Page 1

January 2006

Ice Cream Dipping and Storage Chest

INSTALLATION & SERVICE

INSTRUCTIONS

FOR

HD – HS – HDF-8

First Call for help (US and Canada):

1-800-922-1919

Soporte Tècnico y Asistencia (Mèxico):

01-800-522-1900

For a Service Network Locator and other

Information visit us at

www.hussmann.com

select Worldwide Locations

HUSSMANN - GLOVERSVILLE

P/N OII – HD-HS-8HDF

January 2006

Page 2

TABLE OF CONTENTS

Page

Introduction 3

Inspection 3

Base, Exterior Shell, Interior Liner, Sub-top, Insulation and 3

Main Top

Condensing Unit Cabinet Dimensions, Electrical, and Capacity 4

Installation and Start Up 5

Temperature Control and Defrosting 5

Cleaning Condenser 6

Cleaning Exterior 6

Cleaning Interior 6

Trouble Shooting Chart 7 & 8

Lid Gasket Replacement 8 & 9

Main Top Heater Replacement 9

2

Page 3

INTRODUCTION –

The HS and HD models have been

designed to giv e maximum performance

with minimum energy consumption. They

have the versatility in product temperature

range to be used for storage at sub zero to

dipping at desired above zero temperatures. All cabinets are UL and UL sanitation li sted.

INSPECTION

–

Upon receipt of the cabinet, c arefully ex amine the crating for damage. If

damage is found make a note on the delivery ticket before signing. Carefully remove

shipping crate and examine cabinet for

“concealed” damage. If damage is found

contact the delivering carrier immediately

and have his agent prepare an inspection

report for the purpose of filing a claim

THIS IS YOUR RESPO NSI BILIT Y.

SPECIFICATIONS

–

BASE

–

The cabinet base is an all welded assembly of very he avy g auge steel to establish a strong foundation on which the rest

of the cabinet is built.

EXTERIOR SHELL

–

The shell is formed from heavy

gauge steel and is welded together as an assembly and then welded to the cabinet base

assembly to give complete strength and durability. This assembly is processed

through a chemical treatment and painted

with an enamel powder paint for a lasting

finish.

INTERI OR LINER

–

The li ner is an all welded steel ass embly. Copper evaporator tubing is fastened

to the exterior of the liner; and maximum

heat transfer is further enhanced with the

addition of a conductive material on both

top and bottom of the tubing. The liner is

also chemical treated and painted with an

enamel powder paint for a lasting finish.

SUB-TOP

–

The sub-top is an all welded heavy

gauge galvanized assembly with integral

molded plastic breakers. The sub top ties

the shell and liner assemblies together and

s erves as a back up for the main top to prevent denting.

INSULATION

–

The shell, liner and sub top assemblies are foamed in place with a polyurethane insulation providing outstanding insulating qualities and solid unitized construction.

MAINTOP

–

The main top is a one piece design of

heavy gauge 18-8 rust proof stainless steel.

It has a brush satin finish to minimize

scratching and maintain a lasting clean appearance.

3

Page 4

CONDENSING UNIT –

All models incorporate a slide-out

condensing unit for easy access to all components. All have a bare tube condenser

design to minimize field maintenance.

