Page 1

GSVM

®

Medium Temperature

Self Contained

Open Vertical Merchandisers

IMPORTANT

Keep in store

for future reference!

MANUAL - IO SC GSVM

Installation &

Operation

Manual

P/N 0545716_B

February 2015

Spanish 0545717

French 0545718

Page 2

Page 3

P/N 0545716_B iii

IMPORTANT

KEEP IN STORE FOR FUTURE REFERENCE

Quality that sets industry standards!

12999 St. Charles Rock Road • Bridgeton, MO 63044-2483

U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900

www.hussmann.com

© 2015 Hussmann Corporation

Page 4

Page 5

TABLE OF CONTENTS v

ANSI DEFINITIONS ................. vi

INSTALLATION

Certification

Hussmann Product Control

Shipping Damage

Location

Self Contained Location

Model Description

Unloading

Exterior Loading

Shipping Skid

Merchandiser Leveling

Optional Legs

Serial Plate Location

Refrigeration Unit Access

Sealing Merchandiser to Floor

Night Curtain Installation

Checklists

........................ 1-1

........... 1-1

................... 1-1

........................... 1-1

.............. 1-2

.................. 1-3

......................... 1-3

.................... 1-3

...................... 1-3

............... 1-4

...................... 1-4

................. 1-4

............. 1-4

......... 1-4

............ 1-5

.......................... 1-7

ELECTRICAL / REFRIGERATION

MAINTENANCE

Care and Cleaning ................... 4-1

Do NOT Use:

............................... 4-1

Do:

Removing Scratches from Bumper

Cleaning Discharge Honeycomb

Cleaning Under Display Pan

Cleaning Evaporation Pan

Cleaning Coils

Removing Scratches from Bumper

Maintaining Fluorescent Lamps

...................... 4-1

...... 4-2

....... 4-2

.......... 4-3

............ 4-3

...................... 4-4

...... 4-4

........ 4-4

SERVICE

Replacing Fan Motors and Blades

Replacing Fluorescent Lamps

Repairing Aluminum Coil

Troubleshooting Guide

GSVM Accessories

Definitions

......................... 5-5

.................. 5-4

............ 5-2

............... 5-3

...... 5-1

......... 5-2

Merchandiser Electrical Data

Field Wiring

Power Switch

........................ 2-1

....................... 2-1

.......... 2-1

Electrical Connections . . . . . . . . . . . . . . . . 2-1

Electrical Outlet

Refrigeration (Self Contained)

Waste Outlet and Water Seal

Safe-NET III Controller

Safe-NET Display

Safe-NET Start-Up

Sequence of Operation

Alarms and Codes

Defrost Termination Switch

Temperature Adjustment

..................... 2-1

......... 2-2

.......... 2-2

.............. 2-3

................... 2-4

.................. 2-4

............... 2-5

................... 2-6

........... 2-6

............. 2-7

START UP / OPERATION

Start-Up

TEV Adjustment

Controls and Adjustments

Load Limits

Stocking

Solar Thermometer

Shelf Weight Limits

........................... 3-1

.................... 3-1

............ 3-2

........................ 3-3

........................... 3-3

.................. 3-3

.................. 3-4

APPENDIX

Part Numbers

Plan View

Cross Sections and Refrigeration Data

Electrical Data

..................... A-1

......................... A-2

.. A-3

..................... A-4

Shipping Weights and Amps . . . . . . . . . . A-5

Wiring Diagram GSVM-4060

Wiring Diagram GSVM-4072

Wiring Diagram GSVM-5272

......... A-6

......... A-7

......... A-8

WARRANTY

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 6

vi

REVISION HISTORY

Revision B Changed Shipping Weights, A-5

REVISION A CHANGED PART NUMBER

REVISION H — Added New Replacement Parts A-1

and A-2; Updated Wiring Diagrams Section A Removed

all reference to Remote Models throughout; updated

model number; moved DOE sticker

REVISION October 2013 — Added Checklists Page

1-7; Added Warning Page 1-3; Cleaning Coils 4-4;

Maintaining Fluorescent Lights 4-4. Checklist 4-5

REVISION F — JULY 2013

1. Included Night Curtain Instructions, Page 1-5 and 1-6

2. Added Night Curtain Description, Page 5-5

REVISION E — FEBRUARY 2012

1. Revised Nema Plug, Page 2-1

REVISION D — JANUARY 2012

1. Revised for Wind Chill

REVISION C — JANUARY 2012

1. Removed Remote Models

2. Added Safe-NET III

3. Revised Wiring Diagrams

REVISION B — DECEMBER 2010

1. Added option condensate pan for GSVM

4072 and 5272; Page, 2-2

2. Replaced Bulb illustration; Page 5-2

3. Updated wiring diagram; Page A-11

ORIGINAL ISSUE — NOVEMBER 2010

* * * * * * * * * * * * * * * * * * * * * * * * * *

ANSI Z535.5 DEFINITIONS

• DANGER – Indicate[s] a hazardous

situation which, if not avoided, will

result in death or serious injury.

• WARNING – Indicate[s] a hazardous

situation which, if not avoided, could

result in death or serious injury.

• CAUTION – Indicate[s] a hazardous

situation which, if not avoided, could

result in minor or moderate injury.

• NOTICE – Not related to personal injury –

Indicates[s] situations, which if not avoided,

could result in damage to equipment.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 7

P/N 0545716_B 1-1

INSTALLATION

CERTIFICATION

These merchandisers are manufactured to

meet ANSI / National Sanitation Foundation

®

(NSF

) Standard #7 requirements. Proper

installation is required to maintain certification.

Near the serial plate, each case carries a label

identifying the type of application for which

the case was certified.

ANSI/NSF-7 Type I - Display Refrigerator / Freezer

Intended for 75°F / 55% RH Ambient Application

ANSI/NSF-7 Type II - Display Refrigerator / Freezer

Intended for 80°F / 55% RH Ambient Application

ANSI/NSF-7 - Display Refrigerator

Intended for Bulk Produce

HUSSMANN PRODUCT CONTROL

The serial number and shipping date of all

equipment is recorded in Hussmann’s files

for warranty and replacement part purposes.

All correspondence pertaining to warranty or

parts ordering must include the serial number

of each piece of equipment involved. This is to

ensure the customer is provided with the correct parts.

Apparent Loss or Damage

If there is an obvious loss or damage, it must

be noted on the freight bill or express receipt

and signed by the carrier’s agent; otherwise,

carrier may refuse claim.

Concealed Loss or Damage

When loss or damage is not apparent until

after equipment is uncrated, retain all packing

materials and submit a written response to the

carrier for inspection within 15 days.

LOCATION

These merchandisers are designed for

displaying products in air conditioned stores

where temperature is maintained at or below

the ANSI / NSF-7 specified level and relative

humidity is maintained at or below 55%.

Recommended operating ambient

temperature is between

65°F (18°C) to 80°F (26.6°C).

Maximum relative humidity is 55%.

SHIPPING DAMAGE

All equipment should be thoroughly examined

for shipping damage before and during

unloading. This equipment has been carefully

inspected at our factory. Any claim for loss

or damage must be made to the carrier. The

carrier will provide any necessary inspection

reports and/or claim forms.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Placing refrigerated merchandisers in direct

sunlight, near hot tables or near other heat

sources could impair their efficiency. Like

other merchandisers, these merchandisers are

sensitive to air disturbances. Air currents

passing around merchandisers will seriously

impair their operation. Do NOT allow air

conditioning, electric fans, open doors or

windows, etc. to create air currents around the

merchandiser.

GSVM Open Vertical Merchandisers

Page 8

1-2 InstallatIon

G SVM -5272

G SVM -4072

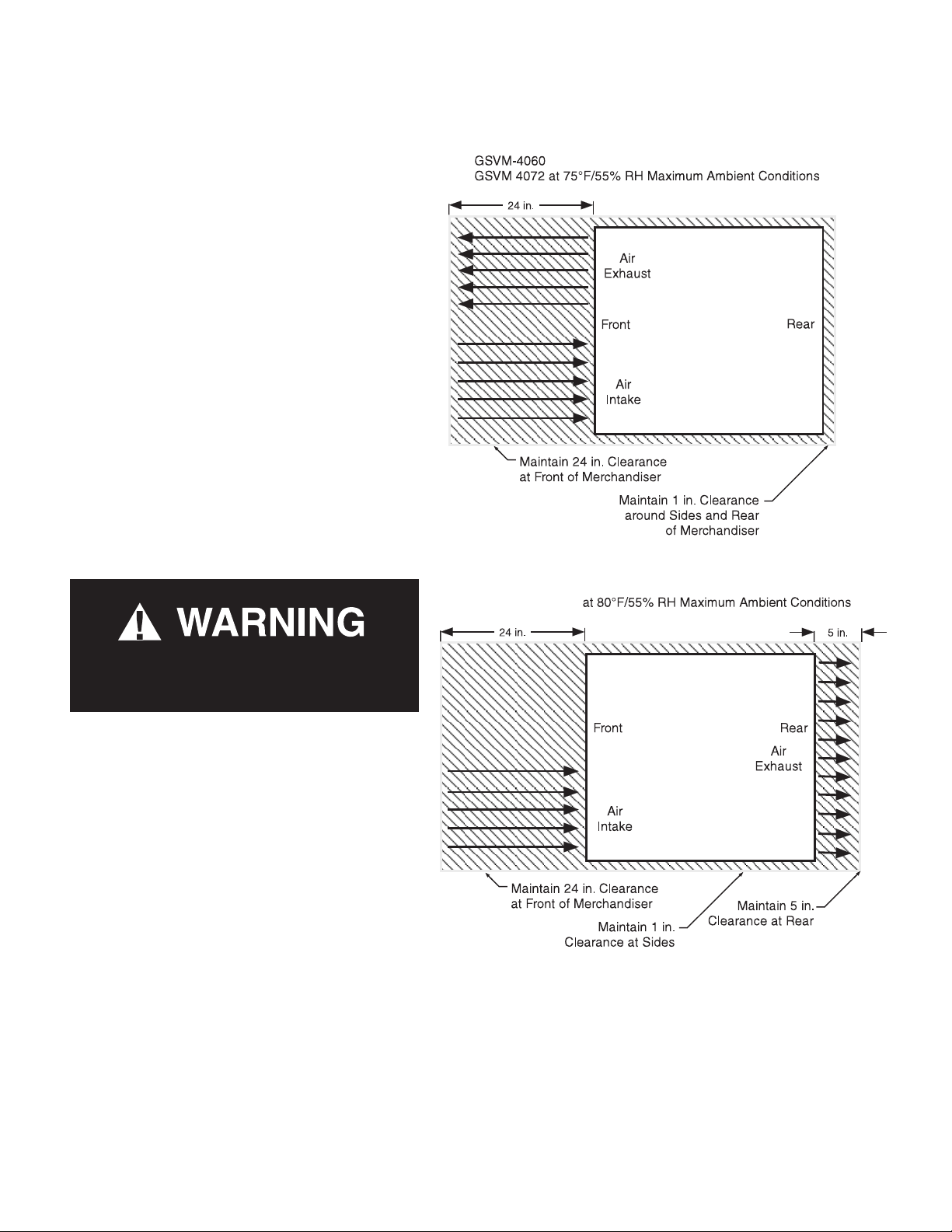

SELF CONTAINED (LOCATION)

GSVM-4060 and GSVM-4072 (at 75°F/55%

relative humidity, maximum ambient conditions) has front condenser air intake and discharge. Maintain a minimum clearance distance

of two feet in front of the merchandiser so that

air discharge and air intake is not obstructed.

