Page 1

HUSQVARNA CONSTRUCTION PRODUCTS

English

DXR-310

Please read the Operator’s Manual carefully and make sure you

understand the instructions before using the machine.

Page 2

Page 3

CONTENTS

Contents

INTRODUCTION

Dear Customer ......................................................... 4

Good service ............................................................ 4

Serial Number ........................................................... 4

Applications .............................................................. 4

User responsibility .................................................... 4

The manufacturer’s reservation ................................ 4

KEY TO SYMBOLS

Symbols on the machine .......................................... 5

SAFETY INSTRUCTIONS

Warning instructions ................................................. 6

Protective equipment ............................................... 6

General safety warnings ........................................... 7

General working instructions .................................... 8

The machine’s safety features .................................. 13

External environmental factors ................................. 15

PRESENTATION

The machine’s functions ........................................... 16

What is what in the machine? .................................. 17

HYDRAULIC SYSTEM

General ..................................................................... 18

Main pressure ........................................................... 18

Pressure cut-off ........................................................ 18

Cooler ....................................................................... 18

The machine’s hydraulic system .............................. 19

ELECTRICAL SYSTEM

General ..................................................................... 20

High-voltage circuit .................................................. 20

Low-voltage circuit ................................................... 20

The machine’s electric system ................................. 21

CONTROL SYSTEM

General ..................................................................... 22

Remote control ......................................................... 22

Signal transmission .................................................. 22

Battery ...................................................................... 22

The machine’s software ............................................ 22

What is what on the remote control? ....................... .23

Symbols on the remote control ................................ 24

STARTING AND STOPPING

Before starting .......................................................... 25

Starting ..................................................................... 25

Stopping ................................................................... 25

Inspection after work ................................................ 25

OPERATION

Operating modes ...................................................... 26

Option ....................................................................... 26

Key to commands .................................................... 26

Designation of the machine’s parts .......................... 26

Work mode ............................................................... 27

Set-up mode ............................................................ 28

Transport mode ........................................................ 29

TOOLS

General ..................................................................... 30

Work mode ............................................................... 30

Changing tools ......................................................... 31

Storage ..................................................................... 31

SETTINGS

Track widener ........................................................... 32

Menu system ............................................................ 33

Operational settings ................................................. 34

MAINTENANCE AND SERVICE

General ..................................................................... .35

Measures to take in advance of maintenance,

service and trouble shooting .................................... 35

Cleaning ................................................................... 36

Service schedule ...................................................... 37

Service review .......................................................... 40

TROUBLE SHOOTING

Error messages ........................................................ 47

Troubleshooting schedule ........................................ 48

TECHNICAL DATA

Guide values for main connection ............................ 50

The hydraulic system pressure ................................. 50

Hydraulic fl uid and lubricant ..................................... 51

Preset limit values .................................................... 51

Technical data .......................................................... 52

EC-DECLARATION OF CONFORMITY

EC-declaration of conformity ................................... 56

English - 3

Page 4

INTRODUCTION

Dear Customer

Thank you for choosing a Husqvarna DXR-310!

We hope you will fi nd this operator’s manual very use-

ful. By following its instructions (on operation, service,

maintenance, etc.) you will signifi cantly extend the life

of the machine and even its second-hand value.

Good service

Husqvarna products are sold all over the world and

ensures that you, the customer, get the best support

and service. When you need spare parts or advice on

service or warranty issues, go to www.husqvarnacp.

com and fi nd your local service agent.

Serial Number

The machine’s serial number is indicated on a plate

located on the hydraulic tank. Stated on the plate are:

• The machine’s type designation

• Weight

• The manufacturer’s type number

• The machine’s serial number

• Manufacturer

The hydraulic pump and hydraulic motors are fi tted

with rating plates that indicate article number and the

machine manufacturer’s manufacture number.

Please state the type designation and serial number

when ordering spare parts and for service matters.

Applications

The machine is intended for:

• Demolishing, fragmenting, cutting, detaching,

separating, picking up and distributing parts of

buildings and constructions.

• Use in risky environments where the operator can

control the machine without being present within

the risk area.

• Use both indoors and outdoors.

• Use in dangerous environments where the machine

is exposed to risk of collapse, hazardous substances, great heat, etc.

The machine is NOT intended for:

• Use in areas classifi ed as ’explosive”.

• Use in water where the level risks damaging the

machine’s equipment.

• Operation on a public highway.

• Use as a towing vehicle, means of transport or lifting device.

• Use in environments where there is danger for

the operator or the life and health of people in the

vicinity.

• Use in applications or environments that are not

compatible with the recommendations in this Operator’s Manual.

User responsibility

It is the owner’s/employer’s responsibility that the operator has suffi cient knowledge about how to use the

machine safely. Supervisors and operators must have

read and understood the Operator’s Manual. They

must be aware of:

• The machine’s safety instructions.

• The machine’s range of applications and limitations.

• How the machine is to be used and maintained.

The manufacturer’s

reservation

Husqvarna Construction Products reserves the right

to alter specifi cations and instructions for the machine

without prior notifi cation. The machine may not be

modifi ed without the manufacturer’s written permis-

sion. If the machine is modifi ed after delivery from

Husqvarna Construction Products and without the

manufacturer’s written permission, it is the owner’s

responsibility.

Modifi cation can entail new risks for operators, the

machine and the surroundings. These can include

impaired strength or inadequate protection. It is the

responsibility of the owner to specify which alterations are going to be made and to contact the supplier

of the machine for approval before commencing the

modifi cations.

• Use in environments classifi ed as ’fl ammable”

provided that it has the correct power connection

and all its equipment is correctly dimensioned and

undamaged. The operator must take the risk of

spark formation into consideration when working in

fl ammable environments..

4

- English

All information and all data in the Operator’s Manual

were applicable at the time the Operator’s Manual was

sent to print.

Contact

Husqvarna Construction Products, Jons väg 19,

SE-433 81 Göteborg, Sweden.

Page 5

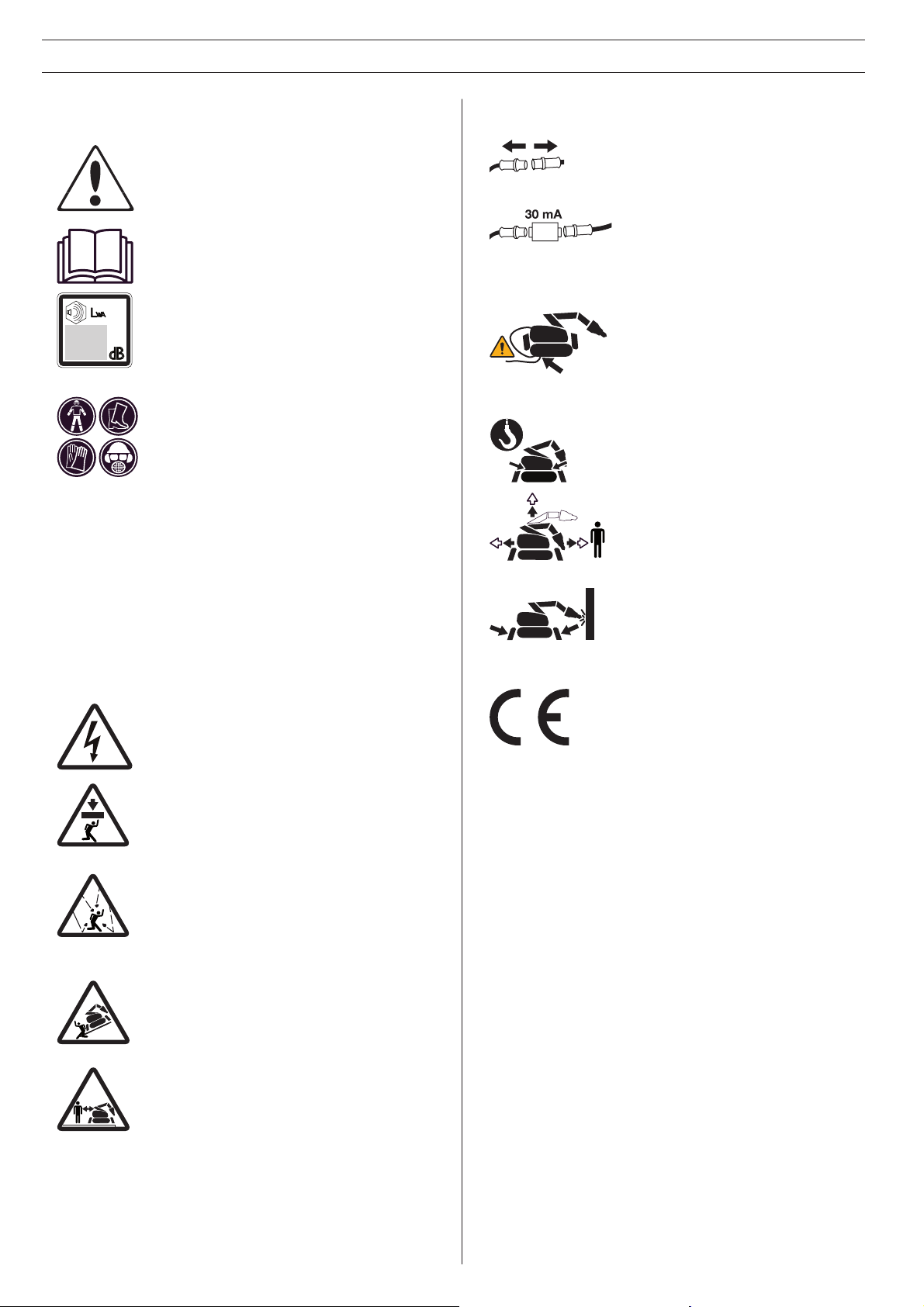

KEY TO SYMBOLS

English - 5

Symbols on the machine

WARNING! The machine can be dangerous if used incorrectly or carelessly, and

can cause serious or fatal injury to the

operator or others.

Please read the Operator’s Manual carefully and make sure you understand the

instructions before using the machine.

Noise emission to the environment according to the European Community’s

Directive. The machine’s emission is

specifi ed in chapter Technical data and on

label.

Always wear:

• Tight-fi tting, heavy-duty and comfort-

able clothing that permit full freedom

of movement.

• Sturdy, non-slip boots or shoes.

• Protective gloves.

• Protective helmet.

• Hearing protection.

• Protective goggles or visor.

• A breathing mask, gas mask or fresh

air helmet must be used when working in environments where the air can

be harmful to health.

WARNING! High-voltage current.

Inspections and/or maintenance must be

carried out with the motor switched off

and the power cord disconnected.

Always connect the machine

through an earth-fault breaker with

personal protection, i.e. an earth

fault circuit breaker that trips at an

earth fault of 30 mA.

Ensure that the power cable cannot be run over. Take particular care

when moving or when the outriggers

are being retracted or extended.

Risk of electric shock.

The lifting equipment must be attached at

all the machine’s lifting points.

Keep your distance! Nobody is

permitted to be within the machine’s

risk area when work is underway.

The machine’s risk area can vary

during the course of the work.

The machine can overturn during

work. During operation the machine

must be positioned as level as possible and the outriggers must be fully

extended.

This product is in accordance with applicable EC directives.

WARNING! Ensure that no material can fall

down and cause damage when you are

using the machine.

WARNING! Watch out for demolition material becoming loose when cutting. Use

personal safety equipment and keep your

distance.