CABINET DIMENSIONS, ELECTRICAL DATA, CABINET CAPACITIES

OUTSIDE INSIDE

Cabinet Length Width He ight Length Width Height

Overall Deep End

2-HS 30 1/2 19 7/16 32 1/2 26 3/8 15 5/16 25 5/8

4-HD 30 1/2 30 1/2 32 1/2 26 3/8 26 3/8 25 5/8

6-HD 43 30 1/2 32 1/2 38 7/8 26 3/8 25 5/8

8-HD 54 1/16 30 1/2 32 1/2 49 15/16 26 3/8 25 5/8

10-HD 66 9/16 30 1/2 32 1/2 6 2 7/16 26 3/8 25 5/8

8-HDF 54 1/16 30 1/2 3 2 1/2* 49 15/16 26 3/8 25 5/8

* Add 8” to top for syrup rail

ELECTRICAL CAPACITY

Volts Run Breaker Ship Cubic 2 1/2 3 # of

Amps Size Wt. Feet gal. gal. Lids

115 3.4 15 amp 188 4.5 4 4 1-S

115 3.5 15 amp 238 7.8 13 8 1-D

115 6.0 15 amp 307 12.7 21 14 1-S, 1-D

115 7.8 15 amp 355 17.0 33 21 2-D

115 7.6 15 amp 419 21.9 41 29 2-D, 1-S

115 7.8 15 amp 386 17.0 33 21 2-S

D=Double Lids S=Single Lids

The step end of each HD is the same height and length with both being 13 3/4.

Check the unit serial plate location in the condensing unit compartment for the type of

refrigerant used. The charges are listed below for the respective refrigerants.

R-12 R404A

HS-2 15 13

HD-4 16 14

HD-6 17 16

HD-8/ HDF-8 16 16

HD-10 23 23

4

Page 5

INSTALLATION and START UP

LEV EL I NG

–

Lev el case front to back and end to

end, shimming where necessary upon installation to assure proper operation of

drains and refrigeration systems.

PLUMBING

–

To simplify cleaning and for sanitary purposes, we s uggest that a connection be made from the cabinet drain tube

to a floor drain. A h ose fitti ng is supplied

for that purpose.

The HS and HD models are

equipped with three wire grounded service

cords . For your own protection, connection mus t be made to a 115 volt grounded

receptacle and a power supply with a fifteen ampere rating minimum.

The cabinets are designed to operate on 115 volts, s ingle phase, 60 cycle current. A separate circuit is recommended to

prevent product l oss due to overloading or

malfunction of other equipment on the

same circuit. Use a 15 amp time delay

fuse. The supply circuit must conform to

National and local electric al codes.

A wiring diagram is provided on

the condenser shroud for case refrigeration.

VO LTAG E, AS ME ASURED AT

THE COMPRESSOR TERMINAL DURING OP ERATION, MUST NOT VARY

MORE THAN 5% FROM CABINET SERIAL PLATE RA TING.

NOTE: DO NOT DRILL ANY HOLES IN

SIDE OF CABINET WITHOUT FIRST

GETTING INSTRUCTIONS FROM FACTORY SERVICE DEPARTMENT.

A space of 4 inches must be left open

at the front and back of the cabinet to insure proper air flow over the condensing

unit.

Cabinets should not be installed in

direct sunlight or near/under heat ducts for

proper operation.

********* IMPORTANT ***********

Cabinet should be started and allowed to cool down to n ormal operating

temperature before loading any products .

OPERATION and NORMAL

MAINTENANCE

TEMPERATURE CONTROL

–

The temperature control which

s enses the cold wall temperature, and is located behind the removable louvered grille

at the s ide of the case, is factory s et at the

3:00 o’clock position. Adjustment of the

contr ol is done by turning the knob clockwise for colder temperatures and counterclockwise for warmer temperatures.

DEFROSTING

–

Defrosting is accomplished manually by scraping frost from areas where it

has collected on cabinet interior. Remove

excess ice and water. After washing and

drying thoroughly reconnect power supply.

5

Page 6

CONDENSING UNIT –

The condens ing unit is mounted on

a slide-out base, acce ssible by removing the

access panel. The condenser is of the baretube des ign. The condenser fan motor

draws air through the condenser and

passes over the condenser for its cooling

and it is expelled out the back of the unit

compartment.

CLEANING CONDENSER

–

The bare-tube conde nser is designed

to require minimum maintenance. However, to keep the unit at top efficiency,

check periodically, and remove any accumulated dust and debris.

To clean condenser, a soft, nylon

brus h should be used to loosen dirt and

lint. Then vacuum up the dirt or blow condenser out with a high pressure gas such as

nitrogen. Never use a wire brush to clean

condens er tubes.

CLEANING EXTERIOR

–

When cleaning the exterior of the

cabinet use a soft cloth or sponge with water and a mild detergent. Rinse and wipe

dry.

