Page 1

GB Operator´s manual

FR Manuel d'utilisation

ES Manual de instrucciones

EDGER ATTACHMENT

ACCESSOIRE TRANCHE-BORDURE

SUPLEMENTO CORTABORDES

Please read these instructions carefully

and make sure you understand them

before using the machine.

Lire attentivement et bien assimiler le

manuel d’utilisation avant d'utiliser la

machine.

Lea detenidamente el manual de

instrucciones y asegúrese de entender su

contenido antes de utilizar la máquina.

GB FR ES

Page 2

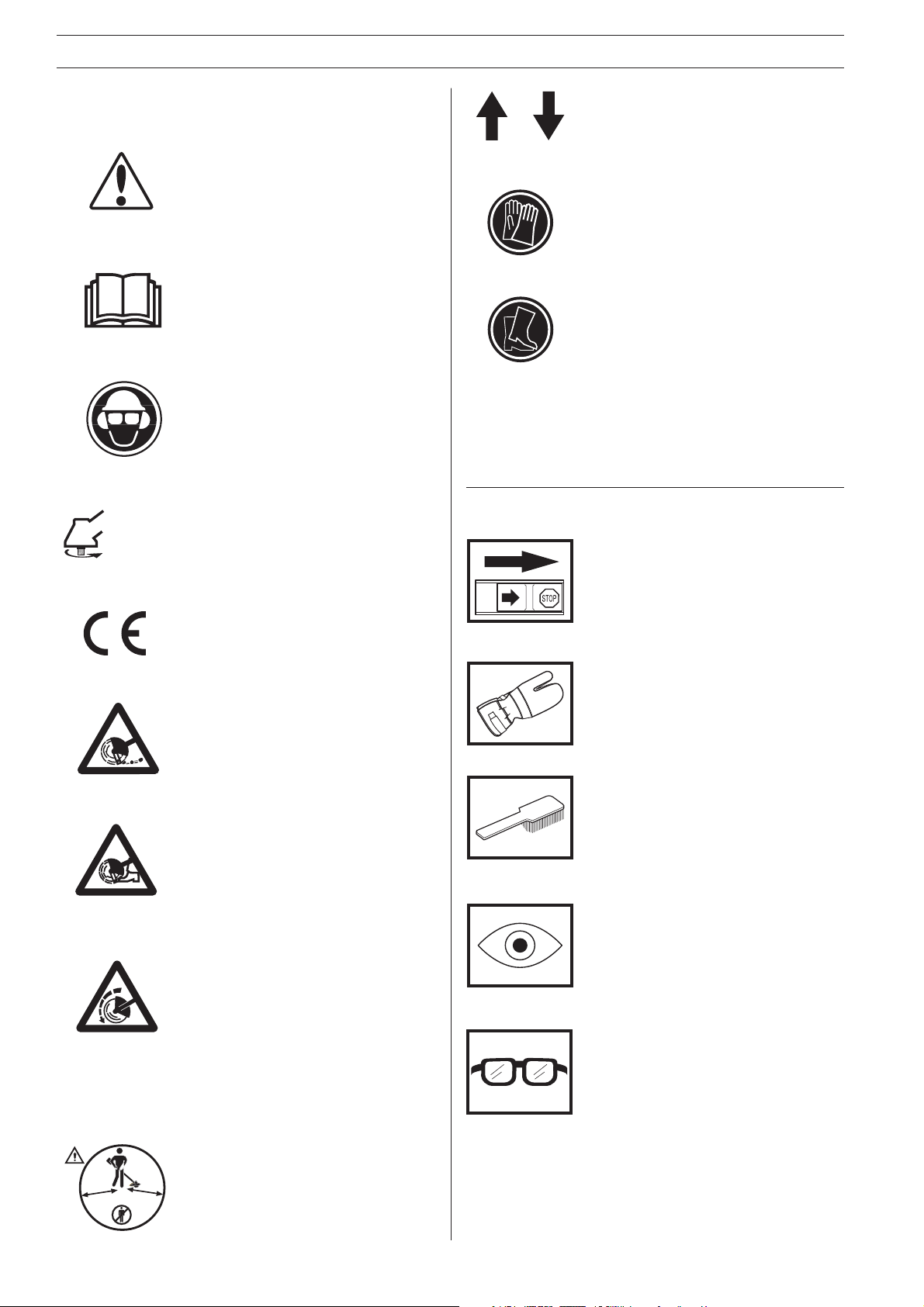

EXPLANATION OF SYMBOLS

Symbols

max

10000 rpm

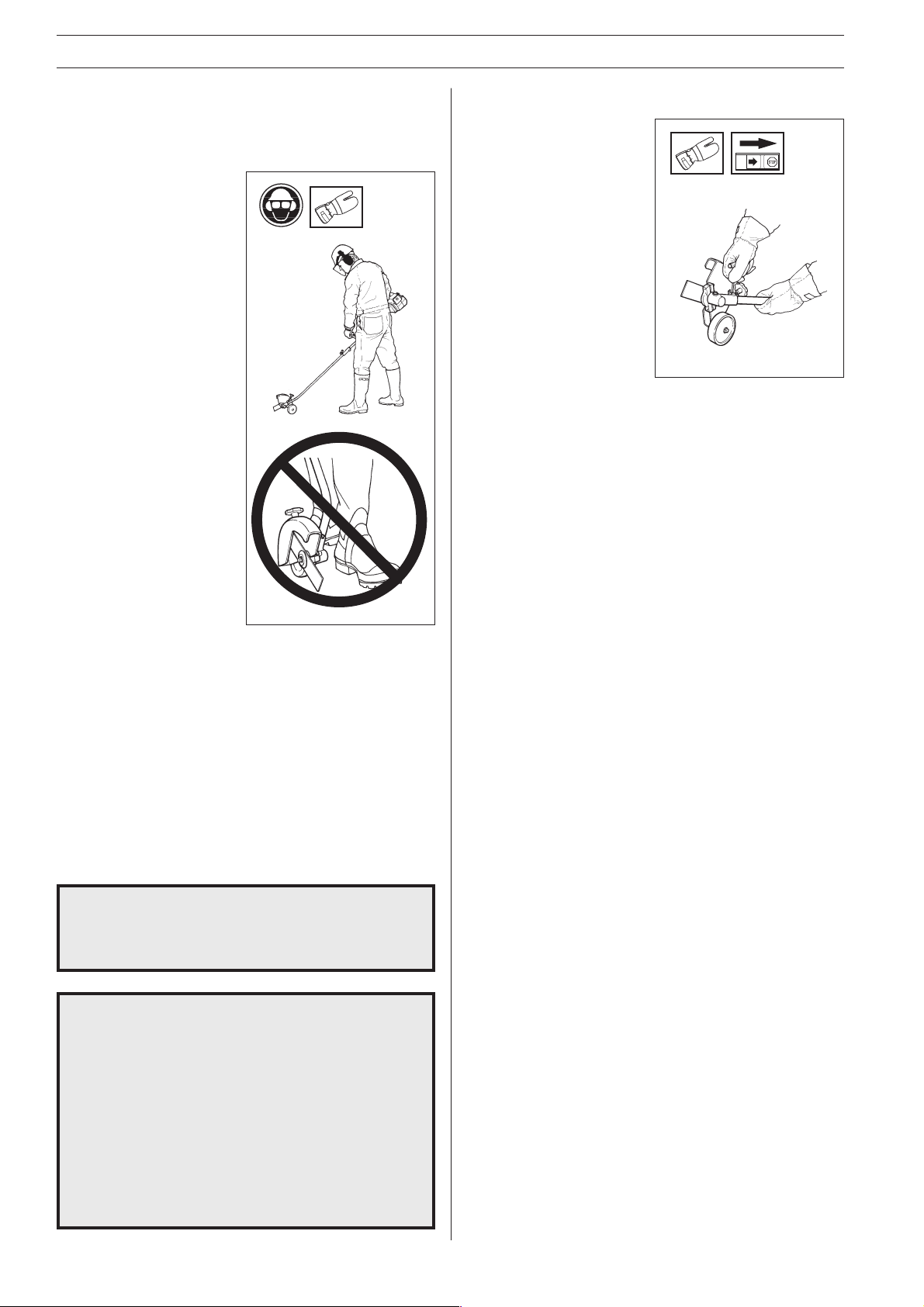

WARNING! The edger can be

dangerous!

Careless or incorrect use can result in

serious or fatal injury to the operator

or others.

Read through the Operator's Manual

carefully and understand the content

before using the machine.

Always use:

• A protective helmet where there is a

risk of falling objects.

• Ear protection

• Approved eye protection

Max. speed of output axle, rpm

This product is in accordance with

applicable CE directives.

Arrows which show limits for handle

mounting.

Always wear approved protective

gloves.

Use anti-slip and stable boots.

Other symbols/decals on the machine refer to

special certification requirements for certain

markets.

Checks and/or maintenance should be

carried out with the engine switched off,

with the stop switch in the STOP

position.

Beware of thrown objects and

ricochets.

Warning for rotating blade. Keep

hands and feet clear.

Warning! The blade continues to

rotate even after the engine has

stopped.

When the engine has stopped, stop

the blade from rotating by letting the

blade come in contact with the

ground.

Indicates the direction of rotation.

Always wear approved protective

gloves.

Regular cleaning required.

Ocular control.

Approved eye protection must always

be used.

2 – English

15 m

50FT

15 m

50FT

The operator of the machine must

ensure that no persons or animals

comes within a 15 metre radius while

working.

Page 3

CONTENTS

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify the

design and appearance of products without prior notice.

Read through the Operator‘s manual

carefully and understand the content before

using the machine.

These instructions supplement the instructions that were

included with the machine. For other procedures, please

refer to the opertaing instructions for hte machine.

WARNING!

Under no circumstances may the design of

!

!

the machine be modified without the

permission of the manufacturer. Always

use genuine accessories. Non authorised

modifications and/or accessories can result

in serious personal injury or the death of

the operator or others.

WARNING!

This accessory may only be used together

with the intended clearing saw/trimmer, see

under heading ”Approved accessories” in

chapter Technical data in the machine's

Operator's Manual.

