Page 1

GB Operator´s manual

FR Manuel d'utilisation

ES Manual de instrucciones

HEDGE TRIMMER ATTACHMENT

COMPLÉMENT TAILLE-HAIE

TIJERAS CORTASETOS (SUPLEMENTO)

Please read these instructions carefully

and make sure you understand them

before using the machine.

Lire attentivement et bien assimiler le

manuel d’utilisation avant d'utiliser la

machine.

Lea detenidamente el manual de

instrucciones y asegúrese de entender su

contenido antes de utilizar la máquina.

GB FR ES

Page 2

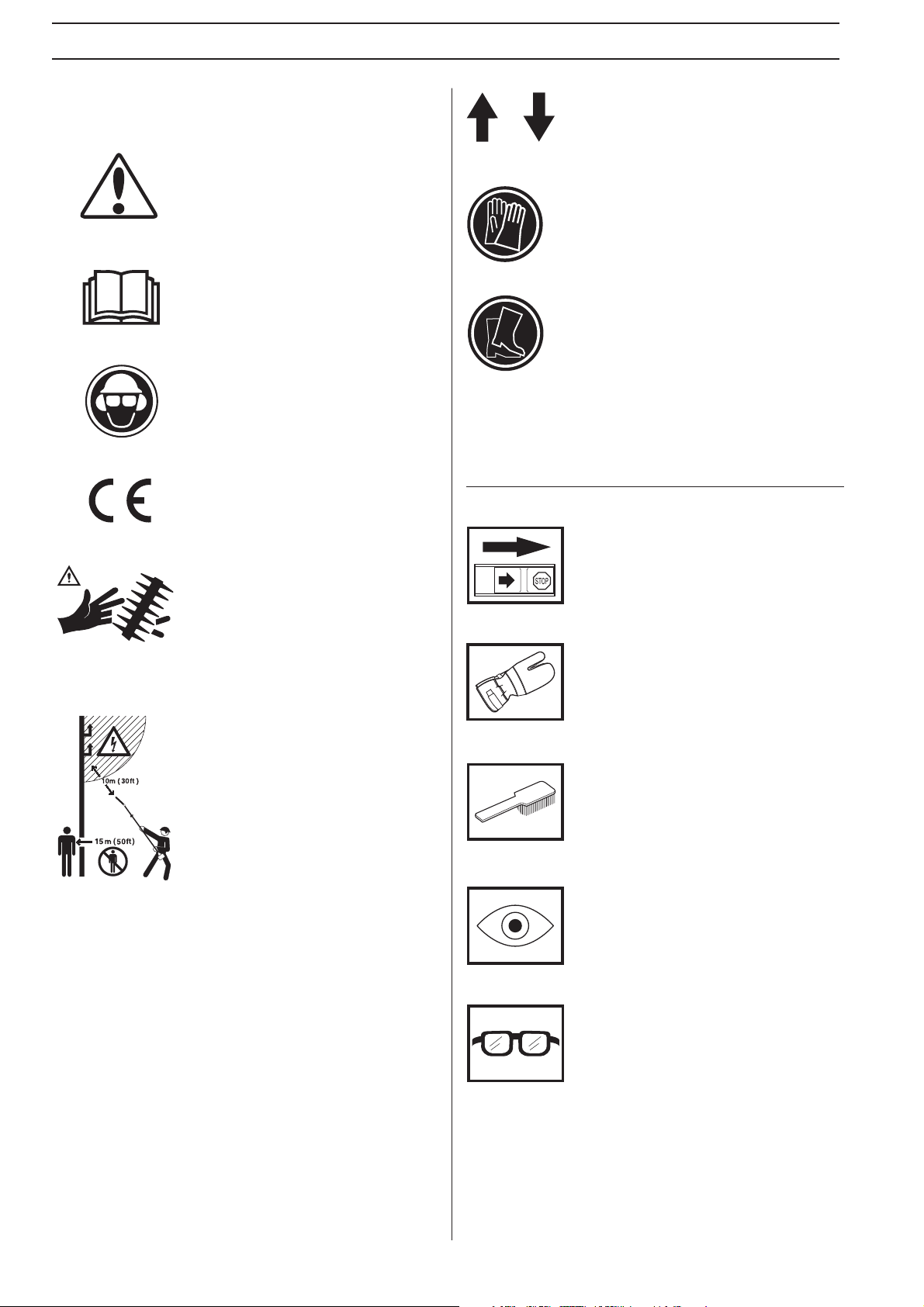

SYMBOL EXPLANATION

Symbols

WARNING! The hedge trimmer can

be dangerous!

Careless or incorrect use can result in

serious, even fatal injury.

Read through the Operator‘s Manual

carefully and understand the content

before using the hedge trimmer.

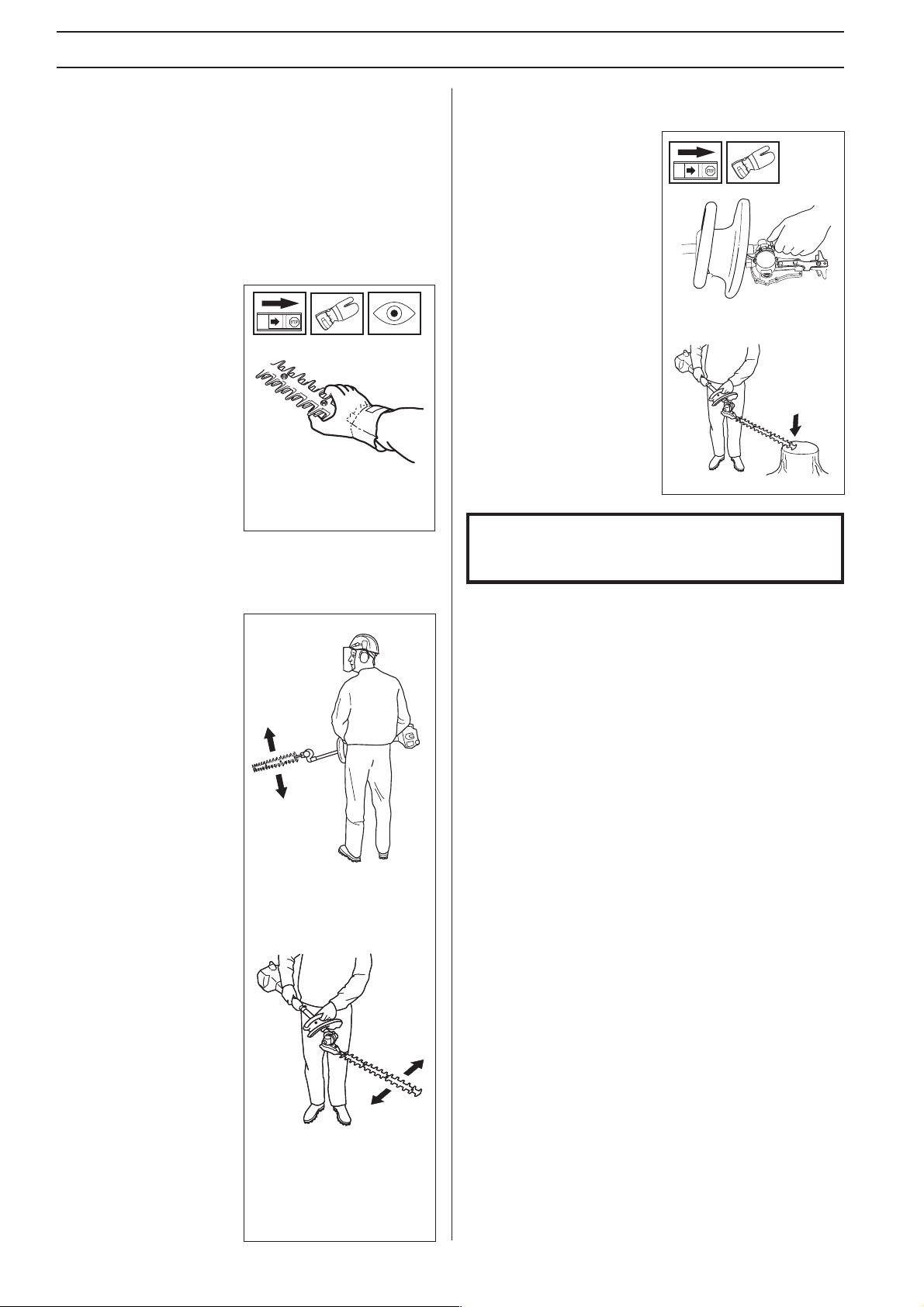

Always use

• Ear protection

• Approved eye protection

This product is in accordance with

applicable CE directives.

Cutting tool. Do not touch the tool

without first switching off the engine.

Arrows which show limits for handle

mounting.

Always wear approved protective gloves.

Use anti-slip and stable boots.

Other symbols/decals on the machine refer to

special certification requirements for certain

markets.

Checks and/or maintenance should be

carried out with the engine switched off,

with the stop switch in the STOP

position.

This machine is not electrically

insulated. If the machine touches or

comes close to high-voltage power lines

it could lead to death or serious injury.

Electricity can jump from one point to

another by arcing. The higher the

voltage, the greater the distance

electricity can jump. Electricity can also

travel through branches and other

objects, especially if they are wet.

Always keep a safe distance of at least

10 m (30 ft) between the machine and

high-voltage power lines and/or any

objects that are touching them. If you

need to work closer than this always

contact the relevant power company to

make sure the power is switched off

before you start work.

The machine can be dangerous. Make

sure that no people or animals come

closer than 15 m (45 ft) when the

machine is running.

Always use approved protective gloves.

Regular cleaning required.

Ocular control.

Approved eye protection must always be

used.

2 – English

Page 3

CONTENTS

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify the

design and appearance of products without prior notice.

Read through the Operator‘s manual carefully

and understand the content before using the

machine.

These instructions supplement the instructions that were

included with the machine. For other procedures, please

refer to the opertaing instructions for hte machine.

WARNING!

!

!

Under no circumstances may the design

of the machine be modified without the

permission of the manufacturer. Always

use genuine accessories. Non-authorised

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

WARNING!

This accessory may only be used

together with the intended clearing saw/

trimmer, see under heading ”Approved

accessories” in chapter Technical data in

the machine's Operator's Manual.

List of contents

SYMBOL EXPLANATION

Symbols .............................................................................. 2

CONTENTS

List of contents .................................................................... 3

SAFETY INSTRUCTIONS

The machine’s protective equipment .................................. 4

Control, maintenance and service of the hedge trimmer’s

protective equipment ..................................................... 4

Safety instructions when using the hedge trimmer ............. 5

WHAT IS WHAT?

What is what on the hedge trimmer attachment? ............... 7

ASSEMBLY

Fitting the hand guard and loop handle .............................. 8

Fitting the cutting attachment .............................................. 8

START AND STOP

Control before starting ........................................................ 8

MAINTENANCE

Carburetor ........................................................................... 9

Gearbox ............................................................................ 10

Lubrication ........................................................................ 10

Maintenance schedule ....................................................... 11

TECHNICAL DATA

Technical Data ................................................................... 11

The machine is only designed for cutting branches and twigs.

