EN

ES

SE

FI

DK

NO

IT

PT

GR

CZ

SK

SI

HU

PL

EE

L V

L T

HR

BG

FR

DE

NL

TR

R O

Operator's Man ual,

Man ual de instrucciones ,

Bruksan visning,

Käyttöohje ,

Brugsan visning,

Bruksan visning,

Istruzioni per l’uso ,

Instruções para o uso ,

∂Á¯ÂÈÚ›‰È Ô ÃÚ‹Û˘ , 157-179

Návod k pouÏití , 180-197

Operátorská príruãka , 198-215

Navodila za uporabo , 216-233

Használati utasítás , 234-252

6-23

24-43

44-61

62-79

80-97

98-115

116-135

136-156

Instrukcja obs∏ugi , 253-273

Käsitsemisõpetus , 274-291

Lieto‰anas pamÇc¥ba , 292-309

Naudojimosi instrukcijos , 310-327

Priruãnik , 328-345

ъководство за експлоатациЯ,

346-368

Man uel d'utilisation,

Bedien ungsanw eisung,

Gebruiksaanwijzing,

Kullaním kílavuzu, 428-445

Instrucöiuni de utilizare, 446-463

369-387

388-407

408-427

235e, 236e

240e, 240e

T

rioBrake

2

A

2

5

1

11

24

23

15

26

25

2

10

9

30

3

11

4

12

5

6

7

3

B

240e TrioBrake

6

1

16

17

18

8

1413

28

4

E

A

7

19

29

27

22

21

20

A

C

B

8

11

9

12

10

13

1154212-26 Re v

.3 2012-02-22

3

14

18

21

24

15

19

22

25

17

A

16

20

23

OFF HALF FULL

26

27

30

1154212-26 Re v .3 2012-02-22

28

31

29

32

4

33

34

37

5

4

10

3

7

6, 8

2

35

9

36

38

39

41

Danger zone

Retreat path

Danger

zone

Felling

Direction

Danger

Retreat path

zone

40

1

2

1

3

1

2

42

1154212-26 Re v

.3 2012-02-22

5

A

43

45

47

49

240e TrioBrake

46

44

50

48

A

1154212-26 Re v .3 2012-02-22

51

52

3

2

1

INTR

ODUCTION

6

W

Dear Customer ,

Cong ratulations on your choice to buy a Husqvarna

product! Husqvarna is based on a tradition that dates back

to 1689, when the Swedish King Karl XI ordered the

construction of a factory on the banks of the Husqvarna

River, for production of muskets. The location was logical,

since water power was harnessed from the Huskvarna

River to create the water-powered plant. During the more

than 300 years of beeing, the Husqvarna factory has

produced a lot of different products, from wood stoves to

modern kitchen appliances, sewing machines, bicycles,

motorcycles etc. In 1956, the first motor driven lawn

mowers appeared, followed by chain saws in 1959, and it

is within this area Husqvarna is working today.

Today Husqvarna is one of the leading manufacturers in

the w

orld of forest and garden products, with quality as our

highest priority. The business concept is to develop,

manufacture and market motor driven products for forestry

and gardening as well as for building and construction

industry. Husqvarna

according to ergonomics, usability, security and

environmental protection. That is the reason why we have

developed many different f eatures to pro vide our products

within these areas.

We are convinced that you will appreciate with great

satisf

action the quality and performance of our product for

a very long time to come. The purchase of one of our

products gives you access to professional help with repairs

and service whenever this may be necessary . If the retailer

who sells your machine is not one of our authorised

dealers, ask for the address of your nearest service

workshop.

It is our wish that you will be satisfied with your product and

that it will be y

operator

′

s manual as a valuable document. By following

its

′

content (using, service, maintenance etc) the life span

and the second-hand value of the machine can be

extended. If you will sell this machine, make sure that the

buyer will get the operator

Thank you for using a Husqvarna product.

′

s aim is also to be in the front edge

our companion for a long time. Think of this

′

s manual.

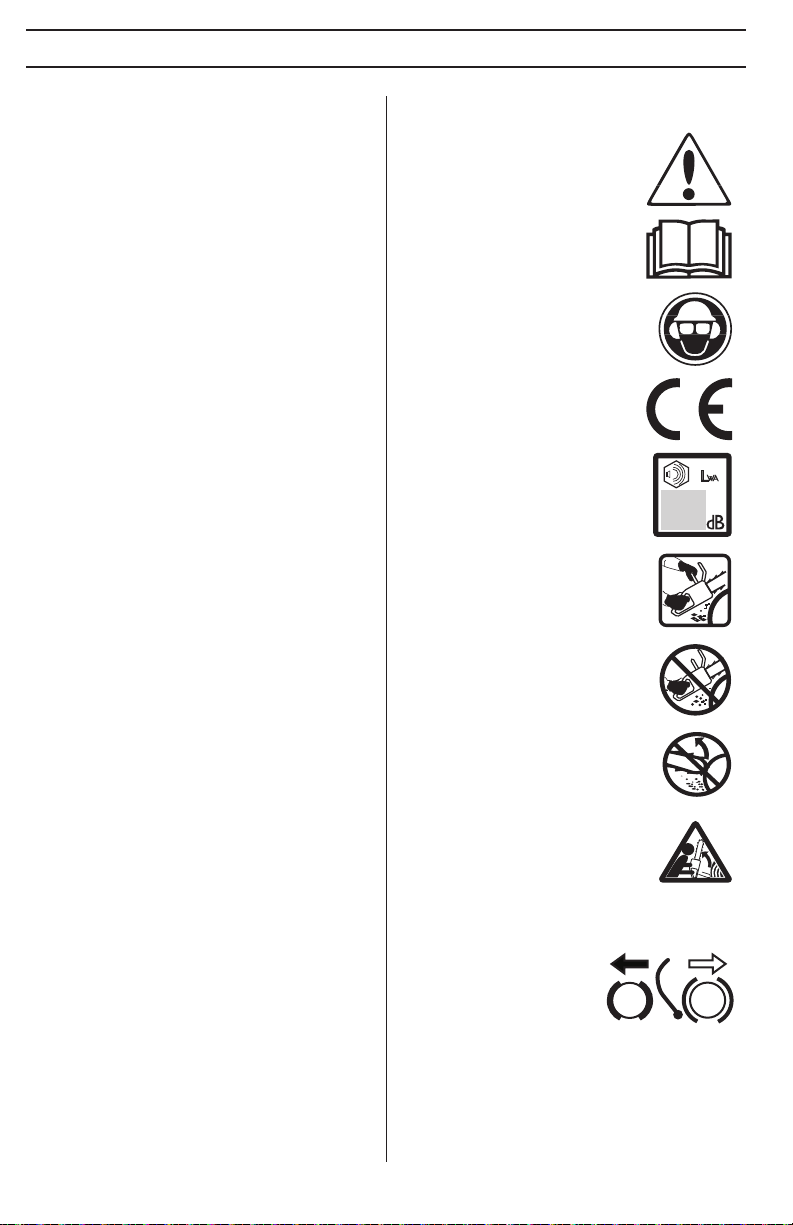

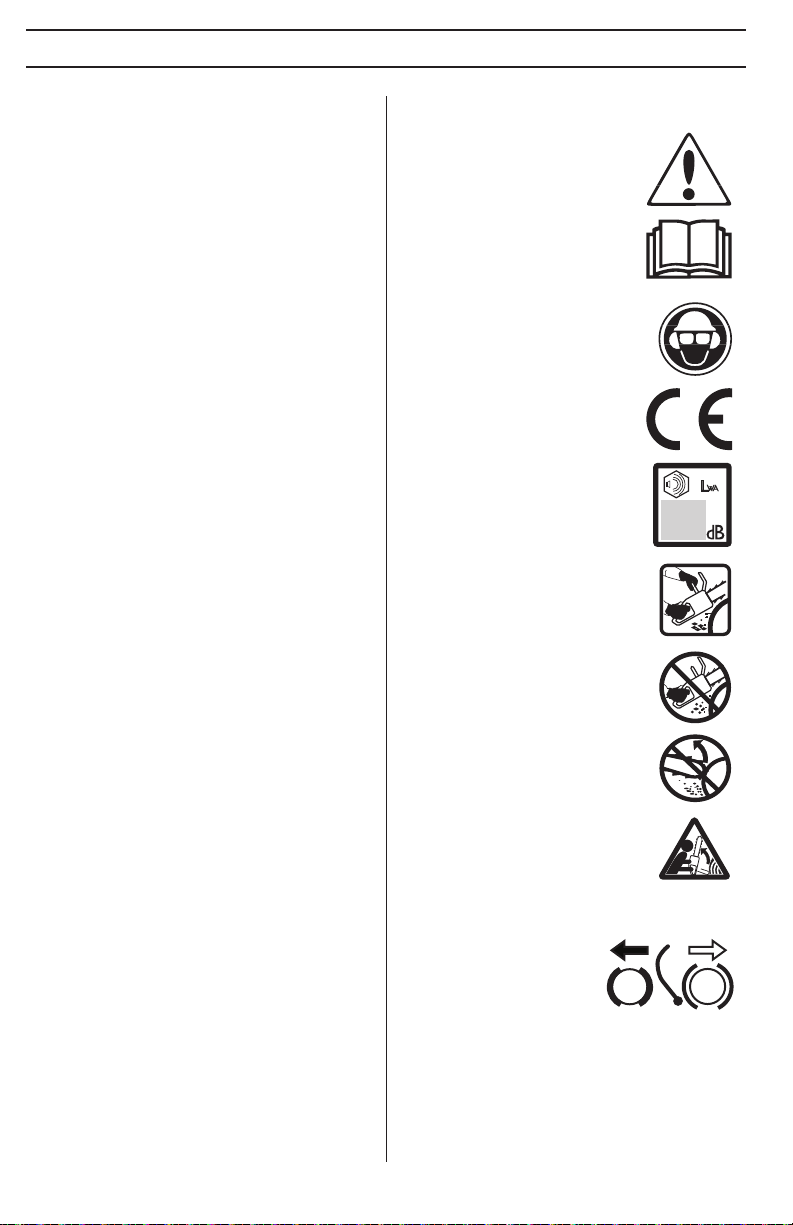

Symbols on the mac hine:

ARNING! Chain saws can be

dangerous! Careless or incorrect use

can result in serious or fatal injury to

the operator or others.

Please read the operator’s manual

carefully and mak

understand the instructions before

using the machine.

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

This product is in accordance with

applicab

Noise emission to the environment

according to the European

Comm

unity’s Directive. The machine’s

emission is specified in chapter

Technical data and on label.

Both of the operator

used to operate the chain saw.

Never operate a chain saw holding it

with one hand only

Contact of the guide bar tip with any

object m

e sure you

le EC directives.

′

s hands must be

.

ust be avoided.

Husqvarna AB has a policy of continuous product

velopment and therefore reserves the right to modify the

de

design and appearance of products without prior notice.

– English

WARNING! Kickback may occur when

the nose or tip of the guide bar touches

an object, and cause a lightning f

reverse reaction, kicking the guide bar

up and towards the operator. May cause

serious personal injury.

