GGGGBBBB EEEESSSS PPPPTTTT GGGGRR

RR

DM 220

GB

ES

PT

GR

Operator’s manual

Please read the operator’s manual carefully and make sure you

understand the instructions before using the machine.

Manual de

instrucciones

Lea detenidamente el manual de instrucciones y asegúrese de

entender su contenido antes de utilizar la máquina.

Instruções para o uso

Leia as instruções para o uso com toda a atenção e

compreenda o seu conteúdo antes de fazer uso da máquina.

√‰ËÁ›Â˜ ¯Ú‹Ûˆ˜

¢И·Я¿ЫЩВ ЪФЫВОЩИО¿ ЩИ˜ √‰ЛБ›В˜ ¯Ъ‹ЫВˆ˜ О·И О·Щ·УФ‹ЫЩВ ЩФ ВЪИВ¯fiМВУФ

ЪИУ ¯ЪЛЫИМФФИ‹ЫВЩВ ЩФ МЛ¯¿УЛМ·.

2 – English

KEY TO SYMBOLS

Symbols on the machine

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or fatal

injury to the operator or others.

Please read the operator’s manual carefully

and make sure you understand the

instructions before using the machine.

Wear personal protective equipment. See

instructions under the heading ”Personal

protective equipment”.

This product is in accordance with

applicable EC directives.

Environmental marking. Symbols on the

product or its packaging indicate that this

product cannot be handled as domestic

waste. It must instead be submitted to an

appropriate recycling station for the recovery

of electrical and electronic equipment.

By ensuring that this product is taken care of

correctly, you can help to counteract the

potential negative impact on the environment and people that

can otherwise result through the incorrect waste

management of this product.

For more detailed information about recycling this product,

contact your municipality, your domestic waste service or the

shop from where you purchased the product.

Ensure that water cannot leak into the

machine when drilling in the ceiling.

Use an appropriate water collector.

Other symbols/decals on the

machine refer to special

certification requirements for certain markets.

Explanation of warning levels

The warnings are graded in three levels.

WARNING!

CAUTION!

NOTICE!

!

WARNING! Used if there is a risk of serious

injury or death for the operator or damage to

the surroundings if the instructions in the

manual are not followed.

!

CAUTION! Used if there is a risk of injury to

the operator or damage to the surroundings

if the instructions in the manual are not

followed.

NOTICE! Used if there is a risk of damage to materials or

the machine if the instructions in the manual are not

followed.

English – 3

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine ............................................. 2

Explanation of warning levels ...................................... 2

CONTENTS

Contents ...................................................................... 3

PRESENTATION

Dear Customer, ............................................................ 4

Features ....................................................................... 4

WHAT IS WHAT?

What is what on the drilling machine? ......................... 5

MACHINE´S SAFETY EQUIPMENT

General ........................................................................ 6

ASSEMBLING AND ADJUSTMENTS

Assembly ..................................................................... 7

OPERATING

Protective equipment ................................................... 8

General safety precautions .......................................... 8

Work safety .................................................................. 9

Basic working techniques ............................................ 10

Transport and storage .................................................. 11

STARTING AND STOPPING

Before starting ............................................................. 12

Starting ........................................................................ 12

Stopping ....................................................................... 12

MAINTENANCE

General ........................................................................ 13

Daily maintenance ....................................................... 13

Cleaning ....................................................................... 13

Water tap ..................................................................... 13

Electrical Feed ............................................................. 13

Changing the gearbox oil ............................................. 13

Replacing the carbon brushes ..................................... 14

TECHNICAL DATA

Drill speed and drill sizes ............................................. 15

EC DECLARATION OF CONFORMITY

EC-declaration of conformity ........................................ 16

WIRING DIAGRAM

230 V ............................................................................ 17

110 V ............................................................................ 18

4 – English

PRESENTATION

Dear Customer,

Thank you for choosing a Husqvarna product!

It is our wish that you will be satisfied with your product and

that it will be your companion for a long time. A purchase of

one of our products gives you access to professional help with

repairs and services. If the retailer who sells your machine is

not one of our authorised dealers, ask him for the address of

your nearest service workshop.

This operator’s manual is a valuable document. Make sure it

is always at hand at the work place. By following its´ content

(using, service, maintenance etc) the life span and the

second-hand value of the machine can be extended. If you

will sell this machine, make sure that the buyer will get the

operator´s manual.

More than 300 years of innovation

Husqvarna AB is a Swedish company based on a tradition

that dates back to 1689, when the Swedish King Charles XI

ordered the construction of a factory for production of

muskets. At that time, the foundation was already laid for the

engineering skills behind the development of some of the

world's leading products in areas such as hunting weapons,

bicycles, motorcycles, domestic appliances, sewing

machines and outdoor products.

Husqvarna is the global leader in outdoor power products for

forestry, park maintenance and lawn and garden care, as well

as cutting equipment and diamond tools for the construction

and stone industries.

User responsibility

It is the owner’s/employer’s responsibility that the operator

has sufficient knowledge about how to use the machine

safely. Supervisors and operators must have read and

understood the Operator’s Manual. They must be aware of:

• The machine’s safety instructions.

• The machine’s range of applications and limitations.

• How the machine is to be used and maintained.

National legislation could regulate the use of this machine.

Find out what legislation is applicable in the place where you

work before you start using the machine.

The manufacturer’s reservation

All information and all data in the Operator’s Manual were

applicable at the time the Operator’s Manual was sent to print.

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify the

design and appearance of products without prior notice.

Features

Values such as high performance, reliability, innovative

technology, advanced technical solutions and environmental

considerations distinguish Husqvarna's products.

Some of the unique features of your product are described

below.

Softstart™

Softstart™ is an electronic current limiter which provides a

softer start.

Smart Start®

The machine runs at a lower speed when the Smart Start

function is activated. This makes it easier to start drilling the

material.

Elgard™

Elgard™ is an electronic overload protection that protects the

motor. The protection spares the machine and extends its

service life. With the help of Elgard™, the machine indicates

when it approaches maximum load.

Level guiding system

The machine's Level guiding system works like an electronic

level and helps the user to drill in the required position. By

reading the LED indicator on the top of the machine and

adjust it accordingly, it makes drilling easier for the operator

and offers better precision.

Twistable handle

The handle can be fully pivoted around the spindle shaft and

can be locked in any position.

Twistable water/dust nozzle

The nozzle can be turned freely around the spindle shaft and

be locked in any position. The nozzle is connected to a water

source when wet drilling and to a vacuum cleaner when dry

drilling.