GSVM-4072 (at 80°F/55% relative humidity,

maximum ambient conditions) and

GSVM-5272 each require a 5 inch minimum

clearance behind the merchandiser and clearance above the merchandiser since its air flows

straight through the condensing unit compartment. Brackets are provided for field attachment

to obtain this rear 5 inch minimum clearance.

For California Businesses:

This product may contain chemicals known

to the State of California to cause cancer,

birth defects, or other reproductive harm.

This warning is the result of the California State

law known as the California Safe Drinking Water

and Toxic Enforcement Act of 1986, which is

commonly referred to as “Proposition 65.”

This warning does not mean that Hussmann

products will cause cancer or reproductive

harm, or is in violation of any product-safety

standards or requirements. As claried by the

California State government, Proposition 65

can be considered more of a ‘right to know’ law

than a pure product safety law. When used as

designed, Hussmann believes that our products

are not harmful. We provide the Proposition 65

warning to stay in compliance with California

State law. It is your responsibility to provide

accurate Proposition 65 warning labels to your

customers when necessary. For more information

on Proposition 65, please visit the California

State government website.

G SVM -5272

G SVM -4072

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 9

P/N 0545716_B 1-3

MODEL DESCRIPTION

The GSVM open vertical merchandiser offers

versatility in the display of medium temperature

(32º F to 41º F) products such as dairy products,

prepared salads, pizza and fresh entrees that

are pre-chilled in a cooler. Carefully read and

follow the instructions prior operating the merchandiser.

UNLOADING

Unloading from Trailer:

Lever Bar (also known as a Mule, Johnson

Bar, J-bar, Lever Dolly, or Pry Lever)

Move the merchandiser as close as possible to

its permanent location and remove all packaging.

Check for damage before discarding packaging.

Remove all separately packed accessories such

as kits and shelves. Improper handling may

cause damage to the merchandiser when unloading

to avoid damage:

SHIPPING SKID

Each merchandiser is shipped on a skid to

protect the merchandiser’s base, and to make

positioning the case easier.

Do not remove the shipping skid until the

merchandiser is near its final location. The

skid provides protection for both the merchandiser and the floor.

Remove the skid by raising one end of the

merchandiser approximately 6 inches. Block the

merchandiser securely, and remove the two skid

bolts from the raised end. Replace the bolts

with (provided) leg levelers. Repeat this procedure at opposing end. Once the leg levelers are

secured in place, the merchandiser may be slid

off the skid and placed in its final location.

DO NOT TILT MERCHANDISER ON ITS

SIDE OR END WHEN REMOVING SKID.

Once the skid is removed, the merchandiser

must be lifted —NOT PUSHED— to reposition.

Do not walk or put heavy objects on case.

1. Do not drag the merchandiser out of the

trailer. Use a Johnson bar (mule).

2. Use a forklift or dolly to remove the

merchandiser from the trailer.

EXTERIOR LOADING

Do NOT walk on top of merchandisers or

damage to the merchandisers and serious

personal injury could occur.

merchandisers are not structurally

designed to support external loading

such as the weight of a person. Do not place

heavy objects on the merchandiser.

Check floor where merchandisers are to be set

to see if it is a level area. Determine the highest

part of the floor.

Do NOT remove shipping crate until the

merchandiser is positioned

for installation.

Do NOT stand or walk on top of

merchandiser. Do not store items or

ammable materials atop the unit.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 10

1-4 InstallatIon

MERCHANDISER LEVELING

Be sure to position merchandisers proper-

ly. Level the merchandiser by all four corners.

Merchandiser(s) must be installed level to

ensure proper operation of the refrigeration

system, and to ensure proper drainage of

defrost water.

OPTIONAL LEGS

®

NSF

approved legs replace the leg levelers if

required by local health codes. The legs raise

the case 6 inches for cleaning purposes. An

optional skirt kit can be provided to snap on

the legs.

SERIAL PLATE LOCATION

The serial plate is located on the interior top,

left side of the merchandiser. It contains all

pertinent information such as model, serial

number, amperage rating, refrigerant type and

charge. This information will be needed to install,

service or order parts for the merchandiser.

REFRIGERATION UNIT ACCESS

The lower front panel may be removed by

removing screw at bottom and lifting the panel

straight upward and over the tabs on which it

is hanging. The panel is installed by reversing the

above procedure.

Ensure lower front panel is flat against the

floor when installed to prevent air circulation

problems for self contained merchandisers.

Safe-NET III Display

Front Panel

Lift up and

out to remove

access panel

Safe-NET III display is

mounted on left side of

access panel. Be careful not

to detach Safe-NET III cable

from display when removing

access panel.

Safe-NET III

Display

SEALING MERCHANDISER TO FLOOR

Serial Plate

If required by local sanitary codes, or if the

customer desires, merchandisers may be sealed

to the floor using a vinyl cove base trim. The

size needed will depend on how much variation

there is in the floor, from one end of the

merchandiser to the other. Sealing of the lower

front and rear panels on self contained models

may hamper their removal for servicing or

maintenance of the condensing unit.

NOTE: Do not allow trim to cover any intake

or discharge grilles located in the lower front

panel.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 11

P/N 0545716_B 1-5

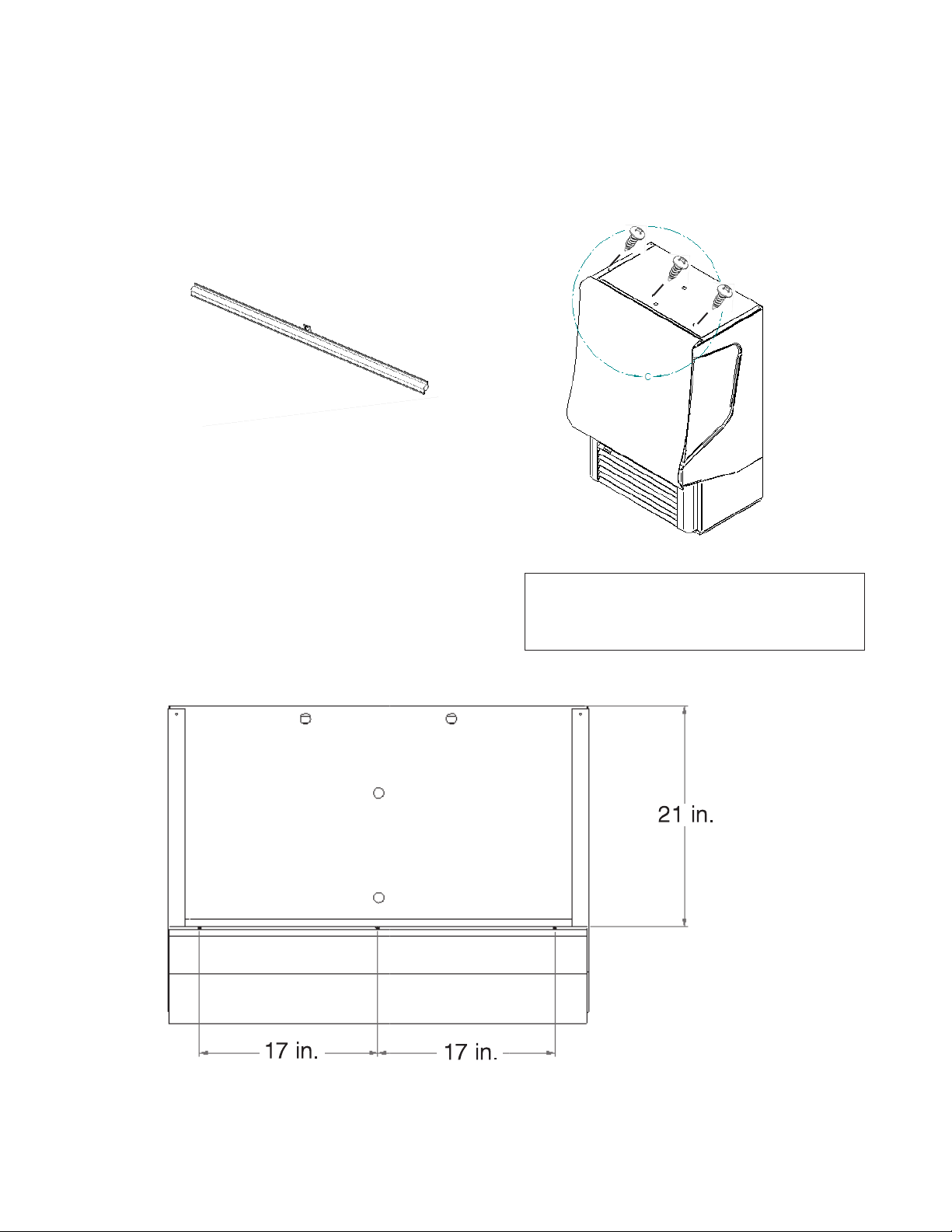

NIGHT CURTAIN INSTALLATION

Night curtains are used to cover the case opening

after normal business hours. The curtains

improve energy consumption, allowing the

refrigeration system to work less.

Night Curtain

Carefully inspect the night curtain kit to

ensure there is no damage from breakage

during shipping. Case should be positioned

and leveled before installing the night curtain.

Position night curtain on top panel. Measure

21 inches to edge of the end night curtain.

Center night curtain to length of case.

