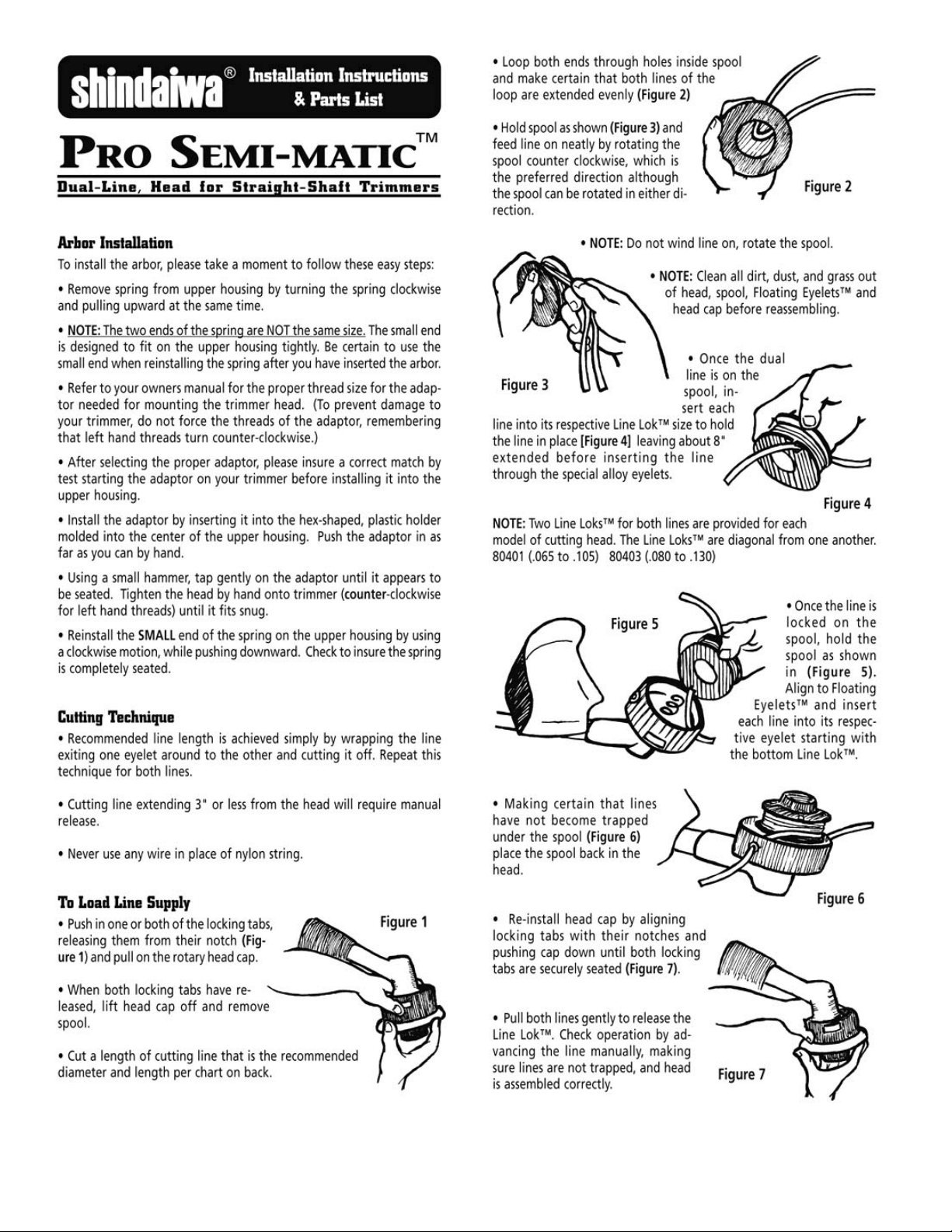

Page 1

Shindaiwa

Trimmer Head

Guide

How to load and service the

most popular Shindaiwa trimmer heads, including complete

replacement parts information

and other important technical

data.

First To Start. Last To Quit.

Item 80792 6/03

Page 2

Shindaiwa Trimmer Head Guide

INTRODUCTION

Shindaiwa offers several types of

trimmer heads to meet the requirements of our customers. This booklet

will help you – the distributor and

dealer – to help your customers

decide which trimmer heads to

purchase, as well as give them stepby-step instructions on how to untangle the mess of installing trimmer

line.

Each Shindaiwa trimmer head

comes with a set of instructions on

line installation. In the event that

these instructions are lost or misplaced, feel free to provide your

customers with a copy of the instructions from this booklet that matches

their particular trimmer head.

CONTENTS

page no.

General Trimmer Head

Information.................................... 3

Low Profile Manual Head.................. 4

SemiMatic Trimmer Head ................. 6

E-Z Load and E-Z Pro

Trimmer Heads............................. 8

High Capacity Trimmer Head ......... 10

Midget Manual and High Profile

Trimmer Heads........................... 12

Pro-Matic and Bump ’N’ Cut

Trimmer Heads........................... 14

HomePro Semi-Auto Feed.............. 16

Pro Semi-Matic ............................... 18

ADAPTER BOLTS BY MODEL

Current Models Bolt Size

22F 8mm / MRH

F230 8mm / MRH

22T 7mm / MLH

T230, T231, C230,

T2500, 65001 7mm / MLH

T250, C250 8mm / MLH

T260, T261, C260 8mm / MLH

T270, T271, C270,

T350 8mm / MLH

C350, B450, B530 10mm / MLH

Discontinued Models Bolt Size

BP35 8mm / MLH

B40 10mm / MLH

B45 10mm / MLH

C35 10mm / MLH

F18 8mm / MRH

F20 8mm / MLH

F21 8mm / MRH

LT18 7mm / MLH

LT20 7mm / MLH

T18 7mm / MLH

T20, C20 7mm / MLH

T25, C25 8mm / MLH

T27, C27 8mm / MLH

MLH Male, Left Hand Thread

MRH Male, Right Hand Thread

FLH Female, Left Hand Thread

FRH Female, Right Hand Thread

UN-10.............................................. 20

UN-30.............................................. 21

UN-32.............................................. 22

Flail Trimmer Head ......................... 23

Super Flail Trimmer Head............... 24

Fixed Line Trimmer Head ............... 25

Heavy-Duty Fixed Line Head.......... 26

Adaptors.......................................... 27

2

Page 3

General Trimmer Head Maintenance Information

The most common cause of trimmer

head malfunction is poor maintenance, especially true for tap-for-line,

bump-feed, and fully automatic heads.

Customers buy these heads for

convenience so they don’t have to

reach down and advance the line–yet

that added convenience often means

the head is not properly maintained.

A Few Tips

■ Clean the head thoroughly each time

line is refilled. Wipe all grass and

debris from internal parts. Water will

dissolve accumulated buildup, but a

cleaner such as 409™ will aid in the

task.

■ Replace worn eyelets. Never run a

trimmer head without eyelets installed. Running with an eyelet

missing will cause the trimmer line to

wear into the body of the head as

well as create excessive vibration.

■ Replace any noticeably worn parts. A

knob at the bottom of a head is a

wear part if it contacts the ground,

especially in abrasive soil conditions

and when the head is run against

sidewalks and curbs.

■ When winding line, keep both strings

separate. Try to wind as evenly as

possible to prevent snarling and

reduce vibration.

■ Trim line ends to equal length from

the eyelet. Operation with uneven

length trimmer line will cause

excessive vibration.

■ Always replace worn or damaged

parts promptly .

■ Make sure line is wound in the

correct direction for the rotation of

the head–

For heads with a LH arbor bolt,

wind line counterclockwise as viewed

from the knob at the end of the

trimmer head.

For heads with a RH arbor bolt,

wind line clockwise as viewed from

the knob.

“Clockwise for RH,

Counterclockwise for LH”

Any plastic material can dry out,

especially when stored at high temperature and when exposed to direct

sunlight. To prevent this, Shindaiwa

packages much of their trimmer line in

all-plastic holders so the line can be

soaked in water to restore moisture.

Trimmer line with very low moisture

content is brittle and inflexible. Winding dry line on a trimmer head can be

very difficult. After soaking in water,

the same line will become very flexible

and far tougher, and service life will

be significantly extended. NOTE: This

also applies to flail blades.

CAUTION: Remove the bearing or

bushing from from Super Flail blades

before soaking in water.

The Shindaiwa Warranty

Shindaiwa warrants trimmer heads to

be free of defects in materials and

workmanship for 90 days. The warranty is for replacement parts only –

not the entire trimmer head. Damage

caused by wear, running with missing

parts, etc. is not covered.

Q

uestion:

carry so many trimmer heads?

