Page 1

GB

Operator’s manual

Please read the operator’s manual carefully and make sure

you understand the instructions before using the machine.

ES

DE

FR

Manual de

instrucciones

Lea detenidamente el manual de instrucciones y asegúrese

de entender su contenido antes de utilizar la máquina.

Bedienungsanweisung

Lesen Sie die Bedienungsanweisung sorgfältig durch und

machen Sie sich mit dem Inhalt vertraut, bevor Sie das

Gerät benutzen.

Manuel d’utilisation

Lire attentivement et bien assimiler le manuel d’utilisation

avant d’utiliser la machine.

HUSQVARNA CONSTRUCTION PRODUCTS

DC 5500

GB ES DE FR

Page 2

Contents

2 - English

Page 3

Contents

English

Contents

Key to symbols 4

Safety Instructions 5

Introduction 6

Transportation 6

Storage 6

What is what 7

Operation (dry use) 11

Operation (wet use) 12

Troubleshooting 13

Maintenance 14

Technical data 15

English - 3

Page 4

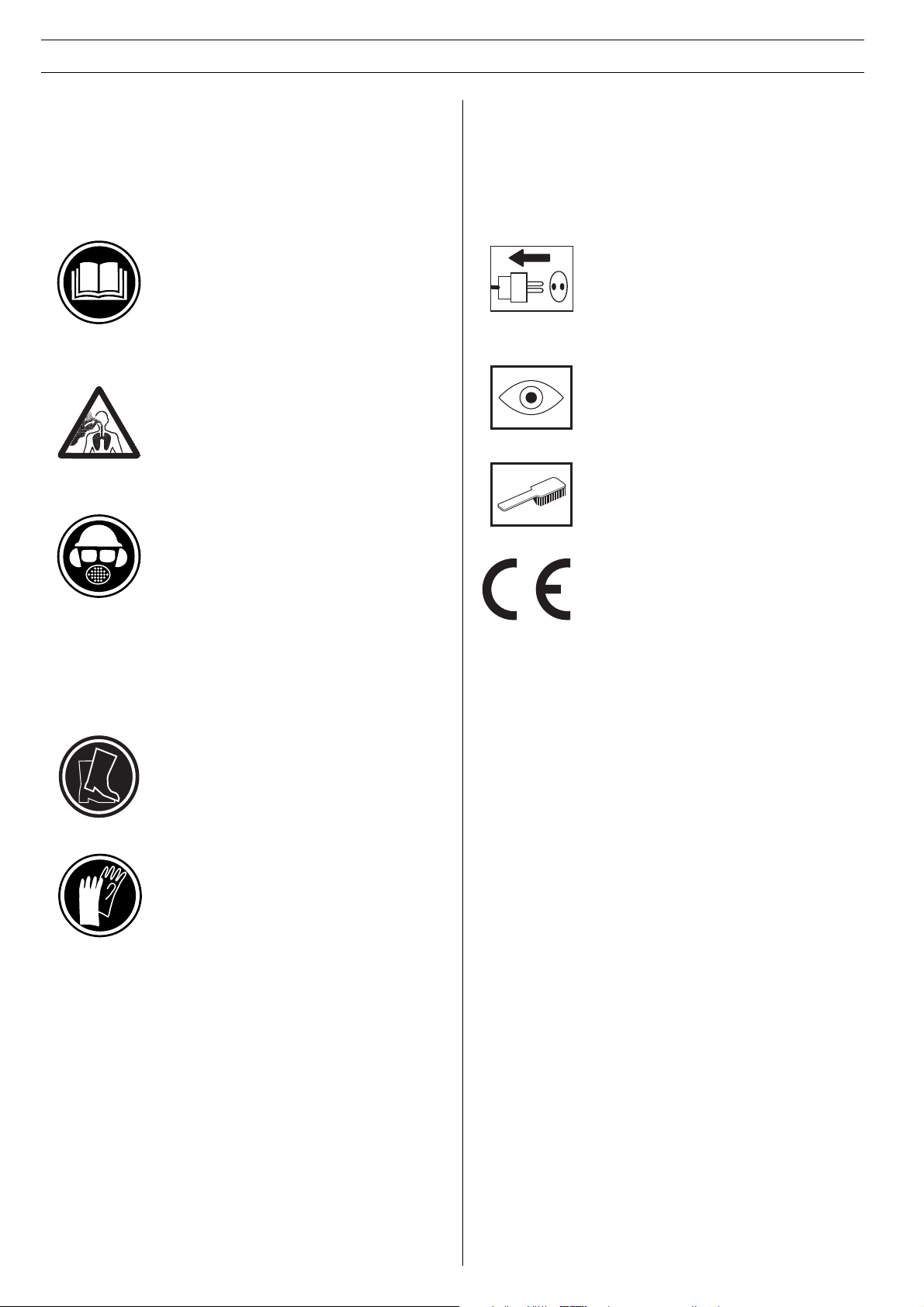

Key to symbols

Key to symbols

The symbols below are used on the machine and in

this Operator’s Manual. It is important that the user

understands the signifi cance of these in order to work

with the machine safely.

Please read the operator’s manual

carefully and make sure you understand the instructions before using the

machine.

WARNING! Dust forms when grinding

which can cause injuries if inhaled. Use

an approved breathing mask. Always

provide for good ventilation.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor.

• Dust forms when grinding, which

can cause injuries if inhaled. Use

dust mask.

Inspection and/or maintenance should

be carried out with the motor switched

off and the plug disconnected.

Visual check.

Regular cleaning is required.

This product is in accordance with applicable EC directives.

Always wear sturdy non-slip boots with

steel toe-caps.

Always wear approved protective

gloves.

4 - English

Page 5

Safety Instructions

Safety Instructions

WARNING

Under no circumstances may the machine be

started without observing the safety instructions. Should the user fail to comply with

these, Husqvarna Construction Products

Sweden AB or its representatives are free

from all liability both directly and indirectly.

Read through these operating instructions

and make sure that you understand the

contents before starting to use the machine.

Should you, after reading these safety instructions, still feel uncertain about the safety

risks involved you must not use the machine,

please contact your dealer for more information.

• Please read the operator’s manual carefully.

• Only qualifi ed staff should be allowed to operate

machinery.

• Check that the cord and extension cord are intact

and in good condition. Never use the machine if the

cord is damaged, hand it in to an authorized service

workshop for repair.

• Do not use a rolled up extension cord

• The machine should be connected to an earthed

outlet socket.

• Check that the mains voltage corresponds with that

stated on the rating plate on the machine.

• Ensure the cord is behind you when you start to

use the machine so that the cord will not be damaged.

At no time should lifting of machinery be attempted without mechanical means such as a hoist or

fork lift.

WARNING!

• Never use a machine that is faulty. Carry out the

checks, maintenance and service instructions

described in this manual. All repairs not covered in

this manual must be performed by a repairer nominated by either the manufacturer or distributor.

• Always wear personal safety equipment such as

sturdy non-slip boots, ear protection, dust mask and

approved eye protection.

• The machine should not be used in areas where

potential for fi re or explosions exist.

• The machine should not be started without the dust

collection bag attached.

• Never use the machine if you are tired, if you have

drunk alcohol, or if you are taking medication that

could affect your vision, your judgement or your

co-ordination.

• Never use a machine that has been modifi ed in any

way from its original specifi cation.

• Be on your guard for electrical shocks. Avoid having

body contact with lightning-conductors/metal in the

ground.

Overexposure to vibration can lead to circulatory damage or nerve damage in people who

have impaired circulation. Contact your doctor if you experience symptoms of overexposure to vibration. These symptoms include

numbness, loss of feeling, tingling, pricking,

pain, loss of strength, changes in skin colour

or condition. These symptoms normally appear in the fi ngers, hands or wrists.

• Never drag the machine by means of the cord and

never pull out the plug by pulling the cord. Keep all

cords and extension cords away from water, oil and

sharp edges.

• Make sure the cord is not pinched in doors, fences

or the like.

English - 5

Page 6

Introduction

Introduction

The Husqvarna DC 5500 dust extraction/vacuum unit

is designed for wet or dry suction of concrete dust and

liquid slurry.

This manual covers the Husqvarna DC 5500 dust collector/ vacuum unit. It is extremely important all users

be familiar with the contents of this manual before commencing operation of either machine. Failure to do so

may result in damage to machinery or expose operator

to unnecessary dangers.

IMPORTANT!

Only staff that have received the necessary

education, both practically and theoretically

concerning their usage should operate the

machinery.

Transportation

When in transportation, it is important to ensure the

unit is properly secured at all times. Machinery should

be transported under cover where possible, unexposed

to natural elements – in particular rain and snow. Protect the unit from water damage.

It is recommended that machinery be transported upright where possible, especially when transported when

uncovered.

It is highly recommended that a dust collection bag

be fi tted to the machine at all times whether in use or

transportation.

Storage

The machine should always be stored in a dry and

warm place when not in use to prevent internal condensation inside.

6 - English

Page 7

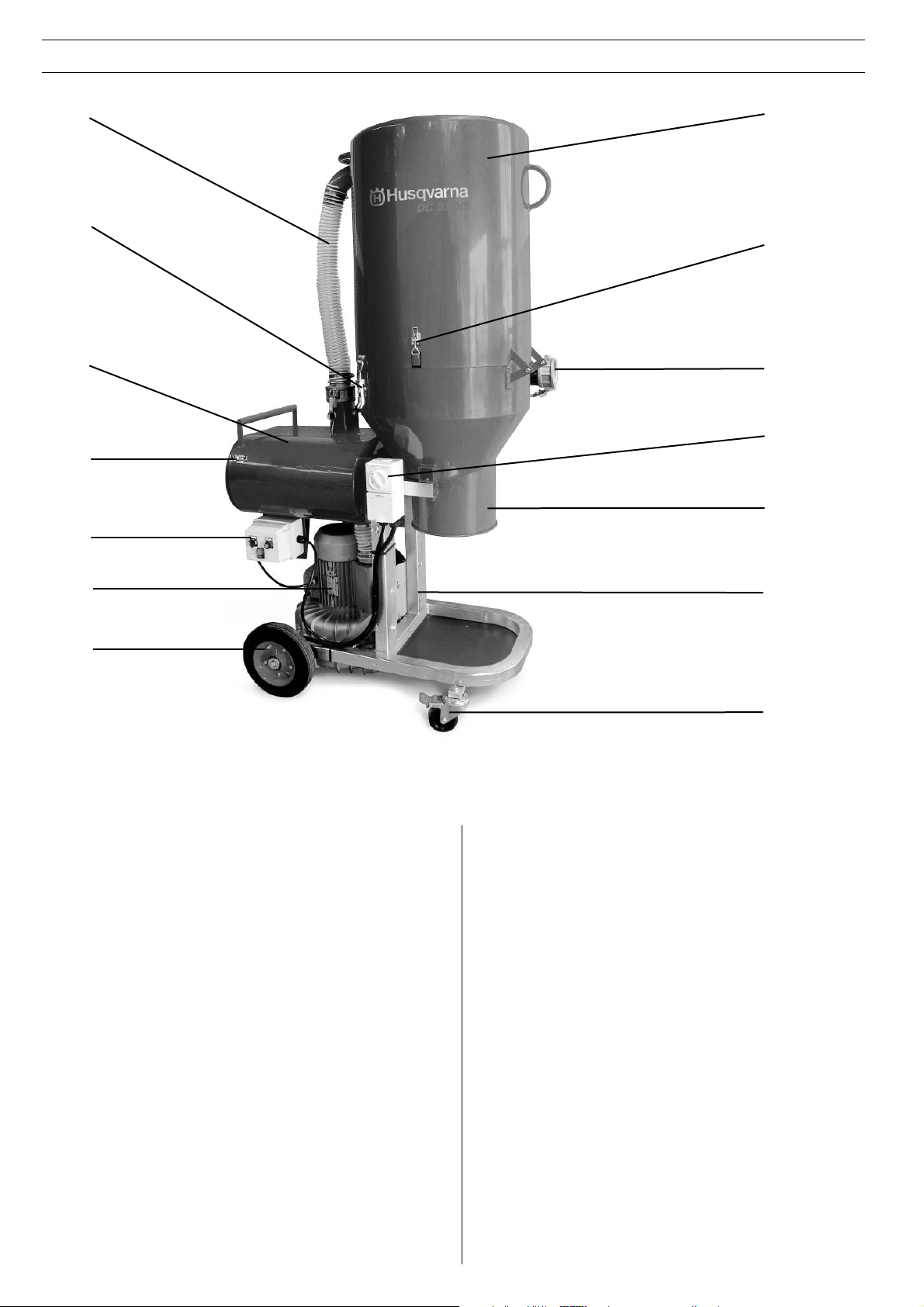

What is what

4.

