Page 1

Workshop Manual

555 560XP/XPG

562XP/XPG

English

Page 2

Page 3

Contents

Workshop Manual

Husqvarna 555, 560XP, 560XPG, 562XP and

562XPG

Contents

Index ...................................................................... 4

Introduction and safety instructions .................. 6

Technical data ......................................................10

Service tools ....................................................... 12

Service data .........................................................14

Safety equipment ................................................ 16

Repair instructions .............................................. 24

Carburettor .......................................................... 34

Troubleshooting ...................................................56

Husqvarna AB has a policy of continuous product development and therefore reserves the right to modify

the design and appearance of products without prior notice.

English - 3

Page 4

Index

B

Index

M

Bar bolt 54

Replacing the bar bolt 53

C

Carburettor 34

Assembly 38

Cleaning and inspection 38

Design 34

Dismantling 36

Function 35

Pressure testing the carburettor 40

Centrifugal clutch 30

Assembly of centrifugal clutch 31

Cleaning and inspection 30

Dismantling the centrifugal clutch 30

Chain brake 17

Assembling the chain brake 18

Cleaning and inspection 17

Dismantling the chain brake 17

Chain catcher 20

Replacing the chain catcher 20

Crankshaft and crankcase 49

Assembling a complete crankshaft 54

Dismantling the crankcase and crankshaft 49

F

Fuel system 44

Replacing the fuel lter 44

Replacing the fuel hose 44

I

Ignition module and flywheel 28

Assembling the ignition module and ywheel 29

Cleaning and inspection 28

Dismantling the ignition module and ywheel 28

Intake system 32

Assembling the intake system 33

Cleaning and inspection 33

Dismantling the intake system 32

Introduction and safety instructions 7

General 7

General Instructions 8

Modications 7

Numbering 7

Safety 7

Special Instructions 8

Structure 7

Target group 7

Tools 7

Muffler 19

Assembling the mufer 19

Dismantling the mufer 19

O

Oil pump and screen 31

Assembling the oil pump and screen 32

Cleaning and inspection 31

Dismantling the oil pump and screen 31

P

Piston and cylinder 45

Assembling the piston and cylinder 47

Dismantling the piston and cylinder 45

Faults and causes 47

Pressure testing the cylinder 48

S

Service data 14

Service tools 12

Starter 25, 26

Cleaning and inspection 25

Cleaning and inspection: 26

Dismantling the starter 25

Replacing a broken or worn starter cord 26

Replacing a broken return spring 27

Starter assembly 27

Stop control 20

Dismantling the stop control 20, 21

Stop function 21

Resistance test - stop function 21

Symbols

Symbols in the Workshop Manual 9

Symbols on the saw 9

T

Tank unit 42

Assembly 43

Dismantling 42

Tank valve 42

Technical Data 10

Threads 54

Repairing damaged threads 54

Throttle control lock, throttle lock and spring 22

Assembling the throttle lockout, throttle control

and spring 23

Cleaning and inspection 22

Dismantling the throttle control lock, throttle

control and spring 22

Troubleshooting 57

Troubleshooting methods 58

4 - English

Page 5

V

Vibration damping system 43

Assembly 43

Cleaning and inspection 43

Dismantling 43

Index

English - 5

Page 6

Introduction and safety instructions

2 Introduction and safety regulations

Contents

2.1 General ...........................................................................................................................7

2.2 Safety .............................................................................................................................7

2.3 Target group ...................................................................................................................7

2.4 Modications....................................................................................................................7

2.5 Tools ...............................................................................................................................7

2.6 Structure .........................................................................................................................7

2.7 Numbering ......................................................................................................................7

2.8 General instructions ........................................................................................................8

2.9 Special instructions .........................................................................................................8

2.10 Symbols on the saw .......................................................................................................9

2.11 Symbols in the Workshop Manual ..................................................................................9

6 - English

Page 7

Introduction and safety instructions

2 Introduction and safety instructions

2.1 General

This Workshop Manual describes in detail how

to be troubleshoot, repair and test the chain saw.

A description of different safety steps that must be

taken during repair work is also given.

2.2 Safety

Note: The section dealing with safety must be

read and understood by all those carrying out

repair work or service on the chain saw.

Warning symbols can be found in this Workshop

Manual and on the chain saw. See “Symbols on

the saw” and “Symbols in the Workshop Manual”.

A new warning symbol decal must be applied as

soon as possible if a warning symbol on the chain

saw has been damaged or is missing so that the

greatest level of safety can be maintained when

using the chain saw.

2.3 Target group

This Workshop Manual is written for personnel who

are assumed to have general knowledge of repairing and servicing chain saws.

The Workshop Manual must be read and understood by personnel who will carry out repair work

and service on the chain saw. The Manual is also

suitable for use when training new employees.

2.4 Modifications

Any modications to the chain saw will be gradually

introduced into ongoing production. As these modications affect service and/or spare parts, specic

service information will be sent out on each occasion. This means that in time this Workshop Manual will become out of date. In order to prevent this,

the Manual should be read together with all service

information concerning the chain saw in question.

2.5 Tools

Special tools are required for some stages. All

service tools are listed in the Workshop Manual.

Usage is made apparent in each section.

Always use Husqvarna’s original:

• Spare parts

• Service tools

• Accessories

2.6 Structure

This Workshop Manual can be used in two different

ways:

• Repair of a specic system on the chain saw.

Dismantling and assembly of the entire chain saw.

•

Repair of a specific system

When a particular system on the chain saw is to be

repaired, proceed as follows:

1. Look up the page for the system in question.

2. Carry out the following steps:

Dismantling

Cleaning and inspection

Assembly

Dismantling and assembling the chain saw.

Proceed as follows when the chain saw is to be

dismantled and assembled:

1. Open the “Repair instructions” chapter which

deals with the Starter and carry out the instructions outlined under the Dismantling

heading.

2. Work forward in the Manual and carry out Dis-

mantling in the order set out in the sections.

3. Go back to the Starter and carry out the instructions under Cleaning and Inspection.

4. Work forward in the Manual and carry out

Cleaning and Inspection in the order set out

in the sections.

5. Order or collect all requisite spare parts from

the stores.

6. Look up the “Repair instructions” chapter which

deals with the Crankcase and carry out the

instructions outlined in Assembling.

7. Work back in the Manual and carry out Assem-

bling in the order set out in the sections.

Some sections include an introductory Descrip-

tion of the actual unit in order to increase the basic

understanding.

2.7 Numbering

Position references to components inside the gures are designated A, B, etc.

The gures are numbered 1, 2 etc.

The position references and gure numbers restart

English - 7

Page 8

Introduction and safety instructions

2.8 General Instructions

The workshop where the chain saw is to be repaired must be equipped with safety equipment in

accordance with local regulations.

No one may repair the chain saw unless they have

read and understood the content of this Workshop

Manual.

This workshop manual contains the following warning boxes in relevant places.

WARNING!

The warning box warns of the risk

of personal injury if the instructions are not followed.

NOTE!

This box warns of material damage if the

instructions are not followed.

2.9 Special Instructions

The fuel used in the chain saw has the following

hazardous properties:

• The uid and its vapour are poisonous.

• Can cause eye and skin irritation.

• Can cause breathing problems.

• Is highly inammable.

When using compressed air, do not direct the jet

towards your body. Air can penetrate into the blood

stream, which can endanger life.

Wear protective earplugs or earmuffs when test

running.

After test running, do not touch the mufer until

it has cooled down. Risk of burns. Use protective

gloves when working with the mufer.

Do not start the chain saw unless the bar, chain

and clutch cover (chain brake) are tted, otherwise

the clutch may loosen and cause personal injury.

Insufcient chain lubrication can result in chain

breakage, which can cause serious or even lifethreatening injury.

Exercise care to ensure the starter spring does not

y out and cause personal injury. Wear protective

glasses. If the spring tension is activated on the

starter pulley when it is to be taken up, the spring

can y out and cause personal injury.

Check that the brake is applied when removing the

pressure spring on the chain brake. Otherwise the

pressure spring can y out and cause personal

injury.

After repairing, check the chain brake, see “Assembling chain brake \ Function check”.

Keep in mind the re risk. The chain saw may emit

sparks, which cause ignition.

Check the chain catcher and replace it if it is damaged.