English – 3

Page 4

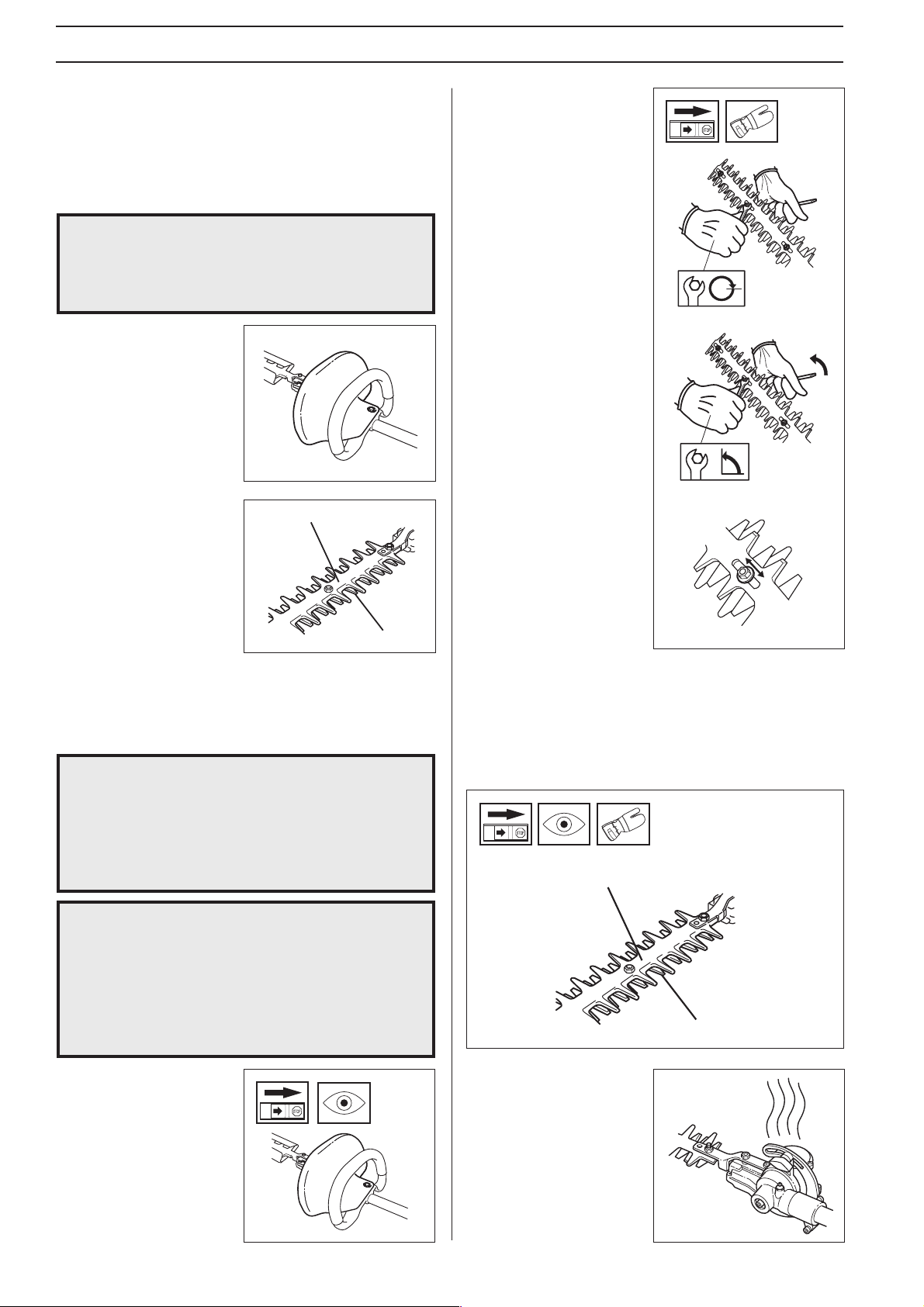

SAFETY INSTRUCTIONS

The machine’s protective equipment

This section describes the hedge trimmer’s protective equipment,

its function and how checks and maintenance are carried out to

ensure that it operates correctly. (See the chapter ”What is what”

to locate where this equipment is positioned on your machine.)

WARNING!

Never use a hedge trimmer with defective

!

1. Hand guard

The hand guard is intended

to protect the hand from

coming into contact with the

working blades. For example, if the user looses his grip

on the front handlebars.

2. Blade guard

The blade guard (A) is

intended to protect against

any part of the body coming

into contact with the blades

(B).

protective equipment. Follow the control,

maintenance and service instructions

described in this section.

A

B

2. Blades

To ensure good cutting results

it is important that the contact

pressure between the blades is

correct.

The contact pressure between

the blades is adjusted by

tightening the screws on the

underside of the bar as far as

they will go, then backing

them off 1/4 turn. Lock the

screws using the locking nuts

on the top face of the bar. The

washers should still slide freely

under the screw heads after the

screws have been tightened.

When the blades are correctly

adjusted the play between the

blades should be 0.2–0.4 mm,

measured at the screws.

The edges of the blade are too

hard to be filed. Dull blades

should be sharpened using a

grinder.

Replace the blades if they are

bent or damaged.

Control, maintenance and service of

the hedge trimmer’s protective

equipment

WARNING!

!

!

1. Hand guard

• Ensure that the blade

guard is fitted correctly.

• Make sure the hand guard

is not damaged in anyway.

Never use a machine with defective safety

equipment. The safety equipment should

be maintained as described in this section.

If your machine does not meet any of these

controls you should contact your service

workshop.

WARNING!

Always stop the engine before starting

work on any part of the cutting equipment.

This continues to rotate even after the

throttle has been released. Ensure that the

cutting equipment has stopped completely

and remove the cable from the spark plug

before you start to work on it.

3. Blade guard

• Check that the blade guard is not damaged or distorted.

• Replace the blade guard if it is bent or damaged.

A

B

4. Gearbox

• The gearbox gets hot

when the hedge trimmer

is in use. To avoid

burning yourself do not

touch the gearbox.

4 – English

Page 5

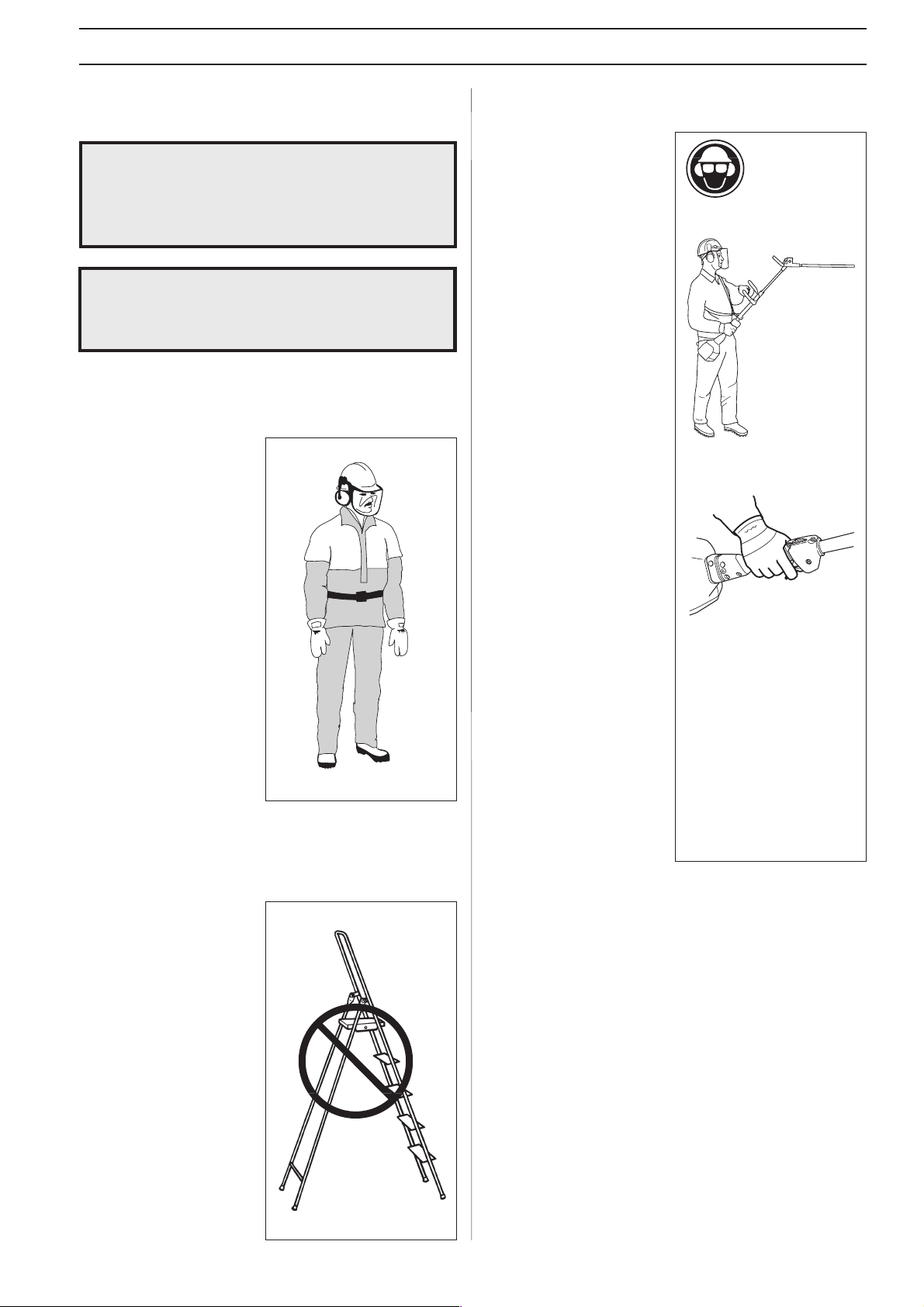

SAFETY INSTRUCTIONS

Safety instructions when

using the hedge trimmer

WARNING!

!

!

NOTE! Read the Operator’s Manual carefully before using

the hedge trimmer.

Personal protection

• Always wear boots, and the

other safety equipment

described in the section

”Personal protective

equipment” in the

machine's Operator's

Manual.

• Always wear working

clothes and thick, long

trousers.

• Never wear loose fitting

clothes or jewellery

The hedge trimmer can cause serious

personal injury. Read the safety

instructions carefully. Learn how to use the

machine.

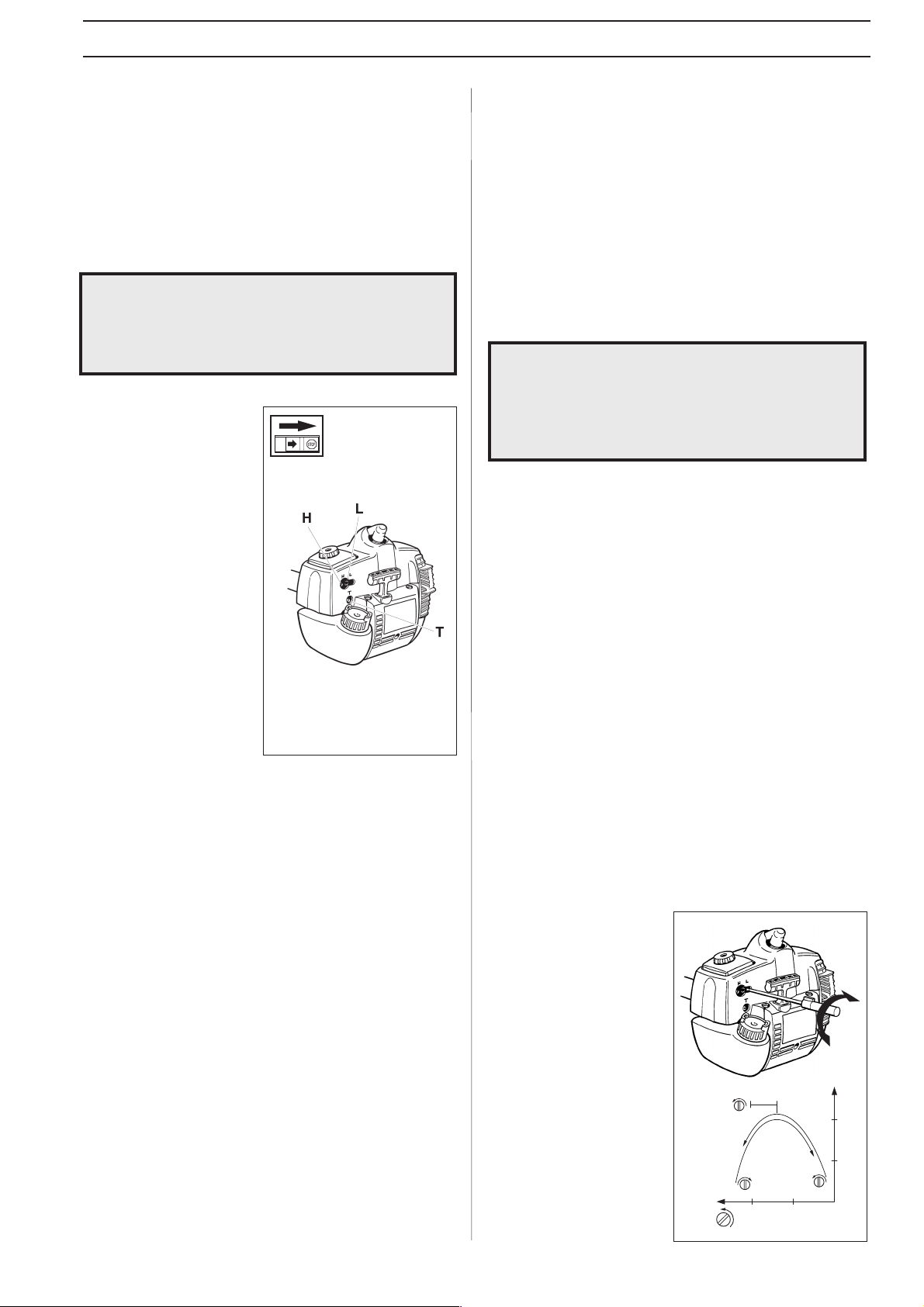

WARNING!

