INSTALLATION & OPERATION GUIDE

Page 2

General Instructions

This equipment is to be installed

to comply with the applicable

NEC, Federal, State , and Local

Plumbing and Construction

Code h a ving j urisdict i o n .

Table of Contents

General Instructions.....................................................2

Cut and Plan Views ......................................................3

Installation .....................................................................4

Leveling/Joining Instructions...................................................... 4

Electrical........................................................................4

Wiring Color Code ..................................................................... 4

Electrical Circuit Identication .................................................... 4

Electrical Service Receptacles .................................................. 4

Field Wiring and Serial Plate Amperage .................................... 4

Ballast Location .........................................................................4

Operation .......................................................................5

Controls .....................................................................................5

Daily Startup .............................................................................. 5

Operation Tips ........................................................................... 5

Shut-down and Cleaning ........................................................... 5

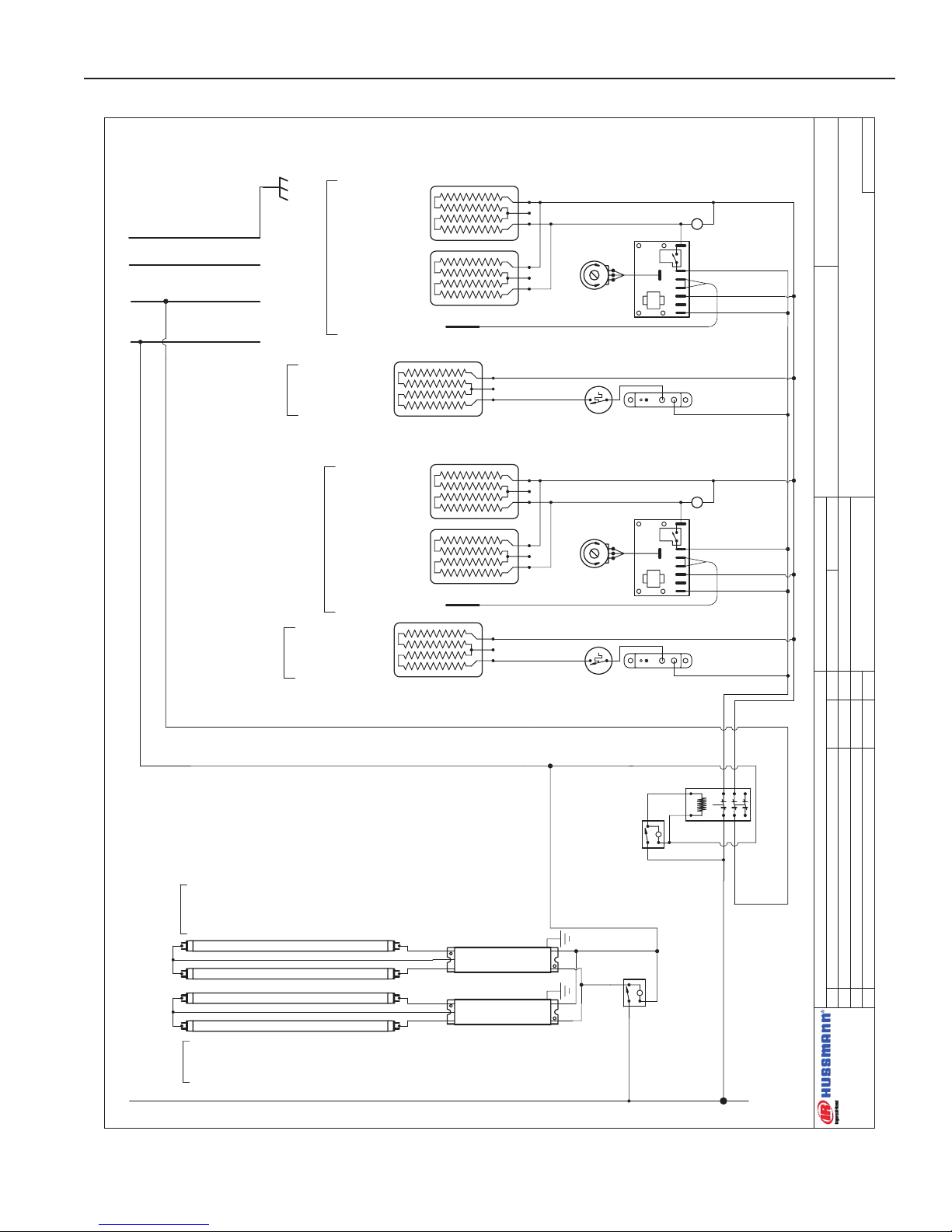

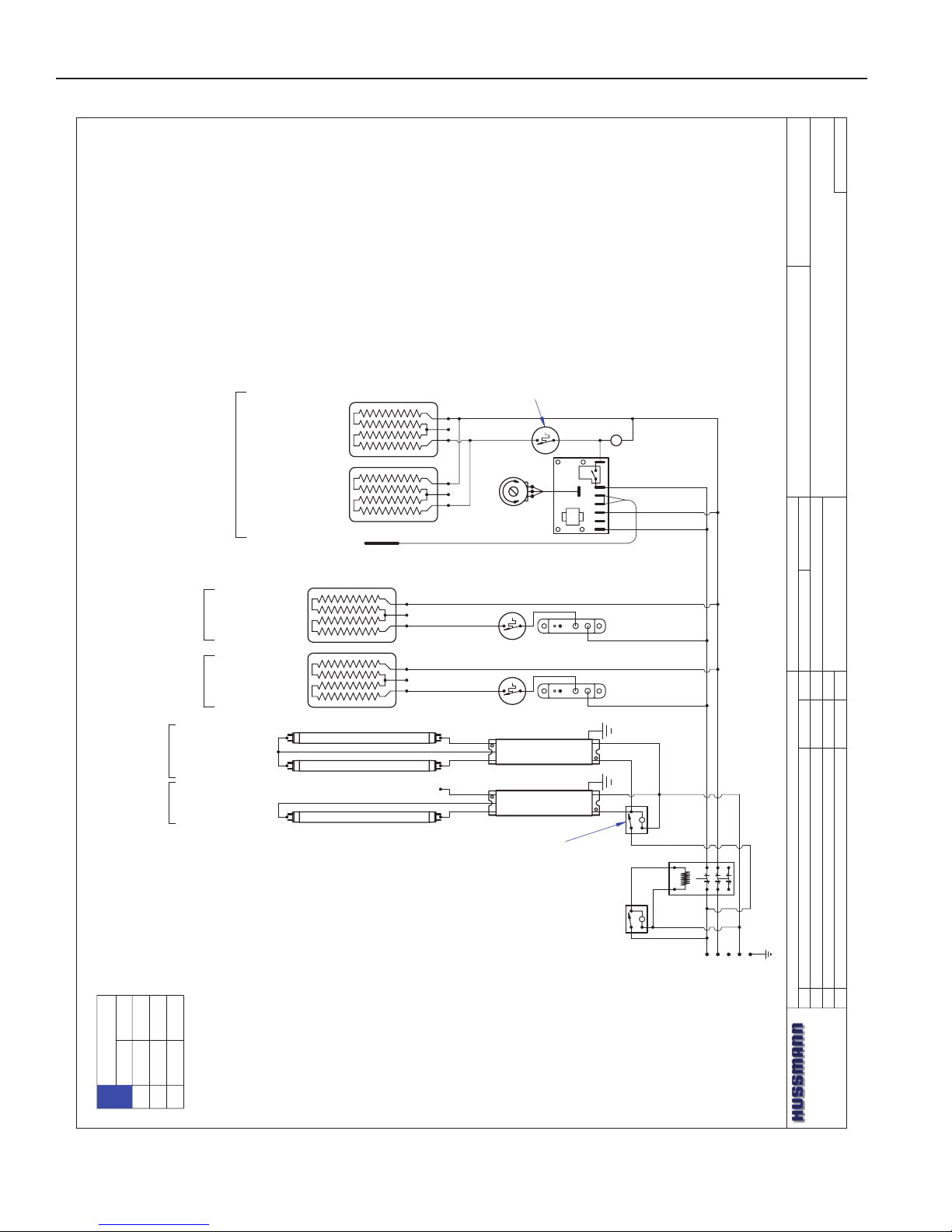

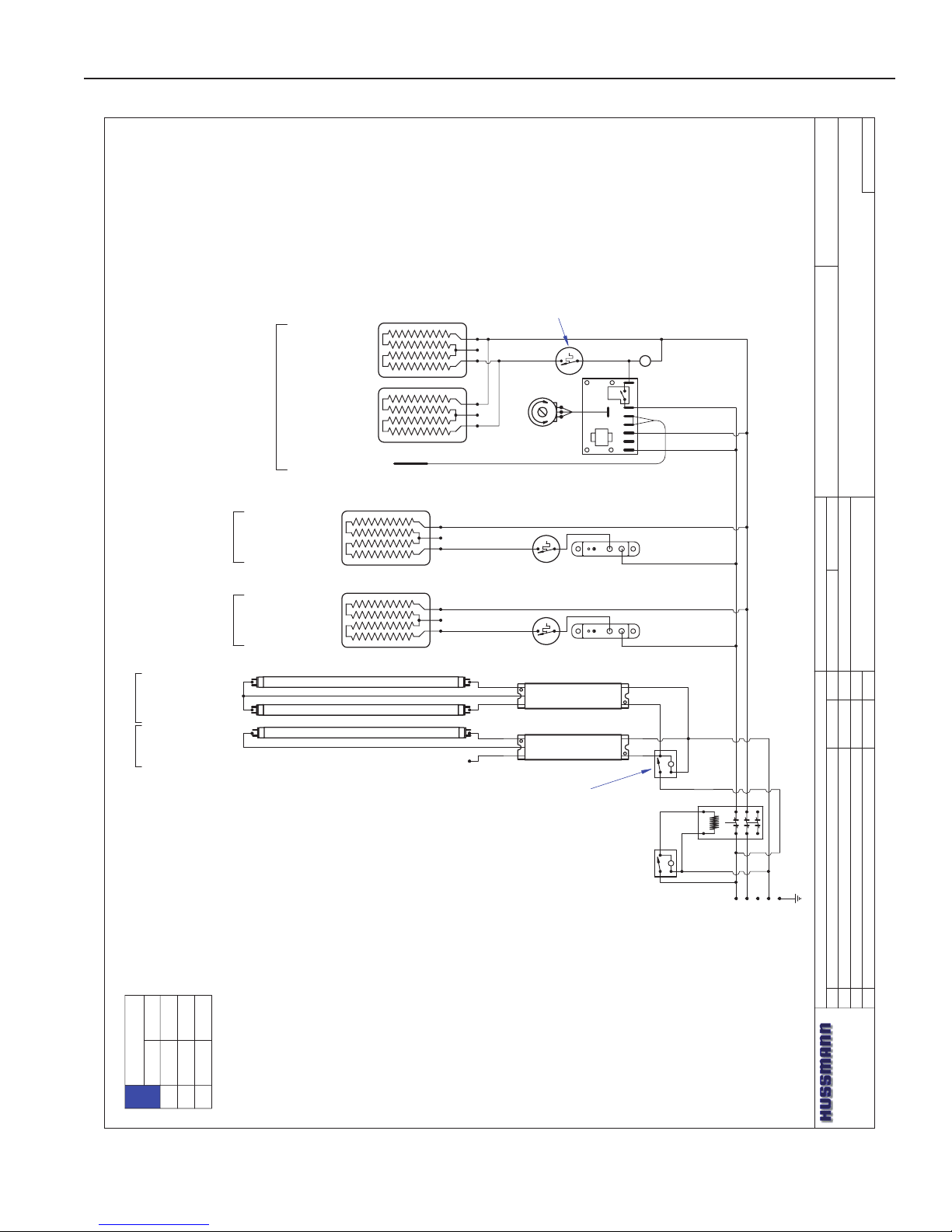

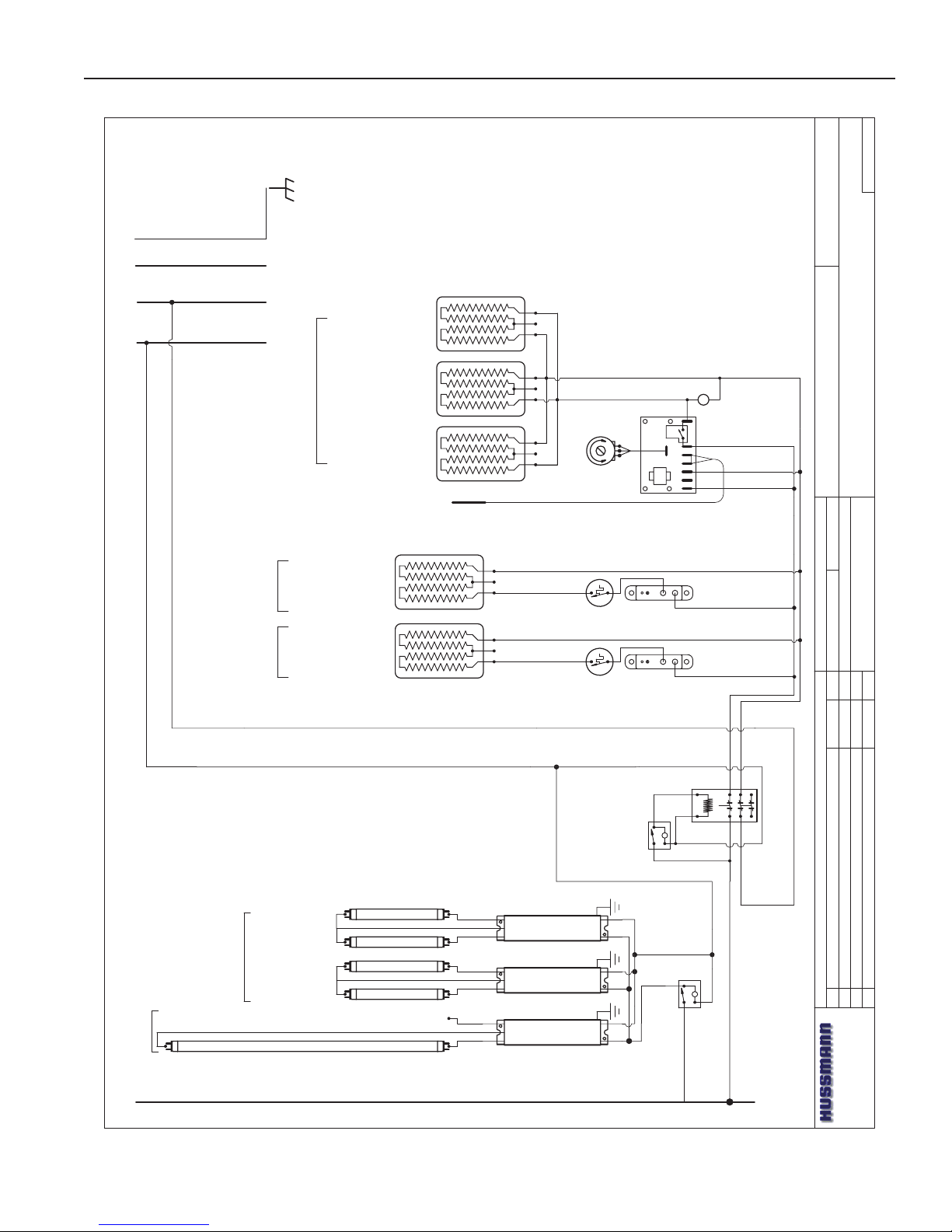

Electrical Wiring Diagrams ..........................................7

Wiring Diagrams ...........................................................8

Appendices ................................................................. 69

Appendix A - Temperature Guidelines - Refrigerated .............. 69

Appendix B - Application Recommendations - Refrigerated .... 69

Appendix C - Field Recommendations - Refrigerated ............. 70

Appendix D - Recommendations to User - Refrigerated ......... 71

IGHT-HEDN, HEDN COMBO, HEDW-0508

This Booklet Contains Information on:

HED HOT CASES

Self Service Hot cases designed to t within a lineup of

multidec self service cases or at the end of a lineup.

