EN Operator's manual 2-9

ES-MX Manual del usuario 10-17

FR-CA Manuel d’utilisation 18-25

IT Manuale dell'operatore 26-33

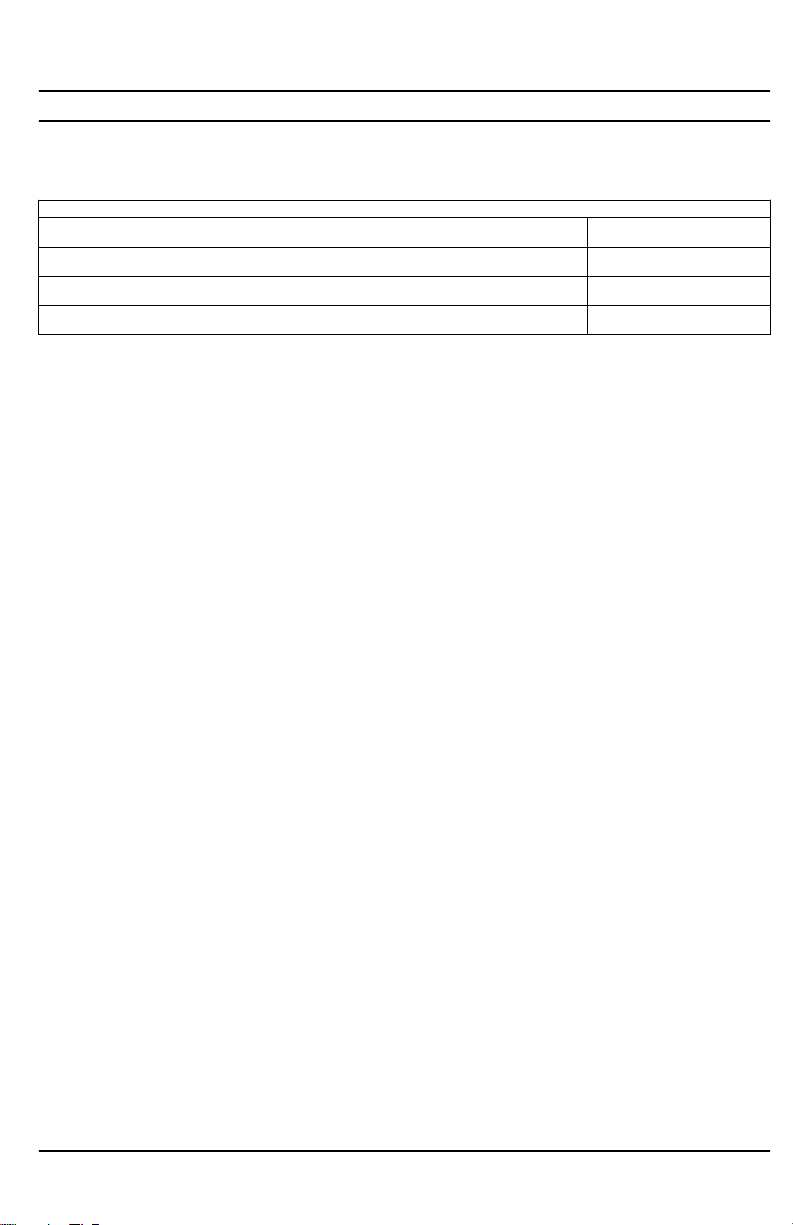

ECA850, ESA850

Contents

1

4

10

11

12

5

2

3

6

7

9

ESA 850

5

3

2

1

4

7

6

8

ECA 850

Introduction..................................................................... 2

Safety..............................................................................3

Assembly........................................................................ 6

Introduction

Product description

We have a policy of continuous product development

and therefore reserve the right to modify the design and

appearance of the products without prior notice.

Intended use

WARNING: Use this attachment only with

products that it is intended for. Refer to the

accessory chapter in the operator's manual

of your product.

