Page 1

Chromalox

®

DIVISION 4 SECTION

SALES

REFERENCE

DATE

SERVICE REFERENCE

PD447-2

161-304262-001

DECEMBER, 2004

Installation Instructions

(Supersedes PD447-1)

© 2010 Chromalox, Inc.

Replacement Thermal Fuses

For Use on Products Listed in Table Below

Model No. PCN Temp. Products Used on

RFM-EC 360321 All All

Note: Single fuse rated to 240V, 25A cold. Resettable fuse rated to 240 V, 5 A cold.

1

Standard fuse from factory for product types listed in box to right.

2

Resettable fuse is bi-metal switch only and requires connection to Resettable Fuse System Circuitry, model

RFM-EC, PCN 360321 which must be ordered separately. RFM-EC includes Manual Reset, Audible Alarm and

Relay rated to 240 V, 5 Amp.

3

Process temperature of solution must always be a minimum of 30˚F below Fuse Temperature Limit.

4

For fluoropolymer series process temperatures over 180˚F, consult factory. (GTF / GXF Series)

5

For QM Series process temperatures above 230˚F, consult factory.

Resettable Fuse System Circuitry

2

Fuse Temp. Fuse Temp. Lead

Model No. PCN Limit (˚F)

3,4,5

Model No.2PCN Limit (˚F)

3,4,5

Applicable Products Length (in)

F 360330 219 RF 360436 219 18

FM

1

360348 262 RFM 360444 262 GS, GT, GS3, GT3 18

FH 360356 330 RFH 360452 330 18

FT 360364 219 RFT 360460 219

GTF, GTFL, GXF 18

FTM

1

360372 262 RFTM 360479 262

GTF6, GTF9, 18

QM, QM3 18

FL 360399 219 RFL 360495 219 GSL, GTL, 86

FLM

1

360401 262 RFLM 360508 262 GSL3, GTL3, 86

FLH 360410 330 RFLH 360516 330 GSV3, GTV3 86

FLT 224717 219 RFLT 224725 219 GTFL, GXFL, GTFL3 86

Single Use Fuse Resettable Fuse

2

INSTALLATION

ELECTRIC SHOCK HAZARD. Disconnect all power

to heater before replacing Fuse. Failure to do so

could result in personal injury or death.

The thermal fuse device must be properly installed and these procedures must be followed or heater failure or fire may result.

A liquid level control is required as an additional safety fea-

ture to help minimize the possibility of fire.

1. Insure all electrical power to the heater is shut-off.

2. Unscrew the terminal head cover. Remove the wire nuts from

the fuse leads and save for reuse.

3. Remove the sealing material and pull the fuse out of the

well. Save the sealing material for reuse.

4. Check the fuse and the inside of the well for wetness. If

wet, the well must be dried out. We recommend using a heat

gun or hair dryer. Immerse the tube into the solution. If moisture again appears inside the well, DO NOT use the heater!

Call your local Chromalox representative for further advice.

5. If the removed fuse is dry, proceed by using it as a guide to

cut and strip the new fuse lead wires to the correct lengths.

6. Reconnect the fuse leads to the extension leads using the original

wire nuts.

7. Reinsert the fuse into the well making sure it is fully seated to

the bottom of the well.

8. Reseal using the original sealing material or an RTV type

sealant.

9. Replace the head cover, return the heater to the tank.

10. Turn power back on.

Thermal Fuse Temperature System —

Grounded electric immersion heaters are practical, efficient

and safe when used properly and installed in tanks that have proper solution levels, good ventilation, trained operators and safeguards such as liquid level controls and Chromalox thermal fuse

over-temperature sensors.

Chromalox thermal fuse systems help reduce the hazards created

by low liquid levels and when properly seated and wired, they will

cut off the power to the heaters, thus avoiding the high temperatures

resulting if solution levels are low enough to expose heater hot zones.

Page 2

TA - Q0 - EF

Litho in U.S.A.

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

Tank with normal

solution level. System

working normally.

Tank has low solution

level, system shuts

off power to heater.

Alarm sounds. Proper

solution level is restored

and system is reset.

Normal operation

resumed.

THERMAL FUSE INSTALLATION/REPLACEMENT

Single Use System —

Sensor consists of a one-time thermal fuse which is stan-

dard on the over-the-side metal, Teflon

®

and quartz heaters,

and L-shaped metal and Teflon

®

heaters, listed in the table on

page 1.

The thermal fuse is wired in series with the controller. To

operate properly, the fuse must be fully seated to the bottom of

the thermowell tube. When the fuse blows, shut off the main

power to the heater, remove the spent fuse, install the new one,

then refill the tank. Turn power back on. Replacement thermal

devices must be purchased from Chromalox.

Resettable Fuse System —

Sensor consists of a Bi-metallic thermostatic sensor, an

audible alarm, alarm relay, and reset button. This option is

available on metal, Teflon

®

and quartz heaters, as listed in the

table on page 1.

The system operates on the same principle as the single

use fuse except that the sensor does not blow. It operates as

a Bi-metallic thermostat which opens and sounds the alarm.

The reset button must be pushed to re-activate the heater

and control after the solution level in the tank has been

raised to the proper level.

In both of the above cases make sure the

cause of the failure has been determined and

corrected.