2.

1.

10.

3.

9.

11.

13.

12.

5.

6.

7.

What is what

1. Small toggle latch

2. Filter link hose

3. Large toggle latch

4. Secondary fi lter housing

5. Control box

6. Vacuum pump

7. Rear wheel

8.

14.

8. Frame

9. Small toggle latch

10. Primary fi lter housing

11. Hose attachment fi tting

12. Collection cone

13. Accessory power point

14. Castor wheel

English - 7

Page 8

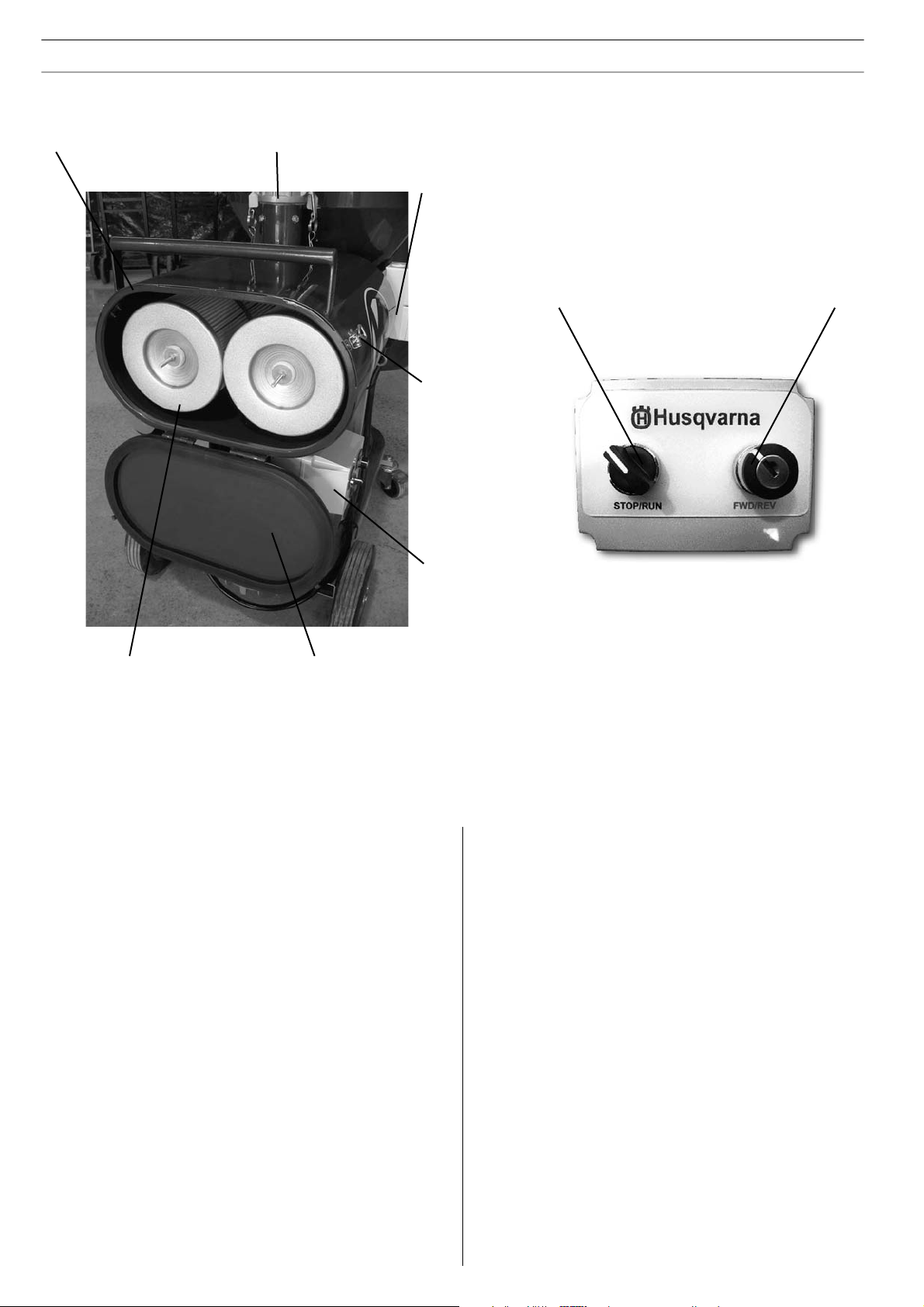

What is what

Diagram 1

2.

1.

Diagram 2

5.

1. 2.

6.

7.

Diagram 1

1. Filter link hose coupling

2. Secondary fi lter housing

3. Secondary fi lter

4. Secondary fi lter housing door

5. Accessory power point

6. Small toggle latch

7. Control box

4.3.

Diagram 2

1. Off/On switch

2. Forward/Reverse switch

8 - English

Page 9

Diagram 3

What is what

2.

3.

Diagram 3

1. Primary clamp part

2. Primary fi lter sock part

3. Primary fi lter seal. Outer part (kit)

4. Primary fi lter seal. Inner part (kit)

4.1.

English - 9

Page 10

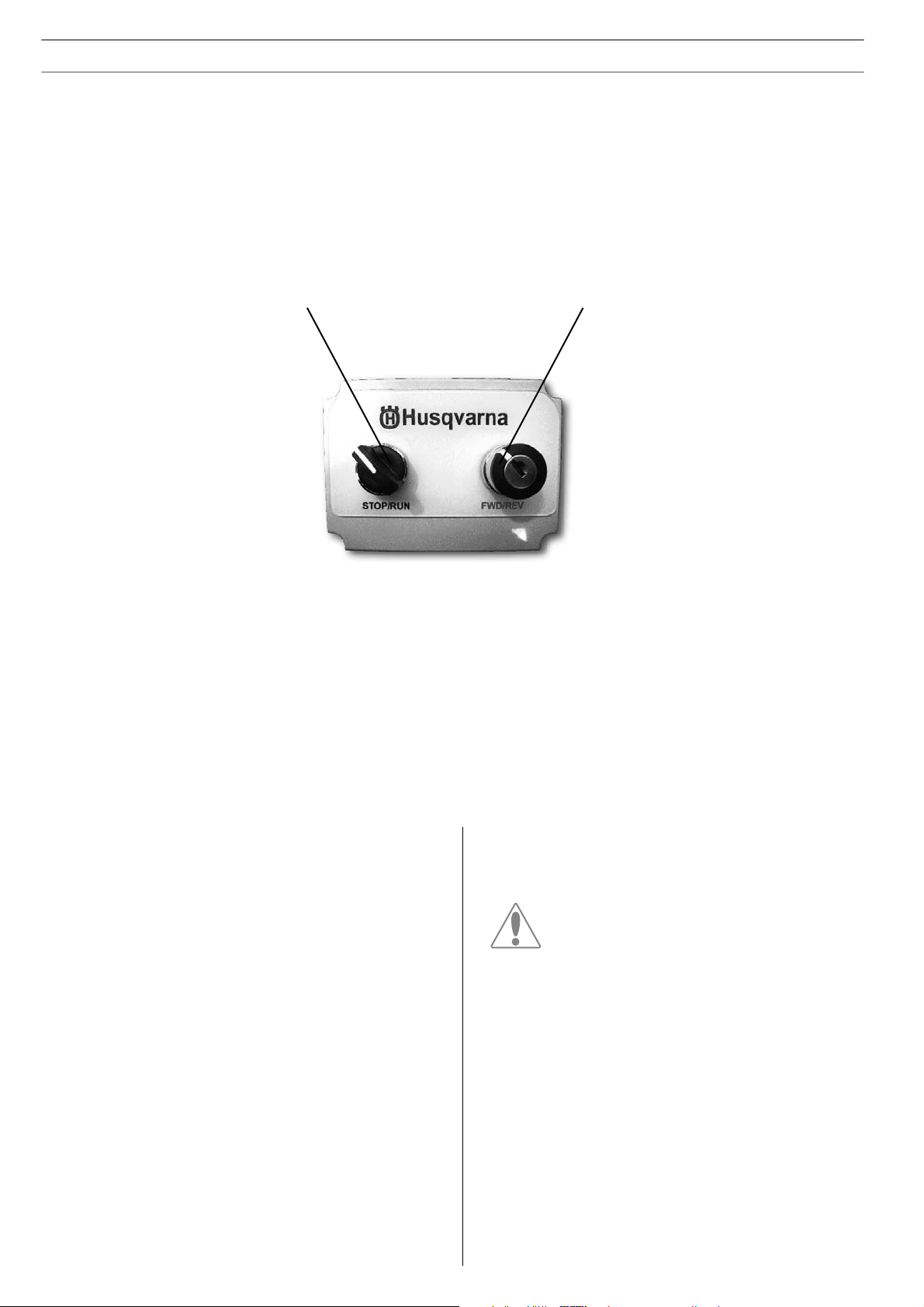

Diagram 4.

What is what

1. 2.

Control box

The control system consists of two switches:

1. On/Off swich.

Turns machine off in OFF position and on in ON position.

2. Fwd/Rev switch.

Changes direction of vacuum pump. Sometimes direction of vacuum will need to be reversed depending on

phase order of power supply.

10 - English

IMPORTANT!

Direction should NEVER be changed while

machine is switched to ON position (this is

why there is a lock on the FWD/REV switch).

If direction needs to be changed, turn machine back to OFF position, wait for 1 minute,

change direction and then switch back on.

Once direction setting has been changed,

remove key from FWD/REV switch before

switching back on.

Changing of direction while machine is running will result in motor failure.

Page 11

Operation (dry use)

Operation (dry use)

Setting up

1. Position the vacuum in the working area.

2. Ensure dust collection bag is fi tted to collection

cone.

3. Plug vacuum into power supply and switch on power

supply.

IMPORTANT!

Ensure vacuum is set to OFF position prior to

turning on power supply.

4. Disconnect fi lter link hose from top of secondary

fi lter housing.

5. Switch machine to ON position for 2 seconds and

place hand over fi lter link hose coupling. Feel with

hand whether machine is sucking or blowing.

1. Switch the machine to the off position.

2. Using a large rubber hammer/mallet, tap the top

surface of the primary fi lter housing 10 times. While

this is happening you will notice all the dust from

inside the unit drop into the plastic bag attached to

the collection cone.

Changing the dust bags.

