Oper

ator’s manual Manuel d’utilisation

Manual de instrucciones

560BTS 570BTS 580BTS

560BFS 570BFS 580BFS

Please r

ead the operator’s manual carefully and make sure you understand the instructions before using the machine.

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

UUUUSSSS ((((2222----22227777))

CCCCAAAA ((((22228888----55553333))

UUUUEEEE ((((55554444---- 77779999))

))

))

))

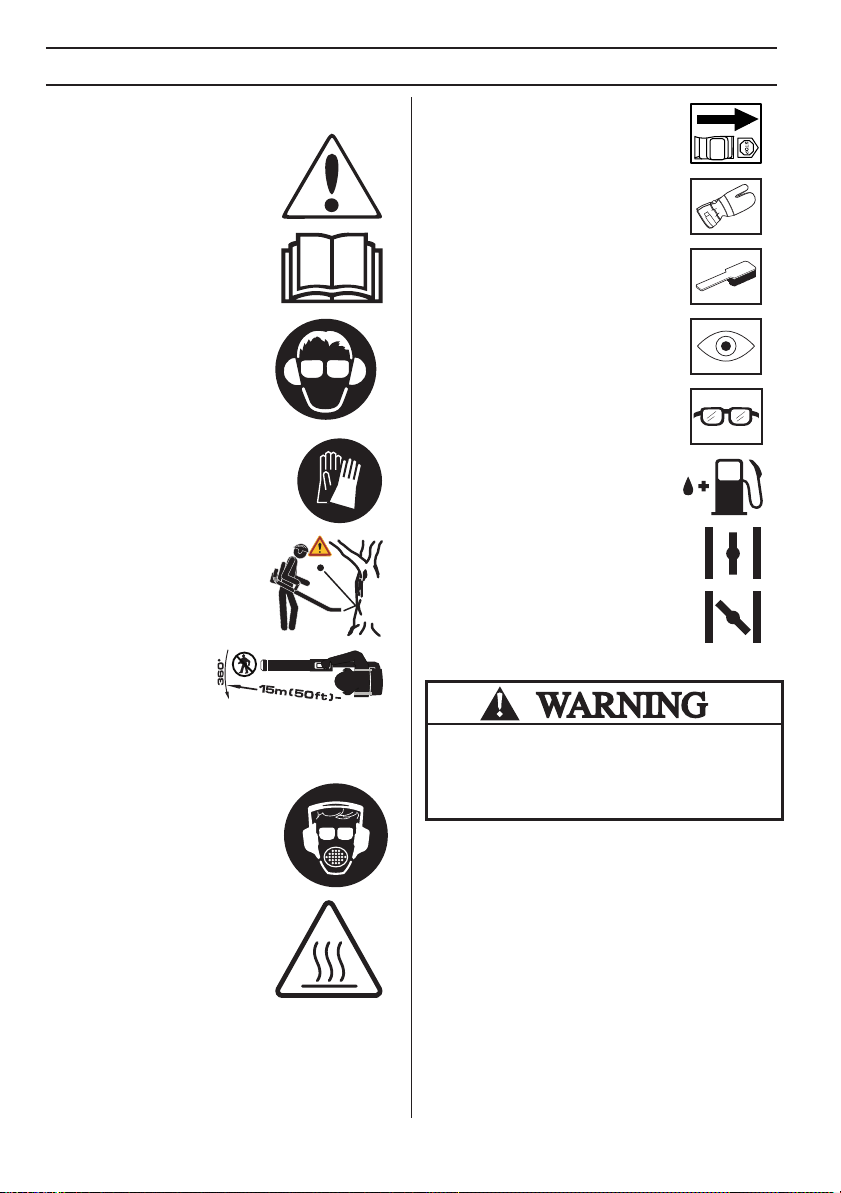

Symbols

W

ARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious

or fatal injury to the operator or

others.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

KEY TO SYMBOLS

Switch off the engine b

switch to the STOP position before

carrying out any checks or

maintenance.

Always wear protective gloves.

Regular cleaning is required.

y moving the stop

Always wear:

• Hearing protection

• Approved eye protection

Gloves should be worn when

necessary.

The blower can forcibly throw

objects that can bounce back.

This can result in serious eye

injuries if the recommended

safety equipment is not used.

The blower operator

must make sure that no

bystanders or animals

come nearer than 15

metres. Whenever

several operators are working in the same work area, they

should maintain a safe distance of at least 15 metres from

one another.

A breathing mask should be used

when there is a risk of dust.

Visual check.

Protective goggles or a visor must be

worn.

Refuelling.

Choke lever in ”open position”.

Choke lever in ”closed position”.

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Keep all parts of your body away

from hot surfaces.

Other symbols/decals on the

machine refer to special certification requirements

for certain markets.

2

–

English

1155849-49

Rev.

2

2013-03-22

CONTENTS

!

!

!

Contents

KEY

TO SYMBOLS

Symbols

................................................................ 2

CONTENTS

Contents

Note the following before starting: ........................ 3

INTR

Dear customer!

WHA

What is what on the b

What is what on the blower? ................................ 6

What is what on the blower? ................................ 7

GENERAL SAFETY PRECA

Gener

SAFETY INSTR

P

Machine′s safety equipment ................................. 10

Checking, maintaining and servicing the

machine

General working instructions ................................ 12

ASSEMBL

Assemb

FUEL HANDLING

Fuel

Fueling .................................................................. 17

ST

Star

MAINTENANCE

Gener

Carburetor ............................................................ 20

Muffler .................................................................. 20

Cooling system ..................................................... 20

Air intake screen ................................................... 21

Spark plug ............................................................ 21

Air filter ................................................................. 21

Shoulder strap ...................................................... 22

Maintenance schedule ......................................... 23

TECHNICAL D

T

FEDERAL AND CALIFORNIA EMISSIONS

CONTROL WARRANTY STATEMENT

Y

............................................................... 3

ODUCTION

..................................................... 4

T IS WHAT?

lower? ................................ 5

UTIONS

al ................................................................. 8

UCTIONS

ersonal protective equipment ............................. 10

′

s safety equipment ................................. 11

Y

ling the blow pipe and control handle ...... 15

...................................................................... 16

ARTING AND STOPPING

ting and stopping ........................................... 18

al ................................................................. 20

ATA

echnical data ...................................................... 24

OUR WARRANTY RIGHTS AND OBLIGATIONS 26

Note the f

ollowing before

starting:

Please read the oper

This decal certifies that the product has been approved in

accordance with American exhaust emissions

requirements EPA Ph III and CARB Tier III. The

Emissions Compliance Period referred to on the

Emissions Compliance label indicates the numbers of

operating hours for which the engine has been shown to

meet Federal and California emission requirements.

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify

the design and appearance of products without prior

notice.

The machine is only designed for blowing lawns,

pathways, asphalt roads and the like.

For customer assistance, contact us at our website:

www.usa.husqvarna.com

ator’s manual carefully.

W

ARNING! Long-term exposure to noise

can result in permanent hearing

impairment. So always use approved

hearing protection.

W

ARNING! Under no circumstances may

the design of the machine be modified

without the permission of the

manufacturer. Always use genuine

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

Your warranty may not cover damage or

liability caused by the use of nonauthorized accessories or replacement

parts.

W

ARNING! A blower is a dangerous tool

if used carelessly or incorrectly and can

cause serious, even fatal injuries. It is

extremely important that you read and

understand the contents of this

Operator’s manual.

Jan. 2011

1155849-49

Rev.

2

2013-03-22

English –

3

INTR

ODUCTION

Dear customer!

Cong

ratulations on your choice to buy a Husqvarna product! Husqvarna is based on a tradition that dates back to 1689,

when the Swedish King Karl XI ordered the construction of a factory on the banks of the Huskvarna River, for production

of muskets. The location was logical, since water power was harnessed from the Huskvarna River to create the waterpowered plant. During over 300 years of continuous operation, the Husqvarna factory has produced a lot of different

products, from wood stoves to modern kitchen appliances, sewing machines, bicycles, motorcycles etc. In 1956, the first

motor driven lawn mowers appeared, followed by chain saws in 1959, and it is within this area Husqvarna is working

today.

Today Husqvarna is one of the leading manufacturers in the world of forest and garden products, with quality as our

highest priority. We develop, manufacture and market high quality motor driven products for forestry and gardening as

well as for building and construction industry.

Your purchase gives you access to professional help with repairs and service whenever this may be necessary. If the

retailer who sells your machine is not one of our authorized dealers, ask for the address of your nearest servicing dealer.

It is our wish that you will be satisfied with your product and that it will be your companion for a long time. Think of this

operator

′

s manual as a valuable document. By following its′ content (using, service, maintenance etc) the life span and

the second-hand value of the machine can be extended. If you ever lend or sell this machine, make sure that the

borrower or buyer gets the operator

Thank you for using a Husqvarna product.

Husqvarna AB has a policy of continuous product development and therefore reserves the right to modify the design and

appearance of products without prior notice.

For customer assistance, contact us at our website: www.usa.husqvarna.com

′

s manual, so they will also know how to properly maintain and use it.

4

–

English

1155849-49

Rev.

2

2013-03-22

8

9

25

26

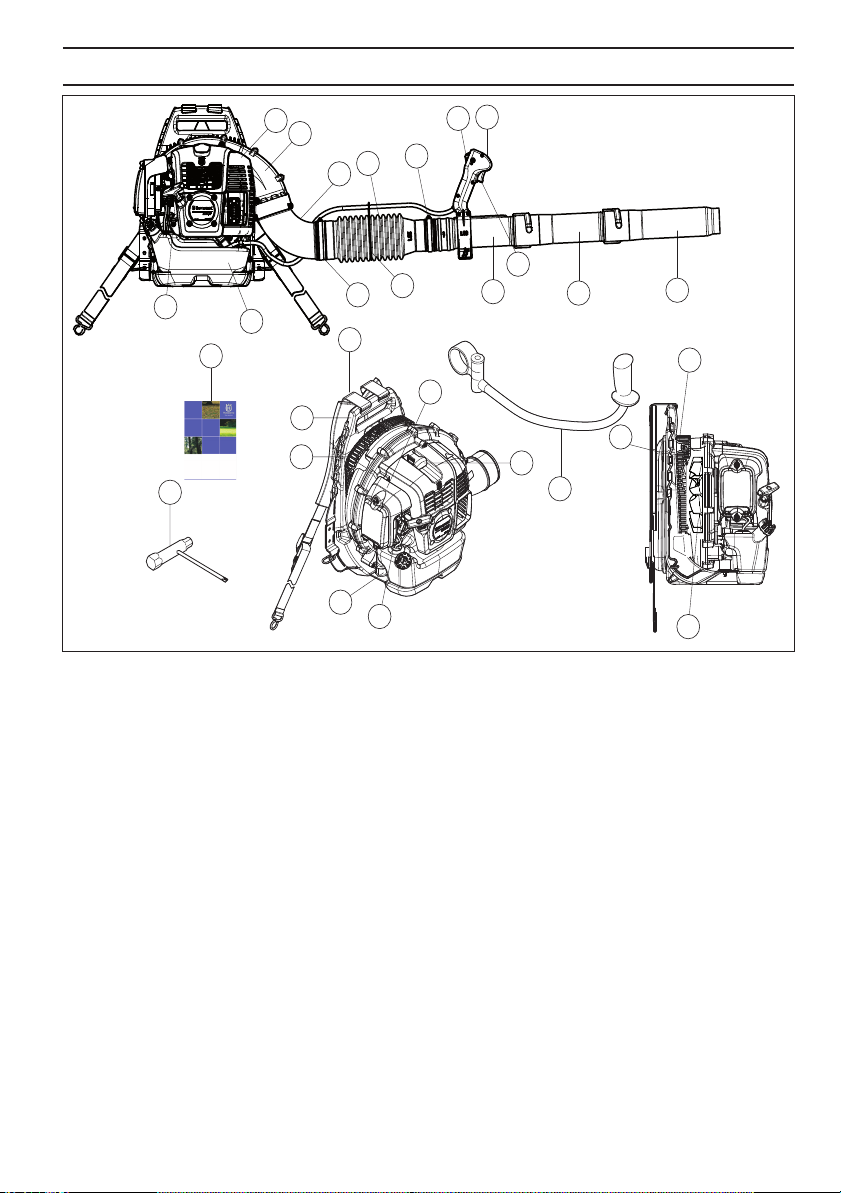

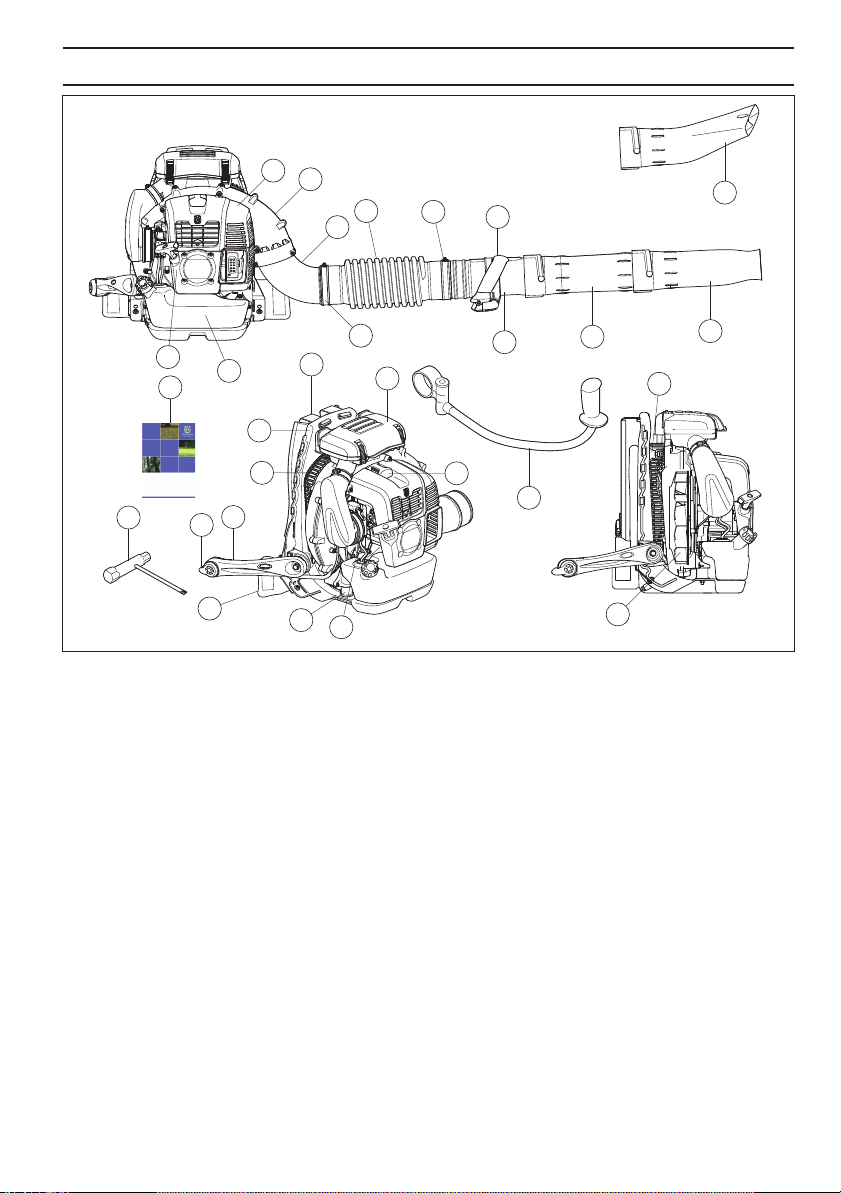

What is what on the b

1

Frame

2 Harness

3 Engine cover

4 Fan shell

5 Air intake screen

6Fan

7 Air filter

8 Starter handle

9 Fuel tank

10 Pad

11 Spark plug

12 Vibration damping system

13 Choke control

14 Control handle/Operating handle

lower? 560BTS, 560BFS

WHA

T IS

WHA

T?

