Page 1

Workshop manual

ZTH

English

Page 2

Svenska – 31

Page 3

Contents

WORKSHOP MANUAL

RIDE-ON LAWN MOWER

ZTH

Contents

Safety Instructions

General Instructions.............................................3

Special Instructions..............................................3

Explanation of Symbols

Tools

Technical Data

Delivery and Dealer Service

Pre-delivery Service...........................................11

After the First 8 Hours........................................12

25 Hour Service.................................................12

50 Hour Service.................................................12

100 Hour Service...............................................13

300 Hour Service...............................................13

At Least Once a Year.........................................14

Maintenance Schedule ......................................15

Delivery Servicing

To our Dealers...................................................19

Removing the Mower from its Packaging ..........19

Delivery Service.................................................20

Test Running......................................................24

Administration....................................................24

Design and Function

General..............................................................25

Mower Identification...........................................25

Engine................................................................27

Drive and Control...............................................27

Brakes................................................................27

Mower Deck.......................................................28

Repairs

Engine................................................................29

Adjusting the Throttle Wire.................................31

Checking and Adjusting the Choke Wire ...........32

Fuel tank............................................................33

Adjusting Motion Control Lever Linkages ..........34

Adjusting Motion Control Lever Spring-back......34

Adjusting the Park Brake ...................................34

Mower Deck.......................................................35

Spindle Blade Bearings.....................................36

Sharpening and Balancing Blades.....................37

Setting the Mower Deck ....................................38

Deck Belt............................................................38

Hydraulic Pump Belt ..........................................40

Front Wheel Bearings........................................41

..................................................................1

.................................................3

........................................5

.......................................................................6

........................................................7

................................11

................................................19

............................................25

..................................................................29

Electrical System

Troubleshooting ................................................ 43

Wiring Assembly ............................................... 43

Battery............................................................... 46

Fuses ................................................................ 46

Relays............................................................... 47

Starter Motor Contactor..................................... 47

Ignition and Start Switch ................................... 48

Hour Meter........................................................ 48

Blade Switch ..................................................... 49

Mower Deck Clutch........................................... 49

Motion Control Switches ................................... 50

Park Brake Interlock Switch.............................. 51

Welding............................................................. 52

Hydraulic System

Hydraulics Hygiene........................................... 53

Hydraulic Oils.................................................... 54

Correct Oil Leaks .............................................. 54

Keep Hydraulic Oil Clean.................................. 54

Work Methods................................................... 54

ZTH Hydraulic System...................................... 55

Hydraulic Tank.................................................. 56

The Cooler for the Hydraulic System................ 57

Hydraulic Filter.................................................. 57

Hydraulic Lines.................................................. 57

Hydraulic Pump................................................. 58

Hydraulic Motors............................................... 60

Troubleshooting

Engine............................................................... 61

Wiring Harness.................................................. 61

Clutch................................................................ 63

Hydraulic Pump................................................. 66

................................................ 43

................................................ 53

.................................................. 61

English-

1

Page 4

English-

2

Page 5

SAFETY INSTRUCTIONS

Safety Instructions

General Instructions

This workshop manual has been written for users who have a good understanding of the repair and

servicing of ride-on mowers.

The workshop where the ride-on mower is repaired must have have all the safety systems demanded by

local regulations.

No one is to attempt to repair the ride-on mower without having first read and understood the contents of

this manual.

The ride-on mower has been safety tested. Safety approval applies only when the ride on-mower uses

parts or equipment supplied or recommended by Husqvarna Turf Care.

Special Instructions

The fuel used in the ride-on mower is hazardous if used incorrectly. Pay particular attention to the following:

• The fuel and the fumes it gives off are toxic.

• Eye and skin complaints can result from incorrect exposure.

• Breathing difficulties can result from incorrect exposure.

• The fuel and fumes are highly flammable.

When using compressed air, users must not direct the air stream towards themselves or any other person.

Air may penetrate the blood stream and cause life-threatening damage.

Use hearing protectors when test driving.

After test driving, do not touch the muffler before it has cooled down (danger of burns). This especially

applies if the ride-on mower has a catalytic converter. If consumed, the lining on and in the catalytic

converter element can damage health. Wear protective gloves whenever working on the catalytic converter

or the silencer.

With the engine running, many engine and drive system components become hot and may cause burns if

touched. Do not touch such components before they have cooled down.

When draining oil from a hot engine or hot hydraulic system, be aware that the oil can be hot enough to

cause burns. Wear protective glasses whenever there is a risk of splashing.

The mower blades are sharp. To avoid cuts, always wear protective gloves when handling the blades.

Wear protective glasses when working with springs. Springs can detach from their mounts and fly with

great force into unprotected eyes.

Use the right tools for each job. Check all tools before using them and repair or replace as necessary.

English-

3

Page 6

SAFETY REGULATIONS

Keep the workplace clean and tidy. Ensure that illumination is good, that tools which are not being used

are stored appropriately and that all waste (scrap, swarf, etc.) is immediately placed in the appropriate

container. Pay particular attention to keeping the floor clean so that there is no risk of slipping or tripping.

Be extremely careful when handling battery acid. Severe burns may result if the acid touches the skin. If

acid is spilt on the skin, drench immediately with running water.

Always wear protective glasses when handling battery acid. Blindness may result if acid gets into the eyes.

If there is an accident, take immediate action and contact a doctor as soon as possible.

Be careful when working on the battery. Explosive gas is formed in the battery. Never handle the battery

when smoking or in the vicinity of naked flames or sparks (the battery may explode and cause severe

injuries).

During certain maintenance and service operations, it is required that the mower be rendered incapable of

starting. This is to prevent injury to those working on or standing near the mower.

Hydrostatic braking may be lost if there is a failure in the hydrostatic drive.

Certain solvents and cleaning agents are flammable. Do not use them whenever there is a less dangerous

alternative. Never use flammable solvents in areas where there is a risk of ignition. Dispose of used

cleaning agents in sealed containers.

Respect the environment. Ensure that all solvents, waste oil and used oil filters are handled in an

environment-friendly way. Observe all local regulations on the environment. A Husqvarna workshop must

look clean at all times!

In this workshop manual, “warning box es” containing further safety instructions will be found next to certain

work instructions. Observe these safety instructions, they are there for your protection.

In this workshop manual, all locators (“right”, “left”, etc.) are judged as viewed from behind the forwardfacing mower (i.e. as if standing directly behind the mower when it is ready to drive forwards).

English-

4

Page 7

EXPLANATION OF SYMBOLS

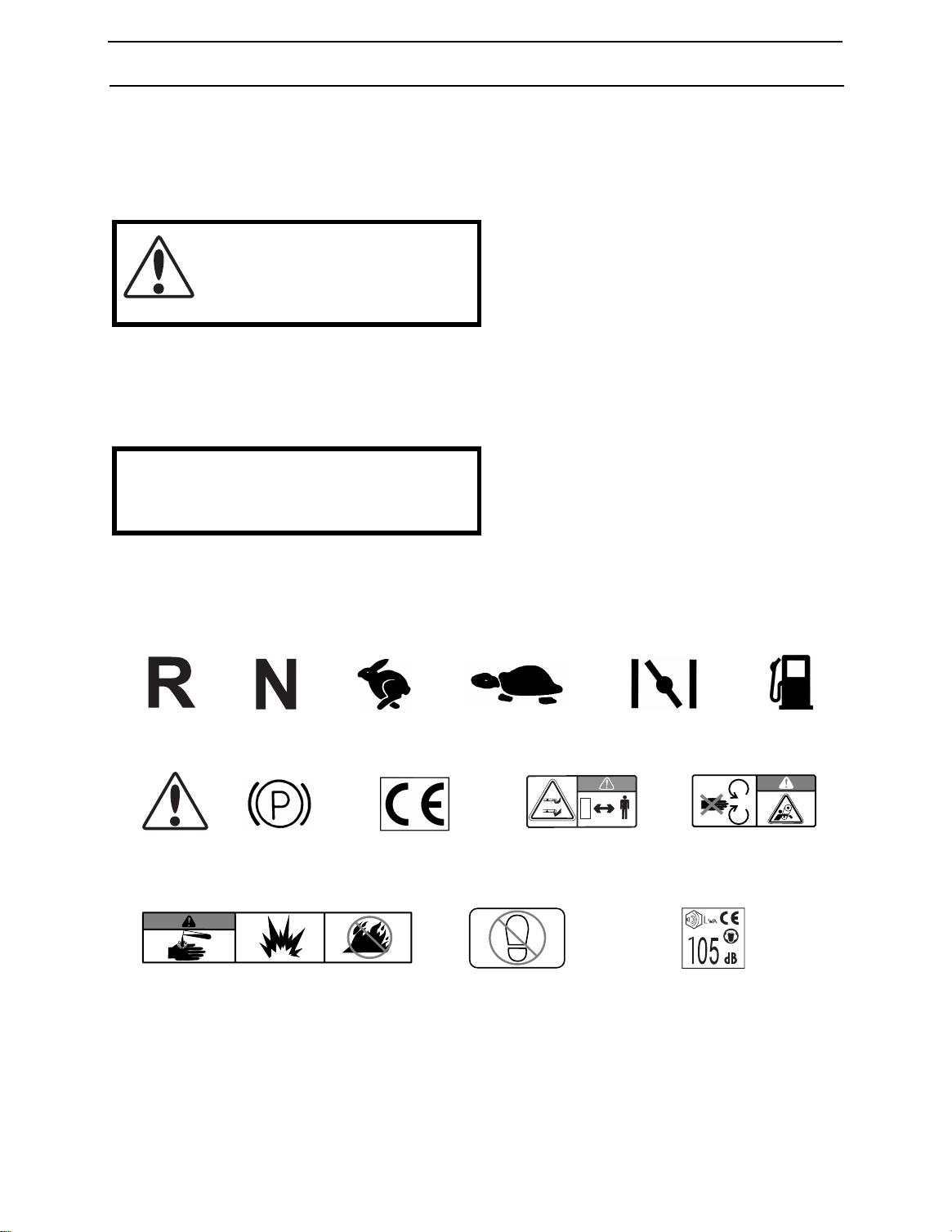

Explanation of Symbols

The symbols below are used on the mower and in this manual. Study them carefully and be aware of what

they mean.

WARNING!

Xxxxxxx xxxx xxxxxxxx xxx x.

xxxx xxxxxx xx.

