Page 1

Manual

DOE 2012

Energy Eciency

Compliant

Hussmann refrigerated merchandisers congured for sale for use in the United States

meet or surpass the requirements of the DOE 2012 energy eciency standards.

Installation

& Operation

REV. 0114

/CHINO

DSF, DSFI, DSFM, DSFN

OPEN FISH SERVICE CASE

DSF, DSFM, DSFI, DSFN

P/N IGSV-DSF, DSFI, DSFM,DSFN-0114

INSTALLATION & OPERATION GUIDE

2

OPEN FISH SERVICE CASE

Page 2

General Instructions

Proper case joint sealing is

extremely important to

prevent water leaks.

Table of Contents

General Instructions........................................................................... 2

Cut and Plan Views ............................................................................ 3

Installation ........................................................................................... 4

Location .................................................................................................................. 4

Uncrating the Stand ................................................................................................ 4

Exterior Loading ..................................................................................................... 4

Setting and Joining ................................................................................................. 4

Leveling .................................................................................................................. 4

Corner Wedges....................................................................................................... 4

Joint Trim ................................................................................................................ 4

Scale Stand Installation Instructions ....................................................................... 5

Wrapping Boards Installation Instructions .............................................................. 6

Bumper Installation Instructions ............................................................................. 8

DSF End Wing Assembly Instructions .................................................................... 9

Parts and Components List .................................................................................... 9

Channel Weldment Assembly ............................................................................... 12

Place Hinges ........................................................................................................ 13

End Wing Attachment ........................................................................................... 14

Plex Post Installation ............................................................................................ 14

Bumper Installation ............................................................................................... 15

Operation Notes ................................................................................................... 15

Critical Dimensions and Measurements ............................................................... 16

DSF Hardware Notes ........................................................................................... 17

Installing and Adjusting DSF Glass ...................................................................... 17

Glass Stop and End Wing Final Position Notes ................................................... 18

Corrigan Retrot Instructions ................................................................................ 21

Plumbing ........................................................................................... 23

Waste Outlet and P-TRAP .................................................................................... 23

Installing Condensate Drain ................................................................................. 23

Humidication ................................................................................... 23

General Description .............................................................................................. 23

Humidication System Hookups ........................................................................... 24

Start-up ................................................................................................................. 24

Maintenance ......................................................................................................... 24

Manifold Flush System .................................................................... 25

General Description .............................................................................................. 25

Basic System Operation: ...................................................................................... 25

Start Up: ............................................................................................................... 25

Manual Flush System ........................................................................................... 25

Refrigeration ..................................................................................... 25

Refrigerant Type ................................................................................................... 25

Piping .................................................................................................................... 25

Refrigeration Lines ............................................................................................... 25

Control Settings .................................................................................................... 25

Access to TX Valves and Drain Lines ................................................................... 25

Electronic Expansion Valve (Optional).................................................................. 25

Thermostatic Expansion Valve Location ............................................................... 25

Measuring the Operating Superheat .................................................................... 25

T-STAT Location ................................................................................................... 26

Electrical............................................................................................ 31

Wiring Color Code ................................................................................................ 31

Electrical Circuit Identication ............................................................................... 31

Electrical Service Receptacles (When Applicable) ............................................... 31

Field Wiring and Serial Plate Amperage ............................................................... 31

Ballast Location .................................................................................................... 31

Wiring Halogen Lights .......................................................................................... 32

Ashrae Color Code ............................................................................................... 32

User Information ............................................................................... 32

Stocking ................................................................................................................ 32

Important Steps .................................................................................................... 32

Case Cleaning ...................................................................................................... 33

Cleaning Glass and Mirrors .................................................................................. 33

Non-glare Glass .................................................................................................... 33

Plexiglass and Acrylic Care .................................................................................. 33

Cleaning ............................................................................................................... 33

Antistatic Coatings ................................................................................................ 33

Maintenance ...................................................................................... 34

Replacing Fluorescent Lamps .............................................................................. 34

Evaporator Fans ................................................................................................... 34

Copper Coils ......................................................................................................... 34

Tips and Troubleshooting ..................................................................................... 34

Stainless Steel Cleaning and Care ....................................................................... 34

Electrical Wiring Diagrams .............................................................. 35

Wiring Diagrams ............................................................................... 35

Appendices ....................................................................................... 42

Appendix A. - Temperature Guidelines - Refrigerated .......................................... 42

Appendix B. - Application Recommendations - Refrigerated ................................ 42

Appendix C. - Field Recommendations - Refrigerated ......................................... 42

Appendix D. - Recommendations to User - Refrigerated ..................................... 43

This Booklet Contains Information on:

DSF, DSFM Straight-glass refrigerated service Open

Fish mechandiser

Shipping Damage

All equipment should be thoroughly examined for shipping

damage before and during unloading.

This equipment has been carefully inspected at our factory

and the carrier has assumed responsibility for safe arrival.

If damaged, either apparent or concealed, claim must be

made to the carrier.

Apparent Loss or Damage

If there is an obvious loss or damage, it must be noted on

the freight bill or express receipt and signed by the carrier’s

agent; otherwise, carrier may refuse claim. The carrier will

supply necessary claim forms.

Concealed Loss or Damage

When loss or damage is not apparent until after equipment

is uncrated, a claim for concealed damage is made. Make

request in writing to carrier for inspection within 15 days,

and retain all packaging. The carrier will supply inspection

report and required claim forms.

Shortages

Check your shipment for any possible shortages of material. If

a shortage should exist and is found to be the responsibility of

Hussmann Chino, notify Hussmann Chino. If such a shortage

involves the carrier, notify the carrier immediately, and

request an inspection. Hussmann Chino will acknowledge

shortages within ten days from receipt of equipment.

Hussmann Chino Product Control

The serial number and shipping date of all equipment

has been recorded in Hussmann’s les for warranty and

replacement part purposes. All correspondence pertaining

to warranty or parts ordering must include the serial number

of each piece of equipment involved, in order to provide

the customer with the correct parts.

Keep this booklet with the case at all times for future reference.

/CHINO

A publication of HUSSMANN® Chino

13770 Ramona Avenue • Chino, California 91710

(909) 628-8942 FAX

(909) 590-4910

(800) 395-9229

2

Page 3

Cut and Plan Views

DSF

Outside Alcove

48"

48"

48"

24"

24"

24"

48"

28'-9"

8'-4"

Fr ont of Lineup

19"

34"34"

34"

34"

19"

19"

19"

DSF

Inside Alcove

48"

48"

48"

24"

24"

24"

48"

22'-9"

8'-9"

Fr ont of Lineup

DSF Center Display

Deeper Display

Scale = 1/2"

40 1/4"

55 7/8"

13

5

/8"

2"

5"

8"

Optional

Scale Platform

Optional

Ledge Lights

54

1

/4"

45

1

/2"

14

5

/8"

45

3

/

4

"

O

p

tio

n

a

l

P

a

n

D

e

p

th

Loa d

Line

20

1

/4"

lo

a

d

lin

e

DSF Inlet

Narrow Depth

Scale = 1/2"

Optional Fold-up

Service Step

8"

5"

14

5

/

8

"

39

3

/

4

"

201/4"

35

7

/8"

20

1

/

4

"

54

1

/

4

"

135/8"

2"

Optional

Ledge Light

60"

Health

Department

Sneeze Guard

Guidelines

55

5

/

8

"

31

3

/

4

"

20

1

/

2

"

23

1

/

4

"

13

5

/8"

41

5

/8"

45

1

/

2

"

3

2

"

DSFM

Deep Service Fish Case - Medium Width

Scale = 1/2"

Optional

Ledge Light

27

3

/4" 2"

41

5

/

8"

8'

(Variable Lengths)

DSFM

Plan

Scale = 1/4"

Water Valve &

Access Panel

FRONT OF CASE

DRAIN

ELEC. &

MECH.

DROP AREA

44" X 21"

OPEN FOR MECHANICAL

44" X 21"

OPEN FOR MECHANICAL

21 5/8

39 3/4

53 1/8

35 7 /8

7 1 /2 26 3 /4 1 5 /8

28 3/ 4

STRAIGHT GLASS

Swing Out

LED LIGHTS

7 7 /8

17 5/8

18 5 /8

24 1/ 2

5 3 /8

DSFN

Deep Service Fish Case - Narrow Width

3

Page 4

Installation

DSF4&5

Deeper Depth

Silicone

DSF2&3

Narrow Depth

Proper case joint sealing is

extremely important to

prevent water leaks.

Location

The refrigerated merchandisers have been designed for

use only in air conditioned stores where temperature and

humidity are maintained at or below 75°F and 55% relative

humidity. DO NOT allow air conditioning, electric fans, ovens,

open doors or windows (etc.) to create air currents around

the merchandiser, as this will impair its correct operation.

Product temperature should always be maintained at a

constant and proper temperature. This means that from the

time the product is received, through storage, preparation

and display, the temperature of the product must be

controlled to maximize life of the product.

Uncrating the Stand

Place the xture as close to its permanent position as

possible. Remove the top of the crate. Detach the walls

from each other and remove from the skid. Unbolt the case

from the skid. The xture can now be lifted off the crate

skid. Lift only at base of stand!

Exterior Loading

These models have not been structurally designed to

support excessive external loading. Do not walk on their

tops; This could cause serious personal injury and damage

to the xture.

Setting and Joining

The sectional construction of these models enable them to

be joined in line to give the effect of one continuous display.

A joint trim kit is supplied with each joint.

