Page 1

or use in the United States

Manual

Installation

& Operation

REV. 0915

/CHINO

DOE 2012

Energy Eciency

Compliant

Hussmann refrigerated merchandisers congured for sale f

meet or surpass the requirements of the DOE 2012 energy eciency standards.

CR3FO

VERSATILE SERVICE TOP AND SELF-SERVICE FRONT

DELI MERCHANDISER

CR3FO

VERSATILE SERVICE TOP AND

SELF-SERVICE FRONT DELI MERCHANDISER

P/N IGFP-CR3FO-0915

INSTALLATION & OPERATION GUIDE

Page 2

General Instructions

This equipment is to be installe d

to comply with the applicable

NEC, Federal, State , and Local

Plumbing and Construction

Code ha v ing jurisdiction.

AT TENTION

INSTALLER

Table of Contents

General Instructions.....................................................2

Cut and Plan Views ......................................................3

Installation .....................................................................4

Location ..................................................................................... 4

Uncrating the Stand ................................................................... 4

Exterior Loading ......................................................................... 4

Glass Adjustment ....................................................................... 4

Setting and Joining .................................................................... 4

Leveling ..................................................................................... 4

Corner Wedges .......................................................................... 5

Joint Trim ................................................................................... 5

Bumper Installation Instructions................................................. 5

Plumbing .......................................................................8

Waste Outlet and P-TRAP ......................................................... 8

Installing Condensate Drain....................................................... 8

Refrigeration .................................................................8

Refrigerant Type ........................................................................ 8

Piping ......................................................................................... 8

Refrigeration Lines ..................................................................... 8

Control Settings ......................................................................... 8

Access to TX Valves and Drain Lines ........................................ 8

Electronic Expansion Valve (Optional) ....................................... 9

Thermostatic Expansion Valve Location .................................... 9

Expansion Valve Adjustment ..................................................... 9

Measuring the Operating Superheat.......................................... 9

Evaporator Pressure Regulator ................................................. 9

Service Case Temperature Control ............................................ 9

T-STAT Location ........................................................................ 9

Refrigeration Data ...................................................................... 9

Defrost Data ............................................................................... 9

Physical Data ............................................................................. 9

Glycol Requirements ................................................................. 9

Electrical......................................................................10

Wiring Color Code ................................................................... 10

Electrical Circuit Identication .................................................. 10

Electrical Service Receptacles (When Applicable) .................. 10

Field Wiring and Serial Plate Amperage .................................. 10

Ballast Location ....................................................................... 10

User Information ......................................................... 11

Stocking ................................................................................... 11

Cleaning Glass and Mirrors ..................................................... 11

Replacing Fluorescent Lamps ................................................. 11

Non-glare Glass ....................................................................... 11

Plexiglass and Acrylic Care ..................................................... 11

Cleaning ................................................................................... 11

Antistatic Coatings ................................................................... 11

Evaporator Fans ...................................................................... 12

Copper Coils ............................................................................ 12

Tips and Troubleshooting ........................................................12

Stainless Steel Cleaning and Care .......................................... 12

Electrical Wiring Diagrams ........................................ 13

Wiring Diagrams ......................................................... 14

Appendices .................................................................24

Appendix A. - Temperature Guidelines .................................... 24

Appendix B. - Application Recommendations .......................... 24

Appendix C. - Field Recommendations ................................... 24

Appendix D. - Recommendations to User ............................... 25

Keep this booklet with the case at all times for future reference.

This Booklet Contains Information on:

CR3FO: Versatile Service Top and Self-Service Front Deli

Merchandiser

Shipping Damage

All equipment should be thoroughly examined for shipping

damage before and during unloading.

This equipment has been carefully inspected at our factory

and the carrier has assumed responsibility for safe arrival.

If damaged, either apparent or concealed, claim must be

made to the carrier.

Apparent Loss or Damage

If there is an obvious loss or damage, it must be noted on

the freight bill or express receipt and signed by the carrier’s

agent; otherwise, carrier may refuse claim. The carrier will

supply necessary claim forms.

Concealed Loss or Damage

When loss or damage is not apparent until after equipment

is uncrated, a claim for concealed damage is made. Make

request in writing to carrier for inspection within 15 days,

and retain all packaging. The carrier will supply inspection

report and required claim forms.

Shortages

Check your shipment for any possible shortages of

material. If a shortage should exist and is found to be the

responsibility of Hussmann Chino, notify Hussmann Chino.

If such a shortage involves the carrier, notify the carrier

immediately, and request an inspection. Hussmann Chino

will acknowledge shortages within ten days from receipt

of equipment.

Hussmann Chino Product Control

The serial number and shipping date of all equipment

has been recorded in Hussmann’s les for warranty and

replacement part purposes. All correspondence pertaining

to warranty or parts ordering must include the serial number

of each piece of equipment involved, in order to provide

the customer with the correct parts.

IGFP-CR3FO-1209

A publication of HUSSMANN® Chino

13770 Ramona Avenue • Chino, California 91710

(909) 628-8942 FAX

(909) 590-4910

(800) 395-9229

/CHINO

2

Page 3

Rev. 1209

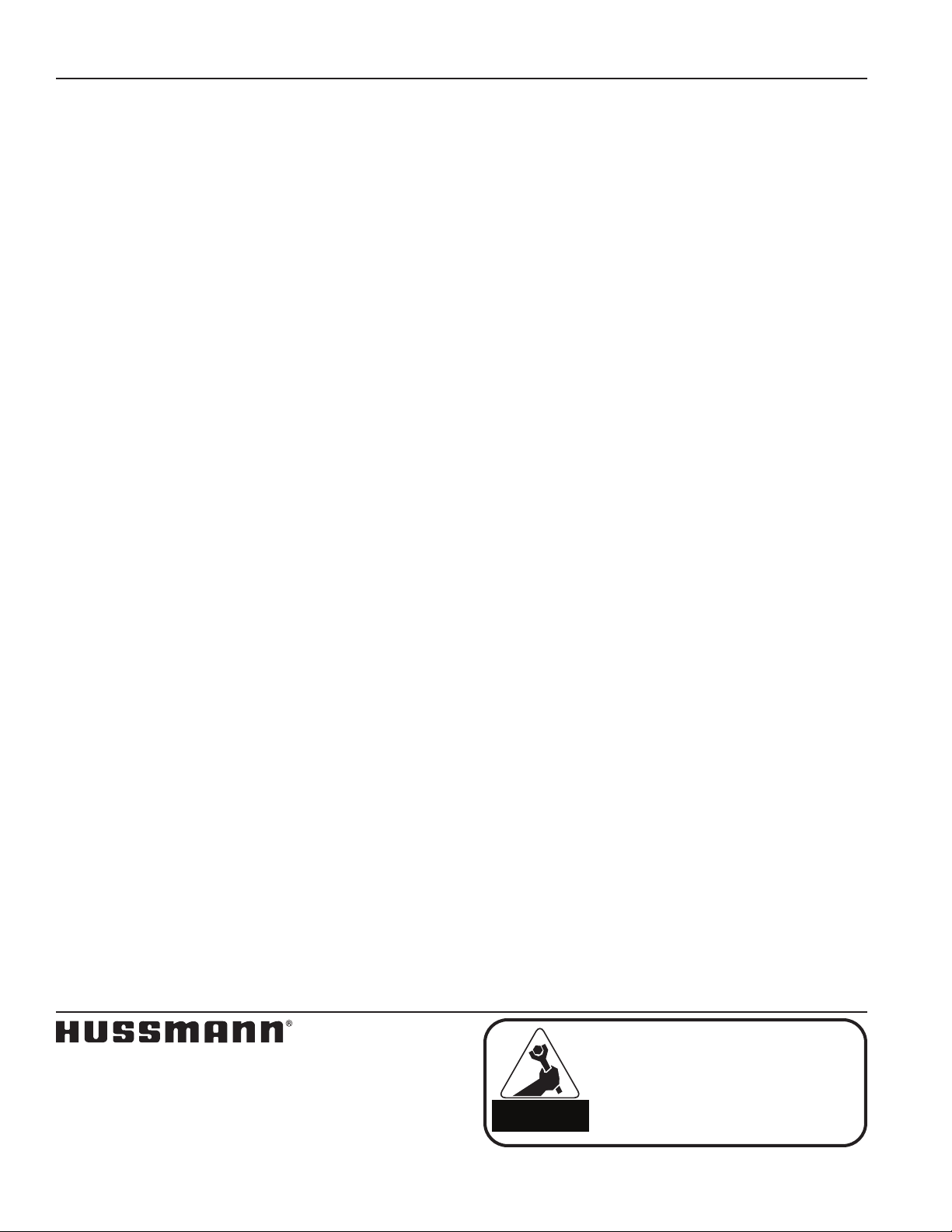

CR3FO

Self Contained

Rear Mount Compressor

12"

18"

22 3/4"

26"

21 3/4"

16 7/8"

20 7/8"

34 1/16"

49 1/2"

Compressor

Housing

Optional Refrigerated

Unit By "Hoshizaki"

CR3FO

Self Contained

Bottom Mount Compressor

12"

18"

22 3/4"

26"

21 3/4"

14"

53"

31 3/4"

36 1/16"

32 3/4"

Compressor

Housing

CR3FO

Self Service - Service

Deli Merchandiser - Remote

12"

18"

26"

22 3/4"

22 3/4"

19 3/4"

Optional

Dry Dome

20 7/8"

42"

9 1/2"

33 1/2"

6 5/8"

26 7/8"

CR3FO

Plan Views - Rear Mount Compressor Option

or Bottom Mount Compressor (Standard)

Scale=1/2"

10 13/16"

5 7/8"

711/16"

4 3/16"

4 3/16"

711/16"

Drain

Rear Mount

Compressor

Option

Electrical

Drop

50"

32 5/8"

311/16" 311/16"

Electrical

Drop

C

L

47 3/4"

1"

1"

Bottom Mount

Compressor

Version

Cut and Plan Views

3

Page 4

Installation

IGFP-CR3FO-1209

Location

The refrigerated merchandisers have been designed for

use only in air conditioned stores where temperature and

humidity are maintained at or below 75°F and 55% relative

humidity. DO NOT allow air conditioning, electric fans, ovens,

open doors or windows (etc.) to create air currents around

the merchandiser, as this will impair its correct operation.

Product temperature should always be maintained at a

constant and proper temperature. This means that from the

time the product is received, through storage, preparation

and display, the temperature of the product must be

controlled to maximize life of the product.

Uncrating the Stand

Place the xture as close to its permanent position as

possible. Remove the top of the crate. Detach the walls

from each other and remove from the skid. Unbolt the case

from the skid. The xture can now be lifted off the crate

skid. Lift only at base of stand!

Exterior Loading

These models have not been structurally designed to

support excessive external loading. Do not walk on their

tops; This could cause serious personal injury and damage

to the xture.

GLASS BREAKAGE MAY OCCUR!

Retighten glass along clamshell after

leveling and first time case is brought

to full operating temperature!

