Page 1

KEEPING THE WORLD SEWING

™

User’s Guide

Page 2

This houshold sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including

the following:

Read all instructions before using this household sewing machine.

DANGER - To reduce the risk of electric shock:

• A sewing machine should never be left unattended when plugged in. Always unplug this sewing machine from the electric outlet immediately after using and before cleaning.

• Always unplug before relamping. Replace bulb with same type rated 15 Watt (for model 116) or

5 Watts (for model 118 and 122).

WARNING - To reduce the risk of burns, À re, electric

shock, or injury to persons:

• This sewing machine is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the sewing machine by a person

responsible for their safety.

• Children should be supervised to ensure that they do not play with the sewing machine.

• Use this sewing machine only for its intended use as described in this manual. Use only attachments recommended by the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. Return the sewing machine to

the nearest authorized dealer or service center for examination, repair, electrical or mechanical

adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings

of the sewing machine and foot controller free from the accumulation of lint, dust, and loose

cloth.

• Keep À ngers away from all moving parts. Special care is required around the sewing machine

needle.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may deÁ ect the needle causing it to break.

• Wear safety glasses.

• Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as

threading needle, changing needle, threading bobbin, or changing presser foot, etc.

• Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or

when making any other user servicing adjustments mentioned in the instruction manual.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

SAVE THESE INSTRUCTIONS

Page 3

1

Overview ........................................................ 2

Extension Table .............................................3

Free-arm sewing ............................................3

Standard Accessories and Storage ..............4

Getting ready to sew 5-20

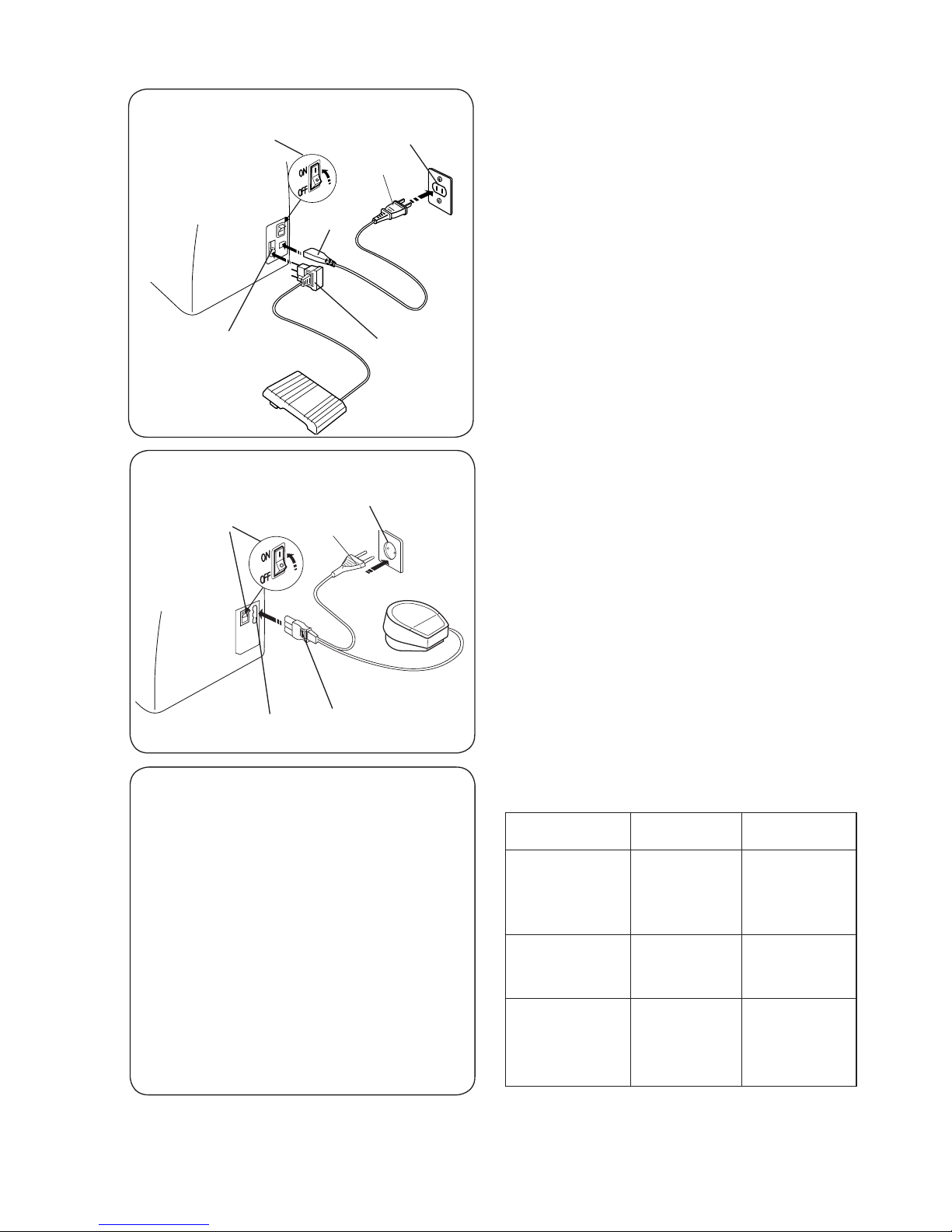

Connecting the Power Supply .....................5

Adjusting the Sewing Speed ........................6

Needle up/down ...........................................6

Sewing Guide Reference Chart ...................7

Reverse Lever .................................................8

Presser Foot Pressure Dial ..........................8

Lowering the Feed Teeth .............................8

Raising and Lowering the Presser Foot

......9

Changing the Presser Foot ..........................9

Changing the Needle ..................................10

Placing the thread spool

on the spool pin ..........................................11

Removing the bobbin .................................11

Bobbin Winding ..........................................12

Placing the bobbin ......................................13

Threading the Machine ..............................14

Needle threader ...........................................15

Bringing up the Bobbin Thread ................16

Stitches ..........................................................17

Stitch Selection ............................................18

Stitch Length ................................................18

Adjusting stretch stitch balance ................19

Stitch Width .................................................19

Variable needle position .............................19

Balancing Needle Thread Tension ...........20

Basic Sewing 21-23

Straight Stitch Sewing .................................21

Finishing sewing ..........................................22

Seam Guides on the Needle Plate ............23

Pivoting .........................................................23

Utility Stitches 24-38

Basic Zigzag ................................................ 24

Three-step Zigzag ...................................... 24

Seam and Overcast ....................................24

Reinforced Straight Stitch .........................25

Button Sewing ............................................ 25

Automatic Buttonhole ............................... 26

Corded Buttonhole .................................... 30

Manual Buttonhole .................................... 31

Sewing Zipper ............................................. 33

Blind Hem ................................................... 37

Non-stick Glide Foot H ............................38

Quilting Guide ............................................ 38

Presser Feet only model 122 38-39

Transparent Foot B .................................... 38

Gathering Foot ........................................... 39

Quilter’s 1/4” Piecing Foot ...................... 39

Care and Maintenance 40-42

Cleaning the Hook Assembly area

and Feed Teeth ...........................................40

Replacing the Bobbin Case ....................... 41

Replacing the Light Bulb ..........................41

Troubleshooting ......................................... 42

Table of Contents

Page 4

2

6

7

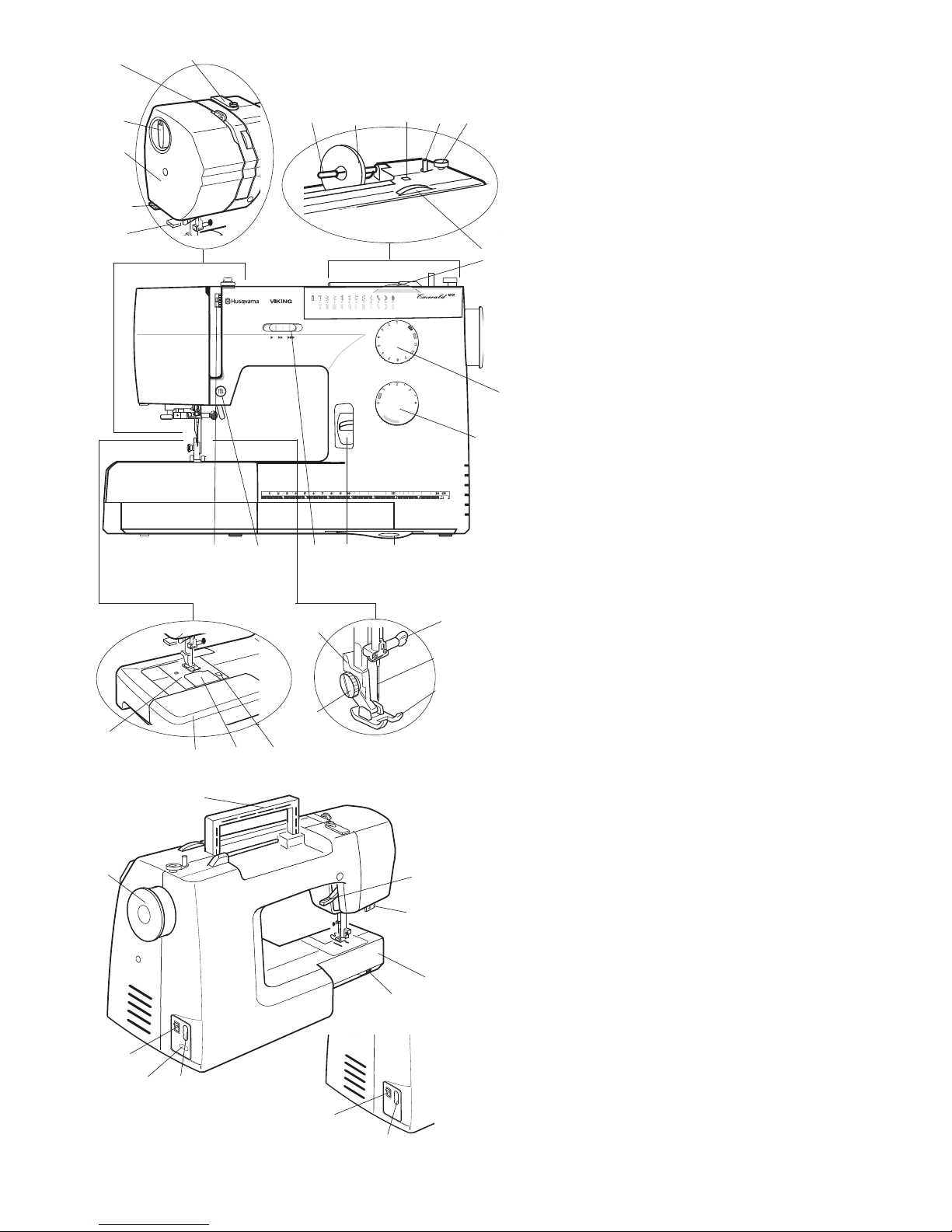

Overview

1. Bobbin stop

2. Bobbin spindle

3. Hole for extra spool pin

4. Spool holder

5. Spool pin

6. Thread guide for bobbin winding

7. Thread take-up lever

8. Presser foot pressure dial

9. Face plate

10. Thread cutter

11. Needle threader

12. Needle plate

13. Extension table (Accessory

storage)