Leveling

IMPORTANT! IT IS IMPERATIVE THAT CASES BE

LEVELED FROM FRONT TO BACK AND SIDE TO SIDE

PRIOR TO JOINING. A LEVEL CASE IS NECESSARY

TO INSURE PROPER OPERATION, WATER DRAINAGE,

GLASS ALIGNMENT, AND OPERATION OF THE HINGES

SUPPORTING THE GLASS. LEVELING THE CASE

CORRECTLY WILL SOLVE MOST HINGE OPERATION

PROBLEMS.

NOTE: A. To avoid removing concrete ooring, begin lineup

leveling from the highest point of the store oor.

B. When wedges are involved in a lineup, set them rst.

All cases were leveled and joined prior to shipment to

insure the closest possible t when cases are joined in

the eld. When joining, use a carpenters level and shim

legs accordingly. Case must be raised correctly, under legs

where support is best, to prevent damage to case.

1. Check level of oor where cases are to be set.

Determine the highest point of the oor; cases will

be set off this point.

2. Set rst case, and adjust legs over the highest part

of the oor so that case is level. Prevent

damage - case must be raised under leg or by use

of 2x6 or 2x4 leg brace. Remove side and back leg

braces after case is set.

3. Set second case as close as possible to the

rst case and level case to the rst using the

instructions in step one. The fronts of the cases

should be in alignment. Caution: do not use

connecting bolts to pull sections together.

4. Apply a thick bead of silicone to adjoining end

panels as illustrated in the following diagram,

especially around bulkhead cutouts and screw

holes. Apply liberal bead of case joint sealant (grey

silicone) between cases along bulkhead and up

the rear discharge (clear silicone). Do not use

Permagum because this does not allow cases to

draw up tight, and therefore leaves gaps at the joint.

5. Bolt* sections together. Typical bolt locations are

illustrated below.

6. Attach bulkhead caps* with silicone*.

7. Slide PVC collar* (23/8-3”) through bulk head at the

humidity system plumbing cut outs. Secure the collar

with 2-part epoxy. Seal joint with silicone*. Fill collar by

encapsulating piping with expanding urethane foam*.

8. Connect applicable electrical, refrigeration, water,

and drain lines. See respective chapters for more

detailed instructions.

9. After cases have been leveled and refrigeration,

electrical, and waste piping work completed, install

the splashguards. (see instructions in the “Finishing

Touches” section of this booklet).

Note: Seal the unit to the oor with an NSF Listed caulk or

equivalent

Corner Wedges

Corner wedges are attached via front and rear camlocks.

Use a 7mm allen wrench to turn the locks. Do not

overtighten! Join the top by using a joint bracket (included

in joint kit) with 3/8” bolts.

Joint Trim

After cases have been leveled and joined, and refrigeration,

electrical, and wasted piping work completed, install the

splashguards. Fasten along the top edge, or center, with

#10 X 3/3” sheet metal screws.

4

Page 5

Scale Stand Installation Instructions

2.-Drill holes and screw in place

(with screws provided –Hex Tek S/S

10-16 X ½”)

Note: Use hole pattern

Installation (Cont'd)

1.- Set Scale Stand to desire location

5

Page 6

Wrapping Boards Installation Instructions

HOLE PATTERN

Screws # 14 X 1”

Installation (Cont'd)

Step 1: Measure 6 inches from wrapping board end.

Note: Line up 6 inch mark with 10 inch mark.

Step 2: Measure 10 inches from top of the case.

Step 3: Use bracket center hole to align with cross mark.

Note: Use pencil/marker to mark hole pattern.

Step 4: Drill holes (7/32”)

Step 5: Install bracket with screws (provided)

Note: Repeat Steps 1 Thru 5 for Second Bracket Installation.

6

Page 7

Installation (Cont'd)

Step 6: Install upper

support bracket

Step 7: mount wrap board on top of bracket using a ¼”

spacer to have a gap between rear wall and board.

Installation Complete

Step 8: screw bracket into wrap board

(screws provided -#8 X 1 ¼”)

7

Page 8

Bumper Installation Instructions

Installation (Cont'd)

Step 1: Make sure the aluminum channel and end caps

are installed.

Step 3: Starting on one end: while inserting the bumper,

push it up against the end cap to prevent

the bumper from shrinking after installation

(when it gets cold).

Step 2: Use silicone lubricant to help the

bumper slide into the channel.

Step 4: As you insert the bumper into the channel with

one hand, pull the bumper toward you with

the other to open the inside lips. Slowly

apply pressure by rolling the bumper into

the track.

8

Page 9

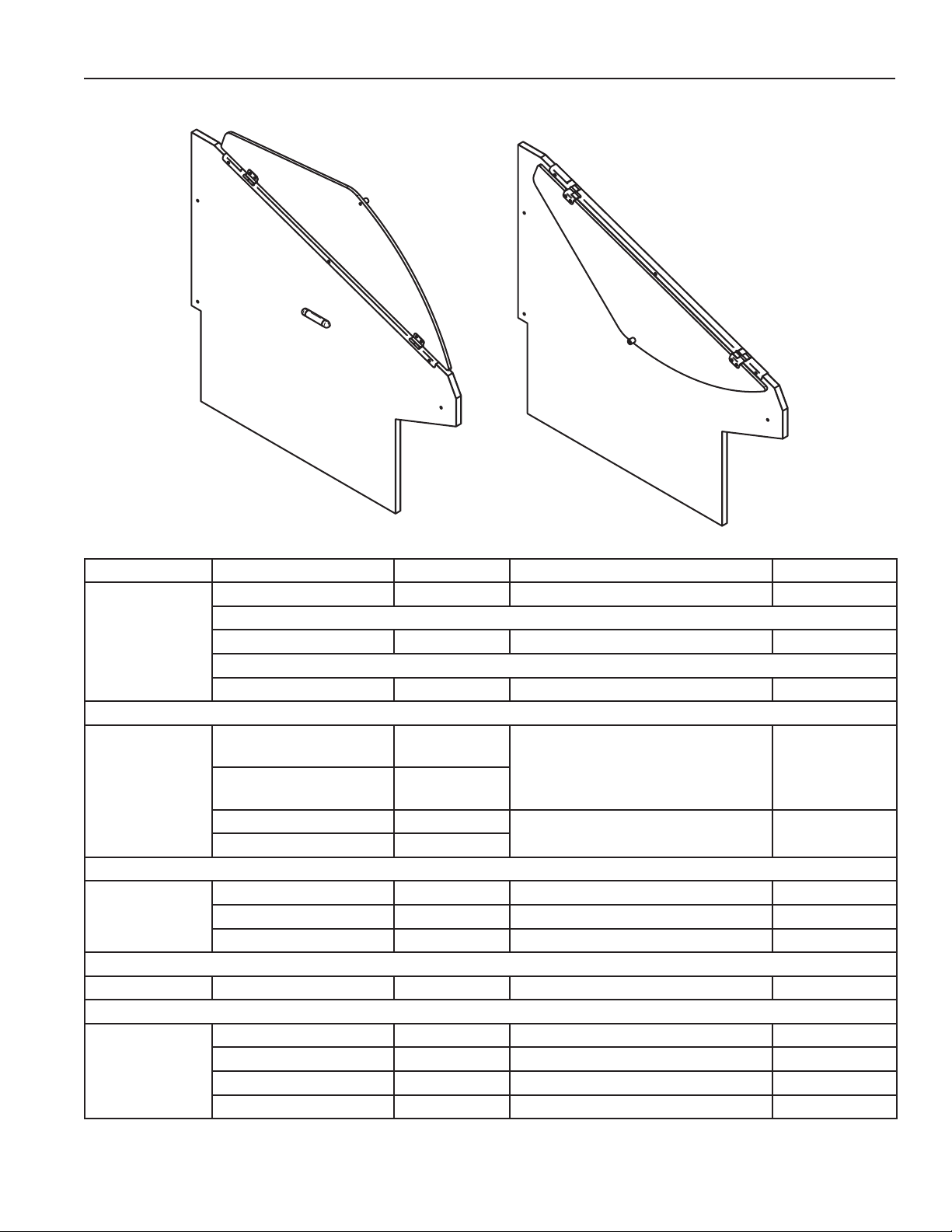

DSF End Wing Assembly Instructions

Installation (Cont'd)