Is used in this manual to make the user aware that there is a danger of

personal injury

, especially if the

special instructions are not followed.

IMPORTANT INFORMATION

Xxxxxxx xxxx xxxxxxxx xxx x

xxxx xxxxxx xx.

Is used in this manual to make the user aware that there is a danger of

material damage

, especially if the

special instructions are not followed. It is also used where it is judged that there is a danger of incorrect

handling or incorrect assembly/fitting.

FuelChokeSlowFastNeutralReverse

Warning!

Battery acid is corrosive, explosive and

flammable.

Park brake

CE conformity

marking

Warning! Rotating blades,

stand clear of the chute.

Do not stand here.

Do not touch rotating

parts.

Max. sound emission.

Use ear protectors.

English-

5

Page 8

TOOLS

Tools

The mower’s special design means that most repair and maintenance work can be carried out using

standard tools.

Servicing of engines and hydraulic pumps requires special tools. These are listed in the service manuals of

the individual manufacturers.

The mower (engine excluded) has mainly UNC or UNF screw/bolt/nut threads. Certain nuts have special

stiffy threads for securing. It is vital that exactly the right size tools (i.e. imperial measurement) are used on

these.

Those working on the mower must hav e ready access to sock et wrench sets and open end wrenches of the

following sizes:

• 3/8"

• 7/16"

• 1/2"

• 9/16"

• 5/8"

• 11/16"

• 3/4"

The following are also required:

• Torque wrenches, 12 Nm - 110 Nm.

• 15/16" socket for torque tightening of blade bolts.

• 7/8" open end wrench or combination wrench for torque tightening of hydraulic lines.

• A set of small, imperial measurement, Allen keys.

WARNING!

If metric or other unsuitable tools are used, there is a danger that they will slip

and cause personal injury. They may also damage the surfaces of the nut or bolt

in such a way that tools can no longer get a firm grip.

English-

6

Page 9

Technical Data

TECHNICAL DATA

Model

Model part number 968 99 91 60

Engine (spec. number) Kawasaki (FH680V-AS15) Kawasaki (FH721V-AS04)

Cylinder diameter 75.2 mm (2.96 in.) 75.2 mm (2.96 in.)

Cylinder stroke 76 mm (2.99 in.) 76 mm (2.99 in.)

Cylinder volume 675 cc (41.19 cu.in.) 675 cc (41.19 cu.in.)

Power 23 hp 25 hp

Engine RPM 2,950 RPM 2,950 RPM

Idle RPM 1,550 RPM 1,550 RPM

Spark plugs (2) NGK BPR4ES NGK BRR1550

Oil capacity, engine (total) 1.8 litres (3.8 US pints) 1.8 litres (3.8 US pints)

Engine weight 40.5 kg (89.3 lbs) 41.2 kg (90.8 lbs)

Cutting width 1321 mm (52 in.) 1549 mm (61 in.)

Blade length 457.2 mm (18 in.) 533.4 mm (21 in.)

Tightening torque, blade bolt 122 Nm (90 ft/lb) 122 Nm (90 ft/lb)

ZTH5223 ZTH6125

Cutting height Adjustable 38 mm (1.5") to

152 mm (6") in 64 mm

(0.25") increments

Blade engagement Warner Mag-Stop

Electromagnetic clutch

Slip torque, clutch 271 Nm (200 ft/lb) 271 Nm (200 ft/lb)

Clutch coil resistance 1.74 - 1.93 ohms at 23°C (68°F) 1.74 - 1.93 ohms at 23°C (68°F)

Supply voltage clutch 12 - 14 V 12 - 14 V

Tightening torque, clutch bolt 67 Nm (50 ft/lb) 67 Nm (50 ft/lb)

Blade tip speed 4,704 m/min. 4,541 m/min

Anti-scalp rollers 6, adjustable 6, adjustable

Tightening torque, bolt for

mower deck pulley

Hydrostatic drive Dual Hydro-gear pumps and

Tightening torque, pipe

couplings

Hydraulic pumps (2) Hydro Gear BDP 10A 404 Hydro Gear BDP 10A 404

61 Nm (45 ft/lb) 61 Nm (45 ft/lb)

Parker/Ross Wheel drive motors

41 Nm (30 ft/lb) 41 Nm (30 ft/lb)

Adjustable 38 mm (1.5") to

152 mm (6") in 64 mm

(0.25") increments

Warner Mag-Stop

Electromagnetic clutch

Dual Hydro-gear pumps and

Parker/Ross Wheel drive motors

English-

7

Page 10

TECHNICAL DATA

Model

Displacement 10.2 cc/r (0.623 cu. in./rev) 10.2 cc/r (0.623 cu. in./rev)

Nominal working pressure 70 bars (1000 PSI) 70 bars (1000 PSI)

Max. hydraulic pressure 145 bars (2,100 PSI) 145 bars (2,100 PSI)

Max. hydraulic oil temp 110°C (230°F) 110°C (230°F)

Weight, hydraulic pump 3.6 kg (8 lbs) 3.6 kg (8 lbs)

Hydraulic motors (2) Parker Ross Parker Ross

Tightening torque, wheel motor

hub nut

Hydraulic oil 1.9 litres (2 qt.), 15W-50

Hydraulic oil cooler Yes Yes

Speed forward Variable, max. 12.9 km/h

Speed reverse Variable, max. 3.23 km/h

Rear tires Carlisle 24" X 12.00 - 12 Tubeless

ZTH5223 ZTH6125

122 Nm (90 ft/lb) 122 Nm (90 ft/lb)

1.9 litres (2 qt.), 15W-50

Synthetic

(8 mph)

(2 mph)

Turf Master

Synthetic

Variable, max. 12.9 km/h

(8 mph)

Variable, max. 3.23 km/h

(2 mph)

Carlisle 24" X 12.00 - 12 Tubless

Turf Master

Tightening torque, lug nuts 100 Nm (75 ft/lb) 100 Nm (75 ft/lb)

Front tires Carlisle 13" X 5.00 - 6 Tubeless Carlisle 13" X 5.00 - 6 Tubeless

Electrical system 12 V with 15 A charging system 12 V with 15 A charging system

Fuel capacity 44 litres (11.4 US Gal.), 22 litres/

tank

Seat Adjustable, high-back seat with

armrests

Overall length 2057 mm (81 in.) 2057 mm (81 in.)

Overall width (chute up) 1346 mm (53 in.) 1575 mm (62 in.)

Overall width (chute down) 1600 mm (63 in.) 1829 mm (72 in.)

Overall height 1073 mm (42.25 in.) 1073 mm (42.25 in.)

Weight 464.5 kg (1024 lbs.) 464.5 kg (1024 lbs.)

Tightening torque, standard

bolts

1/4" 12 Nm (9 ft/lb) 12 Nm (9 ft/lb)

5/16" 25 Nm (18 ft/lb) 25 Nm (18 ft/lb)

3/8" 44 Nm (33 ft/lb) 44 Nm (33 ft/lb)

44 litres (11.4 US Gal.), 22 litres/

tank

Adjustable, high-back seat with

armrests

English-

8

Page 11

TECHNICAL DATA

Model

7/16" 70 Nm (52 ft/lb) 70 Nm (52 ft/lb)

1/2" 110 Nm (80 ft/lb) 110 Nm (80 ft/lb)

Accessories

BioClip adapter Optional Optional

Foot controlled mower deck lift Optional Optional

Deluxe seat Optional Optional

ZTH5223 ZTH6125

English-

9

Page 12

TECHNICAL DATA

English-

10

Page 13

DELIVERY AND DEALER SERVICE

Delivery and Dealer Service

Pre-delivery Service

1. Charge the battery.

2. Mount the rear tires.

3. Check and adjust the tire pressure in all

tires. All tires should be1 bar (15 PSI).

4. Fit the motion control levers in the normal

position.

5. Connect the rod to the seat stop.

6. Connect the contactor to the cable for the

seat’s safety switch.

7. Fit the armrests to the seat’s back

support.

8. Check that the engine has the right

quantity of oil.

9. Check that the hydraulic tank has the

right quantity of oil.

10. Adjust the position of the motion control

levers.

11. Fuel the mower and open the gas valve.

12. Connect exhaust fume extraction.

13. Start the engine.

14. Vent the hydraulic system.

15. .Check that there is drive to both wheels

16. Check mower deck settings.

17. Check:

The park brake safety switch.

The seat safety switch.

The motion control lever safety switches.

Correct park brake operation.

Forward drive.

Reverse drive.

Blade engagement.

18. Check the idling speed (1,550 ±50 rpm).

19. Check max. engine speed (2,800 ±75

rpm).

English-

11

Page 14

DELIVERY AND DEALER SERVICE

20. Inform the customer of the:

Necessity and advantages of following

the maintenance schedules.

Necessity and advantages of having the

mower inspected every 300 hours.

The effect on resale value of regular

servicing and a fully stamped service

book.

The use of BioClip.

21. Complete the sales certificate, etc.

After the First 8 Hours

Change the motor oil.

25 Hour Service

1. Check the fuel pump air filter.

2. Check the oil level in the hydraulic

system.

3. Check tire pressure.

4. Lubricate the mower deck’s belt

tensioner.

5. Lubricate the hydraulic pump’s belt

tensioner.

6. Check/clean the engine’s cold air intake.

7. Clean the air cleaner’s pre-filter (Oilfoam).

50 Hour Service

1. Carry out a 25 hour service.

2. Clean/change the air cleaner’s filter

cartridge (paper filter). Perfom more

reqularly in dusty operating conditions.

3. Lubricate the bearings of the front

wheels.

4. Lubricate the shafts of the motion control

levers.

5. Lubricate the mower deck struts.

6. Lubricate the cutting height regulator.

7. Check/adjust the park brake.

English-

12

Page 15

DELIVERY AND DEALER SERVICE

100 Hour Service

1. Carry out a 25 hour service.

2. Carry out a 50 hour service.

3. Change the engine oil.

4. Check if the hydraulic oil needs changing

(every 300 hours).

5. Check if the engine’s oil filter needs

changing (every 200 hours).

6. Clean/change the spark plugs.

7. Change the fuel filter in the fuel line.

8. Clean the engine and transmission

cooling fins.

9. Clean and check if the air filter’s paper

cartridge needs changing (every 200

hours).

300 Hour Service

1. Inspect the machine. Reach agreement

with the customer on what additional

work is to be carried out.

2. Carry out a 25 hour service.

3. Carry out a 50 hour service.

4. Carry out a 100 hour service.

5. Change the oil and the filter in the

hydraulic system.

