Husqvarna 968999108 - W3613A, 968999103 - W3614A, 968999107 - W3213A, 968999102 - W3612A, 968999101 - W3212A User Manual

...

Adjustments manual for:

Gear Drive, ETS Gear Drive, Walk Hydro, ETS W alk Hydro, Mini Rider , Large Rider Gen 2

MANUAL NO. 539105471 REV . 01(03/14/02)

Gear Drive Intermediate Walk Behind

Adjustment Instructions for:

MODELS / I.D. : 968999101 / W3212A

968999107

968999102

968999108

968999103

968999104

968999110

2

/ W3213A

/ W3612A

/ W3613A

/ W3614A

/ W4814A

/ W4815A

ADJUSTMENTS FORADJUSTMENTS FOR

ADJUSTMENTS FOR

ADJUSTMENTS FORADJUSTMENTS FOR

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERSHUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERSHUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

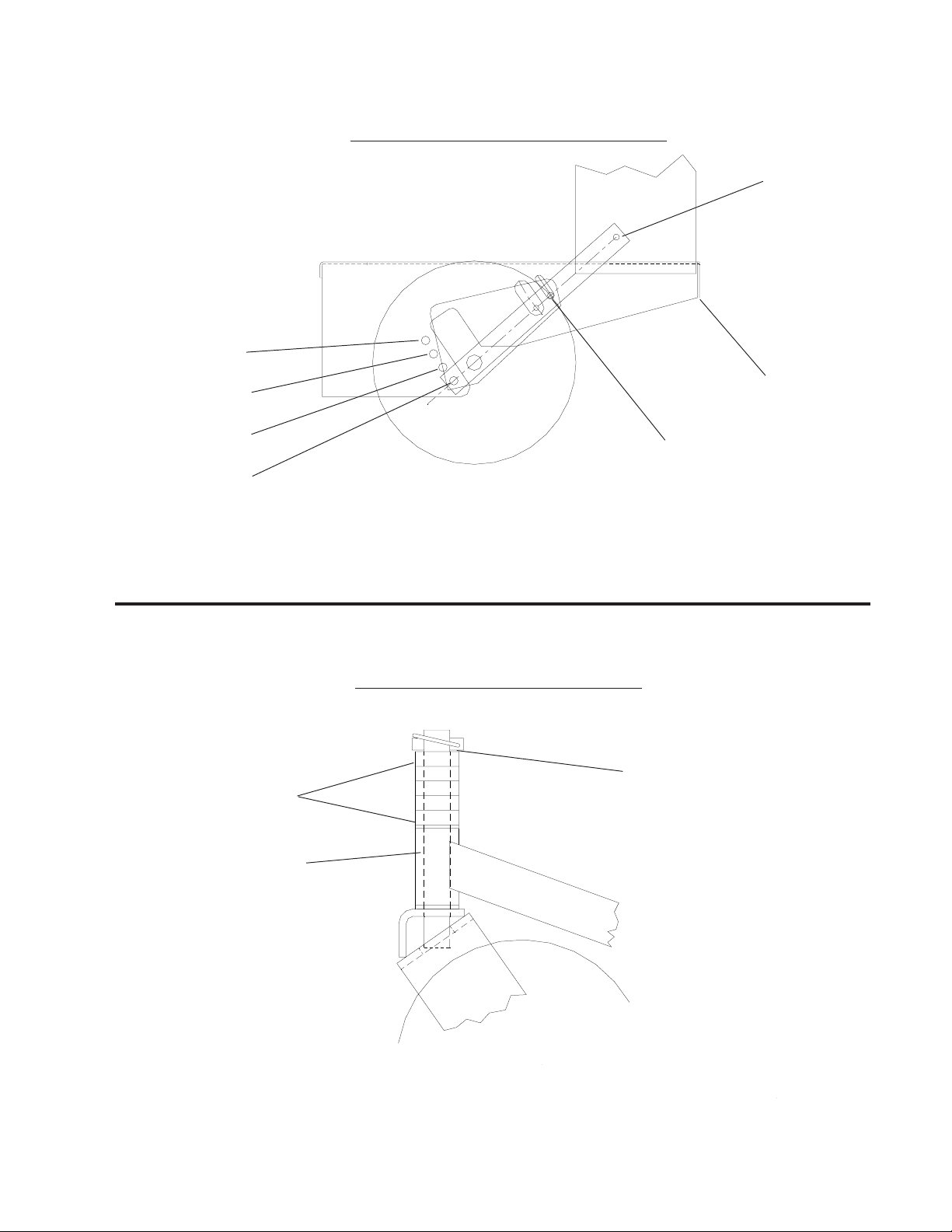

AXLE HEIGHT ADJUSTMENTAXLE HEIGHT ADJUSTMENT

AXLE HEIGHT ADJUSTMENT

AXLE HEIGHT ADJUSTMENTAXLE HEIGHT ADJUSTMENT

1. To adjust rear axle, stop engine and place drive levers

in the neutral lock position, remove spark plug wire.

2. Remove lower belt shield from underside of rear deck

for better access to axle adjustment bolts.

3. Loosen axle pivot bolts and axle adjustment bolts.

See figure # 1.

4. Place a jack under center of rear deck raise the jack

slightly so axle adjustment bolts may be removed.

5. With the jack raise or lower the rear deck to the desired

position using the chart to ensure proper height. Reinstall

the axle adjustment bolts and tighten.

A tapered punch may be used to help align the holes.

See figure #1.

NOTE:

It may be necessary to readjust drive and brake linkages.