Once the dust bag has collected around 20 kg of

dust, to avoid lifting hazards caused by overfi lling of

dust bags, the dust bag should be changed.

1. Clear the primary fi lters of dust as outlined previous-

ly and agitate bag so that dust settles in the bottom

of the bag.

2. Switch the machine back into ON position (you will

notice the air is sucked from the plastic bag).

3. Tie bag off below the collection cone using a cable

tie or other bag tie.

4. Release elastic strap and remove sealed bag.

6. If machine is blowing, wait 1 minute (for motor to

completely stop turning) and switch machine to

other direction using FWD/REV switch.

IMPORTANT!

Always remove key from FWD/REV switch.

This will lock switch and make it impossible

to change direction of motor when machine is

running.

7. Once machine direction is set correctly it is ready

for use with grinding machine.

Cleaning the primary fi lters.

After every 10-20 minutes of operation, the primary

fi lters will need cleaning as dust will buildup on the

inside of the fi lter socks. The easiest and most effec-

tive way to clear the dust buildup on the fi lter sock is

as follows:

IMPORTANT!

Use extreme caution when releasing and reattaching elastic strap.

5. Using elastic strap, attach new empty plastic bag

(you will notice the air is sucked from the plastic

bag).

6. Machine is now ready to be used for duct collection

again.

IMPORTANT!

It is important to keep vacuum running during

the bag changing process. This will keep the

valve in the collection cone closed ensuring

no dust will drop out from within the collection

cone when bag changing is being performed.

This method will greatly reduce operator

exposure to fi ne dust particles when using

the equipment. It is strongly advisable that all

operators use a dust mask/respirator when

changing dust bags or performing maintenance on the machine.

English - 11

Page 12

Operation (wet use)

Operation (wet use)

The Husqvarna DC 5500 can also be used for collection

of wet materials such as slurry formed from the wet grinding process.

In order to use the machine for wet collection, simply

remove the primary fi lter socks from the unit.

1. Disconnect the fi lter link hose.

2. Release the large toggle latch.

3. Fold the primary fi lter housing into the forward

position.

4. Release the 2 small toggle latches.

5. Lift the primary fi lters from within the primary

fi lter housing.

IMPORTANT!

It is strongly advisable that all operators use a

dust mask/respirator when removing primary

fi lter socks from the machine.

12 - English

Page 13

Troubleshooting

Troubleshooting

Whilst every measure has been undertaken by the

manufacturer to ensure smooth reliable operation of

the machine, sometimes problems can arise.

The following possible problems may arise:

1. The machine will not run.

Ensure power connected to machine is on. If ma

chine still will not run, remove cover from control

box and test for presence of power supply at top of

left side contactor. If no power at contactors, test

power supply at power source. If power supply is ok

at source but there is no supply at contactors in con

trol box, check connections inside accessory power

point. These checks should only be performed by a

licensed electrician)

2. The machine makes a low humming sound when

switched to ON.

This indicates there are only two-phases of power

supply at the motor. Switch off machine immediately

to avoid motor burn-out. Have an electrician check

the machine to determine the cause of the missing

phase. If all three-phases are ok at motor then there

is a strong possibility the motor is faulty.

(B) Make sure fl ap in bottom of collection cone

is closing properly and creating a seal.

If this fl ap is not functioning properly, machine will

tend to suck up dust bag when switched on.

6. The machine is blowing dust out the exhaust.

(A) Normally this means the secondary fi lters

are not installed properly and dust is bypassing

them. Ensure the seals on the ends of the second

ary fi lters opposite the secondary fi lter housing door

are creating a proper seal. This can be viewed by

looking down the fi lter link hose coupling.

(B) Secondary fi lters may need replacing.

3. The machine will only run in one direction.

This indicates a problem with either the FWD/REV

switch mechanism or one of the contactors. Have

an electrician test the machine.

4. The machine will run but there is not power at

the accessory power point.

Check connections inside accessory power point.

5. The machine does not have much suction.

(A) Inspect inside secondary fi lter housing

and make sure secondary fi lters are not blocked

with dust. If blocked up with dust, remove and clean

fi lters by either tapping out or using compressed air.

IMPORTANT!

A respirator should be worn at all times when

performing fi lter cleaning activities.

If large amounts of dust present in secondary fi lter

housing, this indicates a problem with the primary

fi lters. Usually this means there is a hole in one or

more of the primary fi lters or one of the primary

fi lters has come loose.

Check primary fi lters for small holes or perforations.

Small holes can be repaired/patched using silicone

sealant.

English - 13

Page 14

Maintenance

Maintenance

The following maintenance steps should be followed

to maximise optimal performance and reliability of the

machine:

Daily Inspection of Micro Filters:

It is highly recommended that operators check dust

levels inside secondary fi lter housing on a daily basis.

This will indicate the effectiveness of the primary fi lters.

If there is dust building up inside the secondary fi lter

housing, it is more than likely due to one of the following reasons:

1. Small holes or perforations have developed in

primary fi lters.

2. There is a problem with a seal in the primary fi lter

housing assembly. If when inspected, it is found that

there is dust building up inside the secondary fi lter

housing, it is recommended to remove the primary

fi lters and check for small holes or perforations.

Usually, small holes will begin to develop around the

stitching of the fi lter media. If small holes are locat-

ed, clean area around hole with either compressed

air or vacuum. Once area is clean, the hole can be

repaired with silicone sealant. If no small holes or

perforations are found, check rubber seals in the

primary fi lter housing assembly and make sure they

are all intact.

Generally speaking, with consistent use, the primary

fi lters should be replaced approximately every 6

months. This will maintain good suction levels and

reduce incidence of holes developing in the fi lters.

The secondary fi lter should be changed every 12

months. Made from a polyester fi lter media, the sec-

ondary fi lters can be washed out with water. Ensure

they are fully dry prior to re-installation.

On re-installation of the secondary fi lter, ensure the

seals are fi rmly pressed against the wall of the sec-

ondary fi lter housing. This contact can be assessed

by looking down through the fi lter link hose coupling.

14 - English

Page 15

Technical data

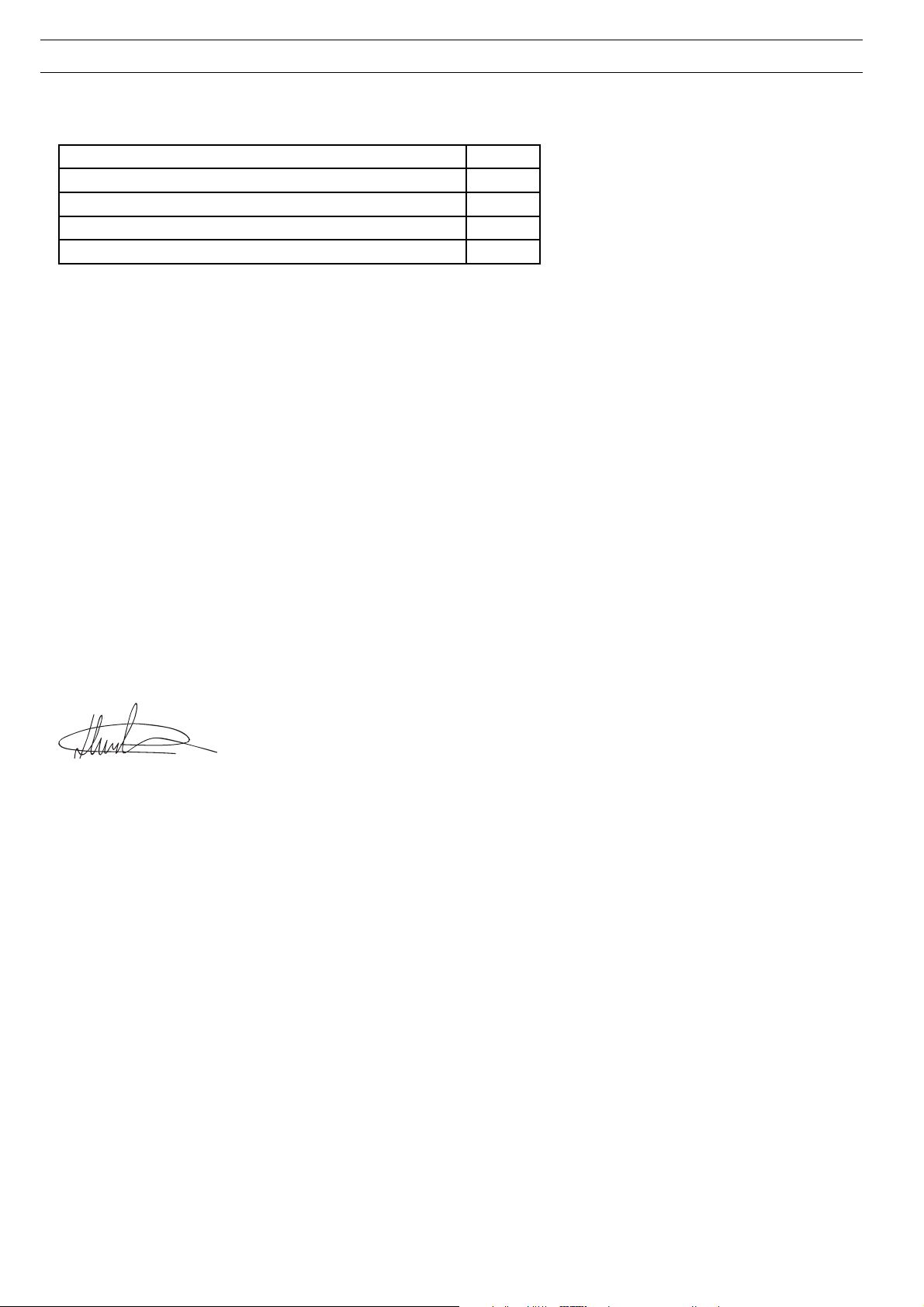

Technical data

Noise emissions (see note 1)

Sound power level, measured dB(A) 92

Sound power level, guaranteed L

Sound levels (see note 2)

Sound pressure level at the operators ear, dB(A) 77

dB(A) 93

WA

Note 1: Noise emissions in the environment measured as sound power (L

Note 2: Noise pressure level according to EN 60335-2-69. Reported data for noise pressure level has a typical statisti-

cal dispersion (standard deviation) of 1.0 dB(A).

) in conformity with EN 60335-2-69.

WA

EC-declaration of conformity

(Applies to Europe only)

Husqvarna AB, SE-433 81 Göteborg, Sweden, tel: +46-31-949000, declares under sole responsibility that the vacuum

cleaner Husqvarna DC 5500 dating from 2010 serial numbers and onwards (the year is clearly stated on the rating

plate, followed by the serial number), complies with the requirements of the COUNCILíS DIRECTIVE:

• of May 17, 2006 “relating to machinery” 2006/42/EC.

• of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

• of December 12, 2006 ”relating to electrical equipment” 2006/95/EC.

The following standards have been applied: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-

3-2:2006, EN 61000-3-3/A1/A2:2005, EN 60335-2-69:2009.

Göteborg December 29, 2009

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

English - 15

Page 16

Índice

16 - Spanish

Page 17

Índice

Español

Índice

Signifi cado de los símbolos 18

Instrucciones de seguridad 19

Introducción 20

Transporte 20

Almacenamiento 20

Componentes de la máquina 21

Manejo (uso en seco) 25

Manejo (uso mojado) 26

Localización de averías 27

Mantenimiento 28

Datos técnicos 29

Spanish - 17

Page 18

Signifi cado de los símbolos

Signifi cado de los símbolos

Los siguientes símbolos se usan en la máquina y en

este manual de instrucciones. Es importante que el

usuario entienda el signifi cado de los mismos para

trabajar con la máquina de forma segura.

