Page 1

EN Operator's manual 2-37

DE Bedienungsanweisung 38-75

ES Manual de usuario 76-113

FR Manuel d'utilisation 114-151

IT Manuale dell'operatore 152-189

NL Gebruiksaanwijzing 190-226

PT Manual do utilizador 227-264

SL Navodila za uporabo 265-300

543 XP®, 543 XP®G

Page 2

Contents

18

19

6

17

7

27

25

1

8

9

10

11

3

4

2

31

30

32

12

15

24

5

5

26

14

16

13

5

21

22

23

28

29

20

5

33

34

35

Introduction..................................................................... 2

Safety..............................................................................4

Assembly........................................................................ 9

Operation...................................................................... 10

Maintenance................................................................. 21

Introduction

Troubleshooting............................................................ 33

Transportation and storage...........................................34

Technical data.............................................................. 34

Accessories.................................................................. 35

EC Declaration of Conformity....................................... 37

Intended use

This product is intended for sawing in wood.

Note: National regulations can set limit to the operation

of the product.

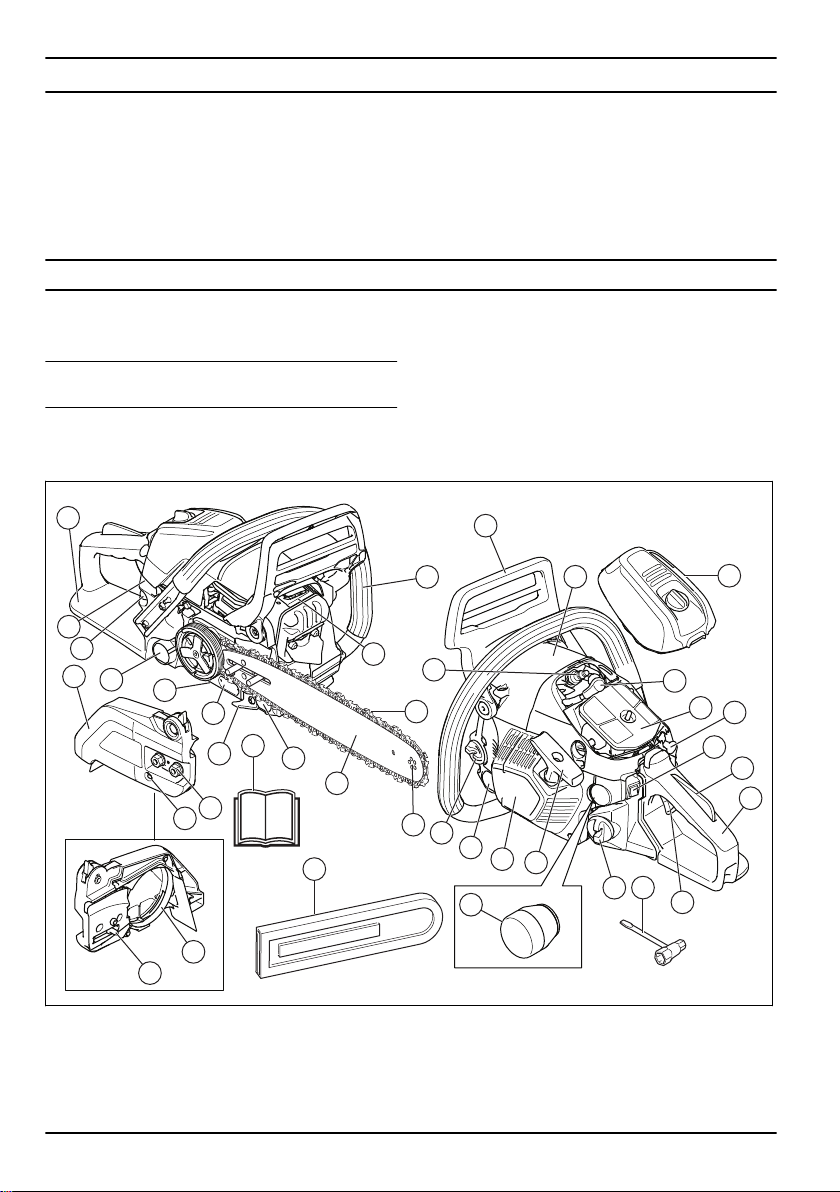

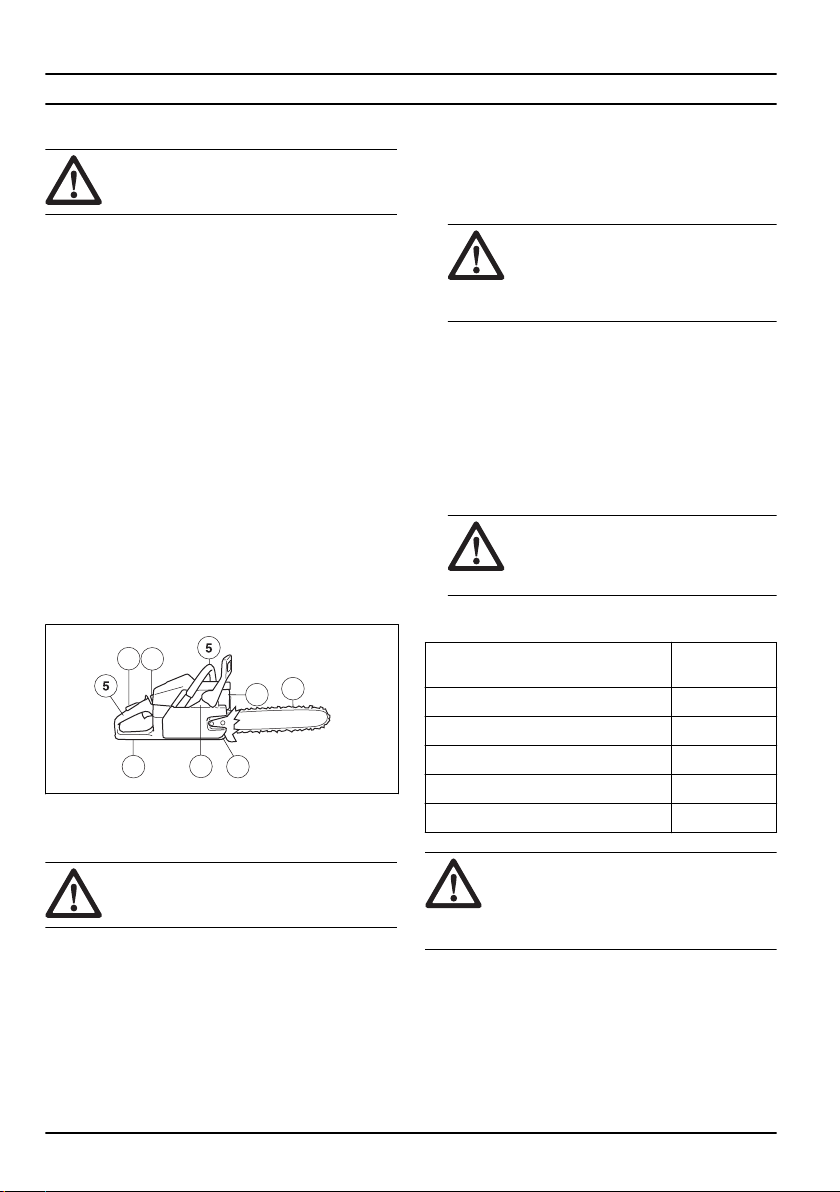

Product overview

1. Air filter cover

2. Spark plug

3. Spark plug cap

4. Air filter

Product description

The Husqvarna 543 XP, 543 XPG are chainsaw models

with a combustion engine.

Work is constantly in progress to increase your safety

and efficiency during operation. Speak to your servicing

dealer for more information.

5. Vibration damping system, 4 units

6. Throttle trigger lockout

7. Rear handle

8. Information and warning decal

2 956 - 003 -

Page 3

9. Throttle trigger

yyyywwxxxxx

10. Start/stop switch

11. Choke control

12. Fuel tank

13. Air purge bulb

14. Starter rope handle

15. Starter housing

16. Chain oil tank

17. Muffler

18. Chain brake and front hand guard

19. Front handle

20. Switch for heated handles (543 XPG)

21. Right hand guard

22. Clutch cover

23. Chain tensioning screw

24. Chain catcher

25. Saw chain

26. Guide bar

27. Bar tip sprocket

28. Chain adjuster pin

29. Brake band

30. Operator's manual

31. Transportation guard

32. Combination wrench

33. Product and serial number plate

34. Oil pump adjustment screw

35. Bar nuts

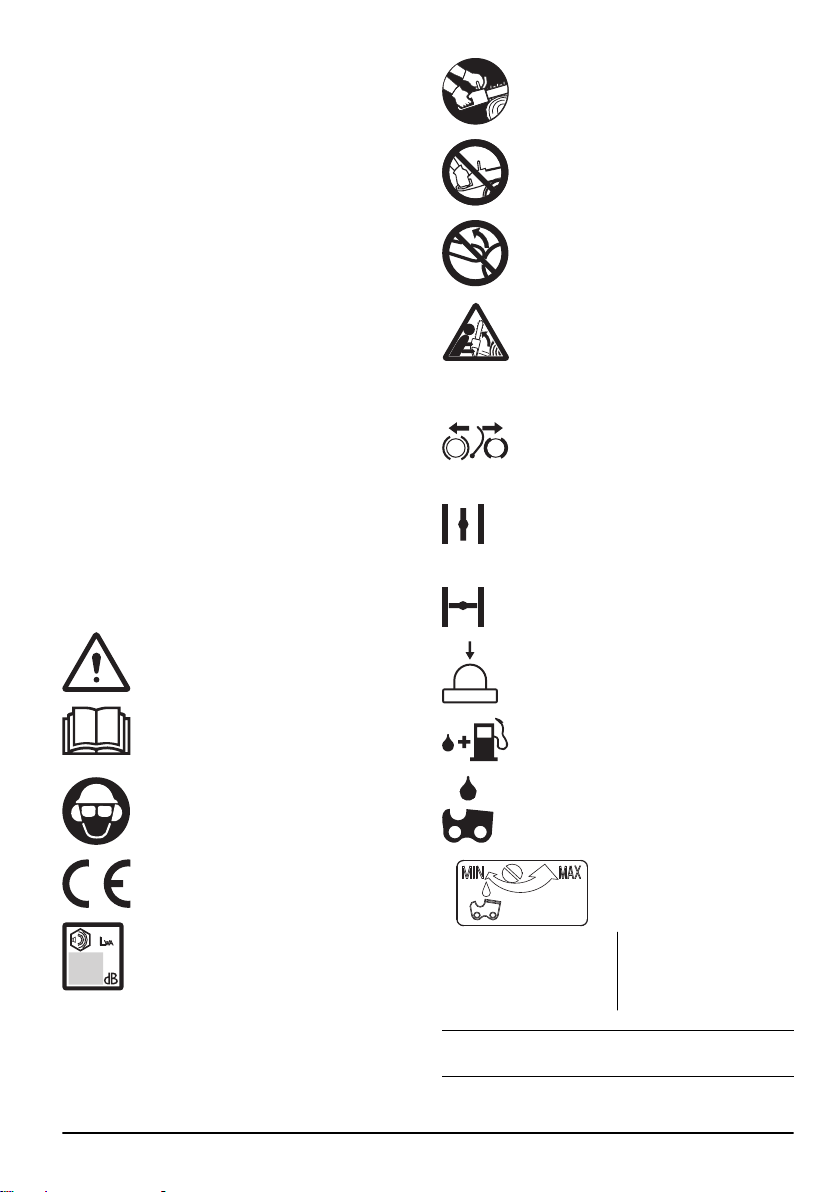

Symbols on the product

Careless or incorrect use of this product can

result in serious or fatal injury to the operator

or others.

Read the operator's manual carefully and

make sure you understand the instructions

before you use this product.

Both of the operator's hands must be used

to operate the chainsaw.

Never operate the chainsaw holding it with

one hand only.

Never let the guide bar tip come in contact

with any object.

Warning! Kickback may occur when the

nose or tip of the guide bar touches an

object, and cause a lightning fast reverse

reaction, kicking the guide bar up and

towards the operator. May cause serious

personal injury.

Chain brake, activated (right). Chain brake,

not activated (left).

Choke lever in "open position".

Choke lever in "closed position".

Air purge.

Refuelling.

956 - 003 - 3

Always wear approved protective helmet,

approved hearing protection and protective

goggles or a visor.

This product is in accordance with

applicable EC Directives.

Noise emissions to the environment

according to European Directive 2000/14/EC

and New South Wales legislation "Protection

of the Environment Operations (Noise

Control) Regulation 2017". Noise emission

data can be found on the machine label and

in the chapter

Technical data on page 34

.

Chain oil fill.

Adjustment of the oil

pump.

The rating plate showing

serial number. yyyy is the

production year, ww is the

production week.

Note: Other symbols/decals on the product refer to

certification requirements for certain markets.

Page 4

Euro V Emissions

WARNING: Tampering with the engine voids

the EU type-approval of this product.

Safety

Safety definitions

Warnings, cautions and notes are used to point out

specially important parts of the manual.

WARNING: Used if there is a risk of injury or

death for the operator or bystanders if the

instructions in the manual are not obeyed.

CAUTION: Used if there is a risk of damage

to the product, other materials or the

adjacent area if the instructions in the

manual are not obeyed.

Note: Used to give more information that is necessary in

a given situation.

General safety instructions

WARNING: Read the warning instructions

that follow before you use the product.

• A chainsaw is a dangerous tool if used carelessly or

incorrectly and can cause serious injury or death. It

is very important that you read and understand the

contents of this operator’s manual.

• Under no circumstances may the design of the

product be modified without the permission of the

manufacturer. Do not use a product that appears to

have been modified by others and only use

accessories recommended for this product. Nonauthorized modifications and/or accessories can

result in serious personal injury or the death of the

operator or others.

• The inside of the muffler contain chemicals that may

be carcinogenic. Avoid contact with these elements

in the event of a damaged muffler.

• Long term inhalation of the engine’s exhaust fumes,

chain oil mist and sawdust can represent a health

risk.

• This product produces an electromagnetic field

during operation. This field may under some

circumstances interfere with active or passive

medical implants. To reduce the risk of serious or

fatal injury, we recommend persons with medical

implants to consult their physician and the medical

implant manufacturer before operating this product.

• The information in this operator's manual is never a

substitute for professional skills and experience. If

you get into a situation where you feel unsafe, stop

and seek expert advice. Contact your servicing

dealer or an experienced chainsaw user. Do not

attempt any task that you feel unsure of!

Safety instructions for operation

WARNING: Read the warning instructions

that follow before you use the product.

• Before using the product you must understand the

effects of kickback and how to avoid them. Refer to

Kickback information on page 11

• Never use a product that is faulty.

• Never use a product with visible damage to the

spark plug cap and ignition cable. A risk of sparking

arises, which can cause a fire.

• Never use the product if you are fatigued, while

under the influence of alcohol or drugs, medication

or anything that could affect your vision, alertness,

coordination or judgement.

• Do not use the product in bad weather such as

dense fog, heavy rain, strong wind, intense cold,

etcetera. Working in bad weather is tiring and often

brings added risks, such as icy ground,

unpredictable felling direction, etcetera.

• Never start a product unless the guide bar, saw

chain and all covers are fitted correctly. Refer to

Assembly on page 9

and saw chain attached to the product the clutch can

come loose and cause serious injury.

• Never start the product indoors. Exhaust fumes can

be dangerous if inhaled.

• The exhaust fumes from the engine are hot and can

contain sparks, which can start a fire. Never start the

product near flammable material!

• Observe your surroundings and make sure that there

is no risk of people or animals coming in contact with

or affect your control of the product.

• Never allow children to use or be in the vicinity of the

product. As the product is equipped with a spring-

for instructions. Without a bar

for instructions.

