Husqvarna-Viking 670 User Manual

User’s Guide

KEEPING THE WORLD SEWING™

This household sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the following:

Read all instructions before using this household sewing machine.

DANGER – To reduce the risk of electric shock:

• A sewing machine should never be left unattended when plugged in. Always unplug this sewing machine

from the electric outlet immediately after using and before cleaning.

• Always unplug before relamping.

WARNING – To reduce the risk of burns,

fi re, electric shock, or injury to person:

• This sewing machine is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the sewing machine by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the sewing machine.

• Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has

been dropped or damaged, or dropped into water. Return the sewing machine to the nearest authorized

dealer or service center for examination, repair, electrical or mechanical adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the

sewing machine and foot controller free from the accumulation of lint, dust, and loose cloth.

• Keep fi ngers away from all moving parts. Special care is required around the sewing machine needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may defl ect the needle causing it to break.

• Wear safety glasses.

• Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot, etc.

• Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned in the instruction manual.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• This sewing machine is provided with double insulation. Use only identical replacement parts.

See instructions for Servicing of Double-Insulated Appliances.

SAVE THESE INSTRUCTIONS

SERVICING OF DOUBLE INSULATED PRODUCTS

In a double-insulated product, two systems of insulation are provided instead of grounding. No ground means is

provided on a double-insulated product, nor should a means for grounding be added to the product. Servicing of a

double-insulated product requires extreme care and knowledge of the system and should be done only by qualifi ed

service personnel. Replacement parts for a double-insulated product must be identical to those parts in the product.

A double-insulated product is marked with the words ‘DOUBLE INSULATION’ or ‘DOUBLE INSULATED’.

CONTENTS

Machine overview ...................................................................4

Included accessories ...............................................................5

Stitch table – Utility Stitches .................................................6

Stitch Overview .......................................................................8

Fonts .........................................................................................8

Getting Ready to Sew 9

Unpacking ..............................................................................10

Packing away after sewing ....................................................10

Accessory tray ........................................................................10

Using the free arm ................................................................10

Connecting the foot control cord ......................................11

Connect the power cord and foot control ........................11

Lower the feed teeth .............................................................12

Presser foot pressure ............................................................12

Raise and lower the presser foot .........................................12

Changing the presser foot ...................................................12

Changing the needle .............................................................13

Needles ...................................................................................13

Spool pins and spool caps ...................................................14

Threading the upper thread .................................................15

Needle threader .....................................................................16

Cutting the thread .................................................................16

Threading for twin needles ..................................................17

Winding the bobbin with the machine threaded..............18

Winding the bobbin using the vertical spool pin .............18

Winding the bobbin using the auxiliary spool pin ...........19

Inserting the bobbin .............................................................19

Thread tension, 650 ..............................................................20

Automatic thread tension, 670 ............................................20

Starting to sew ......................................................................20

Operating Y our OPAL™ 670 Sewing Machine 31

Functions, 670 .......................................................................32

Functions on the TouchScreen ...........................................33

Sewing Mode, 670 .................................................................34

Selecting a stitch ....................................................................35

Selecting a font .....................................................................35

Programming, 670 ................................................................36

My Stitches Menu ...............................................................38

SET Menu ............................................................................39

Pop-Up Messages 41

Pop-up messages ...................................................................42

Sewing 45

Exclusive SEWING ADVISOR™ ....................................46

Seam ........................................................................................47

Overcast ..................................................................................47

Seam and overcast .................................................................48

Baste ........................................................................................48

Blind hem ...............................................................................48

Hem ........................................................................................49

Sewing buttonholes ..............................................................50

Sewing on buttons ................................................................52

Sewing zippers .......................................................................53

Darning and mending ..........................................................54

Bartack (manual) ...................................................................54

Quilting ...................................................................................55

Speciality Stitches ..................................................................56

Smocking Stitches .................................................................57

Automatic Tapering Stitches ..............................................57

Pictogram Stitches ...............................................................58

Operating Y our OPAL™ 650 Sewing Machine 21

Functions, 650 .......................................................................22

Functions on the Touch Panel ............................................23

Sewing Mode, 650 .................................................................24

Selecting a stitch ...................................................................26

Selecting a font .....................................................................26

Programming, 650 ................................................................27

My Stitches Menu ...............................................................29

SET Menu ............................................................................30

Taking Care of Your Machine 59

Cleaning the machine ...........................................................60

Trouble shooting ...................................................................61

Note: The machine models will be referred to as simply

670 and 650 in this User’s Guide.

1

21

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

11

22

23

24

25

26

27

28

29

30

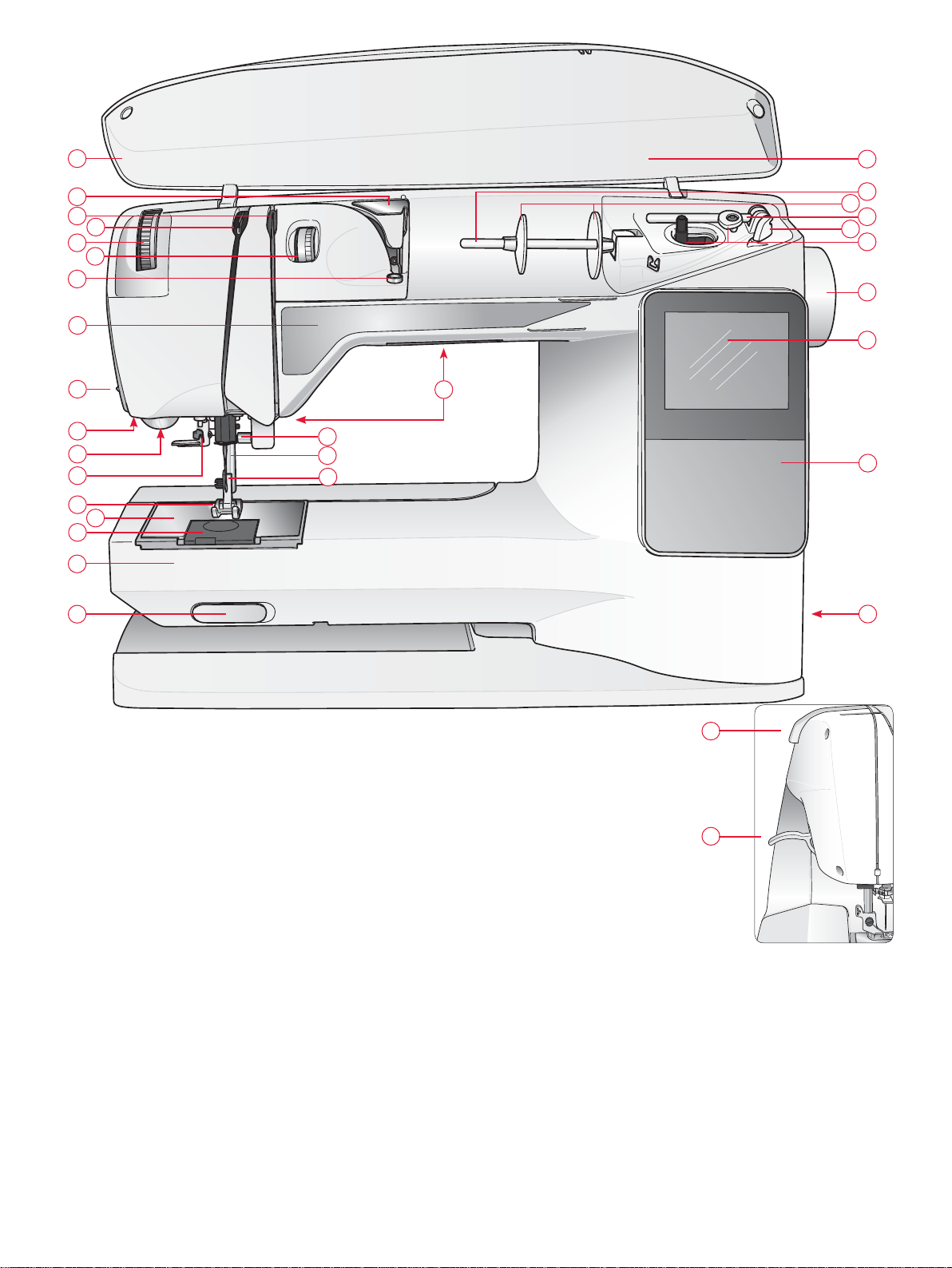

MACHINE OVERVIEW

1. Lid

2. Pre-tension thread guide

3. Thread tension disks

4. Thread take-up lever

5. Presser foot pressure dial

6. Thread tension dial (only 650)

7. Thread tension for bobbin winding

8. Function Panel

9. Thread cutter

10. Sensor One-Step Buttonhole

Foot socket

11. LED-lights

12. Needle threader

13. Presser foot

14. Stitch plate

15. Bobbin cover

16. Free arm

17. Drop feed teeth switch

18. Needle bar with needle clamp screw

19. Presser bar

20. Presser foot ankle

21. Stitch overview

22. Spool pin

23. Spool caps

24. Auxiliary spool pin

25. Thread cutter for bobbin thread

26. Bobbin spindle, Bobbin stop

27. Handwheel

28. GraphicDisplay (650)/

TouchScreen (670)

