husquarna PG280 Operator's Manual

GGGGBBBB DDDDEEEE FFFFRRRR NNNNLL

LL

PG280

Oper ator’s manual Bedienungsanweisung

Manuel d’utilisa

tion Gebruiksaanwijzing

Please r ead the operator’s manual carefully and make sure you understand the instructions before using the machine.

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen Sie sich mit dem Inhalt vertraut, bevor Sie das Gerät

ben

utzen.

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

Neem de gebruiksaanwijzing grondig door en gebruik de machine niet voor u alles duidelijk heeft begrepen.

KEY T O SYMBOLS

2

– English

Symbols on the mac hine:

W

ARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the

machine.

Wear personal protective equipment.

See instructions under the ”Personal

protective equipment” heading.

WARNING! Dust forms when grinding,

which can cause injuries if inhaled. Use

an approved breathing mask. Always

provide for good ventilation.

This product is in accordance with

applicable EC directives.

En

vironmental marking. Symbols

on the product or its packaging indicate

that this product cannot be handled as

domestic waste.

By ensuring that this product is taken

care of correctly, you can help to

counteract the potential negative

impact on the environment and people

that can otherwise result through the

incorrect waste management of this product.

For more detailed information about recycling this

product, contact your municipality, your domestic waste

service or the shop from where you purchased the

product.

Other symbols/decals on the mac hine refer to special

certification requirements for certain markets.

Explanation of warning le vels

The w arnings are graded in three levels.

W

ARNING!

CAUTION!

NOTICE!

!

W

ARNING! Indicates a hazardous

situation which, if not avoided, will result

in death or serious injury.

!

CA

UTION! Indicates a hazardous

situation which, if not avoided, could

result in minor or moderate injury.

NO

TICE! Is used to address practices not related to

personal injury.

CONTENTS

English

–

3

Contents

KEY TO SYMBOLS

Symbols on the machine: ..................................... 2

Explanation of warning levels ............................... 2

CONTENTS

Contents ............................................................... 3

PRESENT ATION

Dear Customer , .................................................... 4

Design and features ............................................. 4

PG280 .................................................................. 4

WHA T IS WHAT?

What is what on the g rinder? ................................ 5

MA

CHINE´S SAFETY EQUIPMENT

Gener al ................................................................. 6

Stop/run switch ..................................................... 6

Emergency stop ................................................... 6

OPERA TING

Gener al safety precautions ................................... 7

Personal safety ..................................................... 8

Various machine modes ....................................... 9

Handlebar adjustment .......................................... 9

Frame height adjustment ...................................... 9

Grinding pressures ............................................... 10

Connect the vacuum cleaner ................................ 10

Grinding guide ...................................................... 10

Determining the hardness of concrete ................. 11

The motor’s direction of rotation ........................... 11

Diamond selection ................................................ 12

Changing the diamonds ....................................... 14

Edge grinding ...................................................... 15

Transport and storage .......................................... 16

ST

ARTING AND STOPPING

Bef ore starting ...................................................... 18

Starting ................................................................. 18

Stopping ............................................................... 18

MAINTENANCE

F

aults and trouble shooting .................................. 19

Maintenance ......................................................... 19

Service ................................................................. 19

TECHNICAL D ATA

T

echnical data ...................................................... 20

EC Declaration of Conformity ............................... 21

PRESENT A TION

4

– English

Dear Customer ,

Thank y ou for choosing a Husqvarna product!

It is our wish that you will be satisfied with your product

and that it will be your companion for a long time. A

purchase of one of our products gives you access to

professional help with repairs and services. If the retailer

who sells your machine is not one of our authorized

dealers, ask him for the address of your nearest service

workshop.

This operator’s manual is a valuable document. Make

sure it is always at hand at the work place. By following its

content (operating, service, maintenance etc.) the life

span and the second-hand value of the machine can be

extended. If you will sell this machine, make sure that the

buyer will get the operator´s manual.

More than 300 y ears of innovation

Husqv arna AB is a Swedish company based on a tradition

that dates back to 1689, when the Swedish King Karl XI

ordered the construction of a factory for production of

muskets. At that time, the foundation was already laid for

the engineering skills behind the development of some of

the world's leading products in areas such as hunting

weapons, bicycles, motorcycles, domestic appliances,

sewing machines and outdoor products.

Husqvarna is the global leader in outdoor power products

for forestry, park maintenance and lawn and garden care,

as well as cutting equipment and diamond tools for the

construction and stone industries.

Owner responsibility

It is the o wner’s/employer’s responsibility that the operator

has sufficient knowledge about how to use the machine

safely. Supervisors and operators must have read and

understood the Operator’s Manual. They must be aware

of:

• The machine’s safety instructions.

• The machine’s range of applications and limitations.

• How the machine is to be used and maintained.

National legislation could regulate the use of this

machine. Find out what legislation is applicable in the

place where you work before you start using the machine.

The man ufacturer’s reservation

Subsequent to pub lishing this manual Husqvarna may

issue additional information for safe operation of this

product. It is the owner’s obligation to keep up with the

safest methods of operation.

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify

the design and appearance of products without prior

notice.

For customer information and assistance, contact us at

our website: www.husqvarna.com

Design and f eatures

V

alues such as high performance, reliability, innovative

technology, advanced technical solutions and

environmental considerations distinguish Husqvarna's

products. Safe operation of this product requires the

operator to read this manual carefully. Ask your

Husqvarna dealer if you need more information.

Some of the unique features of your product are

described below.

PG280

•

The machine is intended for grinding concrete

surfaces with varying hardness.

• PG280 is robust and easy to use

• The machine can be folded and is collapsible for

simpler transport.

• The machine is equipped with a floating cover.

• The machine is an edge grinder.