8 - English

Page 9

Introduction and safety instructions

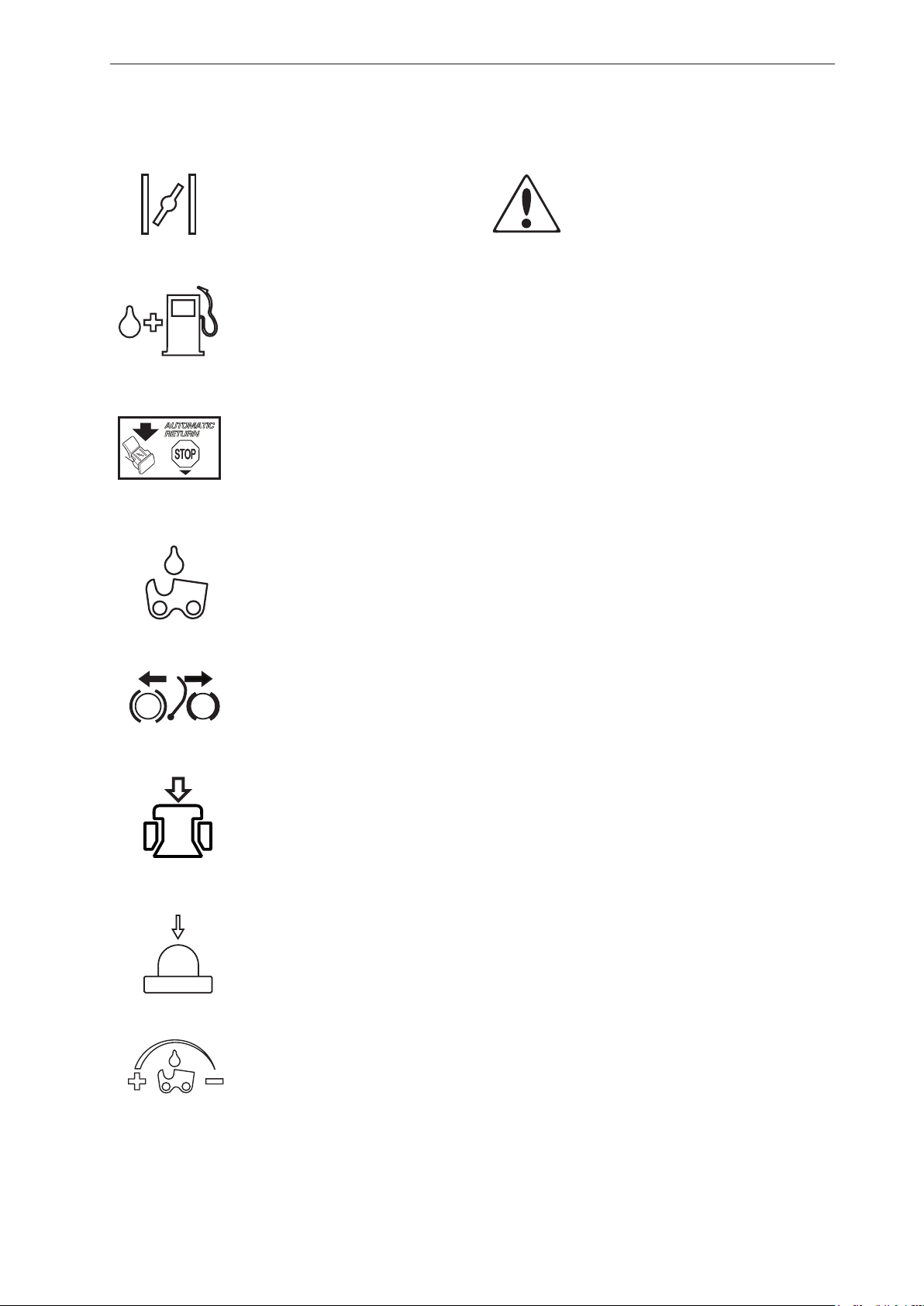

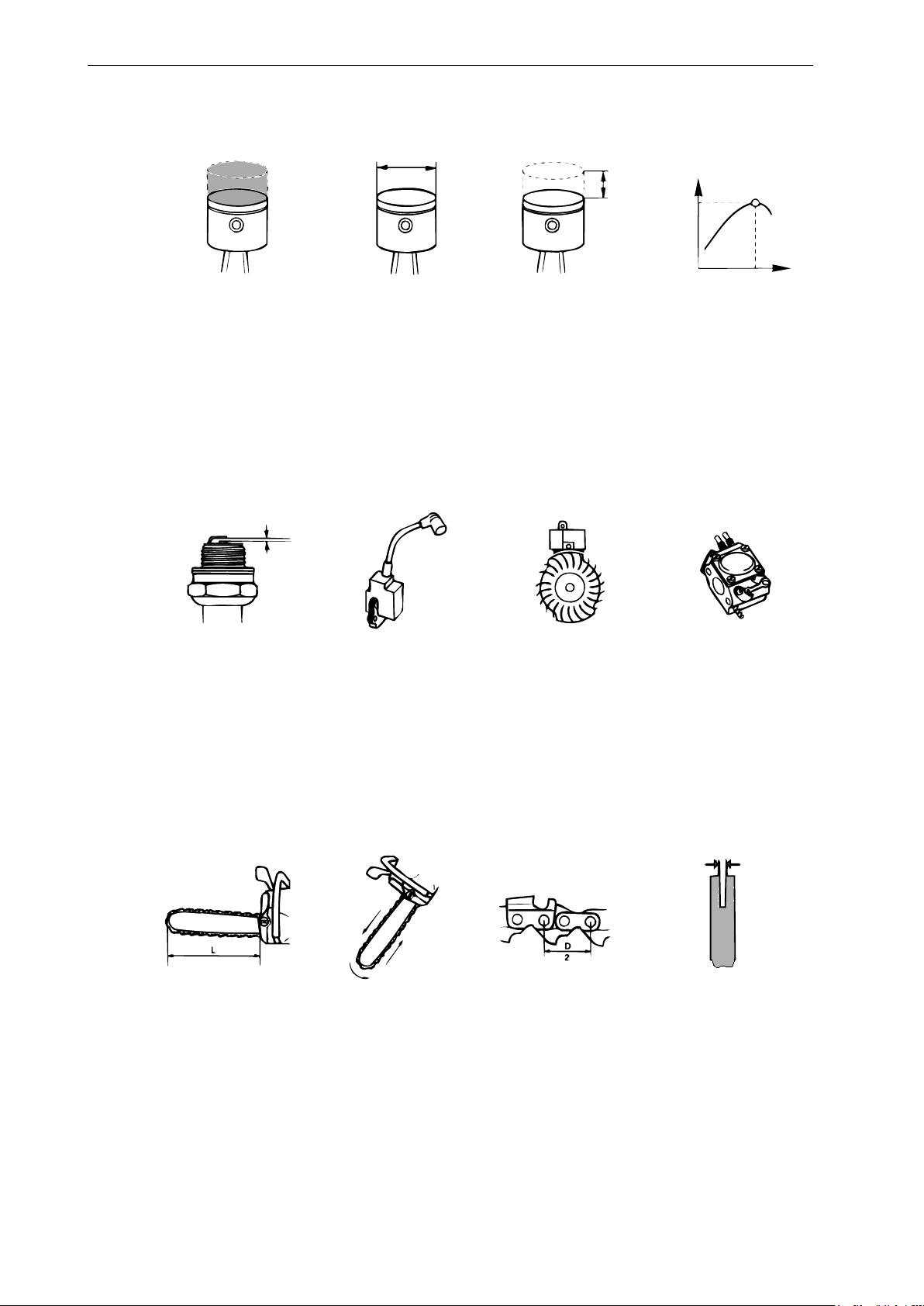

2.10 Symbols on the saw

The symbols below are embedded on the chain

saw.

Choke Lever

Refuelling

Stop button

2.11 Symbols in the Workshop Manual

This symbol warns of personal injury

when the instructions are not followed.

Chain oil ll.

Chain brake

Decompression valve

Fuel pump

Adjusting the oil pump

English - 9

Page 10

Technical data

3 Technical data

Displacement Cylinder diameter Stroke length Max. output/speed

cm3/cubic inch Ø mm/Ø inch mm/inch kW/hp/ rpm

555: 59,8 / 3.65 46 / 1.81 36 / 1.42 3.1 / 4.2 / 9600

560XP/XPG: 59,8 / 3.65 46 / 1.81 36 / 1.42 3.5 / 4.8 / 9600

562XP/XPG: 59,8 / 3.65 46 / 1.81 36 / 1.42 3.5 / 4.8 / 9600

Electrode gap Ignition system Air gap Carburettor type

mm/inch mm/inch

555: 0,5 / 0.02 SEM 0,3 / 0.012 Zama

560XP/XPG: 0,5 / 0.02 SEM 0,3 / 0.012 Zama

562XP/XPG: 0,5 / 0.02 SEM 0,3 / 0.012 Zama

Usable cutting length Chain speed at Chain pitch Drive link

cm/inch max. output - speed mm/inch mm/inch

m/s - rpm

555: 33-61 / 13-24 21,3 / 9600 8.25 / 0.325 9,53 / 0.375 1.3 / 0.050 - 1,5 / 0.058