Chain brake, activated (left)

Chain br

ake, not activated

(right)

Other symbols/decals on

the machine refer to special certification requirements

for certain markets.

ast

1154212-26 Re v .3 2012-02-22

INTRODUCTION / CONTENTS

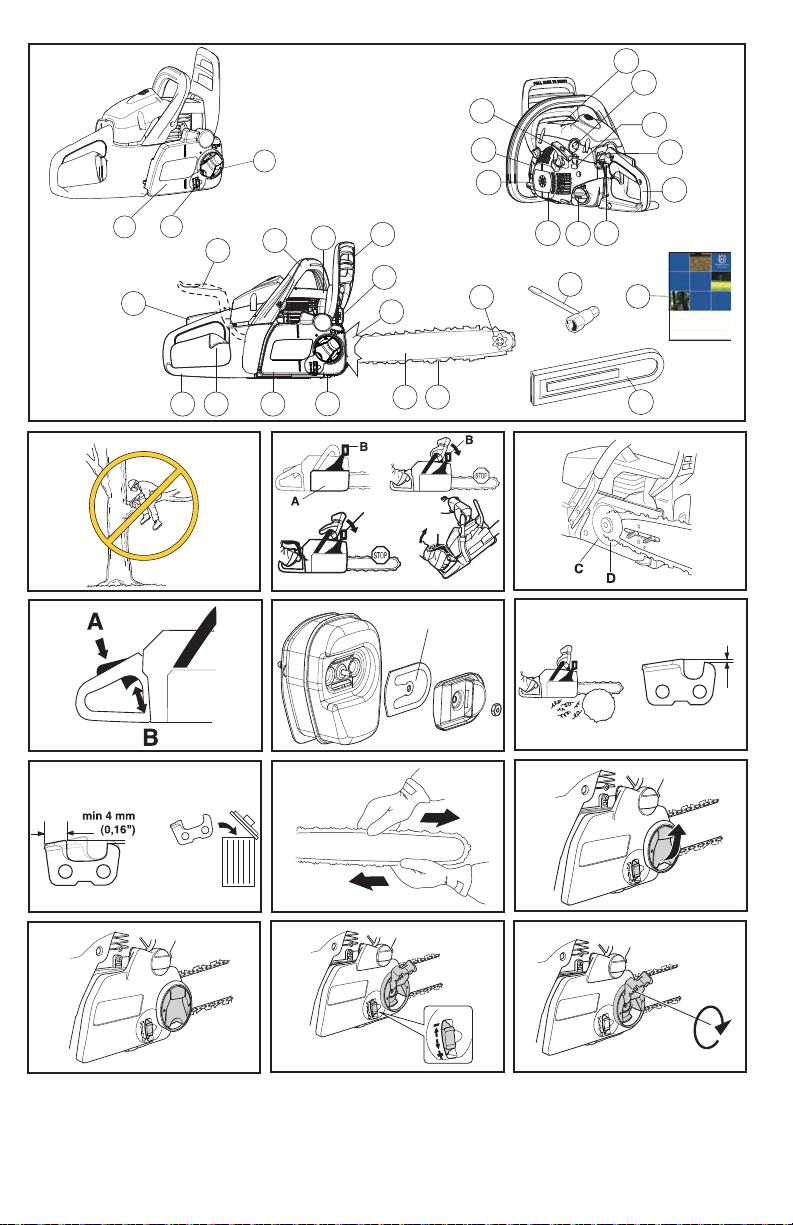

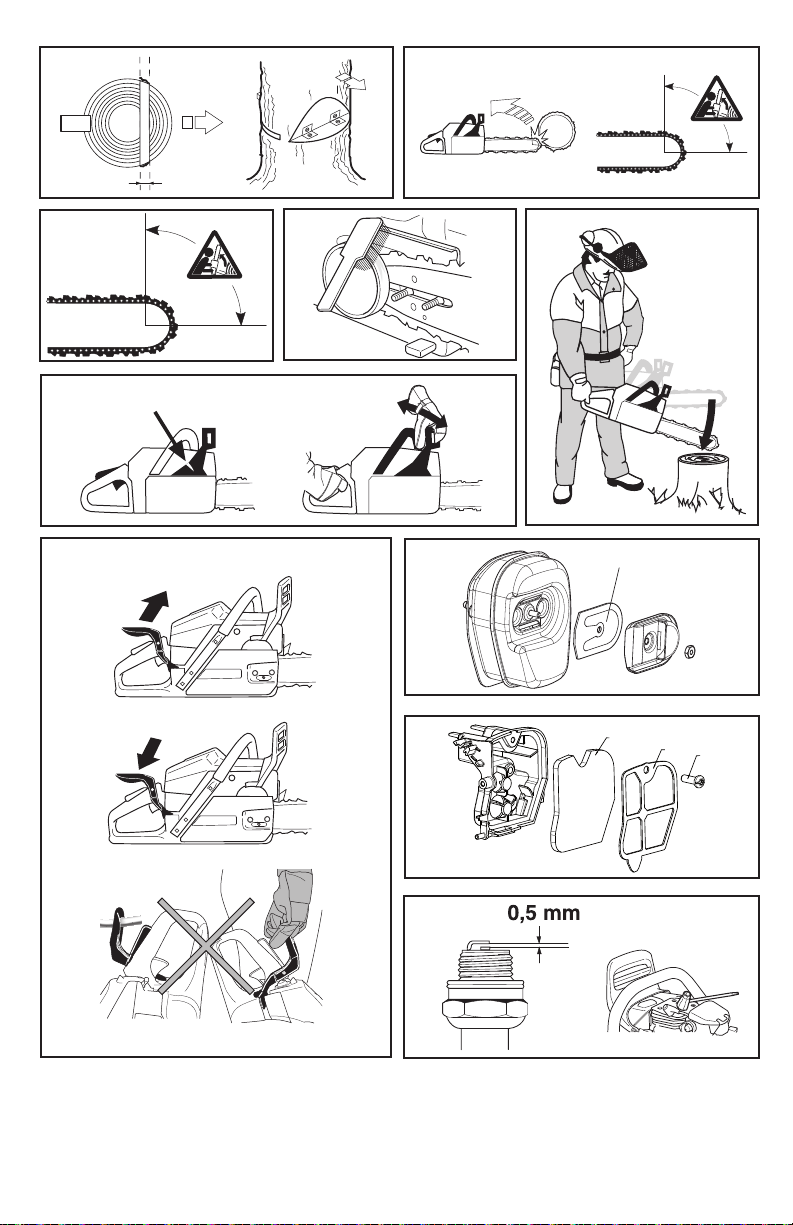

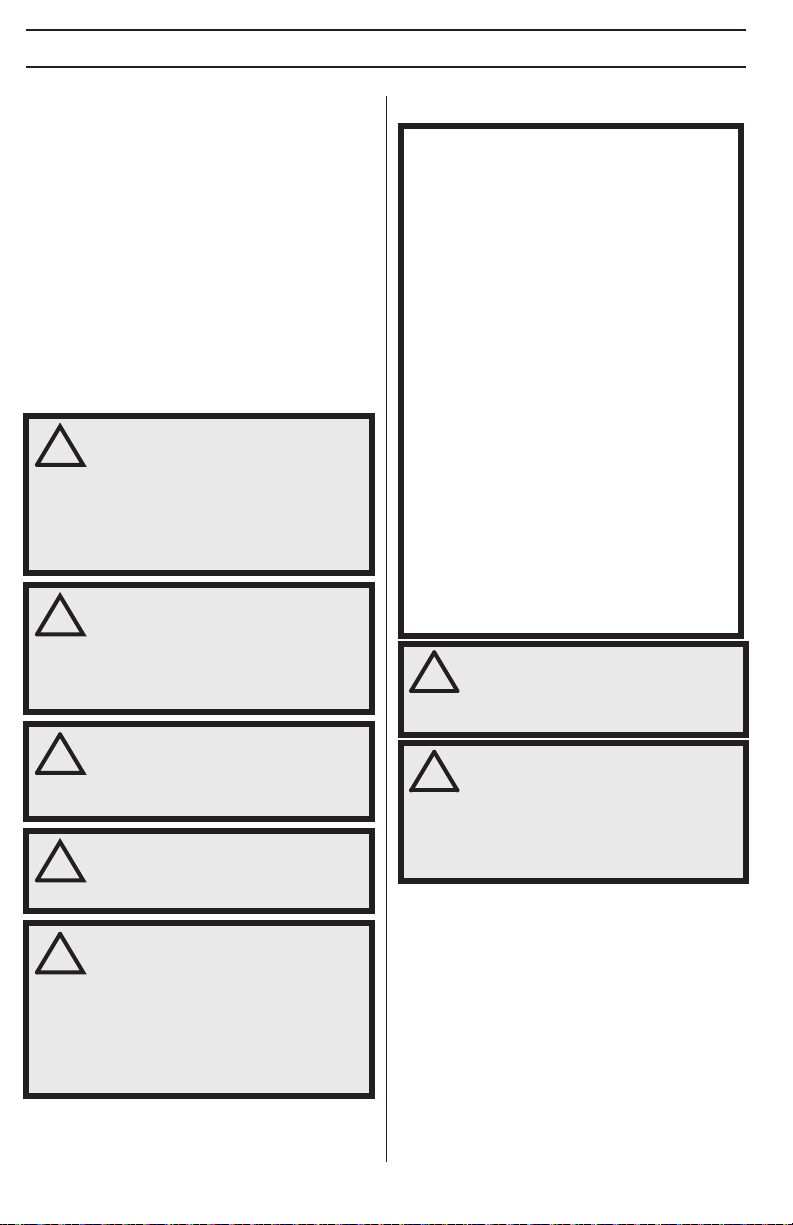

What is what on the chain saw? (1)

1 Product and serial number plate

2 Throttle lockout (Prevents accidental operation of

throttle control.)

3 Front handle

4 Cylinder cover

5 Front hand guard

6 Muffler

7 Spike bumper

8 Bar tip sprocket

9 Rear handle with right hand guard

10Throttle control

11Clutch cover

12Chain catcher

13Guide bar

14Saw chain

15Starter handle

16Chain oil tank

17Starter

18Fuel tank

19Choke control/Start throttle lock

20Rear handle

21Stop switch (Ignition on/off switch)

22Adjuster screws carburettor

23Air purge

24Information and warning decal

25Chain tensioner wheel

26Knob

27Guide bar cover

28Combination spanner

29Operator

30Right-hand brake trigger (240e TrioBrake)

′s manual

Contents

INTRODUCTION

Dear Customer, .......................................................... 6

Symbols on the machine: .......................................... 6

What is what on the chain saw? ................................ 7

CONTENTS

Contents .................................................................... 7

GENERAL SAFETY PRECAUTIONS

Before using a new chain saw .................................... 8

Important .................................................................... 8

Always use common sense ........................................ 8

Personal protective equipment ................................... 9

Machine

′s safety equipment ....................................... 9

Cutting equipment ...................................................... 10

ASSEMBLY

Fitting the bar and chain ............................................. 13

FUEL HANDLING

Fuel ............................................................................ 14

Fuelling ....................................................................... 14

Fuel safety .................................................................. 14

STARTING AND STOPPING

Starting and stopping ................................................. 15

WORKING TECHNIQUES

Before use: ................................................................. 16

General working instructions ...................................... 16

How to avoid kickback ................................................ 19

MAINTENANCE

General ...................................................................... 19

Carburettor adjustment .............................................. 19

Checking, maintaining and servicing chain saw safety

equipment .................................................................. 19

Muffler ........................................................................ 20

Air filter ....................................................................... 20

Spark plug .................................................................. 20

Maintenance schedule ............................................... 21

TECHNICAL DATA

Technical data ............................................................ 22

Bar and chain combinations ....................................... 23

EC-declaration of conformity ...................................... 23

1154212-26 Rev.3 2012-02-22

English – 7

GENERAL SAFETY PRECAUTIONS

Before using a new chain saw

• Please read this manual carefully.

•

(1) - (51) refer to figures on p. 2-5.

• Check that the cutting equipment is correctly fitted and

adjusted.

See instructions under the heading Assembly.

• Refuel and start the chain saw. See the instructions

under the headings Fuel Handling and Star

Stopping.

• Do not use the chain saw until sufficient chain oil has

reached the chain.

Lubricating cutting equipment.

• Long-term exposure to noise can result in permanent

hear

ing impairment. So always use approved hearing

protection.

!

!

!

!

!

See instructions under the heading

WARNING! Under no circumstances may

the design of the machine be modified

without the permission of the

manufacturer. Always use genuine

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

WARNING! A chain saw is a dangerous

tool if used carelessly or incorrectly and

can cause serious, even fatal injuries. It

is very important that you read and

understand the contents of this

operator’s manual.

WARNING! The inside of the muffler

contain chemicals that may be

carcinogenic. Avoid contact with these

elements in the event of a damaged

muffler.

WARNING! Long term inhalation of the

engine’s exhaust fumes, chain oil mist

and dust from sawdust can represent a

health risk.

WARNING! This machine produces an

electromagnetic field during operation.

This field may under some

circumstances interfere with active or

passive medical implants. To reduce the

risk of serious or fatal injury, we

recommend persons with medical

implants to consult their physician and

the medical implant manufacturer before

operating this machine.

ting and

Important

IMPORTANT!

The machine is only designed for cutting wood.

You should only use the saw with the bar and chain

combinations we recommend in the chapter

data.

Never use the machine if you are fatigued, while under

the influence of alcohol or dr

anything that could affect your vision, alertness,

coordination or judgement.