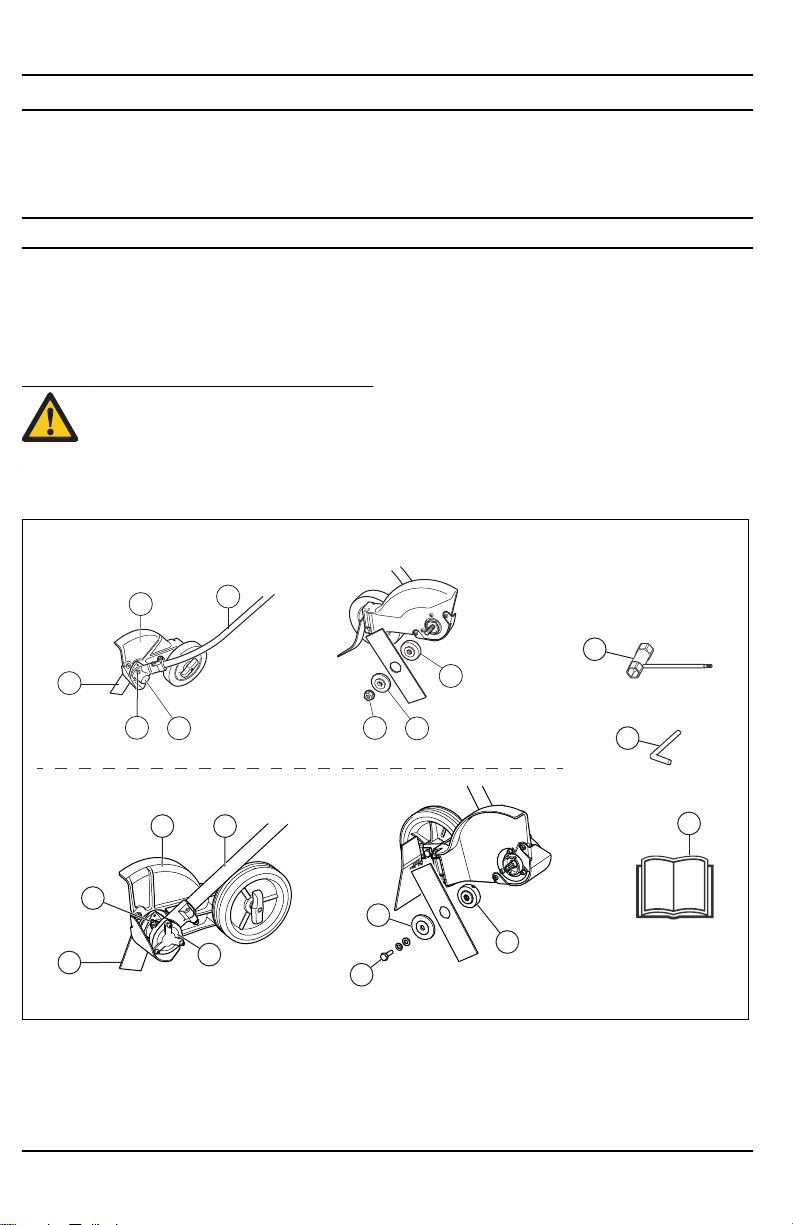

Attachment overview

Maintenance................................................................... 8

Technical data................................................................ 9

Use the attachment for edging lawns only.

1. Blade

2. Grease filler cap, bevel gear

3. Bevel gear

4. Cutting attachment guard

5. Shaft

2 878 - 001 - 23.10.2018

6. Drive disc

7. Support flange

8. Locknut

9. Blade mounting bolt

10. Combination wrench

11. Locking pin

WARNING

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects

or other reproductive harm.