Fasten night curtain to top panel using (3) #8

x 1/2 in. screws.

The night curtain for GSVM is standard

for model 5272 and is an optional kit for

models 4060 and 4072.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 12

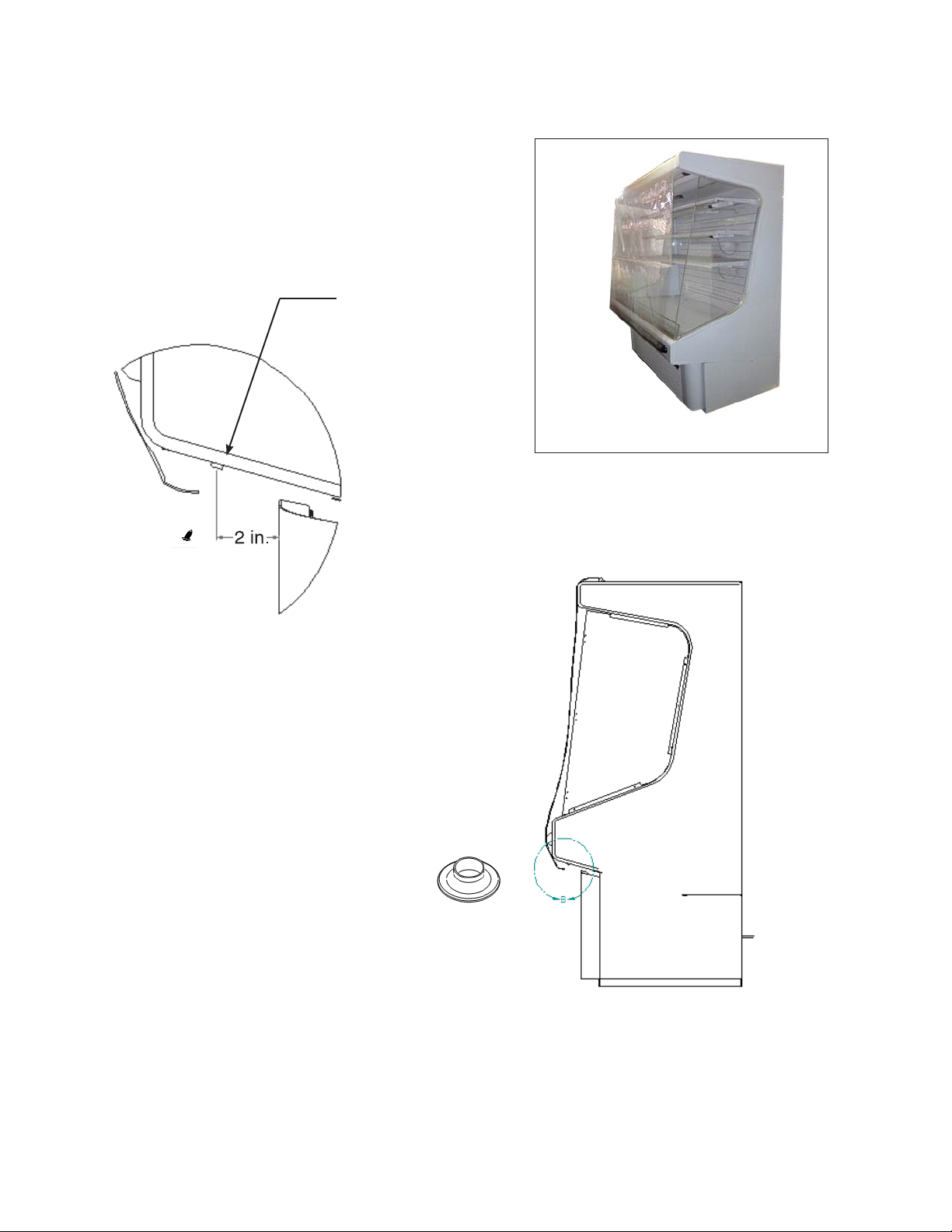

1-6 InstallatIon

Secure bottom of night curtain using bottom

clip as shown below. Clip is to be installed 2

inches in front access panel.

Bottom Clip

Night Curtain Installed

Front Access

Panel

Bottom Clip

A

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 13

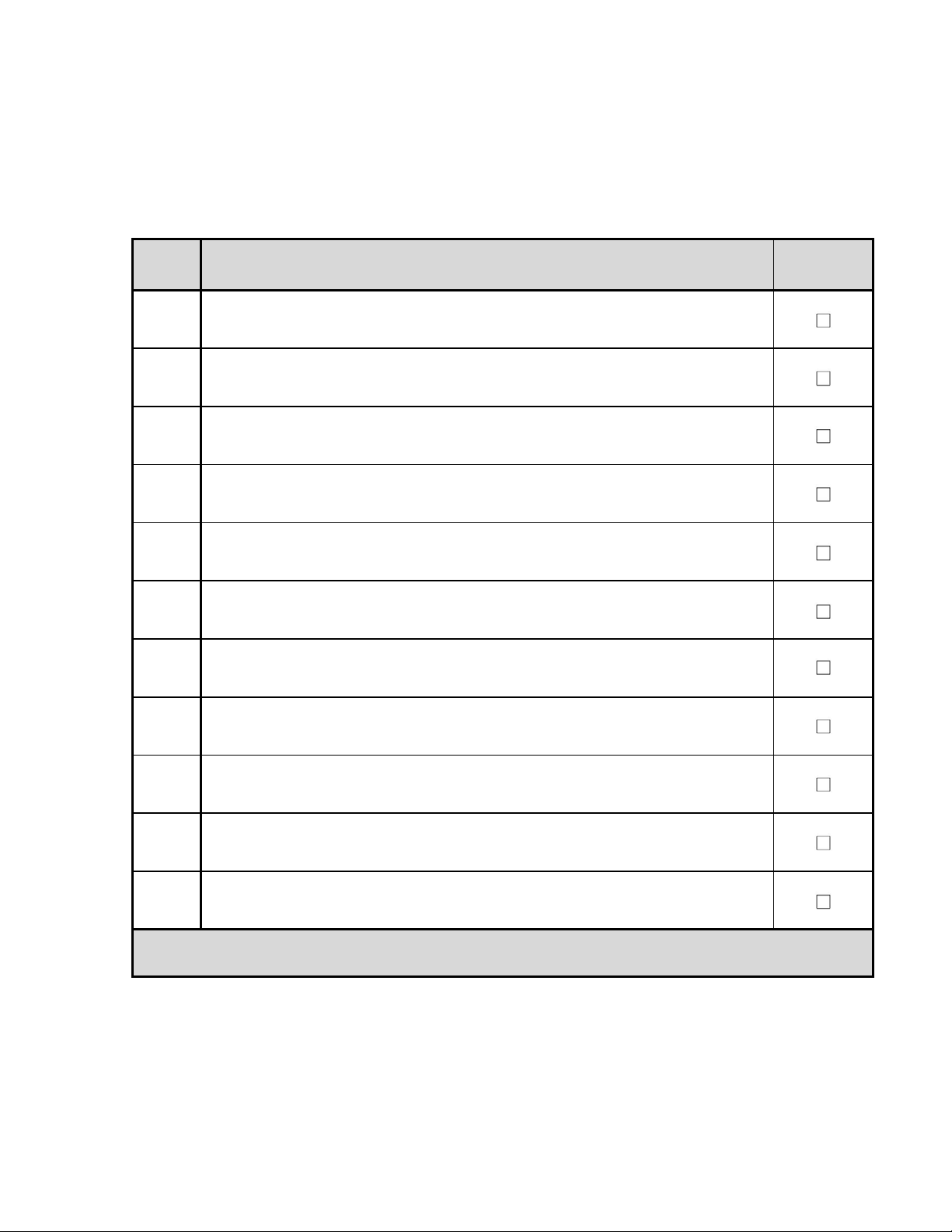

P/N 0545716_B 1-7

Form HSCW01 Rev. 30MAY12 P/N 0525209_B

Hussmann Self-Contained Refrigeration Equip ment Start Up Check List

***Please note that failure to follow this start-up document may void your factory warranty***

Step Startup Activity Check

Locate, read and maintain install/operation manual in a safe place for

1

future reference.

2 Examine unit. Confirm there is NO damage or concealed damage.

3 Level the unit, side to side and front to rear.

4 Remove all shipping brackets/compressor straps/bolts etc.

Unit must be run on a dedicated electrical circuit without the use of

5

an extension cord.

Ensure that the proper electrical requirements for the equipment are

6

supplied.

7 Verify field electrical connections are tight.

Verify all electrical wiring is secured and clear of any sharp edges or

8

hot lines.

9 Verify the condensate drain line is properly trapped and pitched.

10 Verify all required clearances on the sides and back of unit.

11

Advise owner/operator that merchandiser must operate at temperature for 24 hrs prior to loading

Verify there are no air disturbances external to the unit. Heat and air

registers, fans, and doors etc.

with product.

LEGAL DISCLAIMER:

Hussmann shall not be liable for any repair or replacements made without the written consent of Hussmann, or w hen the productis installed or operated in a manner

contrary to the printed instructions covering installation and service which accompanied such product.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 14

1-8 InstallatIon

NOTES:

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 15

P/N 0545716_B 2-1

ELECTRICAL / REFRIGERATION

MERCHANDISER ELECTRICAL DATA

Refer to Appendix A of this manual or the

merchandiser’s serial plate for electrical

information.

FIELD WIRING

Field wiring must be sized for component

amperes stamped on the serial plate. Actual

ampere draw may be less than specified.

ALWAYS CHECK THE SERIAL PLATE FOR

COMPONENT AMPERES

ELECTRICAL CONNECTIONS

All wiring must be in compliance with NEC

and local codes. All electrical connections for

GSVM-5272 self-contained are to be made in

the electrical Handy Box located behind the

removable base panel at the left end of the

merchandiser when facing the discharge air

honeycomb. GSVM-4060 and GSVM-4072 is

provided with a power cord.

ELECTRICAL OUTLET:

Before the merchandiser is connected to any

wall circuit, use a voltmeter to check that the

outlet is at 100% of the rated voltage. The wall

circuit must be dedicated for the merchandiser. Failure to do so voids the warranty. Do

not use an extension cord. Never plug in more

than one merchandiser per electrical circuit.

• Always use a dedicated circuit with the

amperage stated on the unit.

• Plug into an outlet designed for the plug.

• Do not overload the circuit

• Do not use long or thin extension cords.

Never use adapters.