Parts and Components List

1H12007300 2 Curved Plex Wing 10

Wing

Weldments

Bumper

Post 025880 2 Plex Spacer Tube (1 Per Wing) 11

1H16223300 2 Curved Plex Wing, 54" FLAT TOP 10

1H12008300 2 Straight Plex Wing 10

Left Wing Channel

Weldment

Right Wing Channel

Weldment

Left Hinge Weldment 2 Male Hinge + Plex Holder 10

Right Hinge Weldment 2

Boston NE 50 End Cap 4 Bumper End Cap 11

Boston NE 50 Section 2 Bumper 11

Bumper Channel 2 Bumper Channel (Length = 3.75") 11

Part Total Quantity Description Sheet Number

OR

OR

1 Female Hinges + Wing Channel 10

1

Fasteners

175-01-0369 10 Binding Post Cap 1/2" 11

300-03-0610 8 Phillips Stainless Screw 8-32 x 1/2" 11

300-03-0641 6 Phillips Stainless Screw 10-24 x 1" 11

300-03-0620 2 Phillips Stainless Screw 8-32 x 1" 11

9

Page 10

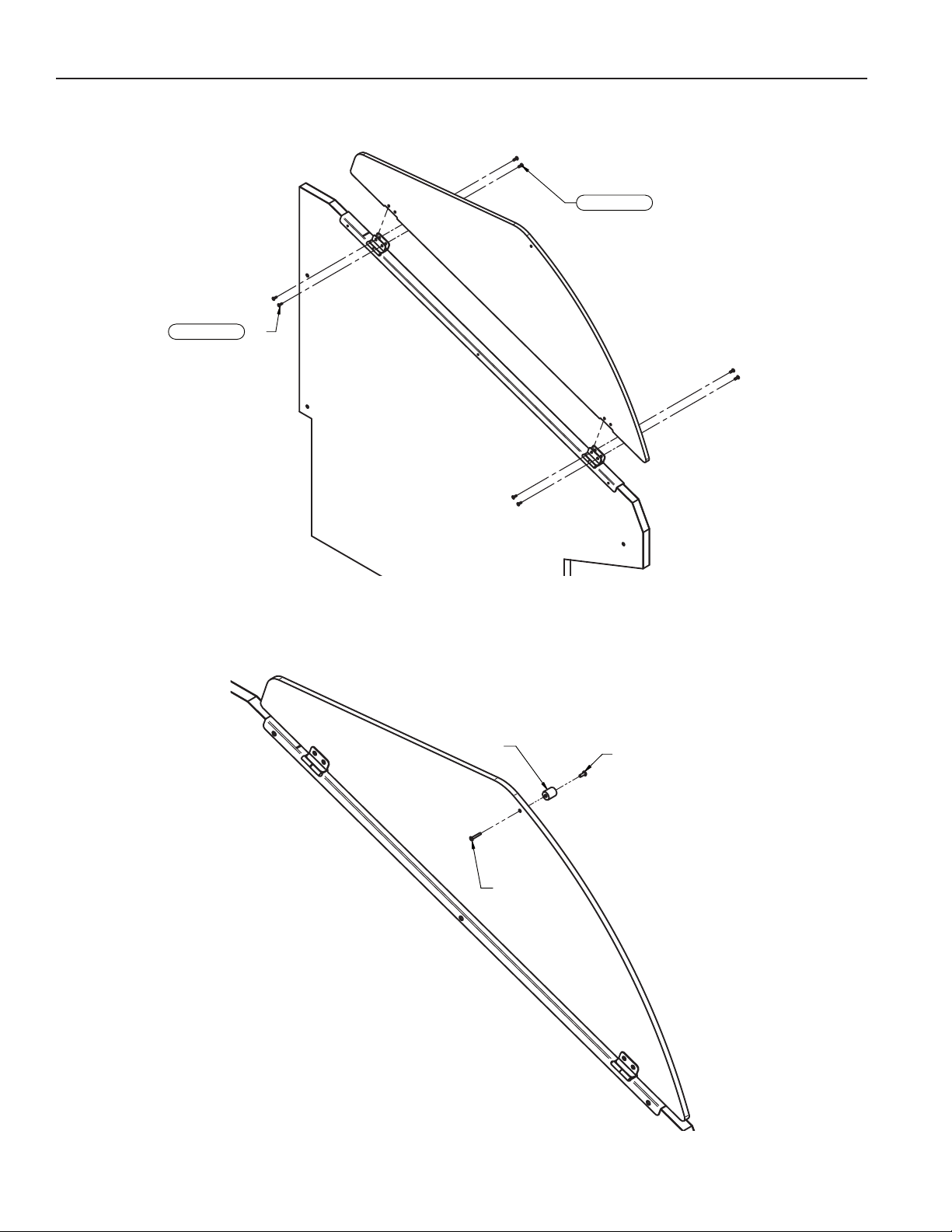

Installation (Cont'd)

1H12007300

x 2

Curved Glass Model

1H12008300

Straight Glass Model

x 2

Front of Case

Rear of Case

1H16223300

Curved Glass Model, 54" FLAT TOP

x 2

This part is used when health codes

require a horizontal end shield at 54"

from the ground

.

Left Hinge Weldment x 2

Right Hinge Weldment x 2

Left Wing Channel Weldment x 1

Right Wing Channel Weldment x 1

10

Page 11

Installation (Cont'd)

Plexiglas Spacer

Bumper Components

025880 x 2

50 Series Bumper

Length = 3"

x 2

50 Series End Capx 4

.875

.750

175-01-5002

3 3/4" Length

x 2

3.750

.500

300-03-0620

8-32 x 1"

x 2

300-03-0610

x 8

8-32 x 1/2"

Machine Screws

Binding Post

Wood Screw

.500

175-01-0369

1/2" Post

x 10

1.000

300-03-0641

x 6

10-24 x 1"

1.000

.188

11

Page 12

Installation (Cont'd)

Left Wing Channel Weldment

Hinges are

welded at Lowe

r

Hash Marks on

Channel

300-03-0641x 3

Channel Weldment Assembly

(Left Wing Channel Shown)

1) Refer to the critical measurements section of the instructions for reference dimensions. (Page 16)

2) Check Position

• Hinges over outer side of end panel

• Holes on outer side of end panel

• Be Sure the left weldment is installed on left end

2) Place channel on end panel to the recommended specication

3) Use a rubber hammer to work channel over T- molding

• Trim the T-molding if necessary

4) When recommended and/or optimal position is found, use the wood screws to secure channel to the end panel

Note: The Optimal Position will be within the recommended range

Note: It may be necessary to adjust the Wing Channel Weldment to optimize the t and position.

Do not fasten Channel until this step is complete.

12

Page 13

Place Hinges

Outer side of DSF

Case

Inner side of DSF Case

Assemble Right Wing in a Mirrored Configuration

RIGHT HINGE WELDMENT

LEFT HINGE WELDMENT

(Left Wing Assembly Shown)

Installation (Cont'd)

NOTES:

1) Pins will face in opposite directions, away from the center of the channel.

2) One "Left" and one "Right" Hinge weldment is required for each wing, regardless of which side is being installed.

3) Use tape to hold the upper hinge so that the plex wing can be installed in the next step.

13

Page 14

End Wing Attachment

Outer side of

DSF Case

Inner side of

DSF Case

175-01-0369x 4

300-03-0610x 4

025880

175-01-0369

300-03-0620

Outer side of

DSF Case

Inner side o

f

DSF Case

Assemble Right Wing in a Mirrored Configuration

(Left Wing Shown)

Installation (Cont'd)

1) Place the plex wing into channels on the hinges.

2) Align all 4 holes on the wing with respective holes on hinges.

3) Securely fasten the binding posts. All binding posts are installed on the inner side.

Plex Post Installation

14

Page 15

Installation (Cont'd)

With wing folded down,

Locate the Bumper so that

the Lowest Edge of the End

Wing will not Crash

27.438

26.375

Bumper Installation

1) Locate the Bumper as Indicated Below

2) Mark this Location

3) Positiion Bumper Channel on End

• Install Both End caps on Aluminum Channel

4) Use 300-03-0641 x 4 to Fasten to End Panel

5) Press Bumper over Exposed Screws and Ends Caps

Operation Notes

• Always place both wings in the Down position before attempting to open and/or close the front glass.

• Securely close the front glass, then close side wings.

• Use care when placing wings in the Down position.

• The bumpers offer a reasonable amount of protection from impact, but will not endure excessive abuse.

• The wing is designed to accept pressure from the weight of the glass.

• Be sure that the glass seats properly on the Plexiglas stops to prevent the wings from falling over.

• Fine Tuning and adjustment of the Front Glass may be necessary to t glass prole.

Front Glass can be adjusted per the recommendations on the following pages. Professional installation and

adjustment is recommended.

15

Page 16

Critical Dimensions and Measurements

C

A

B

F

G

D

E

Installation (Cont'd)

CALLOUT DESCRIPTION MODEL VALUE (Inches)

A Normal Distance from the ground to the bottom of

B Overall Hardware depth (Hardware fully closed) 3-5/16 ~ 3-7/16

C Overall Distance from the ground to the highest

D Normal Distance from Wing Channel to highest

E Distance from the back of the end panel to the

F Distance from the front corner of the end wing to

G Distance from the outside edge of the plex wing

the hardware (Sampled at the ends)

point on glass (Wings Up)

point on glass (Wings Down)

rst hole in the Wing Channel

the center of the glass stop

to the center hold of the glass stop

27-1/4 ~ 27-3/8

54-3/8 ~ 54-1/2

14-3/8 ~ 14-7/16

8 ~ 8-1/16

28 ~ 28-1/8

5/8 ~ 11/16

16

Page 17

Installation (Cont'd)

• Glass is Heavy and can cause serious injury.

• Professional installation recommended.

• Have an assistant hold glass while adjusting

glass and/or hardware to prevent breakage!

STEP 1:

PULL OUT HARDWARE ARM

TO OUTER MOST POSITION

STEP 2:

LOOSEN ALL CLAMP

BOLTS EVENLY UNTIL

GLASS IS LOOSE

STEP 3:

PULL GLASS

FROM CLAMP

DSF Hardware Notes

If NEM hardware is replaced or needs adjustment. Be sure that the following notes are followed.

1) NEM glass hardware must be attached to front of merchandiser with 1/4"- 20 taper head machine screws

2) Loctite 242 thread locker must be applied to the threads of all screws used to attach the glass hardware to the

merchandiser.

Installing and Adjusting DSF Glass

17

Page 18

Installation (Cont'd)

STEP 4:

ATTACH SHIM TO GASKET IN DESIRED

POSITION USING CLEAR 3/8" DOUBLE

SIDED TAPE

PLACE SHIM

HERE TO ROTATE

GLASS UPWARD

STEP 5:

REPLACE SHIMMED

GLASS AND TIGHTEN

ALL CLAMP SCREWS

EVENLY AND SECURELY

CASE

INTERIOR

STEP 6:

CHECK GLASS HEIGHT

AGAINST SPECIFICATIONS(PAGE 13).

REPEAT SHIM PROCEDURE IF MEASURED

HEIGHT IS NOT WITHIN SPECIFICATIONS

ALTER THE SHIM LOCATION ON THE GASKET

TO CHANGE THE DEGREE OF SHIM

PLACE SHIM

HERE TO ROTATE

GLASS DOWNWARD

NOTE: Place shims along the length of the glass in order to evenly distribute clamping forces.

