Page 1

Operators Manual

Please read these instructions carefully and make

sure you understand them before using the machine.

MANUAL NO. 539107619 REV. 02 (04/15/03)

Models:

968999219 / CZ4815KAA

968999220 / CZ4817KOA

Page 2

Congratulations on the purchase of your HUSQVARNA mower. This manual has been prepared

for the owners and operators of the models called out on the front cover of this manual. Read,

understand and follow the safety and operating instructions.

! WARNING

Failure to follow cautious operating practices can result in serious injury to the operator or other

persons. The owner must understand these instructions, and must allow only trained persons who

understand these instructions to operate the mower. Each person operating the mower must be of

sound mind and body and must not be under the influence of any mind altering substance.

! CAUTION

1. Keep all shields, guards and safety devices in place and in proper working condition.

2. Stop engine and remove spark plug wires or remove key before adjusting, servicing, or performing

maintenance.

TECHNICAL ASSISTANCE

If you have any questions pertaining to your mower contact your dealer. To locate the nearest dealer

please call: 1-800-HUSKY-62.

For technical assistance please write: Husqvarna, 7349 Statesville Road, Charlotte, NC, 28269 or

call: 1-800-HUSKY-MD.

WARNING: Engine exhaust, some of it’s constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer and birth defects

or other reproductive harm.

WARNING: Battery posts, terminals and related accessories contain lead and lead com-

pounds, chemicals known to the State of California to cause cancer and

birth defects or other reproductive harm. Wash hands after handling.

Continuous dedication to improve our products require that specifications and design are

subject to change without notice.

©2003 Husqvarna. All Rights Reserved.

Beatrice, NE. Printed in U.S.A.

2

Page 3

CONTENTS

SAFETY INSTRUCTIONS .................... 4

General use and safety rules ...... 4

Driving on slopes ........................ 4

Children safety............................ 5

Service safety ............................. 6

Transportation ............................ 6

SPECIFICATIONS ................................. 7

ASSEMBLY ........................................... 8

Tools Required............................ 8

Unpacking ................................... 8

Seat Attachment ......................... 8

Control Lever Attachment ........... 8

Check Tire Pressure .................. 9

Assembly Checklist .................... 10

OPERATION .......................................... 11

Controls ...................................... 11

Operation Instructions ................ 11-17

CUSTOMER RESPONSIBILITIES ...... 18

Maintenance Schedule ............... 18

Lubrication Chart ........................ 19

Tires ........................................... 19

Air Screen & Air Filter ................. 22

Oil Filter ...................................... 22

Spark Plugs ................................ 22

Fuel Filter .................................... 22

Cleaning ..................................... 23

SERVICE AND ADJUSTMENT ............. 24

Mower ......................................... 24

Deck Level .................................. 24

Deck Belt Replacement ............. 25

IZT (Integrated Zeroturn

Transaxle) Belt Replacement ..... 26

Seat Adjustment ......................... 27

Control Levers Adjustment ......... 27

Wheel Removal .......................... 27

Jump Starting Engine ................. 27

Battery Replacement .................. 28

Park Brake .................................. 28

Tracking ...................................... 29

STORAGE ............................................. 30-31

TROUBLESHOOTING ......................... 32-33

WIRING SCHEMATIC ........................... 34

Operator Presence System ....... 19

Blade Care ................................. 19

V-Belts ........................................ 21

Engine ........................................ 21

3

Page 4

SAFETY RULES

SAFE OPERATION PRACTICES FOR RIDE-ON MOWERS

DANGER !

THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING

OBJECTS. FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD

RESULT IN SERIOUS INJURY OR DEATH.

I. GENERAL OPERATION

• Read, understand and follow all instruc-

tions in the manual and on the machine

before starting.

• Only allow responsible adults, who are

familiar with the instructions, to operate the

machine.

• Clear the area of objects such as rocks,

stones, toys, wire etc., which could be

picked up and thrown by the blades.

• Be sure the area is clear of all people and

pets before mowing. Stop the machine if

anyone enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely

necessary. Always look down and behind

before and while backing.

• Be aware of the mower discharge direction

and do not direct it towards anyone. Do not

operate the mower without either the entire

grass catcher or the guard in place.

• Slow down before turning.

• Never leave the machine unattended when

the engine is running. Always turn off the

blades, set the parking brake, stop the

engine and remove the key before leaving

the machine.

• Turn off blades when not mowing.

• Stop engine before removing grass catcher

or unclogging chute.

• Mow only in daylight or good artificial light.

• Do not operate the machine while under the

influence of alcohol or drugs.

• Watch out for traffic when operating near or

crossing roadways.

• Use extra care when loading and unloading

the machine onto a trailer or truck.

• Data indicates that operators, age 60 years

and above, are involved in a large percentage of riding mower-related injuries. These

operators should evaluate their ability to

operate the riding mower safely enough to

protect themselves and others from serious

injury.

• Keep machine free of grass, leaves or other

debris buildup which can touch hot exhaust/

engine parts and burn. Do not allow the

mower deck to plow leaves or other debris

which can cause buildup to occur. Clean

any oil or fuel spillage before operating or

storing the machine. Allow machine to cool

before storage.

II. SLOPE OPERATION

Slopes are a major factor related to loss-ofcontrol and tip-over accidents, which can result

in severe injury or death. All slopes require extra

caution. If you cannot back up the slope or if you

feel uneasy on it, do not mow it.

DO:

• Mow up and down slopes, not across.

• Remove obstacles such as rocks, tree

limbs, etc.

• Watch for holes, ruts, or bumps. Uneven

terrain could overturn the machine. Tall

grass can hide obstacles.

• Use slow speed. Choose a low gear so that

you will not have to stop or shift while on the

slope.

• Use extra care with grass catchers or other

attachments. These can change the

stability of the machine.

• Keep all movement on the slopes slow and

gradual. Do not make sudden changes in

speed or direction.

• Avoid starting or stopping on a slope. If tires

lose traction, disengage the blades and

proceed slowly straight down the slope.

4

Page 5

SAFETY RULES

SAFE OPERATION PRACTICES FOR RIDE-ON MOWERS

DO NOT:

• Do not turn on slopes unless necessary,

and then, turn slowly and gradually downhill,

if possible.

• Do not mow near drop-off, ditches, or

embankments. The mower could suddenly

turn over if a wheel is over the edge of a cliff

or ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction could cause sliding.

• Do not try to stabilize the machine by

putting your foot on the ground.

• Do not use grass catcher on steep slopes.

III. CHILDREN

Tragic accidents can occur if the operator is not

alert to the presence of children. Children are

often attracted to the machine and the mowing

activity. Never assume that children will remain

where you last saw them.

• NEVER allow children to operate the

machine.

• Keep children out of the mowing area and

under the watchful care of another responsible adult.

• Be alert and turn off the machine if children

enter the area.

• Before and when backing, look behind and

down for small children.

• Never carry children. They may fall off and

be seriously injured or interfere with safe

machine operation.

• Use extra care when approaching blind

corners, shrubs, trees, or other objects that

may obscure vision.

III. SERVICE

• The operation of any mower can result in

foreign objects thrown into the eyes, which

` can result in severe eye damage. Always

wear safety glasses or eye shields while

operating your mower or performing any

adjustments or repairs. We recommend a

wide vision safety mask over spectacles or

standard safety glasses.

• Use extra care in handling gasoline and

other fuels. They are flammable and vapors

are explosive.

- Use only an approved container.

- Never remove gas cap or add fuel with the

engine running. Allow engine to cool before

refueling. Do not smoke.

- Never refuel the machine indoors.

- Never store the machine or fuel container

inside where there is an open flame, such

as a water heater.

• Never run a machine inside a closed area.

• Keep nuts and bolts, especially blade

attachment bolts, tight and keep equipment

in good condition.

• Never tamper with safety devices. Check

there proper operation regularly.

• Keep machine free of grass, leaves, or other

debris buildup. Clean oil or fuel spillage.

Allow machine to cool before storing.

• Stop and inspect the equipment if you strike

an object. Repair, if necessary, before

restarting.

• Never make adjustments or repairs with the

engine running.

• Grass catcher components are subject to

wear, damage, and deterioration, which

could expose moving parts or allow objects

to be thrown. Frequently check components

and replace with manufacturer’s recommended parts, when necessary.

• Mower blades are sharp and can cut. Wrap

the blade(s) or wear gloves, and use extra

caution when servicing them.

• Check brake operation frequently. Adjust and

service as required.

5

Page 6

SAFETY RULES

SAFE OPERATION PRACTICES FOR RIDE-ON MOWERS

• NEVER allow children to operate the

machine.

• Be sure the area is clear of other people

before mowing. Stop machine if anyone

enters the area.

• Never carry passengers or children even

with the blades off.

• Do not drive in reverse unless absolutely

necessary. Always look down and behind

before and while backing.

• Never carry children. They may fall off and

be seriously injured or interfere with safe

machine operation.

• Keep children out of the mowing area and

under the watchful care of another responsible adult.

• Be alert and turn machine off if children

enter the area.

• Before and when backing, look behind and

down for small children.

• Mow up and down slopes (10° Max), not

across.

• Remove obstacles such as rocks, tree

limbs, etc.

• Watch for holes, ruts, or bumps. Uneven

terrain could overturn the machine. Tall

grass can hide obstacles.

• Use slow speed. Choose a low gear so that

you will not have to stop or shift while on the

slope.

• Avoid starting or stopping on a slope. If tires

lose traction, disengage the blades and

proceed slowly straight down the slope.