• If in doubt, call an electrician.

GSVM-4060 and

GSVM-4072 has a

factory-installed power

NEMA 5-20R

Receptacle

GSVM-4060

GSVM-4072

cord that is attached at

the electrical box.

POWER SWITCH

The main electrical power switch is located

behind the front louvered access panel. The

power switch must be turned OFF before

servicing the merchandiser.

— LOCK OUT / TAG OUT —

To avoid serious injury or death from electrical shock, always disconnect the electrical

power at the main disconnect when servicing

or replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Risk of Electric Shock. If cord or plug

becomes damaged, replace only with

a cord and plug of the same type.

Merchandiser must be grounded.

Do not remove the power supply cord ground.

GSVM Open Vertical Merchandisers

Page 16

2-2 InstallatIon

REFRIGERATION

(Self Contained Models)

Each self contained model is equipped with

its own condensing unit and control panel

located beneath the display area. The correct

type of refrigerant will be stamped on each

merchandiser’s serial plate. The merchandiser

refrigeration piping is leak tested. The unit is

charged with refrigerant, and shipped from

the factory with all service valves open.

GSVM models have a refrigeration system

that uses a hermetic compressor. GSVM-4060

and GSVM-4072 systems use a capillary tube

for refrigerant control. The capillary tube is

soldered to the suction line pull-out coil for

proper heat exchange. If the capillary should

become plugged or damaged, it is best to replace

the heat exchanger.

GSVM-5272 employs a bleed port type

expansion valve for proper refrigerant control.

Read the merchandiser’s serial plate for the

appropriate refrigerant type and weight.

WATER OUTLET AND WATER SEAL

GSVM models 4072 and 5272 require a floor

drain. The condensate water outlet is located

in the center of the merchandiser. The outlet

has a factory-installed external water seal.

For self contained models like GSVM-4060,

this water seal drains into an electric condensate

pan located beneath the merchandiser. The

pan uses a thermistor that senses water in the

pan, adjusting the amount of heat required

to evaporate the water. Ensure the drain hose

is properly trapped, and the drain area is not

clogged.

NOTE: All lower base panels must be in place

when the refrigerator is operating. If not, airflow

from the condenser will be directed over the evaporator pan and defrost water in the pan may overflow.

OPTIONAL ELECTRIC

CONDENSATE PAN

An optional high-humidity condensate pan

kit requires a dedicated 15 Amp circuit - 120V

(GSVM-4072 and GSVM-5272).

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 17

P/N 0545716_B 2-3

Safe-III™

TEMPERATURE AND DEFROST

CONTROLLER

SAFE-NET III™ USER INSTRUCTIONS

Your refrigerated case uses a Hussmann

Safe-NET™ III temperature and defrost

controller to precisely maintain the temperature and prevent frost buildup on the cooling

coil. LEDs indicate when the compressor or

refrigeration is on, when the case is in a defrost

cycle, if the temperature is outside the desired

range, or if there is a sensor failure.

An adjustment knob allows the temperature

to be set within the configured range and can

power off the controller and compressor. Your

controller has been custom-configured to provide the best temperature and defrost control

for your chilled or frozen food.

The front of the controller has an adjustment

knob and status LEDs. The back of the

controller has connections for sensors and

switched equipment.

The Safe-NET III controller includes the

following features and connections.

• Adjustment knob:

Adjusts the temperature setpoint.

Turn adjustment knob to OFF to turn off

refrigeration system. Unplug merchandiser

from power before servicing the unit.

• Controller LEDs:

Compressor Powered On LED (green):

Lights while the compressor is running or

the refrigeration valve is open.

Defrost Cycle LED (yellow):

Lights while the refrigeration coil is

defrosting.

Temperature or Sensor Alarm (red):

Lights if the temperature is too warm or

too cold. Flashes if a sensor fails.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 18

2-4 InstallatIon

• Rear connections:

– Case temperature sensor:

• Typically senses the temperature

of the air in the case.

Used by the controller to determine when

to power on or power off the compressor

or refrigeration.

– Evaporator temperature sensor:

• Senses the temperature of the

refrigeration coil.

Terminates a defrost cycle when

refrigeration coil ice melts.

– Compressor or refrigeration relay:

• Switches on the compressor or

refrigeration valve for cooling.

– Defrost / reversing condenser switch

• Swtiches on the defrost or reversing

condenser fan motor - when used with

the condenser fan motor option.

DISPLAY

The display includes three red LEDs and two

digits for temperature, defrost status, and error

codes.

The optional evaporator fan remains ON

when the adjustment knob is in the OFF

position.

START-UP

The OFF Position does not disconnect line

voltage to the case, refrigeration unit, fan,

or heater.

1. Plug in the merchandiser.

NOTE: The 65°C Version Controller includes

a Parameter Code Number. This number

is 51 and indicates what program has

been loaded into the controller. When the

Controller is first powered up or is turned

off and then back on a 2 digit Parameter

Code Number will display for 3 seconds.

Then the Self Check will Start.

2. Wait for the self check to complete. During

the self check, each LED flashes for one

second, then all LEDs turn on for two

seconds. If the LEDs do not flash, make

sure the adjustment knob is not in the Off

position.

• After the self check, all LEDs turn off

until the compressor starts. There may be

a delay before the compressor starts. If the

red Temperature or Sensor Alarm LED

stays on after the self check.

• The green Compressor Powered On LED

turns on when the compressor starts.

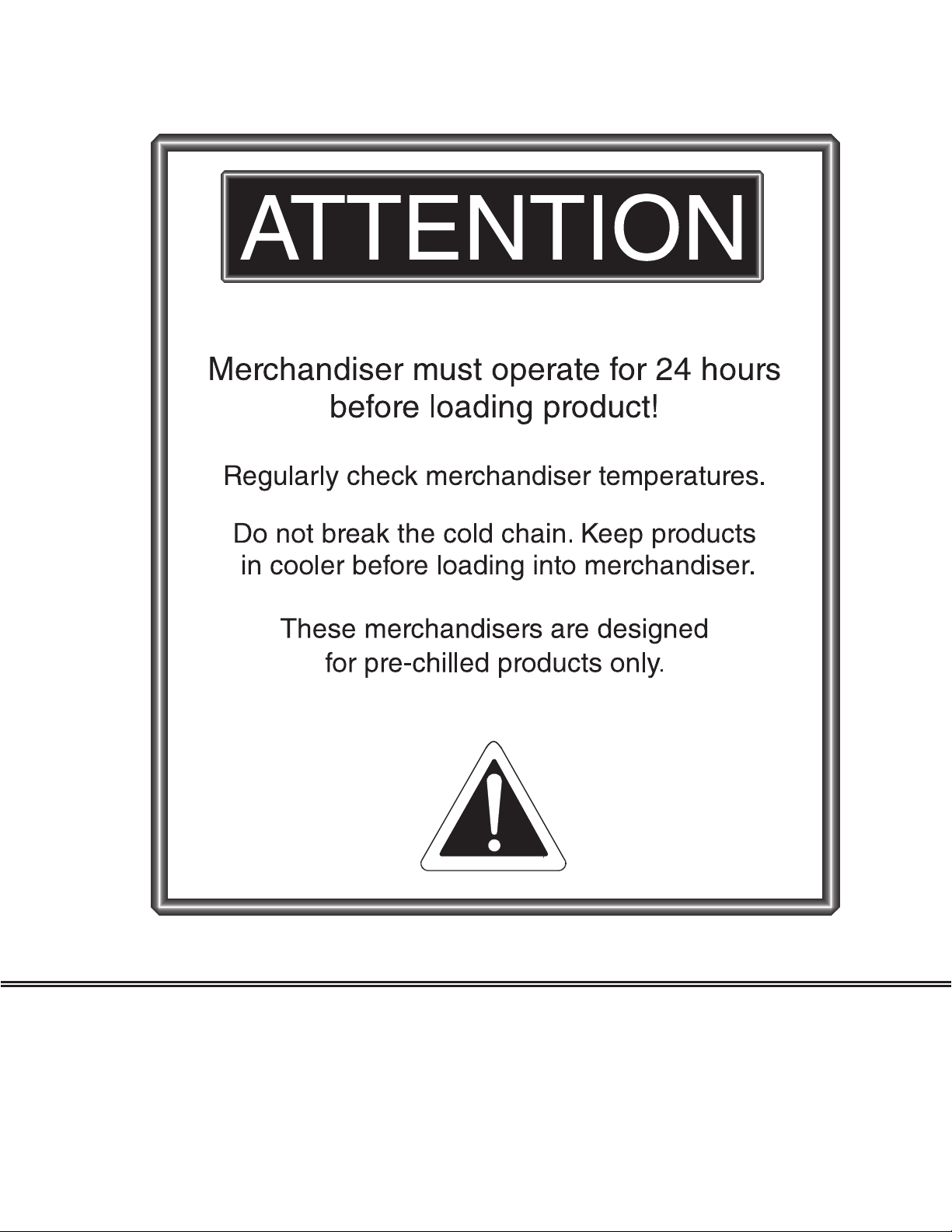

NOTE: Do NOT load product until AFTER

merchandiser operates for 24 hours and reaches

desired operating temperature. Behavior matches

the LEDs on the controller.

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 19

P/N 0545716_B 2-5

1. Apply power to the merchandiser. Wait for

the self check to complete. During the self

check, each LED flashes for one second and

then all LEDs turn on for two seconds. If the

LEDs do not flash, make sure the adjustment

knob is not in the “OFF” position.

1A. The merchandiser temperature displays at

startup. The initial defrost starts two hours

later. The display will show the temperature at

the start of defrost. This reading will remain

displayed during defrost and until it times out,

even though the refrigeration mode has been

initiated. (The green LED will be lit.)

2. The compressor will start after a 1-minute delay

once power is applied.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

3. The compressor will continue to run until it

reaches its cut-out temperature (Pulldown).

4. The refrigeration cycle will continue for the next

subsequent scheduled (8-hours) or demand

defrost. The digital display will display the

temperature reading for 10 minutes after

defrost.

5. The above process will repeat (steps 3 and 4)

until the power is interrupted.

6. If power stops, the process will start over at step

1, and the time to subsequent defrost will reset.

GSVM Open Vertical Merchandisers

Page 20

2-6 InstallatIon

ALARMS AND CODES

Flashing TemperaTure or sensor alarm

leD, e1 or e2

If the Temperature or Sensor Alarm LED

(red) on the controller and display is flashing,

a temperature sensor has failed. The display

shows E1 if the case sensor has failed or E2 if

the evaporator sensor has failed.

