Page 1

B

D

C

F

A

E

E2SPH

Data Sheet Set

P/N 0453532_A

NSF

®

Certified

April 2010

Item Part # Description Wiring Item #

FAN ASSEMBLIES AND THERMOSTATS

A. 12W Fan Assembly (1)

0047000 Fan Motor, Evaporator

(MO.4410311)

0124150 Fan Blade, (FB.0124150)

embossing toward motor

B. 0411744 Standard Non-adjustable (2)

Defrost Thermostat (CT.0411744)

C. Optional Adjustable Refrigeration Thermostat (3)

Item Part # Description Wiring Item #

L

AMPS AND BALLASTS

D. 0466234 Ballast, Electronic

2 lamps (BA.4480823) (4)

E. Fluorescent Lamp (5)

Replace with like fixtures

OTHER

F. 0464718 Hot Well Assembly (6)

©2010 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

U.S. & CANADA 1-800-922-1919 • MEXICO 1-800-522-1900 • WWW.HUSSMANN.COM

P/N0453532A

Note: Revision A adds page 5, adds aftermarket numbers on page 1, updates load limit line on page 9 and updates pages 2 &

4. Changes are underlined, circled or marked with a vertical line in the margin.

We reserve the right to change or revise specifications

and product design in connection with any feature of

our products. Such changes do not entitle the buyer to

corresponding changes, improvements, additions or

replacements for equipment previously sold or shipped.