• 1-phase

• 280 mm grinding surface

English – 5

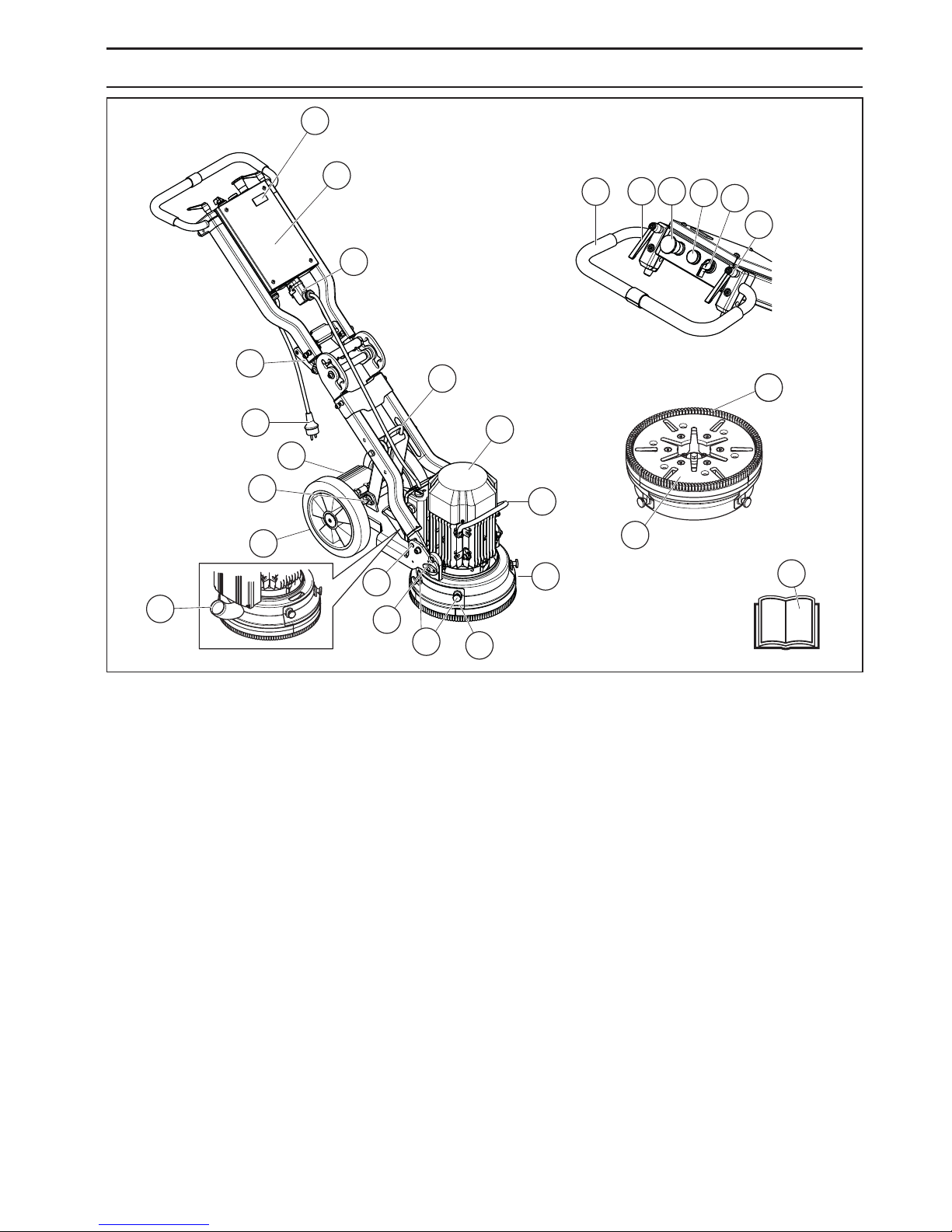

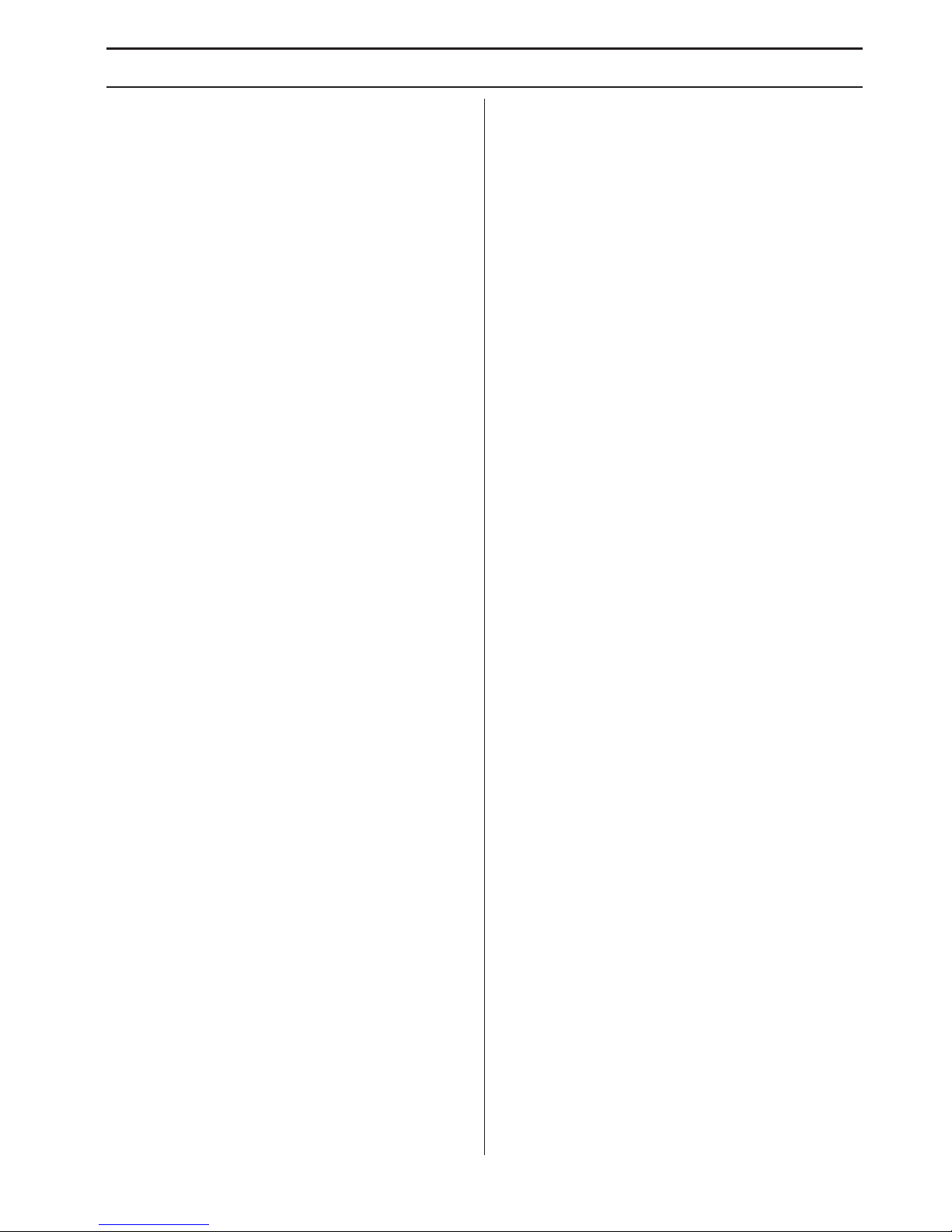

WHA T IS WHA T?

