Husqvarna EN EPA, POWER CUTTER User Manual

Oper ator’s manual (EPA)

K750

Please r ead the operator’s manual carefully and make sure you understand the

instructions before using the machine.

EEEEnnnngggglllliiiisssshh

hh

2

K

W

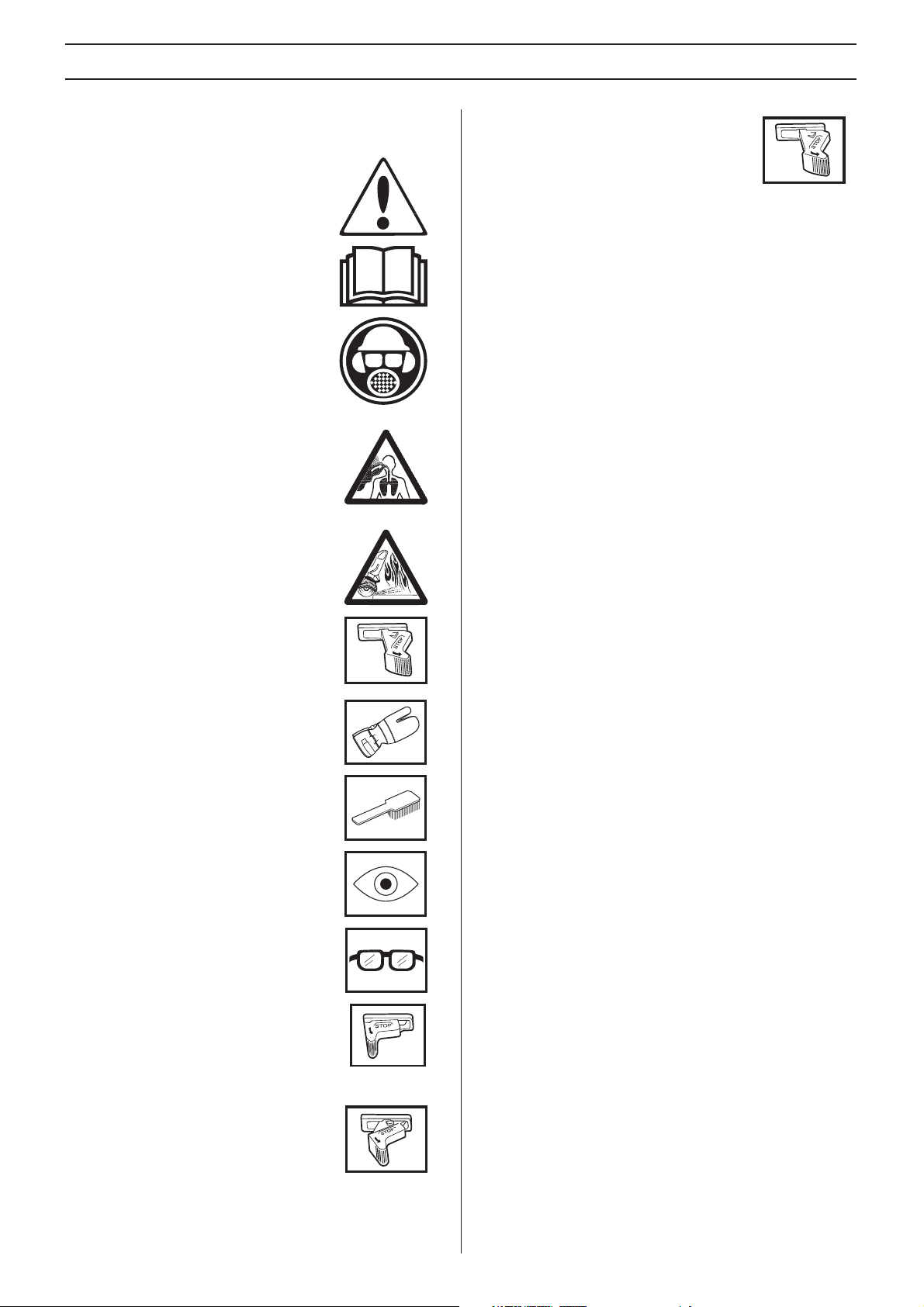

ey to symbols

ARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the machine.

Always wear:

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

WARNING! Dust forms when cutting, this

can cause injuries if inhaled. Use an

approved breathing mask. Avoid inhaling

petrol fumes and exhaust fumes. Always

provide for good ventilation.

KEY T O SYMBOLS

Stop, in the fixed position.

Other symbols/decals on the mac hine

refer to special certification

requirements for certain markets.