Glass Adjustment

During shipment, the lubricant inside the cylinders may

have settled. This settling may cause excessive or uneven

tension on the glass - to the point of breakage. To avoid

any damage, please follow these three easy steps:

1. Slowly raise and lower each glass section 6 times to

a height of 6 inches.

2. Increase the height to 12 inches, and raise and

lower the glass 6 more times.

3. Finally raise the glass to its full extension, and lower.

These steps should release any settled lubricant within the

cylinders and prevent any stress on the front glass.

Setting and Joining

The sectional construction of these models enable them to

be joined in line to give the effect of one continuous display.

A joint trim kit is supplied with each joint.

Leveling

IMPORTANT! IT IS IMPERATIVE THAT CASES BE

LEVELED FROM FRONT TO BACK AND SIDE TO SIDE

PRIOR TO JOINING. A LEVEL CASE IS NECESSARY

TO INSURE PROPER OPERATION, WATER DRAINAGE,

PLEXIGLASS ALIGNMENT.

NOTE: A. To avoid removing concrete ooring, begin lineup

leveling from the highest point of the store oor.

B. When wedges are involved in a lineup, set them rst.

All cases were leveled and joined prior to shipment to

insure the closest possible t when cases are joined in

the eld. When joining, use a carpenters level and shim

legs accordingly. Case must be raised correctly, under legs

where support is best, to prevent damage to case.

1. Check level of oor where cases are to be set.

Determine the highest point of the oor; cases will

be set off this point.

2. Set rst case, and adjust legs over the highest part

of the oor so that case is level. Prevent

damage - case must be raised under leg or by use

of 2x6 or 2x4 leg brace. Remove side and back leg

braces after case is set.

3. Set second case as close as possible to the rst

case and level case to the rst using the instructions

in step one.

4. Apply masking tape 1/8” in from end of case on

inside and outside rear mullion on both cases to be

joined.

5. Apply liberal bead of case joint sealant (butyl) to

(dotted area shown in gure) rst case. Apply heavy

amount to cover entire shaded area.

DO NOT USE PERMAGUM!

This equipment is to be installe d

to comply with the applicable

NEC, Federal, State , and Local

AT TENTION

INSTALLER

Plumbing and Construction

Code ha ving jurisdiction.

6. Slide second case up to rst case snugly. Then level

second case to the rst case so glass front, bumper

and top are ush.

7. To compress silicone at joint, use two Jurgenson wood

clamps. Make sure case is level from front to back and

side to side on inside bulkheads at joint.

8. Attach sections together via a 2 bolts located in the

base of the case. Secure the overhead structure by

bolting the bracket, located inside behind lights.

9. Apply bead of silicone to top of bulkheads and slip

on stainless steel bulkhead cap. Also apply silicone

to seam between overhead light tubes.

4

Page 5

Rev. 1209

Installation (Cont'd)

10. Use nger to smooth silicone as thin as possible at

masking tape on inside and outside of rear mullion

(apply additional silicone if necessary). Remove

tape applied on line #3.

Corner Wedges

Corner wedges are attached via front and rear camlocks.

Use a 7mm allen wrench to turn the locks. Do not

overtighten! Join the top by using a joint bracket (included

in joint kit) with 3/8” bolts.

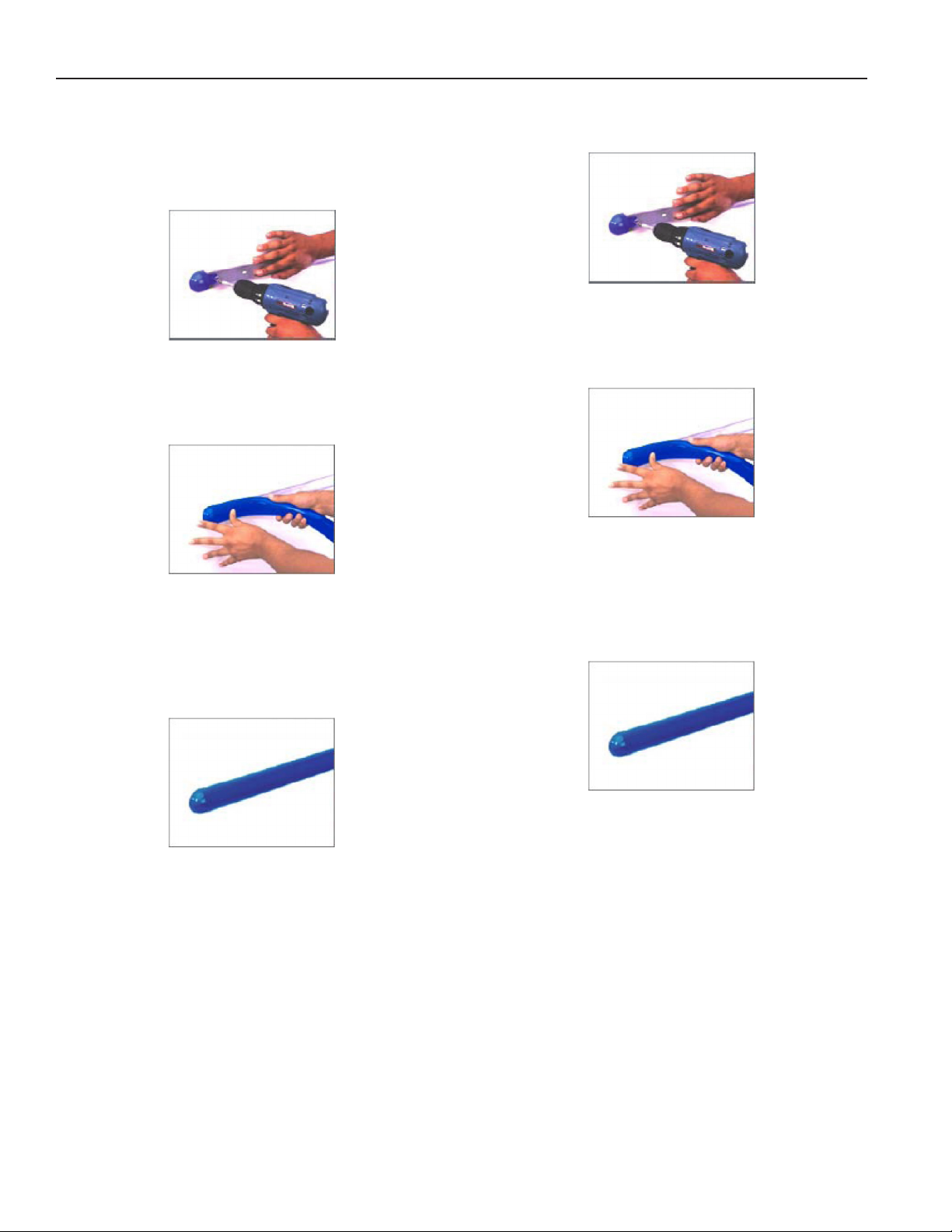

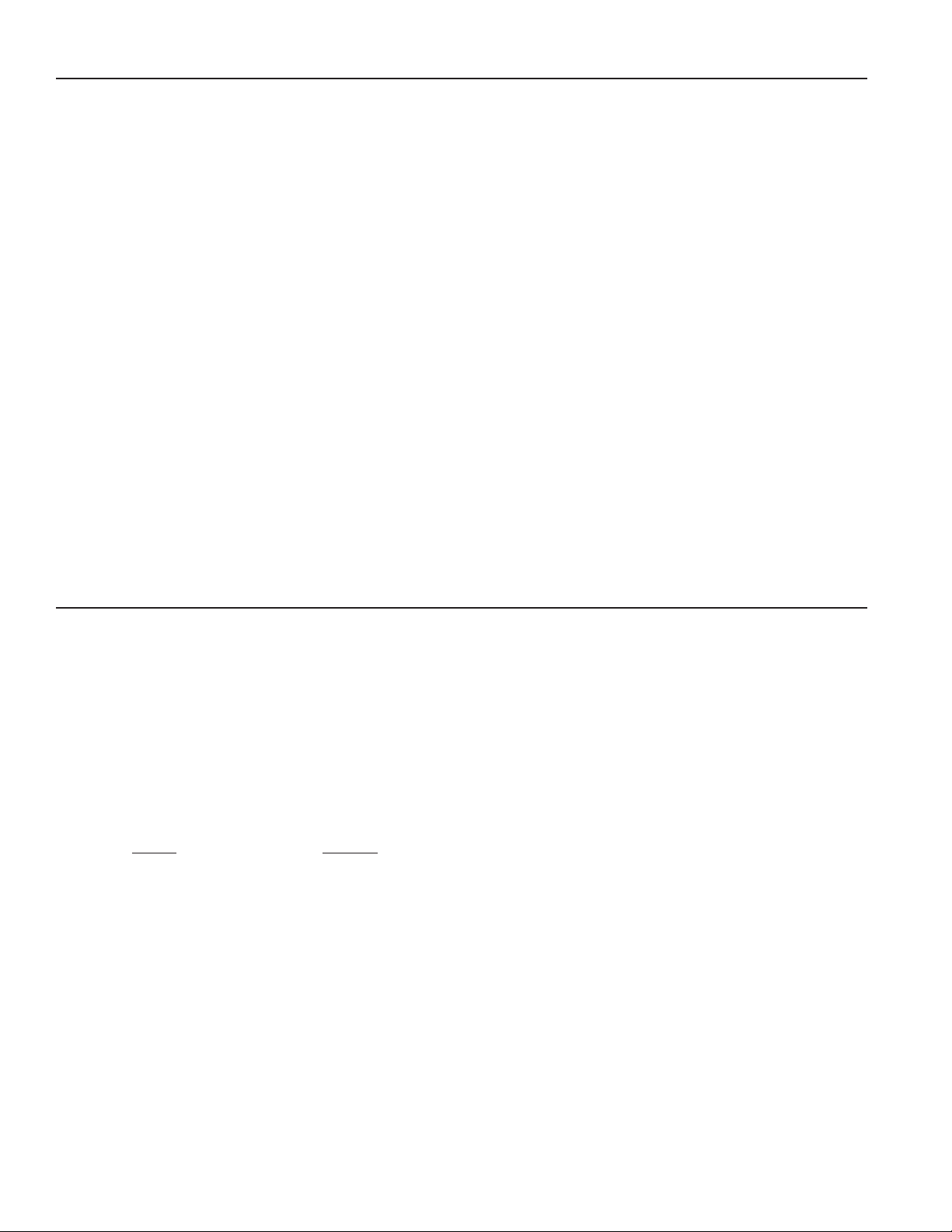

Bumper Installation Instructions

Step 1: Make sure the aluminum channel and end caps

are installed.

Joint Trim

After cases have been leveled and joined, and refrigeration,

electrical, and wasted piping work completed, install the

splashguards. Fasten along the top edge, or center, with

#10 X 3/3” sheet metal screws.

DO NOT SEAL JOINT TRIM TO FLOOR!

Step 2: Use silicone lubricant to help the

bumper slide into the channel.

Step 3: Starting on one end: while inserting the bumper,

push it up against the end cap to prevent

the bumper from shrinking after installation

(when it gets cold).