A

nswer:

for different applications. Some heads

feature manual adjustment of line

length while others are tap-for-line

models. In addition, some trimmer

heads are intended for consumer use

and others are intended primarily for

commercial applications.

Why does Shindaiwa

There are different heads

CONSUMER HEADS

Manual

Midget Head

manual head for small-displace-

ment trimmers.

Tap-for-Line

Bump & Cut

for-line head for small-displace-

ment trimmers.

3-Blade Flail

Economical flail head for weeds,

light brush and grass.

An inexpensive

An inexpensive tap-

COMMERCIAL HEADS

Manual

Low Profile

medium-duty manual head.

High Profile

manual head. Best choice for

abrasive soil conditions where

head is in contact with the ground.

Tap-for-Line

Pro-Matic

for-line head.

EZ-Load

reassemble.

EZ-Pro

larger line capacity.

SemiMatic

head. Stays clean by design. Reel

in cover for fast reloading.

Pro-Head

head.

Fixed-Line Head

One-piece die cast metal head. No

moving parts to lose. First choice

for many commercial users.

Contains grooves in sides to

prevent line shearing when head

contacts solid objects. Permits

cutting lower to the ground than

any other line cutting attachment.

Super Flail Head

Heavy-duty head for thick, tough

grass and brush.

NOTE: Flail-type heads are not a

good choice for stemmy material

such as mature blackberry vines

and tree seedlings.

Reasonably priced

Proven “old reliable”

General purpose tap-

Simple to load, easy to

Similar to EZ-Load with

Tough tap-for-line

Professional tap-for-line

3

Page 4

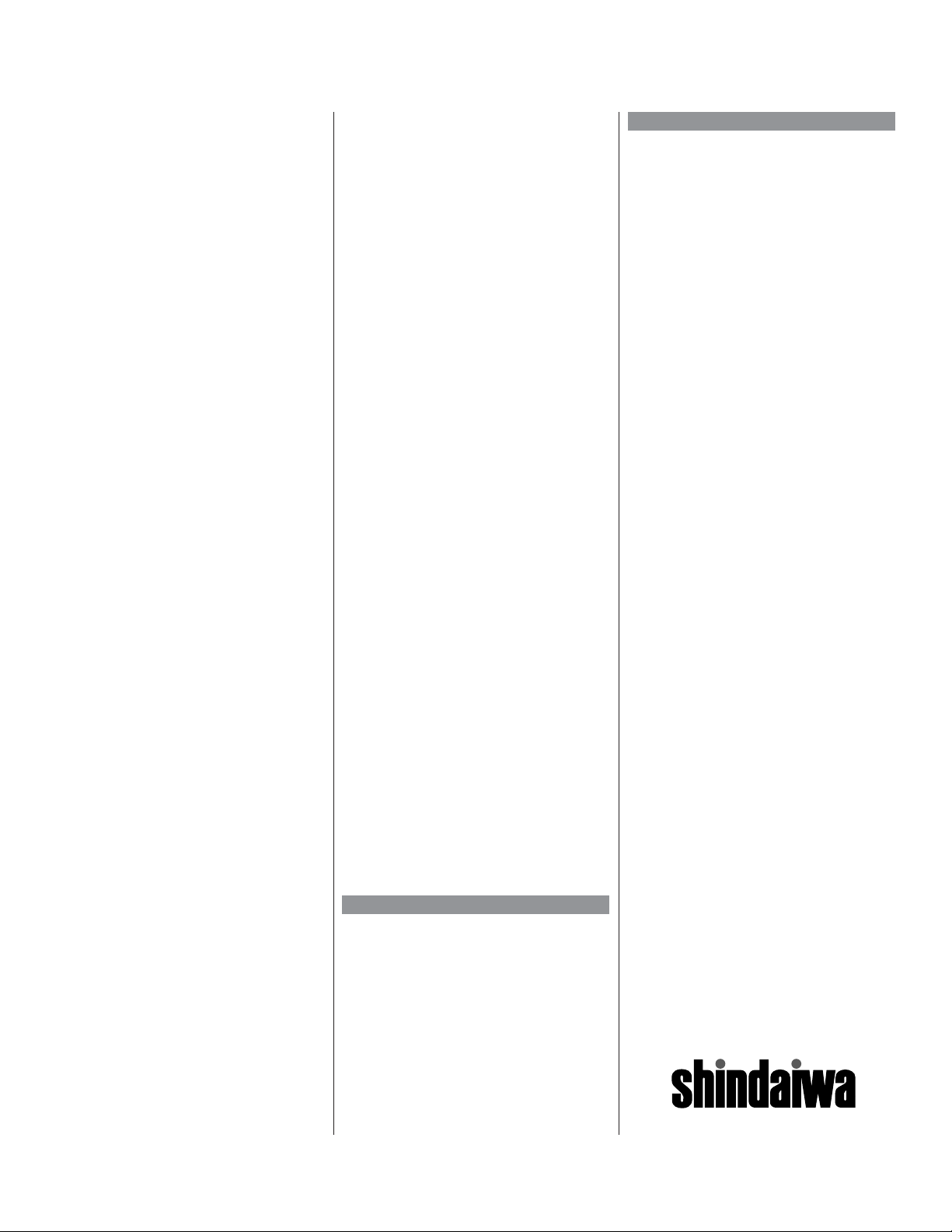

INSTALLATION INSTRUCTIONS

Low Profile Manual Trimmer Head

Model View

72036-15200

Fits LT18, T18, T20, C20, LT20, T230,

C230, 22T

72005-92001

Fits F20, T25, C25, T27, C27, BP35,

T250, C250, T270, C270, T260, C260,

T350

72017-92001

Fits C35, C350, RC45, B45, B450

NOTE: Operating with trimmer line of

uneven length will cause excessive

vibration. Always make sure the line is

wound evenly and trimmed to equal

lengths from the eyelets.

Line Chart

72036-15200

72005-92001

72017-92001

Shipped with

20 feet of .080 line.

Maximum fill–

40 feet of .080

30 feet of .095

26 feet of .105

1 2 3

Remove the knob and spring (turn

counterclockwise to remove).

Remove the line spool. Clean the spool, housing and eyelets.

4 5 6

Reattach the eyelets if they were

removed. Never operate a trimmer

head head without eyelets!

Replace the line by threading it

through the eyelet in the spool until

the line ends are of about equal

length. Refer to the Line Chart

(above) for the proper amount of line.

Inspect for wear and damage.

Replace damaged components.

Bend the line at the eyelet to form two

lengths. Wind both ends clockwise as

viewed from the underside of the

head.

4

Page 5

To advance line: With the engine off, loosen the bottom knob a few turns in

the direction of rotation. Grasp the trimmer head in both hands. Rotate the

bottom of the spool clockwise and pull the line through the eyelets. Re-tighten

the knob before operating the trimmer.

7 8

Use your finger to separate the line

into two sections. Doing so will assist

in a smooth line feed when the head

is reassembled.

9 10

Hold the spool over the housing and

feed one line end into an eyelet. As

you place the spool in the head, feed

the other line into the opposite eyelet.

Make sure one line does not slide

under the spool.

11 12

Holding the spool and wound line

in one hand, place the lines 180

degrees apart.

Tip: Sometimes it’s easier to remove

one eyelet to install the second piece

of line. Slide the eyelet over the line

two to three inches, then push the

eyelet in place as the spool is replaced in the housing.

1" to 2"

PARTS LIST

1 Adapter Bolt

2 Outer Housing

3 Inner Spool

4 Eyelets

5 Spring

6 Button/Knob

Low Profile Head

72036-15200

Item Part No.

1 72036-15210

2 72005-92740

3* 72005-92630

4 72005-92720

5 72005-92660

6 72005-92770

72005-92001

Item Part No.

1 72005-92710

2 72005-92740

3* 72005-92630

4 72005-92720

5 72005-92660

6 72005-92770

Reinstall the spring and knob. Tighten

securely.

A properly wound and reassembled

head should have four or five inches

of line extending from each eyelet and

the overlap should be one to two

inches. Trim as needed to final length.

72017-92001

Item Part No.

1 72017-92710

2 72005-92740

3* 72005-92630

4 72005-92720

5 72005-92660

6 72005-92770

*2 required

5

Page 6

INSTALLATION INSTRUCTIONS

SemiMatic Trimmer Head

Model View

99909-15500

Fits LT18, T18, T20, C20, LT20, T230,

C230, 22T

99909-15600

Fits F20, T25, C25, T27, C27, BP35,

T250, C250, T260, C260

NOTE: Operating with trimmer line of

uneven length will cause excessive

vibration. Always make sure the line is

wound evenly and trimmed to equal

lengths from the eyelets.