• If machine stops while going uphill, disengage blades, shift into reverse and back

down slowly.

• Do not turn on slopes unless necessary,

and then, turn slowly and gradually downhill,

if possible.

CAUTION

In order to prevent accidental starting when

setting up, transporting, adjusting or making repairs, always disconnect spark plug

wire and place wire where it cannot contact

spark plug.

CAUTION

Do not coast down a hill in neutral, you may

lose control of the mower.

WARNING

Do not tow any trailers, etc. with this

mower. They may jackknife or over turn

causing damage to the mower and possibly serious injury to the operator.

WARNING

Engine exhaust, some of its constituents,

and certain vehicle components contain or

emit chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm.

CAUTION

Look for this symbol to point out important safety precautions. It means CAUTION!!! BECOME ALERT!!! YOUR SAFETY

IS INVOLVED.

WARNING

Battery posts, terminals and related accessories contain lead and lead compounds,

chemicals know to the State of California to

cause cancer and birth defects or other reproductive harm. Wash hands after handling.

6

Page 7

SPECIFICATIONS

GASOLINE CAPACITY 5.6 GALLONS

AND TYPE UNLEADED REGULAR

OIL TYPE (SPI-SF-SJ): SEE YOUR ENGINE

OWNERS MANUAL

SPARK PLUG: SEE ENGINE MANUAL

GROUND SPEED (MPH): FORWARD: 0 - 6.5

REVERSE: 0 - 3.5

TIRE PRESSURE: FRONT: 15 PSI

REAR: 15 PSI

CHARGING SYSTEM: KOHLER: 15 AMPS REGU-

LATED @3600 RPM

KAWASAKI 13 AMP @ 3600 RPM

BATTERY: MIN. CCA: 300

CASE SIZE: 5 1/4W X 7 3/4 L X 6 T

BLADE BOLT TORQUE: 45-55 FT./LBS.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining,

caring for and using your mower.

• Follow the instructions under "Customer

Responsibilities” and "Storage” sections of

this owner’s manual.

WARNING

This mower is equipped with an internal

combustion engine and should not be used

on or near any unimproved forest-covered,

brush-covered or grass-covered land unless the engine’s exhaust system is

equipped with a spark arrester meeting

applicable local or state laws (if any). If a

spark arrester is used, it should be maintained in effective working order by the operator.

CONGRATULATIONS on your purchase of a

new mower. It has been designed, engineered

and manufactured to give you the best possible

dependability and performance.

Should you experience any problem you cannot

easily remedy, please contact your nearest

authorized service center/ department. We

have competent, well-trained technicians and

the proper tools to service or repair this mower.

Please read and retain this manual. The instructions will enable you to assemble and

maintain your mower properly. Always observe

the "SAFETY RULES”.

A spark arrester for the muffler is available

through your nearest authorized engine service

center/department.

7

Page 8

ASSEMBLY

Your new mower has been assembled at the factory with the exception of those parts left unassembled for shipping purposes. To ensure safe and proper operation of your mower, all

parts and hardware you assemble must be tightened securely. Use the correct tools as

necessary to insure proper tightness.

TOOLS REQUIRED

FOR ASSEMBLY

1. 9/16" wrench or 9/16" socket w/ drive

ratchet

2. Tire pressure gauge

3. Nail bar or claw hammer

4. Wire snips

When right or left hand is mentioned in this

manual, it means when you are in the operating

position (seated).

TO REMOVE THE MOWER

FROM CRATE

UNPACK CRATE

• Using the nail bar or hammer, remove the

top of the crate first. Then remove the

sides of the crate and place these out of

the way. Be careful of any exposed nails

or staples.

• Remove the plastic bag that covers the

mower.

• Using the wire snips, cut any plastic ties

that are holding the mower to the crate.

• Remove the seat off of the front of the

mower and place in a safe location.

• Securing one of the three prong knobs

and washers, insert it thru the seat pan

slot and into the corresponding threaded

hole in the seat bottom.

• Repeat for the other three holes.

• Tighten the three prong knobs in the

approximate position desired for the

seat.

• Connect the wiring harness to the seat

switch.

Adjustments may be required to position the

seat in the desired position. Refer to the

"Service and Adjustment" section of this

manual.