Antes de utilizar la máquina, lea atentamente el manual de instrucciones y

asegúrese de haber comprendido las

instrucciones.

¡ADVERTENCIA! El polvo se forma

cuando se desbasta, lo que puede

provocar lesiones si se inhala. Use una

máscara respiratoria autorizada. Mantenga siempre una buena ventilación.

Utilice siempre:

• Casco protector aprobado

• Protección auditiva aprobada

• Gafas protectoras o un visor.

• El polvo se forma cuando se desbasta, lo que puede provocar

lesiones si se inhala. Use una máscara para el polvo.

La inspección y/o el mantenimiento se

deberá llevar a cabo con el motor apagado y el enchufe desconectado.

Comprobación visual.

Se requiere una limpieza regular.

Este producto cumple las disposiciones

de las Directivas CE aplicables.

Lleve siempre botas robustas antideslizantes con puntera de acero.

Utilice siempre guantes protectores

aprobados.

18 - Spanish

Page 19

Instrucciones de seguridad

Instrucciones de seguridad

ADVERTENCIA

La máquina no se podrá poner en marcha

bajo ninguna circunstancia si no se observan

las instrucciones de seguridad. Si el usuario

no cumpliera este requisito, Husqvarna

Construction Products Sweden AB o sus

representantes no tendrán ningún tipo de

responsabilidad, ya sea directa o indirecta.

Léase detenidamente estas instrucciones

de manejo y asegúrese de que entiende su

contenido antes de empezar a usar la máquina. Si después de leer estas instrucciones

de seguridad siguiera sin estar seguro de

los riesgos que implica para la seguridad, no

deberá usar la máquina; por favor, póngase

en contacto con su distribuidor para más

información.

• Por favor, lea con sumo cuidado el manual de

instrucciones.

• Sólo se le permitirá manejar la maquinaria a personal cualifi cado.

• No use nunca una máquina que esté defectuosa.

Lleve a cabo las comprobaciones, instrucciones

de mantenimiento y asistencia descritas en este

manual. Todas las reparaciones que no cubra este

manual las deberá llevar a cabo un reparador designado ya sea por el fabricante o por el distribuidor.

• Lleve siempre equipamiento de seguridad personal

como botas robustas antideslizantes, protección

auditiva, máscara para el polvo y protección ocular

aprobada.

• Asegúrese de que el cordón no se quede atrapado

en puertas, vallas u objetos similares.

• Compruebe que el cordón y el cordón de extensión

están intactos y en buen estado. No use nunca

la máquina si el cordón está dañado, llévelo a un

taller de asistencia autorizado para su reparación.

• No use un cordón de extensión enrollado

• La máquina deberá conectarse a una toma de corriente de salida con toma de tierra.

• Compruebe que el voltaje principal se corresponde

con el que se indica en la placa de características

de la máquina.

• Asegúrese de que el cordón está detrás de Ud.

cuando empiece a usar la máquina, de modo que

no se pueda dañar el cordón.

No se deberá intentar levantar la maquina en

ningún momento sin medios mecánicos como un

cabrestante o un elevador de horquilla.

¡ADVERTENCIA!

La sobreexposición a la vibración puede

provocar lesiones circulatorias o del sistema

nervioso en personas que tengan mala circulación. Póngase en contacto con su médico

si tiene síntomas de sobreexposición a la

vibración. Estos síntomas incluyen entumecimiento, pérdida de sensación, cosquilleo,

ardor, dolor, pérdida de fuerza, cambios en

el color o el estado de la piel. Estos síntomas

aparecen normalmente en los dedos, manos

o muñecas.

• La máquina no se usará en áreas donde haya posibilidad de incendios o explosiones.

• La máquina no deberá ponerse en marcha si no

lleva la bolsa para recoger el polvo.

• No use nunca la máquina si está cansado, si ha bebido alcohol, o si ha tomado alguna medicación que

pudiera afectar a su visión, su capacidad mental o

su coordinación.

• No use nunca una máquina que se haya modifcado

en algún sentido de su especifi cación original.

• Esté atento ante posibles descargas eléctricas.

Evite tener contacto corporal con pararrayos/metal

en el suelo.

• No arrastre la máquina nunca por el cordón y no

quite nunca el enchufe tirando del cordón. Mantenga todos los cordones y cordones de extensión

lejos del agua, aceite y bordes afi lados.

Spanish - 19

Page 20

Introducción

Introducción

La unidad aspiradora/extractora de polvo Husqvarna

DC 5500 se ha diseñado para la succión en mojado o

en seco del polvo de cemento y lechada de cemento.

Este manual se refi ere a la unidad aspiradora/extrado-

ra de polvo Husqvarna DC 5500. Es extremadamente

importante que todos los usuarios estén familiarizados

con el contenido de este manual antes de empezar a

manejar una de las máquinas. Si no fuera así, esto podría provocar daños en la maquinaria o la exposición

del operador a peligros innecesarios.

¡IMPORTANTE!

Sólo deberá manejar la maquinaria aquel

personal que haya recibido la formación

necesaria, tanto práctica como teórica acerca

de su uso.

Transporte

Cuando se esté transportando, es importante asegurarse de que la unidad esté fi jada de forma adecuada

en todo momento. La maquinaria se deberá transportar

cubierta siempre que sea posible, sin exponerse a los

elementos naturales, en particular a la lluvia y la nieve.

Aunque es resistente al agua, se deberán tomar todas

las medidas necesarias para proteger la unidad de

daños por agua.

Se recomienda que la maquinaria se transporte derecha siempre que sea posible, sobre todo cuando se

transporte sin cubrir.

Se recomienda encarecidamente que se ajuste una

bolsa de recogida de polvo a la máquina en todo momento, ya esté en uso o se esté transportando.

Almacenamiento

La máquina se deberá almacenar siempre en un lugar

seco y cálido cuando no esté en uso para evitar condensación interna dentro de ella.

20 - Spanish

Page 21

Componentes de la máquina

4.

2.

1.

10.

3.

9.

11.

13.

12.

5.

6.

7.

Componentes de la máquina

1. Cerrojo de palanca pequeño

2. Manguera de enlace al fi ltro

3. Cerrojo de palanca grande

4. Caja del fi ltro secundario

5. Caja de control

6. Bomba de vacío

7. Rueda trasera

8.

14.

8. Bastidor

9. Cerrojo de palanca pequeño

10. Caja del fi ltro principal

11. Accesorio de acoplamiento de manguera

12. Cono de recogida

13. Punto accesorio de toma de corriente

14. Rueda pequeña

Spanish - 21

Page 22

Componentes de la máquina

Diagrama 1

2.

1.

Diagrama 2

5.

1. 2.

6.

7.

4.3.

Diagrama 1

1. Acoplamiento de la manguera de enlace al fi ltro

2. Caja del fi ltro secundario

3. Filtro secundario

4. Puerta de la caja del fi ltro secundario

5. Punto accesorio de toma de corriente

6. Cerrojo de palanca pequeño

7. Caja de control

Diagrama 2

1. Interruptor Off/On

2. Interruptor adelante/atrás

22 - Spanish

Page 23

Diagrama 3

Componentes de la máquina

2.

3.

Diagrama 3

1. Abrazadera principal

2. Plantilla del fi ltro principal

3. Junta del fi ltro principal. Parte exterior (kit)

4. Junta del fi ltro principal. Parte interior (kit)

4.1.

Spanish - 23

Page 24

Diagrama 4

Componentes de la máquina

1. 2.

Caja de control

El sistema de control consta de dos interruptores:

1. Interruptor On/Off.

Apaga la máquina en posición OFF y la enciende en

posición ON.

2. Interruptor Fwd/Rev.

Cambia la dirección de la bomba de vacío. A veces se

deberá invertir la dirección de vacío dependiendo del

orden de fases y la alimentación de corriente.

24 - Spanish

¡IMPORTANTE!

La dirección no se deberá cambiar NUNCA

cuando la máquina esté en posición ON (ésa

es la razón por la que hay una cerradura en

el interruptor FWD/REV). Si hay que cambiar

la dirección, apague la máquina volviendo a

la posición OFF, espere un minuto, cambie

la dirección y vuelva a encender la máquina.

Una vez que se haya cambiado el ajuste

de la dirección, quite la llave del interruptor FWD/REV antes de volver a encender la

máquina.

Si se cambia la dirección cuando la máquina

esté funcionando se producirá un fallo del

motor.

Page 25

Manejo (uso en seco)

Manejo (uso en seco)

Puesta en marcha

1. Coloque la aspiradora en la zona de trabajo.

2. Asegúrese de que la bolsa de plástico se ha fi jado

al cono de recogida.

3. Enchufe la aspiradora en la corriente y encienda la

máquina.

¡IMPORTANTE!

Asegúrese de que la aspiradora está en

posición Off antes de encenderla.

4. Desenganche la manguera de enlace al fi ltro de la

parte superior de la caja del fi ltro secundario.

5. Ponga la máquina en la posición On durante 2 segundos y coloque la mano en el acoplamiento de la

manguera de enlace al fi ltro. Sienta con la mano si

la máquina está aspirando o soplando.

6. Si la máquina está soplando, espere un minuto (a

que el motor deje de girar por completo) y cambie

la máquina a la otra dirección usando el interruptor

FWD/REV.

¡IMPORTANTE!

Quite siempre la llave del interruptor FWD/

REV. Esto bloqueará el interruptor e impedirá

que se pueda cambiar la dirección del motor

cuando la máquina esté en funcionamiento.

7. Una vez se haya fi jado correctamente la dirección

de la máquina, estará lista para su uso con la desbastadora.

Limpieza de los fi ltros primarios.

1. Apague la máquina en la posición off.

2. Usando un martillo / mazo de goma, dé 10 golpecitos a la parte superior de la superfi cie de la caja del

fi ltro principal. Cuando esté haciendo esto, notará

que todo el polvo del interior de la unidad caerá a la

bolsa de plástico sujeta al cono de recogida.

Cambio de las bolsas de polvo.

Una vez que la bolsa de polvo haya recogido unos

20kg de polvo, para evitar riesgos de levantamiento

provocado por un llenado excesivo de la bolsa de

polvo, ésta se deberá cambiar.

1. Quite el polvo de los fi ltros primarios como se ha

indicado anteriormente y agite la bolsa para que el

polvo se asiente en el fondo de la bolsa.

2. Vuelva a poner la máquina en posición On (notará

que el aire es aspirado desde la bolsa de plástico).

3. Desate la bolsa por debajo del cono de recogida

usando una unión de cable u otro nudo de bolsa.

4. Suelte la correa elástica y quite la bolsa fi jada.

¡IMPORTANTE!

Extreme la precaución cuando suelte y

vuelva a colocar la correa elástica.

5. Con la correa elástica, vuelva a fi jar una bolsa de

plástico vacía (notará que el aire es aspirado desde

la bolsa de plástico).

6. Ahora la máquina volverá a estar preparada para

aspirar polvo de nuevo.

¡IMPORTANTE!

Es importante mantener funcionando el vacío

durante el proceso de cambio de bolsa. Esto

mantendrá cerrada la válvula del cono de

recogida, garantizando que no salga nada

de polvo de dentro del cono cuando se esté

cambiando la bolsa.