Cutting blades.

Do not touch the blades without first

switching off the engine.

Protective instructions while working

• Always ensure you have a

safe and firm working

position.

• Always use both hands to

hold the machine. Hold

the machine on the side

of the body.

• Use your right hand to

operate the throttle.

• Make sure that your

hands and feet cannot

come into contact with

the blades when the

engine is running.

• When the engine is

switched off, keep your

hands and feet away from

the blades until they have

stopped.

• Watch out for stumps of

branches that can be

thrown out during

cutting.

• Secure hair so it is above

shoulder level.

Protective instructions regarding the

surroundings

• Never allow children to use

the machine.

• Ensure no one comes

within 15 metres while

working.

• Never allow anyone to use

the machine without first

being absolutely sure that

they understand the

contents of the Operator’s

Manual.

• Never work on a ladder,

stool or any other raised

position that is not fully

secured.

• Always lay the hedge

trimmer on the ground

when you are not using

it.

• Do not cut too close to the ground. Stones and other

objects can be thrown.

• Check the hedge you intend to trim for foreign objects such

as electricity cables, insects and animals, etc, and for other

objects that could damage the cutting attachment, such as

metal items.

• If any object is hit or if vibrations occur stop the machine

immediately. Remove the spark plug cable from the spark

plug. Check that the machine is not damaged. Repair any

damage.

• If anything jams in the blades while you are working, switch

off the engine and wait until it has stopped completely

before cleaning the blades. Disconnect the HT lead from

the spark plug.

English – 5

Page 6

SAFETY INSTRUCTIONS

Protective instructions when

work is completed

• The transport guard should always be fitted to the blades

when the machine is not in use.

• Ensure the blades have stopped and remove the spark plug

cable from the spark plug before carrying out cleaning,

repairs or an inspection.

• Always wear heavy duty

gloves when repairing the

blades. The blades are

extremely sharp and can

easily causes cuts.

• Store the machine out of

reach from children.

• Only use original spare

parts when carrying out

repairs.

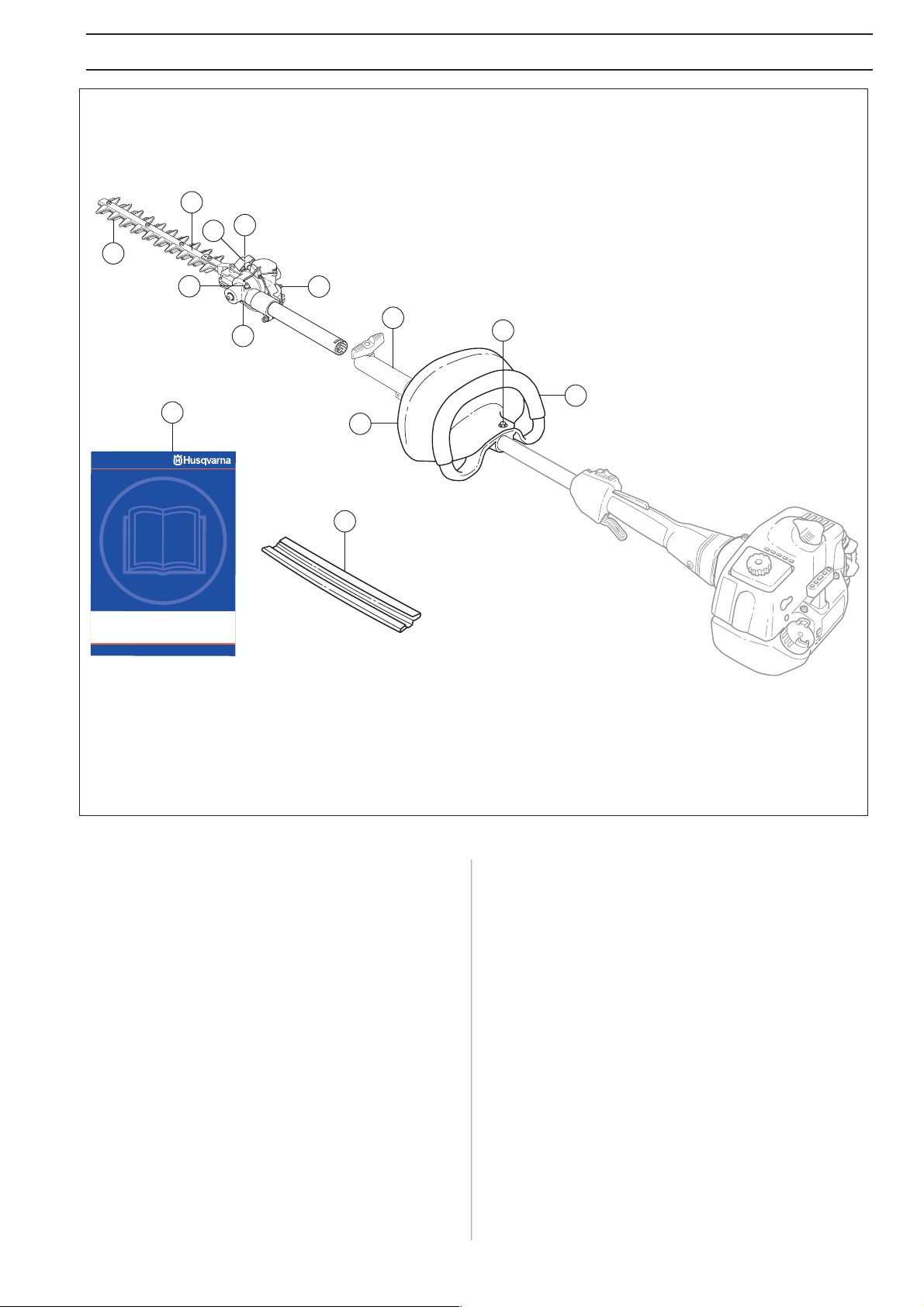

Basic working techniques

Changing the hedge trimmer angle

• Loosen the knob on the

angle adjuster.

• Press the cutting attachment against the ground

or some other solid

object to set the desired

angle.

• Tighten the knob.

NOTE! Do not hold the cutting attachment when

you adjust the angle. The blades are sharp and you

could easily cut yourself.

• Work with a swinging

action from the bottom

upwards when trimming

sides.

• Adapt the throttle

according to resistance.

• When trimming a hedge

the engine should always

be turned away from the

hedge.

• The hedge trimmer

should be held as close to

the body as possible to

get the best balance.

• Make sure that the tip

does not touch the

ground.

• Do not try to force the

work, but move at a

steady speed so that all

the stems are cut evenly.

6 – English

Page 7

WHAT IS WHAT?

4

2

7

1

2

3

9

2

11

6

5

8

10

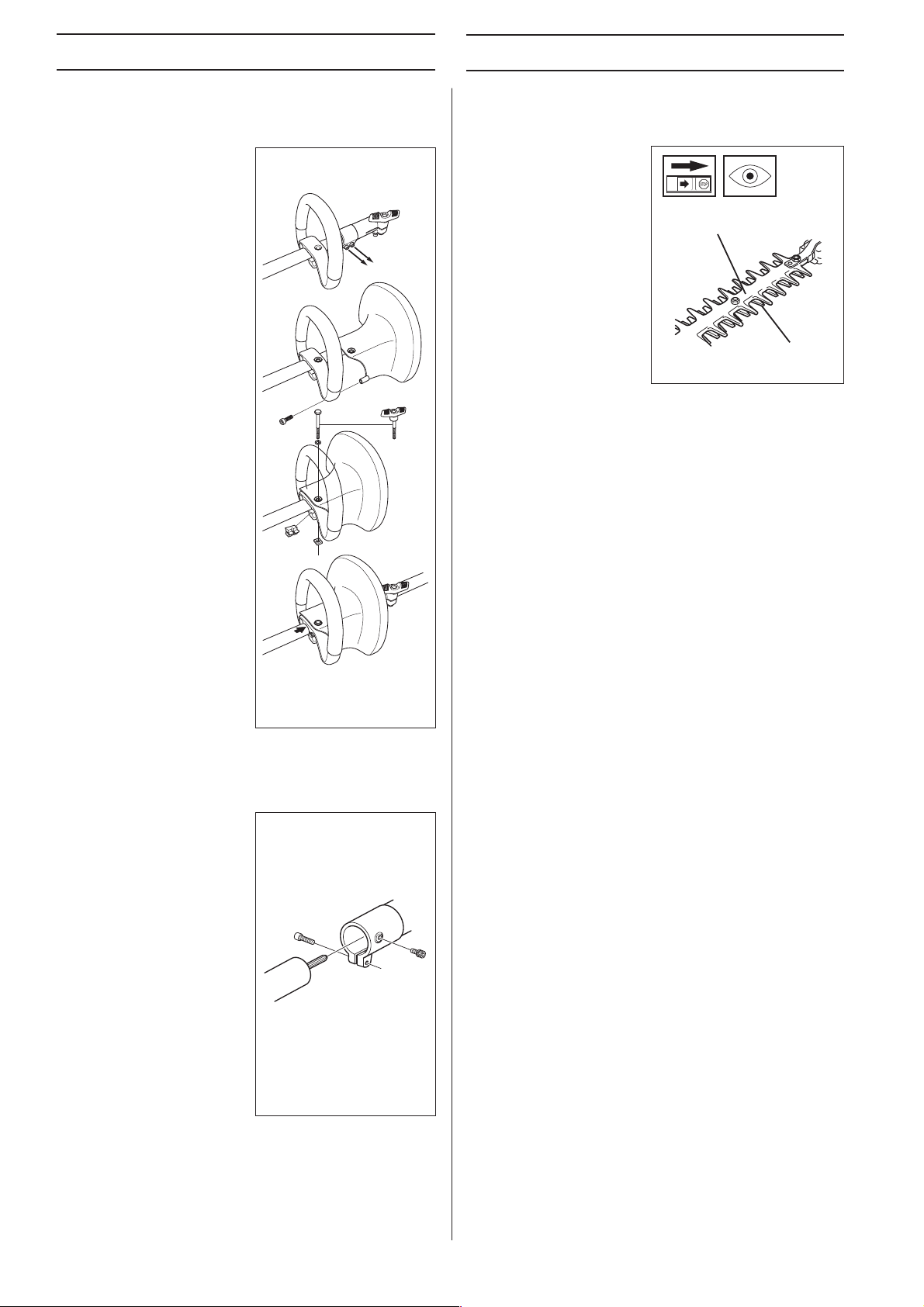

What is what on the hedge trimmer

attachment?

1. Blade

2. Grease nipple (3)

3. Gearbox

4. Blade guard

5. Front handle

6. Hand guard fastening screw

7. Angle adjuster knob

8. Hand guard

9. Operator’s manual

10. Transport guard

11. Shaft coupling

English – 7

Page 8

ASSEMBLY

START AND STOP

Fitting the hand guard and loop

handle

1. Loosen the clutch sleeve’s

two mounting bolts and

dismantle the clutch sleeve.