WARNING! Sparks from the cutting blade

can cause fire in combustible materials

such as: petrol (gas), wood, dry grass etc.

Switch off the engine b y moving the stop

switch to the STOP position before carrying

out any checks or maintenance.

Alw ays wear protective gloves.

Regular cleaning is required.

Visual chec k.

Protectiv e goggles or a visor must be worn.

Run position.

Stop , with the return spring to the operating

position.

–

English

K

ST

T

T

Y

CONTENTS

Contents

KEY TO SYMBOLS

ey to symbols ............................................................. 2

CONTENTS

Contents ...................................................................... 3

WHA T IS WHAT?

What is what on the po wer cutter? ............................... 4

SAFETY INSTR UCTIONS

Steps bef ore using a new power cutter. ....................... 5

Personal protective equipment ..................................... 5

Machine ′ s safety equipment ........................................ 6

Checking, maintaining and servicing the machine ′ s

safety equipment .......................................................... 7

General safety precautions .......................................... 8

General working instructions ....................................... 9

Cutting blades .............................................................. 11

ASSEMBL Y

Chec king the drive axle and flange washers ............... 13

Fitting the cutting blade ................................................ 13

Guard for the blade ...................................................... 13

FUEL HANDLING

Fuel .............................................................................. 14

K750 ............................................................................ 14

K750 OilGuard ............................................................. 14

Fueling ......................................................................... 15

ARTING AND STOPPING

Star ting and stopping ................................................... 16

MAINTENANCE

ensioning the drive belt .............................................. 17

Replacing the drive belt ............................................... 17

Belt pulley and clutch ................................................... 17

Carburetor .................................................................... 17

Fuel filter ...................................................................... 18

Air filter ......................................................................... 18

Starter .......................................................................... 19

Spark plug .................................................................... 20

Cooling system ............................................................ 20

Muffler .......................................................................... 20

