UUUUSSSS CCCCAAAA EEEESS

SS

DC 6000

Oper ator’s manual Manuel d’utilisation

Manual de instrucciones

Please r ead the operator’ s man ual car efull y and mak e sur e y ou understand the instructions bef or e using the machine .

Lir e attentiv ement et bien assimiler le man uel d’utilisation a vant d’utiliser la machine .

Lea detenidamente el man ual de instrucciones y asegúr ese de entender su contenido antes de utilizar la máquina

KEY T O SYMBOLS

2

– English

Symbols on the mac hine

W

ARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious

or fatal injury to the operator or

others.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

Wear personal protective

equipment. See instructions under

the heading ”Personal protective

equipment”.

WARNING! Dust forms when

grinding, which can cause injuries if

inhaled. Use an approved breathing

mask. Always provide for good

ventilation.

En

vironmental marking. Symbols

on the product or its packaging

indicate that this product cannot be

handled as domestic waste.

By ensuring that this product is taken

care of correctly, you can help to

counteract the potential negative

impact on the environment and

people that can otherwise result

through the incorrect waste

management of this product.

For more detailed information about recycling this

product, contact your municipality, your domestic waste

service or the shop from where you purchased the

product.

Other symbols/decals on the mac hine refer to special

certification requirements for certain markets.

Explanation of warning le vels

The w arnings are graded in three levels.

W

ARNING!

CAUTION!

NOTICE!

!

W

ARNING! Used if there is a risk of

serious injury or death for the operator

or damage to the surroundings if the

instructions in the manual are not

followed.

!

CA

UTION! Used if there is a risk of injury

to the operator or damage to the

surroundings if the instructions in the

manual are not followed.

NO

TICE! Used if there is a risk of damage to materials

or the machine if the instructions in the manual are not

followed.

CONTENTS

English

–

3

Contents

KEY TO SYMBOLS

Symbols on the machine ...................................... 2

Explanation of warning levels ............................... 2

CONTENTS

Contents ............................................................... 3

PRESENT ATION

Dear customer! ..................................................... 4

Design and features ............................................. 4

PRESENT ATION

What is what on the machine? ............................. 5

ASSEMBLING AND ADJUSTMENTS

Connect the machine ........................................... 6

OPERA TING

Protectiv e equipment ............................................ 7

General safety precautions ................................... 7

Work safety ........................................................... 8

Transport and storage .......................................... 9

ST

ARTING AND STOPPING

Bef ore starting ...................................................... 10

Auto dump ............................................................ 11

Starting ................................................................. 11

Stopping ............................................................... 12

MAINTENANCE

Gener al ................................................................. 13

Maintenance schedule ......................................... 13

Check the cyclone and container ......................... 14

Cleaning of compressor filter ................................ 14

Cleaning of compressed air dryer filter ................. 14

Cleaning of cyclone and container ....................... 15

Cleaning/replacement of filter ............................... 15

Washing the filter .................................................. 16

Cleaning of cyclone cone ..................................... 16

Transport position ................................................. 17

Service ................................................................. 17

TR

OUBLESHOOTING

T

roubleshooting .................................................... 18

TECHNICAL D ATA

T

echnical data ...................................................... 19

PRESENT A TION

4

– English

Dear customer!

Thank y ou for choosing a Husqvarna product!

It is our wish that you will be satisfied with your product

and that it will be your companion for a long time. A

purchase of one of our products gives you access to

professional help with repairs and services. If the retailer

who sells your machine is not one of our authorised

dealers, ask him for the address of your nearest service

workshop.

This operator’s manual is a valuable document. Make

sure it is always at hand at the work place. By following its

content (operating, service, maintenance etc.) the life

span and the second-hand value of the machine can be

extended. If you ever lend or sell this machine, make sure

that the borrower or buyer gets the operator

′

s manual, so

they will also know how to properly maintain and use it.

More than 300 y ears of innovation

Husqv arna AB is a Swedish company based on a tradition

that dates back to 1689, when the Swedish King Karl XI

ordered the construction of a factory for production of

muskets. At that time, the foundation was already laid for

the engineering skills behind the development of some of

the world's leading products in areas such as hunting

weapons, bicycles, motorcycles, domestic appliances,

sewing machines and outdoor products.

Husqvarna is the global leader in outdoor power products

for forestry, park maintenance and lawn and garden care,

as well as cutting equipment and diamond tools for the

construction and stone industries.

Owner responsibility

It is the o wner’s/employer’s responsibility that the operator

has sufficient knowledge about how to use the machine

safely. Supervisors and operators must have read and

understood the Operator’s Manual. They must be aware

of:

• The machine’s safety instructions.

• The machine’s range of applications and limitations.

• How the machine is to be used and maintained.

National legislation could regulate the use of this

machine. Find out what legislation is applicable in the

place where you work before you start using the machine.

Local regulations could restict the use of this machine.

Find out what regulations are applicable where you work

before you start using the machine.

The man ufacturer’s reservation

Subsequent to pub lishing this manual Husqvarna may

issue additional information for safe operation of this

product. It is the owner’s obligation to keep up with the

safest methods of operation.

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify

the design and appearance of products without prior

notice.

For customer information and assistance, contact us at

our website: www.husqvarna.com

Design and f eatures

V

alues such as high performance, reliability, innovative

technology, advanced technical solutions and

environmental considerations distinguish Husqvarna's

products. Safe operation of this product requires the

operator to read this manual carefully. Ask your dealer or

Husqvarna should you need more information.

Some of the unique features of your product are

described below.

• EPA 13 filter with efficient particle filtration 99.95% @

0.1-0.3 micron.

• An efficient dual shell cyclone with >95% separation

efficiency.

• Power outlet for Husqvarna PG 680 and PG 820.

• 75 mm (3”) hose inlet.

• The DC 6000 can be put in transport mode, when the

height of the machine is reduced in order to facilitate

transporting the vehicle.

• Easy to service.

• Robust hose couplings made of cast aluminum.

• Efficient filter cleaning.

• Automatic emptying of the cylone.

English – 5

PRESENT A TION

What is what on the mac hine?