Wear personal protective equipment. See instructions

under the heading P

Do not modify this product or use it if it appears to have

been modifi

Never use a machine that is faulty. Carry out the

chec

described in this manual. Some maintenance and

service measures must be carried out by trained and

qualified specialists. See instructions under the

heading Maintenance.

Never use any accessories other than those

recommended in this manual.

the headings Cutting equipment and Technical data.

CAUTION! Always wear protective glasses or a face

visor to reduce the risk of injury from thrown objects. A

chain saw is capable of throwing objects, such as wood

chips, small pieces of wood, etc, at great force. This

can result in serious injury, especially to the eyes.

ed by others.

ks, maintenance and service instructions

WARNING! Running an engine in a

confined or badly ventilated area can

!

result in death due to asphyxiation or

carbon monoxide poisoning.

WARNING! Faulty cutting equipment or

the wrong combination of bar and saw

!

chain increases the risk of kickback!

Only use the bar/saw chain

combinations we recommend, and

follow the filing instructions. See

instructions under the heading T echnical

data.

ugs, medication or

ersonal protective equipment.

See instructions under

Technical

Always use common sense (2)

It is not possible to cover every conceivable situation you

can face when using a chain saw. Always exercise care

and use your common sense. Avoid all situations which

you consider to be beyond your capability. If you still feel

uncertain about operating procedures after reading these

instructions, you should consult an expert before

continuing. Do not hesitate to contact your dealer or us if

you have any questions about the use of the chain saw . We

will willingly be of service and provide you with advice as

well as help you to use your chain saw both efficiently and

safely. Attend a training course in chain saw usage if

possible. Your dealer, forestry school or your library can

provide information about which training materials and

courses are available. Work is constantly in progress to

improve the design and technology - improvements that

8 – English

1154212-26 Rev.3 2012-02-22

GENERAL SAFETY PRECAUTIONS

increase your safety and efficiency. Visit your dealer

regularly to see whether you can benefit from new features

that have been introduced.

Personal protective equipment

WARNING! Most chain saw accidents

happen when the chain touches the

!

operator. You must use approved

personal protective equipment whenever

you use the machine. Personal

protective equipment cannot eliminate

the risk of injury but it will reduce the

degree of injury if an accident does

happen. Ask your dealer for help in

choosing the right equipment.

• Approved protective helmet

• Hearing protection

• Protective goggles or a visor

• Gloves with saw protection

• Trousers with saw protection

• Boots with saw protection, steel toe-cap and non-slip

sole

• Always have a first aid kit nearby.

• Fire Extinguisher and Shovel

Generally clothes should be close-fitting without restricting

y

our freedom of movement.

IMPORTANT! Sparks can come from the muffler, the

bar and chain or other sources. Always have fire

extinguishing tools available if you should need them.

Help prevent forest fires.

Machine′′′′s safety equipment

In this section the machine’s safety features and their

function are explained. For inspection and maintenance

see instructions under the heading Checking, maintaining

and servicing chain saw safety equipment. See

instructions under the heading, What is what?, to find

where these parts are located on your machine.

The life span of the machine can be reduced and the risk

of accidents can increase if machine maintenance is not

carr

ied out correctly and if service and/or repairs are not

carried out professionally. If you need further information

please contact your nearest service workshop.

WARNING! Never use a machine with

defective safety components. Safety

!

equipment must be inspected and

maintained. See instructions under the

heading Checking, maintaining and

servicing chain saw safety equipment. If

your machine does not pass all the

checks, take the saw to a servicing

dealer for repair.

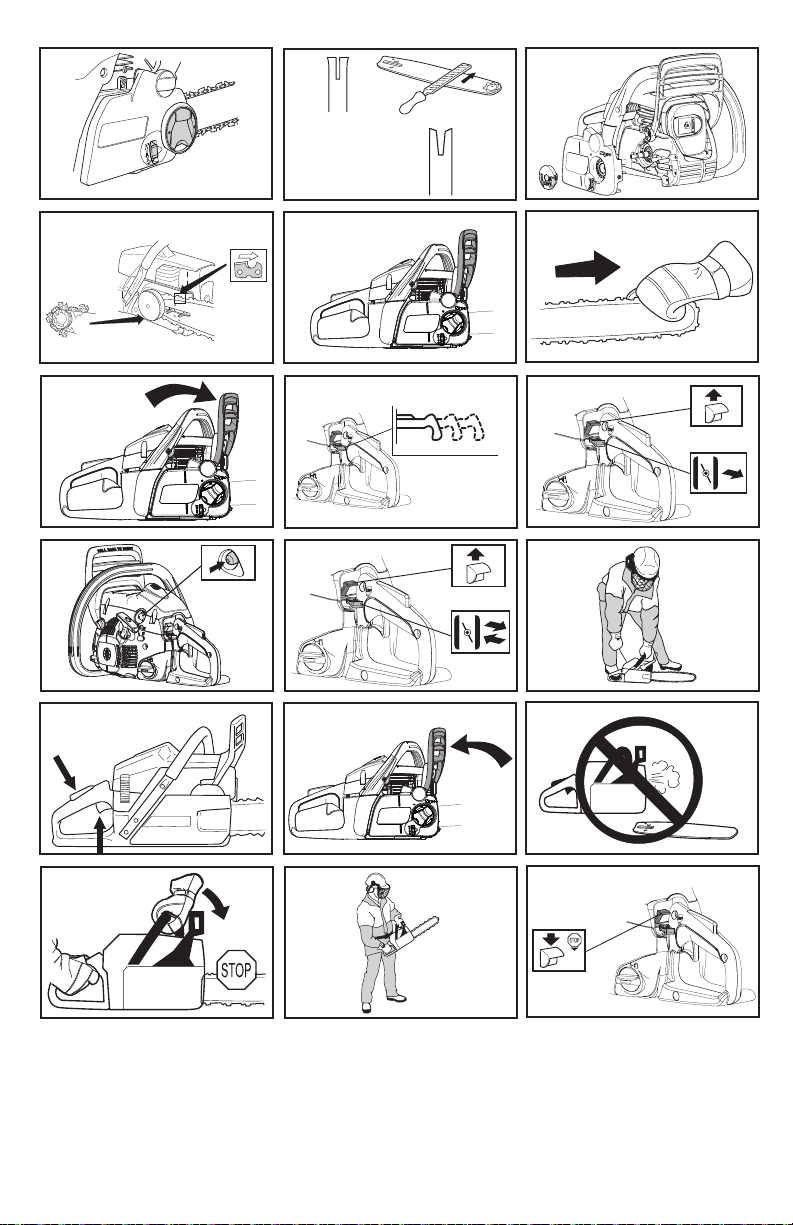

Chain brake and front hand guard

Your chain saw is equipped with a chain brake that is

designed to stop the chain if you get a kickback. The chain

brake reduces the risk of accidents, but only you can

prevent them.

Take care when using your saw and make sure the

kic

kback zone of the bar never touches any object

• The chain brake (A) can either be activated manually

y your left hand) or automatically by the inertia release

(b

mechanism.

• The brake is applied when the front hand guard (B) is

pushed forwards or when the right-hand brake trigger

(E) is pushed up and forwards (240e TrioBrake).

• This movement activates a spring-loaded mechanism

that tightens the brake band (C) around the engine drive

system (D) (clutch drum).

• The front hand guard is not designed solely to activate

the chain brake. Another important feature is that it

reduces the risk of your left hand hitting the chain if you

lose grip of the front handle.

• The chain brake must be engaged when the chain saw

is star

• Use the chain brake as a ”parking brake” when starting

and when mo

risk of moving chain accidentally hitting your leg or

anyone or anything close by.

• To release the chain brake pull the front hand guard

bac

• Kickback can be very sudden and violent. Most

kic

chain brake. If this happens you should hold the chain

saw firmly and not let go.

• The way the chain brake is activated, either manually or

automatically b

depends on the force of the kickback and the position of

the chain saw in relation to the object that the kickback

zone of the bar strikes.

If you get a violent kickback while the kickback zone of

the bar is f

designed to be activated by the inertia in the kickback

direction.

If the kickback is less violent or the kickback zone of the

bar is closer to y

manually by the movement of your left hand.

• In the felling position the left hand is in a position that

mak

With this type of grip, that is when the left hand is placed

so that it cannot affect the movement of the front hand

guard, the chain brake can only be activated by the

inertia action.

(3)

(4)

ted to prevent the saw chain from rotating.

ving over short distances, to reduce the

kwards, towards the front handle.

kbacks are minor and do not always activate the

y the inertia release mechanism,

arthest away from you the chain brake is

ou the chain brake will be activated

es manual activation of the chain brake impossible.

(45).

(3)

Will my hand always activate the chain brake during a kickback?

No. It tak es a certain force to move the hand guard forward.

If your hand only lightly touches the front guard or slips

over it, the force may not be enough to trigger the chain

brake. You should also maintain a firm grip of the chain saw

handles while working. If you do and experience a

kickback, your hand may ne ver leave the front handle and

will not activate the chain brake, or the chain brake will only

activate after the saw has swung around a considerable

distance. In such instances, the chain brake might not ha ve

enough time to stop the saw chain before it touches you.

There are also certain positions in which your hand cannot

reach the front hand guard to activate the chain brake; for

example, when the saw chain is held in felling position.

1154212-26 Rev.3 2012-02-22

English – 9

GENERAL SAFETY PRECAUTIONS

Will my inertia activated chain brake always activate during kickback in the event of a kickback?

No. First your brake must be in working order. Testing the

brake is simple, see instructions under the heading

Checking, maintaining and servicing chain saw safety

equipment. W e recommend y ou do bef ore y ou begin each

work session. Second the kickback must be strong enough

to activate the chain brake. If the chain brake is too

sensitive it would activate all the time which would be a

nuisance.

Will my chain brake always protect me from injury in the event of a kickback?

No. First, the chain brake must be in working order to

provide the intended protection. Second, it must be

activated during the kickback as described above to stop

the saw chain. Third, the chain brak e ma y be activ ated but

if the bar is too close to you the brake might not have

enough time to slow down and stop the chain before the

chain saw hits you.

Only you and proper working technique can eliminate

kickback and its danger.

Throttle lockout

The throttle lockout is designed to prevent accidental

operation of the throttle control. When you press the lock

(A) (i.e. when you gr asp the handle) it releases the throttle

control (B). When you release the handle the throttle

control and the throttle lockout both move back to their

original positions. This arrangement means that the throttle

control is automatically locked at the idle setting.

(5)

Chain catcher

The chain catcher is designed to catch the chain if it snaps

or jumps off. This should not happen if the chain is properly

tensioned (see instructions under the heading Assembly)

and if the bar and chain are properly serviced and

maintained (see instructions under the heading General

working instructions).

Right hand guard

Apart from protecting your hand if the chain jumps or

snaps, the right hand guard stops branches and twigs from

interfering with your grip on the rear handle.

Vibration damping system

Your machine is equipped with a vibration damping system

that is designed to minimize vibration and make operation

easier.

The machine

transfer of vibration between the engine unit/cutting

equipment and the machine

chain saw, including the cutting equipment, is insulated

from the handles by vibration damping units.

Cutting hardwoods (most broadleaf trees) creates more

vibr

′s vibration damping system reduces the

′s handle unit. The body of the

ation than cutting softwoods (most conifers). Cutting

with cutting equipment that is blunt or faulty (wrong type or

badly sharpened) will increase the vibration level.

WARNING! Overexposure to vibration

can lead to circulatory damage or nerve

!

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists. These

symptoms may be increased in cold

temperatures.

Stop switch

Use the stop switch to switch off the engine.

Muffler

The muffler is designed to reduce noise levels and to direct

exhaust fumes away from the user.

WARNING! The exhaust fumes from the

engine are hot and may contain sparks

!

which can start a fire. Never start the

machine indoors or near combustible

material!

In areas with a hot, dry climate there is a high risk of fires.

These areas are sometimes subject to go

requiring among other things the muffler must be equipped

with an approved type of spark arrestor mesh (A).

CAUTION! The muffler gets very hot during and after

use. This also applies during idling. Be a ware of the fire

hazard, especially when working near flammable

substances and/or vapours.

WARNING! Never use a saw without a

muffler, or with a damaged muffler. A

!

damaged muffler may substantially

increase the noise level and the fire

hazard. Keep fire fighting equipment

handy. If a spark arrestor screen is

required in your area, never use the saw

without or with a broken spark arrestor

screen.

vernment rules

(6)

Cutting equipment

This section describes how to choose and maintain your

cutting equipment in order to:

• Reduce the risk of kickback.