Single Use System

Resettable Fuse System

WIRING

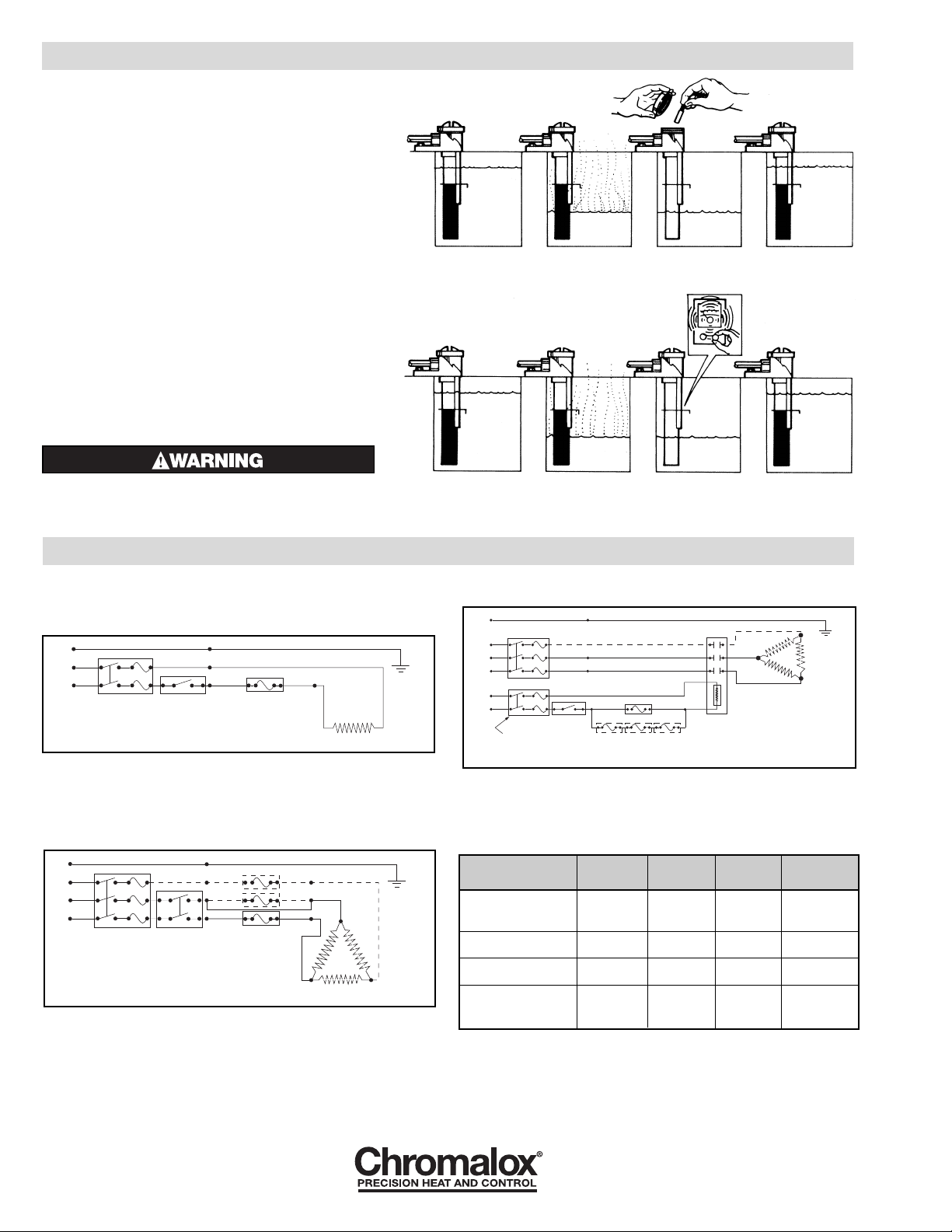

Representative wiring diagrams for heaters with Thermal Fuses —

Single phase heater circuit using a SPST thermostat. Line

Voltage and/or current do not exceed thermostat or thermal fuse

rating (Figure A).

One Single phase heater or (3) single phase heaters equal in

size and each having a thermal fuse wired as a 3 phase heater circuit using a DPST thermostat. Line voltage and current do not

exceed thermostat or thermal fuse(s) rating (Figure B). Dotted

line and L3 indicate 3 phase connections.

Single phase or 3 phase heater circuit. Line voltage and/or

current exceeds thermostat or thermal fuses ratings (Figure C).

Dotted line and L3 indicate 3 phase connections.

Thermal Fuse Electrical and Temperature Ratings —

Electrical Ratings:

Single Use Fuses rated at 25 amps, 240 VAC max.

Resetable Fuses rated at 5 amps, 240 VAC max.

Ground

L2

Thermostat

Thermal Fuses

Black

Black

Green

Fused

Disconnect

(Customer Supplied)

*

*

*

*

*

*

L3

L1

Heater

Black

Figure B

Ground

L2

L1

Thermostat

Thermal Fuse

Heater

Black

Black

Green

Fused

Disconnect

(Customer Supplied)

**

Figure A

Fused Disconnect

(Customer Supplied)

Ground

L3

L2

L1

L2

L1

*

*

Thermostat

Thermal Fuses

Magnetic

Contactor

Black

Black

Heater

Black

Green

Figure C

Tank has low solution level, fuse shuts

off power to heater.

Spent fuse removed,

new fuse installed.

Proper liquid level

restored and normal

operation resumed.

Tank with normal

solution level. Fuse

system on heater

working normally.

Heater

Single Use Reset

Temp.

Process

Wire Color Wire Color Temp.

GS, GT,

White White 219 <180

GS3, GT3

Blue Blue 262 <230

Red Red 330 <300

QM, QM3

Red White 219 <180

Blue Blue 262 <230

GTF, GTFL, GXF, GXFL

Red White 219 <180

GTF6, GTF9, GTFL3

GSL, GTL or White White 219 <180

GSL3, GTL3 or Blue Blue 262 <230

GSV3, GTV3 Red Red 330 <300

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...