WARNING! Always position yourself above

the machine when driving on a slope.

There is a risk of the machine tipping.

WARNING! Exercise particular caution

when working close to edges. Ensure that

the machine is stable and does not move

closer to the edge while the work is in

progress. Ensure that the underlying surface has satisfactory bearing capacity.

Page 6

SAFETY INSTRUCTIONS

Warning instructions

Warning

WARNING!

Used if there is a risk of serious injury or death

for the operator or damage to the surroundings

if the instructions in the manual are not followed.

Important

IMPORTANT!

Used if there is a risk of injury to the operator or

damage to the surroundings if the instructions in

the manual are not followed.

Note

NB! Used if there is a risk of damage to materials or

the machine if the instructions in the manual are not

followed.

Protective equipment

Personal protective equipment

WARNING!

You must use approved personal protective

equipment whenever you use the machine.

Personal protective equipment cannot eliminate

the risk of injury but it will reduce the degree

of injury if an accident does happen. Ask your

dealer for help in choosing the right equipment.

Always wear:

• Protective helmet.

• Hearing protection.

• Protective goggles or a visor.

• Tight-fi tting, heavy-duty and comfortable clothing

that permits full freedom of movement.

• Protective gloves.

• Sturdy, non-slip boots or shoes.

• A breathing mask, gas mask or fresh air helmet

must be used when working in environments where

the air can be harmful to health.

• Always have a fi rst aid kit nearby.

Other protective equipment

• Fall protection must be used when working at

height or if there is a risk of collapse. The operator

and the machine must be safeguarded with separate fall protection.

• Screening equipment and modifi ed protective

clothing must be used when working in hot environments.

• Barriers must be used to inform people in the vicinity of the machine’s risk area.

• Equipment must be used to secure machine parts

during maintenance and service.

6 - English

Page 7

SAFETY INSTRUCTIONS

General safety instructions

WARNING!

Please read the Operator’s Manual carefully

and make sure you understand the instructions

before using the machine.

The machine is used in a large range of environments

and for different types of work, making it impossible

to forewarn of all risks. Always exercise care and use

your common sense. Avoid all situations which you

consider to be beyond your capability. If you still feel

uncertain about operating procedures after reading

these instructions, you should consult an expert before

continuing.

Do not hesitate to contact your dealer if you have any

more questions about the use of the machine. We will

willingly be of service and provide you with advice as

well as help you to use your machine both effi ciently

and safely.

Use the safety instructions as guidelines and support

so that you can detect possible risks yourself and take

measures to prevent them.

Let your Husqvarna dealer regularly check the machine and make essential adjustments and repairs.

Management and operator

The management and the operator are responsible

for identifying and preventing risks so that staff and

equipment are not exposed to danger.

Responsibility

It is the responsibility of the management and the

operator to confi rm:

• National and local laws, regulations and other

directions are followed. This might concern protective equipment, limit levels for noise, barriers, etc.

• The operator has the relevant training and experience to be able to perform the work safely.

• Unauthorized persons are not permitted to enter

areas where there is a risk of accidents.

Requirements of the operator

• The operator must be given suffi cient information

and training to have satisfactory knowledge of the

machine’s functions, properties and limitations.

• The operator must try to foresee risky elements of

the job and assess the machine’s risk area. Always

exercise caution and use common sense!

• It is the responsibility of the operator to suspend

work with the machine if a safety risk arises and

ensure that the machine is not used by mistake.

The machine must not be put into operation before

the safety risk has been eliminated.

• The operator must not be under the infl uence of

drugs or anything else that can affect his/her reactions or judgement.

• The operator must use protective equipment suited

for the particular work situation.

• The operator must ensure that the machine cannot

be used by unauthorized persons, e.g. do not leave

the remote control unattended.

If there is an accident

It is the responsibility of the employer to produce an

action plan and train operators how to deal with incidents. First take action to save human life and second

to avoid material damage. Learn how to administer

fi rst aid!

Measures to take in the event of an accident:

• Get an overview. Is anyone injured? Is anyone still

in the area where the accident took place?

• Alert emergency services and be prepared to provide information.

• Administer fi rst aid and prepare a route for the

emergency personnel.

• Ensure that someone accompanies the injured to

the hospital.

• Secure the scene of the accident.

• Contact management.

• Nobody is permitted to be within the machine’s risk

area when work is underway.

• Persons who are admitted to the work area are

trained in and have access to protective equipment.

• The machine is used solely for the functions for

which it is intended.

• The machine is used safely.

• The machine is correctly connected to a suitable

power supply and correctly fused.

• The operator is informed of the work area surroundings, e.g. strength in the fl oor structure, positioning

of load-bearing walls, cables and pipes.

• Contact relatives.

• Investigate the cause of the accident.

• Put measures in place to prevent future accidents.

• Always notify Husqvarna Construction Products in

the event of near-accidents or accidents regardless

of whether the machine was directly or indirectly

involved in the incident.

English - 7

Page 8

SAFETY INSTRUCTIONS

8 - English

General working

instructions

WARNING!

Read all safety warnings and all instructions.

Neglecting to follow the warnings and instructions can lead to serious injury or death for the

operator or others..

This section describes basic safety directions for

using the machine. This information is never a substitute for professional skills and experience. If you get

into a situation where you feel unsafe, stop and seek

expert advice. Contact your dealer, service agent or

an experienced user. Do not attempt any task that you

feel unsure of!

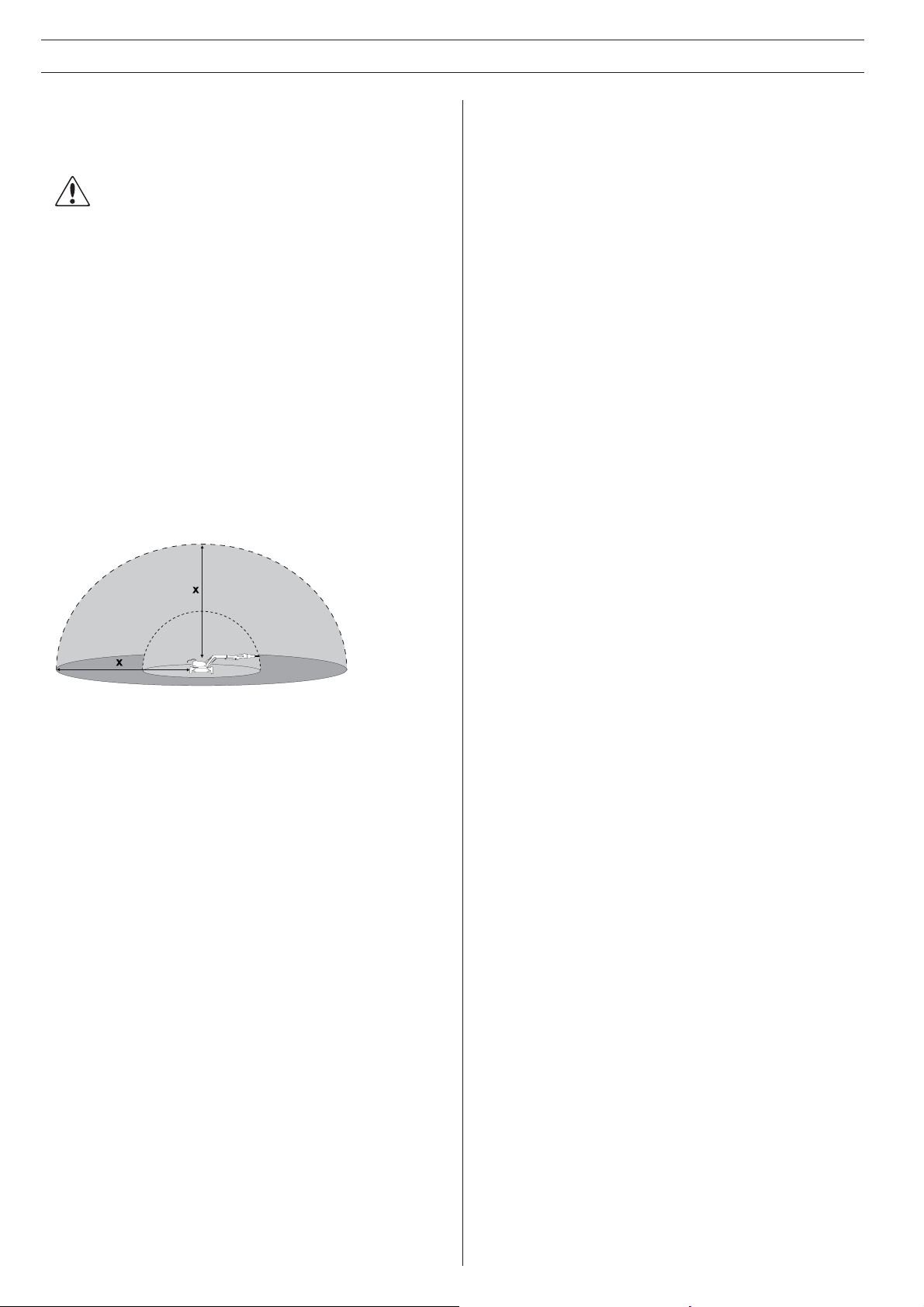

Work area safety

The machine’s risk area

Nobody is permitted to be within the machine’s risk

area when work is underway.

• When working at a height, for instance on roofs,

platforms and the like, increase the size of the risk

area. Defi ne and cordon off the risk area at ground

level and ensure that no material can fall down and

cause injury.

• Ensure when cutting that no material can become

loose and fall, causing operating injury. Take great

care when working on sloping ground.

• Do not use the machine in environments where

there is a risk of explosion. Take the risk of spark

formation into account when working in fl ammable

environments.

• Always check and mark where electricity cables

and pipelines are routed.

• The air in confi ned spaces can rapidly become

harmful to health due to, for example, dust and

gases. Use protective equipment and ensure that

there is satisfactory ventilation.

Electrical safety

• Check that the main voltage corresponds with the

machine’s rating plate.

The working area is limited by the machine’s reach,

however, the risk area varies depending on working

method, work object, surface etc. Study possible risks

before starting work. If conditions change during the

course of the work, the risk area must be redefi ned.

Workplace

• Defi ne and cordon off the risk area. Nobody is per-

mitted to be within the machine’s risk area when

work is underway.

• Ensure that the working area is suffi ciently illumi-

nated to create a safe working environment.

• The machine can be remote controlled over long

distances. Do not operate the machine unless you

have clear supervision of the machine and its risk

area.

• Never start working with the machine until the

working area has been cleared of obstacles.

• Be on the alert when working in environments

where there is a substantial risk of slipping due to

unevenness, loose material, oil, ice or suchlike.

• The machine must be connected to a functioning

protective earth.

• Check all cables and connections. Damaged

electric cables can impede the machine’s function

and lead to personal injuries. Do not use damaged

connectors or cables.

• The electric cabinet must not be opened when the

machine is connected to power. Some components

in the electric cabinet are permanently live, even if

the machine is turned off.

• Always connect the machine through an earth-fault

breaker with personal protection, i.e. an earth fault

circuit breaker that trips at an earth fault of 30 mA.

• The machine must never be driven to such a depth

in water that it reaches up to the machine’s equipment. The equipment can be damaged and the

machine can be live, resulting in personal injuries.

• Ensure that the power cable cannot be run over.

Take particular care when moving or when the

outriggers are being retracted or extended. Risk of

electric shock.

