Hussmann ESC Installation And Operation Manual

Manual

Installation

& Operation

/Chino

ESC

REV. 0303

DELI/MEAT/FISH SERVICE CASE

ESC

DELI/MEAT/FISH SERVICE CASE

P/N IGSV-ESC-0303

INSTALLATION & OPERATION GUIDE

General Instructions

Ta b l e of Contents

General Instructions ................................................. 2

SHIPPING DAMAGE............................................................................................... 2

Important Information ............................................. 3

Cut & Plan Views ....................................................... 4

Installation ................................................................. 5

LIFT-UP GLASS RE-ADJUSTMENT .......................................................................... 5

LEVELING.............................................................................................................. 5

Glass Adjustment ...................................................... 8

Plumbing .................................................................... 9

WASTE OUTLET AND P-TRAP .............................................................................. 9

Manifold Flush System ............................................. 9

Humidity System ...................................................... 10

Refrigeration ............................................................. 12

T-STAT LOCATION.................................................................................................. 12

Electrical .................................................................... 13

WIRING COLOR CODE ......................................................................................... 13

ASHRAE COLOR CODE .......................................................................................... 13

Finishing Touches ...................................................... 14

JOINT TRIM........................................................................................................... 14

User Information ...................................................... 15

STOCKING.............................................................................................................. 15

CASE CLEANING.................................................................................................... 15

Lift Up Glass .............................................................. 17

Maintenance .............................................................. 23

ELECTRICAL PRECAUTIONS ................................................................................... 23

REPLACING FLUORESCENT LAMPS ....................................................................... 23

TIPS & TROUBLESHOOTING ................................................................................. 23

Case Specifications ................................................... 24

Electrical Schematics ............................................... 25

Appendices ................................................................ 36

APPENDIX A. – Temperature Guidelines ............................................................ 36

APPENDIX B. – Application Recommendations .................................................. 36

APPENDIX C. – Field Recommendations -......................................................... 36

APPENDIX D. – Recommendations to user - .................................................... 37

IGSV-ESC-0303

THIS BOOKLET CONTAINS INFORMATION ON:

ESC: European-style Refrigerated Service Case for Deli,

Meat, Fish, and matching Refrigerated Wedges.

**NOTE: Be sure to read the “Important Information”

secion for proper case operation, before loading the

merchandiser.

SHIPPING DAMAGE

All equipment and separately packaged accessories

should be carefully removed, and thoroughly examined

for shipping damage during unloading. This equipment

has been carefully inspected at our factory, and the

carrier has assumed responsibility for it's safe arrival.

If it is indeed damaged, either apparent or concealed a claim must be filed with carrier. If there is obvious loss

or damage, it must be noted on the freight bill or

express receipt, and signed by the carrier’s agent;

otherwise, carrier may refuse claim. The carrier will

supply the necessary claim forms. When loss or damage

is not apparent until after all equipment is uncrated, a

claim for concealed damage is made. Make request in

writing to carrier for inspection within 15 days. Retain

all packaging. The carrier will supply inspection report

and required claim forms. Check your shipment for any

possible shortages of material. If a shortage should exist

and is found to be the responsibility of Hussmann Chino,

notify Hussmann Chino. If such a shortage involves the

carrier, notify the carrier immediately and request an

inspection. Hussmann Chino will acknowledge shortages

within ten days from receipt of equipment.

HUSSMANN CHINO PRODUCT CONTROL

The serial number and shipping date of all equipment

is recorded in Hussmann's files for warranty and

replacement part purposes. All correspondence

pertaining to warranty or parts ordering must include

the serial number of each piece of equipment involved,

in order to provide the customer with the correct parts.

Keep this booklet with the case at all times for future reference.

/Chino

A publication of

Hussmann® Chino

13770 Ramona Avenue • Chino, California 91710

(909) 628-8942 FAX

(909) 590-4910

(800) 395-9229

The Hussmann warranty is printed in the back of

this guide.

2

Rev. 0303

Important Information

The ESC service cases are easy to work, attractive

merchandising display cases capable of maintaining superb

product quality, with the installation of the proper

controlling devices. These should be set according to the

manufacturer’s specifications and combined with a properly

maintained humidity system. Incorrect settings and failure

to maintain the humidity system will result in short product

life from dehydration, shrinkage and discoloration. Below

are a few guidelines to ensure optimum performance and

product life.

•Review the Case Specification in this book to verify

thermostat setting. Do not set temperature too cold,

as this causes product dehydration.

•Temperatures should be achieved by a t-stat and

suction solenoid at each case. Do not use EPR valves,

liquid line solenoids or electronic control devices of

any kind. These controls allow temperature

swings causing product dehydration and

excessive energy consumption.

•Defrost cycles should be set according to the Case

Specifications in this book

•Clean humidity system a minimum of every 90 days

for proper system operation.

•Work and rotate product – not to exceed a four (4)

hour period.

•At night turn off case lights and cover product with

moistened cheesecloth or fabric towels.

•Keep meat holding box at 32°.

•Keep meat prep room refrigerated at 55°.

• Meat bloom box (if applicable) should be at 36°.

• Meat must enter the case at 40° or below. Product

deterioration is very rapid above 40°.

•Maintain sanitary conditions throughout the meat

holding, prep and working areas.

•Do not display product directly within the air

discharge.

• Turn and rotate the meat. The blood which

gives the pink color works down in time which

causes surface discoloration and dehydration.

When turned before this condition occurs the

other side is kept in good color (bloom)

condition. The meat can even be turned (3)

three and (4) four times.

• It is not required at night to remove the

product from the case. Turn the lights off at

night and cover the product. We recommend

you use a moistened cheesecloth or towels.

This helps slow down the product dehydration

process by taking the moisture from the cloth

and not from the product. This is an old

method that meat shops have used for many

years. It works and helps to gain extended

product life.