4

956 - 003 -

Page 5

loaded start/stop switch and can be started by low

speed and force on the starter handle, even small

children under some circumstances can produce the

force necessary to start the product. This can mean

a risk of serious personal injury. Therefore remove

the spark plug cap when the product is not under

close supervision.

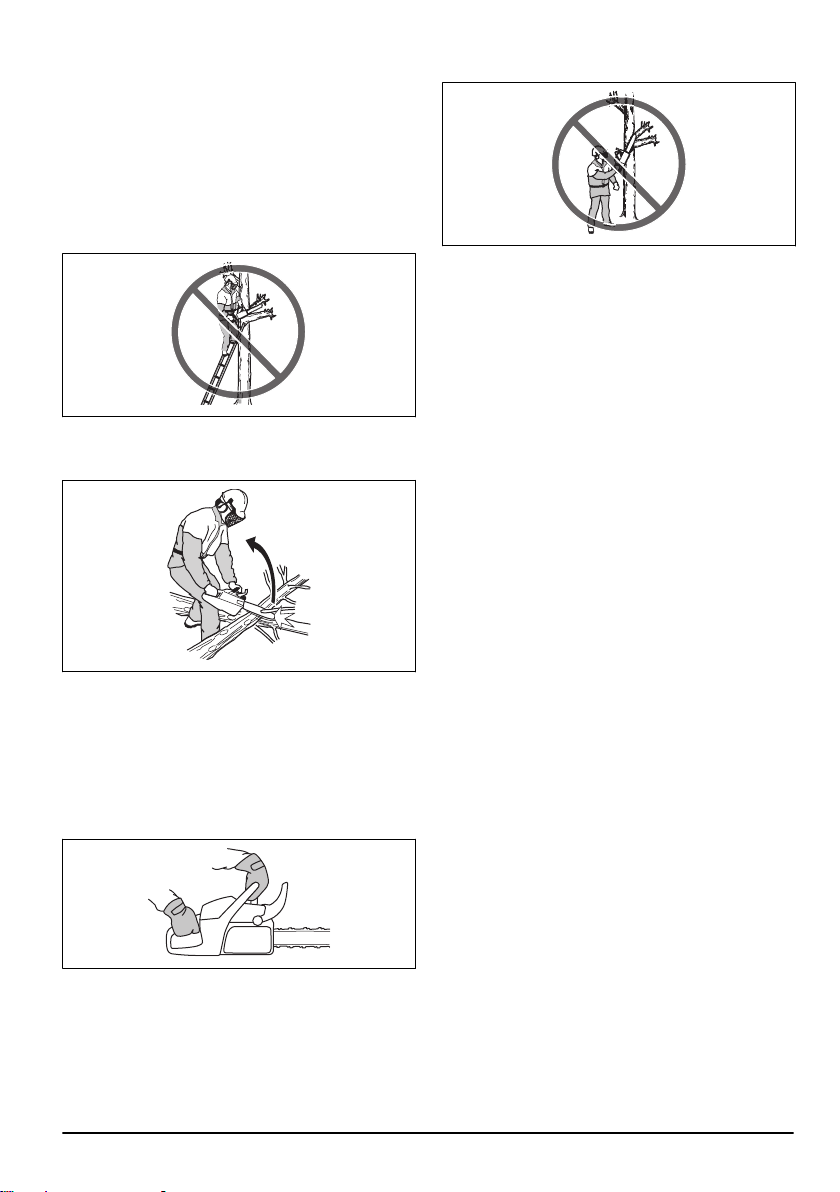

• You must have a steady stance in order to have full

control of the product. Never work standing on a

ladder, in a tree or where you do not have a firm

ground to stand on.

• Lack of concentration can lead to kickback if the

kickback zone of the bar accidentally touches a

branch, nearby tree or some other object.

• Never use the product by holding it with one hand.

This product is not safely controlled with one hand.

• Always hold the product with both hands. The right

hand should be on the rear handle, and the left hand

on the front handle. All people, whether right or left

handed, should use this grip. Use a firm grip with

thumbs and fingers encircling the handles. This grip

minimizes the risk of kickback and lets you keep the

product under control. Do not let go of the handles!

• Never use the product above shoulder height.

• Do not use the product in a situation where you

cannot call for help in case of an accident.

• Before moving your product, switch off the engine

and lock the saw chain using the chain brake. Carry

the product with the guide bar and saw chain

pointing backwards. Fit a transportation guard to the

guide bar before transporting the product or carrying

it for any distance.

• When you put the product on the ground, lock the

saw chain using the chain brake and ensure you

have a constant view of the product. Switch the

engine off before leaving your product for any length

of time.

• Sometimes chips get stuck in the clutch cover

causing the saw chain to jam. Always stop the

engine before cleaning.

• Running an engine in a confined or badly ventilated

area can result in death due to carbon monoxide

poisoning.

• The exhaust fumes from the engine are hot and may

contain sparks which can start a fire. Do not start the

product indoors or near flammable material.

• Use the chain brake as a parking brake when you

start the product and when you move short

distances. Always carry the product in the front

handle. This decreases the risk that you or a person

near you get hit by the saw chain.

• Overexposure to vibration can lead to circulatory

damage or nerve damage in people who have

impaired circulation. Contact your doctor if you

experience symptoms of overexposure to vibration.

Such symptoms include numbness, loss of feeling,

tingling, pricking, pain, loss of strength, changes in

skin colour or condition. These symptoms normally

appear in the fingers, hands or wrists. These

symptoms may be increased in cold temperatures.

• It is not possible to cover every conceivable situation

you can face when using this product. Always

exercise care and use your common sense. Avoid all

situations which you consider to be beyond your

capability. If you still feel uncertain about operating

procedures after reading these instructions, you

should consult an expert before continuing. Do not

hesitate to contact your dealer or Husqvarna if you

have any questions about the use of the product. We

will willingly be of service and provide you with

advice as well as help you to use your product both

efficiently and safely. Attend a training course in

chainsaw usage if possible. Your dealer, forestry

956 - 003 -

5

Page 6

school or your library can provide information about

A

B

A

B

which training materials and courses are available.

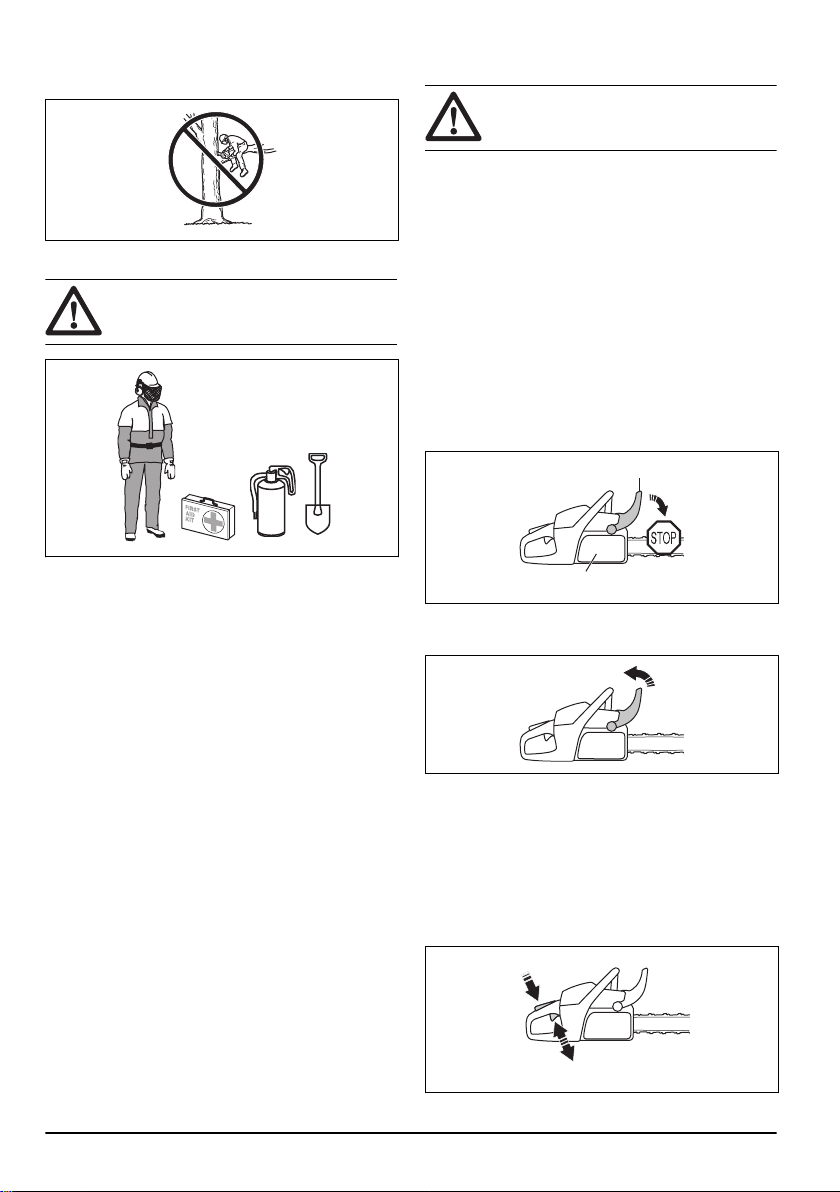

Personal protective equipment

Safety devices on the product

WARNING: Read the warning instructions

that follow before you use the product.

• Do not use a product with defective safety devices.

• Do a check of the safety devices regularly. Refer to

Maintenance and checks of the safety devices on

the product on page 23

• If the safety devices are defective, speak to your

Husqvarna servicing dealer.

.

WARNING: Read the warning instructions

that follow before you use the product.

• Most chainsaw accidents occur when the saw chain

touches the operator. You must use approved

personal protective equipment during operation.

Personal protective equipment does not give you full

protection from injuries but it decreases the degree

of injury if an accident occurs. Speak to your

servicing dealer for recommendations about which

equipment to use.

• Your clothing must be close-fitting but not limit your

movements. Regularly do a check of the condition of

the personal protective equipment.

• Use an approved protective helmet.

• Use approved hearing protection. Long-term

exposure to noise can result in permanent damage

to the hearing.

• Use protective glasses or a face visor to decrease

the risk of injury from thrown objects. The product

can throw objects, such as wood chips, small pieces

of wood and more, at large force. This can result in

serious injury, especially to the eyes.

• Use gloves with saw protection.

• Use pants with saw protection.

• Use boots with saw protection, steel toe-cap and

non-slip sole.

• Always have a first-aid kit with you.

• Risk of sparks. Keep fire extinguishing tools and a

shovel near to prevent forest fires.

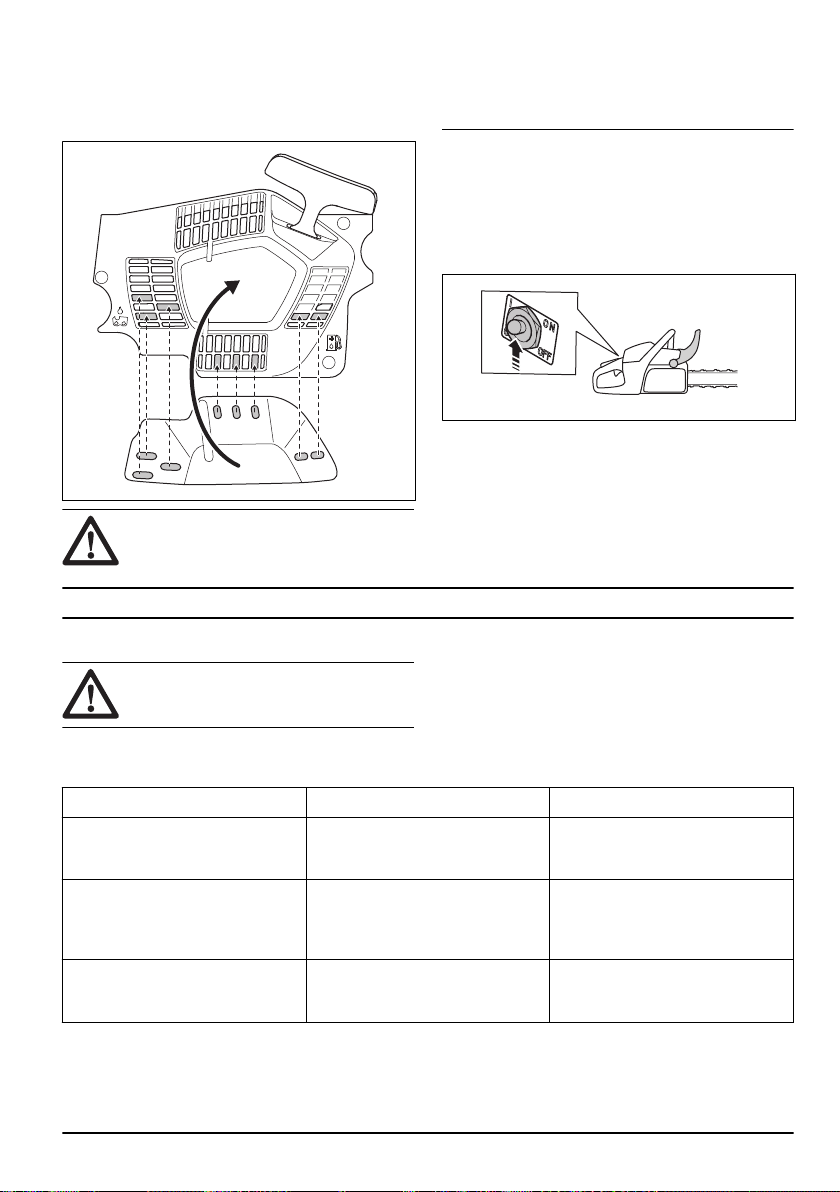

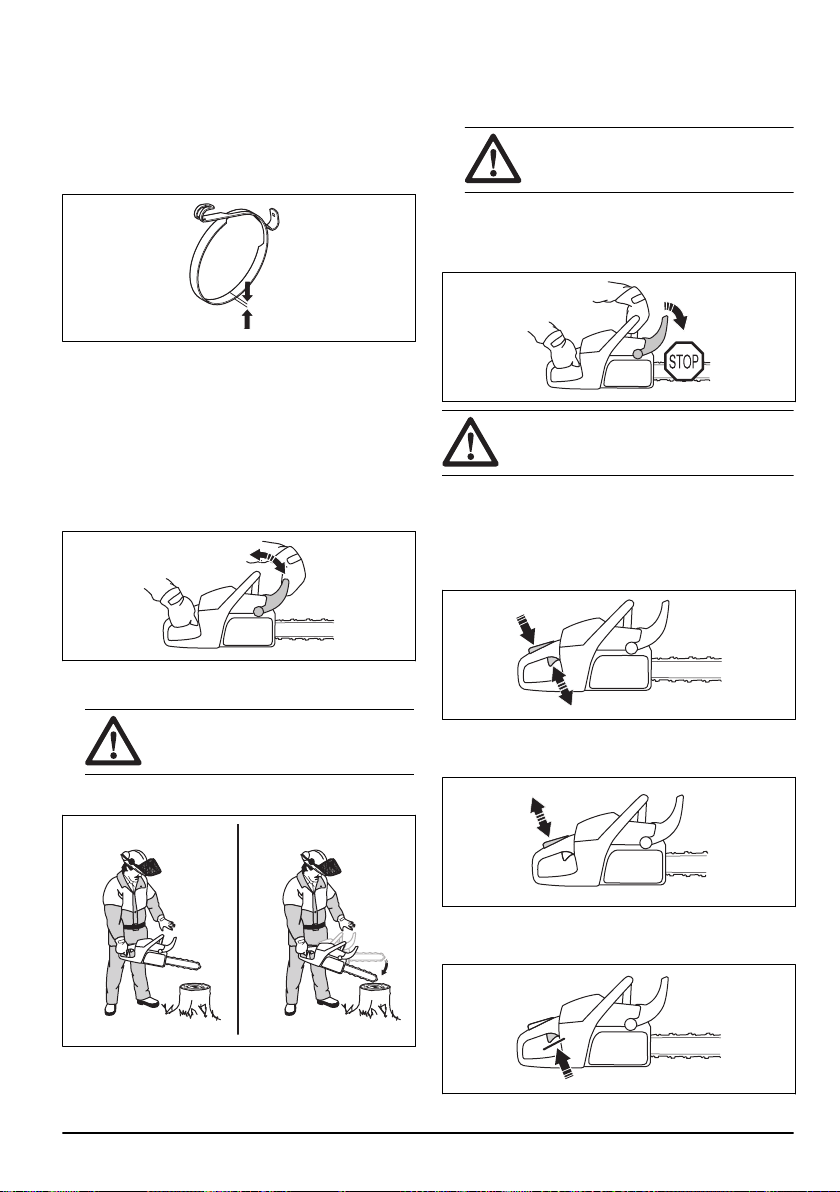

Chain brake and front hand guard

Your product has a chain brake that stops the saw chain

if you get a kickback. The chain brake decreases the

risk of accidents, but only you can prevent them.