560XP/XPG: 33-61 / 13-24 21,3 / 9600 8,25 / 0.325 9,53 / 0.375 1,3 / 0.050 - 1,5 / 0.058

562XP/XPG: 38-71 / 15-28 21,3 / 9600 9,53 / 0.375 1,3 / 0.050 - 1,5 / 0.058

10 - English

Page 11

GAS

OIL

Technical data

Engage speed Spark plug Automatic oil pump

rpm

555: 3800 NGK CMR6H Yes

560XP/XPG: 3800 NGK CMR6H Yes

562XP/XPG: 3800 NGK CMR6H Yes

Volume fuel tank Capacity oil pump at Volume oil tank

Litre/US. pint 9,000 rpm, Litre/US. pint

ml/min

555: 0,65 / 1.37 6-15 0.33 / 0.70

560XP/XPG: 0,65 / 1,37 6-15 0,33 / 0.70

562XP/XPG: 0,65 / 1.37 8-18 0,35 / 0.74

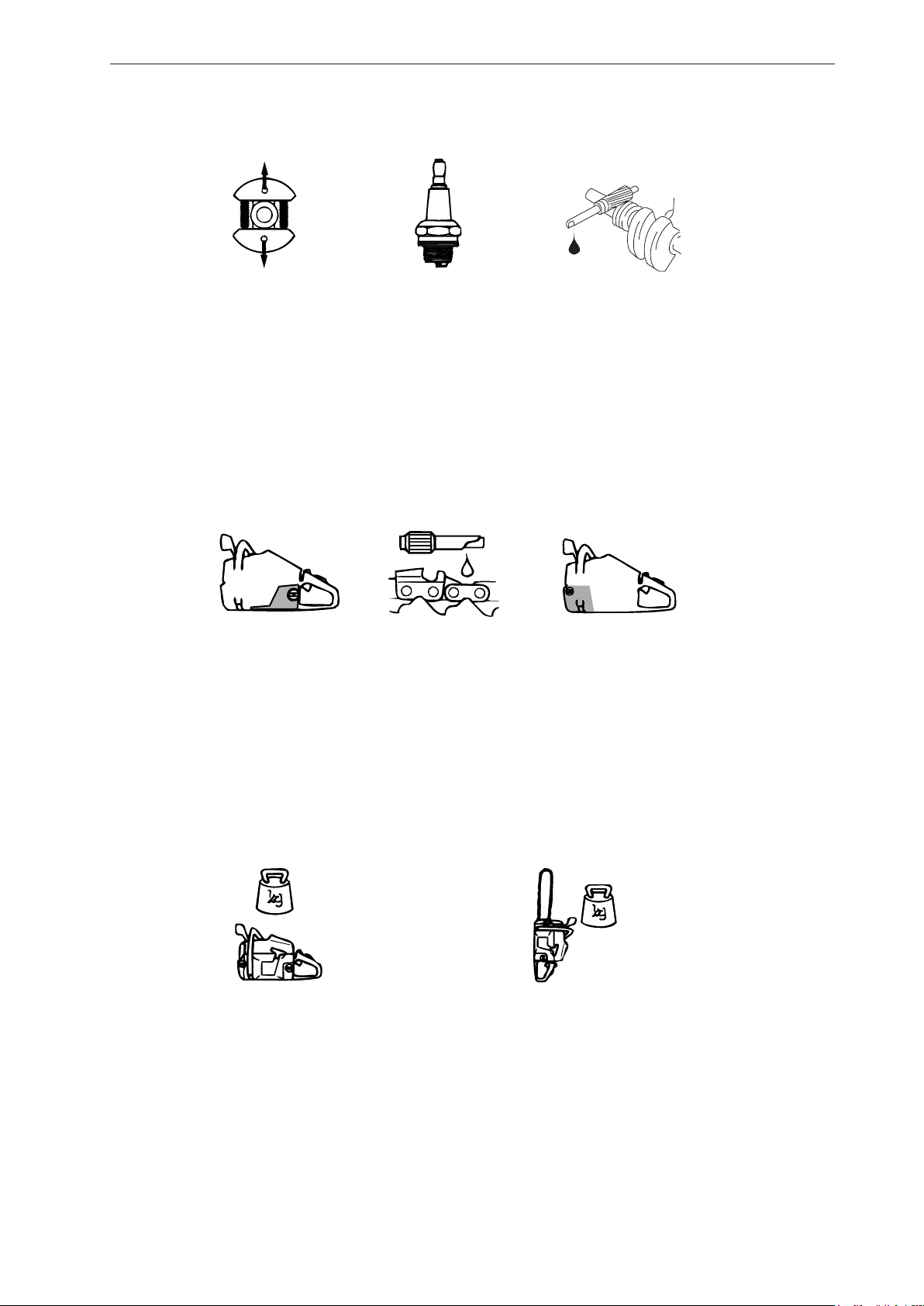

Weight without bar and chain Weight with bar and chain

kg/lbs kg/lbs

555: 5,6 / 12.3 Weight depending on selected cutting equipment

560XP/XPG: 5,6 / 12.3

562XP/XPG: 5,7 / 12.6

English - 11

Page 12

Service tools

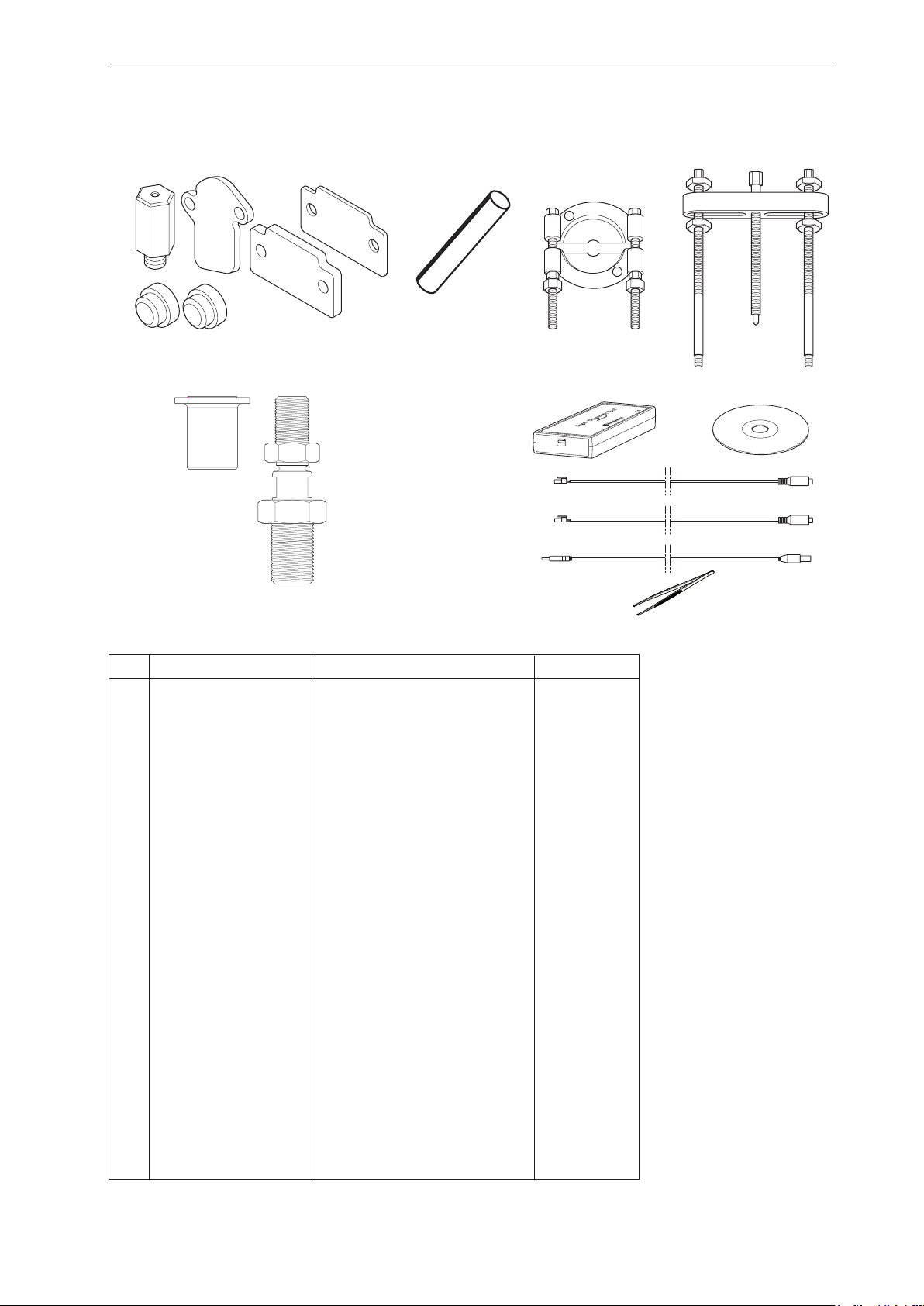

4 Service tools

1 2

3 5

4 mm

7

4

4 mm

5 mm

6

8

9

10

12 - English

11

12a

12b

Page 13

Service tools

13c

15

13a13d

13b

14

16

17

Pos Description Used for Order No.

1 Piston stop Locking the crankshaft 575 29 36-01

2 Hook for fuel lter Suspending the fuel lter 502 50 83-01

3 Allen key, 4 mm For M5 bolts 502 50 87-01

4 Allen key, 4 mm For M5 bolts 502 50 18-01

4 Allen key, 5 mm For M6 bolts 502 50 64-01

5 Air gap tool Setting, ignition module 502 51 34-02

6 Clutch tool Centrifugal clutch 575 25 14-01

7 Assembly xture Securing the chain saw 502 51 02-01

8 Pressure gauge Pressure testing 531 03 06-23

9 Test spark plug Checking the ignition module 501 97 64-01

10 Assembly pliers Fitting the spark plug guard 502 50 06-01

11 Dismantling device Dismantling the crankcase 575 28 69-01

12a Assembly tool Assembling the sealring 575 34 70-01

12b Guide sleeve Assembling the sealring 575 34 69-01

13a Cover plate, outlet Closure of outlet 574 71 14-01

13b Cover plate, inlet Closure of inlet 575 29 81-01

13c Cover plug, inlet Closure of inlet 574 70 12-01

13d Pressure tester Pressure testing the cylinder 503 84 40-03

14 Mandrel Dismantling the ywheel 502 51 94-01

15 Assembly tool Assembling the crankshaft 502 50 30-23

16 Puller Dismantling the crankshaft 531 00 48-67

17 Engine Diagnostic Tool Diagnosis and troubleshooting 576 69 23-01

English - 13

Page 14

Service data

18-20Nm 16mm

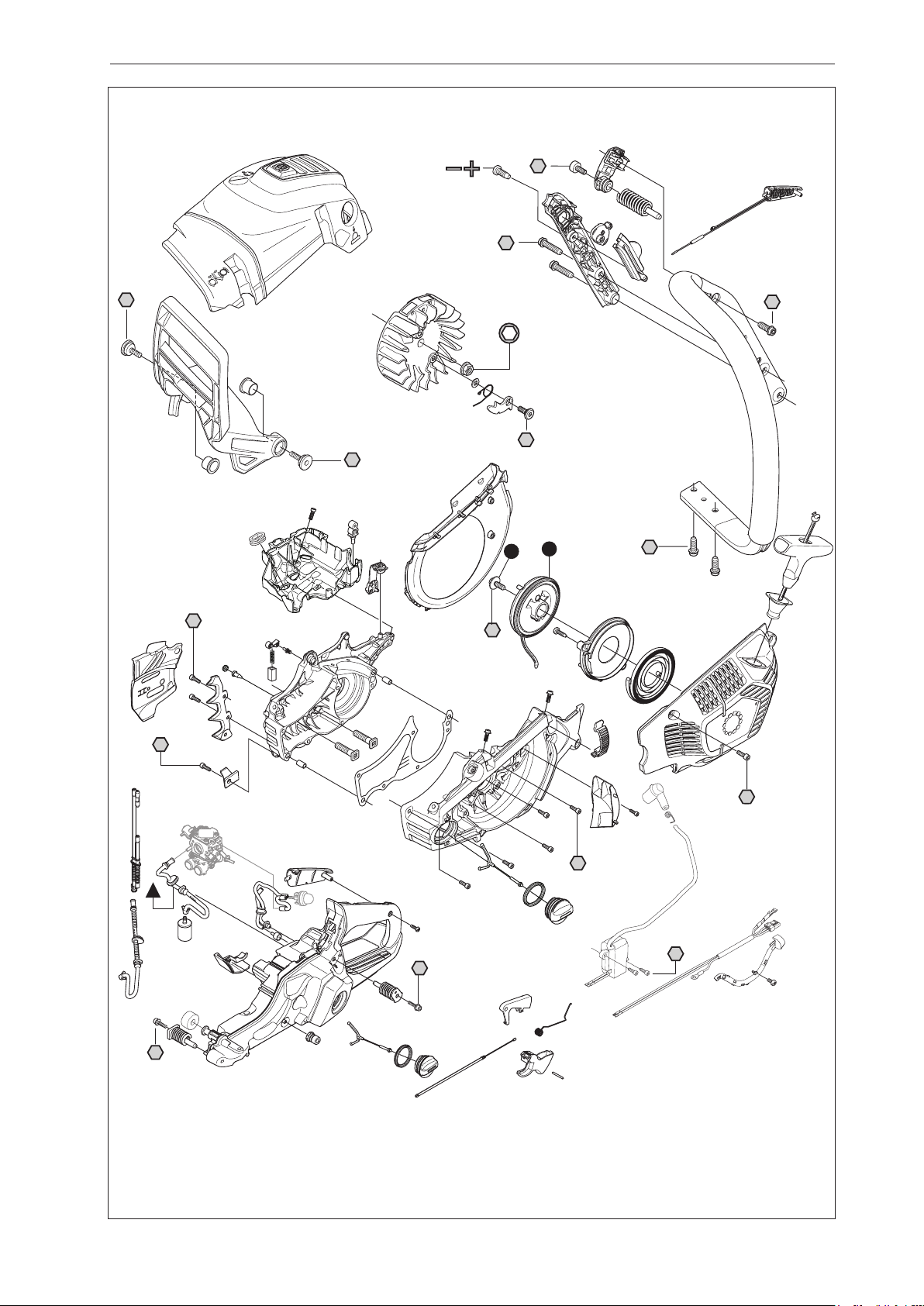

5 Service data

12-14Nm 13mm

12-15 Nm 5mm

12-15 Nm 5mm

1-2Nm

8-10Nm 4mm

1,5-2Nm 4mm

1-2Nm

5-6Nm 4mm

1-2Nm

Min. 15Nm 13mm

1-2Nm

Key

The numbers by the components to be assembled with

screws state the tightening torque in Nm.

4-5Nm 4mm

Min. 25Nm

s = Lubricate using two-stroke oil.

n = Lubricate using chain oil.

l = Lubricate using grease.

