Page 1

GB

Operator’s manual

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

ES

DE

FR

Manual de instrucciones

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

Bedienungsanweisung

Lesen Sie die Bedienungsanweisung sorgfältig durch und

machen Sie sich mit dem Inhalt vertraut, bevor Sie das

Gerät benutzen.

Manuel d’utilisation

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

HUSQVARNA CONSTRUCTION PRODUCTS

DMS 160

A/AT/Gyro

GB ES DE FR

Page 2

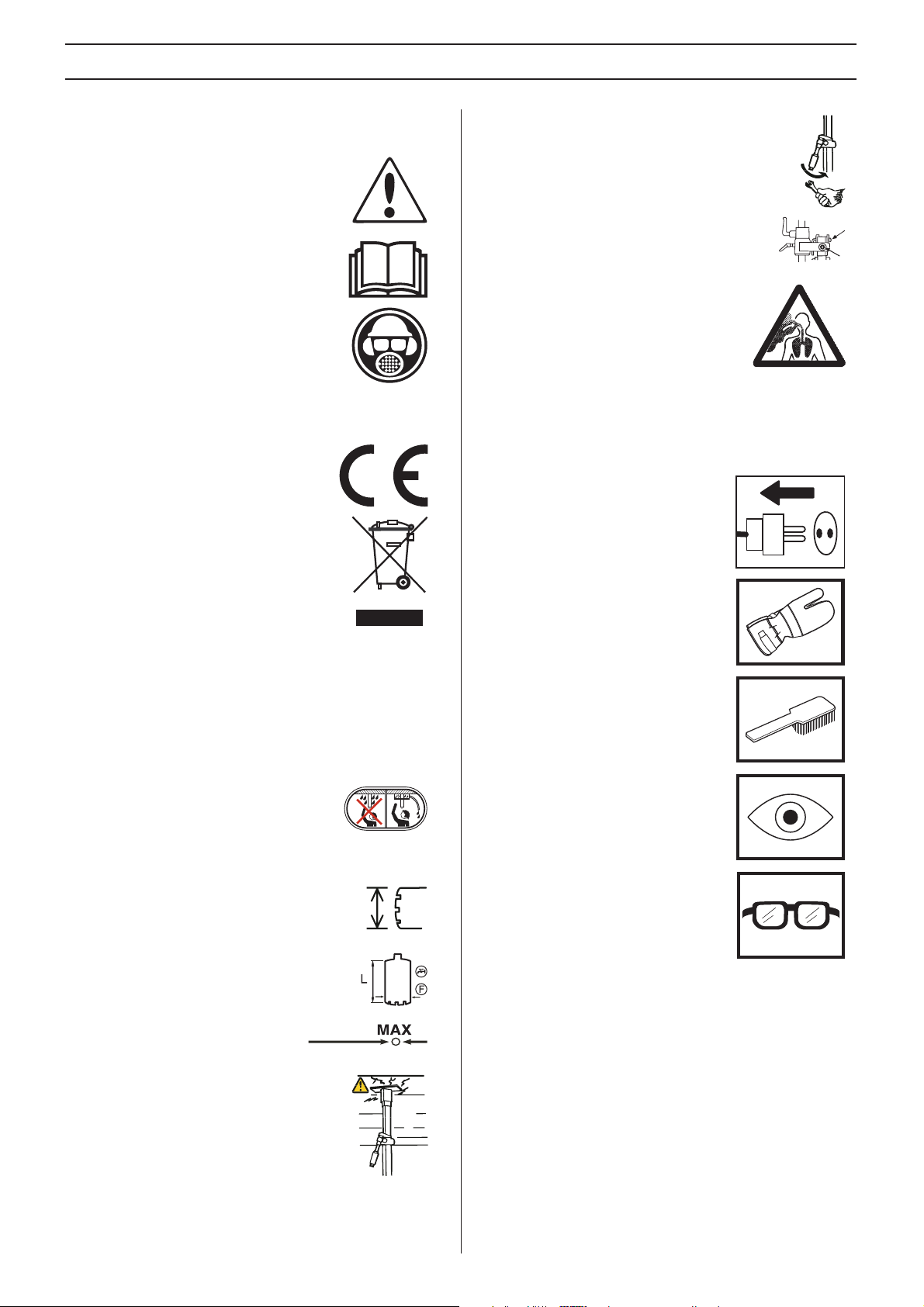

KEY TO SYMBOLS

Symbols on the machine:

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or fatal

injury to the operator or others.

Please read the operator’s manual carefully

and mak

instructions before using the machine.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

• Breathing mask

This product is in accordance with

applicab

Environmental marking. Symbols on the

product or its packaging indicate that this

product cannot be handled as domestic

waste. It must instead be submitted to an

appropriate recycling station for the recovery

of electrical and electronic equipment.

By ensuring that this product is taken care of

correctly

potential negative impact on the environment and people that

can otherwise result through the incorrect waste

management of this product.

For more detailed information about recycling this product,

contact y

shop from where you purchased the product.

Ensure that water cannot leak into the

machine when dr

appropriate water collector and cover the

machine in plastic, but do not cover the air

intakes and air outlets.

The drilling machine must be suitable and

designed f

diameter is stated on the machine.

e sure you understand the

le EC directives.

, you can help to counteract the

our municipality, your domestic waste service or the

illing in the ceiling. Use an

or the size of drill bit. The max drill bit

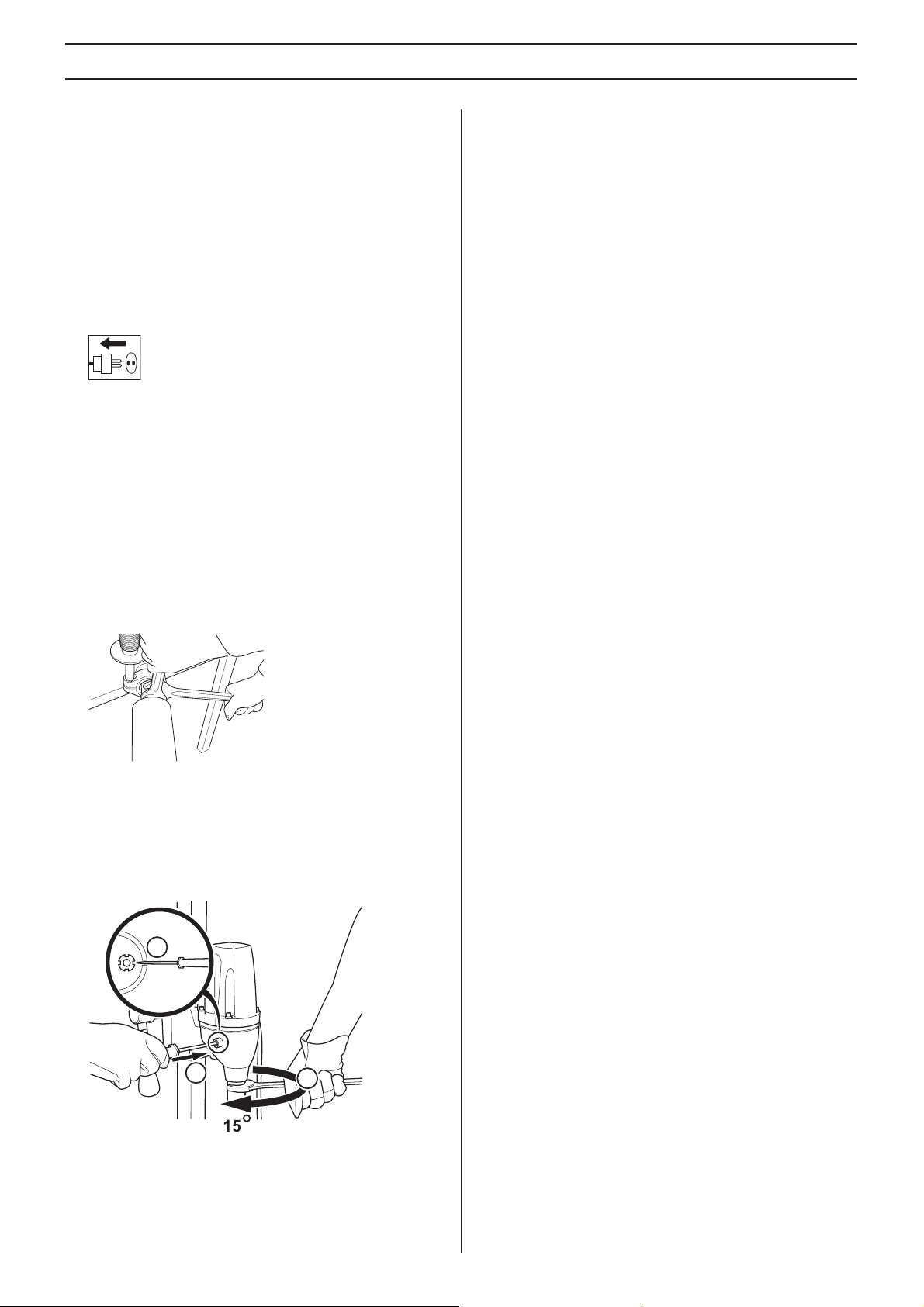

Make sure that the fork grips in the inner ear.

Tighten using a suitable spanner.

Lock the nut using a 30 mm spanner. Check

the loc

k nut on the L-handle. Mak e sure that it

is tightened.

WARNING! Dust forms when drilling,

which can cause injur

an approved breathing mask. Always

provide for good ventilation.

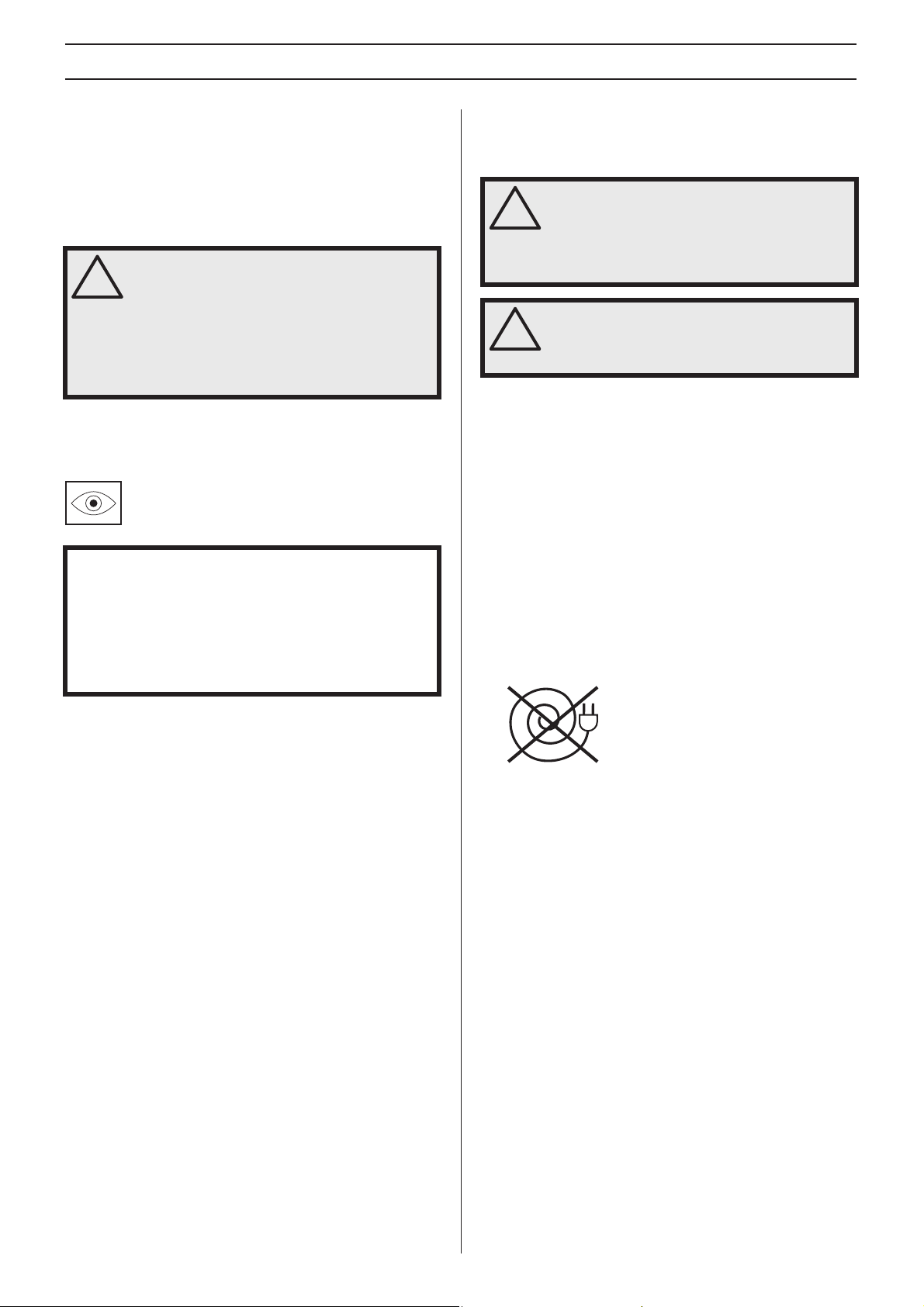

Other symbols/decals on the machine

refer to special certification

requirements for certain markets.

ies if inhaled. Use

Symbols in the operator’s manual:

Inspection and/or maintenance should

be carried out with the motor switched

off and the plug disconnected.

Always wear approved protective

glo

ves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be

worn.

Use a drill suitable for the work.

Load/power indication (LCS-Load

control system).

Check that the ceiling is strong enough. The

ceiling should be solid.