What is what on the grinder?

2

1

4

24

3

4

5

6

7

8

9

10

11

12

13

15

16

17

18

19

20

21

22

23

24

25

14

1

Counter

2 Electrical cabinet

3 Handle / handlebar

4 Locking lever for handlebar adjustment

5 Emergency stop

6 Overload lamp

7 Stop/run switch

8 Connection, quick connection for motor cable

9 Handle for angle joint

10 Plug

11 Foot pedal

12 Locking knob

13 Rubber wheels

14 Connection, vacuum hose

15 Lock function

16 Attachment for motor/grinding head

17 Screws for edge grinding hatch

18 Hatch, edge grinding

19 Lifting eye

20 Electric motor

21 Lift handle, motor

22 Floating cover

23 Tool plate

24 Brush list

25 Operator’s manual

MA CHINE´S SAFETY EQ UIPMENT

6

– English

General

This section descr ibes the machine´s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly.

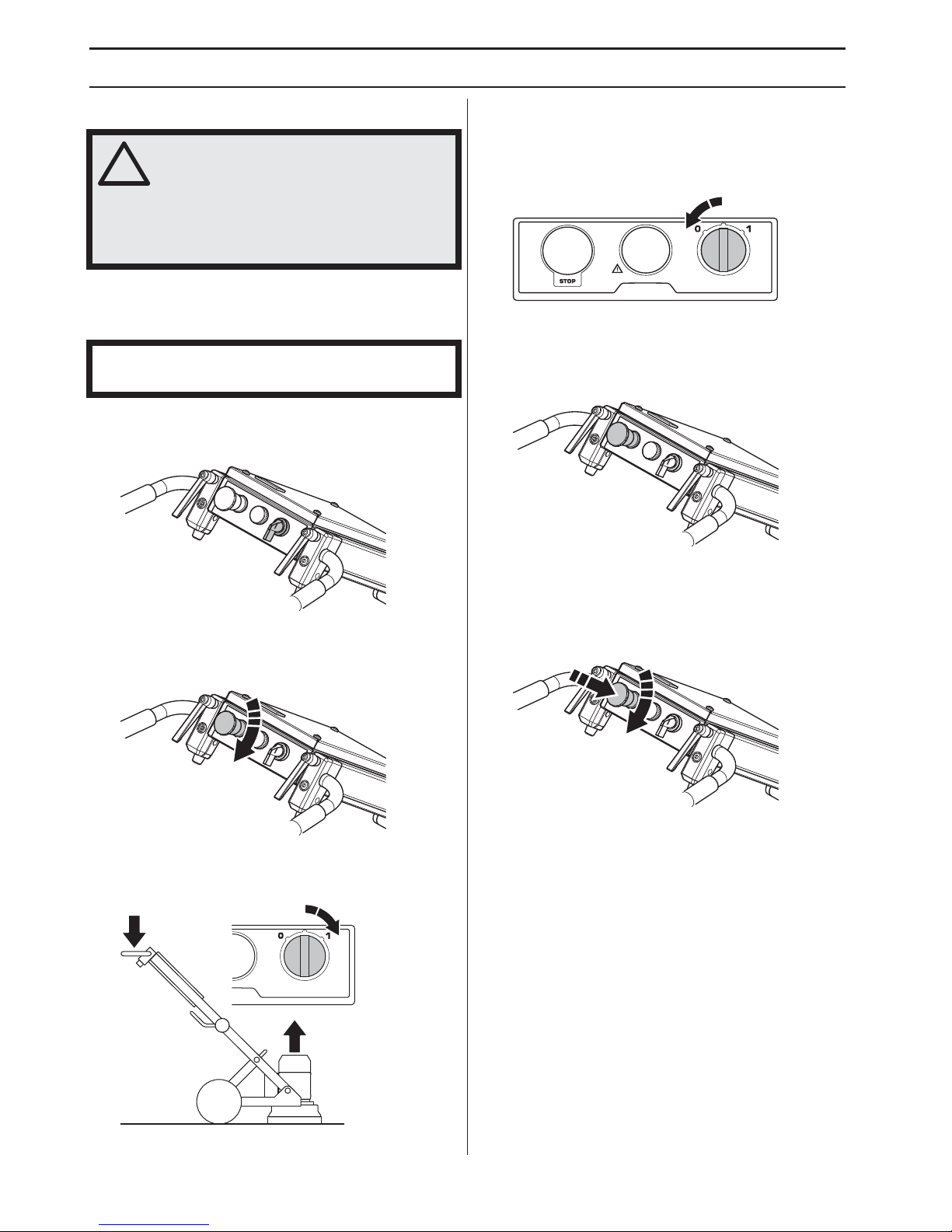

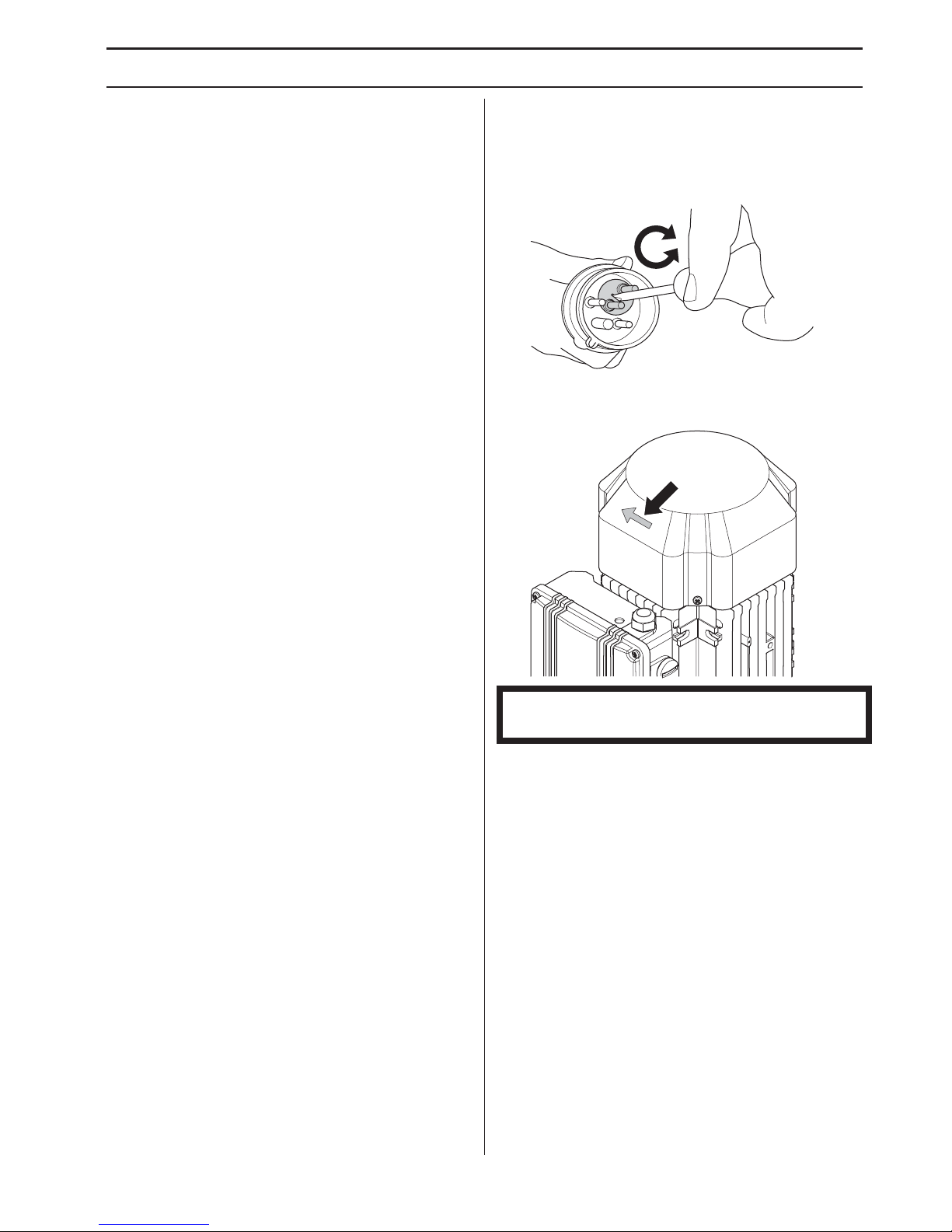

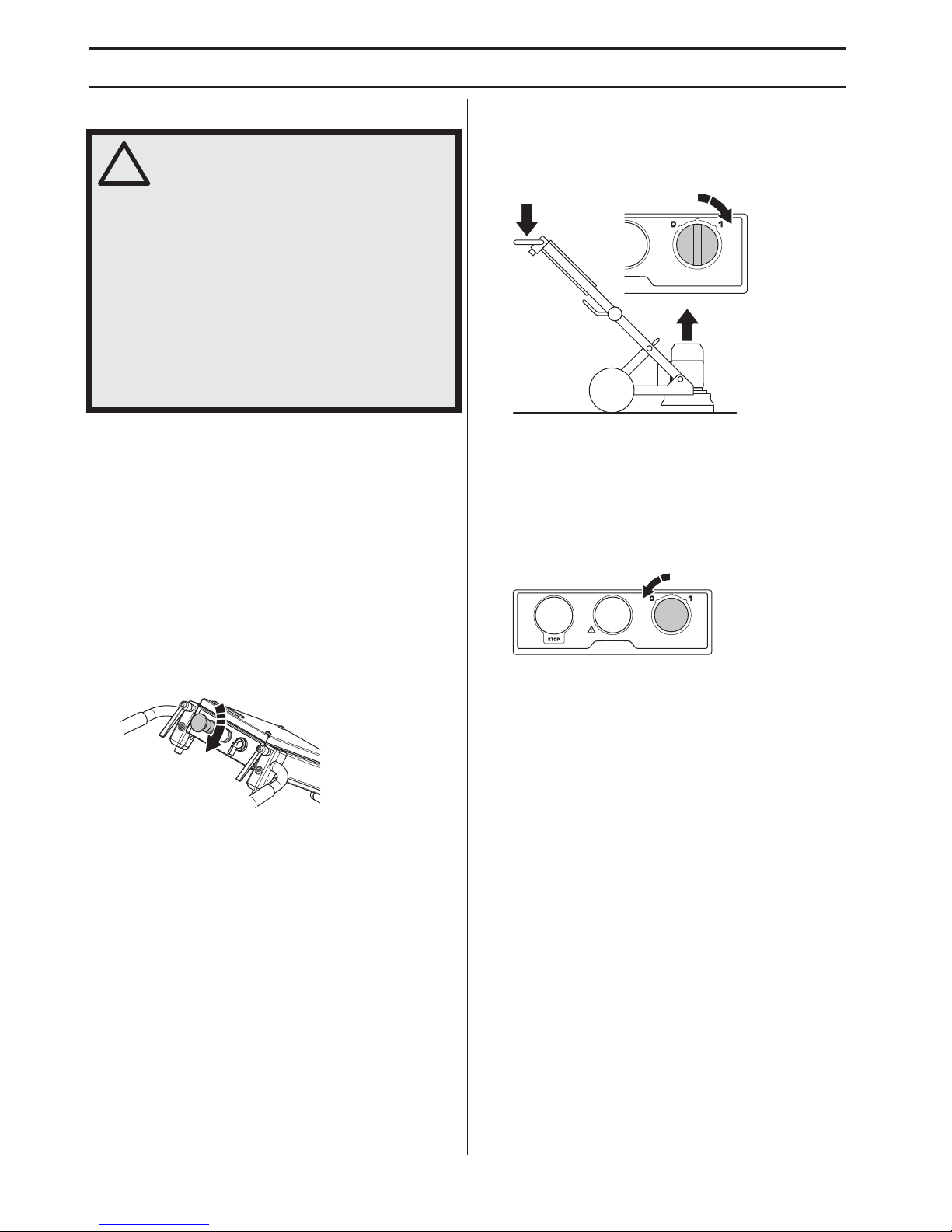

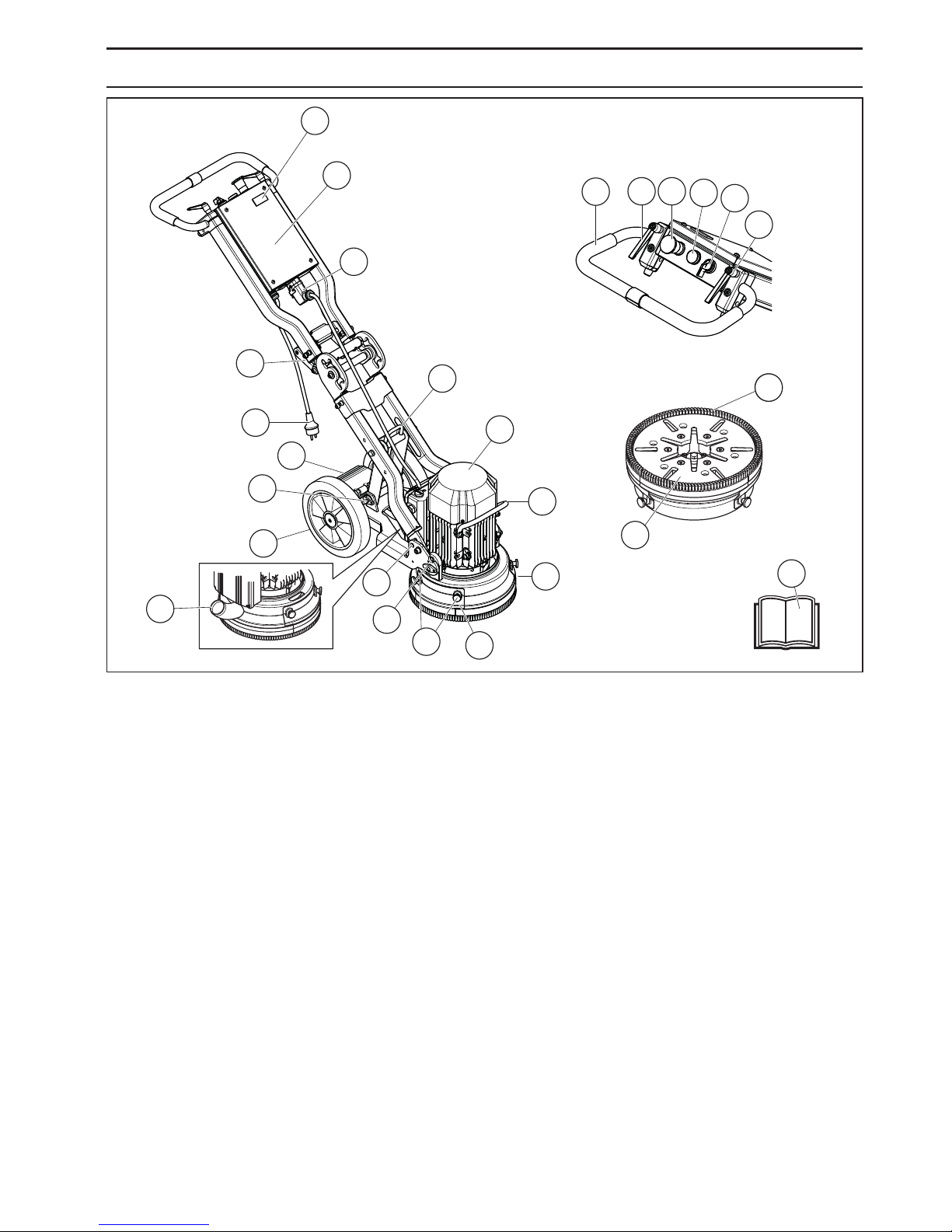

Stop/run s witch

The star t/stop knob is used to start and stop the machine.

Chec king the stop/run switch

Chec k that the emergency stop or machine stop button

are not pressed by turning them clockwise.

• Reduce the pressure between grinding disc and floor

by pushing down the handle without lifting the grinding

unit from the floor when starting.

• Start the machine by turning the 0/1 knob to position

1 (drive). The machine will then start smoothly and

accelerate to the set speed within 5 seconds.

• Turn the start/stop knob to '0' (stop) to stop the

machine.

Emer gency stop

The emergency stop is used to quic kly switch off the

engine. The emergency stop at the machine breaks the

mains power supply.

T

esting the emergency stop

•

Press the emergency stop. Check that the engine

stops.

• Disengage Emergency Stop button (twist clockwise).

!

W

ARNING! Never use a machine with

