Page 1

January 2006

INSTALLATION & SERVICE

INSTRUCTIONS

FOR

DDS – DDSS SELF-CONTAINED AND REMOTE

Multi-deck, Spot display

Refrigerator Merchandisers

First Call for help (US and Canada):

1-800-922-1919

Soporte Tècnico y Asistencia (Mèxico):

01-800-522-1900

For a Service Network Locator and other

Information visit us at

www.hussmann.com

select Worldwide Locations

HUSSMANN - GLOVERSVILLE

P/N OII – DDS, DDSS Merchand isers

January 2006

Page 2

TABLE OF CONTENTS

SECTION 1 General Information Page 3

SECTION 2 Installation Page 4

SECTION 3 Refrigeration Page 5

Self Contained Models

SECTION 4 Refrigeration Page 6

Remote Models

SECTION 5 Electrical Page 12

SECTION 6 Replacement Parts List Page 14

SECTION 7 User Instructions Page 20

SECTION 8 Service Tips and Wiring Diagrams Page 22

Page 3

SECTION 1

GENERAL INFORMATION

MODEL DESCRIPTION

The DDS model seri es are multi-deck, spot merchandisers designed for medium tem pe ratu re

area of the case ready for operation wh en electrical service is connec ted.

requi rements for the rem ote model will be 120 v olt, 60 hertz (Hz).

MODEL ELECTRICAL DESCRIPTION

MODEL

DESCRIPTION

ELECTRICAL SERVICE

Symbol

∅

den otes

APPLICATION

less and relative hu midity does not exceed 55%.

HUSSMANN - GLOVERSVILLE

applica ti ons such as : deli/dairy/bevera ge /floral. They are avail ab l e as eithe r remote ty pe

models, which requi re sepa rate condensing unit connections, or self -con tain ed m odels. Each

self -c ontai n ed model will have i t’s own c on de nsing unit, fac tory installed ben ea th the di s pl ay

The f ollowing table lists the standa rd models wi th a brief description of each, incl uding the

elec trical requi rem en ts of the self-con tained m odel. Unless otherwis e specifi ed , the elec trical

DDS/DDF-4B Self-Contained 4’ Merchandiser 115 / 60 Hz / 1

DDS/DDF-4D/G Self-Contained 4’ Merchandiser 230v - 208v / 60 Hz / 1

DDS/DDF-6D/G Self-Contained 6’ Merchandiser 230v - 208v / 60 Hz / 1

DDS/DDF-8D/G Self-Contained 8’ Merchandiser 230v - 208v / 60 Hz / 1

DDS/DDF-4R Remote Type 4’ Merchandiser 115 / 60 Hz / 1

DDS/DDF-6R Remote Type 4’ Merchandiser 115 / 60 Hz / 1

DDS/DDF-8R Remote Type 4’ Merchandiser 115 / 60 Hz / 1

DDSS-4D/G Self-Contained 4’ Merchandiser 230v- 208v / 60 Hz / 1

∅

∅

∅

∅

∅

∅

∅

∅

These models are designe d for use only in air-conditioned stores where temperature is 75°F or

Page 4

03 Page 4

SECTION 2

INSTALLATION

SHIPPING DAMAGE

All equipment should be examined for shipping damage before and during unloading. If there is

any damage, the carrier should be notified immediately and an inspection requested. The

delivery receipt must be noted that equipment was received damaged. If damage is of a

concealed nature, we suggest the carrier be contacted immediately, or no later than (3) days

following delivery. The consignee for all damages must file a claim with the carrier.

SHIPPING BRACES

Move the fixture as close as possible to its permanent location then remove all packaging and

shipping braces. Remove all separately packed accessories such as kits, shelves, etc.

EXTERIOR LOADING

These cases are not structurally designed to support excessive external loading such as the

weight of a person, therefore, do not walk on the top of these refrigerators or damage to the

refrigerator and serious personal injury could occur.

LOCATION

These refrigerators, like other open refrigerators, are sensitive to air disturbances. Air currents

passing around them will seriously impair their operation. Do not allow air-conditioning,

electric fans, open doors or windows, etc. to create air currents around these cases.