2 – English

Ø

Page 3

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine: ............................................. 2

Symbols in the operator’s manual: ............................... 2

CONTENTS

Contents ...................................................................... 3

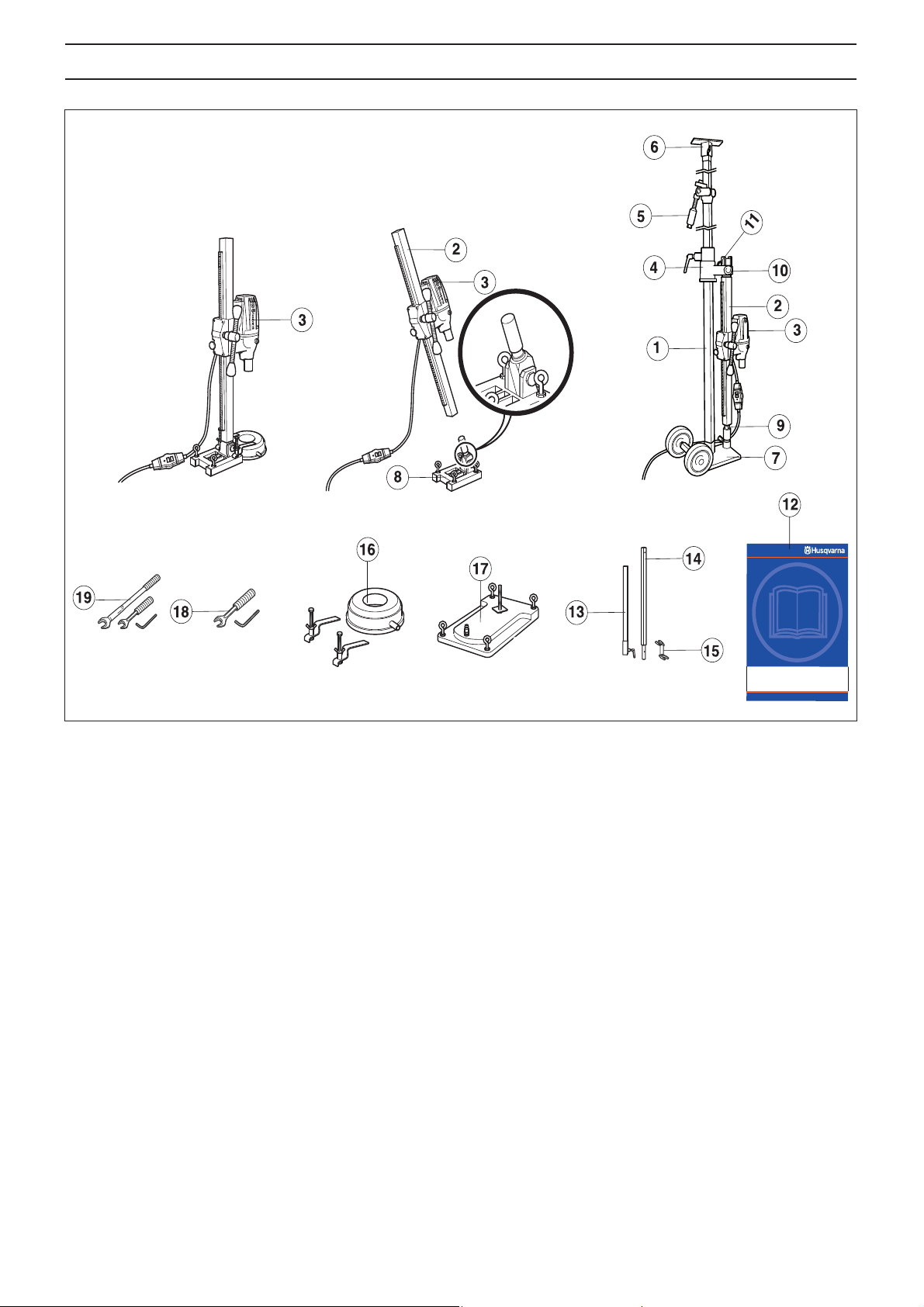

WHAT IS WHAT?

What is what on the drilling machine? ......................... 4

WHAT IS WHAT?

What is what on the stand? ......................................... 5

SAFETY INSTRUCTIONS

Steps before using a new drilling machine .................. 6

Personal protective equipment ..................................... 6

Machine

Checking, maintaining and servicing the machine

safety equipment .......................................................... 7

General safety precautions .......................................... 7

PRESENTATION

Drill motor and stand .................................................... 8

Drill motor DMS160 ..................................................... 8

Stand DMS160 ........................................................... 8

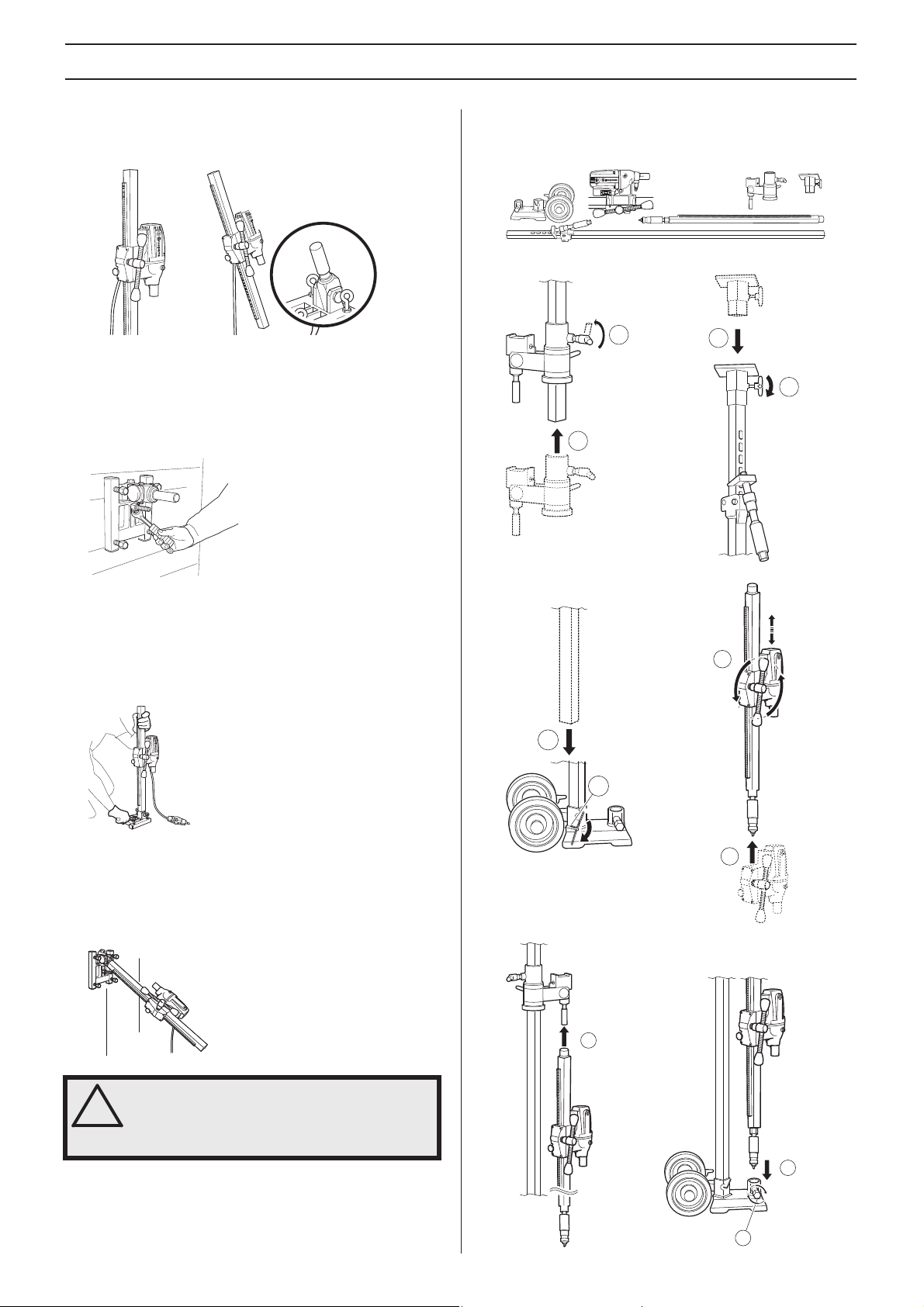

ASSEMBLY

Assembling the stand - DMS160 A/AT ......................... 9

Assembling the stand - DMS160 Gyro ......................... 9

STARTING AND STOPPING

Before starting ............................................................. 12

Starting ........................................................................ 12

Stopping ....................................................................... 12

WORKING TECHNIQUES

General working instructions ....................................... 13

Using the machine ....................................................... 14

MAINTENANCE

Maintenance of the drill motor ..................................... 15

Stand maintenance ...................................................... 16

TECHNICAL DATA

Drill motor DMS160 ..................................................... 17

Stand DMS160 ........................................................... 18

EC-declaration of conformity ........................................ 18

′s safety equipment ........................................ 7

′s

English – 3

Page 4

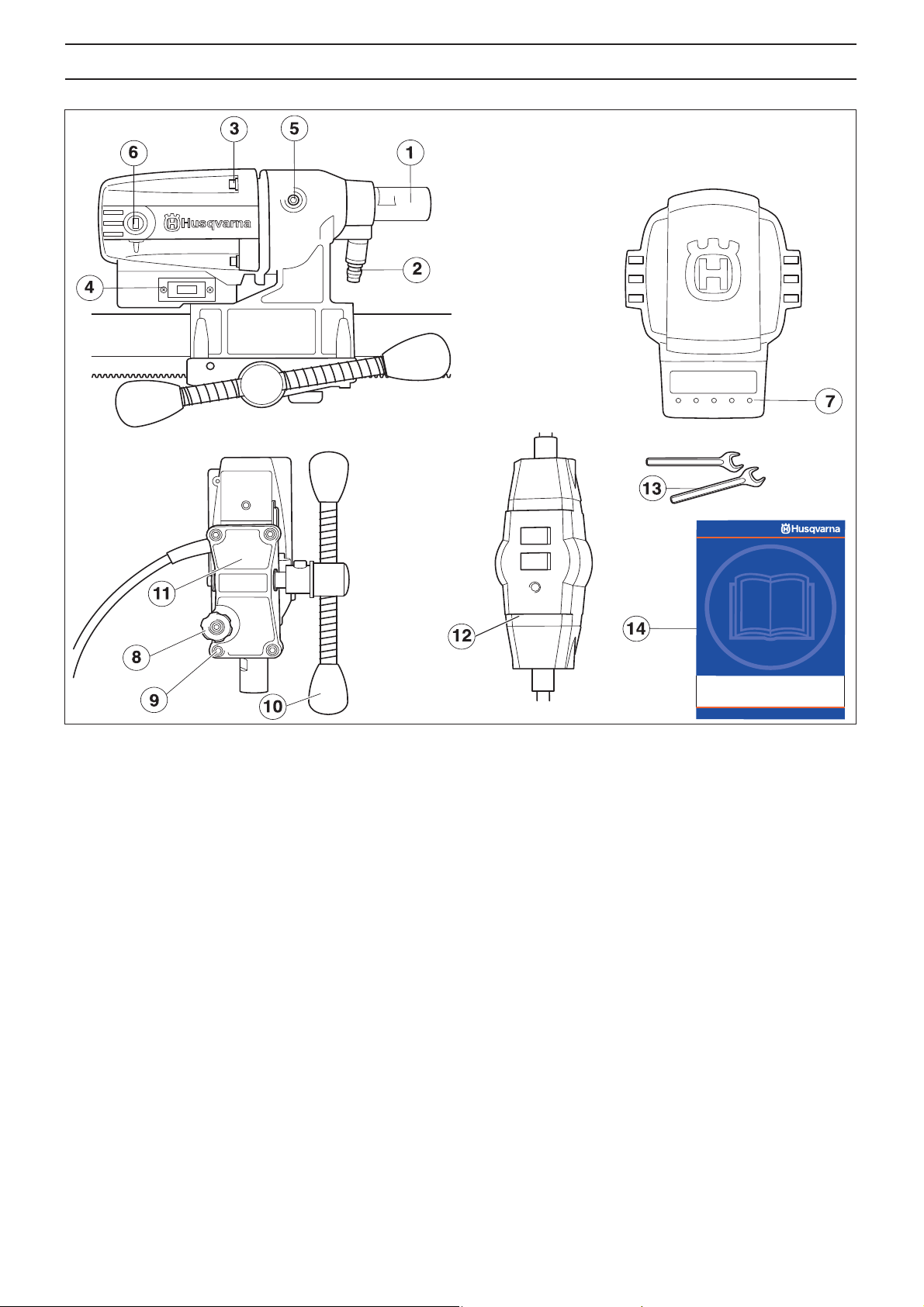

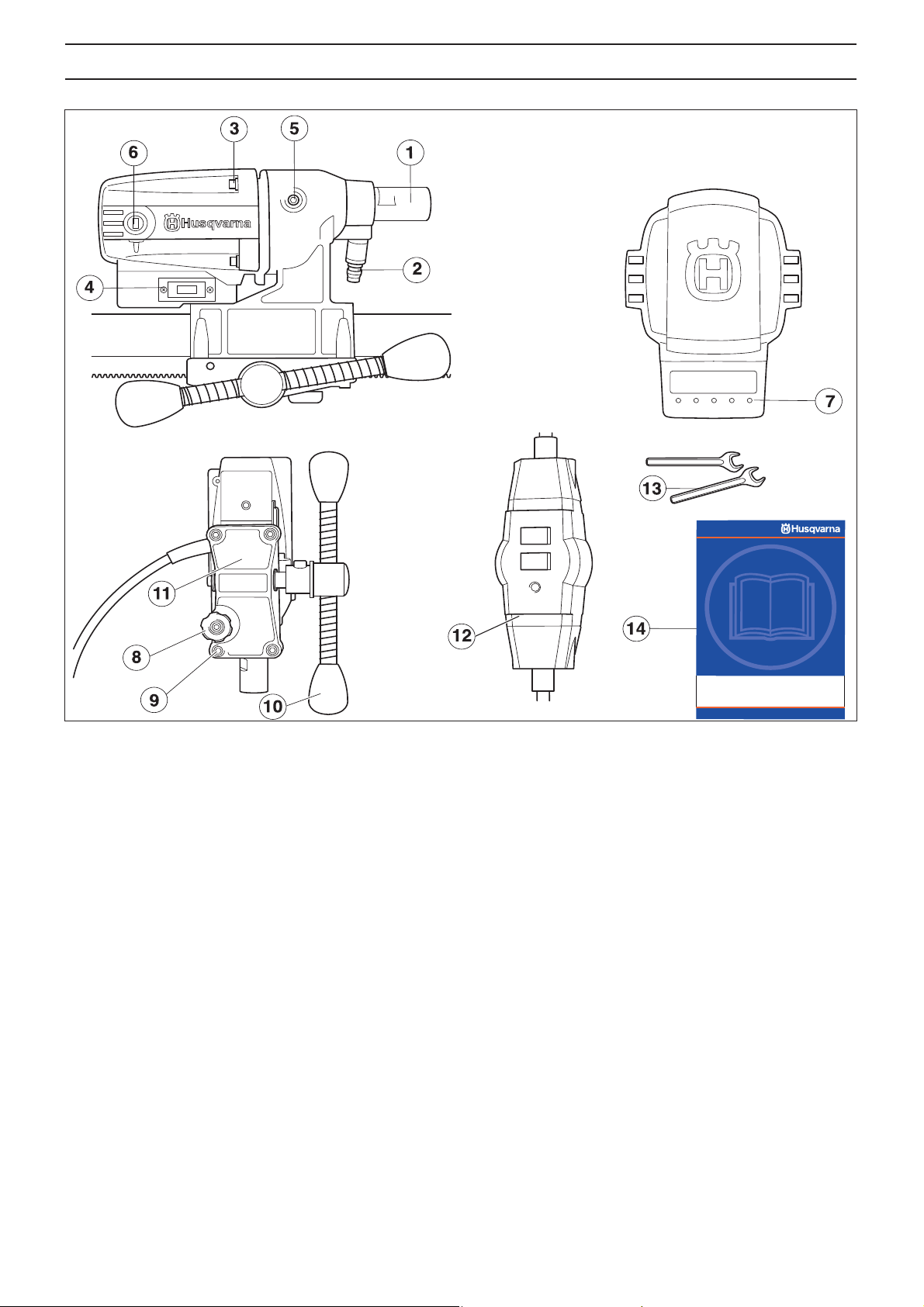

WHAT IS WHAT?

What is what on the drilling machine?