31

32

29. Function Panel (650)

30. ON/OFF switch, connectors for

power cord and foot control

31. Handle

32. Presser foot lever

4 – Overview

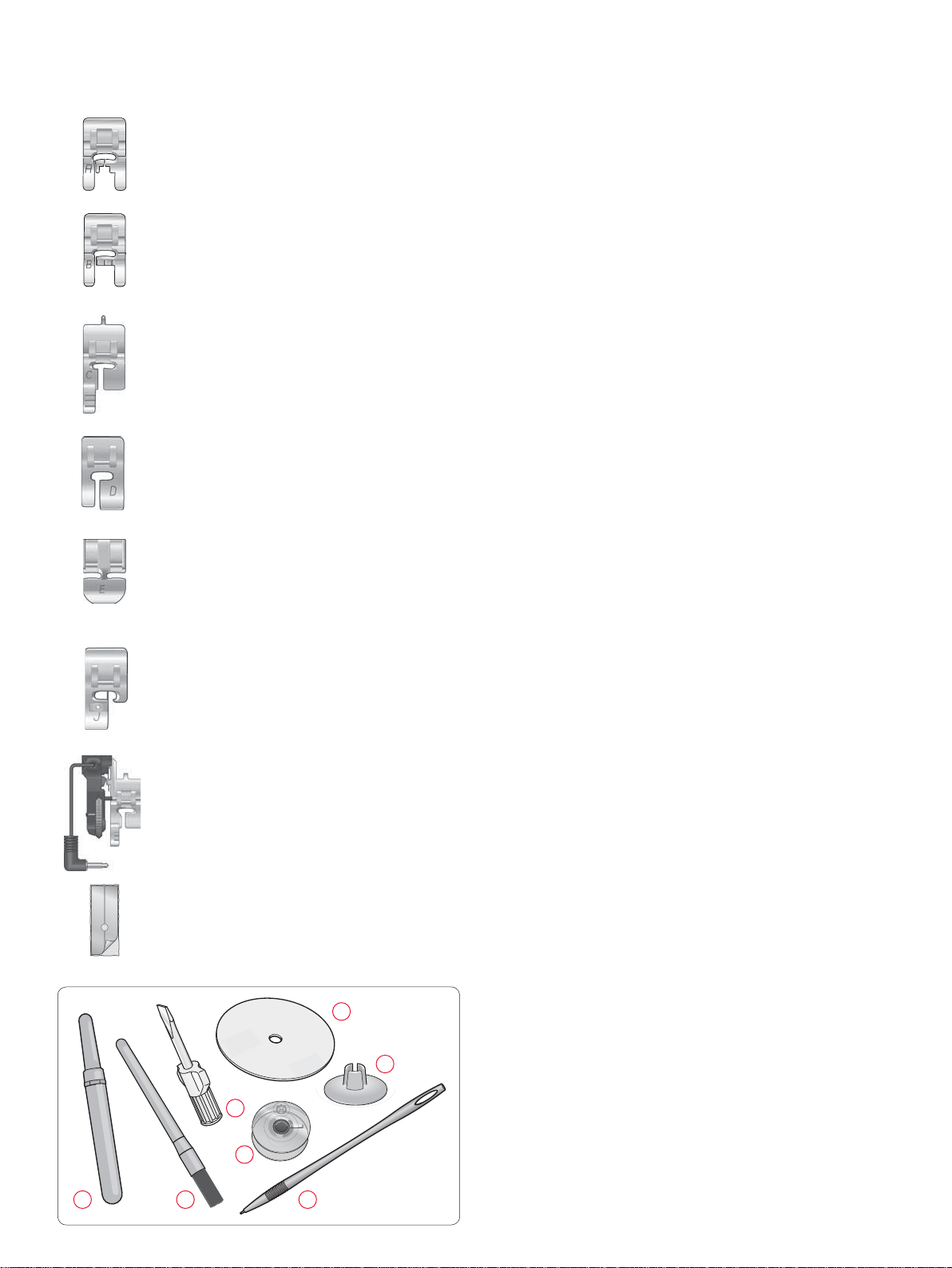

INCLUDED ACCESSORIES

Presser Feet

Utility Foot A

Attached on the machine upon delivery. This foot is used mainly for straight stitching and zigzag stitching with

a stitch length longer than 1.0.

Utility Foot B

When sewing decorative stitches or short zigzag stitches and other utility stitches with less than 1.0 mm stitch

length, use this foot. The tunnel on the underside of the foot is designed to feed smoothly over the stitches.

Buttonhole Foot C

This foot is used for sewing buttonholes step by step. Use the guide lines on the toe of the foot to position

the garment edge. The two tunnels on the bottom of the foot ensures a smooth feed over the buttonhole

columns. The fi nger on the back of the foot holds cording for corded buttonhole.

Blind Hem Foot D

This foot is used for blind hem stitches. The inner edge of this foot guides the fabric. The right toe of the

foot is designed to ride along the hem edge.

Zipper Foot E

This foot can be snapped on either to the right or to the left of the needle, making it easy to sew close to both

sides of the zipper teeth. Move needle position to right or left to sew closer to zipper teeth or for covering

large cording.

Edging Foot J

This foot is used for overcasting and seam/overcasting. Stitches form over the pin which prevents puckering

at the edge of the fabric.

Sensor One-Step Buttonhole Foot

When connected to the machine, the buttonhole is sewn in a suitable length to the button size that has been

entered into the machine.

Glide Sole

If sewing on foam, vinyl, plastic, or leather, the material might stick to the foot and prevent the sewing

machine from feeding properly. When using any of the above materials, sew on a piece of scrap fabric, to

make sure the machine feeds smoothly. If not, fasten the self-adhesive glide soles to the underside of the

presser foot.

1. Seam ripper

4

2. Brush

1 2

6

3

5

7

3. Screwdriver

4. Felt pad (2)

5. Bobbins (5)

6. A small spool cap

7. Stylus (only 670)

Needles (not pictured), see page 13

Overview – 5

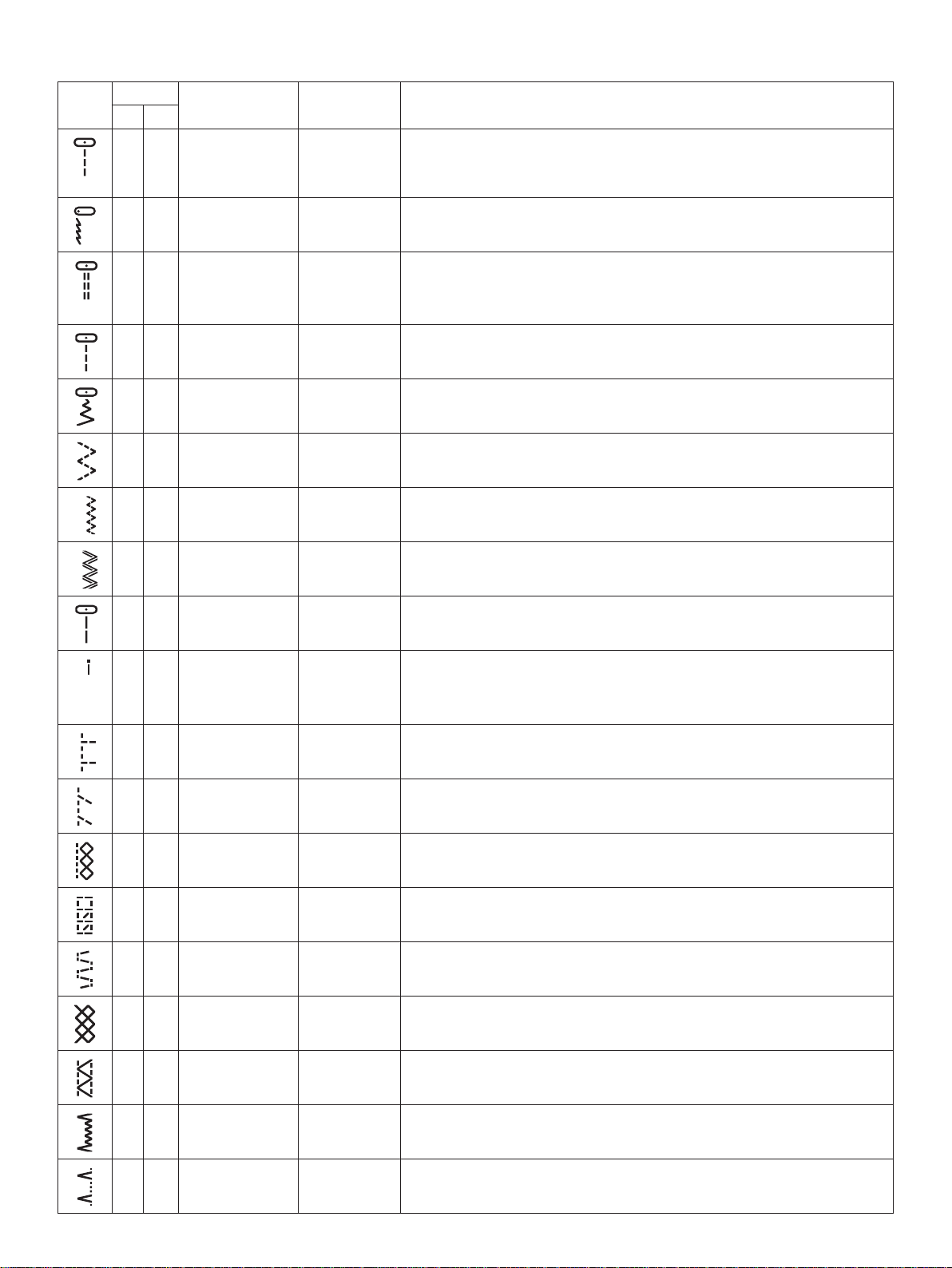

STITCH TABLE – UTILITY STITCHES

Stitch Stitch No. Stitch Name Presser Foot Application

670 650

1 1 Straight Stitch,

center needle

position

A/B For all types of sewing. Select 29 different needle positions.

2 2 Stretch Stitch,

left needle position

3 3 Reinforced Straight

4 – Straight Stitch

5 4 Zigzag A/B For appliqué work, lace edging, sewing on bands etc. Stitch width increases equally to

6 5 Three-Step Zigzag A/B For mending, sewing on patches and elastics. Suitable for light and medium weight

7 6 Two-Step Zigzag A/B For joining two pieces of fabric with fi nished edges and for elastic shirring.

8 7 Reinforced Zigzag B For joining fabric edge to edge or overlapping in leather. For decorative sewing.

9 8 Baste Stitch A/B For joining two pieces of fabric with a long stitch length (reduce thread tension

10 – Straight Basting

Stitch, center

needle position

with FIX

Stitch

A/B For seams in tricot and stretch fabric.

A/B For seams which are subject to considerable strain. Triple and elastic for reinforced

seams. Use to reinforce and topstitch sportswear and working clothes. For topstitch,

increase the stitch length.

A/B Begins and ends with forward and reverse sewing.

the left and right.

fabric..

according to recommendations on the GraphicDisplay (650)).

A Use together with the foot control to baste layers of the fabric together. Lower the

feed teeth. Sew a stitch, raise the presser foot and move the fabric. Lower the presser

foot and make the next stitch. Repeat until the basting is done.

11 9 Overcast Stitch J Seam and overcast in one step along the edge or trim later. For light stretch and non-

stretch fabrics.

12 10 Stretch Seam

Overcast Stitch

13 11 Double Overlock

Stitch

14 12 Overlock Stitch B Seam and overcast in one step along the edge or trim later. For medium stretch fabrics.