14

3

4

20

18

15

19

16

19

22

21

23

24

2

12

7

1

10

5

11

17

12

13

15 Throttle setting lever. Stop switch positioned behind

lever. (BFS)

16 Stop switch with throttle position setting (BTS),

17 Throttle trigger (BTS)

18 Handlebar (Accessory)

19 Elbow

20 Clamp

21 Flexible hose

22 Control pipe

23 Clamp

24 Intermediate pipe

25 Blow pipe

26 Operator’s manual

27 Combination spanner

28 Control handle/operating handle (BFS)

6

1155849-49

Rev.

2

2013-03-22

English

–

5

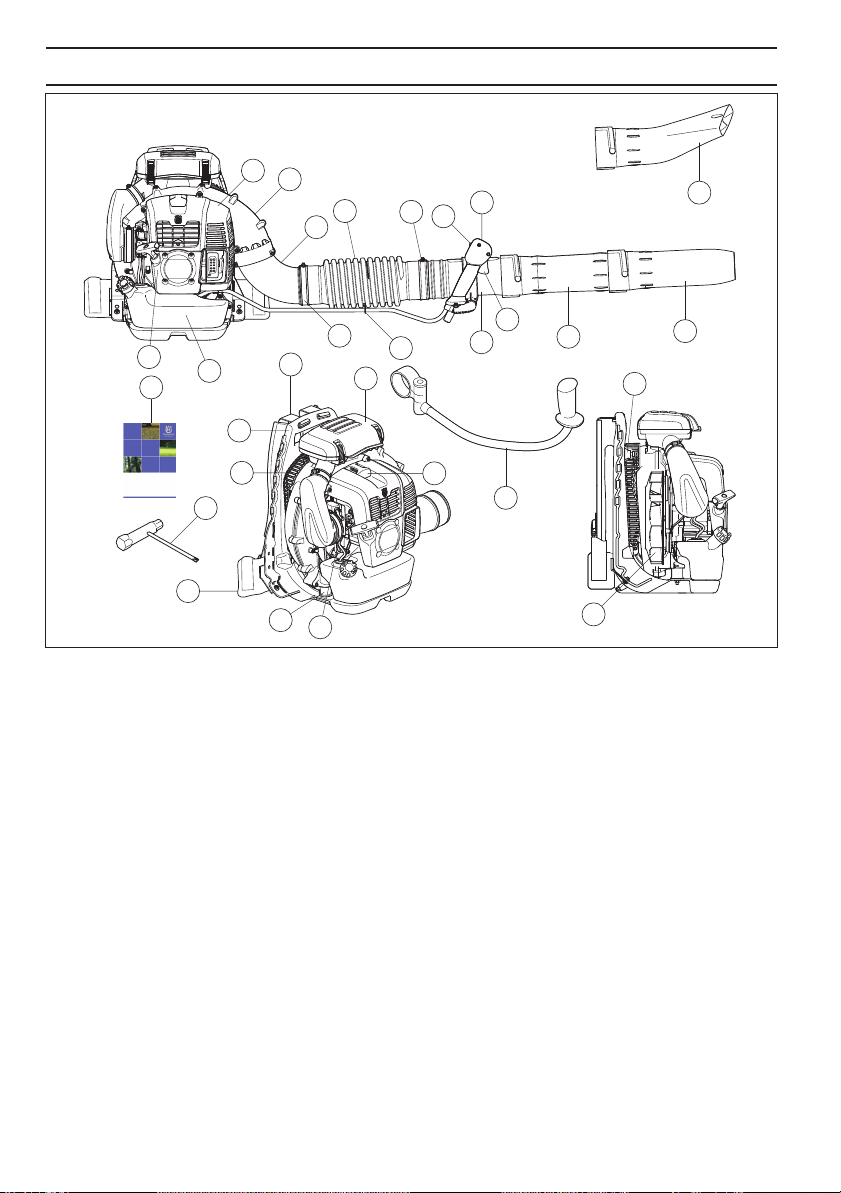

WHA

T IS

WHA

T?

3

4

20

18

19

14

15

25

8

26

What is what on the b

1

Frame

2 Harness

3 Engine cover

4 Fan shell

5 Air intake screen

6Fan

7 Air filter

8 Starter handle

9 Fuel tank

10 Pad

11 Spark plug

12 Vibration damping system

13 Choke control

14 Control handle/Operating handle

9

1

5

27

10

lower? 570BTS, 580BTS

19

2

12

13

22

7

11

15 Stop switch with throttle position setting

16 Throttle trigger

17 Handlebar (Accessory)

18 Elbow

19 Clamp

20 Flexible hose

21 Control pipe

22 Clamp

23 Intermediate pipe

24 Blow pipe

25 Flat nozzle (Accessory)

26 Operator’s manual

27 Combination spanner

16

21

17

23

6

24

12

6

–

English

1155849-49

Rev.

2

2013-03-22

WHA

T IS

WHA

T?

3

4

20

18

19

14

25

8

26

27

What is what on the b

1

Frame

2 Harness

3 Engine cover

4 Fan shell

5 Air intake screen

6Fan

7 Air filter

8 Starter handle

9 Fuel tank

10 Pad

11 Spark plug

12 Vibration damping system

13 Choke control

14 Control handle/Operating handle

9

1

5

16

15

10

lower? 570BFS, 580BFS

19

2

12

7

13

21

11

17

15 Stop switch with throttle position setting

16 Throttle trigger

17 Handlebar (Accessory)

18 Elbow

19 Clamp

20 Flexible hose

21 Control pipe

22 Clamp

23 Intermediate pipe

24 Blow pipe

25 Flat nozzle (Accessory)

26 Operator’s manual

27 Combination spanner

23

6

24

12

1155849-49

Rev.

2

2013-03-22

English

–

7

GENERAL SAFETY PRECA

General

IMPORTANT!

The machine is only designed for blowing lawns,

pathways, asphalt roads and the like.

Do an overall inspection of the machine before use, see

maintenance schedule.

Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

Wear personal protective equipment. See instructions

under the heading ”Personal protective equipment”.

Never use a machine that has been modified in any way

from its original specification.

Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures

must be carried out by trained and qualified specialists.

See instructions under the heading Maintenance.

All covers and guards must be fitted before starting.

Ensure that the spark plug cap and ignition lead are

undamaged to avoid the risk of electric shock.

The blower operator must make sure that no bystanders

or animals come nearer than 15 metres. Whenever

several operators are working in the same work area,

they should maintain a safe distance of at least 15

metres from one another.

Never allow children to use the machine.

Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

Always check for any objects that may block the air

intake screen before beginning work.

Never remove the air intake screen.

In case of emergency, release yourself from the

machine by opening the waist and chest belt and let the

machine fall backwards.

Always contact local authorities and make sure you are

following applicable directives.

Keep all parts of your body away from hot surfaces.

UTIONS

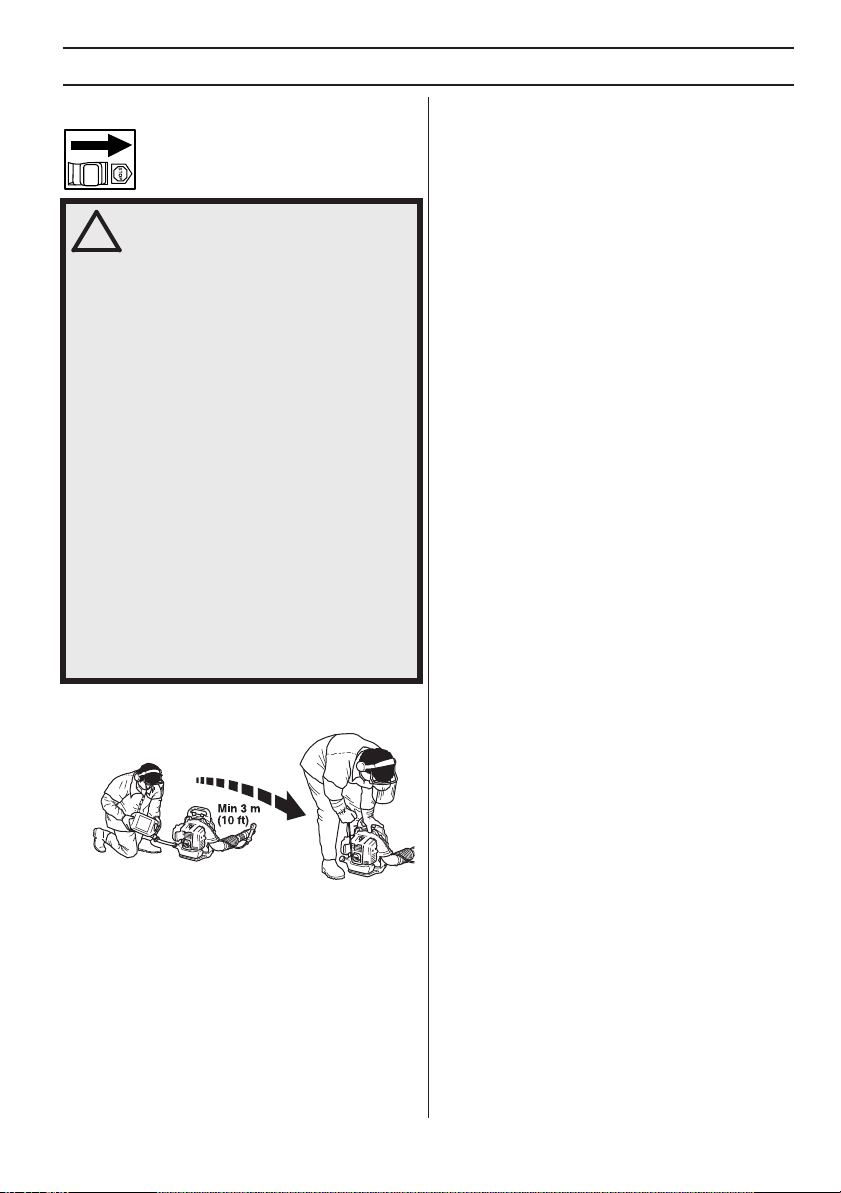

Star

ting

•

Never start the machine indoors. Exhaust fumes can

be dangerous if inhaled.

• Observe the surroundings and ensure that no people

or animals can come into contact with the blower.

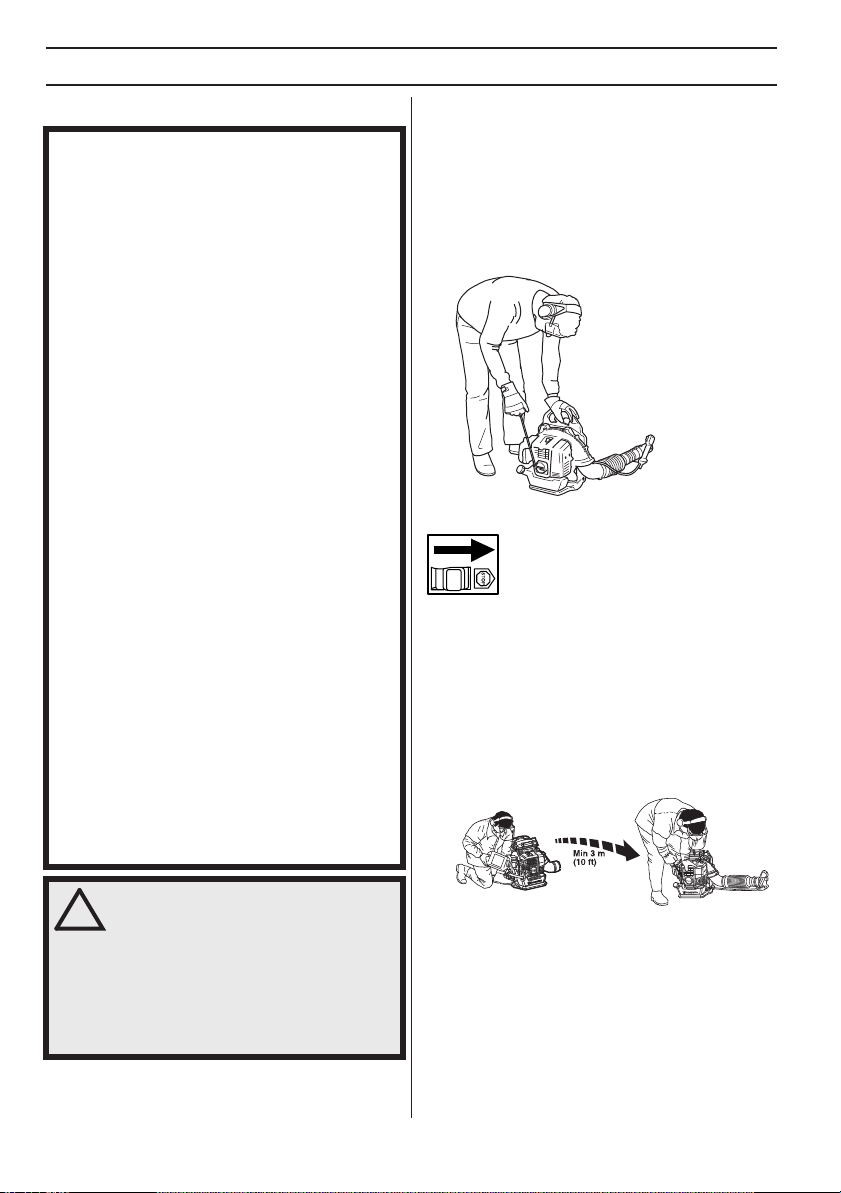

• Place the machine on the ground, press the machine

body against the ground with your left hand (NOTE!

Not your foot). Now grasp the starter handle with your

right hand and then pull quickly and firmly.

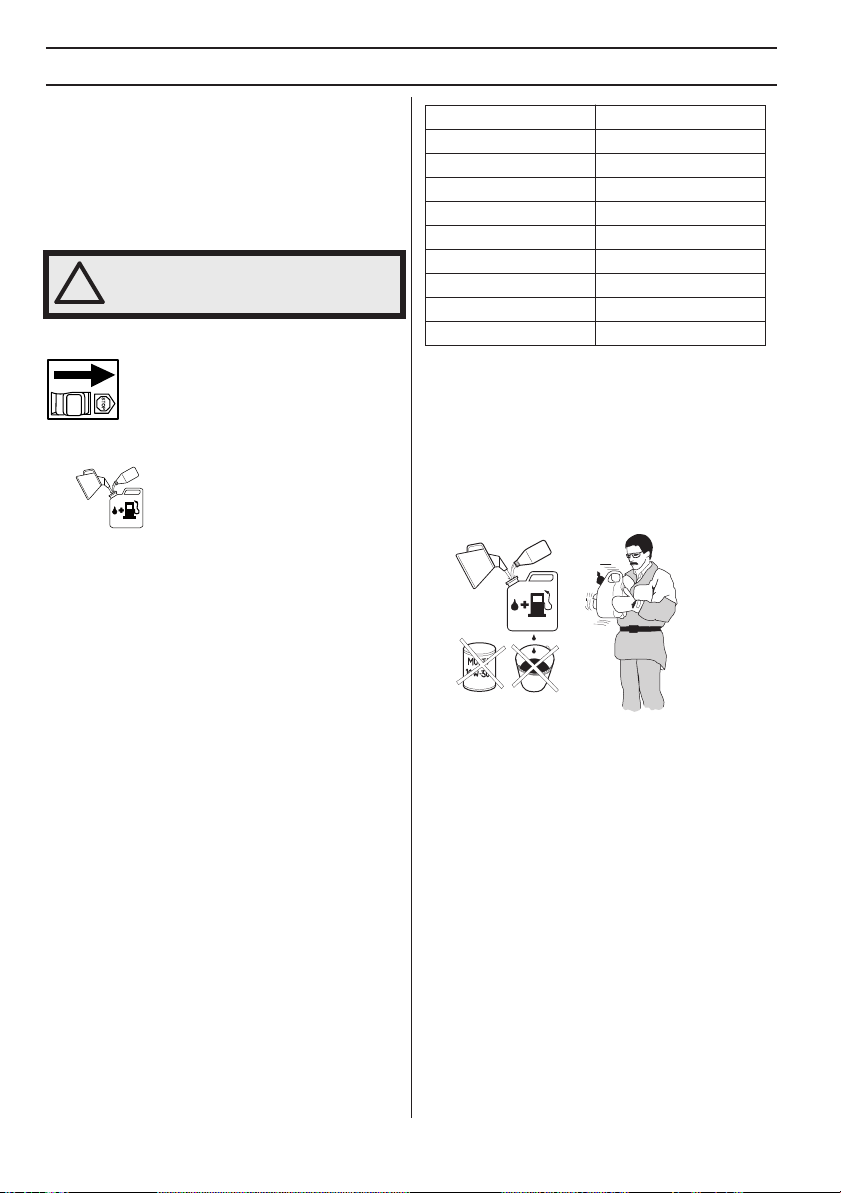

Fuel saf

•

• Never refuel the machine while the engine is running.