• To avoid overheating do not use an electric cable

while it is coiled.

• Always de-energize the machine when carrying

out maintenance work and when it is not in use.

Disconnect the power cable and place it so that it

cannot be connected by mistake.

• Inspect ground conditions, load-bearing structures

etc. to prevent materials, machines and staff falling

and deal with any risks there might be before starting work.

Page 9

SAFETY INSTRUCTIONS

English - 9

Personal safety

• Never use the machine if you are tired, if you have

consumed alcohol, or if you are taking other drugs

or medication that can affect your vision, judgement or co-ordination.

• Wear personal protective equipment. See instructions under the heading ”Personal protective

equipment”.

• Chemicals such as degreasing agent, grease and

hydraulic fl uid can give rise to allergies in conjunc-

tion with repeated skin contact. Avoid contact with

the skin and use protective equipment.

• When in use, the machine can generate dust and

fumes that can contain harmful chemicals. Know

the nature of the material being worked on and

wear appropriate dust mask or respirator protection.

A face mask is especially important when working indoors due to the limited ventilation. In some

situations it can also be suitable to apply water in

order to decrease the dust.

• Do not stand on the control cable or the power cable as there is a risk of your feet becoming tangled.

• Do not use remote control with cable steering while

working or moving where there is a risk that the

machine can topple. The operator must be disengaged from the machine.

• An incorrect manoeuvre or unforeseeable incident

can result in collapse. Never stand underneath the

work object.

• Never stand where there is a risk of being crushed.

The machine can rapidly change position. Never

stand underneath a raised arm, even if the machine

is turned off.

• Reduce the risk when working alone by making

sure that an emergency alarm is available via mobile phone or other equipment.

• When moving on a fl at surface you must always

walk behind or at the side of the machine. When

working or moving on a sloping surface position

yourself above the machine.

Operation

General

• Only authorized and trained operators are permitted to operate the machine and its tools.

• Never use a defective machine. Carry out inspections, maintenance and service in accordance with

the instructions in the Operator’s Manual.

• Rectify any faults or damage that occur immediately. Prevent the machine from being used before

the fault has been rectifi ed.

• The machine has been tested and approved solely

with equipment supplied and recommended by the

manufacturer.

• Under no circumstances should you modify the

original design of the machine without approval

from the manufacturer. Always use original spare

parts. Unauthorized modifi cations and/or accesso-

ries may lead to serious injury or death to the user

or others.

• Do not modify the machine’s safety devices and

check regularly that they are working properly. The

machine must not be driven if protective plates,

protective covers, safety switches or other protective devices are not fi tted or are defective.

• Make sure all nuts and bolts are tightened correctly.

• The machine must be kept clean. Signs and stickers must be fully legible.

• Follow the machine’s and the tool’s instructions

carefully when changing tools in order to avoid

injuries.

• Turn off the electricity supply to the machine before

you take off the remote control or when you leave

the machine to avoid the risk of unintentional operation.

• Firm handling of the joysticks does not make the

machine stronger or faster. On the contrary, the

joysticks can buckle with unnecessary repairs as a

consequence.

• Do not lift the remote control by the joysticks.

Education and training

• New operators must be trained by experienced

operators with the capacity to use sound judgment

when supervising the work.

• Practice stopping the machine and locating the

stop button quickly. Practice manoeuvring in different directions, on a slope and different surfaces.

• Test the machine’s stability under controlled conditions. Practice rapid evacuation.

• On completion of the training, the operator should

be properly acquainted with the machine’s limitations with respect to reach, capacity and stability,

and also be able to manoeuvre the machine safely.

Page 10

SAFETY INSTRUCTIONS

10 - English

Manoeuvring

General

• If several machines are used at the same workplace

there is a risk of mixing up the remote controls.

Switch on the current to the remote control and

the machine. Press the horn to see which machine

is connected to the remote control. The machine

will beep and fl ash three times. Do not activate the

remote control before you have ensured that the

correct machine is being operated.

• Wait until the remote control has been turned off

and the motor has stopped before you enter into

the machine’s risk area.

• Never leave the machine unsupervised with the

motor running.

• The machine can overturn during work. During operation the machine must be positioned as level as

possible and the outriggers must be fully extended.

• In some cases it can be diffi cult to determine which

end of the machine is the front and which is the

rear. Look at the direction markings on the sides of

the machine’s tracks to avoid incorrect operation.

Arm system

• Do not use the arm system and the rotation function for striking, demolishing or scraping.

• Do not work with the arm if the machine’s outriggers are folded. The outriggers provide stability

and reduce the risk of the machine tipping.

• When the arm system’s reach is being used, the

load increases as does the risk of tipping. Position the machine as close to the working object as

possible.

• Never use the telescopic arm to press the tool

against the working object.

• Do not secure the machine to fi xed objects, e.g.

walls, to increase the force on the working object.

Both the machine and the tool can be subject to

overloading.

Outriggers

• When the outriggers are folded, the arm must be

retracted to minimize the risk of the machine overturning.

• The machine’s outriggers can leave the ground,

especially when working with a hydraulic hammer or

bucket. The higher the machine rises the greater the

load the rest of the support mechanism is subject

to.

• When working with a hydraulic hammer there is an

increased risk of the machine tipping or landing with

a large force on the outrigger on impact. Take this

risk into account and institute appropriate safety

measures to avoid any personal injury or mechanical

damage.

Rotation function

• If there is a breakdown in the machine’s rotation

mechanism the machine’s upper part may rotate

freely, potentially causing personal injury or mechanical damage. Keep your distance.

• The machine is most stable when working directly

forwards or backwards. When the machine’s upper

part rotates to the side, the outriggers should be

down and the arm system manoeuvred so that it is

as close to the ground as possible.

• In some cases it can be diffi cult to predict the

direction of rotation. Operate the turning motion

carefully until you have apprehended the direction

of rotation.

• Do not work with the machine’s cylinders in the

inner or outer end positions to avoid overloading.

Leave a few centimetres to the maximum position.

The hydraulic fl uid then has a greater capacity to

alleviate impacts and vibrations.