15 13 Elastic/Casing

Stitch

16 14 Elastic Stitch

or Smocking

17 15 Flatlock Stitch B Decorative hems and overlapped seams, belts and bands. For medium/heavy stretch

18 16 Stretch Blind

Hem Stitch

19 17 Woven Blind Hem D Blind hems in medium and heavy woven fabrics.

B Seam and overcast in one step along the edge or trim later. For medium and medium/

heavy stretch fabrics.

B Seam and overcast in one step along the edge or trim later. For hea vy stretch and heavy

woven fabrics.

B For overlapped seams in tricot. To sew casing over narrow elastic.

A/B Sew over two rows of elastic thread for elastic shirring.

fabrics.

D Blind hems in medium and heavy stretch fabrics.

6 – Overview

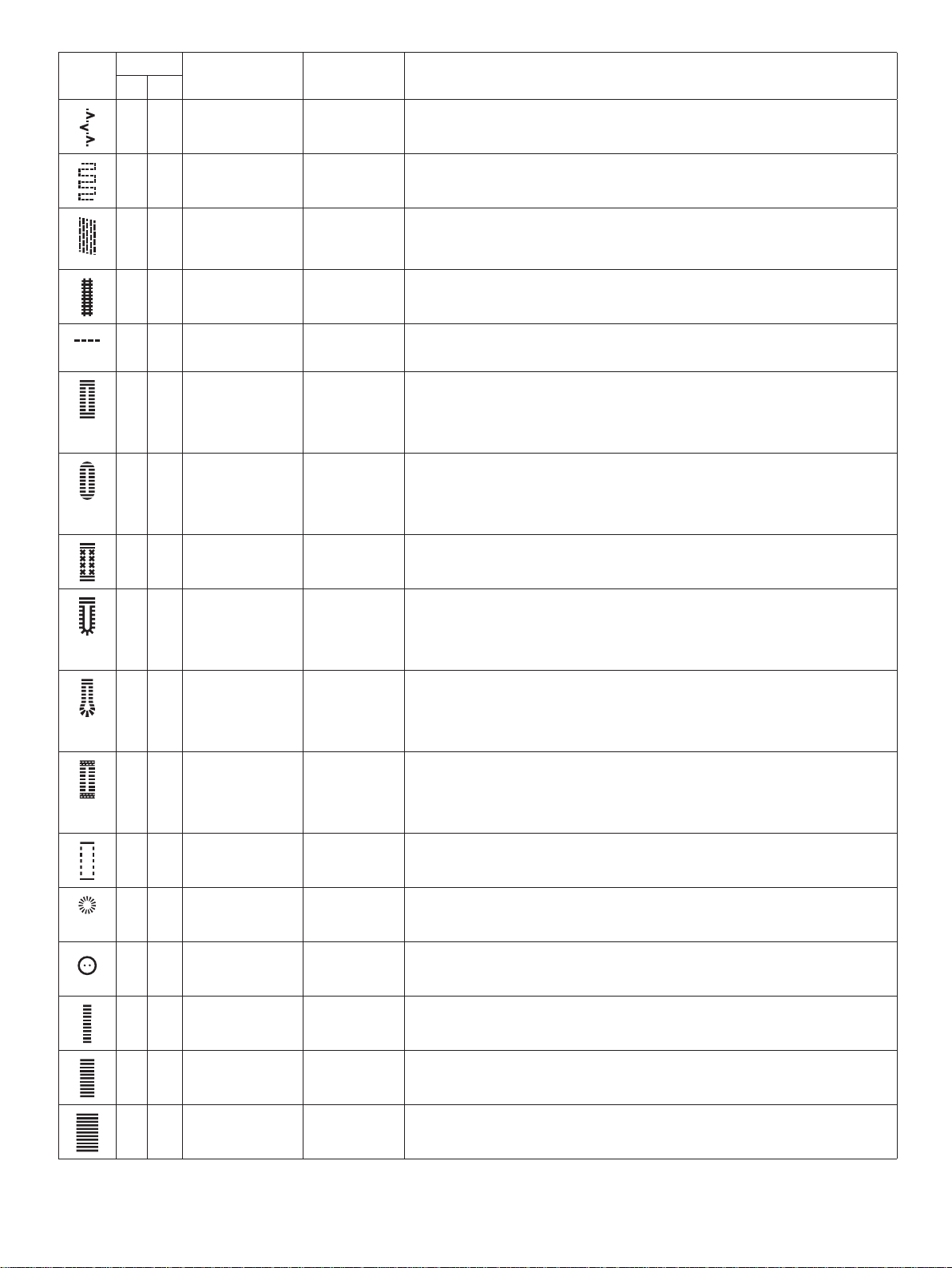

Stitch Stitch No. Stitch Name Presser Foot Application

670 650

20 18 Bridging Stitch A/B For joining two pieces of fabric with fi nished edges and for elastic shirring.

21 – Darning Stitch

A For mending small tears.

(side to side)

22 19 Darning Stitch (for-

ward and backward)

23 20 Bartack

A/B Darn and mend small holes in work clothes, jeans, tablecloths and more. Stitch over

the hole, press reverse for continuous darning and auto stop.

A/B Reinforce pockets, shirts openings, belt loops as well as at lower end of a zipper.

(manual)

24 – Belt Loop Stitch A For securing belt loops.

25 21 Bartack Buttonhole Sensor

Standard buttonhole for most fabric weights.

One-Step

Buttonhole

Foot/C

26 22 Round End

Buttonhole

Sensor

One-Step

For blouses and children’s garments.

Buttonhole

Foot/C

27 23 Medium Reinforced

C For medium and heavy fabrics

Buttonhole

28 24 Heirloom

Buttonhole

Sensor

One-Step

Buttonhole

For “hand look” on fi ne and delicate fabrics.

Tip: For jeans buttonholes, increase length and width of the buttonhole. Use thicker thread.

Foot/C

29 25 Keyhole

Buttonhole

Sensor

One-Step

For tailored jackets, coats, etc.

Buttonhole

Foot/C

30 26 Heavy Duty

Buttonhole

Sensor

One-Step

Buttonhole

With reinforced bartacks.

Foot/C

31 27 Leather Straight

A/B For leather and suede.

Stitch Buttonhole

32 28 Eyelet B For belts, laces, etc.

33 29 Automatic Button

Sewing

No presser foot For sewing on buttons. Set the number of stitches on the GraphicDisplay/

TouchScreen.

34 30 Satin stitch, narrow B For appliqués, sewing on laces and trims. For light and medium fabrics.

35 31 Satin stitch,

B For appliqués, sewing on laces and trims. For light and medium fabrics.

medium

36 32 Satin stitch, wide B For appliqués, sewing on laces and trims. For heavy fabrics.

Overview – 7

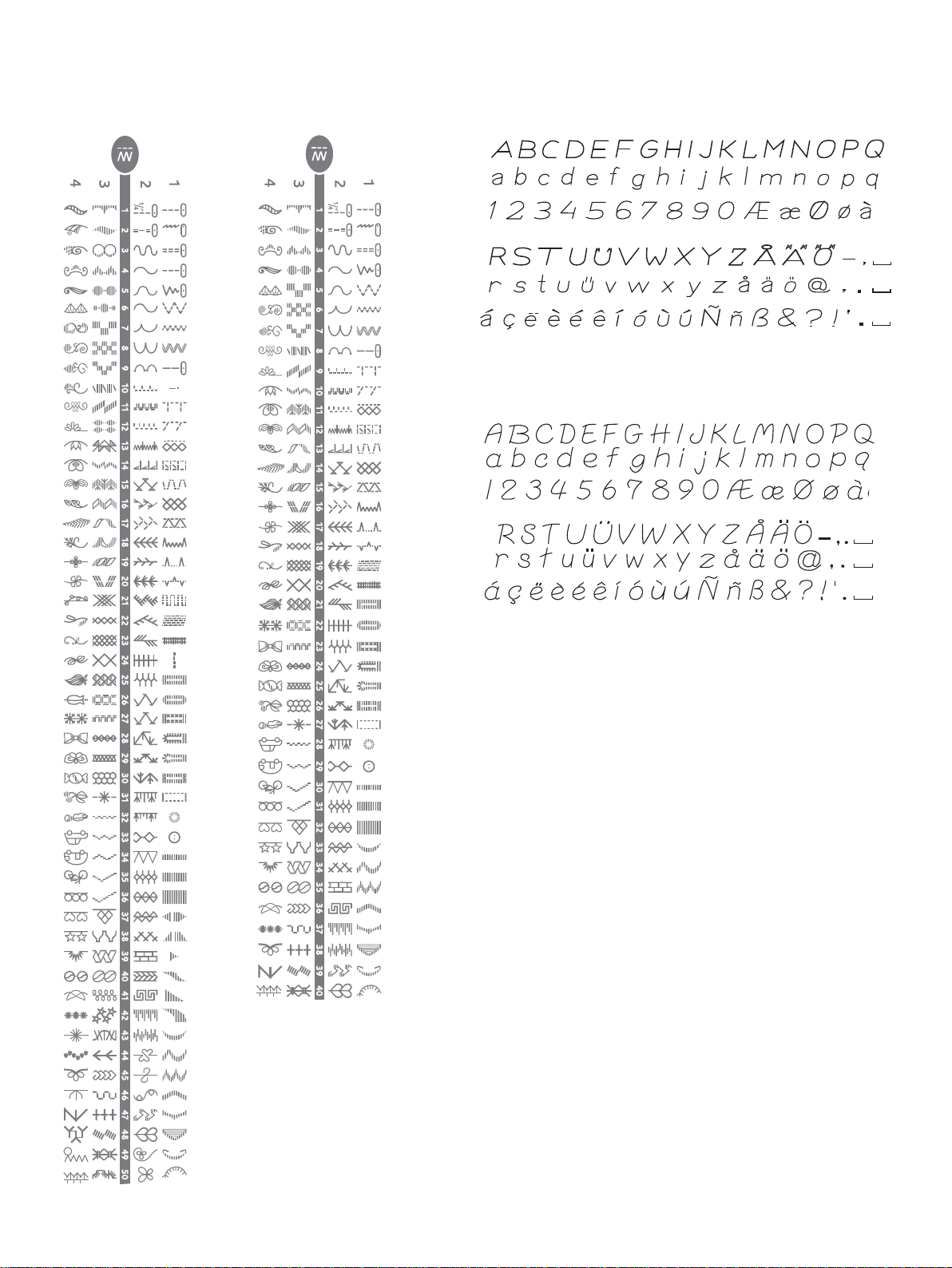

FONTSSTITCH OVERVIEW

670 650

Block (670/650)

Brush Line (670)

Cyrillic and Hiragana (670/650)

Russian and Japanese fonts. See the fonts on the

GraphicDisplay/TouchScreen of your sewing machine.