If the merchandiser sensor fails, refrigeration

will run continuously. Turn off, or repeat a

duty cycle of a few minutes on and a few

minutes off.

DEFROST TERMINATION SWITCH

Merchandisers may use a defrost termination

switch, instead of an evaporator sensor to

terminate a defrost cycle. The defrost

termination switch is temperature activated

and senses the completion of defrost.

MANUAL DEFROST

Note:

This procedure initiates

a manual or forced

defrost.

IMPORTANT: Return the control knob to

its original setting (Step1) once the manual

defrost has been initiated.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 21

P/N 0545716_B 2-7

TEMPERATURE ADJUSTMENT

1. Rotate the adjustment knob counter clock-

wise for a warmer setpoint or clockwise for

a colder setpoint.

2. While adjusting the temperature, the display

shows the setpoint (cut out value). A few

seconds after the temperature is set, the

controller reverts to the sensed temperature

in the merchandiser.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

3. To verify merchandiser settings, turn the

dial to warm and cold as shown above.

Output readings should be within one

degree of the temperatures shown above.

GSVM Open Vertical Merchandisers

Page 22

2-8 InstallatIon

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 23

P/N 0545716_B 3-1

START UP / OPERATION

START UP

Follow the electromechanical controls start

up procedures as detailed in Section 2 of this

manual.

Each self contained merchandiser has its own

evaporator coil. Model GSVM-5272 has an

expansion valve (TEV). The TEV has been

factory set at design conditions to provide the

recommended performance. GSVM-4060 and

GSVM-4072 have capillary tubes.

a. Check the interior cabinet thoroughly for

loose nuts, bolts and electrical connections.

b. Inspect the refrigeration lines for visible

damage or chafing.

c. Replace electrical box cover and access

panel.

d. Turn on the electrical power, power switch

and start the merchandiser. The merchan

diser must pull down in temperature.

TEV Adjustment (GSVM-5272 only)

Expansion valves may be adjusted to fully feed

the evaporator. Before attempting to adjust

valves, make sure the evaporator is clear or

only lightly covered with frost, and the

merchandiser is within 10°F of its expected

operating temperature. Adjust the valve as

Follows:

a. Attach a probe to the suction line near the

expansion valve bulb.

b. Obtain a pressure reading from the factory

installed Schraeder valve. Convert the pressure

reading to a saturated temperature for the

refrigerant.

Temperature (b) minus Temperature (a) is the

superheat. The valve should be adjusted so

that the greatest difference between the two

temperatures is 3° F (-16º C) to 5° F (-15º C).

Allow merchandiser 24 hours to operate before

loading product.

Make adjustments of no more than

1

/2 turn of

the valve stem at a time and wait for at least

15 minutes before rechecking the probe temperature and making further adjustments.

Schrader Valve

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 24

3-2 Start up / OperatiOn

1. The T-stat controller controls refrigeration

temperature. This is factory installed in the

control panel. Adjust this control knob to

maintain the discharge air temperature shown.

Measure discharge air temperatures at the

center of the discharge honeycomb.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01800-890-2900 • www.hussmann.com

Defrosts are time initiated and time terminated

for self contained. The defrost setting is factory

set as shown above.

Page 25

P/N 0545716_B 3-3

LOAD LIMITS

Each merchandiser has a load limit decal. Shelf

life of perishables will be short if load limit is

violated.

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

At no time should merchAndisers be

stocked beyond the loAd limits indicAted.

do not block Air louvers.

STOCKING

Product should NOT be placed inside the

merchandisers until merchandisers are at

proper operating temperature.

Allow merchandiser 24 hours to operate before

loading product.

Proper rotation of product during stocking is

necessary to prevent product loss. Always

bring the oldest product to the front and set

the newest to the back.

Air dischArge And return flues must

remAin open And free of obstruction At

All times to provide proper refrigeration and

air curtain performance. Do not allow product, packages, signs, etc. to block these grilles.

Do not use non-approved shelving, baskets,

display racks, or any accessory that could

hamper air curtain performance.

Do not allow product to be placed outside of

the designated load limits in the illustration at

left. Air flows through the back wall, over the

product on the shelves, across the face of the

product (air curtain), and into the return air

grille.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

SOLAR THERMOMETER

GSVM models have solar thermometers. The

thermometer is located at the top, front center

of the merchandiser’s cabinet interior.

Temperature is displayed in Fahrenheit

degrees as a standard option. Celsius is also

an available option. The thermometer may be

replaced if it becomes damaged.

To replace: remove the two screws securing the

thermometer to its mounting bracket. Remove

the sensing element from the clip, and install

the new thermometer in reverse order.

GSVM Open Vertical Merchandisers

Page 26

3-4 Start up / OperatiOn

SHELF MAXIMUM WEIGHT LIMITS

Hussmann merchandiser shelves are designed

to support the maximum weight load limits as

indicated in the table below.

Exceeding these maximum weight load limits

may cause damage to the shelf or shelves,

damage to the merchandiser, damage to store

products, and potentially create a hazardous

condition for customers and staff. Exceeding

the indicated maximum weight load limits constitutes misuse as described in the Hussmann

Limited Warranty.

GSVM-4060 has two standard shelves for

product display. The 13 in. shelf should be

positioned above the 15 in. shelf. Models

GSVM-5272 and GSVM-4072 have an

additional standard 13 in. shelf that is also to

be positioned above the 15 in. shelf.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01800-890-2900 • www.hussmann.com

Page 27

P/N 0545716_B 4-1

MAINTENANCE

CARE AND CLEANING

Long life and satisfactory performance of

any equipment is dependent upon the care it

receives. To ensure long life, proper sanitation

and minimum maintenance costs, these

merchandisers should be thoroughly cleaned,

all debris removed and the interiors washed

down, weekly.

Exterior Surfaces

The exterior surfaces must be cleaned with a

mild detergent and warm water to protect and

maintain their attractive finish.

abrasive cleaNsers or scouriNg pads.

Never use

Interior Surfaces

The interior surfaces may be cleaned with most

domestic detergents, ammonia based cleaners

and sanitizing solutions with no harm to the

surface. Self contained models empty into a

limited capacity evaporation pan, which will

overflow if excess water is used in cleaning.

Do NOT Use:

Do:

•Disconnect electrical power before cleaning.

•Remove the product and all loose debris to

avoid clogging the waste outlet.

•Store product in a refrigerated area such as a

cooler. Remove only as much product as can

be taken to the cooler in a timely manner.

•Thoroughly clean all surfaces with soap and

hot water.

pressure hoses to wash the iNterior.

These will desTroy The merchandisers’

sealing causing leaks and poor performance.

•Lift hinged fan plenum for cleaning. Hook

chain in rear panel to secure plenum during

cleaning.

num afTer cleaning merchandiser.

•Take care to minimize direct contact between

fan motors and cleaning or rinse water.

•Do NOT flood merchandiser with water.

Never iNtroduce water faster thaN the

do Not use steam or high water

Be sure To reposiTion The fan ple-

•Abrasive cleansers and scouring pads, as these

will mar the finish.

•Coarse paper towels on coated glass.

•Ammonia-based cleaners on acrylic parts.

•Solvent, oil or acidic based cleaners on any

interior surfaces.

•Do not use high pressure water hoses.

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Do NOT allow cleaning agent or

cloth to contact food product.

waste outlet caN remove it.

self coNtaiNed models empty iNto aN

evaporatioN paN that will overflow if

too much water is iNtroduced duriNg

cleaNiNg.

•Allow merchandisers to dry before resuming

operation.

•After cleaning is completed, turn on power to

the merchandiser.

GSVM Open Vertical Merchandisers

Page 28

4-2 Maintenance

— LOCK OUT / TAG OUT —

To avoid serious injury or death from electrical shock, always disconnect the electrical

power at the main disconnect when servicing

or replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

CLEANING DISCHARGE HONEYCOMB

Discharge air honeycombs should be cleaned

every six months. Dirty honeycombs will

cause merchandisers to perform poorly.

The honeycombs may be cleaned with a vacuum cleaner. Soap and water may be used if

all water is removed from the honeycombs cells

before replacing. Be careful not to damage the

honeycombs.

1. Using a flat object such as a screw driver,

compress the honeycomb and remove it

from its retainer.

2. Clean and dry the air honeycombs.

CLEANING STAINLESS STEEL SURFACES

Use non-abrasive cleaning materials, and

always polish with grain of the steel. Use warm

water or add a mild detergent to the water and

apply with a cloth. Always wipe rails dry after

wetting.

Use alkaline chlorinated or non-chlorine

containing cleaners such as window cleaners

and mild detergents. Do not use cleaners

containing salts as this may cause pitting and

rusting of the stainless steel finish. Do not use

bleach.

CLEANING SOLAR THERMOMETER

GSVM models have solar thermometers. The

thermometer is located at the top, front center

of the merchandiser’s cabinet interior.

To clean the thermometer:

1. Remove the two screws securing the thermometer to its mounting bracket. Remove

the sensing element from the clip

2. Use non-abrasive cleaning materials and a

mild detergent to clean thermometer.

3. After cleaning, replace in reverse order.

Damaged honeycombs must be replaced.

DO NOT FLOOD!

Use only enough water necessary to clean

surface. Water must not drip down the case!

Never use ammonia based cleansers, abrasive

cleansers, or scouring pads.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

3. Be sure to wipe the element clean of any

residues.

Do NOT use HOT water on Cold glass Surfaces.

This can cause the glass to shatter and could

result in personal injury. Allow glass fronts, to

warm before applying hot water.

Page 29

P/N 0545716_B 4-3

CLEANING UNDER DISPLAY PAN

Remove all product from the merchandiser

and place in cooler. Always disconnect electrical power before cleaning.

1. Remove the display pan

2. Use non-abrasive cleaning materials and a

mild detergent to clean display pan.

3. Wipe down the insides of the merchandiser

with a mild detergent, and replace display

pan. Allow merchandiser to pull down in

temperature before loading product.

CLEANING EVAPORATION PAN

(GSVM-4060 sTandard)

(GSVM-4072/5272-opTional)

The condensate water outlet for self

contained models empties into a limited

capacity evaporation pan.

Debris or dirt accumulation inside the condensate

evaporation pan or on the heater coil will

reduce the pan’s evaporation capacity and

cause premature heater failure. The evaporation

pan waste water will overflow and spill onto the

floor if the heater is not properly operating.