Step 4: As you insert the bumper into the channel with

one hand, pull the bumper toward you with

the other to open the inside lips. Slowly

apply pressure by rolling the bumper into

the track.

5

Page 6

Installation (Cont'd)

IGFP-CR3FO-1209

Boston Series 2000

NOTE: Flexible top: Over cut vinyl 1/8" for every 4' section for

the exible top to ensure a proper t.

NOTE: Rigid Top: Do not over cut.

1. Attach the base and end/corner cap to the desired

surface by inserting #8 pan head screws through the

pre-slotted holes in both the end cap and the base.

Insert screws through the two holes of end cap and

tighten.

2a. Flexible Top: Butt end of the vinyl top against

end/corner cap. While applying pressure, bend

back vinyl top so that vinyl legs are positioned within

the base grooves. Roll vinyl top over full length of

base, then tap with rubber mallet to ensure vinyl is

securely locked into the base.

2b. Rigid Top: Snap the Rigid Top over the Rigid Base.

Boston 2000 Eco Series

1. Attach the base and end/corner cap to the desired

surface by inserting #8 pan head screws through the

pre-slotted holes in both the end cap and the base.

Insert screws through the two holes of end cap and

tighten.

2a. Flexible Top: Butt end of the vinyl top against

end/corner cap. While applying pressure, bend

back vinyl top so that vinyl legs are positioned within

the base grooves. Roll vinyl top over full length of

base, then tap with rubber mallet to ensure vinyl is

securely locked into the base.

2b. Rigid Top: Snap the Rigid Top over the Rigid Base.

3. If necessary wipe clean with any household cleaning

product.

Helpful Hints:

● For best results, before cutting, install a scrap piece

of base into vinyl top to achieve a clean cut.

● Set the uncoiled flexible vinyl at room temperature

24 hours prior to installation.

● Lubricate the inside of the vinyl with soapy water or

silicone before installing.

● Over cut the flexible vinyl and compression fit.

Adding the additional materials will compensate for

stretching which occurs during installation.

3. If necessary wipe clean with any household

cleaning product.

Helpful Hints:

● For best results, before cutting, install a scrap piece

of base into vinyl top to achieve a clean cut.

● Set the uncoiled flexible vinyl at room temperature

24 hours prior to installation.

● Lubricate the inside of the vinyl with soapy water or

silicone before installing.

● Over cut the flexible vinyl and compression fit.

Adding the additional materials will compensate for

stretching which occurs during installation.

6

Page 7

Rev. 1209

Installation (Cont'd)

Boston 1000 Series

NOTE: Flexible top: Over cut vinyl 1/8" for every 4' section for

the exible top to ensure a proper t.

NOTE: Rigid Top: Do not over cut.

Installation

1. Attach the base and end/corner cap to the desired

surface by inserting #8 pan head screws through the

pre-slotted holes in both the end cap and the base.

Insert screws through the two holes of end cap and

tighten.

2b. Rigid Top: Snap the Rigid Top over the Rigid Base.

3. If necessary wipe clean with any household

cleaning product.

Helpful Hints:

● For best results, before cutting, install a scrap piece

of base into vinyl top to achieve a clean cut.

● Set the uncoiled flexible vinyl at room temperature

24 hours prior to installation.

● Lubricate the inside of the vinyl with soapy water or

silicone before installing.

● Over cut the flexible vinyl and compression fit.

Adding the additional materials will compensate for

stretching which occurs during installation.

2a. Flexible Top: Butt end of the vinyl top against

end/corner cap. While applying pressure, bend

back vinyl top so that vinyl legs are positioned within

the base grooves. Roll vinyl top over full length of

base, then tap with rubber mallet to ensure vinyl is

securely locked into the base.

7

Page 8

Plumbing

Waste Outlet and P-TRAP

The waste outlet is located off the center of the case on

one side allowing drip piping to be run lengthwise under

the xture. There are 3 drains in each xture that can be

easily located.

1-1/2", 1" and 3/4" P-TRAPS and threaded adapters

are supplied with each xture. The 3 P-TRAPS must be

installed to prevent air leakage and insect entrance into

the xture.

NOTE: PVC-DWV solvent cement is recommended. Follow the

manufacturer’s instructions.

Installing Condensate Drain

Poorly or improperly installed condensate drains can

seriously interfere with the operation of this refrigerator, and

result in costly maintenance and product losses. Please

follow the recommendations listed below when installing

condensate drains to insure a proper installation:

1. Never use pipe for condensate drains smaller

than the nominal diameter of the pipe or P-TRAP

supplied with the case.

2. When connecting condensate drains, the P-TRAP

must be used as part of the condensate drain

to prevent air leakage or insect entrance. Store

plumbing system oor drains should be at least 14"

off the center of the case to allow use of the P-TRAP

pipe section. Never use two water seals in series in

any one line. Double P-TRAPS in series will cause a

lock and prevent draining.

IGFP-CR3FO-1209

3. Always provide as much down hill slope ("fall") as

possible; 1/8" per foot is the preferred minimum.

PVC pipe, when used, must be supported to

maintain the 1/8" pitch and to prevent warping.

4. Avoid long runs of condensate drains. Long runs

make it impossible to provide the "fall" necessary for

good drainage.

5. Provide a suitable air break between the ood rim of

the oor drain and outlet of condensate drain. 1" is

ideal.

6. Prevent condensate drains from freezing:

a. Do not install condensate drains in contact with

non-insulated suction lines. Suction lines should

be insulated with a non - absorbent insulation

material such as Armstrong's Armaex.

b. Where condensate drains are located in dead

air spaces (between refrigerators or between a

refrigerator and a wall), provide means to prevent

freezing. The water seal should be insulated to

prevent condensation.

Refrigeration

Refrigerant Type

The standard refrigerant will be R-22 unless otherwise

specied on the customer order. Check the serial plate on

the case for information.

Piping

The refrigerant line outlets are located under the case.

Locate rst the electrical box, the outlets are then on the

same side of the case but at the opposite end. Insulate

suction lines to prevent condensation drippage.

Refrigeration Lines

Liquid Suction

3/8” O.D. 5/8” O.D.

NOTE: The standard coil is piped at 5/8” (suction); however,

the store tie-in may vary depending on the number of

coils and the draw the case has. Depending on the case

setup, the connecting point in the store may be 5/8”, 7/8”,

or 11/8”. Refer to the particular case you are hooking up.

Refrigerant lines should be sized as shown on the

refrigeration legend furnished by the store.

Install P-TRAPS (oil traps) at the base of all suction line

vertical risers.

Pressure drop can rob the system of capacity. To keep the

pressure drop to a minimum, keep refrigerant line run as

short as possible, using the minimum number of elbows.

Where elbows are required, use long radius elbows only.

Control Settings

See CR3FO technical data sheet for the appropriate

settings for your merchandiser. Maintain these parameters

to achieve near constant product temperatures. Product

temperature should be measured rst thing in the morning,

after having been refrigerated overnight. Defrost times

should be as follows: OFF CYCLE - Defrost times should

be as directed in the CR3FO technical data sheet. The

number of defrosts per day and the duration of the defrost

cycle may be adjusted to meet conditions present at your

location.

Access to TX Valves and Drain Lines

Mechanical - Remove product from end of case. Remove

product racks. Remove refrigeration and drain access

panels (labeled). TX valve (mechanical only) and drain are

located under each access panel at end of the case.

Electronic - The Electronic Expansion valve master and

slave cylinder(s) are located within the electrical access

panel(s).

8

Page 9

Rev. 1209

Rear Storage

n

Refrigeration (Cont'd)

Electronic Expansion Valve (Optional)

A wide variety of electronic expansion valves and case

controllers can be utilized. Please refer to EEV and

controller manufacturers information sheet. Sensors for

electronic expansion valves will be installed on the coil inlet,

coil outlet, and in the discharge air. (Some supermarkets

require a 4th sensor in the return air). Case controllers will

be located in the electrical raceway or under the case. The

front Self Service Evaporator has an EPR valve installed to

maintain a constant discharge temperature. It is located in

the front at the right side of the case under the fan plenum

near the TX valve.

Thermostatic Expansion Valve Location

This device is located on the same side as the refrigeration

stub. A Sporlan balanced port expansion valve model

is furnished as standard equipment, unless otherwise

specied by customer.

Expansion Valve Adjustment

Expansion valves must be adjusted to fully feed the

evaporator. Before attempting any adjustments, make

sure the evaporator is either clear or very lightly covered

with frost, and that the xture is within 10°F of its expected

operating temperature.

Measuring the Operating Superheat

1. Determine the suction pressure with an accurate

pressure gauge at the evaporator outlet.

2. From a refrigerant pressure temperature chart,

determine the saturation temperature at the

observed suction pressure.

3. Measure the temperature of the suction gas at the

thermostatic remote bulb location.

4. Subtract the saturation temperature obtained in step

No. 2 from the temperature measured in step No. 3.

The difference is superheat.

5. Set the superheat for 5°F - 7°F.

Evaporator Pressure Regulator

An Evaporator Pressure Regulator is installed in the front

of the self service section to maintain a constant discharge

temperature. It is located at the front right side of the case,

under the fan plenum near the TX Valve.

Service Case Temperature Control

Temperature control in the upper section of the R3 with

the Service Option is done by means of a thermostat and

suction solenoid valve. This controls both temperature

and humidity.

T-STAT Location

T-STATS are located within the electrical raceway. Refer

to diagram below.

