Page 1

Operator and Parts Manual

Collection System

M-ZT 52 /966793002

M-ZT 61 /966793003

Page 2

CONGRATULATIONS on the purchase of a new

collection system. It has been designed, engineered

and manufactured to give you the best possible

dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact the nearest authorized service

center/ department. They have competent, welltrained technicians and the proper tools for service

and repairs.

Please read and retain this manual. The instructions

will enable you to assemble and maintain the

collection system properly. Always observe the

SAFETY RULES.

KNOW YOUR BLOWER SYSTEM

READ THIS OPERATION MANUAL AND SAFETY

RULES BEFORE ASSEMBLING OR OPERATING THE

BLOWER SYSTEM. Compare the illustrations with the

carton contents and become familiar with the parts

before starting the assembly. Study the operating

instructions and safety precautions thoroughly to

insure proper functioning of the Grass Catcher and to

prevent injuries. Save this manual for future reference.

CAUTION

BEFORE ASSEMBLING GRASS

CATCHER TO MOWER:

• Set parking brake.

• Place motion control levers in

NEUTRAL position.

• Turn ignition key OFF and remove

key.

• Make sure the blades and all moving

parts have completely stopped.

CAUTION

• DO NOT operate mower with grass

catcher partially installed.

• Disengage blades and stop engine

before leaving mower seat to empty

containers, unclogging chutes, etc.

• Close cover before starting.

• Disengage mower blades when

crossing driveways or gravel

surfaces and other areas where

thrown objects could be a hazard.

• DO NOT attempt to vacuum cans

or other potentially hazardous

projectiles.

CAUTION

The operation of any mower can result

in foreign objects thrown into the eyes,

which can result in severe eye damage.

ALWAYS wear safety glasses or eye

shields before starting the mower and

while mowing. Standard safety glasses

are recommended or a wide vision safety

mask for over spectacles.

CAUTION

Do not leave grass in bagger containers.

Empty containers after each use and

before storing. Failure to do so may

result in spontaneous combustion which

could develop into a fire.

CAUTION

Grass catcher components are subject

to wear, damage and deterioration,

which could expose moving parts or

allow objects to be thrown. Frequently

check components and replace with

manufacturer’s recommended parts,

when necessary.

©2013 HTC. All Rights Reserved.

Swainsboro, GA. Printed in U.S.A.

Page 3

CONTENTS

SAFETY RULES .........................................................4

ASSEMBLY ................................................................5

OPERATION .............................................................11

BLOWER ASSEMBLY ......................................12

CHUTES ...........................................................14

BAGGER .......................................................... 16

MOUNT, GUARD, BELT ...................................18

TOOLS REQUIRED

7/16" Wrench or ratchet and socket

9/16" Wrench or ratchet and socket

½" Wrench or ratchet and socket

¾" Wrench or ratchet and socket

7/8" Socket

Torque Wrench

Phillips Head Screwdriver

Hacksaw

Pliers

Drill and 3/8" drill bit

NOTE: When the terms RH (right hand) or

LH (left hand) are used, it refers to when the

operator is seated on the mower.

CONTAINER CONTENTS

• Blower/Bagger Assembly • Drive Pulley

• Belt Shield • Belt

• Mounting Brackets • Bag of Hardware

Page 4

SAFETY RULES

SAFE OPERATION PRACTICES FOR RIDE-ON MOWERS

GENERAL OPERATION

• Read, understand and follow all instructions in the

manual and on the machine before starting.

• Only allow responsible adults, who are familiar

with the instructions, to operate the machine.

• Clear the area of objects such as rocks, stones,

toys, wire etc., which could be picked up and

thrown by the blades.

• Be sure the area is clear of all people and pets

before mowing. Stop the machine if anyone enters

the area.

• Never carry passengers or children even with

blades off.

• Do not mow in reverse unless absolutely

necessary. Always look down and behind before

and while backing.

• Do not operate the mower without either the entire

grass catcher or the guard in place.

• Slow down before turning.

• Stop engine before removing grass catcher or

unclogging chute.

• Mow only in daylight or good artificial light.

• Do not operate the machine while under the

influence of alcohol or drugs.

• If the collection system has front weights

included, DO NOT operate mower with the grass

catcher unless the front weights are installed.

• Keep machine free of grass, leaves or other

debris buildup which can touch hot exhaust/

engine parts and burn. Do not allow the mower

deck to plow leaves or other debris which can

cause buildup to occur.

• Allow machine to cool before storage.

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and

tip-over accidents, which can result in severe injury or

death. All slopes require extra caution. If you cannot

back up the slope or if you feel uneasy on it, do not

mow it.