Line Chart

99909-15500

99909-15600

Shipped with 10 feet of .095 line

Maximum fill–

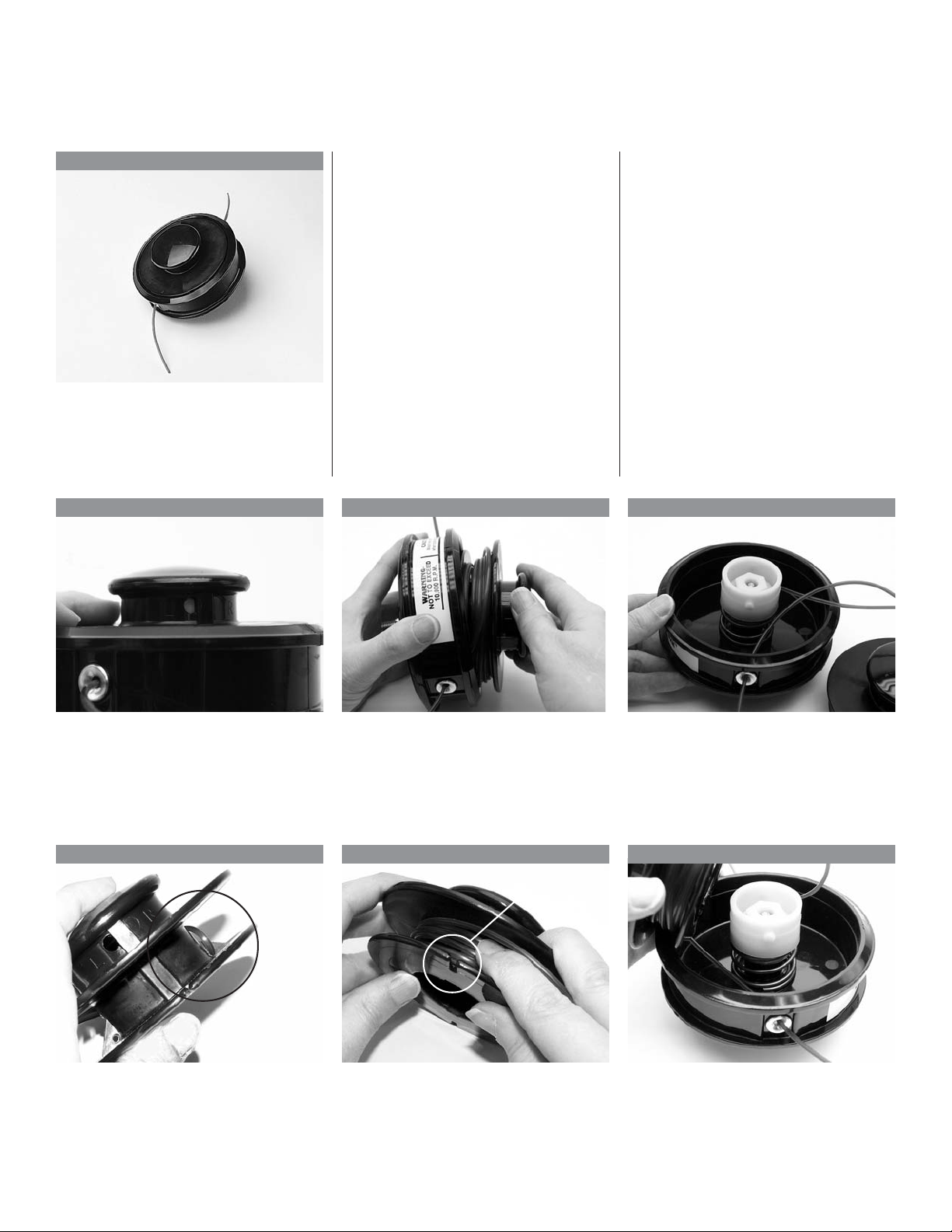

1 2 3

40 feet of .080

26 feet of .095

20 feet of .105

Turn the knob clockwise to remove

the knob and spool (one piece). Make

sure the white lock tab is visible in the

“L” window on the knob before starting

to turn.

Remove the knob and spool. Clean the housing and spool and

4 5 6

Spool Saver

Slot

Replace the line by threading it

through the eyelet in the spool until

the line ends are of equal length.

With the knob facing away from you,

wind the line counterclockwise. Hook

the line into line saver slots in the

spool housing.

inspect for damage and wear. If the

eyelets are worn excessively, replace

the housing. Note: The inner and

outer cams in the spool can be

serviced by a dealer.

Install the knob and spool in the

housing while threading the line

through the eyelets. Pull the line to

seat the spool.

6

Page 7

7

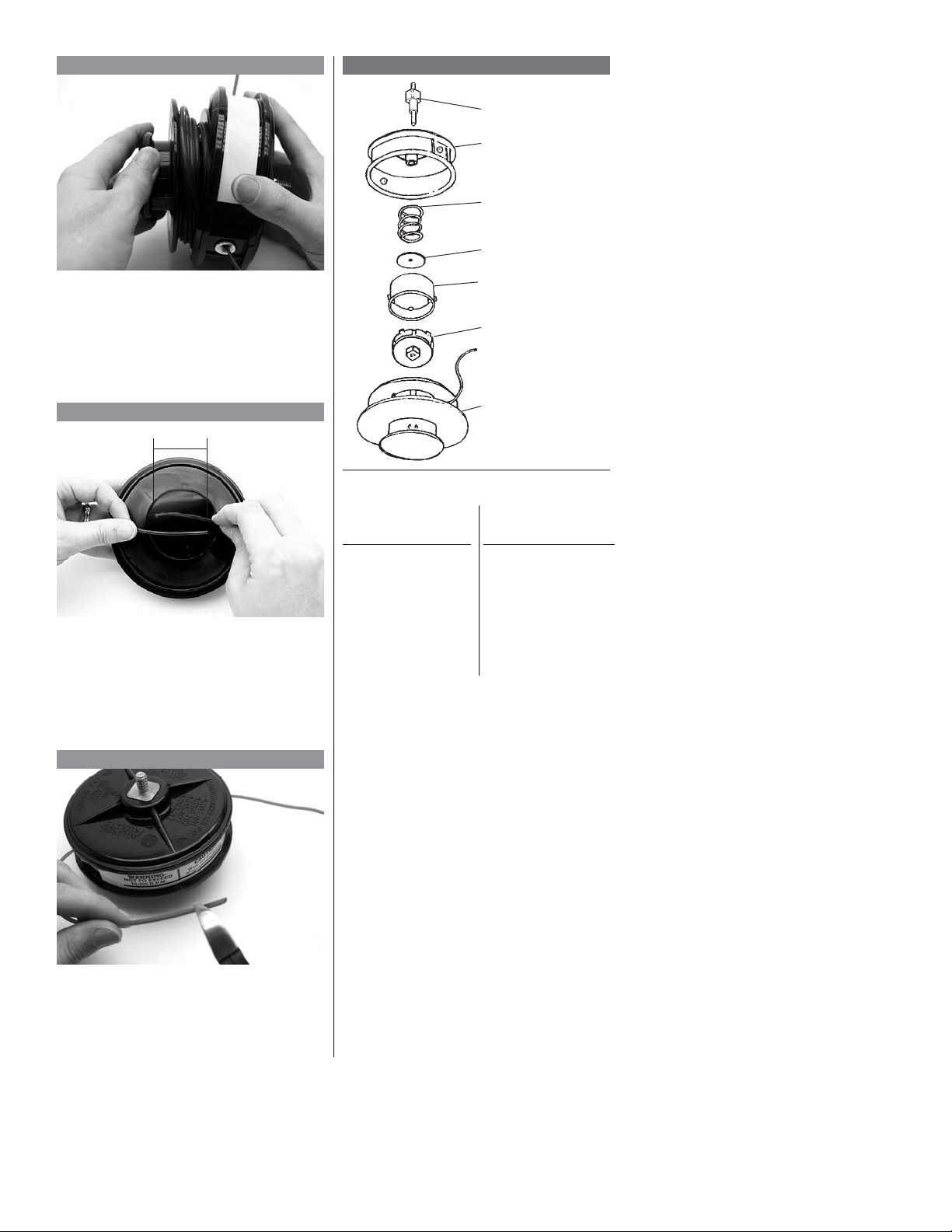

PARTS LIST

1 Adapter Bolt

2 Outer Housing

3 Spring

4 Washer

Turn the knob/spool counterclockwise

to lock the spool in the housing. You

will feel a firm “click” when the white

lock tab snaps into place.

8

1" to 2"

A properly reassembled head should

have four to five inches of line extending from each eyelet, and the total

overlap should be one to two inches.