• Make sure there is plenty of ventilation when refuelling

• Avoid all skin contact with fuel. Fuel is a skin irritant

• Move the machine at least 10 ft (3 m) from the

ety

Always use a fuel container with an anti-spill valve.

Always stop the engine and let it cool for a few minutes

before refuelling.

or mixing fuel (gasoline and 2-stroke oil).

and may even cause skin changes.

refuelling point before starting it.

8

–

W

ARNING! This machine produces an

electromagnetic field during operation.

!

This field may under some

circumstances interfere with active or

passive medical implants. To reduce the

risk of serious or fatal injury, we

recommend persons with medical

implants to consult their physician and

the medical implant manufacturer before

operating this machine.

English

• Never start the machine:

- If you have spilled fuel on it. Wipe off the spillage and

allow remaining fuel to evaporate.

- If you have spilled fuel on yourself or your clothes,

change your clothes. Wash any part of your body that has

come in contact with fuel. Use soap and water.

- If the machine is leaking fuel. Check regularly for leaks

from the fuel cap and fuel lines.

1155849-49

Rev.

2

2013-03-22

GENERAL SAFETY PRECA

T

ransport and storage

•

Store and transport the machine and fuel so that there

is no risk of any leakage or fumes coming into contact

with sparks or naked flames, for example, from

electrical machinery, electric motors, electrical relays/

switches or boilers.

• When storing and transporting fuel always use

approved containers intended for this purpose.

• When storing the machine for long periods the fuel

tank must be emptied. Contact your local gas station

to find out where to dispose of excess fuel. Empty the

fuel tank and press the primer until all fuel has been

emptied. Remove the spark plug and drop a spoon of

2-stroke oil in the cylinder. Turn over the engine a few

times and then put the spark plug back in place.

• Ensure the machine is cleaned and that a complete

service is carried out before long-term storage.

• Secure the machine during transport.

• Store the machine in a dry, cool, well-aired and dustfree location. Store the machine out of reach of

children.

WARNING! Take care when handling fuel.

Bear in mind the risk of fire, explosion

!

and inhaling fumes.

UTIONS

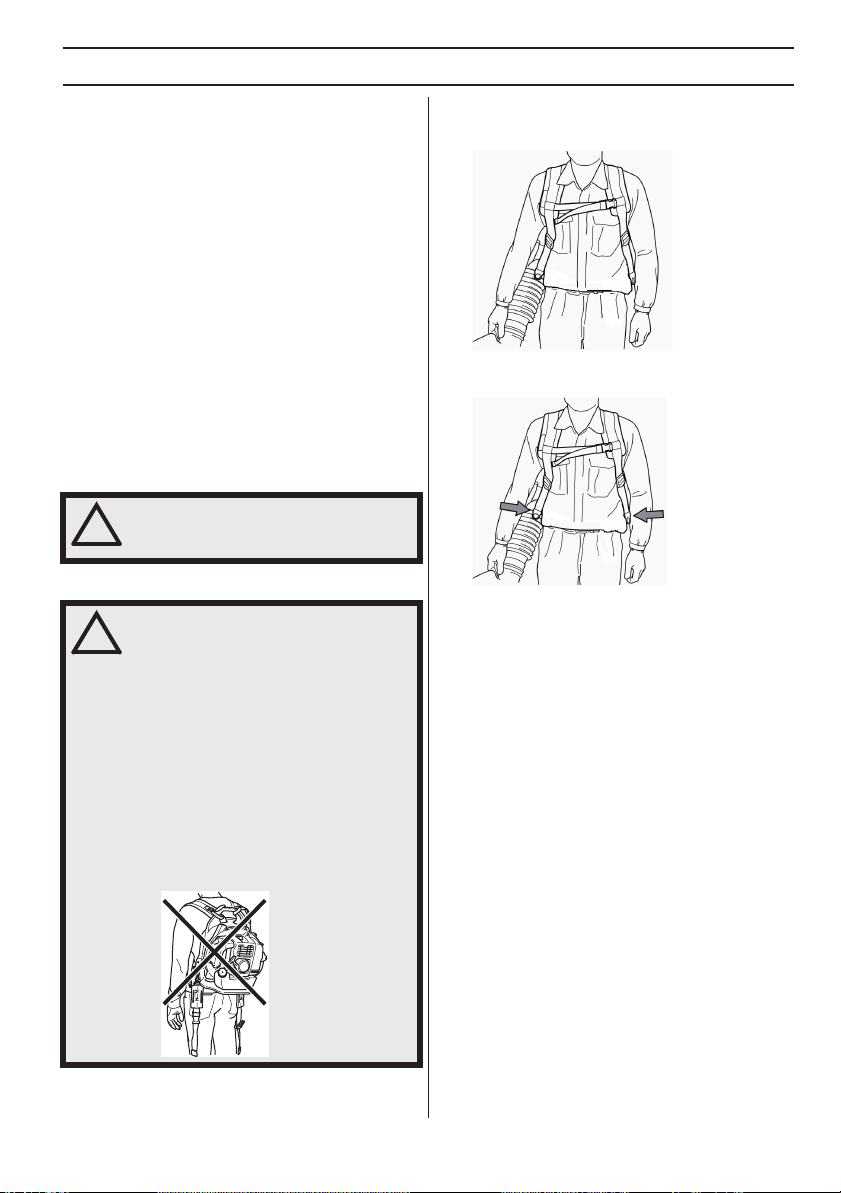

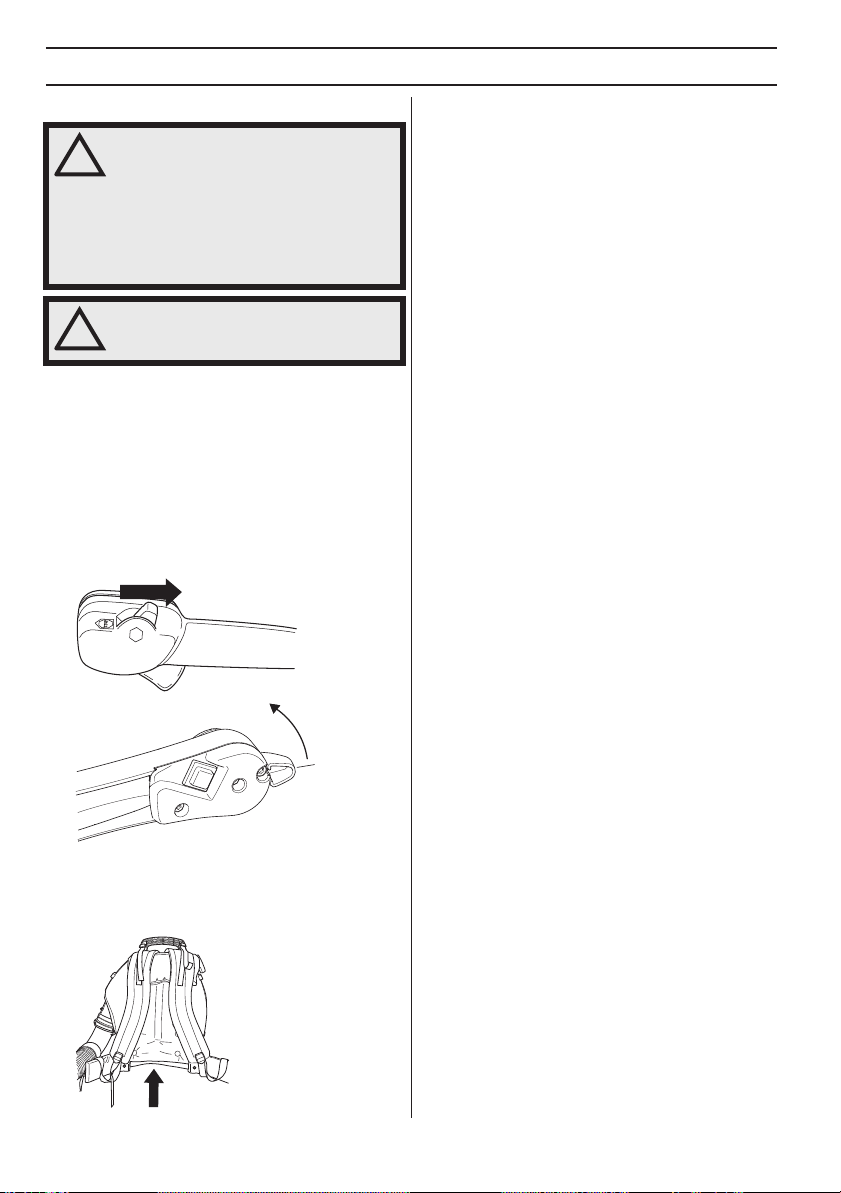

A correctly adjusted harness and machine significantly

facilitates the work. Adjust the harness to give the best

working position.

Tighten the side straps so that the pressure is evenly

distributed across the shoulders.

Adjusting the harness

WARNING! The harness must always be

worn when working with the machine.

!

Failure to do so means you will be unable

to manoeuvre safely and this can result

in injury to yourself or others.

Make sure that the waist belt is closed

and correctly adjusted.

If you not using a waist belt, be sure to

remove it from the unit and store it. There

is a risk that the belt will be caught,

toppling the unit.

There is a risk that an unclosed belt can

get stuck or sucked into the fan of the

machine.

1155849-49

Rev.

2

2013-03-22

Tighten and adjust the breast belt for the best working

position.

NOTE!

560BTS, BFS has no chest belt or waist belt.

English –

9

SAFETY INSTRUCTIONS

!

Personal protective equipment

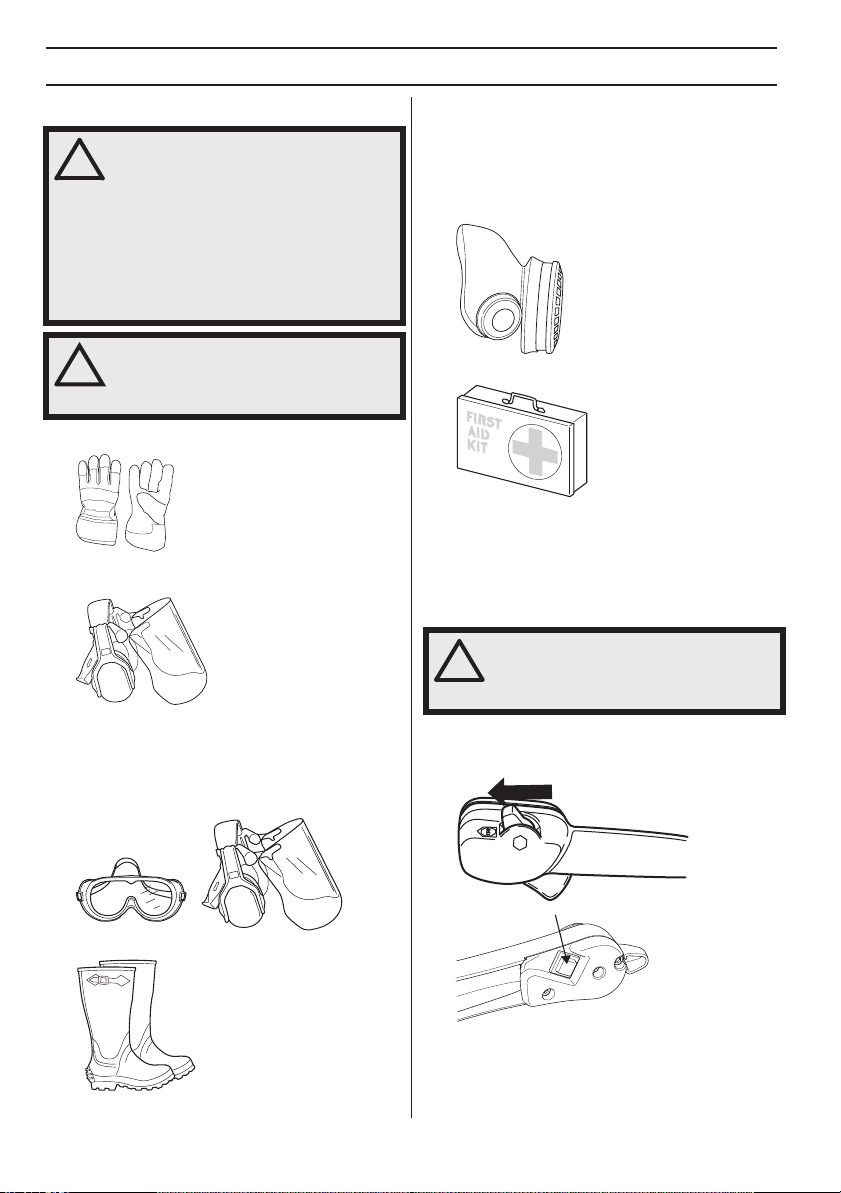

WARNING! You must use approved

personal protective equipment whenever

!

you use the machine. Personal protective

equipment cannot eliminate the risk of

injury but it will reduce the degree of

injury if an accident does happen. Ask

your dealer for help in choosing the right

equipment. Please read the operator’s

manual carefully and make sure you

understand the instructions before using

the machine.

WARNING! Listen out for warning signals

or shouts when you are wearing hearing

!

protection. Always remove your hearing

protection as soon as the engine stops.

• Gloves should be worn when necessary.

• Wear hearing protection that provides adequate noise

reduction.

• Always wear approved eye protection. If you use a

visor then you must also wear approved protective

goggles. Approved protective goggles must comply

with standard ANSI Z87.1 in the USA or EN 166 in EU

countries. Blows from branches or objects that are

thrown can damage the eyes.

• Wear clothes made of a strong fabric and avoid loose

clothing that can catch on twigs and branches. Always

wear heavy, long pants. Do not wear jewellery, shorts

sandals or go barefoot. Secure hair so it is above

shoulder level.

• A breathing mask should be used when there is a risk

of dust.

• Always have a first aid kit nearby.