Remove accumulated debris from the evaporation

pan. Wipe down heater coil with a cloth and

warm water. Be sure to remove any dirt, debris

or liquids from the heater coil.

Water introduced during cleaning will cause

the evaporation pan to overflow.

Fan

Merchandiser with display pan removed

Evaporation Pan is Hot!

and poses risk of bodily injury – Always

Wear gloves and protective eye wear when

servicing. Turn off evaporation pan heater,

and allow pan to cool.

SHUT FANS OFF DURING

CLEANING PROCESS.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 30

4-4 Maintenance

CLEANING COILS

Condenser coils should be cleaned at least

once per month. Additional cleaning may be

needed depending on the operational environment. A dirty condenser blocks normal airflow

through the coils.

Airflow blockage increases energy consumption and reduces the merchandiser’s ability to

maintain operating temperature.

To clean the coils, use a vacuum cleaner with

a wand attachment and a soft (non-metallic)

brush to remove dirt and debris. Do not bend

coil fins. Always wear gloves and protective

eye wear when cleaning near sharp coil fins

and dust particles.

NEVER USE SHARP OBJECTS AROUND

COILS. Use a soft brush or vacuum brush to

clean debris from coils. Do not puncture coils!

Do not bend fins. Contact an authorized

service technician if a coil is punctured,

cracked, or otherwise damaged.

ICE in or on the coil indicates the refrigeration and defrost cycle is not operating properly. Contact an authorized service technician

to determine the cause of icing, and to make

adjustments as necessary. To maintain product

integrity, move all product to a cooler until

the unit has returned to normal operating

temperatures.

MAINTAINING FLUORESCENT LAMPS

Fluorescent lamps should not be allowed to

run to failure. If a re-lamp schedule is not in

place, the tubes should be inspected for signs

of degradation (blackened ends). Degraded or

failed tubes should be replaced.

Allowing severly degraded lamps to operate

may cause a ballast failure or could expose

the lamp holder to excessive heat. Replacing

degraded bulbs is more cost effective

than replacing ballast and lamp-holders.

Traditional re-lamp programs are 18-to-24

month intervals. In the absence of a re-lamp

program, a yearly inspection of the lighting

system is recommended.

1. Inspect all lamp sockets and plug-receptacle

connections for signs of arching. Replace any

component that shows signs of arching.

2. Make sure all unused receptacles have their

close-off covers securely installed.

3. Make sure proper cleaning procedures are

followed. Lights and fans MUST be turned off

when a case is cleaned and MUST be allowed to

dry before turning power back on.

4. Do not use a pressure nozzle to clean inside

of case.

REMOVING SCRATCHES FROM

BUMPER

Most scratches and dings can be removed

using the following procedure.

1. Use steel wool to smooth out the surface

area of the bumper.

2. Clean area.

3. Apply vinyl or car wax and polish surface

for a smooth glossy finish.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 31

P/N 0545716_B 4-5

Record starting date

Store Address

Unit Model Number

Unit Serial Number

Contractor/Technician

Check in with store manager, record any complaints or issues

x

Lookunitover forany damage,vibrationsorabnormalnoise.

x

x

Confirm refrigerant lines properly are secured and not touching

or rubbing other lines, wires or frame work.

x

x

Confirm fan blade/s are tight and not rubbing or hitting.

x

x

x

x

Check all electrical wiring make sure it is secured and not on

any sharp edges or hot lines.

x

registers, fans, and doors etc.

x

x

base cleaner. Rinse off any cleaner residue.

x

base cleaner. Rinse off any cleaner residue.

x

Clean condenser coil/s and fan blade/s. Do not use an acid base

Cleaner. Rinse off any cleaner residue.

x

Clean condensate drain pan and drain line.

x

x

x

x

Record condenser air inlet temperature

x

x

x

x

x

x

Record defrost heater voltage and amp dr a w.

x

Record anti-sweat heater voltage and amp draw.

x

x

Record unit discharge air temperature.

x

x

x

x

Manual for proper controller operation.

x

x

x

x

Self-Contained Refrigeration Equipment Maintenance Check List

* * * * * Warranty does not cover issues caused by improper installation or lackof basic preventative maintenance. * * * * *

Store Name and Number

Technician

PMdate

PMactivity-For visualinspection items,denote "ok or

complete" inthe column to right when PM has been

performed. For measured data requested, record data

requested in the appropriate column to the right)

they have with unit.

Verify unit is level side to side and front to rear.

Verify fan motors and motor mounts are tight.

Make sure all electrical connections, factory and field, are tight.

Verify ele ctric al connections at lamps are they secure and dry.

Check for and replace any frayed or chaffed wiring.

Check for ai r disturbances externall to the unit. He at and air

Check for water leaks.

Clean evaporator coil/s and fan blade/s. Do not use an acid

Clean discharge air honeycombs or grilles. Donot use an acid

Verify condensate drain lines are clear and functioning.

Record voltage reading at unit with unit off?

Verify condenser and evaporator fans are working.

Quarterly

Semi-

Annually

Ql

Q2

Q3 Q4

Ql

Q2

Q3 Q4

Record condenser air outlet temperature

Is condenser air inlet or air exhaust restricted or recirculating?

Verify there are no visual oil or refrigerant leaks.

Record voltage reading with unit running.

Record compressor amp draw.

Record case product temperature.

Record unit return air temperature.

Record ambient conditions around unit (wet Bulb temperature

and dry bulb temperature).

Check product loading, do not load beyond the units load limits.

Verify clearances on sides/back of unit.

Check unit controller for proper operation. See controller or 1/0

Confirm door switches function.

Verify unit doors and lids work and are sealed correctly.

Verify that all the panels, shields and covers are in place.

Technician Notes:

Form HSCW03 Rev-29 OCTOBER13

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

x

P/N 0525210_C

GSVM Open Vertical Merchandisers

Page 32

4-6 Maintenance

NOTES:

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 33

P/N 0545716_B 5-1

SERVICE

REPLACING FAN MOTORS AND

BLADES

Should it ever be necessary to service or

replace the fan motors or blades be certain

that the fan blades are reinstalled correctly.

The blades musT be insTalled wiTh raised

embossing (parT number on plasTic blades)

posiTioned as indicaTed on The parTs lisT.

For access to these fans:

1. Remove product and place in a refrigerated

area. Disconnect electrical power.

2. Remove bottom pan.

3. Disconnect fan from wiring harness.

To avoid serious injury or death from electrical shock, always disconnect the electrical

power at the main disconnect when servicing

or replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

— LOCK OUT / TAG OUT —

4. If it is determined that fan motor needs to

be replaced, remove fan motor brackets

from the fan plenum as shown.

7. Replace fan motor and/or blades.

8. Install brackets to fan motor and motor

bracket to the fan plenum.

9. Reconnect fan motor to wiring harness.

10. Turn on power.

11. Verify that motor is working and blade is

turning in the correct direction.

12. Reinstall display pans. Bring merchandiser

to operating temperature before restocking.

Fan

Motor

Bracket

Fan

Plenum

Product will be degraded and may spoil if

allowed to sit in a non-refrigerated area.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 34

5-2 Service

REPLACING FLUORESCENT LAMPS

Fluorescent lamps have a plastic shield. When

the lamp is replaced, keep the lamp shield to

install over the new lamp.

The switch under the display lamp cover

operates both the display lamp and interior

lamps.

Remove Plastic Pins Attaching Display Lamp.

LED FIXTURE REPLACEMENT

For canopy LEDs, the protective shield is

incorporated as part of the LED fixture.

Rotate the LED fixture to release it from the

lamp holder. Shelf LED fixtures are held in

place by magnets. Pull the fixture down firmly

to release disconnect cord from receptacle on

the rear wall.

Fluorescent lamps contain mercury vapor.

Mercury exposure at high levels can harm

the brain, heart, kidneys, lungs, and

immune system of people of all ages. Do

not break or puncture fluorescent lamps.

Dispose of, or store, all fluorescent lamps

in accordance with Federal (40 CFR 273),

State, and local hazardous waste

requirements. Refer to:

http://www.epa.gov/mercury/about.htm

— LOCK OUT / TAG OUT —

To avoid serious injury or death from electrical shock, always disconnect the electrical

power at the main disconnect when servicing

or replacing any electrical component. This

includes, but is not limited to, such items as

doors, lights, fans, heaters, and thermostats.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 35

P/N 0545716_B 5-3

TROUBLESHOOTING GUIDE

PROBLEM

Compressor will not start.

(no noise)

Compressor will not start;

cuts out on overload.

PROBABLE CAUSE

1. Power disconnected

2. Blown fuse or breaker

3. Defective or broken wiring

4. Defective overload

5. Defective temperature

control

1. Low voltage

2. Defective compressor

3. Defective relay

4. Restriction (pinched cap tube)

5. Restriction (moisture)

6. Condenser blocked with

dust and dirt

SOLUTION

1. Check service cord or

wiring connection

2. Replace fuse or reset

breaker

3. Repair or replace

4. Replace

5. Replace

Cabinet voltage must not be

1.

more than 5% below rating

2. Replace

3. Replace

4. Repair or replace

5. Leak check, replace drier

evacuate and recharge

6. Clean condenser

Warm storage temperature

Compressor runs continuously;

product too warm.

Compressor runs continuously;

product too cold

7. Defective condenser fan

motor

1. Temperature control not set

properly

2. Short or refrigerant

3. Cabinet location too warm

4. Refrigerant over-charge

5. Low voltage, compressor

cycling on overload

1. Short of refrigerant

2. Inefficient compressor

3. Coil iced up

1. Defective control

2. Control sensing element not

in positive contact

3. Short on refrigerant

7. Replace

1. Reset control. Rotate knob

Clockwise

2. Leak check, replace drier

evacuate and recharge

3. Move to cooler location or

correct excessive heat source

4. Purge system, evacuate and

recharge

5. Compressor voltage must not

be more than 5% below rating

1. Leak check, replace drier,

evacuate and recharge

2. Replace

3. Force manual defrost

1. Replace

2. Assure proper contact

3. Leak check, replace drier

evacuate and recharge

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 36

5-4 Service

TROUBLESHOOTING LIGHT GUIDE

PROBLEM

Lights won’t start

Lights flicker

GSVM ACCESSORIES

SOLUTION

1. Check light switch

2. Check continuity to ballast / Power Supply

3. Check to see if bulbs are inserted properly

in sockets

4. Check voltage

1. Allow lamps to warm up

2. Check lamp sleeve for cracks

3. Check sockets for moisture and proper

contact

4. Bulb replacement may be necessary

5. Check voltage

6. New bulbs tend to flicker until used

The following is a description of the various

accessories available for the GSVM.