DO NOT INSTALL THE VENTED PANELS OF THE SELF-CONTAINED MODELS

AGAINST A WALL OR OTHER STORE FIXTURE.

Located in the lower front and rear of the self-contained models are vented panels. These panels

allow air circulation to the condensing unit. Blocking or restricting air circulation through these

panels can cause poor performance and damage the refrigeration system.

INSTALL THE REFRIGERATOR NO CLOSER THAN (4) FOUR INCHES FROM A WALL OR OTHER

STORE FIXTURES.

HUSSMANN - GLOVERSVILLE

Page 5

07/02/03

Page 5

SECTION

3

REFRIGERATION

-

SELF CONTAINED MODELS

Each self-contained model is eq uipped with its own condensing unit located ben eath the display

serv ice valves open, compl e tel y ready for operation when elec trical power h as been connected.

REFRIGERANT

CHARGE

DDS/DDF-8D /G

R – 404A

8

2

DDS – 4D/G c/w

Hp

Condens in g

Unit

R - 22

50DDSS – 4D/G

R-22

5

8

CONTROLS a nd ADJUSTMENTS

TEMPERATURE

FREQUENCY

FAILSAFE

28° to 34

°

F

Every

6 Hours

90 psig (R-22)

105 psi g (R-404A)

45

Minutes

honeycomb.

s

k

HUSSMANN - GLOVERSVILLE

area. The unit will be charged per nameplate refri ge rant and shipped from the fa ctory with all

MODEL REFRIGERANT POUNDS OUNCES

DDS/DDF -4B R - 22 5 8

DDS/DDF-4D /G R - 22 5 8

DDS/DDF-6D /G R - 22 7 11

REFRIGERATION

CONTROLS

DISCHARGE AIR

A ref rigeration thermostat con trol s refrige ration tempera ture . The control i s f actory

installed in th e c ontrol p anel. Adjust this thermostat to m aintai n th e discharge air

temperature sh own . Meas ure dis ch arg e air temperatures at the center of the discharge

Defrosts are time-initiated and pressure terminated. The defrost timer is factory set a

shown. Check that the above settings are imp lemented and correct, and that the cloc

indicated the correc t tim e of day.

Defrost m ust be terminated by def rost termi nation settin g.

DEFROST

DEFROST CONTROLS

PRESSURE

TERMINATION

Page 6

07/02/03 Page 6

SECTION 4

REFRIGERATION - REMOTE MODELS

REFRIGERANT PIPING

Refrigerant line connection sizes: All models LIQUID LINE 3/8” OD

SUCTION LINE 5/8” OD for 4’ & 6’ Models; 1 1/8” for all other models

These connections are made at the right hand end of the cases (facing front) beneath the

refrigerated display area. Refrigerant lines should be sized as shown on the refrigeration legend

(furnished by the owner). If a legend has not been furnished, refer to Section 12 of the

Hussmann Application Engineering Manual for guidance.

OUTLET LOCATION

The refrigerant line outlet is located at the right hand end of the refrigerator beneath the display

pans. After connections have been made, seal this outlet thoroughly both on the inside and the

outside. An aerosol dispensed urethane type of insulation is recommended.

LINE SIZING

Refrigerant lines should be sized as shown on the refrigeration legend prepared for the store and

as (furnished by the owner). If a legend has not been furnished, refer to Section 12 of the

Hussmann Application Engineering Manual for guidance.

OIL TRAPS

P-traps (oil traps) must be installed at the base of all suction line vertical risers.

PRESSURE DROP

Pressure drop reduces capacity of the refrigeration system. To minimize pressure drop, use

proper size tubing, keep the refrigerant line runs as short as possible and use a minimum number

of elbows. Where elbows are needed, use long radius elbows only.

PIPING INSULATION

For refrigerators with other than KOOLGAS defrost, the suction and liquid lines should be

clamped and/or taped together and insulated for a minimum of 30 feet from the refrigerator.

Refrigerators with KOOLGAS defrost should not have their liquid and suction lines in contact

with each other but are to be separately insulated for a minimum of 30 feet from the refrigerator.