12. Operator′s manual

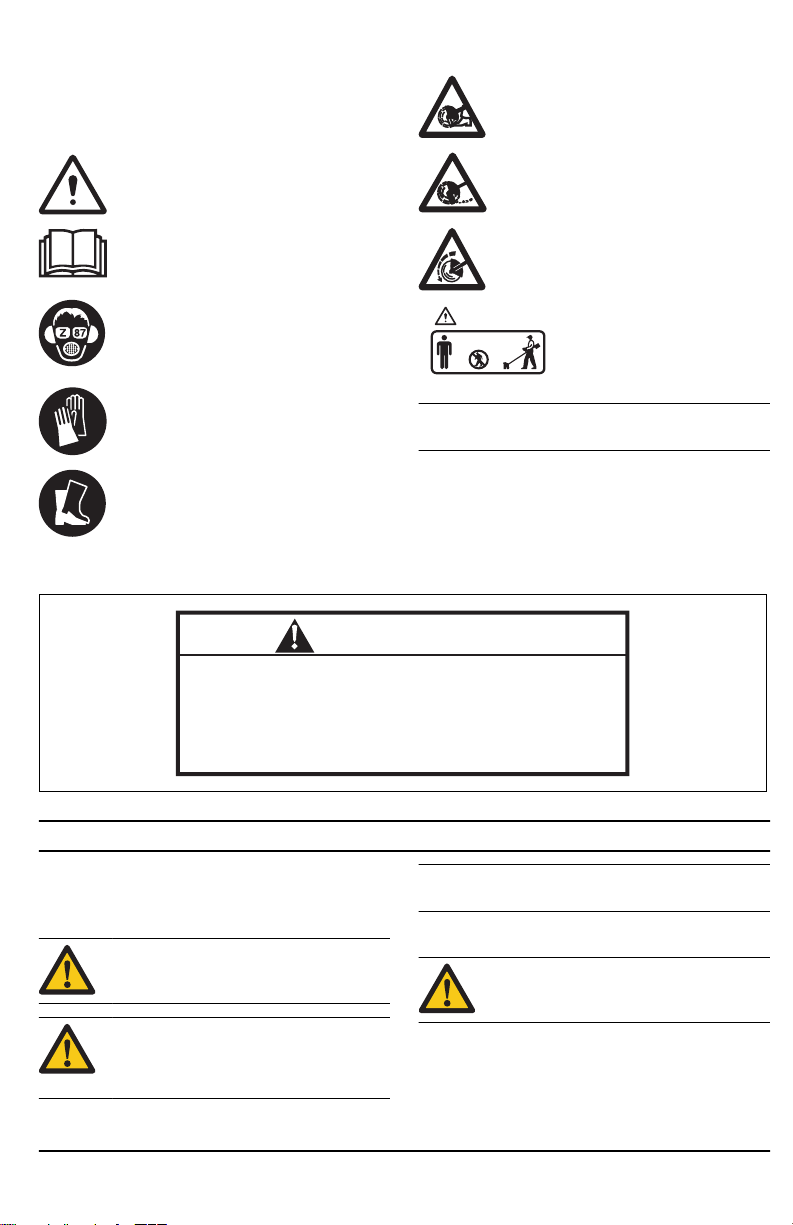

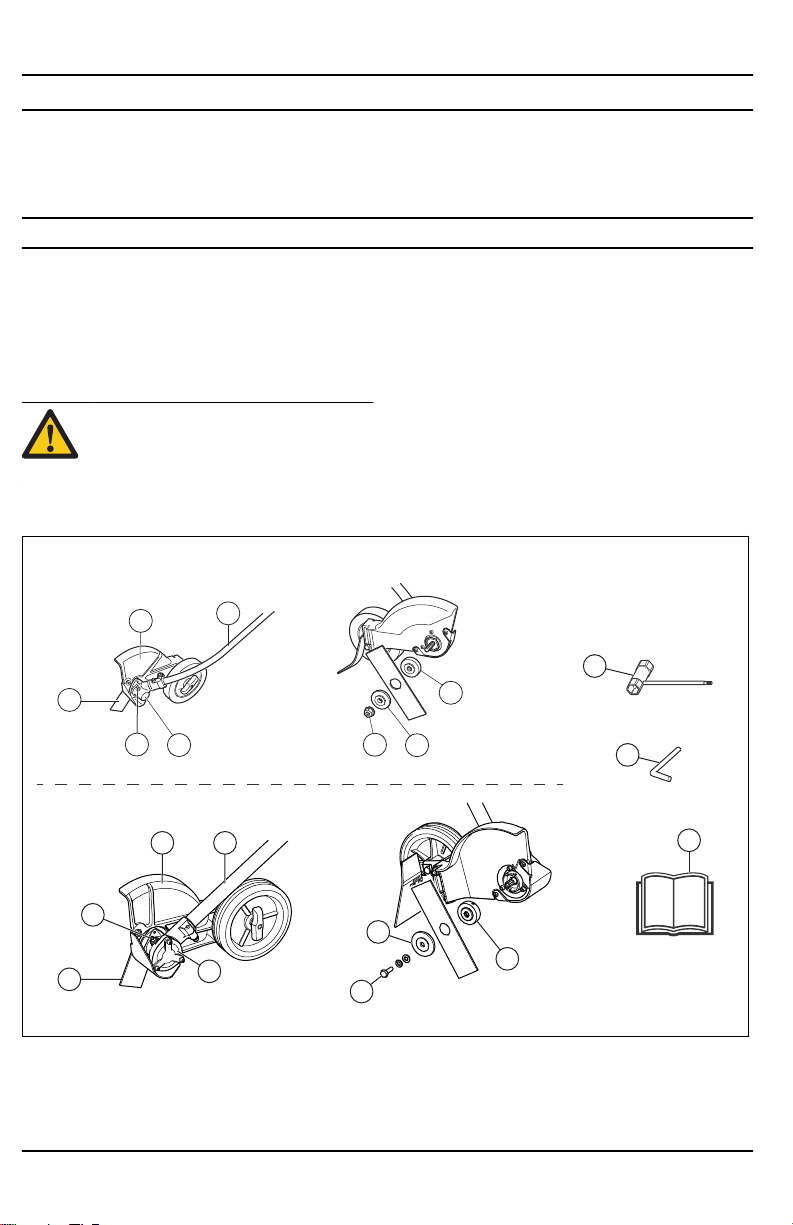

Symbols on the cutting attachment

Careless or incorrect use of this attachment

can result in serious or fatal injury to the

operator or others.

Please read the operator’s manual carefully

and make sure you understand the

instructions before using the attachment.

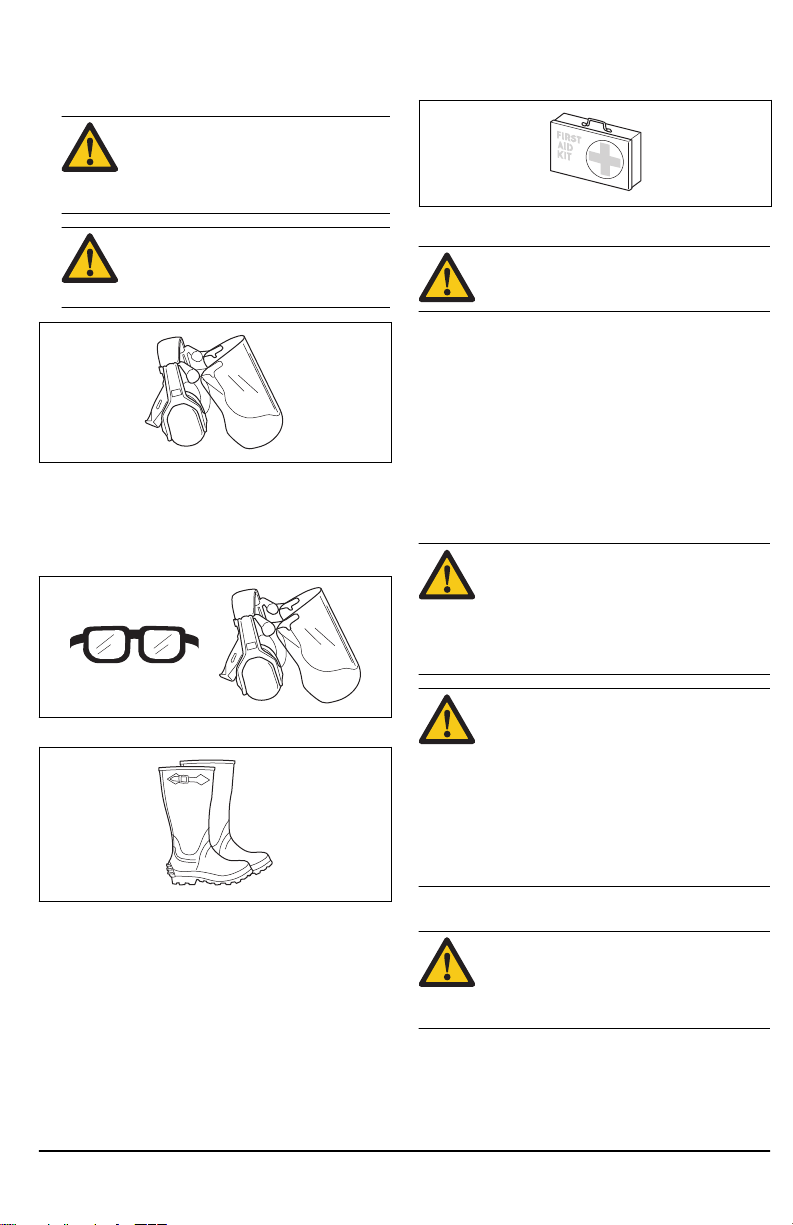

Always wear approved hearing protection

and protective goggles or a visor. A

breathing mask should be used when there

is a risk of dust.