The chain brake engages (A) manually by your left hand

or automatically by the inertia release mechanism. Push

the front hand guard (B) forward to engage the chain

brake manually.

Pull the front hand guard rearward to disengage the

chain brake.

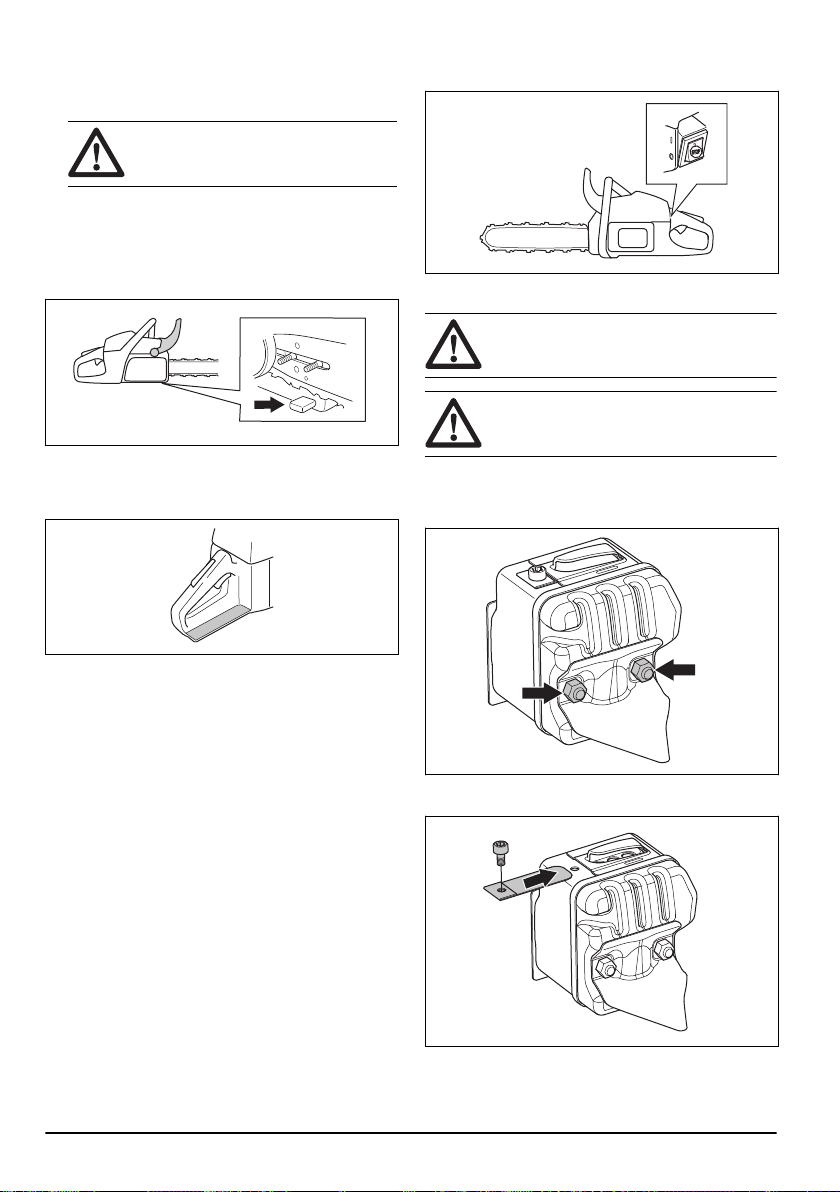

Throttle trigger lockout

The throttle trigger lockout prevents accidental operation

of the throttle trigger. If you put your hand around the

handle and press the throttle trigger lockout (A), it

releases the throttle trigger (B). If you release the

handle, the throttle trigger and the throttle trigger lockout

move back to their initial positions. This function locks

the throttle trigger at idle speed.

6

956 - 003 -

Page 7

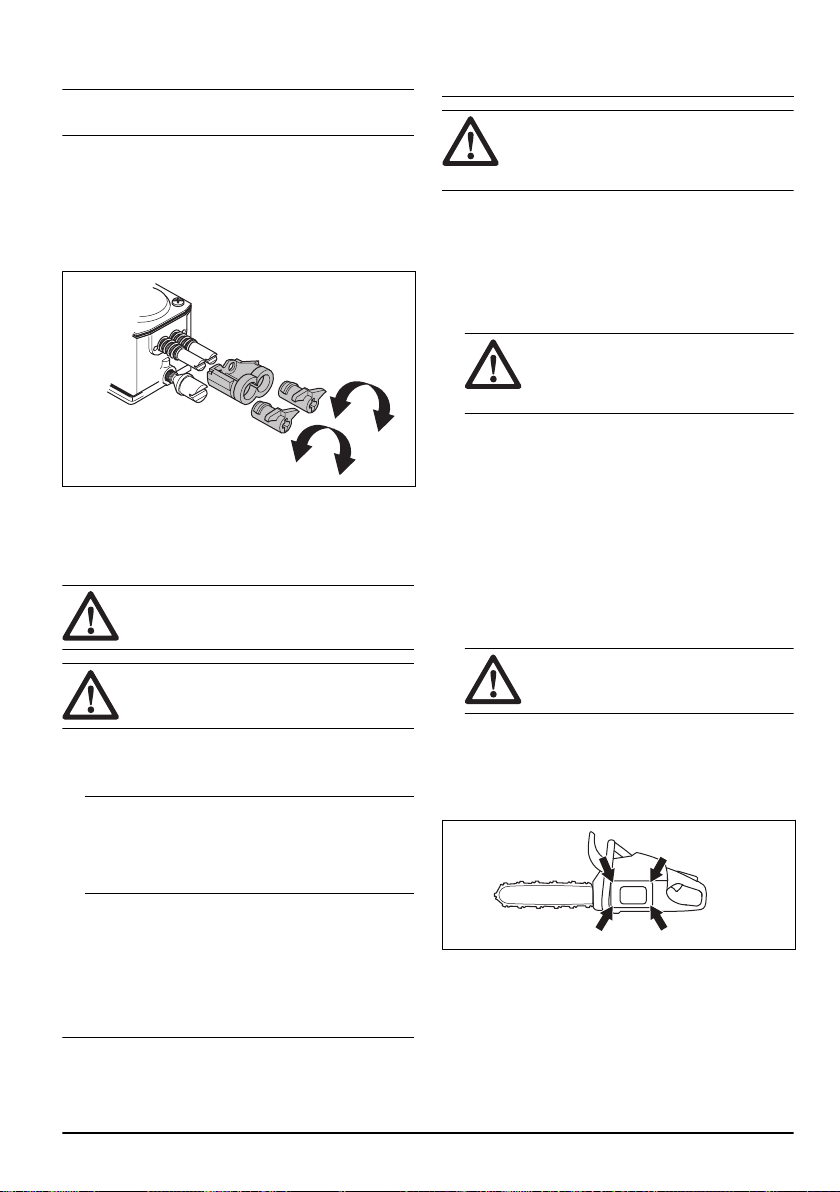

Chain catcher

The chain catcher catches the saw chain if it breaks or

comes loose. Correct saw chain tension and correctly

applied maintenance on the saw chain and guide bar,

decrease the risk of accidents.

Right hand guard

The right hand guard is a protection for your hand on the

rear handle. The right hand guard gives you protection if

the saw chain breaks or derails. The right hand guard

also gives you protection from branches or twigs.

operate the product near flammable

materials and/or fumes.

WARNING: Do not operate a product

without a muffler or with a defective muffler.

A defective muffler can increase the noise

level and the risk of fire. Keep fire

extinguishing tools near. Do not use a

product without, or with a broken, spark

arrestor mesh if you must have a spark

arrestor mesh in your area.

The muffler keeps the noise levels to a minimum and

points the exhaust fumes away from the operator. In

areas with a hot, dry weather there is a high risk of fire.

Obey local regulations and maintenance instructions.

Vibration damping system

The vibration damping system decreases vibration in the

handles. Vibration damping units operate as a

separation between the product body and the handle

unit.

Refer to

Product overview on page 2

about where the vibration damping system is on your

product.

Start/stop switch

Use the start/stop switch to stop the engine.

Muffler

WARNING: The muffler becomes very hot

during/after operation and at idle speed.

There is a risk of fire, especially when you

956 - 003 -

for information

Fuel safety

WARNING:

that follow before you use the product.

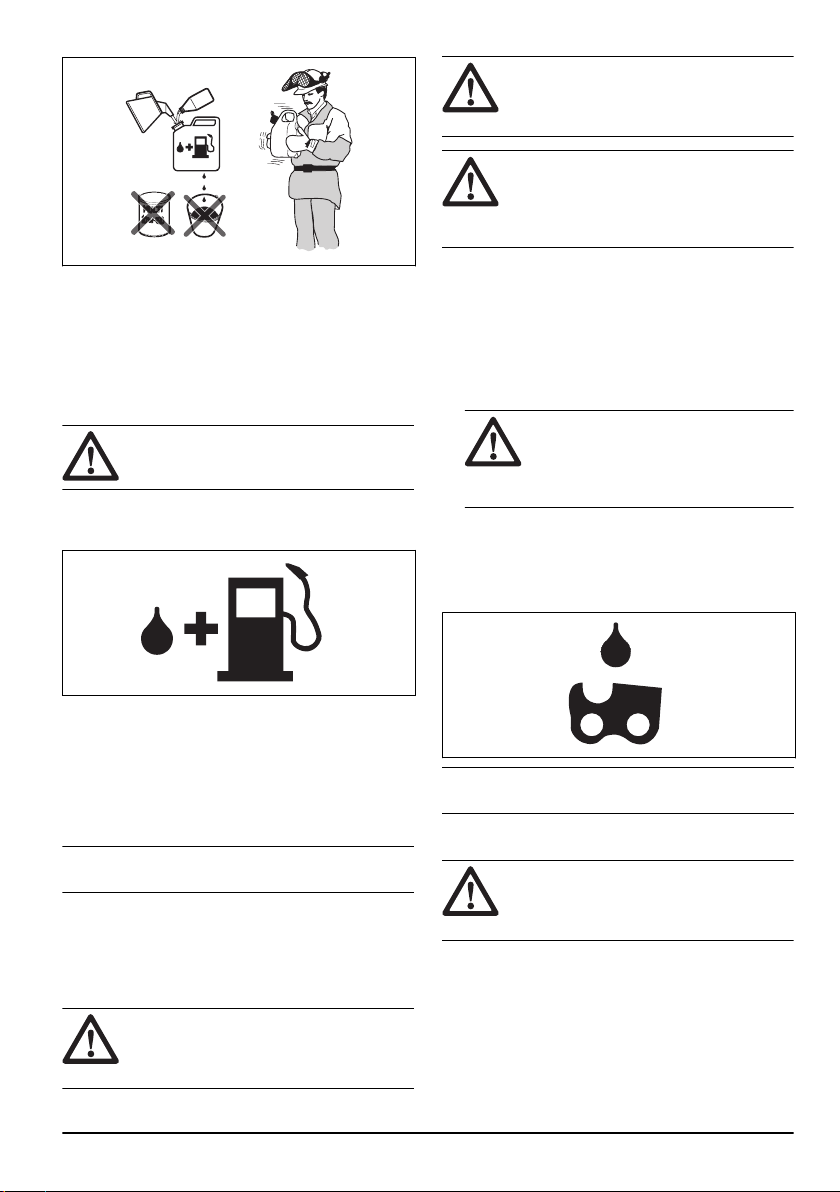

• Make sure there is plenty of ventilation when

refuelling or mixing fuel (petrol and two-stroke oil).

• Fuel and fuel vapour are highly flammable and can

cause serious injury when inhaled or allowed to

come in contact with the skin. For this reason

observe caution when handling fuel and make sure

there is adequate ventilation.

• Take care when handling fuel and chain oil. Be

aware of the risks of fire, explosion and those

associated with inhalation.

• Do not smoke and do not place any hot objects in

the vicinity of fuel.

• Always stop the engine and let it cool for a few

minutes before refuelling.

• When refuelling, open the fuel cap slowly so that any

excess pressure is released gently.

• Tighten the fuel cap carefully after refuelling.

• Never refuel the machine while the engine is

running.

Read the warning instructions

7

Page 8

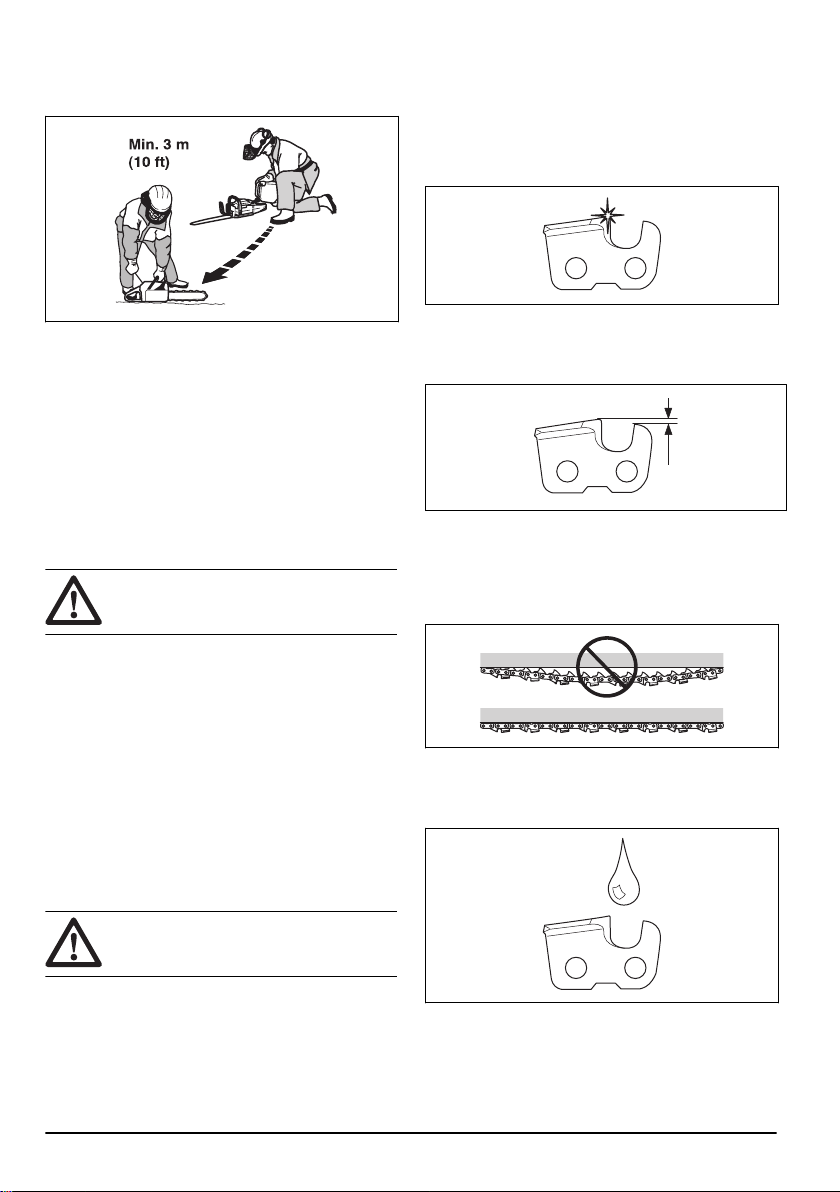

• Always move the product at least 3 m (10 ft) away

from the refuelling area and fuel source before

starting.