14. Bobbin cover plate

15. Bobbin cover plate release button

16. Thread tension dial

17. Needle up/down button (only

model 118 and 122)

18. Speed control slider (only model

118 and 122)

19. Reverse stitch lever

20. Sewing Guide

21. Stitch length dial

22. Stitch selection dial

23. Stitch width dial

24. Presser foot

25. Needle

26. Needle clamp screw

27. Ankle to hold foot

28. Thumbscrew

29. Carrying handle

30. Handwheel

31. Power switch, Emerald™ 118/122

31.a Power switch,Emerald 116

32. Foot control socket (only model

118 and 122)

33. Machine socket, model 118 and

122

33.a Machine socket, model 116

34. Drop feed lever

35. Free-arm

36. Buttonhole lever

37. Presser foot lift

22

21

1

2

3

4

5

8

9

10

11

16

12

13

14

15

17

19

18

20

24

25

26

28

27

29

30

31

32

34

35

36

37

23

33

31.a

33.a

Page 5

3

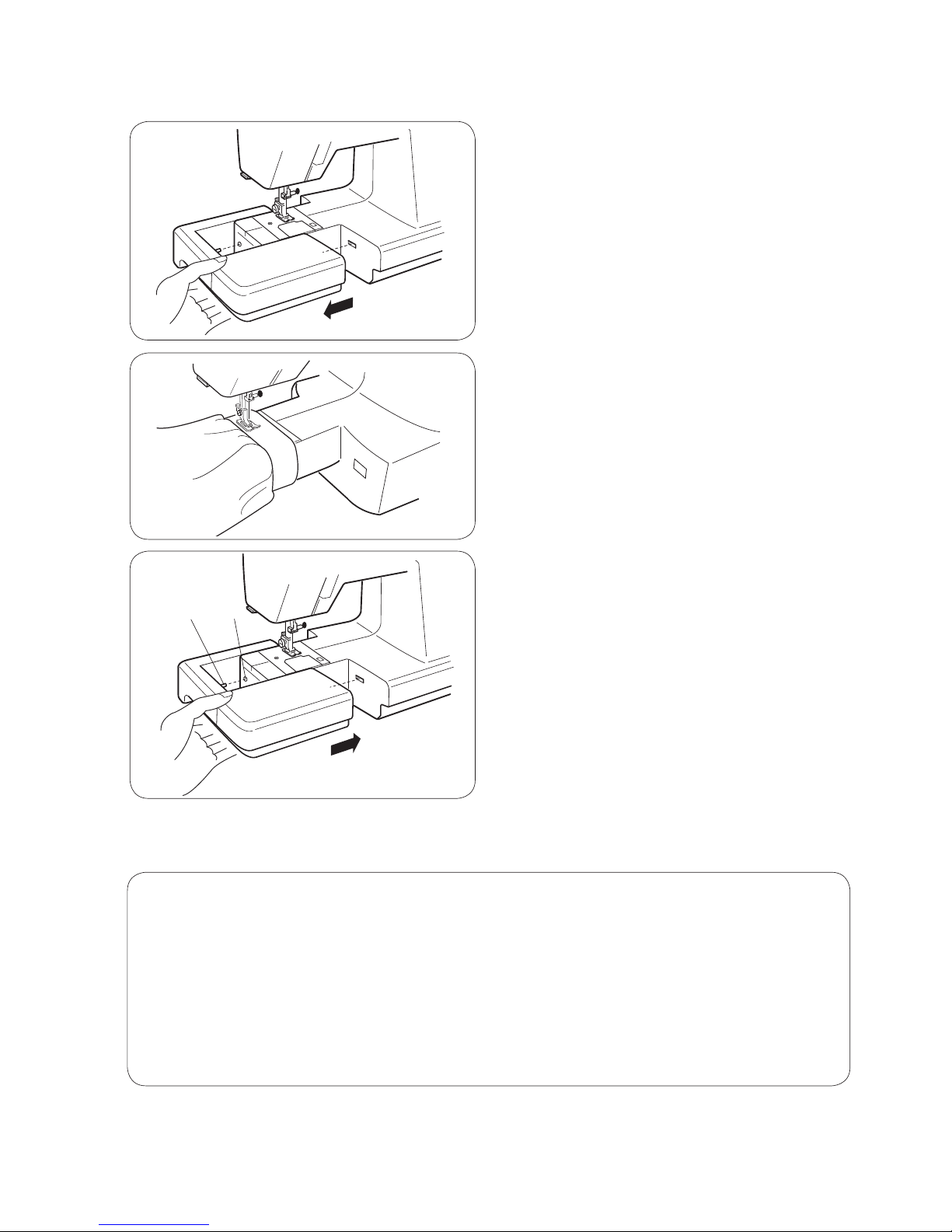

Extension Table

To r e m o v e

Hook your À ngers on the bottom left of

the extension table and pull it to the left.

Free-arm sewing

For stitching sleeves, waistbands, pant

legs or any other tubular garments.

For darning socks or mending knees or

elbows.

To attach

Slide the extension table on and insert

the pins into the holes and push the

extension table to snap it in place.

1 Pin

2 Hole

1

2

Some fabrics have a lot of excess dye which can cause discoloration on other

fabric but also on your sewing machine. This discoloring may be very difÀ cult or

impossible to remove.

Fleece and denim fabric in especially red and blue often contain a lot of excess

dye.

If you suspect that your fabric/ready-to-wear garment contains a lot of excess

dye, always pre-wash it before sewing to avoid the discoloring.

Page 6

4

4

8

16

17

18

13

19

20

21

22

23

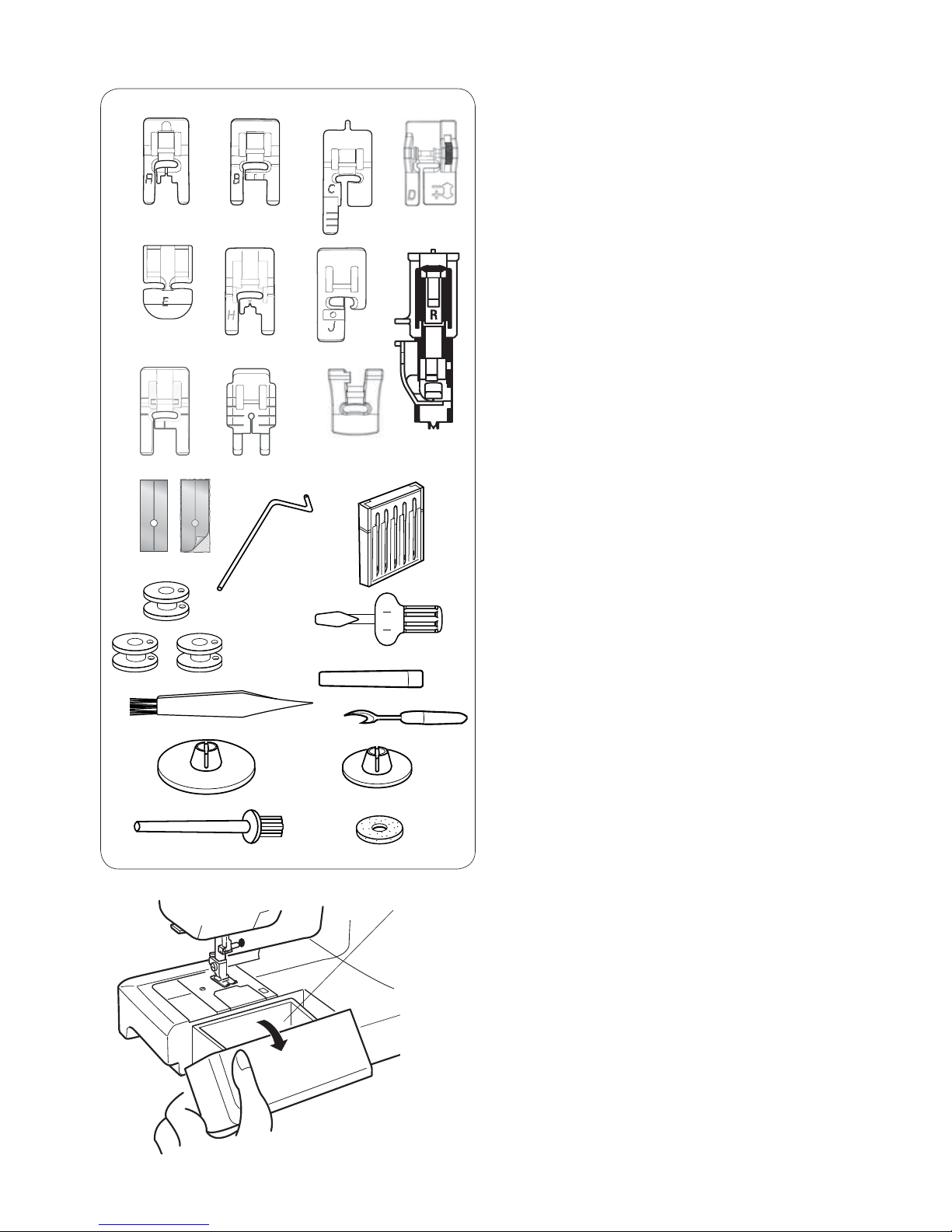

Standard Accessories and

Storage

1. Utility Foot A

2. Utility Foot B

3. Buttonhole Foot C

4. Adjustable Blind Hem Foot

5. Zipper Foot E

6. Non-stick Glide Foot H

7. Edging Foot J

8. Automatic Buttonhole Foot R

9. Transparent Foot B (only model

122)

10. Quilter’s 1/4” Piecing Foot P (only

model 122)

11. Gathering Foot (only model 122)

12. Self-adhesive Glide Plates

13. Edge/quilting Guide

14. Needles

15. Bobbins

16. Screwdriver

17. Lint brush

18. Seam ripper (Buttonhole opener)

19. Spool holder (Large)

20. Spool holder (Small)

21. Vertical spool pin

22. Felt cushion

23. Accessory storage (Open the

extension table for storing

accessories.)