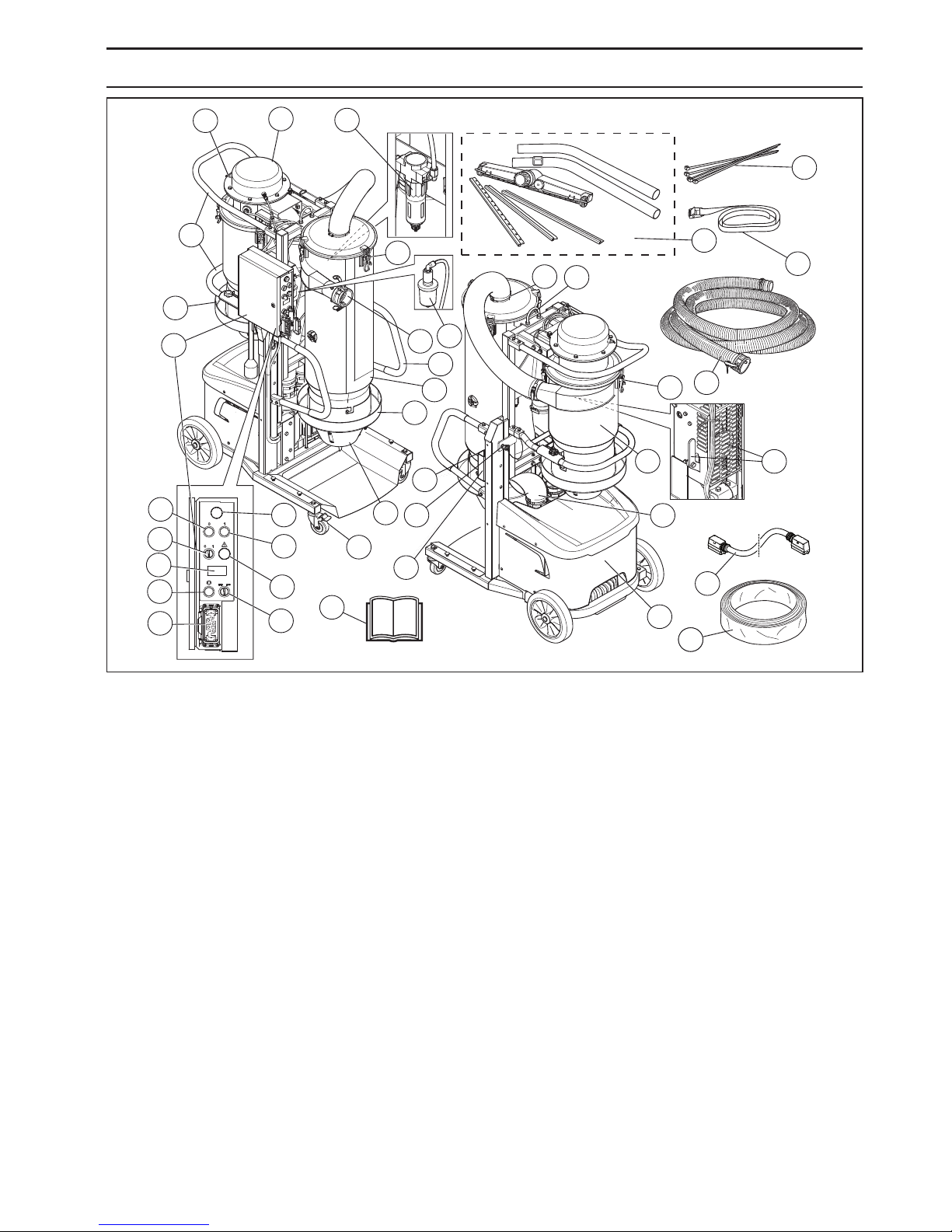

26

23

31

30

24

25

26

27

1

13

15

2

4

3

34

14

17

3

32

28

29

38

39

21

16

18

20

22

19

35

9

10

5

6

7

8

12

11

33

36

37

1

pressure container

2 Rear handle

3 Dust bag holder

4 Control Panel

5 Deactivation button OFF (machine)

6 On and Off knob vacuum

7 Chronometer

8 Manual purge

9 Deactivation button ON (machine)

10 Activation lamp (machine)

11 Warning light

12 Purge setting

13 Cyclone container

14 Front handle

15 Vacuum hose inlet

16 Clamping bracket cyclone

17 Chassis/Frame Transport position

18 Engine

19 Exhaust

20 Filter container

21 Strap, cone filter

22 Hose attachment cyclone

23 Vacuum wand with floor tool

24 2 x hose (3’’ 10 m, 2’’ 10 m)

25 Power cable for grinder

26 Longopac

27 Operator’s manual

28 Lifting eye

29 Cable tie holder

30 Tension strap

31 Cable ties

32 Cyclone cone

33 Compressor filter

34 Compressed air dryer

35 Restriction valve lever

36 Power cable connection

37 Lockable wheels

38 Hose cap

39 Pressure release valve

ASSEMBLING AND ADJUSTMENTS

6

– English

Connect the mac hine

General

•

The machine should be connected to an earthed

outlet socket. See instructions in the section

"Operation".

Dr

y use

•

Fit the dust bags on the machine.

• See dust bag replacement.

• Connect the 3” hose between the outlet port on the

grinder and the inlet port on the vacuumer.

• Connect the power plug from the grinder to the power

outlet on the dust extractor.

• Connect the power plug to the outlet.

Operation (Slurr y management)

Husqv arna DC 6000 can also be used for vacuuming wet

materials, for instance slurry management formed during

wet grinding.

NOTICE! Ensure vacuum is set to OFF position prior to

turning on power supply.

!

CA

UTION! We strongly recommend each

user wear respiratory protection/gas

mask when removing the cone filter from

the machine.

OPERA TING

English

–

7

Pr

otective equipment

General

Do not use the machine unless y ou are able to call for help

in the event of an accident.

P

ersonal protective equipment

Y

ou must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident does happen.

Ask your dealer for help in choosing the right equipment.

Always wear:

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Boots with steel toe-caps and non-slip sole

Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

Other pr otective equipment

•

Fire fighting equipment

• Always have a first aid kit nearby.

General saf ety precautions

This section descr ibes basic safety directions for using

the machine. This information is never a substitute for

professional skills and experience.

• Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

Save all warnings and instructions for

future reference.

•

Keep in mind that the operator is responsible for

accidents or hazards occuring to other people or their

property.

• All operators shall be trained in the use of the

machine. The owner is responsible for ensuring that

the operators receive training.

• The machine must be kept clean. Signs and stickers

must be fully legible.

!

W

ARNING! The use of products such as

cutters, grinders, drills, that sand or form

material can generate dust and vapors

which may contain hazardous chemicals.

Check the nature of the material you

intend to process and use an appropriate

breathing mask.

!

W

ARNING! Long-term exposure to noise

can result in permanent hearing

impairment. So always use approved

hearing protection. Listen out for

warning signals or shouts when you are

wearing hearing protection. Always

remove your hearing protection as soon

as the engine stops.

!

WARNING! There is always a risk of

crush injuries when working with

products containing moving parts. Wear

protective gloves to avoid body injuries.

!

WARNING! Sparks may appear and start

a fire when you work with the machine.

Always keep fire fighting equipment

handy.

!

WARNING! Read all safety warnings and

all instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

!

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Never allow children or other persons

not trained in the use of the machine to

use or service it. Never allow anyone else

to use the machine without first ensuring

that they have read and understood the

contents of the operator’s manual.

Children shall not play with the

appliance.

Never use the machine if you are

fatigued, while under the influence of

alcohol or drugs, medication or anything

that could affect your vision, alertness,

coordination or judgement.

There is always a risk of shocks from

electrically powered machines. Avoid

unfavourable weather conditions and

body contact with lightning conductors

and metal objects. Always follow the

instructions in the Operator’s manual to

avoid damage.

OPERATING

8 – English

Always use common sense

It is not possible to cover every conceivable situation you

can face. Always exercise care and use your common

sense. If you get into a situation where you feel unsafe,

stop and seek expert advice. Contact your dealer, service

agent or an experienced user. Do not attempt any task

that you feel unsure of!

Work safety

Work area safety

• Do not use the machine in bad weather, such as

dense fog, heavy rain, strong wind, intense cold, etc.

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• The machine should not be used in areas where

potential for fire or explosions exist.

Electrical safety

• Check that the mains voltage corresponds with that

stated on the rating plate on the machine.

• Inspection and/or maintenance should be carried out

with the motor switched off and the plug disconnected.

• Always shut down the machine before disconnecting

the power plug.

• Always unplug the machine during longer work

breaks.

• Never drag the machine by means of the cord and

never pull out the plug by pulling the cord. Hold the

plug to disconnect the power cord.

• Never use the machine if any cable or plug is

damaged, but hand it in to an authorized service

workshop for repair.

• The machine must never be driven to such a depth in

water that it reaches up to the machine’s equipment.

The equipment can be damaged and the machine can

be live, resulting in personal injuries.

Grounding instructions

• The machine is equipped with a grounded cord and

plug and should always be connected to a grounded

outlet. This reduces the risk of electric shock in the

event of malfunction.

• The use of adaptors is not allowed with the machine.

Extension cords and cables

• The marking on the extension cable must be the same

or higher than the value stated on the machine’s rating

plate.

• Use grounded extension cables.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

• Keep the connection to the extension cord dry and off

the ground.

• Keep cable away from heat, oil, charp edges or

moving parts. Damaged or entangled cable increase

the risk of electric shock.

• Check that the cables are intact and in good condition.

Never use the machine if any cable or plug is

damaged, but hand it in to an authorized service

workshop for repair.