Glass Stop and End Wing Final Position Notes

End Wings and End panels from the factory should have pre-drilled holes for the plex post and wing channel

respectively.

If a hole has not been pre-drilled into the side plex and end panels, observe the following notes:

1) The glass stop post must be precisely located on the end wing. Refer to dimensions G and H on page 16.

2) The wing channel must be located and mounted precisely on top of the end panel. Refer to dimension F on page 16.

18

Page 19

Installation (Cont'd)

Boston Series 2000

NOTE: Flexible top: Over cut vinyl 1/8" for every 4' section for

the exible top to ensure a proper t.

NOTE: Rigid Top: Do not over cut.

1. Attach the base and end/corner cap to the desired

surface by inserting #8 pan head screws through the

pre-slotted holes in both the end cap and the base.

Insert screws through the two holes of end cap and

tighten.

2a. Flexible Top: Butt end of the vinyl top against

end/corner cap. While applying pressure, bend

back vinyl top so that vinyl legs are positioned within

the base grooves. Roll vinyl top over full length of

base, then tap with rubber mallet to ensure vinyl is

securely locked into the base.

2b. Rigid Top: Snap the Rigid Top over the Rigid Base.

Boston 2000 Eco Series

1. Attach the base and end/corner cap to the desired

surface by inserting #8 pan head screws through the

pre-slotted holes in both the end cap and the base.

Insert screws through the two holes of end cap and

tighten.

2a. Flexible Top: Butt end of the vinyl top against

end/corner cap. While applying pressure, bend

back vinyl top so that vinyl legs are positioned within

the base grooves. Roll vinyl top over full length of

base, then tap with rubber mallet to ensure vinyl is

securely locked into the base.

2b. Rigid Top: Snap the Rigid Top over the Rigid Base.

3. If necessary wipe clean with any household cleaning

product.

Helpful Hints:

● For best results, before cutting, install a scrap piece

of base into vinyl top to achieve a clean cut.

● Set the uncoiled flexible vinyl at room temperature

24 hours prior to installation.

● Lubricate the inside of the vinyl with soapy water or

silicone before installing.

● Over cut the flexible vinyl and compression fit.

Adding the additional materials will compensate for

stretching which occurs during installation.

3. If necessary wipe clean with any household

cleaning product.

Helpful Hints:

● For best results, before cutting, install a scrap piece

of base into vinyl top to achieve a clean cut.

● Set the uncoiled flexible vinyl at room temperature

24 hours prior to installation.

● Lubricate the inside of the vinyl with soapy water or

silicone before installing.

● Over cut the flexible vinyl and compression fit.

Adding the additional materials will compensate for

stretching which occurs during installation.

19

Page 20

Installation (Cont'd)

Boston 1000 Series

NOTE: Flexible top: Over cut vinyl 1/8" for every 4' section for

the exible top to ensure a proper t.

NOTE: Rigid Top: Do not over cut.

Installation

1. Attach the base and end/corner cap to the desired

surface by inserting #8 pan head screws through the

pre-slotted holes in both the end cap and the base.

Insert screws through the two holes of end cap and

tighten.

2b. Rigid Top: Snap the Rigid Top over the Rigid Base.

3. If necessary wipe clean with any household

cleaning product.

Helpful Hints:

● For best results, before cutting, install a scrap piece

of base into vinyl top to achieve a clean cut.

● Set the uncoiled flexible vinyl at room temperature

24 hours prior to installation.

● Lubricate the inside of the vinyl with soapy water or

silicone before installing.

● Over cut the flexible vinyl and compression fit.

Adding the additional materials will compensate for

stretching which occurs during installation.

2a. Flexible Top: Butt end of the vinyl top against

end/corner cap. While applying pressure, bend

back vinyl top so that vinyl legs are positioned within

the base grooves. Roll vinyl top over full length of

base, then tap with rubber mallet to ensure vinyl is

securely locked into the base.

20

Page 21

Corrigan Retrot Instructions

Installation (Cont'd)

Step 1: Marking and Drilling Pilot Holes

If the existing Misting Channel does not have 1/8" diameter

holes in the location shown, these holes will have to be

marked and drilled.

Option 1:

Mark the two hole locations as specied in the

diagram.

After marking a mark, use a sharp 1/8" diameter drill bit to

create a clean through hole.

21

Page 22

Installation (Cont'd)

Step 2: Attach misting nozzle to misting bracket

The spraying end of the nozzle must point toward the end

of the bracket with two holes.

See the diagram below.

Step 3: Attach Nozzle/Bracket assembly to Misting

Channel

The nozzle will protrude into the oblong cutout.

See the diagram below.

Step 4: Final Assembly and Inspection

The nozzle should be positioned as shown. Some nal adjustment may be necessary to optimize misting, depending

on case operating conditions.

Make adjustments to angle by manually bending bracket if necessary. This may require the use of hand tools. Use eye

protection at all times.

Note: The nozzle tip should protrude into the cutout by approximately half of the nozzle head length.

22

Page 23

Plumbing

The DSF is capable of maintaining superb product quality

with the installation of the proper controlling devices.

These devices should be set according to the Hussmann’s

specifications. The humidity system should be properly

maintained. Incorrect settings and failure to maintain the

humidity system will result in short product life. Below

are a few guidelines for optimum performance and product

life:

Waste Outlet and P-TRAP

The waste outlet is located off the center of the case on

one side allowing drip piping to be run lengthwise under

the xture.

A 1-1/2” P-TRAP and threaded adapter are supplied with

each xture. The P-TRAP must be installed to prevent air

leakage and insect entrance into the xture.

NOTE: PVC-DWV solvent cement is recommended. Follow the

manufacturer’s instructions.

Installing Condensate Drain

Poorly or improperly installed condensate drains can

seriously interfere with the operation of this refrigerator, and

result in costly maintenance and product losses. Please

follow the recommendations listed below when installing

condensate drains to insure a proper installation:

1. Never use pipe for condensate drains smaller

than the nominal diameter of the pipe or P-TRAP

supplied with the case.

2. When connecting condensate drains, the P-TRAP

must be used as part of the condensate drain

to prevent air leakage or insect entrance. Store

plumbing system oor drains should be at least 14”

off the center of the case to allow use of the P-TRAP

pipe section. Never use two water seals in series in

any one line. Double P-TRAPS in series will cause a

lock and prevent draining.

3. Always provide as much down hill slope (“fall”) as

possible; 1/8” per foot is the preferred minimum.

PVC pipe, when used, must be supported to

maintain the 1/8” pitch and to prevent warping.

4. Avoid long runs of condensate drains. Long runs

make it impossible to provide the “fall” necessary for

good drainage.

5. Provide a suitable air break between the ood rim of

the oor drain and outlet of condensate drain. 1” is

ideal.

6. Prevent condensate drains from freezing:

a. Do not install condensate drains in contact with

non-insulated suction lines. Suction lines should

be insulated with a non absorbent insulation

material such as Armstrong’s Armaex.

b. Where condensate drains are located in dead

air spaces (between refrigerators or between a

refrigerator and a wall), provide means to prevent

freezing. The water seal should be insulated to

prevent condensation.

General Description

One cont ributor to the spoil age of fresh meats is

dehydration, which causes loss in weight and volume

(shrinkage) and product discoloration. As the refrigeration

system removes heat from the case, it also removes critical

moisture from the air, and any unwrapped products in the

case. The Humidity System replaces the moisture in the

air, in order to compensate for the moisture taken by the

refrigeration system, and disposed of down the drain line.

The system is built into the discharge plenum, and mixes

moisture laden air with refrigerated air before the air is

passed through - and around the product.

The system is constructed almost entirely of PVC pipe,

and uses air that is sub-cooled to approximately the

same temperature as the case. The sub-cooling of air

inhibits the formation of growth found to be a problem

in other humidication systems. Maintenance is almost

unnecessary if you follow a few simple rules:

1. Keep the case clean.

2. Keep the water lter clean, and change it every six

to twelve months or sooner, depending on the kind

of water found in your area.

3. Flush the header every six (6) months, by loosening

the connecting “L”, then removing it from the case,

and ushing with a hose.

Humidification

• Set thermostat to cut in at the discharge temperature

designated in the case specications section of the

appropriate installation guide or specication sheet.

Maintain the recommended product temperature for

Deli, Meat, and Fish. DO NOT set temperature too

cold, as this causes product dehydration.

• Temperatures should be achieved by means of a

T-STAT and Suction Solenoid at each case. DO

NOT use EPR valves, Liquid Line Solenoids,

or electronic control devices of any kind. These

controls allow temperature swings that cause

dehydration and excessive energy consumption.

• Set defrost cycles as listed in the Case

Specications Data for your particular case. The

number of defrosts per day should never change.

The duration of the defrost cycle may be adjusted to

meet conditions present at your location.

23

Page 24

SCOTTDALE NOZZLE

225-01-2089A

WATER

SUPPLY

SPRAY HEADER

RUNS LENGTH

OF CASE

WATER FILTER

3 STAGE #00015

225-01-2026

3" AXIAL FAN

225-01-2026

2ND FAN USED

IN 12' CASE

REAR INTERIOR WALL OF CASE

VIEWED FROM FRONT

BALL VALV E

HAMMON

225-01-2026

1/4" 100 X 1/8FPT

SW ADAPTER

1/4" OD X 1/8" FPT

SW ADAPTER

225-01-3059

1/8" MPT X 1/4" COMP

PVC ADAPTER

225-01-3059

1/4"MPT X 1/4" COMP

PVC ADAPTER

225-01-2026

1/4"MPT X 1/4" OD

COMP ADAPTER

225-01-1312

PAN AND

ACCESS PANEL

Humidification (Cont'd)

• Clean humidity system a minimum of every 90 days

for proper system operation.