• Cold coils remove heat and moisture from the

case and deposit it as frost on the coil. Thus a

defrost is required to remove this frost. Our

humidity system adds moisture to the case and

helps slow down the dehydration process. The

only other moisture in the case is in the

product. A single level of meat in a case will

dry out much faster than a fully loaded case

with three to four levels of meat.

• The colder the case, the faster the product

loses its moisture and shelf life. It is very

important to maintain a constant even

product temperature (see Case

Specifications).

3

Light

IGSV-ESC-0303

Cut & Plan Views

1

2

3

/

4

"

6"

Optional St. Steel Slanted

Deck Pan (Meat/Fish)

/8"

3

36"

1/4"

7

(4 1/4")

45

"

8

/8"

1

1

11

1

10

/2"3

43

1"

5

/8"

1

2

ESC

Service

Scale = 1/2"

8"

8"

DRAIN

MECHANICAL

STUB UP AREA

19" X 19"

1" 1"

CASE FRONT

8'-2"

(VARIABLE LENGTHS)

WATER,

ELEC. &

REFRIG.

MECHANICAL

STUB UP AREA

19" X 19"

ESC

Plan View

Scale = 1/4"

1

1

C

S

E

le

b

ria

a

V

s

th

g

n

e

L

FRONT

30° INSIDE WEDGE

Light

6

1

/4"

7

6

/4")

1

(4

Raceway

1

/4"

"

Water

Optional St. Steel

Slanted Deck

/8"

3

Pan (Meat/Fish)

36"

34

PEDESTAL

OPTION

/4"

1

11

/2" 26"

43

5

/8"

ESC

Pedestal Option

Scale = 3/8"

"

8

/

5

43

3

1

3

"

1

4

/

/

4

"

R

L

ESC

Var i

able

Lengths

"

4

/

3

ESC

3

Var i

able

4

"

4

/

3

3

4

Lengths

1

1

L

3

/

4

"

FRONT

C

S

E

le

b

ria

a

V

s

th

g

n

e

L

R

3

"

4

/

1

1

30° OUTSIDE WEDGE

"

3

4

/

7

1

L

C

S

E

e

l

b

a

i

r

"

s

a

h

V

t

4

g

/

n

e

L

3

3

4

FRONT

45° INSIDE WEDGE

4' - 11 1/4"

"

4

/

3

17

L

ESC

Var iable

Lengths

23

FRONT

INSIDE WEDGE

C

90°

1

7

3

/

4

"

R

E

S

C

V

a

r

i

a

b

L

l

e

e

n

g

t

h

s

E

S

C

V

a

r

i

a

b

L

l

e

e

n

g

t

h

s

R

L

1

7

3

FRONT

3

4

/

/

7

4

"

1

4

3

3

/

4

"

C

S

E

e

l

b

a

i

r

s

a

h

V

t

g

n

e

L

"

45° OUTSIDE WEDGE

17

3

/

4

"

R

ESC

Var iab le

Lengths

"

43

ESC

Var iab le

Lengths

17

"

4

/

3

3

/

4

"

1

/2"

10

L

46"

FRONT

ESC

Var iab le

Lengths

C

R

"

4

/

3

17

90° OUTSIDE WEDGE

4

Rev. 0303

Installation

LOCATION

The refrigerated merchandisers have been designed for

use only in air conditioned stores where temperature and

humidity are maintained at or below 75°F and 55% relative humidity. DO NOT allow air conditioning, electric fans,

ovens, open doors or windows (etc.) to create air currents around the merchandiser, as this will impair its correct operation.

Product temperature should always be maintained at a

constant and proper temperature. This means that from

the time the product is received, through storage, preparation and display, the temperature of the product must

be controlled to maximize life of the product.