1 Drill spindle

2 Water connector

3 Screws holding together the gearbox and the motor.

4 Switch

5 Cover for slip clutch (SMC)

6 Carbon brush cover

7 Load/power indication (LCS-Load control system).

8 Locking knob

9 Screws (4) for feeder rear section and gearbox

10 Feeder handle

11 Feeder rear section

12 PRCD Earth-fault breaker

13 Spanners

14 Operator

′s manual

4 – English

Page 5

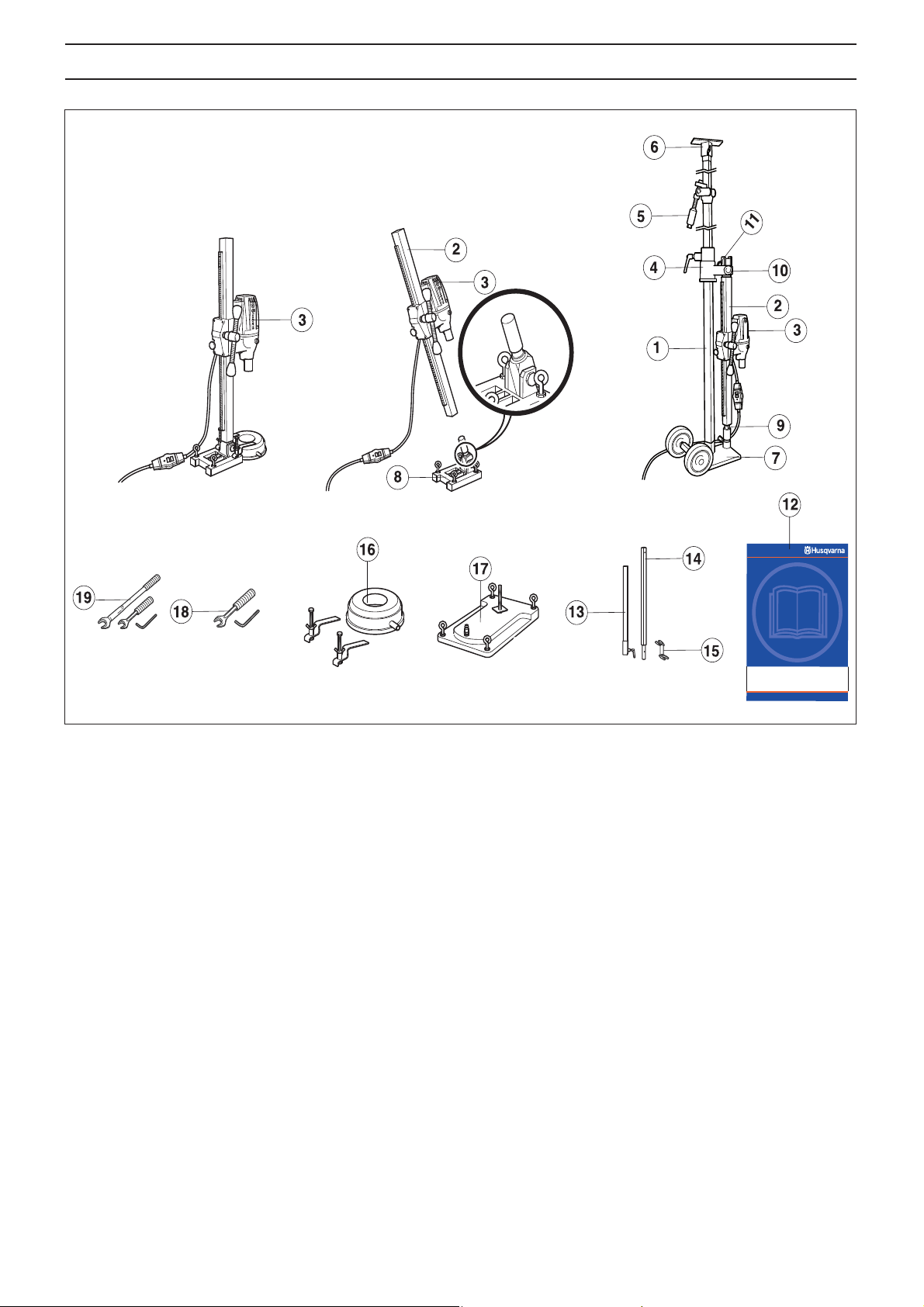

WHAT IS WHAT?

What is what on the stand?

1 Telescopic support column 40

2 Drill column

3 Drill motor DMS160

4 Wall rail

5 Support column/locking mechanism

6 Ceiling plate

7 Base plate (GB 40 T) with transport wheels

8 Expander angle base plate

9 Column screw and lock screw

10 Locking nut

11 L-handle

12 Operator

13 Extension module U (Available as an accessory.)

14 Extension module l (Available as an accessory.)

15 Expansion attachment (Available as an accessory.)

16 Water collector (Available as an accessory.)

17 Vacuum plate (Available as an accessory.)

18 Tool kit DMS160 AT

19 Tool kit DMS160 Gyro

′s manual

English – 5

Page 6

SAFETY INSTRUCTIONS

Steps before using a new drilling machine

• Read through the operating instructions carefully before

you begin using the machine.

• This machine is designed for and intended for drilling

concrete

is improper.

• The machine is intended for use in industrial applications

b

• Check the assembly of the drill, see the section changing

the dr

• Check that the cord and extension cord are intact and in

good condition.

• Keep the workplace tidy. Disorder leads to accident risks.

Always use common sense

It is not possible to cover e v ery conceivable situation y ou can

face when using a drilling machine. Alwa ys ex ercise care and

use your common sense. Avoid all situations which you

consider to be beyond your capability. If you still feel uncertain

about operating procedures after reading these instructions,

you should consult an expert before continuing. Do not

hesitate to contact your dealer or us if you have any more

questions about the use of the drilling machine. We will

willingly be of service and provide you with advice as well as

help you to use your drilling machine both efficiently and

safely.

Let your Husqvarna dealer check the drilling machine

regular

All information and all data in the Operator’s Manual were

applicab

, brick and different stone materials. All other use

y experienced operators.

ill bit.

ly and make essential adjustments and repairs.

le at the time the Operator’s Manual w as sent to print.

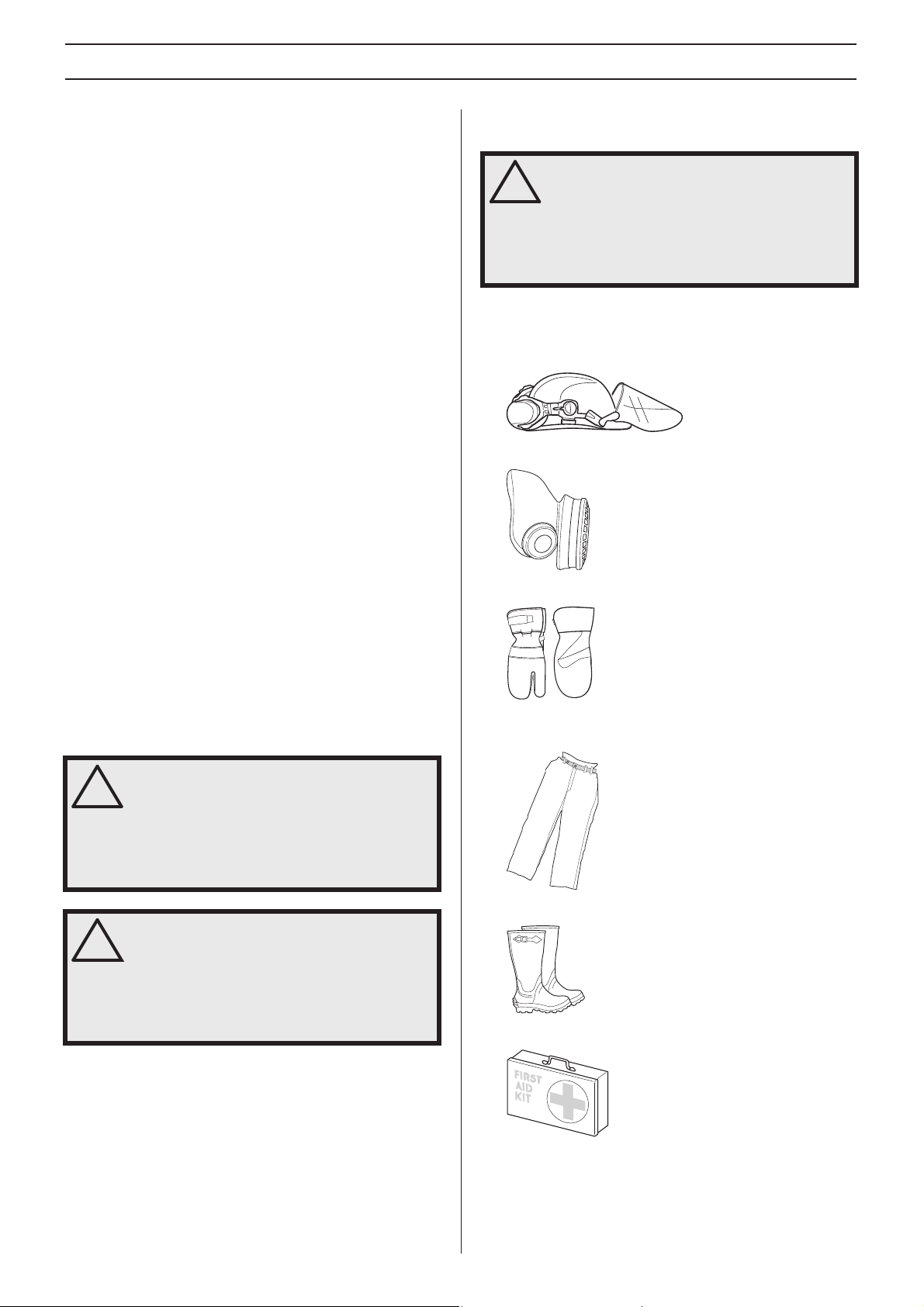

Personal protective equipment

WARNING! You must use approved personal

protective equipment whenever you use the

!

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

mits full freedom of movement.

per

WARNING! Under no cir cumstances may the

design of the machine be modified without

!

the permission of the manufacturer. Always

use genuine accessories. Non-authorized

modifications and/or accessories can result

in serious personal injury or the death of the

operator or others.

WARNING! The use of products such as

cutters, grinders, drills, that sand or form

!

material can generate dust and vapours

which may contain hazardous chemicals.

Check the nature of the material you intend

to process and use an appropriate breathing

mask.

• Boots with steel toe-caps and non-slip sole.

• Always have a first aid kit nearby.

6 – English

Page 7

SAFETY INSTRUCTIONS

Machine′′′′s safety equipment

This section describes the machine′s safety equipment, its

purpose, and how checks and maintenance should be carried

out to ensure that it operates correctly. See the ”What is

what?” section to locate where this equipment is positioned

on your machine.

WARNING! Never use a machine that has

faulty safety equipment! Safety equipment

!

must be inspected and maintained. See

instructions under the heading Checking,

maintaining and servicing the machine’s

safety equipment. If your machine does not

pass all the checks, take it to a service

workshop for repair.

Checking, maintaining and servicing

the machine

IMPORTANT! All servicing and repair work on the machine

requires special training. This is especially true of the

machine′s safety equipment. If your machine fails an y of the

checks described below you must contact your service

agent. When you b uy any of our products we guar antee the

availability of prof essional repairs and service. If the retailer

who sells your machine is not a servicing dealer, ask him for

the address of your nearest service agent.

′′

′′

s safety equipment

General safety precautions

• Do not use the drilling machine without first reading and

understanding the contents of this Operator’s Manual.

WARNING! There is always a risk of shocks

from electrically powered machines. Avoid

!

unfavourable weather conditions and body

contact with lightning conductors and metal

objects. Alwa ys follow the instructions in the

Operator’s manual to avoid damage.

WARNING! There is always a risk of crush

injuries when working with products

!

containing moving parts. Wear protective

gloves to avoid body injuries.

• Never use the machine if y ou are tired, if you have drunk

alcohol, or if y

your vision, your judgement or your co-ordination.

• Wear personal protective equipment. See instructions

under the heading P

• Never carry the machine by means of the cord and ne v er

pull out the plug b

extension cords away from water, oil and sharp edges.

Make sure the cord is not pinched in doors, fences or the

like. Otherwise it can cause the object to become live.

• Check that the cord and extension cord are intact and in

good condition.

outdoor use. Never use the machine if the cord is

damaged, hand it in to an authorized service workshop for

repair.

• Do not use an extension cord while it is rolled up to av oid

verheating.

o

ou are taking medication that could affect

ersonal protective equipment.

y pulling the cord. Keep all cords and

Use an extension cord intended for

Switch

The power switch should be used to start and stop the

machine.

Checking the power switch

• Start the machine by pressing the power switch.

• Shut down the machine by pressing the power switch.

• A defective power switch should be replaced by an

ized service workshop.

author

• The machine should be connected to an earthed outlet

ket.

soc

• Check that the mains voltage corresponds with that stated

on the r

• Never use a machine that is faulty. Carry out the checks,

maintenance and ser

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Never allow anyone else to use the machine without first

ensur

operator’s manual.

• People and animals can distract you causing you to lose

control of the machine

concentrated and focused on the task.

• Be careful as clothing, long hair, and jewellery can get

caught in mo

ating plate on the machine.

vice instructions described in this

ing that they have understood the contents of the

. For this reason, always remain

ving parts.

Transport and storage

Do not store or transport the drilling machine with the drill bit

fitted in order to protect your drilling machine and drill bits

from damage.

Store the drilling machine in a lockable area so that it is out of

reach of children and unauthor

Store the drilling machine and stand in dry and frost free

conditions.

ised persons.

English – 7

Page 8

PRESENTATION

Drill motor and stand

It is our wish that you will be satisfied with your product and

that it will be your companion for a long time. Think of this

operator′s manual as a valuable document. By following its′

content (using, service, maintenance etc) the life span and

the second-hand value of the machine can be extended. If

you will sell this machine, make sure that the b uyer will get the

operator

A purchase of one of our products gives you access to

prof

may be necessary . If the retailer who sells your machine is not

one of our authorised dealers, ask him for the address of your

nearest service workshop.

Husqvarna Construction Products has a policy of continuous

product de

the design and appearance of products without prior notice

and without further obligation introduce design modifications.