2. Assemble the hand guard

and loop handle by

screwing them together.

Take care to align the holes

in both parts.

3. Slide the loop handle and

the hand guard onto the

shaft.

4. Slide the spacer into the

slot in the loop handle.

5. Fit the nut and bolt. Do

not over-tighten.

6. Adjust to give a

comfortable working

position. Tighten the nut.

NOTE! The loop handle

and hand guard must not

be fitted behind the arrow

marked on the shaft.

7. Fit the clutch sleeve and

tighten the two mounting

bolts.

Control before starting

• Inspect the working area. Remove objects that can be

thrown.

• Check the blades. Never

use blades that are dull,

cracked or damaged.

• Check that the hedge

trimmer is in full

working order. Check

that all nuts and bolts are

tightened correctly.

• Check that the blade guard is not damaged or distorted.

• Replace the blade guard if it is bent or damaged.

• Make sure the gearbox is lubricated correctly. See the

section ”Lubricating the blades”.

• Ensure the blades always stop when the engine is idling.

• Only use the machine for what it is intended for.

• Ensure that the handle and safety functions are in order.

Never use a machine that lacks a part or has been modified

outside of the specifications.

A

B

Fitting the cutting attachment

Lay the hedge trimmer on a flat

surface before fitting the

cutting attachment. Otherwise

the cutting attachment may not

be fitted straight.

1. Fit the cutting attachment

to the shaft.

NOTE! Make sure the

drive shaft on the shaft is

aligned with the cut-out in

the cutting attachment.

2. Tighten the lower screw,

followed by the upper

screw.

8 – English

Page 9

MAINTENANCE

Carburettor

Your Husqvarna product has been designed and manufactured

to specifications that reduce harmful emissions.

After your unit has been run 8-10 tanks of fuel the engine has

broken in. To ensure that your unit is at peak performance and

producing the least amount of harmful emissions after break

in, have your authorized servicing dealer, who has a revolution

counter at his disposal, to adjust your carburettor for optimum

operating conditions.

WARNING!

!

Operation

• The carburettor governs

the engine’s speed via the

throttle. Air/fuel is mixed

in the carburettor. The

air/fuel mixture is

adjustable. To take

advantage of the engine’s

optimal output the

adjustment must be

correct.

• The setting of the

carburettor means that

the engine is adapted to

local conditions, for

example, the climate,

altitude, petrol and the

type of 2-stroke oil.

• The carburettor is equipped with three adjustment possibilities:

H = High speed needle

L = Low speed needle

T = Idle speed adjuster screw

• The fuel quantity in relation to the air flow permitted by

the throttle opening is adjusted using the L and H-needles.

Turning the needles clockwise gives a leaner fuel mixture

(less fuel) and turning them anti-clockwise gives a richer

fuel mixture (more fuel). A leaner mixture gives high revs

while a richer mixture give less revs.

• The T-screw regulates the position of the throttle while the

engine is idling. Turning the screw clockwise gives a higher

idling speed while turning it anti-clockwise gives a lower

idling speed.

The complete clutch cover and gear must

be fitted before the machine is started,

otherwise the clutch may come loose and

cause injury.

Basic setting

• The carburettor is set to its basic setting when test run at

the factory. The basic setting is richer than the optimal

setting and should be kept during the machine’s first

working hours. Thereafter the carburettor should be finely

adjusted. Fine adjustment should be carried out by a skilled

technician.

NOTE! If the cutting attachment rotates/moves while the

engine is idling the T-screw should be turned anti-clockwise

until the cutting attachment stops.

Recommended idling speed is 2 700 rpm.

Recommended max. speed: See “technical data”.

WARNING!

If the idling speed cannot be adjusted so

!

that the cutting attachment stops, contact

your service workshop. Do not use the

machine until it has been correctly

adjusted or repaired.

Fine adjustment

• When the machine has been ”run-in” the carburettor should

be finely adjusted. The fine adjustment should be carried

out by qualified person. First adjust the L-jet, then the

idling screw T and then the H-jet.

Conditions

• Before any adjustments are made the airfilter should be clean

and the airfilter cover fitted. Adjusting the carburettor while

a dirty airfilter is in use will result in a leaner mixture when

the filter is finally cleaned. This can give rise to serious

engine damage.

• Carefully turn the L and H needle to the mid point between

fully turned in and fully turned out.

• Do not attempt to adjust the needles beyond the stops as

damage can occur.

• Now start the machine according to the starting instructions

and run it warm for 10 minutes.

NOTE! If the cutting attachment rotates/moves the T screw

should be turned anti-clockwise until the cutting attachment

stops.

Low speed needle L

Try to find the highest idling

speed, turning the low speed

needle L clockwise respectively

counter-clockwise.

When the highest speed has

been found, turn the low

speed needle L 1/4 turn

counter-clockwise.

NOTE! If the blades move

when the engine is idling,

turn the idling speed screw

T counter-clockwise until

the blades stop.

+ 1/4

L

English – 9

Page 10

MAINTENANCE

Adjusting the idle speed, T

Adjust the idling speed with

the screw T, if it is necessary

to readjust. First turn the

idle speed adjusting screw T

clockwise until the cutting

attachment starts to rotate/

move.

Then turn, counter-clockwise until the cutting

attachment stops. A correctly

adjusted idle speed setting

occurs when the engine runs

smoothly in every position.

It should also be good

margin to the rpm when the

cutting attachment starts to

move.

CAUTION! Contact your servicing dealer, if the idle speed

setting cannot be adjusted so that the cutting attachment

stops. Do not use the machine until it has been properly

adjusted or repaired.

+ 1/4

L

Correctly adjusted carburettor

A correctly adjusted carburettor means that the machine

accelerates without hesitation and the machine 4-cycles a little

at max speed. Furthermore, the cutting attachment must not

rotate/move at idling. A too lean adjusted low speed needle L

may cause starting difficulties and bad acceleration.

A too lean adjusted high speed needle H gives lower power =

less capacity, bad acceleration and/or damage to the engine.

A too rich adjustment of the two speed needles L and H gives

acceleration problems or too low working speed.

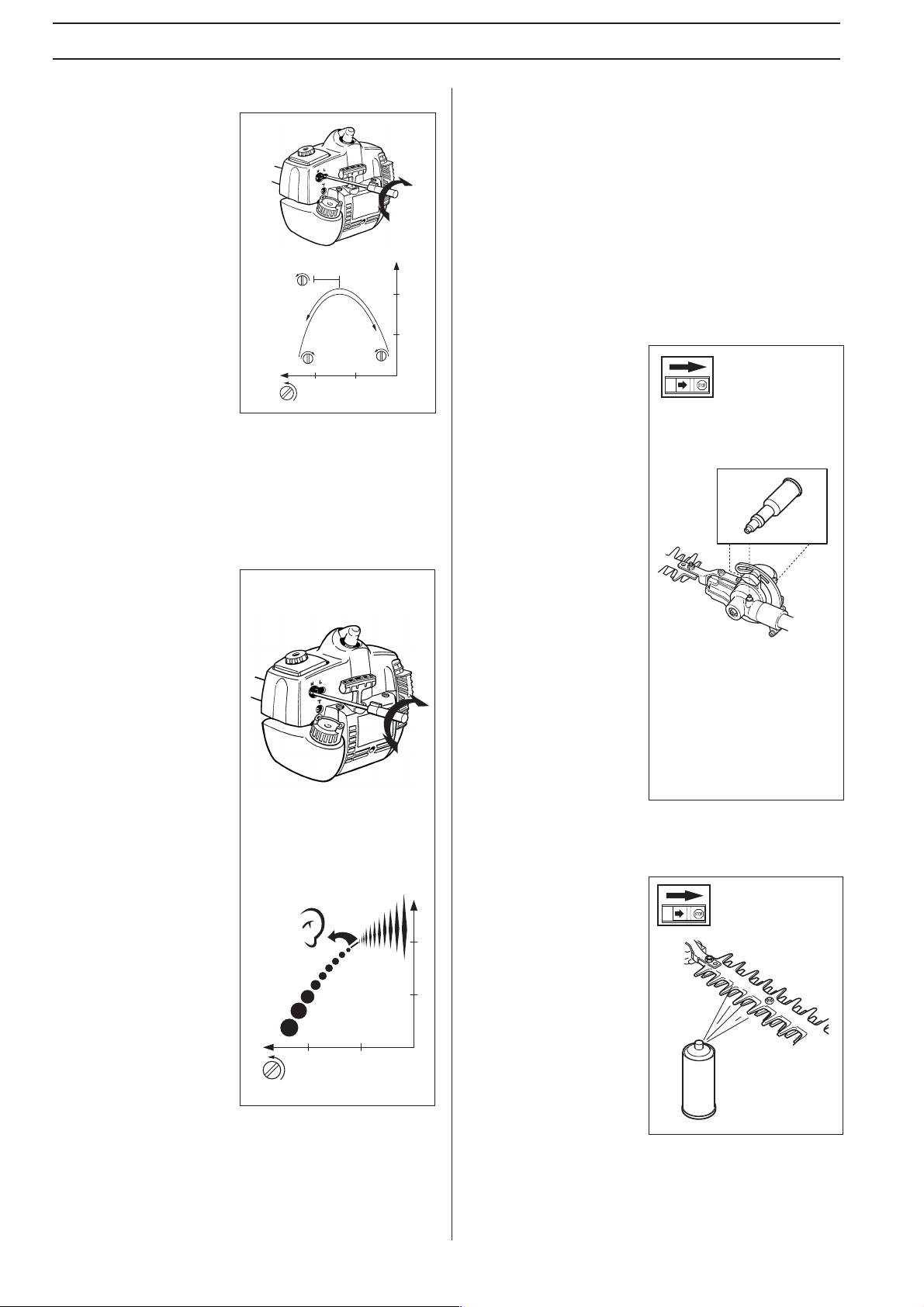

Gearbox

There are three grease

nipples (A) on the gearbox.

Use a grease gun to top up

with grease. This should be

carried out after approximately every 20 working

hours. Use Husqvarna special

grease, No. 503 98 96-01.

High speed needle H

The high speed needle affects

the machine’s power, speed,

temperature and fuel

consumption. A too lean

adjustment on the high

speed needle H (the high

speed needle H is screwed in

too much) gives a too high

speed resulting in engine

damage. Do not allow the

engine to run at full speed

for more than 10 seconds.

Apply full throttle and turn

the high speed needle H

slowly anticlockwise until

the engine runs unevenly.

The high speed needle H is

then turned slowly clockwise

a little until the engine runs

smoothly.

Note the engine should be

run unloaded when

adjusting the high speed

needle. Therefore dismantle

the cutting equipment, nut,

support flange and disc drive

before adjusting the high

speed needle. The high speed

needle is adjusted correctly

when the machine ‘splatters’ a little . If the machine smokes

heavily at the same time as it ‘splatters’ heavily the adjustment

is too rich.

H

Note that the gearbox must

not be filled completely

with grease. The grease

expands as the machine

heats up during operation.

If the gearbox was completely filled with grease it

could damage the seals and

lead to leakage.

The lubricant in the gearbox

does not normally need to be

replaced other than with

repair.

Cleaning and

lubrication

After you have used the

machine clean any resin and

plant residue from the blades

using cleaning agent 531 00

60-75 (UL22).

Always lubricate the blade

runners with special grease

531 00 60-74 (UL 21)

before use.

NOTE! For optimum setting of the carburettor, contact a

qualified servicing dealer who has a revolution counter at his

disposal.

10 – English

Page 11

MAINTENANCE

TECHNICAL DATA

Maintenance schedule

Below follows some general maintenance instructions.

If you need further information please contact your service

workshop.

Daily maintenance

1

B

1. Check that the blades do

not rotate while idling or

when the choke is in the

start position.

2. Check that the hand

guard is not damaged.