SemiMatic

99909-15500

Item Part No.

1 72036-15210

2 99909-15510

3 99909-15520

4 99909-15530

5 99909-15540

6 99909-15550

7 99909-15560

5 Cam Assembly

6 Cam Lock

7 Inner Spool

99909-15600

Item Part No.

1 72005-92710

2 99909-15510

3 99909-15520

4 99909-15530

5 99909-15540

6 99909-15550

7 99909-15560

9

Trim the line to equal length as

required to avoid excessive vibration.

7

Page 8

INSTALLATION INSTRUCTIONS

E-Z Load and E-Z Pro Trimmer Heads

E-Z Load E-Z Pro

E-Z Load

99909-017

Fits LT18, T18, LT20, T20, C20, T230,

C230, 22T

99909-018

Fits F20, T25, C25, T250, C250, T27,

C27, T270, C270, T260, C260, BP35

99909-018RB

Fits 22F

E-Z Pro

99909-028

Fits T25, C25, T27, C27, T250, C250,

T270, C270

99909-020

Fits B40, B45, B450, C35, C350,

RC45

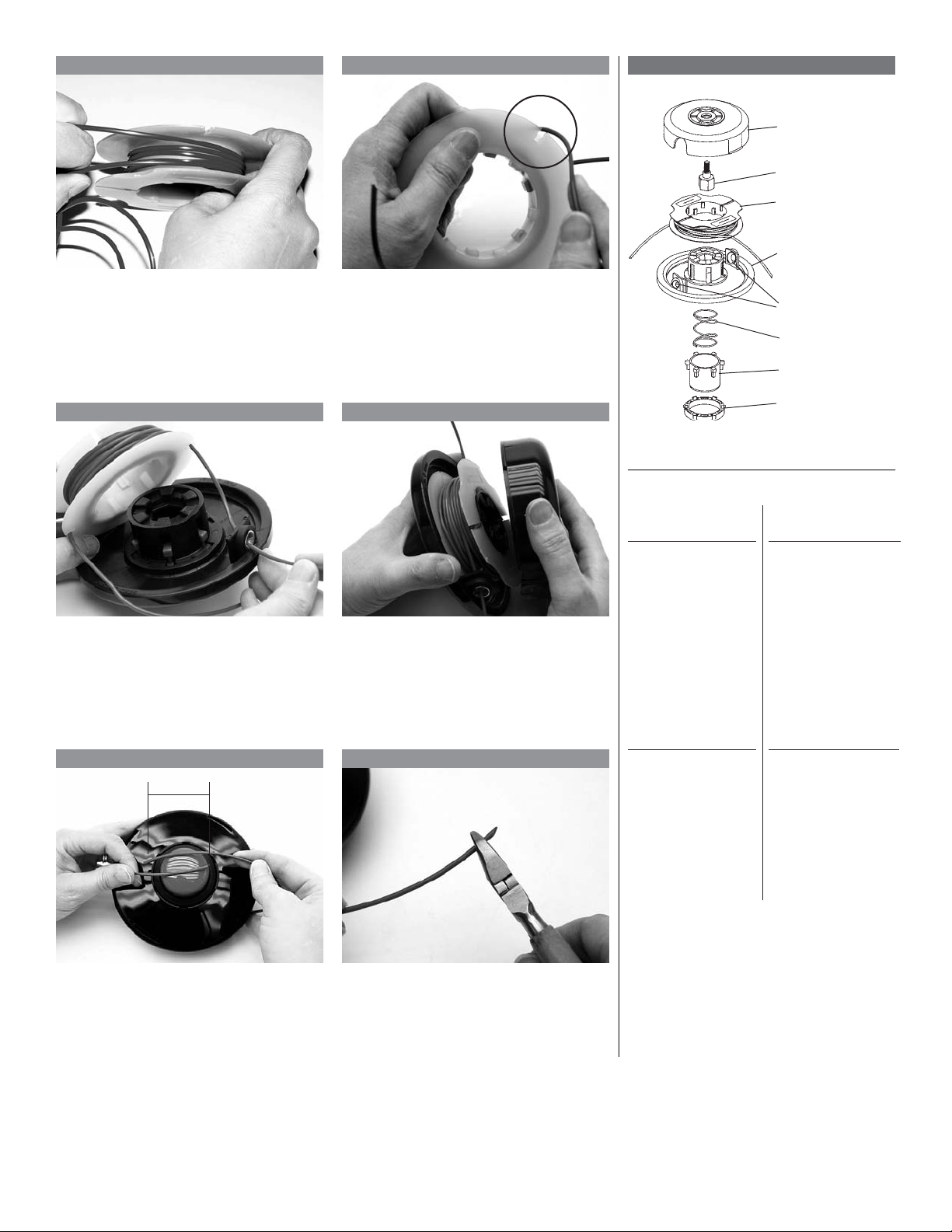

1 2 3

NOTE: Operating with trimmer line of

uneven length will cause excessive

vibration. Always make sure the line is

wound evenly and trimmed to equal

lengths from the eyelets.

Line Chart

E-Z Load

99909-017

99909-018

Shipped with 15

feet of .095 line.

Maximum fill–

45 feet of .080

34 feet of .095

32 feet of .105

E-Z Pro

99909-028

99909-020

Shipped with 15 feet

of .095 line.

Maximum fill–

50 feet of .080

40 feet of .095

36 feet of .105

Press the upper body in at the spots

marked “Push Open”. Pull the lower

part of the trimmer head down.

Remove the line spool from the lower

body of the trimmer.

4 5 6

Clean and inspect the spool, housing

and eyelets. Replace worn or damaged components.

Cut two equal lengths of trimmer line,

no longer than 25 feet each. Place an

end from each piece of line in the

holes in the center of the spool.

If nylon line is extending through the

eyelets, push the bump knob in while

rotating the line spool until the slots in

the spool line up with the eyelets, then

remove the spool.

While holding the line ends, pull each

line down toward the inside of the

spool through the slots next to the

holes.

8

Page 9

7 8

PARTS LIST

1 Outer Housing

2 Adapter Bolt

3 Inner Spool

4 Outer Cover

With line saver slots facing away from

you, wind the line clockwise on the

spool. Use a finger to keep the two

lines separate (spool shown is for

99909-017).

9 10

Thread the ends of the line into the

eyelets in the housing. Do not allow

line to go under spool.

11 12

1" to 2"

Lock the ends of the line in the line

saver slots in the spool.

Replace the cover by aligning the

tabs, then snap the cover in place.

Pull line free from the line saver slots.

E-Z Load

99909-017

Item Part No.

1 101134

2 102351

3 101030

4 101135

5* 105115

6 107001

7 101136

8 101137

99909-028

Item Part No.

1 101170

2 102349

3 101171

4 101172

5* 106007

6 107001

7 101136

8 101137

5 Eyelets

6 Spring

7 Button/Knob

8 Retaining Ring

E-Z Pro

99909-018

Item Part No.

1 101134

2 102350

3 101030

4 101135

5* 105115

6 107001

7 101136

8 101137

99909-020

Item Part No.

1 101170

2 102350

3 101171

4 101172

5* 106007

6 107001

7 101136

8 101137

Check for a maximum line overlap of

one to two inches (four to five inches

of line extending from each eyelet).

*2 required

Trim as required to final length.

9

Page 10

INSTALLATION INSTRUCTIONS

High Capacity Trimmer Head

Model View

Note: This trimmer head can operate

either as a manual feed or a bump

feed.

99909-007

Fits T230 and C230

99909-008

Fits T27, C27, T270, C270, T260,

C260, BP35

NOTE: Operating with trimmer line of

uneven length will cause excessive

vibration. Always make sure the line is

wound evenly and trimmed to equal

lengths from the eyelets.

Line Chart

99909-007

99909-008

Shipped with 21 feet of .080 line.

Maximum fill–

1 2 3

50 feet of .080

40 feet of .095

36 feet of .105

Turn the lower knob at the bottom of

the trimmer head clockwise to disassemble the halves.

Remove the spool from the housing.

4 5 6

Inspect the arbor bolt and replace it if

damaged. Reattach the eyelets if they

were removed or replaced. Never

operate a trimmer head without

eyelets!

Cut two equal lengths of trimmer line,

no longer than 25 feet each. Place an

end from each piece of line into the

holes in the center of the spool.

Clean the spool, housing and eyelets.

Inspect for wear and damage.

Replace damaged components.

Wind the line clockwise onto the spool

following the direction of the arrows

stamped into the spool.

10

Page 11

7 8

Line Saver

Slot

Continue winding the line onto the

spool, keeping one finger between

the lines. Lock the ends of each line

segment into line saver slots in the

spool.