DO

• Use extra care with grass catchers or other

attachments. These can change the stability of

the machine.

• Mow up and down slopes (10° Max.), not across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain

could overturn the machine. Tall grass can hide

obstacles.

• Use slow speed. Choose a low speed so that you

will not have to stop while on the slope.

• Keep all movement on the slopes slow and

gradual. Do not make sudden changes in speed

or direction.

• Avoid starting or stopping on a slope. If tires

lose traction, disengage the blades and proceed

slowly straight down the slope.

DO NOT

• Do not turn on slopes unless necessary, and then,

turn slowly and gradually downhill, if possible.

• Do not mow near drop-off, ditches, or

embankments. The mower could suddenly turn

over if a wheel is over the edge of a cliff or ditch,

or if an edge caves in.

• Do not mow on wet grass. Reduced traction

could cause sliding.

• Do not try to stabilize the machine by putting your

foot on the ground.

SERVICE

• The operation of any mower can result in foreign

objects thrown into the eyes, which can result in

severe eye damage. Always wear safety glasses

or eye shields while operating the mower or

performing any adjustments or repairs. Wide

vision safety mask over spectacles or standard

safety glasses are recommended.

• Keep nuts and bolts, especially blade attachment

bolts, tight and keep equipment in good

condition.

• Never tamper with safety devices. Check there

proper operation regularly.

• Grass catcher components are subject to wear,

damage, and deterioration, which could expose

moving parts or allow objects to be thrown.

Frequently check components and replace

with manufacturer’s recommended parts, when

necessary.