faulty safety equipment. The machine's

safety equipment must be checked and

maintained as described in this section.

If your machine fails any of these checks

contact your service agent to get it

repaired.

CA

UTION! Connect the motor cable to the electrical box

before connecting the plug.

~1 mm

1

2

1

2

OPERATING

English – 7

General safety precautions

• Do not use the machine without first reading and

understanding the contents of this Operator’s Manual.

Save all warnings and instructions for future

reference.

Work area safety

• Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

• The machine should not be used in areas where

potential for fire or explosions exist.

Electrical safety

• Check that the mains voltage corresponds with that

stated on the rating plate on the machine.

• Inspection and/or maintenance should be carried out

with the motor switched off and the plug disconnected.

• Always shut down the machine before disconnecting

the power plug.

• Never drag the machine by means of the cord and

never pull out the plug by pulling the cord. Hold the

plug to disconnect the power cord.

• Never use the machine if any cable or plug is

damaged, but hand it in to an authorized service

workshop for repair.

• The machine must never be driven to such a depth in

water that it reaches up to the machine’s equipment.

The equipment can be damaged and the machine can

be live, resulting in personal injuries.

• Always have the power cable disconnected when

connecting and disconnecting the contact between

the motor and the electrical box.

Grounding instructions

• The machine is equipped with a grounded cord and

plug and should always be connected to a grounded

outlet. This reduces the risk of electric shock in the

event of malfunction.

• The use of adaptors is not allowed with the machine.

Extension cords and cables

