Page 1

Operator's

2008-02

Pressure Washer

5525PW, 6027PW,

9032PW, 1340PW

Manual

O0807301

Operator's Manual

Page 2

English — 1

CONTENTS

Contents

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KEY TO SYMBOLS . . . . . . . . . . . . . . . . . . . . .2

Symbols in the Operator’s Manual . . . . . . . . .2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . .3

Dear Customer . . . . . . . . . . . . . . . . . . . . . . . . .3

WHAT IS WHAT? . . . . . . . . . . . . . . . . . . . . . . .4

What is what on the pressure washer . . . . . .4

FREQUENTLY ASKED QUESTIONS . . . . . . . .5

How do I start my pressure washer? . . . . . . .5

What type of oil do I use? . . . . . . . . . . . . . . .5

Why don’t I have any water pressure? . . . . . .5

How do I get high pressure? . . . . . . . . . . . . . .5

How do I get the soap suction to work? . . . .5

Why doesn’t the pressure washer apply

detergents with high pressure? . . . . . . . . . . .5

What maintenance do I need to perform

on my pressure washer? . . . . . . . . . . . . . . . . .5

Where can I buy accessories for my

pressure washer? . . . . . . . . . . . . . . . . . . . . . . .5

SAFETY GUIDELINES . . . . . . . . . . . . . . . . . . .6

Important Safety Guidelines . . . . . . . . . . . . . .6

PRE-OPERATION . . . . . . . . . . . . . . . . . . . . . . .8

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Trigger Safety Latch . . . . . . . . . . . . . . . . . . . .10

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . .11

1. Surface preparation . . . . . . . . . . . . . . . . . .11

2. Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3. Initial High Pressure Rinse . . . . . . . . . . . . .11

Pressure Adjustment . . . . . . . . . . . . . . . .12

Adjusting the Spray Fan Angle . . . . . . .12

Angle to the Cleaning Surface . . . . . . . .12

Distance from Cleaning Surface . . . . . . .13

How to Avoid Damaging Surfaces . . . . .13

4. Detergent Application . . . . . . . . . . . . . . .13

Detergents . . . . . . . . . . . . . . . . . . . . . . . .13

General Cleaning Tips . . . . . . . . . . . . . . .14

5. Cleaning Power . . . . . . . . . . . . . . . . . . . . .14

6. Final Rinse . . . . . . . . . . . . . . . . . . . . . . . . .14

7. Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . .14

Pressure Relief Procedure . . . . . . . . . . . . . . .14

8. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Long Term Storage Instructions

(More than 30 days in storage) . . . . . . .14

Tips for Extending the Life of Your

Pressure Washer . . . . . . . . . . . . . . . . . . .15

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . .16

Engine Oil Changing Instructions . . . . . . . . .16

Check Pump Oil and Pump Oil Changing . .17

MAINTENANCE SCHEDULE . . . . . . . . . . . .18

TECHNICAL AND CONSUMER

INFORMATION . . . . . . . . . . . . . . . . . . . . . . .19

TROUBLESHOOTING CHART . . . . . . . . . . .20

SERVICE RECORD . . . . . . . . . . . . . . . . . . . .22

CART PARTS LIST . . . . . . . . . . . . . . . . . . . . .23

5525PW Cart . . . . . . . . . . . . . . . . . . . . . . . . . .23

6027PW Cart . . . . . . . . . . . . . . . . . . . . . . . . . .24

9032PW Cart . . . . . . . . . . . . . . . . . . . . . . . . . .25

1340PW Cart . . . . . . . . . . . . . . . . . . . . . . . . . .25

PUMP PART LIST . . . . . . . . . . . . . . . . . . . . .26

5525PW Pump . . . . . . . . . . . . . . . . . . . . . . . .26

6027PW Pump . . . . . . . . . . . . . . . . . . . . . . . .27

9032PW Pump . . . . . . . . . . . . . . . . . . . . . . . .28

1340PW Pump . . . . . . . . . . . . . . . . . . . . . . . .29

PRODUCT REGISTRATION NOTICE . . . . . .31

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . .32

IN469200AV 2/08

Page 3

2 — English

Safety Guidelines

This manual contains information that is very

important to know and understand. This

information is provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help recognize this

information, observe the following symbols.

Warning indicates a potentially

hazardous situation which, if not

avoided, COULD result in death or serious injury.

Caution indicates a potentially

hazardous situation which, if not

avoided, MAY result in minor or moderate injury.

Notice indicates important

information, that if not followed,

may cause damage to equipment.

NOTE: Information that requires special attention.

KEY TO SYMBOLS

Symbols in the Operator’s Manual

Please read the operator’s manual

carefully and make sure you

understand the intructions before

using the tool.

DO NOT overreach or stand on

unstable support. Keep good footing

and balance at all times.

Risk of injection or severe injury. Keep

clear of nozzle.

ALWAYS wear safety glasses or

goggles and protective equipment

(hearing protection, gloves, rubber

boots, protective clothing) when

operating or performing

maintenance.

Risk of explosion.

Risk of fire.

!

WARNING

!

CAUTION

NOTICE

Page 4

English — 3

INTRODUCTION

Dear Customer,

Congratulations on your choice to buy a Husqvarna product! Husqvarna is based on a tradition

that dates back to 1689, when the Swedish King Charles XI ordered the construction of a factory

on the banks of the Husqvarna River, for production of muskets. The location was logical, since

waterpower was harnessed from the Husqvarna River to create the water-powered plant. During

the more than 300 years of being, the Husqvarna factory has produced a lot of different products,

from wood stoves to modern kitchen appliances, sewing machines, bicycles, motorcycles, etc. In

1956, the first motor driven lawn mowers appeared, followed by chain saws in 1959, and it is

within this area Husqvarna is working today.

Today, Husqvarna is one of the leading manufacturers in the world of forest and garden products,

with quality as our highest priority. The business concept is to develop, manufacture and market

motor driven products for forestry and gardening, as well as for the building and construction

industry. Husqvarna’s aim is also to be in the front edge according to ergonomics, usability, security

and environmental protection. That is the reason why we have developed many different features

to provide our products within these areas.

We are convinced that you will appreciate, with great satisfaction, the quality and performance of

our product for a very long time to come. The purchase of one of our products gives you access to

professional help with repairs and service whenever this may be necessary. If the retailer who sells

your machine is not one of our authorized dealers, ask for the address of your nearest service

workshop.

It is our wish that you will be satisfied with your product and that it will be your companion for a

long time. Think of this operator’s manual as a valuable document. By following its’ content (using,

service, maintenance, etc) the life span and the second-hand value of the machine can be

extended. If you will sell this machine, make sure that the buyer will get the operator’s manual.

Thank you for using a Husqvarna product.

Husqvarna AB has a policy of continuous product development and therefore reserves the right to

modify the design and appearance of products without prior notice.