Replace the guard if

damaged.

A

2

Technical data

Weight

Weight without fuel, Lbs/kg

Blades

Length, mm

Blade speed, Cut/min

2,0

550

4184

Weekly

maintenance

1. Fill the gearbox with

grease. This should be

carried out after approximately every 20 working

hours.

2. Check that the bolts

keeping the blades

together are tightened.

1

2

English – 11

Page 12

EXPLICATIONS DES SYMBOLES

Symboles

AVERTISSEMENT! Tronçonneuses,

débroussailleuses et coupe-herbes

peuvent s’avérer dangereux!

Une utilisation imprudente ou

inadéquate peut résulter en des

blessures graves, et même mortelles.

Lire attentivement le mode d’emploi et

assimiler son contenu avant d’utiliser la

machine.

Toujours porter:

• protège-oreilles

• des lunettes de protection

homologuées

Ce produit est conforme à la directive

CE en vigueur.

Outil coupant. Ne jamais toucher

l'outil sans avoir préalablement arrêté le

moteur.

Flèches indicatrices indiquant les limites pour

l’emplacement de la fixation de la poignée.

Utiliser toujours des gants de protection

homologués.

Utiliser des bottes stables et antidérapantes.

Les autres symboles/autocollants présents sur la

machine concernent des exigences de certification

spécifiques à certains marchés.

Contrôles et/ou entretiens sont effectués

avec le moteur arrêté et le contacteur

d’Arrêt en position STOP.

Cette machine ne comporte pas

d'isolation électrique. Si elle entre en

contact avec ou est utilisée à proximité

de lignes conductrices de tension, ceci

peut résulter en des blessures

corporelles graves voire mortelles.

L'électricité peut être transmise d'un

point à un autre par un arc de tension.

Plus la tension est élevée et plus la

longueur de transmission de la tension

est élevée. L'électricité peut également

être transmise par des branches et

d'autres objets, particulièrement s'ils

sont mouillés. Toujours conserver une

distance d'au moins 10 mètres (30

pieds) entre la machine et la ligne

conductrice d'électricité et/ou les objets

en contact avec cette ligne. S'il est

nécessaire que le travail soit effectué

avec des distances de sécurité plus

courtes, toujours contacter la

compagnie électrique afin de s'assurer

que la tension est bien coupée avant de

commencer les travaux.

La machine peut être dangereuse.

Vérifier qu'aucune personne et qu'un

animal ne se trouvent à moins de 15

mètres (45 pieds) quand la machine est

utilisée.

Utiliser toujours des gants de protection

homologués.

La machine demande un nettoyage

régulier.

Contrôle visuel.

Le port de lunettes de protection

homologuées est obligatoire.

12 – Française

Page 13

SOMMAIRE

Husqvarna AB travaille continuellement au développement de

ses produits et se réserve le droit d’en modifier, entre autres, la

conception et l’aspect.

Lire attentivement le manuel d’utlilisation et

assimiler son contenu avant d’utiliser la

machine.

Ces instructions son un complément au manuel qui

accompagne la machine. Pour les autres instructions, se

reporter au manuel d´utilisation de la machine.

AVERTISSEMENT!

!

!

En aucun cas, la conception d’origine de la

machine ne doit être modifiée sans

l’accord du fabricant. Toujours utiliser des

pièces de rechange d’origine. Des

modifications et/ou des pièces de

rechange non autorisées peuvent entraîner

des blessures graves, ou mortelles, pour

l’utilisateur, comme pour autrui.

AVERTISSEMENT!

Cet accessoire ne peut être utilisé que

pour les débroussailleuses/coupebordures auxquels il est expressément destiné.

Voir la section ”Accessoires

homologués” au chapitre

Caractéristiques techniques dans le

manuel d'utilisation de la machine.

Sommaire

EXPLICATIONS DES SYMBOLES

Symboles .......................................................................... 12

SOMMAIRE

Sommaire .......................................................................... 13

CONSIGNES DE SECURITE

Dispositifs de sécurité de la machine ................................ 14

Contrôle, entretien et maintenance des dispositifs de

sécurité de la machine ................................................ 14

Instructions de travail générales pour le taille-haie ........... 15

QUELS SONT LES COMPOSANTS?

Quels sont les éléments du kit taille-haie? ........................ 17

MONTAGE

Montage du protège-mains et de la poignée en boucle .... 18

Montage de l'unité de coupe ............................................. 18

MARCHE ET ARRET

Contrôles avant le démarrage ........................................... 18

ENTRETIEN

Carburateur ....................................................................... 19

Engrenage ........................................................................ 20

Nettoyage et lubrification .................................................. 20

Schéma d’entretien ........................................................... 21

CARACTERISTIQUES TECHNIQUES

Caracteristiques techniques .............................................. 21

Le taille-haie est uniquement destiné à la taille des buissons

et des branches.

Française – 13

Page 14

CONSIGNES DE SECURITE

Dispositifs de sécurité de la machine

Ce chapitre explique les dispositifs de sécurité de la machine,

leur fonction ainsi que les contrôles et entretiens à effectuer

pour s’assurer de leur bon fonctionnement. (Voir le chapitre

”Quels sont les composants” pour voir l’emplacement de ces

dispositifs sur la machine).

AVERTISSEMENT!

!

1. Protège-main

La protection de la main est

destinée à empêcher la main

d'entrer en contact avec les

couteaux en rotation. Par

exemple, si l'utilisateur lâche

la poignée avant.

2. Protège-lame

Le protège-lame (A) est

destiné à empêcher tout

contact entre le corps de

l'utilisateur et les lames (B).

Ne jamais utiliser une machine dont les

dispositifs de sécurité sont hors fonction.

Suivre les instructions de contrôle, d’entretien

et de service listées dans ce chapitre.

A

2. Lames

Pour obtenir un bon résultat de

coupe, il est important que la

pression de contact entre les

lames soit correcte. Le réglage

de la pression de contact

s’effectue en serrant à fond dans

le sens horaire les vis sur la

partie inférieure de la poutrelle

de lame. Dévisser ensuite la vis

d’1/4 de tour dans le sens

antihoraire. Bloquer la vis à

l’aide du contre-écrou sur la

partie supérieure de la poutrelle

de lame. Contrôler que le

serrage de la vis est tel qu’il est

possible de déplacer

latéralement la rondelle située

sous la tête de la vis.

Lorsque les lames sont réglées

correctement, un jeu de 0,2-0,4

mm entre les lames doit

pouvoir être mesuré au niveau

des vis.

Les dents de la lame sont trop dures pour pouvoir être limées.

Utiliser un appareil à aiguiser pour affûter les lames.

B

Contrôle, entretien et maintenance des

dispositifs de sécurité de la machine

AVERTISSEMENT!

!

!

1. Protège-main

• S’assurer que le protègemain est correctement

monté.

• S’assurer que le protègemain n’est pas abîmé.

Ne jamais utiliser une machine avec des

dispositifs de sécurité défectueux. Il faut

contrôler et entretenir les dispositifs de

sécurité en fonction des indications de ce

chapitre. Si la machine ne satisfait pas à l’un

des contrôles, contacter un atelier de service.

AVERTISSEMENT!

Toujours arrêter le moteur avant d’entamer

des travaux sur l’équipement de coupe.

Celui-ci continue à tourner après avoir

relâché l’accélérateur. S’assurer que

l’équipement de coupe est entièrement

immobilisé et retirer le câble de la bougie

d’allumage avant d’effectuer des travaux

sur l’équipement de coupe.

Remplacer les lames si elles sont courbées ou endommagées.

3. Protège-lame

• Contrôler la protège-lame afin de détecter d’eventuels

dommages ou fissurations.

• Toujours remplacer une protège-lame endommagé.

A

B

4. Engrenage

• Après l'utilisation du taillehaie l'engrenage est chaud.

Ne pas toucher l'engrenage

afin d'éviter les brûlures.

14 – Française

Page 15

CONSIGNES DE SECURITE

Instructions de travail générales

pour le taille-haie

AVERTISSEMENT!

Le taille-haie peut provoquer des blessures

!

!

NOTER! Lire attentivement le manuel d’utilisation avant

d’utiliser le taille-haie.

Protection personnelle

• Toujours porter des bottes

et l’équipement décrit dans

Ӄquipement de protection

personnelle” dans le manuel

d'utilisation de la machine.

corporelles graves. Lire attentivement les

consignes de sécurité et apprendre à bien

utiliser la machine.

AVERTISSEMENT!

Couteaux en rotation. Ne pas toucher les

couteaux avant d'avoir arrêté le moteur.

Consignes de sécurité pendant le travail

• Veillez à toujours adopter

une position de travail

sûre et stable.

• Tenez toujours la

machine à deux mains.

Portez la machine sur

votre côté droit.

• Utilisez votre main droite

pour manœuvrer

l'accélération.

• Gardez vos mains et vos

pieds à l’écart des lames

lorsque le moteur est en

marche.

• Après l’arrêt du moteur,

maintenez vos mains et

vos pieds éloignés des

lames, jusqu’à l’arrêt

complet de celles-ci.

• Portez toujours des

vêtements de travail et des

pantalons robustes.

• Ne portez jamais de

vêtements larges ou des

bijoux.

• Il est recommandé aux

personnes aux cheveux

longs de les attacher, pour

leur sécurité personnelle.

Mesures de sécurité pour l’environnement

• Ne permettez jamais aux

enfants d’utiliser la

machine.

• Ne permettez à personne de

s’approcher à moins de 15

m lors du travail.

• Ne permettez pas à autrui

d’utiliser la machine sans

vous assurer qu’ils

connaissent parfaitement le

contenu du manuel

d’instructions.

• Attention aux branchettes

pouvant être projetées lors

du travail avec la machine.

• Posez toujours le taille-haie

sur le sol lorsqu'il n'est

pas utilisé. pas utilisé.

• Ne pas utiliser le taille-haie trop près du sol. Des pierres ou

tout autre object sont susceptibles d’être projetés.

• Inspecter la zone à couper pour détecter les corps étrangers

tels que conduites électriques, insectes, animaux, etc. ou les

objets pouvant endommager l'unité de coupe tels que les

objets métalliques.

• Si la machine bûte sur un objet ou si des vibrations se

produisent, arrêter immédiatement le taille-haie. Retirer le

câble de la bougie et vérifier que la machine n’a subi aucun

dommage. Réparer tout éventuel dommage.

• Si un objet se bloque dans les lames durant le travail, arrêter

le moteur et attendre l'arrêt total du moteur avant de

nettoyer les lames. Débrancher le câble d’allumage de la

bougie.

• Ne jamais travailler debout

sur une échelle, un

tabouret, ou dans toute

autre position élevée

n’offrant pas une sécurité

maximale.

Française – 15

Page 16

CONSIGNES DE SECURITE

Consignes de sécurité après le travail

• La gaine de protection des lames destinée au transport doit

toujours être mise lorsque la machine n’est pas utilisée.

• Avant de procéder aux nettoyages, réparations ou

inspections, assurez-vous de l’arrêt complet des lames.

Débranchez le câble d’allumage de la bougie.

• Toujours utiliser des gants

de protection pour réparer

les lames. Les lames sont

très tranchantes et

peuvent facilement

provoquer des blessures.

• Rangez la machine hors

de portée des enfants.

• Lors des réparations,

n’utilisez que des pièces

de rechange d’origine.

Modification de l'angle du taille-haie

• Desserrer la manette du

limiteur d'angle.

• Appuyer l'unité de coupe sur

le sol ou sur tout autre base

stable pour régler l'angle

souhaité.

• Resserrer la manette.

Techniques de travail de base

• Travailler en effectuant

des mouvements de

balancier de bas en haut

lors de la taille des côtés.

• Régler l’accélération en

fonction de la charge.

• Lors de la taille d’une

haie, le moteur doit

toujours être maintenu

éloigné de la haie.

• Le taille-haie doit être

maintenu aussi près du

corps que possible pour

assurer un bon équilibre.

• S’assurer que l’extrémité

du taille-haie ne touche

pas le sol.