• To avoid overheating do not use the extension cord

while it is rolled up.

• Ensure the cord is behind you when you start to use

the machine so that the cord will not be damaged.

!

WARNING! Unauthorized modifications

and/or accessories may lead to serious

injury or death to the user or others.

Do not modify this product or use it if it

appears to have been modified by others.

Never use a machine that is faulty. Carry

out the safety checks, maintenance and

service instructions described in this

manual. Some maintenance and service

measures must be carried out by trained

and qualified specialists. See

instructions under the heading

Maintenance.

Always use genuine accessories.

!

WARNING! There is always a risk of

shocks from electrically powered

machines. Avoid unfavourable weather

conditions and body contact with

lightning conductors and metal objects.

Always follow the instructions in the

Operator’s manual to avoid damage.

Never connect the machine to a outlet if

plug or cord is damaged.

!

WARNING! Improper connection can

result in the risk of electric shock.

Contact a qualified electrician if in doubt

as to whether the appliance is properly

grounded.

Do not modify the plug. If it will not fit the

outlet have a proper outlet installed by a

qualified electrician. Make sure local

regulations and ordinances are followed.

If the grounding instructions are not fully

understood contact a qualified

electrician.

OPERATING

English – 9

Personal safety

• Wear personal protective equipment. See instructions

under the heading ”Personal protective equipment”.

• Never use the machine if you are tired, if you have

drunk alcohol, or if you are taking medication that

could affect your vision, your judgement or your coordination.

• Never allow anyone else to use the machine without

first ensuring that they have read and understood the

contents of the operator’s manual.

• All operators shall be trained in the use of the

machine. The owner is responsible for ensuring that

the operators receive training.

• People and animals can distract you causing you to

lose control of the machine. For this reason, always

remain concentrated and focused on the task. Never

allow children to use or be in the vicinity of the

machine.

• Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

• There is always a risk of crush injuries when working

with products containing moving parts. Keep your

distance!

• Make sure that there is always another person close

at hand when you use the machines, so that you can

call for help if an accident should occur.

• Never leave the machine unsupervised with the motor

running. Always unplug the machine during longer

work breaks.

• Prevent unintentional starting. Ensure the switch is in

the OFF-position.

• Check that no tools or other objects have been left

lying on the machine.

• Always ensure you have a safe and stable working

position.

Use and care

• Husqvarna concrete dust vacuum cleaner DC 6000 is

designed for wet or dry suctioning of concrete dust

and liquid slurry management.

• The machine is intended for use in industrial

applications by experienced operators.

• Inspection and/or maintenance should be carried out

with the motor switched off and the plug disconnected.

• Keep all parts in good working order and ensure that

all fixtures are properly tightened.

• The machine should not be started without the dust

collection bag attached.

Transport and storage

• It is highly recommended that a dust collection bag be

fitted to the machine at all times whether in use or

transportation.

• At no time should lifting of machinery be attempted

without mechanical means such as a hoist or fork lift.

• The machine should not be lifted by handles, motor,

chassis or other parts. Transportation of the machine

is best done on a pallet / skid to which the machine

must be firmly secured. Always use the machine

mounted lifting eye when lifting. Machine dimensions

are 1892 mm raised and 1612 mm lowered.

• Secure the equipment during transportation in order

to avoid transport damage and accidents.

• The machine should be transported under cover

where possible, limiting the exposed to natural

elements – in particular rain and snow.

• Store the equipment in a lockable area so that it is out

of reach of children and unauthorized persons.

• Store the machine and its equipment in a dry and frost

proof place.

IMPORTANT! It is recommended that machinery be

transported upright where possible.

STARTING AND STOPPING

10 – English

Before starting

• Check that the machine is assembled correctly and do

not show any signs of damage. See instructions in the

section "Assembling and adjustments".

• Perform daily maintenance. See instructions in the

section "Maintenance".

• Use the manual purge at start-up and before

operating.

NOTE!

When running the GM 3000, raise the skirt on the grinder

so that there is a gap of around 0.5 cm between the floor

and the machine skirt.