Thread the ends of the line into the

eyelets in the housing. Do not allow

line to go under the spool.

PARTS LIST

1 Adapter Bolt

2 Outer Housing

3 Eyelets

4 Inner Spool

5 Retaining Ring

6 Outer Cover

7 Spring

8 Spring Housing

9 Button/Knob

9 10

Replace the arbor bolt in the top of

the trimmer head. Install the spacers

as shown.

11 12

1" to 2"

Replace the cover. Tighten the lower

knob by turning counterclockwise.

Pull the line ends free from the line

saver slots.

High Capacity

99909-007

Item Part No.

1 99909-217

2 101061

3* 106003

4 101030

5 103025

6 101053

7 107006

8 101054

9 101074

10 102082

11 101072

*2 required

10 Retainer Bolt

11 Knob Tap

99909-008

Item Part No.

199909-218

2 101061

3* 106003

4 101030

5 103025

6 101053

7 107006

8 101054

9 101074

10 102082

11 101072

Check for maximum line overlap of

one to two inches (four to five inches

of line extending from each eyelet).

Trim as required to final length.

11

Page 12

INSTALLATION INSTRUCTIONS

Midget Manual and High Profile Trimmer Heads

Midget Manual High Profile

72414-15100*

Fits F18, F21, F230

72086-15100

Fits LT18, T18, T20, C20, LT20,

T230, C230, 22T

72031-15100

F20

72005-92600

Fits T25, C25, T27, C27, BP35, T250,

C250, T260, C260, T270, C270, T350

99909-151

Fits C35, B45, RC45, C350, B450

1 2 3

NOTE: Operating with trimmer line of

uneven length will cause excessive

vibration. Always make sure the line is

wound evenly and trimmed to equal

lengths from the eyelets.

Line Chart

Midget Manual

72414-15100

72086-15100

72031-15100

Shipped with 14

feet of .080 line.

Maximum fill–

26 feet of .080

6 feet of .095

High Profile

72005-92600

99909-151

Shipped with 21 feet

of .095 line.

Maximum fill–

26 feet of .095

20 feet of .105

Remove the wing nut knob and spring

(turn counterclockwise to remove on

72414-15100; turn clockwise on all

others).

Remove the line spool. Clean the spool, housing and eyelets.

4 5 6

Reattach the eyelets (if they were

removed). Never run a trimmer head

without eyelets!

Replace the line by threading through

the eyelet in the spool until the line

ends are of equal length. Refer to the

Line Chart (above) for the proper

amount of line.

Inspect for wear and damage, and

replace damaged components.

Bend the line at spool eyelet to form

two lengths. 72414-15100: Wind both

ends clockwise as viewed from the

underside of the head. All others:

Wind counterclockwise.

12

Page 13

To advance line: With the engine off, loosen the wing nut a few turns in the

direction of rotation. Grasp the trimmer head with both hands. Rotate the

bottom of the spool clockwise and pull the line through the eyelets. Re-tighten

the wing nut before operating the trimmer.

7 8

Use your finger to separate the line

end into two separate sections. Doing

so will assist in a smooth line feed

when the head is reassembled.

9 10

Hold the spool over the housing and

feed one line into an eyelet. As you

place the spool in the head, feed the

other line into the opposite eyelet.

Make sure one line does not slide

under the spool.

11 12

Holding the spool and wound line in

one hand, place the line ends 180

degrees apart. Note: The photo

illustrates the spool for 72414-15100.

Tip: Sometimes it’s easier to remove

one eyelet when installing the second

piece of line. Slide the eyelet over the

line for two to three inches, then push

the eyelet in place as the spool is

replaced in the housing.

1" to 2"

PARTS LIST

Midget Manual

Midget Manual

Head

72414-15100

Item Part No.

1 72414-15110

2 72414-15120

3* 72005-92630

4 72414-15140

5 72005-92660

6 72414-15160

72086-15100

Item Part No.

1 72086-15110

2 72414-15120

3* 72005-92630

4 72414-15140

5 72005-92660

6 72031-15160

High Profile

1

Adapter

Bolt

2

Outer

Housing

3

Eyelets

4

Inner

Spool

5

Spring

6

Knob

High Profile

Head

72005-92600

Item Part No.

1 72005-92710

2 72005-92620

3* 72005-92630

4 72005-92640

5 72005-92660

6 72031-15160

99909-151

Item Part No.

1 72017-92710

2 72005-92620

3* 72005-92630

4 72005-92640

5 72005-92660

6 72031-15160

Reinstall the spring and wing nut

knob. Tighten firmly.

A properly reassembled head should

have four to five inches of line extending from each eyelet, and the overlap

should be one to two inches. Trim as

required to final length.

72031-15100

Item Part No.

1 72005-92710

2 72414-15120

3* 72005-92630

4 72414-15140

5 72005-92660

6 72031-15160

*2 required

13

Page 14

INSTALLATION INSTRUCTIONS

Pro-Matic and Bump ‘N’ Cut Trimmer Heads

Pro-Matic Bump ‘N’ Cut

UN32-7L

Fits LT18, T18, T20, C20, LT20, T230,

C230, 22T

UN32-8L

Fits F20, T25, C25, T27, C27, BP35,

TC250, T270, C270, T260, C260

UN32-10L

Fits C35, C350, RC45, B45, B450

UN34-7L

Fits LT18, T18, LT20, T20, C20, T230,

C230, 22T

UN34-8R

Fits F18, F21, F230, 22F

1 2 3

NOTE: Operating with trimmer line of

uneven length will cause excessive

vibration. Always make sure the line is

wound evenly and trimmed to equal

lengths from the eyelets.

Line Chart

UN32-7L

UN32-8L

UN32-10L

Shipped with

18 feet of .080 line.

Maximum fill–

40 feet of .080

28 feet of .095

26 feet of .105

UN34-8R

Shipped with

21 feet of .080 line.

Maximum fill–

33 feet of .080

16 feet of .095

14 feet of .105

Depress the tab on the lower housing

and twist the cover counterclockwise

(clockwise on UN34-8R) to align

arrows. Remove the cover and button.

Remove the spool and spring (the

spring is located under the spool).

4 5 6

Inspect the arbor bolt and replace it if

damaged. Re-attach the eyelets if

they were removed or replaced.

Never operate a trimmer head

without eyelets!

Replace the line by threading it

through the eyelet in the spool until

line lengths are equal. Refer to the

Line Chart (above) for the proper

amount of line.

Clean the spool, housing and eyelets.

Inspect for wear and damage.

Replace damaged components.

With line saver slots facing you,

wind the line clockwise in the spool

using a finger to keep the two lines

separate (UN34-8R: Wind the line

counterclockwise).

14

Page 15

7 8

Lock the ends of line into line saver

slots in spool.

Insert the spring onto the bolt. With

the line saver slots on the spool facing

the bolt, thread the ends of the line

into the eyelets in the housing. Do not

allow the line to go under the spool.