English – 5

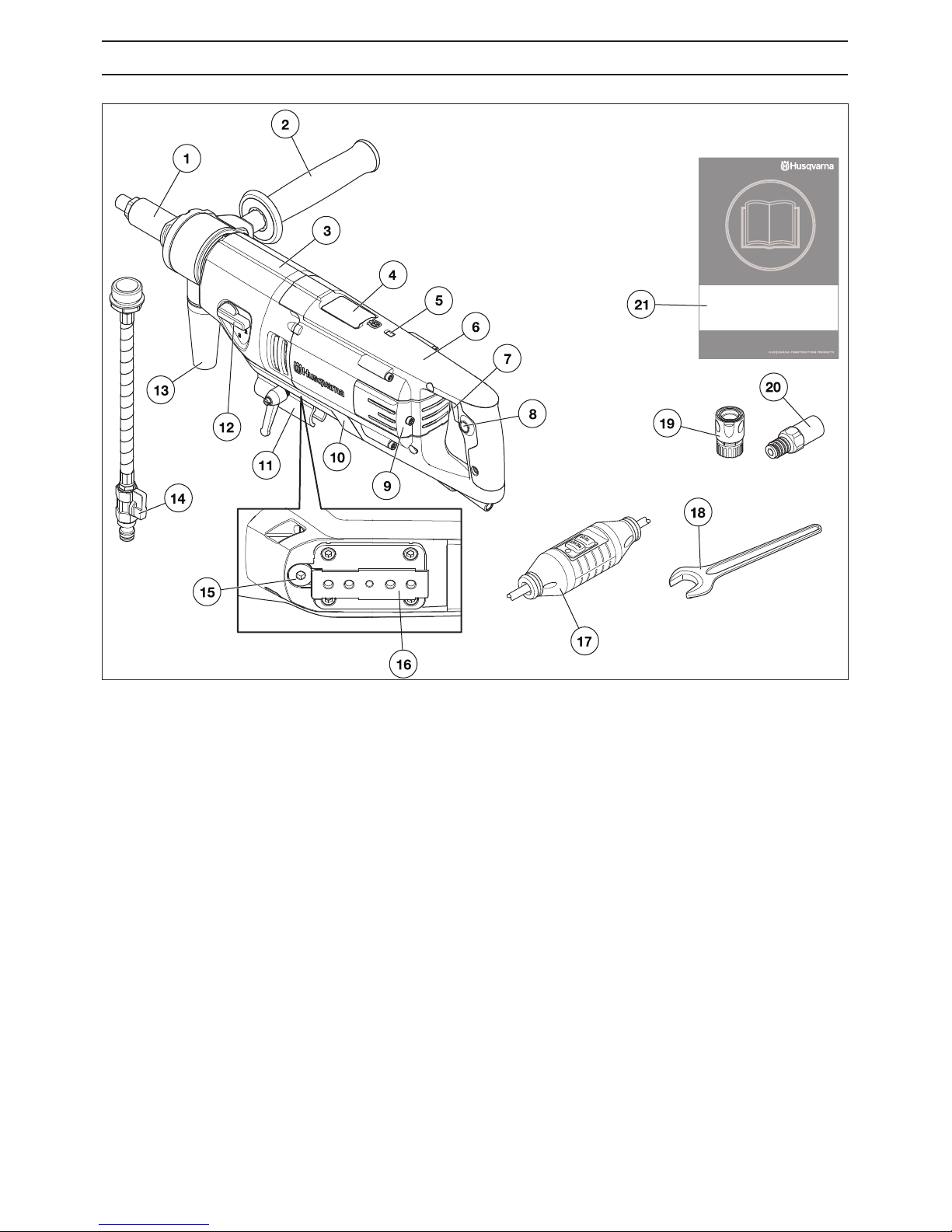

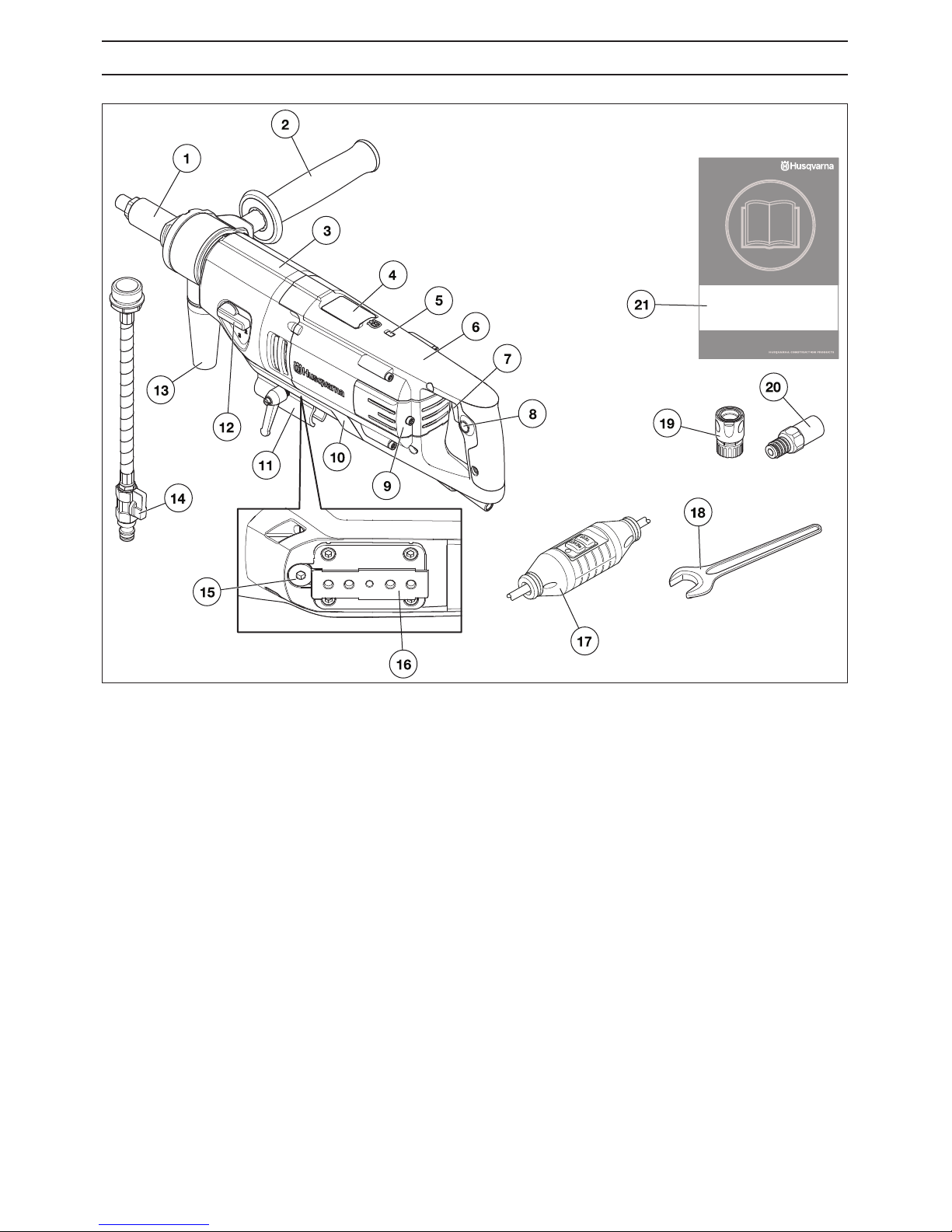

WHAT IS WHAT?

What is what on the drilling machine?

1 Drill spindle

2 Twistable handle

3 Gear box

4 Electronic level indicator

5 Power indicator

6 Motor

7 Power switch with Smart Start®

8 Lock-on button, power switch

9 Inspection cover

10 Protective cover

11 Bracket for ”Starthelper”

12 Gear knob

13 Connection for vacuum cleaner

14 Water connector

15 Oil plug

16 Stand fixing

17 Ground fault circuit interrupter

18 Spanners

19 Water connector

20 Adapter (USA only)

21 Operator′s manual

6 – English

MACHINE´S SAFETY EQUIPMENT

General

This section describes the machine´s safety equipment, its

purpose, and how checks and maintenance should be carried

out to ensure that it operates correctly.

Power switch

The power switch should be used to start and stop the

machine.

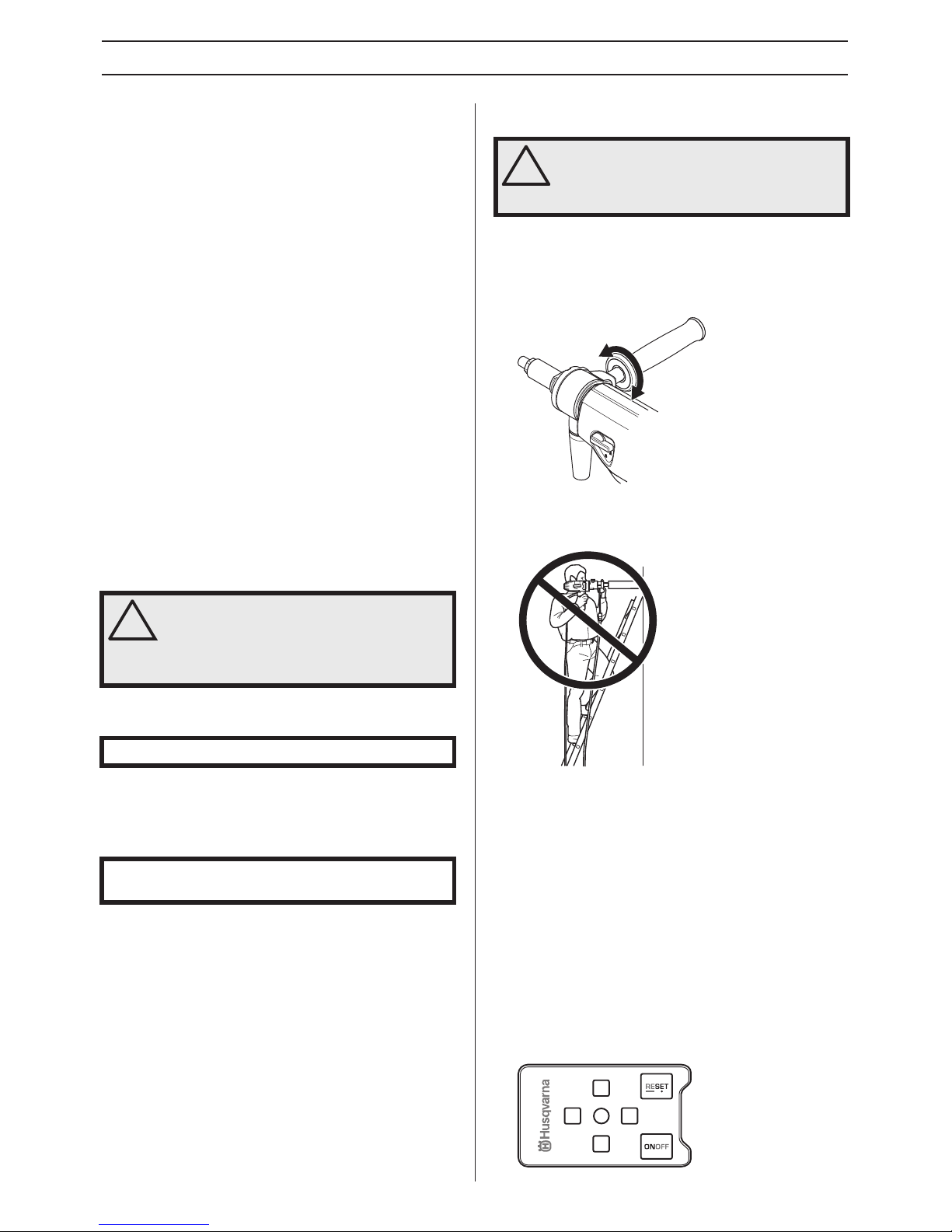

Checking the power switch

• Start the machine, release the power switch and check

that the motor and the drill bit stop.

• A defective power switch should be replaced by an

authorized service workshop.