NOTE:

To achieve the best quality cut, the blades should be

level with the ground or slightly tipped forward

BRAKE / TRACTION ADJUSMENTBRAKE / TRACTION ADJUSMENT

BRAKE / TRACTION ADJUSMENT

BRAKE / TRACTION ADJUSMENTBRAKE / TRACTION ADJUSMENT

1. Disconnect the brake linkage from the brake band

arm.

2. With the mower in gear, place the traction levers in the

drive position. Firmly pull back on the handles until the

tires slide to seat the wheel drive belts into the pulleys.

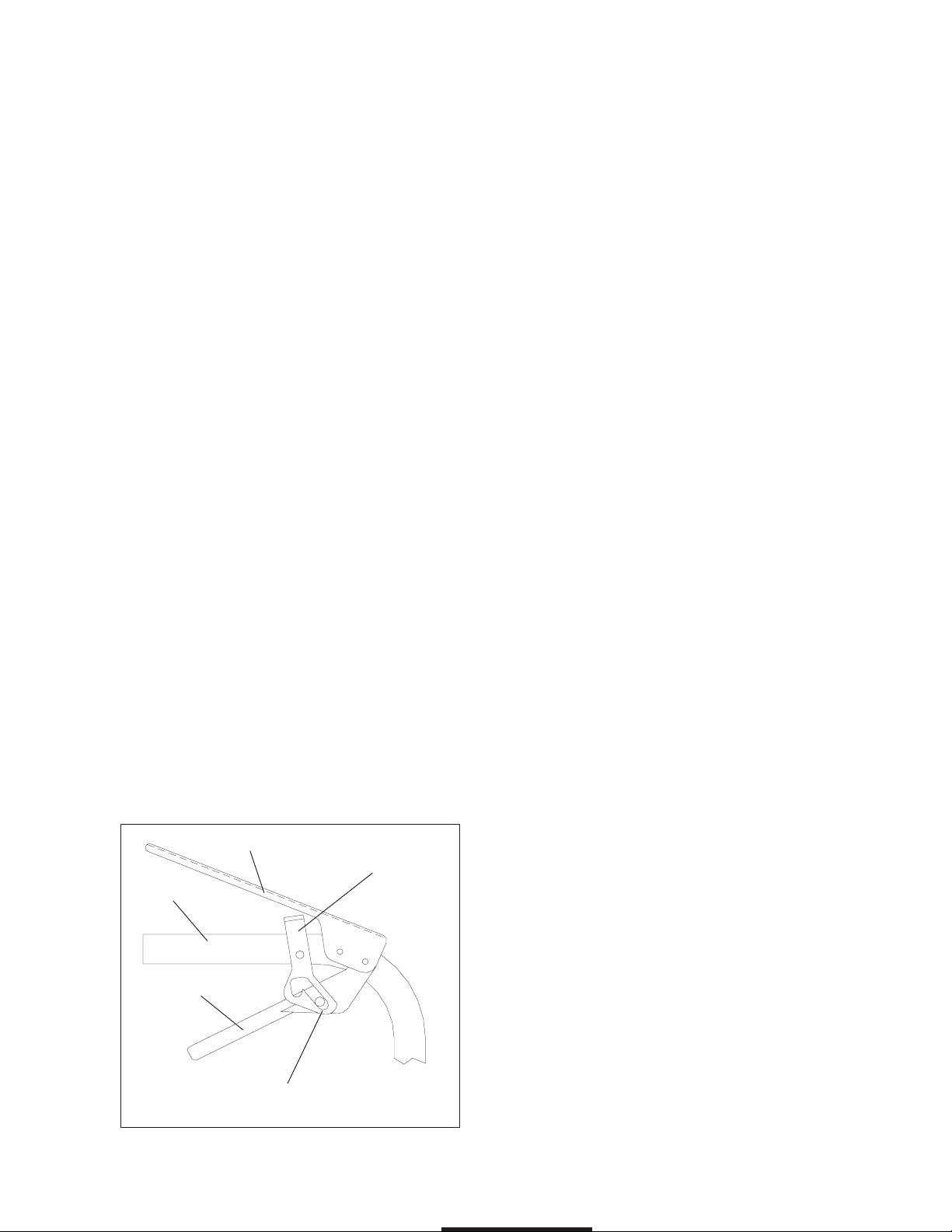

3. Measure the clearance between the bottom of the

traction lever rod and the bottom of the thumb latch slot.

It should be between 3/16" to 1/4", but not exceeding 1/

4". See Figure # 3

O.P. LEVER

THUMB LATCH

HANDLE

4. If the clearance is less than 3/16", disconnect the

traction rod from the traction lever by removing the

hairpin cotter.

5. Adjust the traction rod to the proper clearance by

screwing it out of the swivel if clearance is less than 3 /

16".

NOTE:NOTE:

NOTE:

NOTE:NOTE:

More or less brake pressure may be desired depending

on the operator or conditions of operation. To increase

pressure tighten the wing nut on the brake linkage.

OPERATOR PRESENCE SWITCH ADJUSTMENTOPERATOR PRESENCE SWITCH ADJUSTMENT

OPERATOR PRESENCE SWITCH ADJUSTMENT

OPERATOR PRESENCE SWITCH ADJUSTMENTOPERATOR PRESENCE SWITCH ADJUSTMENT

The operator presence switches can be adjusted by

loosening the screws on the side of the O.P. lever

linkage and sliding the switch up or down. The O.P.

switch should have a 1/32" to 1/16" gap between the

plunger and the bottom side of the control panel when

operator presence levers are released.