List of Contents

EXPLANATION OF SYMBOLS

Symbols .............................................................................. 2

CONTENTS

List of Contents ................................................................... 3

SAFETY INSTRUCTIONS

Personal protective equipment ........................................... 4

The machine's safety equipment ........................................ 4

General safety instructions ................................................. 5

General working instructions ............................................... 5

Basic working techniques ................................................... 6

WHAT IS WHAT?

What is what on the edger attachment? ............................. 7

ASSEMBLY

Assembling the angle gear ................................................. 8

Assembling the blade .......................................................... 8

START AND STOP

Control before starting ........................................................ 8

MAINTENANCE

Angle gear ........................................................................... 9

Lubricating the flexible drive axle ........................................ 9

Adjusting the edger's cutting depth ..................................... 9

Maintenance schedule ........................................................ 9

TECHNICAL DATA

Technical data ..................................................................... 9

The machine is only designed for cutting the edges of lawns.

English – 3

Page 4

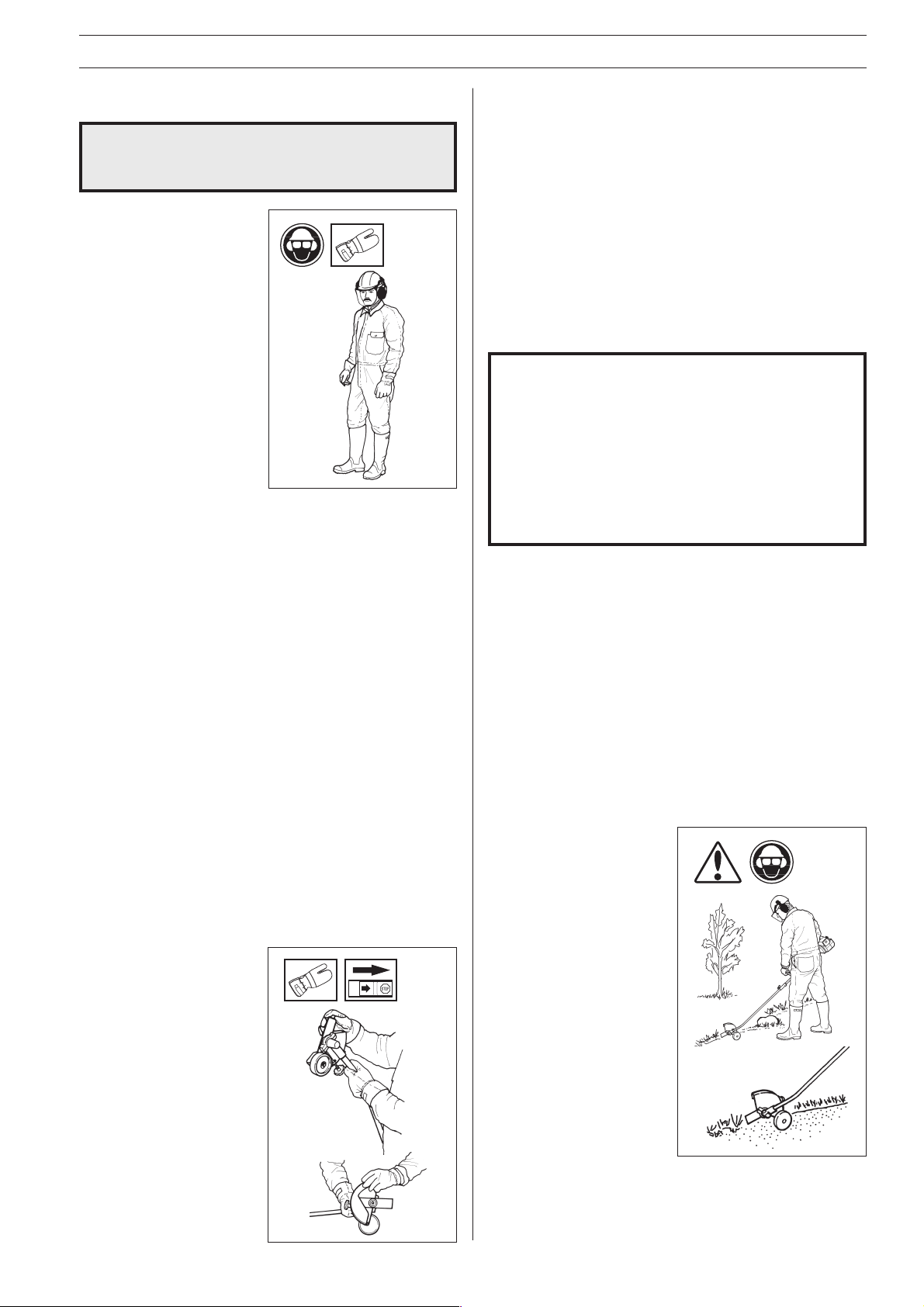

SAFETY INSTRUCTIONS

Personal protective equipment

IMPORTANT INFORMATION

• When using an edger, personal protective equipment

must be used. Personal protective equipment does

not eliminate the risk of accidents, however, it can

reduce the effects of an injury in the event of an

accident. Ask your dealer for help when choosing

protective equipment.

The machine’s safety equipment

This section describes the machine’s safety equipment, its

function and how checks and maintenance are carried out to

ensure that it operates correctly. (See the chapter

to locate where this equipment is positioned on your

what”

machine.)

WARNING!

Never use a machine with defective safety

!

equipment. Follow the control, maintenance

and service instructions described in this

section.

Cutting attachment

guard

This guard is intended to

prevent objects from being

thrown towards the operator

and to protect the operator

from unintentionel contact with

the cutting attachment.

• Ensure that the guard is

undamaged and is not

cracked.

• Replace the guard if it has

been exposed to impact or is

cracked.

• Always use the prescribed

blade and guard combination,

see chapter

in the machine's Operator's

Manual.

"Technical data"

“What is

Cutting equipment

The two basic rules:

1. Only use the cutting

equipment we recommend! See chapter

“Technical data”

machine's Operator's

Manual.

2. Check the cutting

equipment with regard to

damage and crack

formation. Damaged

cutting equipment

should always be

replaced.

WARNING!

Always stop the engine before starting

!

work on any part of the cutting equipment.

This continues to rotate even after the

throttle has been released. Ensure that the

cutting equipment has stopped completely

and remove the cable from the spark plug

before you start to work on it.

in the

Locking nut

• Protect your hand from

injury when assembling,

use the blade guard as

protection when tightening

with a socket spanner.

Tighten the nut by turning

against the direction of

rotation. Loosen the nut by

turning in the direction of

rotation. (NOTE! the nut

has a left-hand thread).

Cutting equipment

The blade is designed and

processed to withstand loads

that edging of a lawn involves.

Locking nut

The locking nut secures the

cutting equipment on the

output shaft.

4 – English

• Tighten the nut using a

socket spanner, 35 - 50 Nm

(3.5 - 5 kpm).

NOTE!

The locking nut’s nylon lock must not be so worn that it can

be turned by hand. The lock shall hold at least 1.5 Nm. The

nut should be replaced after it has been put on approx. 10

times.

WARNING!

Never use a machine with defective safety

!

equipment. The safety equipment should be

maintained as described in this section. If

your machine does not meet any of these

controls you should contact your service

workshop.

Page 5

SAFETY INSTRUCTIONS

General safety instructions

WARNING!

Faulty cutting equipment increases the

!

Personal protection

• Always wear boots and other

equipment described in the

section

equipment”

Operator's Manual.

• Always wear working clothes

and heavy-duty long trousers.

• Never wear loose sitting

clothes or jewellery.

• Persons with long hair should,

for personal safety, put their

hair up.

Safety instructions regarding the

surroundings

risk of accidents.

“Personal protective

in the machine's

• Check that the blade and blade guard are correctly secured.

• When adjusting the carburettor make sure the blade is held

against the ground and that no one is in the immediate

vicinity.

• Make sure the blade does not rotate when idling.

• Make sure the handle and safety features are in order. Never

use a machine that has parts missing or has been changed

in relation to the specification.

• Only use the machine for the purpose it was intended for.

General working instructions

IMPORTANT INFORMATION

• This section takes up the basic safety precautions

for working with the edger.

• If you encounter a situation where you are uncertain

how to proceed you should ask an expert. Contact

your dealer or your service workshop.

• Avoid all usage which you consider to be beyond

your capability.

• Never allow children to use the machine.

• Ensure no one comes closer than 15 metres when working.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

Operator’s Manual.

Safety instructions before starting work

• Inspect the working area. Remove any objects, such as

stones, broken glass, nails, steel wire, string, etc. that can

be thrown or can wrap around the blade or blade guard.

• Keep others at a safe distance. Children, animals,

onlookers and helpers should stand outside of the safety

zone of 15 m (50 feet). Stop the machine immediately if any

one should approach.

• Check the entire machine before starting work. Replace

damaged parts. Check for fuel leakage and that all safety

guards and covers are complete and fastened securely.

Check all nuts and bolts

• Check the blade for cracks

or any other damage.

Basic safety precautions

1. Observe your surroundings:

• To ensure that people, animals or other things cannot affect

your control of the machine.

• To ensure that the above mentioned do not come into

contact with the cutting equipment or objects that can be

thrown by the cutting equipment.

• NOTE! Never use a machine without the possibility of

calling for help in the event of an accident.

2. Avoid usage in unfavour-

able weather conditions.

For example, thick fog,

heavy rain, strong winds

or extreme cold, etc. To

work in bad weather

conditions is tiring and

can create dangerous

circumstances, e.g.

slippery surfaces.

• Ensure the blade guard is

mounted and not damaged.

3. Make sure you can walk

and stand safely. Look

out for any obstacles with

unexpected movement

(roots, stones, branches,

pits, ditches, etc.). Take

great care when working

on sloping ground.

4. The engine should be switched off before moving.

5. Never put the machine down with the engine running

unless you have good sight of it.

English – 5

Page 6

SAFETY INSTRUCTIONS

Basic working techniques

Safety instructions while working

• Always ensure you have a

safe and firm foothold.