General maintenance instructions ............................... 21

TECHNICAL D ATA

echnical data .............................................................. 22

Cutting equipment ........................................................ 22

FEDERAL EMISSION CONTR OL WARRANTY

STATEMENT

OUR WARRANTY RIGHTS AND OBLIGATIONS ..... 23

English

– 3

4

1

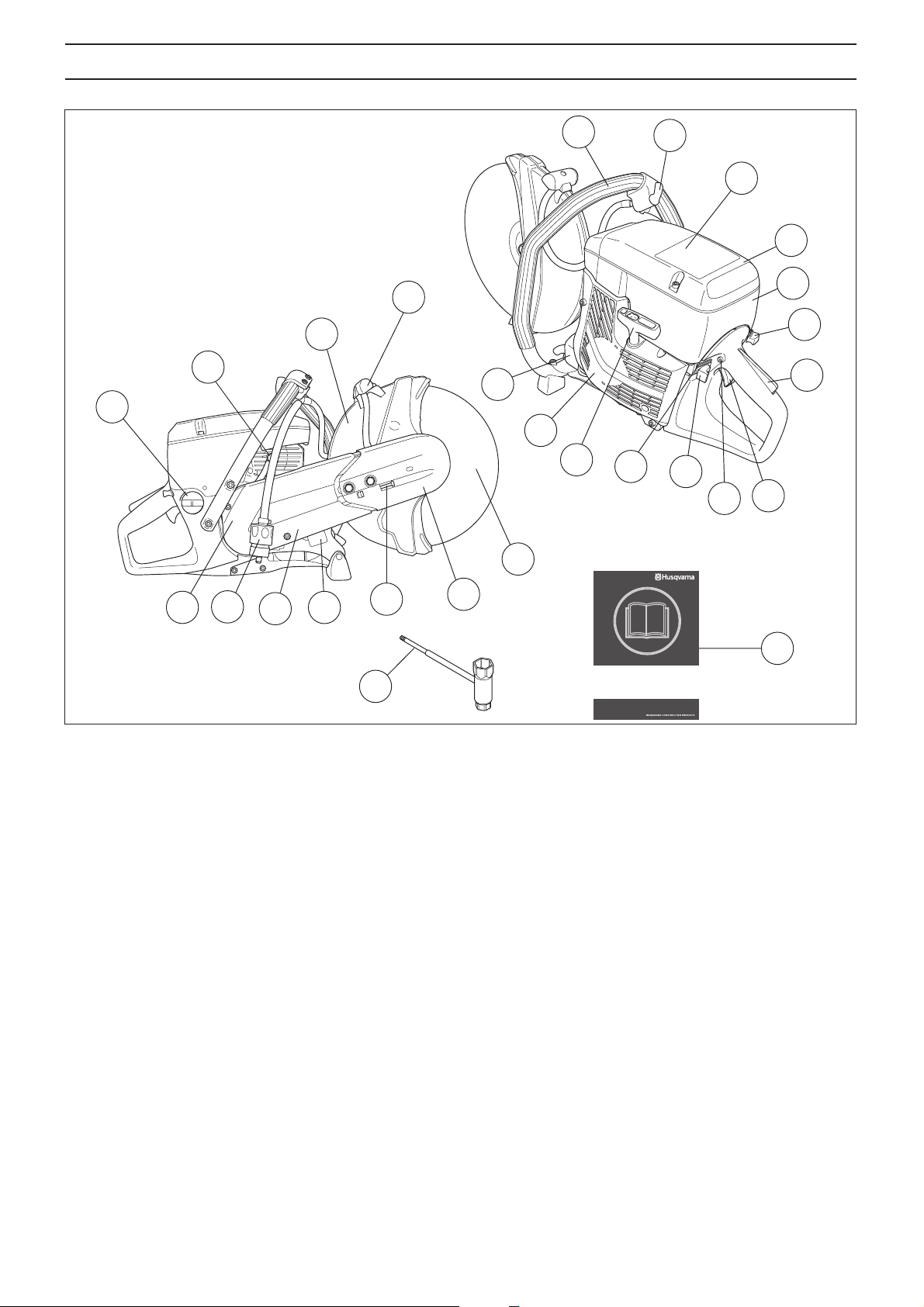

WHA T IS WHA T?

15

16

17

18

14

25

13

1

12

11

2

10

9

3

4

5

6

7

8

19

20

21

22

23

26

What is what on the po wer cutter?

Front handle

2 Water tap

3 Warning decal

4 Air filter cover

5 Cylinder cover

6 Choke

7 Throttle lockout

8 Throttle control

9 Start throttle lock

10 Stop switch

11 Disconnection function for OilGuard (K750 OilGuard)

12 Starter handle

13 Starter

14 Muffler

24

27

15 Fuel tank

16 Decompression valve

17 Guard for the blade

18 Adjustment handle for guard

19 Belt guard

20 Water connection with filter

21 Cutting arm

22 Type plate

23 Belt tensioner

24 Cutting head

25 Cutting blade

26 Combination spanner

27 Operator’s manual (EPA)

–

English

SAFETY INSTR UCTIONS

Steps bef ore using a new power cutter

Please read the operator’s manual carefully.

• Check the cutting blade’s mounting, see the chapter

”Assembly”.

• Start the engine and check the idling setting, see

instructions under the heading Maintenance. When the

carburettor is set correctly the cutting blade should be still

while idling. Setting of the idle speed is described in the

Operator’s Manual. Set the correct speed according to

these instructions. Do not use the power cutter if the idle

speed is not adjusted correctly!

• Let your Husqvarna dealer regularly check the power

cutter and make essential adjustments and repairs.

ARNING! Under no circumstances may the

design of the machine be modified without

!

the permission of the manufacturer. Always

use genuine accessories. Non-authorized

modifications and/or accessories can result

in serious personal injury or the death of the

operator or others.