14 - English

Page 15

Service data

9-11Nm 4mm

9-11Nm 4mm

1-2Nm

3-4Nm 4mm

22-25Nm 13mm

6-8Nm 4mm

7-9Nm 4mm

3-4Nm 4mm

3-4Nm 4mm

6-8Nm 4mm

4-5Nm 4mm

2-3Nm 4mm

3-4Nm 4mm

7-9Nm 4mm

8-10Nm 4mm

3,5-4,5Nm 4mm

3,5-4,5Nm 4mm

English - 15

Page 16

Safety equipment

6 Safety equipment

Contents

6.1 Dismantling the chain brake ...........................................................................................17

6.2 Assembling the chain brake ............................................................................................18

6.3 Dismantling the mufer ...................................................................................................19

6.4 Assembling the mufer ...................................................................................................19

6.5 Replacing the chain catcher ...........................................................................................20

6.6 Dismantling the start/stop control ...................................................................................20

6.7 Assembling the start/stop control ....................................................................................21

6.8 Resistance test - stop function .......................................................................................21

6.9 Dismantling the throttle control lock, throttle control and spring ..................................... 22

6.10 Assembling the throttle control lock, throttle control and spring .....................................23

16 - English

Page 17

6 Safety equipment

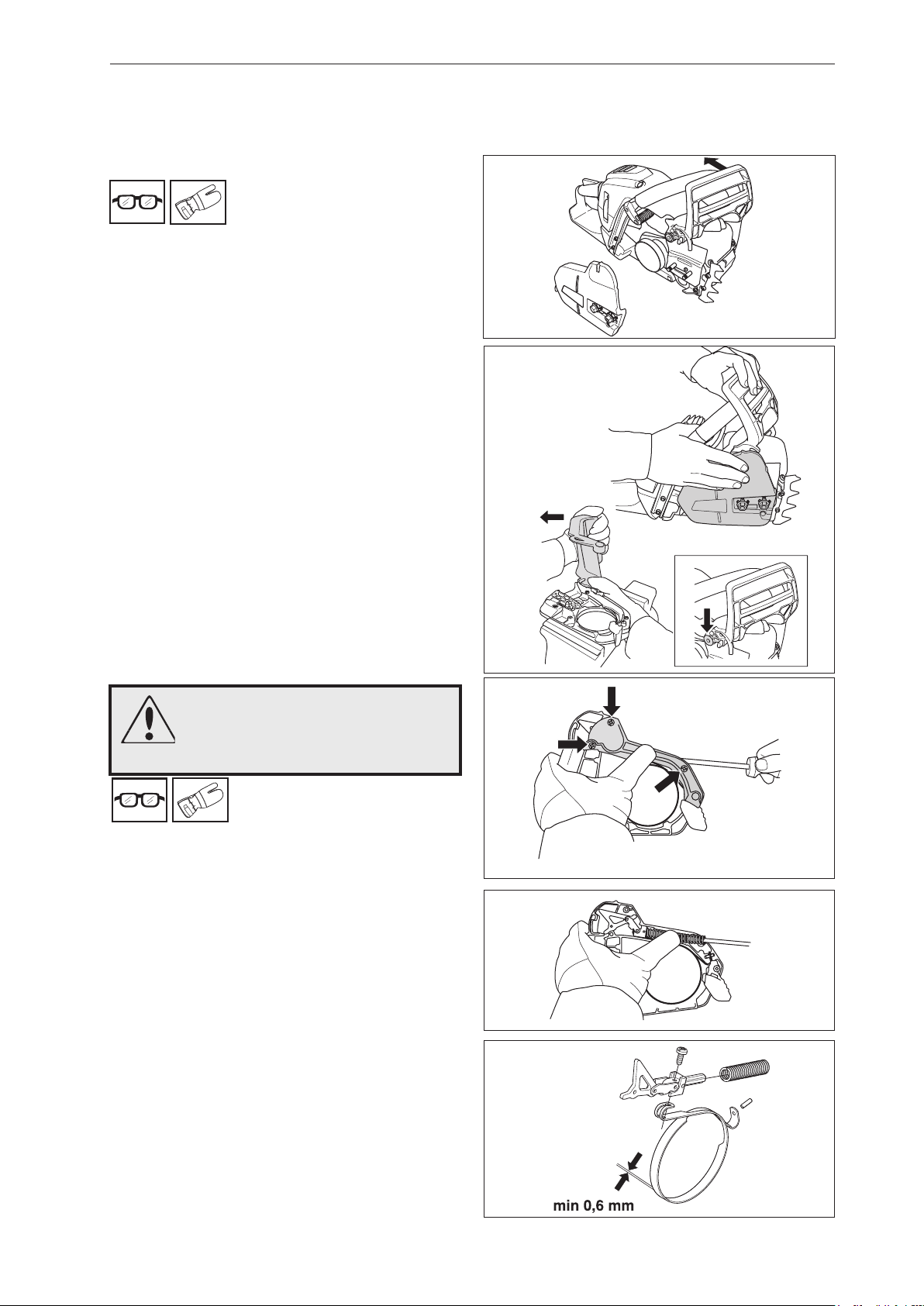

6.1 Dismantling the chain brake

1

Remove the cylinder cover.

Release the brake by moving the front hand guard

backward.

Loosen the bar nuts and remove the clutch cover,

bar and chain, see g. 1.

2

Unscrew the kickback guard and remove it.

NOTE! Make sure that the spring and rocker do not

y out.

Carefully tighten the clutch housing in a vice. Release the brake by using the saw’s hand guard as

a tool. Mesh with the brake and tighten anti-clockwise until the brake is activated, see g. 2.

Safety equipment

Fig 1

Alt. 1

Alt. 2

3

Loosen the screws and insert a screwdriver to

maintain pressure on the spring, and then carefully

remove the cover over the brake spring, see g. 3.

WARNING!

Exercise care to ensure the spring

does not fly out and cause personal

injury. Wear protective goggles.

4

Hold one hand on top of the brake spring and

press in a small screwdriver into the spring. Carefully bend upwards until the spring is released and

it slides onto the screwdriver, see g. 4.

Cleaning and inspection

• Clean and check carefully all components. Parts

must be replaced if cracked or show signs of

other defects. Always use original spare parts.

Fig 2

Fig 3

Fig 4

• Measure the thickness of the chain brake band.

It must not be less than 0.6 mm in any place.

See gure 5.

• Lubricate the knee joint with grease.

Fig 5

English - 17

Page 18

Safety equipment

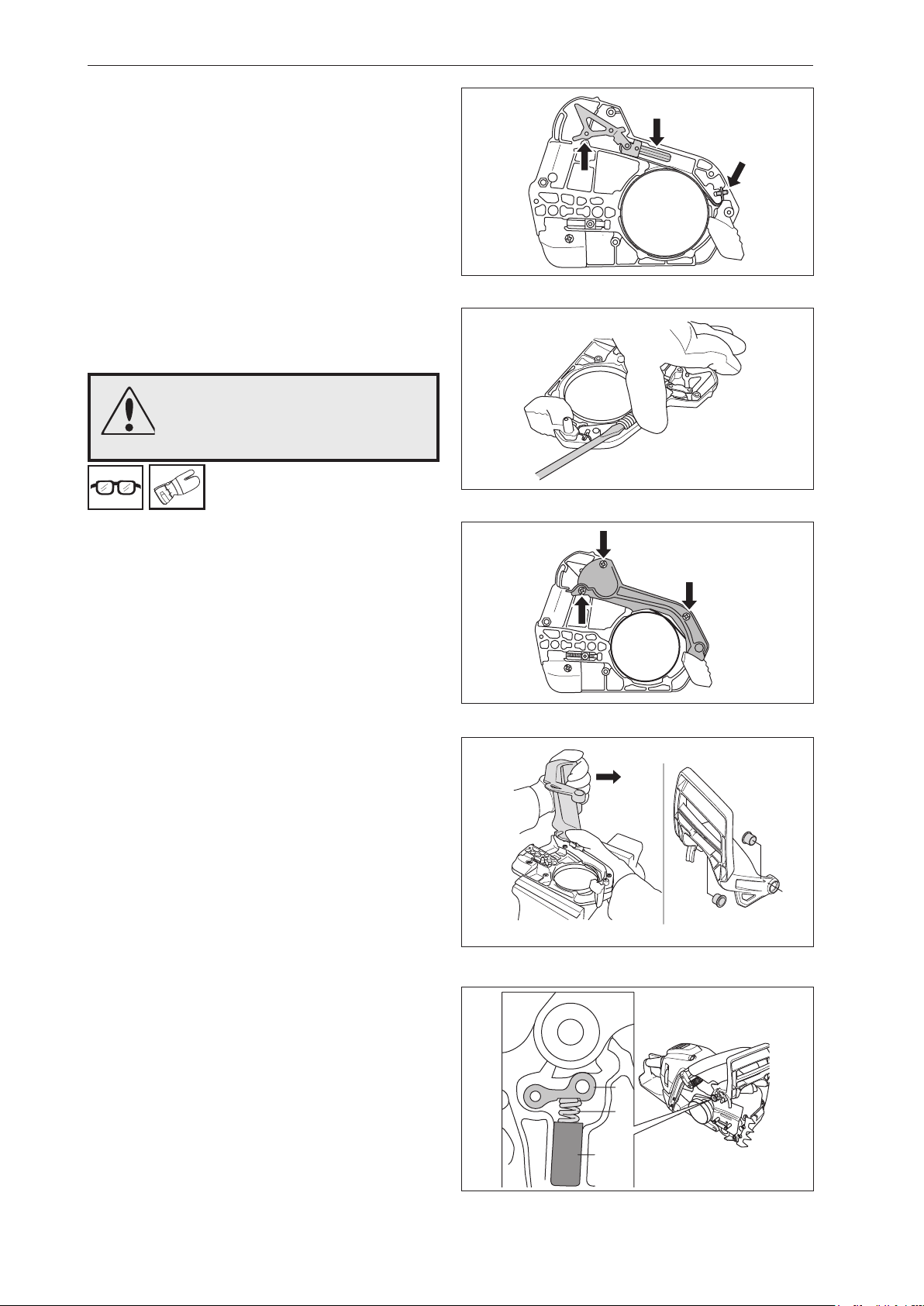

6.2 Assembling the chain brake

1

Screw the knee joint and the brake band together

(see gure 5) using a tightening torque of 1-1.5

Nm. Place the knee joint with the tted chain brake

band in the opening in the clutch cover. The space

for the spring in the cover must be lubricated with

grease. See gure 6.

2

Compress the spring with a wide screwdriver and

press it down with your thumb. See gure 7.

WARNING!

Exercise care to ensure the spring

does not fly out and cause personal

injury. Wear protective goggles.

Fig 6

Fig 7

3

Fit the cover over the brake spring using 1-1.5 Nm

tightening torque. See gure 8.

4

Tighten the brake by using the saw’s hand guard

as a tool. Mesh with the brake and tighten clockwise until the brake is in the off position. See

gure 9.

5

NOTE! Make sure the bushings in the kickback

guard’s attachments are kept in place from the

inside. See gure 9.

Screw the kickback guard in place and put the

rocket in position. Position the spring (B) in the

plastic housing (C) (see gure 10) and press the

spring against the rocker and then press the plastic

housing into its groove. Tighten the chain guide

plate in place.

Fig 8

Fig 9

Fit the:

• bar

• chain

• clutch shoe

• cylinder cover

18 - English

A

B

C

Fig 10

Page 19

NOTE!

After repairing, the chain brake must be in-

spected in line with the instruction below.

Functional inspection:

Do not turn on the motor when carrying out this

inspection.

Bar length Height

38 cm/15” 50 cm/20"

• Hold the chain saw over a stable surface. The

distance between the bar and the surface is

shown in the table above.

• Let go of the front handle and let the chain saw

drop toward the surface underneath.

• When the bar hits the surface the chain brake

must trigger.

6.3 Dismantling the muffler

WARNING!

Do not touch the muffler until it

has cooled. Risk of burns.

Safety equipment

Fig 11

1

Remove the cylinder cover, mufer, gasket and

cooling n.

2

The saw is tted with spark arrestor mesh, which is

removed. If necessary, use the combination spanner to push down the plate edge and remove the

spark arrestor mesh. See gure 12.

Cleaning and inspection

Clean and check all components carefully.

Parts must be replaced if cracked or show signs of

other defects. Always use original spare parts.

The spark arrestor mesh is best cleaned with a

wire brush.

The mesh must be replaced, if damaged.

The saw will overheat if the mesh is clogged resulting in damage to the cylinder and piston.

Never use a saw with a clogged or defective mufer.

