Husqvarna 540200800 User Manual

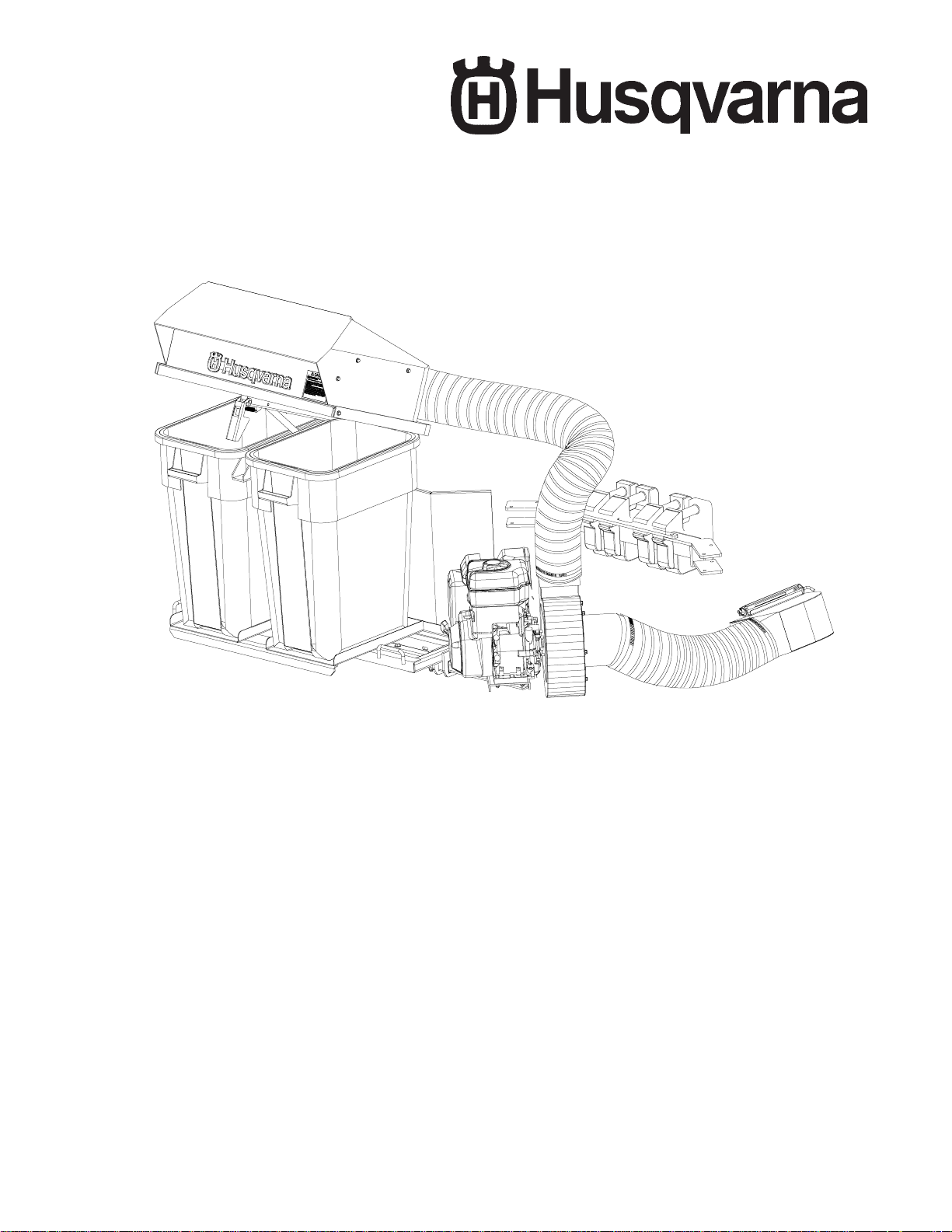

Z2-7 Collection System

Operator’s Manual

Models: 540200800

Parts Manual

Please read these instructions carefully and make

sure you understand them before using the machine.