Additional insulation for the balance of the refrigerant lines is recommended and required

wherever condensation and dripping would be objectionable.

HUSSMANN - GLOVERSVILLE

Page 7

07/02/03 Page 7

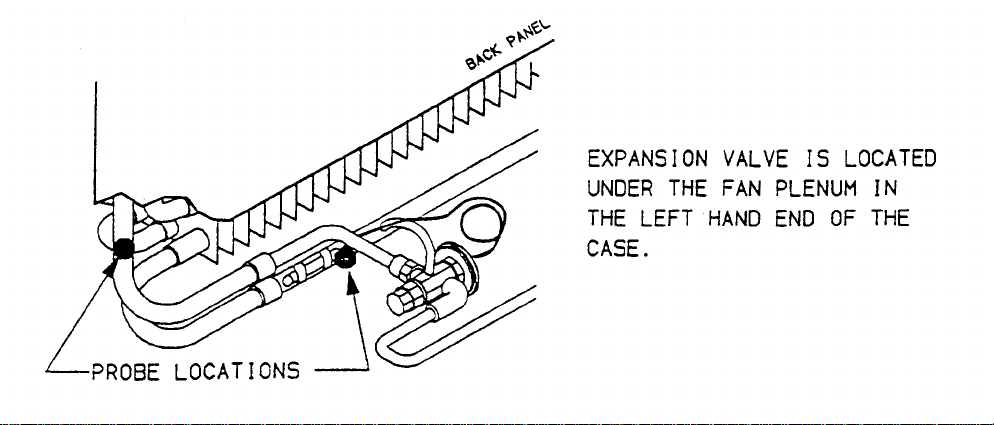

EXPANSION VALVE ADJUSTMENT

Expansion valves must be adjusted to fully feed the evaporator. Before attempting to adjust

valves, make sure the evaporator is either clear of / or only lightly covered with frost, and that

the fixture is within 10° F of it’s expected operating temperature.

Adjust the valve as follows:

A. Attach a probe to the suction line near the expansion valve bulb.

B. Obtain a pressure reading from the factory installed Schraeder valve. Convert

the pressure reading to a saturated temperature for the appropriate refrigerant

Temperature B minus Temperature A = Superheat

Some “hunting” of the expansion valve is normal. The valve should be adjusted so that during

the hunting the greatest difference between the two temperatures is 3° F to 5° F.

With this adjustment, during a portion of the hunting the temperature difference between the

probes will be less than 3° F (at times as low as 0° F).

Make adjustments of no more than (1/2) turn of the valve stem at a time and wait for at

least fifteen minutes before rechecking the probe temperature and making further

adjustments.

Page 8

Page 9

07/02/03 Page 8

REFRIGERATION & DEFROST CONTROLS FOR

CONVENTIONAL OPERATION

(Single Compressor System)

Refrigeration temperature may be controlled by either the condensing unit’s low-pressure

control or by refrigeration thermostat (optional / one per condensing unit). Thermostatic control

is preferred since it will provide a more constant year-round control of temperature. The

thermostat may be field or factory installed, must have a differential of 3° F to 6° F and have its

sensing bulb located to monitor the air leaving the evaporator. One thermostat per condensing

unit is required and should be wired into the compressor motor contactor control circuit.

A pump down system is recommended for outdoor condensing units.

DEFROST:

DDS models have defrost cycles that are time initiated and time terminated.

REFRIGERATION CONTROLS

Discharge

Air

Temp

(Cut-out)

28°F

c

c

Convert

Temperatures

to Pressures for

type of

Refrigerant

Used

LOW PRESSURE CONTROL SETTINGS DEFROST TIMER

If used to control

temperature

d

(Cut-out) (Cut-in)

If thermostat controls

temperature

e

(Cut-out) (Cut-in)

12°F 30°F -7°F 26°F

Measure discharge air temperatures at the center of the honeycomb. If thermostat is

DEFROST CONTROLSf

Defrost

Frequency

Every

6 Hours

used to control temperature, set thermostat to open contacts at the discharge air

d

temperature given in the table.