BLADE SWITCH ADJUSTMENTBLADE SWITCH ADJUSTMENT

BLADE SWITCH ADJUSTMENT

BLADE SWITCH ADJUSTMENTBLADE SWITCH ADJUSTMENT

The blade engagement switch can be adjusted by

loosening the screws on the flange under the control

panel and moving the switch in or out. The blade switch

should be adjusted so the plunger is fully depressed

when the engagement lever is fully disengaged.

ADJUSTMENTS - DRIVE BELTSADJUSTMENTS - DRIVE BELTS

ADJUSTMENTS - DRIVE BELTS

ADJUSTMENTS - DRIVE BELTSADJUSTMENTS - DRIVE BELTS

For all drive belts, tension should be set so that belt

vibration is minimized or eliminated when belts are

moving during normal operation. A properly tensioned

belt should have 1/4" to 3/8" deflection at the center of

belt span between pulleys when blades are engaged.

Blade drive belt tension is preset at the factory.

NOTE:NOTE:

NOTE:

NOTE:NOTE:

DO NOT over tighten belt. Excessive tension will

decrease belt and spindle bearing life.

TRACTION LEVER

3/16" to 1/4" CLEARANCE

Figure 3

3

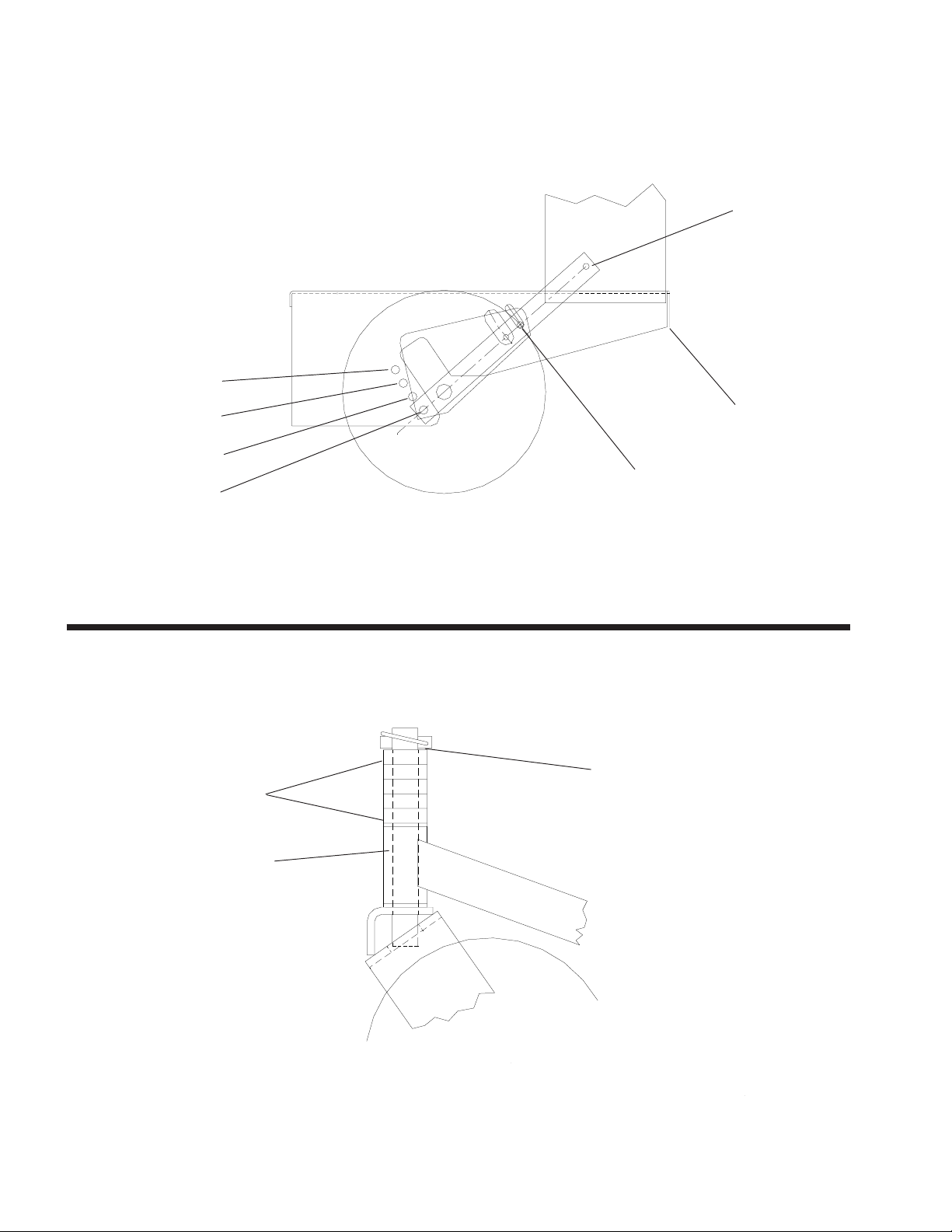

AXLE ADJUSTMENT BOLTS

POSITION

A

POSITION

B

POSITION

C

POSITION

D

REAR AXLE HEIGHT ADJUSTMENTREAR AXLE HEIGHT ADJUSTMENT

REAR AXLE HEIGHT ADJUSTMENT

REAR AXLE HEIGHT ADJUSTMENTREAR AXLE HEIGHT ADJUSTMENT

LOOSEN BOLTS EACH SIDE

Figure 1

AXLE PIVOT BOLTS

PLACE JACK HERE

1/2" SPACERS

CASTER

SWIVEL

CASTER HEIGHT ADJUSTMENTCASTER HEIGHT ADJUSTMENT

CASTER HEIGHT ADJUSTMENT

CASTER HEIGHT ADJUSTMENTCASTER HEIGHT ADJUSTMENT

Figure 2

MACHINERY BUSHING

4

BLADE DRIVE BELT ADJUSTMENTSBLADE DRIVE BELT ADJUSTMENTS

BLADE DRIVE BELT ADJUSTMENTS

BLADE DRIVE BELT ADJUSTMENTSBLADE DRIVE BELT ADJUSTMENTS

WARNINGWARNING

WARNING

WARNINGWARNING