Shipping Damage

All equipment should be thoroughly examined for shipping

damage before and during unloading.

This equipment has been carefully inspected at our factory

and the carrier has assumed responsibility for safe arrival.

If damaged, either apparent or concealed, claim must be

made to the carrier.

Apparent Loss or Damage

If there is an obvious loss or damage, it must be noted on

the freight bill or express receipt and signed by the carrier’s

agent; otherwise, carrier may refuse claim. The carrier will

supply necessary claim forms.

Concealed Loss or Damage

When loss or damage is not apparent until after equipment

is uncrated, a claim for concealed damage is made. Make

request in writing to carrier for inspection within 15 days,

and retain all packaging. The carrier will supply inspection

report and required claim forms.

Shortages

Check your shipment for any possible shortages of

material. If a shortage should exist and is found to be the

responsibility of Hussmann Chino, notify Hussmann Chino.

If such a shortage involves the carrier, notify the carrier

immediately, and request an inspection. Hussmann Chino

will acknowledge shortages within ten days from receipt

of equipment.

Hussmann Chino Product Control

The serial number and shipping date of all equipment

has been recorded in Hussmann’s les for warranty and

replacement part purposes. All correspondence pertaining

to warranty or parts ordering must include the serial number

of each piece of equipment involved, in order to provide

the customer with the correct parts.

Keep this booklet with the case at all times for future reference.

/CHINO

A publication of HUSSMANN® Chino

13770 Ramona Avenue • Chino, California 91710

(909) 628-8942 FAX

(909) 590-4910

(800) 395-9229

2

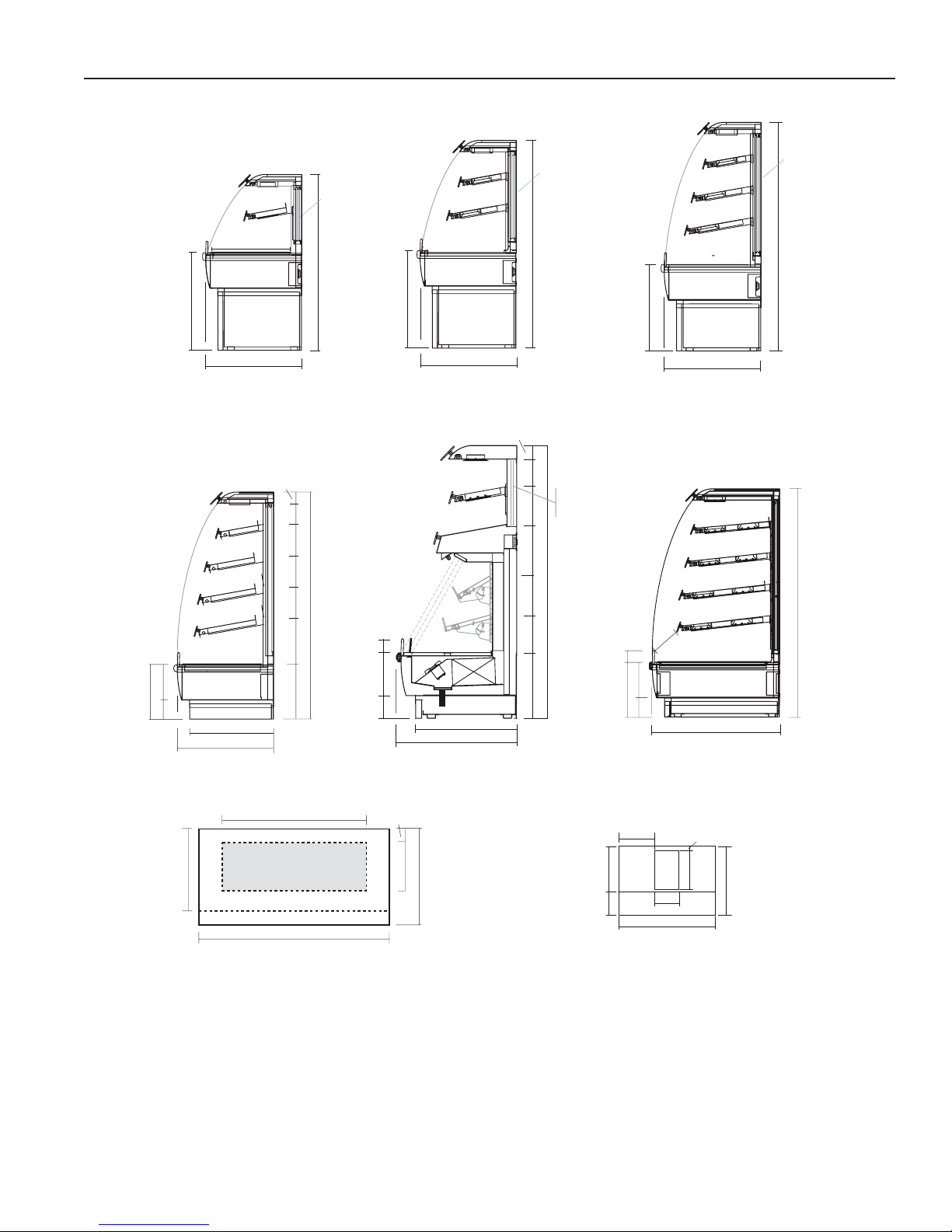

Page 3

Rev. 0508

3"

HEDN-03

Scale 1/2"

53"

9

1

/

2

"

247/8"

25"

11

1

/

2

"

203/8"

Optional

rear doors

HEDN-02

Scale 1/2"

247/8"

45"

25"

9

1

/

2

"

211/4"

Optional

rear doors

9

1

/

2

"

11

1

/

2

"

203/8"

13

1

/

2

"

22"

58"

247/8"

HEDN-04

Scale 1/2"

Optional

rear doors

HEDN-05

Scale = 1/2"

3"

14

1

/

2

"

8"8"8"11

3

/

4

"

58"

9

1

/

2

"

11

1

/

2

"

13

1

/

2

"

203/8"

9"

14"

247/8"

21

3

/4"

5"

2

7

/

4

"

5

3

/8"

14"

Shown

with

optional

rear doors

48"

(VARIABLE LENGTHS)

24

7

/

8

"

12

7

/

8

"

36"

21

3

/

4

"

3

3

/

4

"

HEDN

Plan View

Scale = 1/2"

MECHANICAL CONNECTION AREA

12 7/8" X 21 3/4"

Front of Case

8"

1

0

"

HEDN-05 COMBO

Hot Over Cold Self Service

Scale = 1/2"

247/8"

213/4"

8"

58"

9"

3"5"

9

1

/

2

"

12

1

/

4

"

171/8"

8

1

/

4

"8

1

/

8

"

5

5

/

8

"

3

1

/

4

"

14"

Hot

Section

Cold

Section

Optional

Rear

Doors

58"

1

8

1

/

2

"

1

9

1

/

2

"

20

1

/

2

"

20

1

/

2

"

271/2"

HEDW-05

Hot Self Service End Display

Scale = 1/2"

323/4"

7

1

/

2

"

14"

9"5"

3"

HEDW

Plan View

Scale = 1/4"

19"

22

1

/

4

"

Elec.

Stub-

Up

Area

19"x12"

11

1

/

2

"

33

3

/

4

"

48"

(VARIABLE LENGTHS)

18"

2"

12"

Cut and Plan Views

3

Page 4

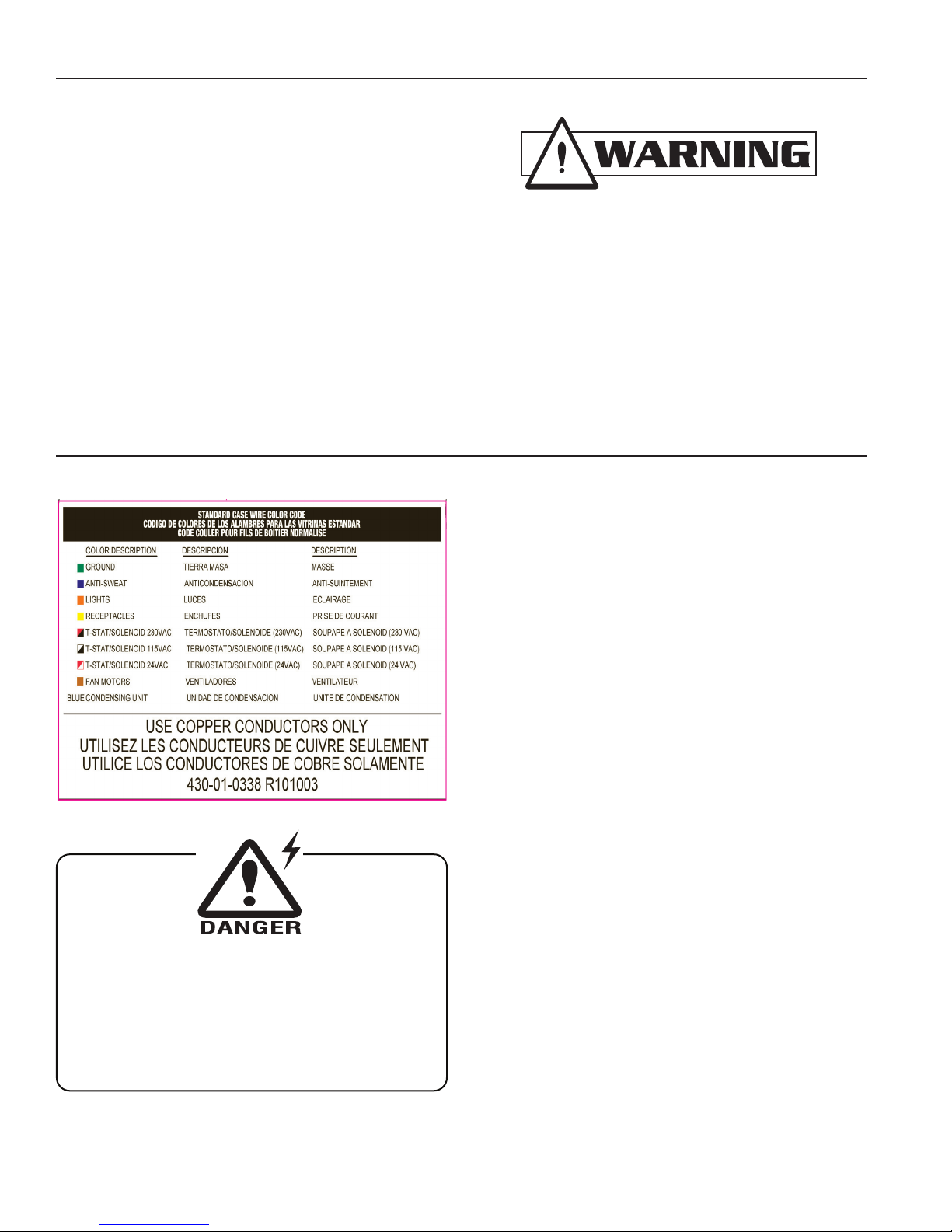

Installation

TO AVOID REMOVING CONCRETE FLOORING, BEGIN

LINEUP LEVELING FROM THE HIGHEST POINT OF

THE STORE FLOOR.

BEFORE SERVICING

ALWAYS DISCONNECT ELECTRICAL

POWER AT THE MAIN DISCONNECT

WHEN SERVICING OR REPLACING ANY

ELECTRICAL COMPONENT.

This includes (but not limited to) Heaters and Lights.

IMPORTANT! IT IS IMPERATIVE THAT CASES BE

LEVELED FROM FRONT TO BACK AND SIDE TO SIDE

PRIOR TO JOINING. A LEVEL CASE IS NECESSARY

TO INSURE PROPER OPERATION, WATER DRAINAGE,

GLASS ALIGNMENT, AND OPERATION OF THE HINGES

SUPPORTING THE GLASS. LEVELING THE CASE

CORRECTLY WILL SOLVE MOST HINGE OPERATION

PROBLEMS.

ALL CASES WERE LEVELED AND JOINED

PRIOR TO SHIPMENT, TO INSURE THE CLOSEST

POSSIBLE FIT WHEN CASES ARE JOINED IN THE

FIELD.

Electrical

Wiring Color Code

CASE MUST BE GROUNDED

IGHT-HEDN, HEDN COMBO, HEDW-0508

Leveling/Joining Instructions

Check oor where cases are to be set to see if it’s level.

Determine where the highest part of the oor is. Cases will

be shimmed off this point. Using case blueprints, measure

off and mark on oor the exact dimensions of the case

footprint. Snap chalk line for front and back position of

base rail. Mark location of each joint front and back. Use

a transit to nd the highest point along both lines. Mark

the difference, and place the appropriate number of shims

required to maintain high - point level.

Electrical Circuit Identication

Standard lighting for all models will be full length uorescent

lamps located within the case at the top. The switch

controlling the lights, the plug provided for digital scale,

and the thermometer are located at the rear of the case

mullion.