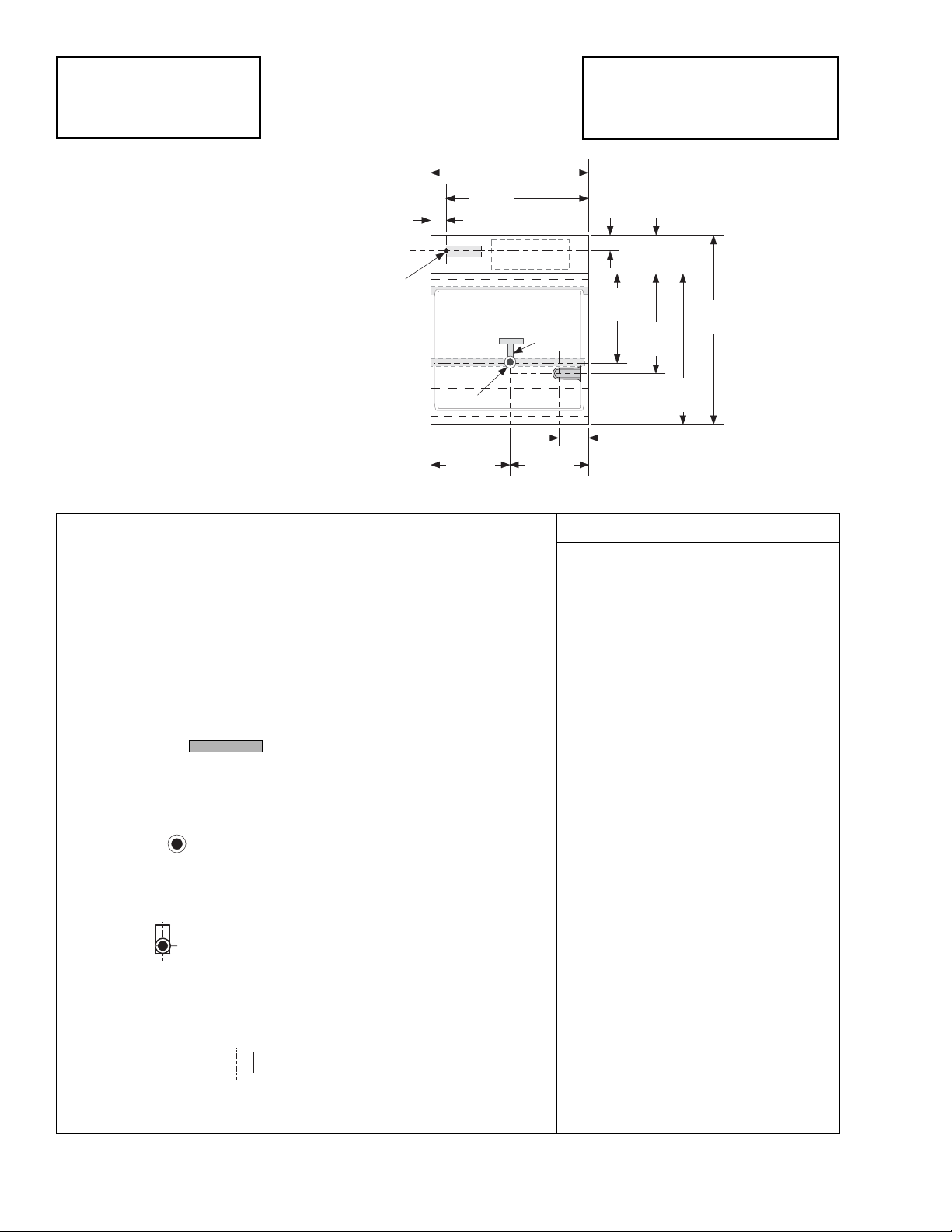

Page 2

2 of 9 E2SPH Technical Data Sheet

U.S. & Canada 1-800-922-1919 • Mexico 1-800-522-1900

E2SPH

Meat, Delicatessen

Precut & Packaged

Produce

—

with 2 Hot Wells

4 ft

General

Case Length (without ends or partitions) 48 1/

8 (1222)

NOTE: Each end or insulated partition adds 1 inch to lineup.

Maximum O/S dimension back to front (with bumper) 63 (1600)

Back of case to front of front panel 35 (889)

Back of case to O/S edge of front skid rail 29 3/

4 (756)

Width of skid rail 4

1

/2 (114)

RH end of case to outside edge of external support 1 3/8 (35)

Stub-up area between front skid rail and front panel 5 3/

4 (146)

Electrical Service (Electrical Field Wiring connection point)

RH End of case to LH end of connection box 42

1

/8 (1070)

Back of storage to connection box,

center of knockout 11 (279)

Waste Outlet

RH End of case to the center of waste outlet 24 1/4 (616)

LH End of case to the center of waste outlet 23 7/8 (606)

Back O/S of case to center of waste outlet 28 1/8 (714)

Water Seal

Edge of water seal to center of waste outlet 4 (102)

Schedule 40

diameter of the drip pipe 1

1

/

2

(38)

NOTE: Water seal outlet must clear front skid rail;

water seal rotation in forward direction only due to low base.

Refrigeration Outlet

Back of case to center of refrigeration outlet 31

1

/4 (794)

RH end of case to center of refrigeration outlet 8 3/8 (213)

Engineering

Plan Views

Dimensions shown as inches and (mm).

10-2005

PHYSICAL DATA

Merchandiser Drip Pipe (in.) 1 1/2

Merchandiser Liquid Line (in.)

3

/8

Merchandiser Suction Line (in.)

7

/8

6

(152)

1

42

(1070)

/

8

48

(1222)

1

/

8

11

(279)

23

(606)

Ballast Tray

4 Ft Case

7

/

8

Front

Water

Seal

24

(616)

1

28

/

8

(714)

31

3

8

/

8 (213)

1

/

4

Connection Box

(Field Connection Point)

Waste

Outlet

16

(406)

1

(794)

(1600)

/

4

47

(1194)