4

Page 5

ASSEMBLY

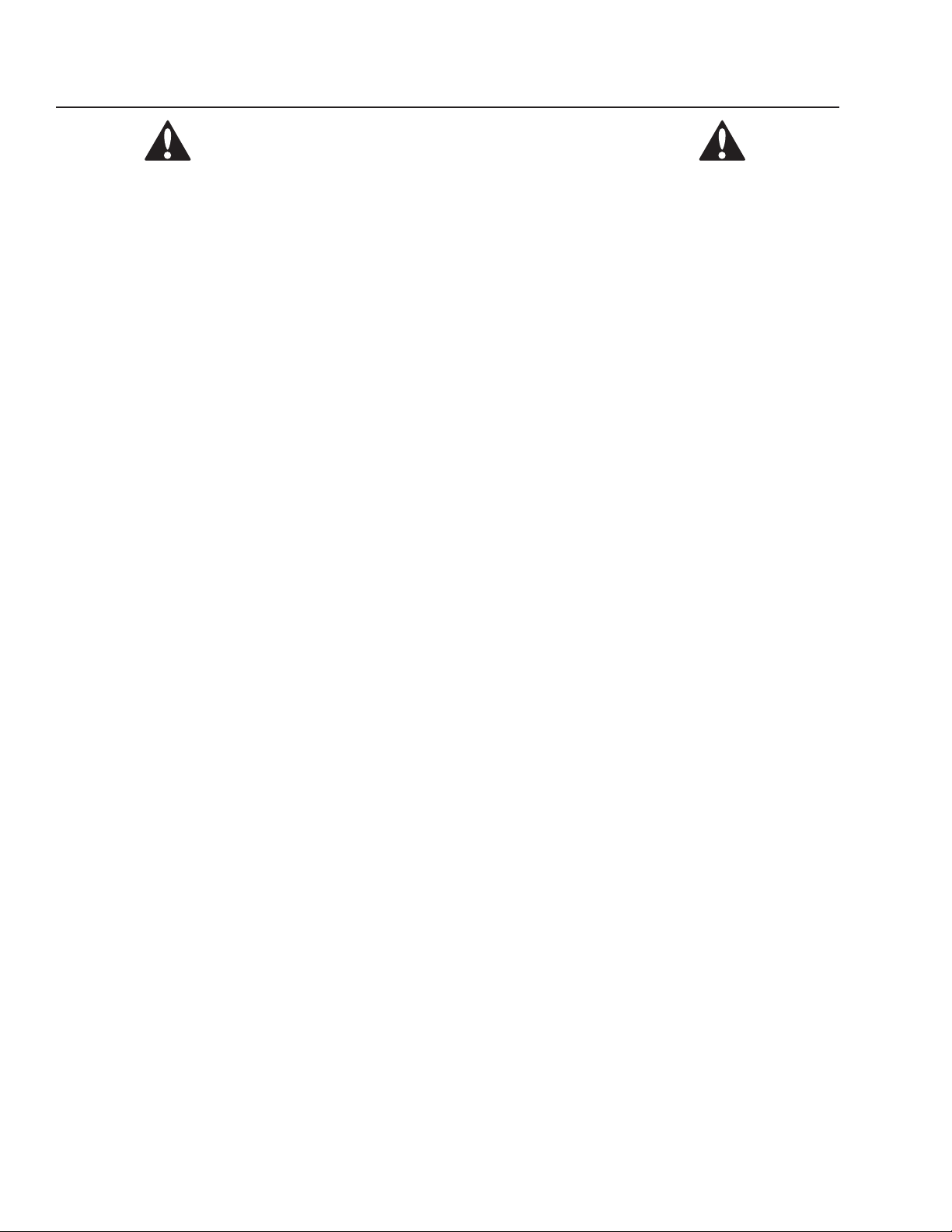

DRIVE PULLEY

1

1. Remove the discharge chute from the deck

by removing the side hardware from the chute

bracket. Retain the hardware for reuse if the

collection system is removed.

2. Lower deck to the lowest cutting position.

3. Remove the right hand (discharge side) belt cover

from the deck.

Belt Cover

Discharge

Chute

Hardware

4. Relieve the tension from the deck belt and remove

the belt from the center deck pulley.

(See Operator Manual if necessary)

5. Remove the nut securing the right hand deck

pulley to the spindle.

6. Install drive pulley included in collection system

kit on top of the current deck pulley.

7. Reinstall the nut on the spindle and torque to 5575 ft/lbs.

8. Reinstall the deck belt.

Drive Pulley

TRIMMING BLOWER

2

1. Place blower assembly on secure table or stable

surface.

2. Remove the bolts securing the rear mount

bracket.

3. Using the hacksaw, trim the blower housing along

the recessed grooves.

4. Reinstall the rear mount bracket with previously

removed bolts.

Mount Bracket

Rear

Trim Line

MOUNTING BLOWER ASSEMBLY

3

1. Position blower over the discharge tabs on the

deck and set blower onto the deck.

2. Install the front mount bracket to the deck with the

pin and hairpin cotter supplied with the kit.