T-Stat and

Solenoid inside

Storage Area

T

-Stat &

Ballast

(Located in the

same place for

hot and cold)

Front Coils

controlled by

EPR Valve

under Deck Pa

(Right side)

9

Page 10

CUT OUT

R22

TIME

(ºF)

DEFROST

DEFROST

ANTI-SWEAT HEATERS

CONDENSING UNIT

DRAI N EVAP P AN

# OF F ANS

GLYCOL FRONT

END

SECTION

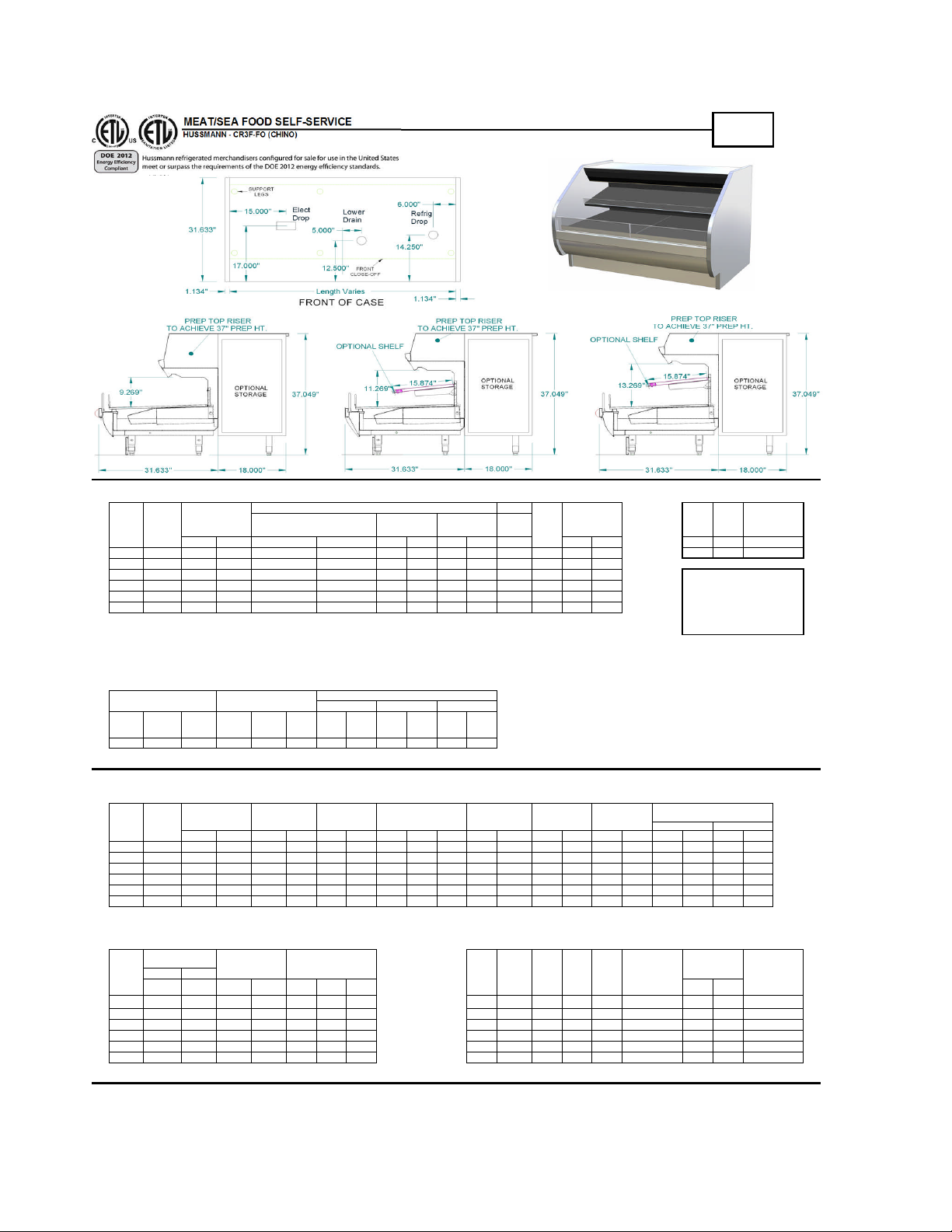

MEAT/SEA FOOD SELF-SERVICE

HUSSMANN - CR3F-FO (CHINO)

PLAN

IGFP-CR3FO-1209

PHOTO

REFRIGERATION DATA:

CASE

LENGTH

3' MEAT 2250 2588

4' MEAT 3000 3452

5' MEAT 3750 4315

6' MEAT 4500 5178

8' MEAT 6000 6904

*2º F less than evaporatorfor pressure loss in refrigerant lines

REFRIGERATION DATA CONTINUED: *** REFRIGERATION NOTES:

ELEC. THERMOSTAT / AIR

SENSOR SETTINGS

USAG E

MEAT +26 +22 40 53 TBD 40 10 40 10 40 10

ELECTRICAL DATA:

STANDARDFANS AND HEATERS (120 VOLT)

CASE

PER CASE

LENGTH

3' 1 0.12 7 N/A N/A 0.05 6 1 0.05 6 N/A N/A N/A N/A 0. 11 12 N/A N/A 0.28 30

4' 1 0.12 7 N/A N/A 0.08 9 1 0.08 9 N/A N/A N/A N/A 0. 17 18 N/A N/A 0.37 40

5' 1 0.12 7 N/A N/A 0.11 12 1 0.11 12 N/A N/A N/A N/A 0.22 24 N/A N/A 0.46 50

6' 2 0.24 14 N/A N/A 0.14 15 1 0.14 15 N/A N/A N/A N/A 0.28 30 N/A N/A 0.56 60

8' 2 0.24 14 N/A N/A 0.17 18 1 0.17 18 N/A N/A N/A N/A 0.33 36 N/A N/A 0.74 80

*** CAPAC ITY

CASE

(BTU/HR TOTAL)

USAG E

PAR CONV PAR CONV PAR CONV

EPR SETTINGS

CUT IN

(ºF)

(ºF)

(PSIG)

** TOTAL

EVAPORATOR

FANS

AMPS WATTS AMPS WATT S AMPS WATT S # ROWS AMP S WATT S AMPS WAT TS AMPS W ATTS AM PS WAT TS AMPS WAT TS AM PS WAT TS

R404A

(PSIG)

DRAI N PAN

HEATERS

EVAPORATOR

PAR

20

20

20

20

20

R407A

(PSIG)

ELECTRICAL DATA CONTINUED: DEFROST DATA:

VOLTS / PHASE

CASE

120/1

LENGTH

AMPS AM PS WAT TS

3' N/A N/A N/A N/A 1 115 15 3'

4' N/A N/A N/A N/A 1 115 15 4'

5' N/A N/A N/A N/A 1 115 15 5'

6' N/A N/A N/A N/A 1 115 15 6'

8' N/A N/A N/A N/A 1 115 15 8'

120V 1 PHASE

# OUTLETS

TEMPERATURE (ºF)

UNIT S IZING*

CONV

20 FRONT

20 FRONT

20 FRONT

20 FRONT

20 FRONT

CONVENTIONAL COMPRESSOR SETT INGS

R22 R404A R407A

CUT IN

(PSI)

CANOPY

LIGHTS LED

CONVENIENCE

OUTLETS (Optional)

VOLTS AMPS

CUT

OUT

(PSI)

+18 +18

+18 +18

+18 +18

+18 +18

+18 +18

CUT IN

(PSI)

FRONT

CUT

OUT

(PSI)

SHELF LIGHTS

(OPTIONAL) LED

VELOCITY

EST.

REFG.

DISCHARGEAIR

+28F +28F 250 TBD TBD TBD 2 1.125

+28F +28F 250 TBD 1.1 5. 7

+28F +28F 250 TBD TBD TBD

+28F +28F 250 1.5 1.6 3.6 PAR- PARALLEL

+28F +28F 250 2.2 2.1 6.4 CONV- CONVENTIONAL

CUT IN

(PSI)

FRONT

CASE

(FT/MIN) GPM PSI

CUT

OUT

(PSI)

NOSE

LIGHT S

DEFROST

CASE

TYPE

LENGTH

OFF TIME

OFF TIME

OFF TIME

OFF TIME

OFF TIME

REQUIREMENTS

CHRG.

(LBS)

1) ADD 10 BTU'S PER FOOT/PER SHELF FOR OPTIONAL LED SHELF LIGHTS

LEDGE LIGHTS

(OPTIONAL)

(MIN.)

40 54 TBD N/A N/A

40 54 TBD

40 54 TBD

40 54 TBD

40 54 TBD

TERM.

TEMP

COIL

ONLY

TOTAL

LIGHTS LED

DRIP

TIME

(MIN.)

END PANEL WIDTH KEY

# OF

END

PNLS

1 1.125

LEGEND

N/A - NOT AVAILABLE

TBD - T O BE DETERMINED

A/S- AIRSW EEP

(On Evap. Fan Circuit)

TOP ARM HTR'S CASE HEATER

ELECTRICAL

4

4

4

4

208V 1 PHASE

AMPS WATT S

N/A N/A

N/A N/A

N/A N/A

N/A N/A

PER DAY

PNL

WIDTH

(IN.)

TO TAL ADD ED

LENGTH (IN.)

1.125

2.25

DEFROST

WAT ER (LB /DAY)

TBD

TBD

TBD

TBD

T B D4

OPTIONS/NOTES:

1) GFCI receptacles are optional and are furnished w ith case when ordered

2) Metallic in-use cover shipped loose - installed in field

3) Mechanical Specs for CR3D are equal to R3D for equal c ase length

10

Page 11

Rev. 1209

CUT OUT

R22

CONDENSING UNIT

DEFROST

DEFROST

END

ANTI-SWEAT HEATERS

GLYCOL FRONT

DRAI N EVAP P AN

# OF F ANS

TIME

(ºF)

SECTION

DELI SELF-SERVICE

HUSSMANN - CR3F-FO (CHINO)

PLAN

PHOTO

REFRIGERATION DATA:

CASE

LENGTH

3' DELI N/A 2588

4' DELI N/A 3450

5' DELI N/A 4315

6' DELI N/A 5178

8' DELI N/A 6904

*2º F less than evaporatorfor pressure loss in refrigerant lines

REFRIGERATION DATA CONTINUED: *** REFRIGERATION NOTES:

ELEC. THERMOSTAT / AIR

SENSOR SETTINGS

USAG E

DELI +28 +24 40 53 TBD 40 10 40 10 40 10

ELECTRICAL DATA:

STANDARDFANS AND HEATERS (120 VOLT)

CASE

PER CASE

LENGTH

3' 1 0.12 7 N/A N/A 0.05 6 1 0.05 6 N/A N/A N/A N/A 0.11 12 N/A N/A 0.28 30

4' 1 0.12 7 N/A N/A 0.08 9 1 0.08 9 N/A N/A N/A N/A 0.17 18 N/A N/A 0.37 40

5' 1 0.12 7 N/A N/A 0.11 12 1 0.11 12 N/A N/A N/A N/A 0.22 24 N/A N/A 0. 46 50

6' 2 0.24 14 N/A N/A 0.14 15 1 0.14 15 N/A N/A N/A N/A 0.28 30 N/A N/A 0.56 60

8' 2 0.24 14 N/A N/A 0.17 18 1 0.17 18 N/A N/A N/A N/A 0.33 36 N/A N/A 0.74 80

*** CAPAC ITY

CASE

(BTU/HR TOTAL)

USAG E

PAR CONV PAR CONV PAR CONV

EPR SETTINGS

CUT IN

(ºF)

(ºF)

(PSIG)

** TOTAL

EVAPORATOR

FANS

AMPS WAT TS AMPS WAT TS AMPS WATT S # ROWS AMPS WATT S AMPS WATT S AMP S WATT S AMPS WAT TS AMPS WATT S AMPS WATT S

R404A

(PSIG)

DRAI N PAN

HEATERS

EVAPORATOR

PAR

20

20

20

20

20

R407A

(PSIG)

TEMPERATURE (ºF)

UNIT S IZING*

CONV

20 FRONT

20 FRONT

20 FRONT

20 FRONT

20 FRONT

CONVENTIONAL COMPRESSOR SETT INGS

R22 R404A R407A

CUT IN

(PSI)

CANOPY

LIGHT S

FRONT

+18 +18

+18 +18

+18 +18

+18 +18

+18 +18

CUT

OUT

(PSI)

CUT

CUT IN

OUT

(PSI)

(PSI)

LIGHTING: T5 WITHELECTRONIC BALLASTS120V INPUT VOLTAGE

SHELF LIGHTS

(OPTIONAL)

VELOCITY

EST.