The receptacle that is provided on the exterior back of these

models is intended for computerized scales with a ve amp

maximum load, not for large motors or other high wattage

appliances. It should be wired to a dedicated circuit.

Electrical Service Receptacles

(When Applicable)

The receptacles located on the exterior of the merchandiser

are intended for scales and lighted displays. They are not

intended nor suitable for large motors or other external

appliances.

Field Wiring and Serial Plate Amperage

Field Wiring must be sized for component amperes printed

on the serial plate. Actual ampere draw may be less than

specied. Most component amperes are listed in the “Wiring

Diagram” section, but always check the serial plate.

Ballast Location

Ballasts are located within the access panel that runs the

length of the rear of the case. Refer to diagram.

4

Page 5

Rev. 0508

The case metal and the light bulbs become

extremely hot when in use.

DO NOT Touch Hot Case or Lights With bare hands!

DO NOT FLOOD!

Use only enough solution necessary to clean

surface. Water must not drip down the case!

Never use ammonia based cleansers, abrasive

cleansers, or scouring pads.

Operation

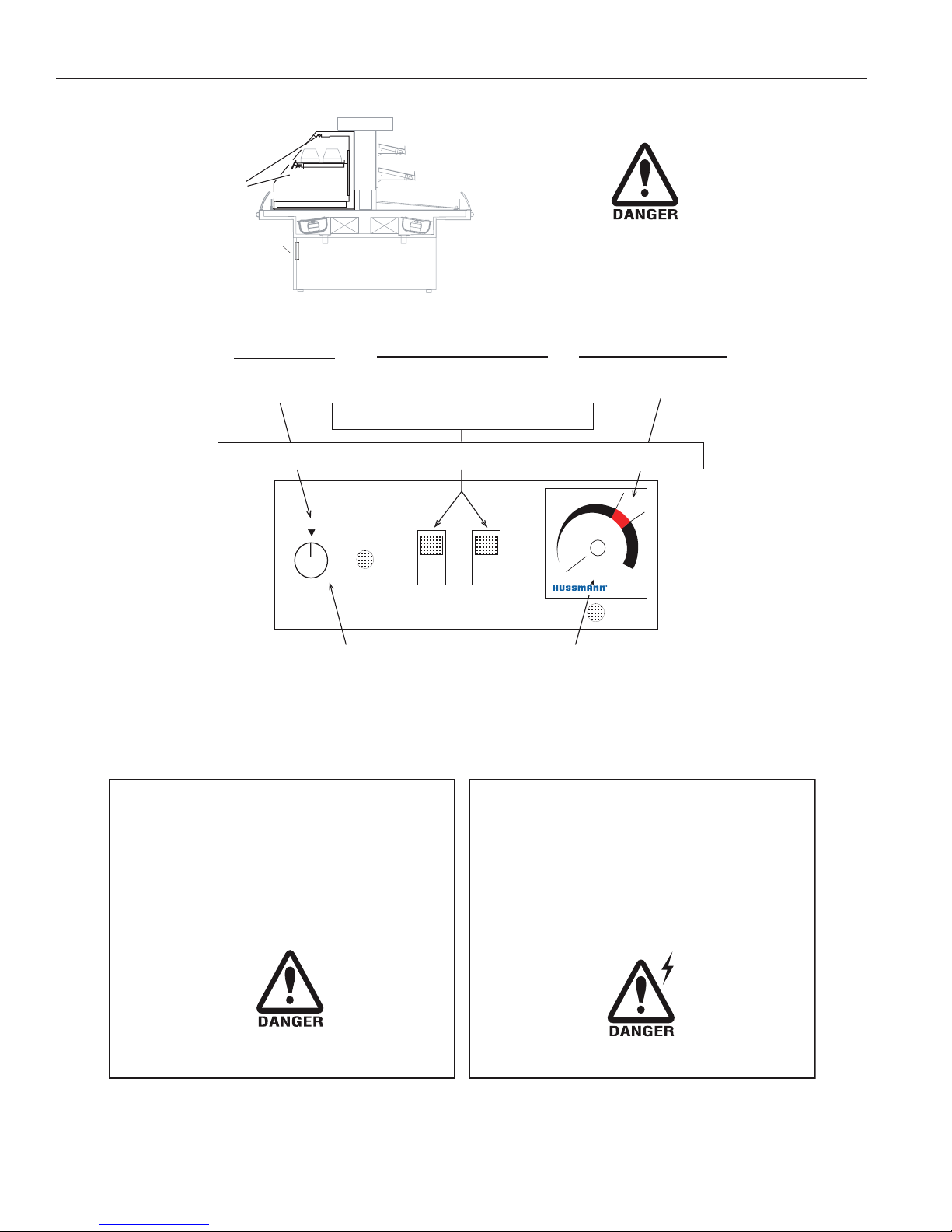

Controls

Pictured on the following page is an HED-02 with the

appropriate controls. All the HED’s have the same controls,

however, as the number of shelves and case lengths vary,

the number of these controls does also. Each is clearly

labeled on the control panel on the back of the case.

Daily Startup

1. Check to make sure All switches are starting in the

"OFF" position

2. Flip O/H Light switches to "ON" position. When

toggle switch is ipped to "on" position, the light to

the left of the on off toggle switches will go on. If it

does not, turn the toggle switch to the off position

and tell your maintenance department the case is

not getting power.

3. Turn shelf light dial (on left hand side) to "5". Light

next to dial will cycle on when the unit is heating, and

cycle off when it has reached temperature.

4. Turn shelf warmer dial (on right hand side) to "7".

The light next to the dial will cycle on when the

unit is heating, and cycle off when it has reached

temperature.

Operation Tips

1. Check the food to make sure the temperature is

correct. Hot foods should be held at a minimum of

140°F.

2. When restocking case, rotate older product to front

of case, load newer product in the back.

3. Clean spills as soon as they occur to avoid baked on

food soil.

Shut-down and Cleaning

1. Unload product from case.

2. Turn the dials for the Overhead Lights and the

Griddle Heat control to the "OFF" position.

3. Allow the case to cool for at least 30-45 minutes

before cleaning.

4. Clean the decks of the case with a mild soapy

solution and a sponge.

5. Wait an hour before loading pre - heated product*.

*These cases are not designed to cook or heat - up

food. Food must be at 150°-160°F BEFORE loading

into the case. Check food temperature with a

thermometer before putting in case.

6. After one hour, measure the product temperature by

using a food thermometer.

7. Adjust if necessary, increase or decrease

(whichever is appropriate) both dials, one number

at a time until the desired temperature has been

reached. Measure the product temperature with

a thermometer an hour after re - setting the case

temperature.

5. Wipe soap residue off with a sponge and clear,

clean water. Using caution not to put too much water

on the shelf.

6. Dry with clean towel or paper towel.

7. Polish and clean glass with a good glass cleaner.

5

Page 6

HED-02

Two Level Display

1. Measure PRODUCT temperature hourly by inserting a food thermometer into the food. Proper holding temperature is 140°.

2. To change temperature, increase or decrease Overhead Heat by one number at a time. Adjust the griddle temperature as

necessary. Measure product temperature again in one hour. Readjust if necessary.

ADJUST TEMPERATURE

SHUTDOWN

Operation Tips

1. Check the food temperature frequently with a thermometer

to make sure it is proper holding temperature.

Hot foods should be held at 140°.

2. Do not display more food than will be sold within a 4 hour

period.

3. When restocking, bring older food to front, stock fresher

food in back.

4. Clean spills as soon as they happen.

5. Oils and splatter will drastically shorten bulb life.

DANGER OF ELECTRICAL SHOCK OR CASE DAMAGE

USE THE MINIMUM AMOUNT OF LIQUID WHEN CLEANING!

Parts of the case exterior, shelves and light

bulbs become extremely hot when in use.

DO NOT

Touch Hot Case or Lights with

bare hands!

Nightly Cleaning

1. Turn case off and unload product.

2. Allow the case to cool for at least 30-45 minutes.

3. Clean the shelves and deck with a mild cleaning solution

and sponge. Never use ammonia based cleansers, abrasive

cleansers, or scouring pads.

WRING OUT CLOTH /

SPONGE THOROUGHLY BEFORE CLEANING!

4. Wipe residue off with a sponge and clear, clean water.

5. Dry with clean cotton or paper towel.

6. Polish and clean glass with a good glass cleaner

Control Panel

on Rear of Case

1. Turn all switches and dials to "OFF" position.

2. Allow case to cool and clean.

O/H HEAT

LIGHT

LO HI

6

5

4

3

2

ON / OFF

OFF

ON / OFF

OVERHEADHEAT

INITIAL

SETTING

"5"

OVERHEAD LIGHTS ON / OFF

TURN

SWITCHES

ON

GRIDDLE TEMPERA

TURE

INITIAL

SETTING

"7"

Check to make sure all lights come on at start-up.

If they do not contact your Service Department

Allow case preheat for 45 minutes prior to loading

NOTE: This equipment is not designed to heat-up or cook food. Food must be 150° - 160° when put in display.

CONTROL PANEL

GRIDDLE

OVERHEAD HEAT & LAMPS

Parts of the case exterior, shelves and light

bulbs become extremely hot when in use.

USE EXTREME CAUTION!

START-UP

©

HUSSMANN Corp. Chino, California HED Oper Lable/Est r00/05 dmd

430-01-0365 9810

1

2

3

4

5

6

7

8

9

10

S

t

a

r

t

u

p

Operation (Cont'd)