• Work and rotate product - not to exceed a four (4)

hour period.

• At night, turn off case lights, and cover unwrapped

product with moistened cheesecloth or fabric towels.

• Keep meat holding box at 32°F.

• Keep meat prep room refrigerated at 55°F.

• Meat Bloom Box (if applicable) should be at 36°F.

• Meat must enter the case at 40°F or below. Product

deteriorates rapidly above 40°F.

• Clean, sanitary conditions are required throughout

the meat holding, prep, and work areas.

• Do not display product directly within the air discharge

• Turn and rotate meat. The blood works down

through the meat over time, which causes the top

surface to discolor and dehydrate. Turn meat 3-4

times per day.

• It is not required to remove product from case

overnight. Turn off case lights, and cover product

with moistened cheesecloth or fabric towel. This

helps slow down product dehydration, by taking

moisture from the cloth and not the product. This is

an old method used by meat shops for many years,

as it extends product life.

• Cold coils remove heat and moisture from the

case and deposit this as frost onto the coil. Thus a

defrost is required to remove this frost. Our humidity

system induces moisture into the case, and helps

slow down the dehydration process. The only other

moisture in the case is that which is in the product.

A single level of meat will dry out faster than a fully

loaded case with 3-4 levels of meat.

• The colder the case, the faster the product loses its

moisture and shelf life. It is very important to maintain

a constant, even, correct, product temperature.

Humidication System Hookups

Remove the raceway panel on the lower back of the case.

The pre-piped water shut-off valve and the water lter are

located on the left hand side of the case. The water line

(which is a 1/4” OD copper tting) can be connected to

the ball shut-off valve, by means of a compression tting

(supplied). The line should be one size larger than the

supply line. The line can then be run from one case to

another from within the raceway(s) using Tee connectors.

Before connecting the water to the humidity system, it is

best to purge the line to ush any debris that may clog the

water lter. If the water line requires purging after the cases

are hooked together, it is not necessary to check each one.

Simply shut ball valves to each humidity system, remove

the water line from the last case in the ow, and purge.

By doing this as a precautionary measure, you may avoid

problems and repeat servicing.

Start-up

Turn on the fan circuit. Check to see if the fan for the

humidity system is running. Remove the right hand bottom

pan (when facing the front of the case), then the TXV cover.

The fan is located up against the right hand side of the

case, as viewed from the front, under the fan plenum (see

diagram). View the blade, and make sure the fan rotation

agrees with the air ow arrows. Turn on the water, by turning

the ball valve in the direction of the ow (OFF is at 90° to

the direction of ow).

After a few minutes, check the spray header by sliding the

honeycomb to the left to expose the discharge tube located

on the right hand side of the case (when viewed from the

rear), by lifting the 4’-0” section of honeycomb with both

ends, until the bottom clears. Pull up and set aside. The

spray header will be exposed. Grasp the header and pull

it loose from the 90° “L” until you see the misting nozzle,

which should be spraying. If not, check the following:

1. Make sure the water is feeding the nozzle.

2. Remove the nozzle, and purge the water.

3. Check strainer at entrance to nozzle.

Reinsert the header into the 90° “L”, making sure that the

nozzle is in the center of the pipe when totally inserted,

and the holes in the header are facing the front of the case

at a level angle. The discharge tube can easily be pulled

to service.

Maintenance

• Clean humidity system a minimum of every 90 days

for proper system operation.

HUMIDITY SYSTEM as viewed from the front.

Note: The axial fans included in the humidity system must be

replaced as a unit.

24

Page 25

Manifold Flush System

General Description

Twice a day for two (2) minutes, a high pressure water

stream will ush most residue build-up from the bottom of

the manifold chamber. This is the area that residue builds

and expands from. Frequency of this periodic maintenance

will vary depending on water mineral content and sanitary

conditions.

Automatic Flush System

Electrical components are located within the electrical

raceway. Electrical components in this area are 115V

AC. Step-down transformer is located in wire-way, and is

controlled by pump switch. Water ow for ush system is

rated at 0.25 GPM at 60PSI water pressure. Flush nozzle

located in the rear of the case.

Refrigeration

Refrigerant Type

The standard refrigerant will be R-22 unless otherwise

specied on the customer order. Check the serial plate on

the case for information.

Piping

The refrigerant line outlets are located under the case.

Locate rst the electrical box, the outlets are then on the

same side of the case but at the opposite end. Insulate

suction lines to prevent condensation drippage.

Refrigeration Lines

Liquid Suction

3/8” O.D. 5/8” O.D.

NOTE: The standard coil is piped at 5/8” (suction); however,

the store tie-in may vary depending on the number of

coils and the draw the case has. Depending on the case

setup, the connecting point in the store may be 5/8”, 7/8”,

or 11/8”. Refer to the particular case you are hooking up.

Refrigerant lines should be sized as shown on the

refrigeration legend furnished by the store.

Install P-TRAPS (oil traps) at the base of all suction line

vertical risers.

Pressure drop can rob the system of capacity. To keep the

pressure drop to a minimum, keep refrigerant line run as

short as possible, using the minimum number of elbows.

Where elbows are required, use long radius elbows only.

Control Settings

See DSF, DSFM technical data sheet for the appropriate

settings for your merchandiser. Maintain these parameters

to achieve near constant product temperatures. Product

temperature should be measured first thing in the

morning, after having been refrigerated overnight. For all

multiplexing, defrost should be time terminated. Defrost

times should be as directed in the DSF, DSFM technical

data sheet. The number of defrosts per day should never

change. The duration of the defrost cycle may be adjusted

to meet conditions present at your location.

Basic System Operation:

1. Filtered water is supplied to the 115V solenoid

valve.

2. At a time of day determined by you, the 115V time

clock will energize the solenoid for 2 minutes.

Start Up:

1. Manually move time clock to initiate a ush cycle.

2. Observe that ush nozzle is spraying down center of

manifold chamber.

3. Set clock to correct time of day.

4. Set trip pins to the “time of day system is to ush”

(NOTE: 2 ush/day!)

Manual Flush System

Water valve is located on the outside of the case, in the

rear, on the left hand side as viewed from the rear.

Access to TX Valves and Drain Lines

Mechanical - Remove product from end of case. Remove

product racks. Remove refrigeration and drain access

panels (labeled). TX valve (mechanical only) and drain are

located under each access panel at end of the case.

Electronic - The Electronic Expansion valve master and

slave cylinder(s) are located within the electrical access

panel(s).

Electronic Expansion Valve (Optional)

A wide variety of electronic expansion valves and case

controllers can be utilized. Please refer to EEV and

controller manufacturers information sheet. Sensors for

electronic expansion valves will be installed on the coil inlet,

coil outlet, and in the discharge air. (Some supermarkets

require a 4th sensor in the return air). Case controllers will

be located in the electrical raceway or under the case.

Thermostatic Expansion Valve Location

This device is located on the same side as the refrigeration

stub. A balanced port expansion valve model is furnished

as standard equipment, unless otherwise specied by

customer.

Expansion Valve Adjustment

Expansion valves must be adjusted to fully feed the

evaporator. Before attempting any adjustments, make

sure the evaporator is either clear or very lightly covered

with frost, and that the xture is within 10°F of its expected

operating temperature.

Measuring the Operating Superheat

1. Determine the suction pressure with an accurate

pressure gauge at the evaporator outlet.

2. From a refrigerant pressure temperature chart,

determine the saturation temperature at the

observed suction pressure.

3. Measure the temperature of the suction gas at the

thermostatic remote bulb location.

25

Page 26

NOTE: Only one T- stat per lineup.

T-Stat

Center Display

Refrigeration (Cont'd)

4. Subtract the saturation temperature obtained in step

No. 2 from the temperature measured in step No. 3.

5. The difference is superheat.

6. Set the superheat for 5°F - 7°F.

T-STAT Location

T-STATS are located within the electrical raceway of the 4’

or 5’ main section of the case. In all the cases, the T-STAT

is located on the same side of the case. If you are looking

at the case from the back, it is on the left hand side.

26

Page 27

HUSSMANN - DSF REMOTE (CHINO)

CASE LENGTH + ENDS

REFRIGERATION DATA:

END PANEL WIDTH KEY

VELOCITY

30 MINs AFTER

DEFORST

PAR CONV PAR CONV PAR CONV

(FT/MIN) GPM PSI

1 1.5

DSF 2'

FRESH

SEAFOOD

800 920 22 22 32 32 350 TBD TBD TBD 2 1.5

DSF 3'

FRESH

SEAFOOD

1200 1380 22 22 32 32 350 TBD 0.7 1.7

LEGEND

DSF 4'

FRESH

SEAFOOD

1600 1840 22 22 32 32 350 TBD 1 3.3

DSF 5'

FRESH

SEAFOOD

2000 2300 22 22 32 32 350 TBD 1.2 5.4 PAR- PARALLEL

DSF 6' (2 - 3')

FRESH

SEAFOOD

2400 2760 22 22 32 32 350 TBD 1.4 3.4 CONV- CONV ENTIONAL

N/A - NOT AVAILABLE

TBD -

TO BE DETERMINED

A/S- AIRSW EEP

*3º F less than evaporator for pr essure loss in refrigerant lines

REFRIGERATION DATA CONTINUED: *** REFRIGERATION NOTES:

USAGE

CUT IN

(ºF)

CUT OUT

(ºF)

R22

(PSIG)

R404A

(PSIG)

R407A

(PSIG)

CUT IN

(PSI)

CUT OUT

(PSI)

CUT IN

(PSI)