MANUAL NO. 540200855 REV 3 (04/14/03)

Index

Operators Guide

Specifications ............................................................................................ 3

Features and Controls (Auxiliary Engine) ................................................... 4

Features and Controls (Spindle Drive) ........................................................5

General Information ................................................................................... 6

Safety Procedures..................................................................................... 6

Unpacking Instructions .............................................................................. 8

Assembly Instructions ............................................................................... 8

Servicing the Engine ............................................................................... 13

Pre-Start Check ....................................................................................... 13

Starting the Engine .................................................................................. 13

Operating the V acuum............................................................................. 13

Maintenance and Service Instructions

Cleaning and Washing ............................................................................ 14

Storage .................................................................................................... 14

Preventative Maintenance Schedule........................................................ 14

Engine Service and Maintenance ............................................................ 15

Caring for Vacuum Hoses ....................................................................... 15

Cleaning Exhaust Screen........................................................................ 15

Trouble Shooting Guide ........................................................................... 16

Replacement Parts

Replacement Parts List........................................................................... 17

WARNING: Engine exhaust, some of it’s constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer and birth defects

or other reproductive harm.

©2003 Husqvarna. All rights reserved.

Beatrice, NE. Printed U.S.A.

2

Operators Guide

Specifications

Auxiliary Engine (For Gen I and Gen II Units Only)

Height 42 in. (107 cm.)

Length 31 in. (79 cm.)

Width (without engine mount or vacuum assembly) 39 in. (99 cm.)

Width (with engine mount and vacuum assembly) 63 in. (160 cm.)

Engine Options 5.5 hp Briggs & Stratton Intek

6 hp Kohler

Weight (without vacuum assembly) 107 lb. (49 kg.)

Weight (with 6 hp Kohler vacuum assembly) 172 lb. (78 kg.)

Capacity 8.5 cu ft (7 bu. or 0.24 m

Hose 7 in. (18 cm.) upper and lower

Spindle Drive (For Gen II, iZ and Mini Units Only) (Will Not Fit on 72” Decks)

Height 42 in. (107 cm.)

Length 31 in. (79 cm.)

Width (without hose or blower) 39 in. (99 cm.)

Width (with hose and blower) 65 in. (165 cm.)

Deck Options 42” 52”

48” 61”

Weight (without spindle drive/blower assembly) 95 lb. (43 kg.)

3

)

Weight (with spindle drive/blower assembly) 155 lb. (70 kg.)

Capacity 8.5 cu ft (7 bu. or 0.24 m3)

Hose 7 in. (18 cm.) upper and lower

3

Operators Guide

Features and Controls (Auxiliary Engine)

T op Assembly

Latch

Inlet

Heat

Shield

Upper Hose

Front Weight

Front Weight

Bar

Gas

Spring

Container

Frame

Engine

Mount

Lower

Hose

V acuum

Assembly

4

Boot

Operators Guide

Features and Controls (Spindle Drive)

T op Assembly

Latch

Inlet

Heat

Shield

Hose

Front Weight

Front Weight

Bar

Gas

Spring

Container

Frame

Hose

Support

Fan

Hitch

5

Assembly

Operators Guide

General Information

This manual will assist you in the safe operation and proper maintenance of your Husqvarna

equipment. Read it thoroughly before attempting to operate the machine. Call your dealer or

Husqvarna if additional information is required.

The following safety symbols are used throughout the manual to alert you to information about

unsafe actions or situations:

DANGER indicates immediate hazards that may result in severe injury or death

WARNING indicates unsafe actions or situations that may cause severe injury , death and/or major

equipment or property damage.

CAUTION indicates unsafe actions or situations that may cause injury, and/or minor equipment or

property damage.

This equipment should not be modified without the manufacturer’s prior written authorization. Doing

so may not only affect the equipments’ performance and durability , but also create safety hazards for

the operator and the surroundings. Warranty will be void if changes are made to the equipment

without the manufacturer’s prior written authorization.

