Hussmann GIM Installation And Service Instructions Manual

January 2006

INSTALLATION & SERVICE

INSTRUCTIONS

FOR

GIM LOW TEMPERATURE SELF-CONTAINED

FOR

Pre Packaged Ice Cream and Ice Cream Novelties

First Call for help (US and Canada):

1-800-922-1919

Soporte Tècnico y Asistencia (Mèxico):

01-800-522-1900

For a Service Network Locator and other

Information visit us at

www.hussmann.com

select Worldwide Locations

HUSSMANN - GLOVERSVILLE

P/N OII – GIM

January 2006

TABLE OF CONTENTS

Page

Introduction 3

Inspection, Location and Clearance 3

Skid, Leveling and Sealing 3

Bottom Louvered Panel Removal 4

Glass Doors and Shelves 4

Air Distribution and Product Loading 5

Electrical Connections 5

Serial Plate Information and Start-up Procedure 5 – 6

Specifications, Dimensions, Electrical, and BTU Capacity 6

General Upkeep, Care and Cleaning 6

Routine Maintenance 6

Operation and Maintenance, Power Switches 7

Temperature Control, Thermometer, and Electrical Box 7 –8

Defrost Time Clock 8

Defrost Heater Thermostat 9

Defrost Heater Replacement 9

Lighting 9

Condensate Heater 9

Expansion Valve Adjustment 10

Refrigeration 10

Leak Testing 10 – 11

Evacuation 11

Operational Data 11

Compressor 11

Condenser Fan Motors 11

Receiver 12

Crankcase Pressure Regulator 12

TABLE OF CONTENTS CONT’D

Page

Trouble Shooting Chart 12 – 13

Electrical Components 14

Troubleshooting Lights 15

Warranty and Parts Information 15

Ordering Replacement Parts 15-16

Warranty Parts Procedure ״

Compressor Replacement Procedure ״

ADDENDUM ******* 06-18-03

Evaporator Fan Blades 17

INTR ODU C TION –

The Gim-6 is a low temperat ure,

self-contained cabinet designed for prepackaged ice cream or ice cream novelties

at below freezing temperat ures. Design

features include self-closing glass doors,

efficient foamed in place non-CFC insulation, low r ail height, f rom both sides, and

a balanced refrigeration system for energy saving performance

INSPECTION

–

Upon receipt of the cabinet, carefully examine the crating for damage. If

crate is damaged, make a note on the delivery ticket be fore signing. Carefully remove shipping crate and examine cabinet

for “concealed” damage. If damage is

found, contact the delivery carrier immediately and have his agent prepare an inspection report for the purpose of filing a

claim. THIS IS Y OUR RESPONSIBILITY.

LOCATION

–

Avoid locating the case where direct sunlight would shine into the fixture

or where drafts from air conditioning

grills, fans, and open doors could effect its

operation.

CL E A R A N C E

–

Because this condensing unit is

located at the bott o m of the cabinet, a

three (3) foot clearance should be allowed

in front of the louvered access panel to

provide f ree air movement to and from

the condenser for maximum operating efficiency.

INSTALLATION and START-UP

–

SKID –

The skid should be left on the unit

until it is near its final location. The skid

provides protection for both cas e and

floor. The skid is removed by removing

the bolts holding the skid clamps to the

case base, then sliding the cas e off the

skid. A “mule” bracket is built in the end

of the cabinet base frame for this purpose.

LEVELING and SEALING

–

Proper drainage of the evaporator

condensate water requires the cabinet to

be properly leveled. This means left to

right as well as front t o back.

The case can be leveled using the

leveling screws in the bottom of the case

or by shimming under the cabinet base

frame. The self-closing doors require the

cabinet to be properly leveled. End to end

leveling will make the doors close with

uniform speed and tightness. Once level

the case should be sealed to the floor as

shown in the f ollowing drawing, using an

NSF approved material such as General

Electric RTV-102 silicone sealer or an

equivalent.