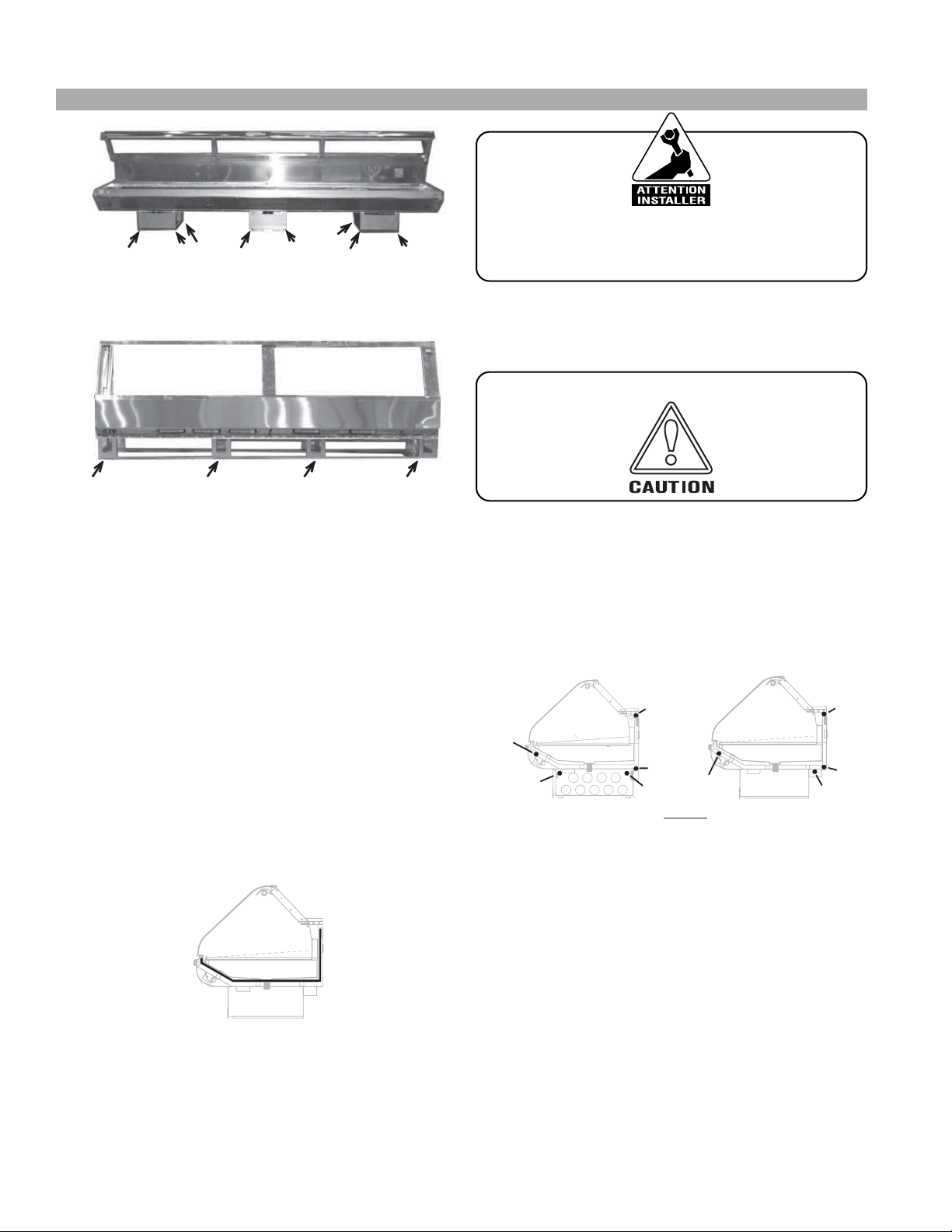

UNCRATING THE STAND

Place the fixture as close to its permanent position as

possible. Remove the top of the crate. Detach the walls

from each other and remove from the skid. Unbolt the

case from the skid. The fixture can now be lifted off the

crate skid. Lift only at base of stand!

NSF7 APPROVED CASES

Cases with the NSF7 are rigidly inspected by our Quality

Control inspectors during construction. The cases are then

temperature and performance tested for 24 hours prior

to shipment.

EXTERIOR LOADING

These models have not been structurally designed to sup-

port excessive external loading. Do not walk on their

tops; This could cause serious personal injury and damage to the fixture.

SETTING AND JOINING

The sectional construction of these models enable them

to be joined in line to give the effect of one continuous

display. A joint trim kit is supplied with each joint.

LIFT-UP GLASS RE-ADJUSTMENT

In addition to verifying that the Allen screws on the lift-up

glass are tightened when the case is delivered, recheck

the Allen screws on the glass ONCE THE CASE IS

IN FULL OPERATION AND BROUGHT TO TEMPERATURE.

Temperature changes can affect the size and shape of the

materials involved, and can cause changes in the secure fit

of the glass and the clamp.

BACK AND SIDE TO SIDE PRIOR TO JOINING. A LEVEL CASE IS NECESSARY TO INSURE PROPER OPERATION, WATER

DRAINAGE, GLASS ALIGNMENT, AND OPERATION OF THE HINGES SUPPORTING

THE GLASS. LEVELING THE CASE CORRECTLY WILL SOLVE MOST HINGE OPERATION PROBLEMS.

NOTE: A. To avoid removing concrete flooring, begin lineup

leveling from the highest point of the store floor.

B. When wedges are involved in a lineup, set them first.

All cases were leveled and joined prior to shipment to

insure the closest possible fit when cases are joined in the

field. When joining, use a carpenters level and shim legs

accordingly.

where support is best, to prevent damage to case.

1. Using case blueprints, measure off and mark on the

floor the exact dimensions of where the cases will

sit. Snap chalk line for front and back positions of

base rail or pedestal. Mark the location of each joint

front and back. Find the highest point throughout

the lineup. FLOORS ARE NORMALLY NOT LEVEL!

Determine the highest point of the floor; cases will

be set off this point. All cases in the entire lineup

must be brought up to the highest level of the case

sitting at the highest point in the lineup. This may be

done a few different ways. 1) Walk the floor looking

for any mounds or dips. 2) Use a string level. 3) Use a

transit. Mark the difference and place the appropriate number of shims required to maintain high-point

level. If a wedge is used in the middle of a lineup, the

wedge must be set of the highest point on the floor

FIRST, with the rest if the lineup being leveled from

it.

NOTE; Pedestals must be shimmed individually

under each corner of the pedestal.

Case must be raised correctly, under legs

LEVELING

IMPORTANT! IT IS IMPERATIVE THAT

CASES BE LEVELED FROM FRONT TO

5

Installation cont’d

Shim standard cases in the middle, and at all other

points under the case along the rail as needed

(depending on case length).

IGSV-ESC-0303

It is the contractor’s responsibility to install

case(s) according to local construction and

health codes.

6. Slide second case up to first case snugly. Then level

second case to the first case so glass front, bumper

and top are flush.

Shimming the cases helps avoid case sag and poor

glass alignment.

2. Set first case, and adjust legs over the highest part of

the floor so that case is level. Prevent damage – case

must be raised under leg or by use of 2x6 or 2x4 leg

brace. Remove side and back leg braces after case is

set.

3. Set second case as close as possible to the first case,

and level case to the first using the instructions in

step one.

4. Apply masking tape 1/8" in from end of case on

inside and outside rear mullion on both cases to be

joined.

5. Apply liberal bead of case joint sealant (butyl) to first

case. Sealant area is shown using a dotted line in

illustration in Step 8. Apply heavy amount to cover

entire shaded area.

DO NOT USE PERMAGUM!

Do not use cam locks to pull cases together.

7. To compress butyl at joint, use two Jurgenson wood

clamps. Make sure case is level from front to back

and side to side on inside bulkheads at joint.