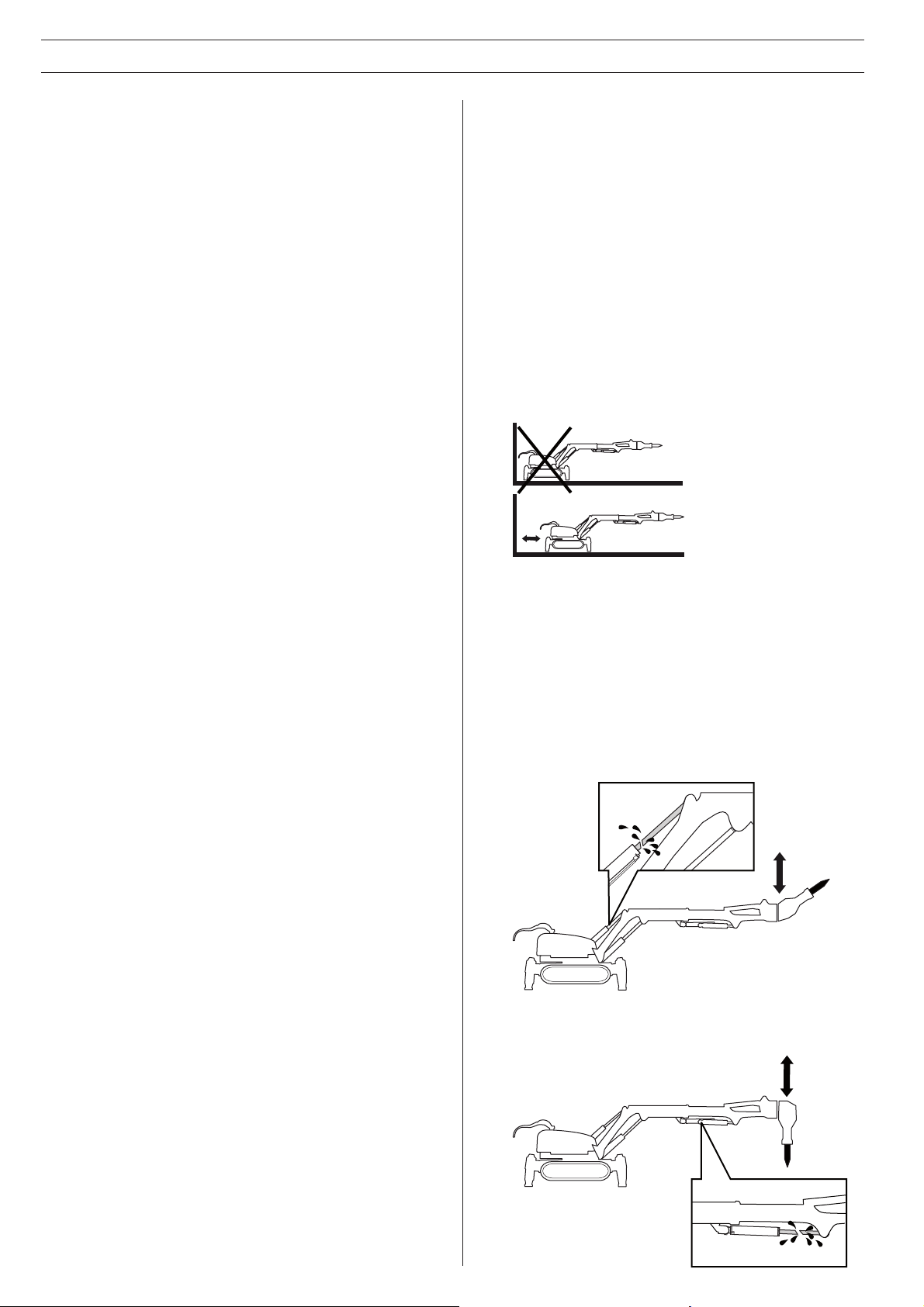

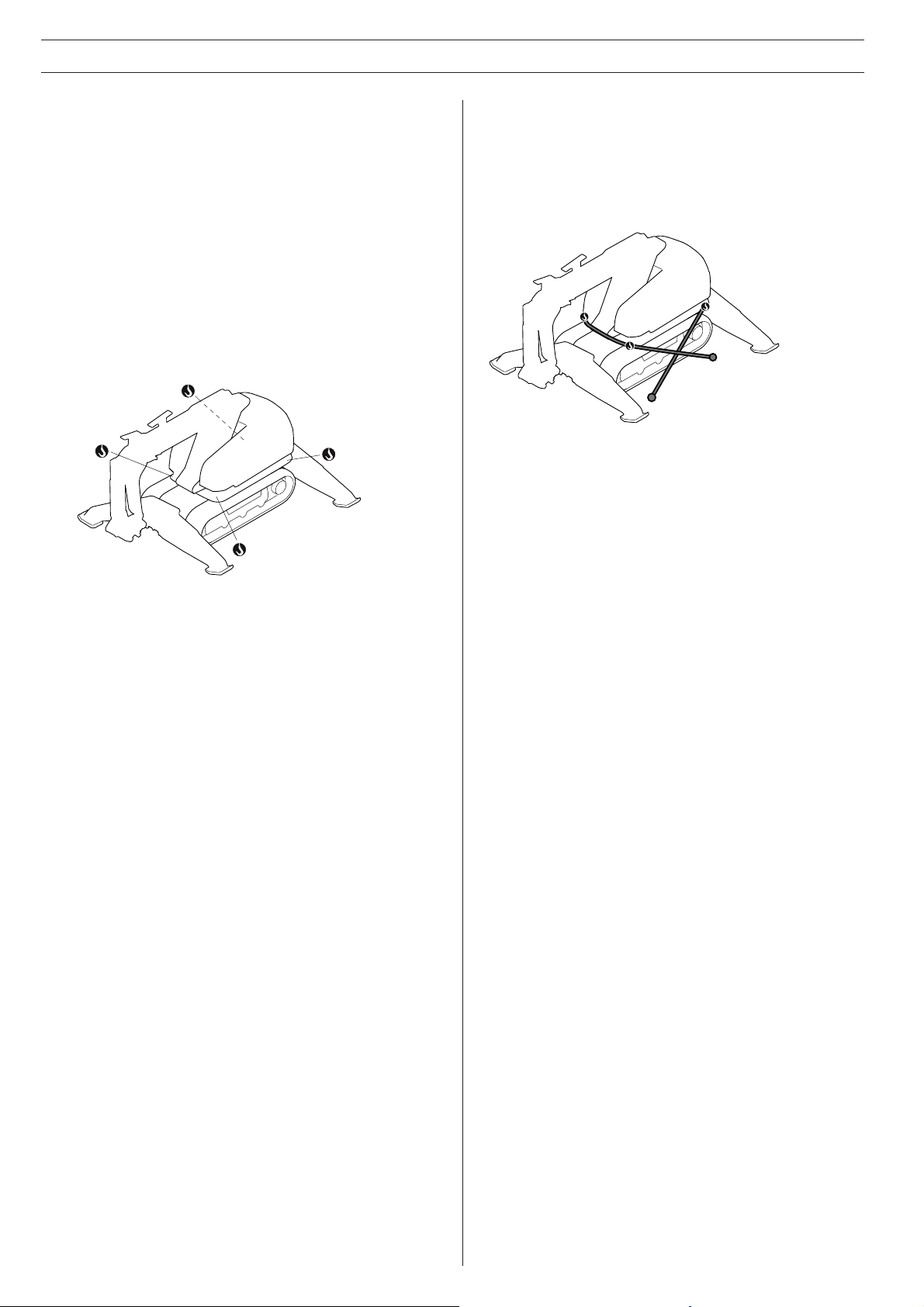

• There are two working positions that put a lot of

strain on individual cylinders.

Cylinders 1 and 2 are in their outer positions and

the hammer is working in the upward direction.

Never operate the cylinders to their end positions.

Cylinder 3 is in its outer position and the hammer is

working in the downward direction. Never operate

the cylinders to their end positions.

Page 11

SAFETY INSTRUCTIONS

Proximity to edges

• Inadequate surfaces, incorrect operation, etc. can

cause the machine to slide. Exercise particular caution when working close to shafts, beside trenches

or when working at height.

• Always anchor the machine and loose tools when

working close to edges.

• Ensure that the machine is stable and does not

move closer to the edge while work is in progress.

• Ensure that the underlying surface has satisfactory

bearing capacity. Vibrations affect bearing capacity.

Uneven surfaces

• Extend the outriggers so that they are positioned

just above the surface when moving over uneven

areas.

• In some cases the arm can be used to lift the drive

gear over bumps. The arm must never be rotated

or raised up high due to the risk of overturning.

• Uneven surfaces can cause the machine to lean

to such an extent that it overturns. Manoeuvre the

machine’s arm system inwards in order to move

the centre of gravity as close to the machine’s centre as possible to reduce the risk of tipping.

• Surfaces with a poor bearing capacity can cause

the machine to change direction or even overturn

without warning. Always check the bearing capacity and properties of the surface before starting the

machine. Also be alert for holes that are covered

by materials with a poor bearing capacity.

• The machine’s caterpillar tracks produce a low

level of friction against smooth surfaces. Water,

dust and contaminants can further reduce friction.

When defi ning the risk area you should take into

account the fact that less friction increases the risk

of the machine starting to slide.

Confi ned spaces

• Working in confi ned spaces with extended outrig-

gers can be diffi cult. The machine’s stability is con-

siderably diminished. Adapt the work accordingly.

There is an increased risk of the machine overturning if the arm swings outside the outrigger.

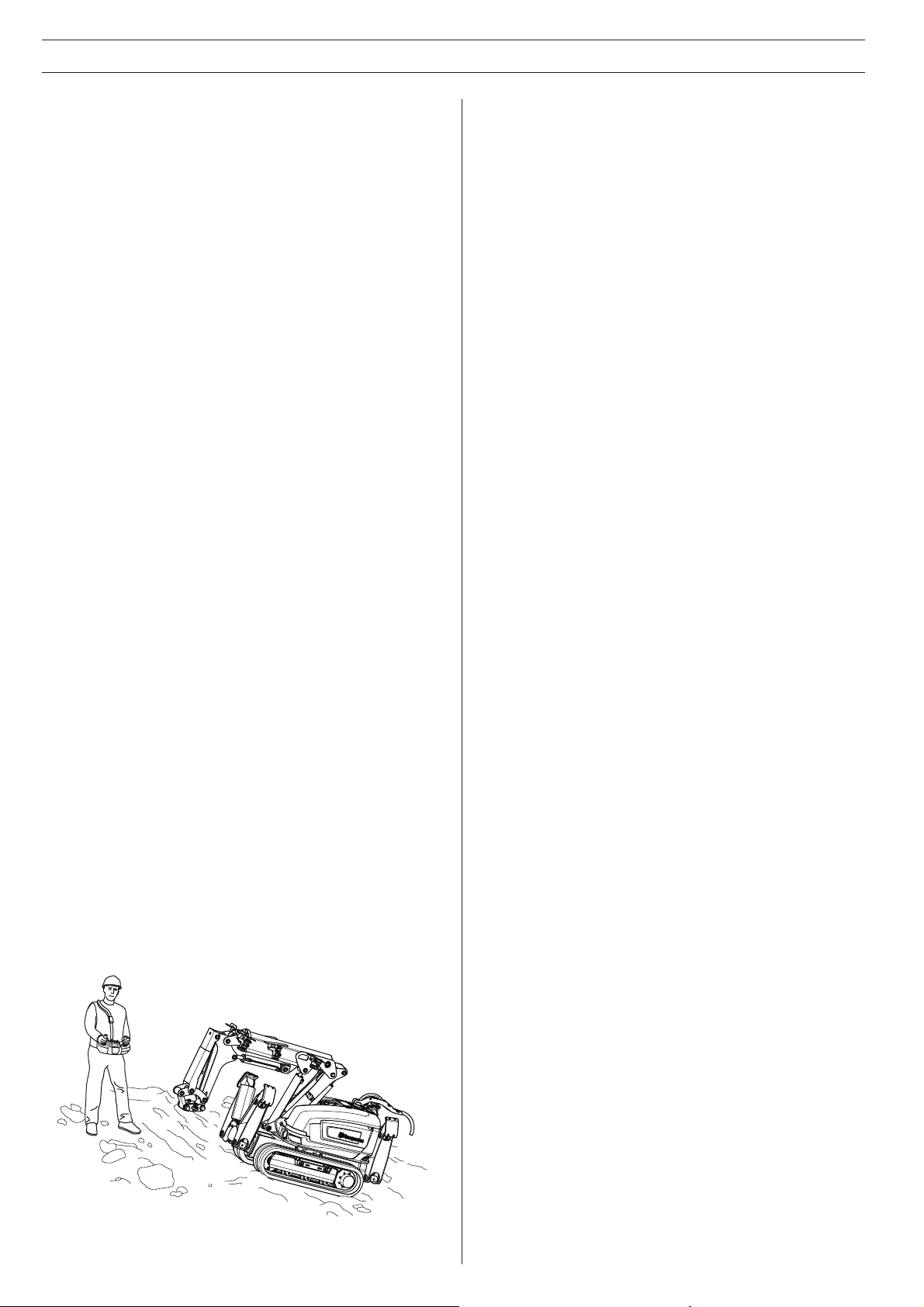

Sloping ground

• Sloping surfaces, stairs, ramps etc. can constitute

major risks when moving and working. With gradients in excess of 35° there is a risk of the machine

tipping.

• The machine’s arm system and outriggers must be

positioned as low as possible to reduce the risk of

tipping.

• Do not run the caterpillar tracks and tower simultaneously when moving on a sloping surface to

reduce the risk of unexpected motion.

• Avoid driving sideways on slopes - drive straight

up or down. Ensure that the machine’s arm system

is turned upwards in sloping terrain.

• Always position yourself above the machine when

driving on a slope. There is a risk of the machine

tipping.

• Anchor the machine if there is a risk of the machine

starting to move.

• Check that there is suffi cient bearing capacity

when driving on ramps and stairs.

Proximity to ducts and pipes

• Always check and mark where electricity cables

and pipelines are routed. Ensure that electricity

cables and pipelines are shut off.

• The machine must not get close to overhead cables. The current can “jump” over long distances.

Falling material

• Watch out for demolition material becoming loose

when cutting. Use personal safety equipment and

keep your distance.

• Ensure that the vibrations from the hydraulic hammer do not cause cracks to form or stones or other

material to loosen and cause personal injury or

damage to property. Keep your distance!

• When moving in confi ned spaces it is possible to

reduce the width of the tracks, increasing the risk

of the machine overturning. There is an increased

risk of the machine overturning if the arm swings

outside the outrigger.