CUT OUT

(PSI)

CUT IN

(PSI)

CUT OUT

(PSI)

DSF 2'

FRESH

SEAFOOD

34 30 43 56 TBD 40 10 40 10 40 10

DSF 3'

FRESH

SEAFOOD

34 30 30 56 TBD 40 10 40 10 40 10

DSF 4'

FRESH

SEAFOOD

34 30 43 56 TBD 40 10 40 10 40 10

DSF 5'

FRESH

SEAFOOD

34 30 43 56 TBD 40 10 40 10 40 10

DSF 6' (2 - 3')

FRESH

SEAFOOD

34 30 43 56 TBD 40 10 40 10 40 10

ELECTRICAL DATA:

FANS AND HEATERS(120 VOLT)

AMPS

WATTS AMPS WATTS AMPS WATTS

# ROWS

AMPS WAT TS AMP S WATT S AMPS

WATTS AMPS WATTS AMPS WATTS AMPS WATTS

DSF 2' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.18 20

DSF 3' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.28 30

DSF 4' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.37 40

DSF 5' 2 1,24 24 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.46 50

DSF 6' (2 - 3') 1 1.24 24 0.2 16 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.56 60

ELECTRICAL DATA CONTINUED: DEFROST DATA *:

# OUTLETS

VOLTS AMPS

AMPS WATTS AMPS WATTS

DSF 2' 1 115 15 2'

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/A

DSF 3' 1 115 15 3'

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/A

DSF 4' 1 115 15 4'

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/A

DSF 5' 1 115 15 5'

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/A

DSF 6' (2 - 3') 1 115 15 6 (2-3')

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/A

OPTIONS/NOTES:

LEDGE

LIGHTS

ANTI-SWEAT HEATERS (On

Fan Circuit)

GLASS HEATER

1) BTU'S EXCLUDE LIGHTS, LEDGE LIGHT OUT OF REFRIG. ZONE: WILL NOT AFFECT BTU'S

CONVENTIONAL COMPRESSOR SETTINGS

SHELF LIGHTS

(OPTIONAL)

TOTAL LIGHTS

CANOPY

LIGHTS

CONVENIENCE OUTLETS

TOTAL

EVAPORATOR

FANS

DISCHARGE AIR

R407AR404A

TEMPERATURE (ºF)

CASE

USAGE

UNIT SIZING*

24

CASE LENGTH

REAR LEDGE HTR

(OPTIONAL) REAR

LIT SIGN PANEL

LIGHTS

HUMIDITY FANS

GLYCOL

REQUIREMENTS

CAPACITY

(BTU/HR)

3.0

1.5

TOTAL ADDED

LENGTH (IN.)

END PNL

WIDTH

(IN.)

# OF END

PNLS

EVAPORATOR

EST.

REFG.

CHRG.

(LBS)

24

AIR

SENSOR

(ºF)

BACK

WALL

CASE LENGTH

PAR CONV

# OF

FANS

PER

CASE

ELEC. THERMOSTAT / AIR

SENSOR SETTINGS

R22

CASE LENGTH

CASE LENGTH

24

EPR SETTINGS

DEFROST

WATER

N/A

N/A

N/A

DEFROST

TYPE

TIME

(MIN.)

TERM.

TEMP (ºF)

COIL: ON

RISE

CASE

LENGTH

(LB/DAY)

DRIP

TIME

(MIN.)

DEFROSTS

PER DAY

(OPTIONAL) COOL GAS

DEFROST 208V 1PH.

ELECTRICAL

DEFROST

208V 1 PHASE

N/A

N/A

24

24 24

24 24

24 24

SERVICE/SELF SERVICE SEAFOOD 100913

27

Page 28

HUSSMANN - DSFI WEDGES REMOTE (CHINO)

REFRIGERATION DATA:

END PANEL WIDTH KEY

VELOCITY

PAR CONV PAR CONV PAR CONV

(FT/MIN) GPM PSI

1 1.5

30 OS

FRESH

SEAFOOD

1000 1150 22 22 32 32 350 TBD .4 .1 2 1.5

45 0S

FRESH

SEAFOOD

1200 1380 22 22 32 32 350 TBD .4 .1

LEGEND

45 IS

FRESH

SEAFOOD

500 575 22 22 32 32 350 TBD TBD TBD

PAR- PARALLEL

CONV- CONVENTIONA L

N/A - NOT AVAILABLE

TBD -

TO BE DETERMINED

A/S- AIRSWEEP

*3º F less than evaporator for pressure lossin refrigerant lines

REFRIGERATION DATA CONTINUED:

*** REFRIGERATION NOTES:

USAGE

CUT IN

(ºF)

CUT OUT

(ºF)

R22

(PSIG)

R404A

(PSIG)

R407A

(PSIG)

CUT IN

(PSI)

CUT OUT

(PSI)

CUT IN

(PSI)

CUT OUT

(PSI)

CUT IN

(PSI)

CUT OUT

(PSI)

30 OS

FRESH

SEAFOOD

34 30 43 56 TBD 40 10 40 10 40 10

45 OS

FRESH

SEAFOOD

34 30 43 56 TBD 40 10 40 10 40 10

45 IS

FRESH

SEAFOOD

34 30 43 56 TBD 40 10 40 10 40 10

ELE CTRI CAL D ATA:

FANS AND HEATERS (120 VOLT)

AMPS

WATTS AM PS WATTS AMPS WATTS

# ROWS

AMPS WATT S AMPS WATTS AMPS

WATTS AMPS WATTS AMPS WATTS AMPS WATTS

30 OS 1 0.62 12 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.18 20

45 OS 1 0.62 12 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.28 30

45 IS 1 0.62 12 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.18 20

ELECTRICAL DATA CONTINUED: DEFROST DATA *:

#OUTLETS

VOLTS AMPS

AMPS WATTS AM PS WATTS

30 OS 1 115 15 30 OS

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/A

45 OS 1 115 15 45 OS

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/A

45 IS N/A N/A N/A 45 IS

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/A

OPTIONS/NOTES:

24

24 24

24 24

(LB/DAY)

DRIP

TIME

(MIN.)

DEFROSTS

PER DAY

(OPTIONAL) COOLGAS

DEFROST 208V 1PH.

ELECTRICAL

DEFROST

208V 1 PHASE

N/A

EPR SETTINGS

DEFROST

WATER

N/A

N/A

DEFROST

TYPE

TIME

(MIN.)

TERM. TEMP

(ºF)

COIL: ON

RISE

CASE

LENGTH

AIR

SENSOR

(ºF)

BACK

WALL

CASE LENGTH

PAR CONV

# OF

FANS

PER

CASE

ELEC. THERMOSTAT / AIR

SENSOR SETTINGS

R22

CASE LENGTH

CASE LENGTH

3.0

1.5

TOTAL ADDE D

LENGTH (IN.)

END PNL

WIDTH

(IN.)

# OF END

PNLS

EVAPORATOR

EST.

REFG.

CHRG.

(LBS)

24

CASE LENGTH

REAR LEDGE HTR

(OPTIONAL) REAR

LIT SIGN PANEL

LIGHTS

HUMIDITY FANS

GLYCOL

REQUIREMENTS

CAPACIT Y

(BTU/HR)

CONVENIENCE OUTLETS

TOTAL

EVAPORATOR

FANS

DISCHARGE AIR

R407AR404A

TEMPERATURE (ºF)

CASE

USAGE

UNIT SIZING*

LEDGE

LIGHTS

ANTI-SWEAT HEATERS

(On Fan Circuit)

GLASS HEATER

1) BTU'S EXCLUDE LIGHTS, LEDGE LIGHT OUT OF REFRIG. ZONE: WILL NOT AFFECT BTU'S

CONVENTIONAL COMPRESSOR SETTINGS

SHELF LIGHTS

(OPTIONAL)

TOTAL LIGHTS

CANOPY

LIGHTS

SERVICE/SELF SERVICE SEAFOOD 100913

28

Page 29

HUSSMANN - DSFI (CHINO)

REFRIGERATION DATA:

END PANEL WIDTH KEY

VELOCITY

30 MINs AFTER

DEFORST

PAR CONV PAR CONV PAR CONV

(FT/MIN) GPM PSI

1 1.5

DSFI 2'

FRESH

SEAFOOD

500 575 24 24 32 32 500 TBD TBD TBD 2 1.5

DSFI 3'

FRESH

SEAFOOD

750 863 24 24 32 32 500 TBD TBD TBD

LEGEND

DSFI 4'

FRESH

SEAFOOD

1000 1150 24 24 32 32 500 TBD TBD TBD

DSFI 5'

FRESH

SEAFOOD

1250 1438 24 24 32 32 500 TBD TBD TBD PAR- PARALLEL

CONV- CONVENT IONAL

N/A - NOT AVAILABLE

TBD -

TO BE DETERMINED

A/S- AIRSWEEP

*3º F less than evaporator for pr essure loss in refrigerant lines

REFRIGERATION DATA CONTINUED:

*** REFRIGERATION NOTES:

USAGE

CUT IN

(ºF)

CUT OUT

(ºF)

R22

(PSIG)

R404A

(PSIG)

R407A

(PSIG)

CUT IN

(PSI)

CUT OUT

(PSI)

CUT IN

(PSI)

CUT OUT

(PSI)

CUT IN

(PSI)

CUT OUT

(PSI)

2) ADD 20 BTU'S PER FOOT/PER SHELF FOR F LOURESCENT LOWER SHELF LIGHTS

DSFI 2'

FRESH

SEAFOOD

34 30 43 55 TBD 40 10 40 10 40 10

3) ADD 10 BTU'S PER FOOT/PER SHELF FOR OPTION AL LED LOWER SHELF LIGHTS

DSFI 3'