Outer Pulley Cover

Pin

5

Page 6

ASSEMBLY

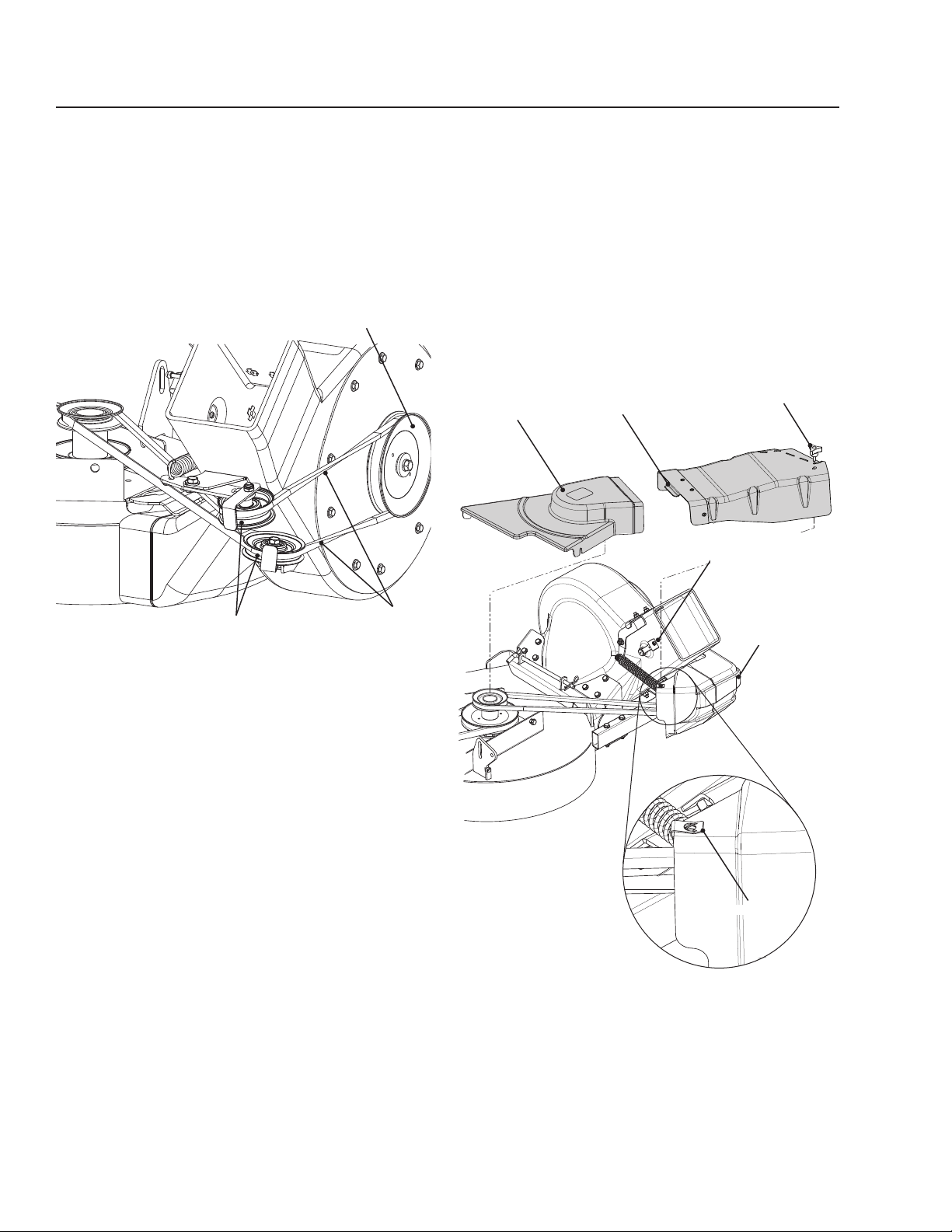

DRIVE BELT

4

1. Make sure the tension release lever is forward

(disengaged).

2. Place the belt over the pulley on the deck. Refer

to illustration for proper routing.

3. Move the tension release arm to the rear and

engage in the latch.

Outer Pulley

BELT COVERS

5

1. Place the deck belt shield on the deck over the

drive pulley and secure with hardware removed

from steel belt shield.

2. Place retainer on the outer pulley cover.

3. Align the tab end of the belt cover into the slot on

the deck belt shield and the other end over the

end of the outer pulley cover.