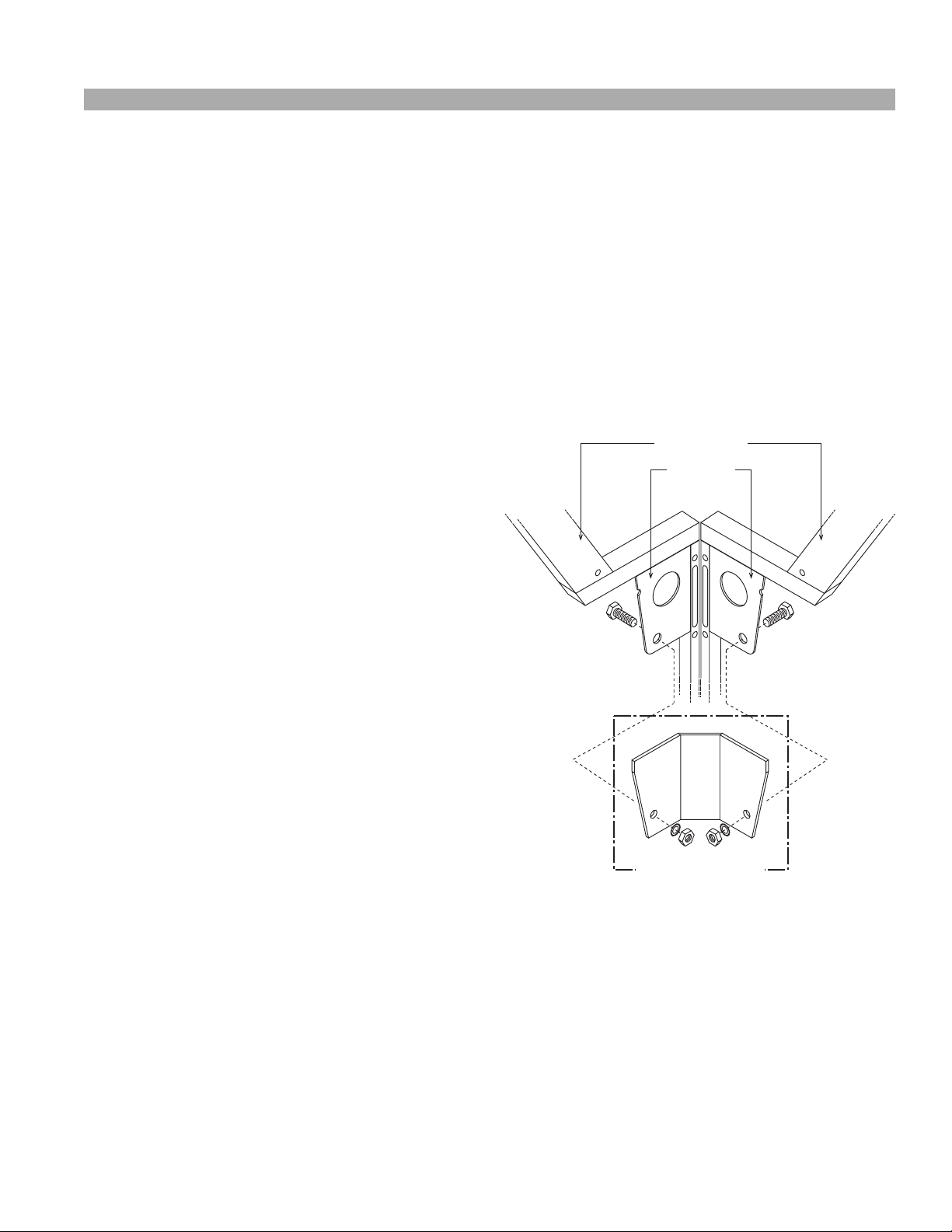

8. Attach sections together via the camlocks pictured

in the illustration below.

A,B

B

A,C,D,E

A,C,D,E

D

Optional St. Steel

Slanted Deck Pan

(Meat/Fish)

A,B,D

A,B,D

A,C,D,E

C,E

LEGEND

A = Straight Case

B = Inside Wedges

°

Wedges

C = 45

D = 30

°

Outside Wedges

°

Outside Wedges

E = 90

9. Apply bead of butyl to top of bulkheads and slip on

stainless steel bulkhead cap. Also apply butyl to

seam between overhead light tubes.

10. VERY IMPORTANT! Apply liberal amounts of

black butyl to area under interior lower legs and fill

all voids down to bulkhead.

11.Use finger to smooth butyl as thin as possible at

masking tape on inside and outside of rear mullion

6

Rev. 0303

Installation cont’d

(apply additional butyl if necessary). Remove tape

applied on line #3.

INSIDE REFRIGERATED WEDGES

Line up taper pins with holes on adjoining case. Turn camlock to lock in. Two camlocks are located at the rear of

the case behind the air discharge and behind the lower

electrical raceway access panel. Bolt the wedge into the

adjoining case in the front. If the adjoining case is refrigerated, the bolt is located under the pans in the front. When

the adjoining case is a hot case, the cases are bolted together by mans of a bracket located behind the front panel.

Remove the front panel by lifting it up and out.

COMMON END BETWEEN UNLIKE CASES AND HOT

CASES

Bolt the end onto the case using the bolts provided in

predrilled holes behind the front of the panel through the

bracket provided and in the rear behind the rear access

panel on the bottom Common ends between refrigerated

cases are also bolted together behind the air discharge

panel. Remove the discharge panel by lifting up and out.

Hot case are only bolted in two places. IN the rear of the

case, behind the access panel and in the front of the case

behind the front panel.

OUTSIDE REFRIGERATED WEDGE:

Ta per pin and camlock locations are the same as a standard case.

INSIDE DRY WEDGES

Bolt the wedge into the sides of the adjoining case. Use

the bolts provided

INSIDE PEDESTAL WEDGES

Set the wedge on adjoining case’s mounting brackets located at the base of the unit, and bolt down. Drive screws

provided through the sides of the wedge (4 screws per

side), accessible through the back of the wedge.

1. Secure the joint backer located behind the cart

bumper support at the joints. To adjust the front

panel. Loosen the screws holding the bumper on the

case on either side the joint, and slide the extrusion

to the center of the joint.