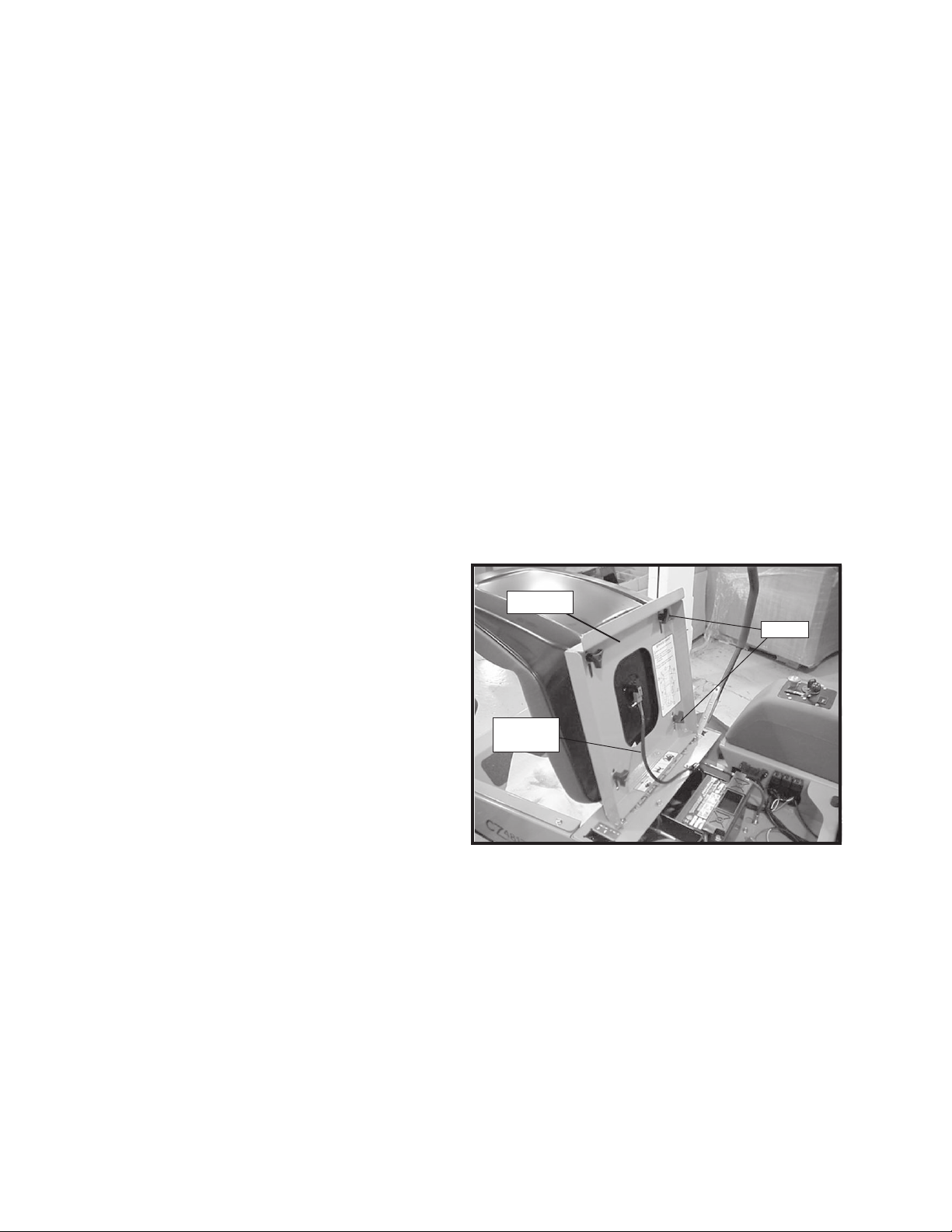

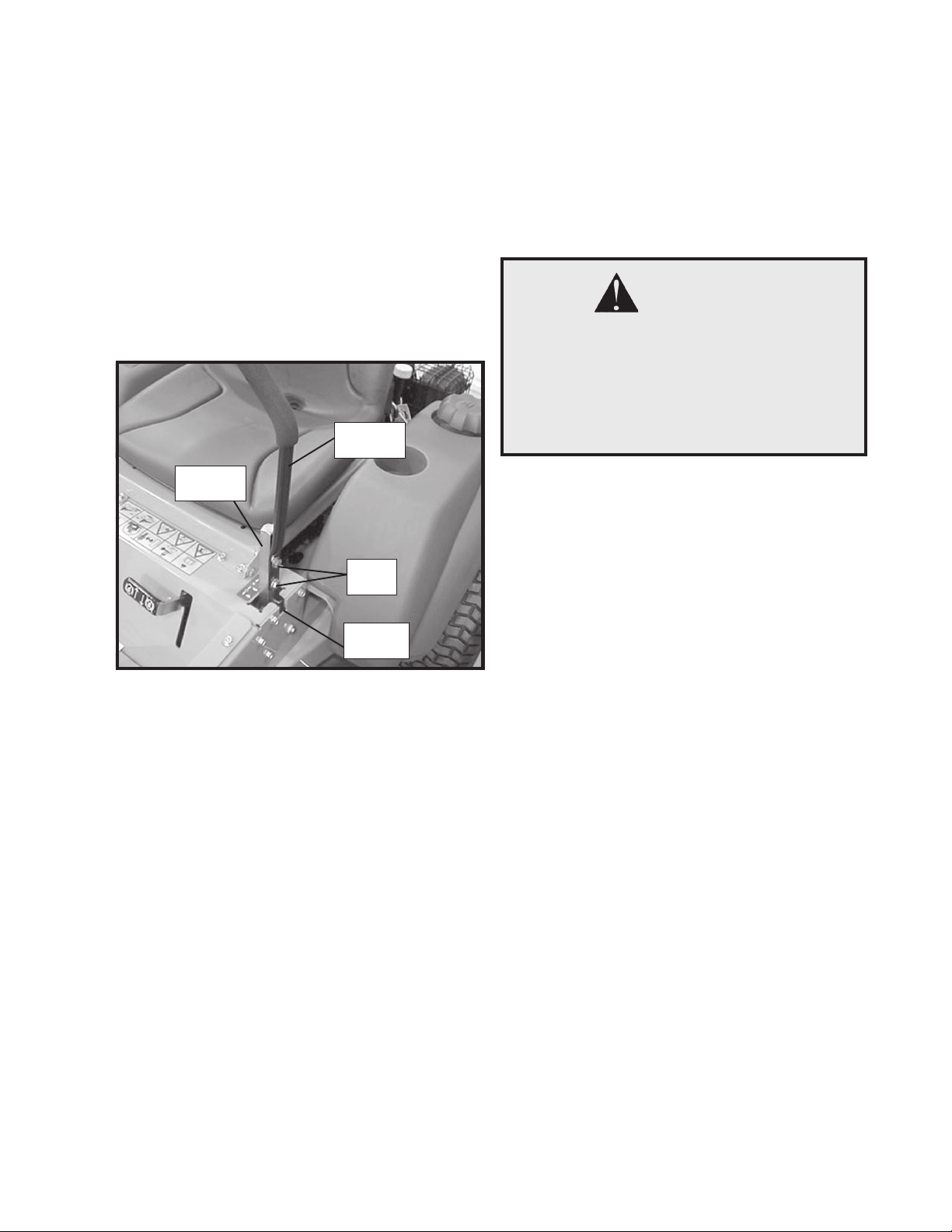

SEAT PAN

WIRE

HARNESS

KNOBS

BEFORE REMOVING THE

MOWER FROM THE SKID

ATTACH SEAT (See Fig. 1)

The seat position should be adjusted forward or

backward so that the operator can comfortably

reach the deck lift pedal and safely operate the

mower. See "Service and Adjustment" Section

of this manual.

• Remove protective wrap from the seat.

• Remove the three prong knobs and

washers from the seat and place in the

storage area in the right side console.

• Raise the seat pan up so that the bottom

can be easily accessed.

FIGURE 1

ATTACH CONTROL LEVERS (See Fig. 2)

• Using the 9/16" wrench or socket and

ratchet, remove the bottom hex bolt and

spring washer from the control arm.

• Rotate the control lever up until the bolt

and spring washer can be placed thru

the slot in the bottom of the control lever

and threaded back into the control arm.

• Center the hex bolt in the slot on the

control lever. Using the wrench or

ratchet, tighten both the top and bottom

hex bolts.

• Repeat on opposite side of the mower.

8

Page 9

ASSEMBLY

Adjustments may be required to get uniform

positioning of the control lever. Refer to the

"Service and Adjustment" section of this manual.

NOTE: You may now roll or drive the mower off

of the skid. Follow the appropriate instruction

below to remove the mower from the skid.

CONTROL

LEVER

CONTROL

ARM

HEX

BOLTS

NEUTRAL

SLOT

FIGURE 2

TO ROLL THE MOWER OFF OF THE SKID

(See Operation section for location and

function of controls

• Move to the rear of the mower, and place

the IZT (Integrate Zeroturn Transaxle)

bypass linkages into the bypass position

to disengage the IZT’s (See “TO

TRANSPORT” in the Operation section

of this manual).

• Sitting on the mower, press the deck lift

pedal in to the highest cutting position.

• Release park brake lever.

• Roll the mower forward or backward off

of the skid.

TO DRIVE THE MOWER OFF OF THE

SKID (See Operation section for location

and function of controls)

WARNING

Before starting, read, understand and

follow all instructions in the Operation

section of this manual. Be sure the mower

is in a well-ventilated area. Be sure the area

in front of the mower is clear of other people

and objects.

• Be sure all of the above assembly

steps have been completed.

• Check engine oil level and fill fuel

tank with gasoline.

• Place the IZT(Integrated Zeroturn

Transaxle) bypass linkages into the

drive position (See “TRANSPORT” in

the Operation section of this manual).

• Sit on the seat in the operating

position, set the park brake lever to

the on position.

• Rotate the control levers outward

into the neutral slot.

• Press forward on the deck lift pedal

to raise the deck into the highest

cutting position.

• Place the throttle control into the

choke position.

• Start the engine. After the engine

has started, move the throttle control

to the idle position.

• Release the park brake.

• Move the control levers into the

operate position.

• Slowly move the control levers

forward and slowly drive the mower

off of the skid.

• Return the control levers back to the

neutral position.

• Apply the park brake.

• Turn the ignition key to the “OFF”

position.

9

Page 10

ASSEMBLY

CHECK THE TIRE PRESSURE

Correct tire pressure is important for best cutting

performance.

• Check the tire pressure and adjust

accordingly. Refer to the

“SPECIFICATIONS” section in this

manual.

CHECKLIST

PLEASE REVIEW THE FOLLOWING

CHECKLIST

• All assembly instructions have been

completed

• No remaining loose parts in crate

• Seat is adjusted properly and securely

fastened

• All tires are properly inflated

• Check wiring. See that all connections

are still secure, and wires are properly

clamped.

• Before driving the mower, be sure the

IZT(Integrated Zeroturn Transaxle)

bypass linkages are in the drive position.

WHILE LEARNING HOW TO USE

YOUR MOWER, PAY EXTRA

ATTENTION TO THE FOLLOWING

ITEMS:

• Engine oil is at proper level

• Fuel tank is filled with fresh, clean,

regular unleaded gasoline. Check your

engine manual for fuel requirements.

• Become familiar with all controls – their

location and function. Operate them

before you start the engine.

• Become familiar with unit operation on a

flat and level area with the mower deck

shut off.

• Be sure the brake system is in a safe

operating condition. If adjustment is

needed see Service and Adjustment

section.

10

Page 11

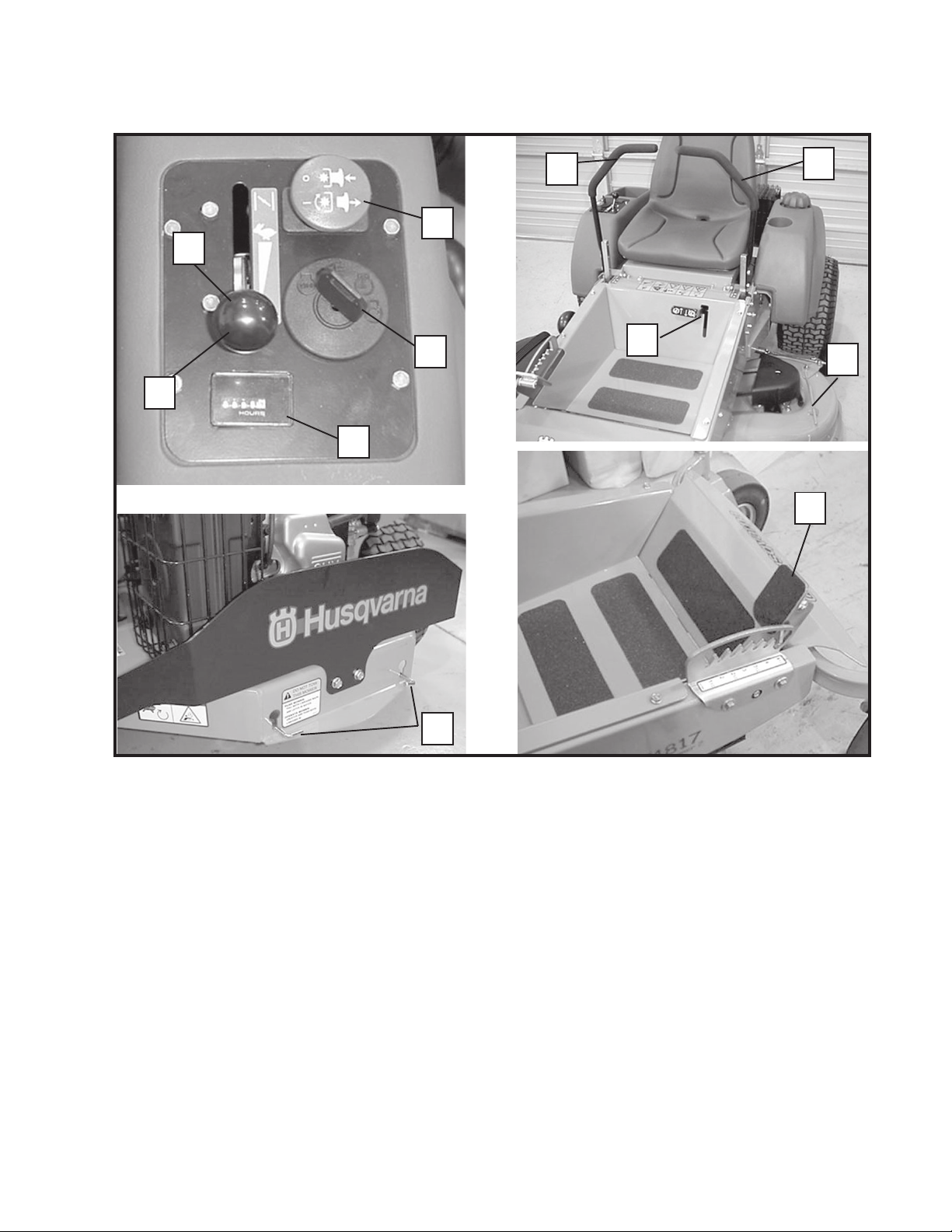

CONTROLS

OPERATION

3

3

1

5

7

8

9

4

10

2

6

FIGURE 3

1. PTO SWITCH –

disengage the deck blades.