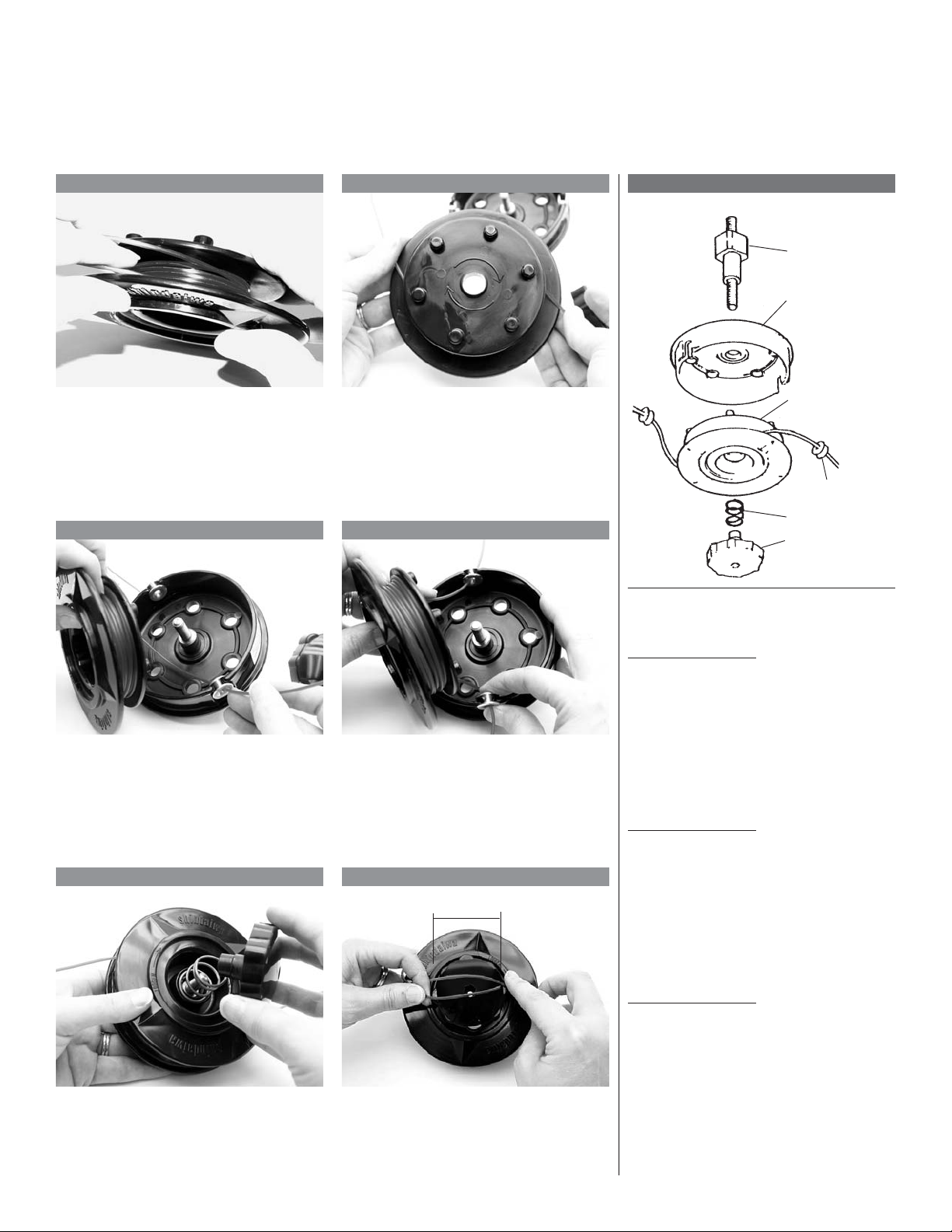

PARTS LIST

2 Eyelet

1 Outer Housing

3 Adapter Bolt

4 Spring

5 Inner Spool

6 Button/Knob

9 10

Place the button in the center of`the

spool.

11 12

1" to 2"

Check for a maximum line overlap of

one to two inches (four to five inches

of line extending from each eyelet).

Replace the cover by aligning the tabs

and then twisting counterclockwise as

viewed from the button side of the

head (UN34-8R: Twist clockwise).

Pull the line free from the line saver

slots.

Trim as required to final length.

Pro-Matic (UN-32)

UN32-7L

Item Part No.

1 99909-15700

2* 72005-92630

3 99909-15720

4 99909-15520

5 99909-15580

6 99909-15590

7 99909-15610

UN32-10L

Item Part No.

1 99909-15700

2* 72005-92630

3 99909-15740

4 99909-15520

Bump ‘N’ Cut (UN-34)

UN34-7L

Item Part No.

1 99909-15710

2* 72005-92630

3 99909-15720

4 72078-15240

5 99909-15770

6 99909-15780

7 99909-15755

UN32-8L

Item Part No.

Item Part No.

UN34-8R

Item Part No.

7 Outer Cover

1 99909-15700

2* 72005-92630

3 99909-15730

4 99909-15520

5 99909-15580

6 99909-15590

7 99909-15610

5 99909-15580

6 99909-15590

7 99909-15610

1 99909-15790

2 72005-92630

3 99909-15800

4 72078-15240

5 99909-15810

6 99909-15780

7 99909-15750

*2 required

15

Page 16

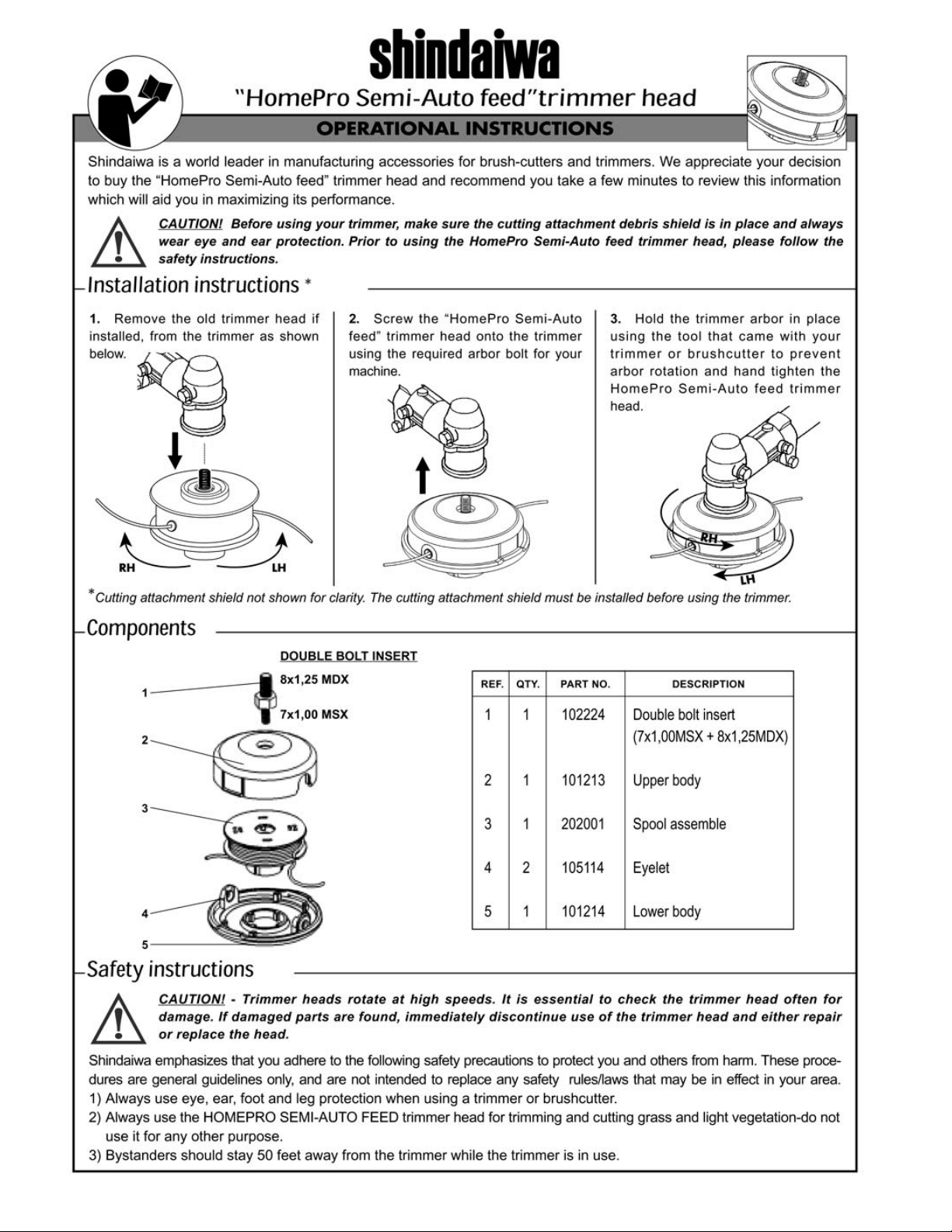

1617181920

Page 17

Page 18

Page 19

Page 20

UN10 Assembly and Rewinding Instructions

WARNING!

䡵 Do not make unauthorized

modifications or alterations to this

unit or its components. Nonstandard parts may not operate

properly with this trimmer head

and may cause damage and lead

to personal injury.

䡵 Always wear eye protection such

as goggles or safety glasses to

shield against thrown objects.

䡵 Reduce the risk of bystanders

being struck by flying debris. Make

sure no one is within 50 feet (15

meters)—that’s about 16 paces—

of an operating attachment.

NOTE:

Each package contains (3) steel studs.

Select the correct stud for your Shindaiwa trimmer or brushcutter model.

A. 7mm LH (gold p/n 80676)

(Fits 22T, 22C, T230, T231, C230,

T2500, T2500X, 65001 multipurpose

tool)

B. 8mm LH (silver p/n 80677)

(Fits T260, T261, C260, T270, T272X,

C270, T350)

C. 10mm LH (silver p/n 80678)

(Fits C350, B450, B530)

Line capacity:

.080” .... 38’

.095” .... 26’

.105” .... 20’

A B C

Arbor Bolt (1)

p/n 80730

Eyelet (2)

p/n 72005-92630

Housing (1)

p/n 72005-92620

Spool (1)

p/n 72005-92640

Spring (1)

p/n 72005-92660

Knob (1)

1

2

p/n 72031-15160

3 4 5

6 7 8

Page 21

UN30 Assembly and Rewinding Instructions

WARNING!