Después de cada 10-20 minutos de funcionamiento,

será necesario limpiar los fi ltros primarios, ya que el

polvo se irá acumulando dentro de las plantillas del

fi ltro. La forma más sencilla y efectiva para limpiar la

formación de polvo en la plantilla del fi ltro es la sigu-

iente:

Este método reducirá enormemente la exposición del operario a las partículas fi nas de

polvo cuando esté usando el equipamiento.

Se recomienda encarecidamente que todos

los operadores usen una máscara de polvo/

oxígeno cuando cambien las bolsas del

polvo o realicen labores de mantenimiento

en la máquina.

Spanish - 25

Page 26

Manejo (uso mojado)

Manejo (uso mojado)

La Husqvarna DC 5500 también se puede usar para

recoger materiales líquidos como puede ser el lodo

formado del proceso de desbastado en mojado.

Para usar la máquina para recogida en mojado, basta

con que quite las plantillas del fi ltro primario de la

unidad.

1. Desacople la manguera de enlace al fi ltro.

2. Suelte el cerrojo de palanca grande.

3. Pliegue la caja del fi ltro principal hacia delante.

4. Suelte los 2 cerrojos de palanca pequeña.

5. Levante los fi ltros principales de dentro de la caja

del fi ltro primario.

¡IMPORTANTE!

Se recomienda encarecidamente que todos

los operadores usen una máscara de polvo/

oxígeno cuando quiten las plantillas del fi ltro

primario de la máquina.

26 - Spanish

Page 27

Localización de averías

Localización de averías

Aunque el fabricante ha llevado a cabo todas las medidas posibles para garantizar un funcionamiento fi able

de la máquina, a veces pueden surgir problemas.

Pueden surgir los siguientes problemas:

1. La máquina no funciona.

Asegúrese de que la máquina está conectada a la

corriente y está encendida. Si la máquina sigue sin

funcionar, quite la cubierta de la caja de control y

pruebe a ver si hay alimentación de corriente en la

parte superior del contactor del lado izquierdo. Si no

hay corriente en los contactores, pruebe si hay corriente en la toma de corriente fuente. Si la alimentación de corriente está bien en esta toma de corriente pero no hay alimentación en los contactores de

la caja de control, compruebe las conexiones dentro

del punto accesorio de toma de corriente. (Estas

comprobaciones sólo las deberá llevar a cabo un

electricista autorizado)

2. La máquina hace una especie de zumbido suave

cuando se enciende.

Esto indica que sólo hay dos fases de alimentación

de corriente en el motor. Apague la máquina inmediatamente para evitar que se queme el motor. Haga

que un electricista compruebe la máquina para

determinar la causa de la fase que falta. Si las tres

fases están bien en el motor, hay muchas posibilidades de que el motor esté averiado.

3. La máquina sólo funciona en una dirección.

Esto indica un problema con el mecanismo del in-

terruptor FWD/REV o uno de los contactores. Haga

que un electricista compruebe la máquina.

¡IMPORTANTE!

Se deberá llevar una máscara de oxígeno en

todo momento cuando se estén realizando

operaciones de limpieza de fi ltros.

Si hay grandes cantidades de polvo en la caja del

fi ltro secundario, esto indicará un problema con los

fi ltros principales. Normalmente signifi ca que hay un

agujero en uno o más de los fi ltros principales o que

uno de los fi ltros principales se ha soltado.

Compruebe si hay pequeños agujeros o perfora-

ciones en los fi ltros principales. Los pequeños agu-

jeros se pueden reparar / remendar usando sellador

de silicona.

(B) Asegúrese de que la tapa del fondo del cono de

recogida se cierra correctamente y queda hermética.

Si esta tapa no está funcionando correctamente, la

máquina tenderá a aspirar la bolsa de polvo cuando

esté encendida.

6. La máquina está sacando polvo del escape.

(A) Normalmente esto signifi ca que los fi ltros se-

cundarios no están instalados correctamente y el

polvo no está pasando por ellos. Asegúrese de que

las juntas de los extremos de los fi ltros secundarios

enfrente de la puerta de la caja del fi ltro secundario

están creando una correcta hermeticidad. Esto se

puede ver examinando el acoplamiento de la manguera de enlace al fi ltro.

(B) Puede que haya que sustituir los fi ltros secunda-

rios.

4. La máquina funcionará, pero no habrá corriente

en el punto accesorio de toma de corriente.

Compruebe las conexiones dentro del punto acce-

sorio de toma de corriente.

5. La máquina no aspira mucho.

(A) Examine el interior de la caja del fi ltro secunda-

rio y asegúrese de que los fi ltros secundarios no

están bloqueados con polvo. Si están bloqueados

con polvo, quite y limpie los fi ltros sacudiéndolos o

usando aire comprimido.

Spanish - 27

Page 28

Mantenimiento

Mantenimiento

Para maximizar el rendimiento óptimo y la fi abilidad de

la máquina se deberán realizar las siguientes labores

de mantenimiento:

Inspección diaria de los microfi ltros:

Se recomienda encarecidamente que los operadores

comprueben diariamente los niveles de polvo dentro

de la caja del fi ltro secundario. Esto indicará la efi cacia

de los fi ltros primarios. Si se está formando polvo den-

tro de la caja del fi ltro secundario, es más que prob-

able que se deba a una de las siguientes razones:

1. Se han hecho pequeños agujeros o perforaciones

en los fi ltros primarios.

2. Hay un problema con una junta en la unidad de la

caja del fi ltro principal. Si al examinarlo se encuen-

tra que se está formando polvo dentro de la caja

del fi ltro secundario, se recomienda quitar los fi ltros

principales y comprobar si hay pequeños agujeros o

perforaciones en ellos. Normalmente los pequeños

agujeros empezarán a formarse en torno al cosido del material fi ltrante. Si se localizan pequeños

agujeros, limpie la zona en torno al agujero con aire

comprimido o aspirando. Una vez que el área esté

limpia, el agujero se podrá reparar con sellador de

silicona. Si no se encuentran pequeños agujeros o

perforaciones, compruebe las juntas de goma de la

unidad de la caja del fi ltro principal y asegúrese de

que todas están intactas.

En términos generales, con un uso habitual, los

fi ltros primarios se deberán sustituir aproximadamente cada 6 meses. Esto mantendrá unos buenos

niveles de aspiración y reducirá el posible desarrollo

de agujeros en los fi ltros.

El fi ltro secundario se deberá cambiar cada 12 me-

ses. Hechos de un material fi ltrante de poliéster, los

fi ltros secundarios se pueden lavar con agua. Asegúrese de que están completamente secos antes de

volver a instalarlos.

Al volver a montar un fi ltro secundario, asegúrese

de que las juntas estén fi rmemente apretadas

contra la pared de la caja del fi ltro secundario. Este

contacto se podrá evaluar mirando a través del

acoplamiento de la manguera de enlace al fi ltro.

28 - Spanish

Page 29

Datos técnicos

Datos técnicos

Emisiones de ruido (vea la nota 1)

Nivel de potencia acústica medido dB(A) 92

Nivel de potencia acústica garantizado L

Niveles acústicos (vea la nota 2)

Nivel de presión acústica en el oído del usuario, dB(A) 77

dB(A) 93

WA

Nota 1: Emisiones sonoras en el entorno medidas como potencia sonora (L

Nota 2: Nivel de presión sonora conforme a EN 60335-2-69. Los datos referidos del nivel de presión sonora tienen

una dispersión estadística habitual (desviación típica) de 1,0 dB (A).

) según la norma EN 60335-2-69.

WA

Declaración CE de conformidad

(Rige sólo para Europa)

Husqvarna AB, SE-433 81 Göteborg, Suecia, teléfono: +46-31-949000, declaramos que las la aspiradora Husqvarna

DC 5500 a partir del número de serie del año 2010 en adelante (el año se indica claramente en la placa de identifi

cación, seguido del número de serie), cumplen con las siguientes disposiciones de la DIRECTIVA DEL CONSEJO:

• 2006/42/CE «relativa a máquinas» del 17 de mayo de 2006.

• 2004/108/CEE, ”referente a compatibilidad electromagnética”, del 15 de diciembre de 2004.

• 2006/95/CE del 12 de diciembre de 2006 relativa a equipos eléctricos.

Se han aplicado las siguientes normas: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-

2:2006, EN 61000-3-3/A1/A2:2005, EN 60335-2-69:2009.

Göteborg, 29 de diciembre de 2009

Henric Andersson

Vicepresidente, jefe de la sección de cortadoras y maquinaria para la construcción

Husqvarna AB

(Presentante autorizado de Husqvarna AB y responsable de la documentación técnica.)

Spanish - 29

Page 30

Inhalt

30 - German

Page 31

Inhalt

Deutsch

Inhalt

Symbole 32

Sicherheitsanweisungen 33

Einleitung 34

Transport 34

Lagerung 34

Maschinenteile 35

Trockenschleifen 39

Nassschleifen 40

Störungsbehebung 41

Wartung 42

Technische Daten 43

German - 31

Page 32

Symbole

Symbole

In diesem Bedienungshandbuch werden die nachstehend beschriebenen Symbole verwendet. Ein sicherer

Betrieb der Maschine ist nur gewährleistet, wenn der

Anwender die Bedeutung dieser Symbole kennt.

Vor der Inbetriebnahme die Bedienungsanleitung aufmerksam durchlesen!

ACHTUNG! Bei Schleifarbeiten entsteht

Schleifstaub. Das Einatmen des Staubs

gefährdet die Gesundheit. Schleifarbeiten nur mit Atemmaske durchführen.

Immer für ausreichend Belüftung

sorgen.

Bei Arbeiten immer folgende Schutzausrüstung tragen:

• Schutzhelm

• Gehörschutz

• Schutzbrille oder Gesichtsschutz

• Bei Schleifarbeiten entsteht Schleifstaub. Das Einatmen des Staubs

gefährdet die Gesundheit. Staubschutzmaske tragen.

Inspektions- und Wartungsarbeiten sind

bei ausgeschaltetem Motor und gezogenem Netzstecker durchzuführen.

Sichtprüfung

Regelmäßige Reinigung erforderlich.

Das Produkt erfüllt alle anwendbaren

EU-Direktiven.

Rutschfeste Schuhe mit Stahlkappen

tragen.

Immer Schutzhandschuhe tragen.

32 - German

Page 33

Sicherheitsanweisungen

Sicherheitsanweisungen

ACHTUNG

Keine Inbetriebnahme der Maschine ohne

Einhaltung der Sicherheitsanweisungen! Bei

Nichteinhaltung der Sicherheitsanweisungen sind die Firma Husqvarna Construction

Products und ihre Vertreter von der Haftung

für alle direkten und indirekten Schäden

freigestellt. Vor der Inbetriebnahme diese Bedienungsanleitung durchlesen und befolgen.

Sollte nach Durchlesen dieser Sicherheitsanweisungen immer noch Unsicherheit über die

Betriebsrisiken bestehen, ist von der Inbetriebnahme abzusehen. Weitere Auskünfte

erteilt der Fachhändler.

• Dieses Bedienungshandbuch aufmerksam durchlesen.

• Die Maschine darf nur von Fachpersonal bedient

werden.

• Eine beschädigte Maschine darf nicht in Betrieb

genommen werden. Alle Prüf-, Wartungs- und

Servicehinweise in diesem Bedienungshandbuch

sind zu beachten. Alle Reparaturen, auf die nicht in

diesem Handbuch eingegangen wird, sind von einer

Werkstatt auszuführen, die vom Hersteller oder

Vertragshändler benannt wird.

