XXXXXXX

For your own safety please read this manual before attempting to operate your new unit.Failure to follow instructions

can result in serious personal injury. Spend a few moments to familiarize yourself with your trimmer before each use.

BC 435L

BC 435L

BC 435B

Husqvarna AB

SE-561 82 Huskvarna

Sweden

WARNING • PLEASE READ

Model No.: BC 435L / BC 435B

GB

2

WARNING! When using gas tools, basic safety precautions, including the following, should always be followed to

reduce the risk of serious personal injury and/or damage to the unit.

Read all these instructions before operating this product and save these instructions.

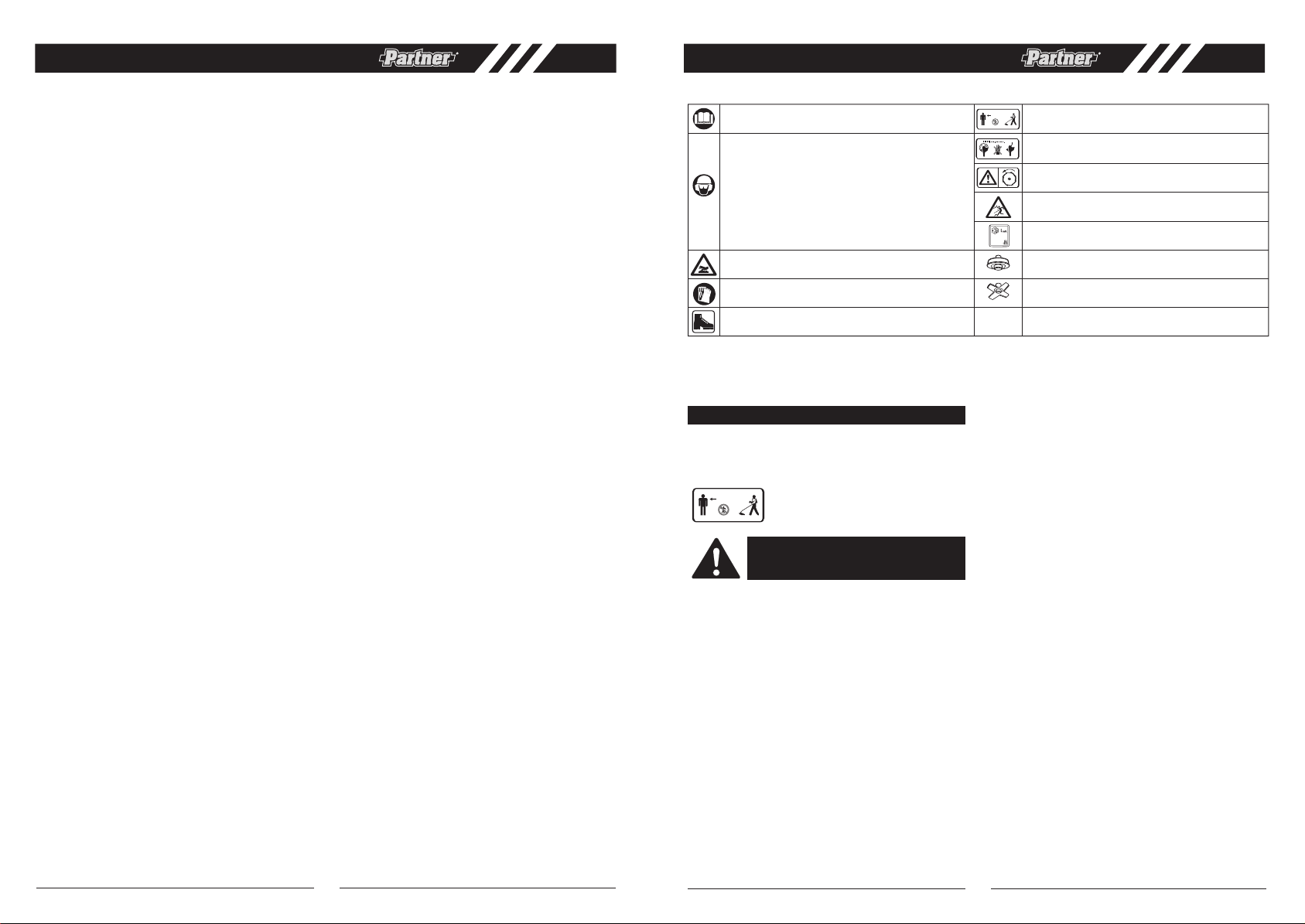

Meaning of symbols marked on the product

Read the user manual before using the machine

Whenever the machine is in use, safety goggles

must be worn to safeguard against flying object,

as must ear protectors, such as a soundproof helmet, in order to protect the operator’s hearing. If

the operator is working in an area where there is

a risk of falling objects, a safety helmet must also

be worn

15m(50ft)

Keep people or animals at least 15m away from

the machine during operation

Warning! Cutting elements continue to rotate

after the engine turned off

Warning! Hot surface

Wear gloves to protect your hands

Warning: Rotating blades

112

Beware of thrown objects

10000 min

-1

Acoustic power level LWA accordance with

directive 2000/14/EC + 2005/88/EC

Maximum rotational frequency of the spindle for

cutting head

Maximum rotational frequency of the spindle for

blade

Wear feet protection

READ YOUR USER MANUAL AND ALL SUPPLEMENTS (IF ANY ENCLOSED) THOROUGHLY BEFORE

OPERATING YOUR UNIT.