Adjust the cutout on the low-pressure control to stop the compressor at the discharge

temperature given in the table. Final adjustment should be made after refrigerator is

stocked with product. If cycle frequency is more than 4 times per hour, cycling should

produce an average discharge air temperature as shown above.

e

These settings are acceptable for outdoor unit applications when the coldest expected

ambient does not go below 0° F. If colder ambient temperatures are expected, set

control accordingly per “Hussmann Condensing Unit Installation Instructions.

f

If these spot display refrigerators are to be multiplexed with a different type refrigerator,

compare these defrost settings with those specified for the other refrigerator. If the

settings are not compatible, refer to page 15 (Controls & adjustments – Mixed

Multiplexing).

Failsafe

Length

Termination

Pressure

45 Min 90 psig

HUSSMANN - GLOVERSVILLE

Page 10

07/02/03 Page 9

REFRIGERATION & DEFROST CONTROLS FOR

CONVENTIONAL OPERATION - Mixed Multiplexing (Parallel Racks)

Refrigeration temperature may be controlled by a refrigeration thermostat sensing discharge air

temperature. The thermostat controls a liquid line solenoid (optional) or a suction line solenoid

(optional). The use of an evaporator pressure regulator (EPR) is recommended to allow fixture

to refrigerate at steady levels.

DEFROST:

DDS models have defrost cycles that are time initiated and time terminated.

MODEL

ALL

c

d

e

f

Each system shown on the “store legend” must have staggered defrosts to maintain stable

compressor loading and a sufficient supply of defrost gas.

Discharge air temperature is to be measured by attaching a service thermometer to the

discharge honeycomb at the centre of the case.

Adjust the refrigeration thermostat or EPR valve to maintain the discharge air

temperature shown above.

If these spot display refrigerators are to be multiplexed with a different type refrigerator,

compare these defrost settings with those specified for the other refrigerator. If these

settings are not compatible, refer to the following page.

KOOLGAS defrost is time initiated and time terminated. The defrost lengths listed

above are based upon laboratory testing but operation under actual store conditions may

require that they be lengthened to accomplish a thorough defrost. Some of the store

conditions that can contribute to a longer defrost are: low head pressure, long runs of

refrigerant lines, store ambient, fixture temperature operating lower than that

recommended, seasonal ambient changes etc.

REFRIGERATION

CONTROLS

DISCHARGE

AIR TEMP c

(Cut-out)

28° F

DEFROST CONTROLS d

DEFROST

Frequency

Every 6 Hours

DEFROST TIMER

Length of Defrost

Off-Time/Electric

45 Min e

14 Min

KOOLGAS

f

HUSSMANN - GLOVERSVILLE

Page 11

07/02/03 Page 10

REMOTE CONTROL KIT (Optional)

The control settings listed in the preceding tables are those that will provide proper case

performance. If these spot display refrigerators are to be multiplexed with different types of

refrigerator models, we suggest that each spot display refrigerator be equipped with a

“REMOTE CONTROL KIT”.

The remote control kit will insure better control of refrigeration temperature and provide

additional defrost controls that maybe needed since most other refrigerators do not have similar

defrost frequencies and terminations (fail safeguards) with these spot display refrigerators.

The remote-control kit will be factory installed below the display area of the spot display

refrigerator. A liquid line solenoid valve will also be installed.

The liquid line solenoid valve will open when energized. During refrigeration, the valve is

controlled by the refrigeration thermostat (close-on-rise of temperature) providing better and

more specific control of refrigeration temperature. The defrost timer controls the valve for

defrost; closing the valve for initiation; opening the valve at termination.

The remote control kit timer must be synchronized with the timer of the unit.

HUSSMANN - GLOVERSVILLE

Page 12

Page 13

07/02/03 Page 12

SECTION 5

ELECTRICAL

CONNECTIONS

Electrical power connections are made at the left hand end of the case, behind the removable

front or rear base panels.

REMOTE MODELS

All electrical connections for remote models will be made in the junction box located behind the

removable front base panel, at the left hand end of the case.