BEFORE PERFORMING ADJUSTMENTS ONBEFORE PERFORMING ADJUSTMENTS ON

BEFORE PERFORMING ADJUSTMENTS ON

BEFORE PERFORMING ADJUSTMENTS ONBEFORE PERFORMING ADJUSTMENTS ON

BLADE BELT, TURN MOWER OFF, CLOSE FUELBLADE BELT, TURN MOWER OFF, CLOSE FUEL

BLADE BELT, TURN MOWER OFF, CLOSE FUEL

BLADE BELT, TURN MOWER OFF, CLOSE FUELBLADE BELT, TURN MOWER OFF, CLOSE FUEL

VALVE, AND DISCONNECT SPARK PLUG WIRE.VALVE, AND DISCONNECT SPARK PLUG WIRE.

VALVE, AND DISCONNECT SPARK PLUG WIRE.

VALVE, AND DISCONNECT SPARK PLUG WIRE.VALVE, AND DISCONNECT SPARK PLUG WIRE.

1. Remove front deck belt shield.

2. Loosen whiz nut on turnbuckle.

3. Set belt tension when engagement lever is in the

engaged position.

4. To increase belt tension rotate turnbuckle toward the

rear of the mower until desired tension is gained. Do not

over tighten belts, to much tension will reduce belt and

spindle bearing life. See figure # 6

5. Tighten whiz nut on turnbuckle and install belt shield.

AUXILIARY BLADE DRIVE BELTAUXILIARY BLADE DRIVE BELT

AUXILIARY BLADE DRIVE BELT

AUXILIARY BLADE DRIVE BELTAUXILIARY BLADE DRIVE BELT

(48" MODELS ONLY)(48" MODELS ONLY)

(48" MODELS ONLY)

(48" MODELS ONLY)(48" MODELS ONLY)

To adjust tension of the auxiliary belt rotate nut on

linkage that is attached to deck strap located on the right

side of cutter deck.

AUXILARY BELT ADJUSTMENT

ROD

IDLER PIVOT POINT

TURNBUCKLE

4

1/4"

5

ENGAGEMENT IDLER

ASSEMBLY

Figure 6

5

SETUP AND ADJUSTMENTS FORSETUP AND ADJUSTMENTS FOR

SETUP AND ADJUSTMENTS FOR

SETUP AND ADJUSTMENTS FORSETUP AND ADJUSTMENTS FOR

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERSHUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERSHUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