1. Wear close fitting, tough work clothing that will

provide protection, such as long slacks or trousers,

safety work shoes, heavy duty work gloves, hard hat,

a safety face shield, or safety glasses for eye protection and a good grade of ear plugs or other sound

barriers for hearing protection.

2. Prequel in a safe place.

Open fuel cap slowly to

release any pressure which may have formed in fuel

tank.To prevent a fire hazard, move at least 10 feet

(3 meters) from fueling area before starting.

3. Comply with all fire prevention regulations. com-

pliance with all local, state, or federal laws in the

united states is the user’s responsibility.Your unit

comes with a spark arrester screen furnished in the

user kit. Replacement spark arrester screen kits are

available from distributor.

4. Turn

unit off before setting it down.

5. Always hold unit firmly with both hands, the

thumb and fingers encircling the handles.

6. Keep all screws and fasteners tight.Never operate

your equipment when it is improperly adjusted or not

completely and securely assembled.

7. Keep handles dry, clean and free of fuel mixture.

8. Keep stringhead as close to ground as practical.

Avoid hitting small objects with stringhead.When cutting on a slope, stand below stringhead. NEVER cut

or trim on a hill or slope, etc. if there is the slightest

chance of slipping, sliding or losing firm footing.

9. Check area you will be trimming for debris that

may be struck or thrown during operation.

10. Keep all parts of your body and clothing away

from stringhead when starting or running engine.

Before starting engine, make sure stringhead will not

come in contact with any obstacle.

11. Stop engine before examining cutting line.

12. Store equipment away from possible ignition

s

ources, such as gas-powered wate

r heaters,

clothes dryers, or oil-fired furnaces, portable

heaters, etc.

13. Always keep the debris shield, stringhead, and

engine free of debris build-up.

14. Operation of equipment should always be restricted

to mature and properly instructed individuals.

15. WARNING: The emission of exhaust gases is toxic.

16. Emergency Stopping Procedure. When it is necessary to stop engine immediately, DEPRESS the

switch to stop.

17. This unit has a clutch, routines for checking that

the cutting attachment stops turning when the engine

idles.

WARNING: Keep children, bystanders, and

animals 50 feet (15 meters) away. If

approached stop unit immediately.

WHAT TO DO

15m(50ft)

GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

• What to do

• Brush / grass blade safety precautions

• What not to do

GENERAL IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

• Safety features

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

• “Loop With Barrier” handle installation

• “Bullhorn” handle installation

• Cutting attachment guard installation

• Cutting head installation

• Remove and installation the blade cover

• Blade installation

• Remove and installation the blade cover

FUEL AND ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

• Refueling

• Engine oil

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

• Shoulder harness

• Starting a cold engine

• Warm engine start

• Low temperature start

• To stop engine

TRIMMING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

• Additional safety precautions

• Cutting head line release

• Trimming procedures

• Cutting with blades

• Using weed blades

• Using a brush blade

MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

• Replacing cutter line

• Air Filter

• Fuel Filter

• Carburetor Adjustment

• Spark Plug

• Cutting attachment guard knife shapening

• Storing a unit

• Removing a unit from storage

TROUBLE SHOOTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

EU DECLARATION OF CONFORMITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

1

GB

GB

-1

11000 min

4

4

5

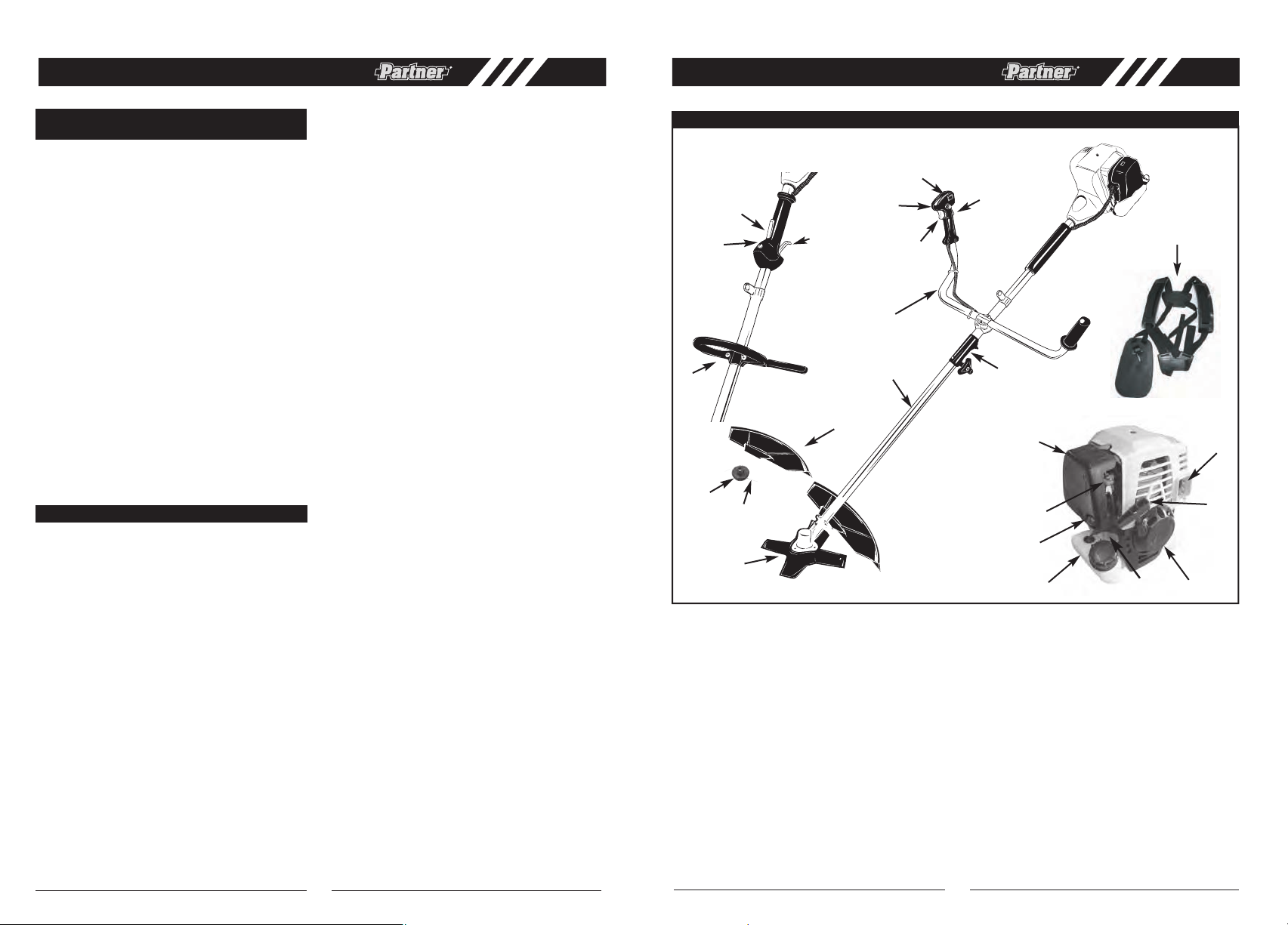

GENERAL IDENTIFICATION

8

9

7

13

21

14

17

18

12

16

15

SAFETY FEATURES

3 cutting attachment guard must be installed to prevent debris from being thrown at the operator and prevent the string

from extending longer than necessary.

17 MUFFLER SHIELD helps prevent hands, body and/or combustible materials from making contact with a hot muffler.

1. CUTTING HEAD

2. FLEXIBLE LINE

3. CUTTING ATTACHMENT

GUARD

4. BLADE

5. OUTPUT SHAFT

6. “LOOP WITH BARRIER”HANDLE

(BC 435L)

7. “BULLHORN” HANDLE

(BC 435B)

8. THROTTLE TRIGGER

9. ON/OFF SWITCH

10. THROTTLE TRIGGER LOCK

OUT

11. THROTTLE LOCK

12. CHOKE LEVER

13. STARTER ROPE HOUSING

14. FUEL TANK

15. AIR FILTER COVER

16. STARTER HANDLE

17. MUFFLER SHIELD

18. PRIMER BULB

19. HARNESS

20. COUPER

21. OIL TANK

(

BC 435B

/ BC 435L )

3

6

8

9

10

10

11

20

19

3

1. FOLLOW ALL WARNINGS and instructions regarding operation and blade installation.

2. BLADE CAN VIOLENTLY THRUST AWAY FROM

MATERIAL IT CANNOT CUT - Blade thrust can

cause amputation of arms or legs. Keep people

and animals 50 feet (15 meters) away in all directions.

If blade contacts foreign objects during operation,

turn off engine and allow coasting blade to stop.Then

check blade for damage. Always discard blade if it is

warped or cracked.

3. BLADE THROWS OBJECTS VIOLENTLY - You can

be blinded or injured. Wear eye, face, and leg protection. Always clear work area of any foreign objects

before using blade. Keep people and animals 50 feet

(15 meters) away in all directions.

4. INSPECT YOUR TRIMMER AND ATTACHMENTS

BEFORE EACH USE - Never use unless all bladeattaching hardware is properly installed.

5. BLADE COASTS AFTER THROTTLE IS RELEASED

- A coasting blade can cut you or bystanders. Before

per

forming any service on the blade, always turn off

engine, and be sure coasting blade has stopped.

6. 50 FEE T (15 meters) DIAMETER HAZARD ZONE Bystanders can be blinded or injured. Keep people

and animals 50 feet (15 meters) away in all directions.

1. DO NOT USE ANY OTHER FUEL than that recom-

mended in your manual. Always follow instructions in

the Fuel and Engine oil section of this manual.

Permanent damage to engine will result,

voiding manufacturer’s warranty.

2. DO NOT SMOKE while refueling or operating equip-

ment.

3. DO NOT OPERATE UNIT WITHOUT A MUFFLER

and properly installed muffler shield.

4. DO NOT TOUCH or let your hands or body come in

contact with a hot muffler or spark plug wire.

5. DO NOT OPERATE UNIT IN AWKWARD POSI-

TIONS, off balance, outstretched arms, or one-handed. Always use two hands when operating unit with

thumbs and fingers encircling the handles.

6. DO NOT RAISE CUTTING HEAD ab

ove ground level

while unit is operating. Injury to operator could result.

7. DO NOT USE UNIT FOR ANY PURPOSES OTHER

than trimming lawn or garden areas.

8. DO NOT OPERATE UNIT FOR PROLONGED PERI-

ODS. Rest periodically.