For customer assistance call 704-921-7000 or contact us at our website: www.husqvarna.com

Page 5

4 — English

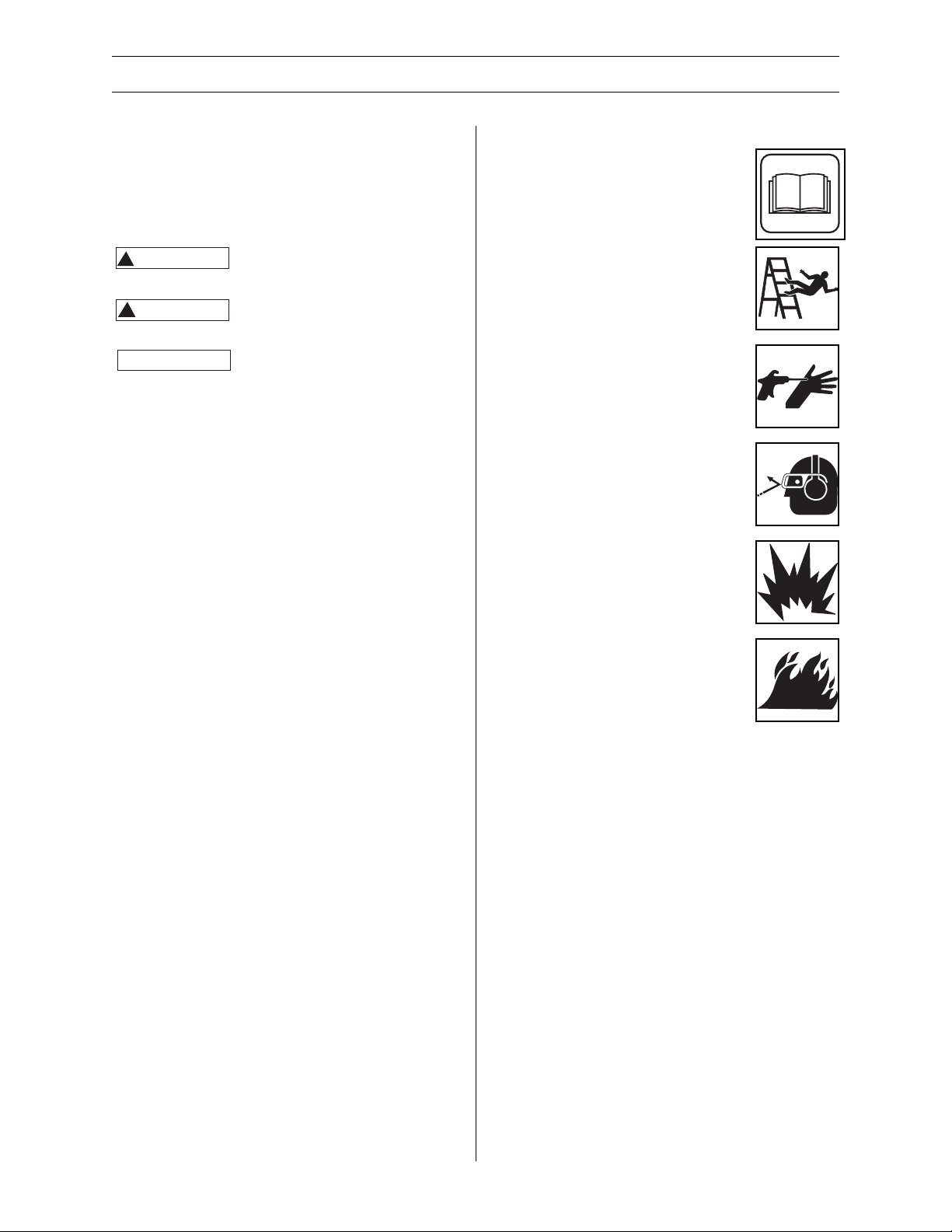

WHAT IS WHAT?

1 Serial Number/ Product Decal

2 Tip Holder with Spray Tips

3 Injection Tube Barb

4 Gun with Trigger

5 Lance

6 Inlet Connection for High Pressure Hose

7 Inlet Connection for Garden Hose

8 Engine Oil Fill

9 Engine switch - On/Off

10 Air Filter

11 Choke

12 Fuel Tank

13 Pressure Adjusting Knob

14 Fuel Valve - On/Off

2

4

6027PW

1

5

7

9

10

11

12

14

8

6

3

7

2

9032PW

1

5

9

10

11

12

14

8

6

3

7

1

2

4

5

6

9

10

11

12

5525PW

7

8

13

4

1340PW

2

1

5

9

10

11

12

14

8

4

Page 6

English — 5

FREQUENTLY ASKED QUESTIONS

How do I start my pressure

washer?

1. Make sure you have gas and oil in the engine.

2. Turn the water on, then squeeze the trigger on

the gun to make sure the water will flow

smoothly out of the nozzle or tip.

3. Put the engine throttle control in the

“Fast/Start” position. Set the fuel valve to “ON”

Set the On/Off switch to “ON” (if applicable).

4. Close the choke.

5. Squeeze and hold the trigger (to relieve any

back pressure in the pump) while pulling the

starter cord.

6. If the engine does not start after three tries, see

Troubleshooting Section (Pages 20-21).

What type of oil do I use?

ENGINE

THE ENGINE DOES NOT COME FILLED WITH OIL. For

engine oil types and quantities refer to Pages 16

and 19 of this manual and also refer to the included

engine owner’s manual for oil changing instructions.

PUMP

See Page 17 for pump oil types and quantities.

Please note the 5525PW model has a pump that is

sealed and does not require service.

Why don’t I have any water

pressure?

• Is the water hose attached to the pressure

washer?

• Is the water turned on?

• Check for any kinks, leaks, or blockage in the

hoses, fittings, or the nozzle.

• Is the inlet filter screen free of debris? Check and

remove debris if needed.

• Is the quick connect tip in place? (See Page 9.)

How do I get high pressure?

• Use any color tip except black. The black tip is

only used for low pressure detergent application.

How do I get the soap

suction to work?

For Detergent Tanks:

1. Attach clear plastic tube to plastic barb on

detergent tank (see Figure 2).

2. Fill detergent tank with detergent formulated

for use with pressure washers.

3. Install the black spray tip to apply low pressure

detergent.

For Other Units:

1. Attach clear plastic tube to brass barb on pump

(see Figure 2).

2. Put the other filter end of the clear tube into

the detergent container.

3. Install the black spray tip to apply low pressure

detergent.

Why doesn’t the pressure

washer apply detergents

with high pressure?

The reason you don’t apply detergents with high

pressure is that the detergents “bounce” off the

cleaning surface as fast as you apply them.

Detergent is only effective when you allow it time

to work on the surface of whatever you are

cleaning. You can only apply detergent at low

pressure, wait 1-3 minutes to allow it to work, and

rinse the surface with high pressure.

What maintenance do I

need to perform on my

pressure washer?

1. After turning off the pressure washer and the

water, depressurize the hose by triggering the

gun.

2. Remove the garden hose and high pressure hose

from the pump.

3. Pull the start rope slowly five times to purge

water from the pump. This will help protect the

pump from damage.