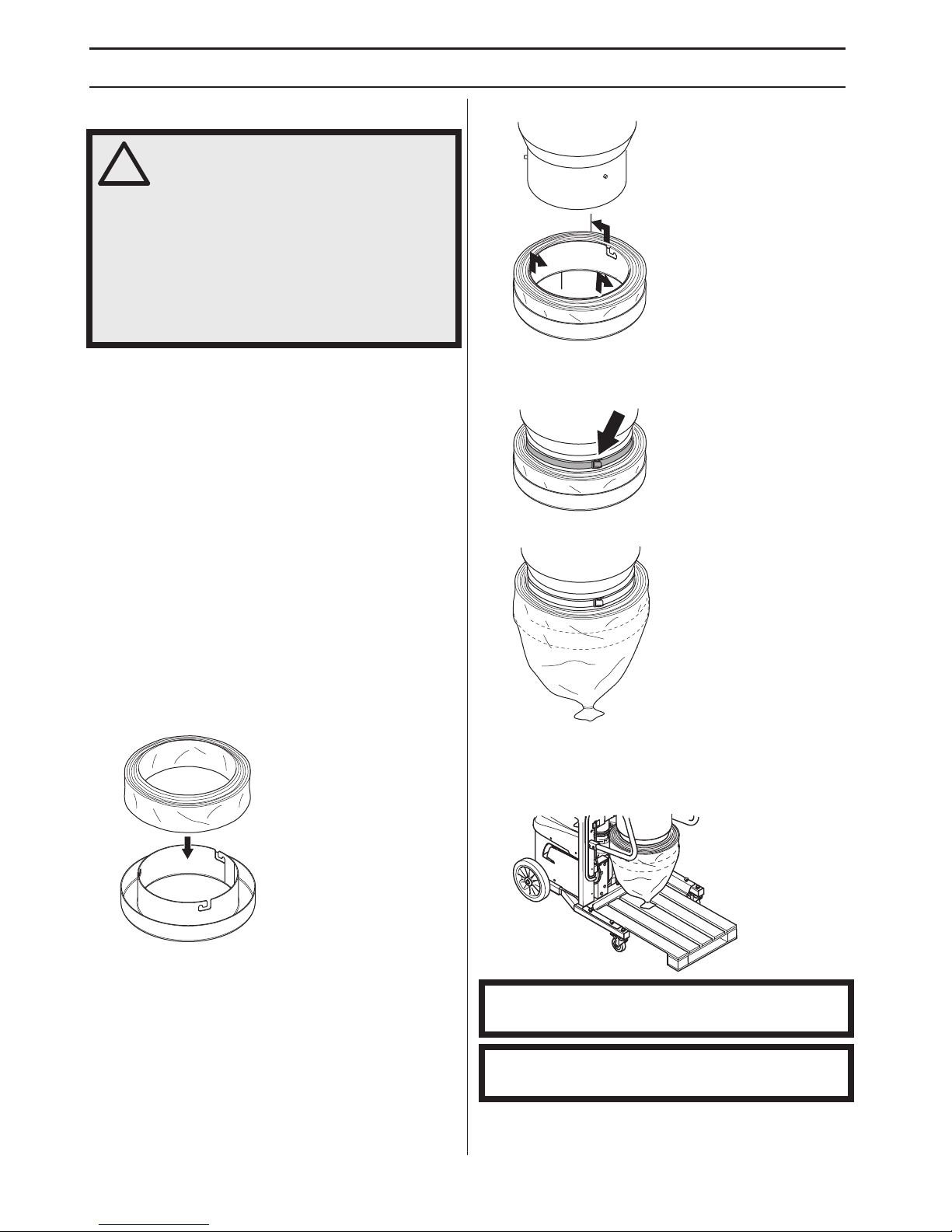

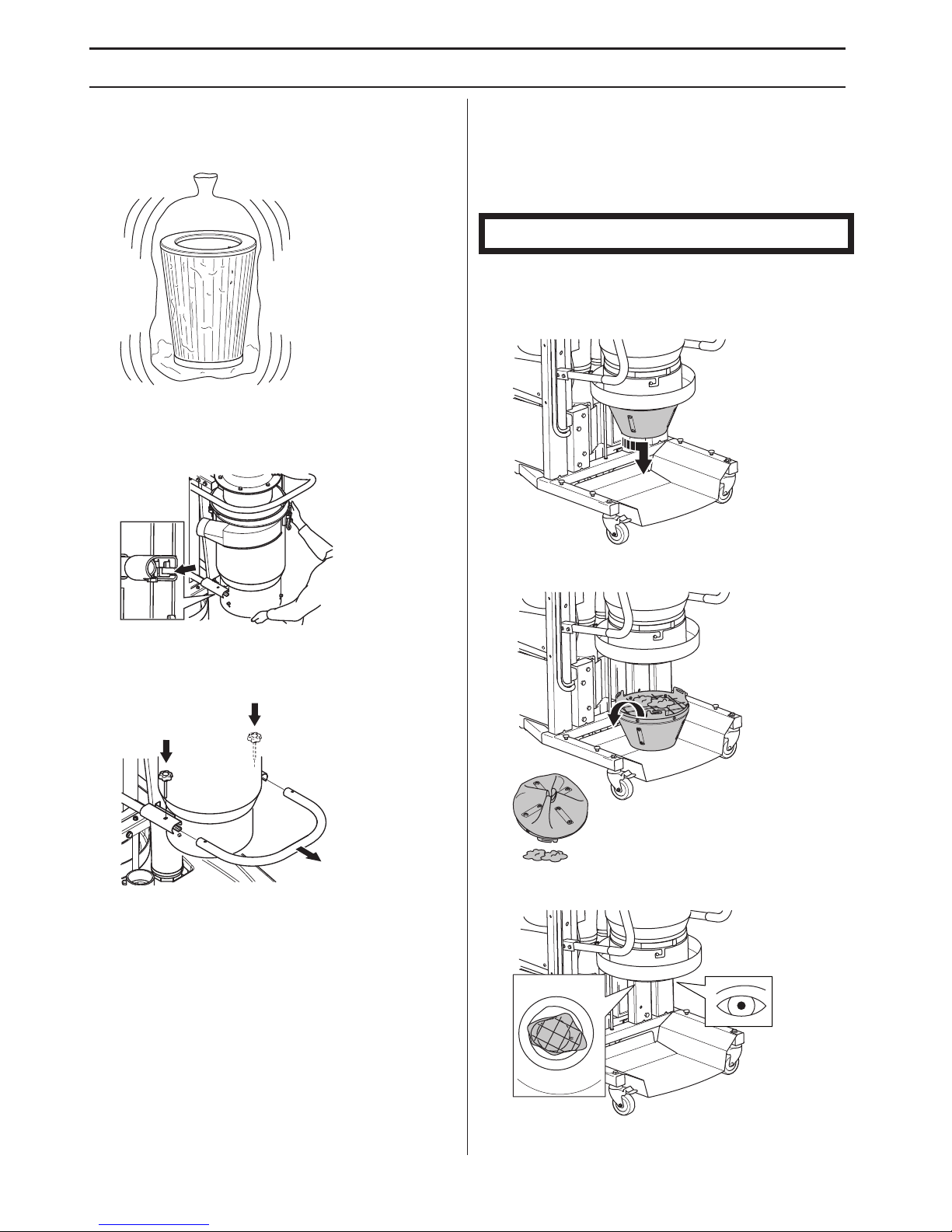

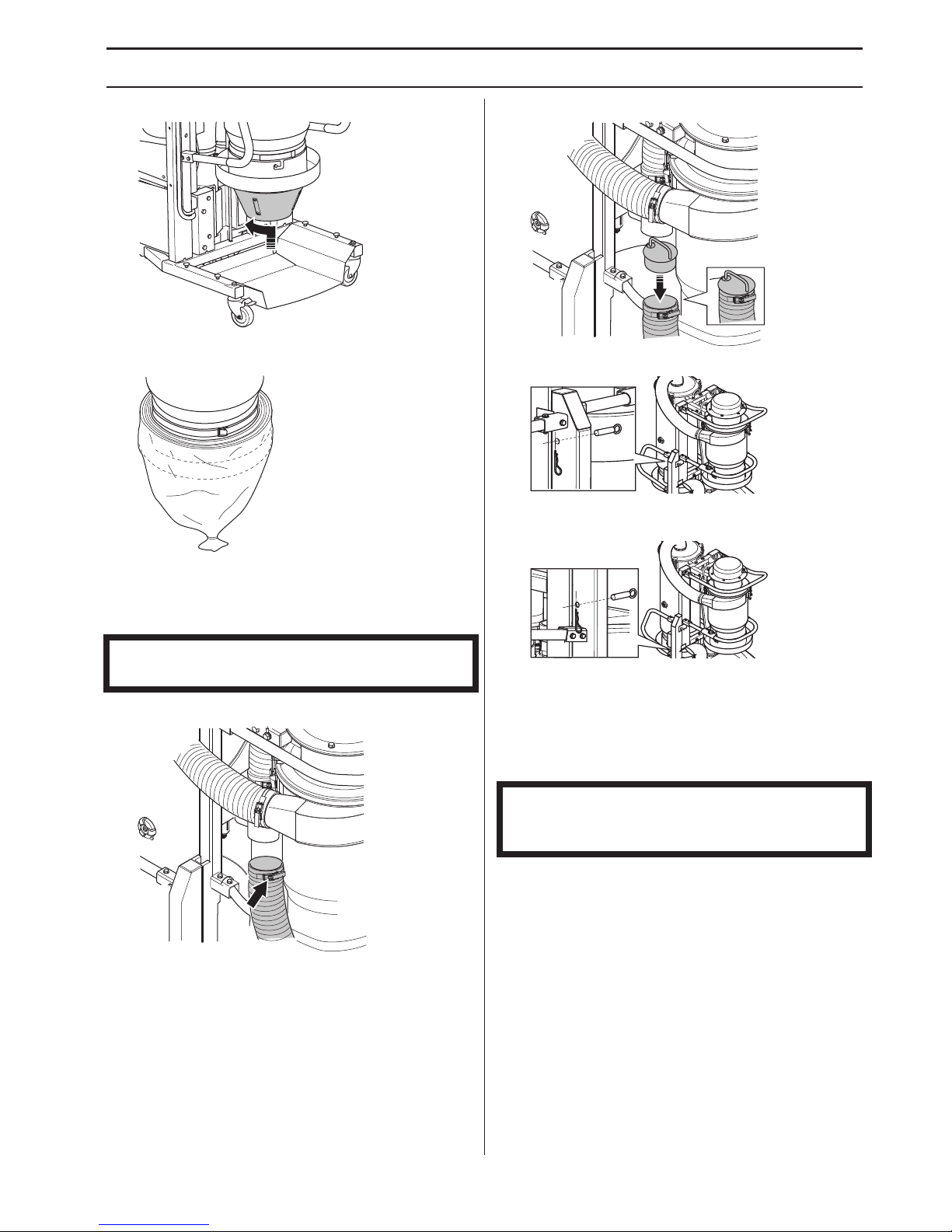

Changing the dust bags

Use Husqvarna recommended dust bags.

Use the manual purge 2 times before replacing the dust

bag. Once the dust bag has collected around 20 kg of

dust, to avoid lifting hazards caused by overfilling of dust

bags, the dust bag should be changed.

• Fit the dust bags in the holder.

• Place the dust bag holder in the container.

• Pull the bag up from the bag holder around the

container. Use a tightening strap to secure the bag

around the container.

• Pull the dust bag around the bag holder.

• Close the bottom of the dust bag with cable ties.

• It is possible to fill a dust bag placed on a half pallet.

Remove the bottom plate under the cyclone container.