After refuelling, there are some situations where you

must never start the product:

• If you have spilled fuel or chain oil on the product.

Wipe off the spillage and allow remaining fuel to

evaporate.

• If you have spilled fuel on yourself or on your

clothes. Change your clothes and wash any part of

your body that has come in contact with fuel. Use

soap and water.

• If the product leaks fuel. Regularly do a check for

leaks from the fuel tank, fuel cap and fuel lines.

Safety instructions for maintenance

WARNING: Read the warning instructions

that follow before you do maintenance on

the product.

• Use protective gloves when you use or do

maintenance on the saw chain. A saw chain that

does not move can also cause injuries.

• Keep the cutting teeth correctly sharpened. Obey the

instructions and use the recommended file gauge. A

saw chain that is damaged or incorrectly sharpened

increases the risk of accidents.

• Keep the correct depth gauge setting. Obey the

instructions and use the recommended depth gauge

setting. Too large depth gauge setting increases the

risk of kickback.

• Make sure that the saw chain has the correct

tension. If the saw chain is not tight against the guide

bar, the saw chain can derail. An incorrect saw chain

tension increases wear on the guide bar, saw chain

and chain drive sprocket. Refer to

tension of the saw chain on page 30

To adjust the

.

• Do only the maintenance and servicing given in this

operator's manual. Let professional servicing

personnel do all other servicing and repairs.

• Regularly do the safety checks, maintenance and

service instructions given in this manual. Regular

maintenance increases the life of the product and

decreases the risk of accidents. Refer to

Maintenance on page 21

• If the safety checks in this operator's manual is not

approved after you do maintenance, speak to your

servicing dealer. We guarantee that there are

professional repairs and servicing available for your

product.

for instructions.

Safety instructions for the cutting equipment

WARNING:

that follow before you use the product.

• Only use the guide bar/saw chain combinations and

filing equipment that we recommend. Refer to

Accessories on page 35

8

Read the warning instructions

for instructions.

• Do maintenance on the cutting equipment regularly

and keep it correctly lubricated. If the saw chain is

not correctly lubricated, the risk of wear on the guide

bar, saw chain and chain drive sprocket increases.

956 - 003 -

Page 9

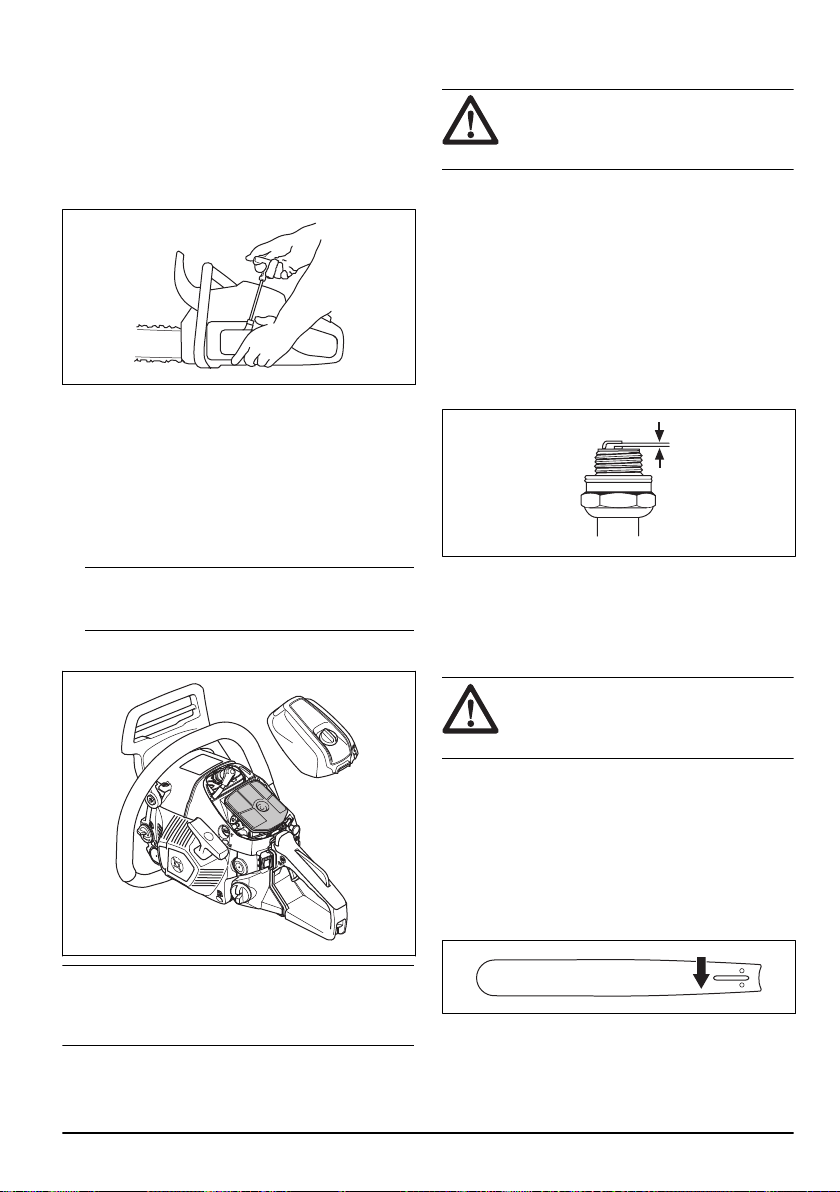

Assembly

A

Introduction

WARNING: Read and understand the safety

chapter before you assemble the product.

To assemble the guide bar and saw chain

1. Disengage the chain brake.

2. Remove the bar nuts and the clutch cover. Remove

the transportation guard (A).

3. Assemble the guide bar onto the bar bolt. Move the

guide bar to its most rear position.

4. Install the saw chain correctly around the drive

sprocket and put it in the groove on the guide bar.

WARNING: Always use protective

gloves when you assemble the saw

chain.

5. Make sure that the edges of the cutters point forward

on the top edge of the guide bar.

6. Align the hole in the guide bar with the chain adjuster

pin and install the clutch cover.

7. Tighten the bar nut finger tight.

8. Tighten the saw chain. Refer to

of the saw chain on page 30

9. Tighten the bar nuts.

To adjust the tension

for instructions.

956 - 003 - 9

Page 10

Operation

7

10

9

1

2

3

6,8

4

Introduction

WARNING: Read and understand the safety

chapter before you use the product.

To do a function check before you use the product

1. Make sure that the chain brake operates correctly

and that it is not damaged.

2. Make sure that the right hand guard is not damaged.

3. Make sure that the throttle lockout operates correctly

and that it is not damaged.

4. Make sure that the start/stop switch operates

correctly and that it is not damaged.

5. Make sure that there is no oil on the handles.

6. Make sure that the vibration damping system

operates correctly and that it is not damaged.

7. Make sure that the muffler is correctly attached and

that it is not damaged.

8. Make sure that all parts of the product are correctly

attached and not damaged or missing.

9. Make sure that the chain catcher is correctly

attached.

10. Do a check of the saw chain tension.

Fuel

This product has a two-stroke engine.

CAUTION: Incorrect type of fuel can result in

engine damage. Use a mixture of gasoline

and two-stroke oil.

To mix fuel

Gasoline

• Use good quality unleaded gasoline with a maximum

of 10% ethanol contents.

CAUTION: Do not use gasoline with an

octane grade less than 90 RON/87 AKI.

Use of a lower octane grade can cause

engine knocking, which causes engine

damages.

• We recommend that you use gasoline of a higher

octane grade for work with continuously high rpm.

Two-stroke oil

• For best results and performance use Husqvarna

two-stroke oil.

• If Husqvarna two-stroke oil is not available, use a

two-stroke oil of good quality for air-cooled engines.

Speak to your servicing dealer to select the correct

oil.

CAUTION: Do not use two-stroke oil for

water-cooled outboard engines, also

referred to as outboard oil. Do not use oil

for four-stroke engines.

To mix gasoline and two-stroke oil

Gasoline, liter Two-stroke oil,

liter

2% (50:1)

5 0.10

10 0.20

15 0.30

20 0.40

CAUTION: Small errors can influence the

ratio of the mixture drastically when you mix

small quantities of fuel. Measure the quantity

of oil carefully and make sure that you get

the correct mixture.

Premixed fuel

• Use Husqvarna premixed alkylate fuel of a good

quality, for best performance and extension of the

engine life. This fuel contains less harmful chemicals

compared to regular fuel, which decreases harmful

exhaust fumes. The quantity of remains after

combustion is lower with this fuel, which keeps the

components of the engine more clean.

10 956 - 003 -

Page 11

WARNING: The saw chain can break if the

lubrication of the cutting equipment is not

sufficient. Risk of serious injury or death to

the operator.

WARNING: This product has a function that

lets the fuel run out before the chain oil. Use

the correct chain oil for this function to

operate correctly. Speak to your servicing

dealer when you select your chain oil.

1. Fill half the quantity of gasoline in a clean container

for fuel.

2. Add the full quantity of oil.

3. Shake the fuel mixture.

4. Add the remaining quantity of gasoline to the

container.

5. Carefully shake the fuel mixture.

CAUTION: Do not mix fuel for more than 1

month at a time.

To fill the fuel tank

1. Clean the area around the fuel tank cap.

2. Shake the container and make sure that the fuel is

fully mixed.

3. Remove the fuel tank cap and fill the fuel tank.

4. Tighten the fuel tank cap carefully.

5. Move the product 3 m/10 ft or more away from the

refueling area and fuel source before you start the

engine.

To see where the fuel tank is on your product,

Note:

refer to

Product overview on page 2

.

To do a run-in

• During the first 10 hours of operation, do not apply

full throttle without load for extended periods.

To use the correct chain oil

WARNING:

cause injury to you and the environment.

Waste oil also causes damage to the oil

pump, the guide bar and the saw chain.

Do not use waste oil, which can

• Use Husqvarna chain oil for maximum saw chain life

and to prevent negative effects on the environment.

If Husqvarna chain oil is not available, we

recommend you to use a standard chain oil.

• Use a chain oil with good adherence to the saw

chain.

• Use a chain oil with correct viscosity range that

agrees with the air temperature.

CAUTION: If the oil is too thin, it runs out

before the fuel. In temperatures below

0°C/32°F some chain oils become too

thick, which can cause damage to the oil

pump components.

• Use the recommended cutting equipment. Refer to

Accessories on page 35

• Remove the cap to the chain oil tank.

• Fill the chain oil tank with chain oil.

• Attach the cap carefully.

To see where the chain oil tank is on you product,

Note:

refer to

Product overview on page 2

.

.

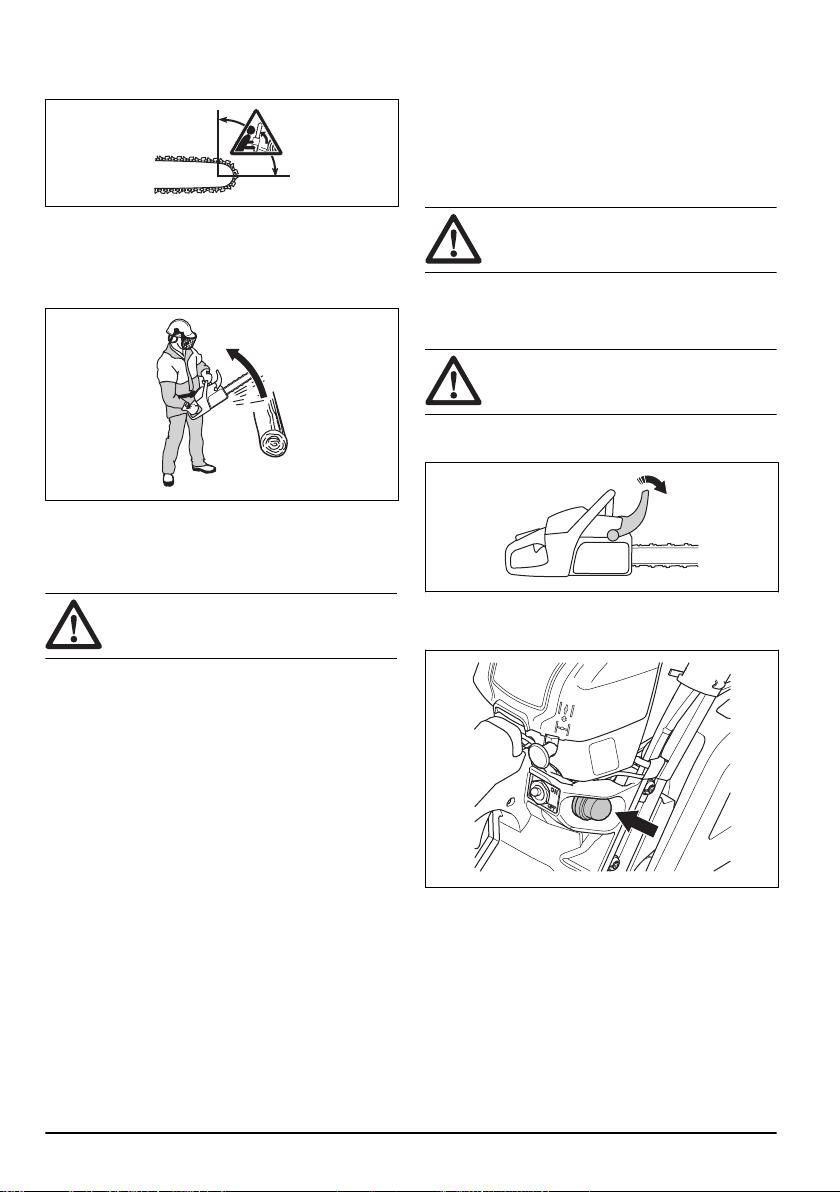

Kickback information

WARNING:

injury or death to the operator or others. To

decrease the risk you must know the causes

of kickback and how to prevent them.