4. DO NOT store your pressure washer in an area

where the temperature will drop below 32˚F /

0˚C) unless pressure washer is properly

winterized (see Page 15).

Where can I buy accessories

for my pressure washer?

• Call your local Husqvarna Dealer.

Page 7

6 — English

SAFETY GUIDELINES

Important Safety Instructions

SAVE THESE INSTRUCTIONS

The engine exhaust from

this product contains chemicals

known to the State of California to cause cancer,

birth defects or other reproductive harm.

When using this product, basic precautions should

ALWAYS be followed, including the following:

• Read all instructions before using

the product.

• To reduce the risk of injury, close

supervision is necessary when the

product is used near children.

• Follow all safety codes as well as the Occupational

Safety and Health Act (OSHA).

• Ensure safety devices are operating properly

before each use. DO NOT remove or modify any

part of the gun or unit.

• Know how to stop this product and bleed

pressure quickly. Be thoroughly familiar with the

controls.

• Stay alert – watch what you are doing.

• DO NOT operate the product when fatigued or

under the influence of alcohol or drugs.

• Keep operation area clear of all persons.

• DO NOT overreach or stand on

unstable support. Keep good

footing and balance at all times.

• Follow the maintenance instructions

specified in the manual.

Risk of injection or

severe injury. Keep

clear of nozzle. DO NOT discharge

streams at persons. This product is to

be used only by trained operators.

ALWAYS remove lance from gun before

cleaning debris from tip.

• Keep clear of nozzle. NEVER direct high pressure

spray at a person, animal, or yourself.

• ALWAYS wear safety glasses or

goggles and protective equipment

(hearing protection, gloves, rubber

boots, protective clothing) when

operating or performing

maintenance.

• NEVER put hand or fingers over the spray tip

while operating the unit.

• NEVER try to stop or deflect leaks with any body

part.

• ALWAYS engage the trigger safety latch in the

safe position when spraying is stopped even if

only for a few moments.

• ALWAYS follow detergent manufacturer’s label

recommendations for proper use of detergents.

ALWAYS protect eyes, skin, and respiratory

system from detergent use.

DO NOT use

pressure that

exceeds the operating pressure of any

of the parts (hoses, fittings, etc.) in

the pressurized system. Ensure all

equipment and accessories are rated

to withstand the maximum working

pressure of the unit.

Explosion hazard.

• NEVER spray flammable liquids or use pressure

washer in areas containing combustible dust,

liquids, or vapors.

• NEVER operate this machine in a closed building

or in or near an explosive environment.

• DO NOT remove fuel tank cap or fill fuel tank

while engine is hot or running (allow engine to

cool two minutes before refueling). ALWAYS fill

the tank slowly.

• NEVER disconnect the high pressure discharge

hose from the machine while the system is

pressurized. To depressurize machine, turn

power and water supply off, then press the gun

trigger 2-3 times.

• NEVER permanently engage the trigger

mechanism on the gun.

• NEVER operate the machine without all

components properly connected to the machine

(handle, gun/wand assembly, nozzle, etc.).

Keep hose away from sharp

objects. Bursting hoses may

cause injury. Examine hoses regularly and replace if

damaged. DO NOT attempt to mend a damaged

hose.

Equipment damage.

• ALWAYS turn water supply “ON” before turning

pressure washer “ON.” Running pump dry causes

serious damage.

• DO NOT operate the pressure washer with the

inlet water screen removed. Keep screen clear of

debris and sediment.

• NEVER operate pressure washer with broken or

missing parts. Check equipment regularly and

repair or replace worn or damaged parts

immediately.

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

CAUTION

NOTICE

Page 8

English — 7

SAFETY GUIDELINES

• Use only the nozzle supplied with this machine.

• NEVER leave the wand unattended while the

machine is running.

• NEVER tamper with the engine governor or

attempt to alter factory settings. Altering factory

settings could damage the unit and will void the

warranty.

• ALWAYS hold gun and wand firmly when

starting and operating the machine.

• NEVER allow the unit to run with the trigger

released (off) for more than two minutes.

Resulting heat buildup will damage the pump.

• NEVER store the pressure washer outdoors or

where it could freeze. Freezing temperatures can

seriously damage the pump.

• Release the trigger when changing from high to

low pressure modes. Failure to do so could result

in damage to the nozzle.

Page 9

8 — English

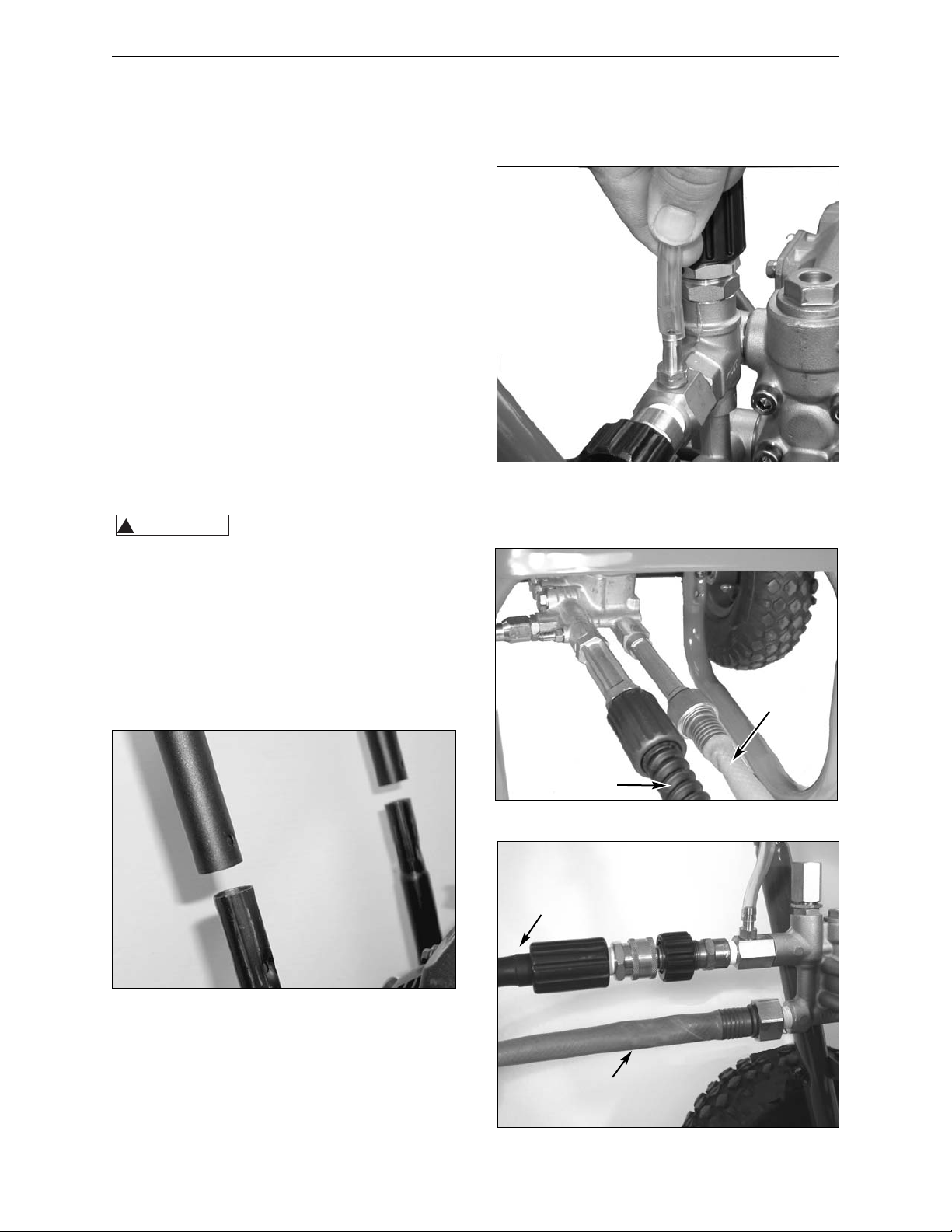

2. Connect clear plastic hose to brass barb on pump

(See Figure 2).