• Bei Arbeiten mit der Maschine immer Schutzausrüstung tragen (feste und rutschfeste Schuhe, Gehörschutz, Staubschutzmaske, Schutzbrille).

• Kein Betrieb der Maschine in feuer- und explosionsgefährdeten Bereichen.

• Zustand des Netz- und Verlängerungskabels vor

Anschluss überprüfen. Kein Betrieb der Maschine

bei beschädigtem Netzkabel. Die Maschine muss

durch eine Fachwerkstätte repariert werden.

• Bei Verwendung von Verlängerungskabel darf das

Kabel nicht aufgerollt sein.

• Die Maschine sollte nach Möglichkeit an eine Schukosteckdose angeschlossen werden.

• Die Netzspannung muss der auf dem Typenschild

der Maschine angegebenen Betriebsspannung

entsprechen.

• Bei Arbeiten mit der Maschine immer darauf

achten, dass das Kabel hinter dem Bediener

verläuft, so dass eine Beschädigung durch die

Maschine ausgeschlossen ist.

Die Maschine nur mit mechanischen Hubhilfen

anheben (Hebezeug, Gabelstapler).

ACHTUNG!

Starke Schwingungsbelastung kann bei

Personen mit Kreislaufproblemen zu Kreislauf- oder Nervenerkrankungen führen. Bei

Symptomen einer starken Schwingungsbelastung ist ein Arzt aufzusuchen. Zu diesen

Symptomen zählen Taubheit, Kribbel- und

Brenngefühle, Schmerzen, Schwächegefühl

und Verfärbungen der Haut. Die Symptome

treten normalerweise in den Fingern, Händen

oder Handgelenken auf.

• Kein Betrieb der Maschine ohne Staubbeutel.

• Kein Betrieb der Maschine, wenn der Bediener

müde oder alkoholisiert ist bzw. Medikamente eingenommen hat, die sich auf das Seh-, Urteils- oder

Bewegungsvermögen auswirken.

• Kein Betrieb der Maschine, wenn Änderungen an

der Maschine vorgenommen wurden.

• Gefahr von Stromschlägen! Kontakt mit Metall

und anderen leitfähigen Gegenständen im Boden

vermeiden.

• Maschine nicht am Netzkabel ziehen und Stecker

nicht am Kabel aus der Steckdose ziehen. Netzund Verlängerungskabel nicht in der Nähe von

Wasser, Öl und scharfen Kanten verlegen.

• Darauf achten, dass das Kabel nicht in Türen,

Zäunen u.ä. gequetscht wird.

German - 33

Page 34

Einleitung

Einleitung

Die Staubsauganlage Husqvarna DC 5500 ist für Nassund Trockenschleifarbeiten geeignet und kann u.a.

Betonstaub und Zementschlämme aufnehmen.

In diesem Handbuch wird die Staubsauganlage Husqvarna DC 5500 beschrieben. Vor der Inbetriebnahme

der Maschine ist das Handbuch vollständig durchzulesen. Bei Nichtbeachtung der Hinweise besteht die

Gefahr von Maschinenschäden und Verletzungen.

WICHTIG!

Die Maschine darf nur von Personal bedient

werden, das theoretisch und praktisch an der

Maschine unterwiesen wurde.

Transport

Während des Transports muss die Maschine gesichert

sein. Die Maschine sollte nur in abgedecktem Zustand

transportiert und insbesondere vor Regen und Schnee

geschützt werden. Obwohl die Maschine wasserfest

ist sollten alle Maßnahmen getroffen werden, um die

Maschine vor einer Beschädigung durch Wasser zu

schützen.

Die Maschine aufrecht stehend transportieren, insbesondere wenn ein Transport ohne Abdeckung

erfolgt.

Der Staubbeutel sollte immer an der Maschine befestigt sein, sowohl im Betrieb als auch während des

Transports.

Lagerung

Die Maschine wird an einem trockenen und warmen

Ort gelagert, um Kondensationsbildung zu verhindern.

34 - German

Page 35

Maschinenteile

4.

2.

1.

10.

3.

9.

11.

13.

12.

5.

6.

7.

Maschinenteile

1. Kleiner Schnappriegel

2. Filteranschlussschlauch

3. Großer Schnappriegel

4. Sekundärfi ltertopf

5. Steuerkasten

6. Vakuumpumpe

7. Hinterrad

8.

14.

8. Rahmen

9. Kleiner Schnappriegel

10. Primärfi ltertopf

11. Schlauchanschlussfi tting

12. Sammeltrichter

13. Stromanschluss für Zubehör

14. Laufrolle

German - 35

Page 36

Maschinenteile

Abbildung 1

2.

1.

Abbildung 2

5.

1. 2.

6.

7.

Abbildung 1

1. Filter, Schlauchanschluss

2. Sekundärfi ltertopf

3. Sekundärfi lter

4. Sekundärfi ltertopfklappe

5. Stromanschluss für Zubehör

6. Kleiner Schnappriegel

7. Steuerkasten

4.3.

Abbildung 2

1. Aus/Ein-Schalter.

2. Vorwärts/Rückwärts-Drehrichtungsschalter.

36 -German

Page 37

Abbildung 3

Maschinenteile

2.

3.

Abbildung 3

1. Primär, Klemmenteil

2. Primärfi lter, Schlauchteil

3. Primärfi lterdichtung. Außenteil (Satz)

4. Primärfi lterdichtung. Innenteil (Satz)

4.1.

German - 37

Page 38

Abbildung 4

Maschinenteile

1. 2.

Steuerkasten

Die Steuerung besteht aus zwei Schaltern:

1. Ein-/Ausschalter.

Schaltet die Maschine ein (ON) und aus (OFF).

2. Fwd/Rev-Schalter.

Ändert die Drehrichtung der Vakuumpumpe. Gelegentlich muss die Drehrichtung der Vakuumpumpe aufgrund der Phasenfolge der Stromversorgung umgekehrt werden.

38 -German

WICHTIG!

Die Drehrichtung darf auf keinen Fall bei

eingeschalteter Maschine (Position ON)

geändert werden (aus diesem Grund ist

der FWD/REV-Schalter absperrbar). Falls

die Drehrichtung geändert werden muss,

schalten Sie die Maschine aus (Position OFF), warten eine Minute, ändern die

Drehrichtung und schalten die Maschine

wieder an. Nach Änderung der Drehrichtung

ziehen Sie den Schlüssel vom FWD/REVSchalter ab, ehe Sie die Maschine wieder

anschalten.

Eine Änderung der Drehrichtung bei laufender Maschine führt zu Motorausfall.

Page 39

Trockenschleifen

Trockenschleifen

Einrichtung

1. Gerät im Arbeitsbereich aufstellen.

2. Verbindung zwischen Kunststoffbeutel und Sammeltrichter kontrollieren.

3. Gerät an Stromversorgung anschließen und einschalten.

WICHTIG!

Vor dem Einschalten kontrollieren, dass die

Ansaugfunktion ausgeschaltet ist.

4. Filteranschlussschlauch vom Oberteil des

Sekundärfi lters abtrennen.

5. Maschine 2 Sekunden lang einschalten (Position

ON) und die Hand an den Filterschlauchanschluss

halten. Fühlen, ob die Maschine ansaugt oder bläst.

6. Falls die Maschine bläst, 1 Minute warten (um den

Motor zum völligen Stillstand kommen zu lassen)

und die Maschine mit dem FWD/REV-Schalter in die

umgekehrte Drehrichtung schalten.

WICHTIG!

1. Maschine ausschalten.

2. Mit einem großen Gummihammer / -klopfer 10 Mal

auf die Oberfl äche des Primärfi ltertopfes schlagen.

Dadurch fällt der gesamte, im Inneren der Einheit

angesammelte Staub in den Kunststoffbeutel, der

am Sammeltrichter befestigt ist.

Auswechseln des Staubbeutels

Sobald sich etwa 20kg Schmutz im Sack angesammelt hat, ist der Beutel auszuwechseln, um Gesundheitsschäden durch das Anheben schwerer Lasten

vorzubeugen.

1. Primärfi lter reinigen (die Reinigung wurde an an-

derer Stelle im Handbuch bereits beschrieben) und

Staubbeutel durchschütteln, damit sich die Verunreinigungen auf dem Boden absetzen können.

2. Maschine wieder einschalten (die Luft wird aus dem

Kunststoffbeutel gesaugt).

3. Beutel unter dem Sammeltrichter mit Kabelbinder

o.ä. abbinden.

4. Spanngurt lösen und zugeschnürten Beutel entfernen.

WICHTIG!

Beim Lösen und Befestigen des Spanngurts

vorsichtig vorgehen.

Ziehen Sie immer den Schlüssel vom FWD/

REV-Schalter ab. Damit wird der Schalter

abgesperrt und es wird verhindert, dass die

Drehrichtung bei laufendem Motor geändert

werden kann.

7. Sobald die Drehrichtung der Maschine korrekt

eingestellt ist, kann die Maschine mit der Schleifmaschine eingesetzt werden.

Reinigung der Primärfi lter.

Die Primärfi lter müssen alle 10 bis 20 Minuten gerein-

igt werden, da sich die Verunreinigungen in den

Schlauchfi ltern absetzen. Die einfachste und effi zien-

teste Methode zur Abreinigung der Schlauchfi lter ist

folgende:

5. Mit Hilfe des Spanngurts einen leeren Kunststoffbeutel an der Maschine befestigen (die Luft wird aus

dem Kunststoffbeutel gesaugt).

6. Anschließend ist die Maschine wieder betriebsbereit.

WICHTIG!

Während des Beuteltausches muss der Ansaugmotor ohne Unterbrechung weiterlaufen.

Dadurch bleibt das Ventil im Sammeltrichter

geschlossen und beim Beuteltausch kann

kein Schmutz aus dem Trichter fallen.

Auf diese Weise ist der Bediener deutlich

weniger Staubpartikeln ausgesetzt. Während

des Beuteltauschs und bei Wartungsarbeiten

sollten alle Personen in der Umgebung eine

Staubschutzmaske bzw. Atemschutzmaske

tragen.

German - 39

Page 40

Nassschleifen

Nassschleifen

Die Husqvarna DC 5500 ist zum Aufsaugen der beim

Nassschleifen anfallenden Schlämme geeignet.

Dazu muss lediglich der Primärfi lterschlauch aus der

Maschine entfernt werden.

1. Filteranschlussschlauch abtrennen.

2. Den großen Schnappriegel lösen.

3. Den Primärfi ltertopf nach vorne klappen.

4. Die beiden kleinen Schnappriegel lösen.

5. Die Primärfi lter aus dem Primärfi ltertopf heraush-

eben.

WICHTIG!

Beim Entfernen der Primärfi lterschläuche

sollten alle Personen in der Umgebung eine

Staubschutzmaske bzw. Atemschutzmaske

tragen.

40 - German

Page 41

Störungsbehebung

Störungsbehebung

Trotz eingehender Qualitätssicherung kann der Hersteller keinen absolut störfreien Betrieb der Maschine

garantieren.

Folgende Störungen können auftreten:

1. Maschine läuft nicht.

Stellung des Betriebsschalters kontrollieren. Sollte

die Maschine eingeschaltet sein, aber nicht laufen,

den Steuerkasten öffnen und mit einem Spannungsprüfer kontrollieren, dass am Schütz links oben

Spannung anliegt. Falls an den Schützen keine

Spannung anliegt, die Stromversorgung kontrollieren. Falls die Stromversorgung in Ordnung ist,

aber an den Schützen im Steuerkasten keine Spannung anliegt, die Anschlüsse im Stromanschluss für

Zubehör kontrollieren. Diese Kontrollen dürfen nur

von einem Elektriker ausgeführt werden)

2. Beim Einschalten ertönt ein leises Brummen.

Dies ist ein Zeichen dafür, dass lediglich zwei

Phasen der Stromversorgung am Motor anliegen.