′s manual.

essional help with repairs and services whenever this

velopment. Husqvarna reserves the right to modify

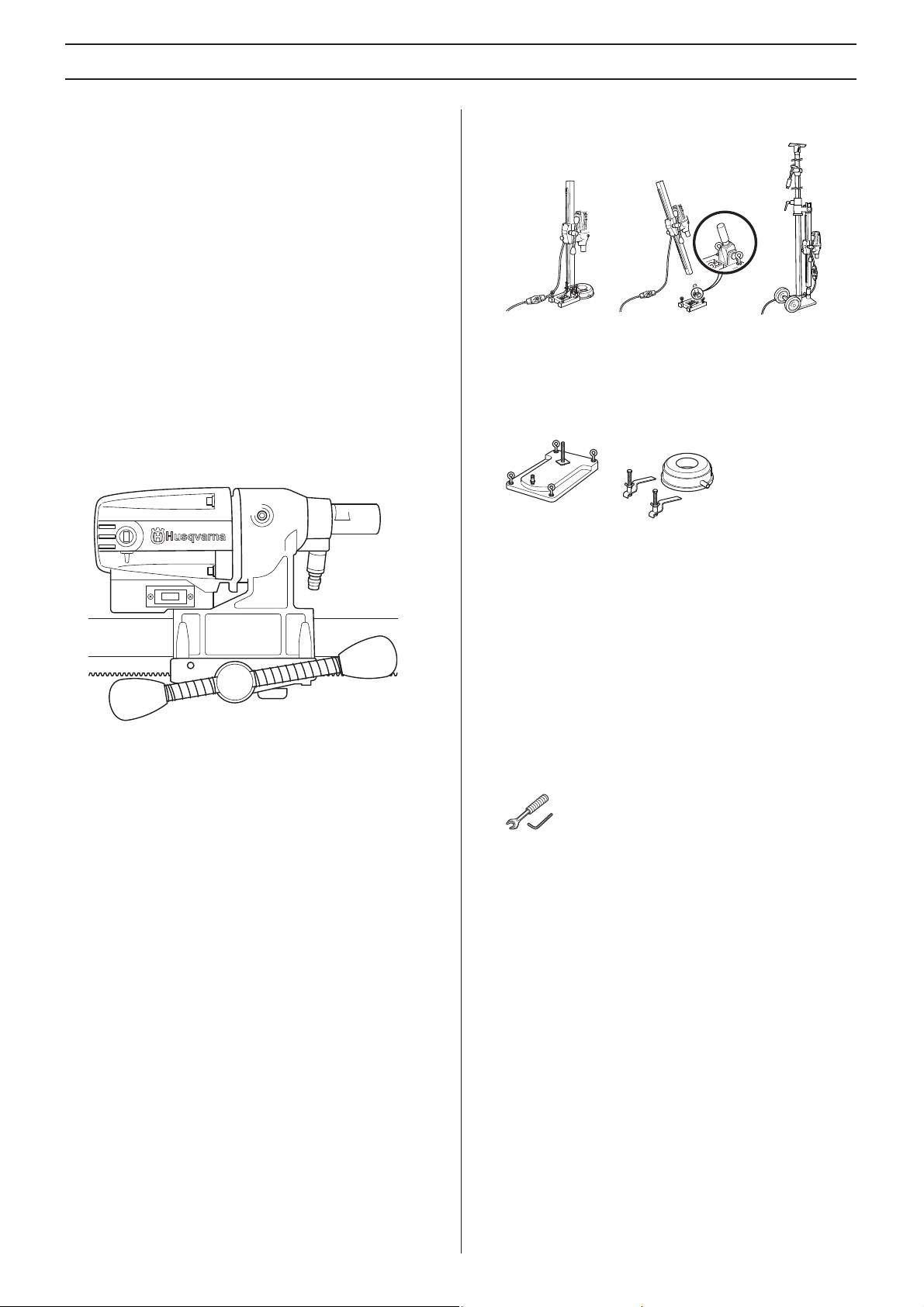

Drill motor DMS160

• DMS160 is an electric drill, intended for drilling concrete,

brick and various stone materials.

• The drilling machine has a modular design and is easy to

assemb

• The machine has a speed range for drill bits with a

diameter(ø) of 120 mm / 4.75 In.

• The design of the slip clutch (SMC- Slide Mechanical

Clutch) giv

adjusted from outside.

• The machine is intended for stand mounted drilling.

• The machine is water cooled.

• The machine is double insulated and has power

indicators

• The machine works at its best if not overloaded, let the

maxim

Load Control System) be on. Max. 10 minutes max. load

the machine must then be run without a load for 2 minutes.

le.

es the greatest power output and it can be

.

um yellow LED on the load/power indicator (LCS-

Stand DMS160

DMS160 A DMS160 AT DMS160 Gyro

DMS160 A/AT

The stands are secured using expanding screws.

• A water collector and vacuum plate are available as

accessor

DMS160 AT

• DMS160 AT has a modular design that permits angle

drilling and a rotation function.

DMS160 Gyro

• DMS160 Gyro has a modular design with telescopic stand

to secure the drill motor.

• The telescopic support column has a maximum length of

3.1 metres

using an extension module.

• A maximum of one extension module may be used.

• Only one spanner (24/30 mm) and an allen key (8 mm)

are required to change the settings

The drill column can be variably adjusted through 360

• The transport wheels can be removed.

ies to suck the stand into place.

, but can be extended an additional 0.75 metres

.

°.

8 – English

Page 9

ASSEMBLY

Assembling the stand - DMS160 A/ AT

DMS160 A/AT

• Drill holes (15 mm) in the floor or in the wall and knock in

the expander bolts.

20 Bolt down the base plate. Check carefully that the

xpander is secured correctly.

e

Assembling the stand - DMS160 Gyro

DMS 160 Gyro

2

1

3

4

DMS160 AT

• The drill column is mounted on the base plate’s angle

bracket. Tighten the lock screw with an 8 mm allen key.

The drill column can be turned through 360° and locked

variably in each position using a locking screw (8 mm allen

key)

• The drill column is set at the required angle by tightening

the n

ut using a 24 mm spanner. If the vacuum plate is

used, make sure the support surface is not porous and

can loosen from the floor or the wall. Make sure that the

vacuum pump has sufficient power to secure the v acuum

plate. A suitable vacuum motor is Husqvarna VP200.

7

5

6

8

9

WARNING! The vacuum plate must never be

used for ceiling drilling. Careless or

!

incorrect use can result in serious or fatal

injury to the operator or others.

10

11

English – 9

Page 10

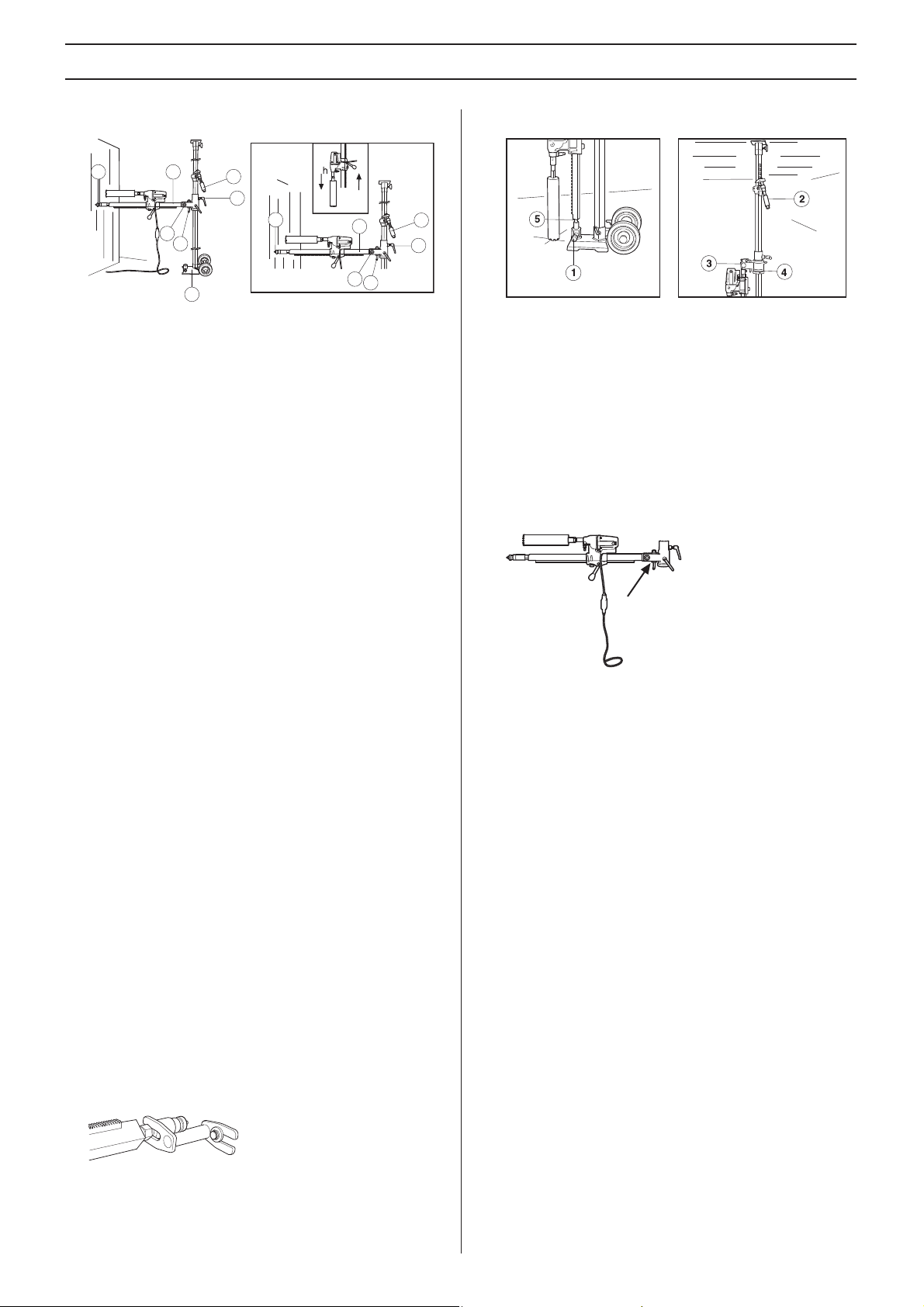

ASSEMBLY

Drilling in walls

6

1 Base plate with locking screw.

2 Column screw and lock screw

3 Locking knob

4 L-handle

5 Drill column

6 Column screw and lock screw

7 Locking nut

8 Drill motor DMS160

• Place the base plate at a drill column’s length from the

all. The support column screw should be screwed in.

w

When drilling is to be performed at a height greater than

1.5 metres, the heavier outer tube should be turned

upwards and vice versa when drilling below 1.5 metres.

Check that the support column is clamped in the base

plate with the locking screw.

• Clamp the telescopic column support against the ceiling.

Choose the closest hole in the holed inner tube

using the support column handle and screw the last bit

using a 24 mm spanner. Do not clamp too tight.

• Loosen the locking handle and rotate the drill column.

old down the drill column using the L-handle.

F

• Fit the drill motor DMS160 on the drill column.

• Then turn back the drill column with the drill motor to the

desired position against the w

• Angle back and fold up the drill column, secure with the L-

handle and n

and set the drill column at the required angle by tightening

the nut using a 30 mm spanner.

• Check the position of the drill bit. Screw in the support

column scre

Secure with a locking nut, 30 mm. Use a wooden batten

as packing. The drill column can be turned through 360

and locked variably in each position using a loc king screw

(8 mm allen key)

• The expander attachment can be used to provide

additional anchor

is adjusted against the support column screw and is

secured on the wall with an expansion bolt. Secure with a

locking nut, 30 mm.

5

7

4

2

3

6

1

5

7

4

2

3

. Clamp

all. Loc k the loc king handle .

ut. When angle drilling, loosen the L-handle

w against the wall to secure the drill column.

age of the drill column. The attachment

°

Drilling in the floor

1 Locking screw

2 Column screw and lock screw

3 Locking knob

4 L-handle

5 Locking screw

• Fold down the drill column using the L-handle.

• Make sure that the support column enters the lock sleeve.

• Tighten the locking nut with a 30 mm key and lock the

king handle.

loc

• Place the stand in the required position.

6 Lock the support column in the lock sleeve with the loc king

w and the nut. Tighten using the 24 and 30 mm

scre

spanners.

• Clamp the telescopic support column against the ceiling

with the suppor

using a 24 mm spanner, do not tighten too tight. The

telescopic support column has a maximum length of 3.1

metres, but can be extended an additional 0.75 metres

using an extension module.

t column mechanism. Tighten the last bit

10 – English

Page 11

ASSEMBLY

Drilling in the ceiling

1 Column screw and lock screw

2 Locking nut

3 Column screw and lock screw

• Place the stand in the required position.

• Check that the support column screw in the drill column is

wed in. F old up and lock the drill column in the vertical

scre

position with the locking nut.

• Check that the drill bit is in the right position. Clamp the

telescopic suppor

support column mechanism.

• Screw in the support column screw against the ceiling to

secure the dr

Use a wooden batten as packing.

• The expander attachment can be used to provide

additional anchor

accessory.) The attachment is adjusted against the

support column screw and is secured on the wall with an

expansion bolt. Secure with a locking nut, 30 mm.

t column against the ceiling with the

ill column. Secure with a loc king nut, 30 mm.

age of the drill column. (Available as an

WARNING! The vacuum plate must never be

used for ceiling drilling. Careless or

!

incorrect use can result in serious or fatal

injury to the operator or others.

English – 11

Page 12

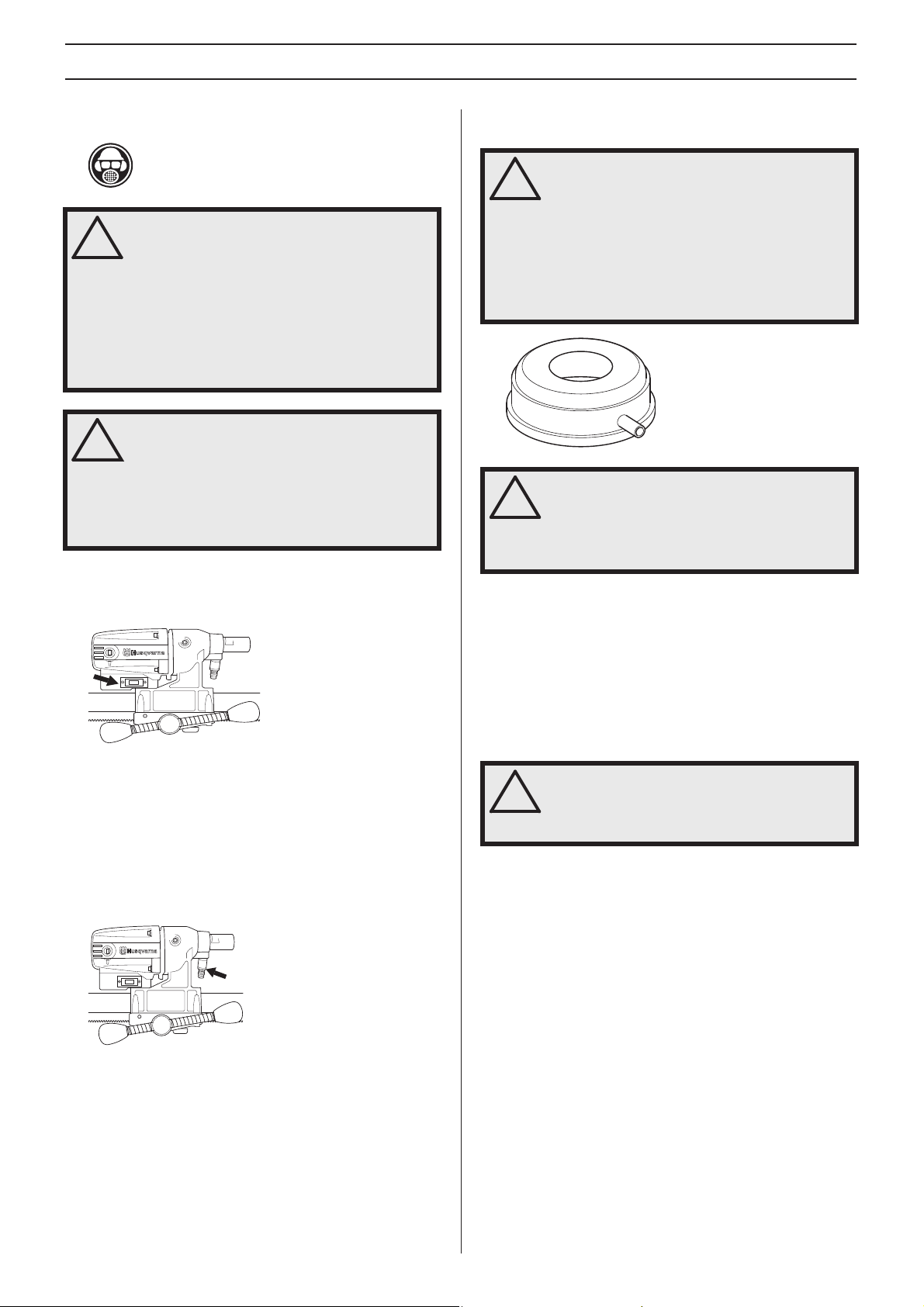

STARTING AND STOPPING

Before starting

WARNING! Note the following before

starting:

!