6.4 Assembling the muffler

1

If the saw is tted with a spark arrestor mesh, put

it in place rst. When tting the mesh, make sure

that the mesh is inserted in the right position. If

necessary, use the combination spanner to insert

the mesh.

2

Fit the:

• cooling n

Fig 12

• gasket

• mufer, tightening torque of 12-14 Nm.

• Cylinder cover

3

Warm up the saw for at least one minute and

retighten the screws on the mufer to 12 to 14 Nm.

English - 19

Page 20

Safety equipment

6.5 Replacing the chain catcher

A worn chain catcher must always be replaced with

a new one. Always use original spare parts.

1

Release the brake by moving the front hand guard

backward.

Loosen the bar nuts and remove the clutch cover,

chain and bar.

2

Remove the chain catcher and replace it with a

new one.

Make sure that the vibration element is tted correctly on the crankcase when a new chain catcher

is screwed in place. See gure 13.

6.6 Dismantling the start/stop control

1

Remove the cylinder cover and air lter. Dismantle

the air lter holder. See the “Dismantling the carburettor” chapter.

Fig 13

2

Loosen screw B and dismantle the stop control A.

See gure 14. Unhook the rubber collar around the

control from the guide plugs.

Cleaning and inspection

Clean and check carefully all components. Parts

must be replaced if cracked or show signs of other

defects. Always use original spare parts.

Fig 14

20 - English

Page 21

6.7 Assembling the start/stop control

1

Fit the new stop control (A) and tighten screw (B) in

place at a torque of 1 Nm. Slide in the stop control

in the rubber sleeve C and hook the sleeve on the

guide taps. See gure 15.

Safety equipment

Fig 15

2

Attach the cables as outlined in gure 16.

3

Attach the air lter holder. See the “Assembling the

carburettor” chapter.

4

Fit air lter and cylinder cover.

6.8 Resistance test - stop function

Dismantle the ignition module as outlined in

“7.7 Dismantling the ignition module and ywheel”.

Cut open the shrink tube covering both cables and

shrink tubing that encloses the cable ends.

Clean the contact areas and check resistance in

the following way:

Test the resistance by connecting a multimeter to

the cable ends. NOTE! The power switch must be

in the “on” position to get the correct reading. See

gure 17.

The stop switch is in the “on” position when the

button is held down (see gure 17) and in the “off”

position when the button is in neutral.

Resistance can be 0.5 Ohm at most with the power

switch in the “on” position.

When assembling (see gure 18), pull the cable

ends apart and slide on a thicker shrink tube over

both cables. Then slide on the thinner shrink tubes

over each cable. Connect the cable ends together.

Slide the thinner shrink tubes over the cable ends

and heat the shrink tube rst on both cables separately. Slide the thicker shrink tube over the thinner

shrink tubes and then heat the thicker shrink tube.

Fig 16

Fig 17

Fig 18

English - 21

Page 22

Safety equipment

6.9 Dismantling the throttle control

lock, throttle control and spring

1

Loosen the screw on the rear handle. Remove the

handle insert (A). See gure 19.

2

Loosen the throttle control lock (B) as shown in the

gure using a screwdriver or similar tool. Remove it

then from the shaft in the handle. See gure 20.

3

Press out the throttle control pin (C) with the help

of a punch. See gure 21.

A

Fig 19

Fig 20

4

Loosen the throttle cable (D) and lift out the throttle

control and the spring. See gure 22.

5

Cleaning and inspection

• Carefully clean and check all parts. See gure

13. Parts must be replaced if cracked or show

signs of other defects. Always use original

spare parts.

• Check that the spring is intact and retains all its

tension.

Fig 21

Fig 22

22 - English

Fig 23

Page 23

6.10 Assembling the throttle control

lock, throttle control and spring

1

Lubricate the pin and joined surfaces with a light

oil. Hook on the throttle cable (D). Slide in the

throttle control and make sure the spring is tted as

outlined in gure 24.

NOTE! Make sure that the rear end of the throttle

control is correctly aligned inside the cut-out edging before the pin is pressed in place.

2

Fit the throttle control’s pin (C) using a punch. See

gure 25.

Safety equipment

Fig 24

C

3

Fit the throttle control lock (B) by sliding it on the

shaft in the handle. See gure 26. Make sure the

spring is positioned inside the throttle control lock

when you press it down so that the barbs are

hooked in place.

4

Fit the handle insert using a screw, when the

throttle control, spring, throttle cable and throttle

control lock with pin are tted correctly.

Fig 25

Fig 26

English - 23

Page 24

Repair Instructions

7 Repair instructions

Contents

7.1 Dismantling the starter ....................................................................................................25

7.2 Replacing a broken or worn starter cord ........................................................................26

7.3 Tensioning the return spring ...........................................................................................26

7.4 Replacing a broken return spring ...................................................................................27

7.5 Starter assembly..............................................................................................................27

7.6 Dismantling the ignition module and ywheel .................................................................28

7.7 Assembling the ignition module and ywheel .................................................................29

7.8 Dismantling the centrifugal clutch ...................................................................................30

7.9 Assemby of centrifugal clutch .........................................................................................31

7.10 Dismantling the oil pump and screen .............................................................................31

7.11 Assembling the oil pump and screen ..............................................................................32

7.12 Dismantling the intake system ........................................................................................32

7.13 Assembling the intake system ........................................................................................32

7.14 Carburettor .....................................................................................................................34

7.15 Tank unit .........................................................................................................................42

7.16 Venting the fuel tank .......................................................................................................42

7.17 Vibration damping system ..............................................................................................43

7.18 Replacing the fuel lter ...................................................................................................44

7.19 Replacing the fuel hose/return hose ...............................................................................44

7.20 Replacing the fuel pump ..................................................................................................44

7.21 Dismantling the piston and cylinder ................................................................................45

7.22 Assembling the piston and cylinder ................................................................................47

7.23 Pressure testing the cylinder ..........................................................................................48

7.24 Dismantling the crankshaft and crankcase .....................................................................49

7.25 Assembling the complete crankshaft ..............................................................................54

7.26 Replacing the bar bolt .....................................................................................................53

7.27 Repairing damaged threads ............................................................................................54

24 - English

Page 25

7 Repair instructions

7.1 Dismantling the starter

1

Loosen the four screws, which hold the starter

against the crankcase and remove the starter.

2

Pull the cord out about 30 cm and lift it into the

notch on the outside of the starter pulley. Release

the tension in the return spring by letting the starter

pulley rotate anti-clockwise. See gures 1 and 2.

Repair Instructions

WARNING!

If the spring tension is activated

on the starter pulley, the spring

can fly out and cause personal

injury. Wear protective glasses.

3

Loosen the screw in the centre of the pulley and

remove the pulley. See gure 3. Loosen the screws

on the cassette and remove the cassette and

spring.

Cleaning and inspection

Clean the parts and check:

• The starter cord.

Fig 1

Fig 2

• That the starter pawls on the ywheel are intact,

i.e. that they spring back to the centre and

move easily.

• To lubricate the return spring using light oil.

Fig 3a

English - 25

Page 26

Repair instructions

7.2 Replacing a broken or worn starter

cord

When the starter cord is worn and must be replaced,

the tension in the return spring must be released.

1

Pull the cord out about 30 cm and lift it into the

notch on the outside of the starter pulley. Release

the tension on the return spring by allowing the

starter pulley to rotate slowly backwards.

WARNING!

If the spring tension is activated on

the starter pulley, the spring can fly

out and cause personal injury.

Wear protective glasses.

2

Loosen the screw in the centre of the pulley and

remove the pulley. See gure 3a.

3

When the starter pulley is removed, insert a new

starter cord and attach it to the starter pulley.

Thread the other end of the starter cord through

the hole in the starter housing and starter handle

and tie a double knot on the cord. Wind approx. 3

turns of the starter cord on the starter pulley. Turn

the starter pulley until it latches into the correct position. Tighten the screw at the centre of the starter

pulley, at a tightening torque of 2-3 Nm.

Fig 3b

Cleaning and inspection:

• Clean and check carefully all components. Worn

or damaged parts must be replaced. Lubricate

the return spring with a light oil.

7.3 Tensioning the return spring

1

Pull the starter cord up into the notch in the starter

pulley and turn the pulley about 3 turns clockwise.

Check that the pulley can be turned at least a further 1/2 turn when the starter cord is pulled all the

way out. See gure 4.

2

Stretch the line with the handle. Remove your

thumb and let the cord spin back. See gure 5.

Fig 4

26 - English

Fig 5

Page 27

7.4 Replacing a broken return spring

WARNING!

Exercise care to ensure the spring

does not fly out and cause personal injury. Wear protective goggles.

1

Loosen the screw at the centre of the starter pulley

and loosen the screws on the cassette. Remove

the starter pulley with the cassette and spring.

2

Remove the broken cassette and replace it with a

new one.

3

Tighten the screw at the centre of the starter pulley,

at a tightening torque of 2-3 Nm. Load the return

spring, see “Loading the return spring”. See also

the “Dismantling the starter” chapter.

Repair Instructions

7.5 Starter assembly

1

Position the starter against the crankcase and

tighten the screws at a tightening torque of

3-4 Nm.

English - 27

Page 28

Repair Instructions

7.6 Dismantling the ignition module

and flywheel

1

Remove the cylinder cover. Remove the starter.

Snap off the ignition cable from the guide rail and

remove the guide rail. See gure 7.

2

Knock out a few of the pins in the tool if it does not

match up with the ywheel.

Use the tool to hold the ywheel in place while the

ywheel nut is loosened using a suitable socket

wrench. See gure 8.

Fig 7

4

Thread the mandrel on the crank pin. Screw in until

1-2 threads are left to the ywheel. Knock on the

mandrel with a suitable metal hammer while at the

same time pulling the ywheel outward until the

ywheel comes off the shaft. Remove mandrel and

ywheel. See gure 9.

Unscrew the air nozzle to replace the ignition module. Loosen the screws on the ignition module. See

gure 10.

Dismantle the air lter, air lter holder and carburettor. See the “Dismantling the carburettor” chapter.

Dismantle the tank unit as outlined in the “Dismantling the tank unit” chapter.

Dismantle the intake system, see the “Dismantling

the intake system” chapter.

Fig 8

Fig 9

Loosen the earth cable. See gure 11. Pull the

cables through the openings in the crankcase.

Cleaning and inspection

• Clean all parts, especially the tapers on the

ywheel and shafts.

• Check the ywheel for cracks or any other signs

of damage.

28 - English

Fig 10

Page 29

7.7 Assembling the ignition module and

flywheel

1

Run the cables through the opening in the crankcase. Screw the earth cable in place. See gure 11.

Fit the cabling to the stop button.

2

Position the cable channel as outlined in gure 10.

NOTE! Take care that the cable channel is positioned correctly under the ignition module so that

the cables are not crushed.

3

Place the ignition module in position. See gure 13.

Do not tighten the screws.

Repair Instructions

4

Fit the ywheel onto the crankshaft pin. Turn the

ywheel until the key ts into the key slot on the

shaft. See gure 12.

Tighten the screw for the ywheel.