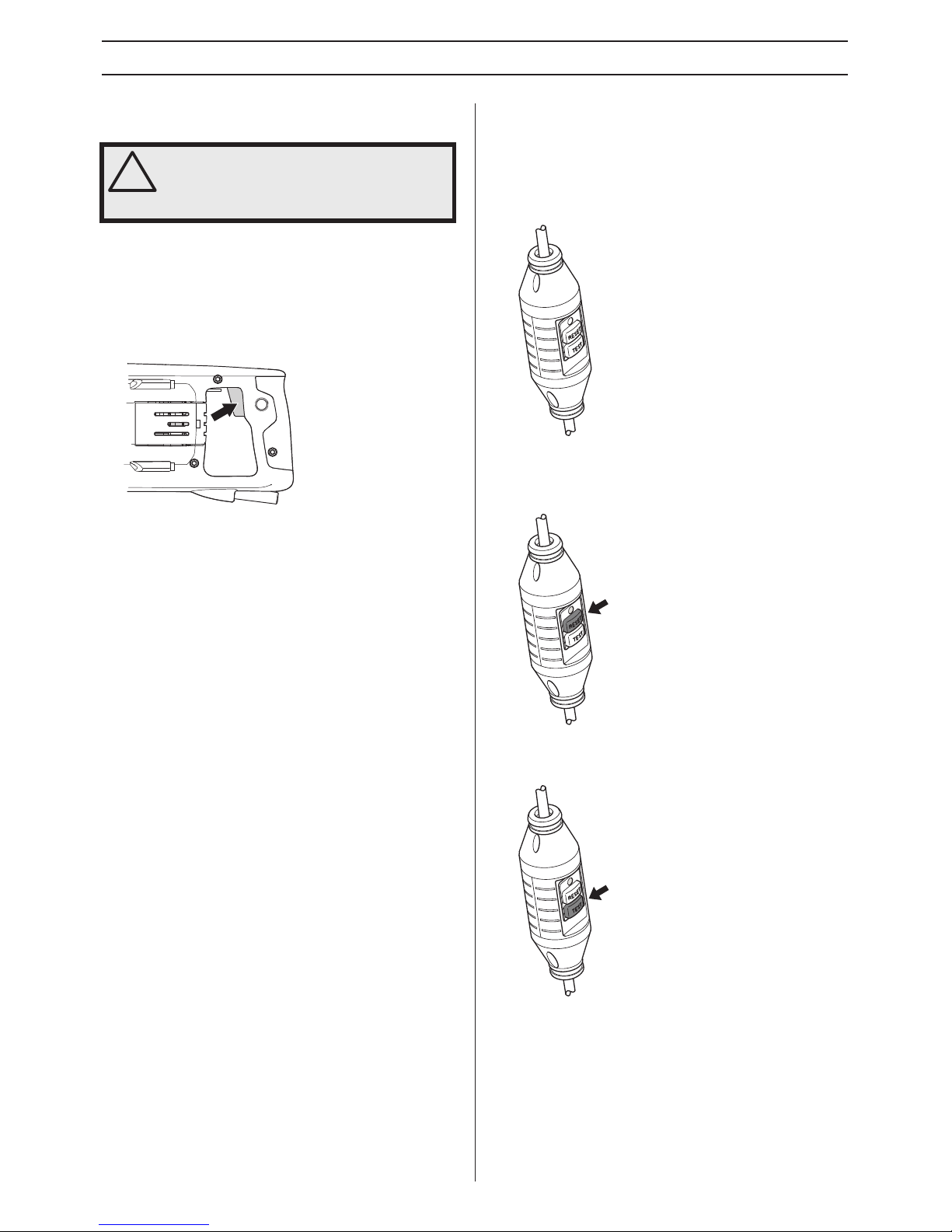

Ground fault circuit interrupter

Ground fault circuit interrupters are for protection in case an

electrical fault should occur.

The LED indicates that the ground fault circuit interrupter is on

and that the machine can be switched on. If the LED is not

on, push the RESET button (green).

Check the ground fault circuit interrupter

• Connect the machine to the socket. Push the RESET

button (green) and the red LED lights up.

• Start the machine by pressing the power switch.

• Push the TEST button (blue).

• The ground fault circuit interrupter should trip and the

machine switch off instantly. If not, contact your dealer.

• Reset with the RESET button (green).

!

WARNING! Never use a machine that has

faulty safety equipment! If your machine

fails any of these checks contact your

service agent to get it repaired.