• Always hold the machine

with both hands. Hold the

machine of the right-hand

side your the body.

• Make sure your hands and

feet do not come into

contact with the blade

when the engine is running.

• When the engine is

switched off, keep your

hands and feet away from

the blade until it has

stopped.

Safety instructions after completing work

• Ensure the blade has

stopped before cleaning,

carrying out repairs or an

inspection. Remove the

spark plug cable from the

spark plug.

• Wear heavy-duty gloves

when carrying out repairs

on the edger.

• Store the machine out of

reach of children.

• Only use original spare

parts with repair.

• Always cut edges at full

throttle.

• Always keep the blade close to the ground.

• Always drop to idling speed after each working operation.

Longer periods running at full throttle without loading the

engine (that is without resistance, which the engine feels

from the cutting equipment when trimming) can lead to

serious engine damage.

• Be especially careful when pulling the edger towards you

during work.

• If heavy vibrations occur, stop the engine. Remove the

spark plug cable from the spark plug. Check that the

machine is not damaged. Repair any damage.

WARNING!

Sometimes grass and stones can collect in

!

!

the blade guard and blade. Always stop the

engine when cleaning.

WARNING!

Beware of thrown objects. Always wear eye

protection. Never lean over the blade guard.

Stones rubbish etc. can be thrown up into

the eyes resulting in blindness or other

serious injury.

Keep unauthorised persons at a distance.

Children, animals, onlookers and helpers

should be outside the safety zone of 15

meters (50 feet). Stop the machine immediately if anyone approaches.

The bevel gear unit can get hot during use

and may remain so for a while afterwards.

There is a risk of slight burns if you touch it.

6 – English

Page 7

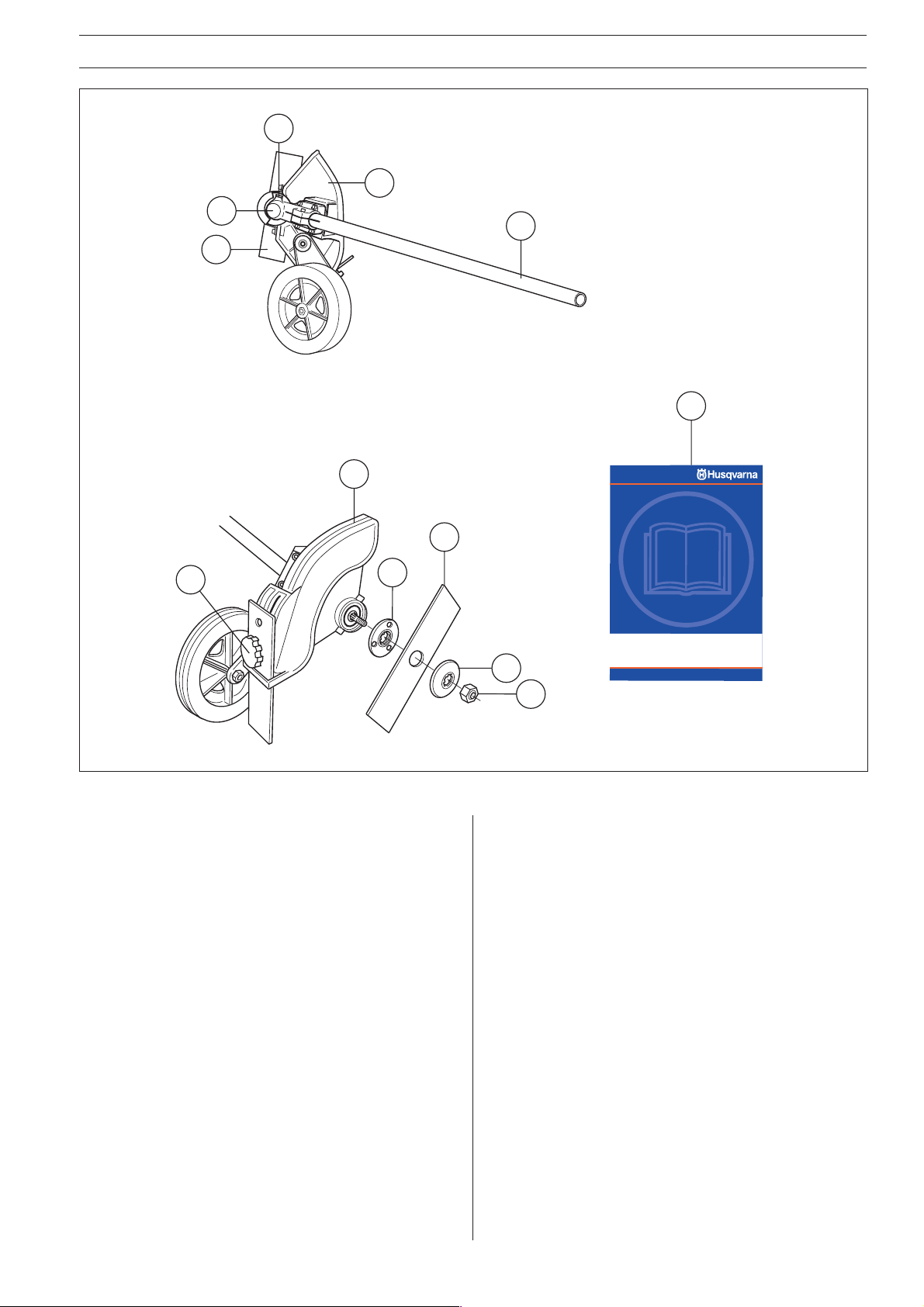

WHAT IS WHAT?

2

4

3

5

1

10

4

1

6

7

What is what on the edger

attachment?

1. Blade

2. Grease filler cap

3. Angle gear

4. Blade guard

5. Shaft

8

9

6. Locking nut

7. Support flange

8. Drive disc

9. Locking handle

10. Operator's Manual

English – 7

Page 8

ASSEMBLY

START AND STOP

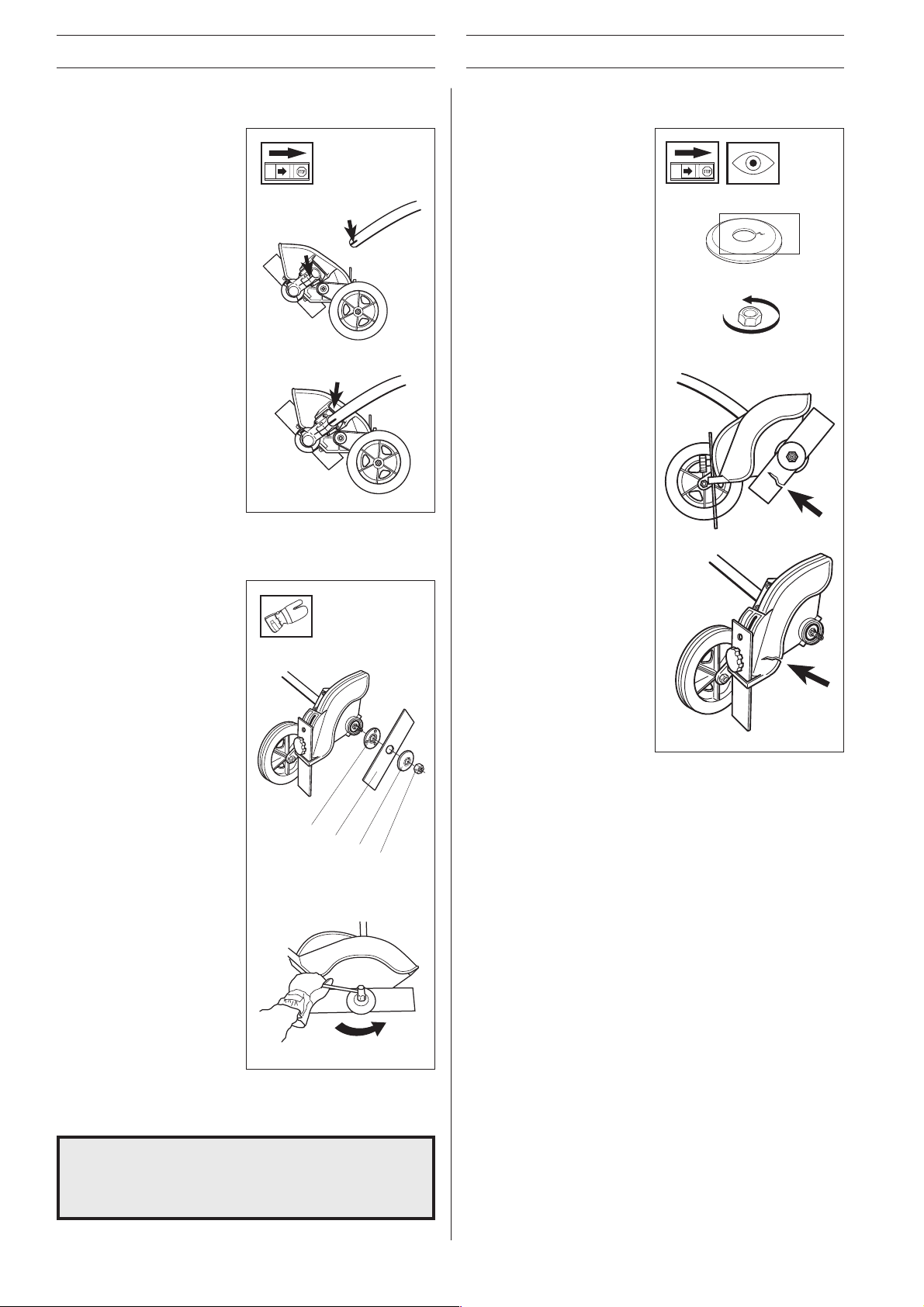

Assembling the angle gear

• Assemble the angle gear

back on the supporting

tube.

Turn the blade so that the

drive shaft engages in the

angle gear.

• Position the angle gear so

that its slot is aligned with

the line on the supporting

tube.

• Firmly tighten the screw.