4. Secure with knob.

Knob

Deck Belt Shield

Belt Cover Tab

Middle Chute

Latch

Idler Pulleys

Belt Twist

Outer Pulley

Cover

Retainer

6

Page 7

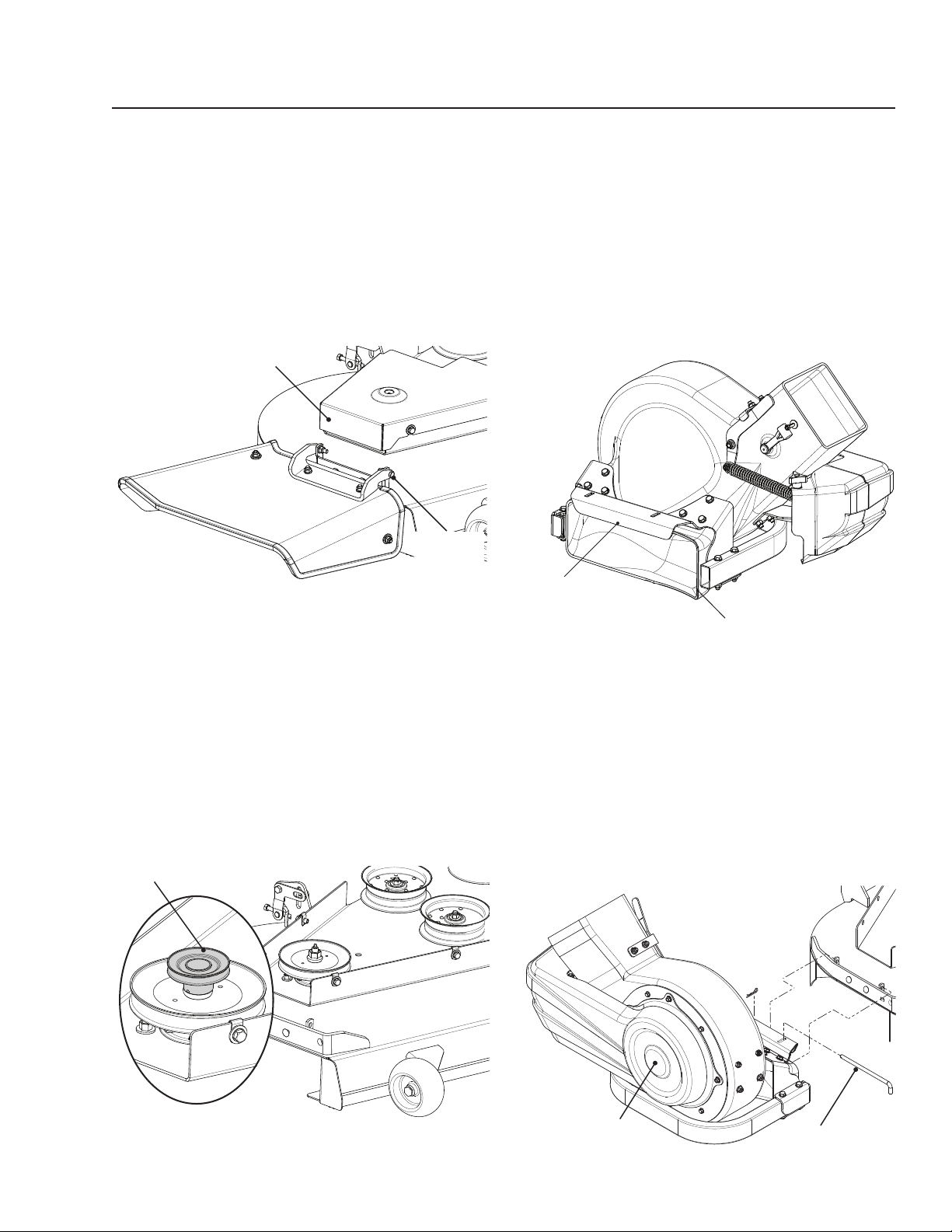

BAGGER MOUNT

6

ASSEMBLY

1. Using 1¾" round head shoulder bolts and nuts,

attach the mount hitch to the mount tube as

illustrated. Make sure the elbowed arm of the tube

is on the right side, with the mount hitch installed

to the front.

2. Attach the support bracket to the tube assembly

with two 1¾" round head shoulder bolts and nuts.

3. With a 1" hex bolt and nut, secure the lower mount

hitch to the frame.

FRONT

Spacer Plate

Support Bracket

4. Install the mount straps (bends are to the inside)

on the outside of the mount tube using 2" hex

bolts and nuts. The front side of the mount straps

are secured to the fuel tank brackets with 1" round

head shoulder bolts and nuts.

5. To prevent contact of the left hand strap with

the EFM (Electronic Fuel Management) box on

the engine, place the foam strip on the inside of

the strap, next to the box. (Illustration location is

approximate.)

6. It may necessary to drill holes into the rear

guard to accept the hardware for the support

bracket and spacer plate. Using the bracket as a

template, drill 5/16" holes.

7. Slip the spacer plate between the support bracket

and the rear guard and attach both to the rear

guard with ¾" hex bolts and nuts as illustrated.

8. Tighten all hardware.

Foam Strip

Mount Straps

Mount Tube

Lower Mount Hitch

Support Bracket and

Spacer Plate

7

Page 8

ASSEMBLY

CHUTE SUPPORT

7

1. Position upper chute support against bagger inlet,

flush at outer edges. See Illustration.

2. Using support as a template, drill two 3/8 holes into

bagger hood.

Upper Chute Support

COVER ASSEMBLY

8

NOTE: For ease of assembly, you may wish

assistance from another person for mounting

the cover assembly to mower.

1. Position cover assembly on ground behind

mower.

2. Lift and rotate cover to align the cover brackets

with support assembly tubes.

3. Slide the cover down over the support tubes until

secure.

Cover Assembly

3. Secure upper chute support to hood with hex

bolts, washers and nyloc nuts.

Flex Trim

MIDDLE CHUTE

9

1. Place middle chute over the top end of the blower

assembly, lining up the blower latch and the

acorn nut on the middle chute.

2. Stretch bungee latch up onto acorn nut to secure.

Middle Chute

Chute Latch

8

Page 9

ASSEMBLY

UPPER CHUTE ASSEMBLY

10

1. Slide upper chute onto middle chute, lining up the

middle chute latch and the acorn nut on the upper

chute.

2. Stretch bungee latch up onto acorn nut to secure.

Upper Chute

CHUTE / HOOD INSTALLATION

11

Push upper chute through the gasketed opening in

the cover assembly.

Cover Inlet

9

Page 10

ASSEMBLY

WEIGHT ASSEMBLY

12

1. Remove the foot plate knob and foot plate. Set

aside for later reuse.

2. Remove and reserve the three rubber grommets

from the foot rest.

3. Remove the foot rest for replacement. Retain

hardware for reuse.

Foot Plate

Foot Rest

6. Fasten the three weight plates to the weight

brackets.

4. Install the three rubber grommets to the new foot

rest and fasten the assembly to the frame with the

hardware from the old foot rest.

5. Reinstall the foot plate and secure with the knob.

Replacement Foot Rest

10

7. Secure the weight plate assembly to the front

frame of the mower between the caster wheels.

Weight Plate

Assembly

Page 11

OPERATION

TIPS FOR IMPROVED BAGGING

• Follow the mower operation instructions in you

mower operator manual.