Always wear approved protective gloves.

Wear sturdy, non-slip boots.

Proposition 65

Rotating blade. Keep hands and feet clear.

The arrow indicates the direction of rotation.

Watch out for thrown objects and ricochets.

The blade continues to rotate even after the

engine has stopped.

The operator of the attachment

must ensure, while working, that

no persons or animals come

closer than 15 meters / 50 ft.

Note: Other symbols/decals on the attachment refer to

special certification requirements for certain markets.

Safety

Safety definitions

Warnings, cautions and notes are used to point out

specially important parts of the manual.

WARNING: Used if there is a risk of injury or

death for the operator or bystanders if the

instructions in the manual are not obeyed.

CAUTION: Used if there is a risk of damage

to the product, other materials or the

adjacent area if the instructions in the

manual are not obeyed.

Note: Used to give more information that is necessary in

a given situation.

General safety instructions

WARNING: Read the safety instructions that

follows before you use the attachment.

• Please read the operator’s manual carefully and

make sure you understand the instructions before

using the attachment.

878 - 001 - 23.10.2018 3

• These instructions supplement the instructions that

were included with the product. For other

procedures, please refer to the operating instructions

for the product.

• Under no circumstances may the design of the

attachment be modified without the permission of the

manufacturer. Do not use an attachment that

appears to have been modified by others and always

use original accessories. Non-authorized

modifications and/or accessories can result in

serious personal injury or the death of the operator

or others.

Safety instructions for operation

WARNING: Read the saftey instructions that

follow before you use the product.

• Never allow children to use the product.

• Never allow anyone else to use the product without

first ensuring that they have understood the contents

of the operator’s manual.

• Keep unauthorized persons at a distance. Children,

animals, onlookers and helpers should be kept

outside the safety zone of 15 m (50 ft) while you

work. Stop the product immediately if anyone

approaches.

• Make sure you can move and stand safely. Check

the area around you for possible obstacles (roots,

rocks, branches, ditches, etc.) in case you have to

move suddenly. Take great care when working on

sloping ground.

• Inspect the working area. Remove all loose objects,

such as stones, broken glass, nails, steel wire,

string, etc. that could be thrown out or become

wrapped around the cutter or cutter guard.

• Watch out for thrown objects. Always wear approved

eye protection. Never lean over the cutting

attachment guard. Stones, rubbish, etc. can be

thrown up into the eyes causing blindness or serious

injury.

• Do not use the product in bad weather, such as

dense fog, heavy rain, strong wind, intense cold, etc.

• Do not use the product unless you are able to call for

help in the event of an accident.

• The engine must be switched off before moving.

• Never put the product down with the engine running

unless you have it in clear sight.

• Always use both hands to hold the product. Hold the

product at the side of your body.

• Use your right hand to control the throttle setting.

• Listen out for warning signals or shouts when you

are wearing hearing protection. Always remove your

hearing protection as soon as the engine stops.

• Make sure that your hands and feet do not come

near the cutting attachment when the engine is

running.

• When the engine is switched off, keep your hands

and feet away from the cutting attachment until it has

stopped completely.

• Always keep the cutter close to the ground.

• Always carry out edging at full throttle.

• Always slow the engine to idle speed after each

working operation. Long periods at full throttle

without any load on the engine (i.e without the

resistance that the cutting attachment exerts on the

engine when you are using the product) can lead to

serious engine damage.

• Be especially careful when pulling the edger towards

you during work.

• If any foreign object is hit or if vibrations occur stop

the product immediately. Disconnect the HT lead

from the spark plug. Check that the product is not

damaged. Repair any damage.

• Sometimes grass or stones can get trapped in the

cutter guard and cutter. Always stop the engine

before cleaning.