CLEANING INT ERIOR

–

F or cleaning the interior of the liner

storage area, a flush out drain has been

provided with a standard hose fitting loca ted in the front o f the c abinet in the bas e

area.

Disc onnect the electrical power cord

and wash using a soft cloth or sponge and

a mild detergent. DO NOT USE AN

ABRASIVE CLEANER OR S TEEL

WOOL – THESE WILL MAR THE FINISH.

Wipe dry before restarting the cabinet. Allow the cabinet to cool down to

proper temperature before reloading product.

PRESSURE CONTROL

–

The 10-HD with R-4 04A utilizes a

high pressure control as a safety device to

ensure the system is not subjected to excessive press ures. It trips out the compressor

at approx. 440 psi. and has an automatic

res et to res tart at 350 ps i .

High pressures normally result

from high ambient conditions and / or

dirty condensers. Correct such application

problems as soon as poss ible.

6

Page 7

TROUBLE SHOOTING CHART

TROUBLE PROBABLE CAUSE SOLUTION

Compressor will not start, no

noise

1. Power disconnected 1. Check service cord for

proper connection

2. Blown fuse or breaker 2. Replace fuse or reset

breaker

3. Defective or broken

3. Repair or replace

wiring

4. Defective overload 4. Replace

5. Defective temperature 5. Replace

Compressor will not cuts out

on overload

1. Low voltage 1. Correct see serial plate for

proper electrical

requirements.