•

P

•

W

W

W

W

W

W

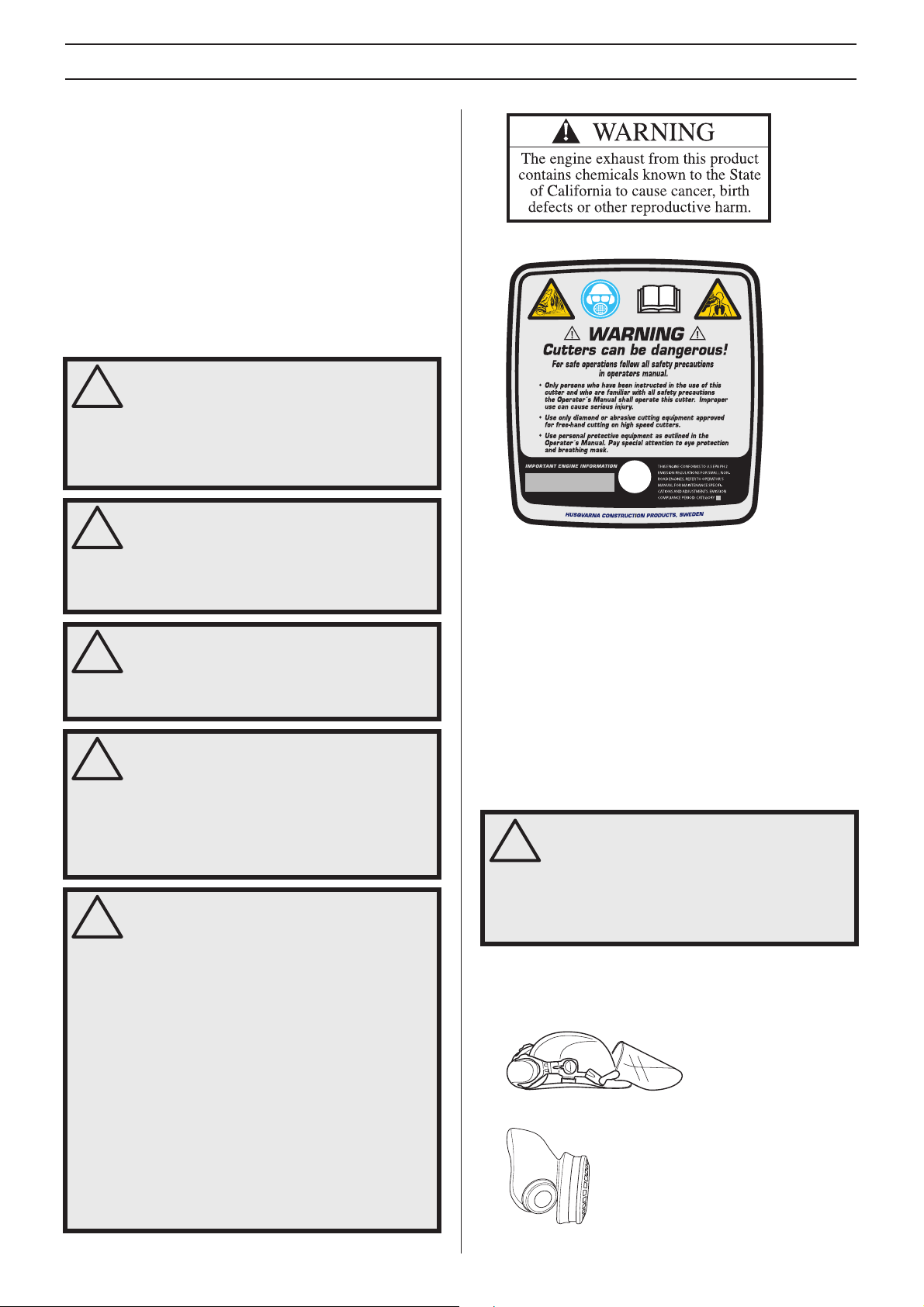

You will find the following labels on your power cutter:

ARNING! Use of products which cut, grind,

drill, sand or shape material can generate

!

dust and vapors which may contain harmful

chemicals. Know the nature of the material

being worked on and wear appropriate dust

mask or respirator protection.

ARNING! A power cutter is a dangerous tool

if used carelessly or incorrectly and can cause

!

serious, even fatal injuries. It is extremely

important that you read and understand the

contents of this Operator’s Manual.

ARNING! The ignition system of this

machine produces an electromagnetic field

!

during operation. This field may under some

circumstances interfere with pacemakers. To

reduce the risk of serious or fatal injury, we

recommend persons with pacemakers to

consult their physician and the pacemaker

manufacturer before operating this machine.

ARNING! Some dust created by power

sanding, sawing, grinding, drilling, and other

!

construction activities contains chemicals

known (to the State of California) to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

Lead from lead-based paints.

Crystalline silica from bricks, cement and

other masonry products.

Arsenic and chromium from

chemicallytreated lumber.

Your risk from these exposures varies,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust makes that are specially

designed to filter out microscopic material.

The Emissions Compliance Period referred to on the

Emission Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal

emissions requirements. Category C = 50 hours, B = 125

hours, and A = 300 hours.

Husqvarna Construction Products has a policy of continuous

product development. Husqvarna reserves the right to modify

the design and appearance of products without prior notice

and without further obligation introduce design modifications.

All information and all data in the Operator’s Manual were

applicable at the time the Operator’s Manual was sent to print.