63

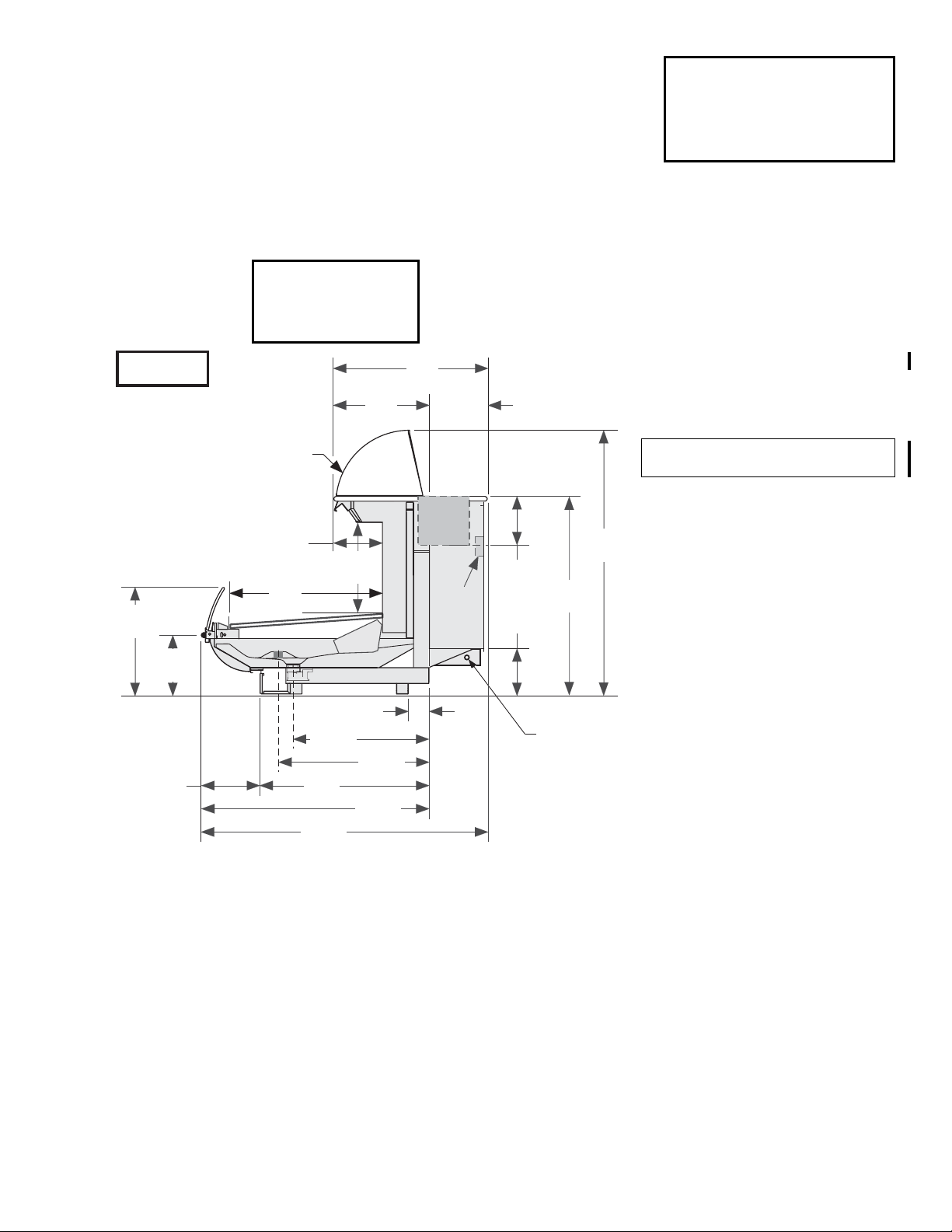

Page 3

Dimensions shown as inches and (mm).

3 of 9P/N 0453532_A

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

C

O

I

L

Refrigeration

Outlet

FAN

Hot

Wells

(2)

Control

Box

Electrical

Connection

12

(305)

22

(559)

40 1/4

(1022)

35

(889)

9 3/4 (248)

12

(305)

19 1/8

(486)

31

(787)

E2SPH

31 1/4

(794)

28 1/8

(714)

20

(508)

Standard Curved

Sneeze Guard

53 3/4

(1365)

47

(1194)

63

(1600)

4 3/4 (121)

9 1/4

(235)

36

(914)

16

(406)

8 5/8

(219)

Impact

Elite

E2SPH

Meat, Delicatessen

Precut & Packaged Produce

Elite Specialty Merchandiser Multi-deck, 2 Display Levels, Prep Top, Hot Wells

See Page 8 for

recommended

shelf configuration.

NSF Certification

This merchandiser model is manufactured to meet ANSI/NSF

(National Sanitation Foundation) Standard #7 requirements for

construction, materials & cleanability.

REFRIGERATION DATA

Note: This data is based on store temperature and

humidity that does not exceed 75 (°F) and 55%

R.H.