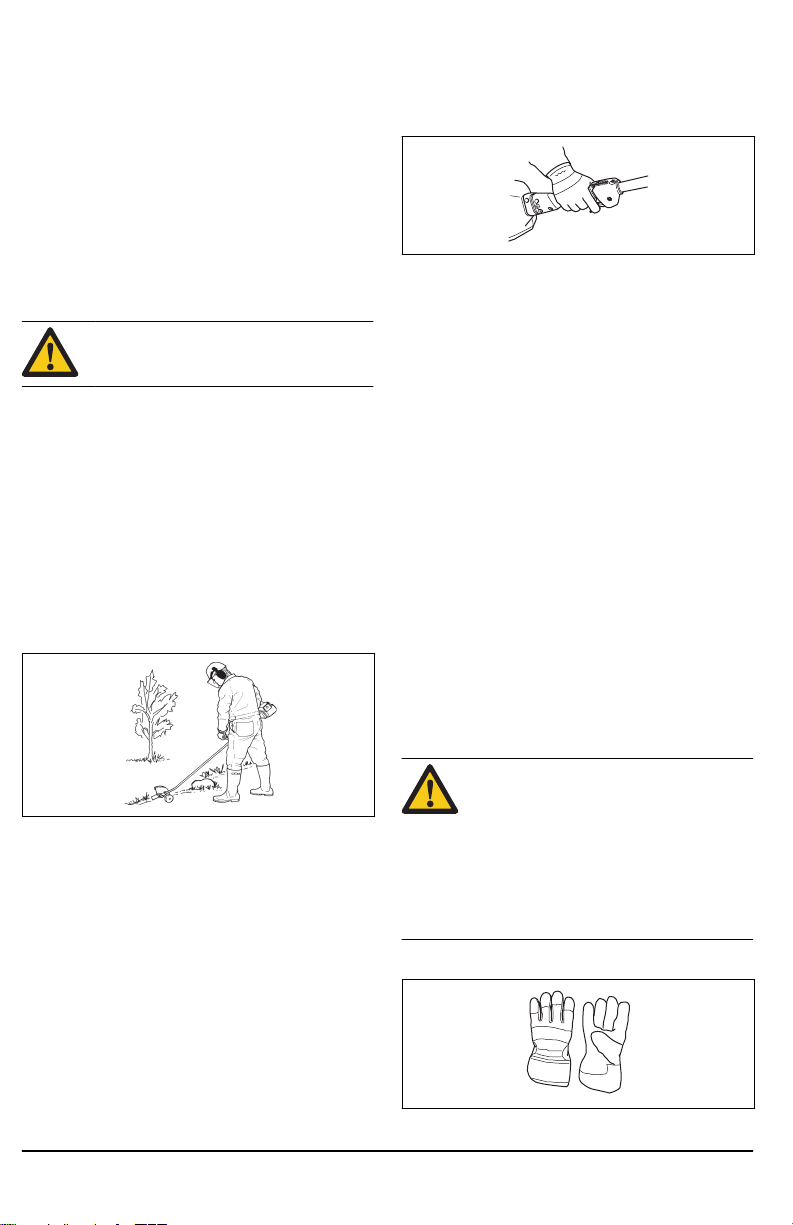

Personal protective equipment

WARNING:

personal protective equipment whenever

you use the procuct. Personal protective

equipment cannot eliminate the risk of injury

but it will reduce the degree of injury if an

accident does happen. Ask your dealer for

help in choosing the right equipment. Please

read the operator’s manual carefully and

make sure you understand the instructions

before using the procuct.

• Gloves should be worn when necessary.

You must use approved

4

878 - 001 - 23.10.2018

• Wear hearing protection that provides adequate

noise reduction.

WARNING: Listen out for warning

signals or shouts when you are wearing

hearing protection. Always remove your

hearing protection as soon as the engine

stops.

WARNING: Long-term exposure to

noise can result in permanent hearing

impairment. So always use approved

hearing protection.

• Always wear approved eye protection. If you use a

visor then you must also wear approved protective

goggles. Approved protective goggles must comply

with the ANSI Z87.1 standard in the USA or EN 166

in EU countries. Blows from branches or objects that

are thrown can damage the eyes.

• Always have a first aid kit nearby.

Safety devices on the attachment

WARNING: Read the warning instructions

that follow before you use the attachment.

In this section the attachment’s safety features, its

purpose and how checks and maintenance should be

carried out to ensure that it operates correctly. See

instructions under the heading

page 2

to find where these parts are located on your

attachment.

The life span of the attachment can be reduced and the

risk of accidents can increase if attachment

maintenance is not carried out correctly and if service

and/or repairs are not carried out professionally. If you

need further information please contact your nearest

servicing dealer.

WARNING: Never use a attachment with

defective safety components. The

attachment's safety equipment must be

inspected and maintained as described in

this section. If your attachment fails any of

these checks, contact your service agent to

get it repaired.

Attachment overview on

• Wear sturdy, non-slip boots.

• Always wear heavy, long pants, boots, gloves, and a

long-sleeve shirt. To reduce the risk of injury

associated with objects being drawn into rotating

parts, do not wear loose clothing, scarves, jewelry,

etc. Secure hair so it is above shoulder level.

• A breathing mask should be used when there is a

risk of dust.

878 - 001 - 23.10.2018

CAUTION: All servicing and repair work on

the product requires special training. This is

especially true of the product′s safety

equipment. If your product fails any of the

checks described below you must contact

your service agent. When you buy any of

our products we guarantee the availability of

professional repairs and service. If the

retailer who sells your product is not a

servicing dealer, ask him for the address of

your nearest service agent.