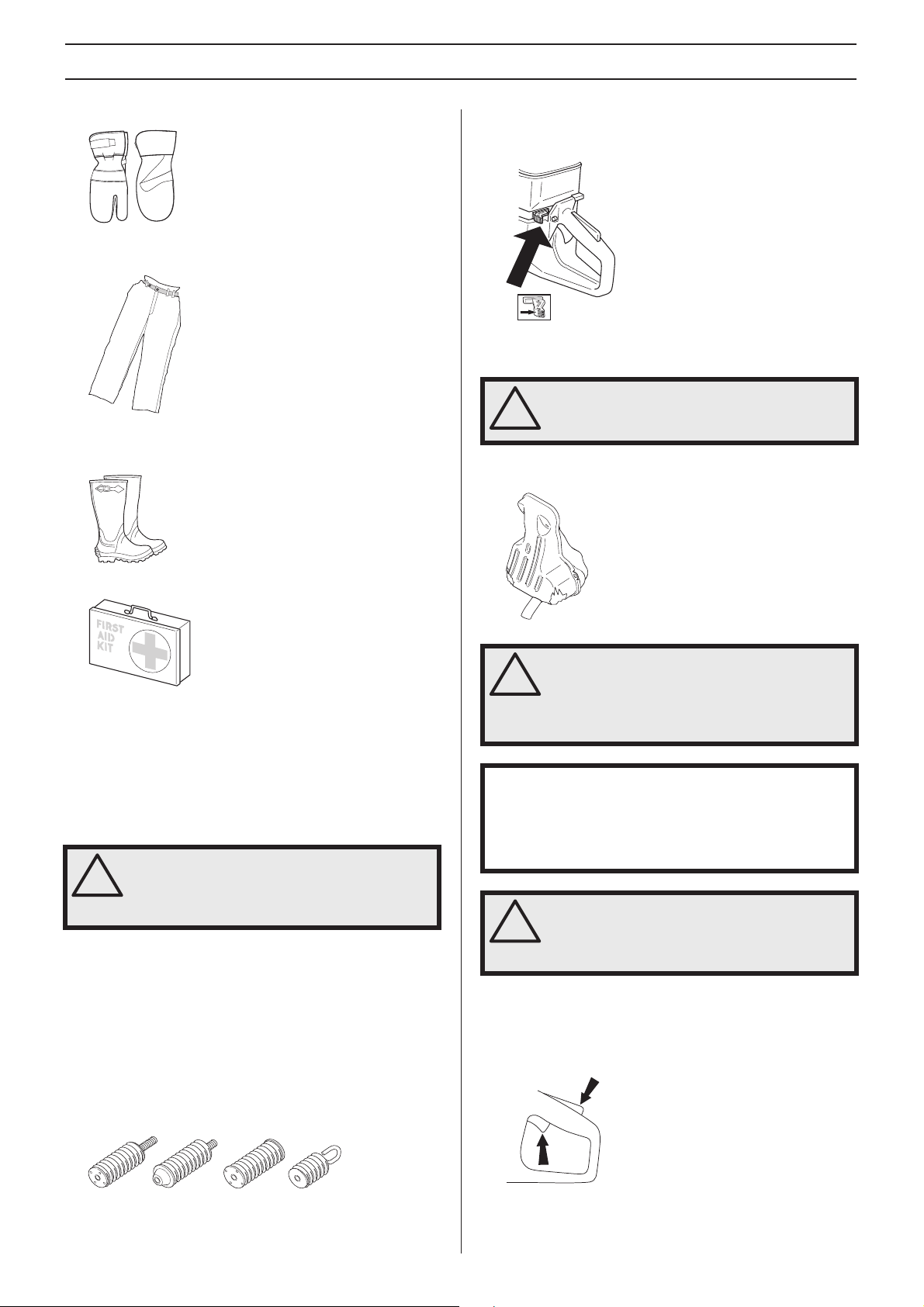

ersonal protective equipment

ARNING! You must use approved personal

protective equipment whenever you use the

!

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

English

– 5

6

SAFETY INSTR UCTIONS

•

Y

W

W

W

F

W

Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Use leg-guards recommended for the material to be cut.

• Boots with steel toe-caps and non-slip sole

Stop s witch

Use the stop s witch to switch off the engine.

Muffl er

ARNING! The muffler gets very hot in use

and remains so for a short time afterwards.

!

Do not touch the muffler if it is hot!

The m uffler is designed to keep noise levels to a minimum

and to direct exhaust fumes away from the user.

• Always have a first aid kit nearby.

Mac hine ′ s safety equipment

This section descr ibes the machine ′ s safety equipment, its

purpose, and how checks and maintenance should be carried

out to ensure that it operates correctly. See the ”What is

what?” section to locate where this equipment is positioned

on your machine.

ARNING! Never use a machine that has

faulty safety equipment! Carry out the

!

inspection, maintenance and service

routines listed in this section.