2

5

11

6

3

9

14

10

12

15

7

1

Page 7

5

Getting ready to sew

Connecting the Power Supply

Turn the power switch off.

Insert the foot control plug into the

machine socket.

Insert the power supply plug into the

machine and the wall outlet.

Turn the power switch on.

1 Power switch

2 Foot control plug

3 Machine plug

4 Machine socket

5 Power supply plug

6 Wall outlet

NOTE: Before connecting to the power

supply, make sure the voltage shown on

the machine conforms to your electrical

power.

The foot control model that has to be

used for each sewing machine model are

shown in the table below.

1

2

4

3

6

5

For the USA and Canada:

This sewing machine has a polarized

plug (one blade wider than the

other). To reduce the risk of electric

shock, this plug is intended to À t in a

polarized outlet only one way. If the

plug does not À t fully in the outlet,

reverse the plug. If it still does not

À t, contact a qualiÀ ed electrician to

install the proper outlet.

DO NOT modify the plug in any

way!

For Emerald 118 and 122

1

2, 3

4

5

For Emerald 116

6

Foot control Model

Model

21361

Emerald

122 and

118

120V or

230 - 240V

Model

YC-190

Emerald

116

230 - 240V

Model

YC-482

Emerald

116

120V

Page 8

6

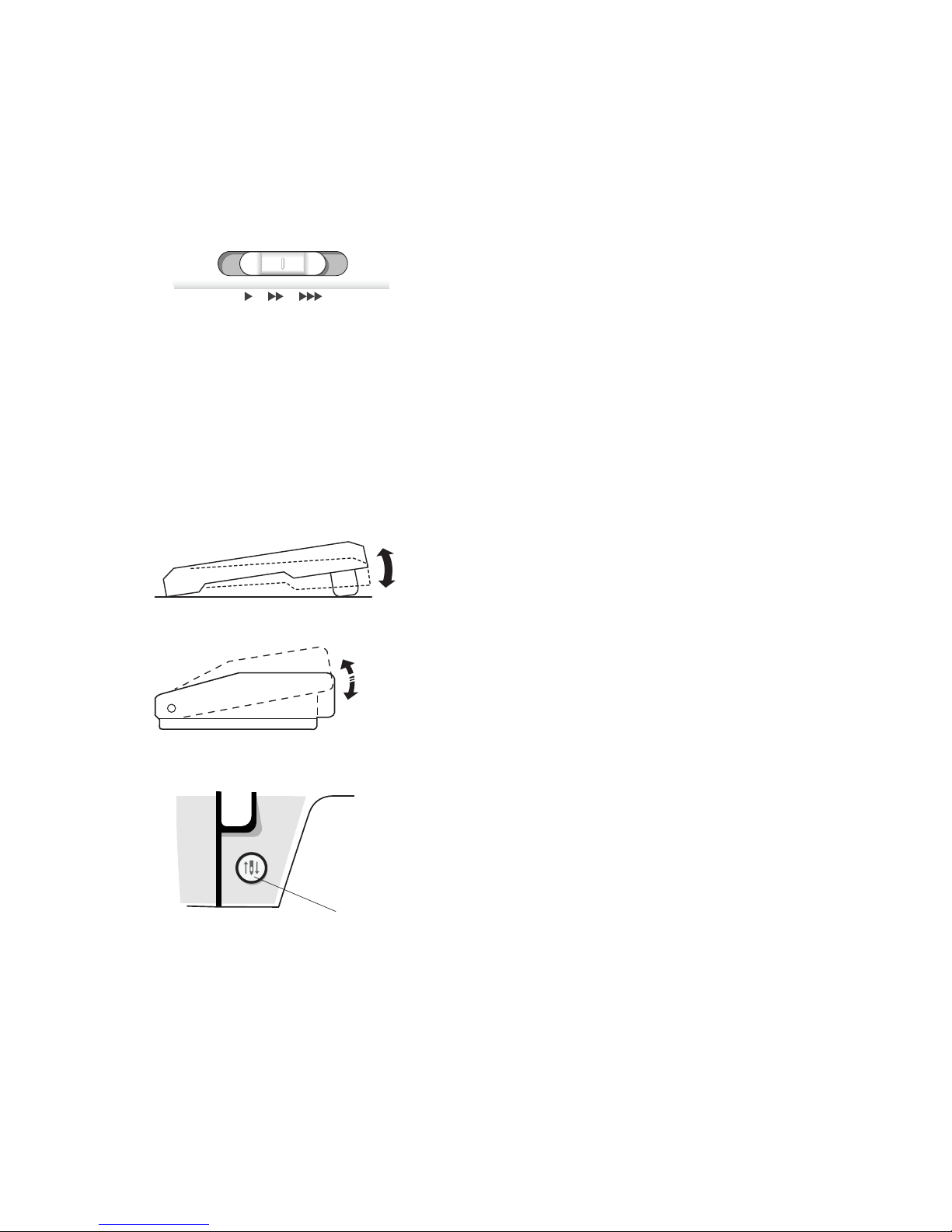

Adjusting the Sewing Speed

You can control the sewing speed in two

ways; with the speed control slide or

with the foot control.

Speed control slide (model 118 and

122)

With the speed control slide, you can

change the sewing speed to suit your

needs. The slide limits how fast you can

sew.

To increase the sewing speed, slide the

bar to the right.

To reduce the sewing speed, slide the bar

to the left.

Foot control

You can control the sewing speed by using

the foot control. The harder you press the

foot control, the faster the machine sews.

If you press the foot control all the way,

the machine runs at the maximum speed

set by the speed control slide.

Needle up/down (model 118 and

122)

Touch this button to move the needle

down or up. The setting of the needle

stop position is changed at the same

time.

1 Needle up/down

1

For model 118 and 122

For model 116

Page 9

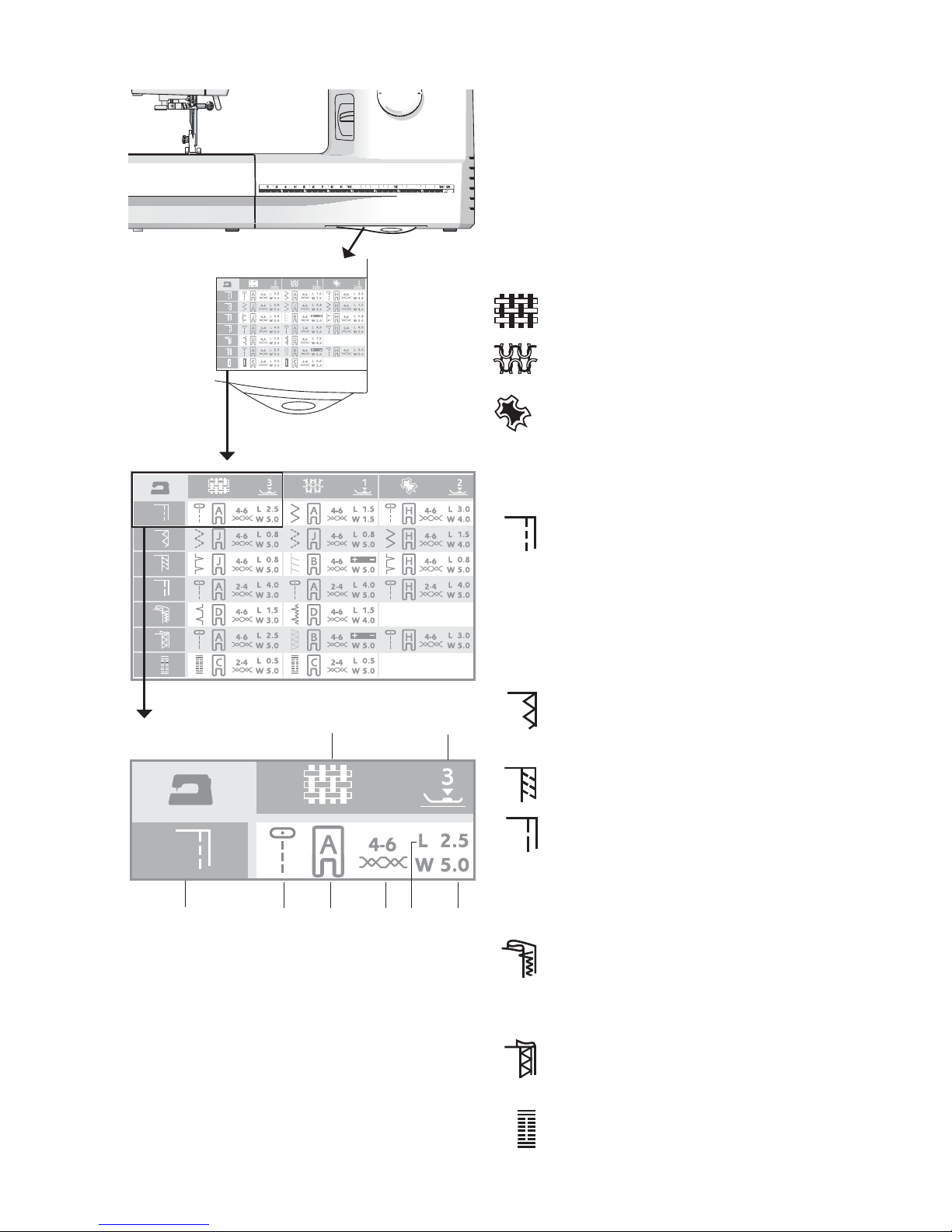

7

Sewing Guide Reference Chart

Consult the Sewing Guide Reference Chart

for the fast easy way to select the best

stitch, stitch length, stitch width, thread

tension, presser foot and presser foot

pressure for your sewing technique and

fabric.