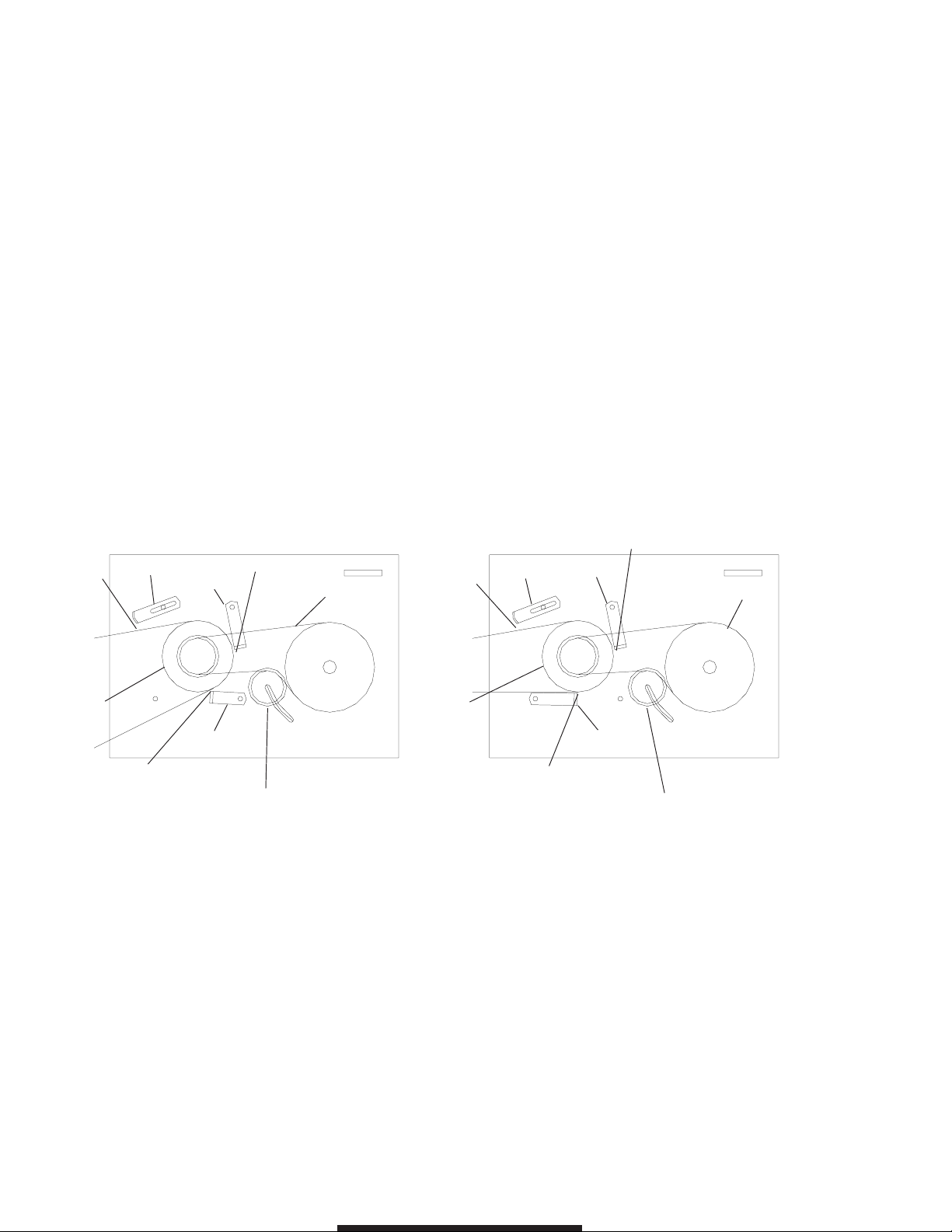

TRANSMISSION DRIVE BELTTRANSMISSION DRIVE BELT

TRANSMISSION DRIVE BELT

TRANSMISSION DRIVE BELTTRANSMISSION DRIVE BELT

To increase the tension of the transmission belt, loosen

the nut on the underside of the transmission idler pulley

located under the rear deck, slide the idler assembly

inward to increase tension and tighten the nut to secure.

See figures 4 & 5.

BELT GUIDESBELT GUIDES

BELT GUIDES

BELT GUIDESBELT GUIDES

Belt guides under rear deck are adjusted as shown in

figures 4 and 5

NOTE: The blades should come to a stop fromNOTE: The blades should come to a stop from

NOTE: The blades should come to a stop from

NOTE: The blades should come to a stop fromNOTE: The blades should come to a stop from

maximum speed within 7 seconds aftermaximum speed within 7 seconds after

maximum speed within 7 seconds after

maximum speed within 7 seconds aftermaximum speed within 7 seconds after

disengaging.disengaging.

disengaging.

disengaging.disengaging.

BLADE ENGAGEMENT LEVERBLADE ENGAGEMENT LEVER

BLADE ENGAGEMENT LEVER

BLADE ENGAGEMENT LEVERBLADE ENGAGEMENT LEVER

The blade engagement lever needs to be adjusted so

the lever does not come in contact with control panel

when the lever is in the off position.

To adjust, remove the clevis pin from the yoke and

adjust by turning the yoke. The clevis pin connects the

blade engagement lever to the yoke, and the yoke is

connected to the blade engagement rod that runs to the

bellcrank on the rear deck.

102036

1/2"

ENGINE PULLEY

1/8" CLEARANCE

TRANSMISSION IDLER PULLEY

32" & 36" MODEL32" & 36" MODEL

32" & 36" MODEL

32" & 36" MODEL32" & 36" MODEL

1/8" CLEARANCE

103462

103463

Figure 4

TRANSMISSION BELT

102036

1/2"

ENGINE PULLEY

1/8" CLEARANCE

48" MODEL48" MODEL

48" MODEL

48" MODEL48" MODEL

1/4" CLEARANCE

103462

TRANSMISSION BELT

103462

TRANSMISSION IDLER PULLEY

Figure 5

6

SETUP AND ADJUSTMENTS FORSETUP AND ADJUSTMENTS FOR

SETUP AND ADJUSTMENTS FOR

SETUP AND ADJUSTMENTS FORSETUP AND ADJUSTMENTS FOR

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERSHUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

HUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERSHUSQVARNA 32", 36" AND 48" COMMERCIAL MOWERS