2. Defective compressor 2. Replace

3. Defective relay 3. Replace

4. Restriction pinched cap

4. Repair or replace

tube

5. Restriction moisture 5. Leak check replace drier

evacuate and recharge

6. Inadequate air over

condenser

6. Move cabinet so it has 4”

front and back of unit

compartment opening

7. Defective condenser fan

7. Replace

motor

High head pressure 1. Cabinet location too

warm

2. Defective condenser fan

1. Relocate cabinet remove

air flow restriction

2. Replace

motor

3. Air or non condensable

gases in system

3. Leak check-change drier,

evacuate and recharge

7

Page 8

Warm storage temperatures 1. Temperature control not

set properly

1. Reset control

2. Short of refrigerant 2. Leak check - change

drier, evacuate and recharge

3. Cabinet location too warm 3. Relocate cabinet

4. Too much refrigerant 4. Change drier evacuate and

recharge

5. Low voltage, compressor

5. Check voltage supply

cycling on overload

Compressor runs

1. Defective control 1. Replace

continuously – product too

cold

2. Control feeler tube not

installed in well

2. Push control feeler tube

into well

3. Short on refrigerant 3. Leak check change drier

and recharge

Compressor runs

continuously – product too

1. Short on refrigerant 1. Leak check – change

dryers evacuate and recharge

warm

2. Inefficient compressor 2. Replace

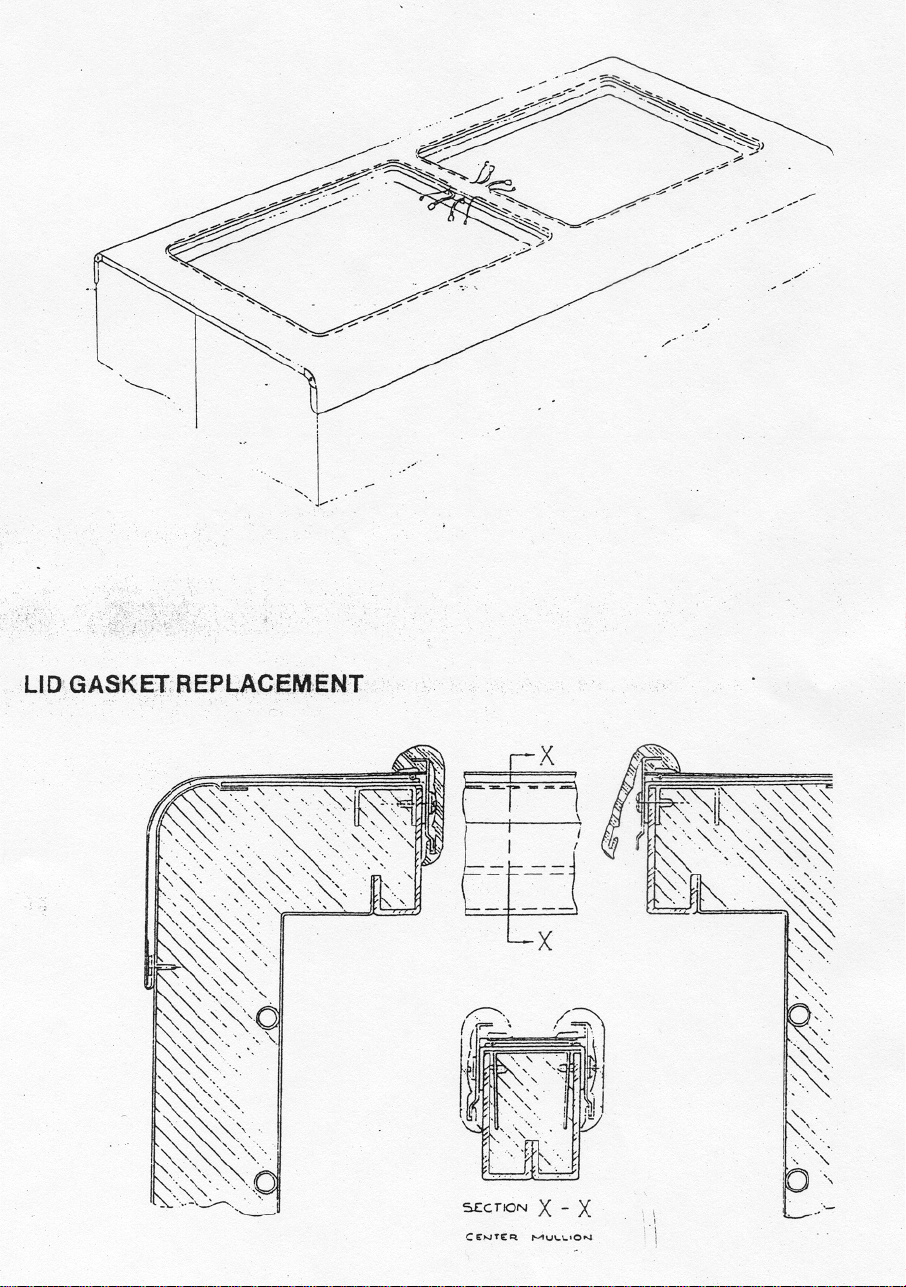

LID GASKET REPLACEMENT

–

Remove lids

Grasp the bottom of the gasket with the fingers and pull outward

Work the bottom of gasket from the retainer all around the perimeter openings.

Lift up the gasket and remove the phillips head screws holding the retainer in place. Note :

Mark retainer location so when reinstalling the screws, the screw holes will line up.

Lift gasket and retainer from opening and remove gasket.

8

Page 9

.

Install gasket on retainer and insert in opening.

Putting downward pressure on gasket-retainer. Reinstall phillips head screws

Stretch gasket downward and install gasket bottom flange over retainer flange.

HOW TO REPLACE HEATERS

–

Disconnect power to cabinet, remove collar as shown.

Lift off collar and retainer, being careful not to put stress on the heater connections.

Remove old heater from slot and carefully remove leads from cavity and disconnect.

Remove old heater from slot with leads aligned with connector cavity.

Connect heater leads and push excess leads into cavity. Avoid bending of heater and

connections other than required for installation. Replace retainer and collar on

cabinet.

Install screws through retainer into cabinet.

Pull rubber collar down over bottom edge of collar retainer, being certain retainer is in

collar groove.

Re-connect cabinet power.