IGHT-HEDN, HEDN COMBO, HEDW-0508

6

Page 7

Rev. 0508

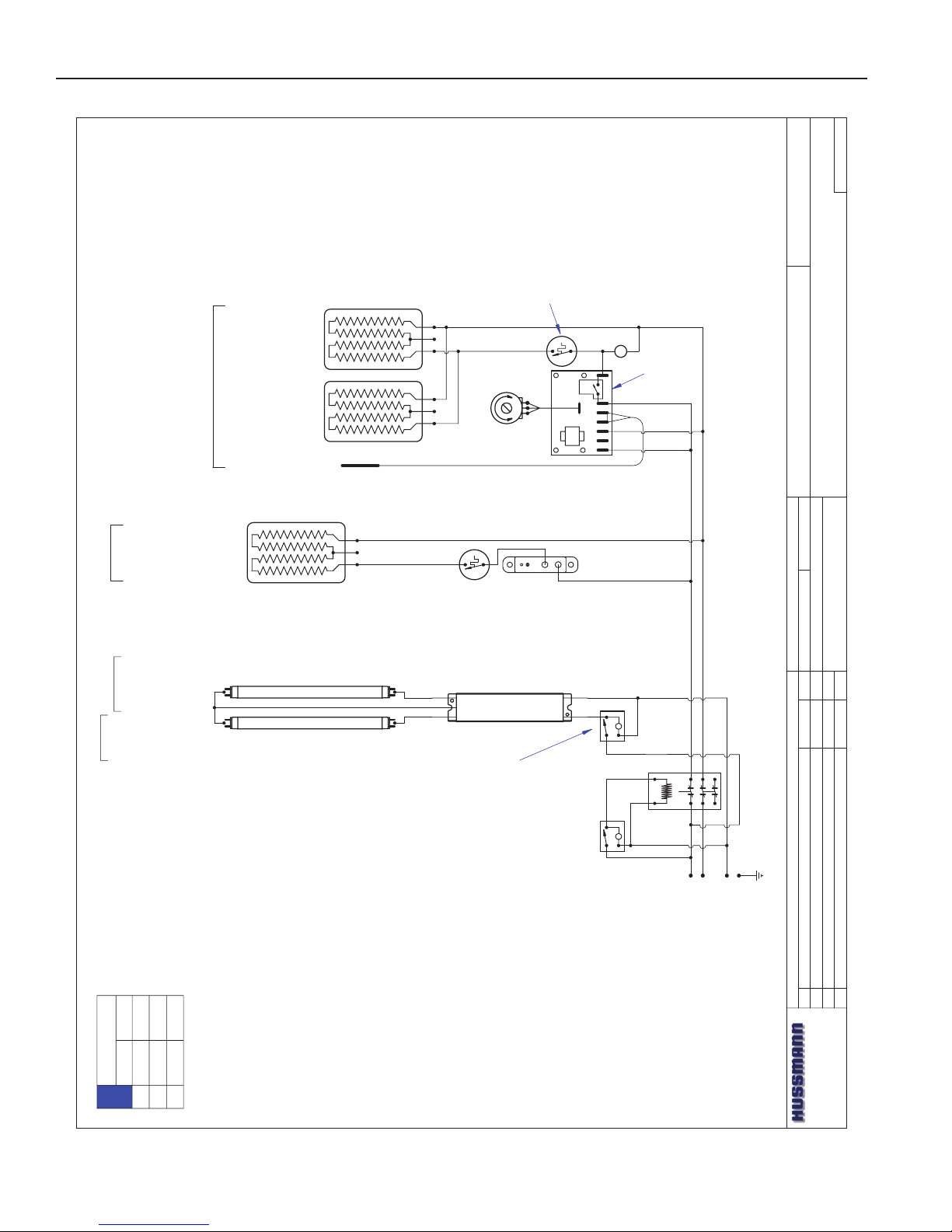

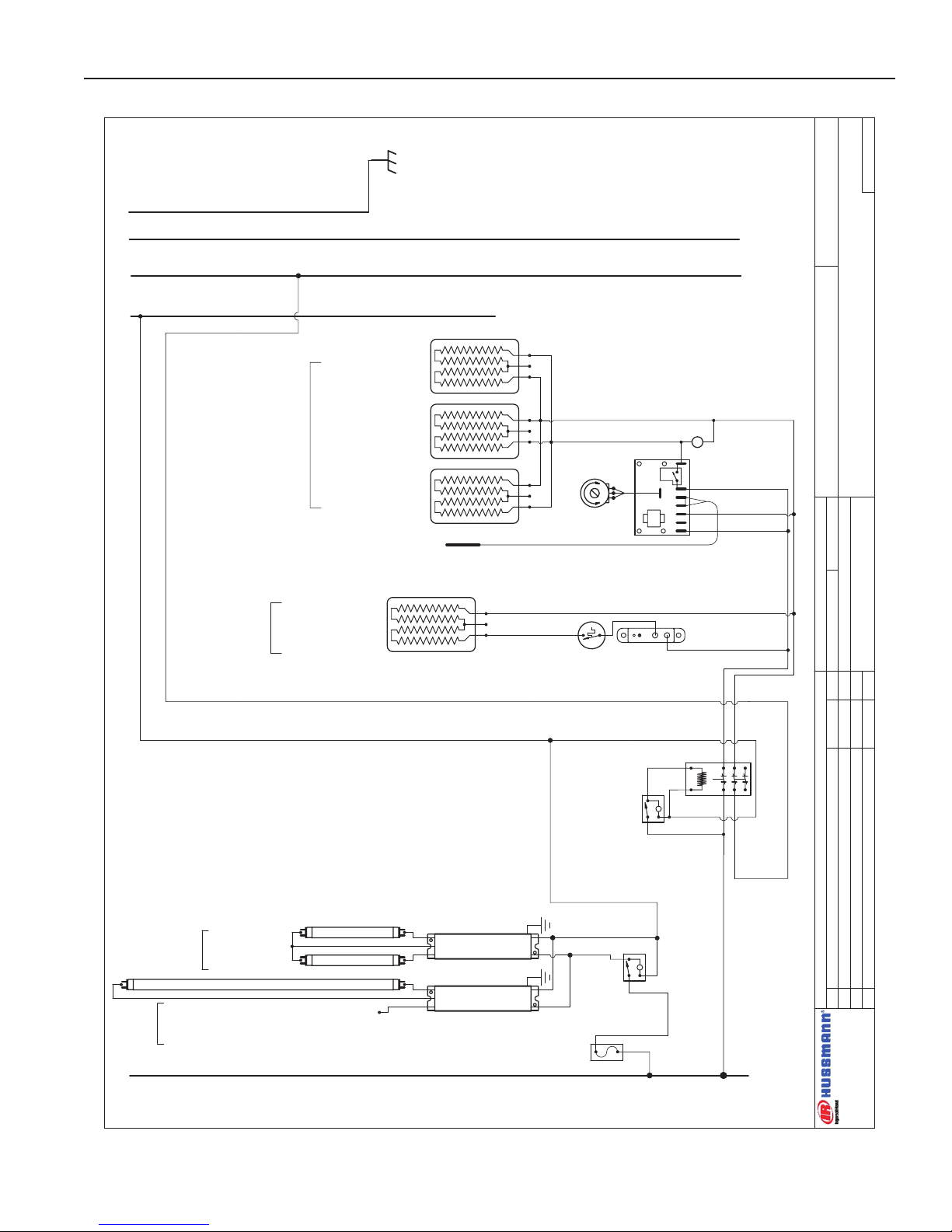

Electrical Wiring Diagrams

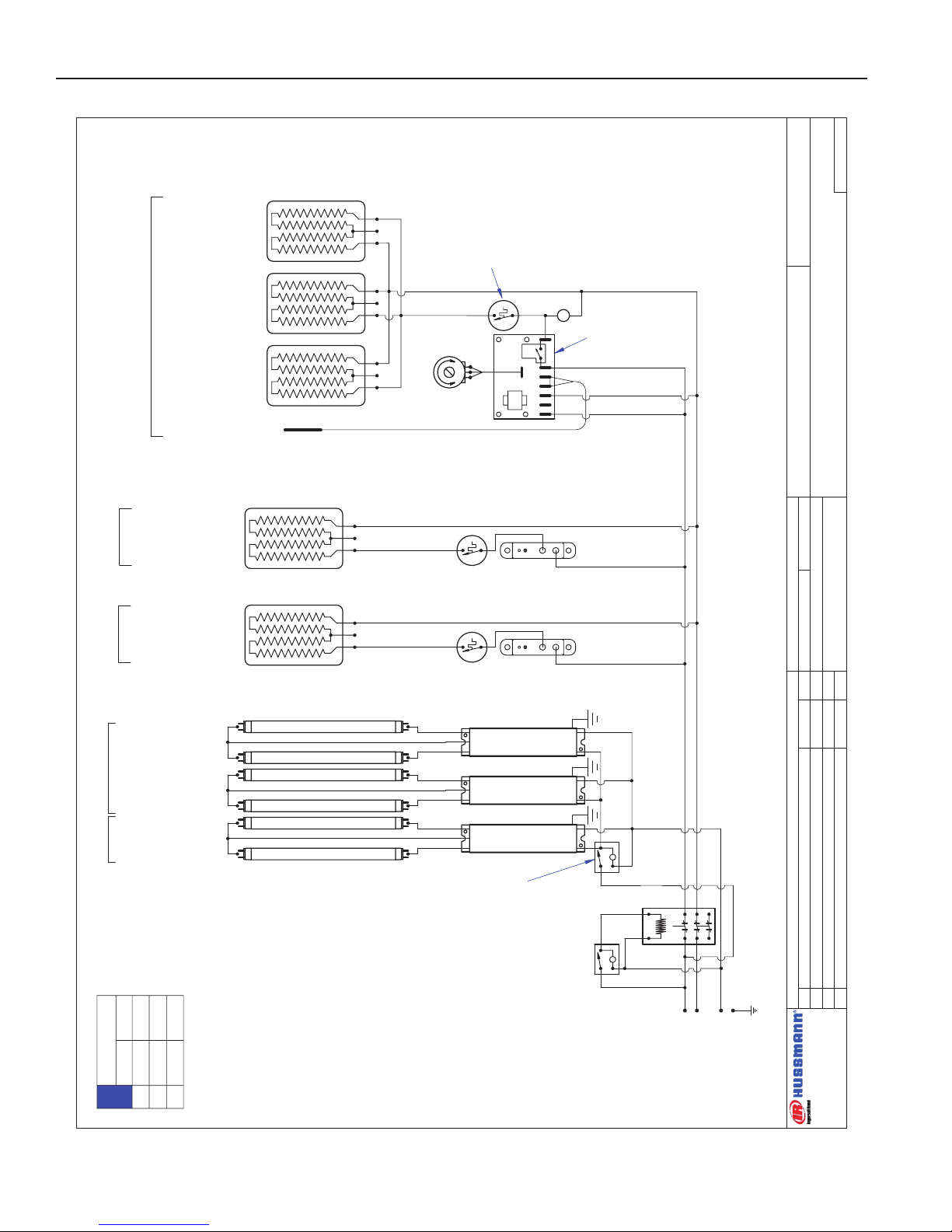

HEDN-02

HEDN-03

HEDN-04

HEDN-05

Hot/Cold Combo

WITHOUT TOP SHELF

HEDW-02

HEDW-03

HEDW-04

HEDW-05

3' W6300092

4' W6300093

5' W6300094

6' W6300095

8' W6300096

3' W6300086

4' W6300097

5' W6300098

6' W6300099

8' W6300100

3' W6300101

4' W6300102

5' W6300103

6' W6300104

8' W6300084

3' W6300105

4' W6300091

4' W6300127

5' W6300106

6' W6300081

6' W6300126

8' W6300107

3' W6300108

4' W6300109

5' W6300110

6' W6300111

8' W6300112

3' W6300113

4' W6300082

5' W6300114

6' W6300115

8' W6300116

3' W6300117

4' W6300118

5' W6300119

6' W6300120

8' W6300121

3' W6300122

4' W6300083

5' W6300123

6' W6300124

8' W6300089

7

Page 8

IGHT-HEDN, HEDN COMBO, HEDW-0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

Mark Cipriani

PAGE OF

?

1

1

01/09/06

A REVISED RATINGS; ADDED SHEET 2 4/10/07 JR

B Updated dwg: removed sheet 2; added limiter 3/3/08 JR

HEDN-02

W6300092

3' CASE WIRING DIAGRAM

BALLAST 125-01-3267

FULHAM LH4-120-L

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L

MAIN

POWER

~208 / ~240 VAC - 50/60 HZ

SWITCH

125-01-0311

225-01-6950

8.6x33.7

473 WATTS

1.97 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

6

4

2

1 5

P1

3 7

SENSOR

225-01-3228

225-01-6787T

19x18

342W

1.43 AMPS @ ~240VAC

GRIDDLE-#2-Bottom

225-01-6786T

11x18

198W

0.83 AMPS @ ~240VAC

SHELF- #1 -9.5"-TOP

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

PILOT LIGHT

175-01-1102C

L1

L2

N

G

BLACK # 14

RED # 14

WHITE # 14

SHELF LIGHTING

(1) FP21T5/830 3'

125-03-1130

SHELF

CANOPY

OVERHEAD LIGHTING

(1) FP21T5/830 3'

125-03-1130

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

LIGHT CIRCUIT= .39A 42W

GRN # 14

LOADING

208 V 240 V

L1

L2

4.1

3.7

4.6

4.2

NOTE:

CASE MUST

BE GROUNDED

1104W @ 240VAC

853W @ 208VAC

Wiring Diagrams

8

Page 9

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

---

PAGE OF1

1

4/19/07

B Updated dwg; added 225-01-1702 to griddle 1/28/08 JR

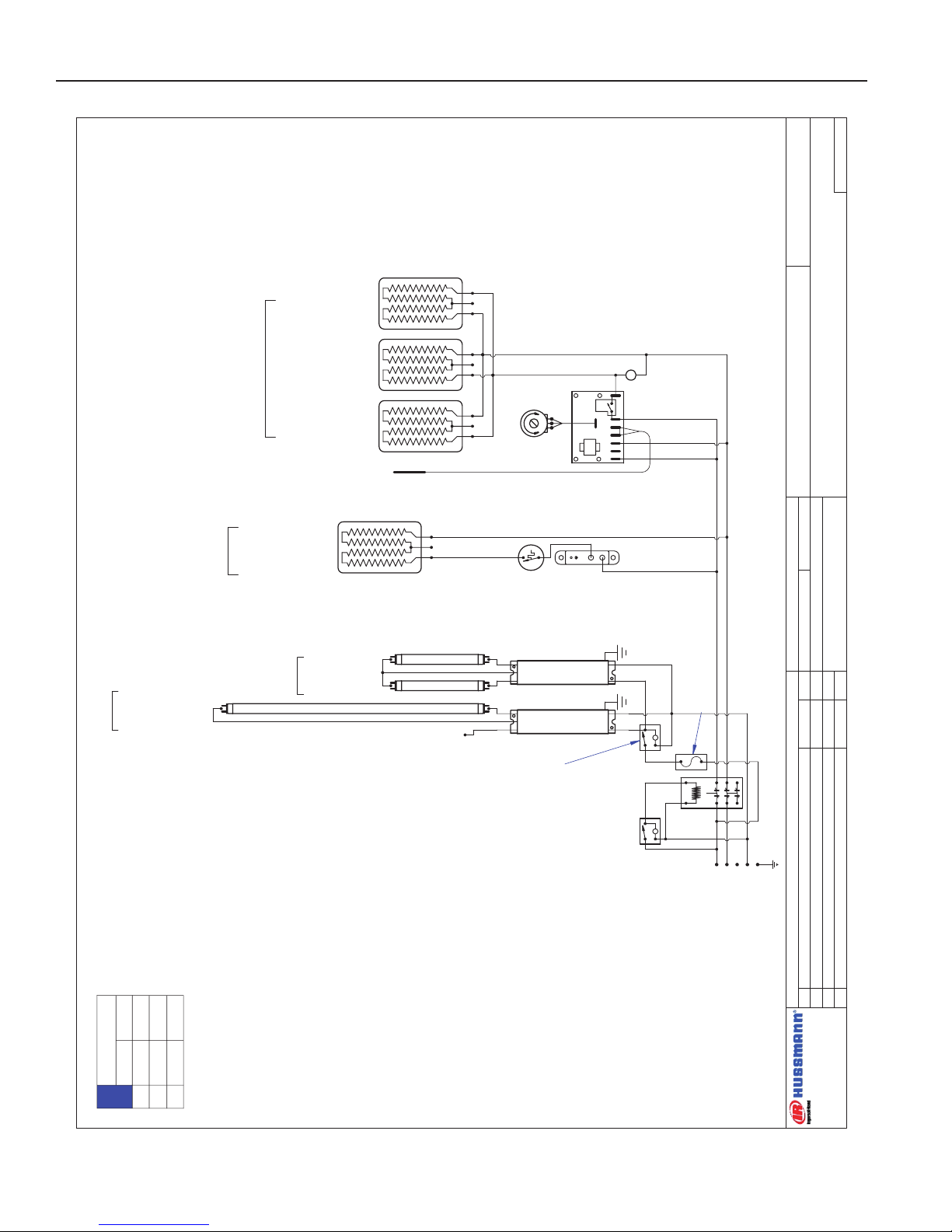

HEDN-02

W6300093

4' CASE WIRING DIAGRAM

BALLAST 125-01-3267

FULHAM LH4-120-L

LL

~208 / ~240 VAC - 50/60 HZ

SWITCH

125-01-0311

225-01-6787T

19x18

342WATTS

1.43AMPS @ 240 VAC

225-01-6787T

19x18

342WATTS

1.43AMPS @ 240 VAC

GRIDDLE-#2-Bottom

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

SENSOR

225-01-3228

6

421 5

P1

3 7

PILOT LIGHT

175-01-1102C

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

SHELF- #1 -9.5"-TOP

LIGHT SWITCH

TIPPETTE

125-01-0311

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

15 AMP FUSE

125-01-3282

FUSE HOLDER

125-01-3283

SHELF

CANOPY

OVERHEAD LIGHTING

(1) FP28T5/830 4'

125-03-1133

SHELF LIGHTING

(1) FP28T5/830 4'

125-03-1133

L1

L2

N

G

LIGHT CIRCUIT= 56W.52A

BLK # 14

RED # 14

WHT # 14

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

LOADING

208 V 240 V

L1

L2

L3

5.3

4.8

6.1

5.5

NOTE:

CASE MUST

BE GROUNDED

1382W @ 240VAC

1054W @ 208VAC

Wiring Diagrams (Cont'd)

9

Page 10

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

PAGE OF1

2

4/19/07

HEDN-02

W6300094

5' CASE WIRING DIAGRAM

BALLAST 125-01-3267

FULHAM LH4-120-L

L

L

~208 / ~240 VAC - 3Ø - 50/60 HZ

SWITCH

125-01-0311

225-01-6958

8.6x57.7

810 WATTS

3.38 AMPS @ 240 VAC

SHELF- #1 -9.5"-TOP

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

225-01-6786T

11.0x18.0

198 WATTS

0.83 AMPS @ 240 VAC

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

PILOT LIGHT

125-01-1102C

LIGHT SWITCH

TIPPETTE

125-01-0311

15 AMP FUSE

125-01-3282

FUSE HOLDER

125-01-3283

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

SENSOR

225-01-3228

6421 5

P1

3 7

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

GRIDDLE-#2-Bottom

OVERHEAD LIGHTING

(1) FP35T5/830 5'

125-03-1136

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

SHELF

CANOPY

BALLAST 125-01-3267

FULHAM LH4-120-L

CAP UNUSED RED LEAD

LIGHT CIRCUIT= .53A

L1L2L3

N

G

BLK # 14

RED # 14

WHT # 14

JESSE RIOS

LOADING

208 V 240 V

L1

L2

L3

6.7

6.1

7.6

7.1

NOTE:

CASE MUST

BE GROUNDED

Wiring Diagrams (Cont'd)

IGHT-HEDN, HEDN COMBO, HEDW-0508

10

Page 11

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

PAGE OF2

2

4/19/07

HEDN-02

W6300094

5' CASE WIRING DIAGRAM

JESSE RIOS

L1

BLACK (BLK)

# 14

WHITE (W)

#14

N

L2

GREEN (G)

# 14

G

BK

RED (R)

# 14

L3

L

SWITCH

125-01-0311

CIRCUIT #1

BLUE

(BL)

R

BL

BLACK

WHITE

L

LIGHT SWITCH

TIPPETTE

125-01-0311

WHITE

RED

BALLAST 125-01-3267

FULHAM LH4-120-L

OVERHEAD LIGHTING

(1) FP35T5/830 5'

125-03-1136

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

SHELF

CANOPY

CAP UNUSED RED LEAD

LIGHT CIRCUIT= .53A

225-01-6958

8.6x57.7

810 WATTS

3.38 AMPS @ 240 VAC

SHELF- #1 -9.5"-TOP

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

225-01-6786T

11.0x18.0

198 WATTS

0.83 AMPS @ 240 VAC

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

PILOT LIGHT

125-01-1102C

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

SENSOR

225-01-3228

64

21 5

P1

3 7

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

GRIDDLE-#2-Bottom

BALLAST 125-01-3267

FULHAM LH4-120-L

Wiring Diagrams (Cont'd)

11

Page 12

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

?