5

Insert the plastic air gap tool, at a thickness of

0.3 +- 0.1 mm, between the lugs on the ignition

module and ywheel. Turn the ywheel so that the

magnets are positioned opposite the ignition module. Tighten the screws, at a tightening torque of

4.5- 6 Nm. Remove the plastic air gap tool. Fit the

intake system as outlined in “7.14 Assembling the

intake system”, the tank unit as outlined in “7.16

tank unit”, and the air lter as outlined in “Assembling the carburettor”.

6

Press the ignition lead into the holder on the partition wall.

7

Then t:

• The air nozzle

Fig 11

Fig 12

Fig 13

• The guide rail and press the cable in place

• the spark plug hat by unscrewing the piston stop.

•

The starter, at a tightening torque of 2.5-3.5 Nm

• The cylinder cover

English - 29

Page 30

Repair Instructions

7.8 Dismantling the centrifugal clutch

1

Remove the cylinder cover. Release the brake by

moving the kickback guard backwards. Loosen the

bar nuts and remove the clutch cover, chain and

bar. See gure 14.

2

Loosen the spark plug hat and remove the

spark plug, and insert the plastic piston stop

(575 29 36-01). See gure 15.

3

Loosen the clutch using tool 575 25 14-01nd a suitable socket wrench or combination spanner. Turn

the clutch clockwise to loosen it. See gure 15.

Fig 14

4

Secure the clutch in a vice as shown in gure 16.

Carefully remove the clutch springs. Remove the

clutch shoe springs from the side that does not

have text.

NOTE!

Be careful with the clutch springs, as

opening them too much can result in

material damage.

Cleaning and inspection

• Clean and check all parts carefully. Parts must

be replaced if cracked or showing signs of

other defects. Always use original spare parts.

• Check the thickness of the clutch shoes by measuring them with slide callipers across the whole

clutch hub. If the thickness is below 60 mm, the

clutch must be replaced. See gure 16.

Fig 15

Min 60 mm

Fig 16

30 - English

Page 31

7.9 Assembly of centrifugal clutch

1

Insert the clutch springs on the side of the shoes

without text. See gure 17.

2

Screw in the clutch (anti-clockwise) until it stops.

Then tighten the clutch using tool 575 25 14-01

and a suitable socket wrench or combination spanner. Tightening torque of at least 25 Nm.

3

Remove the piston stop and t the spark plug

using a tightening torque of 20 Nm and the spark

plug hat.

Then t:

• The cylinder cover

• The bar

• The chain

• The clutch cover

Repair Instructions

Fig 17

7.10 Dismantling the oil pump and

screen

1

Empty and clean the oil tank.

Dismantle the centrifugal clutch as outlined in

“Dismantling the centrifugal clutch”.

2

Loosen the clutch drum, the drive sprocket, the

needle bearing and the pump drive wheel. See

gure 18.

3

Unscrew the chain guide plate. See gure 19.

4

Loosen the screws on the oil pump from the crankcase and remove it together with the oil pressure

hose. See gure 20.

Cleaning and inspection

• Clean and check all parts carefully. Parts must

be replaced if cracked or showing signs of

other defects. Always use original spare parts.

Fig 18

Fig 19

• Lubricate all moving parts with chain oil.

Fig 20

English - 31

Page 32

Repair Instructions

7.11 Assembling the oil pump and screen

1

Lower the oil lter in place and replace the oil pump

as outlined in gure 19 and tighten the screws.

2

Fit the pump drive wheel, the needle bearing, the

drive sprocket, the clutch drum and the clutch, using a tightening torque of 25 Nm.

3

Adjust the oil pump. See Figure 21.

4

Fit the clutch. See the “Assembling the centrifugal

clutch” chapter.

5

Fit the chain, bar and clutch cover.

WARNING!

Insufficient chain lubrication can

result in chain breakage, which

can cause serious personal injury.

Fig 21

7.12 Dismantling the intake system

The intake system consists of:

• The inlet manifold, A

• The partition wall, B

• The intake ange, C

See Figure 22.

1

Dismantle the cylinder cover.

2

Loosen screws D and the movement limiter E as

outlined in gure 23. Loosen the ignition cable.

Fig 22

D

D

32 - English

Fig 23

D

D

E

Page 33

3

Dismantle the air lter, the lter holder, the cable

from the intake ange holder and the carburettor

and the throttle cable as outlined in “Dismantling

the carburettor”. NOTE! The lug on the carburettor

sits on the bracket on the partition wall.

4

Hook off the cabling from the holder on the intake

system (J). Knock out the POP-out window using a

screwdriver. See gure 25. Lower the tank slightly

and slide the fuel hose down into the hole. Loosen

the lower screws of the intake system using the

POP-out hole and the fuel hose hole. Loosen the

other screws.

Repair Instructions

Fig 24

5

Dismantle the intake system. Pull up and then outward. See gure 26.

Cleaning and inspection

Clean and check all parts carefully. Parts must

be replaced if cracked or showing signs of other

defects. Always use original spare parts.

7.13 Assembling the intake system

1

Assemble the intake system.

2

Fit the lower screws of the intake system using the

POP-out hole and the fuel hose hole. Fit the other

screws. Fit the fuel hose and the throttle cable to

their attachments. See gure 24.

Fit the rubber grommet to the throttle cable. Push

the tank back in position. Hook on the cabling to

the holder on the intake system.

3

NOTE! Press the lug on the carburettor in place on

its bracket on the partition wall. See gure 24.

Fig 25a

Fig 25b

Fit the carburettor, the lter holder and the air lter

as outlined in “Assembling the carburettor”.

Fig 26

English - 33

Page 34

Repair Instructions

7.14 Carburettor

WARNING!

The fuel used in the chain saw has

the following hazardous properties:

1. The fluid and its vapour are

poisonous.

2. Can cause skin irritation.

3. Is highly inflammable.

Description

The gures accompanying this description do not

correspond with the carburettor on the chain saw.

They show only the principle of design and function.

Design

The carburettor is based on three sub-systems:

• Metering unit, A.

• Mixing unit, B.

• Pump unit, C.

The needles and the fuel’s control functions are

located in the metering unit, A. Here the correct

quantity of fuel is adjusted for the actual speed and

power output. See gure 27.

The mixing unit B houses the choke, the throttle

valve and the diffuser jets. Here air is mixed with

the fuel to give a fuel/air mixture that can be ignited

by the ignition spark. See gure 28.

In the pump unit C, fuel is pumped from the fuel

tank to the carburettor’s metering unit. One side of

the pump diaphragm is connected to the crankcase

and pulses in time with the pressure changes in

the crankcase. The other side of the diaphragm

pumps the fuel. See gure 29.

Fig 27

B

Fig 28

34 - English

Fig 29

Page 35

Function

The carburettor operates differently in the following

modes:

• Cold start mode

• Idling mode

• Part throttle mode

• Full throttle mode

In cold start mode the choke valve H is completely

shut. This increases the vacuum in the carburettor

and fuel is easier to suck from all the diffuser jets

D, E, and F. The throttle valve I is partly open. The

throttle valve, J, is closed. See gure 30.

In idling mode, the throttle valves I and J are

closed and the choke valve H is open.

Air is sucked in through an aperture in the throttle

valve and a small amount of fuel is supplied

through the diffuser jet D. See gure 31.

Repair Instructions

Fig 30

In part throttle mode, the throttle valve I is partly

open and the choke valve H is fully open. Fuel is

supplied through the diffuser jets D and E. The

throttle valve, J, starts to open. See gure 32.

In the full throttle mode both valves are open and

fuel is supplied through all four diffuser jets (D, E,

F and G). The throttle valve, J, is fully open. See

gure 32.

Fig 31

Fig 32

Fig 33

English - 35

Page 36

Repair Instructions

Dismantling the carburettor

1

Dismantle the cylinder cover and the air lter.

2

Loosen the screws, F. Unhook the rubber attachment G on both sides. See Figure 35.

3

Loosen the suction hose A, the return hose B, and

the tank bleeding hose C. See gure 34.

4

Remove the air lter holder. Let the air lter holder

remain in place in the cabling for the stop button.

Loosen the fuel hose, D. Unhook the throttle cable,

E. See gure 34.

Fig 34

5

NOTE! Press down the lug to release the carburettor. Lift out the carburettor. See gure 36.

NOTE!

The lug on the carburettor is securely

attached to the partition wall.

6

Use a small at screwdriver to snap open the connector from the black attachment. Separate the

connector by pressing down the catch with a at

screwdriver and then pulling the unit apart. See

gure 37.

Fig 35

D

E

Fig 36

36 - English

Fig 37

Page 37

7

Dismantle the pump cover H and carefully remove

the control diaphragm J and gasket K.

8

Unscrew screw P and remove needle valve M with

lever arm Q, shaft L and spring R.

9

Use a needle or similar device and carefully pull up

the fuel screen (W). See gure 39.

10

If necessary, dismantle throttle valve T and choke

valve U and air valve S, and remove the shafts with

lever arms and springs (see gure 39).

11

If necessary, dismantle the AutoTune AB unit. See

gure 39.

Repair Instructions

H

J

K

L

M

Q

R

Fig 38

P

English - 37

Page 38

Repair Instructions

S

T

W

X

U

Y

V

Z

AB

Cleaning and inspection

Clean all units in clean petrol.

Use compressed air to dry the petrol on the components. Direct the air through all channels in the

carburettor housing and ensure that they are not

blocked. Check the following:

1. That the gasket, pump and control diaphragms

are undamaged, as well as the gasket between

the carburettor body and the autotuner.

2. That there is no play on the throttle and choke

valve shafts.

3. That the needle valve M and its lever arm Q are

not worn. See gure 38.

4. That the fuel screen W is intact and clean. See

gure 39.

5. That the inlet manifold V is intact. See gure 39.

6. Use the service tool, Engine Diagnostic Tool

576 69 23-01, to inspect the AutoTune unit.

See separate instruction.

Assembly

Observe cleanliness when assembling the carburettor. The slightest contamination can result in

downtime.

1. If throttle and choke valves with shafts, lever

arms and springs are removed, these must be

assembled. The spring is tensioned 1-2 turns.

Lubricate the shaft bearings using a light oil.

2. Fit the fuel screen W using the handle of a

small screwdriver. See gure 39.

3. Fit the gasket X in the carburettor as well as the

holder Y. Screw in place screw Z as outlined in

gure 39.

4. See gure 39 on how to assemble the

AutoTune AB unit with gasket.

Note! When replacing the AutoTune unit or car-

burettor with an AutoTune unit, the unit must rst

be programmed before it can be used. Refer to

the local support page for more information.

Fig 39

38 - English

Page 39

4. Assemble needle valve M with lever arm Q,

shaft L and spring R, and tighten screw P.

(Fit the expansion washer). See gure 40.

Repair Instructions

Fig 40

5. Check using a ruler or the like that the lever is

level with the assembly plane on the cover.

If necessary, the lever arm can be bent, see

gure 41.

7. Fit gasket K, the control membrane J and the

pump cover H. See gure 42.

8. Carry out a pressure test.

Fig 41

H

J

Fig 42

K

English - 39

Page 40

Repair Instructions

Pressure testing the carburettor

Pressure testing should be carried out with the carburettor fully assembled. Testing should always be

carried out after the carburettor has been repaired,

but a test can also be made for troubleshooting

before dismantling.

Option 1

See the gure and carry out the check as follows:

1

Connect pressure tester to the carburettor fuel inlet.

2

Submerge the carburettor into a container with

water. See gure 43.