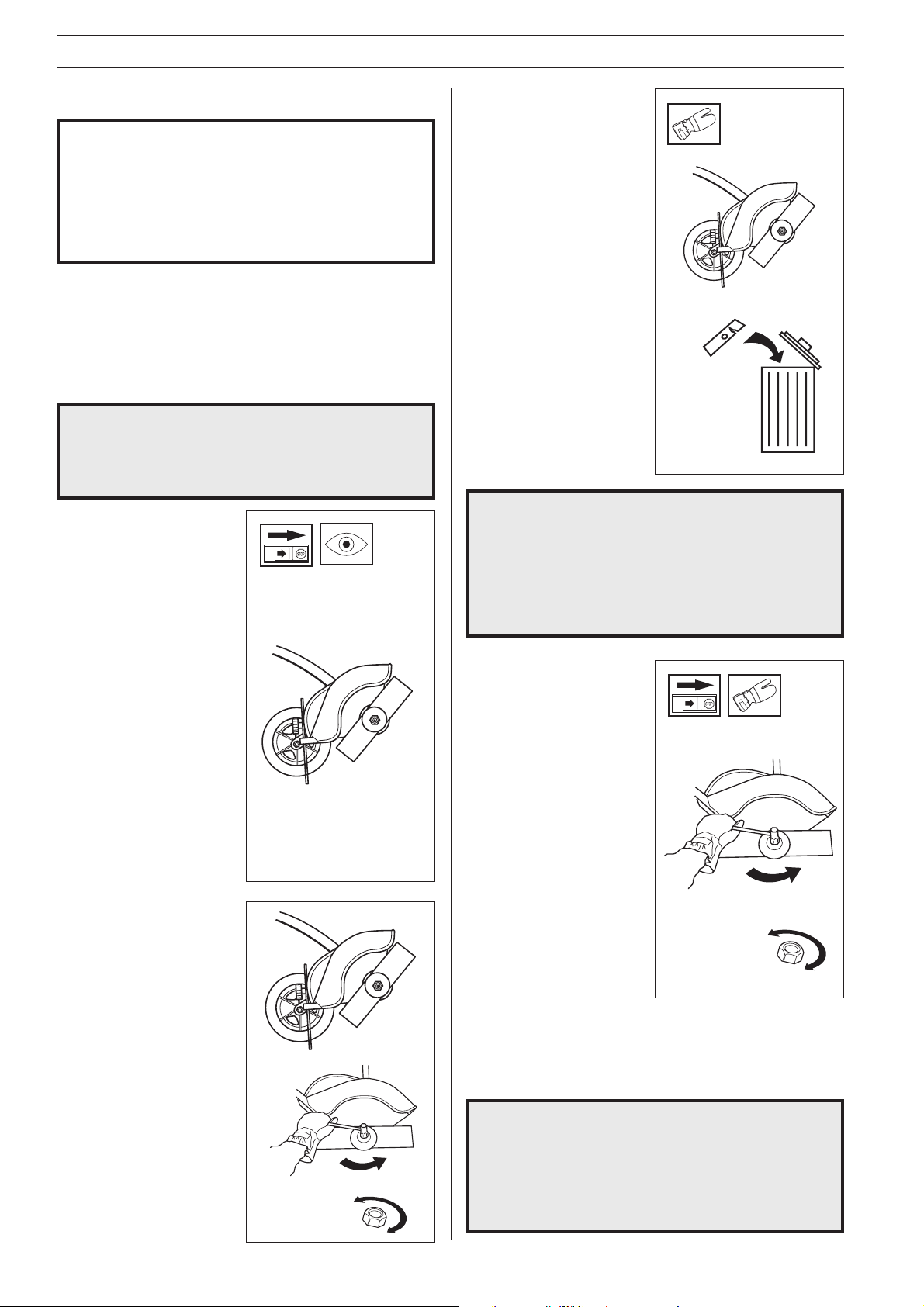

Assembling the blade

Control before starting

For reasons of safety follow

these recommendations!

• Check that the support

flange is not cracked due to

fatigue or due to being

tightened too much.

Discard the support flange

if it is cracked.

• Ensure that the nut has not

lost its tightening capacity.

The nut lock shall have a

locking torque of at least l.5

Nm. The nut’s tightening

torque shall be 35-50 Nm.

• Check that the blade and

blade guard are not

damaged or cracked.

Replace the blade or blade

guard if it has been

exposed to impact or if it is

cracked.

Fit the blade as follows:

1. Fit the drive disc (A) on

the outgoing shaft. Make

sure that the edge that

fits in the hole of the

blade is facing outward.

2. Block the blade rotation

by inserting locking pin

in the hole behind the

blade guard engaging it

in the corresponding

hole in the drive disc.

3. Fit the blade (B) on the

drive disc.

4. Fit the support

flange (C). The support

flange must be fitted

with its outer edge hard

up against the blade.

5. Fit the locknut (D).

NOTE! The locknut has

left-hand threads. The

tightening torque of the

locknut is 35 – 50 Nm.

A

B

C

D

6. Remove the locking pin.

NOTE! Do not forget to remove the locking pin before

using the machine.

WARNING!

Under no circumstances may the edge

!

cutter blade be used without the blade

guard fitted.

8 – English

Page 9

MAINTENANCE

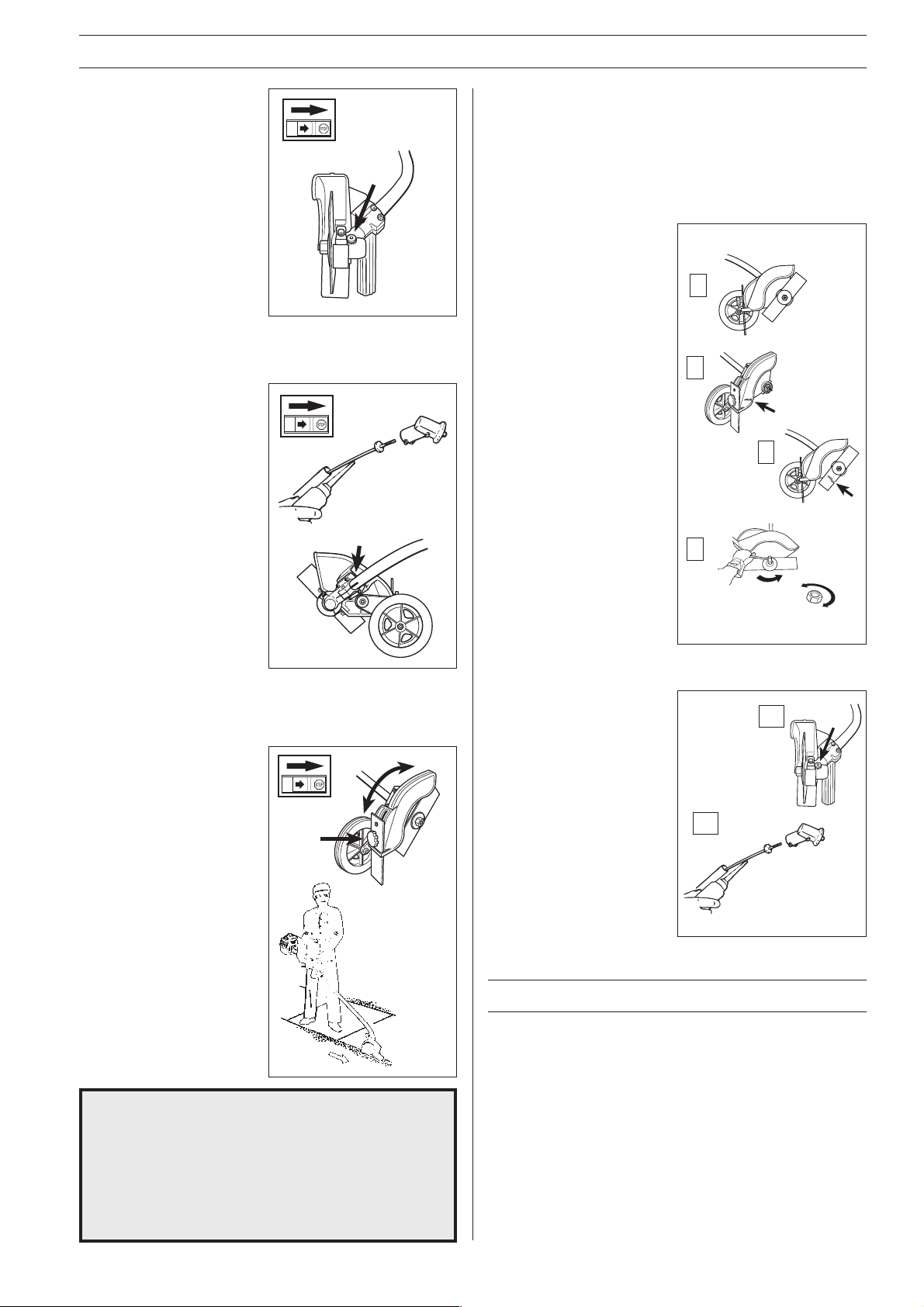

Angle gear

The angle gear is filled

a sufficient quantity of grease

at the factory. However,

before using the machine you

should check that the angle

gear is filled to 3/4 with

grease. Use HUSQVARNA

special grease.

Normally, the grease does not

need to be changed except

when repairs are carried out.

Lubricating the flexible drive axle

Inside the edger‘s drive shaft

is a flexible drive axle. The

flexible drive axle should be

regularly lubricated after 30

hours of operation. Loosen the

two screws on the angle gear

and remove it. The flexible

drive axle is easily removed

from the shaft by taking a firm

grip on the axle end. Lubricate

the flexible drive axle over its

entire length and reinsert it in

the shaft. Turn the axle while

inserting it so that it correctly

engages in the clutch.

Replace the angle gear on the

drive axle shaft and tighten the

two screws.

Maintenance schedule

Below follows some general maintenance instructions. If you

need further information please contact your service

workshop.

Daily maintenance

1. Check that the blade

does not rotate while

idling.

2. Check the guard for

damage and ensure that

it is not cracked.