8 – Overview

GETTING READY TO SEW

UNPACKING

1. Place the machine on a sturdy, fl at surface, remove the packaging and lift off the cover.

2. Remove the packing material and the foot control.

3. The machine is delivered with an accessory bag, a power cord and a foot control cord.

4. Wipe the machine, particularly around the needle and stitch plate to remove any soil before sewing.

Note: Your HUSQVARNA VIKING

®

OPAL™ sewing machine is adjusted to provide the best stitch result at normal room temperature.

Extreme hot or cold temperatures can affect the sewn result.

P ACKING A W A Y AFTER SEWING

1. Press the ON/OFF switch to OFF.

2. Unplug the cord from the wall socket and then from the machine.

3. Unplug the foot control cord from the machine. Wind the foot control cord and place it inside the space on the underside of

the foot control.

4. Check to ensure that all accessories are in the accessory box. Slide the box on to the machine, behind the free arm.

5. Place the foot control in the space above the free arm.

6. Put on the cover.

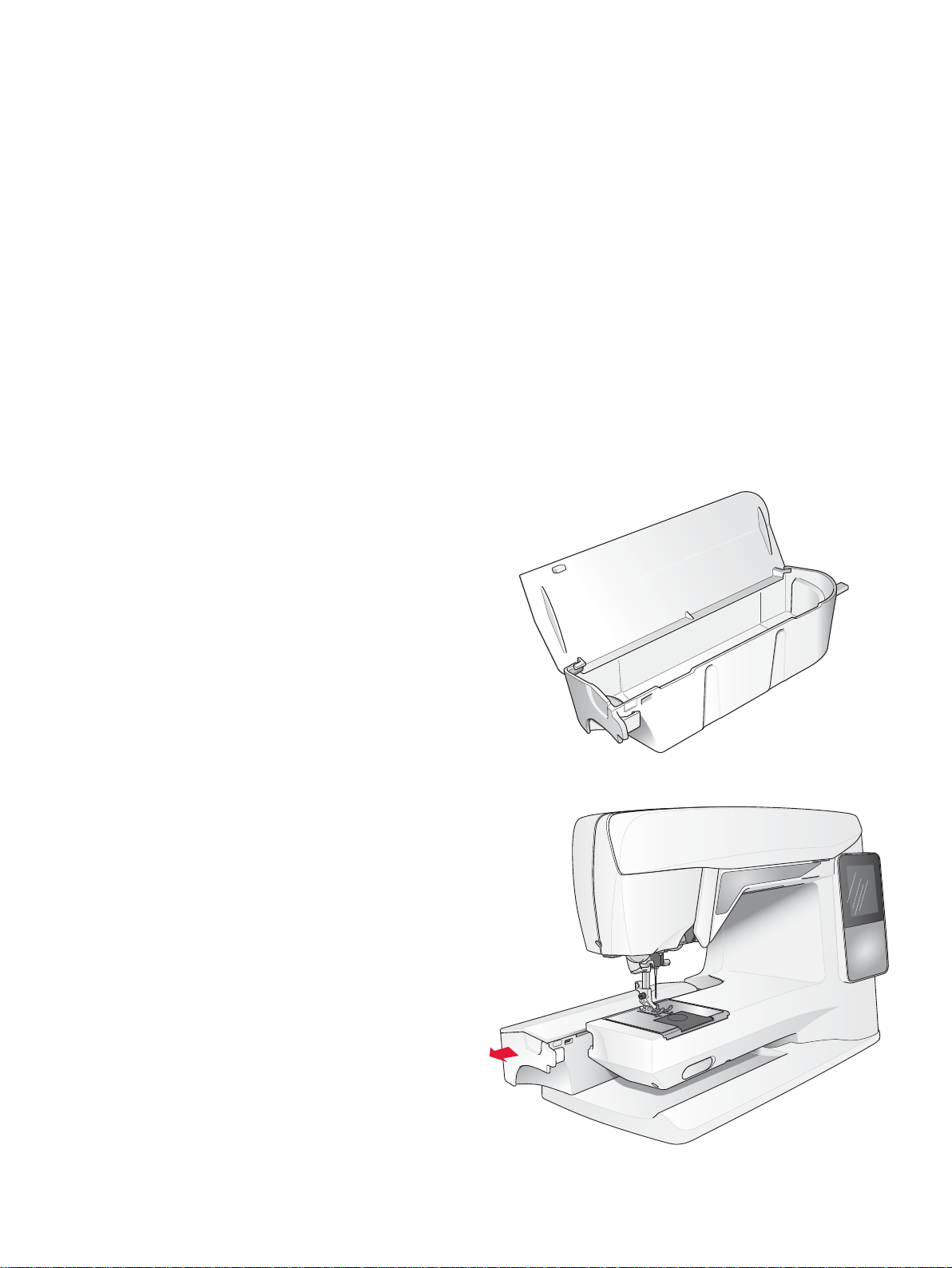

ACCESSOR Y TRA Y

Store presser feet, bobbins, needles and other accessories in

the accessory tray so that they are easily accessible.

Keep the accessory tray on the machine to provide a larger,

fl at work surface.

USING THE FREE ARM

Slide the accessory box to the left when you wish to remove it

and use the free arm.

Use the free arm to facilitate sewing trouser legs and sleeve

hems.

To replace the accessory box, slide it onto the machine until it

fi ts in place.

10 – Getting Ready to Sew

CONNECTING THE FOOT CONTROL CORD

Among the accessories you will fi nd the foot control cord and

the power cord. Connecting the foot control cord to the foot

control is only necessary the very fi rst time you are going to

use the machine.

1. Take out the foot control cord. Turn the foot control over.

Connect the cord to the socket inside the space of the foot

control. Push fi rmly to make sure it is properly connected.

2. Lay the cord in the slot on the underside of the foot

control.

1

2

CONNECT THE POWER CORD

AND FOOT CONTROL

On the underside of the machine you will fi nd information

about the power supply voltage (V) and the frequency (Hz).

Before plugging in the foot control, check to ensure that it is

of type “FR2” (see underside of foot control).

1. Connect the foot control cord to the front socket on the

bottom right side of the machine.

2. Connect the power cord to the rear socket on the bottom

right side of the machine.

3. Press the ON/OFF switch to ON to turn on power and

light.

For the USA and Canada

This sewing machine has a polarized plug (one blade wider

than the other). To reduce the risk of electric shock, this

plug is intended to fi t in a polarized outlet only one way. If

the plug does not fi t fully in the outlet, reverse the plug. If

it still does not fi t, contact a qualifi ed electrician to install

the proper outlet. Do not modify the plug in any way.

1 23

Getting Ready to Sew – 11

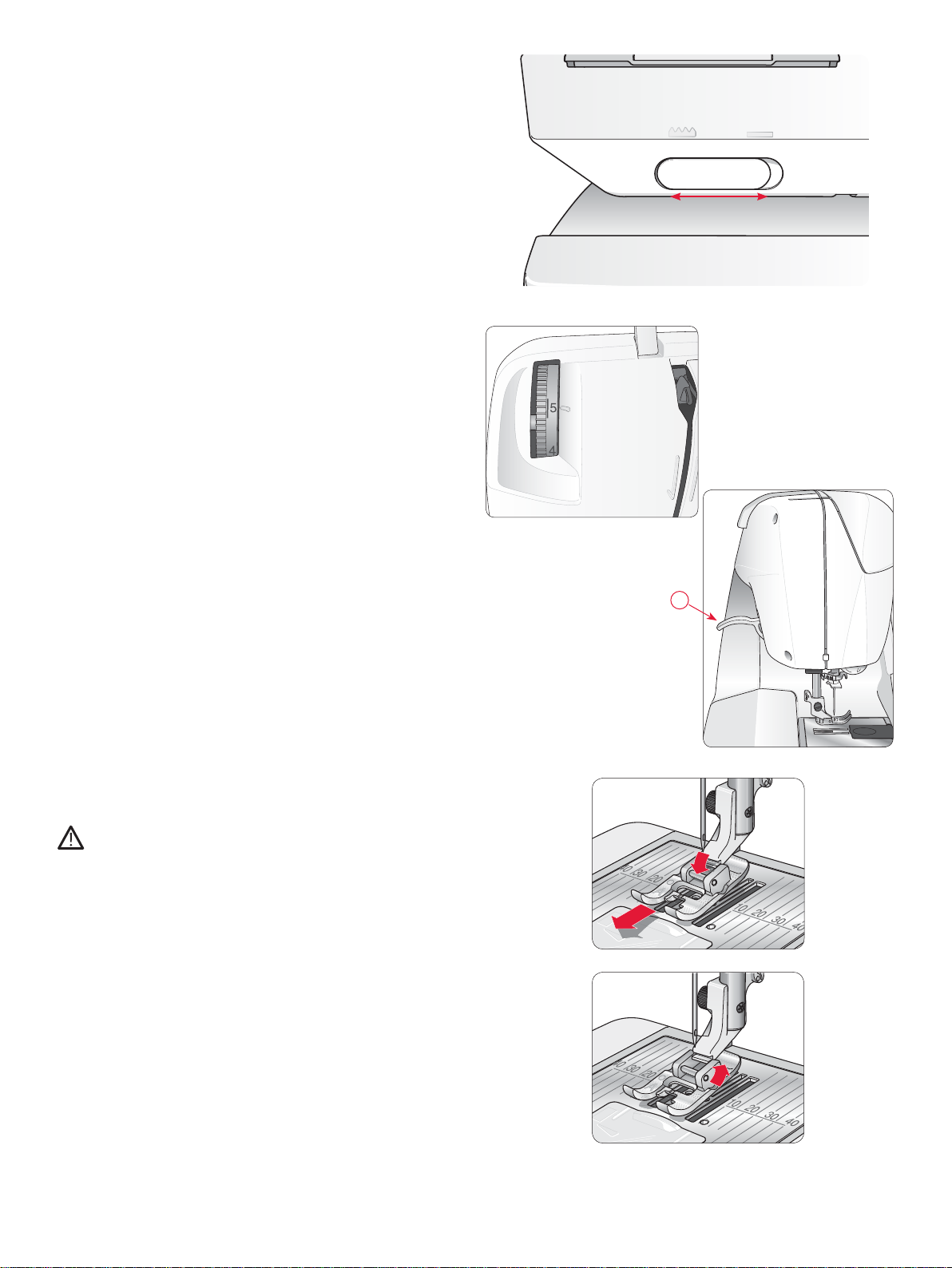

LOWER THE FEED TEETH

The feed teeth are lowered when you move the switch on the

front of the free arm to the right. Move the switch to the left

if you wish to raise the feed teeth. The feed teeth will raise

as you begin to sew. The feed teeth should be lowered when

sewing on buttons and for free motion sewing.