English – 7

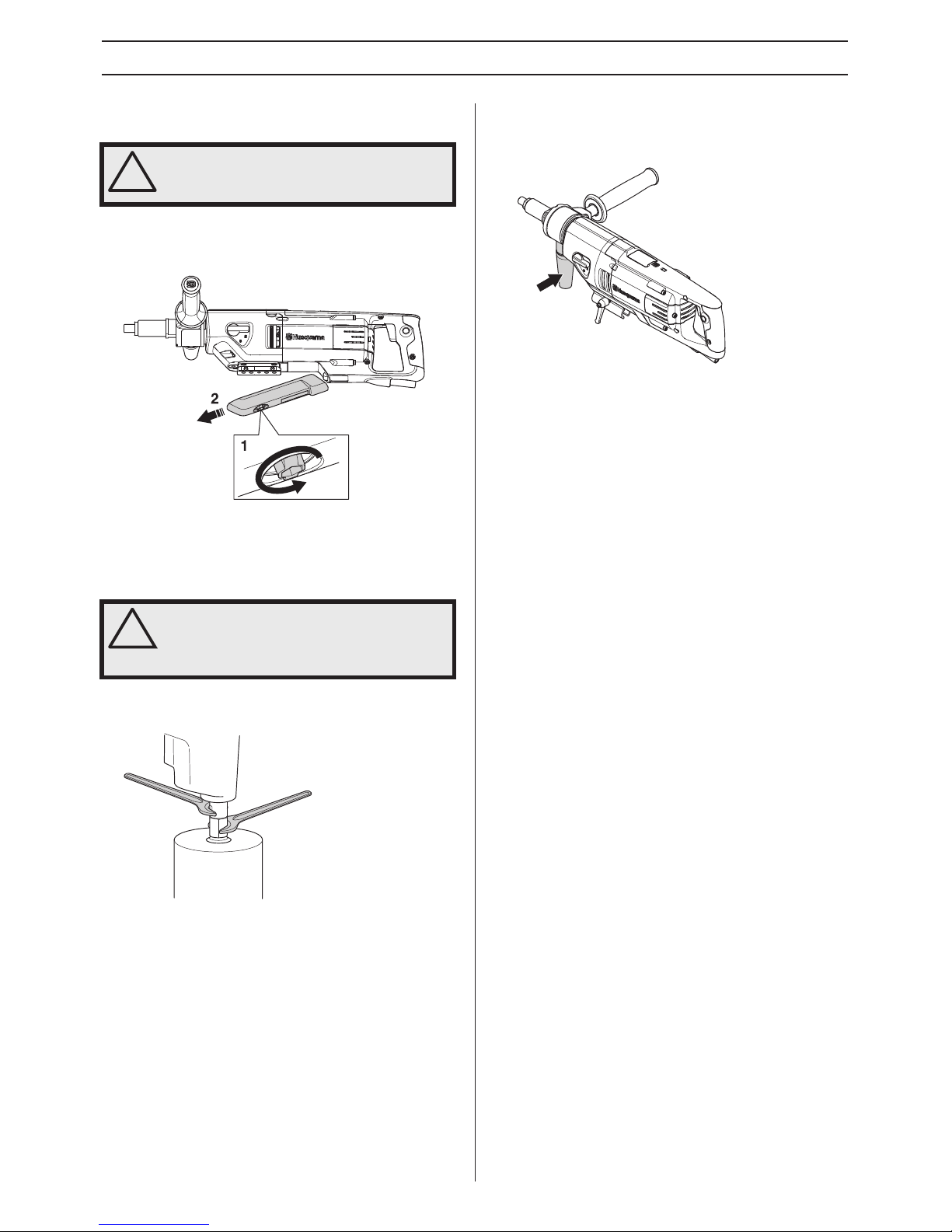

ASSEMBLING AND ADJUSTMENTS

Assembly

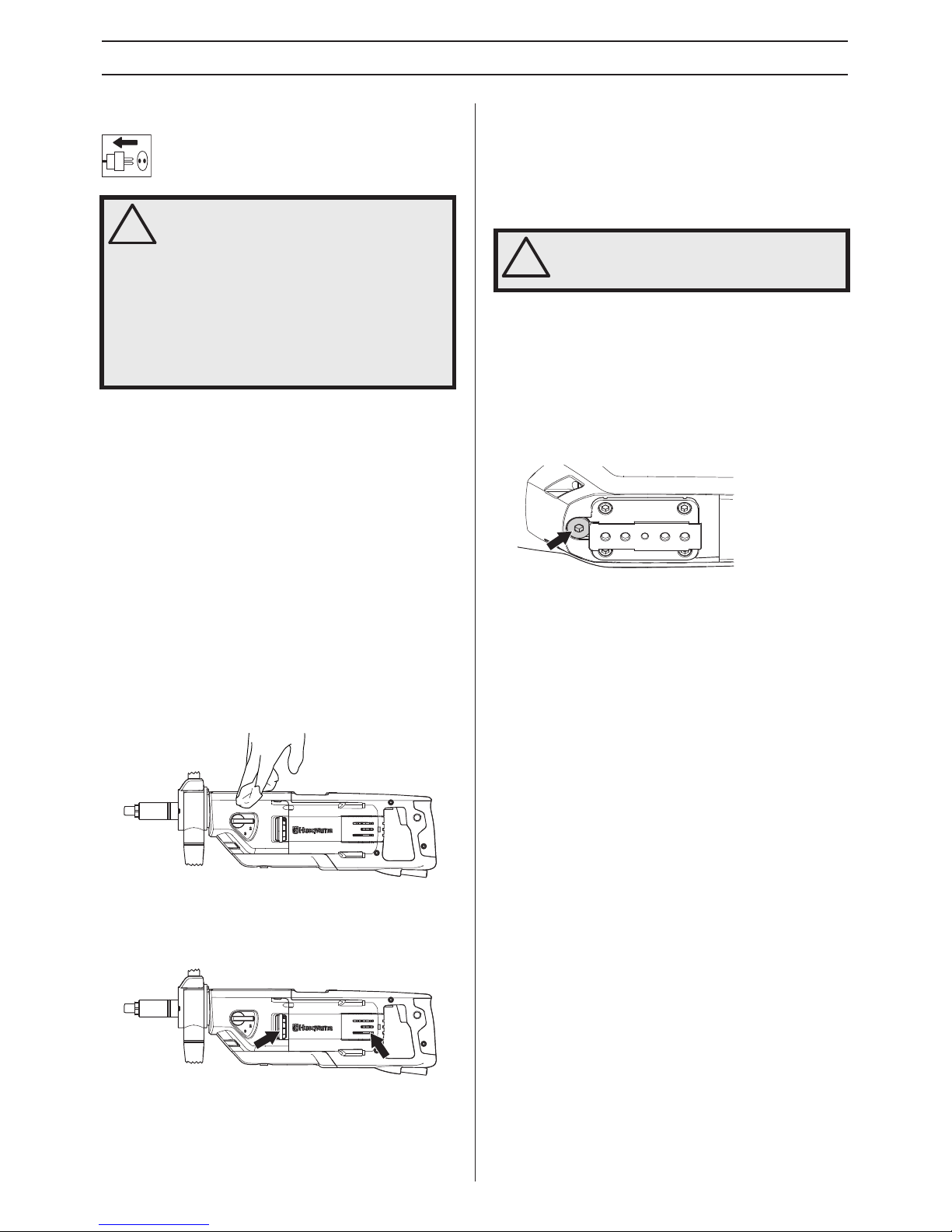

Assembling on stand

• Loosen the screw. Remove the protective cover.

• See instructions in the operator' s manual for the stand in

question.

Fitting/changing the drill bit

• Apply water-resistant grease to the thread of the drill bit.

• Attach the drill bit using the open-ended spanners.

• Before the machine is started, carefully check that the

new bit is firmly attached.

Connect the vacuum cleaner

• Connected the machine to a vacuum cleaner for effective

dust management when dry drilling.

!

WARNING! The machine should be switched

off with the power cable disconnected from

the outlet.

!

CAUTION! The drill bit and the surrounding

area is very hot after use. Leave machine to

cool off before removing the drill bit. Use

protective gloves.

8 – English

OPERATING

Protective equipment

General

Do not use the machine unless you are able to call for help in

the event of an accident.

Personal protective equipment

You must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will reduce

the degree of injury if an accident does happen. Ask your

dealer for help in choosing the right equipment.

Always wear:

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Boots with steel toe-caps and non-slip sole.

Be careful as clothing, long hair, and jewellery can get caught

in moving parts.

Other protective equipment

• Fire fighting equipment

• Always have a first aid kit nearby.

General safety precautions

This section describes basic safety directions for using the

machine. This information is never a substitute for

professional skills and experience.

• Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

• Keep in mind that the operator is responsible for accidents

or hazards occuring to other people or their property.

• All operators shall be trained in the use of the machine.

The owner is responsible for ensuring that the operators

receive training.

• The machine must be kept clean. Signs and stickers must

be fully legible.

!

WARNING! The use of products such as

cutters, grinders, drills, that sand or form

material can generate dust and vapours

which may contain hazardous chemicals.

Check the nature of the material you intend

to process and use an appropriate breathing

mask.

!

WARNING! Long-term exposure to noise can

result in permanent hearing impairment. So

always use approved hearing protection.

Listen out for warning signals or shouts

when you are wearing hearing protection.

Always remove your hearing protection as

soon as the engine stops.

!

WARNING! There is always a risk of crush

injuries when working with products

containing moving parts. Wear protective

gloves to avoid body injuries.

!

WARNING! Sparks may appear and start a

fire when you work with the machine. Always

keep fire fighting equipment handy.

!

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings

and instructions may result in electrtic

shock, fire and/or serious injury.

!

WARNING! The machine can be a dangerous

tool if used incorrectly or carelessly, which

can cause serious or fatal injury to the

operator or others.

Never allow children or other persons not

trained in the use of the machine to use or

service it. Never allow anyone else to use the

machine without first ensuring that they

have understood the contents of the

operator’s manual.

Never use the machine if you are fatigued,

while under the influence of alcohol or

drugs, medication or anything that could

affect your vision, alertness, coordination or

judgement.

There is always a risk of shocks from

electrically powered machines. Avoid

unfavourable weather conditions and body

contact with lightning conductors and metal

objects. Always follow the instructions in the

Operator’s manual to avoid damage.

!

WARNING! Unauthorized modifications and/

or accessories may lead to serious injury or

death to the user or others.

Do not modify this product or use it if it

appears to have been modified by others.

Never use a machine that is faulty. Carry out

the checks, maintenance and service

instructions described in this manual. Some

maintenance and service measures must be

carried out by trained and qualified

specialists. See instructions under the

heading Maintenance.

Always use genuine accessories.

English – 9

OPERATING

Always use common sense

It is not possible to cover every conceivable situation you can

face. Always exercise care and use your common sense. If

you get into a situation where you feel unsafe, stop and seek

expert advice. Contact your dealer, service agent or an

experienced user. Do not attempt any task that you feel

unsure of!

Work safety

Work area safety

• Keep work area clean and well lit. Cluttered or dark areas

invite accidents.

• Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the dust

or fumes.

• People and animals can distract you causing you to lose

control of the machine. For this reason, always remain

concentrated and focused on the task.

• Do not use the machine in bad weather, such as dense

fog, heavy rain, strong wind, intense cold, etc. Working in

bad weather is tiring and can lead to dangerous

conditions, e.g. slippery surfaces.

• Never start to work with the machine before the working

area is clear and you have a firm foothold. Look out for any

obstacles with unexpected movement. Ensure that no

material can become loose and fall, causing injury when

operating the machine.

• Always check the rear side of the surface where the drill

bit will emerge when drilling right through. Secure and

cordon off the area and make sure that no one can be

injured or material damaged.

Electrical safety

• Never use the tool without the ground fault circuit

interrupter delivered with the tool.

• The machine should be connected to an earthed outlet

socket.

• Check that the mains voltage corresponds with that stated

on the rating plate on the machine.

• Check that the cord and extension cord are intact and in

good condition.

• Never use the machine if any cable or plug is damaged,

but hand it in to an authorized service workshop for repair.

• To avoid overheating do not use the extension cord while

it is rolled up.

• Never carry the machine by means of the cord and never

pull out the plug by pulling the cord.

• Keep all cords and extension cords away from water, oil

and sharp edges. Make sure the cord is not pinched in

doors, fences or the like. Otherwise it can cause the object

to become live.

• Do not expose the power tool to rain. Water entering a

power tool will increase the risk of electric shock.

• The power tool should not be exposed to more moisture

than what is provided by the water system. The water

system cools the drill bit with clean water. Make sure that

no drill slurry enters the machine.

• Ensure the cord is behind you when you start to use the

machine so that the cord will not be damaged.

• Always unplug the machine during longer work breaks.

Drilling outdoors

• Always use extension cables that are approved for

outdoor use.

Personal safety

• Never use the machine if you are fatigued, while under the

influence of alcohol or drugs, medication or anything that

could affect your vision, alertness, coordination or

judgement.

• Prevent unintentional starting. Ensure the switch is in the

OFF-position before connecting to power source and/or

battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch or energising

power tools that have the switch on invites accidents.

• Remove any adjusting key or wrench before turning the

power tool on. A wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

• Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

• Remain at a distance from the drill bit when the motor is

running. A rotating drill bit can entail a risk of serious

injury.

• Make sure that no pipes or electrical cables are routed in

the area to be drilled.

• Never leave the machine unsupervised with the motor

running.

• Always unplug the machine during longer work breaks.

• Never work alone, always ensure there is another person

close at hand. Apart from being able to receive help to

assemble the machine, you can also get help if an

accident should occur.

!

WARNING! There is always a risk of shocks

from electrically powered machines. Avoid

unfavourable weather conditions and body

contact with lightning conductors and metal

objects. Always follow the instructions in the

Operator’s manual to avoid damage.

!

WARNING! Do not wash the machine with

water, as water can enter the electrical

system or the engine and cause damage to

the machine or short circuit.

10 – English

OPERATING

Use and care

• This machine is ideal for drilling holes in concrete, bricks

and various stone materials. It can be used both as a

hand-held drill or fitted to a drill stand.

• The machine is intended for use in industrial applications

by experienced operators.

• Inspection and/or maintenance should be carried out with

the motor switched off and the plug disconnected.

• The machine has a very high torque. This demands good

concentration during work, as serious personal injuries

can occur if the drill bit suddenly jams.

• Do not use the power tool if the switch does not turn it on

and off. Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Remain at a distance from the drill bit when the motor is

running.

• Do not overload the machine. Overloading can damage

the machine.

• Keep tools sharp and clean in order to enable safer work.