SELF CONTAINED MODELS

All electrical connections for self-contained models will be made in the control panel of the

case. All electrical connections have been terminated inside the control panel and “pig-tailed”

for ease of connecting field wiring. See appropriate wiring diagram in this section.

CAUTION:

NOTE: ALL WIRING AND CONNECTIONS MUST COMPLY

THE FIXTURE MUST BE ELECTRICALLY GROUNDED.

WITH N.E.C., STATE, PROVINCIAL AND LOCAL CODES.

HUSSMANN - GLOVERSVILLE

Page 14

07/02/03 Page 13

SERIAL PLATE AMPERAGES

Serial plate amperes are the amperage figures that are stamped on the fixture’s Serial Plate.

Although all field installed wiring must be sized to the Serial Plate amperages, the actual current

or amps may be less than specified. DDS Serial Plate is located on the upper left hand corner of

the top interior panel inside the case.

REMOTE MODELS - R

ELECTRICAL SERVICE

DDS / DDF- 4R 115 v / 60 Hz 2.7 1.3

DDS / DDF- 6R 115 v / 60 Hz 6.2 2.6

DDS / DDF- 8R 115 v / 60 Hz 4.7 2.6

CIRCUIT REQUIREMENTS MODEL

LIGHTS

(amps)

FANS

(amps) c

SELF CONTAINED MODELS – B, D/G

ELECTRICAL SERVICE

CIRCUIT REQUIREMENTS MODEL

LIGHTS

(amps)

Condensing Unit,

Evaporator Pan Heater,

(amps) c

Fans

DDS / DDF- 4B 115 v / 60 Hz 2.70 19.0

DDS / DDF- 4D/G

DDS / DDF- 6D/G

DDS / DDF- 8D/G

230 v - 208 v / 60 Hz / 1∅

230 v - 208 v / 60 Hz / 1∅

230 v - 208 v / 60 Hz / 1∅

2.70 10.3

6.2 18.0

5.2 22.65

DDSS-4D/G

115V/208V/230V/1∅/60

0.43 12.01

Hz

DDSS-4D/G

115/208/230V/1∅/60 Hz

0.43 12.01

Fans are to be continuously energized.

c

The amperage figure shown includes the maximum number of

lighted shelves where applicable

HUSSMANN - GLOVERSVILLE

Page 15

07/02/03

Page 14

SECTION 6

REPLACEMENT PARTS LIST: DDS-4B, DDS-4R

ITEM #

HUSSMANN

DESCRIPTION

PART #

1

21-S-138 Fan Motor,

2 21-S-136 Fan Blade

NOTE: Items 1 through 5 are standard parts for both the DDS-4B and DDS-4R

HUSSMANN - GLOVERSVILLE

3 06-S-214 Bulb

4 06-S-187 Ballast –

5 17-s-390 Expansion Valve - R-22

17-S-541 R-404/507

6 04-S-067 Temperature Ctrl

7 03-S-286 Power Switch

8 19-S-757 Condensate Pan Htr. 570W 120V

19-S-766 Co ndensate Pan Htr. 500W 208V

9 02-S-631 Compressor R22 115V

10 17-S-507 Drier

11 03-S-562 Fuse (Elect. Box)