9. DO NOT OPERATE UNIT WHILE UNDER THE

INFLUENCE OF ALCOHOL OR DRUGS.

10. DO NOT OPERATE UNIT UNLESS CUTTING

ATTACHMENT GUARD AND/OR GUARD IS

INSTALLED AND IN GOOD CONDITION.

11. DO NOT ADD, REMOVE OR ALTER ANY COMPONENTS OF THIS PRODUCT. Doing so could cause

personal injury and/or damage the unit voiding the

manufacturer’s warranty.

12. DO NOT operate your unit near or around flammable

liquids or gases whether in or out of doors. An explosion and/or fire may result.

13. DO NOT USE ANY OTHER C

UTTING A

TTACHMENT.

Use only Partner replacement parts and accessories, which are designed specifically to enhance the

performance and maximize the safe operation of our

products. Failure to do so may cause poor performance and possible injury. Use only the cutting head

supplied with this product. Do not use any other cut-

ting attachment. Use of such attachments will void

your factory warranty and could result in serious bodily injury.

WHAT NOT TO DO

BRUSH / GRASS BLADE SAFETY PRECAUTIONS

2

1

BC 435L

BC 435B

GB GB

6

LOOP WITH BARRIER

”HANDLE INSTALLATION

(BC 435L)

•

BULLHORN

¨ HANDLE INSTALLATION

(BC 435B)

, )A(e l dnah”n roh l l ub “ : t i kr esur uoymor fs t nenopmoc

/BC 435B

ASSEMBLY INSTRUCTIONS

WARNING:

Please install the unit according

to the assemblyinstructions,orelse it may be

cause dangerous to the operator.

WARNING:

To avoid serious personal injury,

shut unit off before removing or installing

attachment.

CAUTION:

The release button must be in the

primary hole and the knob securely tightened

before operating this unit.

3 5 0

m

m

90ß

SPECIFICA TIONS

(965874001)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chrome Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Chrome Cylinder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

gK5.6........................................gK53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 730 cm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <15 m/s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <15 m/s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8700 min

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9500 min

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3000

SPECIFICATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chrome

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .35 cm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.2Kg

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .730 cm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Twin Line Bump Feed

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Teeth

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132cm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43cm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23cm

. . . . . . . . . . . . . . . . . . . . . . . .

. . . .

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Electronic

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Centrifugal Clutch

. . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . 101.6 dB(A)

. . . . . . . . . . . . . . . 112 dB(A)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <15m/s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <15m/s

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.90 kW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.90 kW

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .8700 min

. . . . . . . . . . . . .8700 min

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9500 min

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3000

. . . . . .

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700 g/kWh

GB GB

8

2. Install blade (C) with teeth pointing CLOCKWISE as

shown in the illustration (Fig. 6B).

3. Install flange (E) with FLAT SURFACE facing blade

(Fig. 6B).

NOTE: Make sure blade is centered on collar arbor.

4. Tighten nut (B) securely by turning it COUNTER-

CLOCKWISE with socket wrench (F) . Remove holding pin (Fig. 6B).

• Refueling

NOTE:

WARNING:Be sure the blade center hole is

properly sized to the collar arbor.

Fig. 6A

C

F

B

A

D

E

FUEL SYSTEM

GNINRA W :

Gasoline is highly flammable and explosive.

You can be burned or seriously injured when

handling fuel.

• Stop the engine and keep heat, sparks, and

flame away.

• Handle fuel only outdoors.

• Wipe up spills immediately.

7

• CUTTING ATTACHMENT GUARD

2. place the guard on the cutting shaft, then install

1. Install the cutoff knife as shown below.

clamp (A)on the guard. (Fig.3 )

3. Tighten screws (B).

NOIT A LLA T SNI DAEH GNITTUC •

. 1 Install spline sleeve (D) and gear collar (A) in turn

ensuring that collar spacer is in place (Fig. 4).

otno daeh gnittuc daerht dna )C( nip gnidloh t r esnI . 2

4) . giF( ylno dnah y b daeh gnittuc nethgiT . tfahs

• REMOVE AND INSTALLATIONTHE BLADE

COVER

1. Before assembling blades, please remove the blades

cover first.

2. Refer figure 5A and Figure 5B, hold the blades cover,

and pull sligtly the cover outward the cover can be

taken apart.

3. Refer to figure 5C and 5D, andassemblein the opposite way to cover the blades.

• BLADE INSTALLATION

1. To install the blade you will need the items illustrated

above (screwdriver not provided): holding pin (A),

retaining nut (B), blade (C), screwdriver (D), flange

(E), socket wrench (F) (Fig. 6A)

Fig. 2C

A

Fig. 3

B

A

B

A

D

C

Fig. 4

CAUTION: Before you take apart the blades,

wear gloves to prevent any danger.

CAUTION:When the machine is not in use or

in transportation, make sure blades have

been covered.

Fig. 5A Fig. 5B

Fig. 5C Fig.5D

CAUTION: NEVER use unit if blade is

warped or has teeth that are chipped or missing. Replace a damaged blade immediately.

CAUTION: NEVER operate unit with a blade

unless metal blade guard is properly

installed. NEVER operate a unit withadamaged guard.

CAUTION: Always wear heavy-duty work

gloves when handling and installing a blade.

This engine is certified to operate on unleaded gasoline

with a pump octane rating of 93 or higher.