• Keep all parts in good working order and ensure that all

fixtures are properly tightened.

• Always switch off the machine before you move it.

Dry drilling

Drilling in the ceiling

Use a water collector to avoid water penetrating into the

machine.

Elgard™

If the motor is overloaded, the overload protection pulses the

motor. Reduce the load and the motor returns to its normal

speed.

The overload protection disconnects the power, if the

machine is subjected to heavy loads or if the drill bit jams.

Reset the machine by switching it off and then on again.

If the drill bit jams, the mechanical slip clutch protects the

gearbox before the overload protection disconnects the

power.

Handheld drilling

• Always use a drill bit with a max. diameter of 75 mm with

handheld drilling. The larger the drill bit the greater the

reaction if the drill jams.

• Lock the front pivoting handle firmly in place prior to

drilling.

• Never perform handheld drilling from a ladder. Handheld

drilling in these situations is full of risks, as the risk of

falling is very high if the drill bit jams.

Stand drilling

• Always use a drilling stand if drilling is to be performed

from a ladder or scaffold.

• Make sure that the stand is secured correctly.

• Make sure that the drilling machine is secured correctly in

the stand.

Basic working techniques

Level guiding system

The machine's Level guiding system works like an electronic

level and helps the user to drill in the required position. By

reading the LED indicator on the top of the machine and

adjust it accordingly, it makes drilling easier for the operator

and offers better precision.

!

CAUTION! Dust forms when drilling, which

can cause injuries if inhaled. Use an

approved breathing mask. Connected the

machine to a vacuum cleaner for effective

dust management when dry drilling.

NOTICE! The air intake must not be covered.

NOTICE! Do not repeatedly overload the machine. This can

damage the machine.

!

WARNING! Do not perform handheld drilling

in first gear as the machine has a powerful

torque that can result in personal injuries

should the drill bit jam.

English – 11

OPERATING

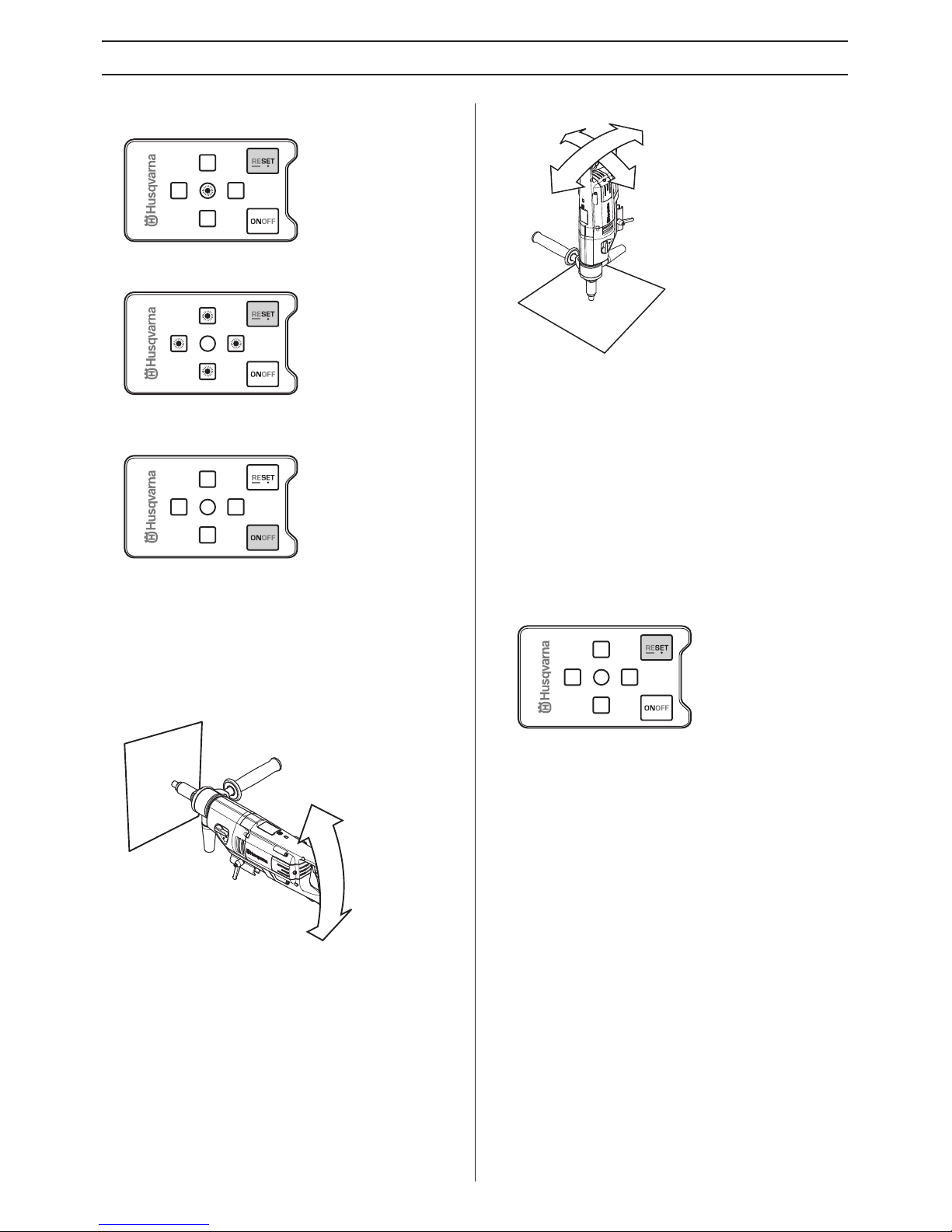

The central green LED is lit as long as the machine is in the

required position.

The surrounding red LEDs indicate which direction the

machine must be angled to achieve the required position.

Activate the system

• Press the ON/OFF button to activate the system.

• This function senses how the machine is angled and

alters it accordingly.

Horizontal position

The central green LED lights up when the machine is aligned

horizontally.

The system senses the machine’s deviation from the

horizontal plane.

If the back of the machine is tilted downwards, the central

green LED goes out and the front red LED lights up. If the

back end of the machine is tilted up, the back red LED lights

up.

Vertical position

The central green LED lights up when the machine is aligned

vertically.

The system senses deviations in two planes.

If the back of the machine is tilted downwards, the central

green LED goes out and the front red LED lights up. If the

back end of the machine is tilted up, the back red LED lights

up.

If the back end of the machine is tilted to the right, the central

green LED goes out and the left red LED lights up. If the back

end of the machine is tilted to the left, the right hand red LED

lights up.

Customised angle setting

The Level guiding system in the machine can be configured

to set a customised drill angle.

• Hold the machine at the required angle and press the

Reset button.

• Zero the angle setting by keeping the Reset button

pressed in for about 3 seconds.

The setting is also zeroed if the machine is disconnected

from the mains supply for a long time.

Deactivate the system

The system can be deactivated temporarily by pressing the

ON/OFF button. Deactivation is set to zero if the ON/OFF

button is pressed again or when the power is disconnected.

The system is deactivated for the time being by pressing the

ON/OFF button for approx. 3 seconds. Press the ON/OFF

button to activate the system again.

Transport and storage

• Do not store or transport the drilling machine with the drill

bit fitted in order to protect your drilling machine and drill

bits from damage.

• Secure the equipment during transportation in order to

avoid transport damage and accidents.

• Store the equipment in a lockable area so that it is out of

reach of children and unauthorized persons.

• Store the machine and its equipment in a dry and frost

proof place.

12 – English

STARTING AND STOPPING

Before starting

• Check that the machine is assembled correctly and do not

show any signs of damage. See instructions in the section

"Assembling and adjustments".

• Perform daily maintenance. See instructions in the section

"Maintenance".

Starting

• Set the working speed by turning the drill spindle and at

the same time move the gear knob to the required

position.

• Turn on the water cooling (wet drilling) or switch on the

vacuum cleaner (dry drilling).

• Press down the power switch halfway to activate Smart

Start and all the way for full drilling speed.

Stopping

• Run the machine unloaded for a minute or two to cool the

motor.

• Stop the motor by releasing the power switch.

!

WARNING! Please read the operator’s

manual carefully and make sure you

understand the instructions before using the

machine.

Wear personal protective equipment. See

instructions under the heading ”Personal

protective equipment”.

Make sure no unauthorised persons are in

the working area, otherwise there is a risk of

serious personal injury.

NOTICE! Changing gear may only be done when the

machine is switched off. Otherwise there is a risk of

damaging the gearbox.

!

CAUTION! The drill bit continues to rotate for

a while after the motor has been switched

off. Make sure that the drill bit can rotate

freely until it is completely stopped.

Carelessness can result in serious personal

injury.

English – 13

MAINTENANCE

General

The life span of the machine can be reduced and the risk of

accidents can increase if machine maintenance is not carried

out correctly and if service and/or repairs are not carried out

professionally. If you need further information please contact

your nearest service workshop.

Daily maintenance

• Check that the machine’s safety equipment is

undamaged. See instructions in the section "Machine’s

safety equipment".

• Check that the cord and extension cord are intact and in

good condition.

• Clean the outside of the machine.

Cleaning

• Keep the machine and drill bit clean in order for drilling to

be carried out safely.

• Keep the handle dry and free of grease and oil.

• In order for the machine to always be cooled sufficiently

the cooling air openings must be kept clear and clean.

Blow down the machine regularly with compressed air.

• Use compressed air to periodically clean the motor.

Remove the inspection cover and clean the cover.