• The marking on the extension cable must be the same

or higher than the value stated on the machine’s rating

plate.

• Use grounded extension cables.

•

When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

• Keep the connection to the extension cord dry and off

the ground.

• Keep cable away from heat, oil, sharp edges or

moving parts. Damaged or entangled cable increase

the risk of electric shock.

• Check that the cables are intact and in good condition.

Never use the machine if any cable is damaged, but

hand it in to an authorized service workshop for repair.

• To avoid overheating do not use the extension cord

while it is rolled up.

• Ensure the cord is behind you when you start to use

the machine so that the cord will not be damaged.

• When using an extension cable, use only certified

extension cables with sufficient reach.

!

WARNING! This section describes basic

safety directions for using the machine.

This information is never a substitute for

professional skills and experience. If you

get into a situation where you feel

unsafe, stop and seek expert advice.

Contact your dealer, service agent or an

experienced user. Do not attempt any

task that you feel unsure of!

!

WARNING! There is always a risk of

shocks from electrically powered

machines. Avoid unfavourable weather

conditions and body contact with

lightning conductors and metal objects.

Always follow the instructions in the

Operator’s manual to avoid damage.

Never connect the machine to a outlet if

plug or cord is damaged.

!

CAUTION! The equipment fulfills the

requirements in EN61000-3-11 and is

subject for conditional connection to the

mains. It may be connected in

consultation with the supply authority.

The equipment will only be connected to

the mains supply with impedance lower

than 0,28 ohm. The system impedance at

the interface point may be obtained from

the supply authority.