6. Clean the combustion chamber and

grind the valve seats.

7. Check the play in the engine valves.

8. Change the air cleaner’s pre-filter (Oilfoam).

English-

13

Page 16

DELIVERY AND DEALER SERVICE

At Least Once a Year

1. Clean the engine’s cold air intake (25

hours).

2. Change the air cleaner’s pre-filter (Oilfoam).

3. Change the paper cartridge in the air

filter (200 hours).

4. Change the engine oil (100 hours).

5. Change the engine’s oil filter (200 hours).

6. Change the oil and the filter in the

hydraulic system.

7. Check/adjust the cutting height regulator.

8. Check/adjust the park brake (50 hours).

9. Clean/change the spark plugs (100

hours).

10. Change the fuel filter in the fuel line (100

hours).

11. Clean the cooling fins (100 tim).

12. Check the play in the engine v alves (300

hours).

13. A 300 hour service to be carried out by

an authorized workshop.

English-

14

Page 17

DELIVERY AND DEALER SERVICE

Maintenance Schedule

The table below lists the maintenance required by the ride-on mower. Several of the points not covered in

this workshop manual will be found in the Operating Instructions.

Maintenance Page Pre-

use

Check for fuel and oil leaks. Check the park brake. Check engine oil level (every fueling). 21

❍

●

●

Check the fuel pump air filter. Check the safety systems. -

▼

Check/clean the engine’s cold air intake. Check the mower deck. 38

Check fasteners (bolts, nuts, etc.). Start engine and blades; check for abnormal

-

noise.

Clean the underside of the mower deck. -

Check hydraulic system oil level. 22

Check the condition of belts, pulleys, etc. 38

Check for any damage. Check tire pressure. 20

Clean thoroughly around the engine. Clean thoroughly around the hydraulic system. 53

Clean thoroughly around belts, pulleys, etc. Lubricate mower deck belt tensioner. Lubricate belt tensioner for hydraulic pumps. Lubricate all wires. Lubricate driver’s seat mechanisms. Lubricate the throttle control. Clean the engine’s cold air intake. Lubricate mower deck links. Lubricate front wheel mounts (every 200 hours). Lubricate front wheel bearings. Lubricate the shafts of the motion control levers. Lubricate mower deck struts. Lubricate the mower deck’s height regulator. -

Daily Weekly At

least

After

use

once

a

year

▼

●

❍

❍

▼

●

❍

❍

●

❍

▼

▼

▼

▼▼

❍

Maintenance intervals

in hours

25 50 100 300

▼

●

●

▼

▼

▼

▼

▼

▼

▼

English-

15

Page 18

DELIVERY AND DEALER SERVICE

Daily Weekly At

Maintenance Page Pre-

use

After

use

Check/adjust the cutting height regulator. 38

Clean the air cleaner’s pre-filter (Oil-foam). -

Clean the air cleaner’s filter 2) (paper filter).

Change the motor oil 1) .

-

22

Change the hydraulic oil (every 300 hours). 56 ●

Maintenance intervals

least

once

a

year

in hours

25 50 100 300

●

▼▼

▼▼

●●

●

Change the engine’s oil filter (every 200 hours). - ▼▼

Clean/change the spark plugs. - ❍❍

Change the fuel filter in the fuel line. - ▼▼

Clean the cooling fins. - ❍❍

Check the play in the engine valves

4)

.

- ❍❍

Change the air cleaner’s pre-filter (Oil-foam). - ▼▼

Change air filter (paper filter)

Carry out a 300 hour service

2)

(every 200 hours).

4)

.

- ▼▼

13 ●●

Check/adjust the park brake. 34 ●●

1)

First change after 8 hours. With heavy operating conditions or high ambient temperature, change every 50 hours. 2) In dusty conditions, clean and

change more frequently.

3)

Where the mower is in daily use, lubrication must be carried out twice a week. 4) To be carried out by an authorized workshop.

●

= Covered in this workshop manual.

❍

= Not coverd in this workshop manual or the Operating Instructions.

▼

= Covered in the Operating Instructions.

WARNING!

Service procedures may only be carried out on the motor or mower deck when:

• The motor has been switched off.

• The ignition key has ben removed.

• The ignition cables have been removed from the spark plugs.

• The park brake has been applied.

• The mower deck has been disengaged.

English-

16

Page 19

DELIVERY AND DEALER SERVICE

Service Records

Remember to enter all service work in the Service Log at the back of the Operating Instructions.

Record details of any major repairs.

Enter the meter reading and date. Stamp and sign the stamp field.

In your customer register, make a note of the work that has been carried out.

English-17

Page 20

DELIVERY AND DEALER SERVICE

English-18

Page 21

DELIVERY SERVICING

Delivery Servicing

To our Dealers

The quality of delivery servicing is vital to aftersales success. It is in e veryone’s interest that the aftermarket

operates smoothly:

• The customer will be satisfied with his/her mower and know who he/she can contact for help with any

problems.

• You will gain a regular customer who recommends you and your company to others.

• Together we will strengthen our brand and take joint responsibility for our products and customers.

Complete all the paperwork meticulously.

Fill in warranty and delivery documents, etc. and ensure that the customer receives the right operating

instructions for his/her mower.

Keep a register of customers and their mowers (with serial numbers , etc.). The information contained in the

customer register is invaluable for marketing and when ordering spare parts.

When supplying a mower, you should also give the customer all information necessary for the safe

operation and care of the machine. Pay particular attention to informing the customer about:

• Safety instructions.

• Mower controls.

• Checking oil levels and the oil to be used when topping-up.

• The first oil change after the running-in period.

• The necessity and advantages of observing the maintenance schedules and regularly returning the

mower for servicing.

• What type of fuel to use.

• Ways of achieving the best results with the mower. The use of BioClip.

• The accessories available for his/her mower.

• Warranty conditions.

• Your company and the person to be contacted if there are any problems.

Removing the Mower from its

Packaging

Mowers are normally delivered from the

factory in special packaging - a wooden crate

with a solid bottom.

WARNING!

Handle the transport crate

carefully. Keep the goods as

level as possible.

Use long pallet forks.

Mower on its delivery baseplate

8011-549

English-19

Page 22

DELIVERY SERVICING

The baseplate itself stands on a pallet and the whole assembly can be handled using a standard forklift

truck. To keep the goods as level as possible, two people should assist the truck driver. Driving and lifting

must both be performed with care.

Remove the upper part of the crate from the wooden baseplate.

The mower (rear wheels not fitted) is secured to the baseplate by plastic straps and wooden b loc ks. Certain

components that are to be fitted to the mower, or handed to the purchaser on delivery, are wrapped

separately in plastic bags.

Remove the plastic sheeting covering the mower.

When unpacking the mower, check that there is no transport damage. Any damage is to be reported to the

transport company in the normal way.

The packaging is not to be returned.

Delivery Service

1. Charge the battery. The mower is

normally delivered with a charged

battery topped-up with electrolyte.

2. Raise the rear of the mower until it is

clear of the baseplate and the rear

wheels can rotate freely. Hold firmly in

position using blocks or jack stands.

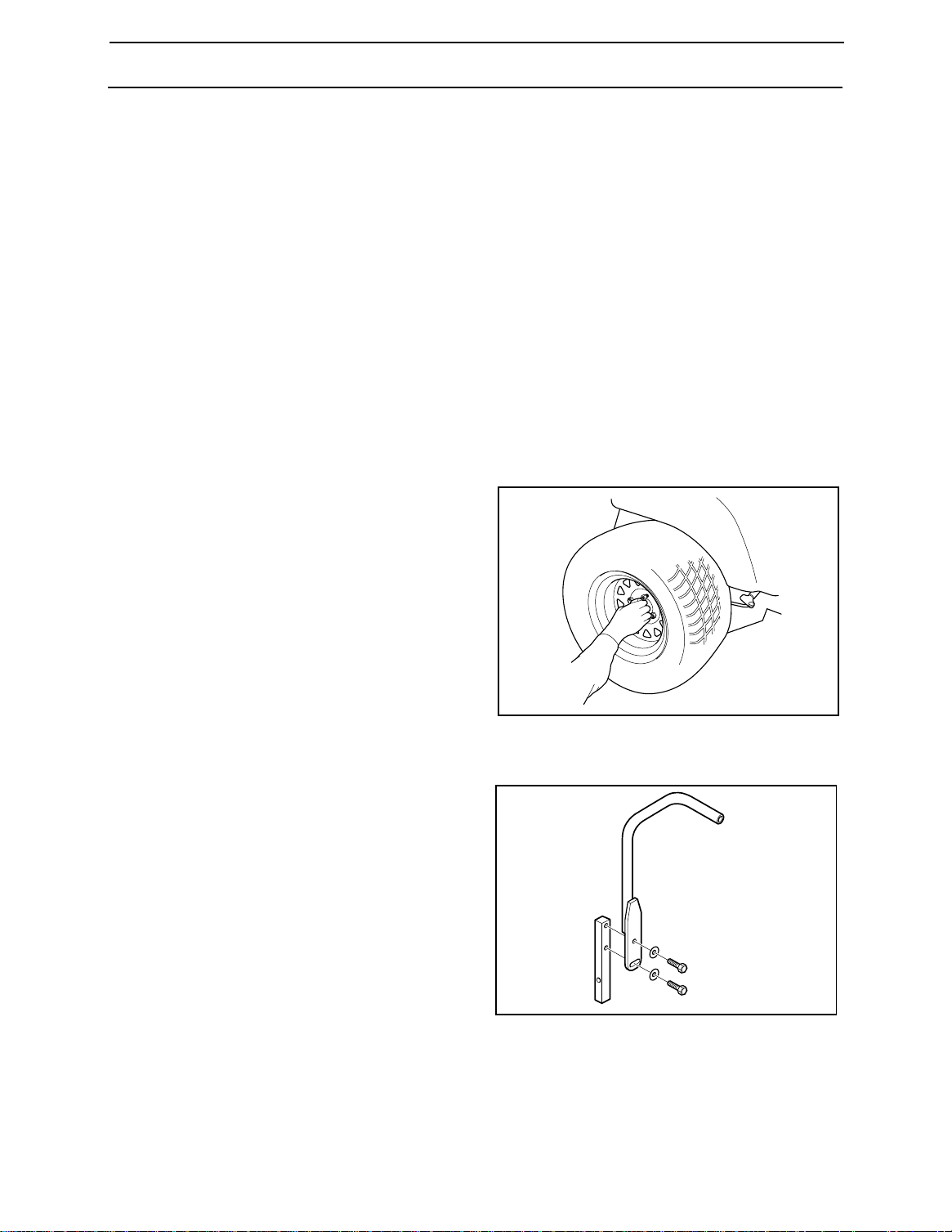

3. With the valves facing outwards, fit the

rear wheels. Fit and tighten the wheel

nuts on the wheel bolts.