• Reduce the risk of the saw chain breaking or jumping off

the bar

.

• Obtain optimal cutting performance.

• Extend the life of cutting equipment.

• Avoid increasing vibration levels.

10 – English

1154212-26 Rev.3 2012-02-22

GENERAL SAFETY PRECAUTIONS

General rules

• Only use cutting equipment recommended by us!

See instructions under the heading Technical data.

•

Keep the chain’s cutting teeth properly sharpened!

Follow our instructions and use the recommended

file gauge.

increases the risk of accidents.

•

Maintain the correct depth gauge setting! Follow

our instructions and use the recommended depth

gauge clearance.

risk of kickback.

•

Keep the chain properly tensioned! If the chain is

slack it is more likely to jump off and lead to increased

wear on the bar, chain and drive sprocket.

•

Keep cutting equipment well lubricated and

properly maintained!

more likely to break and lead to increased wear on the

bar, chain and drive sprocket.

A damaged or badly sharpened chain

Too large a clearance increases the

A poorly lubricated chain is

Cutting equipment designed to reduce kickback

WARNING! Faulty cutting equipment or

the wrong combination of bar and saw

!

chain increases the risk of kickback!

Only use the bar/saw chain

combinations we recommend, and

follow the filing instructions. See

instructions under the heading T echnical

data.

The only way to avoid kickback is to make sure that the

kickback zone of the bar never touches anything.

By using cutting equipment with ”built-in” kickback

reduction and k

maintained you can reduce the effects of kickback.

Bar

The smaller the tip radius the lower the chance of kickback.

Chain

A chain is made up of a number of links, which are

available in standard and low-kickback versions.

IMPORTANT! No saw chain design eliminates the

danger of kickback.

eeping the chain sharp and well-

• Chain pitch (inches). The spacing between the drive

links of the chain must match the spacing of the teeth on

the bar tip sproc

links. The number of drive links is determined by the

length of the bar, the chain pitch and the number of teeth

on the bar tip sprocket.

• Bar groove width (inches/mm). The groove in the bar

ust match the width of the chain drive links.

m

• Chain oil hole and hole for chain tensioner. The bar must

be matched to the chain saw design.

Chain

• Chain pitch (inches)

• Drive link width (mm/inches)

• Number of drive links.

ket and drive sprocket. Number of drive

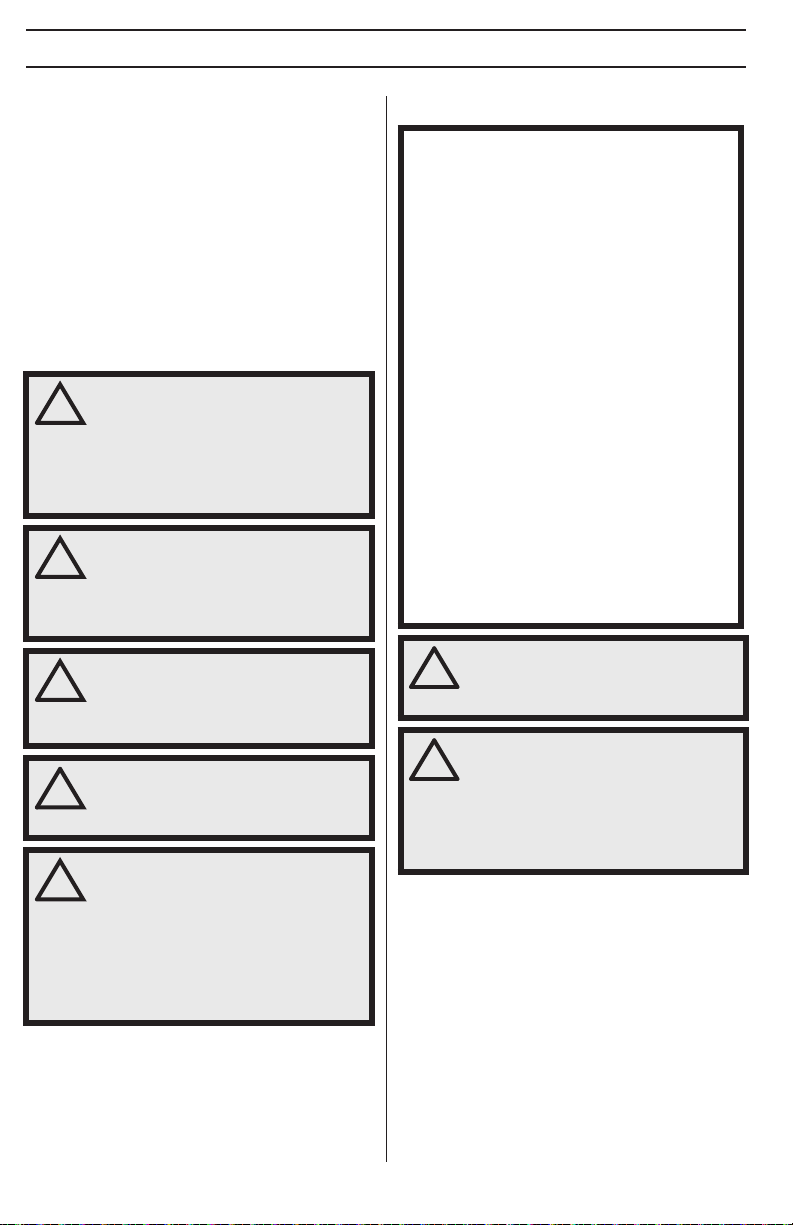

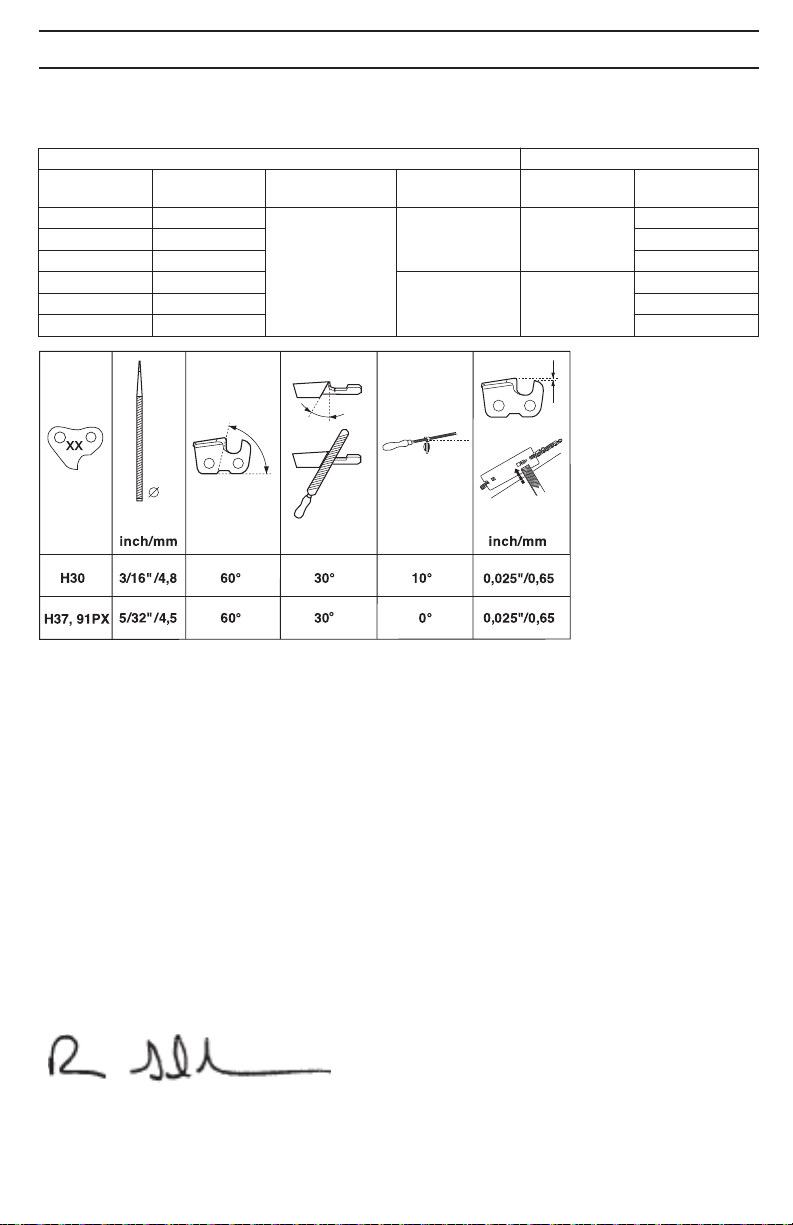

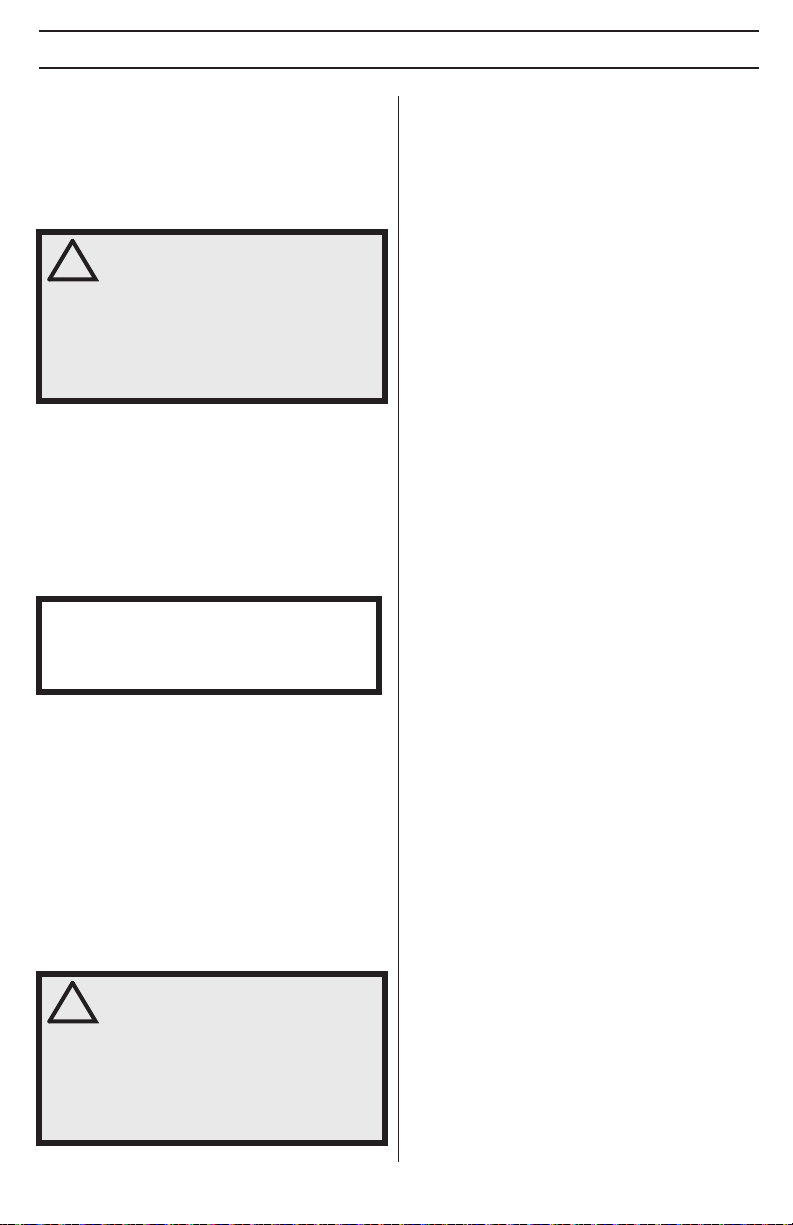

Sharpening your chain and adjusting depth gauge setting

WARNING! Always wear gloves, when

working with the chain, in order to

!

protect your hands from injury.

General information on sharpening cutting teeth

• Never use a blunt chain. When the chain is blunt you

have to ex ert more pressure to force the bar through the

wood and the chips will be very small. If the chain is very

blunt it will produce wood powder and no chips or

shavings.

• A sharp chain eats its way through the wood and

produces long, thic

• The cutting part of the chain is called the cutter and

consists of a cutting tooth (A) and the depth gauge (B).