If the mains supply has higher system

impedance, short voltage dips may

appear when the equipment is started.

This may influence the operation of other

products, e.g flickering lights.

!

WARNING! Improper connection can

result in the risk of electric shock.

Contact a qualified electrician if in doubt

as to whether the appliance is properly

grounded.

Do not modify the plug. If it will not fit the

outlet have a proper outlet installed by a

qualified electrician. Make sure local

regulations and ordinances are followed.

If the grounding instructions are not fully

understood contact a qualified

electrician.

OPERATING

8 – English

Personal safety

• Wear personal protective equipment. See instructions

under the ”Personal protective equipment” heading.

• Never use the machine if you are tired, if you have

drunk alcohol, or if you are taking medication that

could affect your vision, your judgement or your coordination.

• Never allow anyone else to use the machine without

first ensuring that they have read and understood the

contents of the operator’s manual.

• All operators shall be trained in the use of the

machine. The owner is responsible for ensuring that

the operators receive training.

• People and animals can distract you causing you to

lose control of the machine. For this reason, always

remain concentrated and focused on the task. Never

allow children to use or be in the vicinity of the

machine.

• Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

• There is always a risk of crush injuries when working

with products containing moving parts. Keep your

distance!

• Never leave the machine unsupervised with the motor

running.

• Make sure that there is always another person close

at hand when you use the machines, so that you can

call for help if an accident should occur.

• Always ensure you have a safe and stable working

position.

Personal protective equipment

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Boots with steel toe-caps and non-slip sole.

• Always have a first aid kit nearby.

Use and care

• Only use the machine for the purpose it was intended

for.

• Keep all parts in good working order and ensure that

all fixtures are properly tightened.

• Never use a machine that is faulty. Carry out the safety

checks, maintenance and service instructions

described in this manual. Some maintenance and

service measures must be carried out by trained and

qualified specialists. See instructions under the

Maintenance heading.

• Do not modify safety equipment. Check regularly that

they function as they should. The machine must not

be run with defective or disassembled safety

equipment.

• Never use a machine that has been modified in any

way from its original specification.

• Always use genuine accessories. Contact your dealer

for more information.

• Machinery should only be started when grinding

heads are resting on the ground unless carrying out a

testing procedure as outlined in this manual.

• The machine should not be started without the brush

list attached. It is essential a good seal between

machine and floor be established for safety, especially

when operating in dry grinding applications.

• During grinding, the machine must be connected to a

vacuum cleaner for the removal of the dust.

• Make sure the machine is without power when

changing diamond tools by pressing in the emergency

stop and disconnecting from the power outlet.

• Always dismantle the diamond tool after each grinding

operation.

• Make sure that the brush list is intact and clean and

that it seals tightly against the floor. Damaged brush

list should always be replaced.

• The tool plate continues to rotate for a while after the

motor has been switched off. Maintain grinding action

until the fan has come to a complete stop. Ensure the

tool plate has stopped rotating before lifting up the

machine.

• When grinding adhesive, asphalt, paint or the like, lift

the front of the machine slightly after use to prevent it

sticking to the floor from the heat. Ensure the tool

plate has stopped rotating before lifting up the

machine.

• Diamond tools may be very hot after use. Leave

machine to cool off before removing the diamond

segments. Use protective gloves.

• Always use the machine mounted lifting eye when

lifting.

• Always carry the machine by the carrying handle and

the handle.

!

WARNING! Overexposure to vibration

can lead to circulatory damage or nerve

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists. These

symptoms may be increased in cold

temperatures.

!

WARNING! You must use approved

personal protective equipment whenever

you use the machine. Personal protective

equipment cannot eliminate the risk of

injury but it will reduce the degree of injury

if an accident does happen. Ask your

dealer for help in choosing the right

equipment.