Replace the guard if it

has been exposed to

impact or is cracked.

3. Check that the blade is

undamaged and not

cracked. Replace the

blade if necessary.

4. Check that the locking

nut is tight.

1

2

3

4

Adjusting the edger's cutting depth

The cutting depth should be

adjusted before starting

work.

• Loosen the locking handle

(A) and rotate the guard by

moving the locking knob

forwards or backwards. If

the locking handle is moved

forwards (from the

machine) the cutting depth

is increased. If the locking

handle is moved backwards

(towards the machine) the

cutting depth is reduced.

• Adjust the cutting depth.

• Lock the locking handle.

WARNING!

Always bear the machine on the right side of

!

the body. Always wear protective glasses,

long trousers and heavy-duty shoes when

using the machine. Observe your

surroundings, ensure people and animals do

not come in the immediate vicinity or can be

hit by thrown objects. Apply full throttle

before the blade starts to work on the soil.

A

Weekly

maintenance

1. Check that the angle

gear is 3/4 filled with

grease. Fill if necessary

using special grease.

2. The flexible drive shaft

must be lubricated after

every 30 hours in

operation or more often.

TECHNICAL DATA

Technical data

Weight, Lbs/kg

Blade length

Centre hole, blade

Speed, blade

1

2

1,6

195 mm

1" = 25,4 mm

7140 r/min

English – 9

Page 10

EXPLICATION DES SYMBOLES

Symboles

max

10000 rpm

AVERTISSEMENT! Le tranchebordure peut être dangereux!

Une utilisation négligée ou incorrecte

peut entraîner des blessures graves,

voire mortelles pour l'utilisateur ou

d'autres personnes.

Lire attentivement le manuel

d'utilisation et assimiler son contenu

avant d'utiliser la machine.

Toujours porter:

• Un casque de protection en cas de

risque de chute d'objets.

• Des protège-oreilles

• Des lunettes de protection

homologuées

Régime max. de l'arbre sortant, tr.min

Flèches indicatrices indiquant les limites

pour l’emplacement de la fixation de la

poignée.

Toujours porter des gants de protection

homologués.

Porter des bottes solides et

antidérapantes.

Les autres symboles/autocollants présents sur la

machine concernent des exigences de certification

spécifiques à certains marchés.

Contrôles et/ou entretiens doivent être

effectués avec le moteur arrêté et le

contacteur d'arrêt en position STOP.

Ce produit est conforme aux

directives CE en vigueur.

Attention aux objets projetés et aux

ricochets.

Attention à la lame en rotation.

Surveiller les pieds et les mains.

Attention! La lame continue à tourner,

même après l'arrêt du moteur.

Lorsque le moteur est arrêté, arrêter

la lame en l'amenant en contact avec

le sol.

Indique le sens de rotation.

Toujours porter des gants homologués.

La machine demande un entretien

régulier.

Contrôle visuel.

Toujours porter des lunettes de

protection homologuées.

15 m

50FT

10 – Français

15 m

50FT

L'utilisateur de la machine doit

s'assurer qu'aucune personne ou

animal ne s'approchent à moins de 15

mètres pendant le travail.

Page 11

SOMMAIRE

Husqvarna AB travaille continuellement au développement de

ses produits et se réserve le droit d’en modifier, entre autres, la

conception et l’aspect.

Lire attentivement le manuel d’utlilisation et

assimiler son contenu avant d’utiliser la

machine.

Ces instructions son un complément au manuel qui

accompagne la machine. Pour les autres instructions, se

reporter au manuel d´utilisation de la machine.

AVERTISSEMENT!

En aucun cas, la conception d'origine de la

!

!

machine ne doit être modifiée sans

l'accord du fabricant. Toujours utiliser des

pièces de rechange d'origine. Des

modifications et/ou des pièces non

autorisées peuvent entraîner des

blessures graves, voire mortelles, pour

l'utilisateur ou d'autres personnes.

AVERTISSEMENT!

Cet accessoire ne peut être utilisé que

pour les débroussailleuses/coupebordu-

res auxquels il est expressément destiné.

Voir la section ”Accessoires homologués”

au chapitre Caractéristiques techniques

dans le manuel d'utilisation de la

machine.

Sommaire

EXPLICATION DES SYMBOLES

Symboles .......................................................................... 10

SOMMAIRE

Sommaire ........................................................................... 11

CONSIGNES DE SECURITE

Equipement de protection personnelle ............................. 12

Dispositifs de sécurité de la machine ................................ 12

Consignes générales de sécurité ...................................... 13

Instructions générales de travail ....................................... 13

Techniques de travail de base .......................................... 14

QUELS SONT LES COMPOSANTS?

Quels sont les éléments du kit coupe-bordure? ................ 15

MONTAGE

Montage de l'engrenage angulaire.................................... 16

Montage de la lame .......................................................... 16

MARCHE ET ARRET

Contrôles avant le démarrage ........................................... 16

ENTRETIEN

Engrenage angulaire ......................................................... 17

Lubrification de l'arbre souple d'entraînement .................. 17

Réglage de la profondeur de coupe du tranche-bordure .. 17

Schéma d'entretien ........................................................... 17

CARACTERISTIQUES TECHNIQUES

Caracteristiques techniques .............................................. 17

La machine sert uniquement à couper les bordures de

pelouses.

Français – 11

Page 12

CONSIGNES DE SECURITE

Equipement de protection

personnelle

INFORMATION IMPORTANTE

• Lors de l'utilisation du tranche-bordure, un équipement de protection personnelle être utilisé. L'équipe-

ment de protection personnelle n'élimine pas les

risques d'accidents, mais réduit toutefois la gravité

des blessures en cas d'accident.

Dispositifs de sécurité de la machine

Ce chapitre décrit les dispositifs de sécurité de la machine,

leur fonction ainsi que les contrôles et entretiens à effectuer

pour s’assurer de leur bon fonctionnement (se référer au

chapitre "Quels sont les composants?" pour connaître

l’emplacement de ces dispositifs sur la machine).

AVERTISSEMENT!

Ne jamais utiliser la machine si les dispositifs

!

Protège-lame

Cette protection a pour but

d’empêcher la projection

d’objets détachés vers

l’opérateur. Il empêche

également l’utilisateur d’entrer

en contact avec l’outil de

coupe.

de sécurité sont défectueux.

Suivre les instructions de contrôle, d’entretien

et de maintenance listées dans ce chapitre.

Equipement de

coupe

Deux règles fondamentales:

1. Utiliser uniquement

l'équipement de coupe

avec le protège-lame

recommandé. Se

reporter au chapitre

”Caractéristiques

techniques”

manuel d'utilisation de la

machine

2. S'assurer que l'équipe-

ment de coupe n'est pas

endommagé ou fissuré.

Toujours remplacer un

équipement de coupe

endommagé.

!

dans le

.

AVERTISSEMENT!

Toujours arrêter le moteur avant de débuter

des travaux sur l’équipement de coupe. Le

moteur continue à tourner même après

relâchement de l’accélérateur. S’assurer

que la lame est entièrement immobilisée et

retirer le câble de la bougie d’allumage

avant d’effectuer des travaux sur

l’équipement de coupe.

• S’assurer que le protègelame n’est pas endommagé

ou fissuré.

• Remplacer le protège-lame

en cas de chocs ou de

fissurations.

• Toujours utiliser le protègelame recommandé dans les

"Caractéristiques

techniques"

d'utilisation de la machine,

pour l'équipement de coupe.

dans le manuel

Equipement de

coupe

La lame est conçue pour

supporter les charges

entraînées par la coupe des

bordures de pelouse.

Contre-écrou

Le contre-écrou retient

l’équipement de coupe à

l’arbre sortant.

Contre-écrou

• Se protéger la main lors du

montage, se servir du

protège-lame comme

protection lors du serrage

avec la clé à douille.

Serrage de l’écrou dans le

sens contraire au sens de

rotation. Desserrage de

l’écrou dans le sens de

rotation. (IMPORTANT!

L’écrou est fileté à gauche).

• Serrer l’écrou à l’aide de la

clé à douille, 35-50 Nm

(3,5-5 kpm).

IMPORTANT!

L’usure du verrouillage nylon du contre-écrou ne doit pas

être telle qu’il peut se visser à l’aide des doigts. Le ver-

rouillage doit résister à 1,5 Nm au moins. Remplacer le

contre-écrou après l’avoir resserré une dizaine de fois.

AVERTISSEMENT!

Ne jamais utiliser la machine si le dispositif

!

de sécurité est défectueux. Contrôler et

effectuer l'entretien du dispositif de

sécurité en suivant les indications de ce

chapitre. Si l’un des contrôles de la

machine n'est pas satisfaisant, contacter

un atelier de service.

12 – Français

Page 13

CONSIGNES DE SECURITE

Consignes générales de sécurité

AVERTISSEMENT!

Un équipement de coupe défectueux

!

Protection personnelle

• Toujours porter des bottes

ainsi que l'équipement de

protection indiqué au chapitre

”Equipement de protection

personnelle”

d'utilisation de la machine

• Toujours porter des vêtements

de travail et des pantalons

longs résistants.

• Ne jamais porter des

vêtements amples ou des

bijoux.

• La longueur des cheveux ne

doit pas dépasser les épaules.

Consignes de sécurité pour l'entourage

augmente les risques d’accidents.

dans le manuel

.

• S'assurer que la lame et le protège-lame sont correctement

fixés.

• Pendant le réglage du carburateur, s'assurer que la lame est en

contact avec le sol et que personne ne se trouve à proximité.

• S'assurer que la lame s'arrête toujours au ralenti.

• S'assurer que la poignée et le dispositif de sécurité sont en bon

état. Ne jamais utiliser la machine avec une pièce manquante

ou ayant été modifiée.

• Utiliser la machine uniquement pour les travaux auxquels elle

est destinée.

Instructions générales de travail

INFORMATION IMPORTANTE

• Ce chapitre décrit les consignes de sécurité de base

pour travailler avec un tranche-bordure.

• Dans l’éventualité d’une situation rendant le travail

incertain, consulter un expert. S’adresser au revendeur ou à l’atelier de service.