The machine should be connected to an

earthed outlet socket.

Check that the mains voltage corresponds

with that stated on the rating plate on the

machine. Keep people and animals well

away from the working area.

WARNING! Before drilling, check that all

locking screws are tightened well.

!

Serious accidents can occur if the concrete

core remains in the drill when backing out

the drill motor/drill from the floor, wall or

ceiling.

Make sure that:

• The switch is undamaged. If not, the switch must be

replaced b

y an authorised repairman.

Drilling in the ceiling

WARNING! The vacuum plate must never be

used for ceiling drilling.

!

Use a water collector to avoid water

penetrating into the machine. The machine

must be covered with plastic or the like in

order to prevent water penetrating into the

machine, but do not cover the air intakes

and air outlets.

WARNING! A maximum of one extension

module may be used.

!

Check that no one on the floor below can be

injured by falling concrete cores.

Starting

• Turn on the water cooling.

• Press in the switch fully.

• Start to feed the drill bit with the help of the feed handle.

• The machine and its equipment are correctly installed:

- The drill is secured properly.

- The stand is firmly attached.

- Secure the machine on the stand using a suitable method.

• Wear personal protective equipment. See instructions

under the heading P

• Water cooling is connected to the machine.

ersonal protective equipment.

Stopping

WARNING! The drill bit continues to rotate

for a while after the motor has been switched

!

off. Do not stop the drill bit with your hands.

Personal injuries can occur.

Shut down the machine by pressing the power switch.

Cooling

Run the machine unloaded for a minute or two to cool the

motor.

12 – English

Page 13

WORKING TECHNIQUES

General working instructions

WARNING! This section takes up the basic

safety precautions for working with the

!

drilling machine. This information is never a

substitute for professional skills and

experience. If you encounter a situation

where you are uncertain how to proceed you

should ask an expert. Contact your dealer,

service agent or an experienced drilling

machine user. Do not attempt any task that

you feel unsure of!

WARNING! Overexposure to vibration can

lead to circulatory damage or nerve damage

!

in people who have impaired circulation.

Contact your doctor if you experience

symptoms of overexposure to vibration.

Such symptoms include numbness, loss of

feeling, tingling, pricking, pain, loss of

strength, changes in skin colour or

condition. These symptoms normally appear

in the fingers, hands or wrists. These

symptoms may be increased in cold

temperatures.

• Never work alone, alw a ys ensure there is another person

close at hand.

assemble the machine, you can also get help if an

accident should occur.

• Keep all parts in good working order and ensure that all

fixtures are properly tightened.

Apart from being able to receive help to

• Do not use the machine in bad weather, such as dense

fog, rain, strong wind, intense cold, etc. Working in bad

weather is tiring and can lead to dangerous conditions,

e.g. slippery surfaces.

• Never start to work with the power cutter before the

orking area is clear and you have a firm foothold. Look

w

out for any obstacles with une xpected mov ement. Ensure

when cutting that no material can become loose and fall,

causing operating injury.

• Remain at a distance from the drill bit when the motor is

unning.

r

• Ensure that the working area is sufficiently illuminated to

create a saf

• Make sure that no pipes or electrical cables are routed in

the area to be dr

• Ensure the cord is behind you when you start to use the

machine so that the cord will not be damaged.

• Never leave the machine unsupervised with the motor

unning. A rotating drill bit can entail a risk of serious

r

injury.

• Always unplug the machine during longer work breaks.

• Do not overload the machine. Overloading can damage

the machine

• Keep tools sharp and clean in order to enable safer work.

• Always check the rear side of the surface where the drill

bit will emerge when dr

cordon off the area and make sure that no one can be

injured or material damaged.

• Always switch off the machine before you move it.

e working environment.

illed.

.

illing right through. Secure and

English – 13

Page 14

WORKING TECHNIQUES

Using the machine

• Keep your hands at a safe distance from the drill spindle

and drill bit when the machine is running.

• Keep an eye open for oil or water leakage.

Drilling outdoors

Always use extension cables that are approved for outdoor

use.

Changing the drill bit

1 Pull out the plug.

2 Get:

- The new drill bit.

- The supplied open-ended spanners, size 24 mm and 32

mm.

- Water-resistant grease.

3 Remove the old drill bit using the open-ended spanners.

4 Apply water-resistant grease to the thread of the new drill

bit.

5 Attach the drill bit using the open-ended spanners.

Load/power indication (LCS-Load control system).

The machine works at its best if not overloaded, let the

maximum yellow LED on the load/power indicator (LCS- Load

Control System) be on. Max. 10 minutes max. load the

machine must then be run without a load for 2 minutes.

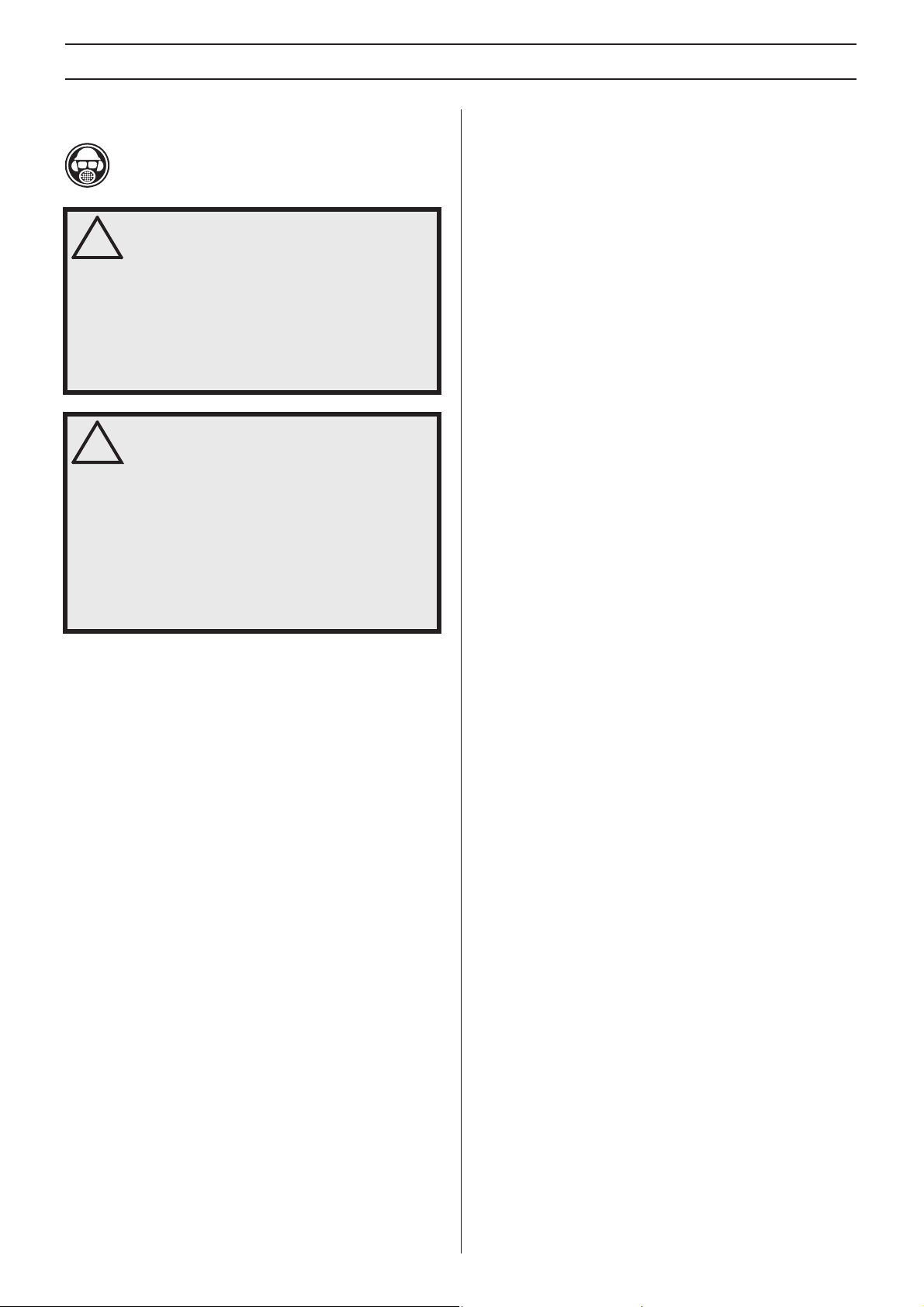

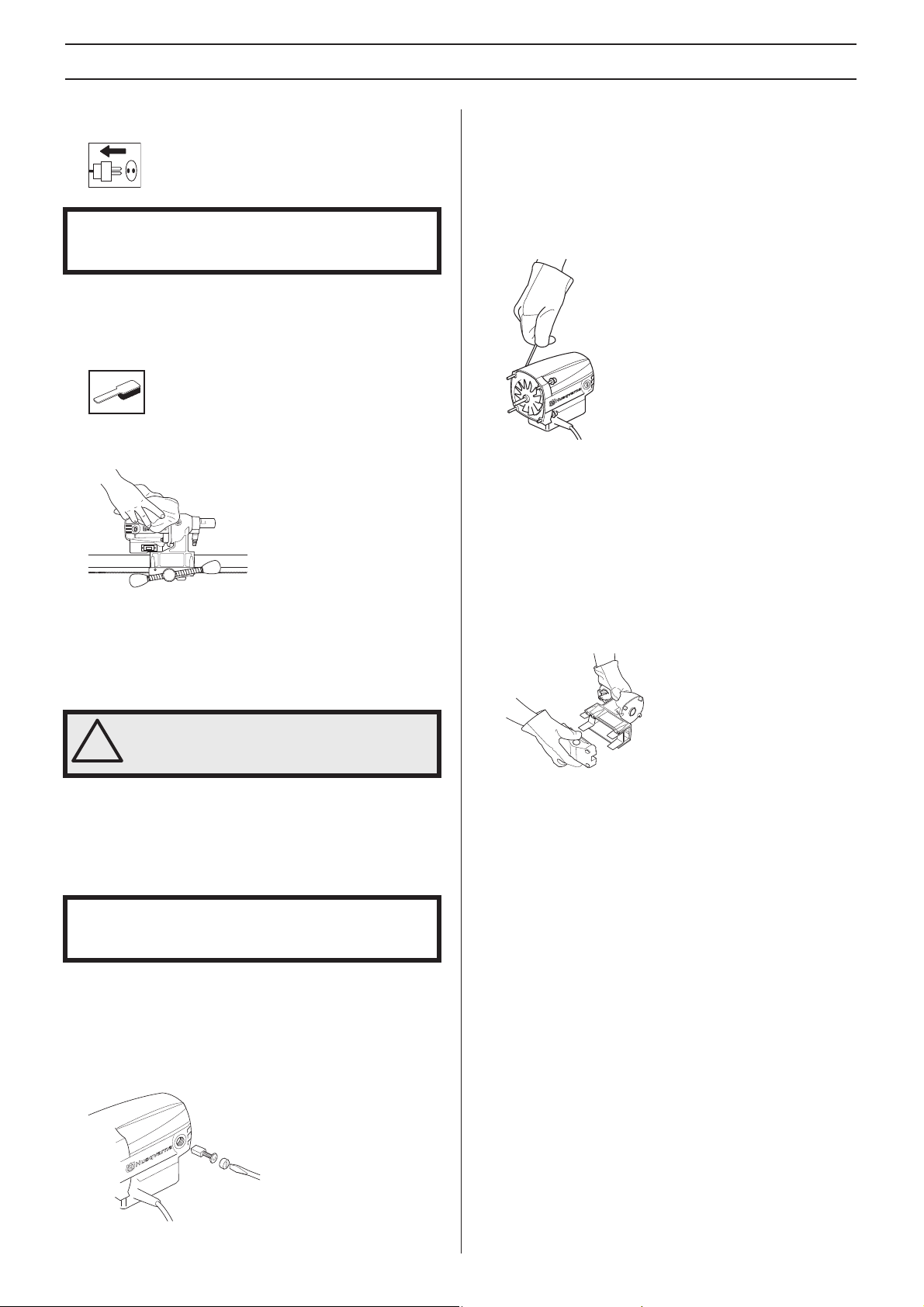

Slip clutch (SMC)

The machine is equipped with a mechanical slip clutch

(SMC).

Tension the slip clutch as follows:

• Loosen the cover for the slip clutch.

2

1

• Carefully lock the hook nut using a flat wide screwdriver in

one of the hook n

• Turn the drill spindle with a 27 mm open-ended spanner

rees.

15 deg

Remove the screwdriver and refit the co ver on the slip clutch.

ut’s four notches.

3

14 – English

Page 15

MAINTENANCE

Maintenance of the drill motor

IMPORTANT! Inspection and/or maintenance should be

carried out with the motor switched off and the plug

disconnected.

The lifetime of your machine can be e xtended considerab ly if

it is used, cared for and maintained in the proper manner.

Cleaning

• Keep the machine and drill bit clean in order for drilling to

be carried out safely.

4 Unscrew the four screws holding together the motor and

x.

gearbo

5 Loosen the ground cable from the gearbox cover (only

applies to 230V).

6 Carefully disassemble the machine.

7 Replace the module that needs to be replaced. Use

Castrol MS3 Molybden

8 Assemble the motor with the gearbox.

9 Replace the screws.

10 Screw on the brush cover.

um grease in the gearbox.

Changing the rear section

• In order for the machine to always be cooled sufficiently

the cooling air openings m

Blow down the machine regularly with compressed air.

ust be kept clear and clean.

Electrical Feed

WARNING! Never use damaged cables that

can cause serious, even fatal, personal

!

injuries.

Check that the cord and extension cord are intact and in good

condition. Never use the machine if the cord is damaged,

hand it in to an authorized service workshop for repair.

Repairs

IMPORT ANT! All types of repairs ma y only be carried out by

authorised repairmen. This is so that the operators are not

exposed to great risks.