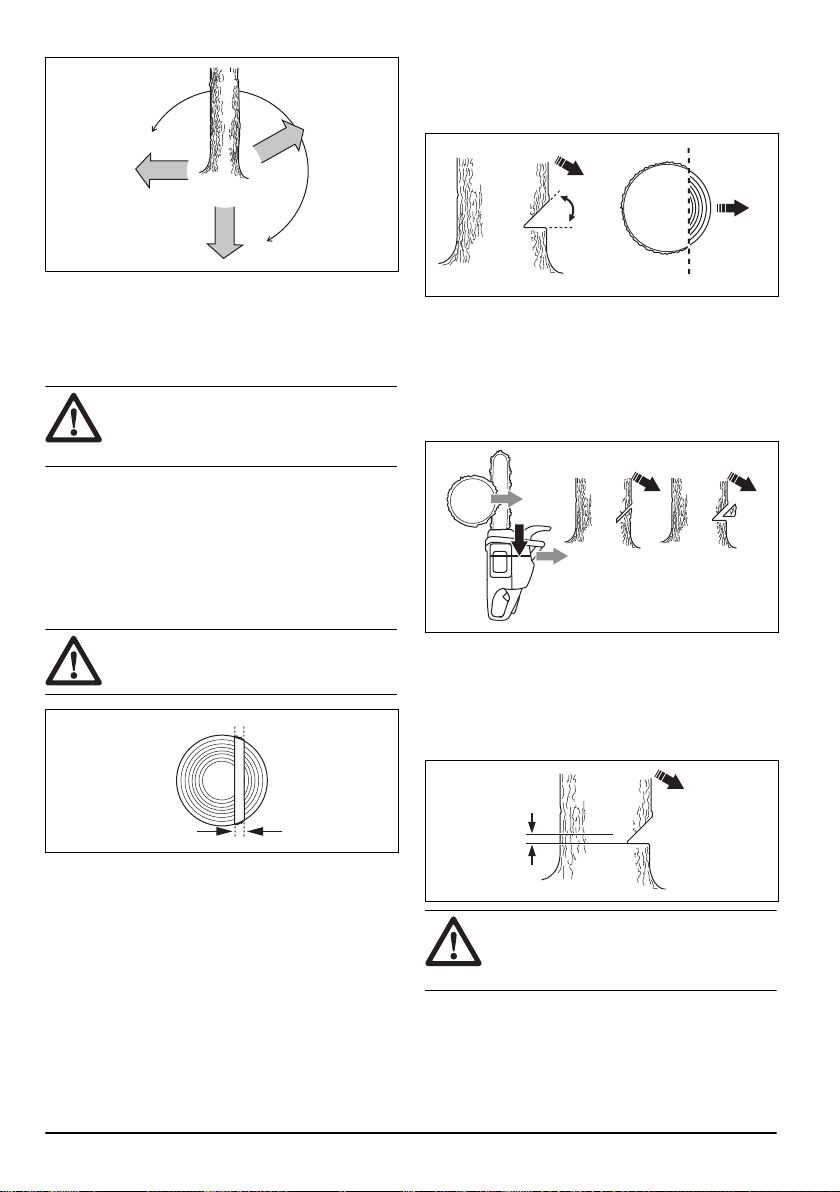

A kickback occurs when the kickback zone of the guide

bar touches an object. A kickback can occur suddenly

A kickback can cause serious

956 - 003 -

11

Page 12

and with large force, which throws the product in the

direction of the operator.

Kickback always occurs in the cutting plane of the guide

bar. Usually, the product is thrown against the operator

but can also move in a different direction. It is how you

use the product when the kickback occurs that causes

the direction of the movement.

A smaller bar tip radius decreases the force of the

kickback.

Use a low kickback saw chain to decrease the effects of

kickback. Do not let the kickback zone touch an object.

WARNING: No saw chain fully prevents

kickback. Always obey the instructions.

Will the chain brake always protect me from injury

•

during a kickback?

No. The chain brake must operate correctly to give

protection. The chain brake must also be engaged

during a kickback to stop the saw chain. If you are

near the guide bar, it is possible that the chain brake

does not have time to stop the saw chain before it

hits you.

WARNING: Only you and the correct

working technique can prevent kickbacks.

To start the product

To prepare to start with a cold engine

WARNING: The chain brake must be

engaged when the product is started to

decrease the risk of injury.

1. Move the front hand guard forward to engage the

chain brake.

2. Push the air purge bulb approximately 6 times or

until fuel starts to fill the bulb. It is not necessary to

fill the air purge bulb fully.

Common questions about kickback

• Will the hand always engage the chain brake during

a kickback?

No. It is necessary to use some force to push the

front hand guard forward. If you do not use the force

necessary, the chain brake will not be engaged. You

must also hold the handles of the product stable with

two hands during work. If a kickback occurs, it is

possible that the chain brake does not stop the saw

chain before it touches you. There are also some

positions in which your hand can not touch the front

hand guard to engage the chain brake. An example

of this is in the felling position.

• Will the inertia release mechanism always engage

the chain brake during kickback?

No. First, the chain brake must operate correctly.

Refer to

To do a check of the chain brake on page

23

for instructions about how to do a check of the

chain brake. We recommend you to do this each

time before you use the product. Second, the force

of the kickback must be large to engage the chain

brake. If the chain brake is too sensitive, it can

engage during rough operation.

12

956 - 003 -

Page 13

3. Set the choke to choke position.

4. Continue to

more instructions.

To start the product on page 13

for

To prepare start with a warm engine

WARNING: The chain brake must be

engaged when the product is started to

decrease the risk of injury.

1. Move the front hand guard forward to engage the

chain brake.

To start the product

WARNING: You must keep your feet in a

stable position when you start the product.

WARNING: If the saw chain rotates at idle

speed, speak to your servicing dealer and

do not use the product.

1. Put the product on the ground.

2. Put your left hand on the front handle.

3. Put your right foot into the footgrip on the rear

handle.

4. Pull the starter rope handle slowly with your right

hand until you feel resistance.

WARNING: Do not twist the starter rope

around your hand.

5. Pull the starter rope handle quickly and with force.

2. Push the air purge bulb approximately 6 times or

until fuel starts to fill the bulb. It is not necessary to

fill the air purge bulb fully.

Do not set the choke to the choke position.

Note:

3. Continue to

more instructions.

956 - 003 -

To start the product on page 13

for

CAUTION: Do not pull the starter rope to

full extension and do not let go of the

starter rope handle. This can cause

damage to the product.

a) If you start your product with a cold engine, pull

the starter rope handle until the engine fires.

You can identify when the engine fires

Note:

through a "puff" sound.

b) Disengage the choke.

6. Pull the starter rope handle until the engine starts.

7. Quickly disengage the throttle trigger lockout to set

the product to idle speed.

13

Page 14

8. Move the front hand guard rearward to disengage

the chain brake.

9. Use the product.

To stop the product

• Push the start/stop switch to position 0 to stop the

engine.

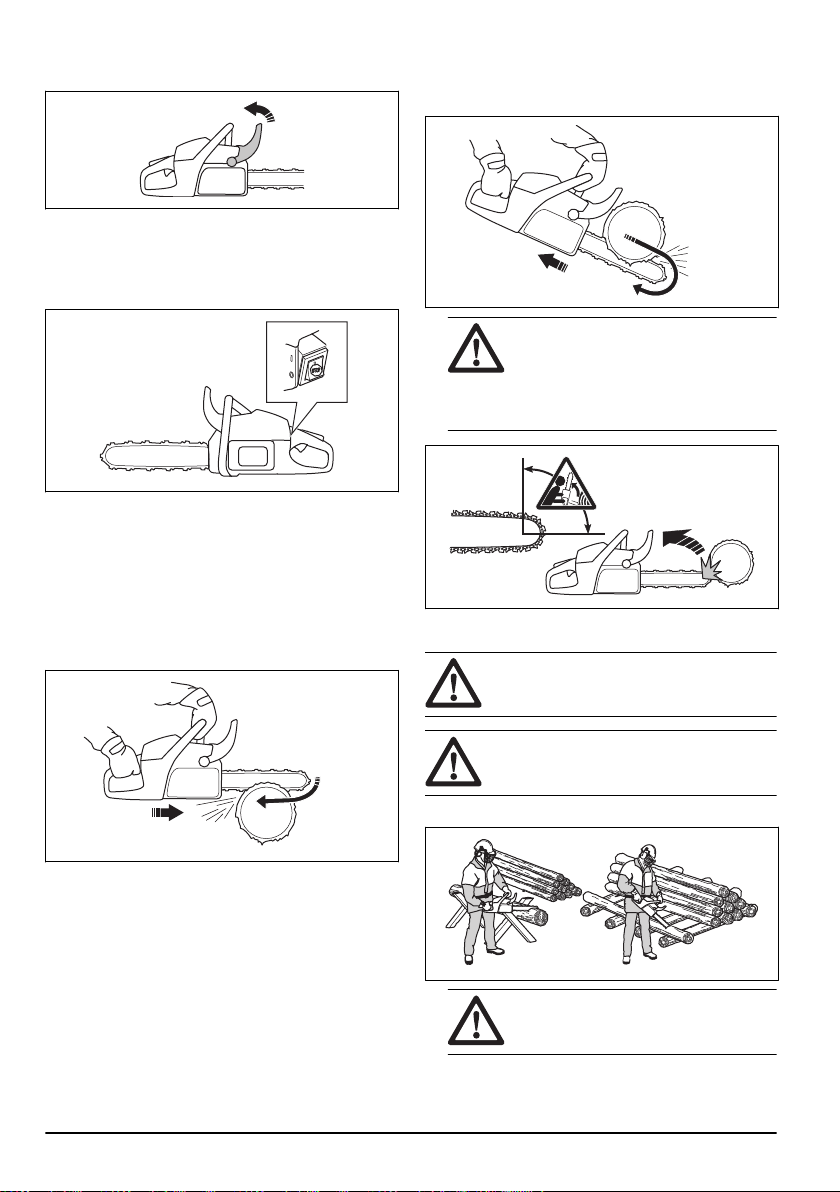

Pull stroke and push stroke

You can cut through wood with the product in 2 different

positions.

• To cut on the pull stroke is when you cut with the

bottom of the guide bar. The saw chain pulls through

the tree when you cut. In this position you have

better control of the product and the position of the

kickback zone.

• To cut on the push stroke is when you cut with the

top of the guide bar. The saw chain pushes the

product in the direction of the operator.

WARNING: If the saw chain is caught in

the trunk, the product can be pushed at

you. Hold the product tightly and make

sure that the kickback zone of the guide

bar does not touch the tree and causes a

kickback.

To use the cutting technique

WARNING: Use full throttle when you cut

and decrease to idle speed after each cut.

CAUTION: Engine damage can occur if the

engine runs for too long at full throttle

without load.

1. Put the trunk on a saw horse or runners.

WARNING: Do not cut trunks in a pile.

That increases the risk of kickback and

can result in serious injury or death.

2. Remove the cut pieces from the cutting area.

14

956 - 003 -

Page 15

WARNING: Cut pieces in the cutting

1.

2.

1.

2.

1.

2.

area increase the risk of kickback and

that you can not keep your balance.

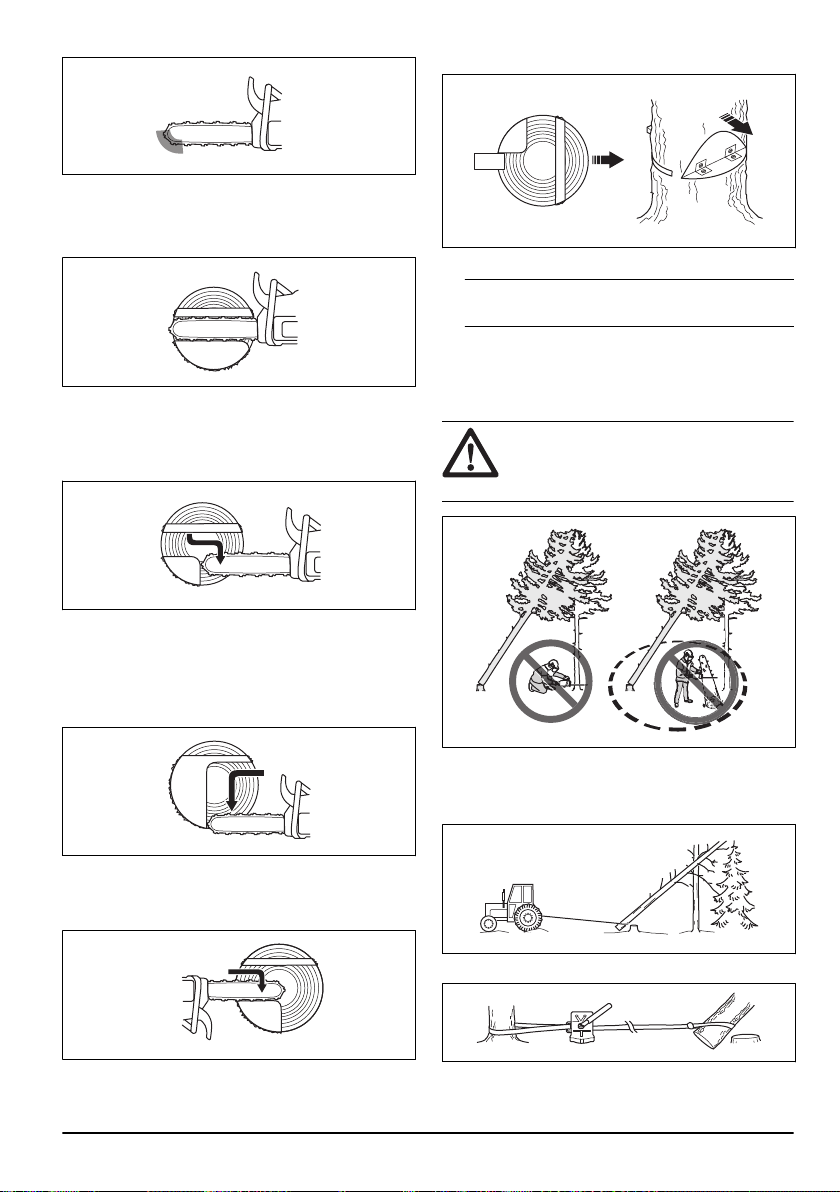

To cut a trunk on the ground

1. Cut through the trunk on the pull stroke. Keep full

throttle but be prepared for sudden accidents.

WARNING: Make sure that the saw

chain does not touch the ground when

you complete the kerf.

2. Cut approximately ⅔ through the trunk and then

stop. Turn the trunk and cut from the opposite side.

To cut a trunk that has support on one end

WARNING:

not break during cutting. Obey the

instructions below.

Make sure that the trunk does

To cut a trunk that has support on two ends

WARNING: Make sure that the saw chain

does not get caught in the trunk during

cutting. Obey the instructions below.

1. Cut on the pull stroke approximately ⅓ through the

trunk.

2. Cut through the remaining part of the trunk on the

push stroke to complete the cut.

WARNING: Stop the engine if the saw chain

gets caught in the trunk. Use a lever to open

up the kerf and remove the product. Do not

try to pull the product out by hand. This can

result in injury when the product suddenly

breaks free.

To use the limbing technique

For thick branches, use the cutting technique.

Note:

Refer to

To use the cutting technique on page 14

.

WARNING: There is a high accident risk

when you use the limbing technique. Refer

to

Kickback information on page 11

instructions how to prevent kickback.

1. Cut on the push stroke approximately ⅓ through the

trunk.

2. Cut through the trunk on the pull stroke until the two

kerfs touch.

956 - 003 - 15

WARNING: Cut limbs one by one. Be careful

when you remove small limbs and do not cut

bushes or many small limbs at the same

time. Small limbs can get caught in the saw

chain and prevent safe operation of the

product.

for

Page 16

Note: Cut the limbs piece by piece if it is necessary.

1

2

3

1. Remove the limbs on the right side of the trunk.

a) Keep the guide bar on the right side of the trunk

and keep the body of the product against the

trunk.

b) Select the applicable cutting technique for the

tension in the branch.

b) Cut on the push stroke.

3. Remove the limbs on the left side of the trunk.

a) Select the applicable cutting technique for the

tension in the branch.

WARNING: If you are not sure about

how to cut the branch, speak to a

professional chainsaw operator

before you continue.

2. Remove the limbs on the top of the trunk.

a) Keep the product on the trunk and let the guide

bar move along the trunk.

Refer to

To cut trees and branches that are in tension on

page 20

for instructions on how to cut branches that

are in tension.

WARNING: If you are not sure about

how to cut the branch, speak to a

professional chainsaw operator

before you continue.

To use the tree felling technique

WARNING:

fell a tree. If possible, engage in a training

course in chainsaw operation. Speak to an

operator with experience for more

knowledge.

16 956 - 003 -

You must have experience to

Page 17

To keep a safe distance

1. Make sure that persons around you keep a safe

distance at a minimum of 2 1/2 tree lengths.

2. Make sure that no person is in the risk zone before

or during felling.