REFG.

DISCHARGEAIR

+28F +28F 250 TBD T BD TBD 2 1.125

+28F +28F 250 TBD T BD TBD

+28F +28F 250 TBD T BD TBD

+28F +28F 250 TBD T BD TBD PAR- PARALLEL

+28F +28F 250 TBD T BD TBD CONV- CONVENTIONAL

CUT IN

(PSI)

FRONT

CASE

(FT/MIN) GPM PSI

CUT

OUT

(PSI)

NOSE

LIGHT S

REQUIREMENTS

CHRG.

(LBS)

1) BTU'S INCLUDE 3 ROWS (2 TOP; 1 FRONT) FLOURESCENT CANOPY LIGHTING BUT NO SHELF LIGHTS

2) ADD 20 BTU'S PER FOOT/PER SHELF FOR FLOURESCENT SHELF LIGHTS

3) ADD 10 BTU'S PER FOOT/PER SHELF FOR OPTIONAL LED SHELF LIGHTS

4) DEDUCT 30 BTU'S PER FOOT FOR OPTIONAL LED CANOPY LIGHTS

LEDGE LIGHTS

(OPTIONAL)

TOTAL

LIGHT S

END PANEL WIDTH KEY

# OF

PNL

END

WIDTH

PNLS

(IN.)

1 1.125

LEGEND

N/A - NOT AVAILABLE

TBD - T O BED ETERMINED

A/S- AIRSW EEP

(On Evap. Fan Circuit)

TOP ARM HTR'S HEATER

* PLUG TYPE IS BASED ON STANDARD FEATURES

ELECTRICAL DATA CONTINUED: DEFROST DATA:

VOLTS / PHASE

CASE

120/1 *240V/1

LENGTH

AMPS W ATTS AM PS WAT TS AM PS WATT S

3' 9.1 1092 5.0 600 1.7 204 % 1 115 15 3'

4' 10.5 1260 8.3 1000 1.7 204 % 1 115 15 4'

5' 10.5 1260 8.3 1000 1.7 204 % 1 115 15 5'

6' *6.8 *1632 *6.25 *1500 1. 7 204 % 1 115 15 6'

8' *9.0 *2160 *6.25 *1500 1. 7 204 % 1 115 15 8'

120V 1 PHASE

*240V/1

SUMP PUMP

120/1

(OPTIONAL)

EVAP

CONVENIENCEOUT LETS

PAN

RUN

TIME

# OUTLETS

(OPTIONAL)

VOLTS AMPS

CASE

LENGTH

DEFROST

TYPE

OFF TIME

OFF TIME

OFF TIME

OFF TIME

OFF TIME

TERM.

TEMP

(MIN.)

COIL

ONLY

25 54 TBD

25 54 TBD

25 54 TBD

25 54 TBD

25 54 TBD

DRIP

TIME

(MIN.)

PER DAY

6

6

6

6

6

ELECTRICAL

208V 1 PHASE

AMPS WATT S

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

TOT AL ADD ED

LENGTH (IN.)

1.125

2.25

PLUG TYPE

L5-30P

L5-30P

L5-30P

L14-30P

L14-30P

DEFROST

WAT ER (LB /DAY)

TBD

TBD

TBD

TBD

TBD

OPTIONS/NOTES:

1) GFCI receptacles are optional and are furnished w ith case when ordered

2) Metallic in-use cover shipped loose - installed in field

3) Mechanical Specs for CR3D are equal to R3D for equal c ase length

11

Page 12

Electrical

Wiring Color Code

CASE MUST BE GROUNDED

NOTE: Refer to label afxed to case to determine the actual

conguration as checked in the “TYPE INSTALLED”

boxes.

Electrical Circuit Identication

Standard lighting for all refrigerated models will be full

length uorescent lamps located within the case at the

top.

The switch controlling the lights, the plug provided for

digital scale, and the thermometer are located at the rear

of the case mullion.

The receptacle that is provided on the exterior back of these

models is intended for computerized scales with a ve amp

maximum load, not for large motors or other high wattage

appliances. It should be wired to a dedicated circuit.

IGFP-CR3FO-1209

Electrical Service Receptacles (When Applicable)

The receptacles located on the exterior of the merchandiser

are intended for scales and lighted displays. They are not

intended nor suitable for large motors or other external

appliances.

DANGER

BEFORE SERVICING

ALWAYS DISCONNECT ELECTRICAL

POWER AT THE MAIN DISCONNECT

WHEN SERVICING OR REPLACING ANY

ELECTRICAL COMPONENT.

This includes (but not limited to) Fans, Heaters

Thermostats, and Lights.

Field Wiring and Serial Plate Amperage

Field Wiring must be sized for component amperes printed

on the serial plate. Actual ampere draw may be less than

specied. Field wiring from the refrigeration control panel to

the merchandisers is required for refrigeration thermostats.

Case amperes are listed on the wiring diagram, but always

check the serial plate.

Ballast Location

Ballasts are located within the access panel that runs the

length of the rear of the case.

CAUTION

Fluorescent Lamps contain mercury

vapor. Mercury exposure at hih levels can

harm the brain, heart, kidneys, lungs and

immune system of people of all ages. Do

not break or puncture flourescent lamps.

Dispose of, or store, all flourescent lamps

in accordance with Federal (40 CFR

273), State and local hazardous waste

requirements. Refer to

http://www.epa.gov/mercury/about.htm

Fluorescent Lamp Disposal: The United States

Environmental Protection Agency has information

regarding environmentally-safe uorescent lamp

waste management programs.

On the Net: EPA Website:

http://www.epa.gov/osw/hazard/wastetypes/

universal/lamps/recycle.htm

12

Page 13

Rev. 1209

User Information

Stocking

Improper temperature and lighting will cause serious

product loss. Discoloration, dehydration and spoilage

can be controlled with proper use of the equipment and

handling of product. Product temperature should always

be maintained at a constant and proper temperature.

This means that from the time the product is received,

through storage, preparation and display, the temperature

of the product must be controlled to maximize life of the

product. Hussmann cases were not designed to “heat up”

or “cool down” product - but rather to maintain an item’s

proper temperature for maximum shelf life. To achieve the

protection required always:

1. Minimize processing time to avoid damaging

temperature rise to the product. Product should be

at proper temperature.

2. Keep the air in and around the case area free

of foreign gasses and fumes or food will rapidly

deteriorate.

3. Maintain the display merchandisers temperature

controls as outlined in the refrigerator section of this

manual.

4. Do not place any product into these refrigerators

until all controls have been adjusted and they

are operating at the proper temperature. Allow

merchandiser to operate a minimum of 6 hours

before stocking with any product.

5. When stocking, never allow the product to extend

beyond the recommended load limit. Air discharge

and return air ow must be unobstructed at all

times to provide proper refrigeration.

6. Keep the service doors closed (when applicable).

Refrigeration performance will be seriously affected

if left open for a prolonged period of time.

7. Avoid the use of supplemental ood or spot lighting.

Display light intensity has been designed for

maximum visibility and product life at the factory.

The use of higher output uorescent lamps (H.O.

and V.H.O.), will shorten the shelf life of the product.

FOR PROMPT SERVICE

When contacting the factory,

be sure to have the Case Model and Serial

Number handy. This information is on a plate

located on the case itself.

Cleaning Glass and Mirrors

Only use a soft cloth and mild glass cleaning for cleaning

any glass or mirrored components. Be sure to rinse and/or

dry completely.

Never use hot water on cold glass surfaces! It may

shatter and cause serious injury! Allow glass surfaces

to warm rst.

Replacing Fluorescent Lamps

Fluorescent lamps are furnished with a shatterproof

protective coating. The same type of lamp with protective

coating must be used if replaced.

ENCAPSULITE

SHATTERPROOF COATING - SA 10645

R

R

U

Complies with FDA USDA

& OSHA Regulations

NSF

for replacement call:

1-800-395-9229

Turn switch off then on after replacing bulb

Non-glare Glass

Windex® or Glass Plus® are the only solutions recommended

to be used to clean the non-glare glass. The damage to the

glass from improper, caustic solutions is irreparable.

In addition to cleaning the glass with the recommended

product, there are precautions that should be taken when

working and cleaning the inside of the case.

• When cleaning the inside of the cases, we

recommend that the glass be fully opened and

covered to prevent to prevent solutions from

splashing onto the glass and ruining the coating on

the inside.

Plexiglass and Acrylic Care

Improper cleaning not only accelerates the cleaning cycle

but also degrades the quality of this surface. Normal daily

bufng motions can generated static cling attracting dust

to the surface. Incorrect cleaning agents or cleaning cloths

can cause micro scratching of the surface, causing the

plastic to haze over time.

Cleaning

Hussmann recommends using a clean damp chamois, or a

paper towel marketed as dust and abrasive free with 210®

Plastic Cleaner and Polish available by calling Sumner

Labs at 1-800-542-8656. Hard, rough cloths or paper towels

will scratch the acrylic and should not be used.

Antistatic Coatings

The 210® has proven to be very effective in not only

cleaning and polishing the Plexiglass surface, but also

providing antistatic and anti-fog capabilities. This product

also seals pores and provides a protective coating.

13

Page 14

User Information (Cont'd)

When cleaning:

• Do not use high pressure water hoses

• Do not introduce water faster than waste outlet can drain

• NEVER ON A SELF CONTAINED UNIT WITH AN EVAPORATOR FAN

• NEVER USE A CLEANING OR SANITIZING SOLUTION THAT HAS AN OIL

BASE (these will dissolve the butyl sealants) or an AMMONIA BASE

(this will corrode the copper componets of the case)

To preserve the attractive finish:

• DO USE WATER AND A MILD DETERGENT FOR THE EXTERIOR ONLY

• DO NOT USE ABRASIVES OR STEEL WOOL SCOURING PADS

(these will mar the finish)

Evaporator Fans

The evaporator fans are located at the center front of these

merchandisers directly beneath the display pans. Should fans

or blades need servicing, always replace fan blades with the

raised embossed side of the blade TOWARD THE MOTOR.

Copper Coils

The copper coils used in Hussmann merchandisers may

be repaired in the eld. Materials are available from local

refrigeration wholesalers.

Hussmann recommends using #15 Sil-Fos for repairs.

Tips and Troubleshooting

Before calling for service, check the following:

1. Check electrical power supply to the equipment for

connection.

2. Check xture loading. Overstocking case will affect

its proper operation.

3. If frost is collecting on xture and/or product, check

that no outside doors or windows are open - allowing

moisture to enter store. These merchandisers were

designed for use in stores were temperature &

humidity does not exceed 75° F and 55% H.

Stainless Steel Cleaning and Care

There are three basic things, which can break down your

stainless steel’s passivity layer and allow corrosion.

1. Mechanical Abrasion

Mechanical Abrasion means those things that

will scratch the steels surface. Steel Pads, wire

Brushes, and Scrapers are prime examples.