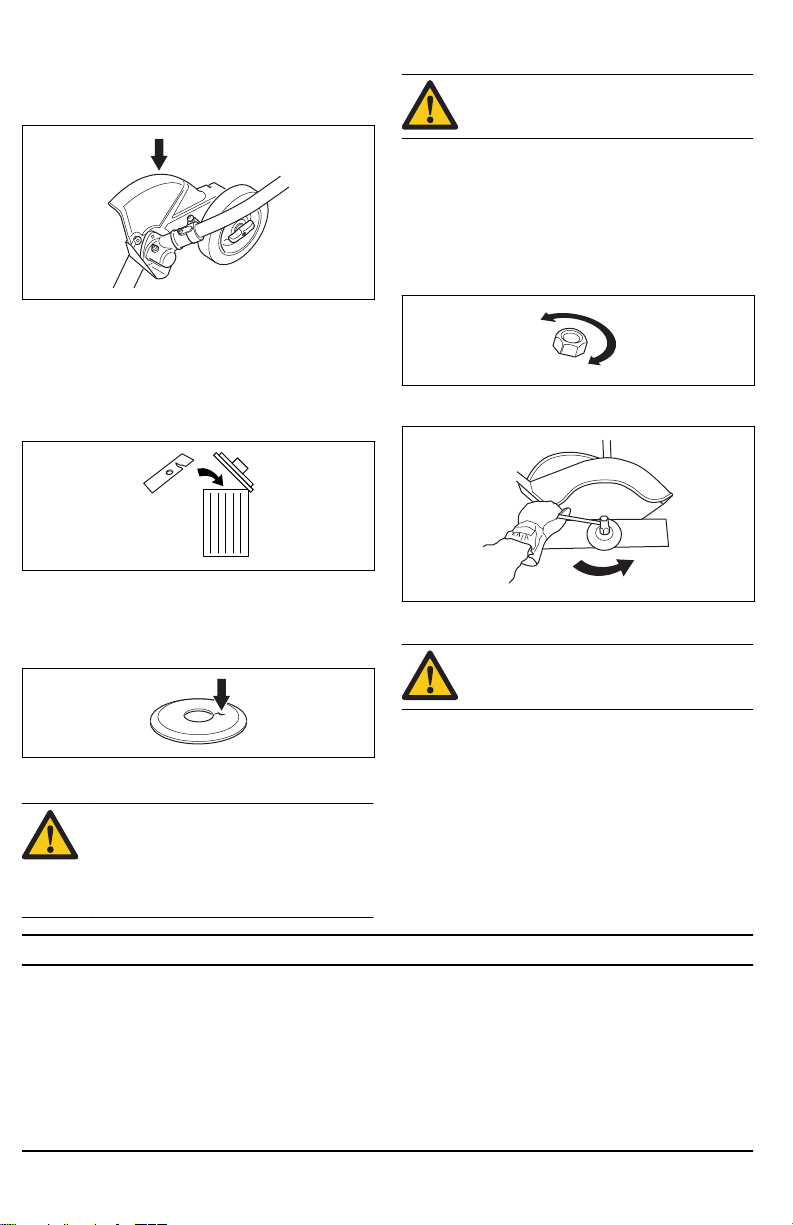

To check the cutting attachment guard

WARNING:

without an approved cutting attachment

guard. If an incorrect or faulty cutting

attachment guard is fitted this can cause

serious personal injury.

This cutting attachment guard is intended to prevent

loose objects from being thrown towards the operator.

The cutting attachment guard also protects the operator

from accidental contact with the blade.

Do not use a cutting attachment

5

• Check that the cutting attachment guard is not

damaged. Replace the cutting attachment guard if it

has been exposed to impact or is cracked.

• Only use original spare parts.

To check the blade

The blade is designed and manufactured to withstand

the loads that edging of a lawn involves.

• Check the blade for damage or cracks. A damaged

blade should always be replaced.

To check the support flange

• Check that the support flange is not cracked due to

fatigue or due to being tightened too much. Discard

the support flange if it is cracked.

CAUTION: The locknut has a left-hand

thread. To tighten the locknut to much can

cause damage to the threads.

The locknut secures the cutting attachment on the

output shaft. Protect your hand from injury when

assembling, use the cutting attachment guard as

protection when tightening with a socket wrench.

1. When fitting, tighten the locknut in the opposite

direction to the direction of rotation of the cutting

attachment. To remove it, undo the locknut in the

same direction as the cutting attachment rotates.

2. Tighten the locknut using a socket wrench to 15-20

Nm / 11-20 ft-lb.

Safety instructions for maintenance

WARNING:

follow before you do maintenance on the

attachment.

Read the safety instructions that

• Always stop the engine before you work on any part

of the cutting equipment. This continues to move

even after the throttle is released. Check that the

To check the locknut

CAUTION:

locknut must not be so worn that you can

turn it by hand. The lining should offer a

resistance of minimum 1.5 Nm / 13 in-lb.

The locknut must be replaced after it has

been put on approximately 10 times.

The nylon lining inside the

cutting equipment has stopped completely and

remove the HT lead from the spark plug before you

start any work on it.

• Always wear heavy-duty gloves when repairing the

cutting attachment. This is extremely sharp and can

easily cause cuts.

• Use only original spare parts for repairs.

• Store the product out of reach of children.