4. Check and adjust the pressure in all the

tires. The recommended pressure is 1

bar (15 PSI).

Fitting the rear wheels

8011-503

5. On both motion control levers, remove

the lower bolts and loosen the upper

bolts. Swing the levers to the upright

position. Hand tighten the lower bolts in

the rectangular holes. The levers are

adjusted at a later stage.

6. Push the levers out into their neutral

slots.

English-20

8011-502

Lever mount

Page 23

DELIVERY SERVICING

7. In the space to the left of the hydraulic

tank, cut the cable tie holding the rod to

the top of the seat. Remove the split

cotter, swing the seat backwards and

connect the rod to the seat. Replace the

split cotter.

Check that the contactor on the cable to

the bottom of the seat is connected.

Swing the seat down and check that it is

held by the catch on the left.

IMPORTANT INFORMATION

Risk of incorrect assembly/fitting

8. Fit the armrests. Position the armrests

with the greatest possible distance

between them. The bolt heads should be

on the inside (i.e. towards the seat back)

and washers and nuts on the outside.

Armrests, bolts, washers and anti-slip

nuts are packed in a plastic bag

accompanying the mower.

8011-504

Connnecting the rod to the seat

8011-505

Fitting the armrests

9. Check the engine oil level.

With the mower standing on a flat

surface, check the engine oil level.

Unscrew the dipstick and pull it out. Wipe

the dipstick dry and push it back.

Do not screw the dispstick down.

Pull the dipstick up again and read the oil

level.

8011-501

Checking the engine oil level

English-21

Page 24

DELIVERY SERVICING

The oil level must be between the

markings on the dipstick. If the level is

near the “ADD” mark, top up with oil to

the “FULL” mark.

Oil is topped up via the hole in which the

dipstick sits.

Use grade SC-SH engine oil with a

viscosity as per the chart below.

The engine (excluding oil filter) holds 1.5

litres of oil.

ADD

ADD

FULL

Engine dipstick

-20 C

SAE5W-20

-4 F 14 F 32 F 50 F 68 F 86 F 104 F

Viscosity chart

FULL

8009-159

-10 C 0 C 10 C 20 C 30 C 40 C

SAE40

SAE30

SAE10W-30/SAE10W-40

8009-140

10. Check the oil level in the hydraulic tank.

The level must be 19 - 25 mm below the

top of the tank. Top up if necessary.

11. Adjust the motion control levers.

a. Set the seat longitudinally in a

comfortable position and swing the le vers

into the drive channel.

b. Hold one of the levers at a comfortable

midpoint and tighten the retaining bolts.

c. Hold the other lever as far forw ard as the

first and tighten the bolts.

8011-565

Hydraulic tank

8011-522

Adjusting the motion control levers

English-22

Page 25

DELIVERY SERVICING

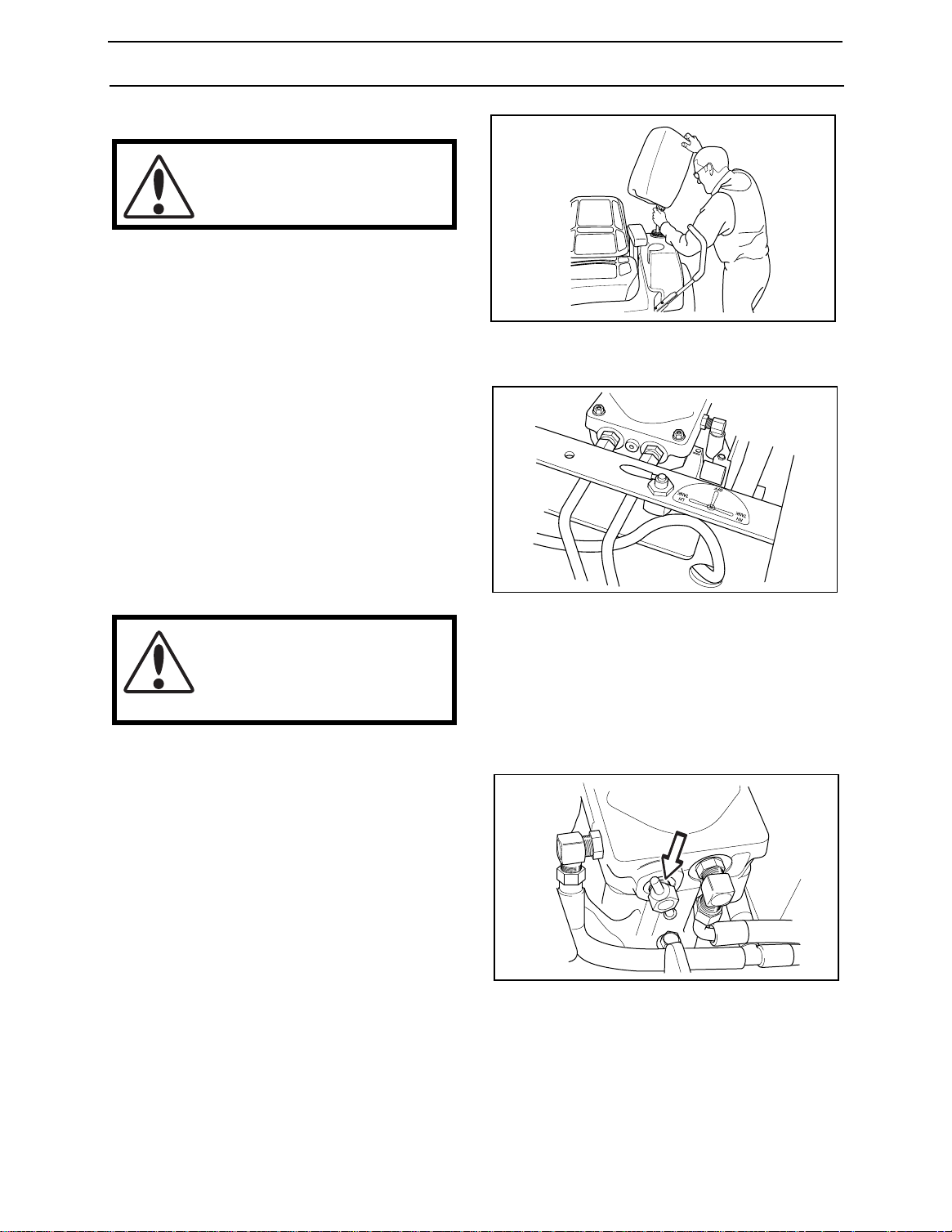

WARNING!

Gasoline is highly flammable.

Take great care.

12. Fill the gasoline tanks (unleaded

gasoline with no oil and a minimum

octane rating of 87).

Environment-friendly, acrylate gas , e.g.

Aspen, can be used to good advantage.

13. Select tank by moving the selector to the

appropriate position.

8011-550

Fueling

WARNING!

Never run the engine indoors in

confined or poorly ventilated

areas. Exhaust fumes contain

carbon monoxide (poisonous).

14. Connect exhaust fume extraction.

15. Start the engine.

16. Check that there is drive to both wheels.

17. Vent the hydraulic system.

18. Check that, with the motion control lev ers

in the neutral position, both rear wheels

are stationary.

19. Remove the blocks supporting the back

end.

20. Raise the mower deck to its highest

position.

21. Raise the back of the baseplate and

drive the mower forwards and off.

22. Check mower deck settings as per the

instructions (see ”Adjusting Motion

Control Lever Linkages” on page 34).

8011-506

Selecting the gasoline tank

8011-507

Air relief screw for the hydraulic system

English-23

Page 26

DELIVERY SERVICING

Test Running

Check that the engine will not start with the park brake engaged.

Check that the engine will not start with the blade engagement button pulled out.

Check that the engine will not start without someone sitting on the driver’s seat.

Start the engine.

Check that the engine stops if, with the park brake engaged, a motion control lever is folded inwards (i.e.

across the operator). Test both the left and the right motion control levers.

Check that the engine stops if, with the park brake disengaged, the operator gets up from the driver’s seat.

Check that, with the drive in neutral and the park brake disengaged, the mower does not move on flat

ground. Increase the throttle setting - the mower must still remain stationary.

Check that the park brake operates correctly.

Check that the mower moves straight forwards/backwards when both motion control levers are

simultaneously moved an equal distance forwards/backwards.

Check that the mower turns normally when driving forwards and backwards.

Check that the mower deck operates correctly and that there is no abnormal noise.

Check that engine idling speed is 1,550 ±50 rpm.

Check that the speed regulator gives a maximum engine speed of 2,800 ±75 rpm.

Administration

Fill in the sales certificate and customer

register, etc. Remember to fill in the serial

number on page 4 and to sign the delivery

service in the Operating Instructions.

English-24

Page 27

DESIGN AND FUNCTION

Design and Function

General

The Husqvarna ZTH is a compact, ride-on mower specially designed for mowing large areas of grass. It is

operated via two motion control levers and has hydrostatic drive to the rear wheels. Each rear wheel is

driven by an independent hydrostatic driv e system comprising a hydr aulic pump and a h ydraulic motor. The

hydraulic pumps are driven by a belt from the engine’s crankshaft.

The mower is steered by the independent adjustment of the speed and direction of each rear wheel. The

front wheels are free to turn in whichever direction is most suitable.

The mower deck is mounted underneath the mower and is supplied with a side discharge chute as

standard. The range of accessories includes a BioClip kit of guide plates and blades for mounting beneath

the mower deck casing.

ZTH ride-on mower

Mower Identification

Each mower is individually identified by the

details given on plate sited between the

battery and the engine.

Reading downwards, the plate gives:

• The model number

• The I.D. code.

• The serial number.

Quote these when ordering spare parts.