121

4/19/07

HEDN-02

W6300095

6' CASE WIRING DIAGRAM

LIGHT SWITCH

TIPPETTE

125-01-0311

L

SWITCH

125-01-0311

~208 / ~240 VAC - 3Ø - 50/60 HZ

L

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

OVERHEAD LIGHTING

(2) FP21T5/830 3'

125-03-1130

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

6421 5

P1

3 7

SHELF LIGHTING

(2) FP21T5/830 3'

125-03-1130

225-01-6962

8.6x69.7

979 WATTS

4.08 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

225-01-6787T

19x18

342 WATTS

1.43AMPS @ 240 VAC

GRIDDLE-#2-Bottom

SENSOR

225-01-3228

PILOT LIGHT

175-01-1102C

SHELF- #1 -9.5"-TOP

SHELVES

CANOPY

L1L2L3NG

BLK # 14

RED # 14

WHT # 14

225-01-6787T

19x18

342 WATTS

1.43AMPS @ 240 VAC

225-01-6787T

19x18

342 WATTS

1.43AMPS @ 240 VAC

LIGHT CIRCUIT= .7A

LOADING

208 V 240 V

L1

L2

L3

8.0

7.3

9.1

8.4

NOTE:

CASE MUST

BE GROUNDED

Wiring Diagrams (Cont'd)

IGHT-HEDN, HEDN COMBO, HEDW-0508

12

Page 13

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

?

L1

BLACK (BLK)

# 14

WHITE (W)

#14

N

L2

GREEN (G)

# 14

G

BK

RED (R)

# 14

L3

L

SWITCH

125-01-0311

CIRCUIT #1

BLUE

(BL)

R

BL

BLACK

WHITE

L

LIGHT SWITCH

TIPPETTE

125-01-0311

WHITE

RED

LIGHT CIRCUIT= .7A

OVERHEAD LIGHTING

(2) FP21T5/830 3'

125-03-1130

SHELF LIGHTING

(2) FP21T5/830 3'

125-03-1130

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

SHELVES

CANOPY

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

6421 5

P1

3 7

225-01-6962

8.6x69.7

979 WATTS

4.08 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6787T

19x18

342 WATTS

1.43AMPS @ 240 VAC

GRIDDLE-#2-Bottom

SENSOR

225-01-3228

PILOT LIGHT

175-01-1102C

SHELF- #1 -9.5"-TOP

225-01-6787T

19x18

342 WATTS

1.43AMPS @ 240 VAC

225-01-6787T

19x18

342 WATTS

1.43AMPS @ 240 VAC

RED

HEDN-02

W6300095

6' CASE WIRING DIAGRAM

2

2

4/19/07

Wiring Diagrams (Cont'd)

13

Page 14

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

---

PAGE OF1

2

4/19/07

HEDN-02

W6300096

8' CASE WIRING DIAGRAM

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L

~208 / ~240 VAC - 3Ø - 50/60 HZ

SWITCH

125-01-0311

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6787T

19x18

342WATTS

1.43AMPS @ 240 VAC

225-01-6787T

19x18

342WATTS

1.43AMPS @ 240 VAC

SENSOR

225-01-3228

225-01-6787T

19x18

342WATTS

1.43AMPS @ 240 VAC

225-01-6787T

19x18

342WATTS

1.43AMPS @ 240 VAC

SENSOR

225-01-3228

OVERHEAD LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELVES

CANOPY

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

SHELF-9.5"-RIGHT-TOP

SHELF-9.5"-LEFT-TOP

GRIDDLE-RIGHT-BOTTOM

GRIDDLE-LEFT-BOTTOM

642

1 5

P1

3 7

TEMP. CONTROL

L

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

64

2

1 5

P1

3 7

TEMP. CONTROL

L

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

LIGHT CIRCUIT= .93A

L1

L2

L3NG

BLK # 14

RED # 14

WHT # 14

LOADING

208 V 240 V

L1

L2

L3

9.9

9.0

12.0

11.1

NOTE:

CASE MUST

BE GROUNDED

Wiring Diagrams (Cont'd)

IGHT-HEDN, HEDN COMBO, HEDW-0508

14

Page 15

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

---

PAGE OF2

2

4/19/07

HEDN-02

W6300096

8' CASE WIRING DIAGRAM

L1

BLACK (BLK)

# 14

WHITE (W)

#14

N

L2

GREEN (G)

# 14

G

BK

RED (R)

# 14

L3

L

SWITCH

125-01-0311

CIRCUIT #1

BLUE

(BL)

BLACK

WHITE

L

LIGHT SWITCH

TIPPETTE

125-01-0311

WHITE

RED

RED

225-01-6954

8.6x45.7

590 WATTS

2.46 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6954

8.6x45.7

590 WATTS

2.46 AMPS @ 240 VAC

225-01-6787T

19x18

342WATTS

2.30AMPS @ 240 VAC

225-01-6787T

19x18

342WATTS

2.30AMPS @ 240 VAC

SENSOR

225-01-3228

225-01-6787T

19x18

342WATTS

2.30AMPS @ 240 VAC

225-01-6787T

19x18

342WATTS

2.30AMPS @ 240 VAC

SENSOR

225-01-3228

SHELF-9.5"-RIGHT-TOP

SHELF-9.5"-LEFT-TOP

GRIDDLE-RIGHT-BOTTOM

GRIDDLE-LEFT-BOTTOM

6421 5

P1

3 7

TEMP. CONTROL

L

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

6421 5

P1

3 7

TEMP. CONTROL

L

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

OVERHEAD LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELVES

CANOPY

BALLAST 125-01-3267

FULHAM LH4-120-L

LIGHT CIRCUIT= .93A

BALLAST 125-01-3267

FULHAM LH4-120-L

Wiring Diagrams (Cont'd)

15

Page 16

IGHT-HEDN, HEDN COMBO, HEDW-0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

?

1

1

4/20/07

1

B Updated dwg; added 225-01-1702 to griddle 1/28/07 JR

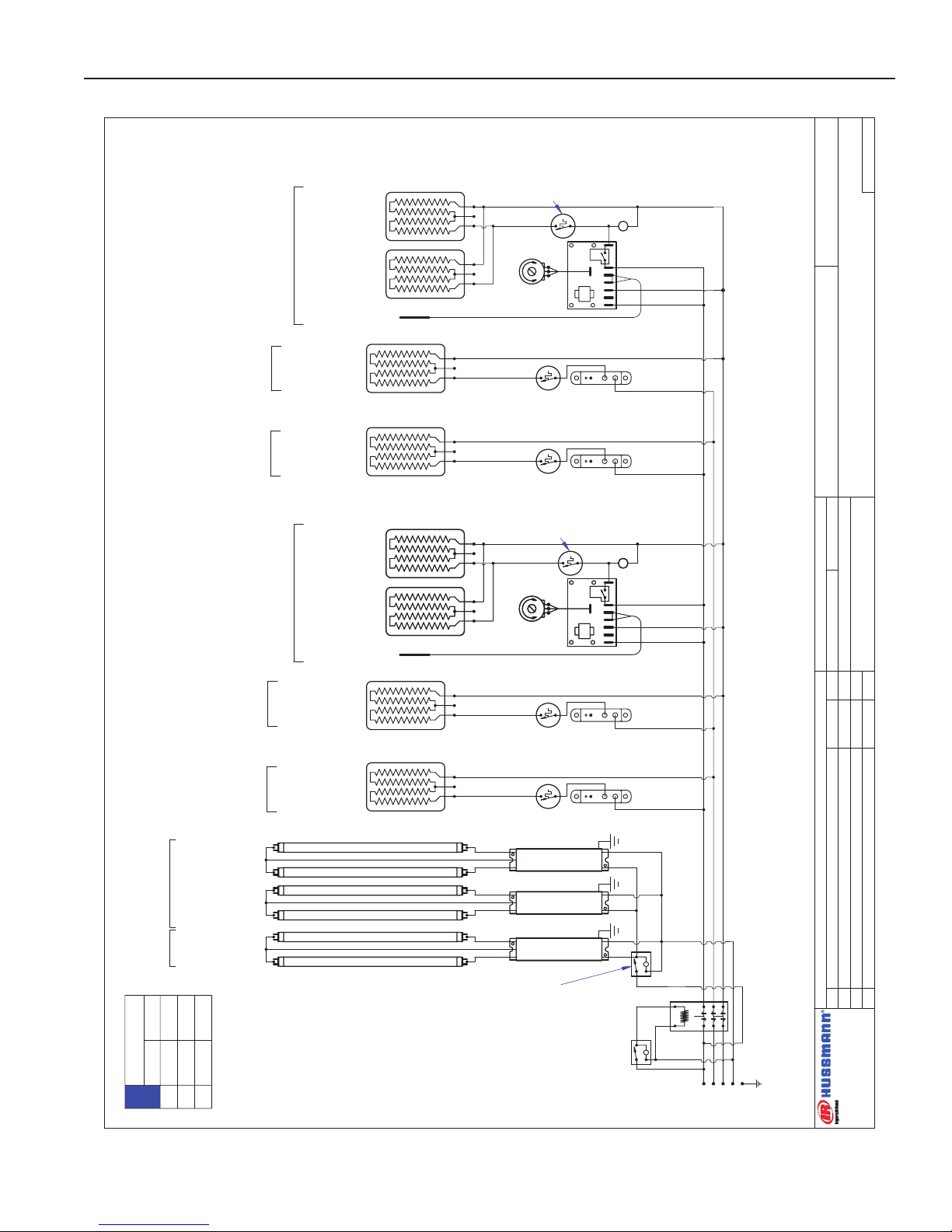

HEDN-03

W6300086

3' CASE WIRING DIAGRAM

L

L

MAIN

POWER

~208 / ~240 VAC - 3Ø - 50/60 HZ

SWITCH

125-01-0311

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

225-01-6950

8.6x33.7

473 WATTS

1.97 AMPS @ 240 VAC

225-01-6951

10.6x33.7

583 WATTS

2.43AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

SENSOR

225-01-3228

6421

5

P1

3 7

LIGHT SWITCH

TIPPETTE

125-01-0311

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

PILOT LIGHT

175-01-1102C

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5"

GRIDDLE-#3-Bottom

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

225-01-6786T

11.0x18.0

198 WATTS

0.83 AMPS @ 240 VAC

CAP UNUSED RED LEAD

OVERHEAD LIGHTING

FP21T5/830 3'

125-03-1130

SHELF LIGHTING

(2) FP21T5/830 3'

125-03-1130

SHELVES

CANOPY

L1

L2

L3

N

G

LIGHT CIRCUIT= .58A 63W

BLK # 14

RED # 14

WHT # 14

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

NOTE:

CASE MUST

BE GROUNDED

7.2

6.7

6.4

5.8

L1

L2

208 V 240 V

LOADING

1659W @ 240VAC

1264W @ 208VAC

Wiring Diagrams (Cont'd)

16

Page 17

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

?

111

4/20/07

B Updated dwg; added limiter to griddle circuit 3/19/08 JR

HEDN-03

W6300097

4' CASE WIRING DIAGRAM

BALLAST 125-01-3267

FULHAM LH4-120-L

LL

~208 / ~240 VAC - 50/60 HZ

SWITCH

125-01-0311

BALLAST 125-01-3267

FULHAM LH4-120-L

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6955

10.6x45.7

791 WATTS

3.30 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6787T

19x18

342WATTS

1.43 AMPS @ 240 VAC

225-01-6787T

19x18

342WATTS

1.43 AMPS @ 240 VAC

GRIDDLE-#3-Bottom

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

SENSOR

225-01-3228

6421 5

P1

3 7

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5"

PILOT LIGHT

175-01-1102C

CAP UNUSED RED LEAD

LIGHT SWITCH

TIPPETTE

125-01-0311

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

OVERHEAD LIGHTING

(1) FP28T5/830 4'

125-03-1133

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELVES

CANOPY

LIGHT CIRCUIT=.78 A 84W

BLK # 14

RED # 14

WHT # 14

L1L2L3

N

G

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

LOADING

208 V 240 V

L1

L2

8.4

7.7

9.5

8.8

NOTE:

CASE MUST

BE GROUNDED

2280W @ 240VAC

1747W @ 208VAC

Wiring Diagrams (Cont'd)

17

Page 18

IGHT-HEDN, HEDN COMBO, HEDW-0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

?