䡵 Do not make unauthorized

modifications or alterations to this

unit or its components. Nonstandard parts may not operate

properly with this trimmer head

and may cause damage and lead

to personal injury.

䡵 Always wear eye protection such

as goggles or safety glasses to

shield against thrown objects.

䡵 Reduce the risk of bystanders

being struck by flying debris. Make

sure no one is within 50 feet (15

meters)—that’s about 16 paces—

of an operating attachment.

NOTE:

Each package contains (3) steel studs.

Select the correct stud for your Shindaiwa trimmer or brushcutter model.

A. 7mm LH (gold p/n 80676)

(Fits 22T, 22C, T230, T231, C230,

T2500, T2500X, 65001 multipurpose

tool)

B. 8mm LH (silver p/n 80677)

(Fits T260, T261, C260, T270, T272X,

C270, T350)

C. 10mm LH (silver p/n 80678)

(Fits C350, B450, B530)

Line capacity:

.080” .... 40’

.095” .... 26’

.105” .... 20’

A B C

Arbor Bolt (1)

p/n 80730

Housing (1)

p/n 99909-15510

Spring (1)

p/n 99909-15520

Washer (1)

p/n 99909-15530

Cam Assy. (1)

p/n 99909-15540

Cam Lock (1)

p/n 99909-15550

Spool (1)

p/n 99909-15560

1

2

3 4 5

6 7

21

Page 22

UN32 Assembly and Rewinding Instructions

WARNING!

䡵 Do not make unauthorized

modifications or alterations to this

unit or its components. Nonstandard parts may not operate

properly with this trimmer head

and may cause damage and lead

to personal injury.

䡵 Always wear eye protection such

as goggles or safety glasses to

shield against thrown objects.

䡵 Reduce the risk of bystanders

being struck by flying debris. Make

sure no one is within 50 feet (15

meters)—that’s about 16 paces—

of an operating attachment.

NOTE:

Each package contains (3) steel studs.

Select the correct stud for your Shindaiwa trimmer or brushcutter model.

A. 7mm LH (gold p/n 80676)

(Fits 22T, 22C, T230, T231, C230,

T2500, T2500X, 65001 multipurpose

tool)

B. 8mm LH (silver p/n 80677)

(Fits T260, T261, C260, T270, T272X,

C270, T350)

C. 10mm LH (silver p/n 80678)

(Fits C350, B450, B530)

Line capacity:

.080” .... 40’

.095” .... 28’

.105” .... 26’

A B C

Arbor Bolt (1)

p/n 80731

Housing (1)

p/n 99909-15700

Eyelet (2)

p/n 72005-92630

Spring (1)

p/n 99909-15520

Spool (1)

p/n 99909-15580

Button (1)

p/n 99909-15590

Cover (1)

p/n 99909-15610

1

2

3 4 5

6 7 8

22

Page 23

INSTALLATION INSTRUCTIONS

Flail Trimmer Heads

Model View

1 2

Trimmer

Gearcase

Spacer

Flail Head

The three-blade flail head is recommended for light- to medium-duty

applications. The flail head is great for

clearing weeds and heavy grass.

NOTE: The three-blade flail head will

fit straight shaft grass machines

ranging from the Shindaiwa T18

through T270/C270. When installing

the head onto a trimmer, notice that

Holder B is included with the flail head

package.

T18, T230/C230

Item Part No.

Spacer 22035-13230

Holder A 22035-13242

Holder B 99909-331

Bolt Guard 22035-13290

Arbor Bolt 22035-13271

T250/C250, T260/C260

Item Part No.

Holder A 22420-13510

Holder B 99909-331

Bolt Guard 22024-13291

Arbor Bolt 22000-13512

T270/C270

Item Part No.

Holder A 22024-13912

Holder B 99909-331

Bolt Guard 22014-13291

Arbor Bolt 22000-13512

Replacement Blades (3 required)

Part No. 99909-148

Holder A

Holder B

Bolt Guard

Arbor Bolt

If the machine is equipped with a

trimmer line head (T18/T230 models),

unscrew the head (turn clockwise to

remove) and remove all adapters.

Replace the spacer and install all

parts as shown above. Tighten the

arbor bolt securely.

If blades become worn or damaged,

they can be replaced by removing the

shoulder bolt with a standard flatblade screwdriver.

3 PARTS LIST

Flail Head

1 Nut (not shown)

2 Washer (not shown)

99909-147

Item Part No.

1 99909-75

2 99909-82

Insert the new blade and shoulder

bolt, and tighten securely.

3* 99909-149

4* 99909-148

*3 required

3 Bolt

4 Flail Blade

23

Page 24

INSTALLATION INSTRUCTIONS

Super Flail Trimmer Heads

Model View

WARNING! NEVER USE A METAL

CUTTING BLADE ON A SUPER

FLAIL TRIMMER HEAD!

The three-blade super flail head is a

perfect attachment for trimming grass,

vegetation, and light brush. The nylon

blades are supported by a metal

bearing surface for superior performance and durability.

NOTE: The three-blade super flail

head will fit straight shaft grass

machines ranging from the Shindaiwa

T18 through B530. When installing the

head onto a trimmer, notice that

Holder B is included with the flail head

package (except C350 and T350 units

that use a different Holder B).

1 2

Trimmer

Gearcase

Spacer

Holder A

Holder B

Bolt Guard

If the machine is equipped with a

trimmer line head (T18/T230 models),

unscrew the head (turn clockwise to

remove) and remove all adapters.

Replace the spacer and install all

parts as shown above. Tighten the

arbor bolt securely.

NOTE:

Replacement flail blades may be purchaced in a pack of 3 (p/n 101058-03 or

a pack of 12 (p/n 101058-12).

Super

Flail Head

Arbor Bolt

If blades become worn or damaged,

they can be replaced by removing the

locking bolt with a 4 mm allen wrench.

3

Push the bearing out and install it into

the new blade, insert the blade and

locking bolt, then tighten securely.

T18, T230/C230

Item Part No.

Spacer 22035-13230

Holder A 22035-13242

Holder B 99909-331

Bolt Guard 22035-13290

Arbor Bolt 22035-13271

T250/C250–T260/C260

Item Part No.

Holder A 22020-13510

Holder B 99909-331

Bolt Guard 22024-13291

Arbor Bolt 22000-13512

T270/C270

Item Part No.

Holder A 22024-13912

Holder B 99909-331

Bolt Guard 22024-13291

Arbor Bolt 22000-13512

T350

Item Part No.

Holder A 22000-13241

Holder B 99909-331

Bolt Guard 22000-13290

Arbor Bolt 22000-13212

C350, B450

Item Part No.

Holder A 22015-13241

Holder B 109010

Bolt Guard 22015-13270

Arbor Bolt 22015-13261

PARTS LIST

Super Flail Head

1 Upper Body

4 Bolt

6 Bushing

5 Flail Blade

3 Lower

Body

99909-1566

Item Part No.

1 101017

2* 103012

3 101018

*3 required

2 Nut

Item Part No.

4* 103011

5* 101058

6* 105014

24

Page 25

INSTALLATION INSTRUCTIONS

Fixed Line Trimmer Heads

Model View

1 2

Trimmer

Gearcase

Spacer

(T18-T230)

Fixed Line

Trimmer

Head

The fixed line trimmer head is a tough

aluminum die-cast trimmer head that

is virtually impossible to break. It

accepts line up to .130 in. diameter

and will perform well in heavy-duty

applications.

NOTE: The fixed line trimmer head

will fit straight shaft grass trimmers

ranging from the T18 through the

B450. When installing the head onto a

trimmer, pay special attention to the

correct use assembly components as

shown to the right (supplied with the

trimmer head):

Option 1–Single Line

Option 2–Double LineHolder A

T18, T230/C230

Item Part No.

Spacer 22035-13230

Holder A 22035-13242

Bolt Guard 22035-13290

Arbor Bolt 22035-13271

T250/C250, T260/C260

Item Part No.

Holder A 22024-13912

Bolt Guard 22024-13291

Arbor Bolt 22000-13512

T270/C270

Item Part No.

Holder A 22420-13510

Flat Washer 99909-92810

Bolt Guard 22024-13291

Arbor Bolt 22000-13512

T350

Item Part No.

Holder A 22000-13241

Bolt Guard 22015-13270

Arbor Bolt 22000-13512

Washer

(270 only)

Bolt Guard

Arbor Bolt

If the machine (size ranging from T18

to T230) is already equipped with a

trimmer head, unthread the existing

trimmer head (clockwise to remove)

and remove all adapters. Replace the

spacer and install all the components

shown here. Tighten the arbor bolt

securely.