To calculate the felling direction

1. Examine in which direction it is necessary for the

tree to fall. The goal is to fell it in a position where

you can limb and cut the trunk easily. It is also

important that you are stable on your feet and can

move about safely.

WARNING:

possible to fell the tree in its natural

direction, fell the tree in a different

direction.

2. Examine the natural fall direction of the tree. For

example the tilt and bend of the tree, wind direction,

the location of the branches and weight of snow.

3. Examine if there are obstacles, for example other

trees, power lines, roads and/or buildings around.

4. Look for signs of damage and rot in the stem.

WARNING: Rot in the stem can mean a

risk that the tree falls before you

complete the cutting.

5. Make sure the tree has no damaged or dead

branches that can break off and hit you during

felling.

If it is dangerous or not

6. Do not let the tree fall onto a different standing tree.

It is dangerous to remove a caught tree and there is

a high accident risk. Refer to

on page 19

.

WARNING: During critical felling

operations, lift your hearing protection

immediately when the sawing is

complete. It is important that you hear

sounds and warning signals.

To free a trapped tree

To clear the trunk and prepare your path of retreat

Cut off all branches from your shoulder height and

down.

1. Cut on the pull stroke from the top down. Make sure

that the tree is between you and the product.

2. Remove undergrowth from the work area around the

tree. Remove all cut off material from the work area.

3. Do a check of the area for obstacles such as stones,

branches and holes. You must have a clear path of

retreat when the tree starts to fall. Your path of

retreat must be approximately 135 degrees away

from the felling direction.

1. The danger zone

2. The path of retreat

3. The felling direction

956 - 003 -

17

Page 18

1

2

2

1

3

To make the directional cuts

45º-70º

2

1

1. Make the directional cuts ¼ of the diameter of the

tree. Make a 45°-70° angle between the top

directional cut and bottom directional cut.

To fell a tree

Husqvarna recommends you to make the directional

cuts and then use the safe corner method when you fell

a tree. The safe corner method helps you to make a

correct felling hinge and control the felling direction.

WARNING: Do not fell trees with a diameter

that is more than two times larger than the

guide bar length. For this, you must have

special training.

The felling hinge

The most important procedure during tree felling is to

make the correct felling hinge. With a correct felling

hinge, you control the felling direction and make sure

that the felling procedure is safe.

The thickness of the felling hinge must be equal and a

minimum of 10% of the tree diameter.

WARNING: If the felling hinge is incorrect or

too thin, you have no control of the felling

direction.

a) Make the top directional cut. Align the felling

direction mark (1) of the product with the felling

direction of the tree (2). Stay behind the product

and keep the tree on your left side. Cut with a

pull stroke.

b) Make the bottom directional cut. Make sure that

the end of the bottom directional cut is at the

same point as the end of the top directional cut.

2. Make sure that the bottom directional cut is

horizontal and at a 90° angle to the felling direction.

To use the safe corner method

The felling cut must be made slightly above the

directional cut.

WARNING:

guide bar tip. Start to cut with the lower

section of the guide bar tip as you make a

bore cut into the trunk.

Be careful when you cut with the

18 956 - 003 -

Page 19

1. If the usable cutting length is longer than the tree

diameter, do these steps (a-d).

a) Make a bore cut straight into the trunk to

complete the felling hinge width.

b) Cut on the pull stroke until ⅓ of the trunk is left.

c) Pull the guide bar 5-10 cm/2-4 in rearward.

d) Cut through the remaining of the trunk to

complete a safe corner that is 5-10 cm/2-4 in

wide.

2. If the usable cutting length is shorter than the tree

diameter, do these steps (a-d).

a) Make a bore cut straight into the trunk. The bore

cut must extend 3/5 of the tree diameter.

b) Cut on the pull stroke through the remaining

trunk.

3. Put a wedge in the kerf straight from behind.

4. Cut off the corner to make the tree fall.

Note: If the tree does not fall, hit the wedge until it

does.

5. When the tree starts to fall, use the path of retreat to

move away from the tree. Move a minimum of 5

m/15 ft away from the tree.

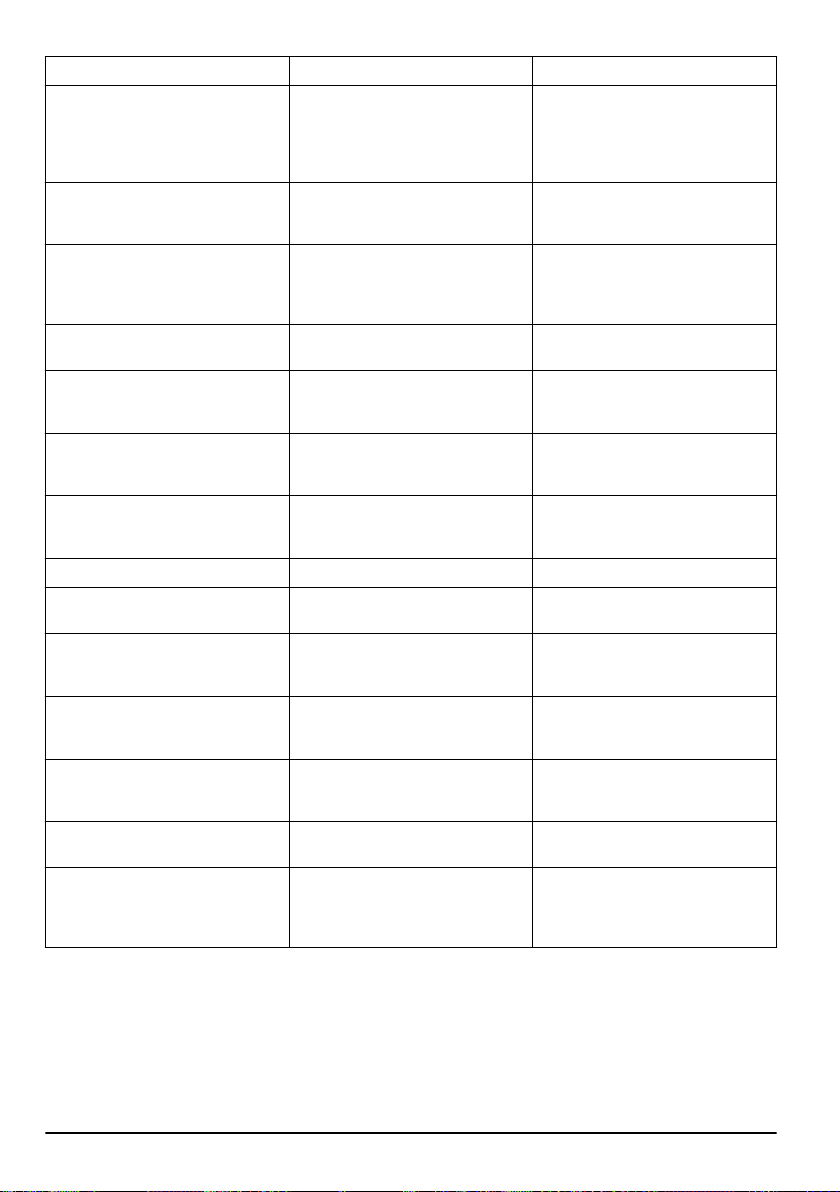

To free a trapped tree

WARNING: It is very dangerous to remove a

trapped tree and there is a high accident

risk. Keep out of the risk zone and do not try

to fell a trapped tree.

c) Cut straight into the trunk from the other side of

the tree to complete the felling hinge.

d) Cut on the push stroke, until ⅓ of the trunk is left,

to complete the safe corner.

956 - 003 -

The safest procedure is to use one of the following

winches:

• Tractor-mounted

• Portable

19

Page 20

To cut trees and branches that are in tension

1

2

1. Figure out which side of the tree or branch that is in

tension.

2. Figure out where the point of maximum tension is.

3. Examine which is the safest procedure to release the

tension.

Note: In some situations the only safe procedure is

to use a winch and not your product.

4. Keep a position where the tree or branch can not hit

you when the tension is released.

5. Make one or more cuts of sufficient depth necessary

to decrease the tension. Cut at or near the point of

maximum tension. Make the tree or branch break at

the point of maximum tension.

7. Continue to cut more into the tree until the tree/

branch bends and the tension is released.

8. Cut the tree/branch from the opposite side of the

bend, after the tension is released.

To use the product in cold weather

CAUTION: Snow and cold weather can

cause operation problems. Risk of too low

engine temperature or ice on the air filter

and the carburetor.

1. In temperatures below 0°C/32°F, move the plug from

position 1 to position 2.

WARNING: Do not cut straight through a

tree or branch that is in tension.

WARNING: Be very careful when you

cut a tree that is in tension. There is a

risk that the tree moves quickly before or

after you cut it. Serious injury can occur

if you are in an incorrect position or if

you cut incorrectly.

6. If you must cut across tree/branch, make 2 to 3 cuts,

1 in. apart and with a depth of 2 in.

20 956 - 003 -

Page 21

2. For temperatures below -5°C/23°F or in conditions

with snow, a winter cover is available. Assemble the

winter cover on the starter housing. The winter cover

decreases the flow of cool air and keeps snow away

from the carburetor space.

CAUTION: Remove the winter cover if the

temperature increases above -5°C/23°F. Put

Maintenance

Introduction

the winter plug in in position 1 if the

temperature increases above 0°C/32°F. Risk

of too high engine temperature and damage

to the engine.

Heated handles (543 XPG)

On models with the designation "G", the front and rear

handles have electrical heating coils. A generator

supplies power to the heating coils.

Push the switch to engage the heat in the handles. The

heat is on when you can see the red mark on the switch.

Electrical carburetor heating (543 XPG)

Adjustment of the carburetor heating is done electrically

through a thermostat. This keeps the correct carburetor

temperature and prevents ice in the carburetor.

WARNING: Read and understand the safety

chapter before you do maintenance on the

product.

Maintenance schedule

Daily maintenance Weekly maintenance Monthly maintenance

Clean the external parts of the product and make sure that there is no oil

on the handles.

Do a check of the throttle trigger and

throttle trigger lockout. Refer to

a check of the throttle trigger and

throttle trigger lockout on page 23

Make sure that there is no damage

on the vibration damping units.

956 - 003 - 21

Clean the cooling system. Refer to

To clean the cooling system on page

32

.

Do a check of the starter, starter rope

To do

and return spring.

.

Lubricate the needle bearing. Refer

to

To lubricate the needle bearing on

page 30

.

Do a check of the brake band. Refer

to

To do a check of the brake band

on page 23

Do a check of the clutch centre,

clutch drum and clutch spring.

Clean the spark plug. Refer to

.

To do

a check of the spark plug on page

27

.

Page 22

Daily maintenance Weekly maintenance Monthly maintenance

Clean and do a check of the chain

brake. Refer to

To do a check of the

chain brake on page 23To do a

Remove burrs from the edges of the

guide bar. Refer to

the guide bar on page 31

To do a check of

.

Clean the external parts of the carburettor.

check of the front hand guard and the

chain brake activation on page 23

Do a check of the chain catcher. Refer to

To do a check of the chain

catcher on page 24

Turn the guide bar, do a check of the

lubrication hole and clean the groove

in the guide bar. Refer to

.

check of the guide bar on page 31

Make sure that the guide bar and

saw chain are getting sufficient oil.

Do a check of the saw chain. Refer to

To do a

.

Clean or replace the spark arrestor

mesh on the muffler.

Clean the carburetor area. Do a check of all cables and connec-

.

Clean or replace the air filter. Refer

to

To clean the air filter on page 27

Clean between the cylinder fins. Empty the oil tank.

Do a check of the fuel filter and the

fuel hose. Replace if necessary.

tions.

Empty the fuel tank.

.

To examine the cutting equipment on

page 31

.

Sharpen the saw chain and do a

check of its tension. Refer to

sharpen the saw chain on page 27

Do a check of the chain drive sprocket. Refer to

To do a check of the rim

sprocket on page 30

Clean the air intake on the starter.

Make sure that nuts and screws are

tightened.

Do a check of the stop switch. Refer

to

To do a check of the start/stop

switch on page 24

Make sure that these are no fuel

leaks from the engine, tank or fuel

lines.

Make sure that the saw chain does

not rotate when the engine is at idle

speed.

Make sure that there is no damage

on the right hand guard.

Make sure that the muffler is correctly attached, has no damages and

that no parts of the muffler are missing.

.

To

.

.

22 956 - 003 -

Page 23

Maintenance and checks of the safety devices on the product

To do a check of the brake band

1. Use a brush to remove wood dust, resin and dirt

from the chain brake and clutch drum. Dirt and wear

can decrease the function of the brake.

2. Do a check of the brake band. The brake band must

be at a minimum of 0.6 mm/0.024 in thick at its

thinnest point.

To do a check of the front hand guard and the chain brake activation

1. Make sure that the front hand guard is not damaged

and that there are no defects, such as cracks.

2. Make sure that the front hand guard moves freely

and that it is attached safely to the clutch cover.

To do a check of the chain brake

1. Start the product. Refer to

page 12

for instructions.

WARNING: Make sure that the saw

chain does not touch the ground or other

objects.

2. Hold the product tightly.

3. Apply full throttle and tilt your left wrist against the

front hand guard to engage the chain brake. The

saw chain must stop immediately.

WARNING: Do not let go of the front handle.

To start the product on

To do a check of the throttle trigger and throttle trigger lockout

1. Make sure that the throttle trigger and throttle trigger

lockout move freely and that the return spring works

correctly.

3. Hold the product with 2 hands above a stump or

other stable surface.

WARNING: The engine must be off.

4. Let go of the front handle and let the guide bar tip fall

against the stump.

5. Make sure that the chain brake engages as the

guide bar tip hits the stump.

956 - 003 -

2. Press down the throttle trigger lockout and make

sure that it goes back to its initial position when you

release it.

3. Make sure that the throttle trigger is locked at the

idle position when the throttle trigger lockout is

released.

23

Page 24

4. Start the product and apply full throttle.

5. Release the throttle trigger and make sure that the

saw chain stops and stays stationary.

WARNING: If the saw chain rotates

when the throttle trigger is in the idle

position, speak to your servicing dealer.

To do a check of the chain catcher

1. Make sure that there is no damage on the chain

catcher.

2. Make sure that the chain catcher is stable and

attached to the body of the product.

To do a check of the right hand guard

• Make sure that the right hand guard is not damaged

and that there are no defects, such as cracks.

2. Push the start/stop switch to the STOP position. The

engine must stop.

To do a check of the muffler

WARNING: Do not use a product that has a

defective muffler or a muffler that is in bad

condition.

WARNING: Do not use a product if the spark

arrestor mesh on the muffler is missing or

defective.

1. Examine the muffler for damages and defects.

2. Make sure that the muffler is correctly attached to

the product.

To do a check of the vibration damping system

1. Make sure that there are no cracks or deformation

on the vibration damping units.

2. Make sure that the vibration damping units are

correctly attached to the engine unit and handle unit.

Refer to

Product overview on page 2

about where the vibration damping system is on your

product.

for information

To do a check of the start/stop switch

1. Start the engine.

24

3. If your product has a special spark arrestor mesh,

clean the spark arrestor mesh weekly.

4. Replace a damaged spark arrestor mesh.

956 - 003 -

Page 25

Carburetor with adjustment limitations

1/2

1/2

H

L

Note: If you do not know which carburetor type that you

have on your product, speak to your servicing dealer.

Carburetor adjustment

Because of environmental and emissions laws, your

product has adjustment limitations on the carburetor

adjuster screws. This decreases the harmful exhaust

fumes from your product. You can only turn the

adjustment screws maximum ½ turn.

Basic adjustments and run-in

The basic carburetor adjustments are done at the

factory. For the recommended idle speed, refer to

Technical data on page 34

CAUTION: Do not operate the product at too

high speed during the first 10 hours of

operation.