Assembly

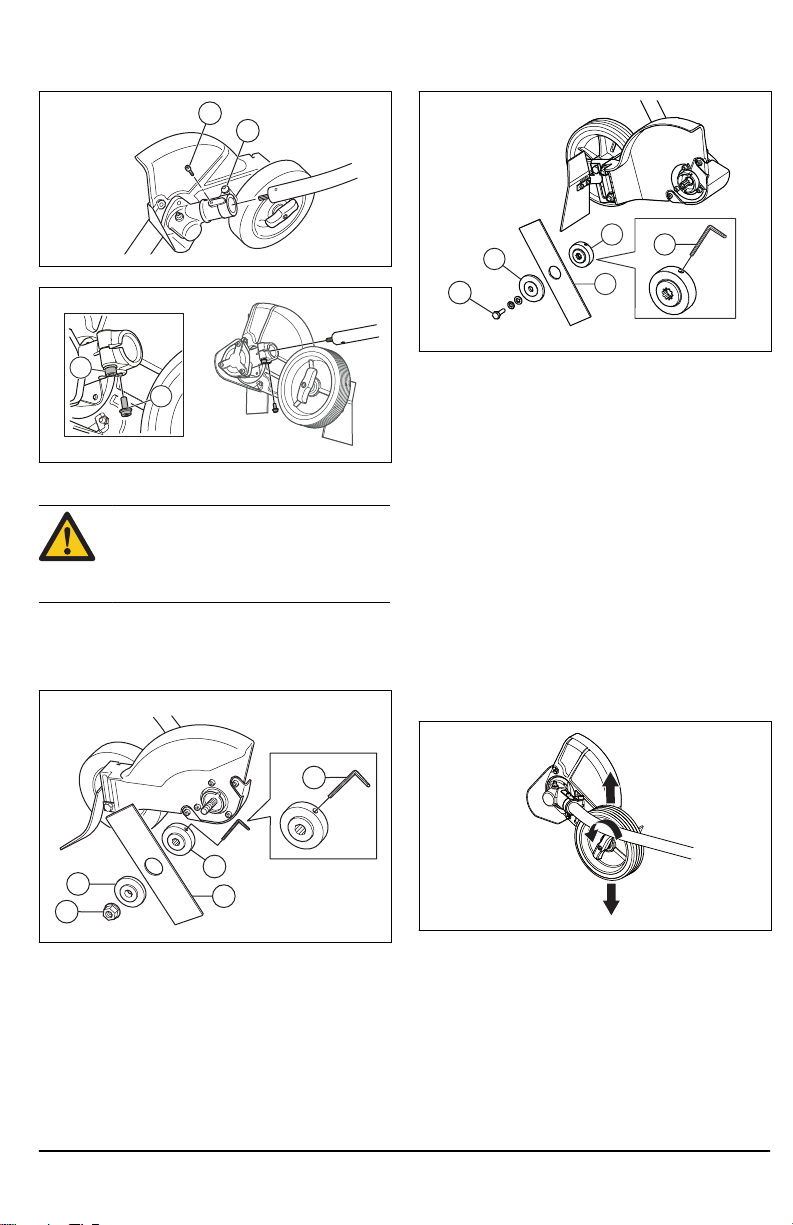

To assemble the bevel gear

1. Insert the driveshaft into the bevel gearbox housing.

Turn the cutting attachment so that the shaft

engages in the bevel gear.

2. Attach the bevel gear box to the shaft tube aligning

the positioning holes.

6 878 - 001 - 23.10.2018

3. Fasten the screw (A), then fasten the clamp bolt (B)

firmly, 6-8 Nm / 53-70 in-lb.

a) For model ECA850:

B

A

B

A

B

A

E

D

C

B

A

C

E

D

b) For model ESA850:

To assemble the cutting attachment

WARNING: Never use a cutting attachment

without without an approved cutting

attachment guard. If an incorrect or faulty

cutting attachment guard is fitted this can

cause serious personal injury.

1. Fit the drive disc (A) on the output shaft. Make sure

that the edge of the drive disc, that fits in the hole of

the blade, is facing outwards.

a) For model ECA850:

b) For model ESA850:

2. Lock the blade rotation by inserting the locking pin

(E) in the hole on the drive disc.

3. Fit the blade (B) on the drive disc.

4. Fit the support flange (C). The support flange must

be fitted so that its outer edge presses against the

cutter.

5. Fit the locknut / blade mounting bolt (D). The

locknut / blade mounting bolt has a left-hand thread.

Tighten the locknut / blade mounting bolt to a torque

of 15-20 Nm / 12-15 ft-lb.

6. Remove the locking pin.

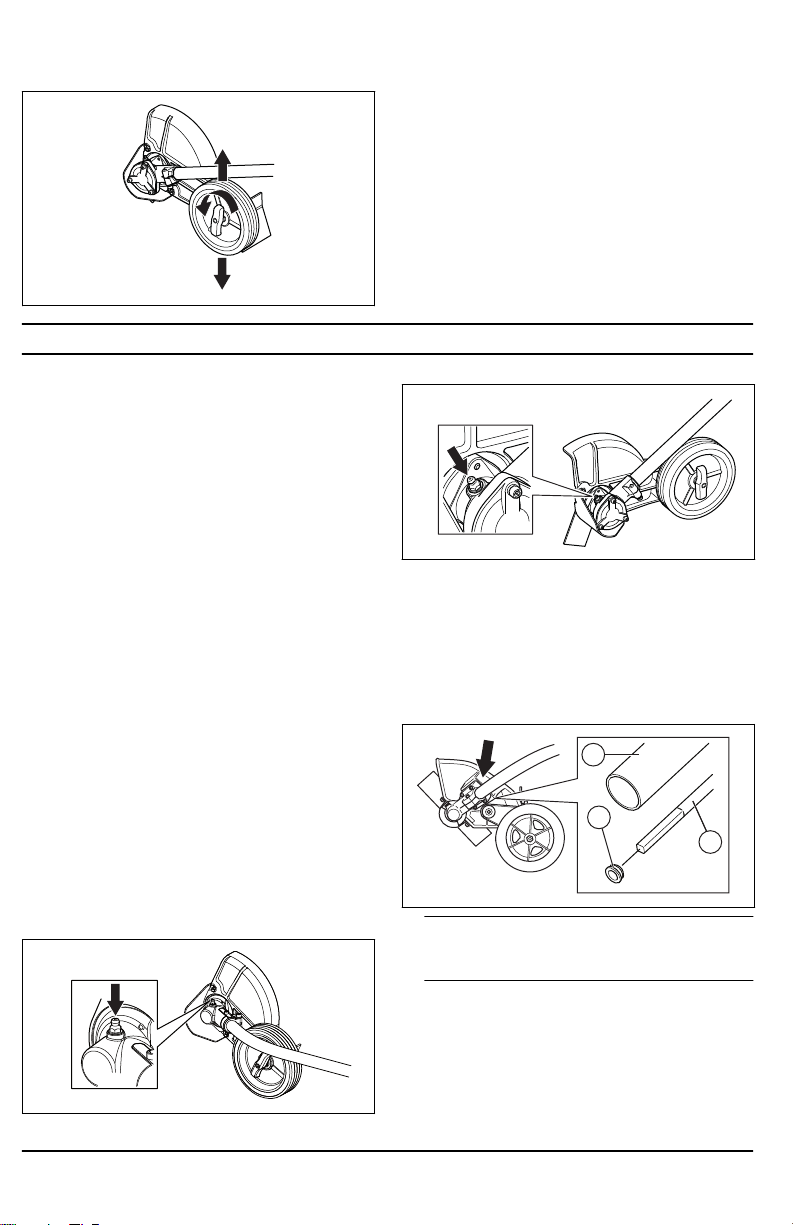

To adjust the cutting depth of the cutting attachment

The cutting depth of the cutting attachment must be

adjusted before starting work.