You may use regular unleaded gasoline containing no

more than 10% ethanol (E10) or 5% methanol by volume.

In addition, methanol must contain cosolvents and

corrosion inhibitors. Use of fuels with content of ethanol or

methanol greater than shown above may cause starting

and/or performance problems. It may also damage metal,

rubber, and plastic parts of the fuel system. Engine

damage or performance problems that result from using a

fuel with percentages of ethanol or methanol greater than

shown above are not covered by warranty.

Check the fuel level by looking through the translucent

fuel tank. If the fuel level is low, refuel in a well-ventilate d

area with the engine stopped. If the engine has been

running, allow it to cool first.

Never use stale or contaminated gasoline or an

oil/gasoline mixture.

Avoid getting dirt or water in the fuel tank.

To refuel, rest the trimmer on the ground with the fuel

tank cap facing up, as shown. Remove the fuel tank cap

and fill the tank with gasoline to the bottom of the filler

neck. Refuel carefully to avoid spilling fuel.

Do not overfill. There should be no fuel in the filler neck.

After refueling, tighten the fuel tank cap securely.

Never refuel the engine inside a building where gasoline

fumes may reach flames or sparks. Keep gasoline away

from appliance pilot lights, barbecues, electric appliances,

power tools, etc.

Spilled fuel is not only a fire hazard, it causes

environmental damage. Wipe up spills immediately.

Move at least 10 feet (3 meters) away from the fueling

source and site before starting the engine.

Fuel can damage paint and plastic. Be careful not to spill

fuel when filling your fuel tank. Damage caused by spilled

fuel is not covered under warranty.

GB GB

A

Fig. 6B

E

C

F

B

Fig. 7A

9

The trimmer is shipped WITHOUT OIL in the engine.

NOTE:Fill oil before starting engine.

Running the engine with too little or too much oil can

cause engine damage.

Check the engine oil level before each use, or every 10

hours if operated continuously. Rest the trimmer on a level

surface, with the engine stopped and in an upright position.

NOTE:

• Engine Oil Level Check

1. Place the trimmer on a level surface, and then

remove the oil filler cap/dipstick.

4. Screw in the oil filler cap/dipstick securely.

Running the engine with too little or too much oil can

cause engine damage.

NOTE:

4. Screw in the oil filler cap/dipstick securely.

2. Slowly add the recommended oil (included in the box)

to the bottom edge of the oil filler opening. Do not

overfill, as the engine oil tank capacity is small.

3. If the supplied oil is not used, add enough SAE 10W-

30 API service category SJ or later oil. Add oil until

the oil level is to the bottom edge of the oil filler

opening.

1. Remove the filler cap/dipstick and wipe it clean.

2. Insert and remove the dipstick without screwing it into

the filler opening. Check the oil level shown on the

dipstick.

3. If the oil level is low, fill to the edge of the oil filler hole

with the recommended oil . To avoid overfilling or

underfilling, be sure the engine is in a level position,

as shown.

ENGINE OIL

Drain the used oil while the engine is warm. Warm oil

drains quickly and completely.

• Engine Oil Change

• Engine Oil Recommendations

1. Place a suitable container below the engine to catch

the used oil, then remove the filler cap/dipstick and

drain the used oil through the filler opening. Allow the

used oil to drain completely.

Please dispose of used motor oil in a manner that is

compatible with the environment. We suggest you

take used oil in a sealed container to your local

recycling center or service station for reclamation. Do

not throw it in the trash, pour it on the ground, or pour

it down a drain.

2. With the engine in an upright position, fill to the edge

of the oil filler hole with the recommended oil.

3. Screw in the filler cap/dipstick securely.

Oil is a major factor affecting performance and service

life. Use 4-stroke automotive detergent oil.

SAE 10W-30 is recommended for all temperatures within

the recommended operating range for these trimmers.

The recommended operating range extends from 23° ~

104°F (-5° ~ 40°C).

The SAE oil viscosity and service classification are on the

API label on the oil container. Recommend that you use

API service category SJ or later.

NOTE: change the engine oil after first month or 10 hours.

NOTE: change the engine oil every 6 months or 50 hours.

GB GB

Fig. 8A Fig. 8B

C

Fig.7B

Fig.7C

Fig.7D

OPERATING INSTRUCTIONS

• SHOULDER HARNESS

WARNING: ALWAYS WEAR SHOULDER

HARNESS when operating unit withablade.

Attach harness to trimmer after starting unit

and engine is running at IDLE. Turn ENGINE

OFF before disconnecting shoulder harness.

NOTE: When you install the cutting attachment, please

follow the below requirements:

1. Put the harness on so the shoulder strap is over your

shoulders.

2. Attache the harness clip (C) to the ring (D) mounted

on the shaft (Fig. 8A and 8B).

3. Adjust length of shoulder strap so stringhead is parallel to the ground as it hangs from the strap. A few

practice swings without starting engine should be

made to determine correct balance.

NOTE: Detach the shoulder harness from the unit before

starting engine.

D

BC 435L

BC 435B

D

• STARTING A COLD ENGINE

NOTE: To minimize load on engine during starting and

warm-up, trim excess cutter line to 13cm (Fig. 9A).

1. Press ON/OFF switch to the “RUN (I)” position (Fig.

9B).