Place a half pallet underneath.

!

WARNING! Please read the operator’s

manual carefully and make sure you

understand the instructions before using

the machine.

Wear personal protective equipment. See

instructions under the heading ”Personal

protective equipment”.

Make sure no unauthorised persons are

in the working area, otherwise there is a

risk of serious personal injury.

NOTICE! Check the dust bag regularly during operation

to avoid overfilling.

NOTICE! Be careful not to damage the cyclone cone

when cutting off a full dust bag.

STARTING AND STOPPING

English – 11

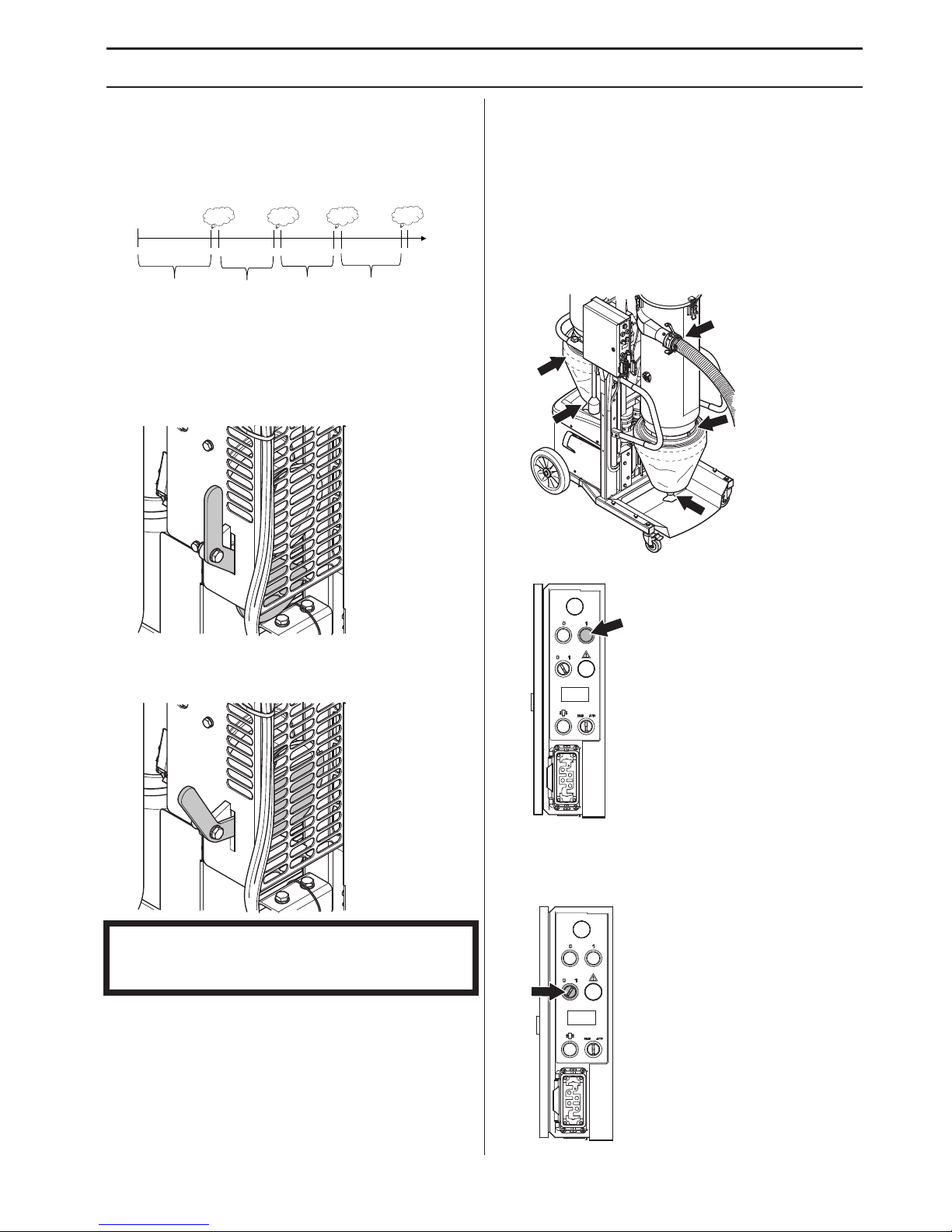

Auto dump

The Auto dump function will automatically open/release

pressure and empty the cyclone in pre set intervals. This

function also significantly improves the cleaning of the

filter.

Restriction valve

With the restriction valve you can choose to enable/

disable the Auto dump function. It is recommended to run

the machine with the valve open. NOTE! Dust control of

dust under the grinding head is less efficient with the valve

open during the 3 second auto dump/filter purge function.

Run the machine with the valve closed for more efficient

dust control during the 3 second auto dump/filter purge

function.

Starting

• Position the vacuum in the working area.

• Ensure the machine is raised.

• Ensure the dust bag holder is secured in its mountings

on the containers. Ensure the dust bag is secured

around the containers and is gathered with cable ties

at the bottom.

• Check that the suction hose is secured to the

connector.

• Push the green button (1).

• A white lamp is lit up. Wait around 30 seconds until

the compressor has reached the correct pressure.

The machine has power and is in stand-by mode.

• Turn the switch to the ON position (I).

NOTE! It is important that the dust skirt on the grinder is

in good condition for efficient containment of dust during

operation.

3 min

3 min 3 min

3 min

3 sec

3 sec

3 sec

3 sec

STARTING AND STOPPING

12 – English

Stopping

• Turn the switch to the OFF position (O).

• Let the machine slow down for around 20-25

seconds.

English – 13

MAINTENANCE

General

The life span of the machine can be reduced and the risk of accidents can increase if machine maintenance is not carried

out correctly and if service and/or repairs are not carried out professionally. If you need further information please contact

your nearest servicing dealer.

Maintenance schedule

In the maintenance schedule you can see which parts of your machine that require maintenance, and with which

intervals it should take place. The intervals are calculated based on daily use of the machine, and may differ depending

on the rate of usage.