2. Water

Water comes out of our tap in varying degrees of

hardness. Depending on what part of the country

you live in, you may have hard or soft water. Hard

water may leave spots. Also, when heated, hard

water leaves deposits behind that if left to sit, will

break down the passive layer and rust your stainless

steel. Other deposits from food preparation and

service must be properly removed.

CLEANING PRECAUTIONS

14

IGFP-CR3FO-1209

3. Chlorides

Chlorides are found nearly everywhere. They

are in water, food and table salt. One of the worst

perpetrators of chlorides can come from household

and industrial cleaners.

Don’t Despair! Here are a few steps that can help prevent

stainless steel rust.

1. Use the Proper Tools

When cleaning your stainless steel products, take care

to use non-abrasive tools. Soft Clothes and plastic

scouring pads will NOT harm the steel’s passive

layer. Stainless steel pads can also be used but the

scrubbing motion must be in the same direction of the

manufacturer’s polishing marks.

2. Clean With the Polish Lines

Some stainless steels come with visible polishing lines

or “grain”. When visible lines are present, you should

ALWAYS scrub in a motion that is parallel to them.

When the grain cannot be seen, play it safe and use a

soft cloth or plastic scouring pad.

3. Use Alkaline, Alkaline Chlorinated or

Non-chloride Containing Cleaners

While many traditional cleaners are loaded with

chlorides, the industry is providing an ever increasing

choice of non-chloride cleaners. If you are not sure of

your cleaner’s chloride content contact your cleaner

supplier. If they tell you that your present cleaner

contains chlorides, ask for an alternative. Also, avoid

cleaners containing quaternary salts as they also can

attack stainless steel and cause pitting and rusting.

4. Treat your Water

Though this is not always practical, softening hard

water can do much to reduce deposits. There are

certain lters that can be installed to remove distasteful

and corrosive elements. Salts in a properly maintained

water softener are your friends. If you are not sure of

the proper water treatment, call a treatment specialist.

5. Keep your Food Equipment Clean

Use alkaline, alkaline chlorinated or non-chlorinated

cleaners at recommended strength. Clean frequently

to avoid build-up of hard, stubborn stains. If you boil

water in your stainless steel equipment, remember the

single most likely cause of damage is chlorides in the

water. Heating cleaners that contain chlorides has a

similar effect.

6. RINSE, RINSE, RINSE

If chlorinated cleaners are used you must rinse, rinse,

rinse and wipe dry immediately. The sooner you

wipe off standing water, especially when sit contains

cleaning agents, the better. After wiping the equipment

down, allow it to air dry for the oxygen helps maintain

the stainless steel’s passivity lm.

7. Never Use Hydrochloric Acid (Muriatic Acid) on

Stainless Steel

8. Regularly Restore/Passivate Stainless Steel

Page 15

Rev. 1209

Electrical Wiring Diagrams Index

Model Description Size Diagram

CR3-FO-SC CR3-FO-3-SC 3' W0180083

CR3-FO-4-SC 4' 1H66893

CR3-FO-4-SC 4' 1H62501

CR3-FO-4-SC 4' 1H63534

CR3-FO-5-SC 5' 1H69652

CR3-FO-6-SC 6' 1H24193

CR3-FO-8-SC 8' 1H69653

CR3-FO-R CR3-FO-3-R 3' W8700010

CR3-FO-4-R 4' 1H69654

CR3-FO-5-R 5' 1H69655

15

Page 16

IGFP-CR3FO-1209

CR3-FO-6-R 6' 1H69656

CR3-FO-8-R 8' 1H69657

16

Page 17

Rev. 1209

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DES CRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

CRAIG BOOREY

PAGE OF

1

2

11/30/11

B Changed Fan Motor 12/29/11 CB

CR3

1H66893

CR3-FO-4-SC

~120 VAC - 1Ø - 60 Hz.

MCA=.41A

MOP=15A

CONDENSING UNIT

COPELAND®

M4FF-0056-IAA-041

1H28153

L

LIGHT SWITCH

TIPPETTE

125-01-0311

M

CONDENSING UNIT

RLA= 10.5A

LRA= 54.5A

MCC= 14.8A

BALLAST 125-01-3266

FULHAM LH3-120-L

EVAP

FAN MOTOR

(2) 0477653

4W .12A @ 120VAC

LIGHT CIRCUIT= 0.58A 63W

WARMER

125-01-0767

RAYCHEM

10BUT-CR-10W

40 WATTS

0.33AMP@120V

M

FP21/830 T5-36"

125-03-1128

EVAP PAN

DM10W-1D

1000W, 8.33A @ 120V

125-01-0758

BUNDLE

PURPLE

LABELED

EVAP PAN

CIRCUIT

SAFETY

SWITCH

FLOAT SWITCH

N

L1

SWITCH

SQUARE "D" 55447

125-01-0271

RELAY TYCO

T92P7A22-120

0459304001

N

L1

L1

N

BUNDLE

BLUE

BLACK # 14

WHITE # 14

FP21/830 T5-36"

125-03-1128

L1 N

BALLAST 125-01-3266

FULHAM LH3-120-L

FP21/830 T5-36"

125-03-1128

CAP OFF

CANOPY

SHELVES

~120 VAC - 1Ø - 60 Hz.

MCA=.73A

MOP=15A

L1 N

~120 VAC - 1Ø - 60 Hz.

MCA=.73A

MOP=15A

L1 N

BUNDLE

ORANGE

BUNDLE

BROWN

~120 VAC - 1Ø - 60 Hz.

MCA=6.25A

MOP=15A

L1 N G

~120 VAC - 1Ø - 60 Hz.

MCA=11.5A

MOP=15A

L1 N

DANFOSS® CONTROLLER

AK-CC 210 115V # 084B8534

1H56892500

Danfoss®

AK-CC 210

DEF.COMP.

120 VAC

SENSOR EKC-202C

DANFOSS® # 084N0027

1H26193500

NOTE:

WIRES AT

CONTROL

INPUTS/OUTPUTS

14GA MAX

CIRCUIT #1

NOTE:

CASE MUST

BE GROUNDED

20.0L1

120 V

LOADING

Wiring Diagrams (Cont'd)

17

Page 18

IGFP-CR3FO-1209

Hussmann Corporati on, Int'l.

13770 Ramona Av enue

Chino, CA. 91710

(909)-590-4910 Lic.#: 64 4406

B Revised wiring from 220V to 115V 8/15/11 CB

C CN#996474, Changed Cond. Unit 8/25/15 CB

CIRCUIT #1

GROUNDED

125-01-8554

CIRCUIT #1

NOTE: CASE MUST

BE GROUNDED

1 2

PAGE OF

1H62501

NOTE: WIRES AT

CONTROL

INPUTS/OUTPUTS

14GA MAX

DANFOSS® CONTROLLER

AK-CC 210 115V # 084B8534

1H56892500

RELAY OMRON

G7L-2A-TUBJ-CB-120

125-01-3182

DEF.COMP.

SENSOR EKC-202C

DANFOSS® # 084N0027

1H26193500

Danfoss® AK-CC 210

120 VAC

N L1

CONDENSING UNIT

RLA= 10.5A

LRA= 54.5A

MCC= 14.8A

CONDENSING UNIT

COPELAND® 115V

M4FF-0056-IAA-041

1H28153

BUNDLE

BLUE

WHITE # 14

BLACK # 14

DRAWING #:

CR3

CR3-FO-4-SC

PROJECT TITLE:

DRAWING TITLE:

7/26/11

523134

DATE:

SWITCH

MOTOR START

SQ "D"

125-01-0271

CRAIG BOOREY

M

PRODUCTION ORDER #:

FILE LOCAT ION:

CHECKED BY:

EVAP

M

FAN MOTOR EE

(2) 0477653

4W .12A @ 120VAC

LIGHT CIRCUIT= 0.39A 42W

125-03-1129

FP21/835 T5-36"

125-03-1129

FP21/835 T5-36"

WARMER

125-01-0767

RAYCHEM

10BUT-CR-10W

40 WATTS

0.33AMP@120V

BUNDLE

BROWN

WHITE #14

BLK #14

BUNDLE

ORANGE

WHITE #14

FULHAM LH3-120-L

L

BALLAST 125-01-3266

LIGHT SWITCH

TIPPETTE

125-01-0311

BLK #14

BUNDLE

PURPLE

WHITE #14

BLACK #14

DRAWN BY:

BY:

DATE:

#: DESCRIPTION:

REVISIONS:

BLK # 14

L1

LOADING

11.5L1

120 V

18

POWER

CORD

PLUG

NEMA

L5-20P

~115 VAC - 1Ø - 60Hz.

WHITE # 14

GREEN # 10

N

G

Page 19

Rev. 1209

Hussmann Corporati on, Int'l.

13770 Ramona Av enue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

CIRCUIT #2

NOTE: CASE MUST

BE GROUNDED

B Revised wiring from 220V to 115V 8/15/11 CB

C CN#996474, Changed Cond. Unit 8/25/15 CB

2 2

PAGE OF

1H62501

DRAWING #:

CR3

7/26/11

DATE:

CHECKED BY:

BY:

DATE:

DRAWING TITLE:

523134

PRODUCTION ORDER #:

CR3-FO-4-SC

FILE LOCATION:

PROJECT TITLE:

CRAIG BOOREY

GFCI

DUPLEX

125-01-3178

BLK # 14

GRN # 14

CIRCUIT #2

WHT # 14

L1

N

G

BUNDLE

YELLOW

POWER

CORD

PLUG

NEMA

L5-20P

GROUNDED

125-01-8554

DRAWN BY:

#: DESCRIPTION:

REVISIONS:

LOADING

15.0L1

120 V

19

Page 20

IGFP-CR3FO-1209

Hussmann Corporati on, Int'l.

13770 Ramona Av enue

Chino, CA. 91710

(909)-590-4910 Lic.#: 64 4406

B CN#996474, Changed Cond. Unit 8/25/15 CB

AC-1Ø-60Hz.

LIGHT

T= 0.58

A 63W

WARMER

125-01-0767

RAYCHEM

10BUT-CR-10W

40 WATTS

0.33AMP@120V

CIRCUIT #1

NOTE: CASE MUST

BE GROUNDED

1 2

DUPLEX

DUPLEX

(1) 125-01-0096

L1 N

~120 VAC - 1Ø - 60 Hz.

MCA=2.4A

MOP=15A

1H63534

PAGE OF

SAFE NET III SENSORS

PART# 0510533 (4m long)

SAFE NET III CONTROLER

PART# 1H16704001

PLUG NEMA 5-15P

CONDENSING UNIT

RLA= 10.5A

LRA= 54.5A

MCC= 14.8A

CONDENSING UNIT

COPELAND®

M4FF-0056-IAA-041

L1

N

1H28153

m

225-01-1661

1.9A @120VAc

COND. PUMCP-22LP

DRAWING #:

CR3

N

L1

RELAY OMRON

G7L-2A-TUBJ-CB

125-01-3182

PRESSURE

SAFETY

N

L1

225-01-0706B

N

L1

SWITCH

SQUARE "D" 55447

BUNDLE

PURPLE

LABELED

EVAP PAN

CIRCUIT

125-01-0271

M

BUNDLE

BLUE

CR3-FO-4-SC

PROJECT TITLE:

WHITE # 14

BLACK # 14

L1 N

~120 VAC - 1Ø - 60 Hz.