Look in the column for your fabric type:

WOVE N FABRICS: for stable fabrics

that have no stretch. Usually woven.

STRETCH FABRICS: for fabrics that

have stretch. Usually knit.

LEATHER/VINYL: for suede, real

leather and for artiÀ cial leather and

suede.

Select the stitch for the technique you want

to sew:

SEAM: sews two pieces of fabric

together.

NOTE: For Stretch Fabrics the Sewing

Guide Reference Chart recommends

setting the zig zag stitch length to

1.5 and stitch width to 1.5 for a seam

that stretches with the fabric.

OVERCAST: overcast fabric edges to

prevent them from fraying and to

help them lay Á at.

SEAM/OVERCAST: sews the seam and

overcasts the edge all at one time.

BASTE: a temporary stitching for

À tting garments, gathering and

marking. Use maximum stitch length.

NOTE: Basting will leave permanent

holes in leather and vinyl.

BLIND HEM: creates an invisible hem

on garments. Is not recommended

for light weight fabric or for leather/

vinyl.

HEM: sews the best visible or top

stitch hem for your fabric type and

weight.

BUTTONHOLE: sews the best

buttonhole possible for your fabric.

1

3

2

4 5 6 87

1 Fabric

2 Presser foot pressure

3 Sewing technique

4 Stitch

5 Presser foot

6 Thread tension

7 Stitch length

8 Stitch width

Page 10

8

Reverse Lever

When you press the reverse lever

downwards, the machine will sew in

reverse. The machine will only sew in

reverse as long as the reverse lever is

pressed down.

1 Reverse lever

Presser Foot Pressure Dial

Turn the pressure dial to adjust the

pressure of the presser foot on the

fabric when sewing on different

thicknesses of fabric. The pressure dial

should be set at 3 for regular sewing.

Reduce the pressure to 2 for appliqué,

cutwork and basting. Set the setting mark

at 1 when sewing stretch fabrics, chiffon,

lace, organdy and other À ne fabrics. Set

on 0 for free motion.

1 Setting mark

Lowering the Feed Teeth

The drop feed lever is located on the

free-arm on the back of the machine.

To lower the feed teeth, push the lever in

the direction of the arrow, as illustrated.

To raise the feed teeth, push the lever in

the direction of the arrow, as illustrated,

and turn the handwheel toward you or

start sewing to bring the feed teeth up.

The feed teeth must be up for regular

sewing.

1 Raised position

2 Lowered position

1

1

2

1

Page 11

9

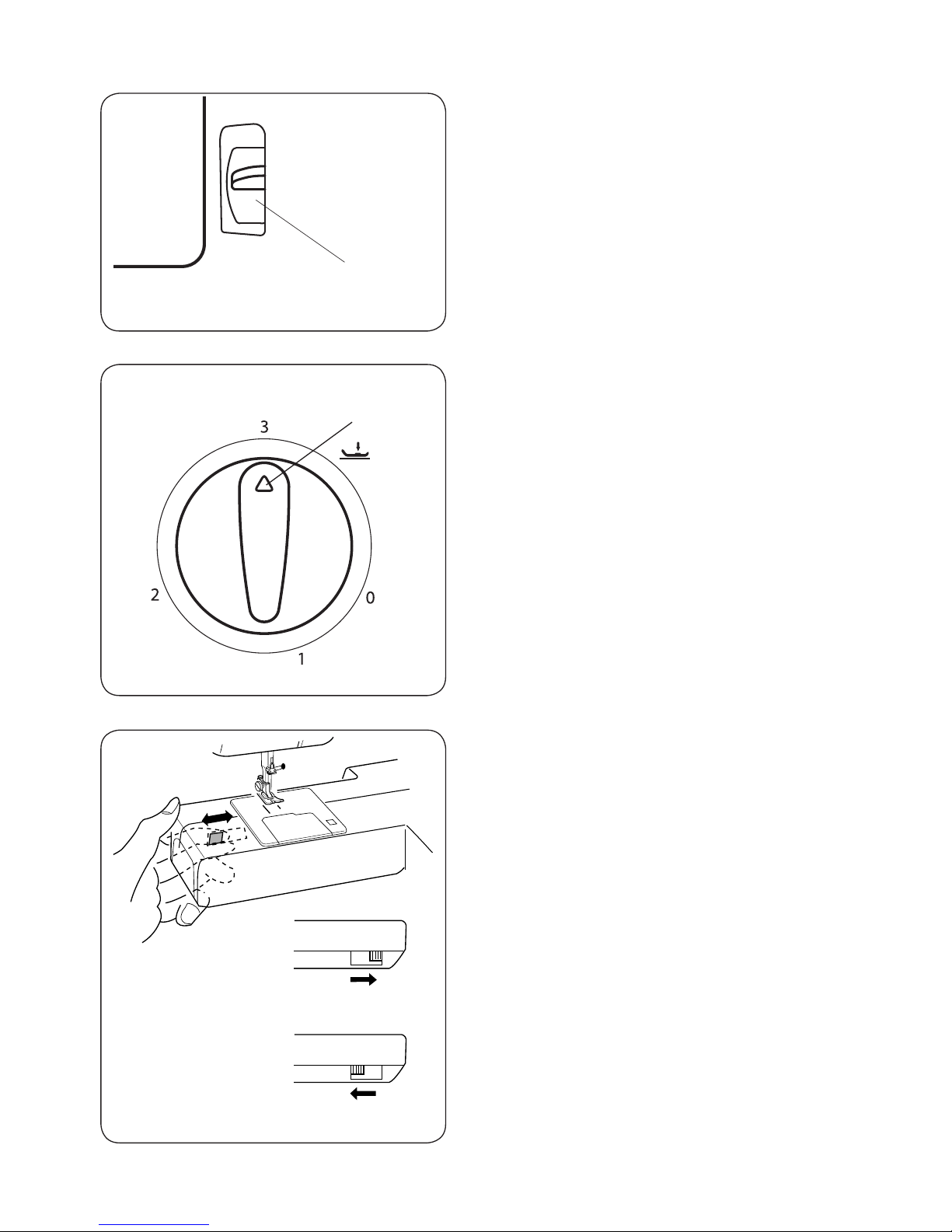

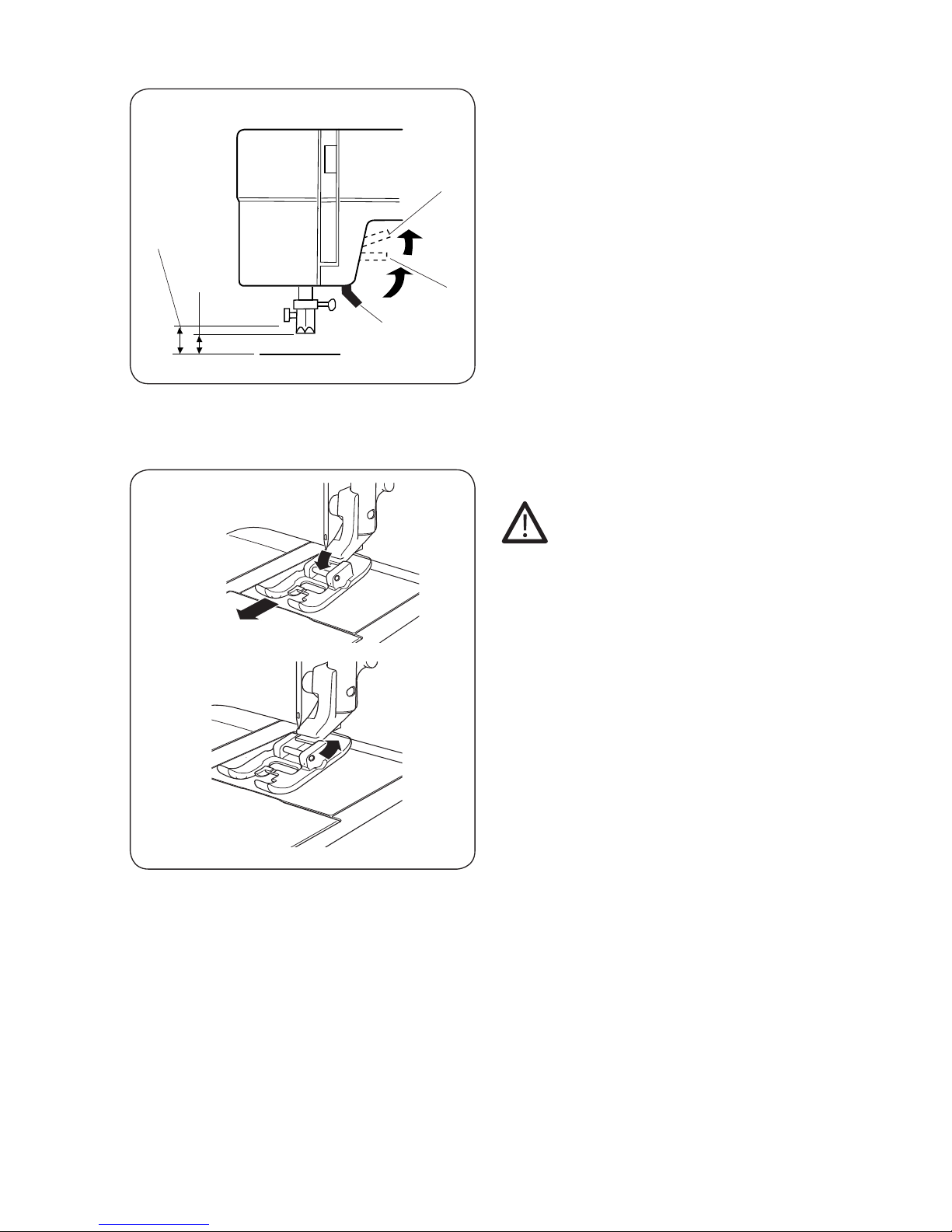

Raising and Lowering the

Presser Foot

The presser foot is raised and lowered

with the presser foot lever. The presser

foot must be down when sewing.