The cutters cutting depth is determined by the

difference in height between the two (depth gauge

(7)

setting).

When you sharpen a cutting tooth there are four important

factors to remember.

1 Filing angle

2 Cutting angle

3 File position

4 Round file diameter

It is very difficult to sharpen a chain correctly without the

r

ight equipment. We recommend that you use our file

gauge. This will help you obtain the maximum kickback

reduction and cutting performance from your chain.

See instructions under the heading Technical data for

ormation about sharpening your chain.

inf

k chips or shavings.

WARNING! Any contact with a rotating

saw chain can cause extremely serious

!

injuries.

Some terms that describe the bar and chain

To maintain the safety features of the cutting equipment,

you should replace a worn or damaged bar or chain with a

bar and chain combinations recommended by Husqvarna.

See instructions under the heading T echnical Data for a list

of replacement bar and chain combinations we

recommend.

Bar

• Length (inches/cm)

• Number of teeth on bar tip sprocket (T).

1154212-26 Rev.3 2012-02-22

WARNING! Departure from the

sharpening instructions considerably

!

increases the risk of kickback.

Sharpening cutting teeth

To sharpen cutting teeth you will need a round file and a file

gauge. See instructions under the heading Technical data

for information on the size of file and gauge that are

recommended for the chain fitted to your chain saw.

• Check that the chain is correctly tensioned. A slack

chain will mo

sharpen correctly.

• Always file cutting teeth from the inside face. Reduce

the pressure on the return stroke. File all the teeth on

ve sideways, making it more difficult to

English – 11

GENERAL SAFETY PRECAUTIONS

one side first, then turn the chain saw over and file the

teeth on the other side.

• File all the teeth to the same length. When the length of

the cutting teeth is reduced to 4 mm (0.16") the chain is

w

orn out and should be replaced.

General advice on adjusting depth gauge setting (7)

• When you sharpen the cutting tooth (A) the depth gauge

setting (C) will decrease. To maintain optimal cutting

performance the depth gauge (B) has to be filed down

to achieve the recommended depth gauge setting. See

instructions under the heading T echnical data to find the

correct depth gauge setting for your particular chain.

WARNING! The risk of kickback is

increased if the depth gauge setting is

!

too large!

Adjustment of depth gauge setting

• The cutting teeth should be newly sharpened before

adjusting the depth gauge setting. W e recommend that

you adjust the depth gauge setting every third time you

sharpen the cutting teeth. NOTE! This recommendation

assumes that the length of the cutting teeth is not

reduced excessively.

• You will need a flat file and a depth gauge tool. We

recommend that y

acheive the correct depth gauge setting and bevel for

the depth gauge.

• Place the depth gauge tool over the chain. Detailed

inf

ormation regarding the use of the depth gauge tool,

will be found on the package for the depth gauge tool.

Use the flat file to file off the tip of the depth gauge that

protrudes through the depth gauge tool. The depth

gauge setting is correct when you no longer feel

resistance as you draw the file along the depth gauge

tool.

ou use our depth gauge tool to

(8)

Tensioning the chain

WARNING! A slack chain may jump off

and cause serious or even fatal injury.

!

WARNING! Always wear approved

protective gloves. Even a non-moving

!

chain can cause serious cuts to yourself

or persons you bump into with an

exposed chain.

The more you use a chain the longer it becomes. It is

therefore important to adjust the chain regularly to take up

the slack.

Check the chain tension every time you refuel. NOTE! A

ne

w chain has a running-in period during which you should

check the tension more frequently.

T ension the chain as tightly as possible, but not so tight that

y

ou cannot pull it round freely by hand.

• Release the knob by folding it out. (10)

• Turn the knob anti clockwise to loosen the bar cover.

(11)

(9)

• Adjust the tension on the chain by turning the wheel

down (+) for tighter tension and up (-) to loosen the

tension. Lift tip of guide bar while adjusting tension.

• Tighten the clutch cover by turning the knob clockwise

while lifting tip of bar.

• Fold the knob back in to lock the tensioning. (14)

(13)

(12)

Lubricating cutting equipment

WARNING! Poor lubrication of cutting

equipment may cause the chain to snap,

!

which could lead to serious, even fatal

injuries.

Chain oil

Chain oil must demonstrate good adhesion to the chain

and also maintain its flow characteristics regardless of

whether it is warm summer or cold winter weather.

As a chain saw manufacturer we have developed an

optimal chain oil which, with its v

biodegradable. We recommend the use of our own oil for

both maximum chain life and to minimise environmental

damage. If our own chain oil is not available, standard

chain oil is recommended.

Never use waste oil! Using waste oil can be dangerous

to you and damage the machine and environment.

IMPORTANT! When using vegetable based saw chain

oil, dismantle and clean the groove in the bar and saw

chain before long-term storage. Otherwise there is a

risk of the saw chain oil oxidizing, which will result in the

saw chain becoming stiff and the bar tip sprocket

jamming.

Filling with chain oil

• All our chain saws have an automatic chain lubrication

system. On some models the oil flow is also adjustable.

• The saw chain oil tank and the fuel tank are designed so

that the fuel r

However, this safety feature requires that you use the

r

ight sort of chain oil (if the oil is too thin it will run out

before the fuel), and that you adjust the carburetor as

recommended (a lean mixture may mean that the fuel

lasts longer than the oil) and that you also use the

recommended cutting equipment (a bar that is too long

will use more chain oil).

Checking chain lubrication

• Check the chain lubrication each time you refuel. See

instructions under the heading Lubricating the bar tip

sprocket.

Aim the tip of the bar at a light coloured surface about

20 cm (8 inches) a

throttle you should see a distinct line of oil on the light

surface.

If the chain lubrication is not working:

• Check that the oil channel in the bar is not obstructed.

Clean if necessar

• Check that the groove in the edge of the bar is clean.

Clean if necessary.

uns out before the saw chain oil.

way. After 1 minute running at 3/4

y.

egetable oil base, is also

12 – English

1154212-26 Rev.3 2012-02-22

GENERAL SAFETY PRECAUTIONS / ASSEMBLY

• Check that the bar tip sprocket turns freely and that the

lubricating hole in the tip sprocket is not blocked. Clean

and lubricate if necessary.

If the chain lubrication system is still not working after

carr

ying out the above checks and associated measures

you should contact your service agent.

Chain drive sprocket

The clutch drum is fitted with a Spur sprocket (the chain

sprocket is welded on the drum).

Regularly check the degree of wear on the drive sprocket.

Replace if wear is e

whenever you replace the chain.

Checking wear on cutting equipment

Check the chain daily for:

• Visible cracks in rivets and links.

• Whether the chain is stiff.

• Whether rivets and links are badly worn.

Replace the saw chain if it exhibits any of the points above.

We recommend you compare the existing chain with a new

chain to decide how badly the e

When the length of the cutting teeth has worn down to only

4 mm the chain must be replaced.

Bar

Check regularly:

• Whether there are burrs on the edges of the bar.

Remo

ve these with a file if necessary.

• Whether the groove in the bar has become badly worn.

Replace the bar if necessary.

• Whether the tip of the bar is uneven or badly worn. If a

hollow forms on the underside of the bar tip this is due

to running with a slack chain.

• T o prolong the life of the bar y ou should turn it over daily.

!

xcessive. Replace the drive sprocket

xisting chain is worn.

(15)

(16)

WARNING! Most chain saw accidents

happen when the chain touches the

operator.

Wear personal protective equipment.

See instructions under the heading

Personal protective equipment.

Do not tackle any job that you feel you

are not adequately trained for. See

instructions under the headings

Personal protective equipment, How to

avoid kickback, Cutting equipment and

General working instructions.

Avoid situations where there is a risk of

kickback. See instructions under the

heading Machine

Use the recommended protective

equipment and check its condition. See

instructions under the heading General

working instructions.

Check that all the chain saw safety

features are working. See instructions

under the headings General working

instructions and General safety

precautions.

′′

′′

s safety equipment.

Fitting the bar and chain

WARNING! Switch off the engine before

carrying out any checks or maintenance.

!

The stop switch automatically returns to

the start position. In order to prevent

unintentional starting, the spark plug

cap must be removed from the spark

plug when assembling, checking and/or

performing maintenance.

Always wear gloves, when working with

the chain, in order to protect your hands

from injury.

Check that the chain brake is in disengaged position by

moving the front hand guard towards the front handle.

Remove the knob and remove the clutch cover (chain

br

ake). Take off the transportation ring (A).

Fit the bar over the bar bolts. Place the bar in its rearmost

position. Place the chain over the drive sproc ket locate it in

the groove on the bar. Begin on the top edge of the bar.

(18)

Make sure that the edges of the cutting links are facing

forward on the top edge of the bar.

Fit the clutch cover (chain brake) and locate the chain

adjuster pin in the cut-out in the bar

links of the chain fit correctly on the drive sprocket and that

the chain is in the groove on the bar.

Tension the chain by turning the wheel down (+). The chain

should be tensioned until it does not sag from the

underside of the bar.

The chain is correctly tensioned when it does not sag from

the underside of the bar, but can still be turned easily by

hand. Hold up the bar tip and tighten the bar knob by

turning the knob clockwise.

When fitting a new chain, the chain tension has to be

checked frequently until the chain is run-in. Check the

chain tension regularly. A correctly tensioned chain

ensures good cutting performance and long life.

(12)

(13)

Fitting a spike bumper

To fit a spike bumper – contact your service agent.

(17)

. Check that the drive

(19)

(20)

1154212-26 Rev.3 2012-02-22

English – 13

FUEL HANDLING

Fuel

Note! The machine is equipped with a two-stroke engine

and must always be run using a mixture of petrol and twostroke oil. It is important to accurately measure the amount

of oil to be mixed to ensure that the correct mixture is

obtained. When mixing small amounts of fuel, even small

inaccuracies can drastically affect the ratio of the mixture.

WARNING! Always ensure there is

adequate ventilation when handling fuel.

!

Petrol

• Use good quality unleaded or leaded petrol.

• The lowest recommended octane grade is 90 (RON). If

ou run the engine on a lower octane grade than 90 so-

y

called knocking can occur. This gives rise to a high

engine temperature and increased bearing load, which

can result in serious engine damage.

• When working with continuous high revs (e.g. limbing) a

higher octane is recommended.

Running-in

Avoid running at a too high speed for extended periods

during the first 10 hours.

Two-stroke oil

• For best results and performance use HUSQVARNA

two-stroke engine oil, which is specially formulated for

our air-cooled two-stroke engines.

• Never use two-stroke oil intended for water-cooled

engines

, sometimes referred to as outboard oil (rated

TCW).

• Never use oil intended for four-stroke engines.

• A poor oil quality and/or too high oil/fuel ratio may

jeopardise function and decrease the lif

catalytic converters.

Mixing ratio

1:50 (2%) with HUSQVARNA two-stroke oil.

1:33 (3%) with oils class JASO FB or ISO EGB formulated

or air-cooled, two-stroke engines.

f

Petrol, litre Two-stroke oil, litre

2% (1:50) 3% (1:33)

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

Mixing

• Always mix the petrol and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the petrol to be

used.

Then add the entire amount of oil. Mix (shak e) the

fuel mixture. Add the remaining amount of petrol.

• Mix (shake) the fuel mixture thoroughly before filling the

machine’

• Do not mix more than one month’s supply of fuel at a

• If the machine is not used for some time the fuel tank

s fuel tank.

time

.

should be emptied and cleaned.

e time of

Chain oil

• We recommend the use of special oil (chain oil) with

good adhesion characteristics.

• Never use waste oil. This results in damage to the oil

pump

, the bar and the chain.

• It is important to use oil of the right grade (suitable

viscosity range) to suit the air temperature

• In temperatures below 0

too viscous. This can overload the oil pump and result in

damage to the oil pump components.

• Contact your service agent when choosing chain oil.

°C (32°F) some oils become

.

Fuelling

WARNING! Taking the following

precautions, will lessen the risk of fire:

!

Do not smoke and do not place any hot

objects in the vicinity of fuel.

Always stop the engine and let it cool for

a few minutes before refuelling.

When refuelling, open the fuel cap

slowly so that any excess pressure is

released gently.

Tighten the fuel cap carefully after

refuelling.

Always move the machine away from the

refuelling area before starting.

Clean the area around the fuel cap. Clean the fuel and chain

oil tanks regularly. The fuel filter must be replaced at least

once a year. Contamination in the tanks causes malfunction.