8011-591

8011-593

Mower identification

English-25

Page 28

DESIGN AND FUNCTION

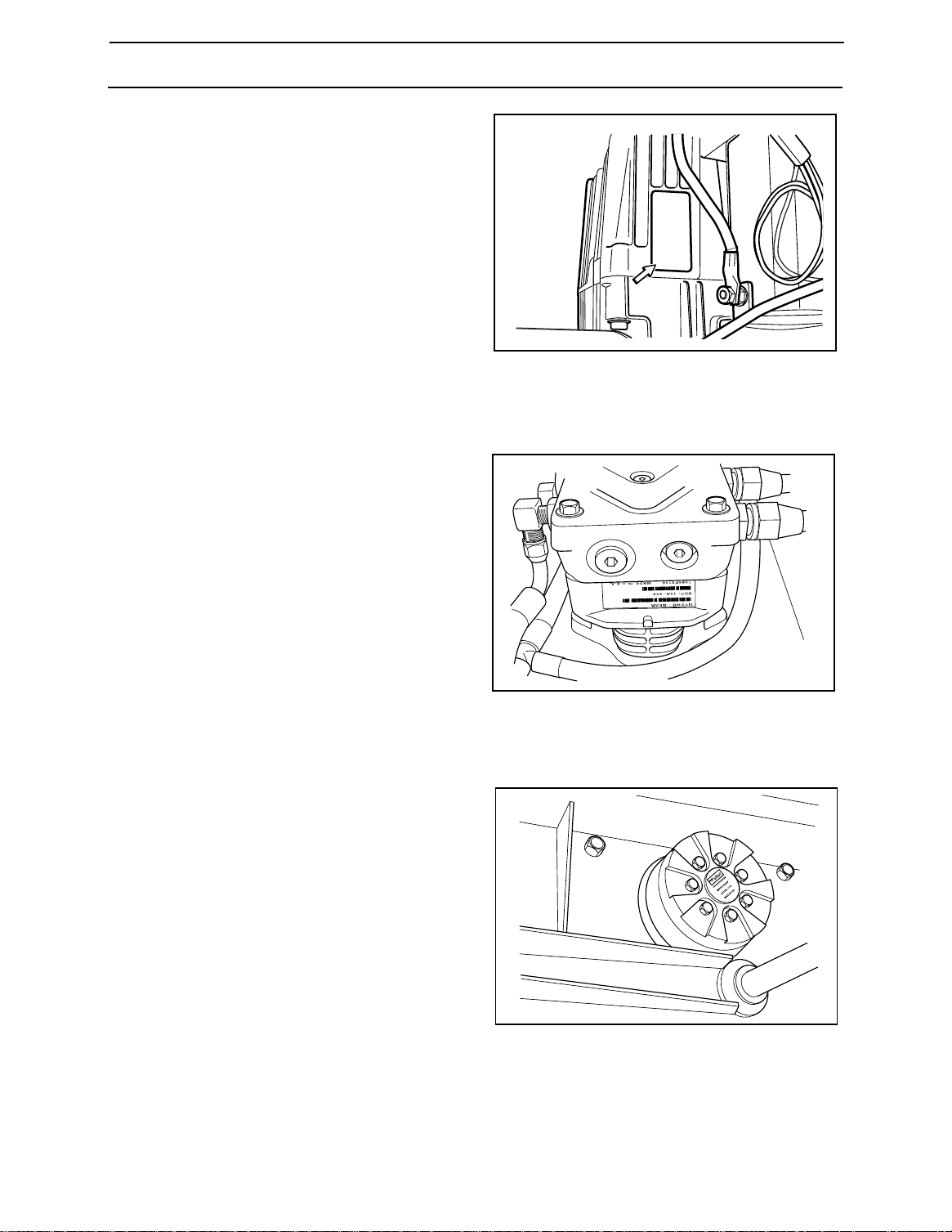

The engine identifiers are located on a

barcoded decal. This is sited on the left side

of the crankcase, directly opposite the starter

motor. The decal gives:

• The engine code.

• The engine number.

Quote these when ordeing spare parts.

The hydraulic pump identifiers are located on

a bardcoded decal. This is sited on the left

side of the pump housing. The decal gives:

• The pump type code (BDP-10....).

• The pump serial number.

8009-205

Engine identification

The hydraulic motor identifiers are located on

a round, metal plate. This is sited on the end

of the motor housing. The plate gives:

• The hydraulic motor type code and

model.

• The hydraulic motor serial number.

English-26

8011-594

Hydraulic pump identification

8011-595

Hydraulic motor identification

Page 29

DESIGN AND FUNCTION

Engine

Husqvarna’s ride-on mowers for professional users have two-cylinder, air-cooled engines from Kawasaki.

Major engine repairs are not covered in this workshop manual. Users are referred to Kawasaki’s own

manuals. These contain detailed information on the adjustment and repair of the engines. The manuals can

be ordered from authorized service workshops.

The table below shows the information to be quoted when ordering engine manuals:

Model

ZTH5223 FH680V-AS15 17.5 kW (23 hp) 99924-2045-03

ZTH6125 FH721V-AS04 18.6 kW (25 hp) 99924-2045-03

When repairing engines, use genuine spare parts only. The warranty will be invalidated if other parts are

used.

Kawasaki’s

engine type

Power

Publication

Kawasaki no.

Drive and Control

Via a belt, the engine supplies direct, clutchles, drive to two hydraulic pumps. The pumps have axial

pistons.

Each pump feeds oil to a fixed (non-adjustable) hydraulic motor (one by each drive wheel). The rate and

direction of oil flow is steplessly adjusted (via a mechanical linkage) by the motion control levers.

Adjustment is actuated by a swash plate that regulates the strok e length of the h ydraulic pistons. The sw ash

plate is an integral part of each pump. The mower can be made to turn or reverse by controling the rate and

direction of flow to the hydraulic motors. The hydraulic motors control the speed and direction of the drive

wheels. To swing the mower around its center, simply drive one wheel forwards and the other backwards.

Hydrostatic braking occurs whenever there is no flow of oil from the pumps.

Instructions for the repair of the hydraulic pumps are given in the “Hydro-Gear BDP-10A/21L Service &

Repair Manual”.

Brakes

Hydrostatic braking (see “Drive and Control”)

provides brake control when the mower is

being powered by its engine. Putting the

motion control levers in the neutral position

brakes the mower. To move the mower

manually, open the air screws on the

hydraulic pumps. Oil is then circulated by the

hydraulic motors and the machine can be

moved short distances at low speed.

The mower also has a park brake. This

operates on both rear wheels. A brake band

on each rear wheel is engaged by a lever on

the left of the mower operator. The lever and

the brake bands are mechanically linked.

8011-507

Air screw on hydraulic pump

English-27

Page 30

DESIGN AND FUNCTION

Mower Deck

WARNING!

The engine must not be started if the operator’s floor plate or any of the guards for

the mower deck’s belt is/are not securely in position.

The blades are driven by a V-belt from the

engine crankshaft (1). The crankshaft has an

electromagnetic clutch. This locks the deck

pulley to the shaft when current is applied to

the clutch (i.e. when the appropriate control

panel switch is operated).

The belt is automatically adjusted by a spring

(2) operating on the pulley (3) attached to the

top of the mower deck casing. Via vertical

shafts, three other pulleys (4,5,7) each drive a

separate blade. Two idler pulleys (6,8) serve

as belt guides. The outermost pulleys are

shielded by removab le guards attached to the

top of the mower deck casing. The operator’s

floor plate acts as a guard preventing contact

with the belt and the other pulleys.

8011-580

Belt routing for the mower deck

WARNING!

The mower blades are extremely sharp. To prevent personal injury, wear protective

gloves when handling the blades.

The blades do not require shear pins. Impact protection is provided by the blades skating on their shafts if

they hit an immoveable object.

The discharge chute is on the right side of the mower deck. It is spring-loaded and can be raised.

For mulching, a BioClip kit is available as an accessory. The kit comprises guide plates and BioClip blades.

It is fitted to the underside of the mower deck.

The mower deck is suspended to the bottom of the mower via two backward inclined struts and four

adjustable chains.

Six anti-scalp rollers on the underside of the mower deck prevent the casing catching on the ground.

Cutting height is set by a lever on the right of the operator. Inserting a pin through the holes in the deck

height adjustment plates sets a limit to the downward movement of the lever.

English-28

Page 31

Repairs

Engine

Removing

1. Close the fuel valve.

2. Disconnect the positive cable (red) from

the battery.

3. If necessary, drain the motor oil.

4. Disconnect the gas and choke wires from

the carburetor.

5. Disconnect the fuel line (with its filter)

from the fuel pump.

6. Disconnect the connecting cable (pigtail)

from the frame harness connector at the

side of the starter motor.

7. Disconnect the cable from the starter

motor.

8. Disconnect the cables from the ground

bolt in front of the starter motor.

9. Raise and support the back of the mower

on blocks or similar.

10. Remove the clip holding the oil drain

hose.

11. Remove the deck belt and clutch (see

Electrical System\Mower deck clutch).

12. Loosen the bolt (2) and twist the clutch

tie down (10) aside (see the “Engine

mounts” diagram).

13. Using a square, 1/2" ratchet wrench,

loosen the pump belt. Roll the belt off the

pulley on the engine crankshaft.

14. Remove the f our outer bolts in the engine

mounts.

REPAIRS

8011-621

Engine assembly

WARNING!

Heavy lift (40.5 kg).

Handle the engine with care.

Place it safely where it cannot

topple over.

15. Lift the motor directly upwards and

secure it in a safe place.

8011-606

Engine mounts

English-29

Page 32

Fitting

1. When changing engines, transfer the

necessary components to the new

engine.

The chamfered side of the spacer (3) on

the crankshaft above the pump pulley

must face the engine.

The hub collar of the pulley (5) must face

downwards.

2. Put the four upper engine mount

isolators (22) in the engine bed (small

diameter end in the engine bed hole).

3. Check that the clutch tie down (10) is not

deformed (straighten if necessary) and

lower the engine into position. The

engine weighs 40.5 kg.

4. Inserting the spacers (22), washers (28,

21) and bolts (19) from below, fit the

engine mounts. The tightening torque for

the retaining nuts (20) is 110 Nm (80 ft/

lb).

5. Fit the pump belt on the pulley. Attach the

spring and use a square, 1/2" ratchet

wrench to cancel the force ex erted by the

belt tensioner.

6. Fit the washer (6) and mower deck clutch

(7). Connect the cable to the connector.

The tightening torque for the bolt (9) is 67

Nm (50 ft/lb).

With the bolt (9) tightened, there should

be perceptible play between the clutch

and the clutch tie down (10) when the

clutch flange is turned by hand. Adjust/

twist the tie down and, using the nut (1),

tighten the bolt (2).