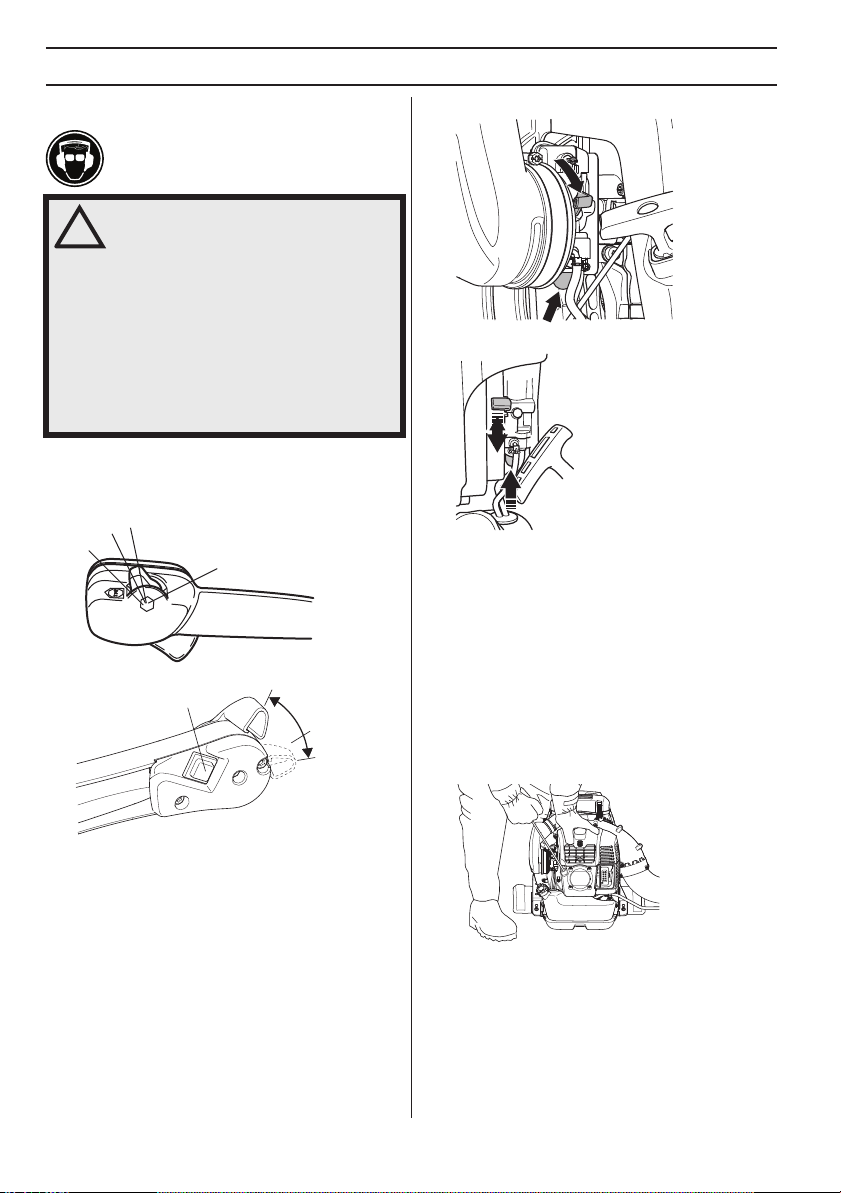

Machine′s safety equipment

This section describes the machine′s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

WARNING! Never use a machine that has

faulty safety equipment! Carry out the

inspection, maintenance and service

routines listed in this section.

Stop switch

Use the stop switch to switch off the engine.

• Wear sturdy, non-slip boots.

10 – English

Remove the ignition cable and the spark plug to carry out

inspection and maintenance.

1155849-49 Rev. 2 2013-03-22

SAFETY INSTRUCTIONS

!

!

!

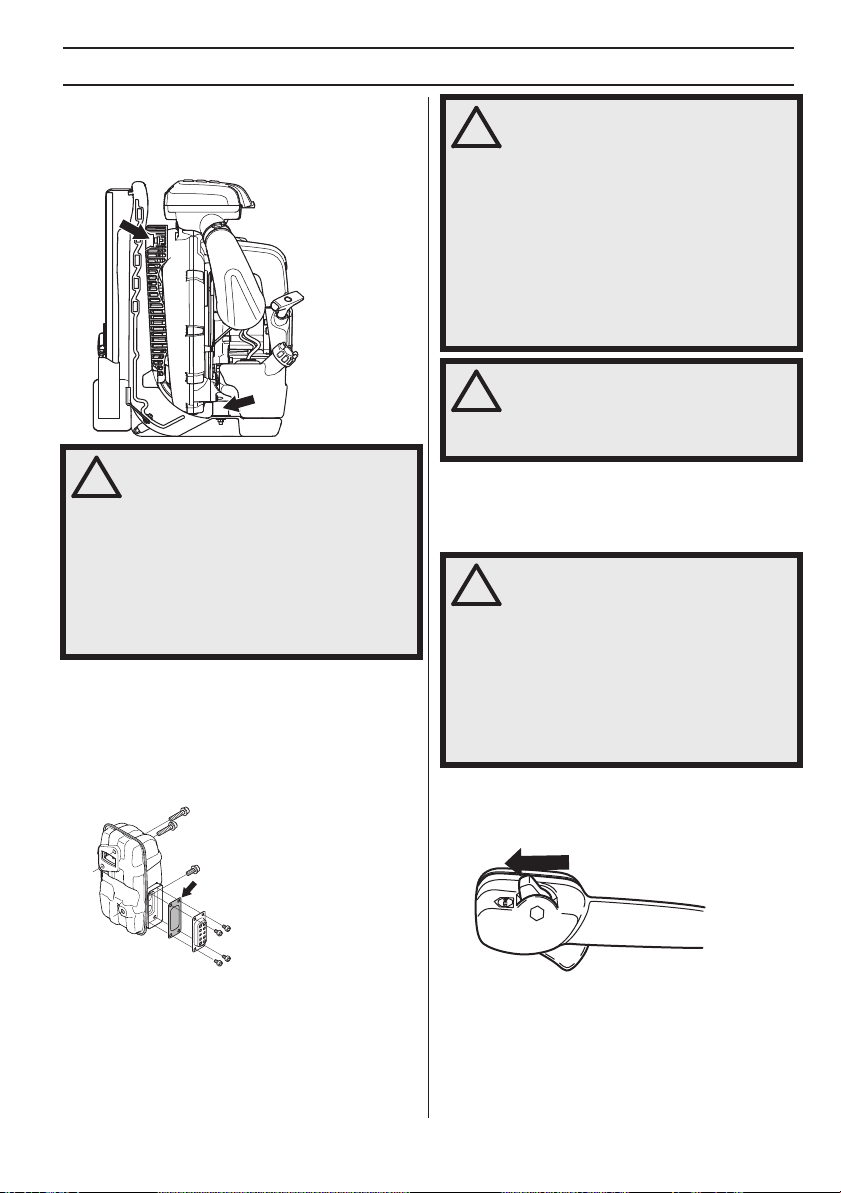

Vibration damping system

Your machine is equipped with a vibration damping

system that is designed to reduce vibration and make

operation easier.

x2

WARNING! Overexposure to vibration

can lead to circulatory damage or nerve

!

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists. The risk

increases at low temperatures.

Muffler

The muffler is designed to keep noise levels to a minimum

and to direct exhaust fumes away from the user.

In countries that have a warm and dry climate there is a

significant risk of fire. Consequently, we have equipped

the muffler with a spark arrestor screen mounted inside

the muffler.

WARNING!

Bear in mind that: Engine exhaust fumes

contain carbon monoxide, which can

cause carbon monoxide poisoning. For

this reason you should not start or run

the machine indoors, or anywhere that is

poorly ventilated.

The exhaust fumes from the engine are

hot and may contain sparks which can

start a fire. Never start the machine

indoors or near combustible material!

WARNING! The inside of the muffler

contain chemicals that may be

carcinogenic. Avoid contact with these

elements in the event of a damaged

muffler.

Checking, maintaining and

servicing the machine

′s safety

equipment

WARNING! All servicing and repair work

on the machine requires special training.

This is especially true of the machine

safety equipment. If your machine fails

any of the checks described below you

must contact your service agent. When

you buy any of our products we

guarantee the availability of professional

repairs and service. If the retailer who

sells your machine is not a servicing

dealer, ask him for the address of your

nearest service agent.

Stop switch

• Start the engine and make sure the engine stops

when you move the stop switch to the stop setting.

′s

For mufflers it is very important that you follow the

instructions on checking, maintaining and servicing your

machine. See instructions under the heading Checking,

maintaining and servicing the machine’s safety

equipment.

1155849-49 Rev. 2 2013-03-22

English – 11

SAFETY INSTRUCTIONS

!

The engine is stopped by switching the ignition off using

the stop switch.

Vibration damping system

• Check the vibration damping units regularly for cracks

or deformation. Replace them if damaged.

x2

• Check that the vibration damping element is

undamaged and securely attached.

Muffler

• Never use a machine that has a faulty muffler.

• Regularly check that the muffler is securely attached

to the machine.

• The muffler on your machine is equipped with a spark

arrestor screen; this must be cleaned regularly. See

the heading Muffler in the Maintenance chapter. A

blocked screen will cause the engine to overheat and

may lead to serious damage. Never use a muffler with

a defective spark arrestor screen.

WARNING! Never use a machine with

faulty safety equipment. The machine’s

safety equipment must be checked and

maintained as described in this section.

If your machine fails any of these checks

contact your service agent to get it

repaired.

Air filter

Never use the leaf blower without an air filter or with a

damaged or deformed filter element as unfiltered, dusty

air can quickly destroy the engine.

General working instructions

IMPORTANT! This section considers basic safety rules

when working with blowers. If you encounter a situation

where you are uncertain how to proceed you should ask

an expert. Contact your dealer or your service

workshop. Avoid all usage which you consider to be

beyond your capability.

Show consideration to persons in your surroundings by

avoiding using the machine at unsuitable times, such as

late in the evening or early in the morning. To reduce

sound levels, limit the number of pieces of equipment

used at any one time. Read through and follow the simple

directions so that you disturb your surroundings as little as

possible.

• Use the blower with the lowest possible throttle. It is

seldom necessary to use full throttle, and many work

procedures can be done at half throttle. A lower

throttle means less noise and less dust, and it is also

easier to keep control over the rubbish collected

together/moved.

• Use a rake or a brush to release rubbish stuck to the

ground.

12 – English

1155849-49 Rev. 2 2013-03-22

SAFETY INSTRUCTIONS

• Hold the opening of the blower as close to the ground

as possible. Utilise the entire length of the blow pipe

to keep the air current close to the ground.

• Clean up afterwards. Make sure that you have not

blown rubbish into someone’s garden.

• Operate power equipment only at reasonable hours,

not early in the morning or late at night when people

might be disturbed. Comply with times listed in local

ordinances.

WARNING! Be aware of your

surroundings. If anyone approaches your

!

work area, set the throttle control to the

lowest throttle until the person is at a

safe distance. Direct the blower away

from people, animals, play areas, open

windows and cars etc.

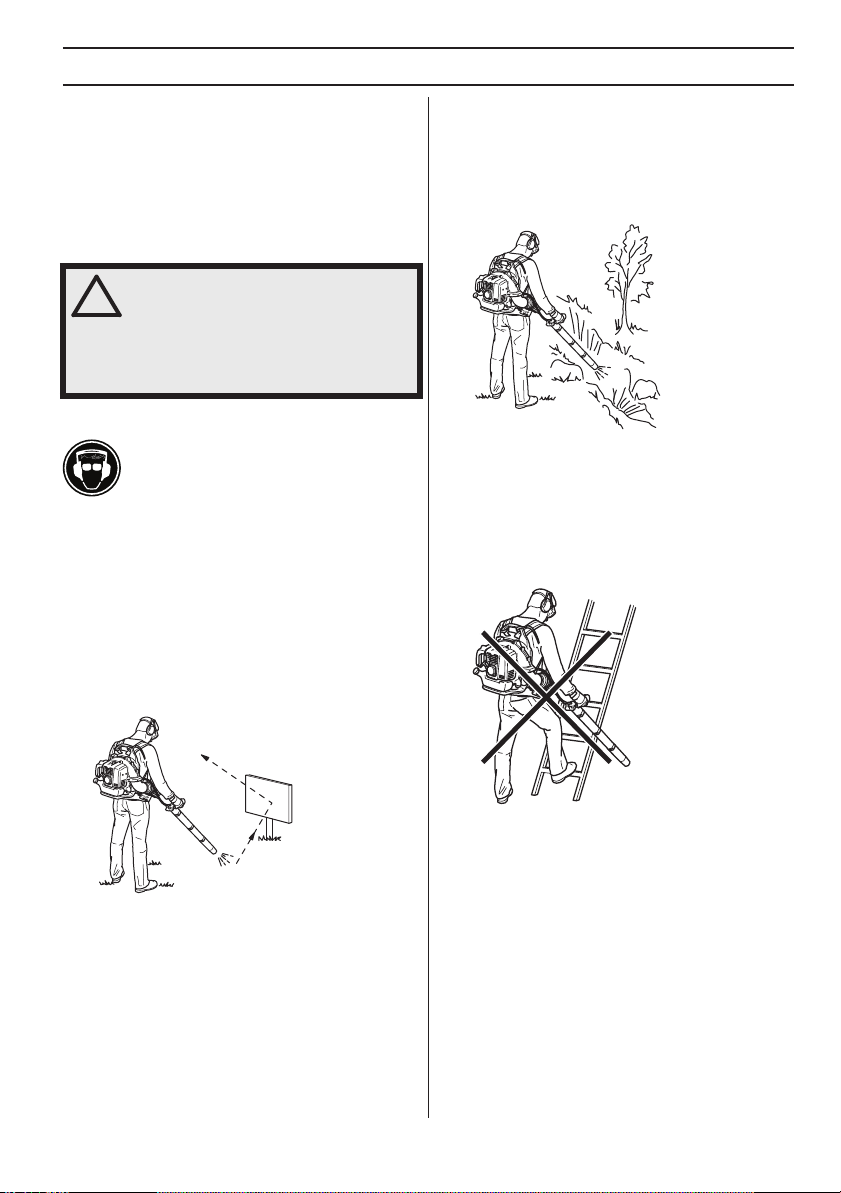

Basic safety rules

• No unauthorised persons or animals may be present

in the working area, which is 15 metres.

• Allow the engine to cool before refuelling.

• Keep all parts of your body away from hot surfaces.

• If the machine catches fire or other emergency occurs

which forces you to release yourself from the

machine, open the harness straps and let the

machine fall backwards.

• The powerful currents of air can move objects at such

a speed that they can bounce back and cause serious

eye injuries.

including areas such as gutters, screens, patios, grills,

porches and gardens.

• Make sure you can move and stand safely. Check the

area around you for possible obstacles (roots, rocks,

branches, ditches, etc.) in case you have to move

suddenly. Take great care when working on sloping

ground.

• Never put the machine down with the engine running

unless you have it in clear sight.

• Engine exhaust fumes contain carbon monoxide,

which can cause carbon monoxide poisoning. For this

reason you should not start or run the machine

indoors, or anywhere that is poorly ventilated.

• The blower must not be used while on a ladder or

scaffolding.

• Do not direct the air jet towards people or animals.

• Stop the engine before assembling or dismantling

accessories or other parts.

• Do not use the machine in bad weather, such as

dense fog, heavy rain, strong wind, intense cold, etc.

Working in bad weather is tiring and can lead to

dangerous conditions, e.g. slippery surfaces.

• Minimise the blowing time by lightly wetting dusty

areas or using spray equipment.

• Conserve water by using power blowers instead of

hoses for many lawn and garden applications,

1155849-49 Rev. 2 2013-03-22

• CAUTION! Do not use the machine unless you are

able to call for help in the event of an accident.

English – 13

SAFETY INSTRUCTIONS

Basic working techniques

WARNING! Watch out for thrown objects.

Always wear eye protection. Stones,

!

rubbish, etc. can be thrown up into the

eyes causing blindness or serious injury.

Keep unauthorised persons at a

distance. Children, animals, onlookers

and helpers should be kept outside the

safety zone of 15 m. Stop the machine

immediately if anyone approaches.

WARNING! Always stop the engine

before cleaning.

!

• This blower is a backpack type, and is carried using a

shoulder harness while operating. It is operated and

controlled with the handle on the tube using the right

hand.

• The speed of the air jet is regulated by means of the

throttle. Select the speed best suited for respective

tasks.

You can set the throttle position using the ”stop switch”

and by doing so not need to hold your finger on the throttle

all the time you are using the blower. Full throttle is

obtained when the control is held back fully.

• Be aware of the wind direction. Work with the wind to

make your work easier.

• Using the blower to move large piles is time

consuming and creates unnecessary noise.