NOTER ! Ne pas toucher l'unité de coupe lors du

réglage de l'angle. Les lames sont très tranchantes

et peuvent facilement causer des coupures.

• Ne pas de travailler trop

vite. Travailler à une

vitesse constante pour

obtenir une taille

régulière.

16 – Française

Page 17

QUELS SONT LES COMPOSANTS?

4

2

7

1

2

3

9

2

11

6

5

8

10

Quels sont les éléments du kit taille-haie?

1. Lame

2. Graisseurs (3 unités)

3. Engrenage angulaire

4. Protège-lame

5. Poignée avant

6. Vis de fixation du protège-mains

7. Manette du réglage de l'angle

8. Protège-mains

9. Manuel d'utilisation

10. Dispositif de protection de transport

11. Accouplement tige

Française – 17

Page 18

MONTAGE

MARCHE ET ARRET

Montage du protège-mains et de la

poignée en boucle

1. Desserrer les deux vis de

fixation de la douille de

raccordement et démonter

la douille.

2. Monter le protège-mains et

la poignée en boucle en les

vissant ensemble. Vérifier

soigneusement que les

trous des deux éléments

correspondent bien.

3. Enfiler la poignée en

boucle et le protège-mains

sur le tube de transmission.

4. Placer l'entretoise dans la

rainure de la poignée en

boucle.

5. Monter l'écrou et la vis.

Ne pas serrer trop fort.

6. Effectuer un réglage

d'appoint pour obtenir une

position de travail confortable. Serrer la vis.

NOTER ! La poignée en

boucle et le protège-mains

ne doivent pas être montés

après la flèche située sur le

tube de transmission.

Contrôles avant le démarrage

• Inspecter la zone de travail. Retirer tout object susceptible

d’être projeté.

• Vérifier les lames. Ne

jamais utiliser des lames

émoussées, craquelées ou

abîmées.

• Vérifier que le taille-haie

est en parfait état

d’utilisation. Contrôler

que tous les écrous et

boulons sont

correctement serrés.

• Contrôler la protège-lame afin de détecter d’eventuels

dommages ou fissurations.

• Toujours remplacer une protège-lame endommagé.

• Contrôler que l’engrenage est correctement lubrifié. Voir le

chapitre “Lubrification des lames“.

• S’assurer que les lames s’arrêtent quand le moteur s’arrête.

• N’utiliser le taille-haie que pour l’usage auquel il est destiné.

• Contrôler que la poignée et les dispositifs de sécurité sont en

bon état de fonctionnement. Ne jamais utiliser une machine

à laquelle il manque des pièces, ou une machine qui a été

modifiée à l’encontre de ses spécifications.

A

B

7. Monter la douille de

raccordement et serrer les

deux vis de fixation.

Montage de l'unité de coupe

Lors du montage de l'unité de

coupe, il est important que le

taille-haie soit posé sur une

surface plane. Autrement,

l'unité de coupe risque d'être

montée de travers.

1. Monter l'unité de coupe

sur le tube de transmission.

NOTER ! Veiller à ce que

l'arbre d'entraînement sur

le tube de transmission se

place correctement dans la

rainure de l'unité de

coupe.

2. Serrer la vis inférieure en

premier, puis la vis

supérieure.

18 – Française

Page 19

ENTRETIEN

Carburateur

Les caractéristiques techniques de cette machine Husqvarna

assurent des émissions de gaz nocifs réduites au minimum.

Après 8-10 pleins, le moteur est "rodé". Pour s'assurer qu'il

fonctionne correctement en libérant peu de gaz d'échappement

après la période de rodage, il convient de demander au

revendeur/atelier de service disposant d'un compte-tours

d'effectuer un réglage fin du carburateur.

AVERTISSEMENT!

Il est indispensable de monter le carter

!

Fonctionnement

• Par l’intermédiaire de

l’accélérateur, le

carburateur commande le

régime du moteur. Dans

le carburateur, l’air se

mélange au carburant. Ce

mélange est réglable. Pour

atteindre la puissance

maximale de la machine,

ce mélange doit être

correctement réglé.

• Le réglage du carburateur

implique que celui-ci est

adapté aux conditions

locales, notamment le

climat et l’altitude, mais

aussi à l’essence et au type

d’huile 2-temps.

• Le carburateur est muni

de trois éléments de

réglage:

L = Pointeau bas-régime

H = Pointeau haut-régime

T = Pointeau de ralenti

• Les pointeaux L et H permettent de régler la quantité de

carburant en fonction du flux d’air autorisé par l’ouverture

de l’accélérateur. En les tournant dans le sens des aiguilles

d'une montre, le mélange air/carburant s'appauvrit (moins

de carburant). En les tournant dans le sens contraire des

aiguilles, le mélange s'enrichit (davantage de carburant). Un

mélange pauvre permet un régime moteur plus haut tandis

qu'un mélange riche donne un régime plus bas.

• Le pointeau de ralenti T permet de régler la position de

l’accélérateur au régime de ralenti. En tournant le pointeau

T dans le sens des aiguilles d'une montre, le régime de

ralenti augmente. En le tournant dans le sens contraire des

aiguilles, le régime de ralenti diminue.

d’embrayage complet avec la transmission avant de démarrer la machine. Sinon,

l’embrayage risque de lâcher et de

provoquer des blessures physiques.

Réglage de base

• Le carburateur est réglé en usine lors des essais de

fonctionnement. Le mélange de base est plus gras que le

mélange optimal et doit être maintenu pendant les premières

heures de service de la machine. Ensuite, il faut effectuer un

réglage fin du carburateur. Le réglage fin doit être effectué

par un personnel compétent.

IMPORTANT!

Si la lame tourne au ralenti, tourner le pointeau de ralenti T

dans le sens contraire des aiguilles jusqu’à l’arrêt de la lame.

Régime de ralenti recommandé: 2 700 tpm.

Régime de ralenti recommandé: voir ”Caractéristiques

techniques”.

AVERTISSEMENT!

S’il est impossible de régler le régime de

!

ralenti pour immobiliser la lame,

contacter le service clientèle. Ne pas

utiliser la machine tant qu’elle n’est pas

correctement réglée ou réparée.

Réglage fin

• Lorsque la machine est "rodée", un réglage fin du

carburateur est nécessaire. Le réglage fin doit être réalisé par

une personne qualifiée. Régler d'abord le pointeau bas-

régime L, puis le pointeau de ralenti T et enfin le pointeau

Conditions

• Pour tous les réglages, le filtre à air doit être propre et son

couvercle posé. Si le carburateur est réglé avec un filtre à air

sale, un mélange de carburant trop pauvre sera obtenu au

prochain nettoyage du filtre. Il en résulterait la détérioration

du moteur.

• Visser prudemment les pointeaux L et H jusqu'à mi-chemin

du serrage à fond.

• Ne pas essayer de dépasser la position d'arrêt pour régler

les pointeaux, une telle tentative pouvant endommager la

machine.

• Mettre la machine en marche en suivant les instructions de

démarrage. La chauffer pendant 10 minutes.

IMPORTANT! Si l'équipement de coupe tourne, tourner le

pointeau de ralenti T dans le sens inverse des aiguilles

jusqu'à l'arrêt de l'équipement de coupe.

Pointeau bas-régime L

Chercher le régime de

ralenti maximum en

tournant le pointeau L.

Arrivé au régime maximum,

tourner le pointeau L d'un

quart de tour dans le sens

inverse des aiguilles.

IMPORTANT! Si les lames

tournent au ralenti, tourner

le pointeau de ralenti T dans

le sens inverse des aiguilles

jusqu’à l’arrêt des lames.

+ 1/4

L

Française – 19

Page 20

Réglage du pointeau de ralenti T

Régler le régime de ralenti

avec le pointeau de ralenti T

si un ajustage est nécessaire.

Tourner d'abord le pointeau

de ralenti T dans le sens des

aiguilles jusqu'à ce que

l'équipement de coupe

commence à tourner.

Tourner ensuite le pointeau

dans le sens inverse jusqu'à

l'arrêt de l'équipement de

coupe. Un régime de ralenti

correctement réglé permet au

moteur de tourner

régulièrement dans toutes les

positions, en offrant une

marge avant la mise en

rotation de l'équipement de

coupe.

AVERTISSEMENT! S’il est impossible de régler le régime de

ralenti pour immobiliser l'équipement de coupe, contacter le

revendeur/atelier de service. Ne pas utiliser la machine tant

qu’elle n’est pas correctement réglée ou réparée.

L

+ 1/4

Pointeau haut-régime H

Carburateur correctement réglé

Un réglage correct du carburateur se traduit par une accéléra-

tion franche de la machine avec 4-temps au régime maximal.

Ne pas laisser l'équipement de coupe tourner au ralenti. Un

réglage du carburant trop pauvre avec le pointeau bas-régime L

peut causer des démarrages difficiles et une mauvaise accélération.

Un réglage du carburant trop pauvre avec le pointeau hautrégime H se traduit par une perte de puissance = capacité

réduite, mauvaise accélération et/ou détérioration du moteur.

Un réglage trop riche du carburant avec les pointeaux L et H se

traduit par des problèmes d'accélération ou un régime de

travail trop faible.

Engrenage

Le carter d'engrenage

comporte trois graisseurs (A).

Utiliser un pistolet graisseur

pour remplir de lubrifiant.

Cette mesure doit être

effectuée toutes les 20 heures

de travail environ. Utiliser le

lubrifiant spécial Husqvarna

No 503 98 96-01.

Le pointeau haut-régime H

agit sur la puissance, le

régime, la température du

moteur et sur la

consommation en carburant.

Un pointeau haut-régime H

trop vissé (carburant trop

pauvre) entraîne un régime

trop élevé et endommage le

moteur. Ne pas laisser le

moteur tourner à plein régime

plus de 10 secondes. Tourner

le pointeau haut-régime très

lentement dans le sens des

aiguilles d’une montre

jusqu’au ralentissement du

moteur. Tourner ensuite le

pointeau haut-régime très

lentement dans le sens inverse

jusqu’à ce que le moteur

tourne de manière irrégulière.

Tourner ensuite légèrement le pointeau H dans le sens des aiguilles

d’une montre jusqu’à ce que le moteur tourne de manière

régulière.Le moteur ne doit pas être chargé lors du réglage du

pointeau haut-régime. Démonter l’équipement de coupe, l’écrou,

la bride de support et le toc d’entraînement avant d’effectuer le

réglage du pointeau haut-régime. Le pointeau haut-régime H est

correctement réglé quand le moteur démarre à quatre temps. Si le

moteur s’emballe, le mélange de carburant est trop pauvre. Si le

moteur tousse fortement et tourne à quatre temps, le mélange est

trop riche.

IMPORTANT! Pour obtenir un réglage optimal du carburateur, il

convient de faire appel à un revendeur qualifié/atelier de service

disposant d'un compte-tours.

H

Noter que l’engr enage ne

doit pas être entièr ement

rempli de lubrifiant. Le

lubrifiant se dilate sous l’effet

de la chaleur qui se dégage

lors du fonctionnement de la

machine. Si l’engr enage est

entièrement r empli de

lubrifiant, les joints

d’étanchéité risquent d’être

endommagés, entraînant des

fuites de lubrifiant.

Utiliser le lubrifiant

spécial Husqvarna No

503 98 96-01.

Nettoyage et graissage

Après chaque utilisation,

nettoyer les lames avec

l’agent de nettoyage 531 00

60-75 (UL22) pour

éliminer la résine et la sève

des plantes.

Lubrifier les poutrelles de

lames avec du lubrifiant

spécial, 531 00 60-74 (UL

21) à chaque utilisation de

la machine.

20 – Française

Page 21

ENTRETIEN

CARACTERISTIQUES TECHNIQUES

Schéma d’entretien

Ci-après, quelques instructions générales d’entretien.

Pour plus d’informations, contacter l’atelier de service.

Contrôles

quotidiens

1. Contrôler que les lames

ne bougent pas au ralenti

ou lorsque le starter est

sur la position de

démarrage.