E2SPH

Meat Deli

Discharge Air (°F) 25 28

Evaporator (°F) 18 21

Unit Sizing (°F) 16 19

Btu/hr/ft — Unlit Shelves

‡

E2SPH

Meat Deli

Parallel 900 890

Conventional 1000 980

‡

Add 20 Btu/hr/ft per shelf row for fluorescent

lamps.

DEFROST DATA

E2SPH

Frequency (hr) 6

Defrost Water (lb/ft/day)8

(± 15% based on case configuration and product

loading).

OFFTIME E2SPH

Temp Term (°F) 48

Failsafe (minutes) 40

ELECTRIC OR GAS Not Recommended

Standard Defrost Thermostat

Close on rise: close 48°F – open 33°F

CONVENTIONAL CONTROLS

Low Pressure Backup Control

CI/CO

* E2SPH

Meat Deli

Temp (°F) 11 / 6 14 / 4

Indoor Unit Only, Pressure Defrost

Termination (Temp °F)

** 48°F

*Use a Temperature Pressure Chart to determine

PSIG conversions.

Estimated Charge ** E2SPH

4 ft 0.9 lb 14 oz 0.4 oz

**This is an average for all refrigerant types

actual refrigerant charge may vary by

approximately half a pound.

Page 4

4 of 9 E2SPH Technical Data Sheet

U.S. & Canada 1-800-922-1919 • Mexico 1-800-522-1900

Impact

Elite

E2SPH

Meat, Delicatessen

Precut & Packaged Produce

Electrical Data

4 ft

Number of Fans — 12W 1

Amperes Watts

Merchandiser 4 ft 4 ft

Fans

120V 60Hz Standard 0.65

50

120V 50Hz Standard 0.75

57

230V 60Hz Export NA

230V 50Hz Export NA

120V 60Hz Energy Efficient N

A

230V 60Hz Energy Efficient NA

Cycling Anti-sweat Heaters N

A

Minimum Circuit Ampacity

120V 60Hz Standard 0.85

120V 50Hz Standard 0.95

230V 60Hz Export NA

230V 50Hz Export N

A

120V 60Hz Energy Efficient NA

230V 60Hz Energy Efficient NA

Maximum Over Current Protection (120V) 20

Maximum Over Current Protection (230V) 15

Hot Wells

208V 60 Hz One Hot Well 5.8 1200

240V 60 Hz One Hot Well 6.7 1600

208V 60 Hz Two Hot Wells 11.6 2400

240V 60 Hz Two Hot Wells 13.4 3200

Standard Lighting (T-8 fluorescent)

1 Row Canopy 0.51 62

Optional Lighting (T-8 fluorescent)

1 Row Rail Lights 0.51 62

1 Row Ledge Lights 0.51 62

Optional Shelf Lighting (T-8 fluorescent)

1 Row of Shelves 0.51 62

2 Rows of Shelves 0.51 62

Optional Overhead Lighting

1 Row of Incandescent Lamps (2 lamps) 1.26 150

1 Row of Heat Lamps (2 lamps) 2.92 350

120V Lighting Circuit Total = Standard Lighting + Total Optional Lighting + Opt. Shelf Lighting + Opt. Overhead Lighting

Page 5

ESTIMATED SHIPPING WEIGHT

4

Case Solid End

4 ft (each)

lb (kg) 700 (318) 75 (34)

4

Actual weights will vary according to optional kits included.

Product Data

Recommended Usable Cube 1(Cu Ft/Ft) 2.27 ft3 /ft (0.21 m3 /m)

AHRI Total Display Area 2(Sq Ft/Ft) 1.84 ft2/ft (0.56 m2 /m)

Shelf Area 3(Sq Ft/Ft) 2.58 ft2/ft (0.79 m2 /m)

1

AHRI Refrigerated Volume less shelving and other unusable space: Refrigerated Volume/Unit of Length, ft3/ft [m3/m]

2

Computed using AHRI 1200 standard methodology: Total Display Area, ft2[m2]/Unit of Length, ft [m]

3

Shelf surface area is composed of bottom deck plus standard shelf complement, as shown in the Hussmann Product

Reference Guide. The standard shelf complement for this model is (1) row of 12-inch shelves and (1) row of 18-inch

shelves.