FRESH

SEAFOOD

34 30 43 55 TBD 40 10 40 10 40 10

DSFI 4'

FRESH

SEAFOOD

34 30 43 55 TBD 40 10 40 10 40 10

DSFI 5'

FRESH

SEAFOOD

34 30 43 55 TBD 40 10 40 10 40 10

ELECTRICAL DATA:

FANS AND HEATERS (120 VOLT)

LIGHTING: T5 WITH ELECTRONIC BALLASTS 120V INPUT VOLTAGE

AMPS

WATTS AMPS WATTS AMPS WATTS AMPS WATTS # ROWS AMPS WATTS AMPS WATTS AMPS

WATTS AMPS WATTS AMPS WATTS AMPS WATTS

DSFI 2' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.18 20

DSFI 3' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.27 30

DSFI 4' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.36 40

DSFI 5' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.45 50

ELECTRICAL DATA CONTINUED: DEFROST DATA *:

# OUTLETS

VOLTS AMPS

AMPS WATTS AMPS WATTS

DSFI 2' 1 120 15 2'

OFF TIME

46 48 30 TBD 3 N/A N/A N/ A N/A

DSFI 3' 1 120 15 3'

OFF TIME

46 48 30 TBD 3 N/A N/A N/ A N/A

DSFI 4' 1 120 15 4'

OFF TIME

46 48 30 TBD 3 N/A N/A N/ A N/A

DSFI 5' 1 120 15 5'

OFF TIME

46 48 30 TBD 3 N/A N/A N/ A N/A

OPTIONS/NOTES:

* PLEASE NOTE: HUSSMANN RECOMMENDS THE USE OF DEFROST TERMINATION FOR ELECTRIC DEFROST F OR SCSS-SL IN

LOW TEMP MODE

CASE LENGTH

(OPTI ONAL) REAR

LIT SIGN PANEL

LIGHTS

1) BTU'S EXCLUDE LIGHTS, LEDGE LIGHT OUT OF REFRIG. ZONE: WILL NOT AFFECT BTU'S

# OF

FANS

PER

CASE

TOTAL

EVAPORATOR

FANS

DEFROST

TYPE

TIME

(MIN.)

TERM. TEM P

(ºF)

COIL: ON

RISE

AIR

SENSOR

(ºF)

BACK

WALL

GLYCOL

REQUIREMENTS

EST.

REFG.

CHRG.

(LBS)

LEDGE LIGHTS

R407A

EPR SETTINGS

R22

CONVENTIONAL COMPRESSOR SETTINGS

R404A

3.0

1.5

TOTAL ADDE D

LENGTH (IN.)

END PNL

WIDTH

(IN.)

# OF END

PNLS

TEMPERATURE (ºF)

CASE

USAGE

UNIT SIZING*EVAPORATOR

PAR CONV

CAPACI TY

(BTU/HR)

DISCHARGE AIR

CASE LENGTH

CASE LENGTH

CONVENIENCE OUTLETS

HUMIDITY FANS

ELEC. THERMOSTAT / AIR

SENSOR SETTINGS

ELECTRICAL

DEFROST

208V 1 PHASE

CANOPY

LIGHTS

CASE LENGTH

DEFROST

WATER

TBD

TBD

TBD

TBD

CASE

LENGTH

ANTI- SWEAT H EATERS

(On Fan Circuit)

GLASS HEATER

REAR LEDGE

26 26

(LB/DAY)

DRIP

TIME

(MIN.)

DEFROSTS

PER DAY

(OPTIONAL) COOL GAS

DEFROST 208V 1PH.

26 26

26 26

SHELF LIGHTS (OPTIONAL) TOTAL LIGHTS

CANOPY LIGHTS

(LED)

26 26

SERVICE/SELF SERVICE SEAFOOD 100913

29

Page 30

HUSSMANN - DSFM REMOTE (CHINO)

REFRIGERATION DATA:

END PANEL WIDTH KEY

VELOCITY

30 MINs AFTER

DEFORST

PAR CONV PAR CONV PAR CONV

(FT/MIN) GPM PSI

1 1.5

DSFM 3'

FRESH

SEAFOOD

900 1035 22 22 31 31 500 TBD 0.5 1.0 2 1.5

DSFM 4'

FRESH

SEAFOOD

1200 1380 22 22 31 31 500 TBD 0. 7 2.1

LEGEND

DSFM 5'

FRESH

SEAFOOD

1500 1725 22 22 31 31 500 TBD 0. 9 3.5

DSFM 6'

FRESH

SEAFOOD

1800 2070 22 22 31 31 500 TBD 1. 1 5.1 PAR- PARALLEL

DSFM 8'

FRESH

SEAFOOD

2400 2760 22 22 31 31 500 TBD 1. 4 1.7 CONV- CONVENTIONAL

DSFM 10'

FRESH

SEAFOOD

3000 3450 22 22 31 31 500 TBD 1.8 2.6

N/A - NOT AVAILABLE

DSFM 12'

FRESH

SEAFOOD

3600 4140 22 22 31 31 500 TBD 2.1 3.6

TBD -

TO BE DETERMINED

DSFM-45 OS

FRESH

SEAFOOD

1800 2070 22 22 31 31 500 TBD TBD TBD

A/S- AIRSWEEP

*3º F less than evaporator for pres sure loss in refrigerant lines

REFRIGERATION DATA CONTINUED: *** REFRIGERATION NOTES:

USAGE

CUT IN

(ºF)

CUT OUT

(ºF)

R22

(PSIG)

R404A

(PSIG)

R407A

(PSIG)

CUT IN

(PSI)

CUT OUT

(PSI)

CUT IN

(PSI)

CUT OUT

(PSI)

CUT IN

(PSI)

CUT OUT

(PSI)

DSFM 3'

FRESH

SEAFOOD

33 29 43 56 TBD 40 10 40 10 40 10

DSFM 4'

FRESH

SEAFOOD

33 29 43 56 TBD 40 10 40 10 40 10

DSFM 5'

FRESH

SEAFOOD

33 29 43 56 TBD 40 10 40 10 40 10

DSFM 6'

FRESH

SEAFOOD

33 29 43 56 TBD 40 10 40 10 40 10

DSFM 8'

FRESH

SEAFOOD

33 29 43 56 TBD 40 10 40 10 40 10

DSFM 10'

FRESH

SEAFOOD

33 29 43 56 TBD 40 10 40 10 40 10

DSFM 12'

FRESH

SEAFOOD

33 29 43 56 TBD 40 10 40 10 40 10

DSFM-45 OS

FRESH

SEAFOOD

33 29 43 56 TBD 40 10 40 10 40 10

ELECTRICAL DATA:

FANS AND HEATERS (120 VOLT)

LIGHTING: T5 WITH ELECTRONIC BALLASTS 120V INPUT VOLTAGE

AMPS

WATTS AMPS WATTS AMPS WATTS # ROWS AMPS WATTS AMPS WATTS AMPS

WATTS AMPS WATTS AMPS WATTS AMPS WATTS

DSFM 3' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.30 36

DSFM 4' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.40 48

DSFM 5' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.42 50

DSFM 6' 2 1.24 24 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.50 60

DSFM 8' 2 1.24 24 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.67 80

DSFM 10' 3 1.86 36 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.83 100

DSFM 12' 3 1.86 36 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 1.00 120

DSFM-45 OS 1 0.62 12 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.28 30

ELECTRICAL DATA CONTINUED: DEFROST DATA *:

#OUTLETS

VOLTS AMPS

AMPS WATT S AMPS WATTS

DSFM 3' 1 115 15 3 '

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/ A

DSFM 4' 1 115 15 4 '

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/ A

DSFM 5' 1 115 15 5 '

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/ A

DSFM 6' 1 115 15 6 '

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/ A

DSFM 8' 1 115 15 8'

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/ A

DSFM 10' 1 115 15 10'

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/ A

DSFM 12' 1 115 15 12'

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/ A

DSFM-45 OS N/A N/A N/A 45OS

OFF TIME

46 48 30 N/A 3 N/A N/A N/A N/ A

OPTIONS/NOTES:

TOTAL

EVAPORATOR

FANS

DISCHARGE AIR

R407AR404A

24 24

24

24

CONVENTIONAL COMPRESSOR SETTINGS

SHELF LIGHT S

(OPTIONAL)

TEMPERATURE (ºF)

CASE

USAGE

UNIT SIZING*EVAPORATOR

# OF END

PNLS

CASE LENGTH

24

REAR LEDGE HTR

(OPTIONAL) REAR

LIT SIGN PANEL

LIGHTS

HUMIDITY FANS

GLYCOL

REQUIREMENTS

24

CAPACIT Y

(BTU/HR)***

EST.

REFG.

CHRG.

(LBS)

LEDGE

LIGHTS

ANTI-S WEAT HE ATERS

(On Fan Circuit)

GLASS HEATER

1) BTU'S EXCLUDE LIGHTS, LEDG E LIGHT OUT OF REFRIG. ZONE: W ILL NOT AFFECT BTU'S

3.0

1.5

TOTAL ADDED

LENGTH ( IN.)

END PNL

WIDTH

(IN.)

PAR CONV

CASE LENGTH

TOTAL LIGHTS

DEFROST

TYPE

TIME

(MIN.)

TERM.

TEMP (ºF)

COIL: ON

RISE

CASE

LENGTH

AIR

SENSOR

(ºF)

BACK

WALL

CASE LENGTH

CANOPY

LIGHTS

CASE LENGTH

CONVENIENCE OUTLETS

# OF

FANS

PER

CASE

ELEC. THERMOSTAT / AIR

SENSOR SETTINGS

R22

N/A

24

EPR SETTINGS

DEFROST

WATER

N/A

N/A

N/A

24 24

N/A

24

24 24

24 24

24 24

N/A

(LB/DAY)

DRIP

TIME

(MIN.)