PRESSER FOOT PRESSURE

Normal presser foot pressure is around fi ve. The higher the

number the more pressure the foot puts on the fabric. Knit

and soft fabrics should be sewn at lower pressure.

The presser foot pressure is adjusted with the dial found under

the lid. When adjusting the pressure lower the presser foot

fi rst.

RAISE AND LOWER THE PRESSER FOOT

The presser foot is raised and lowered with the presser foot

lever (A). The presser foot must be lowered when sewing.

By raising the presser foot lever and then pressing it farther

upwards, the lift height of the presser foot is increased to an

extra height allowing you to slide very thick projects under the

foot.

CHANGING THE PRESSER FOOT

Press the ON/OFF switch to OFF.

1. Make sure the needle is in the highest position and the

presser foot is lifted. Pull the presser foot towards you.

2. Line up the cross pin on the foot with the gap in the

presser foot ankle. Push back until the foot snaps into

place.

A

12 – Getting Ready to Sew

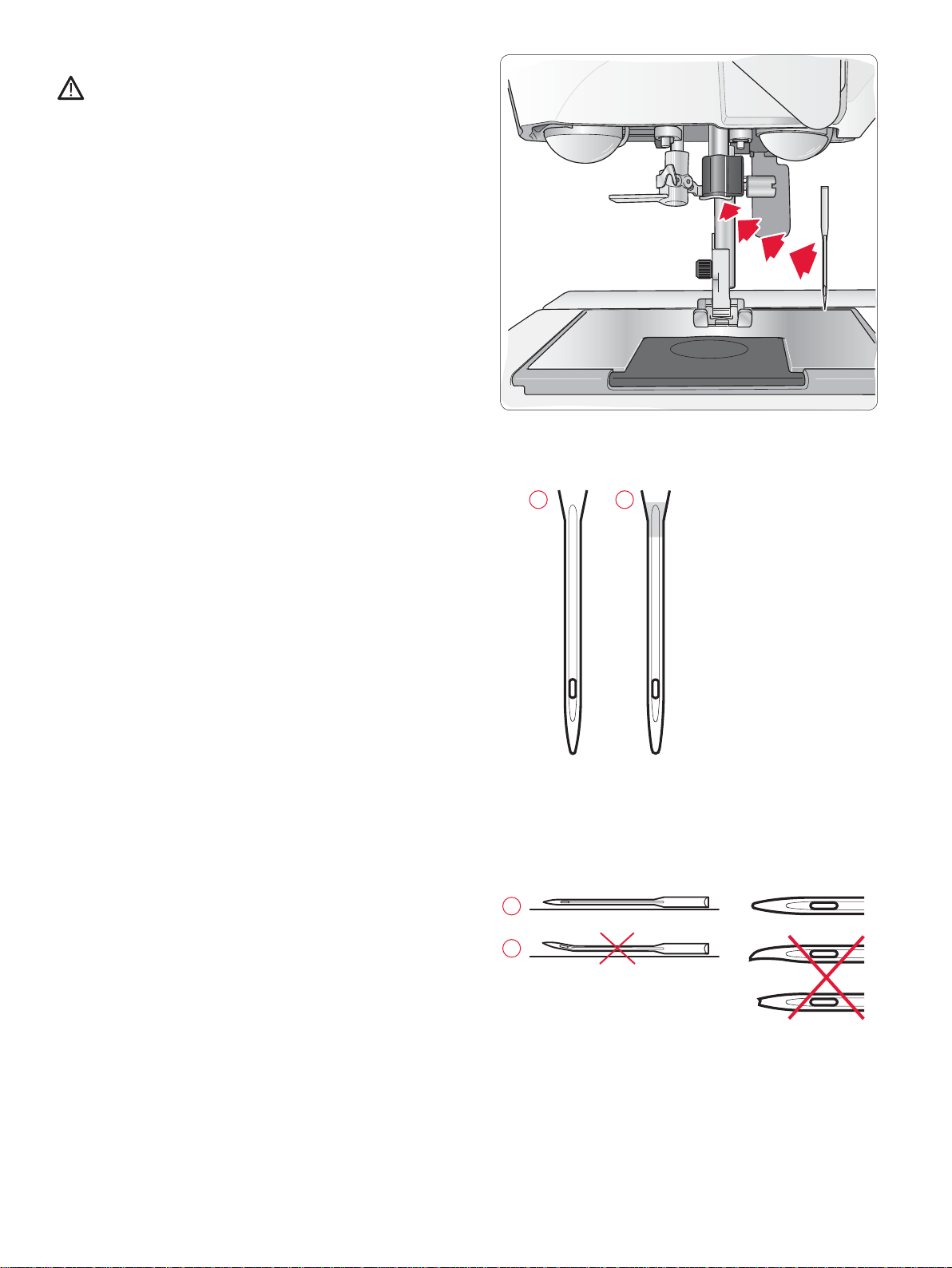

CHANGING THE NEEDLE

Press the ON/OFF switch to OFF.

1. Loosen the screw in the needle clamp with the screwdriver.

2. Remove the needle.

3. Push the new needle upwards with the fl at side away from

you until it will go no further.

4. Use the screwdriver to tighten the screw properly.

NEEDLES

The sewing machine needle plays an important role in

successful sewing. To ensure you will get a quality needle, we

recommend needles of system 130/705H. The needle package

included with your machine contains needles of the most

frequently used sizes for sewing on woven and stretch fabrics.

A B

Universal needle (A)

Universal needles have a slightly rounded point and come in a

variety of sizes. For general sewing in a variety of fabric types

and weights.

Stretch needle (B)

Stretch needles have a special scarf to eliminate skipped

stitches when there is a fl ex in the fabric. For knits, swimwear,

fl eece, synthetic suedes and leathers. Marked with a yellow

band.

Tip: Read more about different needles in the HUSQVARNA

VIKING Accessory User’s Guide at www.husqvarnaviking.com.

Note: Change the needle often. Always use a straight needle with a sharp

point (1). A damaged needle (2) can cause skipped stitches, breakage of

needles or snapping of thread. A damaged needle can also damage the

stitch plate.

1

2

Getting Ready to Sew – 13

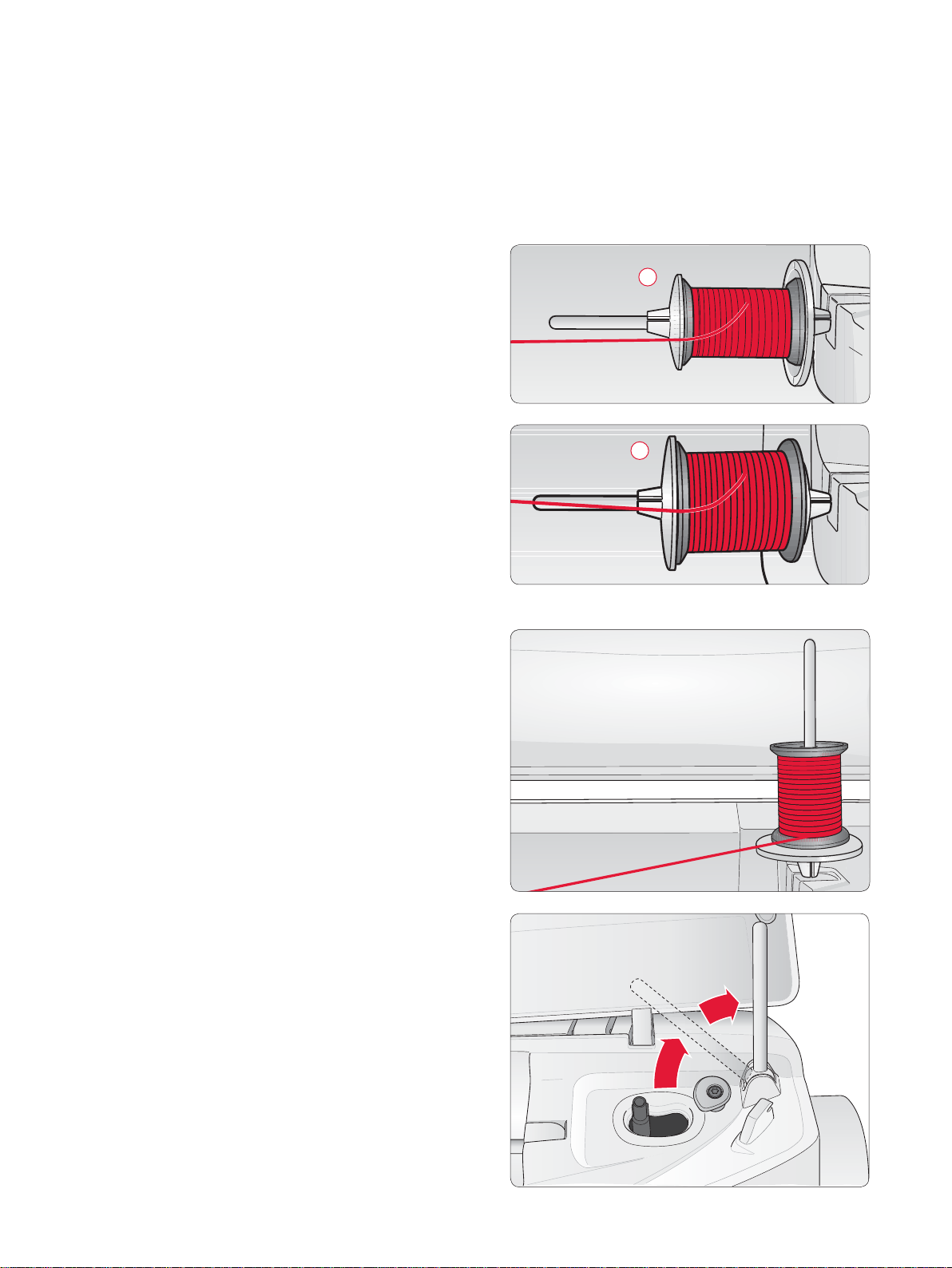

SPOOL PINS AND SPOOL CAPS

Your sewing machine has two spool pins, a main spool pin and an auxiliary spool pin. The spool pins are designed for all types

of thread. The main spool pin is adjustable and can be used in a horizontal position (the thread reels off the stationary spool) or

in a vertical position (the thread spool rotates). Use the horizontal position for all regular sewing threads and the vertical position

for large spools or specialty threads.