3

Pump up the pressure to 20 kPa.

4

No leakage is permitted. If a leakage occurs refer

to the table below.

Option 2

1

Plug the connections to the fuel inlet.

2

Create a vacuum to the purge nipple on the carburettor. No leakage is permitted. In the case of

leakage, leakage spray can be used even it if is difcult. Try and identify where the spray is absorbed.

It can be used to show leakages in main jets, idling

needles, measuring cover gaskets and measuring

diaphragms, and autotune gaskets.

Leak in Fault with

Fig 43

Diffuser jets Needle valve

Leak in the impulse pipe Pump membrane

Ventilation hole on the Control membrane

metering unit.

Fitting on the saw

1

Press the connector together as outlined in gure

44 and push it into place in the holder.

Fig 44

Fig 45

40 - English

Page 41

2

Make sure the cabling is tted to its mounting on

the intake ange.

Press the fuel hose (D) in place in the collar on the

intake bellows.

Hook on the throttle cable (E) in its mounting on

the intake bellows. See gure 46.

Make sure the lug on the carburettor hooks in

place on its mounting on the intake system.

Make sure that the following components are

correctly fitted:

• Position the air lter holder against the carburettor.

• Make sure the carburettor cover’s intake channel

is aligned correctly with the slot for the air lter

holder.

• The spring must be tted under the choke pin on

the carburettor. See gure 47.

• The rubber collar on the stop button must be on

the inside of the bottom of the carburettor compartment. See gure 47.

• NOTE! Make sure that the fuel and return hoses

are not crushed.

Repair Instructions

D

E

Fig 46

3

Position the guide taps on the air lter holder in the

rubber grommets, G. See gure 48.

4

Hook on the throttle cable, E. See gure 46.

Fasten the return hose B and secure it in its mountings on the air lter holder.

Attach the pressure hose A, with the short hose on

the short plastic plug on the fuel pump.

Attach the tank bleeding hose, C. See gure 49.

5

Hook it on the left side and then the right side of

the carburettor in the rubber mounting. Then screw

the carburettor in place. See gure 48.

Fig 47

Fig 48

6

Fit the air lter.

Fig 49

English - 41

Page 42

Repair Instructions

7.15 Tank unit

WARNING!

The fuel used in the chain saw has

the following hazardous properties:

1. The fluid and its vapour are poisonous.

2. Can cause skin irritation.

3. Is highly inflammable.

Dismantling

1. Drain the fuel from the tank.

2. Remove the cylinder cover, the clutch cover, the

chain and the bar. See the Operator’s Manual.

Dismantle the carburettor as outlined in “Dismantling the carburettor”.

3. Loosen the hoses A to D. See gure 50.

4. Loosen the screws F. See gure 51.

5. Loosen the movement limiter H. See gure 53.

6. Pull out the hoses A to D in the bottom of the carburettor compartment. Unhook the throttle cable,

E, from the intake bellows before pulling out from

the bottom of the carburettor compartment.

Fig 50

NOTE!

Exercise care so that the fuel hose and

throttle cable are not damaged.

7.16 Venting the fuel tank

The two-way valve has the following properties:

• Controlled opening pressure in both directions,

which prevents a positive pressure or a vacuum developing in the fuel tank and impairing

engine performance. This also prevents fuel

leakage.

• Opening pressure outward 100-450 mbar.

• Opening pressure inward (vacuum) max.

70 mbar. (2 locations)

Test

Opening pressure outwards:

1. Open the tank lock and leave it open during the

entire test. Drain the fuel from the tank.

2. Loosen the positive pressure hose as outlined

in gure 54. Connect the pump, ref. no. 531 03

06-23, to the tank valve J.

3. Switch the pump to vacuum mode.

4. After pumping the indicator should be between

10-45 kPa.

Opening pressure inwards:

1. Open the tank lock and leave it open during the

entire test. Drain the fuel from the tank.

2. Loosen the positive pressure hose as

outlined in gure 54. Connect the pump,

ref. no. 531 03 06-23, to the tank valve J.

3. Switch the pump to pressure mode.

4. After pumping the indicator should stop at max.

7 kPa.

Fig 51

G

G

Fig 52

Fig 53

42 - English

Page 43

Assembly

1. Thread the throttle cables in the connection M

as outlined in gure 55. NOTE! The gure is

shown from underneath.

2. Run the fuel hose D through hole K and hoses

B and C in hole L. See gure 55. Pull the hoses

so that the collars are on each side of the bottom on the carburettor compartment.

3. Tighten the chain catcher in place.

4. Press the movement limiter H into position. See

gure 53.

5. Tighten the screws F. See gure 51.

6. Hook on the throttle cable E in the intake bellow.

See gure 50.

7. Fit the tank unit. The two short screws are tted

to the bottom of the handle bar.

8. Assemble the carburettor as outlined in “Assembling the carburettor”. Assemble the air lter

and cylinder cover.

Repair Instructions

Fig 54

7.17 Vibration damping system

Dismantling

1. Dismantle the following parts:

• Bar and chain. See the Operator’s Manual.

• Cylinder cover. See the Operator’s Manual.

• Tank unit and handle. See “Dismantling the

tank unit”.

2. Dismantle the spring on the handle bar using a

4 mm Allen key (see gure 57).

3. Dismantle the springs on the tank unit using

a 4 mm Allen key (tool 502 50 18-01). See

gure 57.

Cleaning and inspection

Clean and inspect all parts.

Assembly

1. Fit the springs on the handle bar using a 4 mm

Allen key (tool 502 50 18-01).

Fig 55

Fig 56

2. Assemble the following parts:

• Tank unit and handle. See “Assembling the

tank unit”.

• Cylinder cover. See the Operator’s Manual.

• Bar and chain. See the Operator’s Manual.

Fig 57

English - 43

Page 44

Repair Instructions

7.18 Replacing the fuel filter

NOTE!

Fluted pliers may not be used with the fuel

hose. They can cause material damage

resulting in damage to the fuel hose.

1

When replacing the fuel lter, the old fuel lter must

be taken out of the tank unit using special tool

502 50 83-01.

2

Pull out fuel hose B from the tank unit and pull

away the lter A. See gure 58.

3

Fit the new fuel lter A and press the

fuel hose back into place.

7.19 Replacing the fuel hose/return hose

The fuel hose is moulded and can only be removed

from outside of the fuel tank.

Use suitable pliers with a smooth cutting face and

loosen the hose B from the fuel tank. See gure 58.

Replace the return hose when required. Tighten

the fuel hose on the lter side with your ngers.

Fig 58

7.20 Replacing the fuel pump (Purge)

Dismantle

1. Dismantle the cylinder cover and the air lter.

2. Loosen suction hose C and return hose from

the fuel pump. See gure 59.

3. Snap off the fuel pump from the lter holder.

Assembling

1. Snap the fuel pump in place in the lter holder.

See gure 59.

2. Fit the return and suction hose on the fuel

pump.

3. Assemble the air lter and cylinder cover.

Fig 59

44 - English

Page 45

7.21 Dismantling the piston and cylinder

1

Dismantle:

• The cylinder cover

• The carburettor (see “Dismantling the

carburettor”)

• The mufer

• The vibration element

• The spark plug cap

• The intake system

2

Unscrew the cylinder’s four screws

and carefully lift away the cylinder and the gasket.

See gure 60.

NOTE!

Take care to prevent any dirt and foreign

particles from entering the crankcase.

Repair Instructions

Fig 60

3

Cover over the crankcase opening.

4

Remove the circlips for the gudgeon pin and press

out the gudgeon pin. The lift off the piston. See

gure 61.

5

Remove the gudgeon pin bearing (the needle bearing) using a pliers. See gure 61. Replace with a

new bearing.

Cleaning and inspection of the cylinder

Clean all components, scrape off all gasket remains and soot from the following areas:

• The piston crown

• The top of the cylinder bore (inside)

• The cylinder exhaust port

• The base of the cylinder and/or crankcase

Fig 61

English - 45

Page 46

Repair Instructions

Check the following:

• That the cylinder’s surface coating is not worn.

Especially the upper part of the cylinder.

• That the cylinder does not have any chafe or

cutting marks.

• That the piston is free of score marks. Minor

scratches can be polished off using ne emery

paper.

• That the piston ring is not burnt into its groove.

• Measure the wear on the piston ring. This must

not exceed 1 mm. See gure 62. Use the piston to push the piston ring downward.

• That the gudgeon pin bearing is intact.

• That the intake bellows is intact.

• Pressure test the decompression valve. Carry

out pressure testing on the decompression

valve as follows. See also gure 68.

Fig 62

A. Fit the pressure gauge tool 531 03 06-23 to

the decompression valve.

B. Pump up the pressure to 80 kPa (0.8 bar).

C. Wait 30 seconds.

D. The pressure must not fall below 60 kPa

(0.6 bar).

Unscrew the cover plates for the carburettor and

mufer. Tighten the screws to the stated torque.

Remove the pressure test connection 503 84 40-02

and t the spark plug.

Fig 68

46 - English

Page 47

Faults and causes

Score marks on the piston (A)

1. Leakage, check not carried out.

2. Too low octane fuel.

3. Too low or incorrect oil in the fuel.

Carbon build-up (B)

1. Too much or incorrect oil in the fuel.

See Figure 63.

Piston ring breakage

1. Piston ring worn out.

2. Oversized piston ring groove.

7.22 Assembling the piston and cylinder

Fig 63

A

Repair Instructions

B

1

Oil the gudgeon pin bearing with two-stroke oil and

insert it into the crank rod. See gure 64.

2

Replace the piston with the arrow facing the exhaust port, and slide in the gudgeon pin and t the

circlips. NOTE! Use new circlips. See gure 64.

3

Oil the piston and piston ring with two-stroke oil.

4

Put a new cylinder base gasket in place. Compress

the piston ring and carefully push the piston into

the cylinder opening.

5

Attach the cylinder. The screws must be tightened

crosswise with a tightening torque of 8-10 Nm.

NOTE!

It is very important that the intake system is

sealed. Otherwise the engine may seize up.

Fig 64

Fig 65

English - 47

Page 48

Repair Instructions

7.23 Pressure testing the cylinder

1

Loosen

• The cylinder cover

• The carburettor

2

Attach the cover plate 574 71 14-01 and plug

574 70 12-01. See gure 66.

3

Loosen the screws on the mufer and press the

cover plate 575 29 05-01 between the mufer and

cylinder. Tighten the screws for the mufer. See

gure 66. Use the plastic piston stop 575 29 36-01.

Fig 66a

4

Screw the pressure test connection 503 84 40-02

in place. Connect tool 531 03 06-23 to the nipple.

5

Pump the pressure up to 80 kPa (0.8 bar). Wait

30 seconds. The pressure should not be less than

60 kPa (0.6 bar). Remove the cover plates from

the silencer and carburettor, tighten the bolts to the

specied torque. Remove the pressure test nipplleand ret the spark plug.

WARNING!

Once the cylinder has been

pressure tested, make sure the

inlet manifold is fitted correctly.

Otherwise the chainsaw can be

damaged.

Fig 66b

Fig 67

48 - English

Page 49

Repair Instructions

7.24 Dismantling the crankshaft and

crankcase

1

Dismantle the following:

• The clutch cover

• The chain and bar.