2. Vérifier que le protègemain et le protège-lame

ne sont pas abîmés.

Remplacer si nécessaire.

Contrôles

hebdomadaires

A

B

2

Caractéristiques

techniques

Poids

Poids, sans carburant, kg

Lames

1

Longueur, mm

Vitesse de la lame, taille/min

1

2,0

550

4184

1. Remplir l’engrenage

d’huile. Ceci devra être

effectué environ toutes

les 20 heures

d’utilisation.

2. Vérifier que les boulons

assemblant les lames sont

bien serrés.

2

Française – 21

Page 22

SIGNIFICADO DE LOS SÍMBOLOS

Símbolos

ATENCIÓN: ¡Las desbrozadoras, quita

arbustos y recortadoras pueden ser

peligrosas!.

El uso indebido o poco cuidadoso

puede resultar en trágicas

consecuencias, incluso con heridas de

peligro mortal.

Antes de utilizar la máquina lea

atentamente las Instrucciones de Uso

asegurándose de entender el contenido.

Utilice siempre:

• Protección auditiva

• Protección ocular homologada

Este producto cumple con la directiva

CE vigente.

Herramienta de corte. Antes de tocar la

herramienta, apague siempre el motor.

Marcas de flechas que indican los límites para

colocar la sujeción del mango.

Utilice siempre guantes protectores

homologados.

Utilice siempre guantes protectores

homologados.

Los demás símbolos/pegatinas que aparecen en la

máquina corresponden a requisitos de

homologación específicos en determinados

mercados.

Cualquier tipo de control o medida de

mantenimiento a realizar debe efectuarse

con el motor parado, con el mando de

parada en la posición STOP.

Esta máquina no tiene aislamiento

eléctrico. Si entra en contacto o está en

las proximidades de cables conductores

de tensión, puede provocar la muerte o

lesiones graves. La electricidad puede

ser transmitida de un punto a otro

formando un ìarco de tensión". A

mayor tensión, mayor es la distancia

que puede ser transmitida la

electricidad. Ésta también puede ser

transmitida a través de ramas y otros

objetos, especialmente si están mojados. Por eso, mantenga siempre como

mínimo una distancia de 10 m entre la

máquina y un cable conductor de

tensión, u objetos que estén en

contacto con el mismo. Si debe trabajar

con una distancia de seguridad más

corta, póngase en contacto con la

central eléctrica para cerciorarse de que

la tensión está desconectada antes de

empezar a trabajar.

La máquina puede ser peligrosa.

Cerciórese de que ninguna persona ni

animal se aproxime más de 15 m a la

máquina cuando la misma esté en

funcionamiento.

Utilice siempre guantes protectores

homologados.

Limpie la máquina regularmente.

Control visual.

Debe utilizarse protección ocular

homologada.

22 – Español

Page 23

CONTENIDO

Husqvarna AB trabaja constantemente para perfeccionar sus

productos y se reserva, por lo tanto, el derecho a introducir

modificaciones en la construcción y el diseño sin previo aviso.

Antes de utilizar la máquina lea bien el

manual de instrucciones hasta comprender su

contenido.

Estas instrucciones son complemento del manual que se

adjunta a la máquina. Para más información sobre el manejo,

consultar el manual de la máquina

ATENCIÓN: El diseño original de la

!

!

máquina no debe ser modificado por

ningún motivo sin autorización explícita

del fabricante. Utilice siempre accesorios

originales. Modificaciones y/o accesorios

no autorizados pueden ocasionar heridas

graves y hasta mortales al operario o

terceros.

ATENCIÓN: Este accesorio sólo puede ser

utilizado con las desbrozadoras/

recortadoras destinadas al mismo, vea

”Accesorios aprobados” en el capítulo

Datos técnicos del manual de

instrucciones de la máquina.

Indice

SIGNIFICADO DE LOS SÍMBOLOS

Símbolos ........................................................................... 22

CONTENIDO

Índice................................................................................. 23

INSTRUCCIONES DE SEGURIDAD

Equipo de seguridad de la máquina ................................. 24

Control, mantenimiento y servicio del equipo de

seguridad de la máquina ............................................. 24

Instrucciones de seguridad para el uso del cortasetos ..... 25

¿QUÉ ES QUÉ?

¿Qué es qué en el suplemento para cortar setos? ........... 27

MONTAJE

Montaje de la protección para la mano y el mango

cerrado ........................................................................ 28

Montaje del equipo de corte .............................................. 28

ARRANQUE Y DETENCIÓN

Control antes de arrancar ................................................. 28

MANTENIMIENTO

Carburador ........................................................................ 29

Caja de engranajes ........................................................... 30

Limpieza y lubricación ....................................................... 30

Plan de mantenimiento ..................................................... 31

DATOS TÉCNICOS

Datos técnicos .................................................................. 31

La máquina está diseñada para cortar únicamente ramas y

ramitas.

Español – 23

Page 24

INSTRUCCIONES DE SEGURIDAD

Equipo de seguridad de la máquina

En esta sección se describen los distintos componentes de

seguridad de la máquina, qué función cumplen y cómo se debe

realizar la revisión y el mantenimiento para garantizar su

correcta función. (Ver el capítulo ”Qué es qué” para encontrar

el lugar de cada componente en la máquina).

ATENCIÓN

!

No utilice nunca el cortasetos con un

equipo de protección defectuoso. Siga las

instrucciones de control, mantenimiento y

servicio descritas en esta sección.

1. Protección para

la mano

La protección para la mano

esta destinada a impedir que la

mano entre en contacto con las

cuchillas en funcionamiento,

por ejemplo si el usuario suelta

el mango delantero.

2. Protección de las

A

cuchillas

La protección de las cuchillas

(A) está destinada a evitar que

cualquier parte del cuerpo

entre en contacto con las

cuchillas (B).

B

Control mantenimiento y servicio del

equipo de seguridad de la máquina

2. Cuchillas

Para lograr un buen resultado de

corte es importante que la

presión entre las cuchillas sea

correcta. Para ajustarla, enrosque

en el sentido de las agujas del

reloj y hasta el fondo los tornillos

en la cara inferior de las

cuchillas. Después, aflójelos en

sentido contrario 1/4 de vuelta.

Bloquee los tornillos con las

contratuercas en la parte

superior de las cuchillas.

Controle que los tornillos no

estén apretados más de lo

necesario como para permitir

que las arandelas debajo de las

cabezas de los tornillos puedan

moverse lateralmente.

Si las cuchillas están bien

ajustadas, debe haber un juego

entre las mismas de 0,2-0,4 mm,

medido junto a los tornillos.

Los bordes de la cuchilla son

demasiado duros para ser

limados. Las cuchillas obtusas

deben afilarse mediante una

muela abrasiva.

Cambie las cuchillas si están

dobladas o dañadas.

3. Protección de las cuchillas

ATENCIÓN

!

!

No utilice nunca una máquina cuyo sistema

de seguridad sea defectuoso. El equipo de

seguridad debe ser controlado y mantenido

como se ha descrito en esta sección. Si su

máquina no cumple con alguno de los

requisitos mencionados, debe dirigirse a un

taller de servicio oficial para la reparación.

ATENCIÓN

Pare siempre el motor antes de trabajar con

alguna parte del equipo de corte, éste sigue

girando incluso después de haber soltado

el acelerador. Controle que se haya

detenido completamente y retire el cable de

la bujía antes de comenzar a trabajar.

1. Protección para

la mano

• Verifique que la protección

de las cuchillas esté

correctamente montada.

• Verifique que la protección

para la mano esté intacta.

• Revise la protección de las cuchillas para ver si está dañado o

agrietado.

• Unaa protección de las cuchillas dañado debe ser cambiado.

A

B

4. Engranaje

• Después de trabajar con el

cortasetos, el engranaje está

caliente. No toque el

engranaje para evitar

quemaduras.

24 – Español

Page 25

INSTRUCCIONES DE SEGURIDAD

Instrucciones de seguridad para el

uso del cortasetos

¡ATENCIÓN!

El cortasetos puede provocar heridas

!

!

¡ATENCIÓN! Lea atentamente el manual de instrucciones

antes de utilizar el cortasetos.

Protección

personal

• Utilice siempre botas y

además el equipo indicado

en la sección ”Equipo de

protección personal”del

manual de instrucciones de

la máquina.

• Utilice siempre

indumentaria de trabajo y

pantalones largos fuertes.

graves. Lea atentamente las instrucciones

de seguridad. Aprenda a utilizar la

máquina.

¡ATENCIÓN!

Cuchillas cortantes. No las toque sin

haber apagado primero el motor.

Instrucciones de

seguridad durante

el trabajo

• Debe tener siempre una

posición de trabajo segura

y firme.

• Utilice la mano derecha

para maniobrar el

acelerador.

• Utilice siempre las dos

manos para sostener la

máquina. Mantenga la

máquina en el lado

derecho de su cuerpo.

• Controle que ni las manos

ni los pies entren en

contacto con la cuchilla

estando el motor en

marcha.

• Tenga cuidado con los

trozos

de rama que pueden salir

despedidos durante el

corte.

• No utilice nunca ropas

amplias ni joyas.

• Las personas que tengan

cabellos largos, deben

levantarlo como medida de

seguridad personal.

Instrucciones de seguridad para el

entorno

• No permita nunca que los

niños utilicen la máquina.

• Controle que nadie se

acerque a menos de 15

metros durante el trabajo.

• No permita nunca utilizar

la máquina a nadie sin estar

seguro que ha

comprendido el contenido

del manual de

instrucciones.

• Siempre apoye el cortasetos en el suelo cuando no lo utilice.

• Al parar el motor, mantenga las manos y los pies alejados de

la cuchilla hasta que se haya detenido completamente.

• No corte demasiado cerca del suelo, dado que pueden ser

lanzadas piedras y otros objetos.

• Inspeccione la zona a cortar para ver si hay cables de

electricidad, insectos o animales, etc. u objetos que puedan

dañar el equipo de corte, por ejemplo objetos de metal.

• Si choca con algún objeto o si se producen vibraciones

fuertes, pare inmediatamente la máquina. Quite el cable de

la bujía. Controle que la máquina no esté dañada. Repare

posibles averías.

• Si las cuchillas se atascan en algún objeto durante el corte,

apague primero el motor y espere a que las cuchillas se

detengan completamente antes de despejar el objeto.

Desconecte el cable de encendido de la bujía.

• No trabaje nunca desde

una escalera, taburete u

otra posición elevada que

no tenga un apoyo

completamente seguro.

Español – 25

Page 26

INSTRUCCIONES DE SEGURIDAD

Instrucciones de seguridad después del

trabajo

• Coloque siempre la protección de las cuchillas cuando no

use la máquina.

• Antes de la limpieza, reparación o inspección, controle que

la cuchilla se haya detenido. Quite el cable de la bujía.

• Utilice siempre guantes

resistentes al reparar las

cuchillas. Las mismas

tienen mucho filo y

pueden provocar cortes

muy fácilmente.

• Mantenga la máquina

fuera del alcance de los

niños.

• Al reparar utilice

solamente repuestos

originales.

Cambio de ángulo del cortasetos

• Afloje el botón del

limitador de ángulo.

• Presione el equipo de corte

contra el suelo u otra base

firme hasta que se ajuste el

ángulo deseado.

• Apriete el botón.

Técnicas de trabajo básicas

• Trabaje con movimientos

pendulares de abajo hacia

arriba al cortar los

costados del seto.

• Adapte la aceleración a la

carga.

• Al recortar un seto, el

motor siempre debe estar

dirigido hacia afuera del

seto.

• Mantenga el cortasetos lo

más cerca posible del

cuerpo a fin de lograr el

mejor equilibrio posible.

• Asegúrese de que la punta

no toque el suelo.

• No trate de forzar el

trabajo. Desplácese a una

velocidad constante para

cortar todos los tallos en

forma pareja.

ATENCIÓN: No agarre el equipo de corte cuando

va a ajustar el ángulo. Las cuchillas son filosas y

pueden provocar cortes.