• L’utilisateur doit éviter les utilisations pour lesquel-

les il n’est pas qualifié.

• Ne jamais laisser un enfant utiliser la machine.

• S'assurer qu'aucune personne ne s'approche à moins de

15 m pendant le travail.

• Ne jamais laisser d'autres personnes utiliser la machine

avant d'avoir vérifié que le contenu du manuel d'utilisation a

été assimilé par ces personnes.

Consignes de sécurité avant la mise en

service

• Inspecter la zone de travail. Enlever tout objet traînant par

terre, tels que cailloux, débris de verre, clous, fil de fer,

ficelle etc., pouvant être projetés ou s'enrouler autour de la

lame ou dans le protège-lame.

• Maintenir les enfants, animaux, spectateurs et aides à 15 m

(50 pieds) de la zone de travail. Stopper la machine

immédiatement si quelqu'un s'approche.

• Contrôler toute la machine

avant de la mettre en

service. Remplacer les

pièces endommagées.

S'assurer que le carburant

ne fuit pas et que toutes les

protections et carters ne

sont pas endommagés et

correctement fixés. Vérifier

toutes les vis et écrous.

• S'assurer que la lame n'est

pas endommagée ou

fissurée.

• S'assurer que le protègelame est monté et en bon

état.

Consignes de sécurité de base

1. Inspecter les environs:

• Afin de s’assurer que ni personnes, ni animaux ou autres

facteurs ne peuvent entraver le contrôle de la machine.

• Afin d’éviter que des personnes ou des animaux n’entrent

en contact avec l’équipement de coupe ou avec d’éventuels

objets projetés par l’équipement de coupe.

• IMPORTANT! Ne jamais utiliser une machine en l’absence

de possibilités d’appeler au secours en cas d’accident.

2. Eviter d’utiliser la ma-

chine en cas d’intempéries. Par exemple, en cas

de brouillard épais, fortes

pluies, vents forts, grands

froids, etc. Ce type

d’intempéries, notamment le verglas, peut

rendre les conditions de

travail dangereuses.

3. S'assurer de pouvoir

marcher et se tenir

debout de manière sûre.

Lors des déplacements

inattendus, prendre

garde aux obstacles

éventuels (racines,

cailloux, branches,

fossés, etc). Faire preuve

de beaucoup de prudence lors du travail sur

des terrains en pente.

4. Arrêter le moteur pour se déplacer.

5. Ne jamais placer la machine sur le sol avec le moteur en

marche sans pouvoir la surveiller.

Français – 13

Page 14

CONSIGNES DE SECURITE

Techniques de travail de base

Consignes de sécurité pendant le travail

• Toujours adopter une

position de travail sûre et

stable.

• Toujours tenir la machine à

deux mains. Porter la

machine sur le côté droit du

corps.

• Garder les mains et les

pieds à l’écart de la lame

lorsque le moteur tourne.

• Après l’arrêt du moteur,

garder les mains et les

pieds éloignés de la lame,

jusqu’à l’arrêt complet de

celle-ci.

• Le moteur doit toujours

tourner à plein régime pour

couper les bordures de

pelouse.

Consignes de sécurité après le travail

• Avant de nettoyer, réparer

ou inspecter la machine,

s'assurer que la lame est

entièrement arrêtée.

Débrancher le câble

d’allumage de la bougie.

• Toujours porter des gants

de protection pour réparer

le tranche-bordure.

• Ranger la machine hors de

portée des enfants.

• Toujours utiliser des pièces

de rechange d’origine pour

réparer la machine.

• Toujours maintenir la lame à proximité du sol.

• Faire tourner le moteur au ralenti après chaque étape de

travail. Une période prolongée de plein régime alors que le

moteur n'est soumis à aucune charge (c'est-à-dire

résistance exercée sur le moteur par l'intermédiaire de

l'équipement de coupe) peut endommager sérieusement le

moteur.

• Etre particulièrement vigilant au moment de ramener le

tranche-bordure vers soi pendant le travail.

• En cas de fortes vibrations, arrêter la machine. Débrancher

le câble d’allumage de la bougie. S'assurer que la machine

n’est pas endommagée. Réparer les avaries éventuelles.

AVERTISSEMENT!

Il arrive que l’herbe s’accroche au protège-

!

!

lame et à la lame. Toujours arrêter le

moteur avant de nettoyer la machine.

AVERTISSEMENT!

Attention aux objets projetés. Toujours

porter une protection des yeux.

Ne jamais se pencher sur la lame ou le

protège-lame. Des pierres, déchets ou

autres objets peuvent être projetés dans les

yeux, provoquant des blessures graves,

voire la cécité.

Maintenez autrui à distance. Enfants,

animaux, spectateurs et aides doivent être

maintenus à une distance de sécurité de 15

m (50 pieds). Arrêtez immédiatement la

machine si quelqu’un s’approche.

Après l’utilisation, l’engrenage angulaire

peut demeurer chaud pendant un certain

temps. Risque de brûlures légères en cas

de contact.

14 – Français

Page 15

QUELS SONT LES COMPOSANTS?

2

4

3

5

1

10

4

1

6

7

Quels sont les éléments du kit

coupe-bordure?

1. Lame

2. Arrivée de lubrifiant

3. Engrenage angulaire

4. Protège-lame

5. Tige

8

9

6. Contre-écrou

7. Bride d'arrêt

8. Toc d'entraînement

9. Vis de verrouillage

10. Manuel d'utilisation

Français – 15

Page 16

MONTAGE

MARCHE ET ARRET

Montage de l'engrenage angulaire

• Monter l'engrenage

angulaire sur la tige.

Tourner la lame pour que

l'arbre s'enclenche dans

l'engrenage angulaire.

• Placer l'engrenage

angulaire pour faire

correspondre la rainure

avec le trait de la tige.

• Serrer entièrement la vis.

Montage de la lame

Pour monter la lame, procé-

der comme suit:

Contrôles avant le démarrage

Pour plus de sécurité, suivre

les recommandations cidessous:

• Contrôler la bride d'arrêt

pour détecter d’éventuelles

fissures dues à l’usure ou à

un serrage trop fort. En cas

de fissures, remplacer la

bride d'arrêt.

• S’assurer que le contre-

écrou n’a pas perdu sa

capacité de blocage. Le

contre-écrou doit résister à

1,5 Nm au moins. Couple

de serrage du contre-écrou:

35-50 Nm.

• Contrôler la lame et le

protège-lame afin de

détecter d’éventuels

dommages ou fissures.

Remplacer la lame ou le

protège-lame en cas de

choc ou de fissures.

1. Monter le toc d'entraîne-

ment (A) sur l'arbre

sortant. S'assurer que le

bord pénétrant dans le

trou de la lame est

monté vers le haut.

2. Stabiliser la lame en

introduisant la goupille

d'arrêt dans le trou situé

derrière le protège-lame,

de telle sorte qu'elle

pénètre aussi dans le

trou correspondant du

toc d'entraînement.

3. Placer la lame (B) sur le

toc d'entraînement.

4. Monter la bride d'arrêt

(C) de telle sorte que

son bord extérieur

repose contre la lame.

5. Monter le contre-écrou

(D). IMPORTANT: le

contre-écrou est fileté à

gauche. Couple de

serrage du contre-écrou:

35-50 Nm.

A

B

C

D

6. Retirer la goupille d'arrêt

IMPORTANT! Ne pas oublier de retirer la goupille d’arrêt

avant d’utiliser la machine.

AVERTISSEMENT!

Ne jamais utiliser la lame si le protège-lame

!

n'est pas monté.

16 – Français

Page 17

ENTRETIEN

Engrenage angulaire

L’engrenage angulaire est

enduit à l'usine de la quantité

de graisse nécessaire.

Toutefois, avant d’utiliser la

machine, il convient de

s’assurer que l’engrenage

angulaire est au 3/4 rempli de

graisse. Utiliser une graisse

HUSQVARNA spéciale.

En général, il n’est pas

nécessaire de remplacer le

lubrifiant du carter, sauf en

cas de réparations.

Lubrification de l'arbre souple

d'entraînement

A l’intérieur du tube de l’arbre

d’entraînement du tranche-

bordure se trouve un arbre

d’entraînement souple. Il

convient de lubrifier cet arbre

souple toutes les 30 heures de

service. Desserrer les deux vis

de l’engrenage angulaire, puis

démonter celui-ci. Il est facile

d’extraire l’arbre souple du tube

d’arbre, en le saisissant

fermement par l’extrémité.

Lubrifier l’arbre souple sur toute

sa longueur, puis le réinsérer

dans le tube de l’arbre d’entraî-

nement. En insérant l’arbre

souple, le tourner pour qu’il se

positionne correctement en

fonction de l’engrenage.

Remonter l’engrenage angulaire, resserrer les deux vis.

Réglage de la profondeur de coupe

du tranche-bordure

Avant de commencer, il faut

régler la profondeur de coupe.

• Desserrer la vis de blocage

(A), tourner le protège-lame

(B) en faisant aller et venir la

vis de blocage. Pour

augmenter la profondeur de

coupe, déplacer la vis vers

l'avant (depuis la machine).

Pour diminuer la profondeur,

déplacer la vis vers l'arrière

(vers la machine).

A

Schéma d'entretien

Quelques instructions générales d’entretien sont données cidessous. Pour plus d’informations, contacter l’atelier de

service.

Contrôles

quotidiens

1. S’assurer que la lame ne

tourne pas lorsque le

moteur tourne au ralenti.

2. S’assurer que le protègelame n’est pas

endommagé et ne

présente aucune

fissuration. Remplacer le

protège-lame en cas de

chocs ou de fissurations.

3. S’assurer que la lame est

intacte et qu’elle n’est pas

fissurée. Si nécessaire,

remplacer la lame.

4Vérifier le serrage du

contre-écrou.

1

2

3

4

Contrôles

hebdomadaires

1

1. S'assurer que

l’engrenage angulaire

est au 3/4 rempli de

graisse. Si nécessaire,

effectuer un remplissage

d’appoint avec une

graisse spéciale.