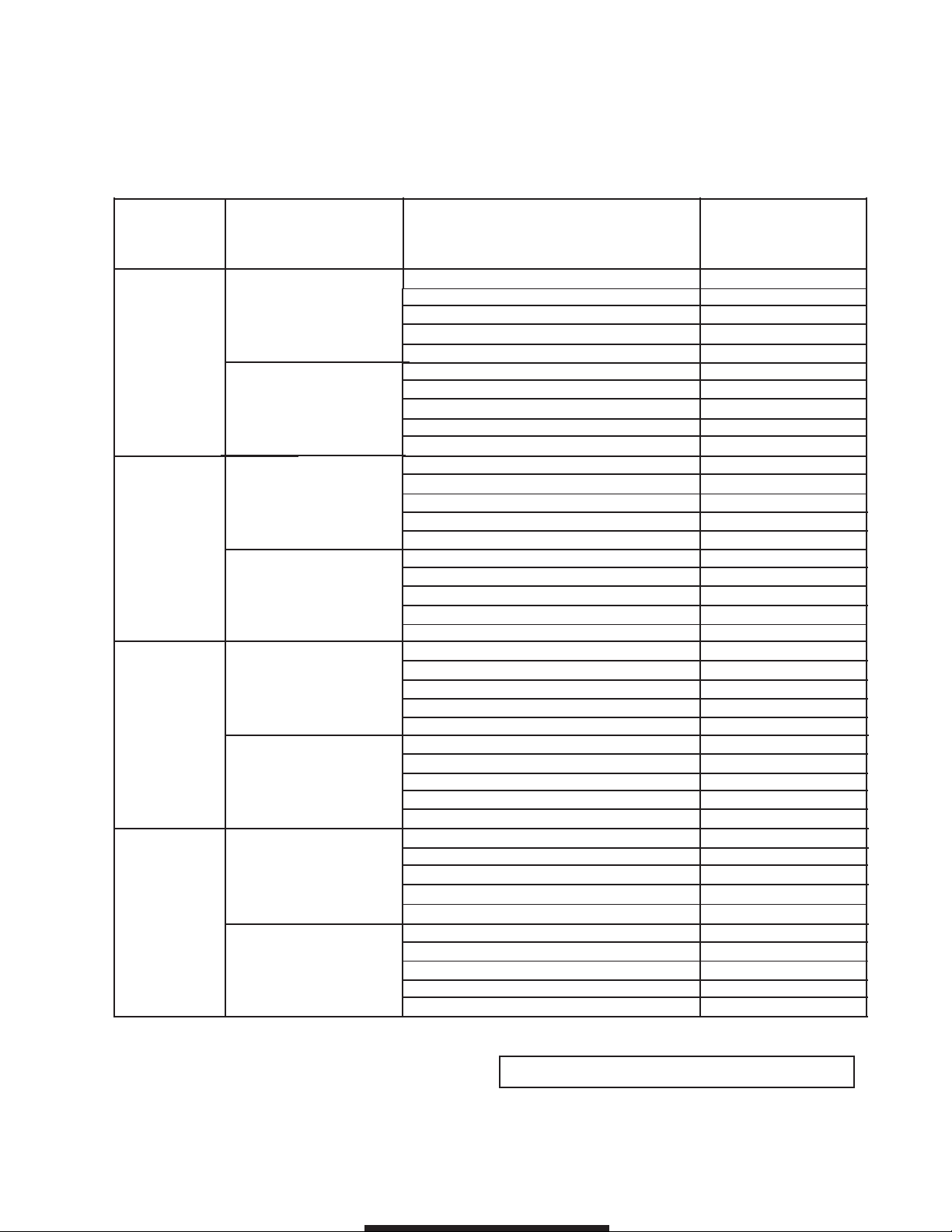

CUTTING HEIGHT ADJUSTMENT CHARTCUTTING HEIGHT ADJUSTMENT CHART

CUTTING HEIGHT ADJUSTMENT CHART

CUTTING HEIGHT ADJUSTMENT CHARTCUTTING HEIGHT ADJUSTMENT CHART

AXLE

POSITION

A

B

C

D

NUMBER OF

SPACERS BELOW

CASTER ARM

0

1

2

3

3

4

4

5

NUMBER OF 1/4" BLADE SPACERS

UNDER CUTTER HOUSING

4

3

2

1

0

4

3

2

1

0

4

3

2

1

0

4

3

2

1

0

4

3

2

1

0

4

3

2

1

0

4

3

2

1

0

4

3

2

1

0

CUTTING HEIGHT

(IN INCHES)

1 1/2

1 3/4

2

2 1/4

2 1/2

1 3/4

2

2 1/4

2 1/2

2 3/4

2 1/2

2 3/4

3

3 1/4

3 1/2

3

3 1/4

3 1/2

3 3/4

4

3 1/4

3 1/2

3 3/4

4

4 1/4

3 1/2

3 3/4

4

4 1/4

4 1/2

3 3/4

4

4 1/4

4 1/2

4 3/4

4

4 1/4

4 1/2

4 3/4

5

1. To quickly achieve small changes in cutting heights,

move the spacers from under the cutter housing to

above the cutter pulley. (Each spacer moved will give an

additional 1/4" of cutting height ).