• Keep a good balance and a firm foothold.

• When work is finished the machine should be stored

vertically.

• Check that the air intake is not blocked, for example,

by leaves or rubbish. A clogged air intake reduces the

machine’s blowing capacity and increases the

engine’s working temperature, which can result in

engine failure. Stop the engine and remove the object.

14 – English

1155849-49 Rev. 2 2013-03-22

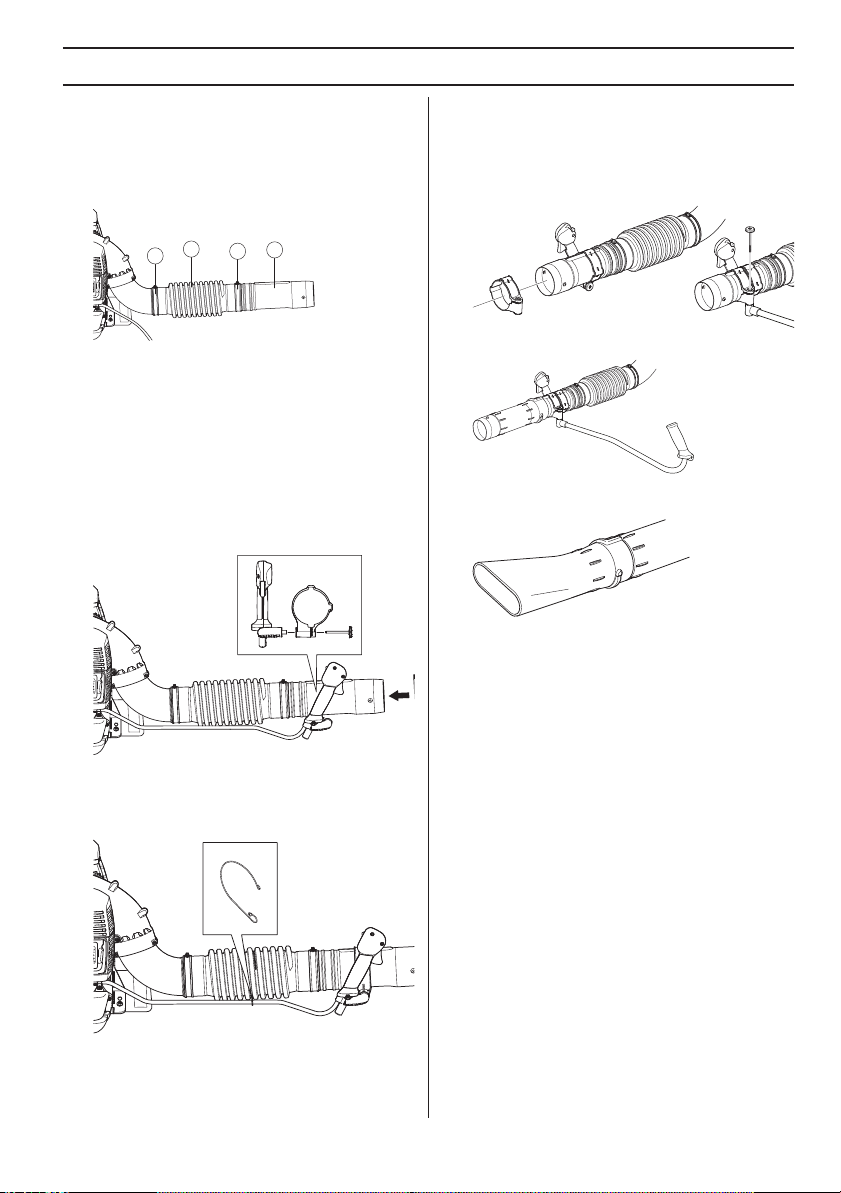

ASSEMBLY

Assembling the blow pipe and control handle

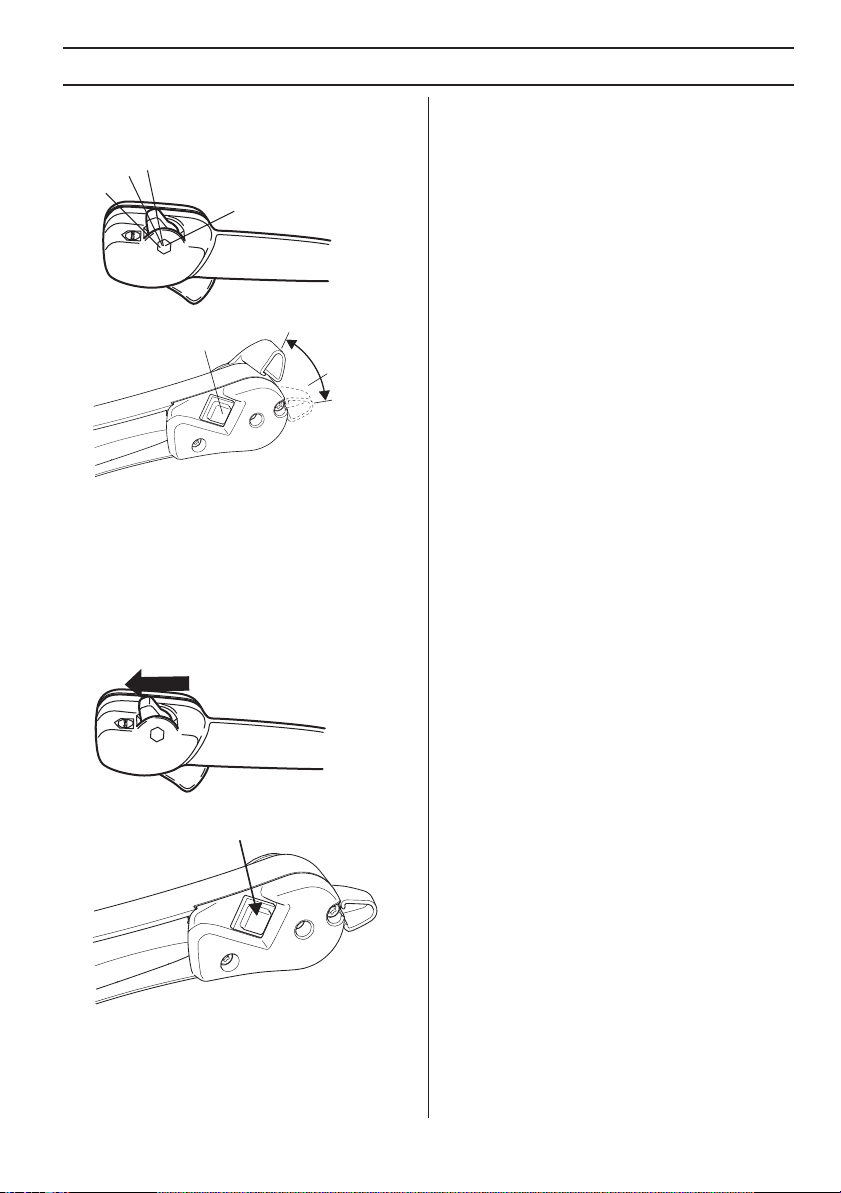

• Connect the blower and control pipe with the flexible

hose. Clamp both ends of the flexible hose in place.

Use the accompanying hardware.

Accessories

Handlebar

Disassemble the intermediate pipe. Disassemble the

knob from the holder and puch the holder on to the holder

pipe. Assemble the knob and tighten.

1

3

1 Flexible hose

2 Control pipe

3 Clamp

4 Clamp

NOTE!

Lubricate the pipes a little to facilitate assembly.

• Fasten the handle holder to the control pipe and

tighten the knob on the holder. Please make sure to

align the handle holder with the convex of the control

pipe.

• Adjust the position and angle to achieve a comfortable

working position, and tighten.

• Use the clamp to fasten the cabling to the flexible

hose. (BTS)

2

4

Assemble the intermediate pipe.

• If higher air speed is required, the round blow pipe is

replaced by the flat nozzle.

• Connect the straight pipe and pipe end. Push the

pipes together and turn them so they lock.

1155849-49 Rev. 2 2013-03-22

English – 15

FUEL HANDLING

Fuel

CAUTION! The machine is equipped with a two-stroke

engine and must always been run using a mixture of

gasoline and two-stroke engine oil. It is important to

accurately measure the amount of oil to be mixed to

ensure that the correct mixture is obtained. When mixing

small amounts of fuel, even small inaccuracies can

drastically affect the ratio of the mixture.

WARNING! Always ensure there is

adequate ventilation when handling fuel.

!

Gasoline

CAUTION! Always use high grade oil mixed gasoline

(minimum 87 RON).

• This engine is certified to operate on unleaded

gasoline.

• The lowest recommended octane rating is 87. If you

run the engine on lower octane rating than 87 socalled “knocking“ can occur. This leads to an

increased engine temperature, which can result in a

serious engine breakdown.

• When working at continuous high revs a higher octane

rating is recommended. Use good quality unleaded

gasoline.

Two-stroke oil

• For best results and performance use HUSQVARNA

two-stroke oil, which is specially formulated for our

two-stroke engines. Mixture 1:50 (2%).

• If HUSQVARNA two-stroke oil is not available, you

may use another two-stroke oil of good quality that is

intended for air cooled engines. Contact your dealer

when selecting an oil.

• Never use two-stroke oil intended for water-cooled

outboard engines, sometimes referred to as outboard

oil.

• Never use oil intended for four-stroke engines.

Gasoline, litre Two-stroke oil, litre

2% (1:50)

5 0,10

10 0,43/0,20

15 0,6/0,30

20 0,40

US gallon US fl. oz.

1 2 1/2

2 1/2 6 1/2

5 12 7/8

Mixing

• Always mix the gasoline and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the gasoline

to be used. Then add the entire amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount of

gasoline.

• Mix (shake) the fuel mixture thoroughly before filling

the machine’s fuel tank.

• Do not mix more than one month’s supply of fuel at a

time.

• If the machine is not used for some time the fuel tank

should be emptied and cleaned.

• This engine is certified to operate on unleaded

gasoline.

16 – English

1155849-49 Rev. 2 2013-03-22

Fueling

!

FUEL HANDLING

WARNING! Taking the following

precautions, will lessen the risk of fire:

Refuel in a well ventilated area. Never

fuel the machine indoors.

Do not smoke or place hot objects near

fuel.

Always shut off the engine before

refuelling.

Always stop the engine and let it cool for

a few minutes before refuelling.

When refuelling, open the fuel cap slowly

so that any excess pressure is released

gently.

Tighten the fuel cap carefully after

refuelling.

If you have spilled fuel on it. Wipe off the

spillage and allow remaining fuel to

evaporate.

Always move the machine away from the

refuelling area and source before

starting.

• Move the machine at least 10 ft (3 m) from the

refuelling point before starting it.

• Clean the area around the fuel cap. Contamination in

the tank can cause operating problems.

• Ensure that the fuel is well mixed by shaking the

container before filling the tank.

• Check the fuel level before each use and leave space

for the fuel to expand, because the heat from the

engine and the sun may otherwise cause the fuel to

expand and overflow.

1155849-49 Rev. 2 2013-03-22

English – 17

STARTING AND STOPPING

Starting and stopping

WARNING! Always move the machine

away from the refuelling area and source

!

before starting. Place the machine on a

flat surface.

Make sure no unauthorised persons are

in the working area, otherwise there is a

risk of serious personal injury. The safety

distance is 15 metres.

The machine may only be started in its

complete design. If the machine is

started without all the guards fitted there

is a risk of personal injuries.

Cold engine

Ignition: Set the stop switch to the start position. About

one third open.

(2)

(3)

(4)

(1)

1

4

2

3

570, 580 - BTS, BFS

560BTS, BFS

Primer bulb: Press the air purge repeatedly until fuel

begins to fill the bulb. The bulb need not be completely

filled.

Warm engine

Use the same starting procedure as for a cold engine but

without setting the choke control in the choke position.

Starting

Hold the body of the machine on the ground using your

left hand (CAUTION! Not with your foot!). Grip the starter

handle, slowly pull out the cord with your right hand until

you feel some resistance (the starter pawls grip), now

quickly and powerfully pull the cord.

It is not allowed to set the stop switch in full throttle

position.

Choke: Set the choke control in the choke position.

18 – English

Never wrap the starter cord around your hand

Repeat pulling the cord until the engine starts. When the

engine starts, return choke control to run position.

CAUTION! Do not pull the star ter cord all the way out and

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

NOTE!

1155849-49 Rev. 2 2013-03-22

STARTING AND STOPPING

Air is released as soon as the engine is started, even

when idling.

Set the required engine speed with the throttle control.

(2)

(3)

(4)

Allow the engine to warm for a few minutes.

1 Full throttle

2 About one third open.

3 Idle speed

4 Stop switch

Stopping

The engine is stopped by moving the stop switch to the

stop position.

(1)

1

4

2

3

The engine is stopped by switching the ignition off using

the stop switch.

1155849-49 Rev. 2 2013-03-22

English – 19

MAINTENANCE

!

General

Remove the ignition cable and the spark plug to carry out

inspection and maintenance. Keep all parts of your body

away from hot surfaces.

Carburetor

Adjustment of the idle speed

Before any adjustments are made, make sure that the air

filter is clean and the air filter cover is fitted.

The factory idle speed setting is 2,000 rpm. Use the

adjustment screw at the upper edge of the carburettor if

the idle speed has to be adjusted.

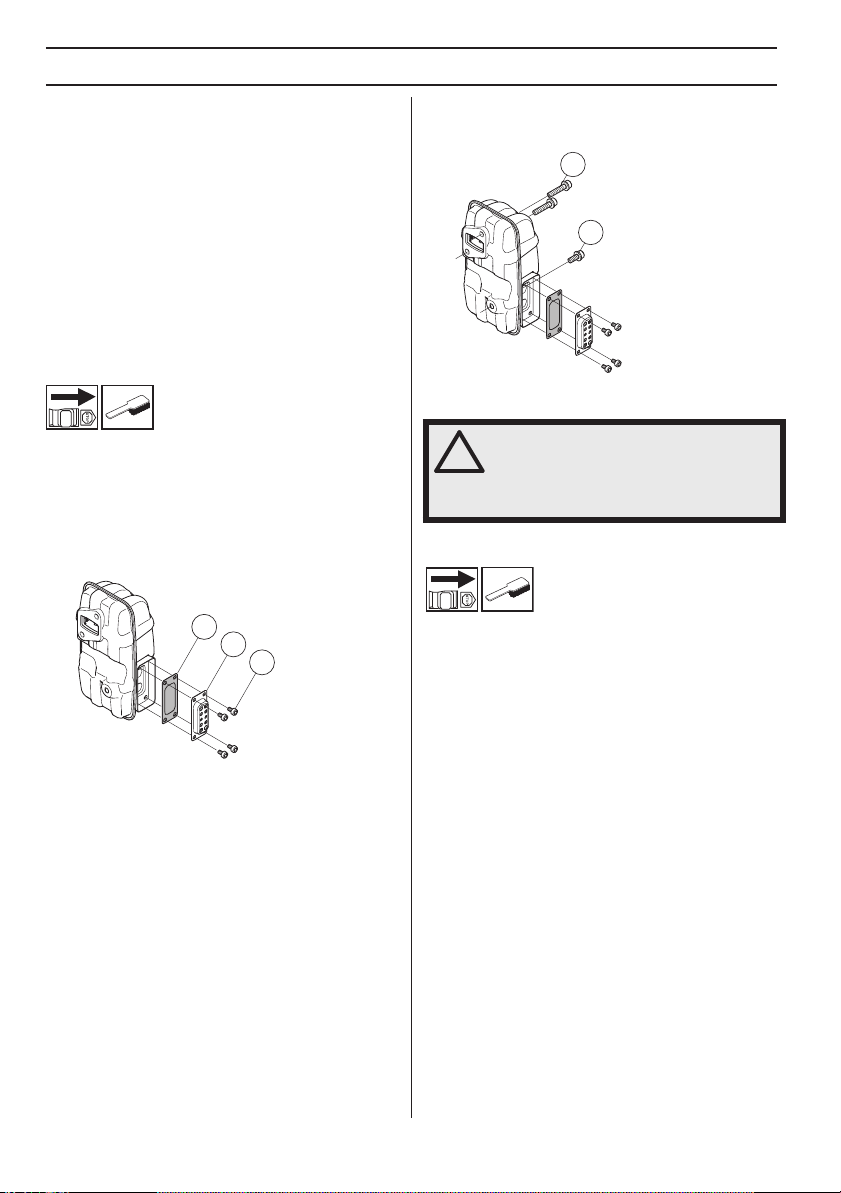

Muffler

CAUTION! Never use a machine with a defective muffler.