By raising the presser foot lever as far as

it goes the lift height of the presser foot

can be increased by 1/4” (0.6 cm). This

is useful for easy removal of the presser

foot or when placing heavy fabrics under

the foot.

1 Lowered position

2 Normal lift height

3 Extra lift height

Changing the Presser Foot

Turn off the power switch

1 Make sure the needle is in the

highest position. Pull the presser

foot towards you.

2 To put foot on, line up the cross pin

on the foot between the spring and

the presser foot ankle. Press back

until the foot snaps into place.

1

2

3

2

3

1

2

Page 12

10

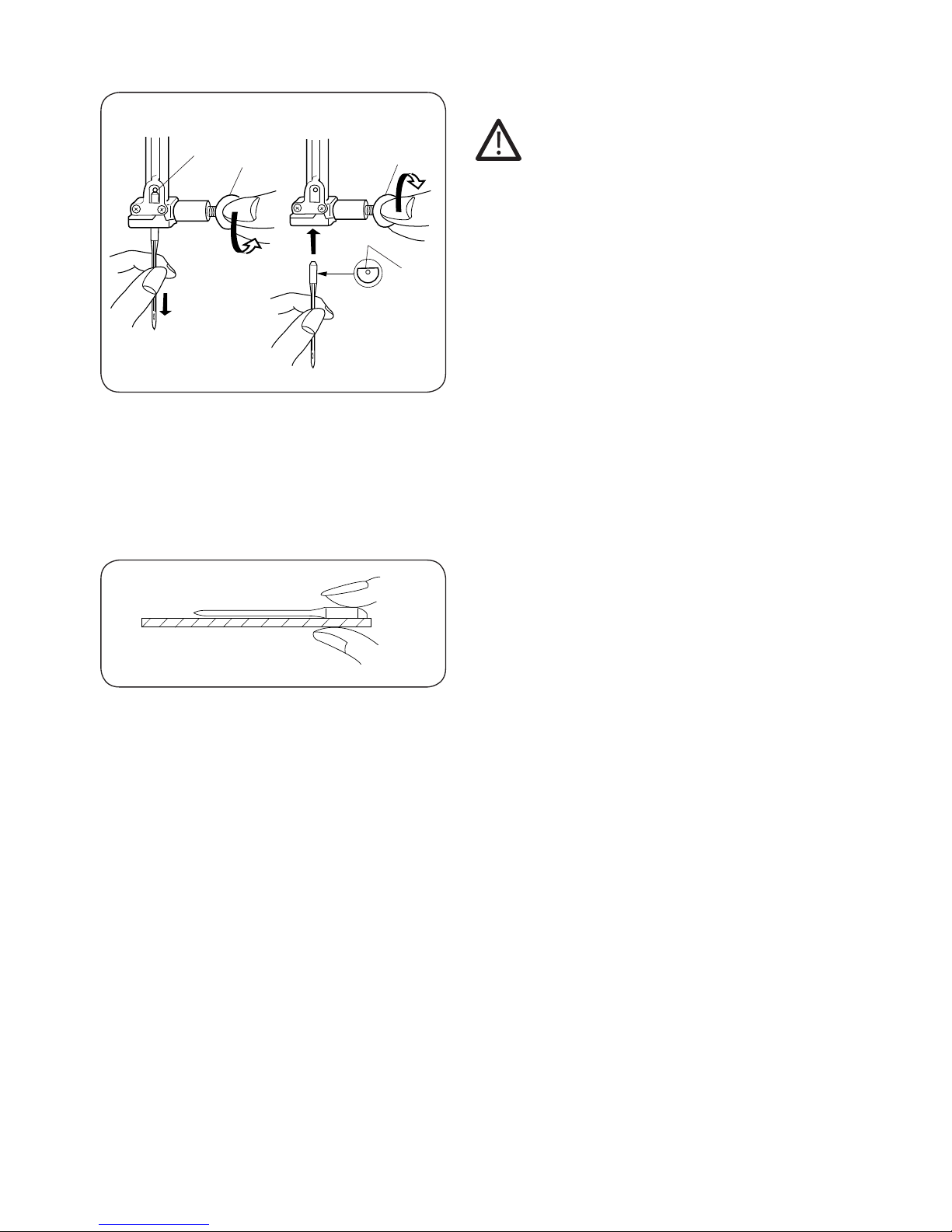

Changing the Needle

Turn off the power switch.

Your machine uses standard sewing

machine needles.

1 Lower the presser foot. Loosen the

screw in the needle clamp by turning

it counterclockwise. Remove the

needle.

2 Push up the new needle as far as it

will go with the Á at side away from

you. Tighten the screw À rmly by

turning it clockwise.

a Stop

b Flat side

c Needle clamp screw

To check for a good needle:

Put the Á at side of the needle onto

something Á at (needle plate, glass etc.).

The gap between the needle and the Á at

surface should be consistent.

Never use a blunt needle. A damaged

needle can cause permanent snags or

runs in knits, À ne silks and silk-like-

fabrics.

NOTE: Check the needle frequently for

barbed or blunt points.

a

b

c

c

2

1

Page 13

11

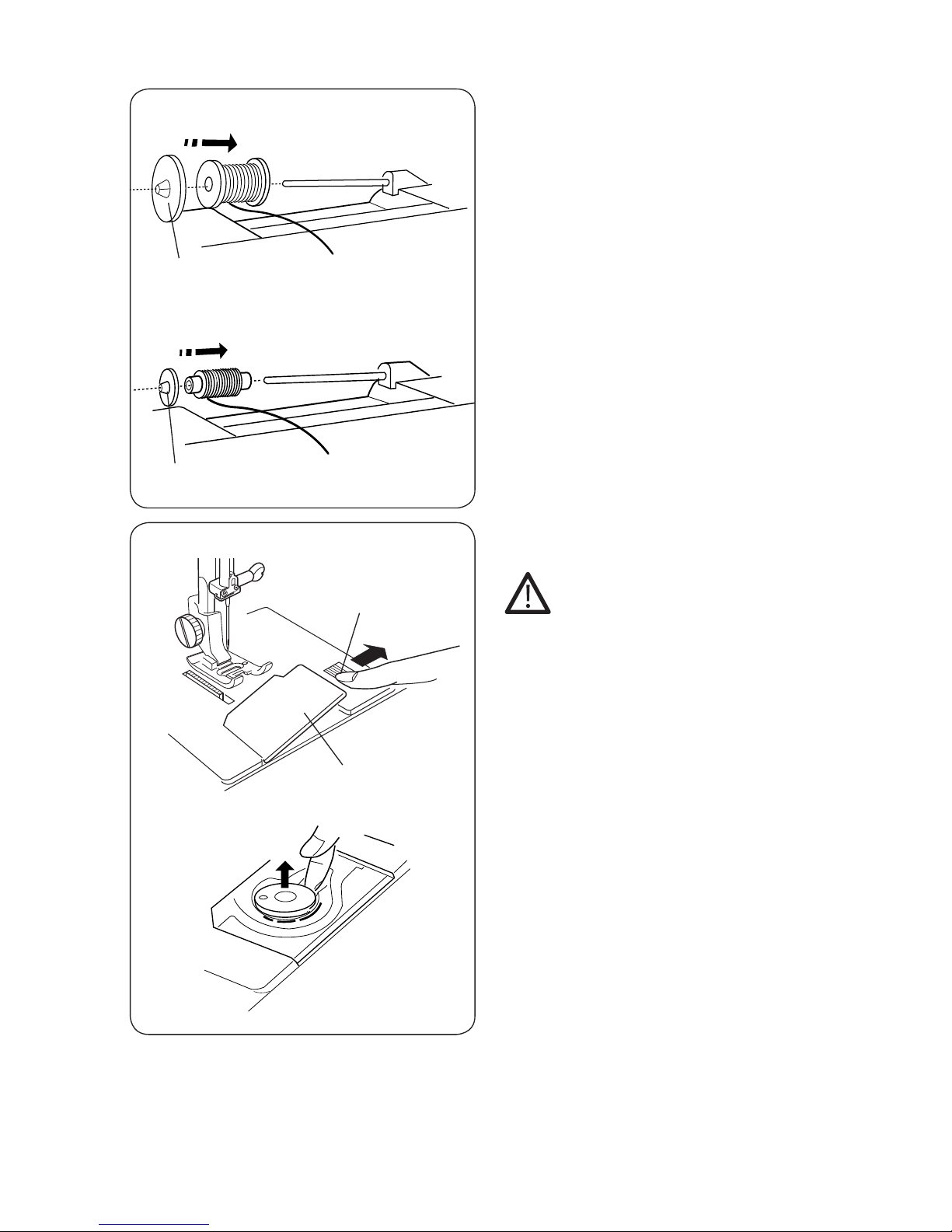

Placing the thread spool on

the spool pin

Place the thread spool on the spool pin

with the thread coming off as illustrated.

With large thread spools, the large

holder is placed in front of the thread. If

you use narrow thread spools, the small

holder is placed in front of the thread.

1 Large spool holder

2 Small spool holder

Removing the bobbin

Turn off the power switch.