MCA=11.5A

MOP=15A

BUNDLE

BROWN

DRAWING TITLE:

8/29/11

895151

DATE:

CRAIG BOOREY

PRODUCTION ORDER #:

FILE LOCAT ION:

CHECKED BY:

DRAWN BY:

BY:

SAFETY

FLOAT SWITCH

EVAP PAN

600W 5.0A @ ~120 vac

00007274

125-03-1128

18.9L1

FP21/830 T5-36"

125-03-1128

FP21/830 T5-36"

125-03-1128

FP21/830 T5-36"

CANOPY

SHELVES

LOADING

120 V

SWITCH

EVAP

FAN MOTOR

L1 N G

~120 VAC - 1Ø - 60 Hz.

MCA=6.25A

MOP=15A

CAP OFF

(2) 0392457

M

4W .29A @ 120VAC

L1 N

~120 VAC - 1Ø - 60 Hz.

MCA=.73A

MOP=15A

FULHAM LH3-120-L

BALLAST 125-01-3266

BUNDLE

ORANGE

FULHAM LH3-120-L

BALLAST 125-01-3266

L

125-01-0311

TIPPETTE

LIGHT SWITCH

L1 N

~120 VAC - 1Ø - 60 Hz.

MCA=.73A

MOP=15A

5A

41A

L1 N

DATE:

#: DESCRIPTION:

REVISIONS:

20

Page 21

Rev. 1209

Hussmann Corporati on, Int'l.

13770 Ramona Av enue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

CIRCUIT #2

NOTE: CASE MUST

BE GROUNDED

B CN#996474, Changed Cond. Unit 8/25/15 CB

2 2

PAGE OF

1H63534

DRAWING #:

CR3

8/29/11

DATE:

CHECKED BY:

BY:

DATE:

DRAWING TITLE:

895151

PRODUCTION ORDER #:

CR3-FO-4-SC

FILE LOCATION:

PROJECT TITLE:

CRAIG BOOREY

DRAWN BY:

BLACK # 14

BUNDLE

G

GFCI

125-01-3178

YELLOW

WHITE # 14

CIRCUIT #2

PLUG NEMA 5-15P

125-01-0986

(OPTIONAL CIRCUIT #2)

#: DESCRIPTION:

REVISIONS:

LOADING

15.0L1

120 V

21

Page 22

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DES CRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

CRAIG BOOREY

PAGE OF

1

1

12/29/11

CR3

1H69652

CR3-FO-5-SC

CONDENSING UNIT

COPELAND®

M4FF-0056-1AA-041

1H28153

L

LIGHT SWITCH

TIPPETTE

125-01-0311

PRESSURE

SAFETY

225-01-0706B

CONDENSER FAN

F28T5-48"

125-03-1134

M

M

CONDENSING UNIT

RLA= 10.5A

LRA= 54.5A

MCC= 14.8A

N

L1

BALLAST 125-01-3267

FULHAM LH4-120-L

EVAP

FAN MOTOR

(2) 0477653

4W .12A @ 120VAC

LIGHT CIRCUIT= 0.52A 56W

WARMER

125-01-0767

50 WATTS

0.46AMP@120V

M

SWITCH

MOTOR ST ART

SQ "D"

125-01-0271

RELAY MARS 90341

COIL: ~110/120VAC

125-01-1343

6

5

3

2

4

1

BUNDLE

PURPLE

BUNDLE

BROWN

BUNDLE

ORANGE

BUNDLE

BLUE

BUNDLE

YELLOW

SAFETY

SWITCH

FLOAT SWITCH

PLUG NEMA 5-15P

G

BLACK # 14

WHITE # 14

DUPLEX

125-01-0096

~120 VAC - 60 Hz

BLK # 14

L1

N

MCA= 13.1A

MOP= 20A

WHT # 14

~120 VAC - 60 Hz

L1

N

MCA= .65A

MOP= 15A

BLK # 14

WHT # 14

~120 VAC - 60 Hz

L1

N

MCA= .65A

MOP= 15A

BLK # 14

WHT # 14

~120 VAC - 60 Hz

L1

N

MCA= .58A

MOP= 15A

BLK # 14

WHT # 14

BUNDLE

PURPLE

~120 VAC - 60 Hz

L1

N

BLK # 14

WHT # 14

15A FUSE

125-01-8604

15A FUSE

HOLDER

125-01-8605

FUSE

15A

FISHER™ EVAPOWAY™

DM10W-1D

1000W 8.33A @ ~ 120 VAC

125-01-0758

L1

N

NOTE:

WIRES AT

CONTROL

INPUTS/OUTPUTS

14GA MAX

DANFOSS® CONTROLLER

AK-CC 210 115V # 084B8534

1H56892500

Danfoss

®

AK-CC-21 0

DEF.

COMP.

120 VAC

SENSOR EKC-202C

DANFOSS® # 084N0027

1H26193500

F28T5-48"

125-03-1134

CIRCUIT #1

NOTE:

CASE MUST

BE GROUNDED

20.1L1

120 V

LOADING

IGFP-CR3FO-1209

Wiring Diagrams (Cont'd)

22

Page 23

Rev. 1209

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DES CRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

1

1

6/9/09

B Evap pan changed per lab testing 7/7/09 JR

C Changed Contoller to Dan Foss AK-CC 210 12/29/11 CB

CR3

1H24193

CR3-FO-6-SC

621810

CONDENSING UNIT

COPELAND®

M4FF-0075-CAV-212

1H28155

L

LIGHT SWITCH

TIPPETTE

125-01-0311

PRESSURE

SAFETY

225-01-0706B

CONDENSER FAN

F35T5-60"

125-03-1135

M

M

CONDENSING UNIT

RLA= 6.8A

LRA= 33.7A

MCC= 9.7A

N

L1

BALLAST 125-01-3267

FULHAM LH4-120-L

EVAP

FAN MOTOR

(2) 0477653

4W .12A @ 120VAC

LIGHT CIRCUIT= 0.65A 70W

WARMER

125-01-0767

60 WATTS

0.5AMP@120V

M

SWITCH

MOTOR ST ART

SQ "D"

125-01-0271

RELAY MARS 90341

COIL: ~110/120VAC

125-01-1343

6

5

3

2

4

1

F35T5-60"

125-03-1135

BUNDLE

PURPLE

BUNDLE

BROWN

BUNDLE

ORANGE

BUNDLE

BLUE

BUNDLE

YELLOW

SAFETY

SWITCH

FLOAT SWITCH

PLUG NEMA 5-15P

G

BLACK # 14

WHITE # 14

DUPLEX

125-01-0096

~120 VAC - 60 Hz

BLK # 14

L1

N

MCA= 14.3A

MOP= 20A

WHT # 14

~120 VAC - 60 Hz

L1

N

MCA= .65A

MOP= 15A

BLK # 14

WHT # 14

~120 VAC - 60 Hz

L1

N

MCA= .81A

MOP= 15A

BLK # 14

WHT # 14

~120 VAC - 60 Hz

L1

N

MCA= .63A

MOP= 15A

BLK # 14

WHT # 14

BUNDLE

PURPLE

~120 VAC - 60 Hz

L1

N

BLK # 14

WHT # 14

15A FUSE

125-01-8604

15A FUSE

HOLDER

125-01-8605

FUSE

15A

FISHER™ EVAPOWAY™

DM15WW-3D

1500W 6.25A @ ~ 120 VAC

125-01-0765A

L1

N

NOTE:

WIRES AT

CONTROL

INPUTS/OUTPUTS

14GA MAX

DANFOSS® CONTROLLER

AK-CC 210 115V # 084B8534

1H56892500

Danfoss®

AK-CC-21 0

DEF.

COMP.

120 VAC

SENSOR EKC-202C

DANFOSS® # 084N0027

1H26193500

CIRCUIT #1

NOTE:

CASE MUST

BE GROUNDED

14.4L1

240 V

LOADING

Wiring Diagrams (Cont'd)

23

Page 24

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DES CRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

CRAIG BOOREY

PAGE OF

1

1

12/29/11

CR3

1H69653

CR3-FO-8-SC

CONDENSING UNIT

COPELAND® 240V

FJAF-0100-CAV-020

1H35476

L

LIGHT SWITCH

TIPPETTE

125-01-0311

PRESSURE

SAFETY

225-01-0706B

CONDENSER FAN

F28T5-48"

125-03-1134

M

M

CONDENSING UNIT

RLA= 9.0A

LRA= 43.0A

MCC= 12.4A

N

L1

BALLAST 125-01-3267

FULHAM LH4-120-L

EVAP

FAN MOTOR

(2) 0477653

4W .12A @ 120VAC

LIGHT CIRCUIT= 0.78A 84W

WARMER

125-01-0767

80 WATTS

0.74AMP@120V

M

SWITCH

MOTOR ST ART

SQ "D"

125-01-0271

RELAY MARS 90341

COIL: ~110/120VAC

125-01-1343

6

5

3

2

4

1

BUNDLE

PURPLE

BUNDLE

BROWN

BUNDLE

ORANGE

BUNDLE

BLUE

BUNDLE

YELLOW

SAFETY

SWITCH

FLOAT SWITCH

PLUG NEMA 5-15P

G

BLACK # 14

WHITE # 14

DUPLEX

125-01-0096

~120 VAC - 60 Hz

BLK # 14

L1

N

MCA= 14.3A

MOP= 20A

WHT # 14

~120 VAC - 60 Hz

L1

N

MCA= .65A

MOP= 15A

BLK # 14

WHT # 14

~120 VAC - 60 Hz

L1

N

MCA= .9 7A

MOP= 15A

BLK # 14

WHT # 14

~120 VAC - 60 Hz

L1

N

MCA= .9 3A

MOP= 15A

BLK # 14

WHT # 14

BUNDLE

PURPLE

~120 VAC - 60 Hz

L1

N

BLK # 14

WHT # 14

15A FUSE

125-01-8604

15A FUSE

HOLDER

125-01-8605

FUSE

15A

FISHER™ EVAPOWAY™

DM15WW-3D

1500W 6.25A @ ~ 240 VAC

125-01-0765A

L1

N

NOTE:

WIRES AT

CONTROL

INPUTS/OUTPUTS

14GA MAX

DANFOSS® CONTROLLER

AK-CC 210 115V # 084B8534

1H56892500

Danfoss®

AK-CC-21 0

DEF.

COMP.