English - 11

Page 12

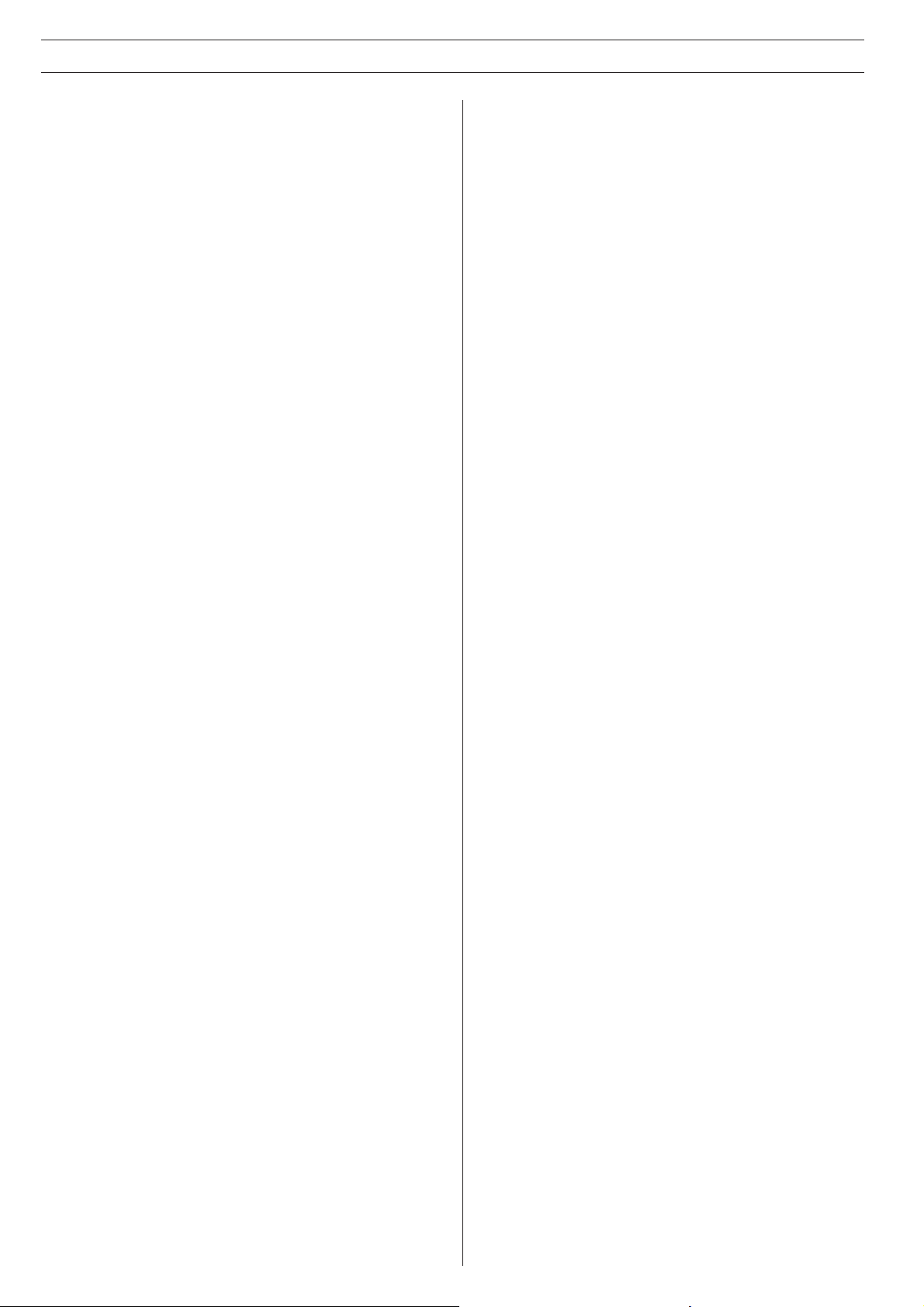

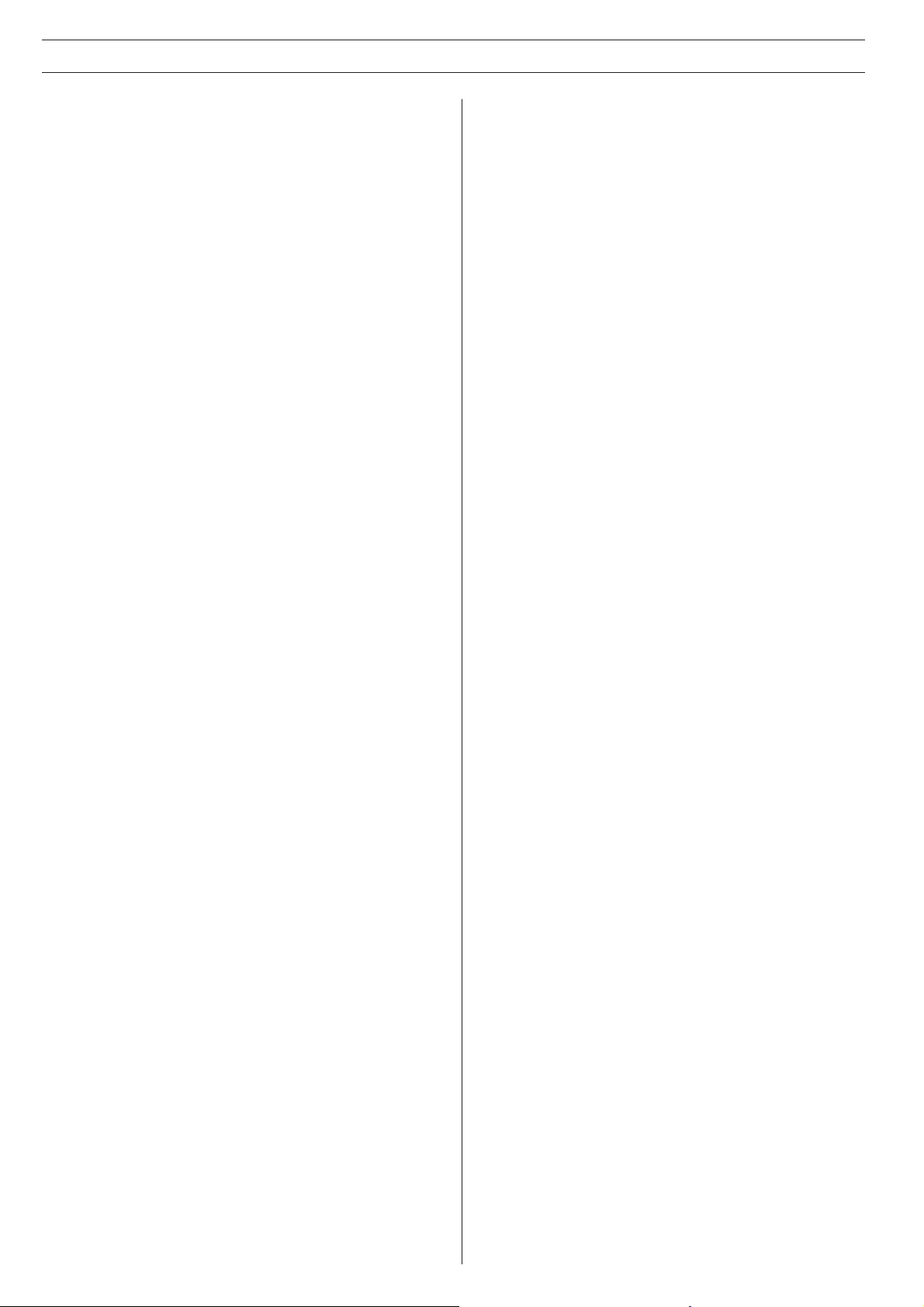

Securing the machine

• Secure the machine with approved tightening

straps. Use the machine’s lifting eye bolts. Ensure

that no part of the machine are squashed or damaged by the tightening straps. It is a good idea to

cover the machine.

• Tools and other equipment must be secured with

separate tightening straps.

• Regularly check that the load is secure during

transportation.

Storage

• Remove the tool from the machine.

• Retract the arm system to attain a centre of gravity

that is as low as possible and to save space.

• Store the equipment in a lockable area so that it is

out of reach of children and unauthorized persons.

• Store the machine and its equipment in a dry and

frost proof place.

Towing

The machine is not designed to be towed. When the

machine is depressurized, the drive motor’s parking

brakes are activated and the caterpillar tracks cannot

rotate. Only tow the machine if its position constitutes

a risk and there is no other solution. Tow it for the

shortest possible distance.

• If possible, retract the outriggers before towing the

machine in order to reduce the risk of them getting

stuck and being damaged.

• To minimize the load on the towing device and

mechanical components, reduce the friction by

preparing the route that the machine is going to be

towed.

• If possible tow in the direction of the tracks.

• Use the lifting eye bolts to connect to the towing device. Use a towing device intended for the

particular load.

• Parts can loosen during towing. Keep your distance!

SAFETY INSTRUCTIONS

12 - English

Transport and storage

Lifting the machine

• When lifting the machine there is a risk of injuring

persons or damaging the machine or the surroundings. Defi ne the risk area and check that nobody is

present within the area when lifting.

• Use an approved lifting device to secure and lift

heavy machine parts. Also ensure that there is

equipment to secure machine parts mechanically.

• Retract the arm system. The centre of gravity must

be as close to the machine’s centre as possible.

• The lifting equipment must be attached at all the

machine’s lifting eye bolts.

• Lift slowly and carefully. Make sure that the lift is in

equilibrium and if the machine starts to lean, rectify

it by using an alternative lifting device or change

the position of the arm system.

• Ensure that the machine’s parts are not crushed or

damaged when lifting and that the machine does

not hit surrounding objects.

Loading and unloading using a ramp

• Ensure that the ramp is intact and the right size for

the machine.

• Check that the ramp is free of oil, mud or anything

else that might make it slippery.

• Ensure that the ramp is properly secured to both the

vehicle and the ground. The vehicle being used for

transportation must also be secured so that it cannot

move.

Transport

• The machine may only be transported on a fl atbed

truck or a trailer that is approved for the machine’s

weight, refer to the machine’s rating plate. The

remote control must be properly protected in the

vehicle during transportation.

• Check applicable road traffi c regulations before

transporting on public roads.

The machine’s position on the loading platform

• Position the machine against the front edge of the

platform in order to reduce the risk of it sliding

forward if the vehicle brakes.

• Manoeuvre the arm system so that it is resting

against the platform, positioned as low as possible.

Extend the outriggers without lifting the machine.

Page 13

SAFETY INSTRUCTIONS

Maintenance and service

Most accidents involving machines occur during trouble shooting, service and maintenance as staff have

to locate themselves within the machine’s risk area.

Prevent accidents by being alert and by planning and

preparing the work. You can also refer to ’Preparations

for maintenance and service” in the ’Maintenance and

service” section.

• The user must only carry out the maintenance and

service work described in this Operator’s Manual.

More extensive work must be carried out by an

authorized service workshop.

• Never carry out repairs without having the necessary expertise.

• Only trained service personnel are permitted to

intervene in the electrical or hydraulic systems.

• Use personal protective equipment as well as

equipment to mechanically secure machine components during maintenance and service.

• Set out clear signs to inform persons in the vicinity

that maintenance work is in progress.

• If service operations or trouble shooting does not

require the machine to be switched on, the power

cable must be removed and positioned so that it

cannot be connected by mistake.

• Ensure there is no current to the machine by removing the power cable before opening or removing the electric cabinet or any other component

that contains electrical current.

• Pipe and hose couplings can remain pressurized

despite the motor being switched off and the power cable disconnected. It must always be assumed

that hydraulic hoses are pressurized and they must

be opened with great care. Relieve the pressure on

the arm system by resting it on the ground and turn

off the electric motor before undoing the hoses.

• Never try to stop hydraulic fl uid leaking from a bro-

ken hose by hand. Finely dispersed hydraulic fl uid

at high pressure can permeate under the skin and

cause very severe injuries.

• When dismantling machine parts, heavy components can start moving or fall down. Secure moving

parts mechanically before loosening screw joints or

hydraulic hoses.

• Use an approved lifting device to secure and lift

heavy machine parts.

• Several components heat up during work with the

machine. Do not commence any servicing or maintenance tasks until the machine has cooled.

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• The machine’s movements can be defective if a

terminal, cable or hose is incorrectly assembled.

Exercise caution during test runs and be prepared

to turn off the machine immediately in the event of

a fault.

The machine’s

safety features

The machine’s safety features can be divided into

safety features for personal protection and those for

mechanical protection. Some of the safety features

provide both mechanical and personal protection.

WARNING!

Do not modify the machine’s safety devices and

check regularly that they are working properly.

The machine must not be driven if protective

plates, protective covers, safety switches or

other protective devices are not fi tted or are

defective.

Personal protection

Indication of zero position

If either of the joysticks is in an operative position

when the remote control is started, the function will be

blocked. The operator is informed of this by means of

an error message appearing on the screen. To reset

the function, the remote control must be turned off

and on again.

The function also protects against faults in the potentiometer or cable breaks.

Signal voltage limitation

Signal voltage limitation prevents the machine executing unexpected movements in the event of a cable

breaking or a short-circuit.

The voltage level of the control signals is limited to

within a maximum and minimum value. If the voltage

level falls outside the permitted interval, the machine

stops.