Ensure that the cable cannot be

damaged and secure it with a cable tie.

7. Roll the mower belt into place on the

clutch pulley. Check that the belt is

routed as per the diagram and that it is

not twisted.

8. Fit the operator’s foot plate.

9. Fit the clip for the oil drain hose.

10. Connect the 3 cables to the ground bolt.

11. Connect the cable to the starter motor.

12. Connect the pigtail to the frame harness.

13. Connect the fuel line to the fuel pump

REPAIRS

8011-606

Engine mounts

8011-580

Belt routing for the mower deck

English-30

Page 33

REPAIRS

inlet.

14. Connect and adjust the gas and choke

wires (see below).

15. Check that the oil drain valve is closed

and fill the engine with oil (see Delivery

Servicing\Delivery Service).

16. Connect the positive cable (red) to the

battery’s positive terminal.

17. Open the fuel valve.

Dismantling and Assembling

Adjustments and Specific Repairs

See the Kawasaki Service Manual for the engine and auxiliary systems.

Troubleshooting

See section 8 of the Kawasaki Service

Manual.

The above section contains a troubleshooting guide for the engine and auxiliary systems. It also has

separate troubleshooting instructions for the starter motor.

Adjusting the Throttle Wire

Adjusting Throttle Lever Tension

If there is insufficient throttle lever friction,

throttle settings can alter while the mower is

being operated. This can be corrected via the

lever’s pivot bolt.

1. Free the control console and pull

forwards.

2. Tighten the throttle lever’s pivot bolt.

Checking and Adjusting the Throttle Wire

Check that the engine responds to the throttle

control and that the correct engine speed is

achieved at full throttle.

If adjustment is necessary, adjust the lower

wire as follows:

1. Loosen the clamping screw holding the

wire’s outer casing and set the lever to

the full throttle position.

2. Check that the throttle wire is attached to

the correct hole in the lower lever, see

8011-599

Freeing the controle console

8011-554

Checking and adjusting the throttle wire

English-31

Page 34

the diagram.

3. Pull the throttle wire casing to the far

right and tighten the clamping screw.

Checking and Adjusting the Choke

Wire

If the engine produces black smoke or is

difficult to start, the choke wire (upper wire)

may be incorrectly adjusted.

To adjust the choke, proceed as follows:

1. Release the clamping screw that secures

the wire casing and set the choke control

to maximum choke.

2. Check that the throttle wire is attached to

the upper lever, see the diagram.

3. Pull the choke wire casing to the far right

and tighten the clamping screw.

REPAIRS

Checking and adjusting the choke wire

8011-555

English-32

Page 35

REPAIRS

Fuel tank

Removing

Before removing the tank on the right of the mower, the rear wheel and the bolts holding the oil cooler for

the hydraulics must be removed.

1. Close the fuel valve (13).

WARNING!

Fire and health hazard.

Avoid spills.

Wipe dry if necessary.

2. Drain the tank that is to be removed.

Keep the drained fuel in a closed

container.

3. Remove the hose clamp (5) from the fuel

line (6).

4. To catch any spills, position a container

below the outlet from the tank to the fuel

line. To ensure no damage is caused,

hold the hose barb (4) with pliers and pull

the fuel line away. Even when the tank is

empty, a small amount of fuel may leak

out.

5. The tank is fitted to the splashguard by a

bolt and two studs. Remove the bolt (16)

and three nuts (10) - all with washers (8)

and springs (9) - located on the

underside of the splashguard.

6. Remove the bolt (12) and tank spacer

located on the inside of the splashguard.

7. Lift the fuel tank (2) away.

Fuel tank

8011-607

Fitting

The fitting procedure is the reverse of the removal procedure.

Working from the underside of the splashguard, tighten each washer (8) spring (9) washer (8) combination

using the appropriate nut (10) or bolt (16). Tighten until the spring starts to compress and then a further 1.5

turns.

English-33

Page 36

REPAIRS

Adjusting Motion Control Lever

Linkages

See “Hydraulic system\Hydraulic pump\Adjusting the linkages”.

Adjusting Motion Control Lever

Spring-back

See “Hydraulic system\Hydraulic pump\Adjusting the Reverse Detent Spring”.

Adjusting the Park Brake

1. Raise the rear of the unit and place it on

stable jack stands. Engage the parking

brake and remov e both rear tires/wheels.

2. With the parking brake still engaged,

remove all spring tension by loosening

the spring locknut. Unlock the jam nut

against the yoke and loosen the bolt until

the head is about 1/2 inch away from the

trunnion. Relock the jam nut against the

yoke. Tighten the spring locknut until bolt

head/trunnion gap closes to 1/8 to 1/4

inch.

3. Disengage the parking brake hand lever

and check that the spring is still under

tension. This is important in order to hold

the linkage from going over-center.

4. Repeat steps 2 and 3 on the opposite

brake band.

5. If the brake band is making noise while in operation, rattling, squealing, etc, it may be necessary to

readjust the parking brake band.

Spring 1/8 - 1/4" Space

Yoke Jam nut Trunnion

8011-581

Adjusting the park brake

IMPORTANT INFORMATION

This brake system has been designed as a parking brake and is intended to hold the unit

in place when it is not being operated. It must not be used as an emergency stopping

brake, or brake and linkage damage may occur.

This brake system is not designed to be the only means of holding the unit in place while

transporting in a truck or on a trailer. The unit must be tied down at all times while it is

being transported, or brake and linkage damage may occur

English-34

Page 37

Mower Deck

WARNING!

No work is to be done on the mower deck or belts until the engine has been

rendered incapable of starting. Remove the ignition key or both spark plug cables.

Removing

1. Drop the deck as far as it will go and lock

the control lever in position with a pin.

2. Remove the operator’s foot plate.

3. Remove the deck belt outer guards.

4. Using a 9/16" socket on the bolt of the

idler pulley, loosen the deck belt. Roll the

belt off the deck pulleys.

5. Remove the deck’s rear anti-scalp

rollers.

WARNING!

Danger of personal injury (crushed fingers or limbs, etc.).

If the deck height control lever is not secured by a locking pin, the deck will spring

upwards when the chains are released.

REPAIRS

6. Release the four chains from their

mounts on the lift arms (top of chain).

7. On both sides of the deck, remove the

bolts (17) and pivot pins (50) of the rear

bearings (see the “ZTH mower deck”

diagram).

8. Pull the deck out.

Fitting

1. Slide the deck into position under the

mower.

2. Using two lengths of 2" x 4" (one towards

the edge of each of the deck’s short

sides) support the deck 4" off the ground.

3. Grease the pivot pins (50) of the rear

bearings with copious amounts of

corrosion preventing grease. Line up the

shaft bearings and slide the pivot pins

into place. Fit the bolts and nuts (17, 5)

holding the pivot pins in place (see the

“ZTH mower deck” diagram).

8011-601

Supporting the deck on lengths of 2” x 4”

English-35

Page 38

4. Fit the deck’s rear anti-scalp rollers.

5. Attach the chains to the lift arms.

6. Fit the belt as per the routing diagram.

7. Check that the belt is not twisted and that

it runs correctly around all the pulleys.

8. Check deck height and horizontality as

per “Setting the mower deck”.

9. Fit the operator’s foot plate.

10. Fit the deck belt outer guards.

Spindle Blade Bearings

WARNING!

Wear protective gloves when

working on or with blades.

To remove a blade, undo the retaining bolt

(25).

When fitting a blade, tighten the bolt to 122

Nm (90 ft/lb).

REPAIRS

8011-580

Belt routing of the mower deck

Removing Bearings

1. Roll the belt off (see “Changing Belts”).

2. Remove the bolt (28) and the pulley (3).

Lock the pulley using a bolt through the

hole in the pulley and a holding tool.

3. Raise the mower deck to its highest

position. Lift the front end of the mower

and support it on blocks or similar.

4. Remove the bolts (12) and nuts (5) and

pull downwards to remove the bearing

and blade.

5. Separate the blade from its bearing.

Repairing Bearings

If there is too much play, the bearing (44) can

be replaced if the bearing surfaces of the

housing (46) have not been damaged.

Pressing downwards, remove the spindle

(41).

If there is extensive damage, replacement of

the complete bearing assembly (2) is

recommended.

To ensure safe transport, the bearing

8011-618

ZTH mower deck

English-36

Page 39

assembly is supplied with an “O” ring (47) .

The “O” ring must be removed before the

pulley is fitted.

Replacing Bearings

The fitting procedure is the reverse of the

removal procedure.

Tightening torques:

• Blade bolts 122 Nm (90 lb/ft).

• Pulley bolts 61 Nm (45 lb/ft).

Sharpening and Balancing Blades

WARNING!

Blades with any cracking must

not be used. Do not straighten

a damaged blade if there is any

danger of crack formation.

REPAIRS

• Remove the blades.

• Check that the blades do not hav e cracks

or any other damage. If they do, scrap

them.

• Clamp in a screw vice (see diagram) and

file until sharp.

Balancing is as follows:

• Fix a mandrel (for example) horizontally

in a screw vice (see diagram).

• Push a blade onto the mandrel and

check that it is evenly balanced. The

diagram shows a blade which needs

adjusting. This b lade should be ground at

the edge indicated by the straight arrow.

• The fitting procerdure is the reverse of

the removal procedure.

The tightening torque for the blade bolts

is 122 Nm (90 lb/ft).

6012-088

Grinding a blade

6012-089

Balancing a blade

English-37

Page 40

Setting the Mower Deck

Leveling

1. Position the mower on a level, preferably

concrete, surface.

2. Check the pressure in all four tires. This

should be 15 psi.

3. Raise the mower on lengths of 2" x 4"

placed edgewise under the cutting deck

from front to rear (see diagram).

4. Place a 0.635 cm (1/4") shim between

the 2" x 4" and the rear edges of the

deck. This will allow the correct down

angle at the front of the deck.

5. Adjust the four lower chain bolts so that

they are centered in the oblong slots.

IMPORTANT INFORMATION

Ensure that all four bearings suspending

the deck to the mower are tightly bolted to

the frame.

REPAIRS

8011-601

Leveling the mower deck

6. Check that all the chains are equally

tensioned. If they are not, adjust the

appropriate lower chain bolt in its slot.

Adjusting Cutting Height

Raise and secure the deck height lev er to the

transport position (6"). Measure from the

cutting edge of the blades to the flat level

surface. The distance should be150 mm (6").