Maschine sofort abschalten, um ein Ausbrennen des

Motors zu vermeiden. Die Ursache für die fehlende

Phase von einem Elektriker feststellen lassen. Falls

alle drei Phasen der Stromversorgung in Ordnung

sind, ist vermutlich der Motor defekt.

Größere Mengen an Staub im Sekundärfi lter sind

ein Hinweis auf ein Problem mit den Primärfi ltern.

In der Regel ist in einem oder in mehreren Primär

fi ltern ein Loch oder einer der Primärfi lter hat sich

gelockert.

Primärfi lter auf kleine Löcher oder Risse kontrol-

lieren. Kleinere Löcher können mit Silikondichtstoff

repariert / abgedichtet werden.

(B) Die Klappe im Boden des Sammeltrichters muss

richtig schließen und abdichten.

Falls die Klappe nicht richtig funktioniert, kann die

Maschine beim Einschalten den Staubbeutel ansaugen.

6. Durch den Auslass wird Staub ausgeblasen.

(A) Normalerweise ist dies ein Hinweis darauf, dass

die Sekundärfi lter nicht vorschriftsmäßig eingesetzt

sind und der Staub daran vorbeigedrückt wird.

Die Dichtungen am Sekundärfi lter, die sich an

der gegenüberliegenden Seite zur Sekundärfi lter-

topfklappe befi nden, müssen vollständig abdich-

ten. Zur Kontrolle der Abdichtung in den Filterschlauchanschluss blicken.

(B) Die Sekundärfi lter müssen eventuell ausg-

etauscht werden.

3. Die Maschine dreht nur in einer Richtung.

Dies ist ein Hinweis auf ein Problem entweder mit

dem FWD/REV-Schaltmechanismus oder mit einem

der Schütze. Die Maschine von einem Elektriker

kontrollieren lassen.

4. Die Maschine läuft, aber am Stromanschluss für

Zubehör liegt keine Spannung an.

Die Anschlüsse im Stromanschluss für Zubehör

kontrollieren.

5. Die Maschine saugt nicht richtig.

(A) Das Innere des Sekundärfi ltertopfes kontrollieren

und sicherstellen, dass die Sekundärfi lter nicht mit

Staub verlegt sind. Zugesetzte Filter herausnehmen

und entweder durch Klopfen oder mit Druckluft reinigen.

WICHTIG!

Bei allen Filterreinigungsarbeiten immer ein

Atemschutzgerät tragen.

German - 41

Page 42

Wartung

Wartung

Durch Befolgen der nachstehenden Wartungshinweise

wird eine optimale Leistung und Zuverlässigkeit der

Maschine gewährleistet.

Tägliche Sichtprüfung der Mikrofi lter:

Der Bediener sollte die Menge der Schleifrückstände

im Sekundärfi ltertopf täglich kontrollieren. Die Menge

gibt Auskunft über die Wirksamkeit der Primärfi lter.

Sollten sich im Inneren des Sekundärfi ltertopfes Rück-

stände absetzen, ist mit großer Sicherheit von einer

der folgenden Ursachen auszugehen:

1. In den Primärfi ltern haben sich kleine Löcher oder

Risse gebildet.

2. Eine Dichtung in der Primärfi ltertopfbaugruppe ist

beschädigt. Falls bei der Kontrolle festgestellt wird,

dass sich im Sekundärfi ltertopf Schleifrückstände

ansammeln, ist es ratsam, die Primärfi lter zu ent-

fernen und auf kleine Löcher oder Risse zu kontrollieren. Kleine Löcher bilden sich in der Regel an

den Nähten des Filtermediums. Falls kleine Löcher

sichtbar sind, den Bereich um das Loch entweder

mit Druckluft oder Vakuum säubern. Sobald der

Bereich sauber ist, kann das Loch mit Silikondichtstoff repariert werden. Falls keine kleinen Löcher oder

Risse sichtbar sind, die Gummidichtungen in der

Primärfi ltertopfbaugruppe kontrollieren und sichers-

tellen, dass sie intakt sind.

Bei gleichmäßiger Nutzung müssen die Primärfi lter

alle sechs Monate ausgetauscht werden. Dadurch

wird eine gute Saugkraft garantiert und die Wahrscheinlichkeit der Lochbildung in den Filtern bleibt

niedrig.

Der Sekundärfi lter sollte alle 12 Monate ausgewech-

selt werden. Er besteht aus Polyester und kann mit

Wasser gereinigt werden. Vor dem Wiedereinbau

muss der Sekundärfi lter vollständig getrocknet sein.

Beim Wiedereinbau sind die Dichtungen kräftig ge-

gen die Wand des Sekundärfi ltertopfes zu drücken.

Die Abdichtung kann geprüft werden indem Sie

durch den Filterschlauchanschluss blicken.

42 - German

Page 43

Technische Daten

Technische Daten

Geräuschemissionen (siehe Anmerkung 1)

Gemessene Schallleistung dB(A) 92

Garantierte Schallleistung L

Lautstärke (siehe Anmerkung 2)

Schalldruckpegel am Ohr des Benutzers, dB(A) 77

dB(A) 93

WA

Anmerkung 1: Umweltbelastende Geräuschemission gemessen als Schallleistung (L

Anmerkung 2: Schalldruckpegel gemäß EN 60335-2-69. Berichten zufolge liegt der Schalldruckpegel normalerweise

bei einer Ausbreitungsklasse (standardmäßige Ausbreitung) von 1,0 dB (A).

) gemäß EN 60335-2-69.

WA

EG-Konformitätserklärung

(nur für Europa)

Husqvarna AB, SE-433 81 Göteborg, Schweden, Tel.: +46 31 949000, versichert hiermit, dass der Staubsauger

Husqvarna DC 5500 von den Seriennummern des Baujahrs 2010 an (die Jahreszahl wird im Klartext auf dem Typenschild angegeben, mitsamt der nachfolgenden Seriennummer) den Vorschriften folgender RICHTLINIEN DES RATES

entsprechen:

• vom 17. Mai 2006 „Maschinen-Richtlinie’ 2006/42/EG.

• vom 15. Dezember 2004 ”über elektromagnetische Verträglichkeit” 2004/108/EWG.

• vom 12. Dezember 2006 „betreffend elektrische Betriebsmittel’ 2006/95/EG.

Folgende Normen wurden angewendet: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-

2:2006, EN 61000-3-3/A1/A2:2005, EN 60335-2-69:2009.

Göteborg, den 29. Dezember 2009

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

Husqvarna AB

(Bevollmächtigter Vertreter für Husqvarna AB, verantwortlich für die technische Dokumentation.)

German - 43

Page 44

Sommaire

44 - French

Page 45

Sommaire

Français

Sommaire

Explication des symboles 46

Consignes de sécurité 47

Introduction 48

Transport 48

Remisage 48

Quels sont les composants? 49

Fonctionnement (utilisation sèche) 53

Fonctionnement (utilisation avec eau) 54

Recherche de pannes 55

Maintenance 56

Caractéristiques techniques 57

French - 45

Page 46

Explication des symboles

Explication des symboles

Les symboles ci-dessous se trouvent sur la machine

et dans le manuel d'utilisation. Il est important que

l'utilisateur comprenne la signifi cation de ces consignes

afi n de travailler en toute sécurité avec la machine.

Lisez attentivement le manuel d’utilisation et vérifi ez que vous avez bien

compris les instructions avant d’utiliser

la machine.

AVERTISSEMENT! La poussière

générée par le meulage peut causer

des lésions si elle est inhalée. Utilisez

un masque respiratoire approprié. Veillez à disposer d'une bonne ventilation.

Portez toujours :

• Casque de protection homologué

• Protection auditive homologuée

• Lunettes enveloppantes de sécurité

ou visière

• La poussière générée par le meulage peut causer des lésions si elle

est inhalée. Utilisez un masque antipoussière.

L'inspection et/ou la maintenance doivent être effectuées avec le moteur à

l'arrêt et la bougie débranchée.

Inspection visuelle

Un nettoyage régulier est nécessaire.

Ce produit est conforme aux directives

CE applicables.

Portez toujours des bottes anti-dérapantes avec coquilles en acier.

Portez toujours des gants de protection

homologués.

46 - French

Page 47

Consignes de sécurité

Consignes de sécurité

AVERTISSEMENT!

La machine ne doit en aucun cas être démarrée sans respecter les consignes de sécurité. Une négligence de ces consignes par

l'utilisateur libère Husqvarna Construction

Products Sweden AB ou ses représentants

de toute responsabilité directe ou indirecte. Lisez attentivement ces instructions

d'utilisation et assurez-vous d'en comprendre

le contenu avant de commencer à utiliser la

machine. En cas de doute, après la lecture

des consignes de sécurité, sur les risques et

dangers rencontrés, n'utilisez pas la machine

mais contactez le représentant pour obtenir

davantage d'informations.

• Lisez attentivement le manuel d'utilisation.

• Seul un personnel qualifi é est autorisé à utiliser la

machine.

• N'utilisez jamais une machine défectueuse. Effectuez les contrôles, les mesures d'entretien et de

maintenance décrites dans ce manuel. Les réparations qui ne sont pas mentionnées dans ce manuel

doivent être effectuées par un réparateur recommandé par le fabricant ou le distributeur.

• Utilisez toujours un équipement de protection personnelle tels que des bottes anti-dérapantes, des

protections auditives, un masque anti-poussière et

des protections occulaires homologuées.

• La machine ne doit pas être utilisée dans des zones

à risque d'incendie ou d'explosion.

• La machine ne doit pas être démarrée tant que le

sac collecteur de poussière n'est pas en place.

• Vérifi ez que le câble d'alimentation n'est pas coincé

dans une porte, une clôture ou similaire.

• Vérifi ez que le câble et la rallonge sont intacts et

en bon état. N'utilisez jamais la machine si le câble

d'alimentation est abîmé; faites réparer la machine

dans un atelier agréé.

• N'utilisez pas une rallonge encore enroulée.

• La machine doit être branchée sur une prise mise à

la terre.

• Contrôlez que la tension du secteur correspond

à celle indiquée sur la plaque signalétique de la

machine.

• Vérifi ez que le câble d'alimentation est bien derrière

vous quand vous commencez à utiliser la machine

afi n qu'il ne risque pas d'être endommagé.

La machine ne doit en aucun cas être levée sans

l'assistance mécanique d'un palan ou d'un transpalette.

AVERTISSEMENT!

Une surexposition aux vibrations peut causer

des problèmes de circulation ou des lésions

névralgiques, particulièrement chez les

personnes souffrant d’une mauvaise circulation sanguine. Contactez un médecin en cas

de symptômes pouvant avoir été provoqués

par une surexposition aux vibrations. Ces

symptômes comprennent notamment des

sensations de douleur et de fourmillement

suivies d’une perte de couleur, de force et de

sensation dans les doigts. Ces symptômes

apparaissent le plus souvent dans les doigts,

les mains et les poignets.

• N’utilisez pas la machine si vous êtes fatigué, si

vous avez bu de l’alcool ou pris des drogues ou des

médicaments pouvant affecter votre vision, votre

jugement ou votre coordination.

• N'utilisez jamais une machine qui a été modifi ée de

quelque manière que ce soit par rapport à sa version d'origine.