3. Secure garden hose (not included) to the inlet

connection on pump (See Figures 3 and 4).

PRE-OPERATION

UNPACKING

Remove the equipment and all parts from the

carton. The carton should contain the following.

• One pressure washer (pump, engine, cart base).

• One cart handle assembly.

• One spray gun.

• One lance.

• Two spray tips for Model 5525PW

Five spray tips for Models 1340PW, 6027PW and

9032PW

• One high pressure hose.

• One pack of nuts, bolts, and manuals.

• One bottle of engine oil.

If any parts are missing, Please contact your

Husqvarna dealer.

After unpacking the product, inspect it carefully for

any damage that may have occurred during transit.

Make sure to tighten fittings and bolts before using

the pressure washer.

DO NOT operate the unit if it’s

damaged during shipping,

handling, or use. Damage could result in bursting

and cause injury or property damage.

ASSEMBLY

Use 1/2” (13 mm) wrench to assemble pressure

washer. On model 5525PW use two adjustable or

7/16” wrenches.

1. Slide the handle assembly over the lower legs of

the cart base. Use the standard nut and bolt to

secure the legs. See Figure 1.

Figure 1 - Assemble Handle

Figure 2 - Connect hose to brass barb

Figure 3 - Secure garden hose

Garden Hose

High Pressure

Hose

Figure 4 - Connect high pressure hose to pump

Garden Hose

High Pressure

Hose

!

WARNING

Page 10

English — 9

4. Connect the high pressure hose to the pump outlet

(See Figure 4).

5. Attach the lance with nozzle to the gun (See

Figure 5).

6. Install quick connect tip by pulling back on collar

and pressing in tip. Release collar, make sure it

completely returns to its forward position and tip is

secure (See Figure 6).

PRE-OPERATION

Figure 5 - Attach lance to gun

Figure 6 - Quick Connect Tip

Pull collar back

For models 5525PW: Insert spray tips into the

rubber tip holder. Then attached the tip holder to

handle by wrapping around and inserting tail end

through hole to secure (See Figure 7).

For models 6027PW, 9032PW, and 1340PW: Insert

spray tips into rubber grommets on placard (See

Figure 8).

Figure 7 - Insert spray tips into the rubber tip

holder

Figure 8 - Insert spray tips into the placard

Page 11

10 — English

PRE-OPERATION

TRIGGER SAFETY LATCH

In the engaged position, the trigger safety latch

prevents the gun from being triggered accidentally.

Pull the latch up to engage it (See Figure 9). ALWAYS

engage the trigger safety latch when the unit is not in

use.

Figure 9 - Trigger lock

Trigger lock

(not engaged)

Trigger lock

(engaged)

Page 12

English — 11

OPERATION

1. Surface Preparation

ALWAYS engage the trigger safety latch when unit

is not in use. The following cleaning procedure will

help you organize your cleaning task and ensures

that you will achieve the best results in the shortest

amount of time. Remember to use the spraying /

cleaning techniques mentioned in the following

section.

Before starting a pressure washer cleaning job,

prepare the surface you intend to clean. Clear

furniture from the area and make sure that all

windows and doors are closed tightly. Also, protect

all plants and trees near the cleaning area with a

drop cloth. A covering ensures that your plants

won’t be sprayed by the detergents.

2. Start Up

ALWAYS use this start up procedure to ensure that

the unit is started safely and properly.

If water has frozen in the

pressure washer, thaw the

pressure washer in a warm room before starting. DO

NOT pour hot water on or into the pump; internal

parts will be damaged.

1. Check engine oil levels. Add oil as necessary.

NOTE: Some units are equipped with a low oil

sensor that shuts the engine off if the oil level falls

below a certain level. If the unit stops unexpectedly,

check both the oil and fuel levels. Check the oil

level each time you refuel the unit.

2. Check fuel level. Add unleaded gasoline (rated

86 octane or higher) as required.

DO NOT refuel a

hot engine.

Refueling a hot engine could cause a

fire. Use only fresh, clean unleaded

gasoline. Close the fuel shutoff valve

during refueling.

3. Attach a garden hose to the inlet connection for

garden hose and connect it to the water supply.

Use a hose with a minimum inside diameter of

5/8” (.016 m) and a length of 50 ft. (15 m) or

less.

Some local plumbing codes

require backflow prevention

when connecting to a fresh water supply. Install a

backflow preventer upstream from the pump if

necessary.

a. If inlet water pressure is over 100 psi, install a

regulating water valve at the garden hose

connection.

b. DO NOT exceed 100˚ F (38˚ C) inlet water

temperature.

NOTE: The inlet water supply must have a

minimum flow rate of 8 gpm (30 lpm) or 5 gpm

(191 lpm) on 5525PW.

4. Turn the water supply ON.

NEVER run the unit dry. Be sure

the water supply is completely

turned on before operating the unit.

5. Squeeze the gun until water sprays from the tip

indicating that all air is purged from the system.

Set the trigger safety latch.

6. On model 5525PW: Honda GC Engine:

Open the fuel shutoff valve by turning the knob

counterclockwise until it stops. Close the choke

(if engine is cold) by pulling the choke lever out.

The throttle is fixed.

On model 1340PW, 6027PW, and 9032PW:

Honda GX engine:

Open the fuel shutoff valve by pushing the lever

to the right. Close the choke (if the engine is

cold) by moving the choke lever fully to the left.

The throttle is fixed. Turn the On/Off switch to

the "ON" position.

7. Start the engine:

If the engine is cold, completely close the

engine choke.

If the engine is warm, leave the choke open or

just partially closed. Unlock the trigger safety

latch on the gun. Grasp the starter rope and

brace one foot on the chassis. While squeezing

the trigger on the gun, pull the starter rope

rapidly and firmly. Continue holding the rope as

it returns. Repeat these steps until the engine

starts. In cool weather, the choke may have to

be kept closed for 10 to 30 seconds to keep the

engine running. Otherwise, open the choke as

soon as the engine starts.

When pulling the starter rope,

make sure to keep your hand

and arm clear of the engine and cart components.