11 2

4/20/07

HEDN-03

W6300098

5' CASE WIRING DIAGRAM

BALLAST 125-01-3267

FULHAM LH4-120-L

L

L

~208 / ~240 VAC - 3Ø - 50/60 HZ

SWITCH

125-01-0311

BALLAST 125-01-3267

FULHAM LH4-120-L

CAP UNUSED RED LEAD

225-01-6959

10.6x57.7

999 WATTS

4.17 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6958

8.6x57.7

810 WATTS

3.38 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5"

GRIDDLE-#3-Bottom

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

225-01-6786T

11.0x18.0

198 WATTS

0.83 AMPS @ 240 VAC

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

125-01-1102C

L

TEMP. CONTROL

SENSOR

225-01-3228

642

1 5

P1

3 7

LIGHT SWITCH

TIPPETTE

125-01-0311

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

OVERHEAD LIGHTING

(1) FP35T5/830 5'

125-03-1136

SHELVES

CANOPY

BALLAST 125-01-3267

FULHAM LH4-120-L

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

LIGHT CIRCUIT=.76 A

BLK # 14

RED # 14

WHT # 14

L1L2L3NG

LOADING

208 V 240 V

L1

L2

L3

10.5

9.7

12.0

11.2

NOTE:

CASE MUST

BE GROUNDED

Wiring Diagrams (Cont'd)

18

Page 19

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

?

L1

BLACK (BLK)

# 14

WHITE (W)

#14

N

L2

GREEN (G)

# 14

G

BK

RED (R)

# 14

L3

L

SWITCH

125-01-0311

BLUE

(BL)

BLACK

WHITE

L

LIGHT SWITCH

TIPPETTE

125-01-0311

WHITE

RED

RED

225-01-6959

10.6x57.7

999 WATTS

4.17 AMPS @ 240 VAC

225-01-6958

8.6x57.7

810 WATTS

3.38 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5"

GRIDDLE-#3-Bottom

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

225-01-6786T

11.0x18.0

198 WATTS

0.83 AMPS @ 240 VAC

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

125-01-1102C

L

TEMP. CONTROL

SENSOR

225-01-3228

642

1 5

P1

3 7

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

CAP UNUSED RED LEAD

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

OVERHEAD LIGHTING

(1) FP35T5/830 5'

125-03-1136

SHELVES

CANOPY

BALLAST 125-01-3267

FULHAM LH4-120-L

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

LIGHT CIRCUIT=.76 A

2 2

4/20/07

HEDN-03

W6300098

5' CASE WIRING DIAGRAM

Wiring Diagrams (Cont'd)

19

Page 20

IGHT-HEDN, HEDN COMBO, HEDW-0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

---

PAGE OF1

1

4/20/07

B Updated dwg; removed sheet 2; added limiter to griddle 3/17/08 JR

HEDN-03

W6300099

6' CASE - WIRING DIAGRAM

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

6421 5

P1

3 7

LIGHT SWITCH

TIPPETTE

125-01-0311

L

SWITCH

125-01-0311

~208 / ~240 VAC - 50/60 HZ

L

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

225-01-6963

10.6x69.7

1207 WATTS

5.03 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6962

8.6x69.7

979 WATTS

4.08 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

PILOT LIGHT

175-01-1102C

225-01-6787T

19x18

342WATTS

1.43 AMPS @ 240 VAC

225-01-6787T

19x18

342WATTS

1.43 AMPS @ 240 VAC

GRIDDLE-#3-Bottom

SENSOR

225-01-3228

225-01-6787T

19x18

342WATTS

1.43 AMPS @ 240 VAC

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5"

OVERHEAD LIGHTING

(2) FP21T5/830 3'

125-03-1130

SHELF LIGHTING

(2) FP21T5/830 3'

125-03-1130

SHELVES

CANOPY

SHELF LIGHTING

(2) FP21T5/830 3'

125-03-1130

BLK # 14

RED # 14

WHT # 14

L1

L2

N

G

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

LIGHT CIRCUIT= 1.17A 126W

LOADING

208 V 240 V

L1

L2

12.7

11.6

14.5

13.4

NOTE:

CASE MUST

BE GROUNDED

Wiring Diagrams (Cont'd)

20

Page 21

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

---

PAGE OF1

1

4/20/07

B Add limiters to griddle circuits; revised wiring scheme 4/ 1/2008 JR

HEDN-03

W6300100

8' CASE WIRING DIAGRAM

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L

~208 / ~240 VAC - 50/60 HZ

SWITCH

125-01-0311

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6955

10.6x45.7

791 WATTS

3.30 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6955

10.6x45.7

791 WATTS

3.30 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

OVERHEAD LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELVES

CANOPY

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

SENSOR

225-01-3228

6

4

2

1 5

P1

3 7

TEMP. CONTROL

L

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

SHELF-9.5"-LEFT-TOP

SHELF-11.5"-LEFT

SHELF-9.5"-RIGHT-TOP

SHELF-11.5"-RIGHT

225-01-6787T

19x18

342WATTS

1.43 AMPS @ 240 VAC

SENSOR

225-01-3228

GRIDDLE-RIGHT-BOTTOM

6

4

2

1 5

P1

3 7

TEMP. CONTROL

L

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

225-01-6787T

19x18

342 WATTS

1.43 AMPS @ 240 VAC

SENSOR

225-01-3228

GRIDDLE-LEFT-BOTTOM

6

421 5

P1

3 7

TEMP. CONTROL

L

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

L1

L2L3N

G

LIGHT CIRCUIT= 1.56A 168W

BLK # 12

RED # 12

WHT # 14

BLUE # 12

225-01-6787T

19x18

342WATTS

1.43 AMPS @ 240 VAC

225-01-6787T

19x18

342 WATTS

1.43 AMPS @ 240 VAC

BLK # 12

RED # 12

BLUE # 12

GREEN # 12

BLK # 14

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

LOADING

208 V 240 V

L1

L2

L3

11.2

10.4

10.7

12.6

12.0

12.3

NOTE:

CASE MUST

BE GROUNDED

Wiring Diagrams (Cont'd)

21

Page 22

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

Mark Cipriani

PAGE OF1

1

01/09/07

123

Eng\WIRESCHEMATICS\NEW-WIRING

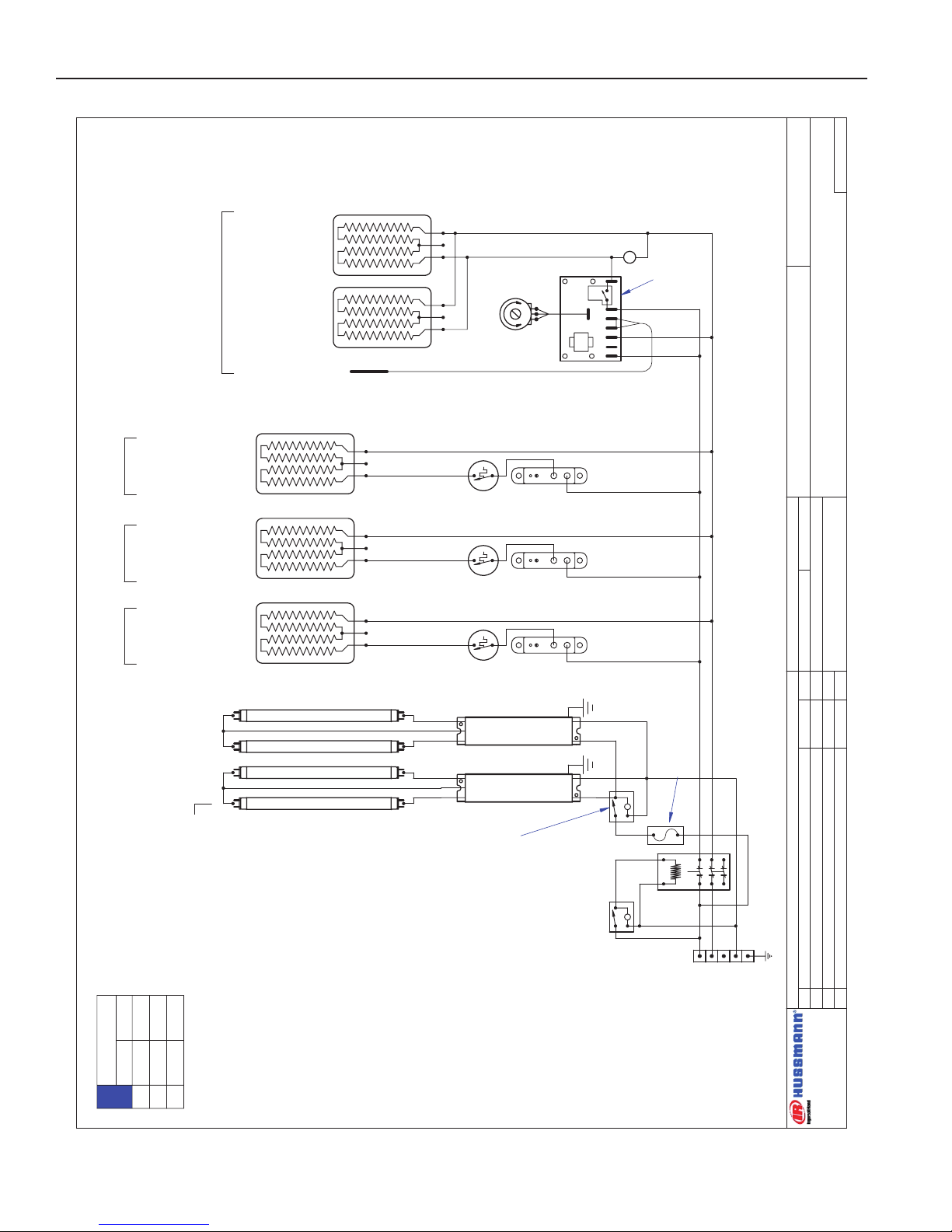

HEDN-04

W6300101

3' CASE WIRING DIAGRAM

BALLAST 125-01-3267

FULHAM LH4-120-L

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L1L2L3NG

L

MAIN

POWER

~208 / ~240 VAC - 1Ø - 50/60 HZ - 4W

125-01-1001

SQUARE -D

CONTACTOR

8910DPA43V02

SWITCH

125-01-0311

CANOPY

SHELVES

BALLAST 125-01-3267

FULHAM LH4-120-L

225-01-6951

10.6x33.7

536 WATTS

2.23 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6950

8.6x33.7

435 WATTS

1.81 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6952

12.6x33.7

637 WATTS

2.65 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

CASE LIGHTS

(4) FP21T5/830 3'

125-03-1130

15 AMP FUSE

125-01-3282

FUSE HOLDER

125-01-3283

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

L

TEMP. CONTROL

6421 5

P1

3 7

SENSOR

225-01-3228

225-01-6787T

19x18

342W

1.43 AMPS @ ~240VAC

GRIDDLE-#4-Bottom

225-01-6786T

11x18

198W

0.83 AMPS @ ~240VAC

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5"

SHELF- #3 -13.5"

LOADING

208 V 240 V

L1

L2

L3

9.5

7.7

~

11.0

8.9

~

NOTE:

CASE MUST

BE GROUNDED

GM

Wiring Diagrams (Cont'd)

IGHT-HEDN, HEDN COMBO, HEDW-0508

22

Page 23

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

ECD

PAGE OF1

1

01/17/06

B Updated dwg; added limiter to griddle circuit 4/23/08 JR

HEDN-04

W6300102

4' CASE WIRING DIAGRAM

BALLAST 125-01-3267

FULHAM LH4-120-L

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L

MAIN

POWER

~208 / ~240 VAC - 50/60 HZ

125-01-1001

SQUARE -D

CONTACTOR

8910DPA43V02

SWITCH

125-01-0311

GRIDDLE HEATING PADS

(2) 342W 1.43A @ 240 VAC

225-01-6787T

BALLAST 125-01-3267

FULHAM LH4-120-L

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6955

10.6x45.7

791 WATTS

3.30 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6956

12.6x45.7

940 WATTS

3.92 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5"

SHELF- #3 -13.5"

GRIDDLE-#4-Bottom

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

L

TEMP. CONTROL

SENSOR

225-01-3228

6421 5

P1

3 7

OVERHEAD LIGHTING

(1) FP28T5/830 4'

125-03-1133

SHELVES

CANOPY

OVERHEAD LIGHTING

(3) FP28T5/830 4'

125-03-1133

L1

L2NG

LIGHT CIRCUIT= 1.04A 112W

RED # 12

BLACK # 12

WHITE # 14

BLACK # 14

GREEN # 12

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

GM

LOADING

208 V 240 V

L1

L2

12.1

11.1

13.8

12.8

NOTE:

CASE MUST

BE GROUNDED

3312W @ 240VAC

2517W @ 208VAC

Wiring Diagrams (Cont'd)

23

Page 24

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

?

121

4/23/07

HEDN-04

W6300103

5' CASE WIRING DIAGRAM

BALLAST 125-01-3267

FULHAM LH4-120-L

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L

~208 / ~240 VAC - 50/60 HZ

SWITCH

125-01-0311

BALLAST 125-01-3267

FULHAM LH4-120-L

225-01-6960

12.6x57.7

1187 WATTS

4.95 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6959

10.6x57.7

999 WATTS

4.16 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6958

8.6x57.7

810 WATTS

3.38 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5"

SHELF- #3 -13.5"

GRIDDLE-#4-Bottom

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

225-01-6786T

11.0x18.0

198 WATTS

0.83 AMPS @ 240 VAC

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

125-01-1102C

L

TEMP. CONTROL

SENSOR

225-01-3228

6

4

21 5

P1

3 7

OVERHEAD LIGHTING

(1) FP35T5/830 5'

125-03-1136

SHELVES

CANOPY

BALLAST 125-01-3267

FULHAM LH4-120-L

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

BALLAST 125-01-3267

FULHAM LH4-120-L

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

CAP UNUSED RED LEAD

L1

L2L3N

G

LIGHT CIRCUIT= 1.0A

BLK # 14

RED # 14

WHT # 14

BLUE # 14

BLK # 14

BLK # 14

RED # 14

BLUE # 14

LOADING

208 V 240 V

L1

L2

L3

10.7

10.8

7.5

12.2

12.5

8.6

NOTE:

CASE MUST

BE GROUNDED

Wiring Diagrams (Cont'd)

IGHT-HEDN, HEDN COMBO, HEDW-0508

24

Page 25

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

?