Water tap

Check that the water tap functions. Do not use hoses that are

distorted, worn or damaged.

Electrical Feed

Check that the cord and extension cord are intact and in good

condition. Never use the machine if the cord is damaged,

hand it in to an authorized service workshop for repair.

Changing the gearbox oil

The oil in the gearbox must be changed after every 400 hours

of operation.

• Unscrew the oil plug.

• Empty the oil into a container. Handle oil carefully of

environmental considerations. Follow local recycling

requirements.

If necessary contact your dealer to clean the gearbox.

• Pour the new oil into the gearbox, about 0.25 litres. Refer

to Technical Data for recommendations on which oil type

to use.

• The oil plug is fitted with a magnet that captures metal

particles. Wipe the oil plug clean and screw it back.

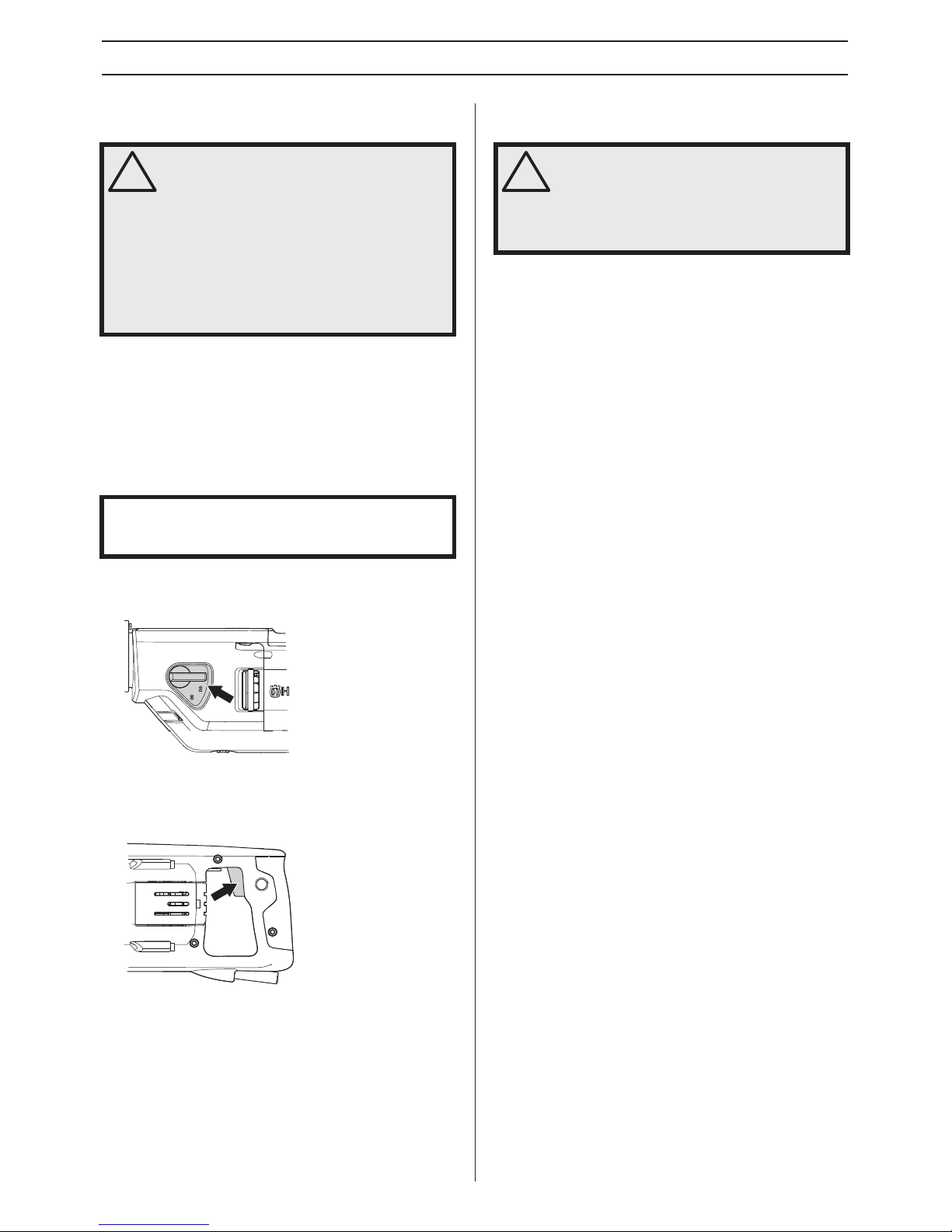

!

WARNING! The user must only carry out the

maintenance and service work described in

this Operator’s Manual. More extensive work

must be carried out by an authorized service

workshop.

Shut down the machine and disconnect the

power plug.

Wear personal protective equipment. See

instructions under the heading ”Personal

protective equipment”.

!

WARNING! Never use damaged cables. They

can cause serious, even fatal, personal

injuries.

14 – English

MAINTENANCE

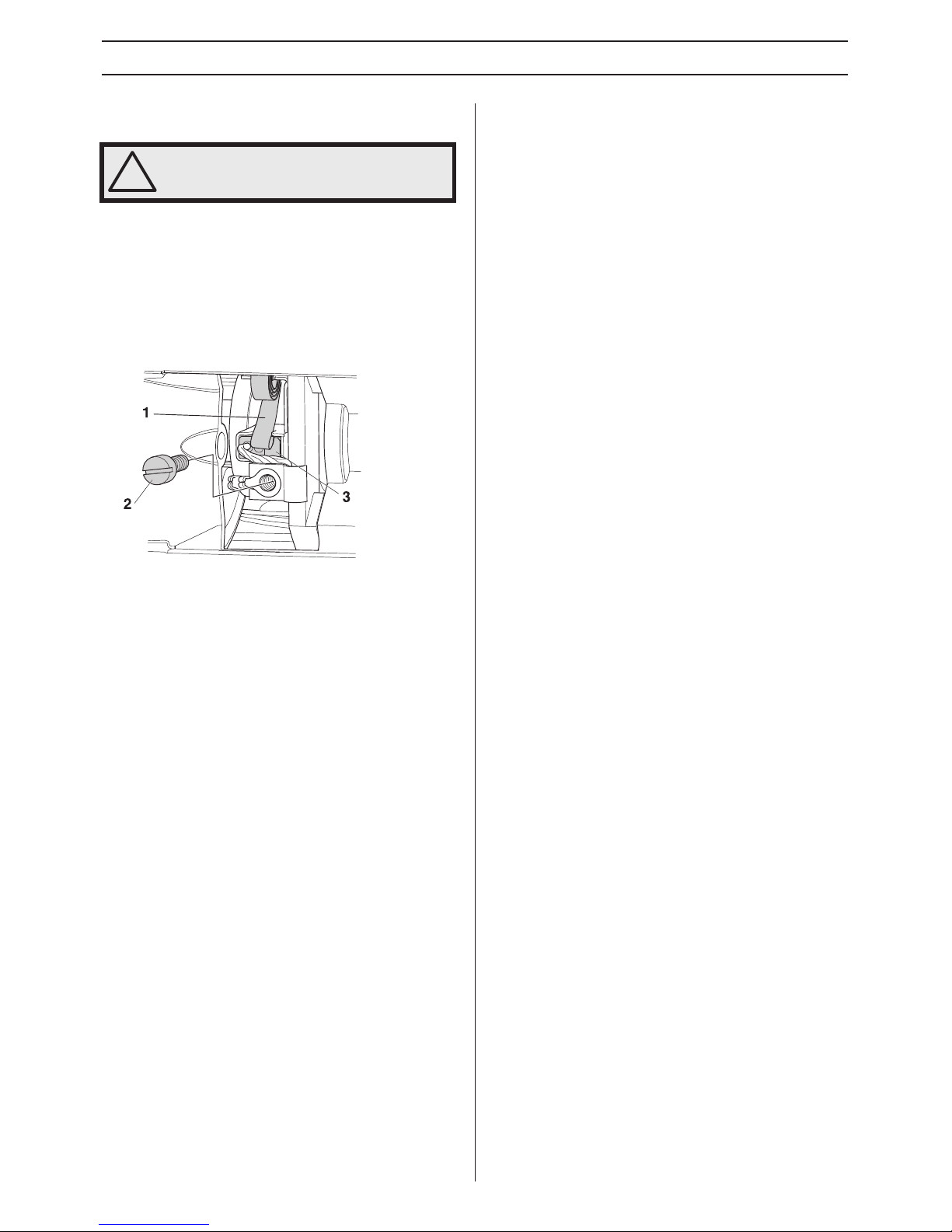

Replacing the carbon brushes

The carbon brushes must be removed and checked regularly.

Weekly if the machine is used daily or at longer intervals if the

machine is used more seldom. The area of wear should be

even and undamaged.

Both carbon brushes must always be replaced as a pair, but

one at a time.

• Remove the inspection cover.

• Lift the brush retainer spring to one side (1).

• Loosen the screw (2).

• Pull out the carbon brush connector.

• Pull out the coal brush from the holder (3).

• Clean the brush holder with compressed air or a brush.

Replace the brush if worn.

• Fit the new carbon brushes and, at the same time, check

that they slide easily in the brush retainers.

• Put the brush holder spring back into place.

• Insert the carbon brush connection under the screw.

• Repeat the procedure with the other carbon brush.

• Screw the inspection cover back in place.

• Let the machine idle for 10 minutes to run in the new

carbon brushes.

!

WARNING! Shut down the machine and

disconnect the power plug.