USE ONLY 4 BLADE SPACERS MAXIMUM

7

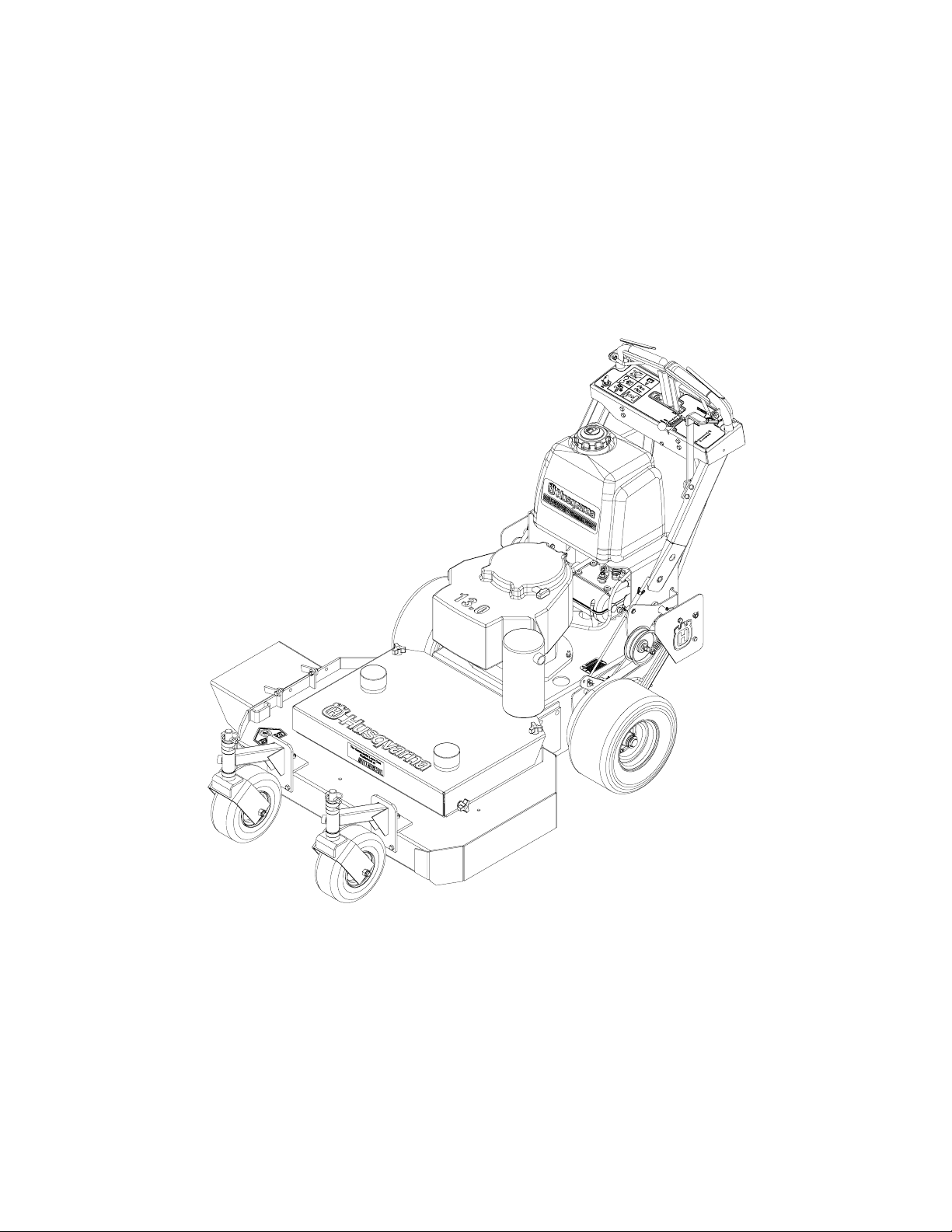

ETS Gear Drive Intermediate Walk Behind

Models:

968999117 / W3613ETS

968999120 / W4815ETS

8

Setup & Adjustments

MAINTENANCE

1. Keep all nuts, bolts, and screws tight to

keep mower in safe operating condition.

2. Never store the mower with gas in the tank

inside a building where fumes can reach an

open flame or spark. Allow engine to cool

before storing in an enclosure.

3. To reduce fire hazard, keep mower free of

grass, leaves, or excessive grease.

4. Check grass catcher assembly frequently

for wear or deterioration. Replace bag if

loose seams or tears are evident.

5. Have your mower inspected and serviced

each year by an authorized HUSQVARNA

dealer. Determine if any additional devices

are available which might upgrade the safety

of your mower .

6. Use only authentic HUSQVARNA re-

placement parts to insure the safety and

quality of your mower is maintained.

7. Safety decals should be replaced if they

are missing or illegible. Decals may be

purchased from your HUSQVARNA dealer.

FRONT CASTER WHEELS

1. Mount front caster wheel assemblies.

Installation includes fastening casters to front

of the cutter deck using 3/8 x 1" hex head

capscrews.

FUEL TANK

1. Place fuel tank on tank support, making sure

to get the studs through the slots on the top of

the tank support. Place the 5/16” flat washer ,

spring, the other 5/16 flat washer and the 5/16”

nut on the stud. Snug 5/16” nut, but do not over

tighten.

HANDLE ASSEMBLY

1. Align the upper mounting holes in handle

with the upper hole in the tank support.

2. Install two 3/8" x 1" screws through

matched holes and loosely install 3/8" nuts.

3. Align the lower holes and inst all hardware

as above, tighten upper and lower hardware.

LINKAGE INSTALLATION

1. Install drive linkage into the hole in the idler

arm on the inside of the tank support. The drive

linkages are fastened to the drive levers on the

handle assembly . Secure the drive linkages to

the idler arm by inserting a retaining ring

through the small hole in the end of the drive

linkage.

2. Install shifter to transmission with 1/4" x 1"

screws.

The shifter is located in the inner box and

hardware is pre-assembled into the bracket

on the transmission.

3. Install blade control rod into the bellcrank

on the left side of the tank support. Secure

rod with ring type retainer .

4. Refer to the section of this manual on

adjustments for the proper adjustment of the

linkages you are installing. The linkages were

set at the factory but must be checked before

operating mower to insure of the proper

setting. Always check 100% of the adjustments before you operate the mower.

5. Connect the two halves of the wiring harness together. The four prong connectors

have a locking tab that shows which way to

line them up and guarantees that they are

connected properly when the lock snaps.

6. Install the chute deflector to the side of the

mower deck. Bolt it into place using the two

5/16" x 1" screws and nuts pre-assembled

into the mounting tabs on the deck. T ighten

the screws very securely with the chute

completely covering the discharge opening

and tight against the side of deck.

THROTTLE INSTALLATION

1. Connect the throttle cable end to the

throttle mechanism on engine, leaving the

cable clamp loose. Push throttle lever on

console completely forward. Then pull the

cable through the clamp on engine and

tighten the cable clamp. Move the throttle

lever back and forth to ensure proper installation.

9

Setup & Adjustments

GAS LINE INSTALLATION

1. The gas line is factory installed on the engine.

Attach loose end to fuel tank hose barb and

secure with hose clamp.

POSITIONING FRONT CASTER SPACERS

1. Using the cutting height chart, find the correct

number of spacers to be placed under the

caster swivel.