2

2

4/23/07

HEDN-04

W6300103

5' CASE WIRING DIAGRAM

L1

BLACK (BLK)

# 14

WHITE (W)

#14

N

L2

GREEN (G)

# 14

G

BK

RED (R)

# 14

L3

L

SWITCH

125-01-0311

BLUE

(BL)

BLACK

WHITE

L

LIGHT SWITCH

TIPPETTE

125-01-0311

WHITE

RED

RED

225-01-6960

12.6x57.7

1187 WATTS

4.95 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6959

10.6x57.7

999 WATTS

4.16 AMPS @ 240 VAC

225-01-6958

8.6x57.7

810 WATTS

3.38 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5"

SHELF- #3 -13.5"

GRIDDLE-#4-Bottom

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

225-01-6786T

11.0x18.0

198 WATTS

0.83 AMPS @ 240 VAC

225-01-6787T

19.0x18.0

342 WATTS

1.43 AMPS @ 240 VAC

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

125-01-1102C

L

TEMP. CONTROL

SENSOR

225-01-3228

642

1 5

P1

3 7

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

OVERHEAD LIGHTING

(1) FP35T5/830 5'

125-03-1136

SHELVES

CANOPY

BALLAST 125-01-3267

FULHAM LH4-120-L

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

BALLAST 125-01-3267

FULHAM LH4-120-L

SHELF LIGHTING

(2) FP14T5/830 2'

125-03-1127

CAP UNUSED RED LEAD

LIGHT CIRCUIT= 1.0A

BLUE

BLUE

Wiring Diagrams (Cont'd)

25

Page 26

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

ECD

KM

PAGE OF1

1

02/14/07

B Updated dwg; added 225-01-1702 to griddle

1/24/08 JR

C Revised wiring scheme from 4 to 5 wire 3 phase 1/28/08 JR

D Revised load ratings per UL request 1/29/08 JR

HEDN-04

W6300104

6' CASE - WIRING DIAGRAM

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

L

TEMP. CONTROL

6421 5

P1

3 7

SENSOR

225-01-3228

LIGHT SWITCH

TIPPETTE

125-01-0311

L

SWITCH

125-01-0311

~208 / ~240 VAC - 50/60 HZ

MAIN

POWER

L

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

225-01-6964

12.6x69.7

1434 WATTS

5.98 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6963

10.6x69.7

1207 WATTS

5.03 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6962

8.6x69.7

979 WATTS

4.08 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6787T

19x18

342WATTS

1.43AMPS @ 240 VAC

225-01-6787T

19x18

342WATTS

1.43AMPS @ 240 VAC

GRIDDLE-#4-Bottom

225-01-6787T

19x18

342WATTS

1.43AMPS @ 240 VAC

OVERHEAD LIGHTING

(2) FP21T5/830 3'

125-03-1130

SHELF LIGHTING

(2) FP21T5/830 3'

125-03-1130

SHELVES

CANOPY

SHELF LIGHTING

(2) FP21T5/830 3'

125-03-1130

SHELF LIGHTING

(2) FP21T5/830 3'

125-03-1130

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

SHELF- #1 -9.5"

TOP

SHELF- #2 -11.5"

SHELF- #3 -13.5"

LIGHT CIRCUIT= 168W 1.56A

L1

L2

L3NG

BLK # 12

RED # 12

WHITE # 14

GRN # 12

BLK # 14

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

BLUE # 12

BLK # 12

RED # 12

BLUE # 12

LOADING

208 V 240 V

L1

L2

L3

12.3

10.4

7.7

13.9

12.1

8.7

NOTE:

CASE MUST

BE GROUNDED

4814W @ 240VAC

3663W @ 208VAC

Wiring Diagrams (Cont'd)

IGHT-HEDN, HEDN COMBO, HEDW-0508

26

Page 27

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

---

PAGE OF1

2

5/1/07

HEDN-04 - WITH 225-01-1700

W6300084

8' CASE - WIRING DIAGRAM

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

6

4

21 5

P1

3 7

SENSOR

225-01-3228

SWITCH

125-01-0311

~208 / ~240 VAC -50/60 HZ

L

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

L

BALLAST 125-01-3267

FULHAM LH4-120-L

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

225-01-6955

10.6x45.7

791 WATTS

3.30 AMPS @ 240 VAC

225-01-6955

10.6x45.7

791 WATTS

3.30 AMPS @ 240 VAC

225-01-6956

12.6x45.7

940 WATTS

3.92 AMPS @ 240 VAC

225-01-6956

12.6x45.7

940 WATTS

3.92 AMPS @ 240 VAC

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

6

4

2

1

5

P1

3 7

SENSOR

225-01-3228

225-01-6787T

19.0x18.0

(2) 342 WATTS

1.43 AMPS @ 240VAC

BALLAST 125-01-3267

FULHAM LH4-120-L

SHELF- #1 -9.5"

-TOP LEFT

GRIDDLE- #4 -20.5" - LEFT

SHELF- #2 -11.5"

-LEFT

SHELF- #3 -13.5"

-LEFT

SHELF- #1 -9.5"

-TOP RIGHT

SHELF- #2 -11.5"

-RIGHT

SHELF- #3 -13.5"

-RIGHT

225-01-6787T

19.0x18.0

(2) 342 WATTS

1.43 AMPS @ 240VAC

GRIDDLE- #4 -20.5" - RIGHT

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

OVERHEAD LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELVES

CANOPY

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

LIGHT SWITCH

TIPPETTE

125-01-0311

15 AMP FUSE

125-01-8604

FUSE HOLDER

125-01-8605

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

PILOT LIGHT

175-01-1102C

PILOT LIGHT

175-01-1102C

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

L1L2L3NG

LIGHT CIRCUIT= 1.87A

BLK # 12

RED # 12

WHT # 14

BLUE # 12

BLK # 14

BLK # 12

RED # 12

BLUE # 12

RED # 12

BLUE # 12

GRN # 12

LOADING

208 V 240 V

L1

L2

L3

13.3

15.3

17.5

15.1

17.7

20.2

NOTE:

CASE MUST

BE GROUNDED

Wiring Diagrams (Cont'd)

27

Page 28

IGHT-HEDN, HEDN COMBO, HEDW-0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

---

PAGE OF2

2

5/1/07

HEDN-04 - WITH 225-01-1700

W6300084

8' CASE - WIRING DIAGRAM

L1

BLACK (BLK)

# 12

WHITE (W)

#14

N

L2

GREEN (G)

# 12

G

BK

RED (R)

# 12

L3

L

SWITCH

125-01-0311

BLUE

(BL) # 12

BLACK

WHITE

L

WHITE

RED

RED

BLUE

BLUE

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

6421 5

P1

3 7

SENSOR

225-01-3228

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

225-01-6955

10.6x45.7

791 WATTS

3.30 AMPS @ 240 VAC

225-01-6955

10.6x45.7

791 WATTS

3.30 AMPS @ 240 VAC

225-01-6956

12.6x45.7

940 WATTS

3.92 AMPS @ 240 VAC

225-01-6956

12.6x45.7

940 WATTS

3.92 AMPS @ 240 VAC

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

6421 5

P1

3 7

SENSOR

225-01-3228

225-01-6787T

19.0x18.0

(2) 342 WATTS

1.43 AMPS @ 240VAC

SHELF- #1 -9.5"

-TOP LEFT

GRIDDLE- #4 -20.5" - LEFT

SHELF- #2 -11.5"

-LEFT

SHELF- #3 -13.5"

-LEFT

SHELF- #1 -9.5"

-TOP RIGHT

SHELF- #2 -11.5"

-RIGHT

SHELF- #3 -13.5"

-RIGHT

225-01-6787T

19.0x18.0

(2) 342 WATTS

1.43 AMPS @ 240VAC

GRIDDLE- #4 -20.5" - RIGHT

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

OVERHEAD LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELVES

CANOPY

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

Wiring Diagrams (Cont'd)

28

Page 29

Rev. 0508

DATE:1/9/07

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

Mark Cipriani

PAGE OF1

1

B Updated drawing; added limit switch to griddle 3/3/08 JR

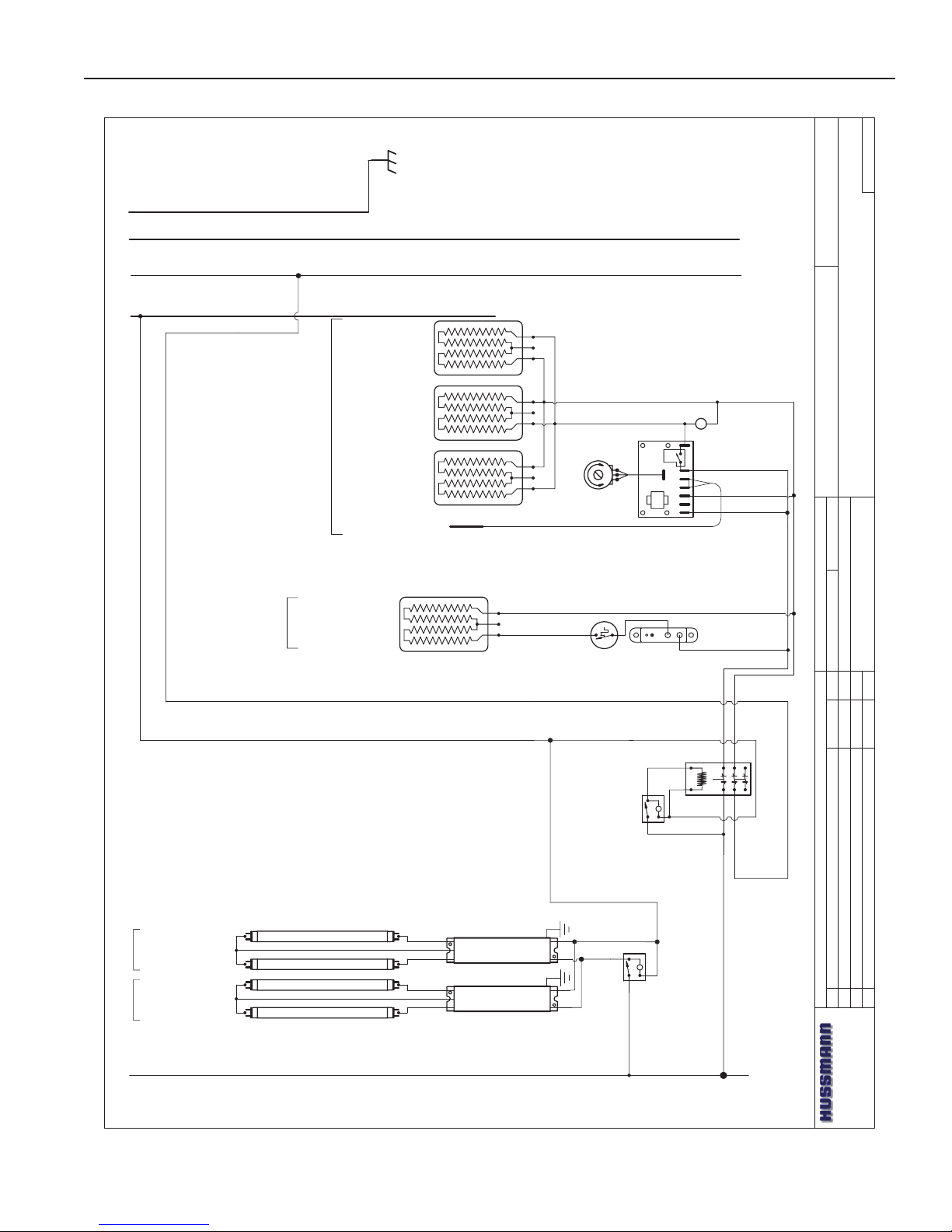

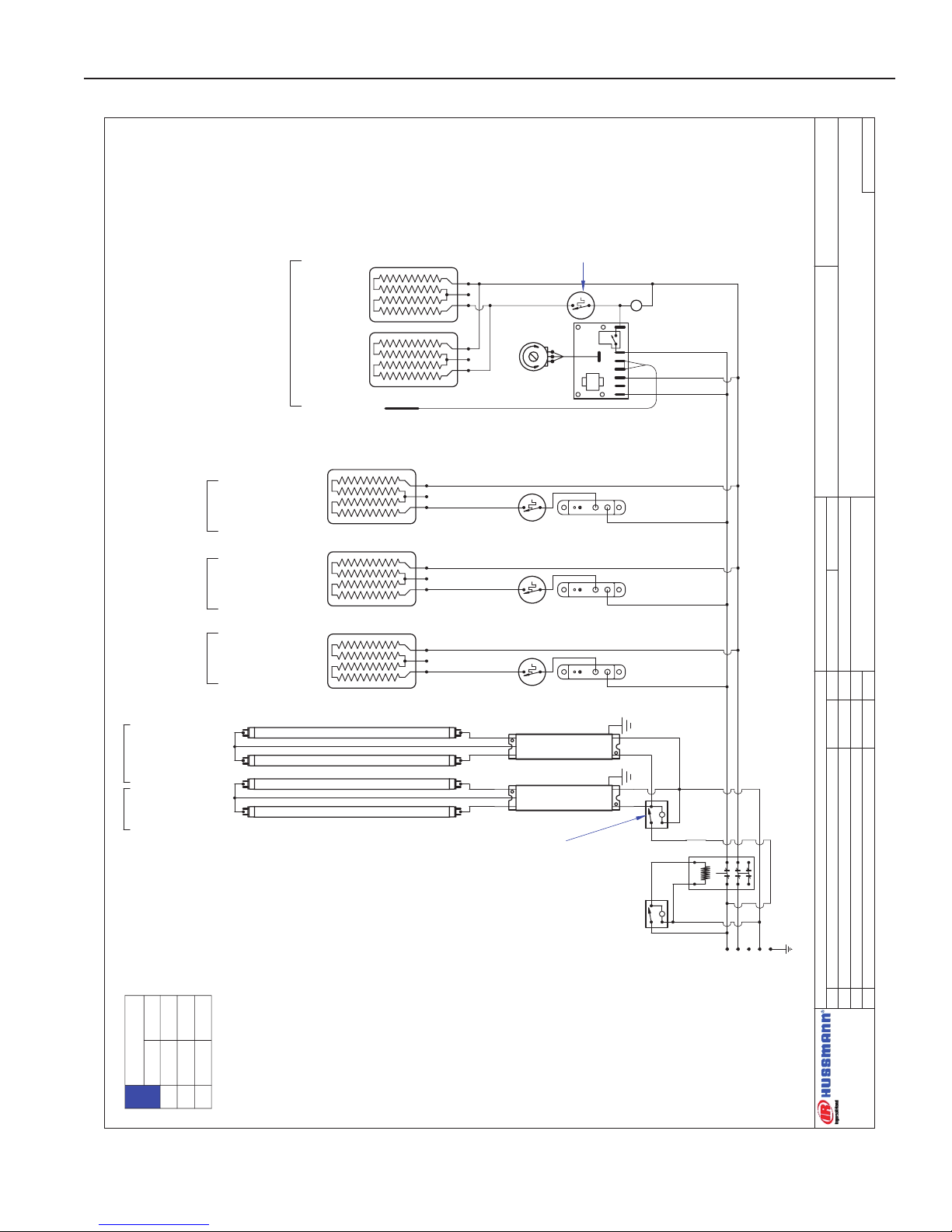

HEDN-05

W6300105

3' CASE WIRING DIAGRAM

L

L1

L2L3N

G

L

MAIN

POWER

~208 / ~240 VAC - 50/60 HZ

SWITCH

125-01-0311

225-01-6951

10.6x33.7

583 WATTS

2.43 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6950

8.6x33.7

473 WATTS

1.97 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6952

12.6x33.7

694 WATTS

2.89 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6953

13.6x33.7

749 WATTS

3.12 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

LIGHT SWITCH

TIPPETTE

125-01-0311

BALLAST 125-01-3267

FULHAM LH4-120-L

CAP UNUSED RED LEAD

BALLAST 125-01-3267

FULHAM LH4-120-L

CANOPY SHELVES

BALLAST 125-01-3267

FULHAM LH4-120-L

CASE LIGHTS

(5) FP21T5/830 3'