26 – Español

Page 27

¿QUÉ ES QUÉ?

4

2

7

1

2

3

9

2

11

6

5

8

10

¿Qué es qué en el suplemento para

cortar setos?

1. Cuchilla

2. Boquillas de engrase (3 unidades)

3. Engranaje angulado

4. Protección de las cuchillas

5. Mango delantero

6. Tornillo de sujeción, protección para la mano

7. Botón para ajuste de ángulo

8. Protección para la mano

9. Manual de instrucciones

10. Protección para transportes

11. Conexión del tubo

Español – 27

Page 28

MONTAJE

ARRANQUE Y DETENCIÓN

Montaje de la protección para la

mano y el mango cerrado

1. Afloje los dos tornillos de

sujeción del manguito de

acoplamiento y desmonte el

manguito.

2. Ensamble la protección para

la mano con el mango

cerrado y atorníllelos

formando una unidad.

Preste atención a que

coincidan los orificios de

ambas partes.

3. Calce el mango cerrado y la

protección para la mano en

el tubo.

4. Introduzca el distanciador

en la ranura del mango

cerrado.

5. Monte la tuerca y el tornillo.

No los apriete a fondo.

6. A continuación, haga un

ajuste exacto para lograr una

postura de trabajo cómoda.

Apriete el tornillo.

NOTA: El mango cerrado y

la protección para la mano

no se deben montar más

atrás que la marcha de la

flecha que hay en el tubo.

Control antes de arrancar

• Inspeccione el área de trabajo. Retire objetos que puedan ser

lanzados.

• Controle las cuchillas.

Nunca utilice cuchillas sin

filo, agrietadas o

averiadas.

• Controle que el cortasetos

esté en excelentes

condiciones de

funcionamiento.

Verifique que todas las

tuercas y tornillos estén

bien apretados.

• Revise la protección de las cuchillas para ver si está dañado o

agrietado.

• Unaa protección de las cuchillas dañado debe ser cambiado.

• Asegúrese de que la caja de engranajes esté correctamente

lubricada. Lea la sección «Lubricación de las cuchillas».

• Verifique que las cuchillas paren siempre que el motor

funcione en marcha lenta.

• Utilice la máquina únicamente para lo que ha sido diseñada.

A

B

7. Monte el manguito de

acoplamiento y apriete los

dos tornillos de sujeción.

Montaje del equipo de corte

Al montar el equipo de corte,

es importante que el cortasetos

esté apoyado sobre una base

plana. De lo contrario, el

equipo de corte puede quedar

mal montado.

1. Monte el equipo de corte

en el tubo.

NOTA: Preste atención a

que el eje motriz del tubo

quede introducido en la

cavidad del equipo de

corte.

2. Apriete primero el tornillo

inferior y después, el

superior.

28 – Español

Page 29

MANTENIMIENTO

Carburador

Su producto Husqvarna ha sido construido y fabricado conforme

a especificaciones que reducen los gases de escape tóxicos. Cuando

el motor ha consumido 8-10 depósitos de combustible, el mismo

ha sido ”rodado”. Para asegurarse de que funcione de la mejor

manera y despida la menor cantidad posible de gases tóxicos

después del período de rodaje, contacte a su representante o

servicio oficial, que tiene acceso a un tacómetro, para que regule su

carburador, así funciona de manera óptima.

ATENCIÓN:

Antes de arrancar la máquina, debe

!

Función

• El carburador regula las revoluciones del motor a través del

acelerador. En el carburador se mezclan el aire y el combustible, formando una mezcla que debe ser correcta para

aprovechar la potencia máxima de la máquina.

• El reglaje del carburador se realiza para adaptar el motor a

condiciones particulares como, por ejemplo, clima, altura

sobre el nivel del mar, gasolina y tipo de aceite para motores

de dos tiempos.

• El carburador tiene tres

posibilidades de regulación:

L = Boquilla para bajas

H= Boquilla para altas

T = Tornillo de ajuste

haberse montado primero la cubierta del

embrague con el engranaje, de lo contrario

el embrague puede zafar y ocasionar daños

personales.

revoluciones

revoluciones

para ralentí

Regulación de fábrica

• El carburador se regula en fábrica al probarlo. Esta regulación

produce una mezcla más rica que la óptima y se debe mantener

durante las primeras horas de uso de la máquina. Posteriormente, se

debe realizar el reglaje final. Éste debe ser realizado por un técnico

especializado.

Importante: Si el equipo de corte gira en ralentí, debe girarse el

tornillo T en sentido contrario a las agujas del reloj hasta que el equipo

de corte quede inmóvil.

Régimen recomendado en ralentí: 2 700 rpm.

Aceleración máxima recomendada (sin carga): véase ”Datos técnicos ”

ADVERTENCIA

Si no puede regular la marcha en ralentí

!

para que el equipo de corte deje de girar,

debe dirigirse a un servicio oficial. No

utilice la máquina hasta que no esté

correctamente reparada o regulada.

Reglaje de precisión

• Una vez que la máquina fue ”rodada”, es necesario regular el

carburador en forma precisa. Este ajuste debe ser realizado

por un técnico cualificado. Ajuste primero la aguja de bajas

revoluciones L, después del tornillo de ralentí T y, finalmente, la aguja de altas revoluciones H.

Requisitos

• Antes de hacer un ajuste, controle que el filtro de aire esté

limpio y que tenga colocada la tapa. Si se regula el carburador

con un filtro sucio, se obtiene una mezcla más pobre después de

limpiar el filtro. Esto puede ocasionar serios fallos del motor.

• Gire cuidadosamente las agujas L y H hasta el punto central

entre las posiciones de totalmente atornillada y totalmente

desatornillada.

• No trate de ajustar las agujas más allá del tope, porque esto

puede causar daños.

• Ahora, arranque la máquina según las instrucciones y hágala

funcionar durante 10 minutos.

Importante: Si el equipo de corte gira, debe girarse el tornillo de

ralentí T en sentido contrario a las agujas del reloj, hasta que el

equipo de corte se detenga.

• Con las boquillas L y H se regula la cantidad de combustible

deseado para el caudal de aire producido por la abertura del

acelerador. Al girarlos en el sentido de las agujas del reloj, la

mezcla aire-combustible se empobrece (menos combustible),

y al girarlos en sentido contrario a las agujas del reloj, la

mezcla se enriquece (más combustible). Una mezcla pobre

hace trabajar al motor a más rpm y una mezcla rica, a menos

rpm.

• El tornillo T regula la posición del acelerador para el funcionamiento en ralentí. Al girarlo en el sentido de las agujas del

reloj, las rpm en ralentí aumentan y al girarlo en sentido

contrario a las agujas del reloj, las rpm en ralentí se reducen.

Aguja de bajas revoluciones L

Trate de encontrar el máximo

régimen de ralentí girando la

aguja de bajas revoluciones L

en el sentido de las agujas del

reloj o en el sentido contrario.

Una vez obtenido el régimen

máximo, girar la aguja de

bajas revoluciones L un

cuarto de vuelta en el sentido

contrario a las agujas del reloj.

Importante: Si las cuchillas se

mueven en ralentí, debe

girarse el tornillo T a

izquierdas hasta que se

detengan.

L

+ 1/4

Español – 29

Page 30

MANTENIMIENTO

Reglaje definitivo del régimen de ralentí T

Regule el régimen de ralentí

con el tornillo L, si es

necesario un reajuste. Gire

primero el tornillo de ralentí

T en el sentido de las agujas

del reloj, hasta que comience a

girar el equipo de corte.

Después gire el tornillo en el

sentido contrario, hasta que el

equipo de corte se detenga. El

régimen de ralentí es correcto

cuando el motor funciona en

forma uniforme en cada

posición. También debe existir

un buen margen hasta el

régimen en que empieza a

girar el equipo de corte.

ADVERTENCIA: Póngase en contacto con su representante o

servicio oficial si no puede ajustar la el reglaje de ralentí para

que el equipo de corte deje de girar. No utilice la máquina

antes de que sea regulada o reparada correctamente.

Boquilla H para altas revoluciones

La boquilla H para altas

revoluciones regula la potencia,

el número de revoluciones, la

temperatura y el consumo de

combustible del motor. Una

ajuste muy pobre de la boquilla

H (muy atornillada) hacer

trabajar régimen muy alto y lo

daña. Nunca haga funcionar al

motor a máxima velocidad

durante más de 10 minutos.

Acelere a fondo y gire la

boquilla H muy despacio en el

sentido de las agujas del reloj,

hasta reducir la velocidad del

motor. Después, gírela muy

despacio en el sentido contrario, hasta que el motor

funcione en forma irregular.

Por último, gire lentamente la

boquilla H en el sentido de las

agujas del reloj, un poco hasta

que el motor funcione en formar regular.

Durante el ajuste de la boquilla para altas revoluciones, el motor

debe estar sin carga. Por eso, desmonte antes el equipo de corte, la

tuerca, la brida de apoyo y la pieza de arrastre. La boquilla H está

bien ajustada cuando la máquina ”galopa” un poco en cuatro

tiempos. Si el motor se embala, el ajuste es muy pobre. Si el motor

se sacude violentamente y, al mismo tiempo, ”galopa” mucho en

cuatro tiempos, el ajuste es muy rico.

IMPORTANTE: Si desea un reglaje óptimo del carburador,

debe dirigirse a un representante o servicio oficial cualificado,

que tenga acceso a un tacómetro.

H

Reglaje correcto del carburador

El carburador está correctamente regulado cuando la máquina

acelera sin dificultad y cuando ”galopa en cuatro tiempos” un

poco a velocidad máxima. Además, el equipo de corte no debe

girar durante la marcha en ralentí. Una aguja de bajas

revoluciones L ajustada muy pobremente puede ocasionar

problemas en el arranque y mala aceleración.

Una aguja de altas revoluciones H ajustada muy pobremente

significa menos fuerza, esto es menos capacidad, mala

aceleración y/o daños del motor.

Un reglaje muy rico de las dos agujas L y H significa problemas

de aceleración o un régimen de trabajo muy bajo.

Caja de engranajes

En la caja de engranajes hay

tres boquillas de engrase

(A).En la caja de engranajes

hay una boquilla de engrase

(A). Utilice una pistola de

engrase para rellenar grasa.

Este procedimiento debe

repetirse cada 20 horas de

trabajo aproximadamente.

Utilice grasa especial de

Husqvarna, nº 503 98 96-01.

No llene el engranaje

totalmente con grasa. El

calor que se produce al hacer

funcionar la máquina hace

que la grasa se expanda. Una

cantidad excesiva de grasa en

los engranajes puede dañar

las juntas y ocasionar fugas

de grasa.

El lubricante en la caja de

engranajes normalmente no

requiere ser cambiado salvo

durante una reparación.

Limpieza y

lubricación

Limpie los restos de resina y

savia de las cuchillas con

detergente 531 00 60-75

(UL22) después de cada uso.

Antes del uso, lubrique las

hojas de la cuchilla con

lubricante especial

531 00 60-74 (UL 21).

30 – Español

´+H"^¶00¨

Page 31

MANTENIMIENTO

DATOS TÉCNICOS

Plan de Mantenimiento

A continuación siguen algunas instrucciones de

mantenimiento.

Si necesita mayor información contacte con el servicio oficial.

Control diario

1

B

1

1. Controle que las cuchillas

no se muevan en ralentí o

cuando el estrangulador

está en posición de

aceleración de arranque.

2. Controle que la

protección para la mano

no esté averiada.

Reemplace una

protección averiada.

Control semanal

1. Rellene grasa en la caja de

engranajes. Repetir este

procedimiento cada 20

horas de trabajo

aproximadamente.

A

2

Datos técnicos

Peso

Peso sin combustible, kg

Cuchillas

Longitud, mm

Velocidad de cuchilla, corte/min

2,0

550

4184

2. Controle que estén

apretados los tornillos

que sostienen juntas las

cuchillas.

2

Español – 31

Page 32

114 00 26-20

´+H"^¶00¨

2002W12

Loading...

Loading...