Horizontal Position

Lift the spool pin up slightly from its horizontal position to

easily place the thread spool on the pin. The thread should reel

over the top, in a counterclockwise direction, as shown in the

picture. Slide on a spool cap and then move the spool pin back

to the horizontal position.

Each machine comes with two spool caps on the spool pin.

For medium sized thread spools, the medium sized cap (A) is

placed in front of the spool. For large thread spools, the large

cap (B) is placed in front of the spool.

The fl at side of the spool cap should be pressed fi r mly against

the spool. There should be no space between spool cap and

thread spool.

A small spool cap is included as an accessory for your

machine. The small spool cap can be used for small thread

spools.

A

B

Vertical Position

Lift the spool pin up and all the way to the right. Lock the

spool pin in the vertical position by slightly pressing it down.

Slide on the large spool cap. For spools smaller than the

medium size spool cap or when using specialty threads, place

a felt pad under the thread spool to prevent the thread from

reeling off too fast. For larger spools, the felt pad is not

needed.

Note: No spool cap should be placed on top of the spool as this prevents

the spool from rotating.

Auxiliary Spool Pin

The auxiliary spool pin is used when winding a bobbin from

a second spool of thread or for a second spool when sewing

with a twin needle.

Lift the auxiliary spool pin up and to the left. Slide on a spool

cap. For spools smaller than the medium size spool cap, place

a felt pad under the thread spool to prevent the thread from

reeling off too fast. For larger spools, the felt pad shall not be

used.

14 – Getting Ready to Sew

C

D

E

A

B

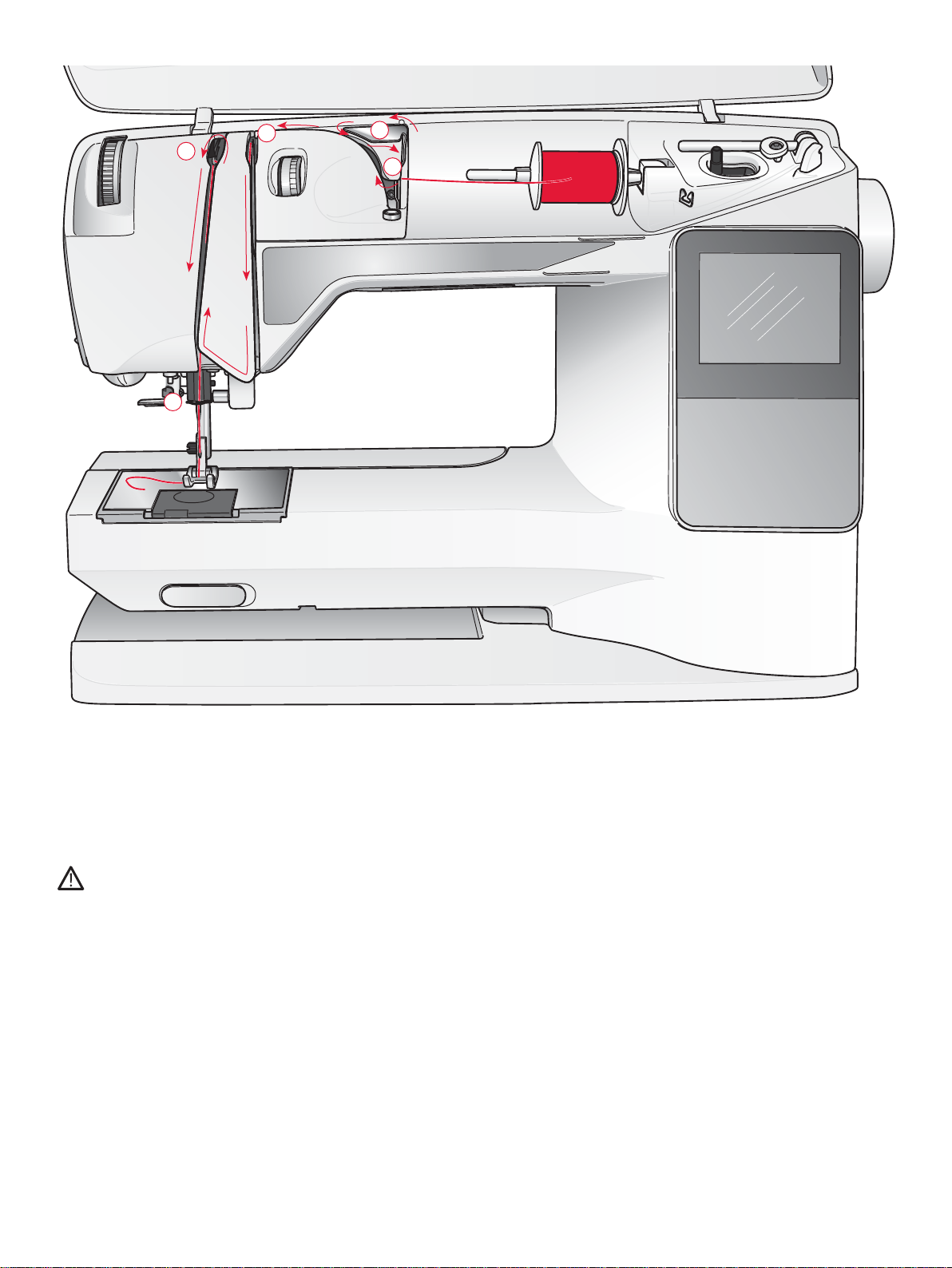

THREADING THE UPPER THREAD

Make sure the presser foot is raised and the needle is in the up

position

Press the ON/OFF switch to OFF.

1. Place the thread on the spool pin and the spool cap on the

spool pin as described on page 14.

2. Spool pin in horizontal position:

Bring the thread over and behind the pre-tension thread

guide (A) and under the thread guide (B).

Spool pin in vertical position:

Instead of bringing the thread into the pre-tension guide

(A), bring it directly under the thread guide (B).

3. Bring the thread down between the thread tension discs

(C).

4. Continue threading in the direction indicated by the arrows.

Bring the thread from the right into the slot on the take-up

lever (D).

5. Take the thread down and behind the last guide just above

the needle (E).

Getting Ready to Sew – 15

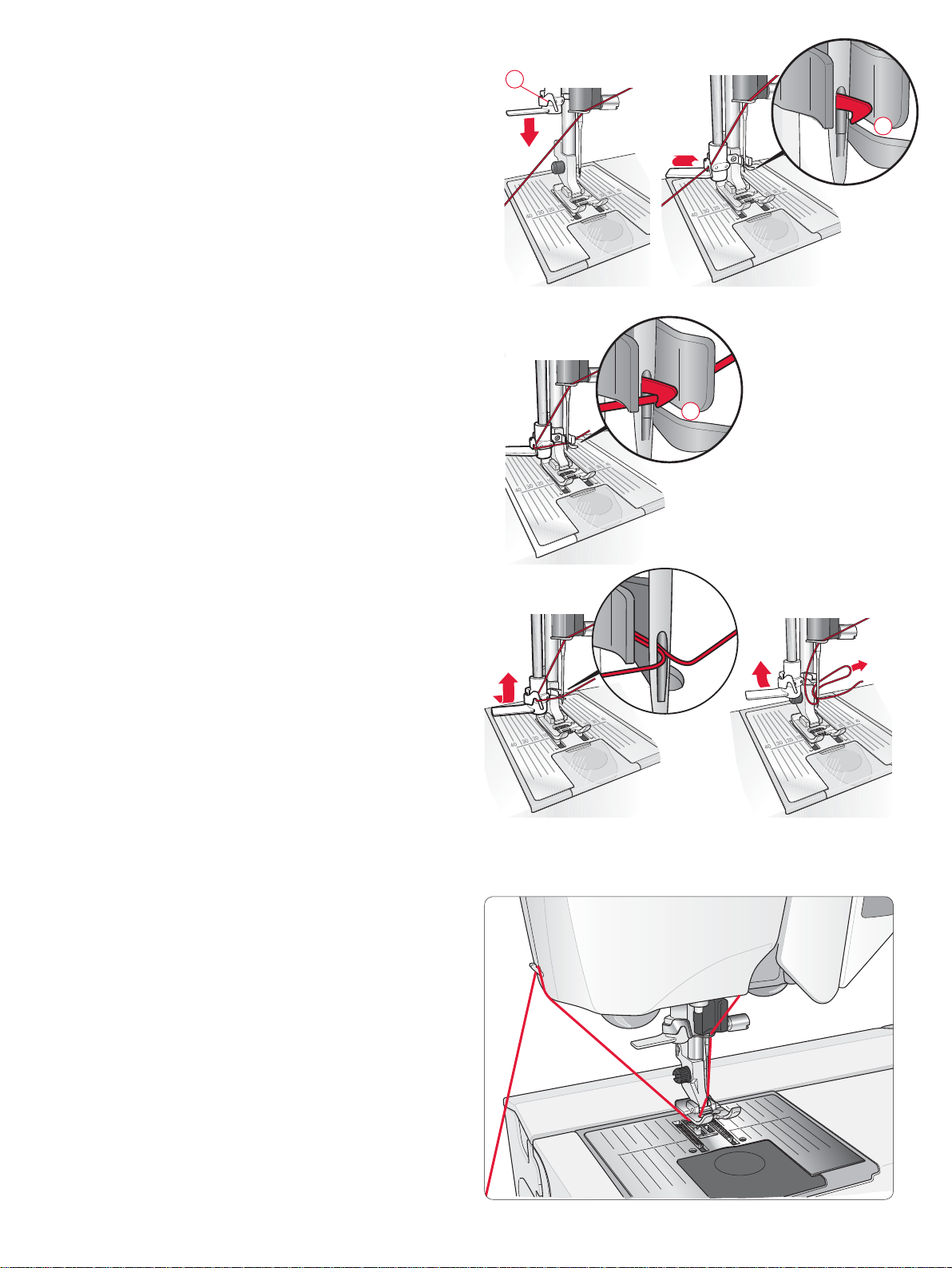

NEEDLE THREADER

The needle must be in the up position to use the built-in

needle threader. We also recommend lowering the presser foot.