SEE THE DIAGRAMS ON THE FOLLOWING PAGE FOR MORE REFERENCE

9

Page 10

Page 11

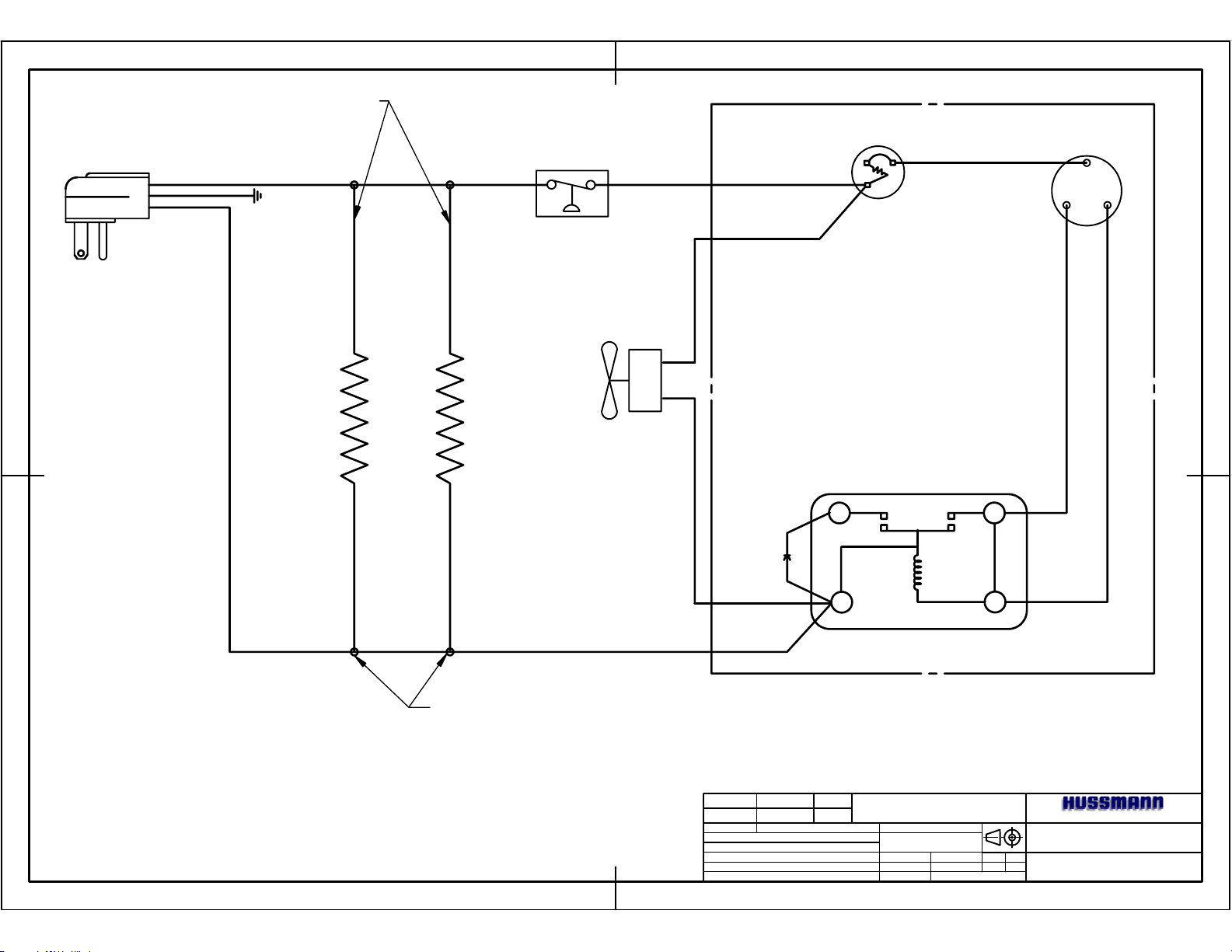

BLK

WHT

GRN

HEATER

CONNECTOR

WIRES

TEMP.

CONTROL

HIGH

PRESSURE

CONTROL

OVERLOAD

COMPRESSOR

MOTOR

C

R

S

POWER CORD

115V

60 HZ

1 PH

RED

RED

ORN

GRAY

RELAY

COND.