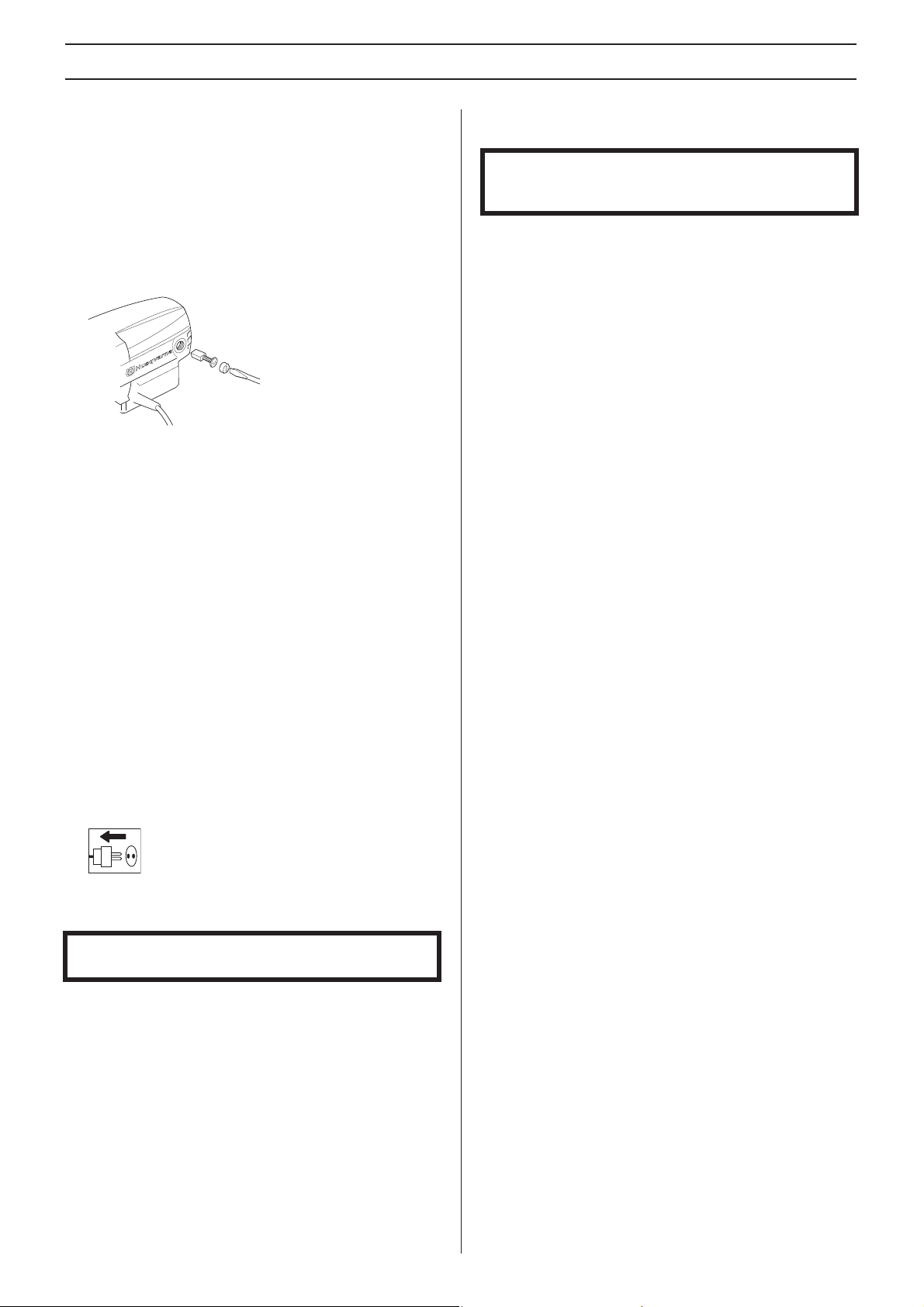

Replacing the motor and the gearbox

1 Secure the machine with drill spindle downwards in a vice

or the like.

2 Remove the cov er for the carbon brushes using a flat wide

wdriver.

scre

1 Loosen the four screws and the locking knob on the rear

of the drill.

2 Replace the two slide plates when the rear section is to be

replaced.

3 Bolt together the rear section using the four screws. Screw

in the loc

king knob.

3 Carefully remove the carbon brushes.

English – 15

Page 16

MAINTENANCE

Replacing the carbon brushes

The carbon brushes must be removed and check ed regularly .

Weekly if the machine is used daily or at longer intervals if the

machine is used more seldom. The area of wear should be

even and undamaged.

Both carbon brushes must always be replaced as a pair, but

one at a time

1 Remove the cov er for the carbon brushes using a flat wide

scre

2 Carefully remove the carbon brushes. The carbon

ushes must be replaced if there is less than 6 mm

br

remaining on the brushes.

3 Fit new carbon brushes.

4 Screw on the brush cover.

5 Let the machine idle for 10 minutes to run in the new

carbon br

. Do as follows:

wdriver.

ushes.

Repairs

IMPORT ANT! All types of repairs ma y only be carried out by

authorised repairmen. This is so that the operators are not

exposed to great risks.

Daily maintenance

1 Check that nuts and screws are tight.

2 Clean the outside of the machine.

Daily maintenance

1 Check that nuts and screws are tight.

2 Check that the power switch unit works smoothly.

3 Clean the outside of the machine.

4 Check and clean the cooling air openings.

5 Check that the cord and extension cord are intact and in

good condition.

Stand maintenance

Cleaning and lubrication

IMPORTANT! Remove the drill motor. For maintenance of

the drill motor see maintenance of the drill motor.

• It is important that the drill stand is kept clean for

functionality to be maintained.

• Clean the stand using a high pressure washer and then

y.

wipe dr

• Lubricate the moving parts on the stand. Apply standard

rease to counteract corrosion on the contact surfaces.

g

16 – English

Page 17

TECHNICAL DATA

Drill motor DMS 160

Electric motor Single-phase

Rated voltage, V 230/100-120

Rated output, W 1560

Rated current, A

230 V 6A

100-120 V 13A

Weight, kg 5,9

Diameter drill bit, mm

Max. diameter of the drill bit, with stand 120 mm (4.7”)

Spindle thread Int. 1/2” R

Water connector G 1/4”

Spindle speed, idle, rpm

Green 1 1100

Green 2 980

Green 3 840

Spindle speed, rpm

Yellow 700

Red 640

Noise emissions (see note 1)

Sound power level, measured dB(A) 102

Sound power level, guaranteed L

Sound levels (see note 2)

Sound pressure level at the operators ear, dB(A) 89

Vibration levels (see note 3)

Handle, m/s

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EN 12348.

Note 2: Noise pressure level according to EN 12348. Reported data for noise pressure level has a typical statistical dispersion

(standard de

Note 3: Vibration level according to EN 12348. Reported data for vibration level has a typical statistical dispersion (standard

viation) of 1 m/s2.

de

2

viation) of 1.0 dB(A).

dB(A) 103

WA

<2,5

English – 17

Page 18

TECHNICAL DATA

Stand DMS 160

Height, mm

DMS 160 A height, mm 840

DMS 160 AT height, mm 900

DMS 160 Gyro height, mm 1900-3100

Stroke, mm 600

Max. drill bit diameter (mm) 120

Weight, kg

DMS 160 A 10,5

DMS 160 AT 12

DMS 160 Gyro 31,4

Tool kit DMS 160 AT 0,3

Tool kit DMS 160 Gyro 0,8

Weight, kg (extra accessory)

Vacuum plate 2,5

Water collector 0,7

Extension module l 2,9

Extension module U 2,9

Expansion attachment 0,8

EC-declaration of conformity

(Applies to Europe only)

Husqvarna AB, SE-433 81 Göteborg, Sweden, tel: +46-31-949000, declares under sole responsibility that drilling machine and

stand Husqvarna DMS 160 drill motor, DMS 160 A/AT/Gyro from 2010’s serial number and onward (the year is stated in plain

text on the type plate plus a subsequent serial number) conform with the regulations in the COUNCIL’S DIRECTIVE:

• of May 17, 2006 "relating to machinery"

• of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

• of December 12, 2006 ”relating to electrical equipment”

The following standards have been applied: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-2:2006,

EN 61000-3-3/A1/A2:2005, EN 12348/A1:2009.

Göteborg December 29, 2009

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

2006/42/EC

2006/95/EC.

18 – English

Page 19

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina:

¡ATENCIÓN! La máquina, si se utiliza de

forma errónea o descuidada, puede ser una

herramienta peligrosa que puede causar

daños graves e incluso la muerte al usuario

y a otras personas.

Lea detenidamente el manual de

instr

ucciones y asegúrese de entender su

contenido antes de utilizar la máquina.

Utilice siempre:

• Casco protector homologado

• Protectores auriculares homologados

• Gafas protectoras o visor

• Máscara respiratoria

Este producto cumple con la directiva CE

.

vigente

Etiquetado ecológico. El símbolo en el

producto o en su envase indica que no se

puede tratar este producto como desperdicio

doméstico. Deberá por lo tanto depositarse

en un centro de recogida adecuado para el

reciclado de equipos eléctricos y

electrónicos.

Haciendo que este producto sea manipulado

adecuadamente

potenciales para el medio ambiente y las personas, lo que

puede ocurrir con la manipulación inadecuada como residuos

del producto.

Para obtener inf ormación más detallada sobre el reciclado de

este producto

servicio de eliminación de desperdicios domésticos o con la

tienda donde compró el producto.

Al perforar en techo, comprobar que no

puede entr

un colector de agua adecuado y cubrir la

máquina con un plástico, pero sin tapar las

bocas de entrada y salida de aire.

La taladradora debe ser adecuada y estar

adaptada par

diámetro máximo de broca está indicado en la

máquina.

, se ayuda a evitar consecuencias negativ as

, contacte con la oficina municipal local, con el

ar agua en la máquina. Utilizar

a el tamaño de la broca. El

Comprobar que la horquilla agarra en la orejeta

ior. Apretar con una llave adecuada.

inter

Fijar la tuerca con una llave de 30 mm.

Controlar la tuerca de segur

L. Comprobar que está apretada.

¡ATENCIÓN! Al taladrar se genera polvo

que puede causar daños por inhalación.

Utilizar una máscara respiratoria

homologada. Procurar que haya buena

ventilación.

Los demás símbolos/etiquetas que

aparecen en la máquina corresponden a requisitos de

homologación específicos en determinados mercados.

idad del mango en

Símbolos en el manual de instrucciones:

El control y/o mantenimiento de la

máquina debe hacerse con el motor

parado y el enchufe desenchufado.

Utilice siempre guantes protectores

homologados

La máquina debe limpiarse

regularmente.

Control visual.

Debe utilizarse gafas protectoras o

visor.

.

Utilizar una broca adecuada para el trabajo a

realizar

.

Indicación de carga/corriente

(sistema de control de carga LCS).

Comprobar que el techo es adecuado. El

techo debe ser maciz

o.

Ø

Spanish – 19

Page 20

ÍNDICE

Índice

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina: ............................................. 19

Símbolos en el manual de instrucciones: .................... 19

ÍNDICE

Índice ........................................................................... 20

¿QUÉ ES QUÉ?

Componentes de la taladradora ................................... 21

¿QUÉ ES QUÉ?

Componentes del soporte ............................................ 22

INSTRUCCIONES DE SEGURIDAD

Medidas a tomar antes de utilizar una taladradora

nueva ........................................................................... 23

Equipo de protección personal .................................... 23

Equipo de seguridad de la máquina ............................ 24

Control, mantenimiento y servicio del equipo de

segur

idad de la máquina ............................................. 24

Instrucciones generales de seguridad ......................... 24

PRESENTACIÓN

Motor de taladradora y soporte .................................... 25

Motor de taladradora DMS160 ..................................... 25

Soporte DMS160 ........................................................ 25

MONTAJE

Montaje del soporte - DMS160 A/AT ........................... 26

Montaje del soporte - DMS160 Gyro ........................... 26

ARRANQUE Y P ARADA

Antes de arrancar ........................................................ 29

Arranque ...................................................................... 29

Parada ......................................................................... 29

TÉCNICA DE TRABAJO

Instrucciones generales de trabajo .............................. 30

Empleo de la máquina ................................................. 31

MANTENIMIENTO

Mantenimiento del motor de taladradora ..................... 32

Mantenimiento del soporte .......................................... 33

DA TOS TECNICOS

Motor de taladradora DMS160 ..................................... 34

Soporte DMS160 ........................................................ 35

Declaración CE de conformidad .................................. 35

20 – Spanish

Page 21

¿QUÉ ES QUÉ?

Componentes de la taladradora

1 Husillo de taladradora

2 Conexión de agua

3 Tornillos que fijan el motor en la caja de cambios.

4 Interruptor

5 Tapa del acoplamiento deslizante (SMC)

6 Tapa de escobillas

7 Indicación de carga/corriente (sistema de control de

carga LCS).

8 Manija de fijación

9 T ornillos (4 unidades) para pieza trasera de alimentador y

caja de cambios

10 Empuñadura de alimentador

11 Pieza trasera de alimentador

12 Ruptor de falla de tierra PRCD

13 Llaves

14 Manual de instrucciones

Spanish – 21

Page 22

¿QUÉ ES QUÉ?

Componentes del soporte

1 Puntal telescópico 40

2 Columna de perforación

3 Motor de taladradora DMS160

4 Riel de pared

5 Puntal / mecanismo de bloqueo

6 Placa de techo

7 Placa base (GB 40 T) con ruedas de transporte

8 Placa base inclinada expansible

9 Tornillo de puntal y tornillo de fijación

10 Contratuerca

11 Mango en L

12 Manual de instrucciones

13 Módulo prolongador U (Disponible como accesorio.)

14 Módulo prolongador I (Disponible como accesorio.)

15 Fijación de expansión (Disponible como accesorio.)

16 Colector de agua (Disponible como accesorio.)

17 Placa de vacío (Disponible como accesorio.)

18 Juego de herramientas DMS160 AT

19 Juego de herramientas DMS160 Gyro

22 – Spanish

Page 23

INSTRUCCIONES DE SEGURIDAD

Medidas a tomar antes de utilizar una taladradora nueva

• Leer detenidamente el manual antes de empezar a

utilizar la máquina.

• Esta máquina está diseñada para y destinada a la

oración de hormigón, ladrillo y diferentes materiales

perf

pedregosos. Cualquier otra aplicación es errónea.

• La máquina está destinada al uso por operadores

xperimentados, en aplicaciones industriales.

e

• Controlar el montaje de la broca; v er el capítulo relativo al

cambio de broca.

• Compruebe que el cable y el cable de empalme está

.

intacto

• Mantener bien ordenado el lugar de trabajo. El desorden

compor

Emplee siempre el sentido común.

Es imposible abarcar todas las situaciones imaginables que

se pueden producir al utilizar una taladradora. Proceder

siempre con cuidado y emplear el sentido común. El usuario

debe evitar usar la máquina en aplicaciones para las que no

se considere suficientemente calificado. Si después de leer

estas instrucciones todavía hay inseguridad en cuanto al

procedimiento de uso, consultar con un experto antes de

proseguir. No dudar en ponerse en contacto con el

distribuidor o con el fabricante si hay alguna duda en cuanto

al empleo de la taladradora. Estamos a su disposición para

dar consejos que ayuden a emplear la taladradora de forma

mejor y más segura.

Encarcar al distribuidor de Husqvarna la revisión regular de

la taladr

necesarios.

Toda la información y todos los datos contenidos en este

man

impresión del manual.

ta riesgo de accidentes.

adora y la realización de los ajustes y reparaciones

ual de instrucciones son vigentes en la fecha de

Equipo de protección personal

¡ATENCIÓN! Para trabajar con la máquina

debe utilizarse un equipo de protección

!

personal homologado. El equipo de

protección personal no elimina el riesgo de

lesiones, pero reduce su efecto en caso de

accidente. Pida a su distribuidor que le

asesore en la elección del equipo.