Joystick guard

The safety feature reduces the risk of unintentionally

moving the machine by locking the control circuit if

the joysticks have been in neutral for three seconds.

The control circuit is activated by means of the left

button on the right joystick. It is activated when the

button is released. This guards against fi xing the but-

ton in an active position.

Radio block

If the remote control has been turned off for two

minutes the electronic unit in the machine is blocked

to radio signals. It is not possible to restart the machine until the supply voltage to the machine has been

turned off and on again.

The safety feature ensures that the operator knows

which machine will start and that the correct remote

control is being used for the machine. This is particularly important when there are several machines at the

same workplace.

English - 13

Page 14

SAFETY INSTRUCTIONS

Identity code

The remote control and the machine are connected

by means of a pre-programmed ID code. The ID code

ensures that the right remote control is used for the

right machine.

If several machines are used at the same workplace

there is a risk of mixing up the remote controls.

Switch on the current to the remote control and the

machine. Press the horn to see which machine is connected to the remote control. The machine will beep

and fl ash three times. Do not activate the remote con-

trol before you have ensured that the correct machine

is being operated.

When steering the machine using cables, the ID code

is suppressed and the same remote control can be

used for different machines if these have the same

control system version.

Automatic frequency hopping

In the event of interference in the communication, the

frequency changes automatically to guarantee interference-free transmission.

Emergency stop/machine stop

When the machine stop on the remote control is

pressed, the power to the circuits controlling the

communication with the machine is interrupted. The

machine engine stops due to the interruption of the

transfer of signals to the machine’s electronic device.

The emergency stop on the machine switches off the

main power to the machine.

Protective earth

The machine and its components are connected to

grounding conductors in the power cable. If there is a

fault, a fuse is tripped and the current is disconnected.

The machine must be connected to a power point with

a protective earth. If there are no grounding conductors, or if they are connected incorrectly, have come

off or are loose in a terminal, the current will remain

connected and touching the machine can be highly

dangerous.

If there is reason to believe that the protective earth

has been damaged, the machine must be turned off

and the power cable removed until such time as the

protective earth has been restored.

Always connect the machine through an earth-fault

breaker with personal protection, i.e. an earth fault

circuit breaker that trips at an earth fault of 30 mA.

Hydraulic brake

Hydraulic motors are used when moving the machine.

All hydraulic motors are fi tted with brakes. These

hydraulic motors contain counter balance valves that

prevent uncontrolled fl ow through the motor, e.g. when

manoeuvring down a slope or when the machine is

parked. The counter balance valve closes the tank

opening when the drive motors are not being operated.

Mechanical brake

The machine’s drive motors are equipped with a mechanical parking brake. The machine is braked until its

drive function is activated.

Mechanical protection

Automatic phase rotation relay

The automatic phase rotation relay prevents the electric motor starting with the wrong rotation direction

thus causing mechanical damage.

Motor protection

To prevent overloading, the motor is equipped with

bimetallic relays in the motor linings that disconnect

the power if the motor gets too hot.

If the motor is too hot it is not possible to operate the

tools. The rest of the machine’s functions can be run

at half speed in order to facilitate evacuation of the

machine from risky environments.

Once the motor’s temperature has fallen to a normal

working temperature all functions can be used again.

The machine’s softstarter is fi tted with a motor cut-out

that trips if the current is too high for too long a period.

The machine’s functions return to normal position after

three minutes.

Fuses

Fuses are used to protect the following components

as well as to prevent fi re in conjunction with faults or if

electrical components are overloaded.

Pressure relief valves

The machine’s hydraulic system is equipped with

pressure relief valves. They protect the hydraulic

system against too high pressure and the mechanical

components against overloading.

Pump-around valve

The pump-around valve drains the hydraulic fl ow into

a tank and relieves the pressure on the hydraulic system. No pressure enters the cylinders and it prevents

the risk of unforeseen movements. This happens, for

example, after three seconds of inactivity.

14

- English

Page 15

SAFETY INSTRUCTIONS

External environmental

factors

Temperature

The ambient temperature, both heat and cold, affects

the machine’s operational reliability. Temperature

variations also have an impact as they produce an

increased risk of condensation forming in the machine’s tanks.

Heat

NB! There is an increased risk of overheating in warm

environments. Both the machine’s hydraulic system

and electronic components can be damaged.

The maximum working temperature for hydraulic fl uid

is 90°C (194°F). Overheating results in deposits forming in the fl uid, leading to increased wear, damaged

seals and leakage. Overheated hydraulic fl uid pro-

vides poor lubrication, resulting in inferior performance.

To avoid overheating:

• Keep the machine clean, in particular its cooler.

• Ensure that there is good ventilation when working

indoors.

• Radiant heat can cause local heating that damages parts of the machine. Screen off vulnerable

components.

Moisture

When working in damp environments the operator

should ensure that electrical components, connectors

for example, are not submerged in water.

The machine must never be driven to such a depth in

water that it reaches up to the machine’s equipment.

The equipment can be damaged and the machine can

be live, resulting in personal injuries.

Dust and particles

Dust and particles can block the machine’s cooler,

cause overheating and increase wear on the machine’s bearings and shafts. Clean and lubricate the

machine regularly.

The hydraulic system is extremely sensitive to contaminants. Small particles can cause breakdowns and

increase wear in the components.

There is a high risk of contamination in conjunction

with servicing and repairs when the hydraulic system

is opened.

Contamination of the hydraulic system can be

prevented by:

• Keeping the machine clean, particularly before

servicing, repairs or changing tools.

• Carrying out daily inspections.

• Carrying out regular servicing.

• Additional cooling is required if there are high

ambient temperatures. Supply the machine with

forced cooling using compressed air.

To avoid damage to the machine:

• Change hydraulic fl uid and fi lters more frequently.

• Check the machine’s seals to prevent dirt in the

hydraulic system due to broken seals.

• Rubber caterpillar tracks must not be exposed to

temperatures of over 70°C (158°F). In hotter environments steel tracks have to be used.

Cold

Do not use maximum pump pressure if the hydraulic

fl uid is less than 10°C (50°F). Allow the machine to

warm up slowly. Warm up the lower section by running the caterpillar tracks, fi rst slowly and then more

quickly with the outriggers extended. Move the upper

section back and forth and operate all cylinders in the

arm system without load. The machine is ready for

use when its temperature has risen to around 40°C

(104°F).

English - 15

Page 16

PRESENTATION

16 - English

The machine’s functions

The machine’s functions are operated by means of

interaction between the hydraulic system, the electric

system and the control system.

A brief description of the machine’s functions follows

below.

Arm system

The arm system is divided into three parts in order to

provide extensive movement, a long reach and compactness. Expanding shafts minimize the risk of play

in the joints.

By running cylinder 1 and cylinder 2 in parallel, the

machine’s reach can be modifi ed without moving the

machine.

Caterpillar tracks

The caterpillar tracks are driven individually by hydraulic motors. The machine can be turned by operating

the caterpillar tracks at different speeds. Operating the

tracks in different directions enables the machine to

make tight manoeuvres. When the drive function is not

activated the passive brakes lock the drive motors.

The machine is also equipped with a telescopic arm

that provides additional reach. Work as close to the

work object as possible as this makes optimum use of

the power to the arm system and cylinders.

Tower

The tower has unlimited rotation, which means that is

possible to work in several directions without having

to move the machine. The machine is equipped with a

slew brake. When the rotating function is not activated, the function is braked by means of passive brakes.

NB! The machine’s rotating function must not be subject to overload, e.g. caused by tools that exceed the

weight limit.

In transport mode, the caterpillar tracks and tower can

be manoeuvred simultaneously. The function can be

used, for example, when the machine is being operated in confi ned spaces.

Outriggers

The main function of the outriggers is to give the

machine stability. They must always be used when

working with the machine.

Tools

The machine should be fi tted with tools that are ap-

propriate for the tasks that are to be carried out. The

weight and performance requirement of the tool is

decisive in ascertaining whether it is suitable for use

with the machine. Further information is available in

the ’Tools” and ’Technical data” chapters and the tool

supplier’s instructions.

External tool (optional)

The machine has been prepared with connections

for external hand tools for the machine’s hydraulic

system.

Page 17

PRESENTATION

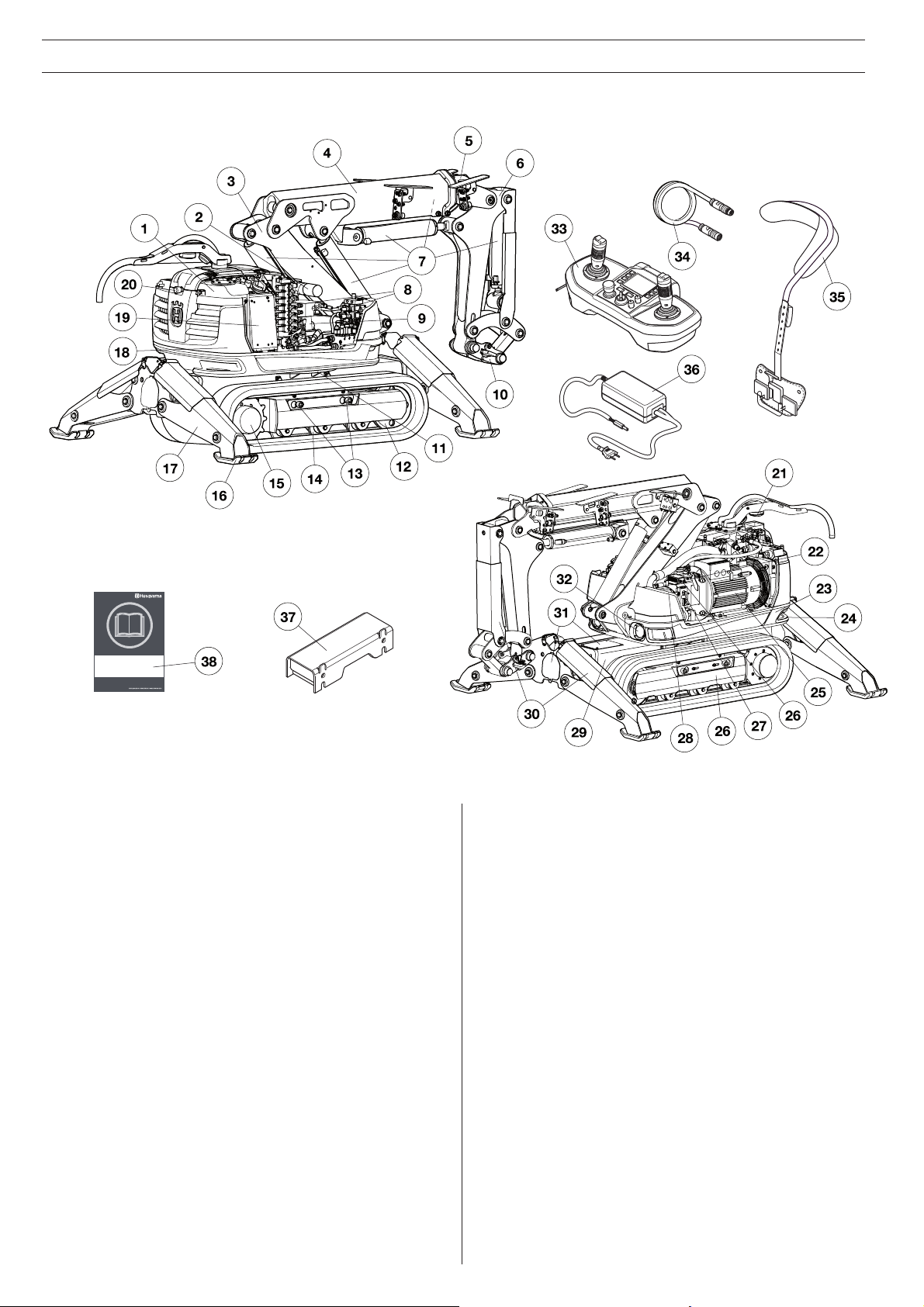

What is what in the machine

1. Hydraulic tank

2. Lubrication pump for lubricating the hammer (accessory)

3. Arm 1

4. Arm 2

5. Telescopic arm

6. Arm 3

7. Cylinders

8. Valve block

9. Slew motor

10. Tool attachment

11. Gear ring

12. Tensioning wheel

13. Screws for widening the tracks

14. Support wheel

15. Drive motor

16. Outrigger foot

17. Outrigger

18. Counterweight in the tower

19. Electric cabinet

20. Emergency stop

21. Warning light

22. Control module

23. Base plate

24. Lifting eye bolts

25. Electric motor

26. Radio module

27. Track unit

28. Hydraulic pump

29. Chassis beam

30. Cylinder guard

31. Inspection covers

32. Work lighting

33. Remote control

34. Communication cable

35. Harness

36. Battery charger

37. Track widener

38. Operator’s Manual

English - 17

Page 18

HYDRAULIC SYSTEM

General

The task of the hydraulic system is to operate the machine’s functions by means of hydraulic pressure and