• When operating the grass catcher on a lawn

where grass and leaf bagging equipment has

not been used, thatch and debris that has

accumulated for long periods of time is picked

up. The amount collected and the total time of

operation may be greater than experienced with

regular use of the grass catcher.

• Always run throttle at full speed when bagging.

• Select a speed low enough to give good mower

cutting performance, good quality cut and good

bagging performance.

NOTE: It may be necessary to overlap width of

cut to suit conditions.

• If grass is extremely tall, it should be mowed

twice. The first time relatively high, the second

time to desired height.

• Use left hand side of mower for trimming.

• Plastic trash bags (3.0 mil, 30 gallon) can be

inserted inside grass catcher containers for ease

of debris disposal. To remove the plastic trash

bags when full:

a. Disengage blades, shift into neutral, engage

the parking brake and stop the engine.

b. Unlatch and raise cover.

c. Remove one container at a time by grasping

container handles and pulling toward the rear,

off of the tube rails.

d. With the container resting on the ground, close

and secure the top of the plastic lawn bag.

e. Tip the container on its side and slide the filled

bag from the container.

f. Install a new plastic lawn bag with the edges

of the bag draped over upper lip of the

Container.

g. Repeat for other containers.

h. Reinstall containers making sure center

containers overlap at center supports.

i. Close cover and secure latches over center

support tubes.

• Avoid cutting wet grass or in the morning while the

dew is still heavy. Grass clippings collected under

these conditions tend to be sticky and adhere to

the walls of the flow path causing clogging.

• If the grass catcher fails to pick up cut grass

or leaves, it is an indication that clogging has

occurred in the system or that the grass catcher

containers are full.

a. Disengage blades, place motion control levers

in neutral position.

- Unlatch and raise cover.

- Slide out containers and dispose of

clippings.

- Replace containers, close cover, and latch.

b. Unlatch chutes and check for clogging.

- Remove all debris in chute.

- Reassemble and latch chutes.

GENERAL RECOMMENDATIONS

Always observe safety rules when performing any

maintenance. Before each use check for loose

fasteners. Clean unit thoroughly after each use.

BLADE CARE

For best results mower blades must be kept sharp.

Replace bent or damaged blades.

See BLADE CARE instructions in the mower operator

manual.

STORAGE

When grass catcher is to be stored for a period of

time, clean it thoroughly, remove all dirt, grass, leaves,

etc. Store in a clean, dry place.