Safety Procedures

1 - Training:

• Read the Operator’s manual. If the operator(s) or mechanic(s) can not read English it is the

owner’s responsibility to explain this material to them.

• Become familiar with the safe operation of the equipment, operator’s controls, and safety signs.

• All operators and mechanics should be trained. The owner is responsible for training the users.

• Never let children or untrained people operate or service the equipment. Local regulations may

restrict the age of the operator.

• The owner/user can prevent and is responsible for accidents or injuries occurring to themselves,

other people, or property .

2 - Preparation:

• Wear appropriate clothing including hard hat, safety glasses and ear protection. Long hair , loose

clothing or jewelry may get tangled in moving parts.

• Inspect the area where the equipment is to be used and remove all objects such as rocks, toys and

wire which can be thrown by the machine.

• Use extra care when handling gasoline and other fuels. They are flammable and vapors are

explosive. Use only an approved container . Never remove gas cap or add fuel with engine running.

Allow engine to cool before refueling. Do not smoke. Never refuel or drain the machine indoors.

• Check that operator’s controls, safety switches, hoses, and shields are securely attached and

function properly . Do not operate unless they are functioning properly.

6

Operators Guide

3 - Operation

• Never run an engine in an enclosed area.

• Only operate in good light, keeping away from holes and hidden hazards.

• Slow down and use extra care on hillsides. Make turns gradually and at slow speed. Do not

operate across the sides of slopes. Operate up and down slopes only . Do not operate on steep

slopes.

• Turf conditions can affect the machine’s stability. Do not operate on wet grass where traction may

be reduced.

• Do not change the engine governor setting or overspeed the engine.

• Stop equipment and inspect vacuum impellar and hoses af ter striking objects or if an abnormal

vibration occurs. Make necessary repairs before resuming operations.

• Look behind and down before backing up to be sure of a clear path.

• Slow down and use caution when making turns and crossing roads and sidewalks. Stop vacuum

and mower blades if not mowing.

• Do not operate machine under the influence of alcohol or drugs.

• Use care when loading or unloading the machine into a trailer or truck.

• Use care when approaching blind corners, shrubs, trees. or other objects that may obscure vision.

4 - Maintenance and Storage:

• Stop engine and disconnect spark plug wire. Wait for all movement to stop before adjusting,

cleaning, or repairing.

• Clean grass and debris from muffler and engine to help prevent fires. Clean up oil or fuel spillage.

• Let engine cool before storing and do not store near flame.

• Shut off fuel while storing. Do not store fuel near flames or drain indoors.

• Never allow untrained personnel to service machine.

• Keep hands and feet away from moving parts. If possible, do not make adjustments with the engine

running.

• Keep all parts in good working condition and all hardware tightened. Replace all worn or damaged

decals.

7

Operators Guide

Unpacking Instructions

1. Wear gloves and eye protection.

2. Cut straps around carton and remove top.

3. Take hoses out of carton.

4. Remove wood pieces. NOTE: Watch for nails and wood splinters.

5. Slide carton sleeve out of bottom tray and lift over Z2-7

Assembly Instructions

1. Attach hitch to unit (see hitch instructions).

2. Mounting the Z2-7

Hitch

T ools Required:

None

Frame

1. Slide the Z2-7 Frame into the Hitch.

2. Line up through holes in the Hitch and Z2-7 Frame and secure with two (2) 3/8” wire lock pins.

Wire Lock

Pin

8

Operators Guide

Assembly Instructions (continued)

3. Attaching the Heat Shield

T ools Required:

1/2” Wrench

1/2” Socket

Ratchet

1. Locate two (2) holes in top corner brace plates of

Hitch.

2. Aligning holes in bottom of Heat Shield, place Heat

Shield onto Hitch.

3. Secure Heat Shield to Hitch using two (2) 5/16”-18

x 1” hex bolts, four (4) 5/16” flat washers, and two

(2) 5/16” nylon lock nuts.

Heat

Shield

Hitch

If installing a spindle drive assembly, skip to step 5.

9

Loading...

Loading...