fl ow. The system consists of hydraulic pump, tank,

cooler, hydraulic motor, hydraulic cylinders, fi lters and

valves of various kinds. Hoses or pipes connect the

components with each other.

Valves are used to control the hydraulic system’s

pressure, volume rate of fl ow and direction. Pressure

control valves limit or reduce the pressure to the value

required. Volume control valves affect the hydraulic

fl uid’s fl ow and thereby the speed of the functions.

Direction control valves direct the hydraulic fl uid to the

machine’s different functions.

The hydraulic pump is of the variable displacement

type and delivers a fl ow of 0-65 l/min (0-17 gal/min).

Main pressure

The hydraulic system has two main pressures.

• Standard pressure is 200 Bar.

• Increased main pressure is 250 Bar.

Increased main pressure is used when the outriggers

are down and when concrete cutters are used with

increased tool pressure.

If concrete cutters with increased tool pressure are

operated at the same time as another function, the

machine returns to standard pressure.

Pressure cut-off

Functions equipped with pressure cut-off have a

reduced pre-set maximum pressure. The telescopic

arm is equipped with a pressure cut-off that produces

a maximum of 180 Bar.

Cooler

The cooler has an integrated bypass valve that protects against overpressure in conjunction with, for

example, cold start.

18

- English

Page 19

HYDRAULIC SYSTEM

English - 19

The machine’s hydraulic

system

1. Air fi lter

2. Oil fi lter

3. Hydraulic tank

4. Cylinder 1

5. Cylinder 5

6. Cylinder 4

7. Cylinder 3

8. Cylinder 2

9. Valve block 1

10. Slew motor

11. Valve block 2

12. Cylinders for outriggers

13. Sight gauge

14. Valve - release track tension

15. Accumulator - track tension

16. Drive motor, drive gear

17. Support wheels

18. Cylinders for track tensioning

19. Tensioning wheel

20. Hydraulic pump

21. Swivel

22. Hose for oil fi lling

23. Filling pump

24. Intermediate piece

Page 20

ELECTRIC SYSTEM

General

The electric system consists of a high-voltage circuit

and a low-voltage circuit.

High-voltage circuit

High-voltage is used as a power source for both the

electric motor and the low-voltage circuit. An automatic phase rotation change-over switch ensures that the

electric motor has the correct rotation direction.

Power supply

The power supply from the main must be suffi ciently

powerful and constant to ensure that the electric motor runs without problems.

Too high or too low voltage causes the electric motor’s power consumption, and consequently also its

temperature, to increase until the motor’s safety circuit

trips.

Fuses

The fuses in the distribution box protect the electrical

system in conjunction with overloading or breakdown.

The power outlet must be correctly fused with respect

to the electric motor, the length of the power cable

and the area of the power cable’s conductor. The table

“Guide values for mains connection” in the “Technical data” section shows which fuse is required for the

electric motor.

The machine is equipped with Softstart and can be

started with most types of fuses.

If a fuse keeps blowing there is a fault in the electrical system or in the machine that is connected to it.

Before restarting the machine the source of the fault

must be removed.

Power cable

The machine is connected to the mains with a 3 phase

power cable. It is very important that the cable that is

used is correctly dimensioned, i.e. that it has the correct cross-sectional area in relation to the length of the

conductor in order to counteract drops in voltage. The

guide values for the cable’s size are set out in the table

’Guide values for main connection” in the ’Technical

data” section.

Low-voltage circuit

The high-voltage current is reduced to low-voltage in

an AC/DC module. It is used to supply power to the

control system and functions such as work lighting

and refi lling pump.

20

- English

Page 21

ELECTRIC SYSTEM

English - 21

The machine’s electric

system

1. Aerial

2. Electric cabinet

3. Pressure switch

4. Temperature sensor

5. Warning light

6. Power cable

7. Electric motor

8. Control module

9. Radio module

10. Work lighting

11. Pressure sensor

12. External tool

13. Main switch

14. Counter

15. Emergency stop

16. Automatic oil refi lling

17. Start button motor

18. Knob for remote control/emergency operating mode

Page 22

CONTROL SYSTEM

Battery

The battery is a Li-ion type. Operating time is about

8-10 hours per charge. Extreme cold impairs the battery’s capacity and operating time. Operating time is

also affected by the extent to which the display has

been active.

To save the battery, the display goes into energy save

mode after 20 seconds. After fi ve minutes of inactiv-

ity the remote control turns off automatically. To use it

again, it must be turned off and on again.

A message appears on the display approx. 30 minutes

before the battery is completely fl at. It is not possible

to activate the remote control if the battery capacity is

too low.

Charging the battery

Before using the remote control for the fi rst time the

battery has to be charged.

Charging time for a fl at battery is approx. 2-3 hours.

The diode is orange when charging starts and becomes green when the battery is fully charged. When

the battery is fully charged the charger supplies the

battery with maintenance current until the battery is

removed from the charger.

Keep the battery charger dry and protected against

temperature fl uctuations.

The machine’s software

Contact your service workshop regarding problems

with the machine’s software or for any updates that

might be needed.

22 - English

General

The remote control, the electronics unit and the pilot

control valves are the main components in the control

system. The signals from the remote control are transmitted to the machine via bluetooth or via a cable. The

electronic unit in the machine transmits the signals

via the pilot control valves to the hydraulic system by

converting electric current into hydraulic pressure.

Remote control

The machine is controlled from the remote control.

Transmission of signals is either wireless, using bluetooth, or via a cable.

The movement of the joysticks is proportional. A small

movement means that the function moves slowly, a

larger movement increases the function’s speed proportionally.

Signal transmission

Identity code

The remote control and the machine are connected by

means of a pre-programmed ID-code. The code is built

into the remote control’s bluetooth transmitter and the receiver on the machine. The ID code cannot be changed.

There is a sticker on the bottom of the remote control

and on the machine’s bluetooth module with a ID code.

The ID code ensures that the right remote control is used

for the right machine.

Wireless signal transmission

Wireless transmission of signals uses bluetooth technology.

Automatic frequency hopping

In the event of interference in the communication, the

frequency changes automatically to guarantee interference-free transmission.

Signal transmission using cables

Connecting a cable shuts off the wireless communication.

When the machine is controlled by means of cables,

the ID code is suppressed and the same remote control can be used for different machines if these have

the same control system version.

Page 23

CONTROL SYSTEM

What is what on the remote

control

1. Left joystick - left button

2. Left joystick - right button

3. Display

4. Right joystick - left button

5. Right joystick - right button

6. Right joystick

7. Main switch

8. Machine stop

9. Left joystick

10-13. Menu buttons

14. Light emitting diode, joysticks active

15. Start button motor

16-19. Menu buttons

20. Flow to machine movement/speed

21. Stop button motor

22. Flow to hydraulic tool

English - 23

Page 24

CONTROL SYSTEM

Symbols on the remote

control

1. Arm 2 telescope out

2. Arm 2 down

3. Right track operation forward

4. Arm 1 and arm 2 out

5. Angle tool outwards

6. Right outrigger down

7. Front/rear right outrigger down

8. Arm 1 out

9. Arm 1 and arm 2 in

10. Right track operation backwards

11. Arm 2 up

12. Arm 2 telescope in

13. Sticker - full fl ow to the tool

14. Sticker - adjustable fl ow to the tool

15. Arm 3 down

2

3

1

16. Left track operation backwards

17. Caterpillar tracks backwards

18. Rear/front left outrigger down

19. Rotation tower anti-clockwise

20. Left outrigger down

21. Caterpillar tracks forward

22. Left track operation forward

23. Arm 3 up

24. Left outrigger up

25. Rotation tower clockwise

26. Rear/front left outrigger up

27. Sticker - open/close cutters

28. Angle tool inwards

29. Right outrigger up

30. Front/rear right outrigger up

31. Arm 1 in

24 - English

Page 25

STARTING AND STOPPING

English - 25

Before starting

The following points should be checked when working

at a new site and every morning before starting:

• Carrying out daily inspections.

• Examine the machine for transport damage.

• Check that the machine’s safety features are intact.

Refer to ’The machine’s safety features” in the

’General working instructions” chapter.

• Check that the power cable and operating cables

are intact and correctly dimensioned.

• Check that the mains voltage is compatible with

the machine and that the correct fuses are used.

• Always connect the machine through an earth-fault

breaker with personal protection, i.e. an earth fault

circuit breaker that trips at an earth fault of 30 mA.

• Check that the emergency stop or machine stop

button are not pressed by turning them clockwise.

• Check that no tools or other objects have been left

lying on the machine.

Starting

Starting the electric motor

• The electric motor is started by pressing the start

button.

• If several machines are used at the same workplace

there is a risk of mixing up the remote controls.

Press the horn to see which machine is connected

to the remote control. The machine will beep

and fl ash three times. Do not activate the remote

control before you have ensured that the correct

machine is being operated.

Activating controls

Connect the machine

• Connect the machine to a 3 phase power supply.

• Turn on the main switch on the machine.

Starting the remote control

• Turn the switch to the ON position (I). In this position the remote control is supplied with current.

The light emitting diode on the remote control

fl ashes rapidly with a blue light when it is searching

for contact. When it fl ashes with a longer interval

the machine is in standby mode.

• To activate the remote control’s operating functions press the left button on the right joystick. The

remote control is now in work mode. The light emitting diode on the remote control has a permanent

blue light.

• If no command is given within three seconds the

operating functions are locked. To return to work

mode, press the left button on the right joystick.

Stopping

• Manoeuvre the arm system down and allow it to

rest against the ground.

• Put all controls into neutral position.

• Press the stop button.

• Put the main switch into the OFF position (O).

• If a function is not working or needs attention, an

error message appears on the display in conjunction with start-up. Refer to ’Error messages” in the

’Trouble shooting” section.

Inspection after work

It can be benefi cial to carry out the daily inspection

after fi nishing work. Detecting damage in time can

prevent a shutdown on the following day.