1 Push the bobbin cover release

button to the right and remove the

cover.

a Release button

b Bobbin cover plate

2 Lift out the bobbin.

1

2

a

b

1

2

Page 14

12

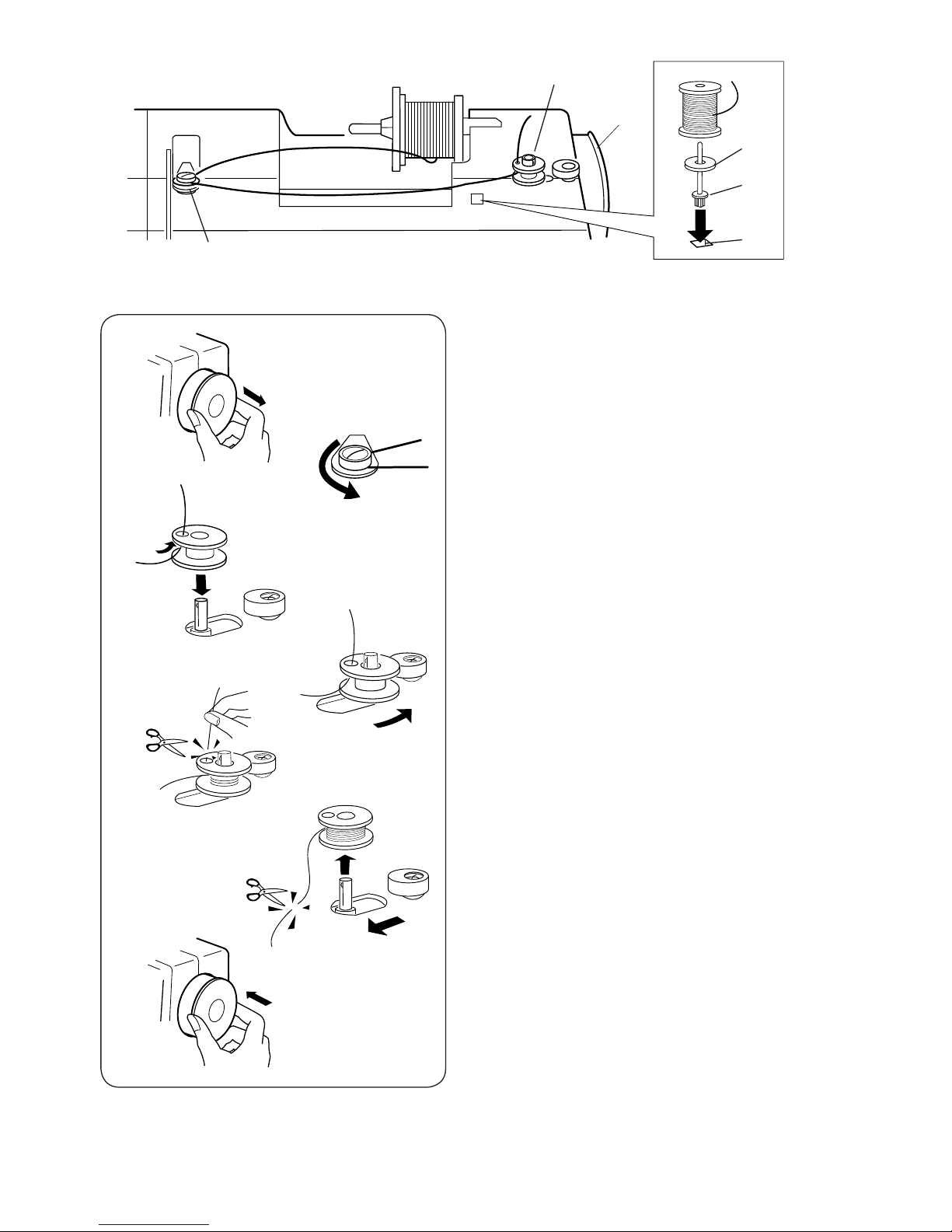

Bobbin Winding

1 Pull the handwheel out to put the

machine in bobbin wind position (the

needle will not go up and down).

2 Guide the thread around the bobbin

thread tension guide into the tension

disk.

3 Thread through the hole in the

bobbin from the inside to the outside.

Put the bobbin on the bobbin winder

spindle with the free end of the

thread coming out at the top.

4 Slide the bobbin winder spindle to the

right.

NOTE: Do not move the bobbin

winder spindle while the machine is

running.

5 With the free end of the thread held

in your hand, press the foot control.

Stop the machine when the bobbin

has made a few turns, and cut the

thread as illustrated.

6 Press the foot control again. When

the bobbin is fully wound, it will stop

automatically. Slide the bobbin winder

to its original position by moving the

spindle to the left, and cut the thread

as illustrated.

7 Push in the handwheel.

To use the vertical spool pin, set the felt

and the spool as shown above.

a Vertical spool pin

b Spool pin felt

c Spool pin hole

a

b

c

3

1

3

1

4

2

5

6

7

2

Page 15

13

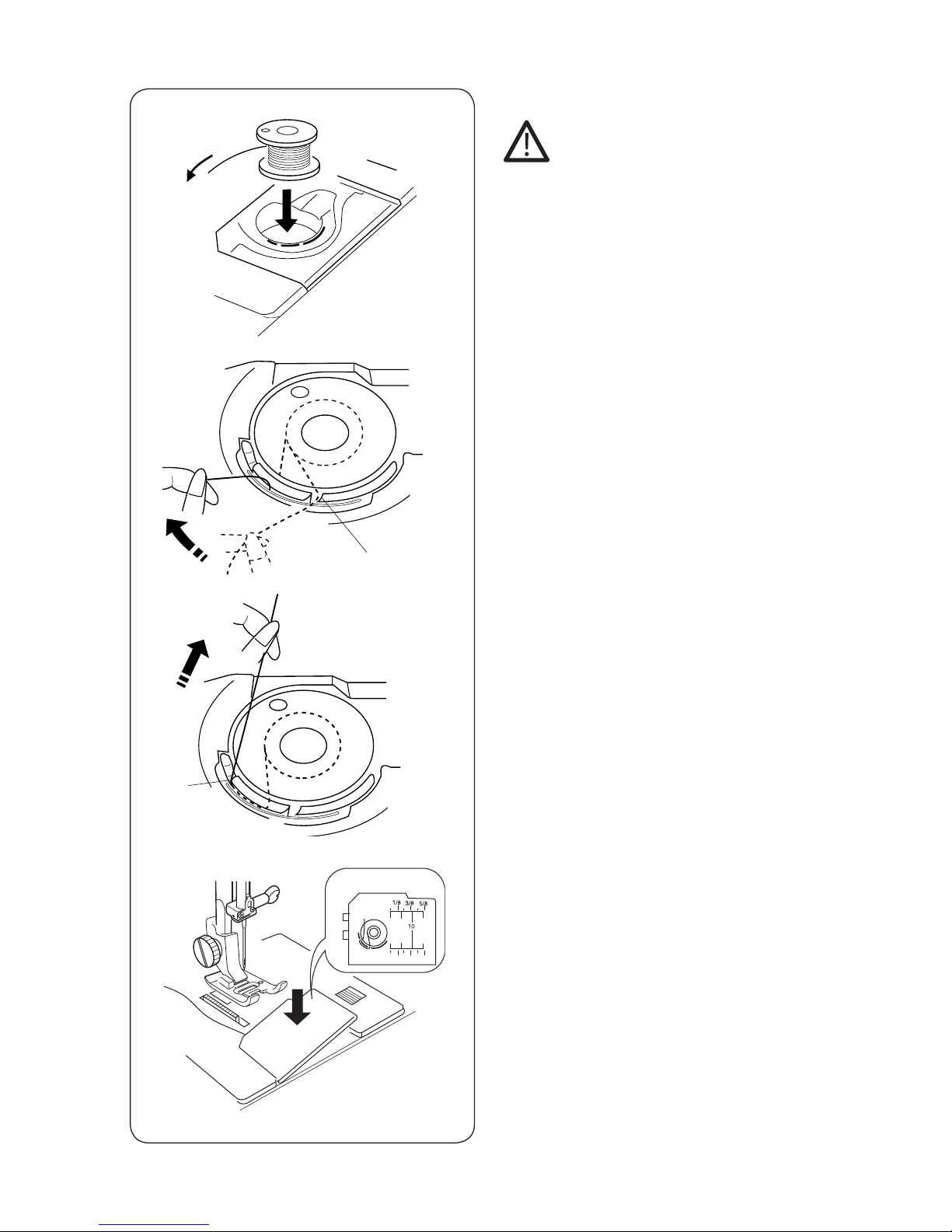

Placing the bobbin

Turn off the power switch

1 Place the bobbin in the bobbin

case with the thread pulling off as

illustrated.

2 Guide the thread into the front

notch (a) on the front side of the

bobbin case. Draw the thread to the

left, sliding it between the tension

spring blades.

3 Continue to draw the thread lightly

until the thread slips into the side

notch (b).

4 Pull out about 10 cm (4”) of thread.

Attach the bobbin cover. Check the

threading by referring to the chart

shown on the bobbin cover.

a

b

1

2

3

4

Page 16

14

Threading the Machine

Turn off the power switch

Make sure the presser foot is raised and

the needle is in the up position.

1 Bring the thread from the spool and

pass it through the thread guide.

Then draw it down along the right

slot.

2 Guide the thread around the bottom

of the thread guide plate.

3 Firmly draw the thread from right to

left over the take-up lever and down

into the take-up lever eye.

4 Slide the thread from the left behind

the needle bar thread guide.

5 Use the needle threader to thread

the needle (see page 15).

1

4

5

2

3

1

2

3

5

4

Page 17

15

Needle threader

Turn off the power switch

1 Raise the needle to its highest position.

Lower the needle threader as far as it

will go. The hook comes through the

needle eye from behind.

2 Bring the thread from the left around

the guide and under the hook.

a

Guide

b Hook

3 Release the knob slowly while

holding the thread end with your

hand. A loop of the thread is pulled

through the needle eye.

4 Pull the loop of thread behind the

needle eye.

1

2

3

4

a

b

Page 18

16

Bringing up the Bobbin

Thread

Turn off the power switch.

1 Raise the presser foot and hold the

needle thread lightly with your left

hand.

2 Turn the handwheel slowly toward

you one complete turn. Bring the

bobbin thread up by pulling the

needle thread as illustrated.

a Needle thread

b Bobbin thread

3 Pull 10 cm (4”) of both threads back

and under the presser foot.

a

b

1

2

3

Page 19

17

Stretch stitches

Emerald 116

Emerald 122

Emerald 118

Stretch stitches

Stretch stitches

Stitches

Page 20

18

Stitch selection

Raise the needle to its highest position.

Turn the stitch selection dial to set the

desired stitch pattern number at the

setting mark.

1 Stitch selection dial

2 Setting mark

NOTE: Always raise the needle above the

fabric and presser foot before you turn

the stitch selction dial.

Stitch Length

Turn the stitch length dial to set the

desired stitch length number at the

setting mark. The higher the number, the

longer the stitch.

The

mark shows the adjustment

range when sewing the buttonhole.

3 Stitch length dial

Set the stitch length dial at “stretch”

when sewing stretch stitches.

NOTE: Always raise the needle above the

fabric and presser foot before you turn

the stitch length dial.