Caster Kit — Consists of 5 in. braking casters,

which screw in to the standard threaded holes

in the four corners under the cage occupied by

the standard leg levelers. The kit will add

5

5

/8 in. of height to the case.

Leg Kit — The legs also go into the same holes

as the standard levelers, which will have to be

removed. The legs are adjustable and will add

5 5/16 in. to the height of the case. The skirt kit

requires the use of these legs.

Four-sided Skirt Kit — This is a four-sided

skirt that encloses the open area under the

merchandiser when the leg kit is used. The

skirt kit clamps to the legs.

Night Cover — This is a clear, 5 mm thick,

polyester shade cover that covers the face of

the merchandiser. It will fasten to the top of

the merchandiser and be drawn to a snap

fastener in the area above the front bumper.

The cover, although loose fitting on the ends,

will conserve energy during periods when the

store is not open. The cover is standard on the

GSVM-5272.

Wrap-Around Bumper Kit — This bumper

replaces the standard front bumper and wraps

around both sides of the merchandiser at the

standard height of 22 inches to the centerline

of the 2 1/4 in. wide bumper.

Colored Accent Panel — This panel can be (a.)

the top front panel over the product, (b.) the

panel behind the bumper, or (c.) the access

panel below the bumper panel, or any

combination of these.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 37

P/N 0545716_B 5-5

Shelf end Trim Kit — Consists of four painted steel ends for the standard 13 in. and 15

in. shelves. This trim conceals and protects

the exposed ends of the shelves. The trim kit

attaches by two snap fasteners supplied with

each trim piece for the GSVM-4060 model.

High Humidity Condensate Pan — (For

GSVM-4072 & 5272) This is a 1,000 watt, 9

Amp. pan with a 6 ft - 9 in. 115V power cord

attached. A dedicated circuit is required.

Shelf Upslope Tilt Adapter Kit — This kit

consists of four zinc coated wire adapters to

increase the two standard shelves, upslope

from 1 1/2º to 6º.

Price Tag Molding Kit — This kit consists of

aluminum price tag molding for the standard

shelves. Price tag moulding will hold both 1 in.

and 1.235 in. standard price tags. (Note that

the standard shelves accept 1.235 in. tags.)

Wire Basket Kits — One kit is available to

replace the top 13 in. shelf or shelves, another

is available to replace the bottom 15 in. shelf.

Each kit consists of a wire basket, two brackets,

and two dividers, which could also be used as

ends. These parts are zinc plated. The baskets

have an 8 in. high back and a 4 in sloped front.

Wire Basket Dividers — These are additional

dividers, which can be with the wire baskets kit

to obtain additional partitioned areas in the

baskets.

Additional Lighted Shelf — This consists of an

additional 13 in. lighted shelf that can be

positioned between the two standard shelves.

It is the same construction as the top standard

13 in. shelf.

LED Lights — LED light fixtures replace fluorscent lights. This technology saves energy

and extends component life.

Wire Product Stop Kit — This kit consists of

a 2 in. high chrome plated open wire stops for

the standard shelf. This stop is mounted under

tension and should not be confused with the

wire front in the partition kit.

Wire Partition Kit — This is a free-standing

wire system, which attaches to the standard

shelves, and consists of a wire front, (different

from the product stop) two wire sides and two

partitions from the front to back, all chrome

plated and 3 inches high.

Wire Cross Divider — This is a 3 inche high

and 4 inch-long divider that could be ordered

to be used with the wire partition kit above.

Night Curtain — Night curtains cover the

throat opening of the case and is installed on

the case after normal business hours. Night

curtains help reduce energy costs, allowing the

refrigeration system to work less when the case

is not in use. The night curtain for GSVM is

standard for model 5272 and is an optional kit

for models 4060 and 4072.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 38

5-6 Service

NOTES:

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 39

Appendix A — TechnicAl dATA A-1

Parts List

MODELS

Standard Parts

Descripon Part Number

Evaporator Fan Motor 21S147 X X X

Evaporator Fan Blade 21S080 X X X

Evaporator Fan Motor Bracket 76218 X X X

Air Sensor (Black) 1500MM 0509122 X X X

Defrost Sensor (Yellow) 1500MM 0509123 X X X

Safe-Net III Controller 65C 0524119 X X X

Safe-Net III Display (F°) 65C H159052 X X X

Safe-Net III Display Interface Cable 0509783 X X X

Safe-Net III Control Harness 0513058 X X X

Compressor Relay (T92P7A22-120) 0459304 X X X

Power Switch 03S286 X X X

Solar Thermometer 05S521 X X X

Assembly Lighted shelf Fluorescent 13” X 36 290631 X X

Assembly Lighted shelf Fluorescent 15” X 36 290632 X X

Assembly Lighted shelf Fluorescent 13” X 48 292131

Assembly Lighted shelf Fluorescent 15” X 48 292132

Shelf 13 X 36 22S2101 X X

Shelf 15 X 36 22S1932 X X

Shelf 13 X 48 22S2102

Shelf 15 X 48 22S244

Lamp Fluorescent (Shelf) 06S149 X X

Lamp Fluorescent (Canopy) 06S029 X X

Lamp Fluorescent (Shelf & Canopy) 06S010

Ballast Canopy Light 06S187 X X

Ballast (lighted shelf) 06S042 X X

Ballast (lighted shelf) 06S016

Safety Shield Canopy light 06S07243 X X

Safety Shield Canopy & Shelf 06S0742

Safety Shield Shelf light 06S07417 X X

Starter Socket (Shelf Light) 06S024 X X X

Starter (Shelf Light) F-S2) 06S041 X X

Starter (Shelf Light) F-S4) 06S019

Lamp Holder (Canopy) 06S004 X X X

Lamp Holder (Shelf Light) 06S185 X X X

Light Switch (Canopy & Shelf) 03S176 X X X

Plug (3 prong (Lighted shelf) 19S691 X X X

Shelf Harness (3 shelf) 19S674 X X

Shelf Harness (4 shelf) 19S688

Evaporator Fan & Light Harness 19S6891 X

Evaporator Fan & Light Harness 19S6892

Side Plexiglass Ends 29S892

Front Plexiglass 29S8961 X X

Front Plexiglass 29S8962

Leg Leveler 35S024 X X X

Black rubber Drain Hose (32”) 18S063 X X X

Night Curtain 35S066

Front Bumper End Cap (Black) 18S2932 X X X

Honeycomb 0519007 X X

Honeycomb 29S6812

Power Cord NEMA 5-20P 19S63612 X X

GSVM4060 GSVM4072 GSVM5272

X X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 40

A-2 Appendix A — TechnicAl dATA

Parts List

MODELS

OPTIONAL LED Canopy & Shelf

Descripon Part Number

LED Canopy Lamp 0515964 X X

LED Canopy Lamp 0515965

LED Shelf Lamp 0523752 X X

LED Shelf Lamp 0523755

LED Power Supply 0518898 X X X

LED Harness 4 plug 0501237 X X X

LED Harness Plug 0523768 X X X

Refrigeraon

Condensing Unit Assy 0522149 X X

Condensing Unit Assy 292122

Drier (C052-S) 17S362 X X

Drier (C082-S) 17S365

Pull out Coil assy 29216 X X

Pull out Coil assy 29435

Assembly Evaporator Coil 291211 X X

Assembly Evaporator Coil 292951

Cap Tube Assembly 29152 X X

TXV (Sporlan EGSE-1-C) Sweat E205982

TEV (Sporlan FS-1-C-B10) Flare 17S506

Evaporator Coil 26S116 X X

Evaporator Coil 26S115

Accumulator 17S098 X X

GSVM4060 GSVM4072 GSVM5272

X

X

X

X

X

X

X

X

X

Condensate Pan

Electric Condensate Pan Assy (350W) 29254 X

Condensate Pan (only) 29253 X

Condensate Pan Heater (350w) 19S678 X

Condensate Pan (1000w) Oponal 1601835

Sheel Metal Replacement Parts Painted

Front Louvered Access Panel w/SNIII KO 291434 X X

Front Louvered Access Panel w/SNIII KO 291435

Boom Display Shelf-White 290211 X X

Boom Display Shelf-White 290212

Front LH Glass Brkt Assy (Metallic Silver) 294861 X X X

Front RH Glass Brkt Assy (Metallic Silver) 294862 X X X

Rear lower Panel-White 290001 X X

All these part numbers below are painted assemblies

X X

X

X

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 41

Appendix A — TechnicAl dATA A-3

Hussmann refrigerated merchandisers configured for sale for use in the United States meet or

surpass the requirements of the DOE 2012 energy efficiency standards.

GSVM

General GSVM-4060 GSVM-5272

Case Length (Note: Includes One Pair Ends) 40 in. (1016 mm) 52 in. (1321)

Optional End Bumpers (One Pair) 2 in. (51 mm) 2 in. (51 mm)

Waste Outlet

LH end of case (from outside of End Assembly) 20 in. (508 mm) 26 in. (660 mm)

to center of waste outlet

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 42

A-4 Appendix A —TechnicAl dATA

Dimensions shown as inches and (mm).

GSVM-4060

REFRIGERATION DATA

GSVM-4060 GSVM-4072

GSVM-5272

Thermostat

Setting CI/CO (°F)

Position: #1 #7

GSVM 36 36

32 16

Condensing Unit (hp) 3/4 hp (All Models)

Condensing Unit

Capacity

GSVM-4060/4072 4410

GSVM-5272 4610

(Btu per hour at std. rating

conditions)

GSVM-4072

GSVM-5272

Note: This data is based on store temperature

and humidity that does not exceed 75°F and

55% R.H. unless otherwise stated. Schedule

defrost at night while lights are off.

DEFROST DATA

Frequency (hour)

GSVM-4060/4072/5272 8

Offtime

Failsafe (minutes)

GSVM-4060/4072/5272 45

Defrost Termination

Temperature Terminated

PHYSICAL DATA

Refrigerant Charge

GSVM-4060 (R134a) 33 oz 0.936 kg

GSVM-4072 (R134a) 32 oz 0.907 kg

GSVM-5272 (R404a) 46.5 oz 1.318 kg

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 43

Appendix A — TechnicAl dATA A-5

Electrical Data

Note: These are rated values for individual components and should not be added together to

determine total merchandiser electrical load.