OPERATING

English – 9

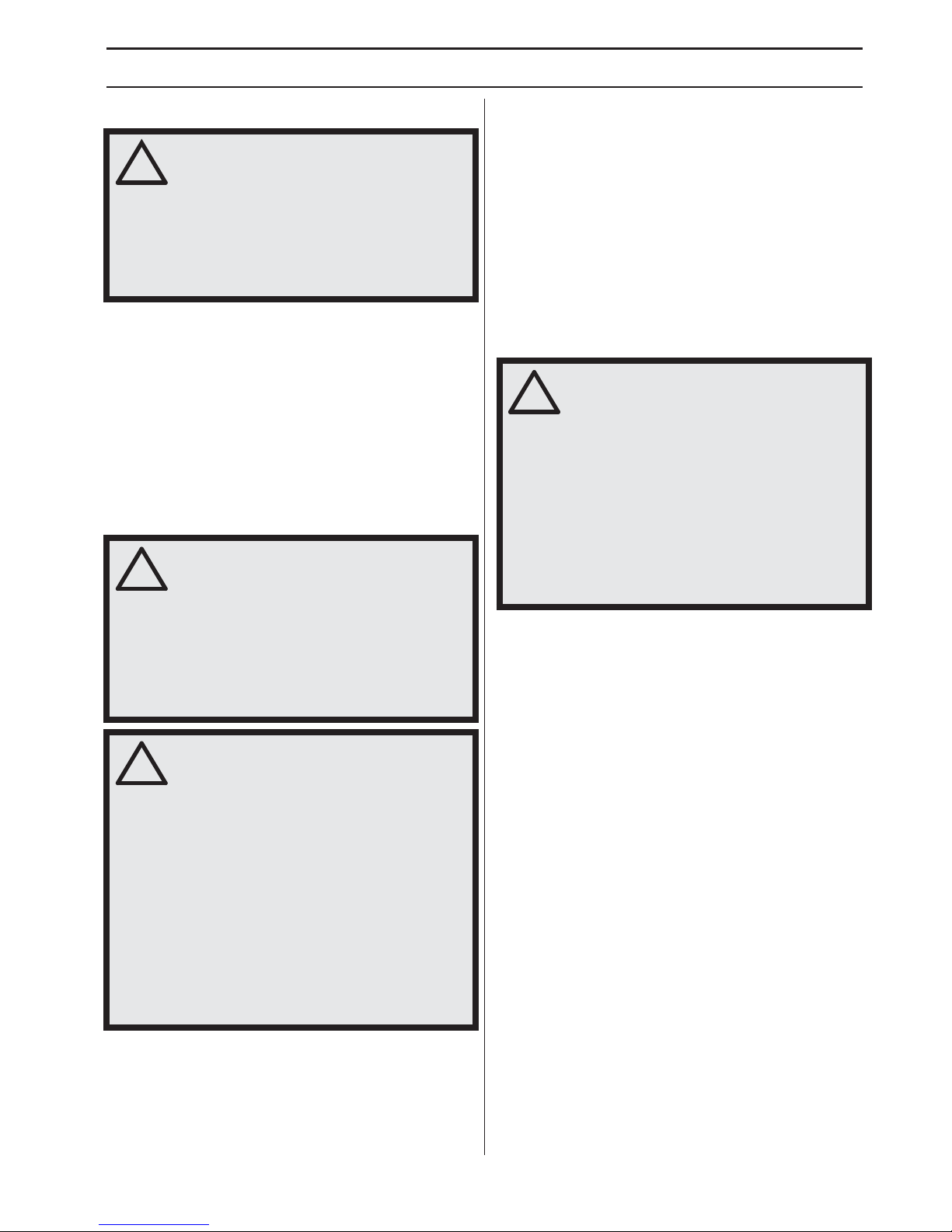

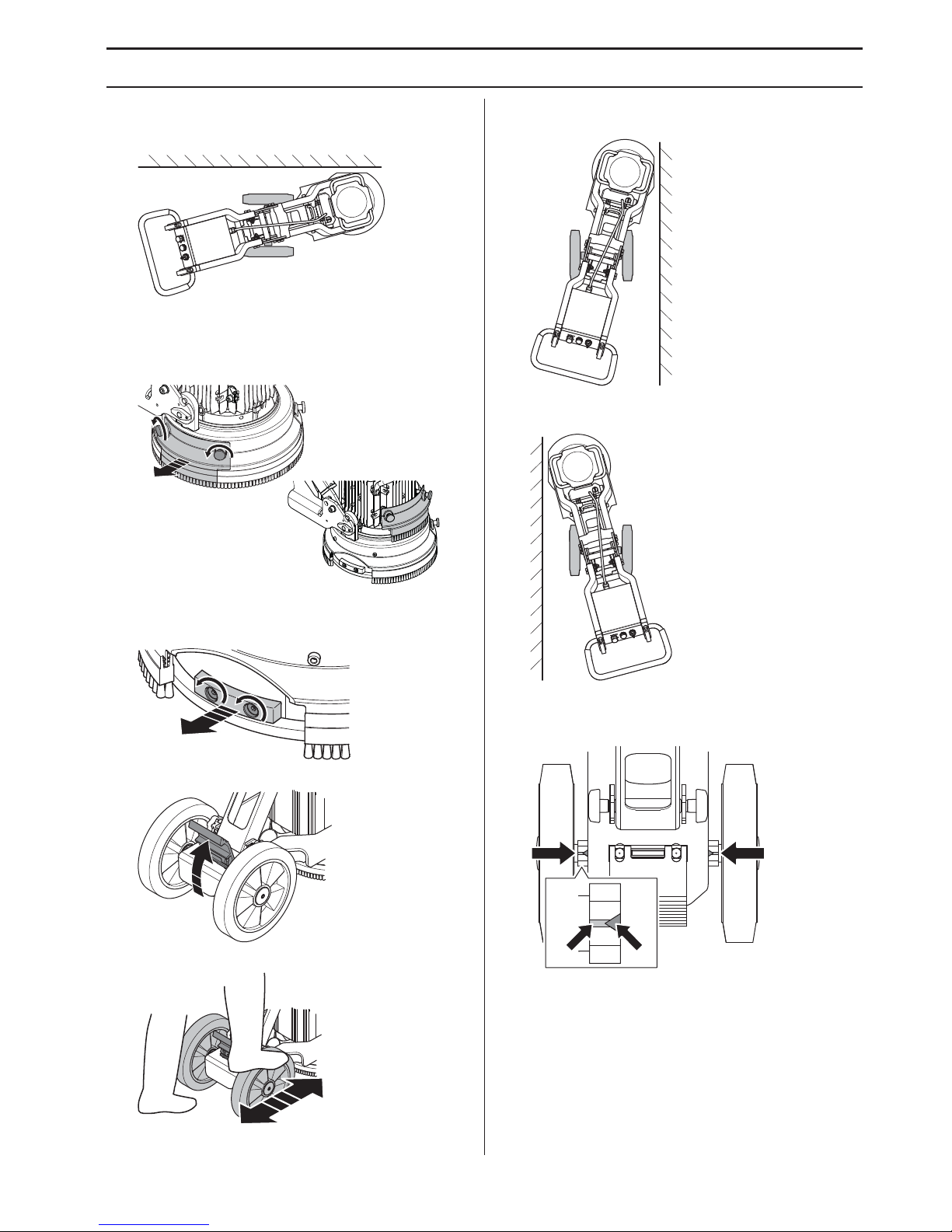

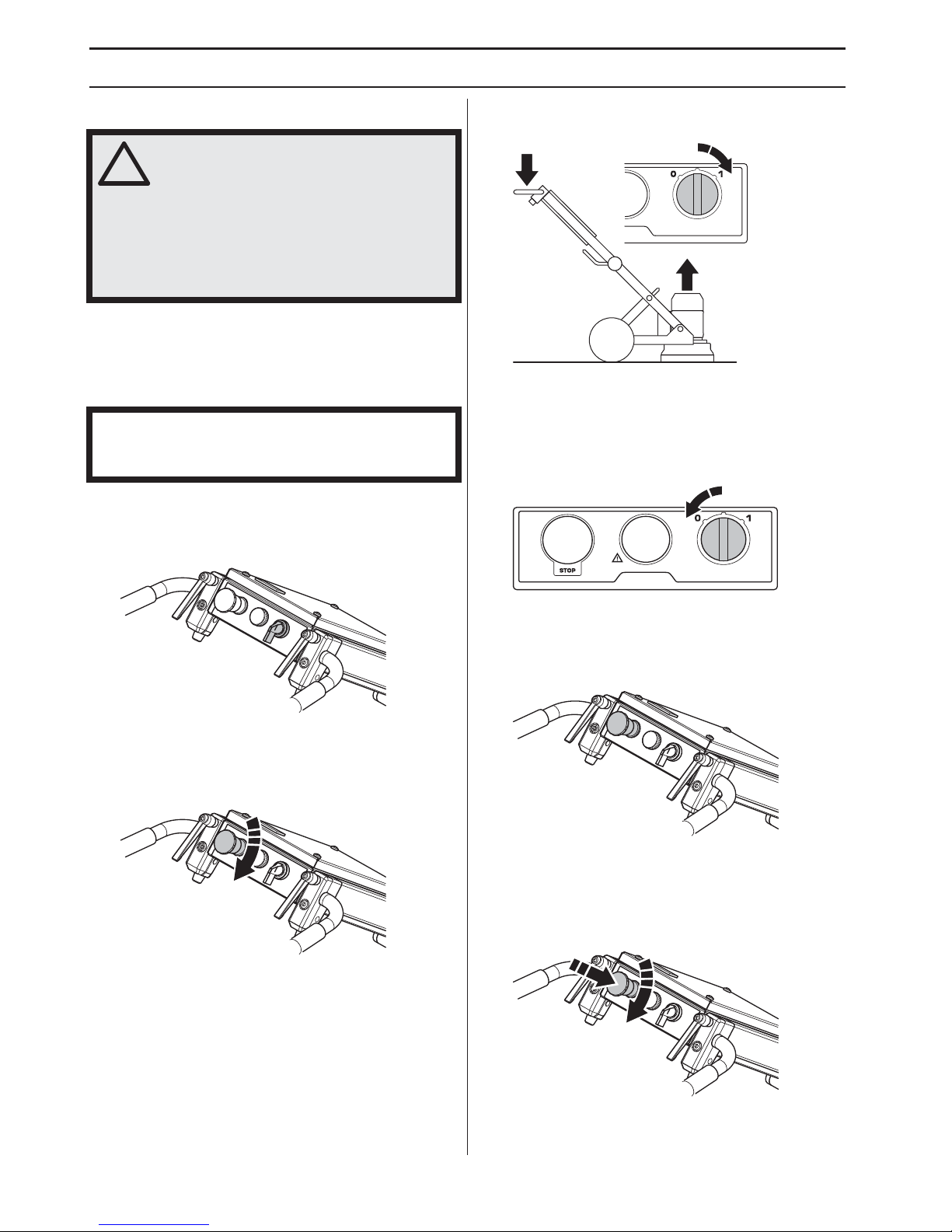

Various machine modes

Operating position

Service position

Tilting transportation position

Lifting transportation position

Put padding between the motor and the electrical cabinet

to prevent damage to the machine.

Handlebar adjustment

The handle can be infinitely adjusted. The handle lock

knobs are operated clockwise, counterclockwise or

placed in idle postion.

• Loosen the lock knobs and adjust the handle to

desired position.

• Fix the position by tightening the lock knobs.

• When not in use, pull the handle lock knobs upwards