Make sure the fuel is well mixed by shaking the container

before refuelling. The capacities of the chain oil tank and fuel

tank are carefully matched. You should therefore always fill

the chain oil tank and fuel tank at the same time.

WARNING! Fuel and fuel vapour are

highly flammable. Take care when

!

handling fuel and chain oil. Be aware of

the risks of fire, explosion and those

associated with inhalation.

Fuel safety

• Never refuel the machine while the engine is running.

• Make sure there is plenty of ventilation when refuelling

or mixing fuel (petrol and 2-stroke oil).

• Move the machine at least 3 m from the refuelling point

ore starting it.

bef

• Never start the machine:

1 If you have spilt fuel or chain oil on the machine. Wipe

off the spillage and allow remaining fuel to e

2 If you have spilt fuel on yourself or your clothes, change

y

our clothes. W ash any part of your body that has come

in contact with fuel. Use soap and water.

3 If the machine is leaking fuel. Check regularly for leaks

from the fuel cap and fuel lines.

WARNING! Never use a machine with

visible damage to the spark plug guard

!

and ignition cable. A risk of sparking

arises, which can cause a fire.

vaporate.

14 – English

1154212-26 Rev.3 2012-02-22

FUEL HANDLING / STARTING AND STOPPING

Transport and storage

• Always store the chain saw and fuel so that there is no

risk of leakages or fumes coming into contact with

sparks or naked flames from electrical equipment,

electric motors, relays/switches, boilers and the like.

• Always store fuel in an approved container designed for

that pur

• For longer periods of storage or for transport of the

• Ensure the machine is cleaned and that a complete

• The bar guard must always be fitted to the cutting

• Secure the machine during transport.

pose.

chain sa

w, the fuel and chain oil tanks should be

emptied. Ask where you can dispose of waste fuel and

chain oil at your local petrol station.

ser

vice is carried out before long-term storage.

attachment when the machine is being tr

storage, in order to prevent accident contact with the

sharp chain. Even a non-moving chain can cause

serious cuts to yourself or persons you bump into with

an exposed chain.

ansported or in

Long-term storage

Empty the fuel/oil tanks in a well ventilated area. Store the

fuel in approved cans in a safe place. Fit the bar guard.

Clean the machine. See instructions under the heading

Maintenance schedule.

Starting and stopping

WARNING! Note the following before

starting:

!

The chain brake must be engaged when

the chain saw is started to reduce the

chance of contact with the moving chain

during starting.

Never start a chain saw unless the bar,

chain and all covers are fitted correctly.

Otherwise the clutch can come loose

and cause personal injuries.

Place the machine on firm ground. Make

sure you have a secure footing and that

the chain cannot touch anything.

Keep people and animals well away from

the working area.

Cold engine

Starting: The chain brake must be engaged when the

chain saw is started. Activate the brake by mo ving the front

hand guard forwards.

1. Air purge: Press the air purge repeatedly until fuel begins

to fill the bulb. The bulb need not be completely filled.

2. Choke: Pull the blue choke/fast idle lever out to the full

extent (to the

fast idle lever is pulled out to the full extent, the correct

throttle setting is set automatically.

Start throttle:

obtained by moving the control to the choke position.

Starting

Grip the front handle with your left hand. Hold the chain

saw on the ground by placing your right foot through the

(21)

(24)

FULL CHOKE position). When the choke/

(22)

The correct choke/start throttle setting is

(23)

rear handle.

3. Pull the starter handle with your right hand and pull out

the starter cord slowly until you feel a resistance (as the

starter pawls engage) then pull firmly and rapidly.

twist the starter cord around your hand.

CAUTION!

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

4. Push in the choke control to the ”1/2 choke” setting as

soon as the engine fires which can be heard through a

"puff" sound.

5. Keep on pulling the cord powerfully until the engine

starts.

squeeze throttle trigger to set normal idle.

As the chain brake is still engaged the speed of the engine

must be set to idling as soon as possible , this is achieved by

quickly pressing the throttle trigger once. This prevents

unnecessary wear to the clutch, clutch drum and brake band.

Note! Reactivate the chain brake by pushing the front hand

guard back (marked ”PULL BACK TO RESET”) towards

the front handle.

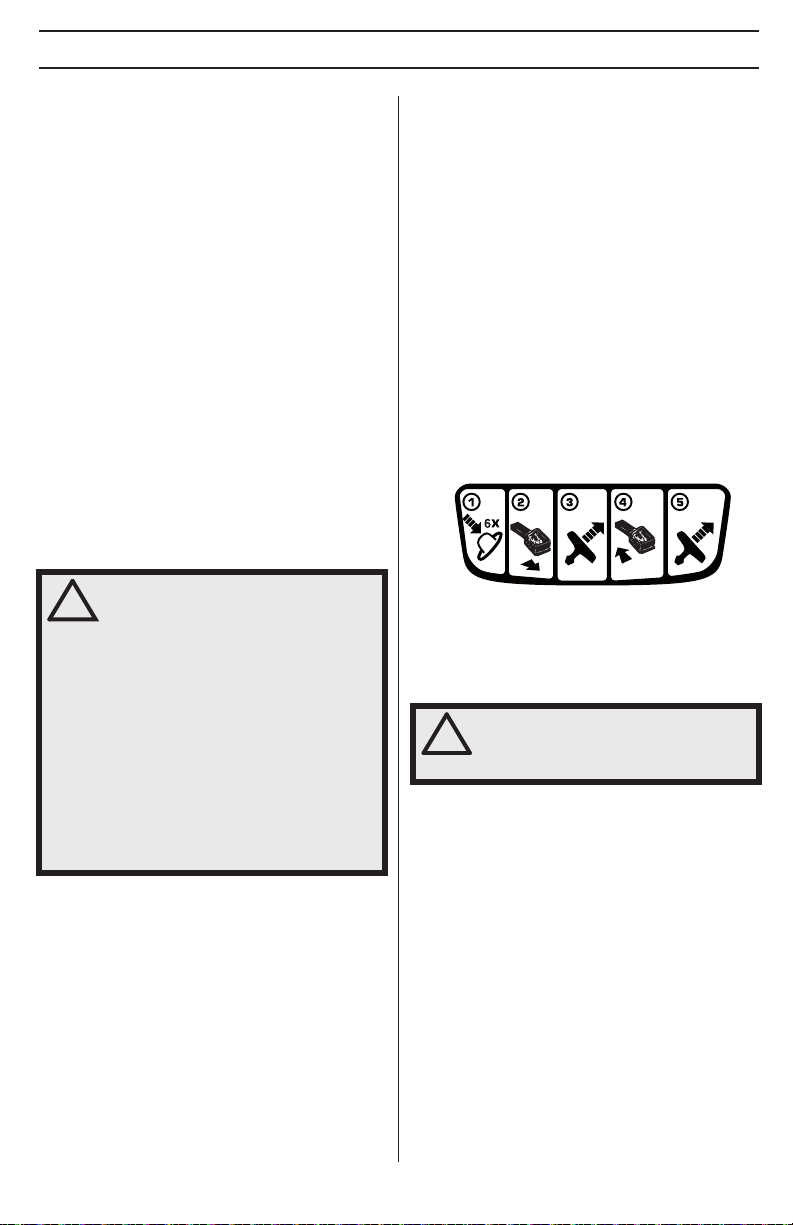

There is a simplified start reminder with illustrations to

describe each step on the rear edge of the saw (A)

Do not pull the starter cord all the way out and

(22)

(27) Allow engine to warm for thirty seconds, then

(28) The chain saw is now ready for use.

Never

(26)

.

Warm engine

Use the same procedure as for starting a cold engine but

without setting the choke control in the choke position. Set

the throttle to the start position by pulling out the blue

choke control to the choke position and then pushing it in

again.

(25)

WARNING! Long term inhalation of the

engine’s exhaust fumes, chain oil mist

!

and dust from sawdust can represent a

health risk.

• Never start a chain saw unless the bar, chain and all

covers are fitted correctly. See instructions under the

heading Assembly . Without a bar and chain attached to

the chain saw the clutch can come loose and cause

serious injury.

• The chain brake should be activated when starting. See

instructions under the heading Start and stop. Do not

drop start. This method is very dangerous because you

may lose control of the saw.

• Never start the machine indoors. Exhaust fumes can be

dangerous if inhaled.

• Observe your surroundings and make sure that there is

no r

isk of people or animals coming into contact with the

cutting equipment.

• Always hold the saw with both hands. The right hand

should be on the rear handle, and the left hand on the

front handle

should use this grip. Use a firm grip with thumbs and

fingers encircling the chain saw handles.

(29)

(30)

. All people, whether right or left handed,

(31)

Stopping

Stop the engine by pressing down the stop button. (32)

1154212-26 Rev.3 2012-02-22

English – 15

WORKING TECHNIQUES

Before use: (33)

1 Check that the chain brake works correctly and is not

damaged.

2 Check that the rear right hand guard is not damaged.

3 Check that the throttle lockout works correctly and is not

damaged.

4 Check that the stop switch works correctly and is not

damaged.

5 Check that all handles are free from oil.

6 Check that the anti vibration system works and is not

damaged.

7 Check that the muffler is securely attached and not

damaged.

8 Check that all parts of the chain saw are tightened

correctly and that the

9 Check that the chain catcher is in place and not

damaged.

10Check the chain tension.

y are not damaged or missing.

General working instructions

IMPORTANT!

This section describes basic safety rules for using a

chain sa

w. This information is never a substitute for

professional skills and experience. If you get into a

situation where you feel unsafe, stop and seek expert

advice. Contact your chain saw dealer , service agent or

an experienced chain saw user. Do not attempt any

task that you feel unsure of!

Before using a chain saw you must understand the

eff

ects of kickback and how to avoid them. See

instructions under the heading How to avoid kickback.

Before using a chain saw you must understand the

diff

erence between cutting with the top and bottom

edges of the bar. See instructions under the headings

How to avoid kickback and Machine’s safety

equipment.

Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

Basic safety rules

1 Look around you:

• To ensure that people, animals or other things cannot

ect your control of the machine.

aff

• T o mak e sure that none of the above might come within

reach of y

CAUTION! Follow the instructions abov e, b ut do not use a

chain sa

case of an accident.

2 Do not use the machine in bad weather, such as dense

3 Take great care when removing small branches and

4 Make sure you can move and stand safely. Check the

our saw or be injured by falling trees.

w in a situation where you cannot call for help in

f

og, heavy rain, strong wind, intense cold, etc. Working

in bad weather is tiring and often brings added risks,

such as icy ground, unpredictable felling direction, etc.

a

void cutting bushes (i.e. cutting many small branches

at the same time). Small branches can be grabbed by

the chain and thrown back at you, causing serious

injury.

area around y

branches, ditches, etc.) in case you have to move

ou for possible obstacles (roots, rocks,

suddenly. Take great care when working on sloping

ground.

5 Take great care when cutting a tree that is in tension. A

tree that is in tension may spring back to its normal

position before or after being cut. If you position yourself

incorrectly or make the cut in the wrong place the tree

may hit you or the machine and cause y ou to lose control.

Both situations can cause serious personal injury.

6 Before moving your chain saw switch off the engine and

lock the chain using the chain brake. Carry the chain

saw with the bar and chain pointing backwards. Fit a

guard to the bar before transporting the chain saw or

carrying it for any distance.

7 When you put the chain saw on the ground, lock the saw

chain using the chain brak

constant view of the machine. Switch the engine off

before leaving your chain saw for any length of time.

WARNING! Sometimes chips get stuck in

the clutch cover causing the chain to

!

jam. Always stop the engine before

cleaning.

e and ensure you have a

General rules

1 If you understand what kickback is and how it happens

then you can reduce or eliminate the element of

surprise. By being prepared you reduce the risk.

Kickback is usually quite mild, but it can sometimes be

very sudden and violent.

2 Always hold the chain saw firmly with your right hand on

the rear handle and y

Wrap your fingers and thumbs around the handles. You

should use this grip whether you are right-handed or

left-handed. This grip minimises the effect of kickback

and lets you keep the chain saw under control.

let go of the handles!

3 Most kickback accidents happen during limbing. Make

sure you are standing firmly and that there is nothing in

the way that might make you trip or lose your balance.

Lack of concentration can lead to kickback if the

kic

kback zone of the bar accidentally touches a branch,

nearby tree or some other object.