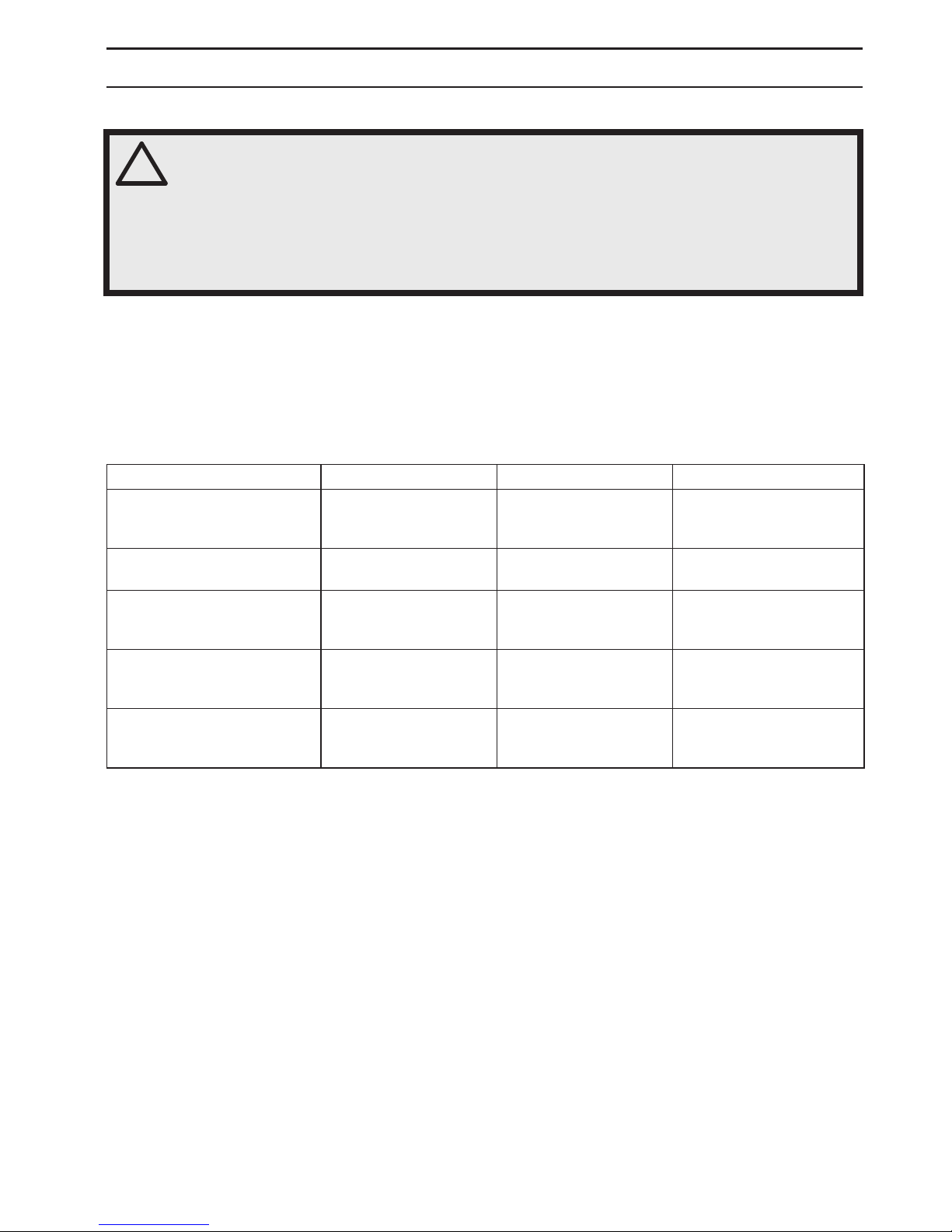

!

WARNING! The user must only carry out the maintenance and service work described in this

manual. More extensive work must be carried out by an authorized service workshop.

The machine should be switched off with the power cable disconnected from the outlet.

Wear personal protective equipment. See instructions under the heading ”Personal protective

equipment”. It is strongly advisable that all operators use a dust mask/respirator when changing

dust bags or performing maintenance on the machine.

Daily Maintenance Weekly maintenance Monthly maintenance Occasional maintenance

Check that the cord and

extension cord are intact and in

good condition.

Check the cyclone and

container

Clean the air dryer filter.

Replace if necessary.

Wash the filter elements

with a gentle soft jet of

water.

Clean the outside of the

machine.

Check the rubber bellows

on the cyclone.

Check the filter and if necessary

shake out the dust.

Make sure the grille on

the cyclone retainer is

clean.

Never clean the filter with air

pressure or sharp objects as

this may damage the filter.

Clean the compressor

filter. Replace if heavily

clogged.

The user should carry out a

daily check on the amount of

dust in the filter housing.

MAINTENANCE

14 – English

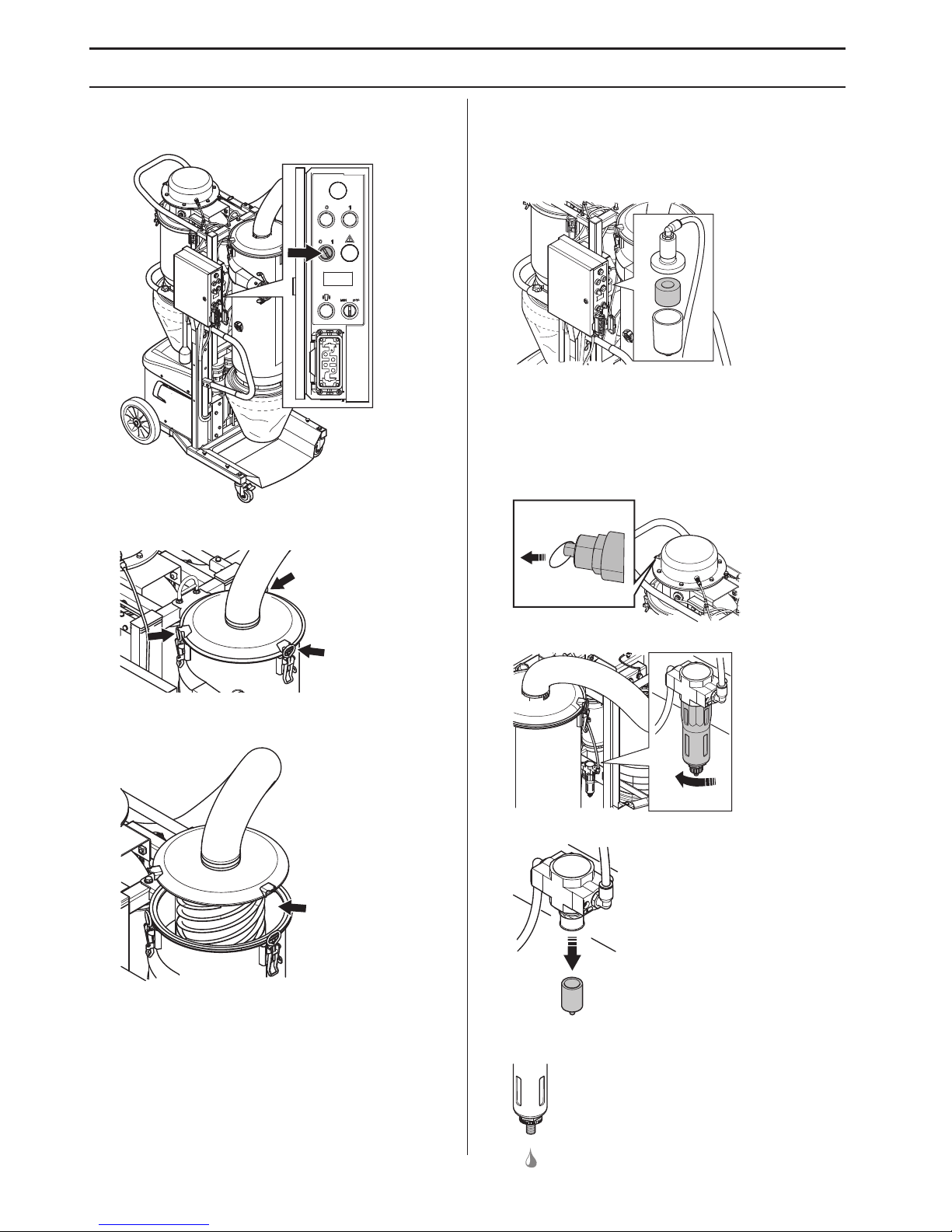

Check the cyclone and container

• Switch the machine to the off position.

• Loosen the clamping brackets for the lid to the cyclone

container.

• Lower the machine to transport position.

• Lift the lid to the cyclone container

• Make sure the cyclone is not clogged by dust or other

substances.

Cleaning of compressor filter

• Switch the machine to the off position.

• Remove the cover and clean the filter. Replace if

heavily clogged.

Cleaning of compressed air dryer

filter

• Switch the machine to the off position.

• Release the pressure in the system with the release

valve on the pressure container.

• Remove the cover.

• Remove and clean the filter. Replace if necessary.

Note! Drops of water will drip from the compressed air

dryer when the machine is running.