120 VAC

SENSOR EKC-202C

DANFOSS® # 084N0027

1H26193500

BALLAST 125-01-3267

FULHAM LH4-120-L

F21T5-36"

125-03-1133

F28T5-48"

125-03-1134

F21T5-36"

125-03-1133

CIRCUIT #1

NOTE:

CASE MUST

BE GROUNDED

17.0L1

240 V

LOADING

IGFP-CR3FO-1209

Wiring Diagrams (Cont'd)

24

Page 25

Rev. 1209

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DES CRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

JESSE RIOS

PAGE OF

1

1

3/27/07

A REMOVED DUPLEX RECEPTACLE 4/2/07 JR

B Removed ballast circuit fuses 11/21/08 JR

C Changed to LED lights, Changed Fan Motor 12/21/11 CB

CR3-FO-3-REM

W8700010

CR3-FO-3-REM

CIRCUIT #1

NOTE: CASE MUST

BE GROUNDED

0 . 5L 1

120 V

LOADING

~120 VAC - 60 Hz.

CIRCUIT #1

RJ-45 NETWORK JACK

125-01-0200

125-01-0203

125-01-0204

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L1

N

G

M

BUNDLE

BROWN

BUNDLE

ORANGE

~120 VAC - 60 Hz.

LI N

WARMER

125-01-0767

TYCO

THERMAL

CONTROLS

10BTV1-CR

30 WATTS

.28AMP@120V

BUNDLE

PURPLE

LI N

~120 VAC - 60 Hz.

MCA= .14A

MOP= 15A

MCA= .15A

MOP= 15A

MCA= .35A

MOP= 15A

WHT # 14

BLK # 14

GREEN # 14

EVAP FAN MOTOR

0477653

0.12A 4W @ 120VAC

WHT # 14

BLK # 14

WHITE # 14

BLACK # 14

LIGHT CIRCUIT= .11A 12W

3500K 2' LED LIGHT

4441677

ADV DRIVER 0499399

LEDINTA-0024-41FO

3500K 2' LED LIGHT

4441677

OPTIONAL SHELF LIGHT

893405

Wiring Diagrams (Cont'd)

25

Page 26

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

CRAIG BOOREY

PAGE OF

1

1

12/21/11

CR3-FO-4-REM

1H69654

CR3-FO-4-R

CIRCUIT #1

NOTE:

CASE MUST

BE GROUNDED

0 . 7L 1

120 V

LOADING

~120 VAC - 60 Hz.

CIRCUIT #1

RJ-45 NETWORK JACK

125-01-0200

125-01-0203

125-01-0204

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L1

N

G

M

BUNDLE

BROWN

BUNDLE

ORANGE

~120 VAC - 60 Hz.

LI N

WARMER

125-01-0767

TYCO

THERMAL

CONTROLS

10BTV1-CR

40 WATTS

.37AMP@120V

BUNDLE

PURPLE

LI N

~120 VAC - 60 Hz.

MCA= .21A

MOP= 15A

MCA= .15A

MOP= 15A

MCA= .46A

MOP= 15A

WHT # 14

BLK # 14

GREEN # 14

EVAP FAN MOTOR

0477653

0.12A 4W @ 120VAC

WHT # 14

BLK # 14

WHITE # 14

BLACK # 14

LIGHT CIRCUIT= .17A 18W

3500K 3' LED LIGHT

4441587

ADV DRIVER 0499399

LEDINTA-0024-41FO

3500K 3' LED LIGHT

4441587

OPTIONAL SHELF LIGHT

IGFP-CR3FO-1209

Wiring Diagrams (Cont'd)

26

Page 27

Rev. 1209

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

CRAIG BOOREY

PAGE OF

1

1

12/21/11

CR3-FO-5-REM

1H69655

CR3-FO-5-R

CIRCUIT #1

NOTE:

CASE MUST

BE GROUNDED

0 . 8L 1

120 V

LOADING

~120 VAC - 60 Hz.

CIRCUIT #1

RJ-45 NETWORK JACK

125-01-0200

125-01-0203

125-01-0204

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L1

N

G

M

BUNDLE

BROWN

BUNDLE

ORANGE

~120 VAC - 60 Hz.

LI N

WARMER

125-01-0767

TYCO

THERMAL

CONTROLS

10BTV1-CR

50 WATTS

.46AMP@120V

BUNDLE

PURPLE

LI N

~120 VAC - 60 Hz.

MCA= .28A

MOP= 15A

MCA= .15A

MOP= 15A

MCA= .58A

MOP= 15A

WHT # 14

BLK # 14

GREEN # 14

EVAP FAN MOTOR

0477653

0.12A 4W @ 120VAC

WHT # 14

BLK # 14

WHITE # 14

BLACK # 14

LIGHT CIRCUIT= .22A 24W

3500K 4' LED LIGHT

4441591

ADV DRIVER 0499399

LEDINTA-0024-41FO

OPTIONAL SHELF LIGHT

3500K 4' LED LIGHT

4441591

Wiring Diagrams (Cont'd)

27

Page 28

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

CRAIG BOOREY

PAGE OF

1

1

12/21/11

CR3-FO-6-REM

1H69656

CR3-FO-6-R

CIRCUIT #1

NOTE:

CASE MUST

BE GROUNDED

1 . 2L 1

120 V

LOADING

~120 VAC - 60 Hz.

CIRCUIT #1

RJ-45 NETWORK JACK

125-01-0200

125-01-0203

125-01-0204

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L1

N

G

M

BUNDLE

BROWN

BUNDLE

ORANGE

~120 VAC - 60 Hz.

LI N

WARMER

125-01-0767

TYCO

THERMAL

CONTROLS

10BTV1-CR

60 WATTS

.56AMP@120V

BUNDLE

PURPLE

LI N

~120 VAC - 60 Hz.

MCA= .35A

MOP= 15A

MCA= .30A

MOP= 15A

MCA= .69A

MOP= 15A

WHT # 14

BLK # 14

GREEN # 14

EVAP FAN MOTOR

(2) 0477653

0.12A 4W @ 120VAC

WHT # 14

BLK # 14

WHITE # 14

BLACK # 14

LIGHT CIRCUIT= .28A 30W

3500K 5' LED LIGHT

4441681

ADV DRIVER 0499399

LEDINTA-0024-41FO

OPTIONAL SHELF LIGHT

M

IGFP-CR3FO-1209

Wiring Diagrams (Cont'd)

28

Page 29

Rev. 1209

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DESCRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

CRAIG BOOREY

PAGE OF

1

1

12/21/11

CR3-FO-8-REM

1H69657

CR3-FO-8-R

CIRCUIT #1

NOTE:

CASE MUST

BE GROUNDED

1 . 3L 1

120 V

LOADING

~120 VAC - 60 Hz.

CIRCUIT #1

RJ-45 NETWORK JACK

125-01-0200

125-01-0203

125-01-0204

L

LIGHT SWITCH

TIPPETTE

125-01-0311

L1

N

G

M

BUNDLE

BROWN

BUNDLE

ORANGE

~120 VAC - 60 Hz.

LI N

WARMER

125-01-0767

TYCO

THERMAL

CONTROLS

10BTV1-CR

80 WATTS

.74AMP@120V

BUNDLE

PURPLE

LI N

~120 VAC - 60 Hz.

MCA= .35A

MOP= 15A

MCA= .30A

MOP= 15A

MCA= .69A

MOP= 15A

WHT # 14

BLK # 14

GREEN # 14

EVAP FAN MOTOR

(2) 0477653

0.12A 4W @ 120VAC

WHT # 14

BLK # 14

WHITE # 14

BLACK # 14

LIGHT CIRCUIT= .33A 36W

3500K 3' LED LIGHT

4441587

ADV DRIVER 0499399

LEDINTA-0024-41FO

OPTIONAL SHELF LIGHT

M

3500K 3' LED LIGHT

4441587

3500K 3' LED LIGHT

4441587

3500K 3' LED LIGHT

4441587

Wiring Diagrams (Cont'd)

29

Page 30

IGFP-CR3FO-1209

DATE:

PROJECT TITLE:

DRAWING #:

DRAWN BY:

PRODUCTION ORDER #:

DRAWING TITLE:

DATE:

Hussmann Corporation, Int'l.

13770 Ramona Avenue

Chino, CA. 91710

(909)-590-4910 Lic.#: 644406

REVISIONS:

#: DES CRIPTION:

CHECKED BY:

BY:

FILE LOCATION:

DENNY QUAN

PAGE OF

1

1

D Chgd Omnistat controller to AK-CC 210, Chgd Relay 10/6/11 CB

E Changed compressor 10/27/11 CB

F Changed Fan Motor 12/29/11 CB

04/21/06

CR3FO-3-SC

W0180083

R3FO-3-S PANDA

910893

NOTE: CASE MUST

BE GROUNDED

OPTIONAL CIRCUIT #2

15.0L1

120 V

LOADING

~120 VAC - 50/60 Hz.

CIRCUIT #1

CONDENSING UNITS - COPELAND®

M4FH-0050-CAA-212

225-03-0081

RJ-45 NETWORK JACK

125-01-0200

125-01-0203

125-01-0204

L

LIGHT SW ITCH

TIPPETTE

125-01-0311

PRESSURE

SAFETY

L1

N

G

F14T5-36"

125-03-1126

WARMER

125-01-0767

RAYCHEM

10BUT-CR-10W

30 WATTS

0.26AMP@115V

RELAY

DPDT MARS 90341

125-01-1343

POWER CORD

15 AMP

125-01-0986

~120V - 15A

PLUG NEMA 5-15P

BGW

DUPLEX

125-01-3178

CIRCUIT #2

L1

N

M

CONDENSING UNIT

RLA= 9.16A 934W

MCC=12.8A

LRA= 33.6A

C

R

BLK # 14

WHT # 14

GRN # 14

EVAP

FAN MOTOR

0477653

4W .12A @

120VAC

BALLAST 125-01-3266

FULHAM LH3-120-L

NOTE: WIRES AT

CONTROL

INPUTS/OUTPUTS

14GA MAX

DEF.

COMP.

120 VAC

F14T5-36"

125-03-1126

OPTIONAL

Wiring Diagrams

Appendices

Appendix A. - Temperature Guidelines

The refrigerators should be operated according to the

manufacturer’s published engineering specifications

for entering air temperatures for specific equipment

applications. Table 1 shows the typical temperature of

the air entering the food zone one hour before the start of

defrost and one hour after defrost for various categories

of refrigerators. Refer to Appendix C for Field Evaluation

Guidelines.

Type of Refrigerator

I. OPEN DISPLAY

A. Non frozen:

1) Meat 28°F

2) Dairy/Deli 32°F

3) Produce

a. Processed 36°F

b. Unprocessed 45°F

B. Frozen 0°F

C. Ice Cream -5°F

II. CLOSED DISPLAY

A. Non frozen:

1) Meat 34°F

2) Dairy/Deli 34°F

3) Produce

a. Processed 36°F

b. Unprocessed 45°F

B. Frozen 0°F

C. Ice Cream -5°F

Table 1

Typical Entering

Air Temperature

Single Deck Multi Deck Service Case Reach-In

I. Open Display Styles II. Closed Display Styles

Appendix B. - Application Recommendations

1.0 Temperature performance is critical for controlling

bacteria growth. Therefore, the following

recommendations are included in the standard.

They are based on conrmed eld experience

over many years.

1.1 The installer is responsible for following the

installation instructions and recommendations

provided by Hussmann for the installation

of each individual type refrigerator.