• The centrifugal clutch *

• The cylinder cover

• The starter *

• The ywheel *

• The carburettor *

• The bottom of the carburettor *

• The hand guard *

• The mufer *

• The handle system *

• The fuel unit *

• The piston and cylinder *

• The ignition module

• Cabling

x4

Fig 69

• The oil pump

* See specic instruction.

NOTE!

Take care to prevent any dirt and foreign

particles from entering the bearings.

2.

If required, remove the circlip on the ywheel side.

3.

Remove the 5 screws from the pulley wheel side.

See Figure 69.

4.

Fit tool 575 28 69-01 as outlined in gure 70.

Remove the crankcase half on the clutch side.

5.

Fit tool575 28 69-01 as outlined in gure 71.

Remove the ywheel side’s crankcase half.

6.

Carefully pull the crankcase halves apart. Two

guide pins keep the crankcase halves together. Lift

out the connecting rod and dispose of the gasket.

Fig 70

WARNING!

Beware of burn injuries as the crankcase

halves are hot. Wear protective gloves.

Fig 71

English - 49

Page 50

Repair Instructions

7.

If required, remove the crankshaft bearing from the

crankcase.

Proceed as follows:

A. Remove the oil rell cap.

B. Heat up the crankcase half in question to 200°C.

C. Use protective gloves. Press the bearing out of

the crankcase half.

8.

If the crankshaft bearings are still attached to the

crankshaft when dismantling, pull them off using

the 531 00 48-67 pulling device. See gure 73.

Also inspect the bearing grip in the crankcase half.

Cleaning and inspection

Fig 72

NOTE!

If the bearings are fitted to the crankcase,

take care to prevent any dirt and foreign

particles from entering.

Clean all parts and scrape off all gasket remains

from the contact surfaces on the crankcase halves.

Check the following:

1.

That the big-end bearing does not have any radial

play. Axial play is permitted. See gures 74 and 75.

2.

That the big-end bearing does not have any score

marks or is discoloured on the sides.

3.

That the bearing surface for the gudgeon pin bearing

does not have any score marks or is discoloured.

4.

That the crankshaft bearing has no play or knocks.

Fig 73

Fig 74

5.

That the sealing surfaces of the sealing rings tted

against the crankshaft are not worn, and that the

rubber is not hard.

6.

That the crankcase is not cracked.

50 - English

Fig 75

Page 51

Assembly

WARNING!

Beware of burn injuries as the

crankcase halves are hot. Wear

protective gloves.

1

Proceed as follows if a bearing must be tted:

A. Heat up the crankcase half in question to 200°C.

B. Use protective gloves. Fit the bearing in the

ywheel side of the crankcase half. When tting

the bearing in the clutch side of the crankcase

half, the bearing must be tted aligned with the

inside of the crankcase.

C. Allow the crankcase half to cool down before

continuing with the work.

NOTE!

Take care to prevent any dirt and foreign

particles from entering the bearings.

Repair Instructions

Fig 76

D. Fit the oil rell cap.

2.

See page 52, gure 80, for how to t new sealing

rings.

NOTE!

Make sure the connecting rod is not crushed

against the crankcase when the crankcase

and crankshaft are fitted together.

3.

Use the 502 50 30-23 tool. Use the back end of

the sleeve and slot the crankshaft in place into the

clutch side of the crankcase half. See Figure 76.

Tighten until the crankshaft collar comes into contact with the bearing.

4.

Insert the guide pin in the crankcase half on the

clutch side, apply grease and t the gasket(C). See

Figure 77.

5

Use the 502 50 30-23 tool. Turn the sleeve and slot

the crankcase half in place on the ywheel side.

Tighten until the gasket is pinned in place between

the crankcase halves. See Figure 78.

6

Fit the screws. Tighten them alternately. Finally

tighten then to 8 Nm. See gure 79.

7

Fit the carburettor bottom with the four screws.

Tighten the screws using 5 Nm of torque. See

gure 79.

Fig 77

Fig 78

x4

NOTE!

Make sure that any excess gasket does

not finish up in the crankcase.

Fig 79

English - 51

Page 52

Repair Instructions

8

Assemble the following parts:

A. Tank unit. See page 43.

B. Piston and cylinder. See page 47.

C. Mufer. See page 19.

D. Carburettor. See page 40.

E. Centrifugal clutch. See page 31.

F. Electrical System. See page 29.

G. Starter. See page 25.

H. Bar and chain. See the Operator’s Manual.

Sealing rings

1

To replace the crankshaft’s sealing rings, rst dismantle the following parts:

On the ywheel side:

• Starter. See page 25.

• Flywheel. See page 28.

On the clutch side:

• Bar and chain. See the Operator’s Manual.

• Chain guide plate. See page 17.

• Centrifugal clutch. See page 30.

• Oil pump. See page 31.

2

Use a screwdriver to remove the sealing ring and

pull it out.

3

Slide the dowel 575 34 69-01 (gure 80) on the

crankcase pin. Knock the new sealing ring in place

using the 575 34 70-01 tool. See Figure 81.

4

Fit the parts as outlined in point 1 above.

Fig 80

Fig 81

52 - English

Page 53

7.25 Assembling a complete crankshaft

1

Fit the complete crankshaft in the crankcase.

Fit the following parts:

• The piston and cylinder *

• The fuel unit *

• The handle system *

• The mufer *

• The hand guard *

• The bottom of the carburettor *

• The carburettor *

• The ywheel *

• The starter *

• The cylinder cover

• The centrifugal clutch *

Repair Instructions

• The chain and bar.

• The clutch cover

* See specic instruction.

English - 53

Page 54

Repair Instructions

7.26 Replacing the bar bolt

Replacing a bar bolt with intact crankcase

1

Empty the oil tank.

2

Knock in the old bar bolts from the outside so that

they end up in the oil tank.

3

Remove the bolts from the oil tank.

4

Attach a wire to the head of the bar bolt, lower the

wire through the oil tank and out through the bolt

opening in the crankcase. See gure 83.

5

Pull out the bar bolt so that it protrudes from its

opening. See gure 83.

Fig 83

6

Pull out the bar bolt with its nut. Insert a spacer

between the nut and the crankcase. See gure 83.

7

Fill with chain oil.

7.27 Repairing damaged threads

If threads on the chainsaw are worn, the reparation kit, 503 27 33-01, is available.

First drill with:

6.1 mm drill for the magnesium crankcase

Then screw in the thread plug using a suitable

screw and wrench.

This type of screw plug is ideal for plastic

and magnesium but cannot be used to repair

threads in aluminium. There is another type of

thread plug and metric screw available for this

purpose. See gure 84. Check the manufacturer’s manual for thread information.

Fig 84

54 - English

Page 55

English - 55

Page 56

Troubleshooting

8 Troubleshooting

Contents

8.1 Troubleshooting ..............................................................................................................57

8.2 Troubleshooting methods ...............................................................................................58

56 - English

Page 57

Troubleshooting

8.1 Troubleshooting

The different faults which may occur on the chain saw are divided into four groups. Within each group

possible operating faults are listed to the left while the probable fault alternatives are listed to the right.

The most likely fault is listed rst, etc. See separate instruction for Autotune troubleshooting.

Starting

Idling (low speed) (continued)

Difcult to start

The carburettor

leaks fuel

Floods when the

engine is not

running

Air lter blocked

Choke does not work

Worn choke axle

Worn choke valve

Blocked fuel lter

Blocked fuel line

Piston ring is stuck

Blocked impulse channel

Loose or faulty fuel pipe

Hole in diaphragm

Worn needle/needle tip

Control system sticking

Control system set too high

Leaking control system

(air or fuel)

The cover on the carburettor

pump side is loose

Worn needle/needle tip

Control system set too high

Control system sticking

Uneven idling

Worn needle/needle tip

Leaking diaphragm/cover plate

Worn lever arm in the control

system

Faulty diffuser jet

Blocked fuel lter

Blocked fuel line

Leaking inlet hose (rubber)

Loose carburettor mounting

Worn throttle valve axle

Loose throttle valve screw

Worn throttle valve

Leaking control system

(air or fuel)

The control system’s centre

knob is worn

Hole in diaphragm

Leaking diaphragm/

cover plate

Leaking crankcase

Idling (low speed)

Does not idle

Too rich idling

Leaking inlet hose (rubber)

Loose carburettor mounting

Loose or faulty fuel pipe

Blocked fuel lter

Blocked fuel line

Tank ventilator blocked

The throttle valve shaft is inert

Throttle stay is binding

Defective throttle return spring

Bent valve axle stop

Faulty diffuser jet

Worn needle/needle tip

Worn lever arm in the control

system

Leaking diaphragm/cover plate

Too much fuel at

idle speed

Blocked fuel line

Leaking control system

(air or fuel)

Leaking diaphragm/cover plate

Faulty diffuser jet

Leaking crankcase

Worn needle/needle tip

Leaking diaphragm/

cover plate

English - 57

Page 58

Troubleshooting

High speed

Will not run

at full throttle

Low power

Will not “four

stroke”

Blocked air lter

Tank venting clogged

Blocked fuel lter

Blocked fuel line

Loose or faulty fuel pipe

Impulse channel leaking

Blocked impulse channel

The cover on the carburettor

pump side is loose

Faulty pump diaphragm

Leaking inlet hose (rubber)

Loose carburettor mounting

Control system set too low

Damaged control system

Control system incorrectly

assembled

Leaking diaphragm/cover plate

Control system sticking

Blocked mufer

Tank venting clogged

Blocked fuel lter

Impulse channel leaking

Blocked impulse channel

The cover on the carburettor

pump side is loose

Faulty pump diaphragm

Blocked air lter

Control system sticking

Leaking control system (air or

fuel)

Control system incorrectly

assembled

Loose diaphragm

Hole in diaphragm

Leaking diaphragm/cover plate

Tank venting clogged

Blocked fuel lter

Blocked fuel line

Loose or faulty fuel pipe

Impulse channel leaking

Blocked impulse channel

The cover on the carburettor

pump side is loose

Faulty pump diaphragm

Leaking inlet hose (rubber)

Loose carburettor mounting

Control system set too low

Leaking control system

(air or fuel)

Control system incorrectly

assembled

Loose diaphragm

Hole in diaphragm

Leaking diaphragm/cover plate

Acceleration and retardation

Does not

accelerate

The engine

stops when

releasing the

throttle

Blocked air lter

Tank venting clogged

Blocked fuel lter

Blocked fuel line

Loose or faulty fuel pipe

Blocked impulse channel

The cover on the carburettor

pump side is loose

Faulty pump diaphragm

Leaking inlet hose (rubber)

Loose carburettor mounting

Control system set too low

Control system incorrectly

assembled

Control system sticking

Faulty diffuser jet

Blocked mufer

Faulty pump diaphragm

Control system set too high

Control system sticking

Faulty diffuser jet

Blocked air lter

Faulty pump diaphragm

Faulty diffuser jet

8.2 Troubleshooting methods

In addition to faults given in the above schematic,

troubleshooting can be carried out on a specic

component or specic chain saw system. The

different procedures are described in respective

sections and are as follows:

• Function check of chain brake

• Resistance testing the stop plate

• Pressure testing the carburettor

• Pressure testing the decompression valve

• Pressure testing the cylinder

58 - English

Page 59

• 115 26 56-26

2011W31

Loading...

Loading...