Drop and secure the lever at (for example)

the 2" cutting height. Measure as above. The

distance should be 50 mm (2").

Deck Belt

Check the belt every 75 to 100 hours of

operation. Inspect carefully for large cracks

and significant damage. The small cracks that

arise from normal use do not make it

necessary to change the belt.

Changing Belts

1. Drop the deck to its lowest position.

2. Remove the operator’s foot plate.

3. Remove the outer deck belt guards.

8011-622

Slackening the belt tensioner

English-38

Page 41

4. Using a 9/16" socket on the bolt of the

idler pulley, loosen the deck belt. Roll the

belt off the deck pulleys.

5. Roll the belt off the clutch pulley on the

crankshaft.

6. Remove the old belt.

7. Fitting the new belt is the reverse of the

procedure given above. Ensure that belt

routing is as per the accompanying

diagram.

8. Check that the belt is not twisted and that

it runs correctly around all the pulleys.

Belt Tensioning Assembly

The belt is automatically tensioned by a

spring (18). T o cancel the force of the spring ,

use a 9/16" socket on the bolt (33) when

removing or fitting the belt.

REPAIRS

8011-580

Belt routing for the mower deck

Check that there is no abnormal noise

indicating that the idler pulley is loose on its

shaft. If it is loose, tighten the bolt (33) or

change the idler pulley.

Check that the idler arm is not loose on its

bearing. If it is, tighten the n ut (34) or change

the bushing (38).

8011-617

Belt tensioning assembly

English-39

Page 42

Hydraulic Pump Belt

Check the belt every 75 to 100 hours of

operation. Inspect carefully for large cracks

and significant damage. The small cracks that

arise from normal use do not make it

necessary to change the belt.

Changing Pump and Deck Belts

1. Drop the deck to its lowest position.

2. Remove the operator’s foot plate.

3. Remove the outer deck belt guards.

4. Using a 9/16" socket on the bolt of the

idler pulley, loosen the deck belt. Roll the

belt off the deck pulleys.

5. Roll the belt off the clutch pulley on the

crankshaft.

6. Loosen the bolt (2) and twist the clutch

tie down (10) aside (see the “Engine

mounts” diagram).

7. Using a square, 1/2" ratchet wrench,

slacken the pump belt and roll it off the

pulley for one of the hydraulic pumps.

8. Remove the old belt.

9. Fit the new belt on the crankshaft pulley.

10. Swing the idler pulley towards the engine

and fit the belt.

11. Fit the belt around the pulley on the right

(looking upwards from below the mower).

12. Attach the spring and use a square, 1/2"

ratchet wrench to cancel the force

exerted by the belt tensioner.

13. Fit the belt around the left pulley (looking

upwards from below the mower).

14. Check that the belt is not twisted and that

it runs correctly around all the pulleys.

15. Check that there is perceptible play

between the clutch and the clutch tie

down (10) when the clutch flange is

turned by hand (see the “Engine mounts”

diagram). Adjust/twist the tie down and,

using the nut (1), tighten the bolt (2).

16. Fit the deck belt. Check that the belt is

not twisted and that it runs correctly

around all the pulleys.

17. Fit the operator’s foot plate.

18. Fit the outer deck belt guards.

REPAIRS

8011-623

Slackening belt tension

8011-624

Belt routing for the hydraulic pumps

English-40

Page 43

Pump Belt Tensioning Assembly

The belt is automatically tensioned by a

spring (37). To cancel the force of the spring

when removing or fitting the belt, use a 1/2"

ratchet wrench in the square hole in the idler

arm (45).

Check that there is no abnormal noise

indicating that the idler pulley is loose on its

shaft. If it is loose, tighten the bolt (42) and

the set screws (41), or change the bushing

(44).

Check that the idler arm is not loose on its

bearing. If it is, tighten the bolt (49) or change

the bushing (47).

Front Wheel Bearings

Dismantling

1. Remove the grease cap (26).

2. Raise and support the front of the mower

on blocks or similar.

3. Remove the cotter pin (30).

4. Remove the castle nut (27) and, pulling

downwards, remove the front fork.

5. Remove the upper bearing (28).

6. Taking great care not to damage the seal

(31), use a hammer and a suitable rod

(or similar) to knock the lower bearing out

in a downwards direction.

Assembling

The assembly procedure is the rev erse of the

dismantling procedure.

REPAIRS

8011-616

Pump belt tensioning assembly

8011-619

Front wheel bearing

Lubricate the bearings with ball bearing

grease.

Taking great care not to damage it, tap the

seal into position.

Adjust the castle nut (27) until there is zero

play in the bearings. Loosen the castle nut to

the nearest hole and fit the cotter pin.

English-41

Page 44

REPAIRS

English-42

Page 45

ELECTRICAL SYSTEM

Electrical System

Troubleshooting

See the “Troubleshooting” section towards the back of this manual.

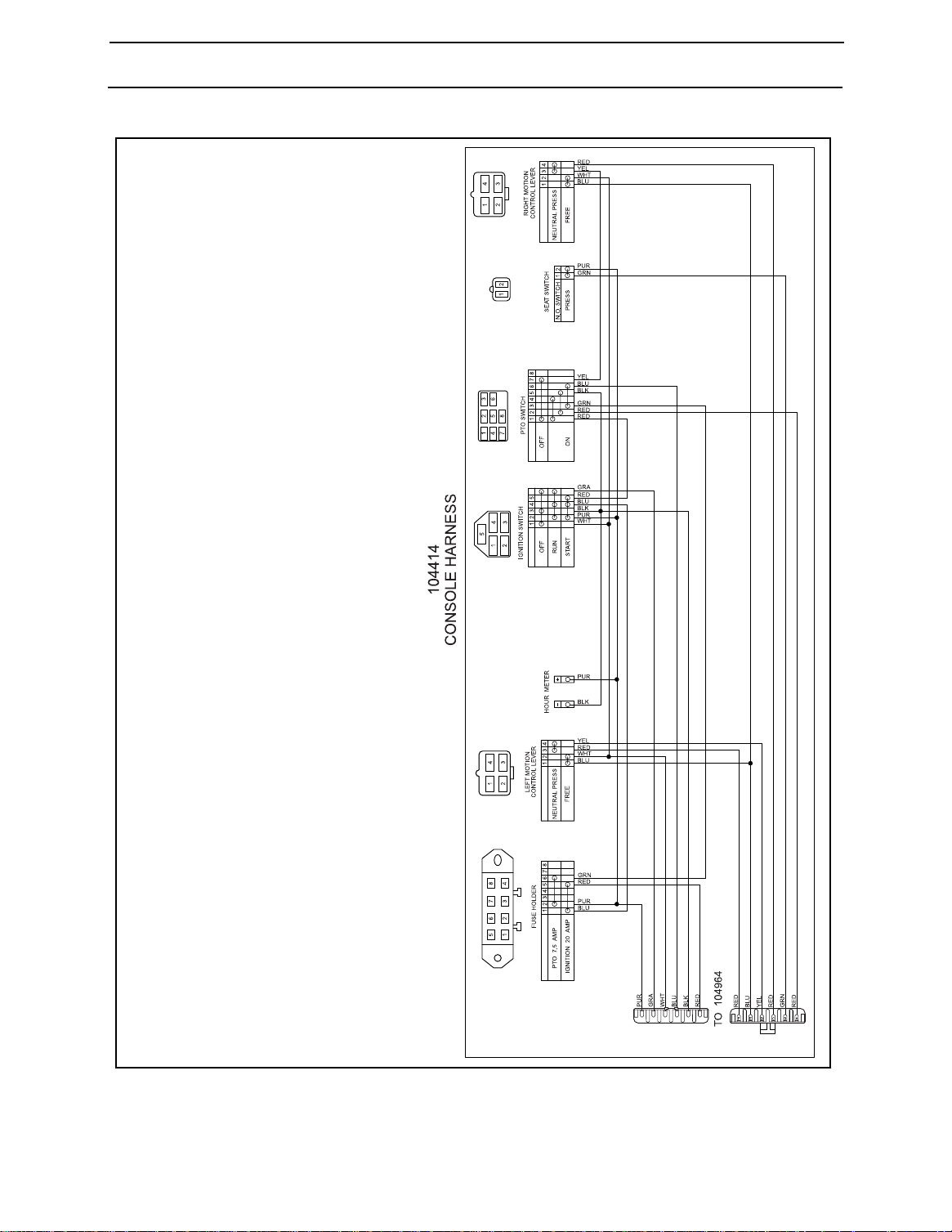

Wiring Assembly

The diagram below shows the structure of the electrical system.

A. To the engine ground bolt

B. To the solenoid

C. To the electric clutch

ZTH electrical system

D. To the pigtail

E. To the park brake

F. To motion control lever

G. To the seat

H. Console harness

J. Frame harness

8011-584

To connect the engine to the frame harness (13), there is a pigtail. This plugs into connector “D” (see

diagram above). The Kawasaki pigtail is illustrated below.

Vio = Violet

Wht = White

Gra = Gray

Kawasaki pigtail

English-43

8011-587

Page 46

ELECTRICAL SYSTEM

The console harness (1) connects the console controls to the frame harness.

Blk = Black

Blu = Blue

Gra = Gray

Grn = Green

Pur = Purple

Wht = White

Yel = Yellow

ZTH console harness

English-44

ABCDEF

8011-629

Page 47

ELECTRICAL SYSTEM

There are two connectors connecting the frame harness (13) to the console harness (1).

Blk = Black

Blu = Blue

Gra = Gray

Grn = Green

Pur = Purple

Wht = White

Yel = Yellow

ZTH frame harness

The engine pigtail (page 43) plugs into the “Engine Pigtail” socket of the frame harness.

8011-628

English-45

Page 48

ELECTRICAL SYSTEM

Battery

The battery is maintenance-free and the cells are sealed. Breaking the seal invalidates the warranty. To

avoid exposing the battery terminals to dangerous stress, use two wrenches when connecting or

disconnecting the battery cables.

WARNING!

The battery contains corrosive acid. Wear goggles. Do not tip the battery over.

The battery gives off explosive fumes. Keep it away from all naked sparks and

flames. Never smoke in the vicinity of the battery.

Never let children or untrained staff handle or work on the battery.

Procedures in the Event of Acid Contact

External: Drench with running water.

Internal: Drink copious quantities of water or milk. See a doctor as soon as possible.