Used to engage or

2. FOOT PEDAL – Used to raise, lower and

select various cutting heights of the deck.

3. CONTROL LEVERS – Sets the speed of

the mower in both forward and reverse

directions and turns the mower.

4. CHOKE CONTROL – Used when staring

a cold engine.

5. THROTTLE CONTROL – Used to control

Engine Speed.

6. IZT (Integrated Zeroturn

Transaxle) BYPASS LINKAGES –

Bypasses IZT’s for pushing or pulling

mower.

7. IGNITION SWITCH – Used to start or stop

the engine.

8. PARKING BRAKE LEVER – Engages

and disengages the park brakes.

9. TENSION RELIEF LEVER – Used to

release the belt tension on the deck belt for

ease in removing or replacing the belt.

10. HOUR METER – Indicates hours of

operation.

11

Page 12

OPERATION

HOW TO USE YOUR MOWER

TO SET PARKING BRAKE (See Fig. 3)

Your mower is equipped with an operator

presence system. When the engine is running,

any attempt by the operator to leave the seat

without first setting the park brake will shut off

the engine.

• Pull park brake lever up and to the right

to engage the park brake. Make sure the

lever is secured to the right.

DECK BLADES

• To stop the deck blades, press down on

the PTO Switch into the disengaged

position.

ENGINE

• Move throttle control to slow position.

TO USE THROTTLE CONTROL (See Fig. 3)

Always operate engine at full throttle. The

Throttle control is equipped with a choke detent.

Pressing the throttle control all of the way

forward will choke the engine. For full throttle,

press throttle control forward until you feel

resistance.

• Operating engine at less than full throttle

reduces the battery charging rate

• Full throttle offers the best mower

performance.

TO USE CHOKE CONTROL (See Fig. 3)

Use choke control whenever you are starting a

cold engine. Do not use to start a warm engine.

• To choke, press the throttle control as far

forward as it will go.

• To take out of choke, pull back on the

throttle control until it clicks.

NOTE: Failure to move the throttle control to

slow position and allow engine to idle before

stopping may cause engine to “backfire”.

• Turn ignition key to “OFF” position and

remove key. Always remove key when

leaving the mower to prevent

unauthorized use.

• Never use choke to stop engine.

IMPORTANT: LEAVING THE IGNITION

SWITCH IN ANY POSITION OTHER THAN

“OFF” WILL CAUSE THE BATTERY TO BE

DISCHARGED, (DEAD).

WARNING

Always stop mower completely before

leaving the operators position; to empty a

grass catcher, etc.

TO MOVE FORWARD AND BACKWARD

(See Fig. 4)

IMPORTANT: CONTROL LEVERS RETURN

TO NEUTRAL WHEN RELEASED. THIS MAY

CAUSE A SUDDEN STOP OF THE MOWER.

The direction and speed of movement is

controlled by the control levers on either side of

the mower.

The left lever controls the flow of oil in the left IZT

(Integrated Zeroturn Transaxle) to the left wheel.

The right lever controls the flow of oil in the right

IZT to the right wheel.

Motion Control Lever Pattern

(Right Side)

NEUTRAL SLOT

NEUTRAL LOCK

FORWARD

NEUTRAL

FRONT OF

MOWER

REVERSE

12

FIGURE 4

Page 13

OPERATION

NOTE: To begin motion the operator must be in

the seat and the parking brake disengaged

before the motion control levers can be moved

from the neutral slots or the engine will kill. Fig. 4

and 4A.

By moving the levers an equal amount forward

or back the machine will move in a straight line

in that direction. Fig. 4 and 4A

Movement of either lever forward will cause the

right or left wheel to rotate in a forward direction.

To stop movement pull both levers into the

neutral position.

To turn right while moving in a forward direction

pull the right lever back towards the neutral

position, this will slow the rotation of the right

wheel and cause the machine to turn in that

direction.

To turn left while moving in a forward direction

pull the left lever back towards the neutral

position, this will slow the rotation of the left

wheel and cause the machine to turn in that

direction.

To zero turn pull one lever back beyond neutral

while holding the other slightly ahead of neutral.

NOTE: The direction of the zero turn will be

determined by which lever is pulled back beyond

neutral. Thus left lever back, left zero turn and

opposite for right zero turn.

Use extra care when using this maneuver

the machine can spin very rapidly if one

lever is positioned to far ahead of the other.

FORWARD

HEX NUTS

AND

WASHERS

CONTROL

ARM

REVERSE

CONTROL

LEVER

NEUTRAL

SLOT

FIGURE 4A

TO ADJUST THE DECK CUTTING

HEIGHT (See Fig. 5)

The deck cutting height is obtained by pressing

the foot pedal forward to lift the deck. To lower

the deck, you apply pressure to the top side of

the foot pedal and allow it to pivot while allowing

the lift arm to rotate to the rear of the unit. To

stop in a desired cutting position, rotate the foot

pedal down into the notch in the height plate.

The cutting height range is from 1 1/2" to 4 1/2"

in 1/2" increments. The heights are measured

from the ground up to the blade tip with the

engine not running.

CAUTION

DO NOT apply excessive force to control

levers or use to assist in dismounting unit.

Misuse will result in bent control levers.

• The average lawn should be cut to 2 1/2"

during the cool season and to over 3"

during the hot months. For healthier and

better looking lawns, mow often and after

moderate growth.

• For best cutting performance, grass over

6 inches in height should be mowed

twice. Make the first cut relatively high;

the second to the desired height.

13

Page 14

OPERATION

FOOT

PEDAL

HEIGHT

PLATE

FIGURE 5

LIFT

ARM

TO ADJUST ANTI-SCALP

ROLLERS (See Figure 6)

Anti-scalp rollers are properly adjusted when

they are just slightly off of the ground when the

deck is at the desired cutting height in the

operating position. Anti-scalp rollers then keep

the deck in the proper position to help prevent

scalping in most terrain conditions.

NOTE: Adjust Anti-scalp rollers with the mower

on a flat level surface.

ANTI-SCALP

ROLLER

FIGURE 6

TO OPERATE MOWER

Your mower is equipped with an operator

presence system. When the engine is running,

any attempt by the operator to leave the seat

without first setting the park brake will shut off

the engine.

• Select desired height of cut.

• Start deck blades by pulling the PTO

switch up into the engaged position.

• To stop the deck blades, press down on

the PTO Switch into the disengaged

position.

• Adjust the deck to the desired cutting

height (see “TO ADJUST DECK

CUTTING HEIGHT” in the operation

section of this manual).

• Using a 3/4" wrench and a 9/16" wrench,

remove the nut and shoulder bolt from

the anti-scalp roller.

• Lower the anti-scalp roller to the ground,

and raise it up to the next highest hole.

• Replace and tighten the nut and shoulder

bolt.

• Be sure to adjust all of the anti-scalp

rollers to the same position.

• Be sure to readjust the anti-scalp rollers

if the cutting height is changed.

IMPORTANT: THE ANTI-SCALP ROLLERS

MUST NOT BE USED FOR GAUGE WHEELS

OR THE ROLLER AND DECK MAY BE

DAMAGED.

WARNING

Do not operate the deck without either

the entire grass catcher, mulch kit or discharge chute installed.

TO OPERATE ON HILLS

WARNING

Do not drive up or down hills with slopes

greater than 10 degrees. And do not drive

across any slopes.

14

Page 15

OPERATION

• The slowest speed possible should be

used before starting up or down hills.

• Avoid stopping or changing speed on

hills.

• If stopping is absolutely necessary, pull

drive levers into the neutral position and

push to the outside of the unit and

engage the park brake.

IMPORTANT: Control levers return to neutral

when released. This may cause a sudden stop

of the mower.

IZT BYPASS LINKAGE

• To restart movement, release the park

brake.

• Pull the control levers back to the center

of the mower and press forward to

regain forward motion.

• Make all turns slowly.

TO TRANSPORT (See Fig. 7)

When pushing or pulling the mower, be sure to

engage the IZT (Integrated Zeroturn Transaxle)

bypass linkages. The IZT bypass linkages are

located on the rear of the frame, below the rear

engine guard.

CAUTION

Do not tow this vehicle, it may cause dam-

age to the drive system.

• Raise the deck into the highest cutting

position.

• Pull the IZT bypass linkages out and into

the slots and release so that it is held in

the bypass position.

• To reengage the IZT’s to drive, reverse

the above procedure.

FIGURE 7

HEAD INSIDE OF

REAR DECK

IZT BYPASS

LINKAGE IN

DRIVE POSITION

FIGURE 7A

HEAD OUTSIDE

OF REAR DECK

IZT BYPASS

LINKAGE IN

BYPASS POSITION

FIGURE 7B

WARNING

Do not tow any trailers, etc. with this mower.