5 of 9P/N 0453532_A

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Impact

Elite

E2SPH

Meat, Delicatessen

Precut & Packaged Produce

Page 6

6 of 9 E2SPH Technical Data Sheet

U.S. & Canada 1-800-922-1919 • Mexico 1-800-522-1900

Shelf Lighting

Defrost

Termination

Thermostat

Refrigeration

Thermostat

Dark Blue

3

To

Condensing

Unit

}

Light Blue

2

1 Fan

120V NEUTRAL

B

ROWN BAND

120V POWER

Fan

1

B

ROWN BAND

Fan Wiring

Offtime Defrost

Receptacle

Electric Service Receptacle

120V NEUTRAL

120V POWER

GFCI Protector

W

G

BK

MAROON

BAND

Optional Shelf Harness and Light Circuits for

One Row of Shelves

Shelf Harness

W

Connector

G

BK

120 V

Power

Connector Connector

W

G

BK

4

BL

Connector

Shelf Light Circuits

Connector

W

R

G

G

BK

G

BL

R

5

WARNING

All components must have mechanical ground, and the merchandiser must be grounded.

Circled Numbers = Parts List Item Numbers

Grayed components in 12 foot models only.

R = Red G = Green BL = Blue LB = Light Blue DB = Dark Blue BK = Black W = White

= 120V POWER = 120V NEUTRAL = Field GROUND

= Case GROUND

Page 7

7 of 9P/N 0453532_A

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

Standard Lighting 1 Row Canopy

Light Circuits

120V NEUTRAL

4 ft case has 1 Lamp

120V POWER

ORANGE OR TAN

AND

B

Light

Switch

ORANGE OR TAN BAND

W

BK

4

Optional Lighting: 1 Row Ledge or 1 Row Rail

120V NEUTRAL

BL

R

R

5

4 ft case has 1 Lamp

BL

R

R

5

120V POWER

ORANGE OR TAN

AND

B

Light

Switch

ORANGE OR TAN BAND

W

BK

4

Optional Lighting: Overhead 75W Incandescent or 175W Heat Lamp

W

G

BK

BK

G

Connector

Connector

Connector

RANGE OR TAN

O

AND

B

BK

Connector

120 V

Power

W

Connector

W

4 ft case has 2 Lamps

Overhead

Light

Switch

BK

W

G

WARNING

All components must have mechanical ground, and the merchandiser must be grounded.

C

IRCLED NUMBERS = PARTS LIST ITEM NUMBERS

R = Red Y = Yellow G = Green BL = Blue BK = Black W = White

= 120V POWER = 120V NEUTRAL

Page 8

8 of 9 E2SPH Technical Data Sheet

U.S. & Canada 1-800-922-1919 • Mexico 1-800-522-1900

Hot Well Wiring

Hot Wells

4 ft case has 2 Hot Wells

Field Ground

Water Level

Solenoid

Valve

208V / 240V POWER

LH or RH Well Marker

Probe

Common

Heating Elements

R

R

Hot Well

6

7

8

1

2

Notes: 1. Hot Wells must be grounded.

All components must have mechanical ground, and the merchandiser must be grounded.

CIRCLED NUMBERS = PARTS LIST ITEM NUMBERS

R = Red Y = Yellow G = Green BL = Blue BK = Black W = White

= 120V P

= 208V POWER

OWER

6

5

4

3

Control Box

WARNING

= 120V NEUTRAL

L1

L2

Indicator Light

Thermostat

= Case GROUND

= Field GROUND

L1

L2

H1

H2

Page 9

9 of 9P/N 0453532_A

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

SHELF CONFIGURATION

This merchandiser is designed for two

shelves.

This illustration shows recommended

shelf depth and shelf angle for the two

locations.

It is critical to case performance that no

product, shelf or stop extend beyond the

load limit, as shown in this illustration.

This configuration supports the air

curtain and provides optimal case

performance.

Check with Hussmann engineering

before using a different configuration.

Impact

Elite

E2SPH

Meat, Delicatessen

Precut & Packaged Produce

Recommended

Angle

Load Limit

Shelf

Size

12 in.

18 in.

Loading...

Loading...