2. Starting from a center case in a lineup or a wedge,

align front panels. Front panels can be loosened and

adjusted laterally by loosening the screws holding

the case bumper channel

**NOTE: Be sure to read the “Important Information” Section

for proper case operation, before loading the merchandiser.

LIFT-UP GLASS RE-ADJUSTMENT

In addition to verifying that the Allen screws on the lift-up

glass are tightened when the case is delivered, recheck

the Allen screws on the glass ONCE THE CASE IS

IN FULL OPERATION AND BROUGHT TO TEMPERATURE.

Temperature changes can affect the size and shape of the

materials involved, and cas cause changes in the secure fit

of the glass and the clamp.

ARM STRUT

GUSSET

WEDGE BRACKET

Corner wedges are attached via front and rear camlocks.

Use a 7mm allen wrench to turn the locks. Do not overtighten! Join the top by using a joint bracket (included in

joint kit) with 3/8" bolts.

7

ESC Glass Adjustment

NOTE: Before making any of the recommended adjustments,

Verify that the case(s) have been leveled properly.

IGSV-ESC-0303

Glass Adjustment

Tech/glassadj/970602 tn

Adjust glass Up and Down

(vertically)

A

Adjust glass Front to Back

B

Adjust glass Side to Side

(horizontally)

C

1. Remove 2. Remove 3. Loosen front 4. Turn height adjustment screw 5. Check alignment

rear prep galvanized locking screw to raise and lower mullion. and retighten

ledge. sub top. ONLY! (1/8" set screw) front locking

1. Remove 2. Loosen front 3. Loosen back 4. Back out 5. Slide the mullion arm

rear prep locking screw locking screw height adjustment forward or backward

ledge and FIRST! SECOND! screw, until arm by moving the mullion

remove (5/16" flat head). (5/16" flat head). bottoms out on structure itself.

galvanized the gusset bracket Max travel = 5/8"

sub top COUNT # of turns!

(see above). (1/8" set screw).

6. Restore the height adjustment screw

to original position (from step 4)

and verify glass alignment.

Retighten

from step 1.

1. Open glass 2. Back out 3. Slide glass

panel. all the set screws in desired direction.

Relieve the along the top

tension on edge of the glass

the hinge. panel to open clamp.

rear then front lockings screws

(3mm set screw)

(5/16"x1.25" Max travel = 1/4" screw and re Flat head). CW – mullion up, install removed

Back

of Case

CCW – mullion dwn. components.

Mullion

Structure

(Case arm)

Inside

of Case

IMPORTANT

PVC

U-channel

CUT VIEW:

rear ledge

and glass

adjustment

screws

LIFT-UP GLASS RE-ADJUSTMENT

In addition to verifying that the Allen screws on the lift-up glass are tightened when the case is delivered, recheck the Allen

screws on the glass ONCE THE CASE IS IN FULL OPERATION AND BROUGHT TO TEMPERATURE.

Te mperature changes can affect the size and shape of the materials involved, and can cause changes in the secure fit of the

Technical Support: 800-395-9229

®

/CHINO

glass and the clamp.

8

Rev. 0303

Plumbing

WASTE OUTLET AND P-TRAP

The waste outlet is located off the center of the case on

one side allowing drip piping to be run lengthwise under

the fixture.

A 1-1/2" P-trap and threaded adapter are supplied with

each fixture. The P-trap must be installed to prevent air

leakage and insect entrance into the fixture.

NOTE: PVC-DWV solvent cement is recommended.

Follow the manufacturer’s instructions.

INSTALLING CONDENSATE DRAIN

Poorly or improperly installed condensate drains can seriously interfere with the operation of this refrigerator,

and result in costly maintenance and product losses. Please

follow the recommendations listed below when installing

condensate drains to insure a proper installation:

1. Never use pipe for condensate drains smaller than

the nominal diameter of the pipe or P-trap supplied

with the case.

2. When connecting condensate drains, the P-trap

must be used as part of the condensate drain to

prevent air leakage or insect entrance. Store plumbing system floor drains should be at least 14" off the

center of the case to allow use of the P-trap pipe

section. Never use two water seals in series in any

one line. Double P-traps in series will cause a lock

and prevent draining.

3. Always provide as much down hill slope (“fall”) as

possible; 1/8" per foot is the preferred minimum.

PVC pipe, when used, must be supported to maintain the 1/8" pitch and to prevent warping.

4. Avoid long runs of condensate drains. Long runs

make it impossible to provide the “fall” necessary for

good drainage.

5. Provide a suitable air break between the flood rim of

the floor drain and outlet of condensate drain. 1" is

ideal.

6. Prevent condensate drains from freezing:

a. Do not install condensate drains in contact with

non-insulated suction lines. Suction lines should be

insulated with a nonabsorbent insulation material

such as Armstrong’s Armaflex.

b. Where condensate drains are located in dead air

spaces (between refrigerators or between a

refrigerator and a wall), provide means to prevent

freezing. The water seal should be insulated to

prevent condensation.

Manifold Flush System

GENERAL DESCRIPTION

Tw ice a day for two (2) minutes, a high pressure water

stream will flush most residue build-up from the bottom

of the manifold chamber. This is the area that residue builds

and expands from. Frequency of this periodic maintenance

will vary depending on water mineral content and sanitary conditions.

AUTOMATIC FLUSH SYSTEM

Electrical components are located within the electrical

raceway. Electrical components in this area are 115V AC.

Water flow for flush system is rated at 0.25 GPM at 60PSI

water pressure. Flush nozzles are located in the front of

the case.

BASIC SYSTEM OPERATION:

1. Filtered water is supplied to the 115V solenoid valve.

2. At a time of day determined by you, the 115V time

clock will energize the solenoid for 2 minutes.

START UP:

1. Manually move time clock to initiate a flush cycle.

2. Observe that flush nozzle is spraying down center of

manifold chamber.

3. Set clock to correct time of day.

4. Set trip pins to the “time of day system is to flush”

(NOTE: 2 flush/day!)