Check regularly that the muffler is complete and secured

correctly. (1,2) Tighten the screws. 8-10Nm

1

2

Check that the spark arrester and the exhaust duct are

screwed in place correctly (5). Tighten to 2-3 Nm.

The muffler is designed to reduce the noise level and to

direct the exhaust gases away from the operator. The

exhaust gases are hot and can contain sparks, which may

cause fire if directed against dry and combustible

material.

The muffler is equipped with a special spark arrestor

screen. The spark arrestor screen should be cleaned

once a month. This is best done with a wire brush.

3

4

5

To remove the spark arrestor screen proceed as follows:

• Remove the exhaust duct (4).

• Remove the spark arrester (3).

• Pull out the spark arrestor screen and clean using a

wire brush. Replace the spark arrestor screen if it is

defective.

WARNING! The muffler gets very hot

during use and remain so for some time

after stopping. This also applies at idle

speed. Contact can result in burns to the

skin. Remember the risk of fire!

Cooling system

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

The cooling system consists of:

• Cooling fins on the cylinder.

• Air intake screen

Clean the cooling system with a brush once a week, more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

damage to the piston and cylinder. Check that the nozzles

are not blocked.

20 – English

1155849-49 Rev. 2 2013-03-22

MAINTENANCE

Air intake screen

Check that the air intake is not blocked on all sides

including the underside, for example, by leaves or

rubbish. A clogged air intake reduces the machine’s

blowing capacity and increases the engine’s working

temperature, which can result in engine failure. Stop the

engine and remove the object.

WARNING! Never use the blower if the

screen is not in place. Before use, check

!

that the screen is in place and

undamaged.

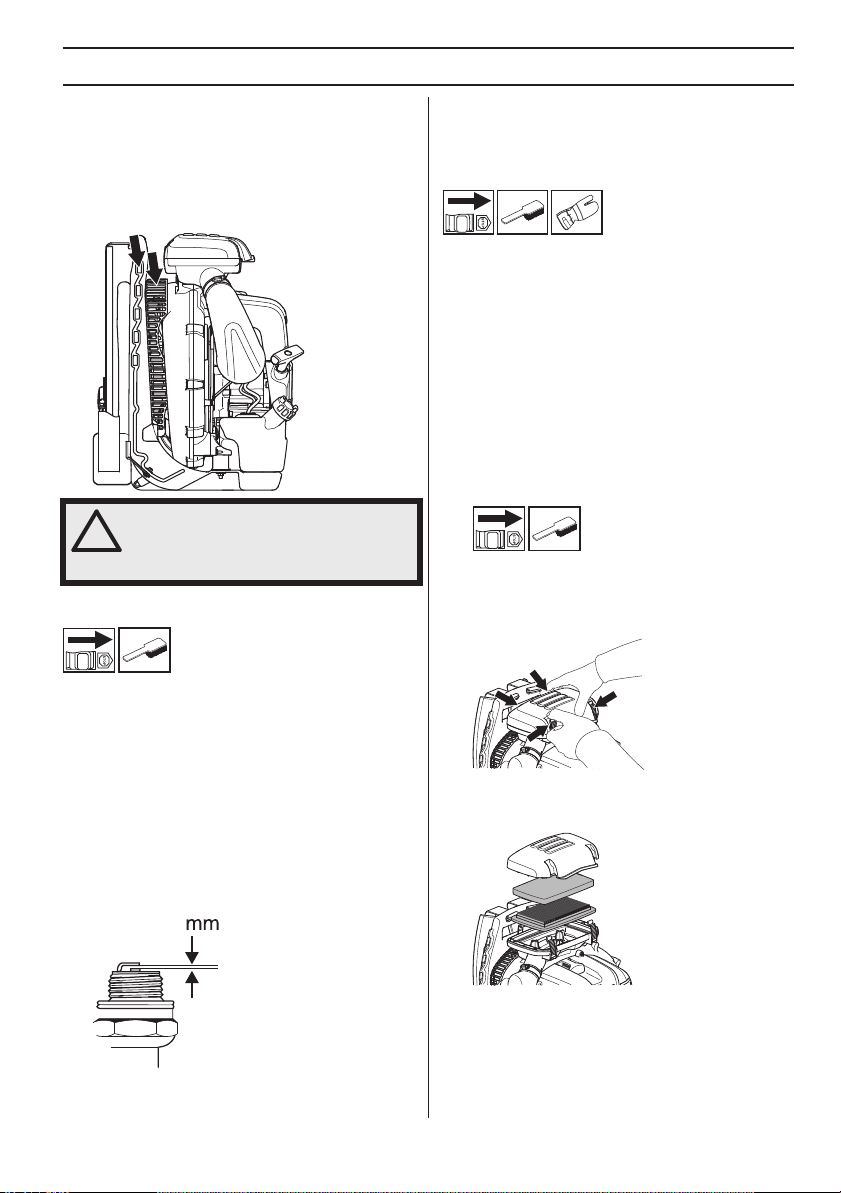

Spark plug

CAUTION! Always use the recommended spark plug

type! Use of the wrong spark plug can damage the piston/

cylinder.

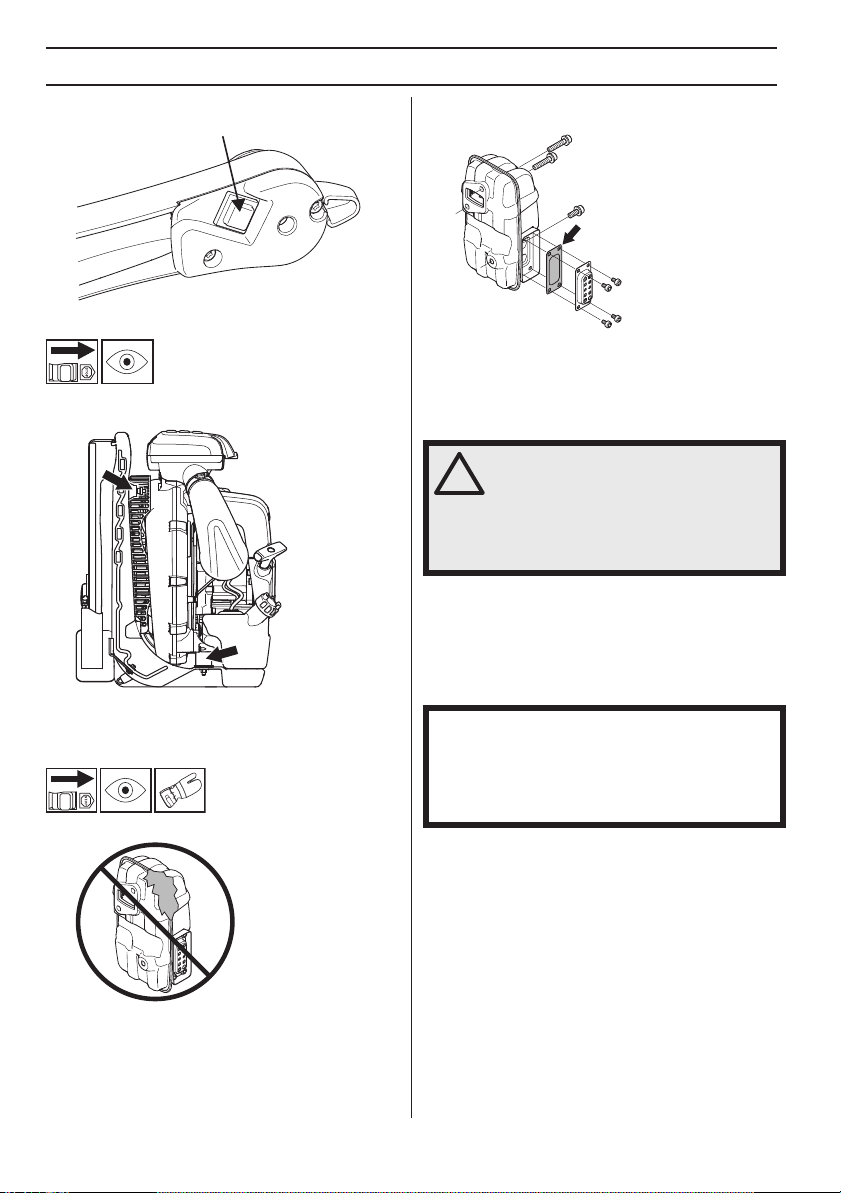

Air filter

The air filter must be regularly cleaned to remove dust

and dirt in order to avoid:

• Carburettor malfunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts

• Excessive fuel consumption.

Clean the filter every 40 hours, or more regularly if

conditions are exceptionally dusty.

Avoid contact with hot surfaces on muffler, cylinder etc.

Contact can result in burns to the skin.

Cleaning the air filter

570, 580 - BTS, BFS

• Loosen the four fasteners holding the air filter cover

and remove the filter. Wash the prefilter in warm soapy

water.

The spark plug condition is influenced by:

• Incorrect carburetor adjustment.

• An incorrect fuel mixture (too much or incorrect type

of oil).

• A dirty air filter.

These factors cause deposits on the spark plug

electrodes, which may result in operating problems and

starting difficulties.

Clean the outside of the spark plug. Remove it and check

the electrode gap. Adjust the gap to 0,6-0,7 mm, or

replace the spark plug. Check that the spark plug is fitted

with a suppressor.

0,6-0,7

1155849-49 Rev. 2 2013-03-22

• Tap the paper filter against a hard surface to shake off

the dust. If the paper filter is still dirty it should be

replaced with a new one.

NOTE!

Do not oil the filter.

English – 21

MAINTENANCE

!

560BTS, BFS

Remove the air filter cover and take out the filter. Wash it

clean in warm, soapy water.

If the machine is used in dusty conditions the air filter

should be soaked in oil. See instructions under the

heading Oiling the air filter.

An air filter that has been in use for a long time cannot be

cleaned completely. The filter must therefore be replaced

with a new one at regular intervals.

must always be replaced.

• Refit the air filter and air filter cover.

Oiling the air filter

560BTS, BFS

Always use special filter oil. Filter oil contains a solvent to

make it spread evenly through the filter. You should

therefore avoid skin contact.

Put the filter in a plastic bag and pour the filter oil over it.

Knead the plastic bag to distribute the oil. Squeeze the

excess oil out of the filter inside the plastic bag and pour

off the excess before fitting the filter to the machine. Never

use common engine oil. This would drain through the filter

quite quickly and collect in the bottom.

A damaged air filter

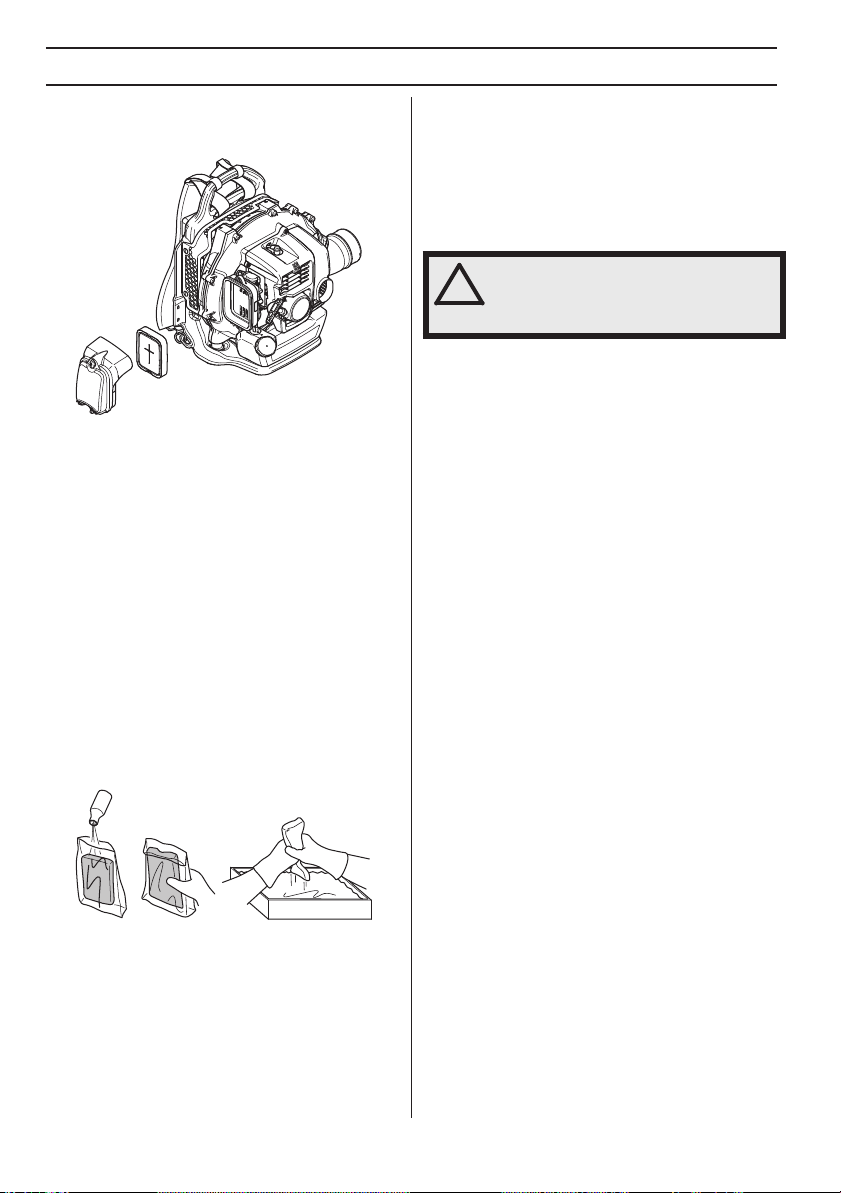

Shoulder strap

If the shoulder strap is damaged, it may break while in use

and the machine may fall causing personal injury. Follow

the instructions below to replace the shoulder strap.

1 Remove the clamp from the strap.

2 Run the end of the strap through the hanger.

3 Refit the clamp to the strap.

WARNING! Check that the thick round

pin in the clamp is inserted in the strap. If

it is inserted incorrectly it may lead to

personal injury.