They may jackknife or overturn causing

damage to the mower and possibly serious

injury to the operator.

15

Page 16

OPERATION

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

• The engine in your mower has been

shipped from the factory, already filled

with 10W-30 motor oil.

• Check engine oil with the mower on level

ground.

• Refer to you Engine Owners Manual for

correct oil level.

• To change engine oil, see the Customer

Responsibilities section of this manual.

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular

unleaded gasoline with a minimum of 87

octane. (Use of leaded gasoline will

increase carbon and lead oxide deposits

and reduce valve life). Do not mix oil

with gasoline. Purchase fuel in

quantities that can be used within 30

days to ensure fuel freshness.

CAUTION

Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or

methanol) can attract moisture which leads

to separation and formation of acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To

avoid engine problems, the fuel system

should be emptied before storage of 30

days or longer. Drain the gas tank, start

the engine and let it the run until the fuel

lines and carburetor are empty. Use fresh

fuel the next season. See Storage Instructions for additional information. Never use

engine or carburetor cleaners in the fuel

tank or permanent damage may occur.

WARNING

IMPORTANT: WHEN OPERATING IN

TEMPERATURES BELOW 32° F. (0° C.), USE

FRESH, CLEAN WINTER GRADE GASOLINE

TO HELP INSURE GOOD COLD WEATHER

STARTING.

Fill to bottom of filler neck. Do not over

fill. Wipe off any spilled oil or fuel. Do

not store, spill or use gasoline near an

open flame.

TO START ENGINE (See Fig. 3)

When starting the engine for the first time or if

the engine has run out of fuel, it will take extra

cranking time to move fuel from the tank to the

engine.

• Be sure IZT (Integrated Zeroturn

Transaxle) bypass linkages are in the

drive position.

• Sit on the seat in the operators position,

release park brake lever.

• Check to be sure the PTO switch is

disengaged.

• Move the throttle control to the choke

position.

• For a warm engine start, the choke

control may not be needed

16

Page 17

OPERATION

NOTE: Before starting, read the warm and cold

starting procedures below.

• Insert key into the ignition and turn the

key clockwise to “START” position and

release the key as soon the engine

starts. Do not run the starter

continuously for more than 15 seconds

per minute. If the engine does not start

after several attempts, push the throttle

control into the choke position, wait a few

minutes and try again. If the engine still

does not start, move the throttle control

back into the fast position and retry.

WARM WEATHER STARTING (50° F and above)

• When the engine starts, slowly pull the

throttle control back until the engine

begins to run smoothly. If the engine

starts to run roughly, press the throttle

control back forward to choke the engine

for a few seconds. Then continue to pull

the throttle control back to the fast

position.

• The PTO switch and ground drive can

now be used. If the engine does not

accept the load, restart the engine and

allow it to warm up for one minute using

the choke as described above.

COLD WEATHER STARTING (50° F and below)

• When the engine starts, slowly pull the

throttle control back until the engine

MOWING TIPS

• The cutting deck should be properly

leveled for best mowing performance.

See “TO LEVEL DECK” in the Service

and Adjustment section of this manual.

• The left hand side of the deck should be

used for trimming.

• Drive so that clippings are discharged

onto the area that has been cut. Have

the cut area to the right of the mower.

This will result in more even distribution

of clippings and a more uniform cut.

• If grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dried clippings. Make

first cut relatively high; second to desired

height.

• Do not mow grass when it is wet. Wet

grass will plug the deck and leave

undesirable clumps. Allow grass to dry

before mowing.

• Always operate engine at full throttle

when mowing to assure better mowing

performance and proper discharge of

material. Regulate ground speed by

going slow enough to allow proper deck

cutting performance as well as the

quality of cut desired. When operating

attachments, select a ground speed that

will suit the terrain and give best

performance of the attachment being

used.

begins to run smoothly. Continue to pull

back on the throttle control in small steps

allowing the engine to accept small

changes in speed and load, until the

throttle control is completely in the fast

position. If the engine starts to run

roughly, press the throttle control back

forward to choke the engine for a few

seconds. Then continue to pull the

throttle control back slowly to the fast

position. This may require an engine

warm up period from several seconds to

several minutes, depending on the

temperature.

17

Page 18

CUSTOMER RESPONSIBILITIES

MAINTENANCE SCHEDULE

Before

each

use

Check Brake Operation

Check Tire Pressure

Check Operator Presence and

Interlock Systems

Check for Loose Fasteners

Sharpen/Replace mower Blades

Lubrication Chart

Check Battery Level

Clean Battery and Terminals

Check V-Belts

Check Engine Oil Level

Change Engine Oil (with oil filter)

Change Engine Oil (without oil filter)

Clean Air Filter

Clean Air Screen

Inspect Muffler/Spark Arrester

Replace Oil Filter

Clean Engine Cooling Fins

Replace Spark Plug

Replace Air Filter Paper Cartridge

Replace Fuel Filter

1 - change more often when operating under a heavy load or in high

ambient temperatures.

2 - Service more often when operating in dirty or dusty conditions.

8 Hours 25 Hours 50 Hours 100 Hours Season

XX

XX

X

X

X

X

X

X

X

X

EVERY

5

X

3

4

Before

Storage

X

X

X

X

X

X

X

X

X

1, 2

2

2

X

1, 2

X

X

1, 2

2

X

X

X

2

X

X

3 - Replace blades more often when mowing in sandy soil.

4 - Not required if equipped with maintenance-free battery.

5 - Tighten front axle pivot bolt to 35 ft./lbs. maximum.

DO NOT overtighten.

GENERAL RECOMMENDATIONS

The warranty on this mower does not cover

items that have been subjected to operator

abuse or negligence. To receive full value from

the warranty, operator must maintain mower as

instructed in this manual.

Some adjustments will need to be made periodically to properly maintain your mower.

All adjustments in the Service and Adjustments

section of the this manual should be checked at

least once each season.

• Once a year you should replace the

spark plug, clean or replace air filter, and

check blades and belts for wear. A new

spark plug and clean air filter assure

proper air-fuel mixture and help your

engine run better and last longer.

BEFORE EACH USE

• Check engine oil level.

• Check brake operation.

• Check tire pressure.

• Check operator presence and interlock

systems for proper operation.

• Check for loose fasteners.

18

Page 19

CUSTOMER RESPONSIBILITIES

LUBRICATION CHART

GREASE LUBE POINTS EVERY 25 HOURS.

CHECK TIRE AIR PRESSURE

FRONT TIRES - 15 PSI

REAR TIRES - 15 PSI

REFER TO ENGINE OPERATORS MANUAL

PRIOR TO SERVICING THE ENGINE.

IMPORTANT: DO NOT OIL OR GREASE THE

PIVOT POINTS WHICH HAVE SPECIAL NYLON

BEARINGS. VISCOUS LUBRICANTS WILL

ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS.

IF YOU FEEL THEY MUST BE LUBRICATED, USE

ONLY A DRY, POWDERED GRAPHITE TYPE

LUBRICANT SPARINGLY.

NOTE: To seal tire punctures and prevent flat

tires due to slow leaks, tire sealant may be

purchased from your local parts dealer. Tire

sealant also prevents tire dry rot and corrosion.

OPERATOR PRESENCE SYSTEM

Be sure the operator presence and interlock

systems are working properly. If your mower

does not function as described, repair the

problem immediately.

• The engine should not start unless the

parking brake is engaged, the PTO

switch is disengaged (pressed down),

the operator is on the seat, and the

control levers are rotated to the outside

of the mower.

• When the engine is running, any attempt

by the operator to leave the seat without

first setting the park brake should shut off

the engine.

• When the engine is running and the PTO

switch is engaged, any attempt by the

operator to leave the seat without first

disengaging the PTO switch, should shut

off the engine.

• When the engine is running and the

control levers are rotated in, any attempt

by the operator to leave the seat without

rotating the control levers out, should

shut off the engine.

• The PTO switch should never engage

without the operator on the seat.

BLADE CARE

For best results, mower blades must be kept

sharp. Replace bent or damage blades.

TIRES

• Maintain proper air pressure in all tires

(See "SPECIFICATIONS" section of this

manual).

• Keep tires free of gasoline, oil, or insect

control chemicals which can harm

rubber.

• Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may

cause tire damage.

BLADE REMOVAL (See Fig. 8)

NOTE: Protect your hands with gloves and/or

wrap blade with heavy cloth.

• Remove blade bolt by turning

counterclockwise.

• Install new or re-sharpened blade with

stamped "THIS SIDE UP" facing deck

and cutter housing.

19

Page 20

CUSTOMER RESPONSIBILITIES

IMPORTANT: TO ENSURE PROPER ASSEMBLY,

CENTER HOLE IN BLADE MUST ALIGN WITH

STAR ON CUTTER HOUSING.

• Install and tighten blade bolt securely

(45-55 ft./lbs. torque).

IMPORTANT: SPECIAL BLADE BOLT IS HEAT

TREATED.

CUTTER

BLADE

CENTER

HOLE

BLADE BOLT

(SPECIAL)

FIGURE 8

HOUSING

STAR

• The blade can be sharpened with a file or

on a grinding wheel. Do not attempt to

sharpen while on the mower.

• To check blade balance, you will need a

5/8" diameter steel bolt, pin, or a cone

balancer. (When using a cone balancer,

follow the instructions supplied with

balancer.)

NOTE: Do not use a nail for balancing the blade.

The lobes of the center hole may appear to be

centered, but are not.