Page 26

OPERATION

26 - English

Operating modes

The machine can be operated in three different

modes: transport mode, set-up mode and work mode.

All commands in each of the modes are described in

this section.

• Work mode - In this mode you can operate everything except the caterpillar tracks and outriggers.

• Set-up mode - In this mode you can operate the

caterpillar tracks and outriggers.

• Transport mode - In this mode you can operate the

caterpillar tracks and some arm functions.

If no controls have been used for three seconds the

machine goes into idling mode. In this mode hydraulic

oil is pumped into the tank and there is no pressure in

the cylinders.

Option

External tools

External hydraulic tools can be connected to the machine. The mode is activated by pressing the button

for external tools. In this mode the machine cannot be

operated from the remote control.

Key to commands

1 2

3

4

1. Right and left button on right joystick

2. Right and left button on left joystick

3. Direction joystick

4. Left and right joystick respectively

Designation of the

machine’s parts

1. Arm 1

2. Arm 2

3. Arm 3

4. Tool

5. Outrigger

7

2

1

3

4

5

Emergency operation

IMPORTANT!

To be driven in the emergency operation mode

the machine must be fi tted with hand levers.

Emergency operation is used in conjunction with

terminal or control system problems. The mode is

activated by putting the knob into the position for

emergency operation.

6. Caterpillar tracks

7. Tower

6

When emergency operation is activated the machine

turns off and has to be restarted using the start button

on the machine. In this mode the machine can only be

moved using emergency operation, other functions are

disconnected. When emergency operation is deactivated the machine turns off and has to be restarted

using the remote control.

Page 27

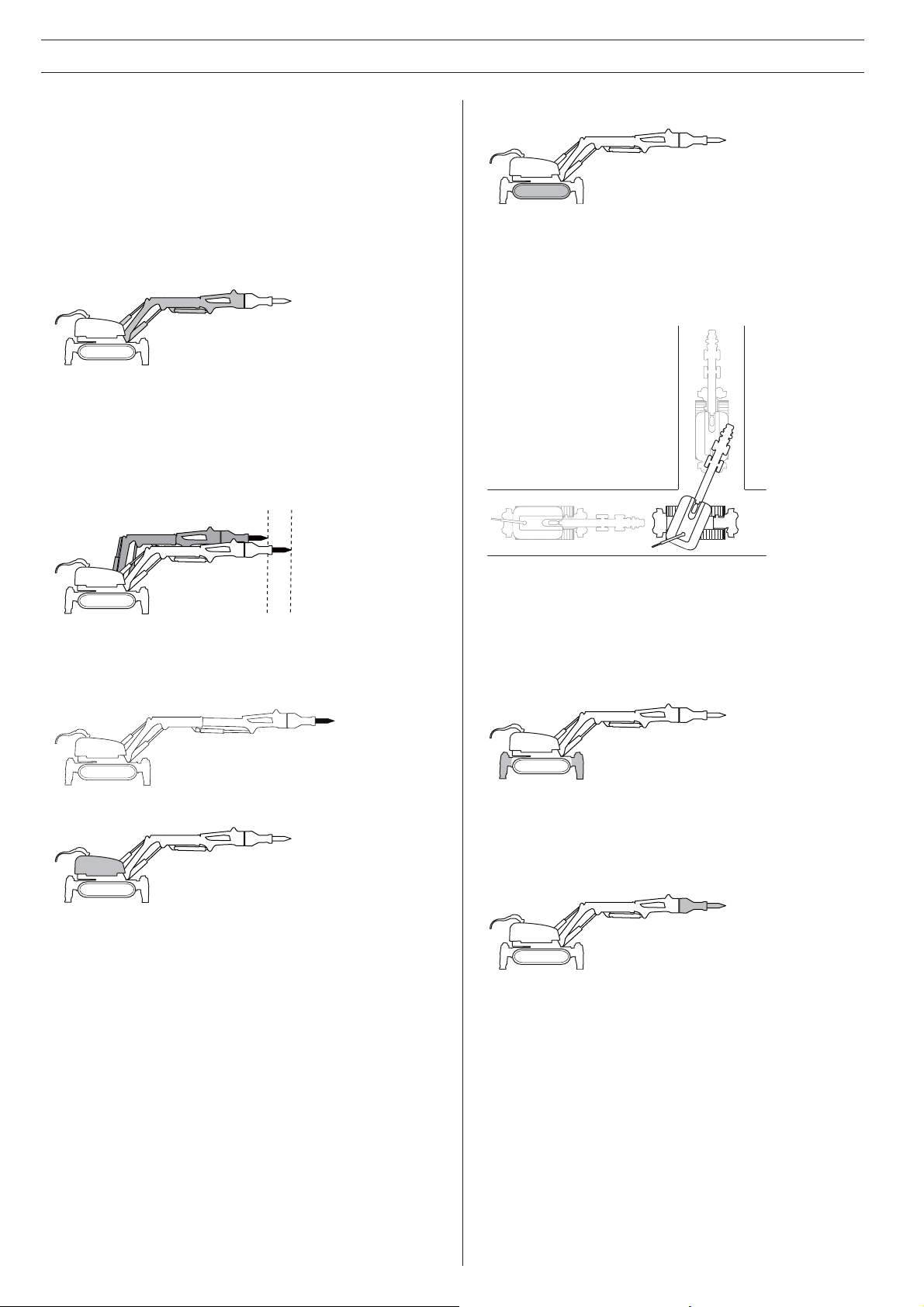

Work mode

English - 27

Rotate tower anticlockwise

Rotate tower clockwise

Arm 1 in

Arm 1 out

Arm 2 down

Arm 2 up

Arm 2 telescope out

Arm 2 telescope in

OPERATION

Arm 1 and arm 2 out

Arm 1 and arm 2 in

Arm 3 up

Arm 3 down

Angle tool inwards*

Angle tool outwards*

Adjustable fl ow to the hammer

Full fl ow to the hammer

Cutters open/close**

* The function works even if the right button on the right joystick is depressed. This can be useful if you simultaneously want to run arm 1 and 2 in parallel.

** The button that opens/closes the cutters varies depending on which type of cutters are being used.

Page 28

OPERATION

Set-up mode

Track operation

Right track operation forward

Right track operation backwards

Left track operation forward

Left track operation backwards

Outriggers

Right outrigger down

Right outrigger up

Rear right outrigger down

Rear right outrigger up

Front right outrigger down

Front right outrigger up

Left outrigger down

Left outrigger up

Rear left outrigger down

Rear left outrigger up

Front left outrigger down

Front left outrigger up

28 - English

Page 29

Transport mode

English - 29

Right track forward

left track forward

Right track backwards

left track forward

Rotate tower clockwise

Rotate tower anticlockwise

Caterpillar tracks forward

Caterpillar tracks backwards

Arm 1 out

OPERATION

Arm 1 in

Arm 2 down

Arm 2 up

Arm 2 telescope out

Arm 2 telescope in

Arm 1 and arm 2 out

Arm 1 and arm 2 in

Arm 3 up

Arm 3 down

Angle tool inwards

Angle tool outwards

Page 30

TOOLS

30 - English

General

IMPORTANT!

Please read the operator’s manual carefully

and make sure you understand the instructions

before using the machine. You should also read

and understand the manual that accompanies

the tool.

Ensure that the tool’s and the machine’s performance (weight, hydraulic pressure, fl ow etc)

are compatible.

Bucket

The bucket is designed to move material. It is not

designed for use as a lifting implement.

Work mode

You can select which tool you want to work with in the

work menu - hammer, concrete cutter or concrete cutter with increased work pressure.

NB! There is a risk of damage to the machine if, for

example, the work pressure is delivered to a singleacting tool’s return side, or if the machine’s or the

remote control’s settings are not correct for the tool in

question. There is more information about the remote

control’s settings in the “Control system” section.

Hydraulic hammer

The hydraulic hammer is designed for demolition

by means of hewing. It is not designed for use as a

crowbar. Continuous hewing with the hydraulic hammer can result in high temperatures in the hydraulic

system.

Concrete cutter

The concrete cutters are designed to crush and cut

material in their jaws. They are not designed for pulling

and prizing loose material.

Page 31

TOOLS

English - 31

Changing tools

IMPORTANT!

Changing tools may mean that the operator has

to be within the machine’s risk area. Ensure that

nobody unintentionally starts the machine while

the tool is being changed. Keep a sharp watch

on the machine and be prepared to turn it off.

Guard hands and feet against crushing.

Cleaning

Prevent dirt from entering the hydraulic system by:

• Wiping dirt off the couplings before assembling or

dismantling.

• Placing dust guards on the machine’s hydraulic

couplings when no tool is mounted.

• Ensuring that the tool’s hoses are always connected together when the tool is not connected to

the machine.

Fitting

IMPORTANT!

Ensure that the tool is correctly and securely

fi tted. If a tool unexpectedly comes loose it can

cause personal injury.

• Ensure that the machine is situated on a stable

surface with the outriggers down.

• Position the tool with the holder facing the machine

at a suitable distance, not too close to the machine.

• Ensure that the tool is turned the right way round.

The tool’s pressure connection must be connected

to the main valve’s B-port and the return hose to

the main valve’s A-port.

• Direct the tool holder so that it grips the tool.

Tighten the tool by raising the arm system and

manoeuvring cylinder 4 in.

• Shut off the machine.

• Insert the wedge so that the holes for the locking

pin fi t.

• Insert the locking pin.

• Connect the hydraulic hoses and any hoses for

hammer lubrication (when fi tting the hammer). The

tool’s pressure connection must be connected to

the main valve’s B-port and the return hose to the

main valve’s A-port.

The hydraulic hoses are equipped with bayonet

couplings with decompression. This facilitates fi t-

ting the hoses even though pressure is trapped.

To dismantle, follow the instructions in the reverse

order.

Storage

Store the tools safely and inaccessible to unauthorised people. Ensure that they are in a stable position

and cannot tip over. If tools are placed high up or on

a slope they must be secured so that they cannot

be put into motion or fall. Protect the tools’ hydraulic

couplings against dirt and damage.

Page 32

SETTINGS

32 - English

Track widener

The machine is equipped with track wideners for

increased stability when working with the machine.

Width with track widener: 1110 mm (44 in)

Width without track widener: 780 mm (31 in)

Fitting the track widener

• Let down the outriggers.

• Shut off the machine. Disconnect the power

cable and place it so that it cannot be connected

by mistake.

• Remove the nuts (A).

• Loosen bolts (C) and nuts (B).

• Move washer (D) to the side.

• Pull the side of the tracks out a suffi cient distance

to enable the track widener to be fi tted.

• The holes of the track widener must be facing the

machine.

• Move the side of the track towards the machine.

• Tighten bolts and nuts.

To dismantle, follow the instructions in the reverse

order.

Page 33

Menu system

English - 33

SETTINGS

Page 34

SETTINGS

34 - English

Operational settings

LCD Adjustment

Use the arrows up and down to adjust the display’s

contrast and brightness.

Software version

This shows the version of the software in the terminal

and the two control modules.

Tuning

The following components can be adjusted in the

Service Menu under Tuning.

• C1-C5 (Cylinder 1-5)

• Rot. (Rotation tower)

• Outriggers

Joystick L/R

Pos. and Neg. Progression

Pos. and Neg. Progression indicate the sensitivity of

the joystick. The higher the value the more sensitive