MANUAL FLUSH SYSTEM

Water valve is located on the outside of the case, in the

rear, on the left hand side as viewed from the rear.

BASIC SYSTEM OPERATION:

1. Open the water valve to allow the flush system start.

It is recommended that the case is flushed two (2) times

daily for two (2) minutes.

MAINTENANCE:

Perform maintenance when servicing humidity system.

9

Humidity System

IGSV-ESC-0303

GENERAL DESCRIPTION

One contributor to the spoilage of fresh meats is dehydration, which causes loss in weight and volume (shrinkage) and product discoloration. As the refrigeration system removes heat from the case, it also removes critical

moisture from the air, and any unwrapped products in

the case. The Humidity System replaces the moisture in

the air, in order to compensate for the moisture taken

by the refrigeration system, and disposed of down the

drain line. The system is built into the discharge plenum,

and mixes moisture laden air with refrigerated air before the air is passed through - and around the product.

The system is constructed almost entirely of PVC pipe,

and uses air that is subcooled to approximately the same

temperature as the case. The sub-cooling of air inhibits

the formation of growth found to be a problem in other

humidification systems. Maintenance is almost unnecessary if you follow a few simple rules:

1. Keep the case clean.

2. Keep the water filter clean, and change it every 6-12

months or sooner, depending on the kind of water found

in your area.

3. Flush the header every 6 months, by loosening the

connecting “L”, then removing it from the case, and flushing with a hose.

**IMPORTANT INFORMATION**

The ESC is capable of maintaining superb product quality with the installation of the proper controlling devices. These devices should be set according to the

manufacturer’s specifications. The humidity system should

be properly maintained. Incorrect settings and failure to

maintain the humidity system will result in short product life. Below are a few guidelines for optimum performance and product life:

• Set thermostat to cut in at the discharge temperature designated in the case specifications section

of the appropriate installation guide or spec. sheet.

Maintain the recommended product temperature

for Deli, Meat, and Fish. DO NOT set temperature

too cold, as this causes product dehydration.

•Temperatures should be achieved by means of a TStat and Suction Solenoid at each case. DO NOT

use EPR valves, Liquid Line Solenoids, or electronic

control devices of any kind. These controls allow

temperature swings that cause dehydration and

excessive energy consumption.

• Set defrost cycles as listed in the Case Specifications Data for your particular case. The number of

defrosts per day should never change. The duration of the defrost cycle may be adjusted to meet

conditions present at your location.

•Clean humidity system a minimum of every 90 days

for proper system operation.

•Work and rotate product - not to exceed a 4-hour

period.

•At night, turn off case lights, and cover unwrapped

product with moistened cheesecloth or fabric

towels.

•Keep meat holding box at 32°F

•Keep meat prep room refrigerated at 55°F

• Meat Bloom Box (if applicable) should be at 36°F

• Meat must enter the case at 40°F or below. Product

deteriorates rapidly above 40°F.

•Clean sanitary conditions throughout the meat

holding, prep, and work areas.

• Do not display product directly within the air

discharge

•Turn and rotate meat. The blood works down

through the meat over time, which causes the top

surface to discolor and dehydrate. Turn meat 3-4

times.

• It is not required to remove product from case

overnight. Turn off case lights, and cover product

with moistened cheesecloth or fabric towel. This

helps slow down product dehydration, by taking

moisture from the cloth and not the product. This is

an old method used by meat shops for many years,

as it extends product life.

• Cold coils remove heat & moisture from the case

and deposit this as frost onto the coil. Thus a defrost

is required to remove this frost. Our humidity

system induces moisture into the case, and helps

slow down the dehydration process. The only other

moisture in the case is that which is in the product. A

single level of meat will dry out faster than a fully

loaded case with 3-4 levels of meat.

• The colder the case, the faster the product loses its

moisture and shelf life. It is very important to

maintain a constant, even, correct, product temperature.