• Slide blade on to an un-threaded portion

of the steel bolt or pin and hold the bolt or

pin parallel with the ground. If the blade

is balanced, it should remain in a

horizontal position. If either end of the

blade moves downward, sharpen the

heavy end until the blade is balanced.

TO SHARPEN BLADE (See Fig. 9)

WARNING

When it is necessary to raise the

mower for any repair or service, use

jackstands to provide adequate support. DO NOT rely on hydraulic or mechanical jacks

Care should be taken to keep the blade balanced. An unbalanced blade will cause excessive vibration and eventual damage to mower

and engine.

CENTER HOLE

5/8" BOLT

OR PIN

BLADE

FIGURE 9

BATTERY

Your mower is equipped with a maintenance

free battery and does not need servicing.

However, periodic charging of the battery with an

automotive type battery charger will extend its

life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Recharge at 6-10 amperes for 1 hour

20

Page 21

CUSTOMER RESPONSIBILITIES

NOTE: Do not attempt to open or remove caps

or covers. Adding or checking level of electrolyte

is not necessary.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals

can cause the battery to “leak” power.

• Remove terminal guard.

• Disconnect BLACK battery cable first,

then the RED battery cable and remove

the battery from the tractor.

• Rinse the battery with plain water and

dry.

• Clean terminals and battery cable ends

with wire brush until shiny.

• Coat terminals with grease or petroleum

jelly

• Reinstall battery (See “REPLACING

BATTERY” in the SERVICE AND

ADJUSTMENT section of this manual).

• Remove oil dipstick. Be careful not to

allow dirt to enter the engine when

changing oil.

• Using a 7/16" open-ended wrench,

remove the drain plug that is in the

bottom of the 90° elbow. The elbow

extends thru the rear deck and points

down.

• Be sure container is located under this

area of the mower.

• Allow a sufficient amount of time for oil to

drain.

• After the oil has drained, reinstall the

drain plug (do not over tighten).

• Refill engine with oil through the oil

dipstick tube. Pour slowly. Do not

overfill.

• See Engine Owners Manual for type and

capacity of the oil.

V-BELTS

Check V-belts for deterioration and wear after

100 hours of operation and replace if necessary.

The Belts are not adjustable. Replace belts if

they begin to slip from wear.

ENGINE

LUBRICATION

Refer to you Engine Owners Manual

TO CHANGE ENGINE OIL (See Figs. 10

[Kohler] and 11 [Kawasaki]).

Depending on the Engine that you have on you

mower will determine if you need to refer to

figure 10 or 11. If your mower is equipped with a

Kohler Engine, refer to figure 10. If it is equipped

with a Kawasaki Engine, refer to figure 11.

• If your mower is equipped with a Kohler

Engine

• Be sure the mower is on a level surface.

• Oil will drain more freely when warm.

• Place a suitable container under the left

rear corner of the rear of the mower.

KOHLER ENGINE

OIL DRAIN PLUG

FIGURE 10

• Be sure the mower is on a level surface.

• Oil will drain more freely when warm.

• Place a suitable container under the left

rear corner of the rear of the mower.

• Remove oil dipstick. Be careful not to

allow dirt to enter the engine when

changing oil.

• Using the clear plastic tube included with

you mower, place it over the end of the

drain valve located on the left side of your

engine.

21

Page 22

CUSTOMER RESPONSIBILITIES

• Place the other end of the tube thru the

2" diameter hole on the left side of the

rear deck.

• Be sure container is located under this

area of the mower.

• Using a 10 mm wrench, turn the hex

head on the oil valve counter clockwise

until the oil is draining out of the tube.

After the oil has drained, turn the hex

head clockwise until it is tight (do not

over tighten).

• Remove the plastic tube from the valve,

clean excess oil off of tube and store in a

safe place for the next use.

• Refill engine with oil through the oil

dipstick tube. Pour slowly. Do not

overfill.

• See Engine Owners Manual for type and

capacity of the oil.

Every 100 hours of operation (more often under

extremely dusty, dirty conditions), remove the

blower housing and other cooling shrouds. Clean

the cooling fins and external surfaces as necessary. Make sure the cooling shrouds are reinstalled.

NOTE: Operating the engine with a blocked

grass screen, dirty or plugged cooling fins, and/

or cooling shrouds removed will cause engine

damage due to overheating.

AIR FILTER

Your engine will not run properly using a dirty air

filter. Service air cleaner more often under dusty

conditions. See Engine Manual.

ENGINE OIL FILTER

Replace the engine oil filter every season or

every other oil change if the mower is used more

than 100 hours in one year.

KAWASAKI ENGINE

OIL DRAIN VALVE

PLASTIC TUBE

FIGURE 11

CLEAN AIR SCREEN

Air screen must be kept free of dirt and chaff to

prevent engine damage from overheating. Refer

to your engine manual for the proper cleaning

procedure.

CLEAN AIR INTAKE/COOLING AREAS

To insure proper cooling, make sure the grass

screen, cooling fins, and other external surfaces

of the engine are kept clean at all times.

SPARK PLUGS

Replace spark plugs at the beginning of each

mowing season or after every 100 hours of

operation, whichever occurs first. For spark plug

type and gap setting refer to your ENGINE

OWNER’S MANUAL.

IN-LINE FUEL FILTER (See Figs. 12 and 13)

The fuel filter should be replaced once each

season. If the fuel filter becomes clogged,

obstructing fuel flow to carburetor, replacement

is required.

• First turn off the fuel valve that is located

under the fuel tank of you mower.

• With the engine cool, remove the filter

and plug fuel line sections.

• Place new filter in position in fuel line with

arrow pointing toward the carburetor.

• Be sure there are no fuel leaks and

clamps are secure and properly

positioned.

• Immediately wipe up any spilled gasoline.

22

Page 23

CUSTOMER RESPONSIBILITIES

KOHLER ENGINE

FUEL FILTER

FIGURE 12

CLEANING

• Clean engine, battery, seat, finish, etc. of

all foreign matter.

• Keep finished surfaces and wheels free

of all gasoline, oil, etc.

• Protect painted surfaces with automotive

type wax

We do not recommend using a garden hose to

clean you mower unless the electrical system,

muffler, air filter and carburetor are covered to

keep water out. Water in the engine can shorten

the engine life.

KAWASAKI ENGINE

FUEL FILTER

FIGURE 13

FIGURE 12A

FUEL SHUT OFF

VALUE

23

Page 24

SERVICE AND ADJUSTMENT

WARNING

BEFORE PERFORMING ANY SERVICE

OR ADJUSTMENTS:

• Set park brake to engaged position.

• Place PTO switch in the disengaged

position (pressed down).

• Turn ignition key "OFF" and remove

the key.

• Make sure the blades and all moving

parts have completely stopped.

• Disconnect spark plug wire from

spark plug and place the wire where

it cannot come in contact with the

plug.

MOWER

TO LEVEL DECK

and rear lift linkages (be sure to tighten

equal amounts).

• To lower one side of the deck, reverse

previous step.

• Recheck measurements after

adjustment.

A A

FIGURE 14

HEX NUT

Adjust the deck while the mower is on a level

surface. Make sure the tires are inflated to the

correct pressure (see “SPECIFICATIONS”

section in this manual). If tires are under or over

inflated, you can not properly adjust your deck.

NOTE: It may be easier to adjust the front lift

linkages by removing the floor pan before any

adjustments are made

SIDE-TO-SIDE ADJUSTMENT (See Figs. 14

and 15)

• Raise the deck into the highest cutting

position (4 1/2")

• Measure height from the bottom edge of

the deck to the ground at both front

corners. Distance “A” at both corners

should be the same.

• If adjustment is necessary, make

adjustment to one side the deck only

• To raise one side of the deck, using a 9/16"

wrench, tighten the hex nuts on both the

front

FRONT LIFT

LINKAGE

FIGURE 15

REAR LIFT

LINKAGE

HEX NUT

FIGURE 15A

24

Page 25

SERVICE AND ADJUSTMENT

FRONT-TO-BACK ADJUSTMENT (See Fig. 16).

IMPORTANT: DECK MUST BE LEVEL SIDETO-SIDE. IF THE FOLLOWING FRONT-TOBACK ADJUSTMENT IS NECESSARY, BE

SURE TO ADJUST BOTH FRONT OR BOTH

REAR LINKAGES EQUALLY SO THE DECK

WILL STAY LEVEL.

To obtain the best cutting performance, the deck

should be adjusted so the front tip of the blades

are approximately 1/8" to 1/4" lower than the rear

tip. If the front tip is higher, this will create a poor

quality of cut.

B

FIGURE 16

B

WARNING

Blades are sharp. Protect your hands with

gloves and/or wrap blades with a heavy

cloth when handling.

Check adjustment on the right side of the

mower. Position any blade so that the tip is

pointing straight forward. Measure distance “B”

at the front and rear tip of the blade.

• Before making any necessary

adjustments, check to make sure that

the deck is level side-to-side.

• With the deck in the highest cutting

position, (4 1/2") measure the front tip of

the blade to see if the deck is higher or

lower than 4 1/2".

• To lower the front tip of the blade, using a

9/16" wrench, loosen the hex nuts that

are on the front lift linkages (be sure to

loosen equal amounts).

• When distance “B” is 1/8" to 1/4" lower at

the front than rear the adjustment is

done.

• Reverse above step to raise the deck.

TO REPLACE DECK BELT

DECK BELT REMOVAL (See Fig. 17 and 18)

• Park on a level surface. Apply park

brake.