English – 15

TECHNICAL DATA

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EN 60745-2-1.

Note 2: Noise pressure level according to EN 60745-2-1. Reported data for noise pressure level has a typical statistical dispersion

(standard deviation) of 1.0 dB(A).

Note 3: Vibration level according to EN 60745-2-1. Reported data for vibration level has a typical statistical dispersion (standard

deviation) of 1 m/s2.

Drill speed and drill sizes

DM 220

Electric motor Single-phase

Rated voltage, V 230/100-120

Rated output, W 1850

Rated current, A

230 V 8 A

100-120 V 13 A

Weight, kg 7

Volume gear box oil, dl 0,25

Gear box oil, type

Mobilube 1 SHC 75W-90 or

similar.

Diameter drill bit, mm

Max. diameter of the drill bit, with stand 150 mm (5,9”)

Max. diameter for the drill bit, handheld 75 mm (3”)

Spindle thread G 1/2” G 1 1/4”

Water connector G 1/4”

Water pressure - max, bar 8

Stand, mm Ø 60 mm

Noise emissions (see note 1)

Sound power level, measured dB(A) 107

Sound power level, guaranteed dB(A) 108

Sound levels (see note 2)

Sound pressure level at the operators ear, dB(A) 93

Vibration levels, ahv (see note 3)

Front handle, m/s

2

2,8

Rear handle, m/s

2

2,6

Handheld drilling Stand drilling

Gear

Drill bit speed

with load, rpm

Drill bit load

without load, rpm

Recommended

drill bit size, mm

Recommended

drill bit size, inch

Recommended

drill bit size, mm

Recommended

drill bit size, inch

1 580 730

Not

recommended

Not

recommended

100-150 4-6

2 1400 1700 40-80 2-4 40-80 2-4

3 2900 3600 0-40 0-2 0-40 0-2

16 – English

EC DECLARATION OF CONFORMITY

EC-declaration of conformity

Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel: +46-36-146500, declares under sole responsibility that the Husqvarna DM

220 , from 2010´s serial numbers and onwards (the year is clearly stated in plain text on the rating plate with subsequent serial

number), conforms with the requirements of the COUNCIL’S DIRECTIVE:

• of May 17, 2006 "relating to machinery" 2006/42/EC

• of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

• of December 12, 2006 ”relating to electrical equipment” 2006/95/EC.

The following standards have been applied:

EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-2:2006, EN 61000-3-3/A1/A2:2005, EN 60745-2-

1:2007.