NEVER let the starter rope

return by itself. Doing so could

jam the recoil system.

3. Initial High Pressure Rinse

After the engine starts, trigger the gun 3 to 5 times

to get any trapped air out of the system. After the

spray becomes constant, you may need to adjust

the pressure (see pages 13 and 14 for cleaning

techniques).

NOTICE

!

WARNING

NOTICE

NOTICE

!

CAUTION

NOTICE

Page 13

12 — English

OPERATION

PRESSURE ADJUSTMENT

Models 9032PW and 1340PW have a pressure

adjustment knob located on the pump (see Figure

10). Turn the knob clockwise to increase the

pressure. Turn the knob counter clockwise to

decrease the pressure. DO NOT try and force the

knob to turn. The knob may already be at either

the lowest or highest setting.

If there is not a plastic adjustment knob located on

the pump (See Figure 10), then the pressure cannot

be adjusted. The only way to adjust the pressure is

to move closer or further away from the cleaning

surface and adjust the spray fan angle as shown in

the next section.

ADJUSTING THE SPRAY FAN ANGLE

Your unit has quick connect tips that have a range

of spray fan angles. Model 5525PW includes the

black detergent and yellow 15° quick connect tips

only.

The quick connect tips can be switched out from a

0° narrow high impact stream to a 65° wide fan

spray.

A narrow stream has high impact force on the

cleaning surface and results in maximum deep

cleaning in a concentrated area. However, this

narrow high impact spray can damage some

surfaces, so use it cautiously. Not recommended for

use on automotive paint, trim and vinyl siding.

A wide fan pattern will distribute the impact of the

water over a larger area resulting in excellent

cleaning action with reduced risk of surface

damage. Clean large surface areas quickly using a

wide fan pattern.

ANGLE TO THE CLEANING SURFACE

When spraying water against a surface, you can

generate maximum impact by striking the surface

head on. However, this type of impact can cause

dirt particles to embed in the surface and can

prevent the desired cleaning action.

Figure 10 - Camshaft pump pressure adjustment

Figure 11 - Installing Quick Connect Tip

Figure 12 - Narrow high impact stream

Figure 13 - Wide fan pattern

Pull collar back

Quick connect tip

The color of the tip shows what spray angle it is:

Red – 0° – Maximum Duty

Yellow – 15° – Heavy Duty

Green – 25° – General Duty

White – 40° – Light Duty

Black – 65° – Low Pressure Detergent

Page 14

English — 13

OPERATION

Spray water against a surface at a 45 degree angle

to achieve the most beneficial impact force and to

efficiently remove debris.

DISTANCE FROM CLEANING SURFACE

The distance between the spray nozzle and the

cleaning surface is another factor that affects the

impact force of the water. The impact force of the

water increases as the nozzle is moved closer to the

surface.

HOW TO AVOID DAMAGING SURFACES

Damage to cleaning surfaces occurs because the

impact force of the water exceeds the durability of

the surface. You can vary the impact force by

controlling the spray tip angle to the cleaning

surface and the distance from the cleaning surface

and by changing the spray tip. NEVER use a narrow

high impact stream on a surface that is susceptible

to damage. Avoid spraying windows with a narrow

high impact stream. Doing so may break the

window. The most sure way to avoid damaging

surfaces is to follow these steps:

1. Before triggering the gun, make sure the quick

connect tip you are using is appropriate for the

application.

2. Place the spray tip approximately 4-5 feet (1,221,52 m) away from the cleaning surface. Then

hold the lance and spray tip at a 45 degree

angle to the cleaning surface. Trigger the gun.

Figure 14 - Optimum angle to cleaning surface

The color of the tip shows what spray angle it is:

Red – 0° – Maximum Duty

Yellow – 15° – Heavy Duty

Green – 25° – General Duty

White – 40° – Light Duty

Black – 65° – Low Pressure Detergent

3. Vary the fan pattern spray angle and the

distance to the cleaning surface until optimum

cleaning efficiency is achieved without

damaging the surface.

4. Detergent Application

NOTE: Use only detergents formulated for pressure

washers.

NOTE: Test detergent in an inconspicuous area

before use.

NEVER replace quick connect tip

when gun is triggered.

DETERGENTS

The use of detergents can dramatically reduce

cleaning time and assist in the removal of difficult

stains. Many detergents are customized for pressure

washer use on specific cleaning tasks. Pressure

washer detergents are as thick as water. Using

thicker detergents – like dish soap – will clog the

chemical injection system and prevent the

application of the detergent.

Once applied to a cleaning surface, detergents take

time to break down dirt and grime. Detergents

work best when applied at low pressure.

You can effectively clean surfaces by combining the

chemical action of detergents with high pressure

rinses. On vertical surfaces, apply the detergent

starting at the bottom and work your way upward.

This method prevents the detergent from sliding

down and causing streaks. Begin high pressure

rinsing at the bottom and work your way upward.

On particularly tough stains, use a brush in

combination with detergents and high pressure

rinsing.

1. Follow manufacturer’s label directions for mixing

correct concentrations of soap/detergents. The

soap detergent to water ratio through the pump

is approximately 10% (1 to 10).

2. Insert the filter end of the clear plastic detergent

tube into the detergent container.

3. Use the BLACK 65° quick connect spray tip (all

models) (See Figure 15).

Figure 15 - Quick Connect Tip

!

WARNING

Page 15

14 — English

OPERATION

GENERAL CLEANING TIPS

1. Apply the detergent so that it thoroughly covers

the cleaning surface. Apply the detergent from

bottom to top to prevent the detergent from

sliding down and streaking. Wait a couple of

minutes for the detergent to break down the

dirt and grime. Use a brush to lightly scrub

heavily soiled areas. NEVER allow the detergent

to dry on the cleaning surface.

2. Replace black 65° quick connect tip with another

color tip.

NEVER replace quick connect tip

when gun is triggered.

3. After using detergents, flush the suction system

by placing the detergent suction tube into a

bucket of clean water.

5. Cleaning Power

The easiest way to regulate the cleaning power of

your pressure washer is by changing the distance

from the surface you are cleaning. Begin spraying

with a wide fan pattern while standing several feet

from the surface. Slowly move closer to the object

you are cleaning, adjusting the spray pattern as

necessary, until you find the most effective cleaning

technique.

NOTE: Some units also may have a pressure

adjustment knob on the pump that can adjust the

pressure (models 9032PW and 1340PW).

6. Final Rinse

The final rinse should start at the bottom and work

upward. Make sure that you thoroughly rinse the

surface and that you remove all detergent.

7. Shutdown

1. Be sure all detergent is flushed from system.

2. Turn the engine OFF.

3 Turn the water supply OFF.

4. After the engine and water supply are turned

OFF, trigger the gun to depressurize the system.

NEVER turn the water supply

off before turning the

engine/motor off. Serious damage could occur to the

pump and/or engine/motor.

NEVER disconnect the high

pressure discharge hose from

the machine while the system is pressurized. To

depressurize, turn engine/motor off, turn water

supply off and squeeze gun trigger 2-3 times.