3

1

2

2

3

2

Page 21

19

Adjusting stretch stitch

balance

If the stretch stitches are unbalanced

when you sew on a particular fabric,

balance them by turning the stitch length

dial, within the stretch range.

To adjust the distorted stitches:

If the stitches are spread out (a),

correct them by turning the dial in the

“–” direction. If the stitches are close

together (b), correct them by turning the

dial in the “+” direction.

Stitch Width

Turn the stitch width dial to set the

desired stitch width number at the

setting mark.

The higher the number, the wider the

stitch.

1 Stitch width dial

2 Setting mark

NOTE: Always raise the needle above the

fabric and presser foot before you turn

the stitch width dial.

Variable needle position

The needle position of the straight

stitches can be varied between the center

(5) and left (0) with the stitch width dial.

1

2

a

b

Page 22

20

Balancing Needle Thread

Tension

The thread tension may be adjusted

depending on the sewing materials,

layers of fabric and sewing method.

Balanced tension:

The ideal straight stitch has threads

locked between two layers of fabric, as

illustrated.

For an ideal zigzag stitch, the bobbin

thread does not show on the right side

(top side) of the fabric, and the needle

thread shows slightly on the wrong side

(bottom side) of the fabric.

1 Needle thread

2 Bobbin thread

3 Right side

4 Wrong side

Needle thread tension is too tight:

The bobbin thread appears on the right

side of the fabric. Loosen the needle

thread tension by moving the dial to a

lower number.

Needle thread tension is too loose:

The needle thread appears on the wrong

side of the fabric. Tighten the needle

thread tension by moving the dial to a

higher number.

1

2

3

4

Page 23

21

Basic sewing

Straight Stitch Sewing

Machine setting

Consult the Sewing Guide Reference

Chart for the settings recommended.

Starting to sew

Raise the presser foot and position the

fabric next to a seam guide line on the

needle plate. Lower the needle to the

point where you want to start. Lower the

presser foot and pull the threads toward

the back. Press the foot control. Gently

guide the fabric along the seam guide

line letting the machine feed the fabric.

Changing the sewing direction

Stop the machine and press the Needle

Up/Down button (model 118 and 122) or

turn the handwheel (model 116) to bring

the needle down into the fabric. Raise the

presser foot. Pivot the fabric to change

sewing direction as desired. Lower the

presser foot and continue sewing in the

new direction.

Page 24

22

Finishing sewing

1 Press the reverse lever and sew

several stitches in reverse at the end

of the seam, to lock the stitch.

2 Raise the presser foot and remove

the fabric, drawing the threads to the

back.

3 Draw the threads up and into the

thread cutter. The threads are cut

the proper length for starting the

next seam.

1

2

3

Page 25

23

Seam Guides on the Needle

Plate

The seam guides on the needle plate help

you measure seam allowance.

The numbers indicate the distance

between the center needle position and

the seam guide.

1 Seam guides

Pivoting

Seam along the 5/8” guide. Stop stitching

and lower the needle when the fabric edge

facing you lines up with the cornering

guides as shown. Raise the presser foot

and pivot the fabric to line up to the edge

with the 1.6 cm (5/8”) seam guide. Lower

the presser foot and begin sewing in the

new direction.

2 Cornering guide

1

2

Number 15 20 4/8 5/8 6/8

Spacing 1.5 2.0 1.3 1.6 1.9

(cm)

Page 26

24

Utility Stitches

Consult the Sewing Guide Reference

Chart for the fast easy way to select the

best stitch, stitch length, stitch width,

thread tension, presser foot and presser

foot pressure for your sewing technique

and fabric.

Basic Zigzag

Simple zigzag stitching is widely used for

overcasting, sewing on buttons etc.

Three-step Zigzag

When using the Edging Foot J for

three-step zigzag, make sure the

needle does not hit the pin in the

needle hole

.

Three-step zigzag is suitable for

overcasting most fabrics. It is used on the

seam allowance to prevent fabrics from

fraying at raw edges. Make sure that the

needle sews over the edge of the fabric.

Seam and Overcast

The Seam/Overcast stitch sews the seam

and overcasts the edge all at one time.

Page 27

25

Reinforced Straight Stitch

Machine setting

1 Stitch pattern: 1

2 Stitch width: 0 or 5

3 Stitch length: stretch

4 Thread tension: 2 – 5

5 Presser foot: Utility foot A

This stitch is stronger than regular straight

stitch, due to the fact that it is a triple and

elastic stitch.

The reinforced straight stitch can be used

for heavy stretch fabrics, for crotch seams

which are subject to considerable strain

and for topstitching in heavy fabrics.

Button Sewing

Machine setting:

1 Stitch: 2

2 Stitch width: Adjust as necessary

3 Stitch length: Any

4 Thread tension: 3 – 7

5 Feed teeth: Lowered

Mark the fabric where the button is to

be located. Lower the feed teeth. Place

the material under the presser foot ankle.

Place the button on marking and lower

the presser bar so that the presser foot

ankle is between the holes of the button.

Hold the thread ends to one side. Turn

the handwheel and check to be sure that

the needle goes into the holes of the

button. Sew 5-6 stitches. Set the stitch

width dial to 0 and lock the threads with a

few stitches.

NOTE: Do not use this technique if

the button is less than 1 cm (3/8”) in

diameter.

Raise the feed teeth after button sewing.

12

4

3

5

1

2

4

5

3

Page 28

26

Automatic Buttonhole

Machine setting

1 Stitch pattern:

2 Stitch width: 4 – 5

3 Stitch length:

4 Thread tension: 3 – 5

5 Presser foot: Automatic buttonhole

foot R

NOTES: The size of buttonhole is

automatically set by placing the button

in the automatic buttonhole foot R. The

button holder of the foot takes a button

size up to 2.5 cm (1”) in diameter. Make

a test buttonhole on a fabric sample

duplicating the interfacing and seams of

the actual garment. Use stabilizer under

all fabric.

Turn the handwheel toward you to raise

the needle to its highest position.

1 Snap on the automatic buttonhole

foot R

2 Pull the button holder to the back,

and place the button in it. Push back

the button holder against the button

to hold it tight.

1

2

1

2

4

5

3

Page 29

27

3

4

3 Pull the buttonhole lever down as far

as it will go.

a Buttonhole lever

4 Raise the foot and put the needle

thread through the hole and under

the foot. Draw both threads to the

left. Insert the fabric under the foot

and lower the needle at the starting

point. Lower the foot.

b Needle thread

c Bobbin thread

d Hole

e Starting point

NOTE: Make sure there is no gap

between the slider and front stop. If

there is a gap, the length of the right and

left rows of the buttonhole will differ.

f Slider

g Front stop

h Difference

i There should be no gap.

b

c

e

d

f

i

g

h

a

Page 30

28

6

5 Sew slowly. The machine will stitch

the complete buttonhole. Stop the

machine at the starting point when

the buttonhole is completed.

The machine sews the front bartack

and left column À rst, then the back

bartack and right column.

6 Raise the foot and remove the

fabric.Cut both needle and bobbin

threads leaving about 10 cm (4”) of

thread ends loose. Draw the needle

thread to wrong side of the fabric

by pulling the bobbin thread. Then,

knot the threads. Place a pin on one

end of the bartack position so that

you do not need to worry about

cutting the end of the buttonhole.

Then cut the opening with seam

ripper.

To sew another buttonhole, turn the

stitch selector to

, then back to

again, as shown. Move fabric to next

buttonhole marking.

Now, simply step on the foot control to

sew an identical buttonhole.

5

Page 31

29

7 When À nished, push the buttonhole

lever up as far as it will go.

Adjusting the buttonhole stitch density

Turn the stitch length dial within

the range of

to adjust the

buttonhole stitch density.

NOTE: If the button is extremely

thick, make a test buttonhole. If it is

difÀ cult to À t the button through the

test buttonhole, lengthen the size by

pulling back the button holder which will

increase the buttonhole length.

1 Gap

7

1

Page 32

30

1

2

3

Corded Buttonhole

Machine setting:

1 Stitch pattern:

2 Stitch width: 4 – 5

3 Stitch length:

4 Thread tension: 3 – 5

5 Presser foot: Automatic buttonhole

foot R

1 With the buttonhole foot raised,

hook the À ller cord on the spur at

the back of the buttonhole foot.

Bring the cord under the foot and

hook the À ller cord into the notches

on the front of the foot to hold

them tight.

a Spur

2 Draw both needle and bobbin

thread to the left. Lower the needle

into the fabric where the buttonhole

will start and lower the foot. Press

the foot control gently and sew

the buttonhole over the cord. The

sewing sequence is the same as the

automatic buttonhole.

b Needle thread

c Bobbin thread

d Starting point

3 Pull the left end of the À ller cord

to tighten it. Thread the end of the

cord through a darning needle, draw

to the wrong side of the fabric and

cut. To cut the buttonhole opening,

refer to the instructions on page 28.

a

b

c

d

1

2

4

5

3

Page 33

31

Manual Buttonhole

Consult the Sewing Guide Reference

Chart for recommended settings.

If the diameter of the button is more

than 2.5 cm (1”), make the buttonhole

manually as follows:

1 Snap on buttonhole foot C.

2 Pull the buttonhole lever down as

far as it will go. Draw both needle

and bobbin thread to the left. Lower

the needle into the fabric where the

buttonhole is to start, and lower the

foot.

a Needle thread

b Bobbin thread

c Starting point

1

2

a

b

c

Page 34

32

4 Sew the front bartack and left

column to the desired length then

stop sewing.

5 Pull the buttonhole lever toward

you.

6 Sew the back bartack and right

column and then stop sewing at the

starting point.

7 When À nished, push the buttonhole

lever up as far as it will go.

4

5

6

7

Page 35

33

Sewing Zipper

Machine setting

1 Stitch pattern: 1

2 Stitch width: 5

3 Stitch length: 1.5 – 4

4 Thread tension: 3 – 6

5 Presser foot: Zipper foot E

To Snap On the Zipper Foot

Snap on the zipper foot.

1 Groove

2 Pin

To sew the left side of the zipper, snap

on zipper foot on the right bar on the

side.

To sew the right side of zipper, snap on

the zipper foot on the left bar on the

side.