Gothenburg March 1, 2011

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

English – 17

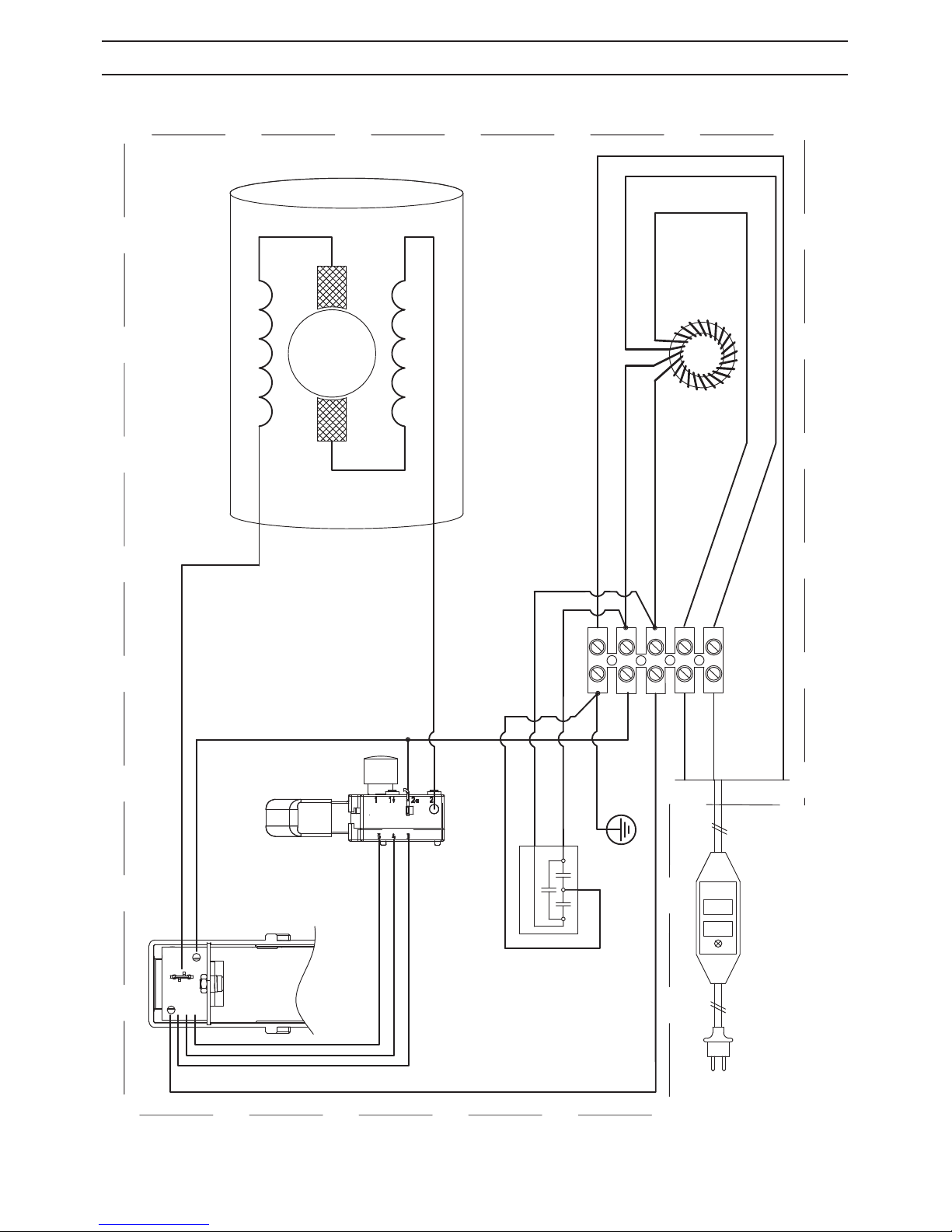

WIRING DIAGRAM

230 V

TEST

RESET

WARNING

=L1

Green/Yellow

Green/Yellow

Brown

Blue

Green/Yellow

Black

Black

White

White

Black

Black

Silver

Black

Condensator

Black

Ground fault circuit interrupter

Circuit board

White

Green

Blue

543

2a

2

Trigger

Grey

Grey

Stator

Stator

Rotor

Grey

Grey

18 – English

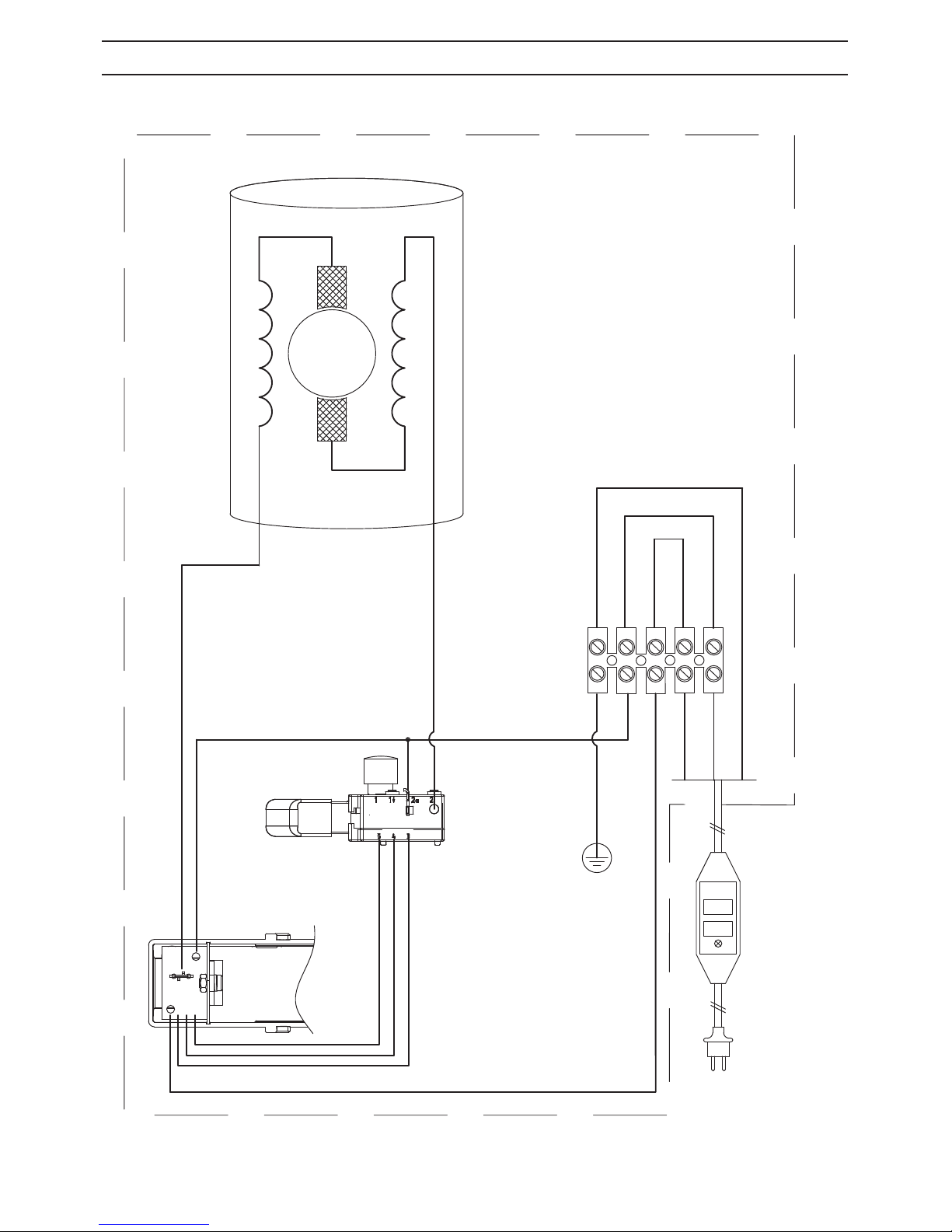

WIRING DIAGRAM

110 V

TEST

RESET

WARNING

White

Green

Blue

Trigger

543

2a

2

Black

Brown

White

Blue

Green/Yellow

Gearbox

Green/Yellow

Ground fault circuit interrupter

Black

Grey

Grey

Circuit board

Stator

Stator

Rotor

Grey

Grey

Black

Spanish – 19

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina

¡ATENCIÓN! La máquina, si se utiliza de

forma errónea o descuidada, puede ser una

herramienta peligrosa que puede causar

daños graves e incluso la muerte al usuario

y a otras personas.

Lea detenidamente el manual de

instrucciones y asegúrese de entender su

contenido antes de utilizar la máquina.

Utilice el equipo de protección personal. Vea

las instrucciones bajo el título ”Equipo de

protección personal”.

Este producto cumple con la directiva CE

vigente.

Etiquetado ecológico. El símbolo en el

producto o en su envase indica que no se

puede tratar este producto como desperdicio

doméstico. Deberá por lo tanto depositarse

en un centro de recogida adecuado para el

reciclado de equipos eléctricos y

electrónicos.

Haciendo que este producto sea manipulado

adecuadamente, se ayuda a evitar consecuencias negativas

potenciales para el medio ambiente y las personas, lo que

puede ocurrir con la manipulación inadecuada como residuos

del producto.

Para obtener información más detallada sobre el reciclado de

este producto, contacte con la oficina municipal local, con el

servicio de eliminación de desperdicios domésticos o con la

tienda donde compró el producto.

Al perforar en techo, comprobar que

no puede entrar agua en la máquina.

Utilice un colector de agua adecuado.

Los demás símbolos/etiquetas que

aparecen en la máquina

corresponden a requisitos de homologación específicos

en determinados mercados.

Explicación de los niveles de

advertencia

Las advertencias se clasifican en tres niveles.

¡ATENCIÓN!

¡NOTA!

AVISO

!

¡ATENCIÓN! Indica un riesgo de daños

graves para el usuario o incluso muerte, o

bien daños al entorno, si no se siguen las

instrucciones del manual.

!

¡NOTA! Indica un riesgo de lesiones para el

usuario o daños al entorno si no se siguen

las instrucciones del manual.

AVISO Indica un riesgo de daños en los materiales o en la

máquina si no se siguen las instrucciones del manual.

20 – Spanish

ÍNDICE

Índice

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina .............................................. 19

Explicación de los niveles de advertencia ................... 19

ÍNDICE

Índice ........................................................................... 20

PRESENTACIÓN

Apreciado cliente: ........................................................ 21

Características ............................................................. 21

¿QUÉ ES QUÉ?

Componentes de la taladradora ................................... 22

EQUIPO DE SEGURIDAD DE LA MÁQUINA

Generalidades .............................................................. 23

MONTAJE Y AJUSTES

Montaje ........................................................................ 24

FUNCIONAMIENTO

Equipo de protección ................................................... 25

Instrucciones generales de seguridad ......................... 25

Seguridad en el trabajo ................................................ 26

Técnica básica de trabajo ............................................ 27

Transporte y almacenamiento ...................................... 28

ARRANQUE Y PARADA

Antes del arranque ....................................................... 29

Arranque ...................................................................... 29

Parada ......................................................................... 29

MANTENIMIENTO

Generalidades .............................................................. 30

Mantenimiento diario ................................................... 30

Limpieza ...................................................................... 30

Grifo de agua ............................................................... 30

Suministro eléctrico ..................................................... 30

Cambio del aceite de la caja de cambios .................... 30

Cambio de escobillas de carbón .................................. 31

DATOS TECNICOS

Velocidad de taladrado y tamaños de taladro .............. 32

DECLARACIÓN CE DE CONFORMIDAD

Declaración CE de conformidad .................................. 33

ESQUEMA DE CONEXIONES ELÉCRICAS

230 V ............................................................................ 34

110 V ............................................................................ 35

Spanish – 21

PRESENTACIÓN

Apreciado cliente:

Gracias por elegir un producto Husqvarna.

Esperamos que su máquina le proporcione plena satisfacción

y le sirva de ayuda por mucho tiempo en adelante. La

adquisición de alguno de nuestros productos da acceso a

asistencia profesional con reparaciones y servicio. Si la

máquina no fue adquirida en un distribuidor oficial, preguntar

en la tienda de compra la dirección del taller de servicio más

cercano.

Este manual de instrucciones es un documento importante.

Procure tenerlo siempre a mano en el lugar de trabajo.

Siguiendo sus instrucciones (de uso, servicio,

mantenimiento, etcétera) puede alargar considerablemente

la vida útil de la máquina e incrementar su valor de reventa.

Si vende su máquina, entregue el manual de instrucciones al

nuevo propietario.

Más de 300 años de innovación

La fundación de la empresa sueca Husqvarna AB data del

año 1689, cuando el Rey Karl XI encargó la construcción de

una fábrica para la fabricación de mosquetes. En ese

momento se establecieron los cimientos de la experiencia

tecnológica en la que se basan muchos de los productos

punteros en el mundo en el sector de las armas de caza,

bicicletas, motocicletas, electrodomésticos, máquinas de

coser y productos para exteriores.

Husqvarna es líder internacional en productos motorizados

para exteriores destinados a la silvicultura, el mantenimiento

de parques y el cuidado del césped y del jardín, así como

equipos de corte y herramientas de diamante para el sector

de la construcción y la piedra.

Responsabilidad del usuario

El propietario / empresario es el responsable de asegurarse

de que el usuario tiene los conocimientos necesarios para

utilizar la máquina con seguridad. Los supervisores y los

usuarios deben haber leído y entendido el manual de

instrucciones. Deben tener conocimiento de lo siguiente:

• Las instrucciones de seguridad de la máquina.

• Las aplicaciones y las limitaciones de la máquina.

• El modo de uso y de mantenimiento de la máquina.

La utilización de esta máquina podría estar regulada por la

legislación nacional vigente. Infórmese sobre la legislación

vigente en el lugar donde trabaja antes de empezar a utilizar

la máquina.

Los derechos que se reserva el fabricante.

Toda la información y todos los datos contenidos en este

manual de instrucciones son vigentes en la fecha de

impresión del manual.

Husqvarna AB trabaja constantemente para perfeccionar sus

productos y se reserva, por lo tanto, el derecho a introducir

modificaciones en la construcción y el diseño sin previo aviso.

Características

El alto rendimiento, la fiabilidad, la tecnología innovadora, las

soluciones técnicas avanzadas y el respeto medioambiental

son los valores que caracterizan a los productos de

Husqvarna.

A continuación se describen algunas de las características

únicas de su producto.

Softstart™

Softstart™ es un limitador de sobreintensidad electrónico

que permite un arranque más suave.

Smart Start®

La máquina funciona a una velocidad inferior si está activada

la función Smart Start. Esto facilita el taladrado del material.

Elgard™

Elgard™ es una protección contra sobrecarga electrónica

que protege el motor. Dicha protección protege la máquina y

amplía su vida útil. Gracias a Elgard™, la máquina indica

cuándo se aproxima a la carga máxima.

Level guiding system

El Level guiding system de la máquina funciona como un

nivel electrónico y ayuda al usuario a taladrar en la ubicación

deseada. El operario solo tiene que leer el indicador LED

situado en la parte superior de la máquina y ajustarlo

debidamente. De esta forma, la perforación resulta más

sencilla y se consigue una mayor precisión.

Empuñadura girable

La empuñadura puede pivotar completamente alrededor del

eje y bloquearse en cualquier posición.

Boquilla de agua / polvo girable

La boquilla puede girarse libremente alrededor del eje y

bloquearse en cualquier posición. La boquilla está conectada

a una fuente de agua al taladrar en húmedo y a un aspirador

al taladrar en seco.

22 – Spanish

¿QUÉ ES QUÉ?

Componentes de la taladradora

1 Husillo de taladradora

2 Empuñadura girable

3 Caja de engranajes

4 Indicador de nivel electrónico

5 Indicador de potencia

6 Motor

7 Bloqueador de interruptor con Smart Start

®

8 Botón de bloqueo, bloqueador de interruptor

9 Tapa de inspección

10 Cubierta protectora

11 Soporte para «Starthelper»

12 Manija de cambio

13 Conexión para la aspiradora

14 Conexión de agua

15 Tapón del aceite

16 Fijación del soporte

17 Interruptor de circuito de pérdida a tierra

18 Llaves

19 Conexión de agua

20 Adaptador (sólo EE.UU.)

21 Manual de instrucciones

Loading...

Loading...