1. Use the handle to pull the needle threader all the way

down, catching the thread under the guide (A).

2. Push back to bring the needle threader forward until the

metal fl anges cover the needle. A small hook will pass

through the needle eye (B).

3. Place the thread under the fl anges in front of the needle,

so the thread catches into the small hook (C).

4. Let the needle threader gently swing back. The hook pulls

the thread through the needle eye and forms a loop behind

the needle.

5. Pull the thread loop out behind the needle. Place the thread

under the presser foot.

Note: The needle threader is designed to be used for size 70-120 needles.

You cannot use the needle threader for size 60 needles or smaller, the wing

needle, twin needle, triple needle or when the Sensor One-Step Buttonhole

Foot is on. There are also some other optional accessories that require

manual threading of the needle.

A

B

1. 2.

C

When threading the needle manually, make sure that the needle

is threaded from front to back. The white presser foot ankle

makes it easy to see the eye of the needle. The bobbin case

cover can be used as a magnifying glass.

CUTTING THE THREAD

Once you have fi nished sewing, cut the threads by raising the

presser foot and pulling the threads from the front to the back

into the thread cutter on the left side of the machine.

3.

4.

5.

16 – Getting Ready to Sew

A

B

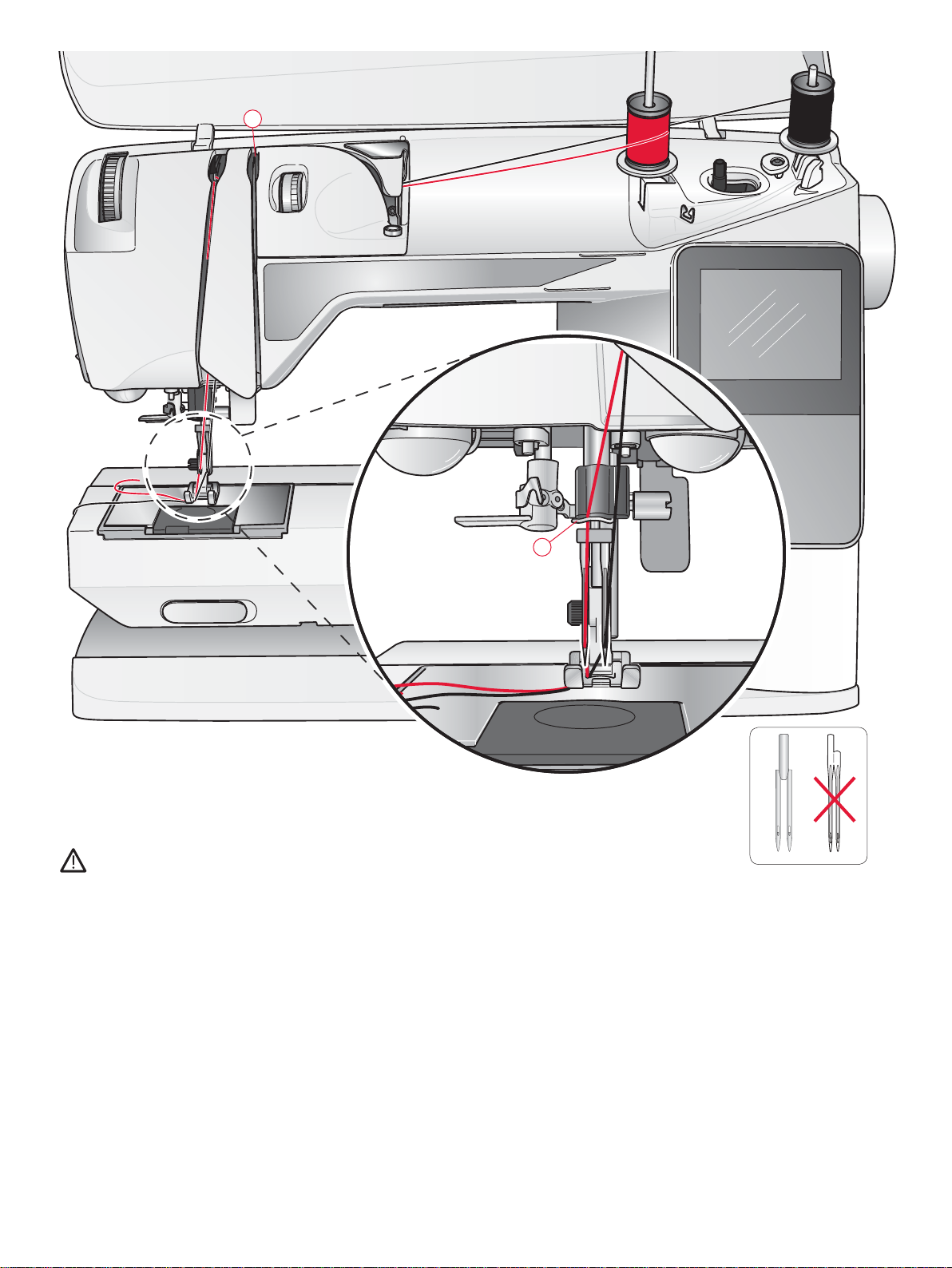

THREADING FOR TWIN NEEDLE

Press the ON/OFF switch to OFF.

1. Insert a twin needle.

2. Use a second thread spool or wind a bobbin with the

thread you are going to use as the second upper thread.

3. Lift the spool pin up and all the way to the right. Lock

the spool pin in the vertical position by slightly pressing

it down. Slide on a spool cap. For spools smaller than the

medium size spool cap, place a felt pad under the thread

spool.

4. Place the fi rst thread spool on the spool pin. The spool

should rotate in a clockwise direction when the thread reels

off the spool.

5. Left needle: Thread the machine as described on page 13.

Check to ensure that the thread lies between the left thread

tension discs (A). Thread the left needle manually.

Note: Only use symmetrical twin needles (C).

Do not use this type of twin needle (D), since

it may damage your sewing machine.

C

D

6. Pull out the auxiliary spool pin and slide on a spool cap.

For spools smaller than the medium size spool cap, place a

felt pad under the thread spool.

7. Place the second thread on the spool pin. The second

spool should rotate in a counterclockwise direction when the

thread reels off the spool.

8. Right needle: Thread the machine as before but this thread

should lie between the right thread tension discs (A) and

outside the needle thread guide (B). Thread the right needle

manually.

Note: If using specialty threads (such as metallic threads) its weight and

irreglular surface increases the thread tension. By reducing the tension, the

risk of needle breakage is prevented.

Getting Ready to Sew – 17

WINDING THE BOBBIN WITH

THE MACHINE THREADED

Make sure that the presser foot is up and the needle is in the

highest position.

Note! Do not use a plastic presser foot when bobbin winding.

1. Place an empty bobbin on the bobbin spindle on the top

of the machine. The bobbin only fi ts on one way, with

the logo facing up. Use only original HUSQVARNA

VIKING

2. Pull the thread from the needle under the presser foot and

to the right through the thread guide (C).

3. Guide the thread through the hole in the bobbin (D) from

the inside to the outside.

Note: When using an earlier version of HUSQVARNA VIKING

bobbins that do not have a hole, wind several turns of thread on the

bobbin to get started.

®

bobbins.

®

C

4. Push the bobbin spindle to the right. A pop-up message

appears on the GraphicDisplay/TouchScreen. Hold the

end of the thread fi rmly when starting to wind. Press the

foot control to start winding. Once the bobbin begins to

wind, cut the excess thread. When the bobbin is full it will

stop rotating. Push the bobbin spindle back to the left,

remove the bobbin and cut off the thread on the thread

cutter.