12 14114 Pressure Control

13 03-S-559 Timer 120V 60Hz

03-S-560 208-203V 60Hz

Page 16

07/02/03

Page 15

SECTION 6

REPLACEMENT PARTS LIST: DDS – 4 D/G

ITEM #

HUSSMANN

DESCRIPTION

PART #

1

21-S-138 Fan Motor

HUSSMANN - GLOVERSVILLE

2 21-S-136 Fan Blade

3 06-S-214 Bulb

4 06-S-187 Ballast 5 17-S-390 Expansion Valve – R-22

17-S-541 R-404/507

6 04-S-067 Temperature Ctrl

7 03-S-286 Power Switch

8 03-S-559 Defrost Timer – 120V 60Hz

03-S-560 208-230V 60 Hz

9 17-S-507 Drier

10 14114 Pressure Control

11 03-S-568 Contactor

12 02-S-632 Compressor R22 208-230V

13 19-S-757 Condensat e Pan Htr. 570W 120V

19-S-766 500W 208V

Page 17

07/02/03

Page 16

SECTION 6

REPLACEMENT PARTS LIST: DDS - 6 D/G and DDS - 6R

ITEM #

HUSSMANN

DESCRIPTION

PART #

1

21-S-138 Fan Motor,

2

21-S-136 Fan Blade

Items 6 through 13 are standard parts for only the DDS-6D/G Model

HUSSMANN - GLOVERSVILLE

3 06-S-233 Bulb

4 06-S-187 Ballast

5 17-S-535 Expansion Valve R-22

17S545 R404

17-S-565 R401

6 04-S-067 Temperature Control

7 03-S-286 Power Switch

8 03-S-559 Defrost Timer 120V 60 Hz

03-S-560 208-230V 60Hz

9 19-S-757 Condensate Pan Htr. 570W 120V

19-S-766 500W 208V

10 17-S-507 Drier 11 03-S-562 Fuse – Electrical Box

12 03-S-568 Contactor

13 02-S-633 Compressor R22 208/230V

NOTE: Items 1 through 5 are standard parts for both the DDS-6D/G and DDS-6R

Models

Page 18

07/02/03

Page 17

SECTION 6

REPLACEMENT PARTS LIST: DDS - 8 D/G and DDS - 8R

ITEM #

HUSSMANN

DESCRIPTION

PART #

1

21-S-138 Fan Motor

HUSSMANN - GLOVERSVILLE

2 21-S-136 Fan Blade

3 06-S-214 Bulb

4 06-S-187 Ballast

5 17-S-545 Expansion Valve R404

6 04-S-067 Temperature Control

7 03-S-286 Power Switch

8 03-S-560 Defrost Timer 208-240V 60 Hz

9 19-S-757 Condensate Pan Htr. 570W 120V

19-S-766 Condensate Pan Htr 500W 208V

10 17-S-507 Drier 11 03-S-563 Fuse Electrical Box

12 03-S-298 Contactor

13 02-S-638 Compressor R404 208/230V

Page 19

07/02/03 Page 18 18

SECTION 7

USER’S INSTRUCTIONS

STOCKING

Merchandise should not be placed in the refrigerator until it is at the designed operating

temperature, approximately 2-3 hours. When stocking, never allow product to extend beyond

into the lower return grill.

AIR DISCHARGE AND RETURN AIR FLUES MUST BE UNOBSTRUCTED AT ALL

TIMES, TO PROVIDE PROPER REFRIGERATION AND AIR CURTAIN PERFORMANCE

Since all food items are perishable, packages should be periodically rotated to maintain

freshness.

DO NOT BLOCK OR RESTRICT THE VENTED LOWER BASE PANELS LOCATED AT

EACH END OF THE SELF-CONTAINED MODELS.

These vented areas are for air circulation to the condensing unit area located behind the panels.

CARE AND CLEANING

Long life and satisfactory performance of any equipment is dependent upon the care given to it.

To ensure long life, proper sanitation and minimum maintenance, the fixture should be

thoroughly cleaned, debris removed and the interior washed down monthly.

DO NOT USE STEAM OR EXTREMELY HOT WATER TO WASH THE INTERIOR

•

BOTTOM OF THE CASE.

• WHEN CLEANING, DO NOT USE A HIGH PRESSURE HOSE

• NEVER INTRODUCE WATER INTO THE FIXTURE FASTER THAN THE WASTE

OUTLET CAN CARRY IT AWAY.

THE WASTE OUTLET OF THE OF THE SELF-CONTAINED MODEL DOES NOT

•

EMPTY INTO A FLOOR DRAIN BUT INTO A LIMITED CAPACITY EVAPORATOR

PAN WHICH WILL OVERFLOW IF EXCESS WATER IS USED IN CLEANING.

SOME PANS ARE EQUIPPED WITH A SIDE OUTLET DRAIN TUBE, OTHERS HAVE

•

A TUBE COMING DOWN FROM THE DRAIN.

.