10

Rev. 0303

Humidity System, cont’d

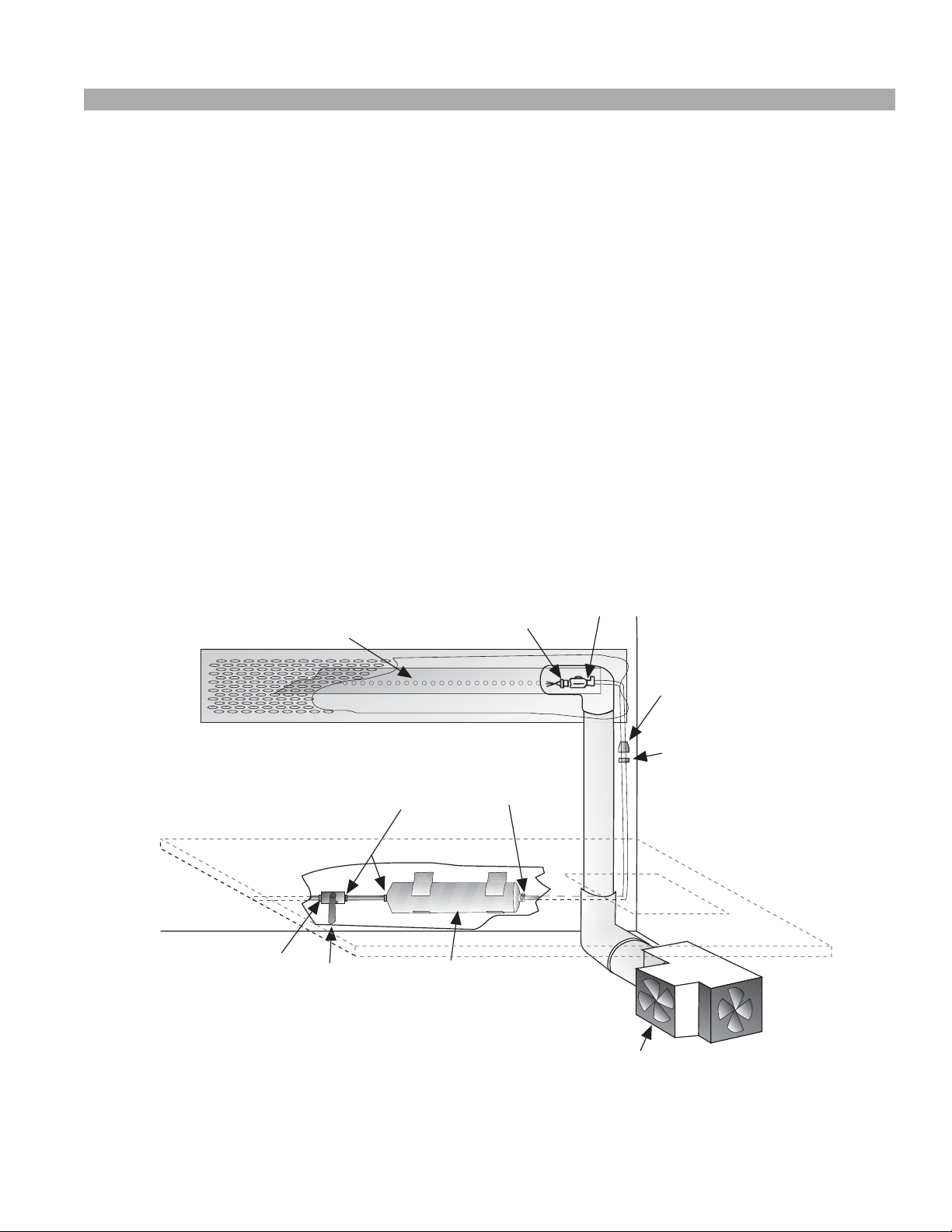

HUMIDIFICATION SYSTEM HOOKUPS

Remove the raceway panel on the lower back of the case.

The pre-piped water shut-off valve and the water filter

are located on the left hand side of the case. The water

line (which is a 1/4" OD copper fitting) can be connected

to the ball shut-off valve, by means of a compression fitting (supplied). The line should be one size larger than the

supply line. The line can then be run from one case to

another from within the raceway(s) using Tee connectors.

Before connecting the water to the humidity system, it is

best to purge the line to flush any debris that may clog the

water filter. If the water line requires purging after the

cases are hooked together, it is not necessary to check

each one. Simply shut ball valves to each humidity system,

remove the water line from the last case in the flow, and

purge. By doing this as a precautionary measure, you may

avoid problems and repeat servicing.

START-UP

Turn on the fan circuit. Check to see if the fan for the

humidity system is running. Remove the right hand bottom pan (when facing the front of the case), then the TXV

cover. The fan is located up against the right hand side of

for proper system operation.

SPRAY HEADER

RUNS LENGTH

OF CASE

SCOTTDALE NOZZLE

225-01-2089A

the case, as viewed from the front, under the fan plenum

(see diagram). View the blade, and make sure the fan rotation agrees with the air flow arrows. Turn on the water, by

turning the ball valve in the direction of the flow (OFF is

at 90° to the direction of flow).

After a few minutes, Check the spray header by removing

the discharge air grill located on the right hand side of the

case (when viewed from the rear), by lifting the 4'-0" section of grill by both ends, until the bottom clears. Pull up

and set aside. The spray header will be exposed. Grasp the

header and pull it loose from the 90° “L” until you see the

misting nozzle, which should be spraying. If not, check the

following:

1. Make sure the water is feeding the nozzle

2. Remove the nozzle, and purge the water

3. Check strainer at entrance to nozzle

Reinsert the header into the 90° “L”, making sure that the

nozzle is in the center of the pipe when totally inserted,

and the holes in the header are facing the front of the case

at a level angle.

MAINTENANCE

•Clean humidity system a minimum of every 90 days

1/4" 100 X 1/8FPT

SW ADAPTER

REAR INTERIOR WALL OF CASE

VIEWED FROM FRONT

1/4"MPT X 1/4" COMP

PVC ADAPTER

225-01-2026

WATER

SUPPLY

1/4"MPT X 1/4" OD

COMP ADAPTER

225-01-1312

BALL VALVE

HAMMON

225-01-2026

WATER FILTER

3 STAGE #00015

225-01-3047

2ND FAN USED

IN 12' CASE

HUMIDITY SYSTEM as viewed from the front.

Note: The axial fans included in the humidity system must be replaced as a unit.

1/4" OD X 1/8" FPT

SW ADAPTER

225-01-3059

1/8" MPT X 1/4" COMP

PVC ADAPTER

225-01-3059

PAN AND

ACCESS PANEL

3" AXIAL FAN

225-01-2026

11

Refrigeration

REFRIGERANT TYPE

The standard refrigerant will be R-22 unless otherwise

specified on the customer order. Check the serial plate

on the case for information.

PIPING

The refrigerant line outlets are located under the case.

Locate first the electrical box, the outlets are then on the

same side of the case but at the opposite end. Insulate

suction lines to prevent condensation drippage.

REFRIGERATION LINES

LIQUID SUCTION

3/8" O.D. 5/8" O.D.

NOTE: The standard coil is piped at 5/8" (suction); however,

the store tie-in may vary depending on the number of

coils and the draw the case has. Depending on the case

setup, the connecting point in the store may be

5

/8", 7/8", or 11/8". Refer to the particular case you are

hooking up.

Refrigerant lines should be sized as shown on the refrigeration legend furnished by the store.

Install P-traps (oil traps) at the base of all suction line vertical risers.

Pressure drop can rob the system of capacity. To keep the

pressure drop to a minimum, keep refrigerant line run as

short as possible, using the minimum number of elbows.

Where elbows are required, use long radius elbows only.

CONTROL SETTINGS

See the “Case Specs” section of this guidebook for the

appropriate settings for your merchandiser. Maintain these

parameters to achieve near constant product temperatures. Product temperature should be measured first thing

in the morning, after having been refrigerated overnight.