Have control over the workpiece. If the pieces you

intend to cut are small and light, they can jam in the sa

chain and be thrown towards you. This is not

necessarily dangerous in itself, but you may be

surprised and lose control of the saw. Never saw

stacked logs or branches without first separating them.

Only saw one log or one piece at a time. Remov e the cut

pieces to keep your working area safe.

4

Never use the chain saw above shoulder height and

try not to cut with the tip of the bar. Never use the

chain saw one-handed!

5 You must have a steady stance in order to have full

control over the chain saw. Never work standing on a

ladder, in a tree or where you do not have firm ground to

stand on.

6 Always use a fast cutting speed, i.e. full throttle.

7 Take great care when you cut with the top edge of the

(35)

, i.e. when cutting from the underside of the object.

bar

This is known as cutting on the push stroke. The chain

tries to push the chain saw back towards the user. If the

saw chain is jamming, the saw may be pushed back at

you.

our left hand on the front handle.

Do not

(34)

w

16 – English

1154212-26 Rev.3 2012-02-22

WORKING TECHNIQUES

8 Unless the user resists this pushing force there is a risk

that the chain saw will move so far backw ards that only

the kickback zone of the bar is in contact with the tree,

which will lead to a kickback.

Cutting with the bottom edge of the bar, i.e. from the top

of the object downwards, is known as cutting on the pull

stroke. In this case the chain saw pulls itself to wards the

tree and the front edge of the chain saw body rests

naturally on the trunk when cutting. Cutting on the pull

stroke gives the operator better control over the chain

saw and the position of the kickback zone.

9 Follow the instructions on sharpening and maintaining

y

our bar and chain. When y ou replace the bar and chain

use only combinations that are recommended by us.

See instructions under the headings Cutting equipment

and T echnical data.

(36)

Basic cutting technique

WARNING! Never use a chain saw by

holding it with one hand. A chain saw is

!

not safely controlled with one hand.

Always have a secure, firm grip around

the handles with both hands.

General

• Always use full throttle when cutting!

• Reduce the speed to idle after every cut (running the

• Cutting from above = Cutting on the pull stroke.

• Cutting from below = Cutting on the push stroke.

Cutting on the push stroke increases the risk of kickback.

See instr

Terms

Cutting = General term for cutting through wood.

Limbing = Cutting branches off a felled tree.

Splitting = When the object you are cutting breaks off

bef

There are five important factors you should consider

before making a cut:

1 Make sure the cutting equipment will not jam in the cut.

2 Make sure the object you are cutting will not split.

3 Make sure the chain will not strike the ground or any

4 Is there a risk of kickback?

5 Do the conditions and surrounding terrain affect how

T wo f actors decide whether the chain will jam or the object

that y

supported before and after cutting, and the second is

whether it is in tension.

In most cases you can avoid these problems by cutting in

tw

support the object so that it will not trap the chain or split

during cutting.

or too long at full throttle without any load, i.e.

engine f

without any resistance from the chain during cutting,

can lead to serious engine damage).

uctions under the heading How to avoid kickback.

ore the cut is complete.

other object dur

ely you can stand and move about?

saf

ou are cutting will split: the first is how the object is

o stages; from the top and from the bottom. You need to

IMPORTANT! If the chain jams in the cut: stop the

engine! Don’t try to pull the chain saw free. If you do

you may be injured by the chain when the chain saw

suddenly breaks free. Use a lever to open up the cut

and free the chain saw.

ing or after cutting.

The following instructions describe how to handle the

commonest situations y

using a chain saw.

Limbing

When limbing thick branches you should use the same

approach as for cutting.

Cut difficult branches piece by piece.

Cutting

WARNING! Never attempt to cut logs

while they are in a pile or when a couple

!

of logs are lying together. Such

procedures drastically increase the risk

of kickback which can result in a serious

or fatal injury.

If you have a pile of logs, each log you attempt to cut should

be removed from the pile, placed on a saw horse or

runners and cut individually.

Remove the cut pieces from the cutting area. By leaving

them in the cutting area, y

inadvertently getting a kickback, as well as increasing the

risk of losing your balance while working.

The log is lying on the ground. There is little risk of the

chain jamming or the object splitting. However there is a

risk that the chain will touch the ground when you finish the

cut.

Cut all the way through the log from above. Av oid letting the

chain touch the ground as y

throttle but be prepared for what might happen.

If it is possible (can you turn the log?) stop cutting about 2/

3 of the way through the log.

Turn the log and finish the cut from the opposite side.

The log is supported at one end. There is a high risk that

it will split.

Start by cutting from below (about 1/3 of the way through).

Finish by cutting from above so that the two cuts meet.

The log is supported at both ends. There is a high risk

that the chain will jam.

Start by cutting from above (about 1/3 of the way through).

Finish by cutting from below so that the two cuts meet.

ou are likely to encounter when

ou increase the risk for

ou finish the cut. Maintain full

(37)

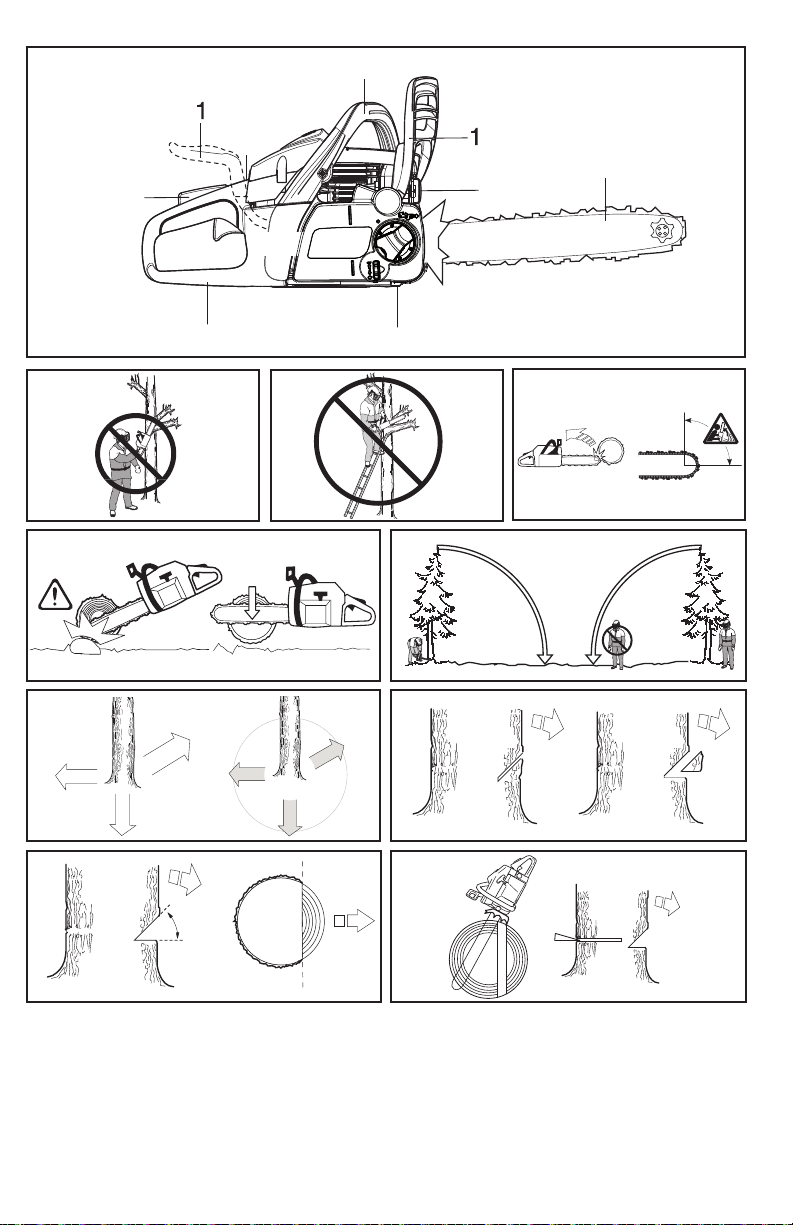

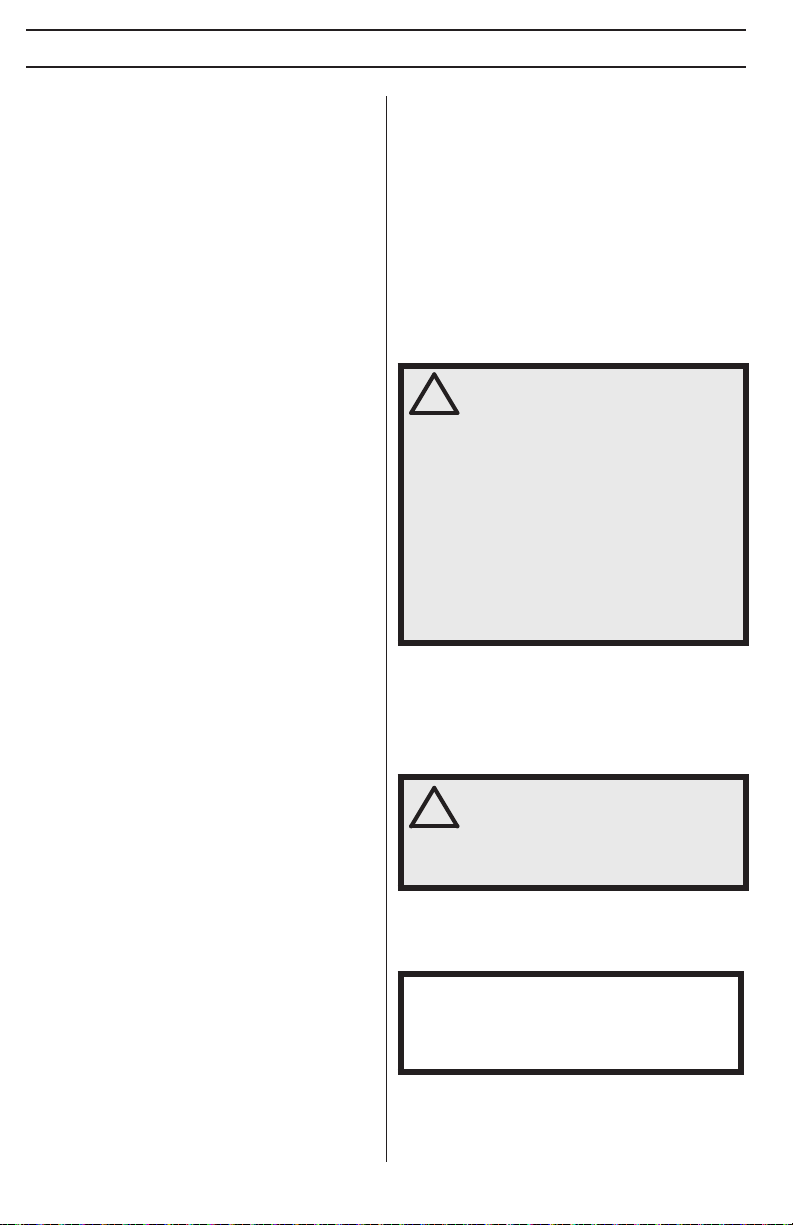

Tree felling technique

IMPORTANT! It takes a lot of experience to fell a tree.

Inexperienced users of chain saws should not fell trees.

Do not attempt any task that you feel unsure of!

Safe distance

The safe distance between a tree that is to be felled and

anyone else working nearby is at least 2 1/2 tree lengths.

Make sure that no-one else is in this ”risk zone” before or

during felling.

Felling direction

The aim is to fell the tree in a position where you can limb

and cross-cut the log as easily as possible. You want it to

fall in a location where you can stand and move about

safely.

Once you have decided which way y ou want the tree to fall

y

ou must judge which way the tree would fall naturally.

Several factors affect this:

• Lean of the tree

• Bend

(38)

1154212-26 Rev.3 2012-02-22

English – 17

WORKING TECHNIQUES

• Wind direction

• Arrangement of branches

• Weight of snow

• Obstacles within the reach of the tree: for example,

other trees

• Look for signs of damage and rot in the stem, this makes

it more probab

before you expect it to.

You may find you are f orced to let the tree f all in its natural

direction because it is impossible or dangerous to tr

make it fall in the direction you first intended.

Another very important factor, which does not affect the

f

elling direction but does affect your safety, is to make sure

the tree has no damaged or dead branches that might

break off and hit you during felling.