5. After each use, when engine has cooled, wipe all

surfaces of the pressure washer with a clean,

damp cloth.

• DO NOT store the pressure washer outdoors.

• DO NOT store the pressure washer where it

might freeze unless it has been properly

winterized.

8. Storage

LONG TERM STORAGE INSTRUCTIONS (MORE

THAN 30 DAYS IN STORAGE)

1. Remove fuel from the tank and run the pressure

washer in a normal operating mode until the

engine stops from a lack of fuel. Normal

operating mode means actually spraying water

from the gun while the engine is running.

Alternate method – Add fuel stabilizer to gas in

the tank and run in normal operating mode for

at least five minutes.

2. Stop the engine, turn off the water supply, and

trigger the gun to release pressure in the highpressure hose.

PRESSURE RELIEF

PROCEDURE

To reduce the risk of bodily injury or property

damage, ALWAYS follow this procedure

whenever spraying is stopped, when work is

completed, and before checking or repairing

any part of the system.

1. Engage the trigger safety latch.

2. Turn the unit off.

3. Shut off the water supply.

4. Disengage the trigger safety latch and

trigger the gun to relieve pressure.

5. Re-engage the trigger safety latch.

6. Before overnight storage, long term

storage, or transporting unit, disconnect

the water supply and turn off the fuel

supply valve.

!

WARNING

NOTICE

!

CAUTION

Page 16

English — 15

OPERATION

3. Disconnect the water supply and high pressure hose

from the pump.

4. Allow the engine to cool.

5. Disconnect the spark plug wire and remove the

spark plug.

6. Pour 1/2 oz. of engine oil into the spark plug hole.

NEVER pull the

starter rope on the

engine when the spark plug is removed

unless the spark plug hole is covered.

Fuel vapor from the hole can ignite by a

spark.

7. Place a rag over the spark plug hole and slowly pull

the starter rope several times to distribute the oil.

8. Disconnect the high pressure hose from the pump.

9. Insert a 12” to 14” piece of garden hose into the

pump inlet.

10. Place a funnel in the other end of the garden hose.

Read the manufacturer’s

instructions for safe handling

and disposal of RV antifreeze.

11. Pour approximately 6 oz. of RV antifreeze into

the funnel.

12. Pull the starter rope several times until the RV

antifreeze comes out of the pump outlet.

13. Disconnect the high pressure hose from the gun

and drain the hose. Hold the gun and lance in a

vertical position and squeeze the trigger to

drain the water.

Never store the pressure washer

with gasoline in the tank inside

a building where fumes may reach an open flame or

spark. Allow the engine to cool before storing in

any enclosure.

NOTE: To winterize unit, please follow the same

intructions for Storage.

TIPS FOR EXTENDING THE LIFE OF YOUR PRESSURE

WASHER

• NEVER operate the unit without water.

• Your pressure washer is not meant to pump hot

water. NEVER connect your pressure washer to a

hot water supply as it will significantly reduce

the life of the pump.

• Running the unit for more than two minutes

without spraying water causes heat to build up

in the pump. Running the unit without spraying

water can damage pump components.

• Release the trigger prior to switching the lance

between high and low pressure. Failure to do so

may reduce the life of the o-rings in the lance.

!

WARNING

NOTICE

!

CAUTION

Page 17

16 — English

MAINTENANCE

Observe regular maintenance intervals to ensure

maximum performance and life from the pressure

washer. Refer to the schedule for recommended

maintenance. If you operate the pressure washer in

dusty conditions, perform maintenance checks more

often.

ENGINE OIL CHANGING INSTRUCTIONS

Before tipping the engine or

equipment to drain oil, drain fuel

from the fuel tank.

NOTE: Change oil while the engine is cool.

1. Disconnect the spark plug wire from the spark

plug.

2. Locate and remove the engine oil drain plug (see

Figure 18).

3. Drain old oil.

4. Replace the drain plug and set the unit upright.

5. Refill the unit with new oil of a recommended

type and quantity. Fill the unit to the proper

level shown on the dipstick (if provided).

Otherwise, fill the unit to the top of the oil filler

neck.

Figure 16

Model 5525PW - Engine Oil Drain Plug

Models 1340PW, 6027PW, and 9032PW - Engine Oil

Drain Plug

Engine Oil Type SAE 10W-30

SAE 30W (Above 60 °F/15.7° C)

Engine Oil Capacity

5525PW - Honda GCV160 - 18.6 fl. oz. (0.550 L)

6027PW - Honda GX160 - 20 fl. oz. (0.591 L)

9032PW - Honda GX270 - 37 fl. oz. (1.090 L)

1340PW - Honda GX390 - 37 fl. oz. (1.090 L)

!

CAUTION

Page 18

English — 17

MAINTENANCE

CHECKING PUMP OIL AND PUMP OIL CHANGING

Checking oil level: Most pumps have either a sight

glass or a dipstick (or both) to check the pump oil

level. The correct oil level is at the center of the

sight glass (center of red dot). The sight glass is

usually located on the back side of the pump [See

Figure 19 (B)].

For model 5525PW: Pump is factory sealed.

Changing or refilling the oil in the pump requires

removal of the pump from the engine and should

not be required unless oil has leaked out due to

worn or damaged oil seals in the pump. If oil has

leaked out of the pump, bring the pressure washer

to a certified service center for repair.

For models 6027PW, 9032PW, and 1340PW: These units

all have a sight glass to check the oil level and have a

drain plug to remove the old oil when changing. To

add oil remove vent cap from top of pump [See

Figure 19 (A)].

Figure 17 - Pump Oil Filler Vent Cap (A), Sight Glass

(B), and Drain Plug (C) Locations

(A)

(B)

(C)

Changing oil: Remove the oil drain plug located at

the backside of the pump [See Figure 19 (C)]. Drain

old oil. Replace drain plug. Refill pump with the

correct type and amount of oil (see below for oil

types and amounts). Check oil level. Upon starting

the pressure washer check for any pump oil leaks.

Pump Oil Type

5525PW - Lavor Pump - Special. See pump

parts list.

6027PW, 9032PW, 1340PW - CAT Pumps Special CAT pump oil. Use 531 30 74-83.

DO NOT use any oil in pumps other than the

manufacturer's oil.

Page 19

18 — English

MAINTENANCE SCHEDULE

Each use

After first 5 hours of operation

After first 50 hours of operation

Every 25 hours of operation

Every 50 hours of operation

Each 100 hours of operation or every 3

months

Every 500 hours of operation (5 months)

• Check water inlet screen and filter.

• Check engine and pump oil levels. Fill as necessary. Cannot check

pump oil on the 5525PW.

• Check gasoline level. Fill as necessary.

• Change engine break-in oil. Use SAE30 or 10W-30 detergent

oil if below 60° F (15.7° C).

• Change pump oil. Cannot check or change pump oil on the

5525PW.

• Change engine oil if operating under heavy load or high

ambient temperature.

• Remove and clean foam pre-cleaner or foam air filter (if

applicable). Wash with water and mild detergent. Dry

thoroughly. Rub with oil and squeeze to distribute oil.