For all multiplexing, defrost should be time terminated.

Loadmaster valves are not recommended. Defrost times

should as directed in the Case Specifications section of

this guide. The number of defrosts per day should never

change. The duration of the defrost cycle may be adjusted

to meet conditions present at your location.

ACCESS TO TX VALVES & DRAIN LINES

MECHANICAL - Remove product from end of case. Remove

product racks. Remove refrigeration and drain access panels

(labeled). TX valve (mechanical only) and drain are located

under each access panel at end of the case.

ELECTRONIC - The Electronic Expansion valve master and

slave cylinder(s) are located within the electrical access

panel(s).

ELECTRONIC EXPANSION VALVE (OPTIONAL)

A wide variety of electronic expansion valves and case

controllers can be utilized. Please refer to EEV and controller manufacturers information sheet. Sensors for elec-

IGSV-ESC-0303

tronic expansion valves will be installed on the coil inlet,

coil outlet, and in the discharge air. (Some supermarkets

require a 4th sensor in the return air). Case controllers

will be located in the electrical raceway or under the case

THERMOSTATIC EXPANSION VALVE LOCATION

This device is located on the same side as the refrigeration stub. A Sporlan balanced port expansion valve model

is furnished as standard equipment, unless otherwise specified by customer.

EXPANSION VALVE ADJUSTMENT

Expansion valves must be adjusted to fully feed the evaporator. Before attempting any adjustments, make sure the

evaporator is either clear or very lightly covered with frost,

and that the fixture is within 10°F of its expected operating temperature.

MEASURING THE OPERATING SUPERHEAT

1. Determine the suction pressure with an accurate

pressure gauge at the evaporator outlet.

2. From a refrigerant pressure temperature chart,

determine the saturation temperature at the

observed suction pressure.

3. Measure the temperature of the suction gas at the

thermostatic remote bulb location.

4. Subtract the saturation temperature obtained in step

No. 2 from the temperature measured in step No. 3.

3. The difference is superheat.

5. Set the superheat for 5°F - 7°F.

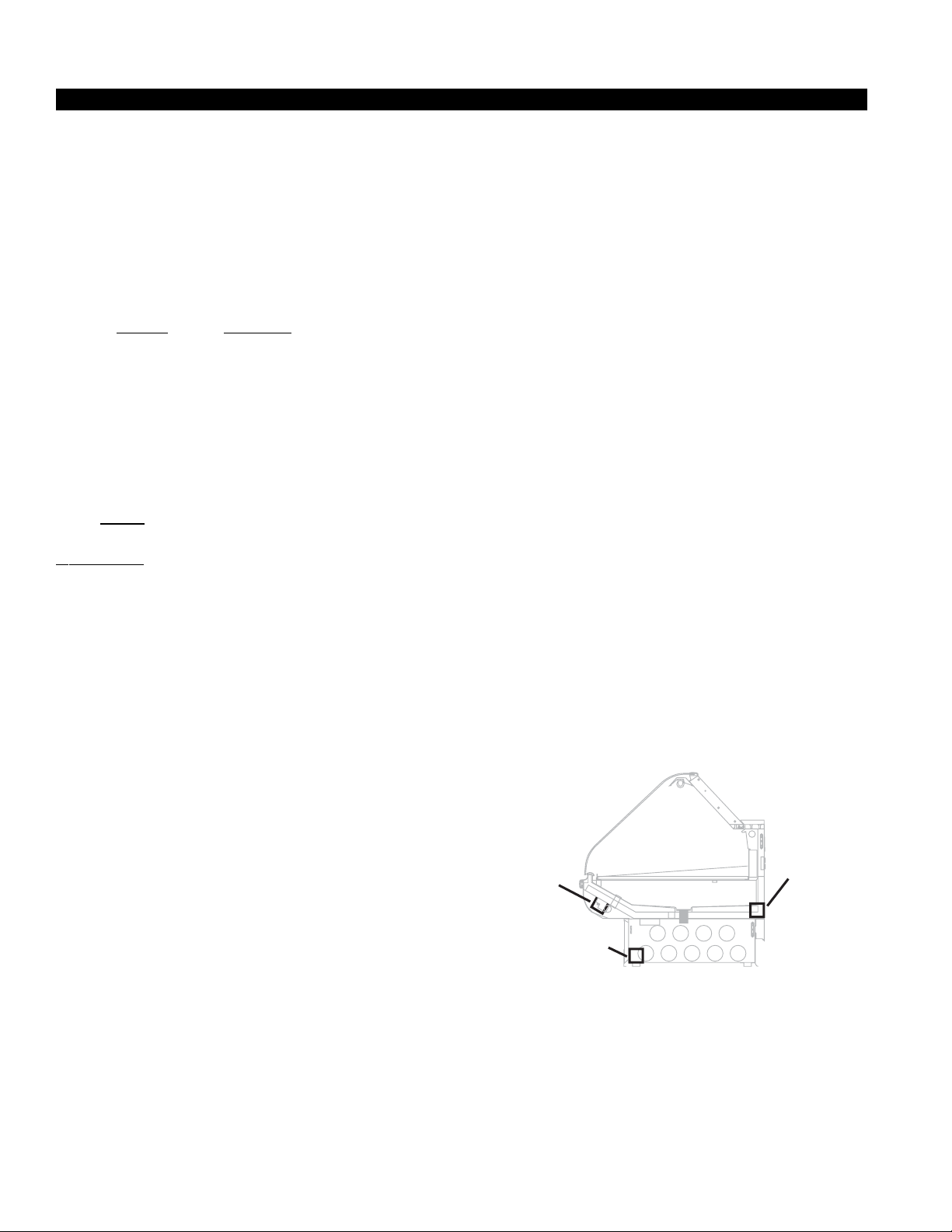

T-STAT LOCATION

T- Stats are located within the electrical raceway. Refer to

diagram below.

Standard

Location

Optional

Location

Optional

Location

12

Loading...

Loading...