• Casco protector

• Protectores auriculares

• Gafas protectoras o visor

• Máscara respiratoria

• Guantes resistentes de agarre seguro.

• Prendas de vestir ceñidas, resistentes y cómodas que

mitan una libertad de movimientos total.

per

¡ATENCIÓN! Bajo ninguna circunstancia

debe modificarse la configuración original

!

de la máquina sin autorización del

fabricante. Utilizar siempre recambios

originales. Las modificaciones y/o la

utilización de accesorios no autorizadas

pueden ocasionar accidentes graves o

incluso la muerte del operador o de terceros.

¡ATENCIÓN! El uso de productos que cortan,

pulen, taladran, alisan o forman materiales

!

puede generar polvo y vapores que pueden

contener sustancias químicas dañinas.

Averiguar la composición del material con

que se trabaja y usar una máscara

respiratoria adecuada.

• Botas con puntera de acero y suela antideslizante.

• Tenga siempre a mano el equipo de primeros auxilios.

Spanish – 23

Page 24

INSTRUCCIONES DE SEGURIDAD

Equipo de seguridad de la máquina

En este capítulo se describen los componentes de seguridad

de la máquina, su función y el modo de efectuar el control y

el mantenimiento para garantizar un funcionamiento óptimo.

En cuanto a la ubicación de estos componentes en su

máquina, vea el capítulo Qué es qué.

¡ATENCIÓN! Nunca utilice una máquina con

componentes de seguridad defectuosos. El

!

equipo de seguridad se debe controlar y

mantener. Ver las instrucciones del capítulo

Control, mantenimiento y servicio del

equipo de seguridad de la máquina. Si el

control de la máquina no da resultado

satisfactorio, hay que acudir a un taller de

servicio para la reparación.

Control, mantenimiento y servicio del equipo de seguridad de la máquina

¡ATENCIÓN! Existe siempre riesgo de

accidentes por apriete al trabajar con

!

aparatos con piezas móviles. Usar guantes

protectores para evitar lesiones.

• Nunca utilice la máquina si está cansado, si ha ingerido

alcohol o si toma medicamentos que puedan af

vista, su capacidad de discernimiento o el control del

cuerpo.

• Utilice el equipo de protección personal. Vea las

ucciones bajo el título Equipo de protección personal.

instr

• No lleve nunca la máquina agarr ando el cable y no tire del

le para desenchufarla. Mantenga todos los cables y

cab

cables de empalme apartados de agua, aceite y cantos

agudos. Proceda con cuidado para evitar que el cable se

apriete en puertas, vallas o similares. Hay riesgo de

cargar objetos con electricidad.

• Compruebe que el cable y el cable de empalme está

. Utilizar un cable de alargue para uso a la

intacto

intemperie. Si se daña el cable, no utilice la máquina.

Llévela a un taller de servicio oficial para reparar.

• Un cable de alargue no debe usarse enrollado porque hay

iesgo de sobrecalentamiento.

r

ectarle la

¡IMPORTANTE! T odos los trabajos de servicio y reparación

de la máquina requieren una formación especial. Esto es

especialmente importante para el equipo de seguridad de

la máquina. Si la máquina no pasa alguno de los controles

indicados a continuación, acuda a su taller de servicio

local. La compra de alguno de nuestros productos le

garantiza que puede recibir un mantenimiento y servicio

profesional. Si no ha adquirido la máquina en una de

nuestras tiendas especializadas con servicio, solicite

información sobre el taller de servicio más cercano.

Interruptor

El interruptor se usa para arrancar y parar la máquina.

Control del interruptor

• Arrancar la máquina pulsando el interruptor.

• Parar la máquina pulsando el interruptor.

• Un interruptor defectuoso debe ser cambiado por un taller

vicio oficial.

de ser

Instrucciones generales de seguridad

• No utilizar la taladradora sin antes haber leído y

comprendido el contenido de este manual de

instrucciones.

¡ATENCIÓN! Existe siempre riesgo de

sacudidas eléctricas al usar máquinas

!

eléctricas. No usar la máquina en

condiciones climáticas desfavorables y

evitar el contacto del cuerpo con pararrayos

y objetos metálicos. Seguir siempre las

instrucciones del manual para evitar daños.

• La máquina se debe enchufar a un enchufe con masa.

• Compruebe que la tensión de red concuerda con la que

se indica en la placa de car

• No utilice nunca una máquina defectuosa. Siga las

ucciones de mantenimiento, control y servicio de este

instr

manual. Algunas medidas de mantenimiento y servicio

deben ser efectuadas por especialistas formados y

cualificados. Vea las instrucciones bajo el título

Mantenimiento.

• Nunca deje que terceros utilicen la máquina sin

arse primero de que hayan entendido el contenido

asegur

de este manual de instrucciones.

• Las personas y los animales pueden distraer y hacer

perder el control de la máquina.

operador debe estar siempre concentrado en su trabajo.

• Tener en cuenta que las ropas, el pelo largo y las joyas

pueden atascarse en piezas móviles

acterísticas de la máquina.

Por consiguiente, el

.

Transporte y almacenamiento

Para proteger la taladradora y las brocas contra daños, no

almacenar ni transportar la taladradora con la broca

montada.

Guardar la taladradora en un espacio cerrado con llav e para

que sea inaccesib

Guardar la taladradora y el soporte en un lugar seco y con

temperatura sobre cero.

le a niños y personas no autorizadas.

24 – Spanish

Page 25

PRESENTACIÓN

Motor de taladradora y soporte

Esperamos que su máquina le proporcione plena satisfacción

y le sirva de ayuda por mucho tiempo en adelante. Tenga en

cuenta que este manual de instrucciones es un documento

de valor. Siguiendo sus instrucciones (de uso, servicio,

mantenimiento, etcétera) puede alargar considerablemente

la vida útil de la máquina e incrementar su valor de reventa.

Si vende su máquina, entregue el manual de instrucciones al

nuevo propietario.

La adquisición de alguno de nuestros productos da acceso a

asistencia prof

necesario. Si la máquina no fue adquirida en un distribuidor

oficial, preguntar en la tienda de compra la dirección del taller

de servicio más cercano.

Husqvarna Construction Products se esfuerza

constantemente por mejor

productos. Por consiguiente, Husqvarna se reserva el

derecho a introducir modificaciones de diseño sin previo

aviso y sin compromisos ulteriores.

esional con reparaciones y servicio en caso

ar la construcción de sus

Motor de taladradora DMS160

• La DSM160 es una taladradora eléctrica destinada a

perforar agujeros en hormigón, ladrillo y diferentes

materiales pedregosos.

• La taladradora es de diseño modular y fácil de montar.

• La máquina tiene una gama de velocidades para brocas

de diámetro (ø) de 120 mm / 4,75 pulgadas

• El diseño del acoplamiento mecánico deslizante (SMC Slide Mechanical Clutch) proporciona la toma de potencia

más alta y se puede ajustar desde el e

• La máquina está diseñada para perforación con soporte.

• La máquina es refrigerada por agua.

• La máquina tiene doble aislamiento e indicador de

iente.

corr

• La máquina funciona mejor si no se sobrecarga. Dejar

como máximo encendido el diodo luminiscente amar

del indicador de carga/corriente (LCS-Load Control

System). Como máximo 10 minutos en carga máxima.

Luego, la máquina debe hacerse funcionar sin carga

durante unos 2 minutos.

.

xterior.

illo

Soporte DMS160

DMS160 A DMS160 AT DMS160 Gyro

DMS160 A/AT

El soporte se fija con tornillo de expansión.

• Hay disponibles como accesorios un colector de agua y

una placa de v

DMS160 AT

• DMS160 AT es un sistema modular que permite la

perforación inclinada y tiene función de giro.

DMS160 Gyro

• DMS160 Gyro es un sistema modular con columna

telescópica para fijar el motor de taladradora.

• El puntal telescópico tiene una longitud máxima de 3,1 m

y se puede prolongar en 0,75 m con un módulo

prolongador

• Sólo se puede usar un módulo prolongador.

• Para cambiar los ajustes basta con una llave fija (24/30

mm) y una lla

La columna de perforación es girable progresivamente en

°.

360

• Las ruedas de transporte son desmontables.

acío para fijar la columna por aspiración.

.

ve Allen (8 mm).

Spanish – 25

Page 26

MONTAJE

Montaje del soporte - DMS160 A/AT

DMS 160 ATDMS 160A

DMS160 A/AT

• Perforar un agujero (15 mm) en la pared e insertar

golpeando los tornillos de expansión.

20 Fijar la placa base. Comprobar cuidadosamente que el

xpansor está bien fijado.

e

Montaje del soporte - DMS160 Gyro

DMS 160 Gyro

2

1

3

4

DMS160 AT

• La columna de perforación se monta en el soporte

angular de la placa base. Apretar el tornillo de fijación con

una llave Allen de 8 mm. La columna de perforación se

puede girar 360° progresivamente y se fija en cada

posición con el tornillo de fijación (Allen de 8 mm).

• La columna de perforación se coloca en la inclinación

deseada apretando la tuerca con una lla

se utiliza la placa de vacío, comprobar que la base no sea

porosa y pueda soltarse del suelo o la pared. Comprobar

que la bomba de vacío tiene capacidad para fijar por

aspiración la placa de vacío. Motor de vacío adecuado,

Husqvarna VP200.

ve de 24 mm. Si

7

5

6

8

9

!

26 – Spanish

¡ATENCIÓN! La placa de vacío no se debe

utilizar nunca para perforar techos. Su uso

descuidado o erróneo puede provocar

heridas graves o mortales al usuario o

terceros.

10

11

Page 27

MONTAJE

Perforación en paredes

6

1 Placa base con tornillo de fijación.

2 Tornillo de puntal y tornillo de fijación

3 Manija de fijación

4 Mango en L

5 Columna de perforación

6 Tornillo de puntal y tornillo de fijación

7 Contratuerca

8 Motor de taladradora DMS160

• Colocar la placa base con la longitud de la columna de

oración desde la pared y el tornillo del puntal

perf

enroscado. Para perforar a más de 1,5 metros de altura,

el tubo exterior grueso debe estar orientado hacia arriba;

y al revés para perfor ar a menos de 1,5 metros de altura.

Comprobar que el puntal está fijado en la placa base con

el tornillo de fijación.

• Fijar el puntal telescópico contra el techo. Usando el

agujero más cercano del tubo inter

la manija de puntal y apretarla con una llave de 24 mm.

Sin apretar demasiado.

• Soltar la manija de fijación y girar la columna de

oración. Bajar la columna de perforación con el

perf

mango en L.

• Montar el motor de taladradora DMS160 en la columna de

oración.

perf

• Girar hacia atrás la columna de perforación con el motor

de taladr

Apretar la manija de fijación.

• Inclinar la columna de perforación hacia atrás y subirla,

fijándola con el mango en L y la tuerca.

perforación inclinada, aflojar el mango en L e inclinar la

columna de perforación en al ángulo deseado , apretando

la tuerca con una llave de 30 mm.

• Controlar la posición de la broca. Enroscar el tornillo de

puntal contr

perforación. Fijar con una tuerca de seguridad, 30 mm.

Utilizando una regla de madera como separador. La

columna de perforación se puede girar 360°

progresivamente y se fija en cada posición con el tornillo

de fijación (Allen de 8 mm).

• Para mayor seguridad de la columna de perforación se

puede usar una fijación de e

ajusta contra el tornillo de puntal y se fija en la pared con

un tornillo de expansión. Fijar con una tuerca de

seguridad de 30 mm.

5

7

4

2

3

6

1

5

7

4

2

3

ior perforado . Fijar con

adora hasta la posición deseada contra la pared.

Para la

a la pared para fijar la columna de

xpansión. La fijación se

Perforación en suelos

1 Tornillo de seguridad

2 Tornillo de puntal y tornillo de fijación

3 Manija de fijación

4 Mango en L

5 Tornillo de seguridad

• Bajar la columna de perforación con el mango en L.

• Comprobar que el tornillo del puntal entra en el casquillo

de fijación.

• Apretar la tuerca de seguridad con una llave de 30 mm y

la manija de fijación.

• Colocar el soporte en la posición deseada.

6 Fijar el tornillo del puntal en el casquillo de fijación con el

nillo de fijación y la tuerca. Apretar con lla ves de 24 mm

tor

y 30 mm.

• Fijar el puntal telescópico contra el techo con el

mecanismo de puntal.

Apretar la última parte con una

llave de 24 mm, sin apretar demasiado. El puntal

telescópico tiene una longitud máxima de 3,1 m y se

puede prolongar en 0,75 m con un módulo prolongador.

Perforación en techos

1 Tornillo de puntal y tornillo de fijación

2 Contratuerca

3 Tornillo de puntal y tornillo de fijación

Spanish – 27

Page 28

MONTAJE

• Colocar el soporte en la posición deseada.

• Comprobar que el tornillo de puntal en la columna de

oración está enroscado. Levantar la columna de

perf

perforación y bloquearla en posición vertical con la tuerca

de seguridad.

• Comprobar que la broca está en posición correcta. Fijar

el puntal telescópico contr

puntal.

• Enroscar el tornillo de puntal contra el techo para fijar la

columna de perf

seguridad, 30 mm. Utilizando una regla de madera como

separador.

• Para mayor seguridad de la columna de perforación se

puede usar una fijación de e

accesorio.) La fijación se ajusta contra el tornillo de puntal

y se fija en la pared con un tornillo de expansión. Fijar con

una tuerca de seguridad de 30 mm.

¡ATENCIÓN! La placa de vacío no se debe

utilizar nunca para perforar techos. Su uso

!

descuidado o erróneo puede provocar

heridas graves o mortales al usuario o

terceros.

oración. Fijar con una tuerca de

a el techo con el mecanismo de

xpansión. (Disponible como

28 – Spanish

Page 29

ARRANQUE Y PARADA

Antes de arrancar

¡ATENCIÓN! Antes de arrancar, observe lo

siguiente:

!

La máquina se debe enchufar a un enchufe

con masa.

Compruebe que la tensión de red concuerda

con la que se indica en la placa de

características de la máquina. Asegúrese de

que no haya terceros desautorizados en la

zona de trabajo.

¡ATENCIÓN! Antes iniciar la perforación,

comprobar que todos los tornillos de

!

fijación están bien apretados.

Hay riesgo de accidentes graves si el núcleo

de perforación de hormigón permanece en

la broca al sacar el motor de taladradora / la

broca del suelo, la pared o el techo.

Comprobar que:

• El interruptor esté intacto. Si no está intacto, debe

cambiarlo un técnico autorizado.

Perforación en techos

¡ATENCIÓN! La placa de vacío no se debe

utilizar nunca para perforar techos.

!

Utilizar un colector de agua para impedir que

entre agua en la máquina. La máquina debe

cubrirse con un plástico o similar para

impedir que entre agua en ella, pero no

deben taparse las bocas de entrada y salida

de aire.

¡ATENCIÓN! Sólo se puede usar un módulo

prolongador.

!

Comprobar que en el piso inferior no hay

personas que puedan ser dañadas por la

caída de núcleos de perforación de

hormigón.