Vibration damping system

our machine is equipped with a vibration damping system

that is designed to reduce vibration and make operation

easier.

The machine ′ s vibration damping system reduces the transfer

of vibration between the engine unit/cutting equipment and

the machine ′ s handle unit.

The engine body, including the cutting equipment, is insulated

from the handles by vibration damping units.

ARNING! The exhaust fumes from the

engine are hot and may contain sparks

!

which can start a fire. Never start the

machine indoors or near combustible

material!

IMPORTANT INFORMATION

or mufflers it is very important that you follow the

instructions on checking, maintaining and servicing your

machine. See instructions under the heading Checking,

maintaining and servicing the machine’s safety equipment.

ARNING! The inside of the muffler contain

chemicals that may be carcinogenic. Avoid

!

contact with these elements in the event of a

damaged muffler.

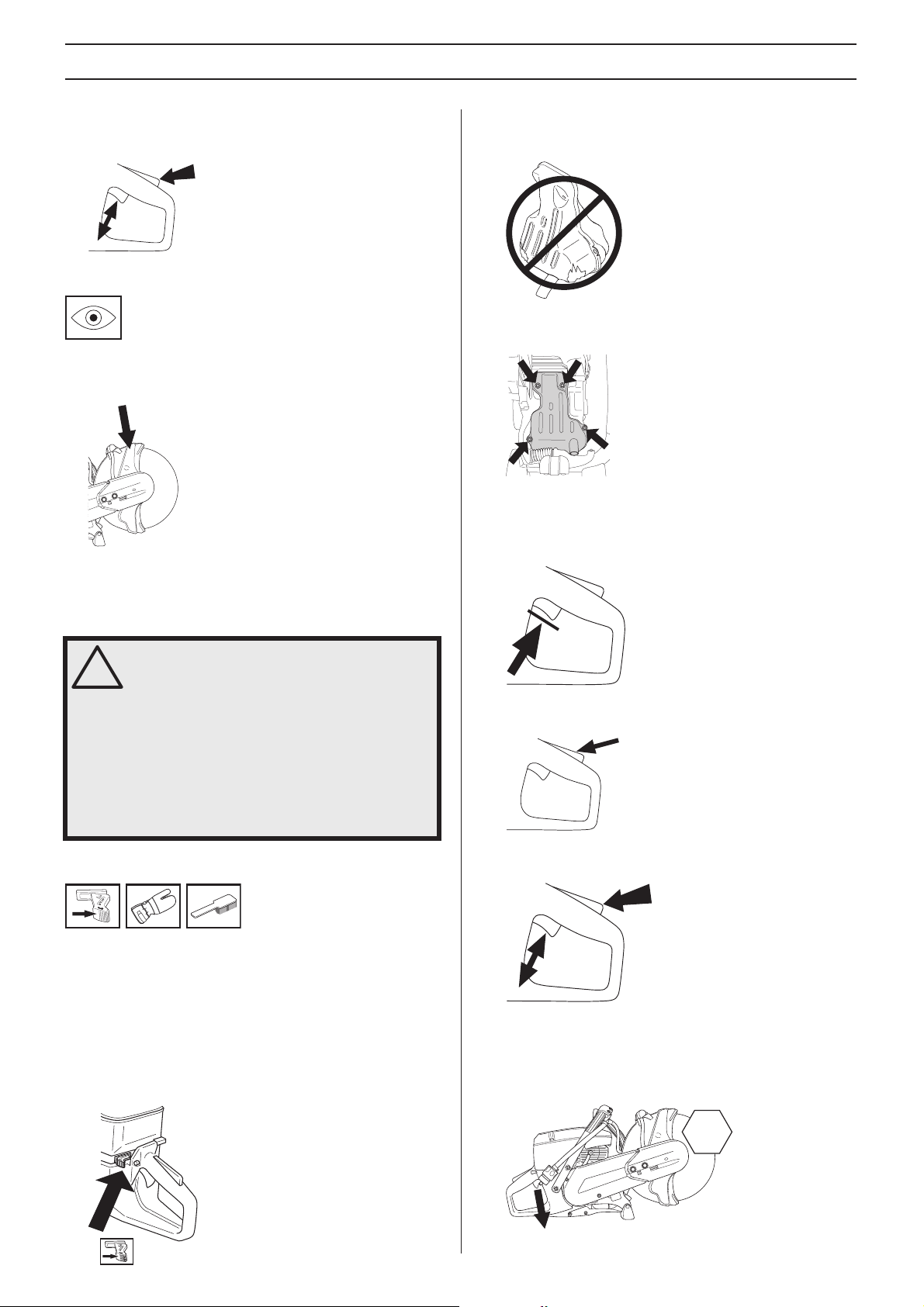

Thr ottle lockout

The throttle tr igger lock is designed to prevent accidental

operation of the throttle. When the lock (A) is pressed in this

releases the throttle (B).