2. L’arbre moteur courbé

doit être graissé après

30 heures d’utilisation ou

plus fréquemment.

2

CARACTERISTIQUES

• Régler la profondeur

souhaitée.

• Serrer la vis de blocage.

AVERTISSEMENT!

Toujours porter la machine à droite du

!

corps. Toujours porter des lunettes de

protection, des pantalons longs et des

chaussures solides pour travailler avec la

machine. Inspecter les environs et s'assurer

qu’aucune personne ou animal se trouve

dans la zone de travail ou risque d’être

blessé par un objet projeté par la machine.

Ne pas mettre le plein régime tant que la

lame n’a pas commencé son travail au sol.

TECHNIQUES

Caractéristiques

techniques

Poids, kg

Longueur de couteau

Trou central, couteau

Régime, couteau

1,6

195 mm

1" = 25,4 mm

7140 r/min

Français – 17

Page 18

SIGNIFICADO DE LOS SÍMBOLOS

Símbolos

max

10000 rpm

ATENCIÓN: Las rebordeadoras

pueden ser peligrosas.

Su uso negligente o erróneo puede

causar heridas graves o mortales al

operador o terceros.

Antes de utilizar la máquina, lea

atentamente las instrucciones de uso

y asegúrese de comprender su

contenido.

Utilice siempre:

• Casco protector cuando exista el

riesgo de objetos que caen

• Protección auditiva

• Protección ocular homologada

Velocidad máxima en el eje de salida,

rpm.

Marcas de flechas que indican los límites

para colocar la sujeción del mango.

Utilice siempre guantes protectores

homologados.

Utilice botas antideslizantes y seguras.

Los demás símbolos/pegatinas que aparecen en la

máquina corresponden a requisitos de

homologación específicos en determinados

mercados.

Este producto cumple con la directiva

CE vigente.

Cuidado con los objetos lanzados o

rebotados.

Cuidado con la cuchilla giratoria.

Mantenga alejados los brazos y pies.

ATENCIÓN: La cuchilla sigue girando

después de apagar el motor.

Una vez apagado el motor, detener el

movimiento giratorio de la cuchilla

apoyándola contra el suelo.

Cualquier tipo de control o medida de

mantenimiento debe efectuarse con el

motor desactivado, con el mando de

parada en la posición STOP.

Utilice siempre guantes protectores

homologados.

Utilice siempre guantes protectores

homologados.

Control visual.

15 m

18 – Español

50FT

15 m

50FT

Muestra el sentido de rotación

Debe utilizarse protección ocular

homologada.

El operador de la máquina debe

cuidar que ninguna persona o animal

se acerque más de 15 metros durante

el trabajo.

Page 19

CONTENIDO

Husqvarna AB trabaja constantemente para perfeccionar sus

productos y se reserva, por lo tanto, el derecho a introducir

modificaciones en la construcción y el diseño sin previo aviso.

Antes de utilizar la máquina lea bien el

manual de instrucciones hasta comprender

su contenido.

Estas instrucciones son complemento del manual que se

adjunta a la máquina. Para más información sobre el manejo,

consultar el manual de la máquina

ATENCIÓN: El diseño original de la

!

!

máquina no debe ser modificado por

ningún motivo sin la autorización explícita

del fabricante. Utilice siempre accesorios

originales. Las modificaciones o

accesorios no autorizados pueden

ocasionar heridas graves y mortales al

operador o terceros.

ATENCIÓN: Este accesorio sólo puede

ser utilizado con las desbrozadoras/

recortadoras destinadas al mismo, vea

”Accesorios aprobados” en el capítulo

Datos técnicos del manual de

instrucciones de la máquina.

Índice

SIGNIFICADO DE LOS SÍMBOLOS

Símbolos ........................................................................... 18

Contenido

Índice................................................................................. 19

INSTRUCCIONES DE SEGURIDAD

Equipo de protección personal ......................................... 20

Equipo de seguridad de la máquina ................................. 20

Instrucciones generales de seguridad .............................. 21

Instrucciones generales de trabajo ................................... 21

Técnica básica de trabajo ................................................. 22

¿QUÉ ES QUE?

¿Qué es que en el suplemento para cortar cantos? ......... 23

MONTAJE

Montaje del reductor angular ............................................ 24

Montaje de la cuchilla ....................................................... 24

ARRANQUE Y PARADA

Control antes de arrancar ................................................. 24

MANTENIMIENTO

Reductor angular .............................................................. 25

Lubricación del eje propulsor flexible ................................ 25

Ajuste de la profundidad de corte de la rebordeadora ...... 25

Plan de mantenimiento ..................................................... 25

DATOS TÉCNICOS

Datos técnicos .................................................................. 25

La máquina está diseñada exclusivamente para recortar

bordes de céspedes.

Español – 19

Page 20

INSTRUCCIONES DE SEGURIDAD

Equipo de protección personal

INFORMACIÓN IMPORTANTE

• Para trabajar con una rebordeadora debe usarse

siempre un equipo de protección personal. El equipo

de protección personal no elimina el riesgo de

daños, pero reduce el efecto de los mismos en caso

de accidente. El concesionario Husqvarna puede

asesorarle para elegir equipo de protección.

Equipo de seguridad de la máquina

En esta sección se describen los distintos componentes de

seguridad de la máquina, qué función cumplen y cómo se

debe realizar la revisión y el mantenimiento para garantizar su

correcto funcionamiento. (Lea el capítulo

encontrar la posición de cada componente en la máquina.)

ATENCIÓN:

No utilizar nunca una máquina con

!

componentes de seguridad defectuosos.

Siga las instrucciones de control,

mantenimiento y servicio listadas en esta

sección.

”Qué es que”

Protección del

equipo de corte

Esta protección tiene por

objeto impedir el lanzamiento

de objetos sueltos contra el

usuario de la máquina. La

protección también impide que

el usuario entre en contacto

con el equipo de corte.

para

Equipo de corte

Las dos reglas básicas:

1. ¡El equipo de corte sólo

debe usarse junto con la

protección recomendada

por nosotros! Vea el

capítulo ”Datos técnicos”

del manual de

instrucciones de la

máquina.

2. Revise el equipo de corte

para comprobar si tiene

daños o grietas. Un

equipo de corte dañado

debe cambiarse siempre.

¡ADVERTENCIA!

Pare siempre el motor antes de iniciar

!

trabajos en el equipo de corte. El equipo

sigue girando aun después de soltar el

acelerador. Antes de iniciar cualquier

trabajo en el equipo de corte, compruebe

que se haya parado totalmente y

desconecte el cable de la bujía.

Tuerca de fijación

• Compruebe que la protección

no esté dañada y que no

tenga grietas.

• Cambie la protección si ha

sido expuesta a golpes o si

tiene grietas.

• Utilice siempre la protección

especificada en los "Datos

técnicos", del manual de

instrucciones de la máquina,

para el equipo de corte.

Equipo de corte

La cuchilla está diseñada y

fabricada para tolerar las

cargas derivadas del recorte

de cantos en céspedes.

Tuerca de fijación

La tuerca fija el equipo de

corte en el eje saliente.

• Proteja la mano contra

daños al montar y utilice la

protección de cuchilla como

protección al apretar con

llave de tubo. Apriete de la

tuerca: en sentido contrario

al de rotación. Aflojamiento

de la tuerca: en el sentido

de rotación. (¡ATENCIÓN!

La tuerca tiene rosca a

izquierdas)

• Apriete la tuerca con la

llave de tubo, con un par de

35-50 Nm (3,5-5 kpm).

¡ATENCIÓN!

El fiador de nylon de la tuerca de fijación no debe tener un

grado de desgaste tal que se pueda enroscar con los dedos.

El fiador debe aguantar un mínimo de 1,5 Nm.

La tuerca debe cambiarse después de haberla enroscado

unas 10 veces.

ATENCIÓN:

Nunca utilice una máquina con el sistema

!

de seguridad defectuoso. El sistema de

seguridad debe ser controlado y mantenido

como se describe en esta sección. Si su

máquina no supera alguno de los controles

mencionados, diríjase a un taller de

servicio oficial para repararla.

20 – Español

Page 21

INSTRUCCIONES DE SEGURIDAD

Instrucciones generales de seguridad

VATENCIÓN:

Un equipo de corte en mal estado puede

!

Protección personal

• Utilice siempre botas y

además, el equipo indicado

en la sección

protección personal”

manual de instrucciones de

la máquina..

• Utilice siempre

indumentaria de trabajo y

pantalones largos fuertes.

• No utilice nunca ropas

amplias ni joyas.

• Las personas que tengan

cabellos largos, deben

levantarlo por arriba de los

hombros.

Instrucciones de seguridad para el entorno

• No permita nunca que los niños utilicen la máquina.

aumentar el riesgo de accidentes.

”Equipo de

del

• Controle que la cuchilla y su protección estén correctamente

montadas.

• Al ajustar el carburador, controle que la cuchilla esté contra el

suelo y que no haya nadie en las cercanías.

• Controle que la cuchilla siempre se detenga en régimen de

ralentí.

• Controle que los mangos y la función de seguridad estén en

orden. No utilice nunca una máquina a la que le falte una parte o

que haya sido modificada y no coincida con las especificaciones.

• Utilice la máquina solamente para lo que está destinada.

Instrucciones generales de trabajo

INFORMACIÓN IMPORTANTE

• Este capítulo trata las reglas de seguridad

fundamentales para trabajar con la rebordeadora.

• Siempre que se encuentre en situaciones que le

crean inseguridad por lo que respecta al empleo de

la máquina, consulte con un experto. Diríjase a su

concesionario o a su taller de servicio.

• Evite todo uso para el cual no se sienta

suficientemente calificado.

• Controle que nadie se acerque a menos de 15 metros

durante el trabajo.

• No permita que otros utilicen la máquina sin asegurarse

primero de que hayan comprendido el contenido del

manual de instrucciones.

Instrucciones de seguridad antes de

arrancar

• Inspeccione el lugar de trabajo. Aleje todos los objetos sueltos,

como piedras, cristales rotos, claves, alambre de acero,

cuerdas, etc., que pueden ser despedidos o enredarse en la

cuchilla o la protección de ésta.