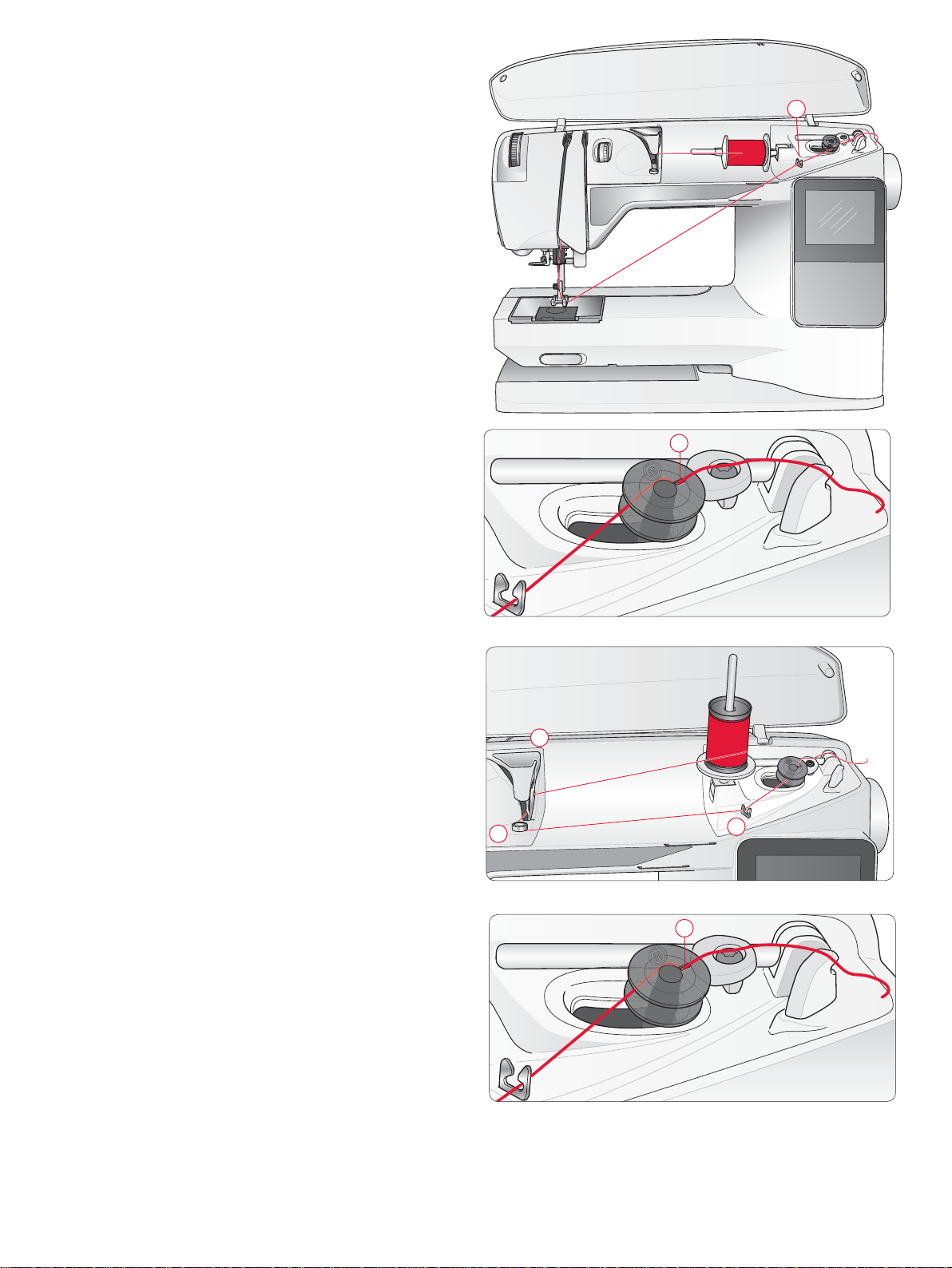

WINDING THE BOBBIN USING

THE VERTICAL SPOOL PIN

1. Place an empty bobbin on the bobbin spindle on the top

of the machine. The bobbin only fi ts on one way, with

the logo facing up. Use only original HUSQVARNA

VIKING

2. Place the large spool cap and a felt pad under the spool on

the main spool pin set in the vertical position.

3. Bring the thread over and behind the pre-tension thread

guide (A) and down around the thread tension disc (B),

then through thread guide (C) as illustrated.

4. Guide the thread through the hole in the bobbin (D) from

the inside to the outside.

5. Push the bobbin spindle to the right. A pop-up message

appears on the GraphicDisplay/TouchScreen. Hold the

end of the thread fi rmly when starting to wind. Press the

foot control to start winding. Once the bobbin begins to

wind, cut the excess thread. When the bobbin is full it will

stop rotating. Push the bobbin spindle back to the left,

remove the bobbin and cut off the thread on the thread

cutter.

®

bobbins.

D

A

B

D

C

Note: When using an earlier version of HUSQVARNA VIKING

bobbins that do not have a hole, wind several turns of thread clockwise

on the bobbin to get started.

18 – Getting Ready to Sew

®

WINDING THE BOBBIN USING

THE AUXILIARY SPOOL PIN

1. Place an empty bobbin on the bobbin spindle on the top

of the machine. The bobbin only fi ts on one way, with

the logo facing up. Use only original HUSQVARNA

VIKING

®

bobbins.

A

2. Fold out the auxiliary spool pin. Place a spool cap and a

felt pad under the spool.

3. Bring the thread over and behind the pre-tension thread

guide (A) and down around the thread tension disc (B),

then through thread guide (C) as illustrated.

4. Guide the thread through the hole in the bobbin (D) from

the inside to the outside.

5. Push the bobbin spindle to the right. A pop-up message

appears on the GraphicDisplay/TouchScreen. Hold the

end of the thread fi rmly when starting to wind. Press the

foot control to start winding. Once the bobbin begins to

wind, cut the excess thread. When the bobbin is full it will

stop rotating. Push the bobbin spindle back to the left,

remove the bobbin and cut off the thread on the thread

cutter.

INSER TING THE BOBBIN

D

B

C

Press the ON/OFF switch to OFF.

1. Remove the bobbin cover by sliding it towards you.

2. Place the bobbin in the bobbin case. It drops in only one

way with the logo facing up. The thread unreels from the

left of the bobbin. The bobbin will then rotate counterclockwise when you pull the thread.

3. Place your fi nger on the bobbin to keep it from turning as

you pull the thread fi rmly to the right and then to the left

into the tension spring (E) until it “clicks” into place.

4. Continue threading around (F) and to the right of the

thread cutter (G). Slide on the bobbin cover (H). Pull the

thread to the left to cut (I).

1. 2.

F

E

G

3. 4.

I

H

Getting Ready to Sew – 19

THREAD TENSION, 650

Use the recommended top thread tension setting given on

the GraphicDisplay. You might need to adjust the top thread

tension for special threads, fabrics and/or techniques. To set

the tension, turn the numbered tension dial. The higher the

number the tighter the tension.

Normal top thread tension is set to 4-6. When sewing

buttonholes and decorative stitches set thread tension to

around 3. When topstitching with a heavy weight thread

in thick fabric, increase the tension to 7-9. Thread tension

recommendation is always given on the GraphicDisplay for

the selected stitch and fabric.

Make a few tests on a scrap piece of the fabric you are going

to sew and check the tension.

AUT OMATIC THREAD TENSION, 670

The 670 model automatically sets the best thread tension

for the selected stitch and fabric. The thread tension can be

adjusted for specialty thread, techniques or fabric. Touch + to

increase the thread tension and - to decrease it.

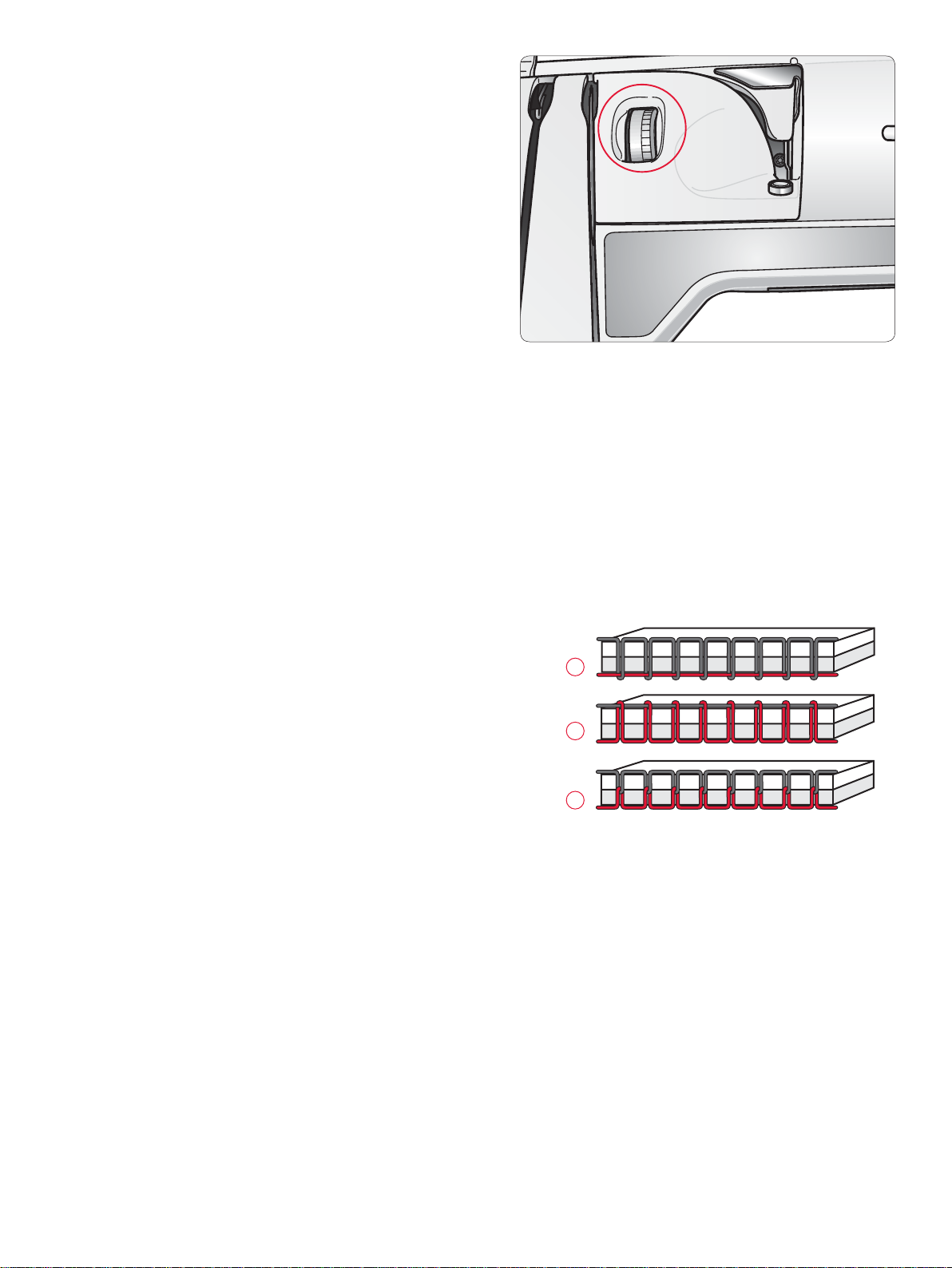

Correct and Incorrect Thread Tension

To understand the correct thread tension, sew a few sample

straight stitches at different settings.

1. Begin with a tension that is too loose, i.e. set at the lowest

number. The bobbin thread will lie straight and the top

thread will be drawn to the underside of the fabric.

2. If you set the tension at the highest number, the bobbin

thread will be visible on the top side of the fabric. The

seam may pucker and the top thread might break.

3. The correct thread tension is set when the threads interlock

in between both fabric layers or, in the case of decorative

stitches, on the underside.

1

2

3

ST ARTING TO SEW

A straight stitch is selected by default when you turn on the machine. Before starting to sew, select your fabric quality in the

Exclusive SEWING ADVISOR™ feature, and set yout machine according to the recommendations on the GraphicDisplay/

TouchScreen (page 46).

To start sewing, place top and bobbin thread under the presser foot and to the back. For best results when beginning at the

edge of the fabric, place a fi nger on the threads to hold them in place as you begin.

Place fabric in position under the presser foot. Lower the presser foot and step on the foot control to begin sewing. Guide the

fabric gently with your hands as the machine is feeding.

See page 26 (650)/35 (670) for reference on how to select another stitch or how to use the Exclusive SEWING ADVISOR™

feature (page 46).

20 – Getting Ready to Sew

Loading...

Loading...