2. Remove the lynch pin and washer from the

top of caster and reposition spacers to the

desired cutting height from the chart. See figure

# 2

AXLE HEIGHT ADJUSTMENT

1. To adjust rear axle, stop engine and place

drive levers in the neutral lock position, remove

spark plug wire.

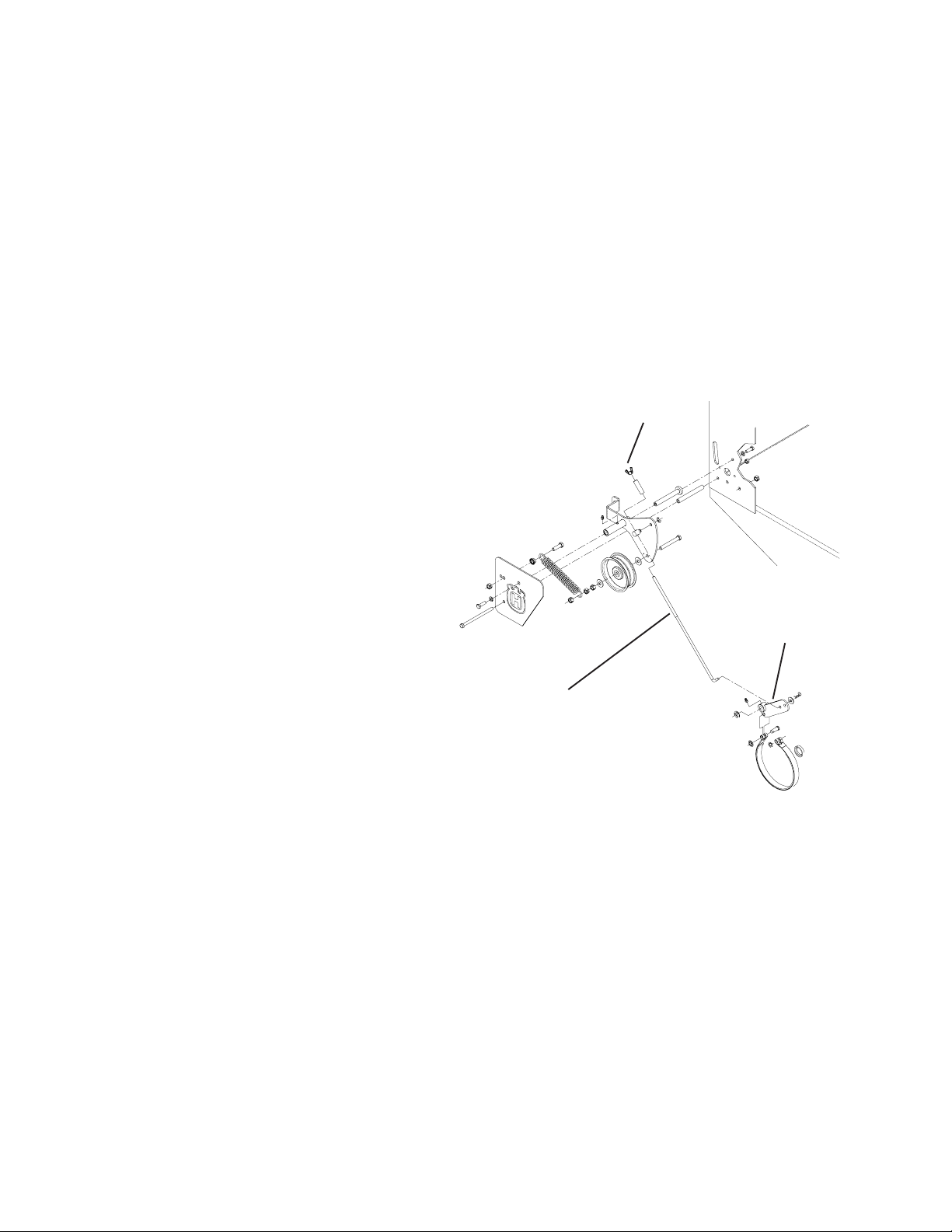

BRAKE ROD ADJUSTMENT

1. Make sure the rod is installed into the proper

hole in the brake arm. The brake rod should be

in bottom hole on the brake arm as shown

below. Never use the upper hole. The proper

adjustment can not be achived in this position.

2. To increase braking. Turn the wing nut down

on the brake rod. Do not turn the wingnut down

to far as this will result a constant braking action

and will excessively wear the brake band and

cause premature failure.

Wingnut

2. Remove lower belt shield from underside of

rear deck for better access to axle adjustment

bolts.

3. Loosen axle pivot bolts and axle adjustment

bolts.

See figure # 1.

4. Place a jack under center of rear deck raise

the jack slightly so axle adjustment bolts may be

removed.

5. With the jack raise or lower the rear deck to

the desired position using the chart to ensure

proper height. Reinstall the axle adjustment

bolts and tighten.

A tapered punch may be used to help align the

holes. See figure #1.

NOTE:

It may be necessary to readjust drive and brake

linkages.

Brake arm

Brake Rod

NOTE:

To achieve the best quality cut, the blades

should be level with the ground or slightly tipped

forward

10

AXLE ADJUSTMENT

BOLTS

POSITION A

Setup & Adjustments

REAR AXLE HEIGHT ADJUSTMENT

POSITION B

POSITION

C

POSITION

D

1/2" SPACERS

PLACE JACK

HERE

LOOSEN BOL TS EACH

SIDE

Figure 1

CASTER HEIGHT ADJUSTMENT

MACHINERY BUSHING

CASTER SWIVEL

Figure 2

11

Loading...

Loading...