• Change engine oil.

• Replace spark plug.

• Clean or replace paper air cleaner cartridge. Tap gently to

remove dirt.

• Change engine oil.

• Change pump oil. Cannot check or change pump oil on the

5525PW.

Maintenance Schedule Action needed

NOTE: This is a general maintenance schedule. Refer to the Engine operation manual for specific information

on your engine.

Page 20

English — 19

TECHNICAL AND CONSUMER INFORMATION

Engine Oil Type SAE 10W-30

SAE 30W (Above 60 °F/15.7° C)

Engine Oil Capacity

5525PW - Honda GCV160 - 18.6 fl. oz. (0.550 L)

6027PW - Honda GX160 - 20 fl. oz. (0.591 L)

9032PW - Honda GX270 - 37 fl. oz. (1.090 L)

1340PW - Honda GX390 - 37 fl. oz. (1.090 L)

Engine Fuel Capacity

5525PW - Honda GCV160 - 1.2 US quarts (1.09 L)

6027PW - Honda GX160 - 3.3 US quarts (3.1 L)

9032PW - Honda GX270 - 5.6 US quarts (5.3 L)

1340PW - Honda GX390 - 6.4 US quarts (6.1 L)

Pump Oil Type

5525PW - Lavor Pump - Special. See pump parts

list.

6027PW, 9032PW, 1340PW - CAT Pumps -Special

CAT pump oil. See pump parts list.

DO NOT use any oil in pumps other than the

manufacturer's oil.

Pressure Washers

Pump Oil Capacity

5525PW - AR RM Pump - 3.5 fl.oz. (0.103 L)

6027PW - CAT 3DNX Pump -8.5 fl.oz. (0.251 L)

9032PW - CAT 66DX Pump -10.15 fl.oz. (0.532 L)

1340PW - CAT 66DX Pump -18 fl.oz. (0.532 L)

Pump Detergent Suction

Water to detergent 8 to 1

ratio (5525PW) (12% detergent)

Water to detergent 10 to 1

ratio (6027PW, 10% detergent)

9032PW, 1340PW)

Water Supply Requirements

Minimum inlet pressure 20 psi

Maximum inlet pressure 100 psi

Maximum inlet

temperature 100° F / 38° C

Minimum inlet flow rate

5525PW 5 gpm (18.9 lpm)

6027PW, 9032PW, 2 times the rated

1340PW flow of unit or

8 gpm (30.3 lpm)

Inlet garden hose size 5/8” ID (15.9 mm)

Maximum inlet garden

hose length 50 ft. (15,2 m)

Page 21

20 — English

TROUBLESHOOTING CHART

Troubleshooting Chart - Gasoline Powered Pressure Washers Only

Symptom Possible Cause(s) Corrective Action(s)

Engine will not start

or is hard to start

Engine misses or

lacks power

Low pressure and/or

pump runs rough

Water leakage from

under pump

manifold

Water in pump

crankcase (milky oil)

Frequent or

premature failure of

the pump water

seals

Strong surging at

the inlet and low

pressure

1. No gasoline in fuel tank or

carburetor

2. Low oil

3. Start/Stop switch in stop position

4. Water in gasoline or old fuel

5. Dirty air cleaner filter

6. Spark plug dirty, wrong gap or

wrong type

7. Spray gun closed

8. Other causes

1. Partially plugged air cleaner filter

2. Spark plug dirty, wrong gap or

wrong type

3. Bad Fuel

1. Worn or wrong size tip

2. Inlet filter on pump clogged

3. Worn water seals, abrasives in

water, or natural wear

4. Fouled or dirty inlet or discharge

valves

5. Restricted inlet

6. Worn inlet or discharge valves

7. Leaking high pressure hose

8. Pump drawing in air

9. Unloader valve seat faulty or worn

10. Inlet water temperature too high

Worn water seals

1. Humid air condensing inside

crankcase

2. Oil seals leaking

3. Water seals leaking

1. Scored damaged or worn plungers

2. Abrasive material in the fluid

3. Inlet water temperature too high

4. Overpressurizing pump

5. Excessive pressure due to partially

plugged or damaged tip

6. Pump running too long without

spraying

7. Pump running dry

Foreign particles in the inlet or

discharge valve or worn inlet and/or

discharge valves

1. Fill the tank with gasoline,open fuel

shut off valve. Check fuel line and

carburetor

2. Check oil level. Fill if necessary

3. Move switch to start position

4. Drain fuel tank and carburetor. Use new

fuel and dry spark plug

5. Remove and clean or replace

6. Clean, adjust the gap, or replace

7. Trigger spray gun

8. See engine owner’s manual

1. Remove and clean or replace

2. Clean, adjust the gap, or replace

3. Drain fuel and carburetor. Use new

fuel.

1. Replace with tip of proper size

2. Clean. Check more frequently

3. Check filter. Replace water seals. See

service center

4. Clean inlet and discharge valve

assemblies. Check filter

5. Check garden hose, may be collapsed or

kinked. Check inlet water flow

6. Replace worn valves

7. Replace high pressure hose

8. Ensure hoses and fittings are tight

9. Check and replace

10. Check water temperature; may not

exceed 100° F / 38° C

Install new water seals. See service center

1. Change oil as specified in maintenance

schedule

2. Install new oil seals. See service center

3. Install new water seals. See service

center

1. Install new plungers. See service center

2. Install proper filtration on pump inlet

plumbing

3. Check water temperature; may not

exceed 100° F / 38° C

4. DO NOT modify any factory set

adjustments

5. Clean or replace tip

6. NEVER run pump more than 2 minutes

without spraying

7. DO NOT run pump without water

Clean or replace valves. See service center

Page 22

English — 21

TROUBLESHOOTING CHART

Symptom Possible Cause(s) Corrective Action(s)

Oil leakage

between the engine

and the pump

Fluctuating pressure

Pressure drops after

period of normal

use

Pump noisy / pump

runs rough

Pressure washer will

not spray detergent

Worn oil seals and/or o-ring

1. Low engine oil

2. Pump valve worn, dirty or stuck

3. Pump drawing in air

4. Tip clogged

1. Worn pump water seals

2. Spray tip worn

3. Pump valve worn, dirty or stuck

4. Unloader valve seat worn or dirty

5. If using high pressure soap lance

accessory; nozzle in low PSI position

1. Pump drawing in air/low water

supply

2. Valves dirty or worn

3. Worn bearings

4. Water too hot

1. Not using quick connect detergent

tip

2. Clog, kink, or hole in detergent

suction hose

3. High pressure hose length too long

4. Detergent injector clogged

Replace oil seals and/or o-ring. See service

center

1. Add oil.

2. Check and replace

3. Ensure hoses and fittings are tight.

Purge air from garden hose

4. Check or replace

1. Check and replace

2. Check and replace

3. Check, clean or replace

4. Check, clean or replace

5. Pull back nozzle to high pressure

position

1. Ensure fittings are tight. Increase water

pressure

2. Check, clean or replace

3. Check and replace

4. Reduce temperature below 100°F / 38°C

1. Use black quick connect detergent tip

2. If clean, unkink or replace hose

3. Use only hose length provided with

initial purchase of pressure washer.