The main point to avoid is letting the tree fall onto another

tree

there is high accident risk. See instructions under the

heading Freeing a tree that has fallen badly.

IMPORT ANT! During critical felling operations, hearing

protectors should be lifted immediately when sawing is

completed so that sounds and warning signals can be

heard.

Clearing the trunk and preparing your retreat

Delimb the stem up to shoulder height. It is safer to work

from the top down and to have the tree between you and

the saw.

Remove any undergrowth from the base of the tree and

chec

so that you have a clear path of retreat when the tree starts

to fall. Your path of retreat should be roughly 135 degrees

away from the intended felling direction.

1 Danger zone

2 Retreat path

3 Felling direction

Felling

Felling is done using three cuts. First you make the

directional cuts, which consist of the top cut and the bottom

cut, then you finish with the felling cut. By placing these

cuts correctly you can control the felling direction very

accurately.

Directional cuts

To make the directional cuts you begin with the top cut.

Stand to the right of the tree and cut on the pull stroke.

Next make the bottom cut so that it finishes exactly at the

end of the top cut.

The directional cuts should run 1/4 of the diameter through

the trunk and the angle between the top cut and bottom cut

should be 45

The line where the two cuts meet is called the directional

cut line

angles (90

Felling cut

The felling cut is made from the opposite side of the tree

and it must be perfectly horizontal. Stand on the left side of

the tree and cut on the pull stroke.

, power lines, roads and buildings.

ly that the tree will break and start to fall

y to

. It is very dangerous to remove a trapped tree and

k the area for obstacles (stones, branches, holes, etc.)

(39)

WARNING! Unless you have special

training we advise you not to fell trees

!

with a diameter larger than the bar

length of your saw!

(40)

°.

. This line should be perfectly horizontal and at right

°) to the chosen felling direction. (41)

Make the felling cut about 3-5 cm (1.5-2 inches) above the

bottom directional cut.

Set the spike bumper (if one is fitted) just behind the felling

hinge

. Use full throttle and advance the chain/bar slowly

into the tree. Make sure the tree does not start to move in

the opposite direction to your intended felling direction.

Drive a wedge or breaking bar into the cut as soon as it is

deep enough.

Finish the felling cut parallel with the directional cut line so

that the distance between them is at least 1/10 of the trunk

diameter. The uncut section of the trunk is called the felling

hinge.

The felling hinge controls the direction that the tree falls in.

(43)

All control over the felling direction is lost if the felling hinge

is too narrow or non-existent, or if the directional cuts and

felling cut are badly placed.

When the felling cut and directional cut are complete the

tree should star

wedge or breaking bar.

We recommend that you use a bar that is longer than the

diameter of the tree, so that y

and directional cuts with single cutting strokes. See

instructions under the heading Technical data section to

find out which lengths of bar are recommended for your

saw.

There are methods for felling trees with a diameter larger

than the bar length.

much greater risk that the kickback zone of the bar will

come into contact with the tree.

(42)

t to fall by itself or with the aid of a felling

ou can make the felling cut

However these methods involve a

Freeing a tree that has fallen badly

Freeing a ”trapped tree”

It is very dangerous to remove a trapped tree and there is

high accident risk.

Never try to fell the tree that is trapped.

Never work in the risk zone of the hanging trapped tree.

The safest method is to use a winch.

• Tractor-mounted

• Portable

Cutting trees and branches that are in tension

Preparations: W ork out which side is in tension and where

the point of maximum tension is (i.e. where it would break

if it was bent even more).

Decide which is the safest way to release the tension and

whether y

ou are able to do it safely. In complicated

situations the only safe method is to put aside your chain

saw and use a winch.

General advice:

Position yourself so that you will be clear of the tree or

branch when the tension is released.

Make one or more cuts at or near the point of maximum

tension.

Make as many cuts of sufficient depth as

necessary to reduce the tension and make the tree or

branch break at the point of maximum tension.

Never cut straight through a tree or branch that is in

tension!

18 – English

1154212-26 Rev.3 2012-02-22

WORKING TECHNIQUES / MAINTENANCE

If you must cut across tree/limb, make two to three cuts,

one inch apart, one to two inches deep.

Continue to cut deeper until tree/limb bends and tension is

released.

Cut tree/limb from outside the bend, after tension has been

released.

How to avoid kickback

WARNING! Kickback can happen very

suddenly and violently; kicking the chain

!

saw, bar and chain back at the user. If

this happens when the chain is moving it

can cause very serious, even fatal

injuries. It is vital you understand what

causes kickback and that you can avoid

it by taking care and using the right

working technique.

What is kickback?

The word kickback is used to describe the sudden reaction

that causes the chain saw and bar to jump off an object

when the upper quadrant of the tip of the bar, known as the

kickback zone, touches an object.

Kickback always occurs in the cutting plane of the bar.

Normally the chain saw and bar are thrown backwards and

upwards towards the user. However, the chain saw may

move in a different direction depending on the way it was

being used when the kickback zone of the bar touched the

object.

Kickback only occurs if the kickback zone of the bar

touches an object.

Limbing

!

Make sure that you can stand and move about safely. Work

on the left side of the trunk. Work as close as possible to

the chain saw for maximum control. If possible, let the

weight of the chain saw rest on the trunk.

Keep the trunk between you and the chain saw as you

mo

ve along the trunk.

Cutting the trunk into logs

See instructions under the heading Basic cutting

technique.

(45)

WARNING! A majority of kickback

accidents occur during limbing. Do not

use the kickback zone of the guide bar.

Be extremely cautious and avoid

contacting the log, other limbs or

objects with the nose of the guide bar.

Be extremely cautious of limbs under

tension. They can spring back toward

you and cause loss of control resulting

in injury.

(44)

General

The user must only carry out the maintenance and service

work described in this Operator’s Manual. More extensive

work must be carried out by an authorised service

workshop.

Carburettor adjustment

Your Husqvarna product has been designed and

manufactured to specifications that reduce harmful

emissions.

Function

• The carburettor governs the engine’s speed via the

throttle control. Air and fuel are mixed in the carburettor .

The air/fuel mixture is adjustable. Correct adjustment is

essential to get the best performance from the machine.

• The T-screw regulates the throttle setting at idle speed.

If the

T -scre w is turned clockwise this gives a higher idle

speed; turning it anti-clockwise gives a lower idle speed.

Basic settings and running in

The basic carburettor settings are adjusted during testing

at the factory. Fine adjustment should be carried out by a

skilled technician.

Rec. idle speed: See the Technical data section.

Fine adjustment of the idle speed T

Adjust the idle speed with the T-screw. If it is necessary to

re-adjust, turn the T-screw clockwise while the engine is

running, until the chain starts to rotate. Then turn anticlockwise until the chain stops. When the idle speed is

correctly adjusted the engine should run smoothly in every

position and the engine speed should be safely below the

speed at which the chain starts to rotate.

WARNING! Contact your servicing

dealer, if the idle speed setting cannot be

!

adjusted so that the chain stops. Do not

use the chain saw until it has been

properly adjusted or repaired.

Checking, maintaining and servicing chain saw safety equipment

Note! All service and repair work on the machine

demands special training. This is especially true of the

machine’s safety equipment. If your machine fails any

of the checks described below we recommend that you

take it to your service workshop. Any maintenance

other than that described in this manual must be

carried out by your servicing dealer (retailer).

Switch off the engine and take off the ignition cable

before repairs or maintenance

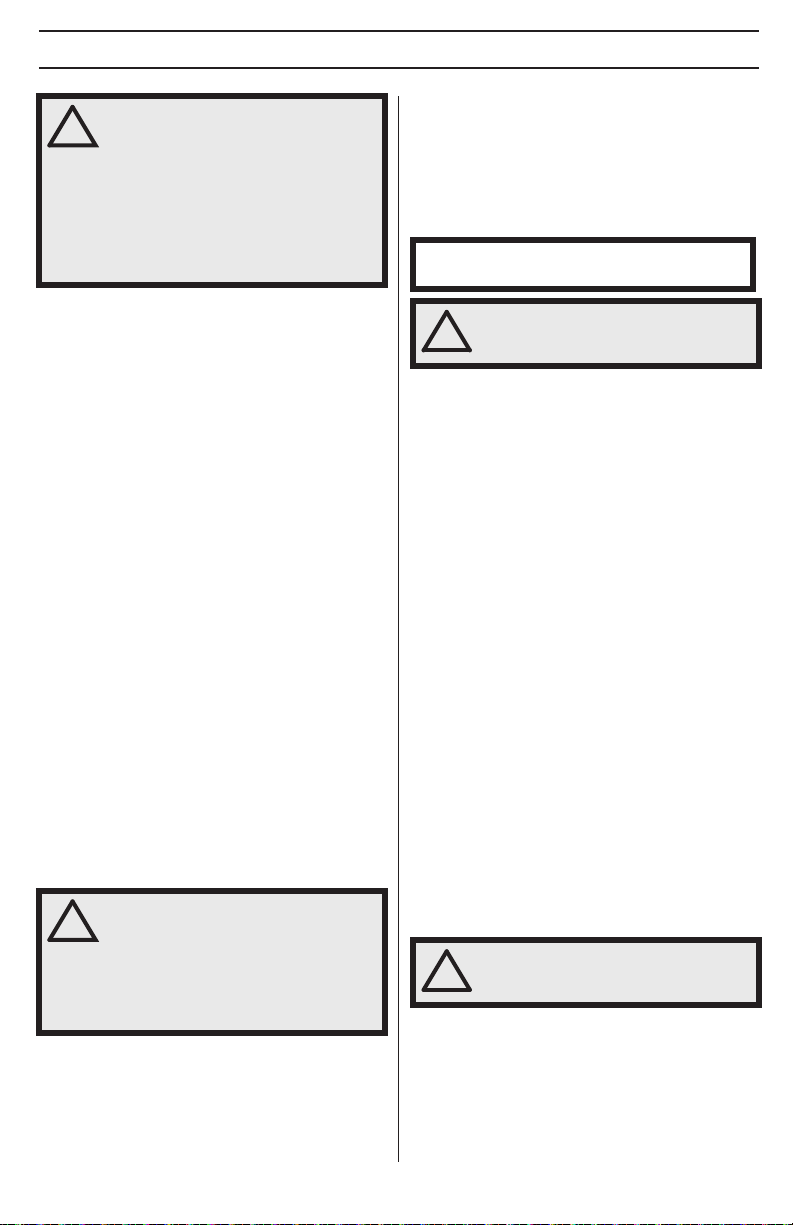

Chain brake and front hand guard

Checking brake band wear

Brush off any wood dust, resin and dirt from the chain

brake and clutch drum. Dirt and wear can impair operation

of the brake.

Regularly check that the brake band is at least 0.6 mm

thick at its thinnest point.

Checking the front hand guard

Make sure the front hand guard is not damaged and that

there are no visible defects such as cracks.

(46)

1154212-26 Rev.3 2012-02-22

English – 19

MAINTENANCE

Move the front hand guard forwards and back to make sure

it moves freely and that it is securely anchored to the clutch

cover.

(47)

Checking the inertia brake release

Place the chain saw, with the engine switched off, on a

stump or other stable surface. Release the front handle

and let the saw fall by its own weight, rotating around the

rear handle towards the stump.

When the bar hits the stump the brake should be

applied. (48)

Checking the right-hand brake trigger (240e TrioBrake)

Check that the right hand guard is not damaged and that

there are no visible defects, such as cracks.

Push the trigger up and forwards to check that it moves

freely and is securely hinged to the clutch co

Never carry or hang the saw by the trigger! This could

damage the mechanism and disable the chain brake.

(49)

Checking the brake trigger

Place the chain saw on firm ground and start it. Make sure

the chain does not touch the ground or any other object.

See the instructions under the heading Start and stop.

Grasp the chain saw firmly, wrapping your fingers and

thumbs around the handles.

Apply full throttle and activate the chain brake by tilting your

left wr

ist forward onto the front hand guard. Do not let go of

the front handle.

The chain should stop immediately.

ver.

Throttle lockout

• Make sure the throttle control is locked at the idle setting

when the throttle lockout is released.

• Press the throttle lockout and make sure it returns to its

or

iginal position when you release it.

• Check that the throttle control and throttle lockout move

freely and that the retur

• Start the chain saw and apply full throttle. Release the

throttle control and chec

remains stationary. If the chain rotates when the throttle

control is in the idle position you should check the

carburettor idle adjustment.