• Lower the deck into the lowest cutting

position

• Disengage the tension relief lever from

the lock bracket.

WARNING

Lever is spring loaded. Have a tight grip

on the lever and release slowly.

• Remove screws from both the left and

right belt shields, and remove shields.

• Remove any dirt or grass that may have

accumulated around the cutter housings

and entire deck surface.

• Carefully roll the belt over the top of the

cutter housing pulleys.

• Remove the belt from around the electric

clutch on the engine shaft.

• The belt can now be removed.

25

Page 26

SERVICE AND ADJUSTMENT

DECK BELT INSTALLATION (See Figs. 17 and 18)

NOTE: For ease in installing the deck belt, refer

to the routing decal on the front edge of the

deck.

• Wrap the deck belt around the electric

clutch that is located on the engine shaft.

• Push the rest of the belt through the

IZT(Integrated Zeroturn Transaxle)

support and up onto the deck.

• Starting on the right hand side of the

deck, wrap the belt around the large right

side idler, right cutter housing pulley,

small center idler, center pulley, left side

pulley and then around the large left side

idler.

• The belt will be loose at this point.

• Tightly secure the belt tension rod and

reengage it in the lock bracket.

TO REPLACE IZT (Integrated Zeroturn

Transaxle) BELT (See Fig. 18)

Park the mower on a level surface. Engage the

park brake.

IZT BELT REMOVAL

NOTE: Be careful not to damage the fan

blades on the IZT’s as this can affect cooling or

damage the IZT’s

• Remove the deck belt (see “TO

REPLACE DECK BELT” in this section

of the manual).

• Create slack in the belt by removing the

spring on the pump idler arm.

• The belt should now be able to be

removed from the engine pulley and IZT

pulleys.

BELT ROUTING DECAL

ON FRONT OF DECK

FIGURE 17

TENSION RELIEF

LEVER

BELT INSTALLATION

• Wrap the IZT belt around the IZT pulleys

• Route the belt around the inside of the

idler pulley.

• Now you can wrap the belt around the

engine pulley.

• Reattach the spring on the pump idler

arm.

• Reinstall the deck belt onto the electric

clutch belt (see “TO REPLACE DECK

BELT” in this section of the manual).

PUMP IDLER

ARM SPRING

PUMP IDLER

ELECTRIC CLUTCH

DECK BELT

IZT SUPPORT

IZT BELT

FIGURE 17A

FIGURE 18

26

Page 27

SERVICE AND ADJUSTMENT

TO ADJUST THE SEAT (See Fig. 1)

• Move the control levers into the neutral

position and rotate to the outside of the

machine.

• Lift up on the back of the seat and rotate

it forward.

• Loosen the three prong knobs on the

bottom of the seat and move the seat to

the desired position.

• Tighten the three prong knobs and rotate

seat back to the operating position.

TO ADJUST CONTROL LEVERS

(See Fig. 2)

Sitting on the seat, in the operators position,

press both control levers forward. If both control

levers line up with each other, then no

adjustment is needed. If they do not line up,

follow instructions below.

• Remove the spacer from the inside of

the caster rim.

• Repair tire

• Reassemble in the reverse order of the

previous steps.

REAR TIRES

IMPORTANT: Block front tires to prevent the

mower from rolling.

• Park mower on a level surface and apply

park brake.

• Jack up the rear end of the mower on the

side of the damaged tire.

• Remove 4 lug nuts to allow wheel

removal

• Repair tire.

• Reassemble in reverse order of previous

steps

NOTE: To seal tire punctures and prevent flat

tires due to slow leaks, tire sealant may be

purchased from your local parts dealer. Tire

sealer also prevents tire dry rot and corrosion.

• Identify which control lever moves further

forward.

• Using a 9/16" wrench, slightly loosen the

bottom hex bolt (about 1/2 turn) on the

opposite control lever.

• Move both control levers to the front

again and apply more pressure to the

control lever that you loosened to bring

the two control levers in line with each

other.

• Tighten hex bolts.

TO REMOVE WHEELS FOR

REPAIR

FRONT CASTER TIRES

• Park mower on a level surface and apply

park brake.

• Jack up the front end of the mower.

• Using a 3/4" wrench and/or socket w/

drive ratchet, remove hex nut and hex

bolt from the caster fork.

• Remove the tire from the fork.

TO START AN ENGINE WITH A

WEAK BATTERY

WARNING

Lead-acid batteries generate explosive

gases. Keep sparks, flame and smoking

materials away from batteries. Always wear

eye protection when around batteries.

If you battery is too weak to start the engine, it

should be recharged. (See “BATTERY” in the

Customer Responsibilities section of this

manual).

If “jumper cables” are used for emergency

starting, follow this procedure:

IMPORTANT: YOUR MOWER IS EQUIPPED

WITH A 12-VOLT NEGATIVE GROUNDED

SYSTEM. THE OTHER VEHICLE MUST ALSO

BE A 12-VOLT NEGATIVE GROUNDED

SYSTEM. DO NOT USE YOUR MOWER

BATTERY TO START OTHER VEHICLES.

27

Page 28

SERVICE AND ADJUSTMENT

TO ATTACH JUMPER CABLES

• Connect each end of the RED cable to

the POSITIVE (+) terminal on each

battery, taking care not to short against

chassis.

• Connect one end of the BLACK cable to

the NEGATIVE (-) terminal of the fully

charged battery.

• Connect the other end of the BLACK

cable to a good CHASSIS GROUND,

away from the fuel tank and battery.

TO REMOVE CABLES, REVERSE ORDER

• BLACK cable first from chassis and then

from the fully charged battery.

• RED cable last from both batteries.

• Connect BLACK grounding cable to

negative (-) battery terminal with

remaining hex bolt and hex nut.

• Tighten securely.

• Close terminal access doors.

• Lower seat.

TERMINAL

GUARD

TERMINAL

ACCESS

DOORS

REPLACING BATTERY (See Fig. 19)

WARNING

Do not short battery terminals by allowing

a wrench or any other object to contact

both terminals at the same time. Before

connecting battery, remove metal bracelets, wristwatch bands, rings, etc.

Positive terminal must be connected first

to prevent sparking from accidental

grounding.

• Lift Seat and rotate forward.

• Open terminal access doors.

• Using two 1/2" wrenches disconnect

BLACK battery cable then RED battery

cable.

• Using 7/16" wrench, remove terminal

guard.

• Carefully remove the battery from the

mower.

• Install new battery with terminals in the

same position as the old battery.

• Reinstall terminal guard

• First connect RED battery cable to

positive (+) battery terminal with hex bolt

and hex nut.

FIGURE 19

TO ADJUST PARK BRAKE

Before making any adjustments:

NOTE: Make sure the brake arm is engaged into

brake sprocket on both sides. You can push the

mower to make it engage into the sprocket. See

Fig. 20.

• With the park brake in the on position,

the compression spring should be 2"

from the "U" shaped brake arm to the

washer. See Fig. 20. If not, use two

wrenches, one to hold the bolt and one to

turn the nut to attain the 2".

BRAKE

COMPRESSION

SPRING

SPRING

ADJUSTMENT

NUT

FIGURE 20

BRAKE

SPROCKET

RIGHT SIDE

IZT BRAKE

ARM

RIGHT SIDE

"U" SHAPED

BRAKE

ARM

28

Page 29

SERVICE AND ADJUSTMENT

• 1/4" gap should exist between the "U"

shaped brake arm and the inside of the

brake bolt head. See Fig. 21.

HEAD OF

BRAKE BOLT

"U" SHAPED

BRAKE ARM

BRAKE CABLE

FIGURE 21

• The 1/4" gap can be adjusted with the

brake swivel (located under the seat),

pull pin and rotate swivel one turn

counterclockwise to increase gap or

clockwise to decrease the gap until the

1/4" gap is attained. See Fig. 22.

SWIVEL

TRACKING ADJUSTMENT

IMPORTANT: DO NOT adjust the drive cables

in an attempt to resolve tracking issues. Cables

are set at the factory and should only be adjusted by authorized service retailers.

If the mower is not tracking straight, check the

air pressure in both rear tires. Recommended air

pressure is 15 psi. If the unit will not track

straight, follow the steps below. Tracking must

be checked on a flat and level concrete or

blacktop surface.

• Mower is tracking to the right. Increase

the air pressure 2-3 psi in the right rear tire

or decrease the air pressure 2/3 psi in the

left rear tire.

• Mower is tracking to the left. Increase

the air pressure 2-3 psi in the left rear tire

or decrease the air pressure 2/3 psi in the

right rear tire.

Recheck tracking and keep making adjustments

with the tire pressure until the unit tracks straight.

DO NOT exceed maximum recommended tire

pressure 24 psi.

Record the tire pressure for future reference.

BRAKE CABLE

HAIR PIN

FIGURE 22

NOTE: After making any adjustments, check to

make sure the brake disengages the brake

sprockets, when the brake is in the "OFF"

position.

29

Page 30

STORAGE

Immediately prepare your mower for storage at

the end of the season or if the mower will not be

used for 30 days or more.

WARNING

Never store the mower with gasoline in

the tank inside a building where fumes may

reach an open flame or spark. Allow the

engine to cool before storing in any enclosure.

MOWER

When mower is to be stored for a period of time,

clean it thoroughly, remove all dirt, grease,

leaves, etc. Store in a clean, dry area.

• Clean entire mower (See "CLEANING" in

the Customer Responsibilities section of

this manual).

• Inspect and replace belts, if necessary

(See belt replacement instructions in the

Service and Adjustments section of this

manual).