22 – English

1155849-49 Rev. 2 2013-03-22

MAINTENANCE

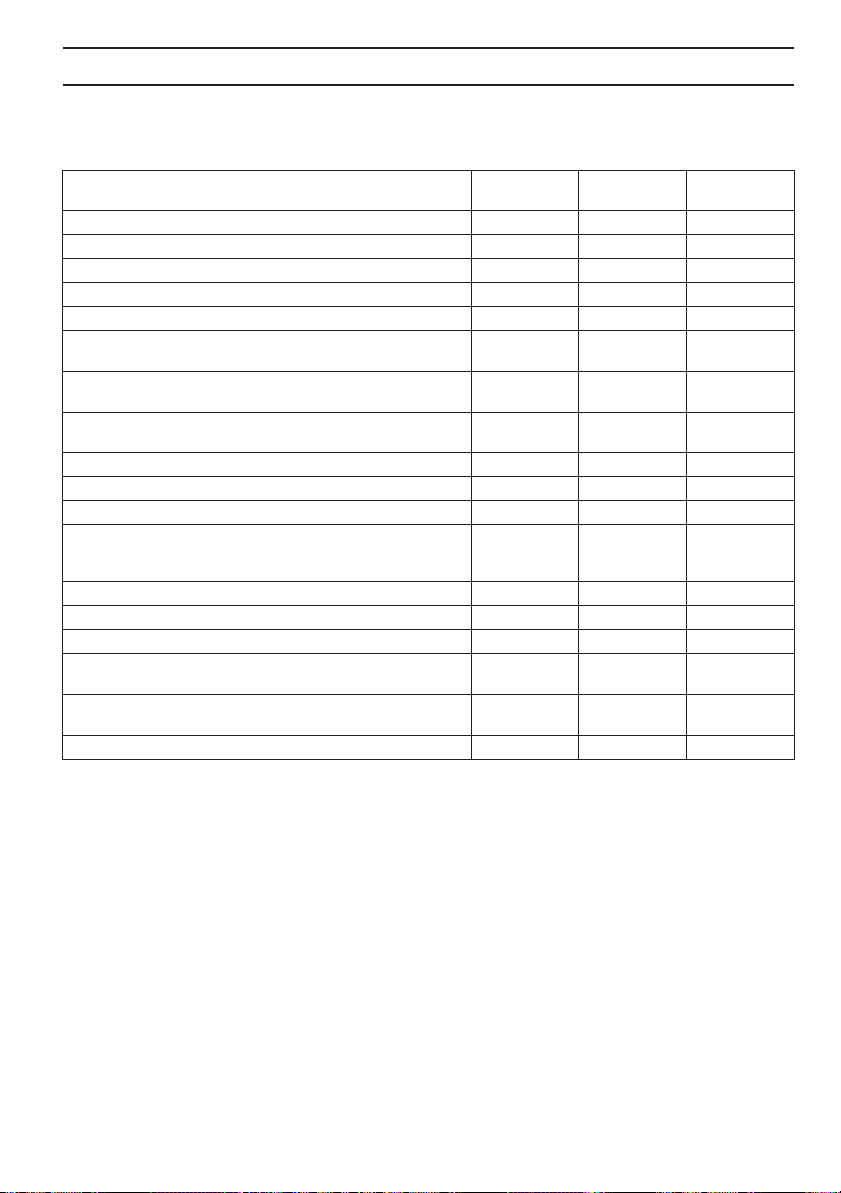

Maintenance schedule

Below you will find some general maintenance instructions. If you need further information please contact your service

workshop.

Maintenance

Clean the outside of the machine. X

Check that the throttle control functions safely. X

Check that the stop switch works correctly. X

Clean the air filter. Replace if necessary. X

Check that nuts and screws are tight. X

Check that there are no fuel leaks from the engine, tank or fuel

lines.

Check the fuel filter from contamination and the fuel hose from

cracks or other defects. Replace if necessary.

Clean or replace the spark arrestor screen on the muffler (only

applies to mufflers without a catalytic converter).

Check that all sides of the air intake screen are not blocked. X

Check the starter and starter cord. X

Check that the vibration damping elements are not damaged. X

Clean the outside of the spark plug. Remove it and check the

electrode gap. Adjust the gap to 0,6-0,7 mm, or replace the spark

plug. Check that the spark plug is fitted with a suppressor.

Clean the machine’s cooling system. X

Clean the outside of the carburettor and the space around it. X

Check all cables and connections. X

Replace the spark plug. Check that the spark plug is fitted with a

suppressor.

Check and clean the spark arrestor screen on the muffler (only

applies to mufflers fitted with a catalytic converter).

Clean the fuel tank. X

IMPORTANT!

Use only HUSQVARNA replacement parts. Use of other brands of replacement parts can cause damage to your unit or

injury to the operator or others. Your warranty does not cover damage or liability caused by the use of accessories and/

or attachments not specifically recommended by HUSQVARNA.

Daily

maintenance

X

X

X

Weekly

maintenance

X

Monthly

maintenance

X

X

1155849-49 Rev. 2 2013-03-22

English – 23

TECHNICAL DATA

Technical data

Technical data 560BTS 560BFS

Motor

Cylinder displacement, cu.in/cm

Idle speed, rpm 2000 2000

Max. engine output, acc. to ISO 8893, kW/ rpm 2.84 / 8100 2.84 / 8100

Catalytic converter muffler No No

Speed-regulated ignition system Ye s Ye s

Emissions Durability Period according to California Air

Resources Board, h.

Ignition system

Spark plug NGK CMR7H NGK CMR7H

Electrode gap, inch/mm 0,024-0,028/0,6-0,7 0,024-0,028/0,6-0,7

Fuel and lubrication system

Fuel tank capacity, US pint/litre 4.6 / 2.2 4.6 / 2.2

Weight

Weight without fuel, Lbs/kg 23.2 / 10,5 23,4/10,6

Sound levels

(see note 1)

Equivalent sound pressure level at the operator’s ear, measured

according to EN15503 dB(A)

Vibration levels

(see note 2)

Equivalent vibration levels (a

according to EN15503, m/s

Fan performance

Max. air velocity vith standard nozzle, m/s / mph: 103.9 / 232 103.9 / 232

Air flow with standard nozzle, m3/min/cfm 17.9 / 632 17.9 / 632

Average air volume at the cover, m3/min / cfm

Note 1: The equivalent sound pressure level value is calculated with a work cycle of a duration of 1/7 for idling and 6/7

for racing. Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion

(standard deviation) of 1 dB(A).

Note 2: The equivalent vibration level value is calculated with a work cycle of a duration of 1/7 for idling and 6/7 for racing.

Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s

3

) at handles, measured

hv,eq

2

4.0 / 65.6 4.0 / 65.6

300 300

95 95

2.3 2.5

2

.

24 – English

1155849-49 Rev. 2 2013-03-22

TECHNICAL DATA

Technical data 570BTS 570BFS 580BTS 580BFS

Motor

Cylinder displacement, cu.in/cm

Idle speed, rpm 2000 2000 2000 2000

Max. engine output, acc. to ISO 8893, kW/ rpm 2.94 / 8000 2.94 / 8000 3.13 / 7200 3.13 / 7200

Catalytic converter muffler No No No No

Speed-regulated ignition system Ye s Ye s Ye s Ye s

Emissions Durability Period according to California Air

Resources Board, h.

Ignition system

Spark plug

Electrode gap, inch/mm

Fuel and lubrication system

Fuel tank capacity, US pint/litre 4,6/2,2 4,6/2,2 5,5/2,6 5,5/2,6

Weight

Weight without fuel, Lbs/kg 24,5/11,1 24,9/11,3 25,8/11,7 26,0/11,8

Sound levels

(see note 1)

Equivalent sound pressure level at the operator’s ear, measured

according to EN15503 dB(A)

Vibration levels

(see note 2)

Equivalent vibration levels (a

according to EN15503, m/s

Fan performance

Max. air velocity vith standard nozzle, m/s / mph: 106/236 106/236 92/206 92/206

Air flow with standard nozzle, m3/min/cfm 21,8/770 21,8/770 25,7/908 25,7/908

Average air volume at the cover, m3/min / cfm 27,5/972 27,5/972 29/1024 29/1024

Note 1: The equivalent sound pressure level value is calculated with a work cycle of a duration of 1/7 for idling and 6/7

for racing. Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion

(standard deviation) of 1 dB(A).

Note 2: The equivalent vibration level value is calculated with a work cycle of a duration of 1/7 for idling and 6/7 for racing.

Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s

3

) at handles, measured

hv,eq

2

65.6 65.6 75.6 75.6

300 300 300 300

NGK

CMR7H

0,024-0,028/

0,6-0,7

NGK

CMR7H

0,024-0,028/

0,6-0,7

NGK

CMR7H

0,024-0,028/

0,6-0,7

NGK

CMR7H

0,024-0,028/

0,6-0,7

99 99 100 100

1,8 5,0 1,6 3,3

2

.

1155849-49 Rev. 2 2013-03-22

English – 25

FEDERAL AND CALIFORNIA EMISSIONS CONTROL WARRANTY STATEMENT

IMPORTANT: This product is compliant with U.S. EPA

Phase 3 regulations for exhaust and evaporative

emissions. To ensure EPA Phase 3 compliance, we

recommend using only genuine Husqvarna brand

replacement parts. Use of non-compliant replacement

parts is a violation of federal law.

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The EPA (U.S. Environmental Protection Agency), CARB

(California Air Resources Board), Environment Canada

and Husqvarna Forest & Garden are pleased to explain

the emissions control system’s warranty on your 20132014* small off-road engine. In U.S. and Canada, new

equipment that use small off-road engines must be

designed, built, and equipped to meet the applicable

Federal or Californian stringent anti-smog standards.

Husqvarna Forest & Garden must warrant the emissions

control system on your small off-road engine for the

period listed below provided there has been no abuse,

neglect or improper maintenance of your equipment. Your

emissions control system may include parts such as the

carburetor, ignition system, catalytic converter, fuel tank,

filters and other associated components. Also, included

may be hoses, belts, connectors, sensors, and other

emission-related assemblies. Where a warrantable

condition exists, Husqvarna Forest & Garden will repair

your small off-road engine at no cost to you including

diagnosis, parts and labor.

MANUFACTURER′S WARRANTY

COVERAGE

The emissions control system is warranted for two years.

If any emissions-related part on your equipment is

defective, the part will be repaired or replaced by

Husqvarna Forest & Garden.

OWNER′S WARRANTY

RESPONSIBILITIES

• As the small off-road engine owner, you are

responsible for performance of the required

maintenance listed in your operator’s manual.

Husqvarna Forest & Garden recommends that you

retain all receipts covering maintenance on your small

off-road engine, but Husqvarna Forest & Garden

cannot deny warranty solely for the lack of receipts or

your failure to ensure the performance of all

scheduled maintenance.

• As the small off-road engine owner, you should

however be aware that Husqvarna Forest & Garden

may deny you warranty coverage if your small off-road

engine or a part has failed due to abuse, neglect, or

improper maintenance or unapproved modifications.

• You are responsible for presenting your small off-road

engine to a Husqvarna Forest & Garden distribution

center or service center as soon as the problem

exists. The warranty repairs should be completed in a

reasonable amount of time, not to exceed 30 days. If

you have any questions regarding your warranty

coverage, you should contact Husqvarna Forest &

Garden at 1-800-438-7297 or send e-mail

correspondence to emission.warranty@us.hvwan.net

WARRANTY COMMENCEMENT DATE

The warranty period begins on the date the engine or

equipment is delivered to an ultimate purchaser.

LENGTH OF COVERAGE

Husqvarna Forest & Garden warrants to the ultimate

purchaser and each subsequent owner that the engine or

equipment is designed, built, and equipped so as to

conform with all applicable regulations adopted by EPA

and CARB, and is free from defects in materials and

workmanship that causes the failure of a warranted part

for a period of two years.

WHAT IS COVERED

REPAIR OR REPLACEMENT OF PARTS Repair or

replacement of any warranted part under the warranty

must be performed at no charge to the owner at a

warranty station. Warranty services or repairs will be

provided at all Husqvarna Forest & Garden distribution

centers that are franchised to service the subject engines.

Throughout the emissions warranty period of two years,

Husqvarna Forest & Garden must maintain a supply of

warranted parts sufficient to meet the expected demand

for such parts.

WARRANTY PERIOD Any warranted part that is

scheduled for replacement as required in the

maintenance schedule, is warranted for the period of time

prior to the first scheduled replacement point for that part.

If the part fails prior to the first scheduled replacement,

the part will be repaired or replaced by Husqvarna Forest

& Garden at no cost. Any such part repaired or replaced

under warranty is warranted for the remainder of the

period prior to the first scheduled replacement point for

the part. Any warranted part that is not scheduled for

replacement as required in the maintenance schedule, is

warranted for two years. If any such part fails during the

period of warranty coverage, it will be repaired and

replaced by Husqvarna Forest & Garden at no cost. Any

such part repaired or replaced under the warranty is

warranted for the remaining warranty period. Any

warranted part that is scheduled only for regular

inspection in the maintenance schedule will be warranted

for a period of two years. A statement in such written

instructions to the effect of ”repair or replace as

necessary” will not reduce the period of warranty

coverage. Any such part repaired or replaced under

warranty will be warranted for the remaining warranty

period.

DIAGNOSIS The owner must not be charged for

diagnostic labor that leads to the determination that a

warranted part is in fact defective, provided that such

diagnostic work is performed at a warranty station.

26 – English

1155849-49 Rev. 2 2013-03-22

FEDERAL AND CALIFORNIA EMISSIONS CONTROL WARRANTY STATEMENT

CONSEQUENTIAL DAMAGES Husqvarna Forest &

Garden is liable for damages to other engine components

proximately caused by a failure under warranty of any

warranted part.

EMISSION WARRANTY PARTS LIST

1 Carburetor and internal parts

2 Intake pipe, airfilter holder and carburetor bolts.

3 Airfilter and fuelfilter covered up to maintenance

schedule.

4 Spark Plug, covered up to maintenance schedule

5 Ignition Module

6 Fuel tank, line and cap

WHAT IS NOT COVERED

All failures caused by abuse, neglect or improper

maintenance are not covered.

ADD -ON OR MODIFIED PARTS

Add-on or modified parts that are not exempted by CARB

or EPA may not be used. The use of any non-exempted

add-on or modified parts will be grounds for disallowing a

warranty claim. Husqvarna Forest & Garden will not be

liable to warrant failures of warranted parts caused by the

use of a non-exempted add-on or modified part.

HOW TO FILE A CLAIM

If you have any questions regarding your warranty rights

and responsibilities, you should contact your nearest

authorized servicing dealer or call Husqvarna Forest &

Garden at 1-800-438-7297 or send e-mail

correspondence to emission.warranty@us.hvwan.net

WHERE TO GET WARRANTY SERVICE

Warranty services or repairs are provided through all

Husqvarna Forest & Garden authorized servicing dealers.

MAINTENANCE, REPLACEMENT AND REPAIR OF EMISSION-RELATED PARTS

Any replacement part may be used in the performance of

any warranty maintenance or repairs and must be

provided without charge to the owner. Such use will not

reduce the warranty obligations of the manufacturer.

MAINTENANCE STATEMENT

The owner is responsible for the performance of all

required maintenance, as defined in the operator’s

manual.

*Current and following model year will be updated

annually in the warranty statement provided to the

consumer. For example, in 2013 model year, 2013-2014

will be specified.

1155849-49 Rev. 2 2013-03-22

English – 27

EXPLICATION DES SYMBOLES

Symboles

AVERTISSEMENT! La machine

utilisée de manière imprudente ou

inadéquate peut devenir un outil

dangereux, pouvant causer des

blessures graves voire mortelles à

l’utilisateur et aux autres personnes

présentes.

Lire attentivement et bien assimiler

le manuel d’utilisation avant

d’utiliser la machine.

Toujours utiliser:

• Protecteur d’oreilles

• Des protège-yeux homologués

Les autres symboles/autocollants présents sur la

machine concernent des exigences de certification

spécifiques à certains marchés.

Couper le moteur avant tout contrôle ou

réparation en plaçant le bouton d’arrêt

sur la position STOP.

Toujours utiliser des gants de

protection.

Un nettoyage régulier est indispensable.

Examen visuel.

Au besoin, utiliser des gants.

L'aspiro-souffleur peut projeter

violemment des objets pouvant

être renvoyés vers l'utilisateur.

Ceci peut provoquer des

blessures graves aux yeux si

l'équipement de protection

personnelle recommandé n'est

pas utilisé.

L’opérateur du souffleur

doit veiller à ce

qu’aucune personne ou

animal ne se trouve à

moins de 15 mètres.

Lorsque plusieurs opérateurs partagent le même lieu de

travail la distance de sécurité doit être de 15 mètres au

minimum.

Utiliser une protection respiratoire

dans les environnements

poussiéreux.

Maintenez toute partie du corps

loin des surfaces chaudes.

Porter des lunettes protectrices ou une

visière.