MAINTENANCE

English – 15

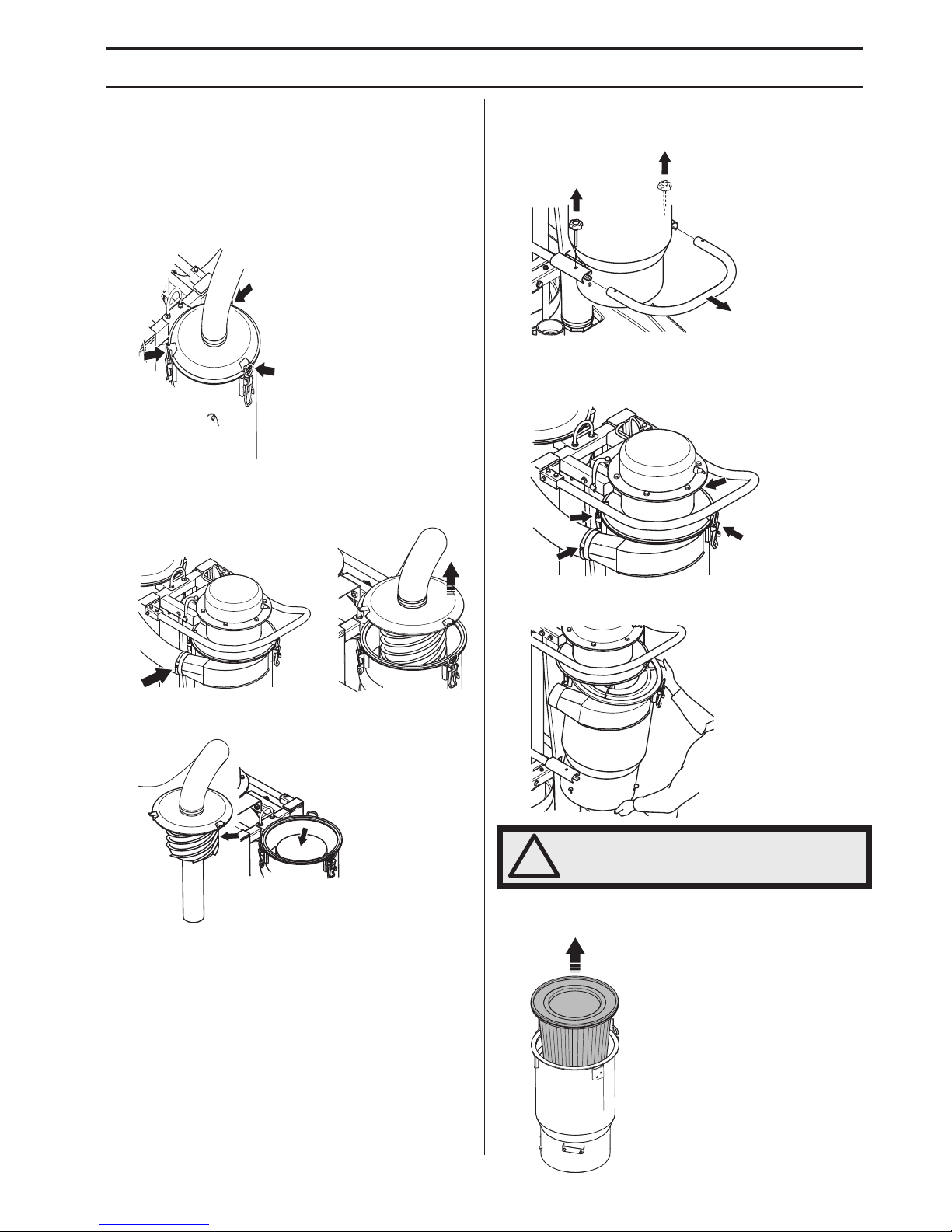

Cleaning of cyclone and

container

• Switch the machine to the off position.

• Loosen the clamping brackets for the lid to the cyclone

container.

• Loosen the hose connector to the filter container. Lift

the lid and remove the cyclone screw from the

container.

• Use compressed air or a brush to clean the cyclone

screw and container.

• Reinstall the cyclone screw in the container.

• Fit the lid and tighten it.

Cleaning/replacement of filter

• Loosen the handle by loosening the knob.

• Loosen the hose connector to the filter container.

• Loosen the clamping brackets for the lid to the filter

container.

• Grasp the lower rim of the filter container and lift the

container out of its guide groove.

• Place the filter container on the floor and remove the

filter.

!

CAUTION! The filter container is heavy.

MAINTENANCE

16 – English

• Clean the air filter by placing it in a bag and shaking

the dust off. Do not use compressed air or any sharp

objects to clean the air filter as this can cause damage

to the filter.

• The filter is a conical shape and the wider section

should be at the top of the filter container.

• Replace the filter container in its guide groove on the

handle.

• Tighten the container using the clamping brackets.

• Connect the hose connector to the filter container.

• Screw on the handle with the knob.

Washing the filter

The filter is made of a polyester material and can be

washed with water as necessary. Change filter after 500

hours or after 6 months.

• In order to avoid destruction of the finish or ePTFE

membrane clean the filter elements with a gentle soft

jet of water. A strong/sharp jet will destroy the ePTFE

membrane. The cleaning can be supported by a soft

brush.

• Wash the filter elements from top to bottom. Avoid

rubbing or scrubbing on selected spots.

• Dry the filter elements carefully. Approximately one

week at a temperature of 15-20 °C, or at 70 °C during

14 hours in the oven. It is important that they are 100%

dry.

• After washing in above mentioned way, the filter

elements can be used again at low pressure drop. The

life time after washing is approximately 60-70 % of the

life time in new condition.

Cleaning of cyclone cone

• Remove the cyclone cone by turning it

counterclockwise.

• Turn the cyclone cone over and empty the dust and

debris on the floor.

• Inspect the gaiter inside the filter container and clean

if necessary.

NOTICE! Ensure that the filter is dry before refitting it.

MAINTENANCE

English – 17

• Reinstall the cyclone cone.

• Pull the dust bag over the cyclone cone and close the

bottom with cable ties.