A

–

B

The trigger lock remains pressed in as long as the throttle is

pressed. When the grip on the handle is released the throttle

trigger and the throttle trigger lock both return to their original

English

SAFETY INSTR UCTIONS

′

positions . This is controlled by two independent return spring

systems. This means that the throttle trigger is automatically

locked in the idle position.

Guar d for the blade

This guard is fi tted above the cutting blade and is designed to

prevent parts of the blade or cutting fragments from being

thrown towards the user.

Muffler

Never use a machine that has a faulty muffler.

Regularly check that the muffler is securely attached to the

machine.

Throttle lockout

• Make sure the throttle control is locked at the idle setting

when the throttle lockout is released.

Chec king, maintaining and servicing

the machine

WARNING! All servicing and repair work on

the machine requires special training. This is

!

especially true of the machine

equipment. If your machine fails any of the

checks described below you must contact

your service agent. When you buy any of our

products we guarantee the availability of

professional repairs and service. If the

retailer who sells your machine is not a

servicing dealer, ask him for the address of

your nearest service agent.

Vibration damping system

Regularly check the vibration damping units for cracks or

deformation.

Make sure the vibration damping units are securely attached

to the engine unit and handle unit.

Keep the handles clean and dry.

Stop switch

Start the engine and make sure the engine stops when you

move the stop switch to the stop setting.

s safety equipment

′s safety

• Press the throttle lockout and make sure it returns to its

original position when you release it.

• Check that the throttle control and throttle lockout move

freely and that the return springs work properly.

• Start the power cutter and apply full throttle. Release the

throttle control and check that the cutting blade stops and

remains stationary. If the cutting blade rotates when the

throttle is in the idle position you should check the

carburettor’s idle adjustment.

STOP

• See instructions under the heading Maintenance.

English

– 7

SAFETY INSTRUCTIONS

Checking the blade guard

WARNING! Always check that the guard is

correctly fitted before starting the machine.

!

Check that the cutting blade is fitted

correctly and does not show signs of

damage. A damaged cutting blade can cause

personal injury. See instructions under the

heading Assembly.

Check that the guard is complete and without any cracks or

deformations.

General safety precautions

• A power cutter is designed to cut hard materials, such as

masonry. Observe the increased risk of kickback when

cutting soft materials. See instructions under the heading

How to avoid kickback.

• Do not use the power cutter until you have read the entire

contents of this Operator’s Manual.

All servicing, in addition to the points listed in the section

”Control, maintenance and service of the power cutter’s

safety equipment”, should be carried out by trained

service specialists.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

• Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

• Never use a machine that has been modified in any way

from its original specification.

• Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

• Never use the machine indoors. Be aware of the dangers

of inhaling the engine’s exhaust fumes.

Transport and storage

Do not store or transport the power cutter with the cutting

blade fitted.

Store the power cutter in a lockable area so that it is out of

reach of children and unauthorised persons.

All blades should be removed from the cutter after use and

stored carefully. Store cutting blades in dry, frost free

conditions.

Special care should be taken with abrasive discs. Abrasive

discs must be stored on a flat, level surface. If blades are

supplied with a backing pad then a spacer should be used to

keep them flat. If an abrasive disc is stored in humid

conditions, this can cause imbalance and result in injury.

Inspect new blades for transport or storage damage.

Fuel safety

(Refuelling/Fuel mixture/Storage.)