2.3.Press the primer bulb 10 times.(Fig.9D)

Move choke lever to CHOKE“ ” position.(Fig.9C)

4. Set throttle lock (C):Press the throttle trigger lockout

(A) down and then while holding throttle trigger (B)

at partially open position, press down and hold

throttle lock (C). Release throttle trigger (B). Throttle

trigger (B)will now remain in the partially depressed

position;

If no throttle lock: Press the throttle trigger lockout

down and then while holding throttle trigger (B) at

one-third open position.(Fig. 9B)

Pull starter rope 3 times. (Fig. 9F)

5.

Move choke lever to RUN “ ” position. Engine will be

started when pull starter rope 1 time. Continually warm

10 seconds after engine started, and then pull throttle

trigger to full position. (Fig. 9G)

6.

If engine fails to start, repeat step 1 to 5.

• WARM ENGINE START

1.

Move choke lever to RUN ” “ position. Engine will be

started after pulling starter rope 2 times.(Fig.9G)

2.

If engine fails to start, refer to Starting a cold engine

section.

NOTE:If engine fails to start after repeated attempts, refer

to Troubleshooting section.

NOTE: Alwayspull starter rope straight out. Pulling starter

at an angle will cause rope to rub against the eyelet. This

friction will cause the rope to fray and wear more quickly.

Always hold starter handle when rope retracts. Never

allow rope to snap back from extended position. This

could cause rope to snag or fray and also damage the

starter assembly.

13cm

For blade

100-400mm

A

BC 435B

• Low temperature start (0-5 C)

1. Press ON/OFF switch to the “RUN (I)” position (Fig.

10A).

2. Press the primer bulb 10 times.(Fig.9D)

3.

Move choke lever to CHOKE” ” position.

10

For String

Head

0-300mm

BC 435L

B

Fig. 9A Fig. 9B

A

Fig. 9C Fig. 9D

BC 435L

B

A

B

Fig. 9E

Fig. 9F

Fig. 9G Fig. 9G

O

BC 435B

C

A

Pull starter rope 6 times.

5.

Move choke lever to RUN ” ” position.

Engine will be started when pull starter rope 2 times.

(Fig.10B)

Continually warm 10seconds after engine started, and

then engine will reach high speed.

6.

If engine fails to start, repeat step 1 to 5.

BC 435L

BC 435B

4. Set throttle lock (C):Press the lockout switch (A) down

and then while holding trigger (B) at partially open

position, press down and hold throttle lock (C).

Release throttle trigger (B).Throttle trigger (B) will now

remain in the partially depressed position If no

throttle lock: Press the throttle trigger lockout down

and then while holding throttle trigger (B) at

one-third open position.(Fig. 9B).

GB GB

A

Fig. 10BFig. 10A

• TO STOP ENGINE

Release throttle trigger.Let engine return to idle.Push and

hold ignition stop switch until engine stops.

TRIMMER INSTRUCTIONS

• ADDITIONAL SAFETY PRECAUTIONS

Before operating your unit, review ALL SAFETY PRECAUTIONS in this manual.

WARNING / CAUTION

• IF UNFAMILIAR WITH TRIMMING OR CUTTING

techniques, practice the procedures with ENGINE in

“OFF” position.

• ALWAYS

• ALWAYS TRIM OR CUT AT HIGH ENGINE SPEEDS.

Do not run engine slowly at start or during trimming

operations.

• DO NOT use equipment for purposes other than

trimming or mowing weeds.

• NEVER raise cutting head above knee height during

operation.

• DO NOT operate unit with other people or animals in

the immediate vicinity. Allow a minimum of 50 feet (15

meters

animals when trimming or mowing.

• Allowadistance of 100 feet (30 meters) between

operator and other people and animals when

SCALPING with cutting head cutter.

CLEAR WORK area of debris such as cans,

bottles, rocks, etc. Striking objects can cause serious

injury to operator or bystanders and also damage

equipment. If an object is accidentally hit, immediately

TURN ENGINE OFF and examine equipment. Never

operate unit with damaged or defective equipment.

) between operator and other people and

• IF OPERATING UNIT ON A SLOPE, stand below the

cutting attachment. DO NOT OPERATE on a slope or

hilly incline if there is the slightest chance of slipping or

losing your footing.

• CUTTING HEAD LINE RELEASE

WARNING: DO NOT use steel wire or plas-

tic-coated steel wire of any kind with yourcutting head. Serious operator injury can result.

To release fresh line, run engine at full throttle and “bump”

cutting head against lawn. Line will automatically release.

The knife in the cutting attachment guard will trim excess

line (Fig.11A).

CAUTION:Periodically remove weed wrap to

prevent overheating the drive shaft. Weed

wrap occurs when strands of weeds become

entangled around the shaft beneath the cutting attachment guard (Fig. 11B). This condition prevents the shaft from being properly

cooled. Remove weed wrap with screwdriver

or similar device.

BUMP

Fig. 11A Fig. 11B

• TRIMMING PROCEDURES

When properly equipped with a cutting attachment guard

and cutting head, your unit will trim unsightly weeds and

tall grass in those hard-to-reach areas - along fences,

walls,foundations and around trees.It can also be used for

scalping to remove vegetation downto the ground for easier preparationofagarden or to cleanoutaparti

NOTE: Evenwith care, trimming around foundations, brick

or stone walls, curves, etc., will result in above normal

string wear.

TRIMMING / MOWING

Swing trimmer withasickle-like motion from side to side.