Detergent suction will not function if

more than once section of hose is

attached to unit

4. Remove 1” (2,54 cm) tapered detergent

barb from pump. Clean the barb, and

make sure that ball and spring are

properly aligned with tapered portion

of the spring facing the ball. The ball

should be on top of the spring

Page 23

SERVICE RECORD

22 — English

Date Maintenance performed Replacement components required

Page 24

English — 23

5525PW

531 30 75-38 Detergent Tube (not shown)

* Tips sold separately; contact your dealer to

purchase

505 27 16-01

531 30 74-97

531 30 74-84

531 30 75-35

531 30 74-69

531 30 74-96

505 19 45-24

531 30 75-41 (x2)

531 30 75-43 (x4)

531 30 75-28

531 30 75-31

531 30 75-30

531 30 75-32

531 30 74-61 (x2)

531 30 75-39 (x1)

531 30 81-11 (x2)

531 30 81-12

531 30 74-72

531 30 74-77 (Soap)

531 30 74-78 (0°) *

531 30 74-79 (15°)

531 30 74-80 (25°) *

531 30 74-81 (40°) *

Page 25

24 — English

6027PW

505 19 45-40

505 27 16-02

505 19 45-42

531 30 75-44

531 30 74-87

531 30 74-68

531 30 74-86

531 30 75-39 (x1)

531 30 75-45 (x2)

531 30 75-47

531 30 74-91

531 30 74-95

531 30 55-49 (x2)

531 30 74-66 (x5)

505 19 45-39

531 30 74-60 Detergent Tube (not shown)

531 30 74-82

531 30 74-84

531 30 74-72

531 30 74-77 (Soap)

531 30 74-78 (0°)

531 30 74-79 (15°)

531 30 74-80 (25°)

531 30 74-81 (40°)

531 30 75-40 (x2)

531 30 75-50 (x6)

Page 26

English — 25

9032PW & 1340PW

505 19 45-41

505 19 45-42

531 30 74-87

531 30 74-86

531 30 74-68

531 30 75-44

531 30 74-77 (Soap)

505 19 45-43 (0°)

505 19 45-44 (15°)

505 19 45-45 (25°)

505 19 45-46 (40°)

505 27 16-03 (9032PW)

505 27 16-04 (1340PW)

531 30 74-71 Detergent Tube (not shown)

531 30 74-82

531 30 74-84

531 30 74-72

531 30 75-39 (x1)

531 30 75-45 (x2)

531 30 75-47

531 30 74-91

531 30 74-95

531 30 55-49 (x2)

531 30 74-66 (x5)

505 19 45-39

531 30 75-40 (x2)

531 30 75-50 (x6)

Page 27

26 — English

Pump for 5525PW

505 27 18-01 Pump Assembly Complete

505 19 45-22

505 19 45-23

Key: P/O = Part Of KIt

505 19 45-21

505 19 45-20

P/O 505 19 45-02

505 19 45-18

P/O 505 19 45-09

505 19 45-17

505 19 45-16

505 19 45-15

505 19 45-14

505 19 45-13

505 19 45-12

505 19 45-11

505 19 45-10

P/O 505 19 45-09

P/O 505 19 45-09

P/O 505 19 45-06

P/O 505 19 45-09

505 19 45-08

505 19 45-07

P/O 505 19 45-06

P/O 505 19 45-02

505 19 45-03

505 19 45-05

505 19 45-04

505 19 45-19

505 19 45-01

Page 28

English — 27

Pump for 6027PW

505 19 45-25

505 19 45-38

505 19 45-27

505 19 45-28

505 19 45-26

530 30 75-85

P/O 505 19 45-35

531 30 75-90

530 30 75-84

530 30 75-13

531 30 75-88

530 30 75-82

530 30 75-81

530 30 75-80

530 30 75-79

530 30 75-78

530 30 75-77

P/O 505 19 45-35

505 27 18-02 Pump Assembly Complete

531 30 75-16

505 19 45-29

505 19 45-31

531 30 75-71

505 19 45-32

531 30 75-73

531 30 75-74

531 30 75-75

531 30 75-76

505 19 45-34

505 19 45-28

505 19 45-33

505 19 45-37

531 30 74-83 Pump Oil (not shown)

Key: P/O = Part Of KIt

531 30 75-87

530 30 75-86

505 19 45-36

531 30 75-53

Page 29

28 — English

Pump for 9032PW

531 30 74-83 Pump Oil (not shown)

Key: P/O = Part Of KIt

505 19 45-27

505 19 45-38

P/O 505 19 45-35

505 19 45-49

505 19 45-48 (x3)

505 19 45-54

505 19 45-51

505 19 45-29

505 19 45-28

505 19 45-55

P/O 505 19 45-35

505 19 45-50

505 19 45-59

505 19 45-34

505 19 45-31

505 19 45-57

505 19 45-56

505 19 45-32

505 19 45-33

505 19 45-58

531 30 75-16

505 19 45-53

P/O 505 19 45-60

P/O 505 19 45-60

505 19 45-52

530 30 75-77

505 19 45-47

530 30 75-79

505 27 18-03 Pump Assembly Complete

505 19 45-61

Page 30

English — 29

505 19 45-63

505 19 45-68

505 19 45-62

505 19 45-64

P/O 505 19 45-67

505 19 45-65

P/O 505 19 45-67

531 30 74-83 Pump Oil (not shown)

Key: P/O = Part Of KIt

505 19 45-66

Pump for 1340PW

505 19 45-69

531 30 75-25

531 30 75-26

531 30 75-24

505 19 45-79

531 30 75-20

531 30 75-21

531 30 75-22

505 19 45-68

531 30 75-19

505 19 45-79

505 19 45-62

531 30 75-27

505 19 45-70

505 19 45-71

505 19 45-72

505 19 45-73

505 19 45-74

505 19 45-75

P/O

531 30 75-92

P/O 505 19 45-78

505 19 45-76

505 19 45-77

P/O 505 19 45-78

P/O 505 19 45-78

505 19 45-80

P/O 531 30 75-92

P/O 531 30 75-92

505 27 18-04 Pump Assembly Complete

531 30 75-23

P/O 531 30 75-62

P/O 531 30 75-62

P/O 531 30 75-60

P/O 531 30 75-60

P/O 531 30 75-64

P/O 531 30 75-64

P/O 531 30 75-65

P/O 531 30 75-65

531 30 75-22

Page 31

30 — English

NOTES

Page 32

English — 31

Product Registration Notice!

Eective May 1, 2007

FAST! EASY! SIMPLE!

Register your Husqvarna product on-line quickly and easily. Paper registration forms will not be accepted.

There will be a grace period for products built prior to January 1, 2007. All Husqvarna products can be

registered online regardless of their model year. Register products online at www.usa.husqvarna.com ,

Page 33

32 — English

Loading...

Loading...