.

must also be safely below the speed at which the saw

chain starts to rotate.

WARNING: If the saw chain does not stop

when you turn the idle speed screw, speak

to your servicing dealer. Do not use the

product until it is correctly adjusted.

To adjust the high speed needle (H)

The engine is adjusted at the factory to operate at sea

level. At higher altitudes, in different weather or different

temperatures it can be necessary to adjust the high

speed needle.

• Turn the high speed needle to make adjustments.

CAUTION: Do not turn the high speed

needle screw across the adjustment

limitation stop. This can cause damage

to the piston and the cylinder.

To examine if the carburetor is correctly adjusted

• Make sure that the product has the correct

acceleration capacity.

• Make sure that the product 4-cycles a little at full

throttle.

• Make sure that the saw chain does not rotate at idle

speed.

• If the product is not easy to start or has less

acceleration capacity, adjust the low and high speed

needles.

CAUTION: If the saw chain rotates at idle

speed, turn the idle speed screw

counterclockwise until the saw chain stops.

To adjust the low speed needle (L)

• Turn the low speed needle clockwise until stop.

If the product has a bad acceleration capacity

Note:

or if the idle speed is not correct, turn the low speed

needle counterclockwise. Turn the low speed needle

until the acceleration capacity and idle speed is

correct.

To adjust the idle speed screw (T)

1. Start the product.

2. Turn the idle speed screw clockwise until the saw

chain starts to rotate.

3. Turn the idle speed screw counterclockwise until the

saw chain stops.

The idle speed is correctly adjusted when the

Note:

engine runs correctly in all positions. The idle speed

956 - 003 -

CAUTION:

cause damage to the engine.

Incorrect adjustments can

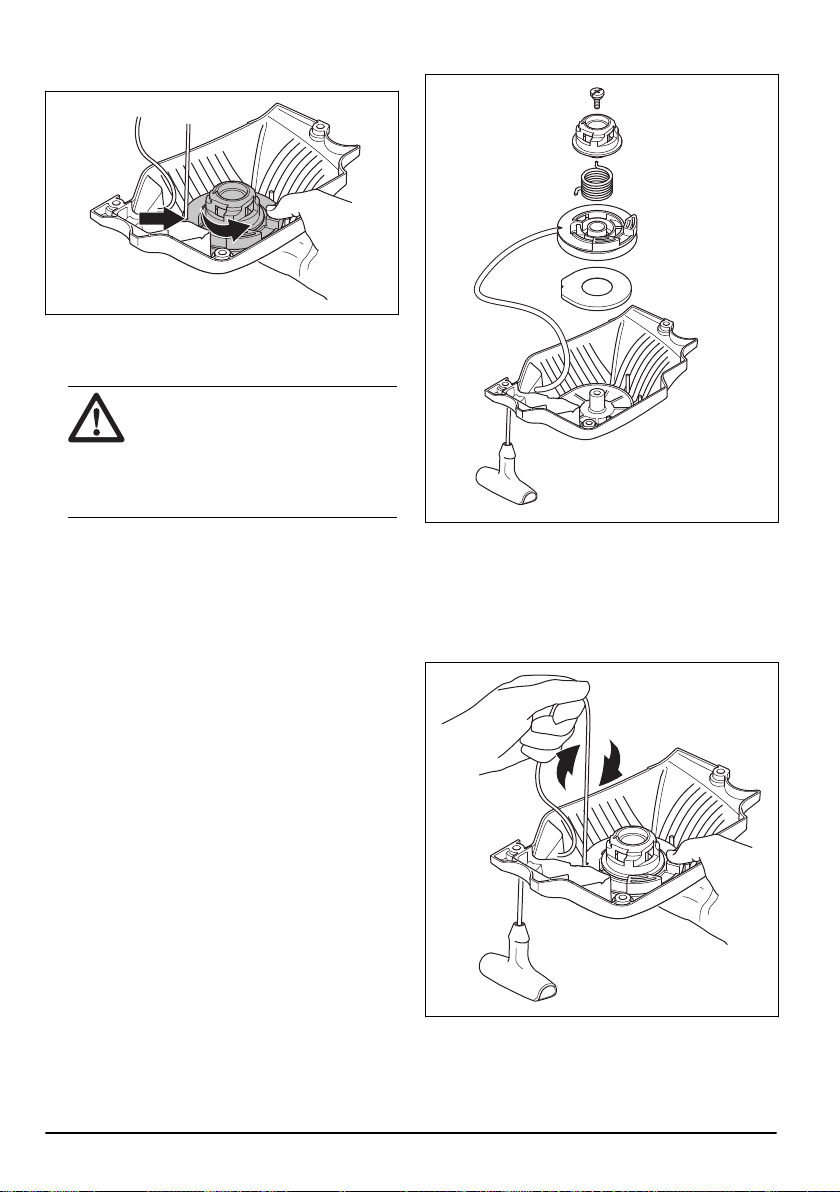

To replace a broken or worn starter rope

1. Loosen the screws to the starter housing.

2. Remove the starter housing.

25

Page 26

3. Pull out the starter rope approximately 30 cm/12 in

and put it in the notch on the pulley.

4. Let the pulley rotate slowly rearward to release the

recoil spring.

5. Remove the center screw and remove the pulley.

WARNING: You must be careful when

you replace the return spring or the

starter rope. The recoil spring is in

tension when it is wound up in the starter

housing. If you are not careful, it can

eject and cause injuries. Use protective

glasses and protective gloves.

6. Remove the used starter rope from the handle and

the pulley.

7. Attach a new starter rope to the pulley. Wind the

starter rope approximately 3 turns around the pulley.

8. Pull the starter rope through the hole in the starter

housing and the starter rope handle.

9. Attach the center screw in the center of the pulley.

10. Make a tight knot at the end of the starter rope.

To tighten the recoil spring

1. Put the starter rope into the notch in the pulley.

2. Turn the starter pulley approximately 2 turns

clockwise.

3. Make sure that you can turn the pulley ½ turn after

the starter rope is fully extended.

26

956 - 003 -

Page 27

To assemble the starter housing on the product

1. Pull out the starter rope and put the starter in

position against the crankcase.

2. Slowly release the starter rope until the pulley

engages with the pawls.

3. Tighten the screws that hold the starter.

To clean the air filter

Clean the air filter regularly from dirt and dust. This

prevents carburetor malfunctions, starting problems,

loss of engine power, wear to engine parts and more

fuel consumption than usual.

1. Remove the cylinder cover and the air filter.

2. Use a brush or shake the air filter clean. Use

detergent and water to clean it fully.

Note: An air filter that is used for a long time can not

be fully cleaned. Replace the air filter regularly and

always replace a defective air filter.

3. Attach the air filter and make sure that the air filter

seals tightly against the filter holder.

To do a check of the spark plug

CAUTION: Use the recommended spark

plug. Refer to

An incorrect spark plug can cause damage

to the product.

1. If the product is not easy to start or to operate or if

the product operates incorrectly at idle speed,

examine the spark plug for unwanted materials. To

decrease the risk of unwanted material on the spark

plug electrodes, do these steps:

a) make sure that the idle speed is correctly

adjusted.

b) make sure that the fuel mixture is correct.

c) make sure that the air filter is clean.

2. Clean the spark plug if it is dirty.

3. Make sure that the electrode gap is correct. Refer to,

Technical data on page 34

4. Replace the spark plug monthly or more frequently if

necessary.

Technical data on page 34

.

.

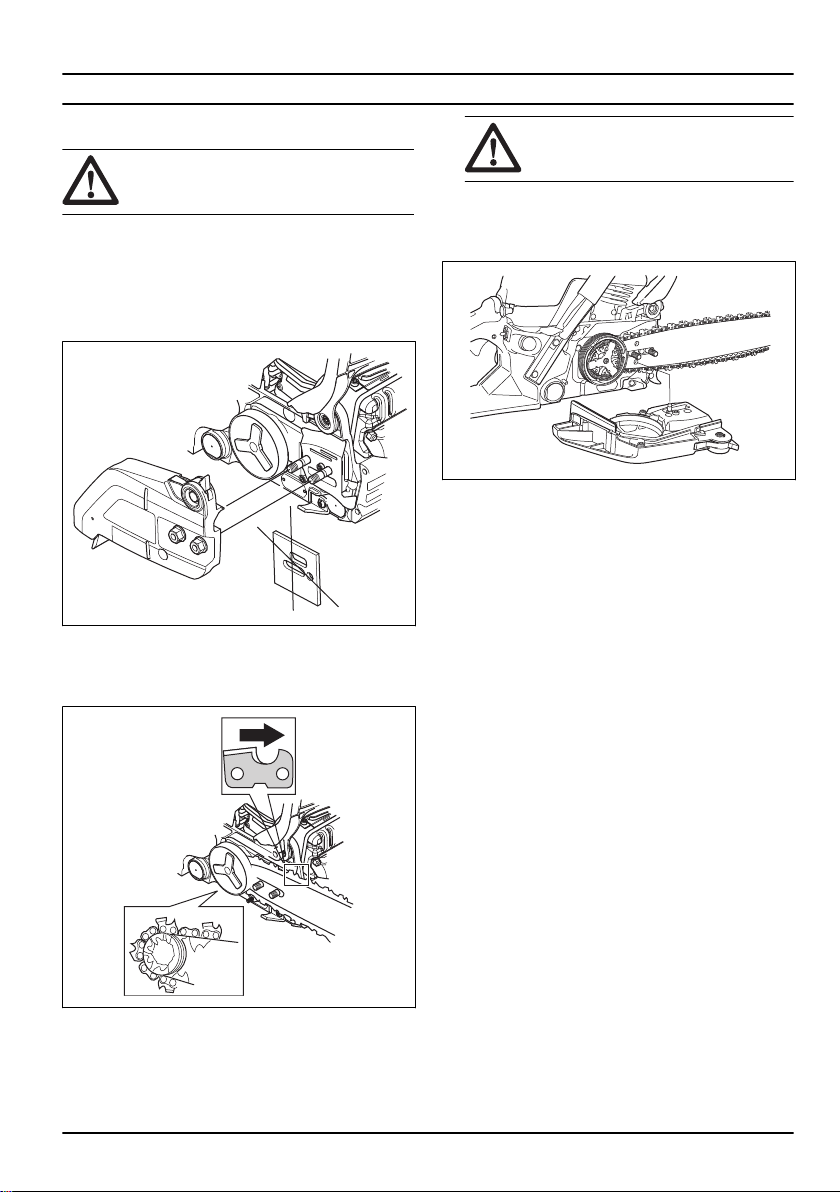

To sharpen the saw chain

Information about the guide bar and saw chain

WARNING:

use or do maintenance on the saw chain. A

saw chain that does not move can also

cause injuries.

Use protective gloves when you

Because of different work conditions, weather or

Note:

season, your product can be used with different types of

air filter. Speak to your servicing dealer for more

information.

956 - 003 -

Replace a worn or damaged guide bar or saw chain with

the guide bar and saw chain combination recommended

by Husqvarna. This is necessary to keep the safety

functions of the product. Refer to

35

, for a list of replacement bar and chain

combinations that we recommend.

• Guide bar length, in/cm. Information about the guide

bar length can usually be found on the rear end of

the guide bar.

Accessories on page

27

Page 28

• Number of teeth on bar tip sprocket (T).

PITCH =

D

D

2

A

B

• Chain pitch, in. The distance between the drive links

of the saw chain must align with the distance of the

teeth on the bar tip sprocket and drive sprocket.

• Number of drive links. The number of drive links is

decided by the type of guide bar.

• Drive link width, mm/in.

General information about how to sharpen the cutters

Do not use a blunt saw chain. If the saw chain is blunt,

you must apply more pressure to push the guide bar

through the wood. If the saw chain is very blunt, there

will be no wood chips but sawdust.

A sharp saw chain eats through the wood and the wood

chips becomes long and thick.

The cutting tooth (A) and the depth gauge (B) together

makes the cutting part of the saw chain, the cutter. The

difference in height between the two gives the cutting

depth (depth gauge setting).

• Bar groove width, in/mm. The groove width in guide

bar must be the same as the chain drive links width.

• Chain oil hole and hole for chain tensioner. The

guide bar must align with product.

28

When you sharpen the cutter, think about the following:

• Filing angle.

• Cutting angle.

• File position.

956 - 003 -

Page 29

• Round file diameter.

A

B

C

It is not easy to sharpen a saw chain correctly without

the correct equipment. Use Husqvarna file gauge. This

will help you to keep maximum cutting performance and

the kickback risk at a minimum.

WARNING: The force of the kickback

increases a lot if you do not follow the

sharpening instructions.

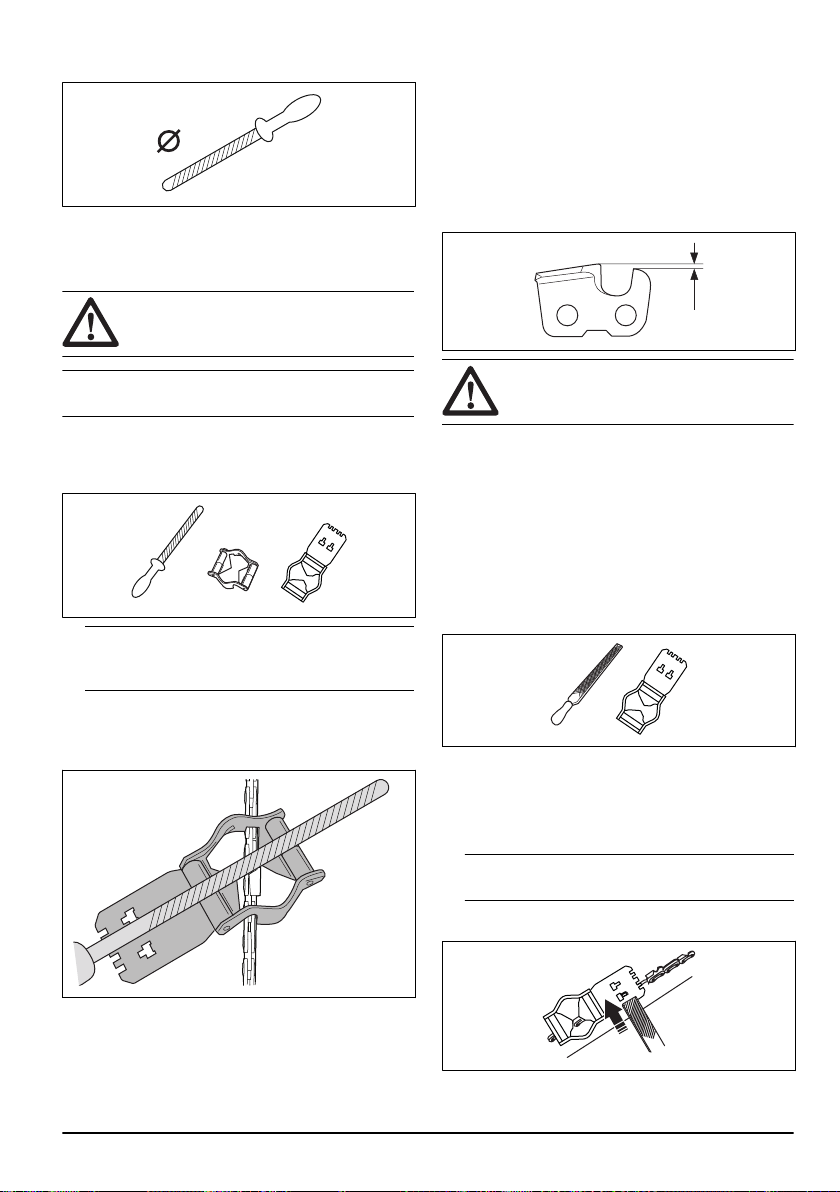

General information about how to adjust the depth gauge setting

The depth gauge setting (C) decreases when you

sharpen the cutting tooth (A). To keep maximum cutting

performance you must remove filing material from the

depth gauge (B) to receive the recommended depth

gauge setting. See

instructions about how to receive the correct depth

gauge setting for your saw chain.