Do not tilt the cutting head during the procedure. Test area

to be trimmed for proper cutting height. Keep cutting head

at same level for even depth of cut (Fig. 12A).

Fig. 12A

11

cular area.

CLOSERTRIMMING

Position trimmer straight ahead with a slight tilt so bottom

of cutting head is above ground level and string contact

occurs at proper cutting point. Always cut away from operator.Do not pull trimmer toward operator.

FENCE/FOUNDATION TRIMMING

Approach trimming around chain link fences, picket

fences, rock walls and foundations slowly to cut close

without whipping string against the barrier. If the string

comes in contact with rock, brick walls, or foundations, it

will break or fray.If string snags fencing, it will snap off.

TRIMMING AROUND TREES

Trim around tree trunks withaslow approach so string

does not contact bark.Walk around the tree trimming from

left to right. Approach grass or weeds with the tip of the

string and tilt cutting head slightly forward.

WARNING: Use extreme caution when

SCALPING. Keepadistance of 50 feet (15

meters) between operator, other people and

animals during these operations.

SCALPING

Scalping refers to removal of all vegetation down to the

ground. To do this, tilt the cutting head to about a 30

degree angle to the right. By adjusting the handle you will

have better control during this operation. Do not attempt

this procedure if there is any chance flying debris could

injure operator, other people or cause damage to property (Fig. 12B).

Fig. 12B

DO NOT SWEEP WITH TRIMMER

Sweeping refers to tilting cutting head to sweep away

debris from walkways, etc.Your trimmer i

and small stones or other such debris may be hurled 50

feet (15 meters) or more, causing injury or damage to

nearby property such as automobiles, homes and windows.

sapowerful tool

• CUTTING WITH BLADES

WARNING:Beforeoperatingthis machinewith

a bladecheck to ensure it is properlyinstalled.

Follow all warnings listed in the blade safety

precautions section in this manual.

Always wear eye protection and protective clothing when

cutting withablade.

Always use the harness for blade operations.

• USING WEED BLADES

SCYTHING WEEDS

Scything refers to cutting by moving the blade from side to

side inalevel arc. It is most effective with grassy weeds

and light undergrowth. It should not be used to cut

tough weeds or woody growth (Fig. 13).

Fig. 13

CAUTION: Do not use weed blades to cut

brush or tree saplings.

• USING A BRUSH BLADE

SCYTHING

Scything may be used with a brush blade for light brush

and undergrowth.It is not recommended for tough growth.

BINDING

Top heavy growth such as saplings and heavy brush can

bind and stop the blade. Avoid binding by anticipating

which way the growth will lean, and cut from the opposite

side.

If the blade binds in a cut stop the engine immediately.

Hold the unit up to prevent the blade from cracking or

breaking while pushing the sapling away from the cut to

free the blade.

AVOID KICKOUT

Kickout is the reaction ofamoving blade if it contacts a

strong tree, brush orasolid object.The force that occurs

violently pushes the blade away in an arc. Kickout could

cause loss of control resulting in injury to the operator or

bystanders.

DO NOT USEABLADE NEAR A CHAIN LINK FENCE,

METAL STAKES, LANDSCAPE BORDERS OR BUILDING FOUN

The Partner

kickout by providing stops to brace the unit against the

object being cut.

Place the sapling against the stop (A) so the rotation of

the blade continually draws it into the stop (A) (Fig. 14).

12

DATIONS.

blade guard is designed to reduce the risk of

A

A

Fig. 14

large,

GB GB

MAINTENANCE INSTRUCTIONS

• REPLACING CUTTER LINE

1. Turn the nut (A) CLOCKWISE and remove it (Fig.

15A).

2. Remove the spool (C), and spring (D) from spindle

(E).

3. Remove any remaining cutter line.

4. Doublea32' (9.8m) length of .095 or .105" (.24 or

.27cm) cutter line. Place the looped center in one of

the slots (G) of the spool divider (Fig. 15B).

5. Wind as shown in illustration (Fig. 15C), keeping tension, with each half separated by the spool divider.

Wind to within 6" (15cm) of the ends.

6. Lock each end of line intoaslot (H) on opposite sides

of the spool (Fig. 15D).

7. Install the spring (D) over the spindle (E). Insert each

end of the line through an eyelet (J) in the housing (F)

(Fig. 15E).

8. Lower the spool into the housing (E)whilefeedingthe

line through the eyelets (J). Ensure the spring seats

itself into the spool (Fig. 15E).

9. Once the spool is in place, apply pressure on the

spool compressing the spring. Pull each end of the

line (B) sharply

15F).

10. Continue to apply pressure to the spool until the knob

can be threaded COUNTERCLOCKWISE onto the

spingle.Tighten the knob securely by hand only (Fig.

15H)

11. Trim the excess line to approximately 5” (13cm).This

wil minimize load on engine durig starting and warmup.(Fig.15H)

A. KNOB

B. CUTTER LINE

C. SPOOL

D. SPRING

E. SPINDLE

F. HOUSING

G. DIVIDER SLOTS

H. SLOTS

J. EYELETS

A

Fig. 15B Fig.15C

to unlock the line from the slots (Fig.

G

B

C

B

Fig. 15A

J

E

D

F

H

Fig. 15D

B

B

Fig. 15F Fig. 15G Fig. 15H

J

E

F

Fig. 15E

5” (13mm)

D

J

• AIR FILTER

CAUTION: NEVER operate trimmer without

the air filter.The air filter must be kept clean.