FAN

1

START

CAP.

S

ANTI-SWEAT HEATERS

ORN

GRAY

2

M

COMPRESSOR

TAP CONNECTORS

HD-10, R-404A

REV.

XX/XX/XX

DATE

XXX

BY

XXXX

E.C.N.

MATERIAL:

XXXXXX-XX

SIZE

XXXXXXXXXX

DIE NO.

XXXX-XXXX

SHEET

SIZE

B

TOLERANCES UNLESS

OTHERWISE SPECIFIED.

FINISH

1/32"

0.031"

1ü

1/64"

XXXXXXXXXX

FRACTIONAL

DECIMAL

ANGULAR

HOLE LOCATION

& SPACING

SCALE:

TITLE

TYPE

CODE

WIRING DIAGRAM

DRAWN

JWL

DATE

CHECKED

12/19/95

XXX

E

Gloversville, N.Y. 12078

DWG. NUMBER

M100-2020

R

REV.

X

Page 12

POWER CORD

115V

60 HZ

1 PH

BLK

WHT

GRN

HEATER

CONNECTOR

WIRES

RED

ANTI-SWEAT HEATERS

RED

ORN

ORN

TEMP. CONTROL

COND.

FAN

START

CAP.

COMPRESSOR

OVERLOAD

MOTOR

C

R

S

RELAY

1

2

S

M

TAP CONNECTORS

XX/XX/XX

REV.

DATE

XXX

BY

XXXX

E.C.N.

MATERIAL:

XXXXXX-XX

SIZE

XXXXXXXXXX

DIE NO.

XXXX-XXXX

SHEET

SIZE

B

TOLERANCES UNLESS

OTHERWISE SPECIFIED.

FINISH

1/32"

0.031"

1ü

1/64"

XXXXXXXXXX

FRACTIONAL

DECIMAL

ANGULAR

HOLE LOCATION

& SPACING

SCALE:

HD-6, R-404A

TITLE

TYPE

CODE

WIRING DIAGRAM

DRAWN

DATE

E

CHECKED

JWL

12/19/95

XXX

COMPRESSOR

Gloversville, N.Y. 12078

DWG. NUMBER

M100-2018

R

REV.

X

Page 13

POWER CORD

115V

60 Hz

1 PH

BLK

WHT

GRN

TEMP. CONTROL

OVERLOAD

RELAY

COMPRESSOR

MOTOR

C

R

S

COND.

FAN

START

CAP.

REV EO # REV DATE REV BY

-

APPROVED BY

-

-

-

-

-

-

1

2

--

S

M

HS-2, HD-4, R-404A

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

EO NUMBER

DRAWN BY:

DATE DRAWN :

APPROVED BY:

-

JWL

SCALE

INCHES

SHEET #

12/19/95

-

1 OF 1

COMPRESSOR

GLOVERSVILLE, NY 12078

WIRING DIAGRAM

M100-2017

Page 14

BLK

WHT

GRND

HEATER

CONNECTOR

WIRES

TEMP.

CONTROL

OVERLOAD

COMPRESSOR

MOTOR

C

SR

POWER CORD

115V

60 Hz

1 PH

BLK

BLK

WHT

ANT-SWEAT HEATERS

WHT

TAP CONNECTORS

COND

FAN

START

CAP.

RELAY

1 S

2

N

COMPRESSOR

REV EO # REV DATE REV BY

-

APPROVED BY

-

-

-

-

-

--

-

HD-8, HDF-8 (R-404A)

TOLERANCES UNLESS OTHERWISE SPECIFIED: FRACTIONAL 1/32"

DECIMAL 0.031" ANGULAR 1° HOLE LOCATION & SPACING 1/64"

EO NUMBER

DRAWN BY:

DATE DRAWN :

APPROVED BY:

-

JWL

SCALE

INCHES

SHEET #

12/19/95

-

1 OF 1

GLOVERSVILLE, NY 12078

WIRING DIAGRAM

M100-2019

Loading...

Loading...