Remplissage d’essence.

Commande de starter en position ”ouvert”.

Commande de starter en position ”fermé”.

28 – French

1155849-49 Rev. 2 2013-03-22

SOMMAIRE

!

!

!

Sommaire Contrôler les points suivants

EXPLICATION DES SYMBOLES

Symboles .............................................................. 28

SOMMAIRE

Sommaire ............................................................. 29

Contrôler les points suivants avant la mise en

marche: .................................................................

INTRODUCTION

Cher client, ........................................................... 30

QUELS SONT LES COMPOSANTS?

Quels sont les composants de l'aspiro-souffleur? 31

Quels sont les composants de l'aspiro-souffleur? 32

Quels sont les composants de l'aspiro-souffleur? 33

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

Généralités ........................................................... 34

INSTRUCTIONS DE SÉCURITÉ

Équipement de protection personnelle ................. 36

Équipement de sécurité de la machine ................ 36

Contrôle, maintenance et entretien des

équipements de sécurité de la machine ...............

Méthodes de travail .............................................. 39

MONTAGE

Montage du tube de soufflage et de la poignée de

commande ............................................................

MANIPULATION DU CARBURANT

Carburant .............................................................. 42

Remplissage de carburant .................................... 43

DÉMARRAGE ET ARRÊT

Démarrage et arrêt ............................................... 44

ENTRETIEN

Généralités ........................................................... 46

Carburateur .......................................................... 46

Silencieux ............................................................. 46

Système de refroidissement ................................. 46

Grille d'entrée d'air ............................................... 47

Bougie .................................................................. 47

Filtre à air ............................................................. 47

Bretelle d’épaule ................................................... 48

Schéma d’entretien .............................................. 49

CARACTÉRISTIQUES TECHNIQUES

Caractéristiques techniques ................................. 50

DÉCLARATION DE GARANTIE CONTRÔLE

DES ÉMISSIONS EN CALIFORNIE ET AU

NIVEAU FÉDÉRAL

VOS DROITS ET OBLIGATIONS EN

GARANTIE ........................................................... 52

avant la mise en marche:

Lire attentivement le manuel d’utilisation.

AVERTISSEMENT! Une exposition

prolongée au bruit risque de causer des

29

38

41

Husqvarna AB travaille continuellement au

développement de ses produits et se réserve le droit d’en

modifier, entre autres, la conception et l’aspect sans

préavis.

La machine est conçue uniquement pour le nettoyage des

pelouses, des allées, des voies en asphalte et similaires.

Si vous avez besoin d’aide, appelez le 704-921-7000 ou

connectez-vous à notre site: www.husqvarna.com

lésions auditives permanentes. Toujours

utiliser des protecteurs d'oreille agréés.

AVERTISSEMENT! Ne jamais modifier

sous aucun prétexte la machine sans

l’autorisation du fabricant. N’utiliser que

des accessoires et des pièces d’origine.

Des modifications non-autorisées et

l’emploi d’accessoires non-homologués

peuvent provoquer des accidents graves

et même mortels, à l’utilisateur ou

d’autres personnes.

Votre garantie ne couvre ni les

dommages ni la responsabilité

qu’entraîne l’utilisation de pièces ou

d’accessoires non autorisés.

AVERTISSEMENT! Un aspiro-souffleur

utilisé de manière erronée ou négligente

peut être un outil dangereux pouvant

occasionner des blessures personnelles

graves, voire mortelles. Il importe donc

de lire attentivement et de bien assimiler

le contenu de ce manuel d'utilisation.

Jan. 2011

1155849-49 Rev. 2 2013-03-22

French – 29

INTRODUCTION

Cher client,

Félicitations pour ce choix d’un produit Husqvarna. Husqvarna a vu le jour en 1689 lorsque le roi Karl XI décida de

construire un arsenal pour la fabrication des mousquets au bord de la rivière Huskvarna. Le choix de l’emplacement

était logique puisque la rivière Huskvarna servait à produire de l’énergie hydraulique et constituait donc une sorte de

centrale hydraulique. En plus de 300 ans d’existence, l’usine Husqvarna a fabriqué de nombreux produits, depuis les

cuisinières à bois jusqu’aux équipements de cuisine modernes, sans oublier les machines à coudre, les bicyclettes, les

motos, etc. La première tondeuse à moteur a été lancée en 1956, suivie en 1959 de la première tronçonneuse. C’est

dans ce secteur que Husqvarna est actif aujourd’hui.

Husqvarna est aujourd’hui un des plus grands fabricants du monde de produits destinés à l’entretien des forêts et des

jardins. La qualité et les performances sont nos priorités. Notre concept d’affaires est de développer, fabriquer et

commercialiser des produits à moteur pour l’entretien des forêts et des jardins et pour les entreprises de construction

et d’aménagement des sols. L’objectif d’Husqvarna est aussi d’être à la pointe du progrès en matière d’ergonomie, de

facilité d’utilisation, de sécurité et de protection de l’environnement; un grand nombre d’innovations ont été développées

pour améliorer les produits dans ces domaines.

Nous sommes persuadés que vous apprécierez la qualité et les performances de nos produits pendant de longues

années. L’achat d’un de nos produits vous garantit une assistance professionnelle au niveau du service et des

réparations en cas de besoin. Si la machine n’a pas été achetée chez un de nos revendeurs autorisés, demandez à un

revendeur l’adresse de l’atelier d’entretien le plus proche.

Nous espérons que cette machine vous donnera toute satisfaction et qu’elle vous accompagnera pendant de longues

années. N’oubliez pas que ce manuel d’utilisation est important. En suivant les instructions qu’il contient (utilisation,

révision, entretien, etc.), il est possible d’allonger considérablement la durée de vie de la machine et d’augmenter sa

valeur sur le marché de l’occasion. En cas de vente de la machine, ne pas oublier de remettre le manuel d’utilisation au

nouveau propriétaire.

Nous vous remercions d'utiliser un produit Husqvarna !

Husqvarna AB travaille continuellement au développement de ses produits et se réserve le droit d’en modifier, entre

autres, la conception et l’aspect sans préavis.

30 – French

1155849-49 Rev. 2 2013-03-22

QUELS SONT LES COMPOSANTS?

14

3

4

20

18

8

9

19

2

25

1

5

26

12

13

Quels sont les composants de l'aspiro-souffleur? 560BTS, 560BFS

1 Cadre

2 Harnais

3 Capot de moteur

4 Coque de ventilateur

5 Grille d'entrée d'air

6 Ventilateur

7 Filtre à air

8 Poignée de lanceur

9 Réservoir d’essence

10 Coussin

11 Bougie

12 Système anti-vibrations

13 Commande de starter

14 Poignée de commande/Poignée de manoeuvre(BTS)

15

19

22

21

7

15 Manette de réglage. Arrêtez interrupteur placé

derrière le levier (BFS)

16 Bouton d'arrêt avec réglage de la position

d'accélération (BTS)

17 Commande de l’accélération

18 Guidon (Accessoires)

19 Coude

20 Collier de serrage

21 Tuyau flexible

22 Tube de manoeuvre

23 Collier de serrage

24 Tube intermédiaire

25 Tube de soufflage

26 Manuel d’utilisation

27 Clé universelle

28 Poignée de commande/Poignée de manoeuvre (BFS)

16

23

24

12

10

11

17

6

1155849-49 Rev. 2 2013-03-22

French – 31

QUELS SONT LES COMPOSANTS?

3

4

20

18

19

14

15

25

19

8

26

Quels sont les composants de l'aspiro-souffleur? 570BTS, 580BTS

1 Cadre

2 Harnais

3 Capot de moteur

4 Coque de ventilateur

5 Grille d'entrée d'air

6 Ventilateur

7 Filtre à air

8 Poignée de lanceur

9 Réservoir d’essence

10 Coussin

11 Bougie

12 Système anti-vibrations

13 Commande de starter

14 Poignée de commande/Poignée de manoeuvre

9

27

10

2

1

5

12

13

22

7

11

15 Bouton d'arrêt avec réglage de la position

d'accélération

16 Commande de l’accélération

17 Guidon (Accessoires)

18 Coude

19 Collier de serrage

20 Tuyau flexible

21 Tube de manoeuvre

22 Collier de serrage

23 Tube intermédiaire

24 Tube de soufflage

25 Buse plate (Accessoires)

26 Manuel d’utilisation

27 Clé universelle

16

21

17

23

6

24

12

32 – French

1155849-49 Rev. 2 2013-03-22

QUELS SONT LES COMPOSANTS?

3

4

20

18

19

14

25

19

8

26

27

Quels sont les composants de l'aspiro-souffleur? 570BFS, 580BFS

1 Cadre

2 Harnais

3 Capot de moteur

4 Coque de ventilateur

5 Grille d'entrée d'air

6 Ventilateur

7 Filtre à air

8 Poignée de lanceur

9 Réservoir d’essence

10 Coussin

11 Bougie

12 Système anti-vibrations

13 Commande de starter

14 Poignée de commande/Poignée de manoeuvre

9

16

15

10

2

1

5

12

7

11

13

15 Bouton d'arrêt avec réglage de la position

d'accélération

16 Commande de l’accélération

17 Guidon (Accessoires)

18 Coude

19 Collier de serrage

20 Tuyau flexible

21 Tube de manoeuvre

22 Collier de serrage

23 Tube intermédiaire

24 Tube de soufflage

25 Buse plate (Accessoires)

26 Manuel d’utilisation

27 Clé universelle

21

17

23

6

24

12

1155849-49 Rev. 2 2013-03-22

French – 33

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

Généralités

IMPORTANT!

La machine est conçue uniquement pour le nettoyage

des pelouses, des allées, des voies en asphalte et

similaires.

Effectuez une inspection générale de la machine avant

de l’utiliser, voir le Calendrier de maintenance.

Éviter d’utiliser la machine en cas de fatigue,

d’absorption d’alcool ou de prise de médicaments

susceptibles d’affecter l’acuité visuelle, le jugement ou

la maîtrise du corps.

Utiliser les équipements de protection personnelle. Voir

au chapitre ”Équipement de protection personnelle”.

Ne jamais utiliser une machine qui a été modifiée au

point de ne plus être conforme au modèle original.

Ne jamais utiliser une machine qui n’est pas en parfait

état de marche. Suivre dans ce manuel d’utilisation les

instructions de maintenance, de contrôle et d’entretien.

Certaines mesures de maintenance et d’entretien

doivent être confiées à un spécialiste dûment formé et

qualifié. Voir au chapitre Entretien.

Tous les carters et toutes les protections doivent être

montés avant le démarrage. Vérifier que le chapeau de

bougie et le câble d’allumage ne sont pas endommagés

afin d'éviter tout risque de choc électrique.

L’opérateur du souffleur doit veiller à ce qu’aucune

personne ou animal ne se trouve à moins de 15 mètres.

Lorsque plusieurs opérateurs partagent le même lieu de

travail la distance de sécurité doit être de 15 mètres au

minimum.

Ne jamais laisser un enfant utiliser la machine.

Ne jamais laisser d’autres personnes utiliser la machine

sans s’être assuré au préalable que ces personnes ont

bien compris le contenu du mode d’emploi.

Vérifiez toujours qu'aucun objet n'obstrue la grille

d'entrée d'air avant de commencer le travail.

Ne retirez jamais la grille d'entrée d'air.

En cas d'urgence, dégagez-vous de la machine en

ouvrant le ceinturon et la ceinture de poitrine et laissez

la machine tomber vers l'arrière.

Toujours consulter les autorités locales pour s’assurer

d’appliquer les règlements en vigueur.

Maintenez toute partie du corps loin des surfaces

chaudes.

Démarrage

• Ne jamais mettre la machine en marche à l’intérieur.

Les gaz d’échappement du moteur sont nocifs.

• Inspecter les environs et s’assurer qu’aucune

personne et qu’aucun animal ne peut se trouver en

contact avec le jet.

• Placer la machine sur le sol et pousser le corps de la

machine contre le sol avec la main gauche

(REMARQUE! Pas avec le pied). Saisir ensuite la

poignée du lanceur avec la main droite et tirer

plusieurs fois rapidement et avec force .

Sécurité carburant

• Utiliser un bidon d’essence comportant un dispositif

d’arrêt de remplissage automatique.

• Ne jamais effectuer le remplissage de la machine

lorsque le moteur tourne. Arrêter le moteur et le

laisser refroidir pendant quelques minutes avant de

faire le plein.

• Veiller à une bonne aération lors du remplissage et du

mélange de carburant (essence et huile 2 temps).

• Éviter tout contact de la peau avec du carburant. Le

carburant a un effet irritant sur la peau et peut aussi

entraîner des altérations dermiques.

• Avant de mettre la machine en marche, la déplacer à

au moins 3 mètres de l’endroit où a été fait le plein.

!

34 – French

AVERTISSEMENT! Cette machine génère

un champ électromagnétique en

fonctionnement. Ce champ peut dans

certaines circonstances perturber le

fonctionnement d’implants médicaux

actifs ou passifs. Pour réduire le risque

de blessures graves ou mortelles, les

personnes portant des implants

médicaux doivent consulter leur

médecin et le fabricant de leur implant

avant d’utiliser cette machine.

• Ne jamais démarrer la machine:

-

Si du carburant a été renversé. Essuyer soigneusement

toute trace et laisser les restes d’essence s’évaporer.

- Si vous avez renversé du carburant sur vous ou sur vos

vêtements, changez de vêtements. Lavez les parties du

corps qui ont été en contact avec le carburant. Utilisez de

l’eau et du savon.

- S’il y a fuite de carburant. Vérifier régulièrement que le

bouchon du réservoir et la conduite de carburant ne fuient

pas.

1155849-49 Rev. 2 2013-03-22

INSTRUCTIONS GÉNÉRALES DE SÉCURITÉ

Transport et rangement

• Transporter et ranger la machine et le carburant de

façon à éviter que toute fuite ou émanation éventuelle

entre en contact avec une flamme vive ou une

étincelle: machine électrique, moteur électrique,

contact/interrupteur électrique ou chaudière.

•

Lors du stockage et du transport de carburant, toujours

utiliser un récipient homologué et conçu à cet effet.

• Lors des remisages de la machine, vider le réservoir

de carburant. S’informer auprès d’une station-service

comment se débarrasser du carburant résiduel. Videz

le réservoir de carburant et appuyez sur l'amorceur

jusqu'à ce que le réservoir soit complètement vide.

Retirez la bougie et versez une cuillerée d'huile deux

temps dans le cylindre. Retournez le moteur deuxtrois fois, puis remettez la bougie en place.

• Avant de remiser la machine pour une période

prolongée, veiller à ce qu'elle soit bien nettoyée et que

toutes les mesures d'entretien aient été effectuées.

• Sécurisez la machine pendant le transport.

• Rangez la machine dans un endroit sec, frais, bien

aéré et exempt de poussières. Ranger la machine

hors de portée des enfants.

AVERTISSEMENT! Manipuler le

carburant avec précaution. Penser aux

!

risques d’incendie, d’explosion et

d’inhalation.

Réglage du harnais

AVERTISSEMENT! Le harnais doit

toujours être utilisé en cas de travail

!

avec la machine. Sinon, il est impossible

d’effectuer le travail en toute sécurité, ce

qui risque de causer des blessures à

l’utilisateur et aux autres.

Assurez-vous que la ceinture est fermée

et réglée correctement.

Si vous n'utilisez pas la ceinture,

assurez-vous de la retirer de l'unité et de

la ranger. La ceinture risque sinon de

coincer et de faire basculer l'unité.

Une ceinture non fermée risquerait de se

coincer ou d'être aspirée dans le

ventilateur de la machine.

Un harnais adapté à la machine facilite considérablement

le travail. Régler le harnais de manière à obtenir la

position de travail la plus confortable possible..

Tendre les courroies latérale afin que la pression soit

répartie de manière égale sur les épaules..

Serrez et ajustez la ceinture de poitrine afin d’obtenir la