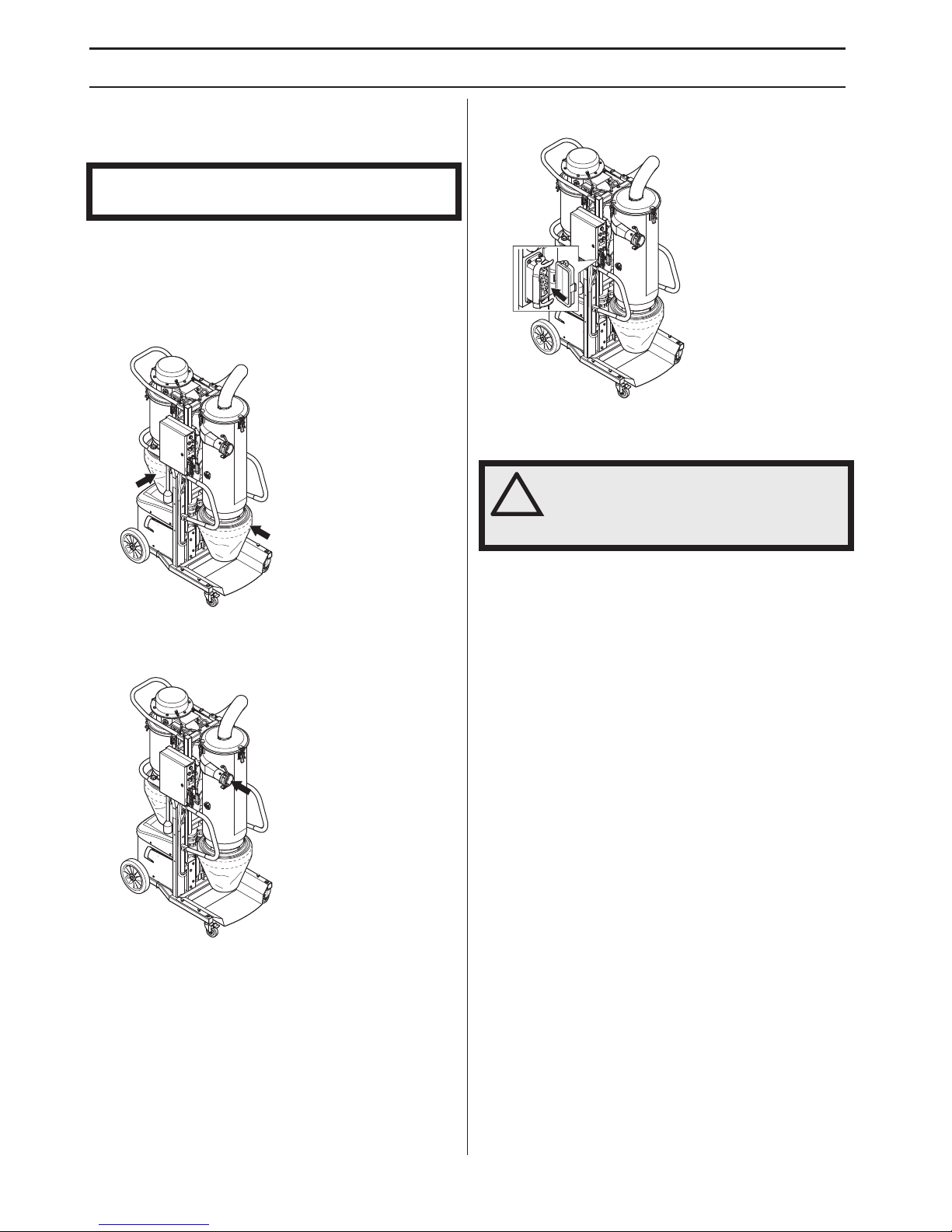

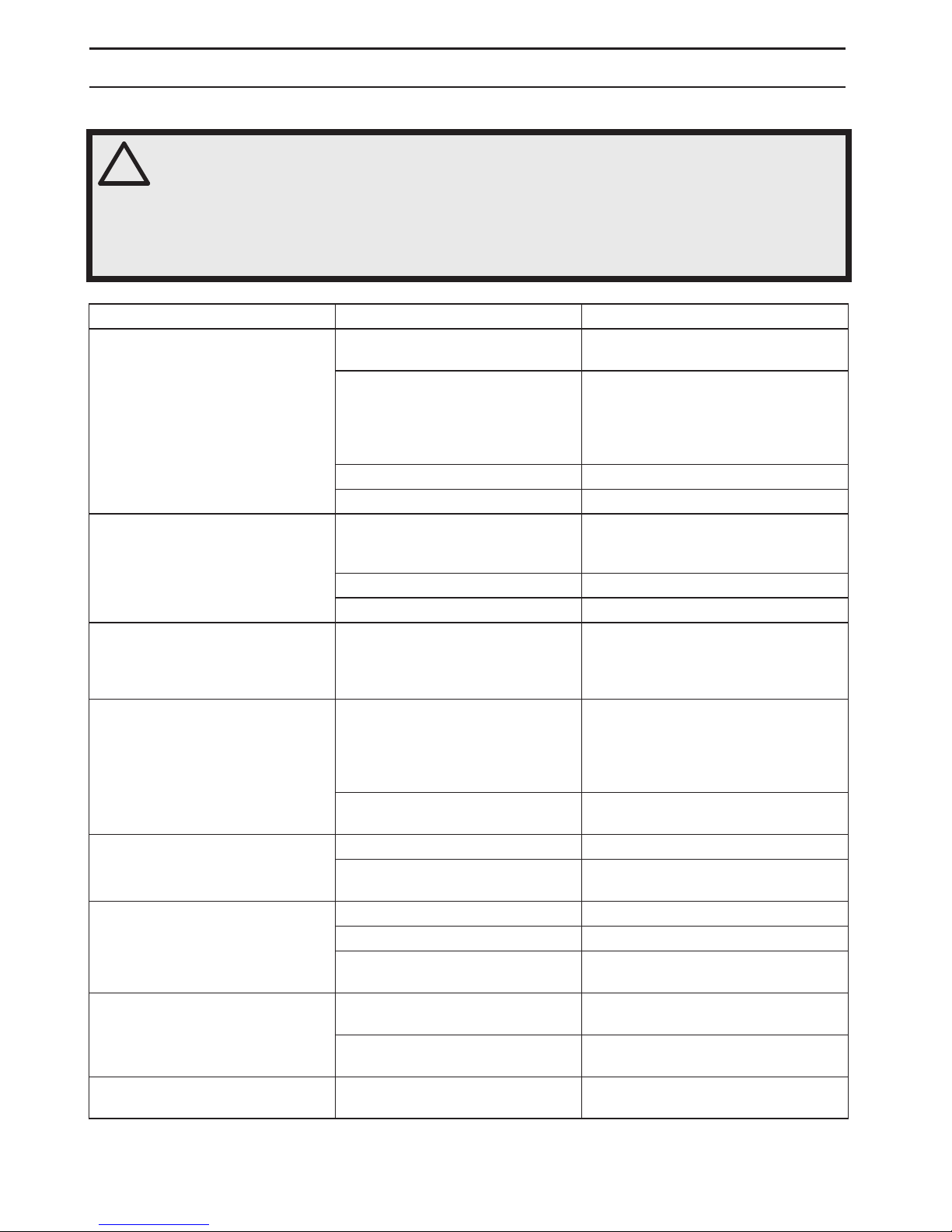

Transport position

The machine can be raised and lowered to make it easier

to handle during transport.

• Loosen the hose clamp and remove the hose.

• Seal the hose with the cap.

• Remove the pin and locking pin.

• Push down the upper part of the machine until it

reaches the attachment point for the lower position.

• The machine is kept in the upper position by means

of a gas spring. There is no risk of the machine falling

down.

• Replace the locking pin and pin.

Service

IMPORTANT! It is recommended that machinery be

transported upright where possible.

IMPORTANT! All types of repairs may only be carried

out by authorised repairmen. This is so that the

operators are not exposed to great risks.

18 – English

TROUBLESHOOTING

Troubleshooting

*If there are large amounts of dust in the filter housing it means that there is some kind of problem with the filter.

!

WARNING! Most accidents involving machines occur during trouble shooting, service and

maintenance as staff have to locate themselves within the machine’s risk area. Prevent accidents

by being alert and by planning and preparing the work.

The engine should be switched off during operations described in this chapter unless otherwise

stated.

All checks involving electric components should only be performed by a licensed electrician.

Problem Possible Cause Possible action

The machine does not start

The machine has no incomming or

outgoing power.

Check that the power cable is connected

and the machine turned on.

Have a licensed electrician check the

presence of power at the top of the left

side contactor. If no power at the

contactors, test for presence of power at

the power source.

Damaged cables. Contact a licensed electrician.

Circuit breaker has triggered. Make sure the circuit breaker is active.

The machine makes a low humming

sound when switched to ON

Phase error. Only two phases

present. Switch off machine

immediately to aviod motor burn-out.

Contact a licensed electrician.

Dust in the motor impellers. Contact a licensed electrician.

Burned out motor. Contact your service agent.

The machine is blowing instead of

sucking when on a different power

source

Phase relay fault.

Unplug the machine and have a

licensed electrician change L1 and L3

on the motor and test for suction to

confirm failed phase relay.

The machine will run but there is not

power at the accessory power outlet

Unit not correctly connected.

Check that the unit is correctly

connected and properly powered up.

(Eg. safety breaker and emergency stop

are in the correct position on the

grinder.)

Contact problems in electrical

cabinet.

Contact a licensed electrician.

The machine does not have much

suction

The filter is blocked Clean or replace the filter.

Cyclone is clogged.

Use compressed air or a brush to clean

the cyclone screw and container.

The machine is blowing dust out the

exhaust

The filter is not correctly fitted. Ensure the filters are fitted correctly.

The filter has become detached. Ensure the filters are fitted correctly.

Holes or perforations in the cone

filter.

Replace the filter.

Purge does not clean filter and/or

does not work.

Compressed air hose has come

loose or broken.

Check the hoses from the compressor,

pressure switch and purge tank.

Filter on compressor is clogged.

Clean or change the filter on the

compressor.

Compressor running continuously. Filter on compressor is clogged.

Clean or change the filter on the

compressor.

Loading...

Loading...