125-03-1130

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

L

TEMP. CONTROL

6

4

21 5

P1

3 7

SENSOR

225-01-3228

225-01-6787T

19x18

342W

1.43 AMPS @ ~240VAC

GRIDDLE-#5-Bottom

225-01-6786T

11x18

198W

0.83 AMPS @ ~240VAC

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5" SHELF- #3 -13.5"

SHELF- #4 -14.5"

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

LIGHT CIRCUIT= .97A 105W

BLK # 12

RED # 12

GRN # 12

WHT # 14

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

LOADING

208 V 240 V

L1

L2

12.0

11.0

13.6

12.7

NOTE:

CASE MUST

BE GROUNDED

3264W @ 240VAC

2496W @ 208VAC

Wiring Diagrams (Cont'd)

29

Page 30

IGHT-HEDN, HEDN COMBO, HEDW-0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

Mark Cipriani

---

PAGE OF1

1

01/19/07

B Updated dwg; revised load ratings; added fuses 1/30/08 JR

C Added fuses 4/7/08 JR

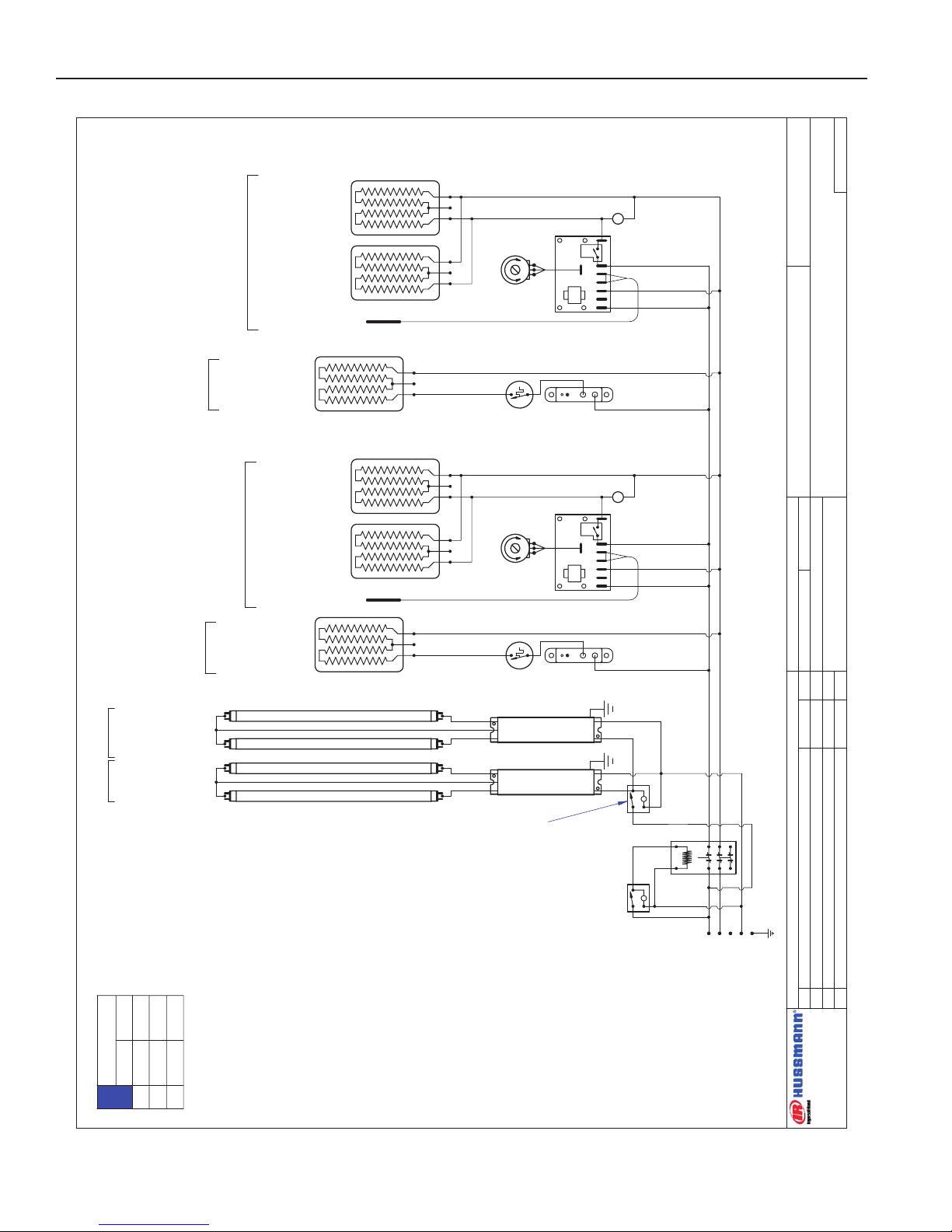

HEDN-05

W6300091

4' CASE WIRING DIAGRAM

BALLAST 125-01-3267

FULHAM LH4-120-L

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L

MAIN

POWER

~208 / ~240 VAC - 50/60 HZ

SWITCH

125-01-0311

BALLAST 125-01-3267

FULHAM LH4-120-L

BALLAST 125-01-3267

FULHAM LH4-120-L

CAP UNUSED RED LEAD

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6955

10.6x45.7

791 WATTS

3.30 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6956

12.6x45.7

940 WATTS

3.92 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6957

13.6x45.7

1015 WATTS

4.23 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

PACKTRONICS

CONTROLLER

225-01-3229

PILOT LIGHT

175-01-1102C

L

TEMP. CONTROL

6421 5

P1

3 7

SENSOR

225-01-3228

225-01-6787T

19x18

342WATTS

1.43 AMPS @ 240 VAC

GRIDDLE-#5-Bottom

SHELF- #1 -9.5"-TOP

SHELF- #2 -11.5" SHELF- #3 -13.5"

SHELF- #4 -14.5"

15 AMP FUSE

125-01-8604

FUSE HOLDER

125-01-8605

OVERHEAD LIGHTING

(1) FP28T5/830 4'

125-03-1133

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

SHELVES

CANOPY

SHELF LIGHTING

(2) FP28T5/830 4'

125-03-1133

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

225-01-6787T

19x18

342WATTS

1.43 AMPS @ 240 VAC

BLK # 12

RED # 12

WHITE # 14

GRN # 12

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

15A

LIGHT CIRCUIT= 140W 1.30A

20A

L1

L2

N

G

BLK # 14

RED # 14

15A

(2)15 AMP

FUSE

125-01-8604

(2)FUSE

HOLDER

125-01-8605

(2) 20 AMP FUSE

125-01-8537

(2) FUSE HOLDER

125-01-8612

20A

15A

LOADING

208 V 240 V

L1

L2

16.1

14.8

18.3

17.0

NOTE:

CASE MUST

BE GROUNDED

4212W @ 240VAC

3203W @ 208VAC

Wiring Diagrams (Cont'd)

30

Page 31

Rev. 0508

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

?

1

1

07/31/07

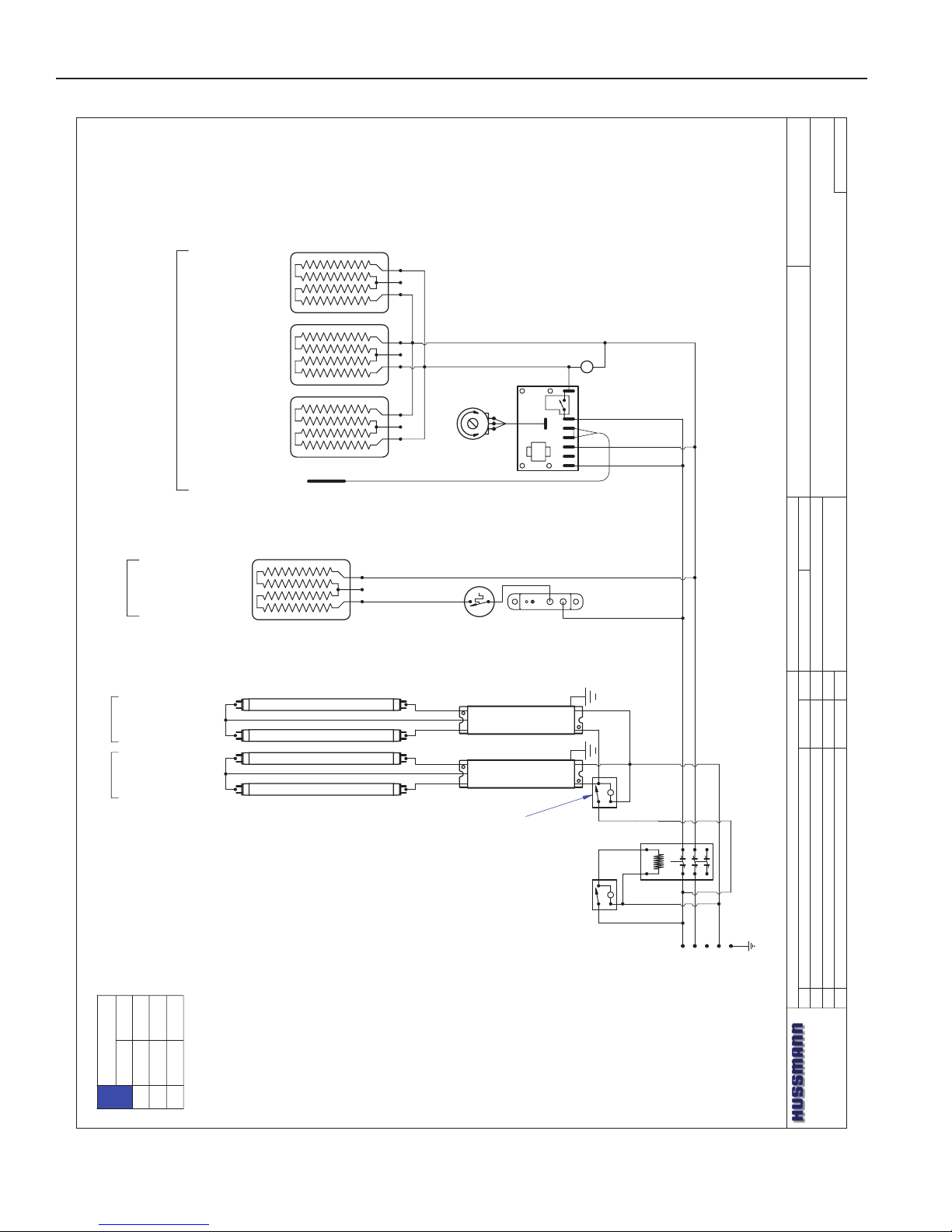

HEDN-05 COMBO

W6300127

4' CASE HOT / COLD COMBO

L

P

H2

L2

L1

H1

PACKTRONICS

CONTROLLER

225-01-3229

L

TEMP. CONTROL

SENSOR

225-01-3228

64

21

5

P1

3 7

BALLAST 125-01-3266

FULHAM LH3-120-L

OVERHEAD HEATER

HATCO™ GLOW-RAY™

950W 3.96A ~240VAC

125-02-1086

GRIDDLE HEATER PAD

487W 2.03A ~240 VAC

225-01-6798T

L

EVAPORATOR

FANS .18A

(2) 4½" AXIAL

125-01-2012

LIGHTS 48"

(4) FP28T8/830

125-03-1133

INFINITE

CONTROL

125-01-1663

OPTIONAL SUCTION

SOLENOID SETUPFOR

COLD SECTION ONLY

LIGHT SWITCH

125-01-0311

BALLAST 125-01-3266

FULHAM LH3-120-L

~ 120 VAC - 50/60 Hz.

L1 N

BUNDLE COLOR

BLACK / WHITE

T-STAT

SUCTION

SOLENOID

VALVE

M

M

L

MAIN POWER

~208 / ~240 VAC - 50/60 HZ

PILOT LIGHT

175-01-1102C

PILOT LIGHT

175-01-1102C

TERMINAL

BLOCK

125-01-0295

L1

L2NG

225-01-6954

8.6x45.7

642 WATTS

2.68 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

SHELF

CONTACTOR

SQUARE -D

8910DPA43V02

125-01-1001

LIGHT CIRCUIT= .93A

BLK # 14

WHT # 14

RED # 14

BLK # 14

BLK # 14

WHITE # 14

RED # 14

BLK # 14

BLK # 14

WHITE # 14

NOTE:

CASE MUST

BE GROUNDED

10.0

8.7

8.8

7.5

L1

L2

L3

208 V 240 V

LOADING

964655

Wiring Diagrams (Cont'd)

31

Page 32

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

ECD

XXX

PAGE OF1

1

01/17/07

123

Eng:\WIRESCHEMATICS\NEW -WIRING

HEDN-05

W6300106

5' CASE WIRING DIAGRAM

225-01-6961

13.6x57.7

1177 WATTS

4.90 AMPS @ 240 VAC

THERMOSTAT

TEMPCO

TEB33000

225-01-1700

LIMIT SWITCH

TEMPCO TST-112-119

225-01-1702

225-01-6960

12.6x57.7