3

Cut either one or two 16-inch lengths

of trimmer line (depending upon how

much line you want exposed for

trimming) and thread it through the

trimmer head as shown.

CAUTION: Make sure the line is

trimmed evenly to avoid vibration.

Some applications may require that

the line be trimmed to clear the cutting

attachment shield, as shown.

C350, B450

Item Part No.

Holder A 22015-13241

Flat Washer 99909-92810

Arbor Bolt 22015-13261

Replacement Line

Up to .130 in. diameter. Refer to the

Shindaiwa Accessory Catalog for

more information.

WARNING!

NEVER USE WIRE ROPE TRIMMER LINE WITH A FIXED LINE

TRIMMER HEAD.

25

Page 26

INSTALLATION INSTRUCTIONS

Shindaiwa Heavy-duty Fixed-line Head

The Shindaiwa Heavy-duty Fixed-line Head package* (p/n 80410) comes complete with the necessary hardware to fit all Shindaiwa straight shaft grass trimmers and brushcutters.

*Package containing Fixed-line Trimmer Head, (2) arbor bolts and spacer washer.

For dedicated grass trimmer installation

First select the correct 7 mm or 8 mm arbor adapter for your Shindaiwa product. A dedicated grass trimmer is not equipped with

brush blade holders. Shindaiwa models 22T, T230, T231, T2500 use the 7 mm arbor adapter while models T260 and T261 use the

8 mm arbor adapter.

22T, T230, T231

and T2500

Holder

*Arbor Bolt

(7 mm LH p/n 80411)

* Fixed Line

Trimmer Head

(p/n 80400)

On grass trimmer models 22T, T230, T231 and T2500, simply

insert the arbor adapter bolt into the fixed line trimmer head

and thread onto the grass trimmer.

Use the scrench supplied with your grass trimmer or

brushcutter to securely tighten the fixed line trimmer head.

Any of the following screnches are suitable for the Heavy-duty

Fixed-line head and can be ordered through a Shindaiwa Dealer

using p/n 72518-91180, 72451-91180 or 72320-91410.

T260 and T261

Holder

*Spacer Washer

(p/n 80058)

*Arbor Bolt

(8 mm LH p/n 80412)

*Fixed Line

Trimmer Head

(p/n 80400)

On the T260 and T261 models, the spacer washer part number

80058 must be inserted between the holder and the fixed line

trimmer head as shown above.

CAUTION!

If the special washer is not used on the T260 and T261

dedicated grass trimmer, the trimmer head will not be

centered correctly against the holder causing vibration and

possible failure of the trimmer head and/or gearcase.

For blade capable grass trimmer or brushcutter models

Using the 7 mm or 8 mm arbor adapter

bolt, install the fixed line trimmer head

as shown. Make sure that both blade

holders A and B are installed with the

safety clip removed, then install the fixed

line trimmer head. The special washer is

For all Shindaiwa brushcutters using a

10 mm arbor (except B530), remove

holder B and the safety clip. Install the

fixed line trimmer head using the original

10 mm arbor bolt and bolt guard as

shown.

not required on blade capable grass

trimmers and brushcutters with a 7 mm

or 8 mm arbor.

26

For B530 models, the special washer p/n

80058 must be installed on the inside of

the fixed line trimmer head over the

splines of the arbor shaft. Then install

and tighten the original 10 mm arbor bolt

with bolt guard.

Page 27

How to Fit a Shindaiwa Trimmer Head

Onto Other Brand Grass Trimmers.

Shindaiwa offers adapter kits that let

you install Shindaiwa trimmer heads

Kit L, left-hand thread

Part number 60819

onto virtually every grass trimmer

model on the market. Find your

machine on the following chart to

identify the kit you need. Kit contents

are shown at the right. Each kit also

includes installation instructions.

MAKE AND MODEL

ARIMATSU AC-ZEK, ACC-15, ACC-17, ACD-17, ACD-18, ACE-30, AM-16D,

AM-24D, AM-31, AM-31K, AM-40, AM-50

ECHO GT-140, GT-160AE, GT-200BE, GT-200CE, GT-1000, GT-1100,

GT-2100, GT-2101, GT-2102, GT-2000, GT-2400, SRM-210AE, SRM-2000,

SRM-2100, SRM-2110, SRM-2400, SRM-2410, SRM-2601

ECHO SRM-200BE, SRM-200DA, SRM-250E, SRM-300AE, SRM-300E/1,

SRM-302, SRM-400AE, SRM-400BE, SRM-1500, SRM-1501, SRM-2200,

SRM-2201, SRM-2300, SRM-2301, SRM-2500, SRM-2501, SRM-2502,

SRM-3000, SRM-3001, SRM-3010, SRM-3800, SRM-4600, GT-1100, GT-2101

GREEN MACHINE (HMC) 1600, 1930, 1940, 2200, 2230, 2331, 2340,

2500LP, 2510LP, 2800, 2840, 3000LP, 3000M, 3040M, 3541,

4000LP, 4500LP

HOFFCO 1600, GT160T, GT210, GT225SPL, GT320B, GT320T, PC380,

WT160H, WT250HT, WT250WT, WT320H, CRITTER

HOFFCO JP260, JP300, JP390, JP390XL, JP420, JP660

HOMELITE HK-24, HK-33 (up to 1986)

HOMELITE ST-160, ST-180, ST-210

HUSQVARNA 16R & 22R (up to 1986), 24R, 25R (up to 1986)

232RJ, 240RJ, 225R, 232R, 235R, 322L, LX, R, RX

HUSQVARNA 26RLC, 32LC, 32R, 32RL, 32RLC,

JOHN DEERE 100G, 110G, 200G, 210G, 250G

JOHN DEERE 240G, 260G, 300G, 350G, 450G

JONSERED LR200, LR220, LR260, LR300, LR400, LR450

KAAZ J40FD, JQ40, JQ50, K10, KQ30B, K40D, RQ30, U10, V15, V18,

V25, V35, V40

LAWNBOY 1480

aluminum

insert

steel insert

KIT

L

R

L

L

R

L

L

R

L

R

R

L

L

L

L

Kit R, right-hand thread

Part number 60820

steel stud

10 x 10 mm

MAKE AND MODEL

MARUYAMA BC184, BC241, BC326, BC402

McCULLOCH 60-A, 80-A, 85-A, 90-A, EB-I, EB-II, EB-III, EB-IV

McCULLOCH 95-A

OLYMPYK (OLEO-MAC) B200, B220, B260, B300, B400, B450

PIONEER B180, B250

POULAN PRO 111, 114, 117

REDMAX BC220DL, BC260DL, BC340DL, BC430DWM, BC440DWM

SACHS-DOLMAR BC-210, BC-212, LT-16, LT-210

SEARS 7934, 79534, 79551, 79552, 79556, 79611, 79612, 79613,

79614, 79616, 79621, 99512, 99515, 99516

SNAPPER 210SS, 211SST, 212CST, 214DCST, 215ORI, 215SST,

240SST, 245ORT, 245SST, 310, 311S, 410, 411SST, 415ORT

SOLO 014, 100, 400

STIHL FS-50E, FS-51AVE, FS-55, FS-60, FS-61E, FS-65AVE, FS-80E,

FS-85, FS-90AVE

TANAKA AST 7000, TBC-210, TBC-215, TBC-220, TBC-232,

TBC-240, TBC-262, TBC-265, TBC-322, TBC-325, TBC-355, TBC-373,

TBC-422, TBC-425, TBC-501, TBC-4500, SUM-301, SUM-321

TANAKA TBC-200

TORO TC600, TC650, TC700, TC800, TC2100, TC3000, TC4000,

TC5000, 51628, 51641, 51650, 51660

WEEDEATER 1400, 1600, 1700, 3500, GT115, GT117, GT118,

GT118B, YardPro 115, YardPro 120, YardPro 130A, XR20, XR30, XR50,

XR70, XR75, XR80, XR85, XT20, XT50, XT85

This chart is based on information that

was available at the time of publication.

gold-

colored

stud

10 x 7 mm

aluminum

insert

steel insert

KIT

L

R

L

L

L

R

L

R

R

L

L

L

L

R

L

R

Always make

sure attachments are

mounted according to

the manufacturer’s

instructions.

Never operate a

grass trimmer with a

blade-type attachment. A

blade-equipped machine

must be fitted with a

harness and handlebar or

other approved barrier

device.

27

Page 28

Shindaiwa Inc.

11975 SW Herman Road

Tualatin, OR 97062

Phone 503 692-3070

FAX 503 692-6696

www.shindaiwa.com

First To Start. Last To Quit.

Printed in U.S.A. Item 80792 6/03

Specifications subject to change without notice.

28

Loading...

Loading...