11

Page 12

BLOWER ASSEMBLY

34

REPAIR PARTS

46

65

51

18

24

16

30

56

11

12

19

53

53

44

9

13

45

50

63

14

58

8

63

41

2

58

6

32

22

60

10

61

62

58

7

33

52

32

58

43

13

66

5

17

26

49

63

1

56

40

15

28

27

55

50

64

40

54

38

37

50

23

57

25

3

4

21

59

60

48

12

47

64

48

59

20

31

42

65

35

29

Page 13

REPAIR PARTS

ITEM PART NO. QTY. DESCRIPTION ITEM PART NO. QTY. DESCRIPTION

ITEM PART NO. QTY. DESCRIPTION ITEM PART NO. QTY. DESCRIPTION

1.. 539 130344 .... 1 .... HOUSING w/DECALS

2.. 539 130293 .... 1 .... COVER, BELT

3.. 574 411501 .... 1 .... COVER, BELT

4.. 539 130292 .... 1 .... IMPELLER

5.. 539 130295 .... 1 .... HUB

6.. 539 113683 .... 1 .... PULLEY, V-IDLER

7.. 539 130324 .... 1 .... PULLEY

8.. 579 150802 .... 1 .... PULLEY, IDLER

9.. 579 137402 .... 1 .... MOUNT, UPPER BLK

10.. 579 137502 .... 1 .... MOUNT, LOWER BLK

11.. 579 137302 .... 1 .... ARM, IDLER

12.. 539 130338 .... 1 .... ARM, TENSION

13.. 539 130301 .... 2 .... BUSHING

14.. 539 132124 .... 1 .... PLATE, BACKING

15.. 539 130341 .... 1 .... PLATE, OUTER

16.. 539 104411 .... 1 .... KNOB w/ STUD

17.. 539 130323 .... 1 .... SPACER

18.. 522 909801 .... 1 .... PIN, RETENTION

19.. 539 108088 .... 1 .... LATCH, HOOD

20.. 539 115667 .... 1 .... KEY 3/16 x ½

21.. 539 125229 .... 1 .... KEY 1½

22.. 539 104763 .... 1 .... RETAINER, U TYPE

23.. 539 130316 .... 1 .... SHAFT, IMPELLER

24.. 539 976988 .... 1 .... HAIRPIN COTTER

25.. 539 130349 .... 1 .... DECAL, BELT ROUTING

26.. 539 105785 .... 1 .... DECAL, WARNING

27.. 539 106741 .... 1 .... DECAL, SEVERING

28.. 539 101977 .... 1 .... SPRING, TRACTION

29.. 522 909402 .... 1 .... TUBE, RUB

30.. 579 137602 .... 1 .... KEEPER, BELT REAR BLK

31.. 539 131085 .... 1 .... KEEPER, BELT OUTER BLK

32.. 579 137702 .... 1 .... KEEPER

33.. 539 130296 .... 2 .... BEARING

34.. 522 909602 .... 1 .... BRACKET, MOUNT

35.. 522 909502 .... 1 .... BRACKET, RETENTION

36.. 525 618302 .... 1 .... SAND LINER, TOP

37.. 522 909702 .... 1 .... SAND LINER, BOTTOM

38.. 539 990645 .... 1 .... RHSNB 3/8-16 x 1

39.. 539 990316 .... 6 .... RHSNB 5/16-18 x ¾

40.. 539 990208 .... 6 .... RHSNB 5/16-18 x 1

41.. 539 976949 .... 1 .... HCS 3/8-16 x 1¾

42.. 539 101721 .... 4 .... HCS 5/16-18 x 2¾

43.. 539 990643 .... 1 .... HCS ¼-20 x 7/8

44.. 539 990209 .... 1 .... HCS 5/16-18 x 1

45.. 539 990655 .... 1 .... HCS 3/8-16 x 1½

46.. 539 130315 .... 6 .... HCS 5/16-18 x ½

47.. 539 108461 .... 3 .... BOLT ¼-20 x ½ HWST

48.. 539 110321 .... 2 .... BOLT 3/8-24 x 1¼ HEX GR 8

49.. 539 990302 .... 8 .... SCREW ¼-20 x 3/8 THD FRM

50.. 539 976952 .... 1 .... SCREW #10-24 x 5/8 MACH

51.. 539 130313 .... 6 .... NUT 5/16-18 TEE

52.. 539 130314 .... 9 .... NUT ¼-20 TEE

53.. 539 108089 .... 1 .... WELDNUT, PLATED

54.. 539 108120 .... 1 .... NUT ¼-20 HEX THIN NYLOC

55.. 539 108735 .... 1 .... NUT ¼-20 HEX FLANGE LK

56.. 539 200282 .... 3 .... NUT 3/8-16 HEX JAM NYLOC

57.. 539 112899 . . 10 .... NUT 5/16-18 HEX FLG NYLOC

58.. 539 990717 .... 9 .... NUT 5/16-18 HEX NYLOC

59.. 539 990118 .... 2 .... WASHER 3/8 SLW

60.. 532 140296 .... 2 .... WASHER, HARDENED

61.. 539 108084 .... 1 .... WASHER 3/16 x ¾ x 16 GA

62.. 539 109552 .... 1 .... WASHER 3/16 SLW

63.. 539 990122 .... 3 .... WASHER 3/8 SAE FLT

64.. 539 990055 .... 4 .... WASHER ¼ FLAT SAE

65.. 539 990188 . . 10 .... WASHER 5/16 SAE FLAT

NOTE: ALL FASTENERS ARE GRADE 5 UNLESS OTHERWISE SPECIFIED.

13

Page 14

CHUTES

REPAIR PARTS

3

7

2

1

5

11

9

10

12

4

11

9

11

5

6

8

14

8

Page 15

REPAIR PARTS

ITEM PART NO. QTY. DESCRIPTION ITEM PART NO. QTY. DESCRIPTION

1.. 539 108141 .... 1 .... CHUTE, UPPER

2.. 539 130294 .... 1 .... CHUTE, MIDDLE

3.. 539 130933 .... 1 .... INDICATOR, BAG DUMP

4.. 539 108088 .... 1 .... LATCH, HOOD

5.. 539 108085 .... 2 .... SPACER, SPLIT

6.. 539 108081 .... 1 .... SCREW #10-14 x ½

7.. 539 976952 .... 1 .... SCREW #10-24 x 5/8

8.. 539 108083 .... 2 .... SCREW #10-24 x 11/8

9.. 539 108086 .... 2 .... NUT #10-24 ACORN

10.. 539 108089 .... 1 .... WELDNUT, PLATED

11.. 539 108084 .... 3 .... WASHER 3/16 x ¾ x 16 GA

12.. 539 109552 .... 2 .... WASHER 3/16 LOCK

NOTE: ALL FASTENERS ARE GRADE 5 UNLESS OTHERWISE SPECIFIED.