• Mantenga alejados a terceros. Los niños, animales, curiosos y

ayudantes deben mantenerse fuera de la zona de seguridad de

15 metros. Pare la máquina inmediatamente si alguien se

acerca.

• Controle toda la máquina

antes de arrancar. Cambie

las piezas defectuosas.

Controle que no haya fuga

de combustible y que todas

las protecciones y tapas

estén en buenas condiciones

y bien fijas. Controle todos

los tornillos y tuercas.

• Controle que la cuchilla no

tenga grietas ni otros

daños.

• Verifique que la protección

de la cuchilla está montada

y sin dañar.

Reglas básicas de seguridad

1. Observe el entorno para:

• Comprobar que no haya personas, animales, etc., que

puedan influir en su control de la máquina.

• Para asegurar que no hay riesgo de que los anteriormente

mencionados entren en contacto con el equipo de corte o

con objetos lanzados por el mismo.

• ¡ATENCIÓN! No use nunca una máquina si no tiene

posibilidad de pedir auxilio en caso de accidente.

2. No utilice la máquina en

climáticas adversas. Por

ejemplo, en caso de

niebla, lluvia intensa,

viento intenso, frío intenso,

etc. El trabajo con mal

tiempo es agotador y

puede crear condiciones

peligrosas, por ejemplo

suelo resbaladizo.

3. Asegúrese de que puede

caminar y permanecer de

pié de forma segura. Vea

si hay obstáculos que

puedan dificultar un

desplazamiento imprevisto

(raíces, piedras, ramas,

agujeros, zanjas, etc.).

Proceda con sumo

cuidado al trabajar en

pendientes.

4. Para desplazar la máquina debe pararse el motor.

5. No apoye nunca la máquina con el motor en marcha sin

tenerla bajo control.

Español – 21

Page 22

INSTRUCCIONES DE SEGURIDAD

Técnica básica de trabajo

Instrucciones de seguridad durante el

trabajo

• Debe tener siempre una

posición de trabajo segura

y firme.

• Utilice siempre las dos

manos para sostener la

máquina. Mantenga la

máquina en el lado derecho

de su cuerpo.

• Tenga cuidado en que las

manos y los pies no entren

en contacto con la cuchilla

cuando el motor está en

marcha.

• Al parar el motor, mantenga

las manos y los pies

alejados de la cuchilla

hasta que se haya detenido

completamente.

Instrucciones de seguridad después del

trabajo.

• Antes de la limpieza,

reparación o inspección,

controle que la cuchilla se

haya detenido. Quite el

cable de la bujía.

• Use guantes gruesos para

reparar la rebordeadora.

• Guardar la máquina fuera

del alcance de los niños.

• Utilizar únicamente

recambios originales al

reparar la máquina.

• Para recortar bordes, utilice

siempre la aceleración

máxima.

• Mantenga siempre la cuchilla cerca del suelo.

• Suelte el acelerador para dejar el motor en ralentí después

de cada fase de trabajo. La plena aceleración sin carga del

motor (es decir, sin la resistencia derivada del equipo de

corte) puede causar averías graves del motor.

• Proceda con especial cuidado cuando tire de la máquina

hacia usted durante el trabajo.

• Si hay vibraciones fuertes, pare la máquina. Desconecte el

cable de encendido de la bujía. Compruebe que la máquina

no esté dañada. Repare eventuales daños.

¡ADVERTENCIA!

En ocasiones se atasca hierba o piedras en

!

!

la protección de cuchilla y en la cuchilla.

Pare siempre el motor cuando para limpiar.

¡ADVERTENCIA!

Peligro de objetos lanzados. Utilice siempre

gafas protectoras. No se apoye nunca sobre

la protección de cuchilla. Hay riesgo de

lanzamiento de piedras, residuos, etcétera,

contra los ojos, causando ceguera o daños

graves. Mantenga apartado al público. Los

niños, animales, espectadores y ayudantes

deben estar fuera de la zona de seguridad

de 15 m. Pare la máquina de inmediato si se

acerca alguien. Durante el trabajo y por un

momento después del mismo, el reductor

angular puede estar caliente. Hay riesgo de

quemaduras leves en caso de contacto.

22 – Español

Page 23

¿QUÉ ES QUE?

2

4

3

5

1

10

4

1

6

7

¿Qué es que en el suplemento para

cortar cantos?

1. Cuchilla

2. Carga de lubricante

3. Engranaje angulado

4. Protección de cuchilla

5. Tubo

8

9

6. Manija de fijación

7. Arrastrador

8. Brida de apoyo

9. Tuerca de fijación

10. Manual de instrucciones

Español – 23

Page 24

MONTAJE

ARRANQUE Y PARADA

Montaje del reductor angular Controles antes de arrancar

• Monte el reductor angular

en el tubo. Gire la cuchilla

para que el eje agarre en el

reductor.

• Coloque el reductor de

forma que la ranura

coincida con la raya del

tubo.

• Apriete el tornillo.

Montaje de la cuchilla

Procedimiento de montaje de

la cuchilla:

1. Coloque el arrastrador

(A) en el eje de salida.

Monte hacia afuera el

borde que se adapta

al agujero de la cuchilla.

¡Observe estas

recomendaciones por

razones de seguridad!

• Revise la brida de apoyo

para comprobar que no se

han producido grietas

debidas a agotamiento o

apriete excesivo. ¡Deseche

la brida de apoyo si tiene

grietas!

• Compruebe que la tuerca

no pierde fuerza de fijación.

La fijación de la tuerca

debe tener un par mínimo

de 1,5 Nm. El par de

apriete de la tuerca debe

ser de 35-50 Nm.

• Revise la cuchilla y la

protección de cuchilla para

comprobar que están

intactas y que no tienen

grietas. Cambie la cuchilla

o la protección si han sido

expuestas a golpes o

tienen grietas.

2. Fije la rotación de la

cuchilla insertando el

pasador en el agujero

detrás de la protección,

de modo que entre en el

agujero equivalente del

arrastrador.

3. Ponga la cuchilla (B) en

el arrastrador.

4. Monte la brida de apoyo

(C). La brida de apoyo

debe montarse con su

borde exterior tocando

en la cuchilla.

5. Monte la tuerca de

fijación (D). ¡ATENCIÓN!

La tuerca de fijación

tiene rosca a izquierdas.

El par de apriete de la

tuerca de fijación es de

35-50 Nm.

6. Quite el pasador.

¡ATENCIÓN! No olvide quitar el pasador antes de utilizar la

máquina.

A

B

C

D

!

24 – Español

¡ADVERTENCIA!

La cuchilla de la rebordeadora no debe

usarse, por ningún concepto, sin que esté

montada la protección de cuchilla.

Page 25

MANTENIMIENTO

Reductor angular

El engranaje angulado se

entrega de fábrica con la

cantidad adecuada de grasa.

No obstante, antes de arrancar

la máquina, verifique que el

engranaje esté lleno con grasa

hasta las 3/4 partes. Utilice

grasa especial de

HUSQVARNA.

Generalmente, el lubricante de

la caja del reductor no requiere

cambiarse excepto cuando se

realizan reparaciones.

Lubricación del eje propulsor flexible

En el tubo de la rebordeadora

hay un eje propulsor flexible. El

eje propulsor flexible debe

lubricarse regularmente cada

30 horas de trabajo

aproximadamente. Afloje los

dos tornillos del reductor y

desmóntelo. El eje propulsor

flexible se saca fácilmente del

tubo sujetándolo con firmeza

en el extremo.

Lubrique el eje propulsor

flexible en toda su longitud y

vuelva a introducirlo en el tubo.

Gire el eje durante la

introducción para adaptarlo

bien en el acoplamiento.

Vuelva a montar el reductor en

el tubo del eje de propulsión y

apriete los dos tornillos.

Ajuste de la profundidad de corte de

la rebordeadora

Antes de iniciar el trabajo debe

ajustarse la profundidad de

corte.

Plan de mantenimiento

Las siguientes son instrucciones generales de

mantenimiento. Si necesita más información, póngase en

contacto con el servicio oficial.

Control diario

1. Controle que la cuchilla

de corte no gire en

ralentí.

2. Compruebe que la

protección no esté

dañada y que no tenga

grietas. Cambie la

protección si ha estado

expuesta a golpes o si

tiene grietas.

3. Compruebe que la

cuchilla no esté dañada

y que no tenga grietas.

Cambie la cuchilla si es

necesario.

4. Controle el apriete de la

tuerca de fijación.

Control semanal

1. Compruebe que el

reductor angular esté

lleno en sus tres cuartas

partes con lubricante. Si

es necesario, añada

grasa especial.

1

2

3

4

1

2

• Afloje la manija de fijación (A)

y gire la protección moviendo

la manija hacia adelante o

hacia atrás. Moviendo la

manija hacia adelante

(apartándola de la máquina)

se aumenta la profundidad

de corte. Moviendo la manija

hacia atrás (acercándola a la

máquina) se reduce la

profundidad de corte.

• Ajuste la profundidad de corte

deseada.

• Apriete la manija de fijación.

¡ADVERTENCIA!

Lleve siempre la máquina en el lado

!

derecho del cuerpo. Use gafas protectoras,

pantalones largos y zapatos gruesos para

trabajar con la máquina. Observe el entorno

y procure que no se acerquen personas o

animales a la máquina, así como que no

puedan ser alcanzados por objetos

lanzados. Acelere al máximo antes de que

la cuchilla empiece a trabajar en la tierra.

A

2. El eje propulsor flexible

debe lubricarse cada 30

horas de trabajo o con

mayor frecuencia.

DATOS TÉCNICOS

Datos técnicos

Peso, kg

Longitud de cuchilla

Agujero central

Velocidad de cuchilla

1,6

195 mm

1" = 25,4 mm

7140 r/min

Español – 25

Page 26

´+H(^¶0B¨

Page 27

Page 28

114 00 86-20

´+H(^¶0B¨

2002W12

Loading...

Loading...