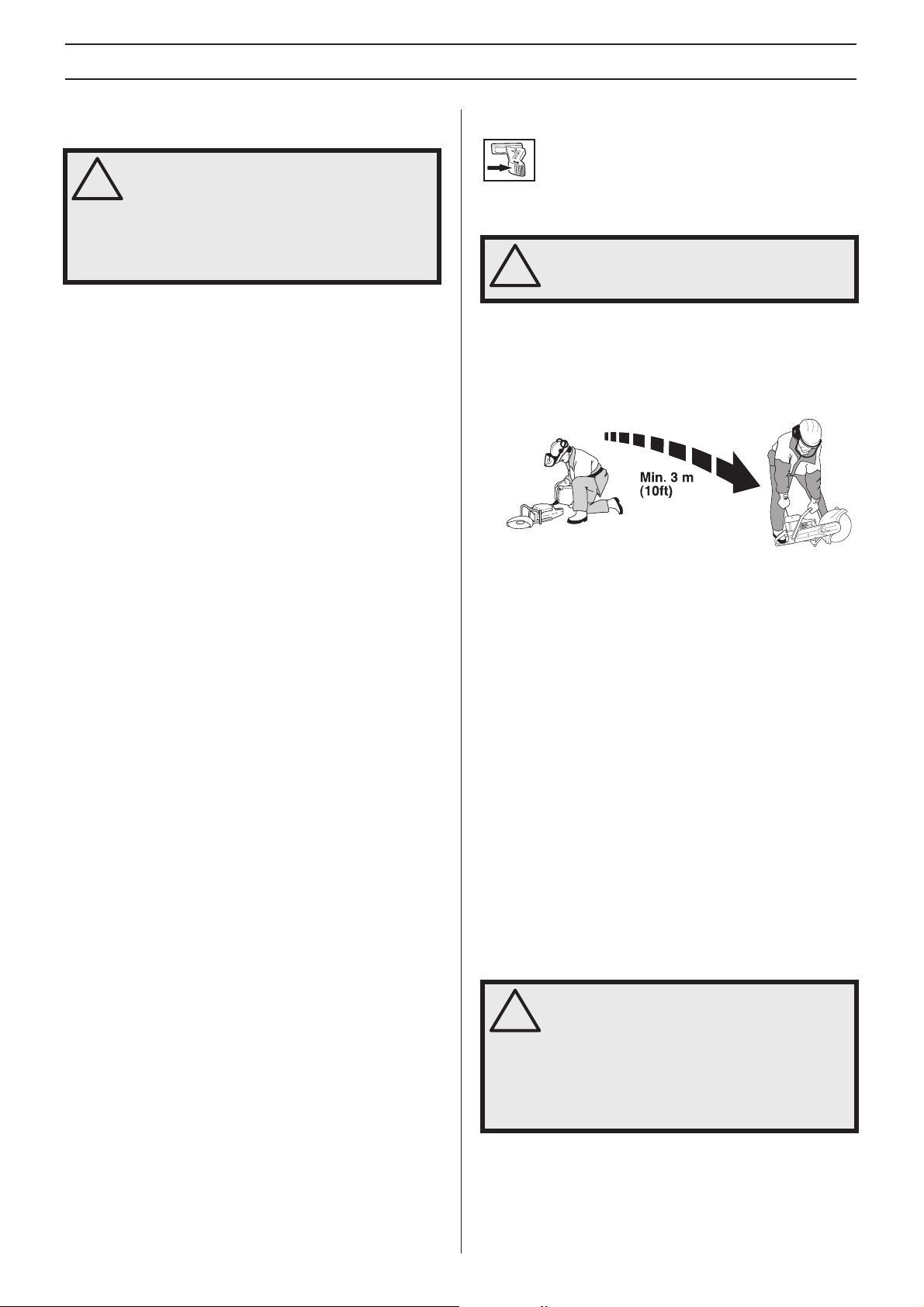

WARNING! Take care when handling fuel.

Bear in mind the risk of fire, explosion and

!

inhaling fumes.

• Never refuel the machine while the engine is running.

• Make sure there is plenty of ventilation when refuelling or

mixing fuel (gasoline and 2-stroke oil).

• Move the machine at least 10 ft (3 m) from the refuelling

point before starting it.

• Never start the machine:

- If you have spilled fuel on it. Wipe off the spillage and allow

remaining fuel to evaporate.

- If you have spilled fuel on yourself or your clothes, change

your clothes. Wash any part of your body that has come in

contact with fuel. Use soap and water.

- If the machine is leaking fuel. Check regularly for leaks

from the fuel cap and fuel lines.

• Store and transport the machine and fuel so that there is

no risk of any leakage or fumes coming into contact with

sparks or naked flames, for example, from electrical

machinery, electric motors, electrical relays/switches or

boilers.

• Always store fuel in an approved container designed for

that purpose.

• When storing the machine for long periods the fuel tank

must be emptied. Contact your local gas station to find out

where to dispose of excess fuel.

• Always use a Husqvarna fuel container with an anti-spill

valve.

WARNING! Bear in mind the risk of fire,

explosion and inhaling fumes. Stop the

!

engine before fuelling. Do not fill so that the

fuel runs over. Wipe up all spillage on the

ground and machine. If you spill fuel on

yourself or your clothes. Change your

clothes. Move the machine at least 3 metres

away from the refuelling area before starting.

8 – English

Loading...

Loading...