If it becomes damaged, installanew filter.

To Clean Air Filter:

1. Remove button (A) holding air filter cover in

2. Wash filter in soap and water. DO NOT USE GASO-

3. Air dry filter.

4. Reinstall filter.

NOTE: clean the air filter element every 3 months or 25 hours.

NOTE: Replace filter if frayed, torn, damaged or unable to

be cleaned.

remove cover (B) and lift filter (C) from air box

place,

(Fig.16).

LINE!

A

B

Fig. 16

C

• FUEL CAP/FUEL FILTER

COUTION:

in approved container before starting this

procedure. Open fuel cap slowly to release

any pressure which may have formed in fuel

tank.

1. Completely remove fuel cap (A) from fuel tank (B)

to be able to remove fuel filter (D) from tank. Use a

piece of wire (C) withahook formed at the end to

pull filter out of tank. (Fig. 17A & Fig. 17B)

2. Pull filter (D) off withatwisting motion.

3. Replace

NOTE: Never operate the trimmer without the fuel

filter.Internal engine damage could result!

Remove fuel from unit and store

fuel filter (D). (Fig. 17C)

A

B

Fig. 17A Fig. 17B

D

Fig. 17C

C

• CARBURETOR ADJUSTMENT

The carburetor was pre-set at the factory for optimum performance. If further adjustments are necessary, please

take your unit to the nearest Authorized Service Center.

• SPARK PLUG

1. Spark plug gap = .025" (.635mm) (Fig. 18).

2. Torque to 105 to 130 inch pounds (12 to 15 N•m).

Connect spark plug boot.

F

E

Fig. 18 Fig. 19

• CUTTING ATTACHMENT GUARD KNIFE

SHARPENING

1. Removecutter knife (A) from cutting attachment guard

(B) (Fig. 19).

2. Place knife inabench vise. Sharpen knife using a flat

file, being careful to maintain the angle of cutting

edge. File in one direction only.

• STORING A UNIT

WARNING:Failure to follow these steps

may cause varnish to form in the carburetor

and difficult starting or permanent damage

following storage.

1. Perform all the general maintenance recommended

in the Maintenance Section of your User Manual.

2. Clean exterior of engine, Output Shaft, cutting attachment guard and cutting head.

3. Drain fuel from the fuel tank.

4. After fuel is drained, start engine.

5. Run engine at idle until unit stops. This will purge the

carburetor of fuel.

w engine to cool (approx. 5 minutes).

6. Allo

7. Using a spark plug wrench, remove the spark plug.

8. Pour 1 teasp

combustion chamber. Pull starter rope slowly several

times to coat internal components. Replace spark

plug.

9. Store unit inacool, dry place away from any source

of ignition such as an oil burner, water heater, etc.

oon of clean 4-cycle oil into the

• REMOVING A UNIT FROM STORAGE

1. Remove spark plug.

2. Pull starter rope briskly to clear excess oil from combustion chamber.

3. Clean and gap spark plug or install a new spark plug

with proper gap.

4. Prepare unit for operation.

5. Fill fuel tank with proper fuel.

13

14

15

TROUBLE SHOOTINGTHE ENGINE

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Unit won’t start or starts but will

not run.

Incorrect starting procedures. Follow instructions in the User Manual.

Incorrect carburetor mixture

adjustment setting.

Have carburetor adjusted by an

Authorized Service Center.

Fouled spark plug Clean / gap or replace plug.

Fuel filter plugged. Replace fuel filter.

Unit starts, but engine has low

power.

Incorrect lever position on choke. Move to RUN position.

Dirty spark arrester screen. Replace spark arrester screen.

Dirty air filter. Remove, clean and reinstall filter.

Incorrect carburetor mixture

adjustment setting.

Have carburetor adjusted by an

Authorized Service Center.

Engine hesitates.

Incorrect carburetor mixture

adjustment setting.

Have carburetor adjusted by an

Authorized Service Center.

No power under load.

Runs erratically.

Incorrectly gapped spark plug. Clean / gap or replace plug.

Smokes excessively.

Incorrect carburetor mixture

adjustment setting.

Have carburetor adjusted by an

Authorized Service Center.

EU Declaration of Conformity

according to the regulations 98/37/EC, 2004/108/EC,

2000/14/EC+2005/88/EC, 2002/88/EC

For the following equipment / product : Brush Cutter/Grass Trimmer, Gasoline

Type Designation

Trademark

:

BC 435L / BC 435B

Partner:

:

We herewith confirm to comply with the requirements set out in the Council

Directive 98/37/EC, 2004/108/EC, 2000/14/EC+2005/88/EC, 2002/88/EC.

For the evaluation of the compliance with these Directives, the following

standards were

applied:

EN ISO 11806 : 1997, EN ISO 11806 : 1997/AC, EN ISO 14982:1998

Sound pressure level : 101.6 dB(A)

Sound power level : 111.17dB(A)

Guarantee sound power level : 112 dB(A)

Person responsible for making this declaration

Name, surname :

Position/Title :

Shanghai, P

. R. C.

2008/12/08

16

Importer's Name Husqvarna AB

Importer's Address :SE-561 82 Huskvarna, Sweden

Ronnie Goldman

Director of Engineering

Handheld Consumer Products

GB

Loading...

Loading...