• Attention aux décharges électriques. Évitez tout

contact physique avec les conducteurs d'allumage/

métal dans le sol.

• Ne tirez jamais la machine par le câble

d'alimentation et ne la débranchez jamais en tirant

sur le câble. Maintenez tous les câbles et rallonges

loin de l'eau, de l'huile et des bords coupants.

French - 47

Page 48

Introduction

Introduction

L'unité d'aspiration/l'extracteur de poussière Husqvarna

DC 5500 est concu pour l'aspiration sèche ou mouillée

de la poussière de ciment et de la boue liquide.

Ce manuel concerne l'unité d'aspiration/le collecteur

de poussière Husqvarna DC 5500. Il est essentiel que

tous les utilisateurs se familiarisent avec le contenu de

ce manuel avant de commencer à utiliser une de ces

machines. Autrement, la machine risque d'être endommagée et l'utilisateur exposé à des dangers inutiles.

IMPORTANT!

Seul le personnel ayant recu la formation pratique et théorique nécessaire à l'utilisation des

machines est autorisé à utiliser ces machines.

Transport

Durant le transport, il est important de vérifi er que l'unité

demeure toujours attachée solidement. La machine doit

être transportée si possible sous une bâche afi n de ne

pas être exposée aux éléments tels que la pluie et la

neige. Bien que résistante à l'eau, efforcez-vous de protéger la machine contre les dommages causés par l'eau.

Il est recommandé de transporter la machine en position

droite si possible, particulièrement quand elle est transportée sans être couverte.

Il est vivement recommandé de toujours monter un sac

collecteur de poussière sur la machine durant le transport et l'utilisation.

Remisage

Quand la machine n'est pas utilisée, remisez-la dans un

endroit sec et chaud afi n d'éviter la formation de conden-

sation intérieure.

48 - French

Page 49

Quels sont les composants?

4.

2.

1.

10.

3.

9.

11.

13.

12.

5.

6.

7.

Quels sont les

composants?

1. Petite boucle de verrouillage.

2. Tuyau du fi ltre.

3. Grande boucle de verrouillage.

4. Carter du fi ltre secondaire.

5. Boîte de commande.

6. Pompe d'aspiration.

7. Roue arrière.

8.

14.

8. Cadre.

9. Petite boucle de verrouillage.

10. Carter du fi ltre primaire.

11. Raccord de la fi xation de tuyau.

12. Cône de collection.

13. Point de puissance accessoire.

14. Roulette.

French - 49

Page 50

Quels sont les composants?

Diagramme 1

2.

1.

Diagramme 2

5.

1. 2.

6.

7.

Diagramme 1

1. Raccord du tuyau du fi ltre.

2. Carter du fi ltre secondaire.

3. Filtre secondaire.

4. Volet du carter du fi ltre secondaire.

5. Point de puissance accessoire.

6. Petite boucle de verrouillage.

7. Boîte de commande.

4.3.

Diagramme 2

1. Interrupteur Off/On (Marche/Arrêt).

2. Interrupteur Forward/Reverse (Avant/Arrière).

50 - French

Page 51

Diagramme 3

Quels sont les composants?

2.

3.

Diagramme 3

1. Collier de serrage, fi ltre primaire

2. Tubulure du fi ltre primaire

3. Joint du fi ltre primaire Joint extérieur (kit)

4. Joint du fi ltre primaire Joint intérieur (kit)

4.1.

French - 51

Page 52

Diagramme 4

Quels sont les composants?

1. 2.

Boîte de commande

Le système de commande est constitué de deux interrupteurs :

1. Interrupteur On/Off

Pour mettre la machine sur Marche (ON) et sur Arrêt

(OFF).

2. Interrupteur Fwd/Rev

Change la direction de la pompe d'aspiration. Parfois, il

est nécessaire de changer la direction de la pompe en

fonction des phases de l'alimentation électrique.

52 - French

IMPORTANT!

Ne changez JAMAIS la direction quand la

machine est sur la position ON (c'est pour

cette raison que l'interrupteur FWD/REV

comporte un dispositif de verrouillage). Pour

changer la direction, mettez la machine sur

la position OFF, attendez une (1) minute,

changez la direction et remettez la machine

sur la position ON. Une fois la direction modifi ée, retirez la clé de l'interrupteur FWD/REV

avant de remettre la machine sur ON.

Un changement de direction pendant le

fonctionnement de la machine causera des

avaries du moteur.

Page 53

Fonctionnement (utilisation sèche)

Fonctionnement

(utilisation sèche)

Préparations

1. Positionnez l'aspirateur dans la zone de travail.

2. Vérifi ez que le sac en plastique est monté sur le

cône de collection.

3. Branchez l'aspirateur sur l'alimentation électrique et

activez l'alimentation électrique.

IMPORTANT!

Vérifi ez que l'aspirateur est réglé sur le mode

d'arrêt OFF avant d'activer l'alimentation

électrique.

4. Débranchez le tuyau du fi ltre du haut du carter du

fi ltre secondaire.

5. Mettez la machine en marche (position ON) pendant

2 secondes et placez la main sur le raccord du tuyau

du fi ltre. Sentez avec la main si la machine aspire

ou souffl e de l'air.

6. Si la machine souffl e de l'air, attendez une (1) minute

(pour que le moteur arrête complètement de tourner)

et changez de direction à l'aide de l'interrupteur FWD/

REV.

IMPORTANT!

Retirez toujours la clé de l'interrupteur FWD/

RE. L'interrupteur est ainsi verrouillé et il est

impossible de changer la direction du moteur

quand la machine tourne.

7. Une fois la direction correctement réglée, la machine

est prête à être utilisée avec la meule.

Nettoyage des fi ltres primaires.

1. Mettez la machine sur la position d'arrêt OFF.

2. À l'aide d'un gros marteau ou maillet en caoutchouc,

tapez sur le dessus du fi ltre primaire une dizaine de

fois. Vous remarquerez que la poussière accumulée

à l'intérieur de l'unité tombe dans le sac en plastique

attaché au cône de collection.Remplacement du sac

collecteur

Afi n d'éliminer les risques suite à un remplissage

excessif du sac collecteur, celui-ci doit être remplacé

quand il contient environ 20kg de poussière.

1. Éliminez la poussière des fi ltres primaires comme

indiqué précédemment et agitez le sac pour que la

poussière se tasse au fond.

2. Faites passer la machine sur la position de marche

ON (vous remarquerez que l'air du sac en plastique

est aspiré).

3. Fermez le sac sous le cône de collection à l'aide

d'un lien twist ou autre.

4. Libérez la sangle élastique et retirez le sac scellé.

IMPORTANT!

Observez la plus grande prudence quand

vous libérez et attachez de nouveau la sangle élastique.

5. Utilisez la sangle élastique pour attacher le nouveau

sac en plastique vide (vous remarquerez que l'air du

sac en plastique est aspiré).

6. La machine est maintenant prête à être utilisée de

nouveau pour recueillir la poussière.

IMPORTANT!

Il est important de maintenir l'aspiration

durant le changement du sac. Ceci permet

de maintenir la vanne du cône de collection

fermée pour que la poussière ne s'échappe

pas du cône durant le changement du sac.

Les fi ltres primaires doivent être nettoyés toutes les

10-20 minutes d'utilisation dans la mesure où la poussière s'accumule à l'interieur des tubulures du fi ltre. La

manière la plus simple et la plus effi cace pour éliminer

l'accumulation de de poussière sur la tubulure du fi ltre

est la suivante:

Cette méthode réduit considérablement

l'exposition de l'opérateur aux fi nes particules

de poussière durant le changement du sac.

Il est fortement recommandé aux opérateurs

d'utiliser un masque anti-poussière/respiratoire lors du remplacement du sac de

poussière ou durant la maintenance de la

machine.

French - 53

Page 54

Fonctionnement (utilisation avec eau)

Fonctionnement

(utilisation avec eau)

Husqvarna DC 5500 peut aussi être utilisé pour le recueil des matériaux mouillés tels que la boue générée

par le processus de meulage sous eau.

Pour utiliser la machine pour la collection de matériaux

mouillés, il suffi t de retirer les tubulures du fi ltre pri-

maire de l'unité.

1. Débranchez le tuyau du fi ltre.

2. Libérez la grande boucle de verrouillage.

3. Poussez le carter du fi ltre primaire vers l'avant.

4. Libérez les 2 petites boucles de verrouillage.

5. Retirez les fi ltres primaires du carter de fi ltre pri-

maire.

IMPORTANT!

Il est fortement conseillé aux opérateurs

d'utiliser un masque anti-poussière/respiratoire lors de la dépose des tubulures du fi ltre

primaire de la machine.

54 - French

Page 55

Recherche de pannes

Recherche de pannes

Bien que le fabricant se soit efforcé de développer une

machine de la plus grande fi abilité d'utilisation possi-

ble, des problèmes peuvent parfois être observés.

Les problèmes suivants peuvent se produire:

1. La machine ne tourne pas.

Vérifi ez que la machine est sous tension. Si la

machine ne tourne pas, retirez le couvercle de la

boîte de commande et testez pour déterminer si le

contacteur, en haut à gauche, est alimenté en courant. Si les contacteurs ne reçoivent pas de courant, testez l'alimentation électrique à la source. Si

l'alimentation électrique n'est pas défectueuse à la

source mais si les contacteurs de la boîte de commande ne sont pas alimentés en courant, contrôlez

les connexions à l'intérieur du point de puissance

accessoire. Ces contrôles doivent être effectués par

un électricien professionnel.

2. La machine émet un bourdonnement quand elle

est mise sur ON.

Ceci indique qu'il n'y a que deux phases

d'alimentation au niveau du moteur. Arrêtez immédiatement la machine pour éviter une avarie du

moteur. Demandez à un électricien de contrôler

la machine pour déterminer la cause de la phase

manquante. Si les trois phases sont OK au niveau

du moteur, il est fort possible que le moteur soit

défectueux.

Si le carter de fi ltre secondaire comporte beaucoup

de poussière, ceci indique un problème au niveau

des fi ltres primaires. Généralement, ceci signifi e

qu'il y a un ou plusieurs trous dans les fi ltres primai

res ou un des fi ltres primaires s'est détaché.

Contrôlez les fi ltres primaires pour détecter les

trous et perforations. Les petits trous peuvent être

réparés/bouchés avec du silicone.

(B) Vérifi ez que le volet au fond du cône de collec-

tion est bien fermé.

Si ce volet ne fonctionne pas correctement, la

machine a tendance à aspirer le sac de poussière

quand elle est en marche.

6. La machine souffl e de la poussière au niveau de

l'évacuation.

(A) Normalement, ceci signifi e que les fi ltres sec-

ondaires ne sont pas montés correctement et la

poussière ne les traverse pas. Vérifi ez que les

joints aux extrémités des fi ltres secondaires en

face du volet du carter du fi ltre secondaire assurent

l'étanchéité souhaitée. Pour vous rendre compte,

regardez dans le raccord du tuyau du fi ltre.

(B) Il est peut-être nécessaire de remplacer les

fi ltres secondaires.

3. La machine ne tourne que dans une direction.

Ceci indqiue un problème au niveau du mécanisme

de l'interrupteur FWD/REV ou d'un des contacteurs.

Demandez à un électricien de tester la machine.

4. La machine tourne mais il n'y a pas de courant

au point de puissance accessoire.

Contrôlez les connexions à l'intérieur du point de

puissance accessoire.

5. La machine aspire mal.