Silico ne Sealant

Floor

BOTTOM LOUVERED PANEL

REMOVAL –

The louvered panel provides access to the condens ing unit and the electrical box. The panel is secured with

screws to prevent injury.

COMPRESSOR

–

The compress or is banded for

s hippi ng . T HE BA N D MU S T B E R EMOVED. The mounting bolts on the

compressor are factory pre-set to allow

the compressor to float freel y on the

mounting springs. DO NOT LOOSEN

NUTS.

CABI NET DRA IN

–

A positive pitched drain tube is

factory-installed which runs to a drain

pan in the condensing unit area from

the evaporator se ction to handle defrost

water. No piping to a floor drain is necessary but the tube should be checked

to make sure the tube has not become

plugged with items such as pricing

stickers, and is over the pan so water

does not run onto the floor.

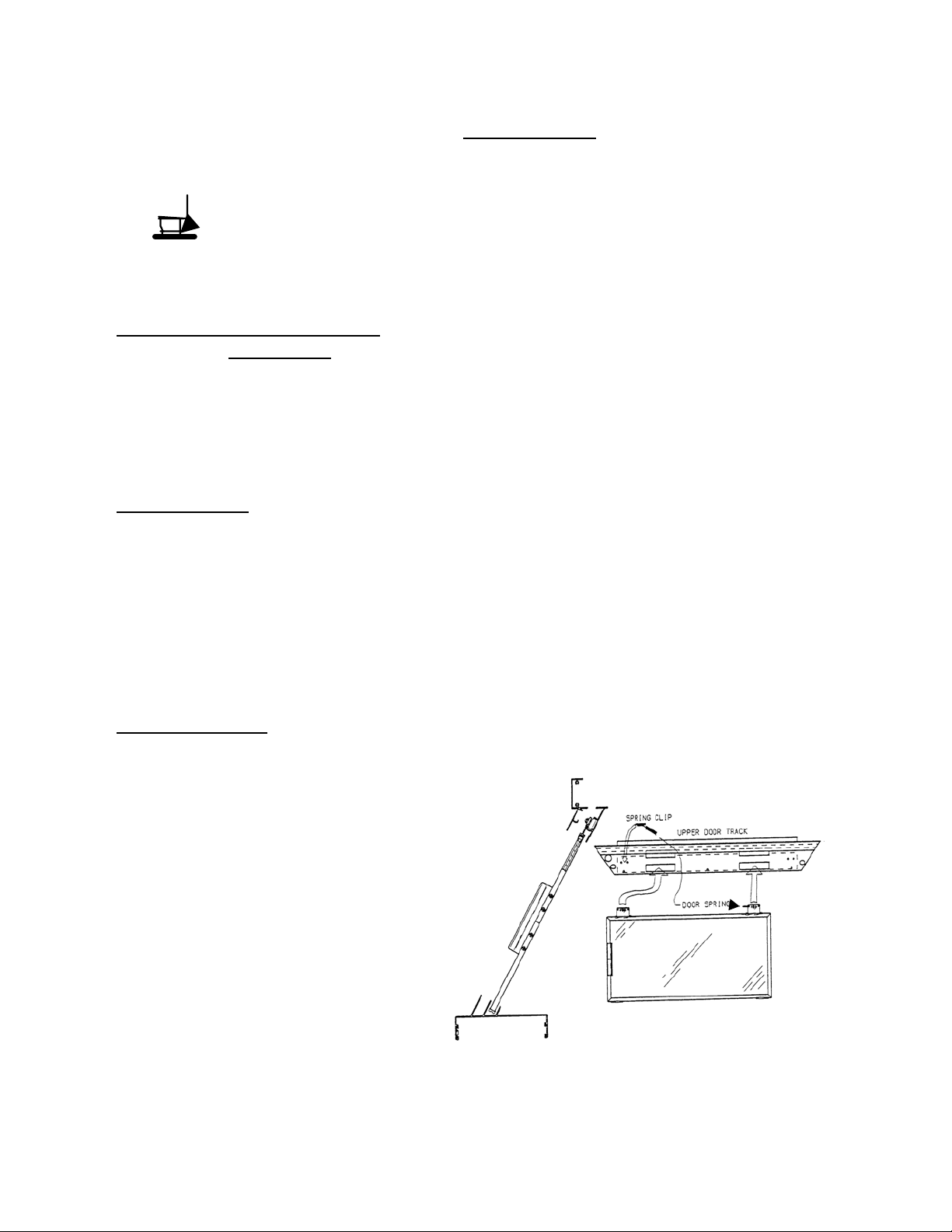

GLASS DOORS –

The doors are made of tempered,

heat reflective glass. The doors mount in

the aluminum top canopy. The bot tom

tr acks are provi ded with wipe outs for

cleaning purposes.

The doors are self-closing and are

supported by rollers that ride on the upper

track. The upper track has cut out areas to

insert the door rollers up into. The door

spring is then slipped over a clip at the end

of the track. Prior to November, 1997 the

upper track also has a ‘bounce back’ spring

mounted to each end to assist the door in

sealing when it closes. There is a thumbscrew on the end of the spring that allows

for adjustment of the amoun t of ‘bounce

back’. Turning the screw ‘in’ will allow

for more ‘ bounce back’.

Cas es produced starting November

1997 eliminate the spring back mechanism

and have rubber channels in the end frames

to grab and seal the door upon cl osing. As

always, proper cleaning of d oor rollers and

tracks is required for proper door operation.