Eyes: Drench with running water. See a doctor as soon as possible.

Fuses

Refer to the “ZTH electrical system” diagram.

The fuses (23, 24) plug into a holder on the

left of the hydraulic tank. They are of the flat

pin type commonly used in automobiles.

There are two active fuses and sockets for

two spares.

Fuse rating and function (working along the

holder from right to left) is:

• 20 A, main fuse.

• 7.5 A, deck clutch.

• Socket for spare fuse.

• Socket for spare fuse.

8011-596

Fuses

English-46

Page 49

ELECTRICAL SYSTEM

Relays

Refer to the “ZTH electrical system” diagram.

The relays (22) plug into a holder under the

seat (on the left). The three relays are

identical and can be plugged into any of the

sockets in the holder.

Relay function (working along the holder from

right to left) is:

• Brake relay

• Run relay

• Start relay

Removing

Pull relays directly upwards. If necessary,

Relays

8011-597

carefully work a screwdriver under the relay

and lever upwards.

Fitting

The relays hav e an asymetric pin pattern and will fit into the sockets in one wa y only. Press each relay do wn

until the body contacts the holder.

Starter Motor Contactor

Changing

1. Disconnect the cable connecting the

battery to the chassis. To avoid

damaging the battery terminals, use two

wrenches.

2. Pull the cables off the contactor.

3. Remove the contactor (the nuts are

under the frame plate).

4. Position the new contactor so that the pin

for the control cable is towards the

chassis wall. The b lack cab le connects to

the front binding screw.

5. Connect the control cable (yellow) to its

pin.

6. Connect the wires to to the battery and

starter motor as shown in the diagram.

Replace the connector guards.

7. Connect the cable between the battery

and the chassis.

Starter motor contactor

8011-598

English-47

Page 50

ELECTRICAL SYSTEM

Ignition and Start Switch

Refer to the “ZTH electrical system” diagram.

Changing

1. Free the control console and pull

forwards.

2. Disconnect the wires at the back of the

ignition switch (10).

3. Remove the ignition key and the rubber

cap (20).

4. Remove the nut (19) and the ignition

switch (10).

5. Thread the toothed plate connector onto

the throat of the new ignition switch.

Feed the switch into the console from the

rear. Turn the switch so that the single pin

faces towards the blade switch.

6. Start the nut (19) off on its thread and

twist the switch to the correct position in

the console panel. Try the key in the

switch and then tighten the nut.

7. Remove the key and fit the rubber cap

(20). Reinsert the key.

8. Reconnect the wires at the back of the

ignition switch.

9. Refit the control console.

8011-599

Freeing the control console

Hour Meter

Refer to the “ZTH electrical system” diagram.

Changing

1. Free the control console and pull forwards.

2. Disconnect the wires at the back of the hour meter (12).

3. Prise the catches apart and remove the hour meter’s locking plate.

4. Pull the hour meter out of the console panel.

5. Ensuring that the numbers are turned to the correct position to be seen by the operator, insert the new

hour meter in the console panel.

6. Fit the locking frame (push in manually and check that the catches have fastened).

7. Connect the two violet wires to the right pin and the black to the left.

8. Refit the control console.

English-48

Page 51

ELECTRICAL SYSTEM

Blade Switch

Refer to the “ZTH electrical system” diagram.

Changing

1. Free the control console and pull forwards.

2. Disconnect the wires at the back of the switch (11).

3. Push in the plastic catch on the switch’s short side and draw the switch out through the console panel.

4. With the plastic catch and two contact pins facing upwards , push the new s witch into the console panel

unitl it is correctly seated.

5. Reconnect the wires at the back of the switch.

6. Refit the control console.

Mower Deck Clutch

Measuring the Supply Voltage

See the “Troubleshooting” section towards

the back of this manual.

Measuring Coil Resistance

See the “Troubleshooting” section towards

the back of this manual.

Troubleshooting Guide

See the “Troubleshooting” section towards

the back of this manual.

Removing

1. Drop the deck to its lowest position.

2. Remove the operator’s foot plate.

3. Using a 9/16" socket on the bolt of the

idler pulley, loosen the deck belt. Roll the

belt off the deck pulleys.

4. Roll the belt off the clutch pulley on the

crankshaft.

5. Disconnect the cable feeding the clutch.

The connector is located next to the left

engine mount.

6. Remove the bolt (9) and the lock w asher

(8).

7. Remove the clutch (7) and the spacer

(6).

8011-592

Deck clutch

8011-6022

Loosen the deck belt

English-49

Page 52

ELECTRICAL SYSTEM

Fitting

The fitting procerdure is the reverse of the removal procedure.

Pay particular attention to the following:

• The tightening torque for the bolt (9) is 67 Nm (50 ft/lb).

• With the bolt (9) tightened, there should be perceptible play between the clutch and the clutch tie do wn

(10) when the clutch flange is turned by hand. If necessary, adjust/twist the tie down.

• Ensure that the cable cannot be damaged and secure it with a cable tie.

Motion Control Switches

These micro switches are difficult to access. By pulling the control console forwards, it is possible to change

the right switch without any other major dismantling. However, this does require two people. When

changing the left switch, the tubular shafts (31, 33) of the motion control levers must be lowered or

removed. The procedure for doing this is detailed below and may also be used for the right switch.

Hydraulic pump linkages

English-50

8011-589

Page 53

ELECTRICAL SYSTEM

Removing

1. Swing the seat completely out of the way.

2. Release the mechanical link between the left park brake and the brake lever.

3. Release the dampeners (23) and springs (17) from the tubular shafts (31, 33) by removing the bolts

(16) - each with two nuts (22) - spacers (21) and washers (11).

4. Release the front end of the ball joints (32) from the tubular shafts (31, 33) by removing the bolts (14),

nuts (22) and washers (11).

5. Remove the control lever by removing the bolts (3) and spring washers (4).

6. Remove the bolt to the park brake arm (on the right side of the park brake shaft). Remove the arm and

the released washers from the park brake shaft.

7. Pull out the park brake shaft and lever to the left. When the shaft is pulled out, the tubular shafts, first

(33) and then (31), will be freed.

8. Disconnect the cable connection to the switch and remove the tubular shaft.

9. Remove the switch from the tubular shaft.

Fitting

The fitting procedure is the reverse of the removal procedure.

Pay particular attention to the following:

• Check and position the switches before fitting the tubular shaft.

• Position the s witches so that there is a click when the inner flat surf ace of the arm continuation shaft (5)

passes over the outside corner of the tubular shaft’s lever mount.

• Check the setting of the linkages (see Hydraulic System\Hydraulic Pump\Linkage Adjustment).

• Check the setting of the rev erse detent spring (see Hydraulic System\Hydraulic Pump\Reverse Spring

Detent Adjustment).

Park Brake Interlock Switch

Refer to the “ZTH electrical system” diagram.

Changing

1. Disengage the park brake.

2. Drop the deck to its lowest position.

3. Remove the bolts (9). The tapped plate

(8) is freed when the switch is loosened.

4. Separate the connector from the switch

(7). Pull it directly upwards.

5. Push the connector onto the new switch

(there is only one way for the parts to

mate).

6. Using the bolts (9) and tapped plate (8),

fasten the switch securely to its bracket.

7. Check that the start interlock functions

correctly.

Park brake interlock switch

8011-600

English-51

Page 54

ELECTRICAL SYSTEM

Welding

The following applies to arc, MIG, TIG and all other electrical welding methods.

IMPORTANT INFORMATION

When performing electric welding on the

mower, take all necessary precautions to

prevent damage to the electrical system.

The engine’s ignition system has sensitiv e electrical components. Electrical welding must not, therefore, be

carried out on the engine. Remove the component to be welded (e.g. the muffler) or the ignition system.

Before carrying out welding on any other part of the mower:

1. Remove the battery cables.

2. Disconnect the connector between the engine pigtail and the frame harness.

3. Connect the welding earth lead as near as possible to the point of welding.

English-52

Page 55

HYDRAULIC SYSTEM

Hydraulic System

Hydraulics Hygiene

If they are to operate well, hydraulic systems must be kept free from all impurities. During operation,

particles that can cause both wear and malfunction are generated inside hydraulic systems. To separate

these particles from the hydraulic fluid, filters are used. Filters are dimensioned to cope with particles

developed within the system. If impurities enter from outside, filters tend to clog quickly and become

ineffective. Any dirt entering a hydraulic system accelerates the production of further impurities. A vicious

circle arises; there is much disruption and a lot of time is lost in cleaning.

The particles causing most damage are those which are of roughly the same size as the play between the

moving parts in system components. Normal play in pumps and v alv es is from 3 - 5 µm and upw ards (1 µm

= 0.001 mm). It should be noted that a particle measuring 40 µm can only just be seen by the naked eye.

The main impurities generated in system operation are:

• Wear particles (mainly from components with moving parts, e.g. pumps and hydraulic motors).

• Dust entering the hydraulic oil tank via air vents.

• Water formed by condensation (water vapor enters with air from outside).

• Particles of dirt entering the system via moving piston rods, etc.

• Sediments, etc. produced by the breaking down of the hydraulic oil.

• Corrosive matter produced in the system as a result of oil not being changed in time. Old oil tends to be

rich in water and other aggressive substances.

• Dirt entering the system during service or repair work, e.g.:

- Contamination during the changing or topping-up of oil.

- Dust in the workshop.

- Sealing agents and similar.

- Dirt from storage and handling prior to fitting.

- Fibers from rags, filters, etc.

- Dirt from parts not cleaned prior to dismantling.

- Dirt and dust entering the system from contaminated protective plugs.

Especially if the system is not regularly used, even microscopic quantities of water will accelerate the

rusting of ground and polished surfaces. This hastens the formation of sediments that can clog filters and

give rise to circulation and cavitation problems in hydraulic pumps.

Minute fibers and threads from cleaning rags or clothing can form fluff which will obstruct nozzles and other

narrow apertures. The fibers themselve do not cause significant damage, but the clogging they generate

greatly accelerates component wear.

Every particle of dirt in hydraulic systems acts as a grinding agent. Abrasion is increased, more impurities

are produced and permanent damage is caused. Particle quantity increases every time work is done on

hydraulic systems. Although most particles will have been trapped by the filters after a few hours operation,

it is obviously good practice to avoid all unnecessary opening of hydraulic systems, even if carried out by

professionals.

English-53

Page 56

HYDRAULIC SYSTEM

Hydraulic Oils