Arranque

• La máquina y sus equipos están correctamente

montados:

- La broca está bien fijada.

- El soporte está bien montado.

- La máquina está fijada en el soporte de forma adecuada.

• Utilice el equipo de protección personal. Vea las

ucciones bajo el título Equipo de protección personal.

instr

• La refrigeración por agua está conectada en la máquina.

• Activar la refrigeración por agua.

• Presionar completamente el interruptor.

• Empezar bajando la broca con la empuñadura de

alimentador

.

Parada

¡ATENCIÓN! La broca continúa girando unos

instantes después de parar el motor. No

!

detener la broca con las manos. De hacerlo,

hay riesgo de daños personales.

Parar la máquina pulsando el interruptor.

Refrigeración

Hacer funcionar la máquina sin carga durante unos minutos

para enfriar el motor.

Spanish – 29

Page 30

TÉCNICA DE TRABAJO

Instrucciones generales de trabajo

¡ATENCIÓN! Este capítulo trata las reglas de

seguridad básicas para trabajar con la

!

taladradora. La información no puede

sustituir nunca a los conocimientos,

formación y experiencia práctica de un

profesional. Si en alguna situación hay

inseguridad en cuanto a seguir empleando

la máquina, consultar con un experto.

Consultar al distribuidor , al taller de servicio

o a un usuario de taladradoras

experimentado. No se debe emplear la

máquina en aplicaciones para las que el

usuario no se considera plenamente

cualificado.

¡ATENCIÓN! La sobreexposición a las

vibraciones puede provocar problemas

!

circulatorios y dolencias de carácter

nervioso, especialmente en personas con

patologías circulatorias. Acuda a un médico

si nota síntomas corporales que puedan

relacionarse con la sobreexposición a las

vibraciones. Son ejemplos de tales síntomas

la pérdida de sensibilidad, el 'cosquilleo', las

'punzadas', el dolor, la pérdida o reducción

de la fuerza normal o los cambios en el color

y la superficie de la piel. Estos síntomas se

presentan normalmente en dedos, manos y

muñecas. Los síntomas pueden aumentar

en temperaturas frías.

• Mantener las herramientas afiladas y limpias para que el

abajo sea más seguro.

tr

• Controlar siempre la parte posterior de la superficie en la

que sale la broca al penetr

la zona de trabajo y procurar que no hay a riesgo de daños

personales o materiales.

• Parar siempre la máquina antes de trasladarla.

• Un operador nunca debe trabajar solo; siempre debe

haber otr

ayuda para montar la máquina, también puede recibirse

asistencia en caso de accidente.

• Mantener todas las piezas en perfecto estado y

comprobar que todos los elementos de fijación estén bien

apretados.

a(s) persona(s) cerca. Así, además de tener

ar. Impedir el acceso cercando

• No usar en condiciones climáticas desfavorables. Por

ejemplo, niebla densa, lluvia, viento fuerte, frío intenso,

etc. Trabajar con mal tiempo es cansador y puede crear

condiciones peligrosas, por ejemplo suelo resbaladizo.

• Antes de comenzar a trabajar con la máquina, controle

siempre que el lugar esté libre y que los pies estén bien

mados al terreno. Controle posibles obstáculos en

afir

caso de movimientos repentinos. Asegúrese de que no

haya elementos que puedan caer y provocar daños al

trabajar con la máquina.

• Mantenerse apartado de la broca cuando el motor está en

marcha.

• Controle que la zona de trabajo esté bien iluminada para

rar un entorno seguro.

log

• Comprobar que en la zona que se va a perforar no haya

tuberías ni cab

• Al emplear la máquina, hágalo con el cable detrás suyo

a evitar dañarlo.

par

• No abandonar nunca la máquina sin vigilar, con el motor

en marcha.

accidentes graves.

• Desenchufar siempre el contacto para paradas

prolongadas del tr

• No sobrecargar la máquina. La sobrecarga puede dañar

la máquina.

les eléctricos instalados.

Las brocas rotativas comportan riesgo de

abajo.

30 – Spanish

Page 31

TÉCNICA DE TRABAJO

Empleo de la máquina

• Mantener las manos apartadas del husillo de taladro y la

broca cuando funciona la máquina.

• Prestar atención a las fugas de aceite o de agua.

Perforación a la intemperie

Usar siempre cables de empalme homologados para uso en

intemperie.

Cambio de broca

1 Desenchufar la máquina.

2 Preparar:

- La broca nueva.

- Las llaves fijas incluidas en la entrega, de 24 mm y 32 mm.

- Grasa hidrófuga.

3 Desmontar la broca vieja con las llaves fijas.

4 Aplicar grasa hidrófuga en la rosca de la broca nueva.

5 Montar la broca con las llaves fijas.

Sacar el destornillador y colocar la tapa del acoplamiento

deslizante

.

Indicación de carga/corriente (sistema de control de carga LCS).

La máquina funciona mejor si no se sobrecarga. Dejar como

máximo encendido el diodo luminiscente amarillo del

indicador de carga/corriente (LCS-Load Control System).

Como máximo 10 minutos en carga máxima. Luego, la

máquina debe hacerse funcionar sin carga durante unos 2

minutos.

Acoplamiento deslizante (SMC)

La máquina está equipada con un acoplamiento mecánico

deslizante (SMC).

Tensar el acoplamiento deslizante, de este modo:

• Soltar la tapa del acoplamiento deslizante.

2

1

• Fijar la tuerca de gancho con cuidado con un

nillador plano ancho en una de las cuatro ranuras

destor

de la tuerca.

• Girar 15 grados el husillo de taladro con una llave fija de

27 mm.

3

Spanish – 31

Page 32

MANTENIMIENTO

Mantenimiento del motor de taladradora

¡IMPORTANTE! El control y/o mantenimiento de la

máquina debe hacerse con el motor parado y el enchufe

desenchufado.

La vida útil de la máquina se alarga considerablemente si se

utiliza, cuida y mantiene correctamente.

Limpieza

• Mantener limpia la máquina y la broca para que la

perforación se pueda hacer de forma segura.

Cambio del motor y la caja de cambios

1 Fijar la máquina en un tornillo de banco o similar, con el

husillo de taladro hacia abajo.

2 Soltar las tapas de las escobillas con un destornillador

plano ancho

3 Sacar las escobillas con cuidado.

4 Quitar los cuatro tornillos que fijan el motor en la caja de

cambios

5 Soltar el cable de tierra de la tapa de la caja de cambios

(aplicab

6 Desmontar la máquina con cuidado.

7 Cambiar el módulo que es necesario sustituir. Usar grasa

Castrol MS3 Molybden en la caja de cambios

.

.

le solamente a 230 V).

.

• Para que la máquina tenga siempre una buena

igeración, las aberturas de paso del aire refrigerante

refr

deben mantenerse libres y limpias. Limpie regularmente

la máquina con aire comprimido.

Suministro eléctrico

¡ATENCIÓN! No usar nunca cables dañados,

puesto que pueden causar daños

!

personales graves e incluso mortales.

Compruebe que el cable y el cable de empalme está intacto.

Si se daña el cable, no utilizar la máquina. Lle varla a un taller

de servicio oficial para reparar.

Reparaciones

¡IMPORTANTE! Las reparaciones de todo tipo deben ser

efectuadas por técnicos autorizados, únicamente. De este

modo se evita someter a los operadores a grandes riesgos.

8 Armar el motor con la caja de cambios.

9 Enroscar los tornillos.

10 Poner las tapas de escobillas.

Cambio de la pieza trasera

1 Aflojar los cuatro tornillos y la manija de fijación de la

parte trasera de la máquina.

2 Cambiar las dos placas deslizantes cuando se va a

cambiar la pieza tr

3 Atornillar la pieza trasera con los cuatro tornillos.

Enroscar la manija de fijación.

asera.

32 – Spanish

Page 33

MANTENIMIENTO

Cambio de escobillas de carbón

Las escobillas deben desmontarse y revisarse regularmente.

Cada semana si la máquina se utiliza a diario, o a intervalos

más largos si se utiliza con menor frecuencia. La superficie

de desgaste debe estar regular e intacta.

Ambas escobillas deben cambiarse siempre en la misma

tunidad, pero de una en una. Procedimiento de cambio:

opor

1 Soltar las tapas de las escobillas con un destornillador

plano ancho

2 Sacar las escobillas con cuidado. Si quedan menos de 6

mm en las escobillas

3 Montar las escobillas nuevas.

4 Poner las tapas de escobillas.

5 Dejar la máquina funcionando en ralentí durante 10

utos para hacer el rodaje de las escobillas nuevas.

min

.

, hay que cambiarlas.

Mantenimiento del soporte

Limpieza y lubricación

¡IMPORTANTE! Desmontar el motor de taladradora. En lo

referente al mantenimiento del motor de taladradora, v er el

capítulo pertinente.

• Para obtener un funcionamiento óptimo es muy

importante mantener el soporte limpio y en orden.

• Se recomienda limpiar el soporte con lavado a alta

presión y secar

• Aceitar todas las piezas móviles del soporte. Usar grasa

estándar par

contacto.

Reparaciones

¡IMPORTANTE! Las reparaciones de todo tipo deben ser

efectuadas por técnicos autorizados, únicamente. De este

modo se evita someter a los operadores a grandes riesgos.

lo.

a prevenir la corrosión de las superficies de

Mantenimiento diario

1 Compruebe que los tornillos y las tuercas estén

apretados.

2 Compruebe que la unidad de interruptor funciona de

orma segura.

f

3 Limpie la parte exterior de la máquina.

4 Revise y limpie las aberturas de aire refrigerante.

5 Compruebe que el cable y el cable de empalme está

.

intacto

Mantenimiento diario

1 Compruebe que los tornillos y las tuercas estén

apretados.

2 Limpie la parte exterior de la máquina.

Spanish – 33

Page 34

DATOS TECNICOS

Motor de taladradora DMS 160

Motor eléctrico Monofásico

Tensión nominal, V 230/100-120

Potencia nominal, W 1560

Amperaje nominal, A

230 V 6A

100-120 V 13A

Peso, kg 5,9

Diámetro de broca, mm

Diámetro máximo de broca, con soporte 120 mm (4,7')

Rosca de husillo Int. 1/2” R

Conexión de agua G 1/4'

Velocidad del husillo, ralentí, r.p.m.

Verde 1 1100

Verde 2 980

Verde 3 840

Velocidad del husillo, r.p.m.

Amarillo 700

Rojo 640

Emisiones de ruido (vea la nota 1)

Nivel de potencia acústica medido dB(A) 102

Nivel de potencia acústica garantizado L

Niveles acústicos (vea la nota 2)

Nivel de presión acústica en el oído del usuario, dB(A) 89

Niveles de vibraciones (vea la nota 3)

Empuñadura, m/s

Nota 1: Emisiones sonoras en el entorno medidas como potencia sonora (LWA) según la norma EN 12348.

Nota 2: Nivel de presión sonora conforme a EN 12348. Los datos referidos del nivel de presión sonora tienen una dispersión

estadística habitual (desviación típica) de 1,0 dB (A).

Nota 3: Nivel de vibración conforme a EN 12348. Los datos referidos del nivel de vibración poseen una dispersión estadística

habitual (desviación típica) de 1 m/s

2

dB(A) 103

WA

2

.

<2,5

34 – Spanish

Page 35

DATOS TECNICOS

Soporte DMS 160

Altura, mm

DMS 160 A altura, mm 840

DMS 160 AT altura, mm 900

DMS 160 Gyro altura, mm 1900-3100

Carrera, mm 600

Diámetro máximo de broca (mm) 120

Peso, kg

DMS 160 A 10,5

DMS 160 AT 12

DMS 160 Gyro 31,4

Juego de herramientas DMS 160 AT 0,3

Juego de herramientas DMS 160 Gyro 0,8

Peso, kg (accesorio extra)

Placa de vacío 2,5

Colector de agua 0,7

Módulo prolongador I 2,9

Módulo prolongador U 2,9

Fijación de expansión 0,8

Declaración CE de conformidad

(Rige sólo para Europa)

Husqvarna AB, SE-433 81 Göteborg, Suecia, teléfono: +46-31-949000, declara por la presente que los bastidores Husqvarna

DMS 160 motor de perforadora, DMS 160 A/AT/Gyro, a partir del número de serie del año 2010 en adelante (el año se indica

textualmente en la placa de identificación, seguido del número de serie), cumple con las siguientes disposiciones de la

DIRECTIVA DEL CONSEJO:

2006/42/CE «relativa a máquinas» del 17 de mayo de 2006.

•

• 2004/108/CEE, ”referente a compatibilidad electromagnética”, del 15 de diciembre de 2004.

2006/95/CE del 12 de diciembre de 2006 relativa a equipos eléctricos.

•

Se han aplicado las siguientes normas: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-2:2006, EN

61000-3-3/A1/A2:2005, EN 12348/A1:2009.

Göteborg, 29 de diciembre de 2009

Henric Andersson

Vicepresidente, jefe de la sección de cortadoras y maquinaria para la construcción

Husqvarna AB

(Presentante autorizado de Husqvarna AB y responsable de la documentación técnica.)

Spanish – 35

Page 36

SYMBOLERKLÄRUNG

Symbole am Gerät:

WARNUNG! Das Gerät kann falsch oder

nachlässig angewendet gefährlich sein und

zu schweren oder gar lebensgefährlichen

Verletzungen des Benutzers oder anderer

Personen führen.

Lesen Sie die Bedienungsanweisung

sorgfältig durch und machen Sie sich mit

dem Inhalt v

benutzen.

Benutzen Sie immer:

• Einen zugelassenen Schutzhelm

• Einen zugelassenen Gehörschutz

• Schutzbrille oder Visier

• Atemschutzmaske

Dieses Produkt stimmt mit den geltenden

CE-Richtlinien überein.

Umweltkennzeichnung Das Symbol auf

dem Produkt oder der Verpackung gibt an,

dass dieses Produkt nicht im Hausmüll

entsorgt werden darf. Zur Entsorgung ist es

stattdessen an eine entsprechende

Recyclinganlage für elektrische und

elektronische Geräte zu übergeben.

Durch eine korrekte Entsorgung dieses

Produkts tr

Auswirkungen auf Ihre Umwelt und Mitmenschen zu

verhindern. Durch eine unsachgemäße Entsorgung dieses

Produkts können Schäden entstehen.

Ausführliche Recyclinginformationen zu diesem Produkt

erhalten Sie v

für Hausmüll oder dem Geschäft, in dem Sie das Produkt

erworben haben.

ertraut, bevor Sie das Gerät

agen Sie dazu bei, mögliche negative

on Ihrer Kommune, Entsorgungsunternehmen

Sicherstellen, dass die Gabel um das Innenrohr

reift. Mit einem geeigneten Schraubenschlüssel

g

anziehen.

Die Mutter mit einem 30-mmSchr

aubenschlüssel anziehen. Die

Sicherungsmutter am L-Griff überprüfen. Die

Mutter muss angezogen sein.

WARNUNG! Beim Bohren bildet sich

Staub

, der beim Einatmen

Gesundheitsschäden hervorrufen kann.

Einen zugelassenen Atemschutz tragen.

Für gute Belüftung sorgen.

Sonstige Symbole/Aufkleber am Gerät

beziehen sich auf spezielle