1. Loosen the wing nut.

a) For model ECA850:

878 - 001 - 23.10.2018

7

b) For model ESA850: 2. Set the desired cutting depth.

C

B

A

3. Tighten the wing nut.

Maintenance

Introduction

Below you will find some general maintenance

instructions. If you need further information please

contact your service workshop.

To perform daily maintenance

• Check that the blade does not rotate when the

engine is idling.

• Check that the cutting attachment guard is

undamaged and not cracked. Replace the cutting

attachment guard if it has been exposed to impact or

is cracked.

• Check that the blade is not damaged and not

cracked. Replace the blade if necessary.

• Check that the support flage is not damaged.

• Check that the locknut is tight.

To perform weekly maintenance

• Check that the bevel gear is filled to ¾ with grease.

Fill if necessary using special grease.

To check the bevel gear

The bevel gear is filled with the right quantity of grease

at the factory. The grease in the bevel gear does not

normally need to be changed except if repairs are

carried out.

• Before using the product check that the bevel gear is

filled to ¾ with grease. Fill if necessary using special

grease.

a) For model ECA850:

8

b) For model ESA850:

To lubricate the flexible drive shaft

Only for model ECA850.

1. Loosen the 2 screws on the bevel gear.

2. Remove the bevel gear.

3. Take a firm grip on the hollow shaft (A) and remove

the flexible drive shaft (B) from the opposite end of

the gear box.

Note: The bushing (C) will fall off when you remove

the flexible driveshaft. Make sure that you do not

lose it. Put the bushing safely aside.

4. Lubricate the entire length of the flexible drive shaft.

5. Reinsert the flexible driveshaft in the hollow shaft.

Turn the flexible driveshaft while inserting it so that it

correctly engages in the bevel gear.

6. Attach the bushing on the flexible drive shaft.

7. Attach the bevel gear on the hollow drive shaft and

tighten the 2 screws.

878 - 001 - 23.10.2018

Technical data

Technical data

ECA850, ESA850

Weight, Lbs / kg 3.5 / 1.6

Blade length, inch / mm 7.7 / 195

Center hole, blade, inch / mm 1 / 25.4

Speed, blade, rpm 7140

878 - 001 - 23.10.2018 9

Contenido

1

4

10

11

12

5

2

3

6

7

9

ESA 850

5

3

2

1

4

7

6

8

ECA 850

Introducción.................................................................. 10

Seguridad..................................................................... 11

Montaje......................................................................... 15

Introducción

Descripción de la máquina

Husqvarna AB tiene una política de desarrollo continuo

de productos y, por lo tanto, se reserva el derecho de

modificar el diseño y el aspecto de los productos sin

previo aviso.

Uso específico

ADVERTENCIA: Utilice este accesorio solo

con productos para los que se diseñó.

Consulte el capítulo de accesorios en el

manual de usuario del producto.

Vista general del accesorio

Mantenimiento.............................................................. 16

Datos técnicos.............................................................. 17

Utilice el accesorio solo para el bordeado de césped.

1. Hoja

2. Tapón de llenado de grasa, engranaje angulado

3. Engranaje angulado

4. Protección del equipo de corte

10 878 - 001 - 23.10.2018

5. Eje

6. Disco de arrastre

7. Brida de apoyo

8. Contratuerca

9. Perno de montaje de la hoja

¡ADVERTENCIA!

10. Llave combinada

11. Pasador de bloqueo

12. Manual de usuario

Símbolos en el equipo de corte

El uso incorrecto o descuidado de este

accesorio puede ocasionar lesiones graves

o mortales al operador u otras personas.

Lea cuidadosamente el manual de usuario y

asegúrese de que entiende las instrucciones

antes de utilizar el accesorio.

Use siempre protectores auriculares

aprobados y gafas protectoras o un visor.

Se debe utilizar una máscara respiratoria

cuando exista riesgo de polvo.

Use siempre guantes protectores

aprobados.

Use botas antideslizantes y resistentes.

Propuesta 65

Cuchilla giratoria. Mantenga las manos y los

pies alejados. La flecha indica el sentido de

rotación.

Tenga cuidado con los objetos que puedan

salir despedidos o producir algún impacto

por efectos de rebote.

La hoja continúa girando, incluso después

de detener el motor.

Mientras trabaja, el operador

del equipo se debe asegurar de

que ninguna persona o animal

se acerque a menos de 15 metros (50 pies).

Tenga en cuenta: Otros símbolos o etiquetas en el

equipo hacen referencia a requisitos de certificación

especiales para ciertos mercados.

Seguridad

Definiciones de seguridad

Las advertencias, precauciones y notas se utilizan para

señalar las piezas particularmente importantes del

manual.

ADVERTENCIA: Se utilizan para señalar el

riesgo de lesiones graves o mortales para el

operador o para aquellos que se encuentren

cerca si no se siguen las instrucciones del

manual.

878 - 001 - 23.10.2018 11

Tenga en cuenta: Se utilizan para entregar más

información necesaria en situaciones particulares.

AVISO: Se utilizan para señalar el riesgo de

dañar la máquina, otros materiales o el área

adyacente si no se siguen las instrucciones

del manual.

Loading...

Loading...