Fabric Preparation

1 Add 1 cm (3/8”) to the zipper size

for the overall opening size.

a Right side of the fabric

b 1 cm (3/8”)

c Opening size

d Zipper size

e Slider

f Zipper teeth

g Zipper tape

h Wrong side of the fabric

i End of the opening

1

2

4

5

3

1

2

a

b

c

d

e

f

g

h

i

1

Page 36

34

2 Place right sides of the fabric

together. Sew a seam from the

bottom 2 cm (5/8”) from the

right edge to the end of the zipper

opening. Sew a few stitches in

reverse to lock. Increase the stitch

length to “4”, set needle thread

tension to “1”, and baste the length

of the zipper opening.

j 2 cm (5/8”)

k Basting

l Reverse stitch

m End of the opening

n Straight stitch

To sew

1 Snap on the zipper foot with the bar

on the right side. Turn under the

right seam allowance to form a 0.4

cm (1/8”) fold.

a Lower layer

b End of opening

c Zipper teeth

d 0.4 cm margin

e Wrong side of the fabric

f Opening size

g Fold

h Basting stitch line

2 Place zipper teeth next to the fold

and pin in place. Align the zipper

foot with the fold. Return thread

tension and stitch length to original

settings. Sew a seam the entire length

of zipper tape, removing pins as you

go.

j

k

l

m

n

a

b

c

d

e

f

g

h

c

e

2

1

2

Page 37

35

3 Sew through all layers next to the

fold. Stop just before the zipper

foot reaches the slider on the zipper

tape. Lower the needle slightly into

the fabric. Raise the zipper foot and

open the zipper. Lower the foot and

stitch the remainder of the seam.

i Slider

j 5 cm (2”)

4 Close the zipper and spread the

fabric Á at with the right side facing

up. Baste the opened fabric and

zipper tape together.

k Basting

l Zipper tape

i

j

i

k

l

3

4

Page 38

36

5 Remove the zipper foot and snap

on with pin on left side. Guide the

edge of the foot along the zipper

teeth and stitch through the fabric

and zipper tape, about 1 cm (3/8”)

distance from the basting line. Stop

about 5 cm (2’’) from the top of the

zipper.

m Remove the basting stitches

n 1 cm (3/8”)

6 Unzip a few centimeters/inches to

clear a path for the stitch. At end of

seam, sew a few stitches in reverse

to lock. Once both sides of zipper

are sewn, use the seam ripper to

open the rest of the basting stitch.

m

n

5

6

Page 39

37

Blind Hem

Consult the Sewing Guide Reference

Chart for recommended settings.

1 Fold the hem under the fabric

as illustrated for À ne or medium

fabrics. Fold a hem with the wrong

side up forming a 0.5 cm (1/8”)

allowance.

a Wrong side of the fabric

b 0.5 cm (1/8”)

c Heavy weight fabric

d Light/medium weight fabric

2 Snap on the adjustable blind hem

foot. Place hem under the presser

foot. When the needle comes to the

left side, position the fabric so that

the folded edge comes to the left

side of the guide. Lower the presser

foot.

3 Turn the orange dial on the blind

hem foot backward or forward to

adjust the foot from side to side

until the wide stitch of the blind

hem barely catches the fabric.

4 Open the fabric after sewing and

press Á at.

e Right side of the fabric

a

b

c

d

a

b

e

1

2

3

4

Page 40

38

Non-stick Glide Foot H

Consult the Sewing Guide Reference

Chart for recommended settings.

When sewing foam, plastic, plastic

coated fabrics, leather and imitation

leathers, the Non-stick Glide Foot

H feeds over the fabric without

sticking. Use it for general sewing and

buttonholes on plastic and leather type

fabrics.

Snap on the Non-stick Glide Foot H.

Select desired stitch and sew.

Quilting Guide

The quilting guide will help keep

stitching lines straight.

Slide the guide into the clip on the ankle.

Adjust from side to side to the correct

position. Sew, guiding the quilt guide

over the previous row of stitching.

1 Clip

2 Quilting guide

3 Seam spacing

Presser Feet

only model 122

Transparent Foot B

Satin stitch applique, taper stitches and

decorative stitches. Length as desired.

The tunnel on the underside of the

foot feeds smoothly over the stitches.

Because it is clear and has red guidelines,

visibility and accuracy is improved. Use

stabilizers as needed.

Snap on foot. Set decorative or satin

stitch. Sew.

3

1

2

Page 41

39

Gathering Foot

Gather fabric or gather and attach a

rufÁ e in one step. Suitable for light to

medium weight fabrics. Straight stitch,

(left needle position), length 4. The

longer the length, the more fabric will

gather. Snap on Gathering Foot.

For gathered fabric:

Place fabric under Gathering Foot and

sew. Increase upper tension for tighter

gathers.

To gather and attach gathered fabric

in one step:

Place fabric to be gathered under the

presser foot right side up. Place fabric to

have rufÁ e attached to it in the groove

of the foot right side down. Sew, guiding

the under fabric but do not hold it

back. Keep the top fabric in the groove

moving steadily as needed. Increase the

stitch length and the upper tension for

more gathers.

Quilter’s 1/4” Piecing Foot

Sew a scant 1/4” seam allowance. Red

lines mark 1/4” and 1/8” pivot points in

front of and behind the needle. Straight

stitch, length 2.0-2.5.

Place to pieces of fabric right sides

together. Sew with edge of fabric at

edge of foot. To pivot 1/4” from end

of fabric, stop sewing with needle stop

down, when fabric edge reaches À rst red

mark on foot.

Page 42

40

Care and

maintenance

Turn off the power switch.

Do not dismantle the machine other

than as explained in this section. Clean

the outside of the machine with a soft

cloth and mild soap.

Cleaning the Hook Assembly

area and Feed Teeth

1 Remove the presser foot and needle.

Remove screw on the left side of

the needle plate with the screwdriver

supplied with the machine. Remove

the needle plate and take out the

bobbin.

a Screw

2 Lift up the bobbin case and remove

it.

3 Brush out dust and lint.

4 Clean the feed teeth and hook

assembly area with the lint brush.

5 Wipe out gently with a soft, dry

cloth.

NOTE: You may also use a vacuum

cleaner.

a

1

2

3

4

5

Page 43

41

Replacing the Bobbin Case

Turn off the power switch.

1 Insert the bobbin case into the hook

assembly area.

2 Make sure the knob of the bobbin

case À ts next to the stopper in the

assembly area.

a Knob

b Stopper

3 Insert the bobbin. Replace the

needle plate, inserting the two needle

plate guide pins into the holes in the

needle plate. Replace the screw.

c Guide holes

d Screw

Replacing the Light Bulb

Turn off the power switch. Wait

for the light bulb to cool down before

touching it.

Remove the cap and screw. Remove the

face plate.

(1) Emerald 116 (max 15W)

To remove: Push and twist to the left.

To replace: Push and twist to the right.

(2) Emerald 118 and 122 (12V, 5W)

To remove: Draw out slowly.

To replace: Push in.

(1)

(2)

a

b

d

c

c

1

2

3

Page 44

42

Troubleshooting

Reference

Page 14

Page 20

Page 10

Page 10

Page 21

Page 22

Page 13

Page 40

Change the bobbin.

Page 10

Page 10

Page 21

Page 10

Page 10

Page 14

Change the needle.

Page 20

Page 14

Make stitch shorter.

Page 40

Make stitch longer.

Page 8

Page 20

Page 5

Page 40

Page 12

Page 40

Page 40

Page 29

Use interfacing.

Page 8

Page 32

Page 32

Page 27

Page 27

Cause

1. The needle thread is not threaded properly.

2. The needle thread tension is too tight.

3. The needle is bent.

4. The needle is incorrectly inserted.

5. The needle thread and the bobbin thread are not placed under

the presser foot at start of sewing.

6. The threads were not drawn to the rear after sewing.

1. The bobbin thread is not threaded properly in the

bobbin case.

2. Lint has collected in the bobbin case.

3. The bobbin is damaged and does not turn smoothly.

1. The needle is incorrectly inserted.

2. The needle clamp screw is loose.

3. The threads were not drawn to the rear after sewing.

4. The needle is incorrectly inserted, bent or blunt.

5. The needle and/or threads are not suitable for the fabric being

sewn.

1. The needle thread is not threaded properly.

2. A poor quality needle is used.

3. The needle thread tension is too tight.

1. The needle thread is not threaded properly.

2. The stitch length is too long for the fabric.

1. The feed teeth are packed with lint.

2. The stitchlength is too short.

3. The feed teeth are not raised after ”drop feed” sewing.

1. The needle thread tension is too loose.

1. The machine is not plugged in.

2. Thread has been caught in the hook.

3. The bobbin winder spindle is still in the winding position.

1. Thread has been caught in the hook assembly area.

2. Lint has built up in the hook assembly area or bobbin case.

1. The stitch density is not suitable for the fabric being sewn.

2. Interfacing is not used when sewing on the stretch

fabrics.

1. Foot pressure is not adjusted properly.

1. Pull down buttonhole lever.

2. Be sure the buttonhole lever is in the back position.

1. Button must be tight in foot.

2. There is space in foot. Check gap.

Condition

The needle

thread breaks.

The bobbin

thread breaks.

The needle

breaks.

Skipped

stitches

Seam

puckering

The cloth is

not fed

smoothly.

Loops on the

seams

The machine

does not

work.

Noisy

operation

Buttonhole

is not sewn

neatly.

Layer slippage

Buttonhole

won't sew

Buttonhole

has gaps

Page 45

Page 46

Page 47

We reserve the right to change the machine equipment and

the assortment of accessories without prior notice, or make

modiÀ cations to the performance or design.

Such modiÀ cations, however, will always be to the beneÀ t of

the user and the product.

Please note that on disposal, this product must be safely

recycled in accordance with relevant National legislation

relating to electrical/electronic products. If in doubt please

contact your retailer for guidance

Intellectual property

HUSQVARNA, VIKING, the "Crowned H-mark" and

EMERALD are registered trademarks or trademarks of

VSM Group AB or its licensor.

Page 48

VSM Group AB • SE-561 84 Huskvarna, Sverige

www.husqvarnaviking.com

412 96 59 - 26F • InHouse • © 2005-2009 VSM Group AB • All rights reserved • Printed on environmentally-friendly paper

Loading...

Loading...