15

Page 16

BAGGER

15

REPAIR PARTS

1

16

3

8

9

14

16

5

11

13

17

10

15

7

6

4

12

2

16

Page 17

REPAIR PARTS

ITEM PART NO. QTY. DESCRIPTION ITEM PART NO. QTY. DESCRIPTION

1.. 532 195373 .... 1 .... COVER

2.. 532 400226 .... 3 .... CONTAINER, SOFT BAG

3.. 532 130895 .... 2 .... HANDLE, BAGGER COVER

4.. 532 176990 .... 1 .... FRAME, BAGGER

5.. 532 192709 .... 1 .... SCREEN, COVER

6.. 532 174083 .... 2 .... PLUG, SPACER

7.. 532 192786 .... 2 .... PIN, HINGE

8.. 532 192550 .... 1 .... SEAL, COVER

9.. 532 192603 .... 1 .... GASKET, COVER

10.. 539 110281 .... 1 .... SUPPORT, CHUTE

11.. 539 112294 .... 1 .... FLEX TRIM

12.. 539 108096 .... 2 .... HAIR PIN

13.. 539 990627 .... 2 .... HCS 5/16-18 x 1¼

14.. 539 976952 .... 6 .... SCREW #10-24 x 5/8

15.. 539 112899 .... 2 .... NUT 5/16-18 HEX FLG NYLOC

16.. 539 976977 .... 6 .... NUT #10-24 CROWNLOCK

17.. 539 990188 .... 4 .... WASHER 5/16 SAE

NOTE: ALL FASTENERS ARE GRADE 5 UNLESS OTHERWISE SPECIFIED.

17

Page 18

REPAIR PARTS

MOUNT, GUARD, BELT

10

2

1

23

18

22

3

9

14

4

27

12

25

25

21

22

25

19

11

7

24

17

6

15

20

8

28

16

13

18

5

26

17

Page 19

REPAIR PARTS

ITEM PART NO. QTY. DESCRIPTION ITEM PART NO. QTY. DESCRIPTION

1.. 539 130307 .... 1 .... SHIELD, BELT, 52"

539 130308 ...1 .... SHIELD, BELT, 61"

2.. 539 130320 .... 1 .... PULLEY, 52"

539 130321 ...1 .... PULLEY, 61"

3.. 539 130347 .... 1 .... BELT 52"

539 130348 ...1 .... BELT 61"

4.. 584 812002 .... 1 .... FOOT REST

5.. 539 132192 .... 1 .... MOUNT, HITCH

6.. 576 221402 .... 1 .... BRACKET, SUPPORT

7.. 539 132198 ... 1 ... STRAP, RT BLK

8.. 575 953302 .... 1 ... STRAP, LT BLK

9.. 539 113232 .... 6 .... PLATE, WEIGHT

10.. 522 989002 .... 2 .... BRACKET, WEIGHT

11.. 539 131091 ... 1 ... TUBE, MOUNT

12.. 539 105743 .... 1 .... DECAL, NO STEP

13.. 532 428676 .... 1 .... DECAL, CROWN

14.. 539 121322 .... 2 .... ABRASIVE PAD

15.. 576 221502 .... 1 .... SPACER

16.. 539 990645 .... 2 .... RHSNB 3/8-16 x 1

17.. 539 990861 .... 4 .... RHSNB 5/16-18 x 1¾

18.. 539 101341 .... 4 .... HCS 3/8-16 x 3

19.. 539 102334 .... 4 .... HCS 3/8-16 x 4½

20.. 539 990646 .... 1 .... HCS ½-13 x 1

21.. 539 976937 ... 2 ... HCS 5/16-18 x 2

22.. 539 990122 ... 8 ... WASHER 3/8 SAE FLT

23.. 539 990118 ... 4 ... WASHER 3/8 LK

24.. 525 464701 ... 3 ... HHFS 5/16-18 x ¾

25.. 539 112899 .... 9 .... NUT 5/16-18 HEX FLG NYLOC

26.. 539 101331 .... 1 .... NUT ½-13 HEX NYLOC

27.. 521 966501 .... 8 .... NUT 3/8-16 HEX FLG NYLOC

28.. 539 976979 ... 2 .... NUT 3/8-16 HEX NYLOC

NOT SHOWN

539 110290 ...1 .... BLOCK, FOAM

NOTE: ALL FASTENERS ARE GRADE 5 UNLESS OTHERWISE SPECIFIED.

19

Page 20

115 584027 Rev A 2013-02-15

Loading...

Loading...