GSVM-4060/4072 GSVM-5272

Number of Fans – 4W (open shell) 2 3

Amperes Watts Amperes Watts

Evaporator Fans

115V 60Hz Standard 0.8 8 1.2 12

Condensate Pan Heaters (115V) 3 350

GSVM-4060 (only)

Condensate Pan Heaters (115V)

9.0 1000

GSVM-4072/GSVM-5272

Condensing Unit (115V, 1Ph, 60Hz) Standard

GSVM-4060/4072

Compressor LRA 78.0

Compressor RLA 13.6

GSVM-5272

Compressor LRA 70.0

Compressor RLA 15.0

Product Data

GSVM-4060

ARI Total Display Area

1

(Sq Ft/Case) 11.04 ft

GSVM-4072

ARI Total Display Area

1

(Sq Ft/Case) 16.65 ft

GSVM-5272

ARI Total Display Area

1

(Sq Ft/Case) 18.47 ft

2

/case ( 1.086 m

2

/case ( 1.546 m

2

/case ( 1.878 m

2

/case)

2

/case)

2

/case)

1 Computed using AHRI 1200 standard methodology:

Total Display Area, ft2 [m2] / Unit of Length, ft [m]

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 44

A-6 Appendix A — Wiring diAgrAmS

Nominal

HP

Refrigerant

Type

Volts Run

Amps

Nema

Plugs

Fuse

Amps

Hz / Ph

GSVM-4060 ¾ R134a 115 16 5-20P 20 60/1

GSVM-4072 ¾ R134a 115 15.5 5-20P 20 60/1

*GSVM-5272 ¾ R134a 115 19.5 Hard Wired 25 60/1

*Requires field wiring.

Optional 1,000W Hi-Humidity Condensate Pan requires a dedicated 120V/15 Amp circuit

ESTIMATED SHIPPING WEIGHT

2

Case Self Contained Case and Crate End

GSVM-4060 384 lb (174kg) 470 lb (213kg) Included

GSVM-4072 417 lb (189kg) 516 lb (234kg) Included

GSVM-5272 531 lb (241kg) 648 lb (294kg) Included

2

Actual weights will vary according to optional kits included.

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 45

Appendix A — Wiring diAgrAmS A-7

WARNING

UNPLUG THE EQUIPMENT BEFORE

ADVERTENCIA:

DESCONECTAR EL EQUIPO ANTES DE

CUALQUIER REPARACIÓN, PARA

1H16704002

FAN

COND.

2

C

1

COMPRESSOR

BL

PROTECTOR

115 V

60HZ

RUN

CAPACITOR

BK

Y

0

1

START

CAPACITOR

4

8

RELAY

6

2

RELAY

POTENTIAL

COMPRESSOR

W

BK

LIMIT

T. START

W

BK

BK

W

ELEC-TRON

25 26

W

23 24

11 12

9 10

7 8

5 6

3 4

1 2

3-S-226

BK

BK

W

BK

W

W

PAN HEATER

CONDENSATE

W

1PH

BK

S1

S3

POWER SWITCH

5-20P

NEMA

GRN

W

YELLOW SHEATH

DEFROST

THERMOSTAT

SENSOR TEMP

GSVM-4060

SENSOR

AIR TEMP

THERMOSTAT

DISPLAY

KEY

LINK

PROG

HACCP

SERIAL

2 M

W

BK

1011

BK

89

BK

LINE 1

7

W

LINE 2

BL

COMP NA

56

BK

PHASE

4

BLACK SHEATH

SAFENET III CONTROL

CAP ENDS

FAN

3

PHASE

HEATER

12

Y

BK

B

W

BK

EVAP. FANS

BK

W

0523611_B

ELECTRIC SPECS

MODEL GSVM4060

VOLTAGE 115 V

FREQUENCY 60 HZ

W

BK

BK

BK

LIGHT SWITCH

BK

POWER SUPPLY

BK

OPTIONAL LED LIGHT KITS

BK

R

BL

BK

BK

LIGHT SWITCH

BK

BALLAST

R

BL

LIGHT SWITCH

BK

BK

BALLAST

R

BL

LIGHT SWITCH

BK

BK

BALLAST

R

BL

OPTIONAL KIT

LIGHT SWITCH

BK

BK

BL

BALLAST

R

BL

HACER

SERVICING

EVITAR ALGUN

R

BL

BL

UPPER LED

SHELF LED

R

R

BL

BL

SHELF LED

R

R

BL

BL

BL

SHELF LED

R

R

R

UPPER LIGHT

SHELF LIGHT

SHELF LIGHT

SHELF LIGHT

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

DAÑO.

CAP ENDS

CAP ENDS

CAP ENDS

CAP ENDS

GSVM Open Vertical Merchandisers

Page 46

A-8 Appendix A — Wiring diAgrAmS

OPTIONAL SHELF LIGHT

1H16704002

FAN

COND.

2

C

1

COMPRESSOR

PROTECTOR

RUN

CAPACITOR

BK

Y

BL

0

1

START

CAPACITOR

4

8

26

RELAY

POTENTIAL

BK

W

BK

DEFROST

THERMOSTAT

YELLOW SHEATH

SENSOR TEMP

GSVM-4072

SENSOR

AIR TEMP

THERMOSTAT

CAP ENDS

EVAP. FANS

DISPLAY

KEY

LINK

PROG

HACCP

SERIAL

2 M

W

11

BK

BK

8 9 10

BK

LINE 1

7

56

4

BLACK SHEATH

3

SAFENET III CONTROL

12

W

LINE 2

BL

COMP NA

BK

PHASE

Y

FAN

BK

PHASE

B

HEATER

W

BK

BK

W

5-20P

NEMA

115 V

60HZ

1PH

BK

RELAY

COMPRESSOR

W

ELEC-TRON

25 26

W

23 24

11 12

9 10

7 8

5 6

3 4

1 2

3-S-226

BK

OPTIONAL

BK

5-15P

NEMA

CONDENSATE PAN HEATER

W

W

BK

W

W

S1

S3

POWER SWITCH

GRN

W

ADVERTENCIA:

DESCONECTAR EL EQUIPO ANTES DE HACER

CUALQUIER REPARACIÓN, PARA EVITAR ALGUN

DAÑO.

ELECTRIC SPECS

MODEL GSVM4072

VOLTAGE 115 V

WARNING

UNPLUG THE EQUIPMENT BEFORE SERVICING

0523613_C

FREQUENCY 60 HZ

W

BK

BK

LIGHT SWITCH

BK

POWER SUPPLY

BK

BK

OPTIONAL LED LIGHT KITS

BK

R

BK

BK

BK

LIGHT SWITCH

BALLAST

R

BL

LIGHT SWITCH

BK

BK

BALLAST

R

BL

LIGHT SWITCH

BK

BK

BALLAST

R

BL

LIGHT SWITCH

LIGHT SWITCH

BK

BK

BALLAST

R

BL

BK

LIGHT SWITCH

BK

BL

BL

BL

BALLAST

R

BL

UPPER LED

R

R

R

BL

BL

BL

SHELF LED

R

SHELF LED

R

BL

BL

SHELF LED

R

R

BL

BL

BL

SHELF LED

R

R

R

UPPER LIGHT

SHELF LIGHT

SHELF LIGHT

SHELF LIGHT

SHELF LIGHT

CAP ENDS

CAP ENDS

CAP ENDS

CAP ENDS

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

CAP ENDS

Page 47

P/N 0545716_B A-9

OPTIONAL SHELF LIGHT

1H16704002

FAN

COND.

2

C

1

115 V

60HZ

BL

0

1

START

CAPACITOR

4

8

26

RELAY

POTENTIAL

BK

BK

RELAY

COMPRESSOR

W

W

ELEC-TRON

25 26

W

23 24

11 12

9 10

7 8

5 6

3 4

1 2

3-S-226

BK

OPTIONAL

BK

5-15P

NEMA

CONDENSATE PAN HEATER

POWER SWITCH

W

W

BK

W

W

1PH

BK

S1

S3

GRN

W

GSVM5272

EL

ECTRIC SPECS

EL

MOD

0523614_B

DEFROST

THERMOSTAT

YELLOW SHEATH

SENSOR TEMP

GSVM-5272

SENSOR

AIR TEMP

THERMOSTAT

CAP ENDS

BLACK SHEATH

EVAP. FANS

FAN

DISPLAY

KEY

LINK

PROG

HACCP

SERIAL

2 M

W

BK

1011

BK

89

BK

LINE 1

7

W

LINE 2

BL

COMP NA

56

BK

PHASE

4

Y

FAN

3

BK

PHASE

HEATER

12

B

SAFENET III CONTROL

COND.

PROTECTOR

2

C

1

COMPRESSOR

RUN

CAPACITOR

BK

Y

W

BK

BK

W

60 HZ

115 V

WARNING

VOLTAGE

FREQUENCY

UNPLUG THE EQUIPMENT BEFORE SERVICING

ADVERTENCIA:

DESCONECTAR EL EQUIPO ANTES DE HACER

CUALQUIER REPARACIÓN, PARA EVITAR ALGUN

.

DAÑO

W

BK

BK

LIGHT SWITCH

BK

POWER SUPPLY

BK

BK

OPTIONAL LED LIGHT KITS

BK

R

BK

BK

BK

LIGHT SWITCH

BALLAST

UPPER LIGHT

R

STANDARD SHELF LIGHT

BL

LAMP

LIGHT SWITCH

BK

BK

BALLAST

R

BL

STANDARD SHELF LIGHT

LAMP

LIGHT SWITCH

BK

BK

BALLAST

R

BL

STANDARD SHELF LIGHT

LAMP

LIGHT SWITCH

LIGHT SWITCH

BK

BK

BALLAST

R

BL

LAMP

BK

LIGHT SWITCH

BK

BL

BL

BL

BALLAST

R

BL

LAMP

UPPER LED

R

CAP ENDS

R

R

CAP ENDS

BL

BL

BL

SHELF LED

R

SHELF LED

R

CAP ENDS

BL

BL

SHELF LED

R

R

CAP ENDS

BL

BL

BL

SHELF LED

R

R

R

CAP ENDS

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

GSVM Open Vertical Merchandisers

Page 48

A-10 Service

NOTES:

P/N 0545716_B U.S. & Canada 1-800-922-1919 • Mexico 01 800-890-2900 • www.hussmann.com

Page 49