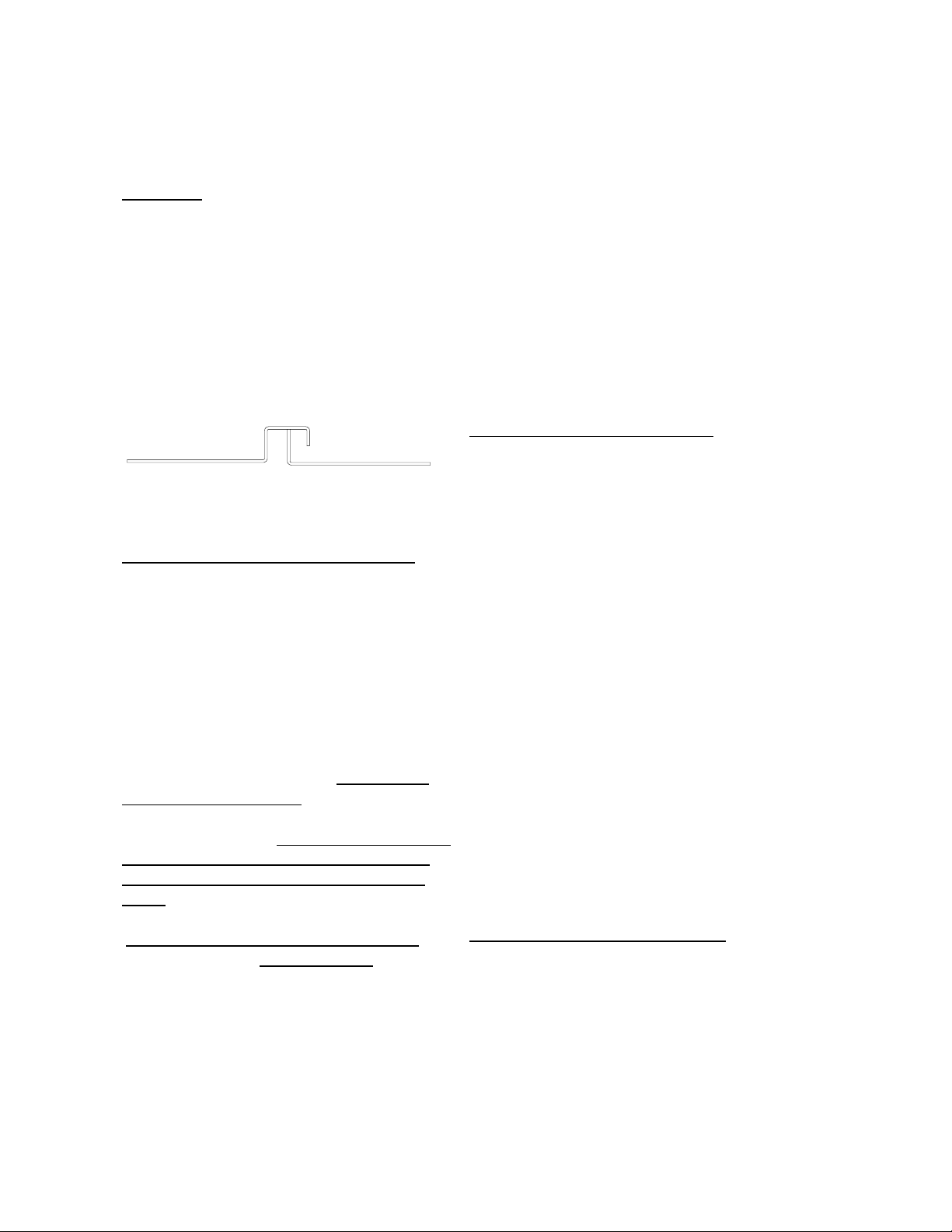

SHELVES

–

The five solid shelves that set

over the evaporator section must be installed

as shown below otherwise the air will not

flow through the cas e and the novelty baskets

will not set in the case correctly.

Example in the diagram below

CABINET AREA

PAN

COIL & FAN AREA

PAN

AIR DISTRIBUTION AND PRODUCT

If desired an optional kit utilizing

twenty-one baskets in place of the fifteen baskets supplied with the cabinet may be ordered. This kit consists of baskets (which are

different size than the fifteen standard ones

supplied with the cabinet) and two shelf covers. The shelf covers, when properly installed over the five solid metal shelves, create a smooth flat surface allowing the use of

additional baskets. When utilizing this kit,

the five solid s helves must be left properly

ins talled as shown above, and the opti onal

covers placed over the shelves with the

formed edges down. If all shelves and covers

are not properly installed, interior airflow

and temperature in the cabinet will be affected.

AIR DISTRIBUTIO N AND PRODUCT

and LOADING

The GIM-6 is a ‘forced-air” cabinet

employing a state-of-the-art honeycomb air

discharge system. Air is discharged from the

honeycomb, flows over the top of the product,

and is returned throug h the return air duct.

The interior of the cabinet has load line

markings showing how high product can be

loaded in the cabinet without affecting the air

curtain. White, epoxy-coated, wire baskets are

provided for the product and they are designed

to fit below the load line. DO NOT LOAD

PRODUCT ABOVE THE LOAD LINE AS IT

WILL ADV ERSE L Y AFFECT CAB INET

TEMPERATURE.

ELE CTRI CA L CONNE CTION S

–

It is very important for safety to you and

your customers to have the cabinet properly

grounded.

The e lectric al installation should be done

by a qualified electrician in accordance with the

National Electrical Code and/or local codes.

NOTE: Connecting this unit to

any electrical supply other than

specified on the serial plate will

void the warranty and may res ult

in serious damage to the unit. The

cabinet should be supplied with its

own service.

Pr ior to performing any s ervice or maintenance on this cabinet, be sure to disconnect the

power supply to the cabinet. Failure to do so

may result in electrical shock and/or serious inju ry .

SERI AL PLAT E I NFORMA TION

–

The serial plate is located in the upper

left hand corner of the case interior. It has all

the pertinent information needed for proper

el ectric al installati on. The serial plate should

not be removed for any reason.

Loading...

Loading...