CAUTION:

.

HUSSMANN - GLOVERSVILLE

Page 20

07/02/03 Page 19

CARE AND CLEANING CONTINUED;

CAUTION:

• WHEN CLEANING, STORE PERSONNEL SHOULD CONNECT THIS TUBE TO A

REMOTE HOSE TO CARRY WATER AWAY.

• BE SURE TO CRIMP AND RE-INSERT THE TUBE BACK INTO ITS HOLDING CLIP

ON THE EVAPORATOR PAN, OR PLACE DRAIN TUBE BACK INTO THE

EVAPORATOR PAN AFTER CLEANING.

The interior bottom of this case is an easy to clean, corrosion resistant material designed for

maximum sanitation. All domestic detergents, even ammonia based cleaners are recommended.

Sanitizing solutions will not harm the case interior bottom, however, these sanitizers should be

used in accordance with manufacturer’s directions.

To preserve the exterior finish of the fixture, use warm water and a mild detergent.

DO NOT USE ABRASIVE CLEANERS OR STEEL WOOL SCOURING PADS

TO CLEAN THE FIXTURE, AS THESE WILL MARR THE FINISH.

To maintain good refrigeration performance, a refrigeration service person should be called

periodically (at least twice a year) to clean the discharge honeycomb and remove any

accumulated dirt from the condenser coil and condensate evaporator pan on self-contained

models.

POOR CIRCULATION OF AIR THROUGH THE CONDENSER COIL

WILL RESULT IN POOR REFRIGERATION PERFORMANCE.

Dirt accumulation inside the condensate evaporator pan will reduce the pan’s capacity and affect

the efficiency of the heater causing a burned out heater and an overflow of defrost water onto

the store floor.

HUSSMANN - GLOVERSVILLE

Page 21

07/02/03 Page 20

SECTION 8

SERVICE TIPS

WARNING

ALWAYS DISCONNECT THE ELECTRICAL POWER AT THE MAIN DISCONNECT

WHEN SERVICING OR REPLACING ANY ELECTRICAL COMPONENT OF THIS

REFRIGERATOR. THIS INCLUDES, BUT IS NOT LIMITED TO SUCH ITEMS AS FANS

AND THERMOSTATS.

FAN BLADE REPLACEMENT

The evaporator fan is located at the back of the case directly beneath the display pan. Should

the fan blade ever need servicing, ALWAYS REPLACE THE FAN BLADE WITH THE

RAISED EMBOSSING SIDE OF THE BLADE INSTALLED TOWARD THE MOTOR.

HONEYCOMB REMOVAL & CLEANING

CAUTION: DO NOT TEAR THE HONEYCOMB

1) Remove the honeycomb assembly as follows:

Insert a small Phillips screwdriver behind the rear edge of the honeycomb on the right

hand end and gently pull down. The bottom of the honeycomb will drop down.

Continue down the length of the case, lifting the honeycomb out.

2) To clean honeycomb:

• Mix powdered detergent, in warm water. (5 to 7 Tablespoons per gallon)

• Immerse or spot clean the honeycomb. Use care not to damage the cell structure of

the honeycomb.

• Rinse thoroughly in clean water. Shake excess water from the honeycomb and dry.

(if heat is used, do not exceed 140° F dry heat)

3) Install honeycomb by inserting the notched side up against the deflector and press

upwards inserting the bottom of the honeycomb into the back ledge. Slide along the

honeycomb, pressing the front edge upward into the ledge. Be careful no to damage the

cells or cut yourself on the edges of the honeycomb

(See diagram on next page)

HUSSMANN - GLOVERSVILLE

Page 22

Page 23

07/02/03 Page 21

BALLAST REPLACEMENT

The ballast for the canopy fluorescent lamps is located beneath the canopy panel at the left hand

end of the case.

For access to the ballast:

• Remove the screws that fasten the canopy to the exterior top of the case

• Pull the top of the canopy forward and rotate it down to remove it from the case

• Replace or service the ballast as required and replace the canopy in reverse order of

removal.

HUSSMANN - GLOVERSVILLE

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Loading...

Loading...