Accessories on page 35

for

Note: Refer to

information about sharpening of the saw chain.

To sharpen the saw chain on page 27

for

To sharpen the cutters

1. Use a round file and a file gauge to sharpen the

cutting teeth.

Note: Refer to

information about which file and gauge that

Husqvarna recommends for your saw chain.

2. Apply the file gauge correctly on to the cutter. Refer

to the instruction supplied with the file gauge.

3. Move the file from the inner side of the cutting teeth

and out. Decrease the pressure on the pull stroke.

Accessories on page 35

for

WARNING: The risk of kickback increases if

the depth gauge setting is too large!

To adjust the depth gauge setting

Before you adjust the depth gauge setting or sharpen

the cutters, refer to

adjust the depth gauge setting on page 29

instructions. We recommend you to adjust the depth

gauge setting after each third operation that you

sharpen the cutting teeth.

We recommend that you use our depth gauge tool to

receive the correct depth gauge setting and bevel for the

depth gauge.

1. Use a flat file and a depth gauge tool to adjust the

depth gauge setting. Only use Husqvarna depth

gauge tool to get the correct depth gauge setting and

bevel for the depth gauge.

2. Put the depth gauge tool on the saw chain.

See the package of the depth gauge tool for

Note:

more information about how to use the tool.

3. Use the flat file to remove the part of the depth

gauge that extends through the depth gauge tool.

General information about how to

, for

4. Remove material from one side of all the cutting

teeth.

5. Turn the product around and remove material on the

other side.

6. Make sure that all cutting teeth are the same length.

956 - 003 -

29

Page 30

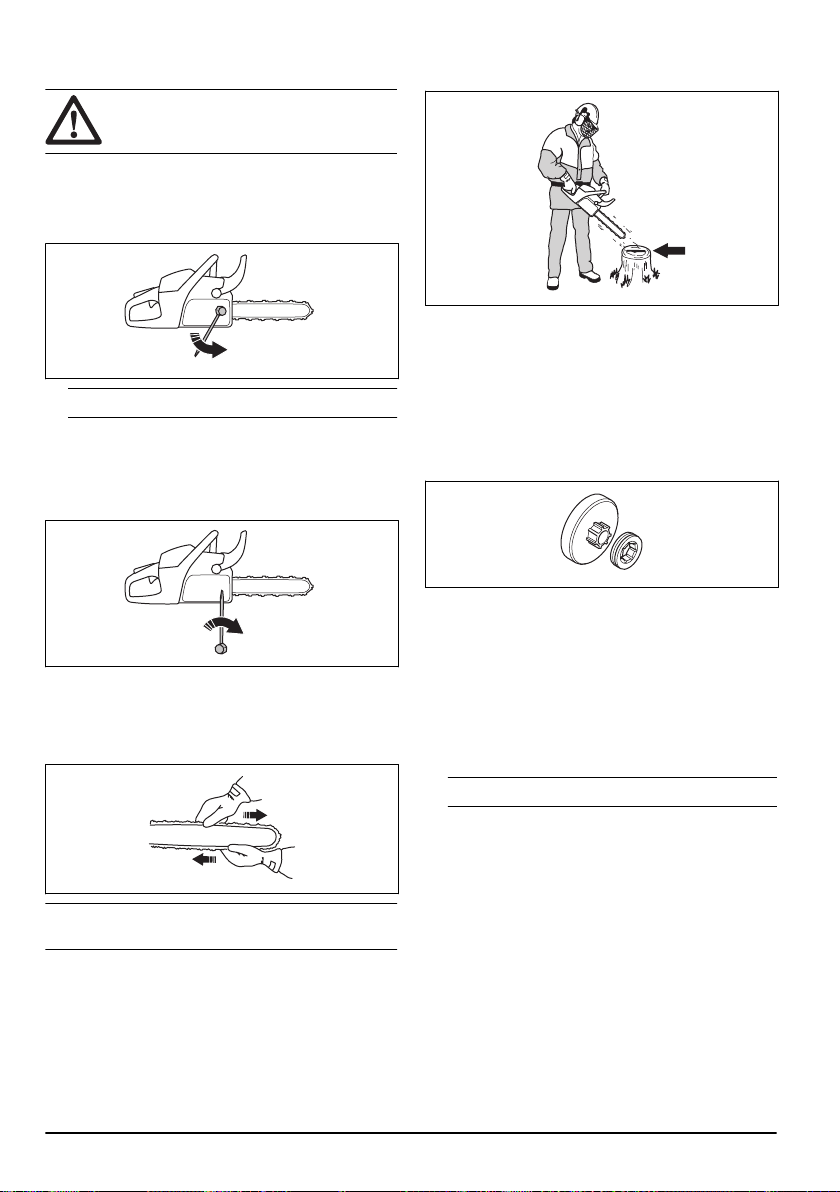

To adjust the tension of the saw chain

WARNING: A saw chain with an incorrect

tension can come loose from the guide bar

and cause serious injury or death.

A saw chain becomes longer when you use it. Adjust the

saw chain regularly.

1. Loosen the bar nuts that hold the clutch cover/chain

brake. Use a wrench.

Note: Some models have only one bar nut.

2. Tighten the bar nuts by hand as tightly as you can.

3. Lift the front of the guide bar and turn the chain

tensioning screw. Use a wrench.

4. Tighten the saw chain until it is tight against the

guide bar but still can move easily.

5. Tighten the bar nuts using the wrench and lift the

front of the guide bar at the same time.

6. Make sure you can pull the saw chain around freely

by hand and that it does not hang from the guide

bar.

2. If the saw chain lubrication is correct, you see a clear

line of oil on the surface after 1 minute.

3. If the saw chain lubrication does not operate

correctly, do a check of the guide bar. Refer to

a check of the guide bar on page 31

instructions. Speak to your servicing dealer if the

maintenance steps does not help.

for

To do

To do a check of the rim sprocket

The clutch drum has a rim sprocket that can be

replaced.

1. Make sure that the rim sprocket is not worn. Replace

if necessary.

2. Replace the rim sprocket each time you replace the

saw chain.

To lubricate the needle bearing

1. Pull the front hand guard rearward to disengage the

chain brake.

2. Loosen the bar nuts and remove the clutch cover.

Some models have only one bar nut.

Note:

3. Put the product on a stable surface with the clutch

drum up.

Refer to

Note:

position of the chain tensioning screw on your product.

Product overview on page 2

for the

To do a check of the saw chain lubrication

1. Start the product and let it operate at ¾ throttle. Hold

the bar approximately 20 cm/8 in above a surface of

light color.

30

956 - 003 -

Page 31

4. Lubricate the needle bearing with a grease gun. Use

engine oil or a bearing grease of high quality.

To examine the cutting equipment

1. Make sure that there are no cracks in rivets and links

and that no rivets are loose. Replace if it is

necessary.

To do a check of the guide bar

1. Make sure that the oil channel is not blocked. Clean

if it is necessary.

2. Examine if there are burrs on the edges of the guide

bar. Remove the burrs using a file.

3. Clean the groove in the guide bar.

4. Examine the groove in the guide bar for wear.

Replace the guide bar if it is necessary.

2. Make sure that the saw chain is easy to bend.

Replace the saw chain if it is rigid.

3. Compare the saw chain with a new saw chain to

examine if the rivets and links are worn.

4. Replace the saw chain when the longest part of the

cutting tooth is less than 4 mm/0.16 in. Also replace

the saw chain if there are cracks on the cutters.

956 - 003 -

5. Examine if the guide bar tip is rough or very worn.

6. Make sure that the bar tip sprocket turns freely and

that the lubricating hole in the bar tip sprocket is not

blocked. Clean and lubricate if it is necessary.

31

Page 32

7. Turn the guide bar daily to extend its life cycle.

To do maintenance on the fuel tank and the chain oil tank

• Drain and clean the fuel tank and the chain oil tank

regularly.

• Replace the fuel filter yearly or more frequently if

necessary.

the air filter. AirInjection

and the engine.

™

extends the life of the air filter

CAUTION: Contamination in the tanks

causes malfunction.

To adjust the chain oil flow

WARNING: Stop the engine before you

make adjustments to the oil pump.

• Turn the adjustment screw of the oil pump. Use a

screwdriver or combination wrench.

a) Turn the adjustment screw clockwise to decrease

the chain oil flow.

b) Turn the adjustment screw counterclockwise to

increase the chain oil flow.

Recommended settings for the oil pump

• Guide bar length 33-38 cm/13-15 in: Minimum flow

• Guide bar length 38-41 cm/15-16 in: Medium flow

• Guide bar length -46 cm/-18 in: Maximum flow

Air cleaning system

AirInjection™ is a centrifugal air cleaning system that

removes dust and dirt before the particles are caught by

To clean the cooling system

The cooling system keeps the engine temperature

down. The cooling system includes the air intake on the

starter and the air guide plate, the pawls on the flywheel,

the cooling fins on the cylinder, the cooling channel and

the cylinder cover.

1. Clean the cooling system with a brush weekly or

more frequently if it is necessary.

2. Make sure that the cooling system is not dirty or

blocked.

CAUTION: A dirty or blocked cooling

system can make the product too hot,

which can cause damage to the product.

32 956 - 003 -

Page 33

Troubleshooting

The engine does not start

Product part to examine Possible cause Action

Starter pawls The starter pawls are blocked. Adjust or replace the starter pawls.

Clean around the pawls.

Speak to an approved service workshop.

Fuel tank Incorrect fuel type. Drain the fuel tank and fill with cor-

The fuel tank is filled with chain oil. If you have tried to start the product,

Ignition, no spark The spark plug is dirty or wet. Make sure that the spark plug is dry

The electrode gap is incorrect. Clean the spark plug. Make sure that

Spark plug and cylinder The spark plug is loose. Tighten the spark plug.

Engine is flooded because of repeated starts with full choke after ignition.

rect fuel.

speak to your servicing dealer. If you

have not tried to start the product,

drain the fuel tank.

and clean.

the electrode gap and spark plug is

correct, and that the correct spark

plug type is the recommended or

equivalent.

Refer to

Technical data on page 34

for the correct electrode gap.

Remove and clean the spark plug.

Put the product on its side with the

spark plug hole away from you. Pull

the starter rope handle 6-8 times. Assemble the spark plug and start the

product. Refer to

on page 12

To start the product

.

The engine starts but stops again

Product part to examine

Fuel tank Incorrect fuel type. Drain the fuel tank and fill with cor-

Carburetor The idle speed is not correct. Speak to your servicing dealer.

Air filter Clogged air filter. Clean or replace the air filter.

Fuel filter Clogged fuel filter. Replace the fuel filter.

956 - 003 - 33

Possible cause Action

rect fuel.

Page 34

Transportation and storage

Transportation and storage

• For storage and transportation of the product and

fuel, make sure that there are no leaks or fumes.

Sparks or open flames, for example from electrical

devices or boilers, can start a fire.

• Always use approved containers for storage and

transportation of fuel.

• Empty the fuel and chain oil tanks before

transportation or before long-term storage. Discard

the fuel and chain oil at an applicable disposal

location.

• Use the transportation guard on the product to

prevent injuries or damage to the product. A saw

chain that does not move can also cause serious

injuries.

• Remove the spark plug cap from the spark plug and

engage the chain brake.

• Attach the product safely during transportation.

To prepare your product for long-term storage

1. Disassemble and clean the saw chain and the

groove in the guide bar.

CAUTION: If the saw chain and guide

bar are not cleaned, they can become

rigid or blocked.

2. Attach the transportation guard.

3. Clean the product. Refer to

for instructions.

4. Do a complete servicing of the product.

Technical data

Technical data

Husqvarna 543 XP Husqvarna 543 XPG

Engine

Cylinder displacement, cm

Idle speed, rpm 2500-2700 2500-2700

Maximum engine power acc. to ISO

8893, kW/hp @ rpm

Ignition system

Spark plug NGK CMR7H NGK CMR7H

Electrode gap, mm 0.65 0.65

Fuel and lubrication system

Fuel tank capacity, liter/cm

Oil tank capacity, liter/cm

Type of oil pump Adjustable Adjustable

Weight

Weight, kg 4.5 4.7

Noise emissions

Sound power level, measured dB(A) 112 112

1

3

3

3

43.1 43.1

2.2/2.9 @ 9600 2.2/2.9 @ 9600

0.42/420 0.42/420

0.27/270 0.27/270

Maintenance on page 21

1

Always use the recommended spark plug type! Use of the wrong spark plug can damage the piston/cylinder.

34 956 - 003 -

Page 35

Sound power level, guaranteed L

dB(A)

Sound levels

Equivalent sound pressure level at

the operator’s ear, dB(A)

Equivalent vibration levels, a

Front handle, m/s

Rear handle, m/s

Saw chain/guide bar

Type of drive sprocket/number of

teeth

Saw chain speed at 133% of maximum engine power speed, m/s.

2

hveq

2

2

Husqvarna 543 XP Husqvarna 543 XPG

WA

113 113

101 101

3

4.5 4.5

4.2 4.2

Rim/7 Rim/7

24.6 24.6

Accessories

Recommended cutting equipment

Chainsaw models Husqvarna 543 XP, 543 XPG have

been evaluated for safety according to EN ISO

11681-1:2011 (Machinery for forestry - Portable

chainsaw safety requirements and testing) and fulfill the

safety requirements when equipped with the below listed

guide bar and saw chain combinations.

Kickback and guide bar nose radius

For sprocket nose bars the nose radius is specified by

the number of teeth, such as 10T. For solid guide bars

the nose radius is specified by the dimension of the

nose radius. For a given guide bar length, you can use a

guide bar with smaller nose radius than given.

Low kickback saw chain

A saw chain that is designated as Low kickback saw

chain, meets the low kickback requirement specified in

ANSI B175.1-2012.

Guide bar Saw chain

Length, in/cm Pitch, in Gauge, in/mm Max. nose ra-

13/33 0.325 0.050/1.3 10T Husqvarna

15/38 64

16/41 66

18/46 72

2

Equivalent sound pressure level, according to ISO 22868, is calculated as the time-weighted energy total for

different sound pressure levels under various working conditions. Typical statistical dispersion for equivalent

sound pressure level is a standard deviation of 1 dB (A).

3

Equivalent vibration level, according to ISO 22867, is calculated as the time-weighted energy total for vibration

levels under various working conditions. Reported data for equivalent vibration level has a typical statistical

dispersion (standard deviation) of 1 m/s2.

dius

Type Length, drive

links (no.)

56 Yes

H30

Low kickback

956 - 003 - 35

Page 36

Guide bar Saw chain

Length, in/cm Pitch, in Gauge, in/mm Max. nose ra-

dius

13/33 0.325 0.050/1.3 10T Husqvarna

15/38 64

16/41 66

18/46 72

13/33 0.325 0.058/1.5 10T Husqvarna

15/38 64

16/41 66

18/46 72

Type Length, drive

SP33G

H25

links (no.)

Low kickback

56

56 Yes

The usable cutting length is usually 1 in less than the

nominal guide bar length.

Pixel

Pixel is a guide bar and saw chain combination that is

more light weight and designated to offer more energy

efficient use by cutting narrow cuts. Both guide bar and

saw chain need to be Pixel to get these benefits. Pixel

cutting equipment is marked with this symbol.

SP33G 4.8 mm / 3/16 in 586 93 84-01

H30 4.8 mm / 3/16 in 505 69 81-08

H25 4.8 mm / 3/16 in 505 69 81-09

Filing equipment and filing angles

Use a Husqvarna file gauge to sharpen the saw chain. A

Husqvarna file gauge makes sure that you get the

correct filing angles. The part numbers are given in the

table below.