• Lubricate as shown in the Customer

Responsibilities section of this manual.

• Be sure that all nuts, bolts and screws

are securely fastened. Inspect moving

parts for damage, breakage and wear.

Replace if necessary.

• Touch up all rusted or chipped paint

surfaces; sand lightly before painting.

BATTERY

• Fully charge the battery for storage.

• After a period of time in storage, battery

may require recharging.

• To help prevent corrosion and power

leakage during long periods of storage,

battery cables should be disconnected

and battery cleaned thoroughly (see "TO

CLEAN BATTERY AND TERMINALS" in

the Customer Responsibilities section of

this manual).

• After cleaning, leave cables

disconnected and place cables where

they cannot come in contact with battery

terminals.

• If battery is removed from mower for

storage, do not store battery directly on

concrete or damp surfaces.

ENGINE

FUEL SYSTEM

IT IS IMPORTANT TO PREVENT GUM DEPOSITS FROM FORMING IN ESSENTIAL FUEL

SYSTEM PARTS SUCH AS CARBURETOR,

FUEL FILTER, FUEL HOSE, OR TANK DURING

STORAGE. ALSO, EXPERIENCE INDICATES

THAT ALCOHOL BLENDED FUELS (CALLED

GASOHOL OR USING ETHANOL OR METHANOL) CAN ATTRACT MOISTURE WHICH

LEADS TO SEPARATION AND FORMATION OF

ACIDS DURING STORAGE. ACIDIC GAS CAN

DAMAGE THE FUEL SYSTEM OF AN ENGINE

WHILE IN STORAGE.

• Drain the fuel tank.

• Start the engine and let it run until the fuel

lines and carburetor are empty.

• Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable alternative in minimizing the formation of fuel gum

deposits during storage. Add stabilizer to gasoline in fuel tank or storage container. Always

follow the mix ratio found on stabilizer container.

Run engine at least 10 minutes after adding

stabilizer to allow the stabilizer to reach the

carburetor. Do not drain the gas tank and carburetor if using fuel stabilizer.

ENGINE OIL

Drain oil (with engine warm) and replace with

clean engine oil. (See "ENGINE" in the Customer

Responsibilities section of this manual).

30

Page 31

CYLINDER(S)

• Remove spark plug(s).

• Pour one ounce of oil through spark plug

hole(s) into cylinder(s).

• Install plugs.

• Turn ignition key to "START" position for

a few seconds to distribute oil.

• Replace with new spark plug(s).

OTHER

• Do not store gasoline from one season

to another.

• Replace your gasoline can if your can

starts to rust. Rust and/or dirt in your

gasoline will cause problems.

• If possible, store your mower indoors

and cover it to give protection from dust

and dirt.

• Cover your mower with a suitable

protective cover that does not retain

moisture. Do not use plastic. Plastic

cannot breathe which allows

condensation to form and will cause your

mower to rust.

STORAGE

IMPORTANT: NEVER COVER MOWER WHILE

ENGINE AND EXHAUST AREAS ARE STILL

WARM.

31

Page 32

TROUBLESHOOTING POINTS

PROBLEM CAUSE CORRECTION

Will not start

Hard to start 1. Dirty air filter.

Engine will not

turn over

1. Out of fuel.

2. Engine not "CHOKED" properly.

3. Engine flooded.

4. Bad spark plug.

5. Dirty air filter.

6. Dirty fuel filter.

7. Water in fuel.

8. Loose or damaged wiring.

9. Carburetor out of adjustment.

10. Engine valves out of adjustment.

11. Extreme cold conditions.

2. Bad spark plug.

3. Weak or dead battery.

4. Dirty fuel filter.

5. Stale or dirty fuel.

6. Loose or damaged wiring.

7. Carburetor out of adjustment.

8. Engine valves out of adjustment.

1. Brake pedal not depressed.

2. Attachment clutch is engaged.

3. Weak or dead battery.

4. Blown fuse.

5. Corroded battery terminals.

6. Loose or damaged wiring.

7. Faulty ignition switch.

8. Faulty solenoid or starter.

9. Faulty operator presence switch(es).

1. Fill fuel tank.

2. See "TO START ENGINE" in Operation section.

3. Wait several minutes before attempting to start.

4. Replace spark plug.

5. Clean/replace air filter.

6. Replace fuel filter.

7. Drain fuel tank and carburetor, refill tank with fresh

gasoline and replace fuel filter.

8. Check all wiring.

9. See Engine Manual.

10. Contact an authorized service center/department.

11. See "To start engine" in operation section.

1. Clean/replace air filter.

2. Replace spark plug.

3. Recharge or replace battery.

4. Replace fuel filter.

5. Drain fuel tank and refill with fresh gasoline.

6. Check all wiring.

7. See Engine Manual.

8. Contact an authorized service center/department.

1. Depress brake pedal.

2. Disengage attachment clutch.

3. Recharge or replace battery.

4. Replace fuse.

5. Clean battery terminals.

6. Check all wiring.

7. Check/replace ignition switch.

8. Check/replace solenoid or starter.

9. Contact an authorized service center/department.

Engine clicks but

will not start

Loss of power 1. Cutting too much grass/too fast.

Excessive vibration 1. Worn, bent or loose blade.

1. Weak or dead battery.

2. Corroded battery terminals.

3. Loose or damaged wiring.

4. Faulty solenoid or starter.

2. Throttle in "CHOKE" position.

3. Buildup of grass, leaves and trash under deck.

4. Dirty air filter.

5. Low oil level/dirty oil.

6. Faulty spark plug.

7. Dirty fuel filter.

8. Stale or dirty fuel.

9. Water in fuel.

10. Spark plug wire loose.

11. Dirty engine air screen/fins.

12. Dirty/clogged muffler.

13. Loose or damaged wiring.

14. Carburetor out of adjustment.

15. Engine valves out of adjustment.

2. Bent blade mandrel.

3. Loose/damaged part(s).

1. Recharge or replace battery.

2. Clean battery terminals.

3. Check all wiring.

4. Check/replace solenoid or starter.

1. Set in "Higher Cut" position/reduce speed.

2. Adjust throttle control.

3. Clean underside of mower housing.

4. Clean/replace air filter.

5. Check oil level/change oil.

6. Clean and re-gap or change spark plug.

7. Replace fuel filter.

8. Drain fuel tank and refill with fresh gasoline.

9. Drain fuel tank and carburetor, refill tank with

fresh gasoline and replace fuel filter.

10. Connect and tighten spark plug wire.

11. Clean engine air screen/fins.

12. Clean/replace muffler.

13. Check all wiring.

14. See Engine Manual.

15. Contact an authorized service center/department.

1. Replace blade. Tighten blade bolt.

2. Replace blade mandrel.

3. Tighten loose part(s). Replace damaged parts.

32

Page 33

TROUBLESHOOTING POINTS

PROBLEM

Engine continues to

run when operator

leaves seat with

attachment

Poor cut - uneven 1. Worn, bent or loose blade.

Mower blades will

not rotate

Poor grass

discharge

1. Faulty operator-safety presence control system. 1. Check wiring, switches and connections. If not

2. Mower deck not level.

3. Buildup of grass, leaves, and trash under mower.

4. Bent cutter housing.

5. Clogged mower deck vent holes from buildup of

grass, leaves, and trash around cutter housing.

1. Obstruction in clutch mechanism.

2. Worn/damaged mower drive belt.

3. Frozen idler pulley.

4. Frozen cutter housing.

1. Engine speed too slow.

2. Travel speed too fast.

3. Wet grass

4. Mower deck not level.

5. Low/uneven tire air pressure.

6. Worn, bent or loose blade.

7. Buildup of grass, leaves and trash under mower.

8. Mower drive belt worn.

9. Blades improperly installed.

10. Improper blades used.

11. Clogged mower deck vent holes from buildup of

grass, leaves and trash around cutter housing.

CAUSE

CORRECTION

corrected, contact an authorized service center/

department.

1. Replace blade. Tighten blade bolt.

2. Level mower deck.

3. Clean underside of mower housing.

4. Replace cutter housing.

5. Clean around cutter housing to open vent holes.

1. Remove obstruction.

2. Replace mower drive belt.

3. Replace idler pulley.

4. Replace cutter housing.

1. Place throttle control in "FAST" position.

2. Shift to slower speed.

3. Allow grass to dry before mowing.

4. Level mower deck.

5. Check tires for proper air pressure.

6. Replace/sharpen blade. Tighten blade bolt.

7. Clean underside of mower housing.

8. Replace mower drive belt.

9. Reinstall blades sharp edge down.

10. Replace with blades listed in this manual.

11. Clean around cutter housing to open bent holes.

Battery will

not charge

Loss of drive

Engine "backfires"

when turning

engine "OFF"

1. Bad battery cell(s).

2. Poor cable connections.

3. Faulty regulator (if so equipped).

4. Faulty alternator.

1. IZT bypass linkages in bypass position.

2. IZT belt worn, damaged, or broken.

1. Engine throttle control not set at "SLOW"

position for 30 seconds before stopping

engine.

1. Replace battery.

2. Check/clean all connections.

3. Replace regulator.

4. Replace alternator.

1. Place IZT bypass linkages in drive in "engaged"

position.

2. Replace IZT belt.

1. Move throttle control to "SLOW" position and

allow to idle for 30 seconds before stopping

engine.

33

Page 34

WIRING SCHEMATIC

34

Page 35

35

Page 36

Loading...

Loading...