DEFROSTS

PER DAY

(OPTIONAL) COOL GAS

DEFROST 208V 1PH.

ELECTRICAL

DEFROST

208V 1 PHASE

N/A

N/A

SERVICE/SELF SERVICE SEAFOOD 111313

30

Page 31

HUSSMANN - DSFN REMOTE (CHINO)

REFRIGERATION DATA:

END PANEL WIDTH KEY

VELOCITY

30 MINs AFTER

DEFORST

PAR CONV PAR CONV PAR CONV

(FT/MIN) GPM PSI

1 1.5

DSFN 2'

FRESH

SEAFOOD

500 575 24 24 32 32 500 TBD 0.5 0.6 2 1.5

DSFN 3'

FRESH

SEAFOOD

750 863 24 24 32 32 500 TBD 0.7 1.7

LEGEND

DSFN 4'

FRESH

SEAFOOD

1000 1150 24 24 32 32 500 TBD 1.0 3.3

DSFN 5'

FRESH

SEAFOOD

1250 1438 24 24 32 32 500 TBD 1.2 5.4 PAR- PARALLEL

DSFN 6'

FRESH

SEAFOOD

1500 1725 24 24 32 32 500 TBD TBD TBD CONV- CONVENTIONAL

DSFN 8'

FRESH

SEAFOOD

2000 2300 24 24 32 32 500 TBD TBD TBD

N/A - NOT AVAILABLE

DSFN 10'

FRESH

SEAFOOD

2500 2875 24 24 32 32 500 TBD TBD TBD

TBD -

TO BE DETERMINED

DSFN 12'

FRESH

SEAFOOD

3000 3450 24 24 32 32 500 TBD TBD TBD

A/S- AIRSW EEP

*3º F less than evaporator for pressure loss in refrigerant lines

REFRIGERATION DATA CONTINUED: *** REFRIGERATION NOTES:

USAGE

CUT IN

(ºF)

CUT OUT

(ºF)

R22

(PSIG)

R404A

(PSIG)

R407A

(PSIG)

CUT IN

(PSI)

CUT OUT

(PSI)

CUT IN

(PSI)

CUT OUT

(PSI)

CUT IN

(PSI)

CUT OUT

(PSI)

DSFI

FRESH

SEAFOOD

34 30 43 55 TBD 40 10 40 10 40 10

ELECTRICAL DATA:

FANS AND HEATERS (120 VOLT)

LIGHTING: T5 WITH ELECTRONI C BALLASTS 120V INPUT VOLTAGE

AMPS

WATTS AMPS WATTS AMPS WATTS

# ROWS

AMPS WATTS AMPS WATTS AMPS

WATTS AMPS WATTS AMPS WATTS AMPS WATTS

DSFN 2' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.17 20

DSFN 3' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.26 30

DSFN 4' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.34 40

DSFN 5' 1 0.62 12 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.43 50

DSFN 6' 2 1.24 24 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.51 60

DSFN 8' 2 1.24 24 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.67 80

DSFN 10' 3 1.86 36 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 0.85 100

DSFN 12' 3 1.86 36 0.1 8 N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A N/A 1.02 120

ELECTRICAL DATA CONTINUED: DEFROST DATA *:

# OUTLETS

VOLTS AMPS

AMPS WATTS AMPS WATTS

DSFN 2' N/A N/A N/A 2'

OFF TIME

46 48 31 N/A 3 N/A N/A N/A N/A N/A N/A

DSFN 3' 1 120 15 3'

OFF TIME

46 48 31 N/A 3 N/A N/A N/A N/A N/A N/A

DSFN 4' 1 120 15 4'

OFF TIME

46 48 31 N/A 3 N/A N/A N/A N/A N/A N/A

DSFN 5' 1 120 15 5'

OFF TIME

46 48 31 N/A 3 N/A N/A N/A N/A N/A N/A

DSFN 6' 1 120 15 6'

OFF TIME

46 48 31 N/A 3 N/A N/A N/A N/A N/A N/A

DSFN 8' 1 120 15 8'

OFF TIME

46 48 31 N/A 3 N/A N/A N/A N/A N/A N/A

DSFN 10' 1 120 15 10'

OFF TIME

46 48 31 N/A 3 N/A N/A N/A N/A N/A N/A

DSFN 12' 1 120 15 12'

OFF TIME

46 48 31 N/A 3 N/A N/A N/A N/A N/A N/A

OPTIONS/NOTES:

26

26 26

2626

26 26

26 26

CASE LENGTH

DEFROST

WATER

26 26

(LB/DAY)

DRIP TIME

(MIN.)

DEFROSTS

PER DAY

(OPTIONAL) COOL GAS

DEFROST 208V 1PH.

ELECTRICAL

DEFROST

208V 1 PHASE

AIR

SENSOR

(ºF)

BACK

WALL

CASE LENGTH

CANOPY

LIGHTS

TOTAL

EVAPORATOR

FANS

EPR SETTINGS

R22

CONVENTIONAL COMPRESSOR SETTINGS

SHELF LIGHTS

(OPTIONAL)

R404A

TEMPERATURE (ºF)

CASE

USAGE

UNIT SIZING*EVAPORATOR

PAR CONV

CAPACITY

(BTU/HR)

DISCHARGE AIR

3.0

1.5

TOTAL ADDED

LENGTH (IN.)

END PNL

WIDTH

(IN.)

# OF END

PNLS

REAR LEDGE HTR

(OPTIONAL) REAR

LIT SIGN PANEL

LIGHTS

HUMIDITY FANS

GLYCOL

REQUIREMENTS

26

EST.

REFG.

CHRG.

(LBS)

TOTAL LI GHTS

R407A

26

CONVENIENCE OUTLETS

26

CASE

LENGTH

DEFROST

TYPE

TIME

(MIN.)

TERM.

TEMP (ºF)

COIL: ON

RISE

* PLEASE NOTE: HUSSMANN RECOMMENDS THE USE OF DEFROST TERMINATION FOR ELECTRIC DEFROST FOR SCSS-SL IN

LOW TEMP MODE

26 26

CASE LENGTH

LEDGE LIGHTS

ANTI-SWEAT HEATERS

(On Fan Circuit)

GLASS HEATER

1) BTU'S EXCLUDE LIGHTS, LEDGE LIGHT OUT OF REFRIG. ZONE: WILL NOT AFFECT BTU'S

# OF

FANS

PER

CASE

ELEC. THERMOSTAT / AIR

SENSOR SETTINGS

SERVICE/SELF SERVICE SEAFOOD 100913

31

Page 32

BEFORE SERVICING

ALWAYS DISCONNECT ELECTRICAL

POWER AT THE MAIN DISCONNECT

WHEN SERVICING OR REPLACING ANY

ELECTRICAL COMPONENT.

This includes (but not limited to) Fans, Heaters

Thermostats, and Lights.

Electrical

Wiring Color Code

CASE MUST BE GROUNDED

NOTE: Refer to label illustrated above that is afxed to case

to determine the actual conguration as checked in the

“TYPE INSTALLED” boxes.

Electrical Circuit Identication

Standard lighting for all models will be full length uorescent

lamps located within the case at the top.

The switch controlling the lights, the plug provided for

digital scale, and the thermometer are located at the rear

of the case mullion.

The receptacle that is provided on the exterior back of these

models is intended for computerized scales with a ve amp

maximum load, not for large motors or other high wattage

appliances. It should be wired to a dedicated circuit.

Electrical Service Receptacles (When Applicable)

The receptacles located on the exterior of the merchandiser

are intended for scales and lighted displays. They are not

intended nor suitable for large motors or other external

appliances.

Field Wiring and Serial Plate Amperage

Field Wiring must be sized for component amperes printed

on the serial plate. Actual ampere draw may be less than

specied. Field wiring from the refrigeration control panel to

the merchandisers is required for refrigeration thermostats.

Case amperes are listed on the wiring diagram, but always

check the serial plate.

Ballast Location

The DSF, DSFM has no lights other than Optional Ledge

lights. The ballasts for ledge lights are located in the xture

itself.

32

Page 33

Electrical (Cont'd)

Wiring Halogen Lights

Halogen lamps must not be operated above recommended

rated voltage. They should be wired on a 3 wire, 3Ø system

with a neutral. Feed the lights from the balanced leg if you

have a high leg.

User Information

Stocking

Improper temperature and lighting will cause serious

product loss. Discoloration, dehydration and spoilage

can be controlled with proper use of the equipment and

handling of product. Product temperature should always

be maintained at a constant and proper temperature.

This means that from the time the product is received,

through storage, preparation and display, the temperature

of the product must be controlled to maximize life of the

product. Hussmann cases were not designed to “heat up”

or “cool down” product-but rather to maintain an item’s

proper temperature for maximum shelf life. To achieve the

protection required always:

1. Minimize processing time to avoid damaging

temperature rise to the product. Product should be

at proper temperature.

2. Keep the air in and around the case area free

of foreign gasses and fumes or food will rapidly

deteriorate.

3. Maintain the display merchandisers temperature

controls as outlined in the refrigerator section of this

manual.

4. Do not place any product into these refrigerators

until all controls have been adjusted and they

are operating at the proper temperature. Allow

merchandiser to operate a minimum of 6 hours

before stocking with any product.

5. When stocking, never allow the product to extend

beyond the recommended load limit. Air discharge

and return air ue must be unobstructed at all

times to provide proper refrigeration.

6. There are vents located at the base of the front of the

glass, just above the front rail. These vents supply a

continuous, gentle ow of air across the front glass

which inhibits condensation. Do not place any