and place them into idle position.

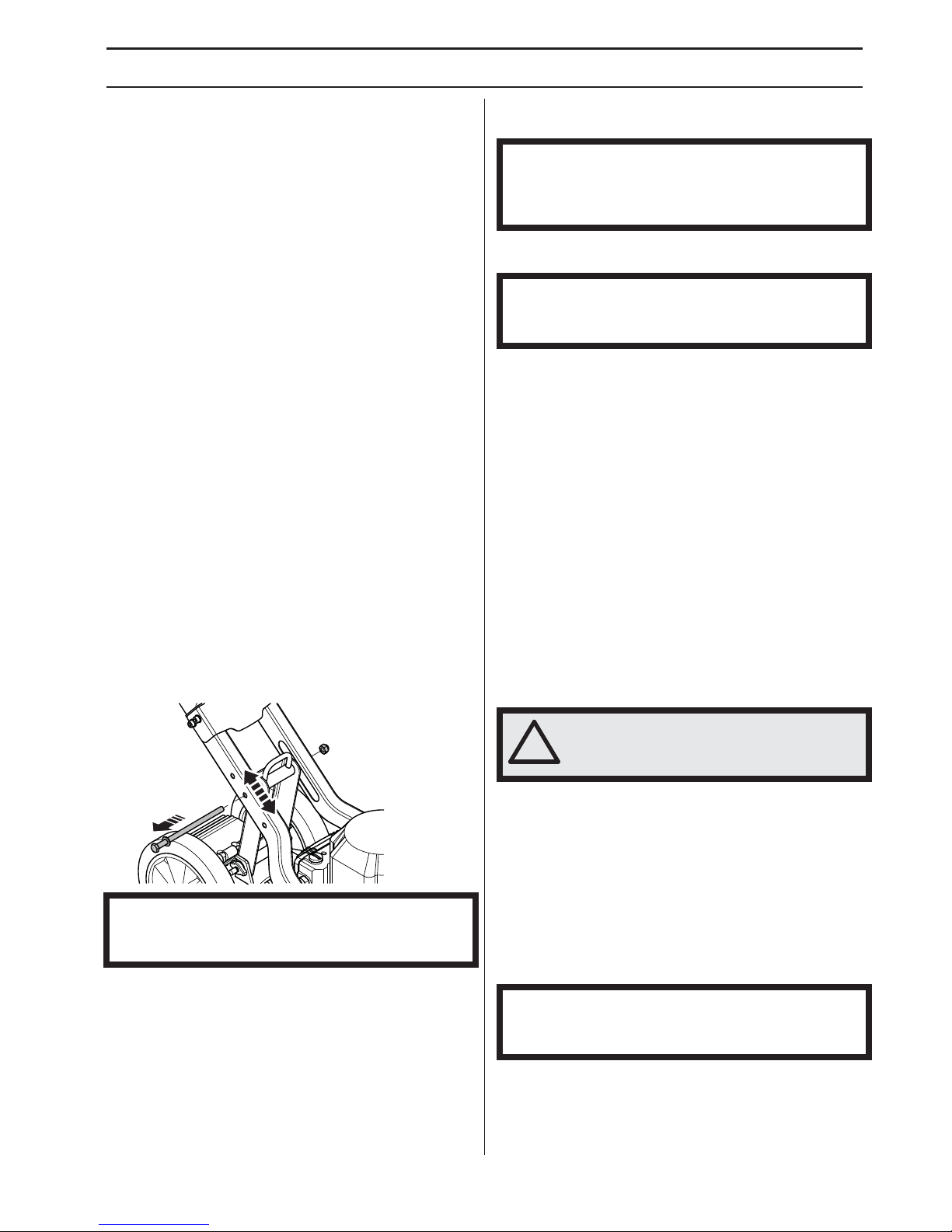

Frame height adjustment

The angle of the frame can be adjusted to alter the weight

distribution of the chassis to decrease or increase

grinding pressure. It can also be used to allow a more

comfortable working position for different operators.

• Disconnect the motor cable from the electrical box.

• Loosen the locking knob to adjust the length.

• Choose the appropriate position required by

tightening up the locking knobs in the correct hole.

NOTICE! The lower hole for a higher handlebar and

greater grinding pressure. The upper hole for a lower

handlebar and less grinding pressure.

2

1

OPERATING

10 – English

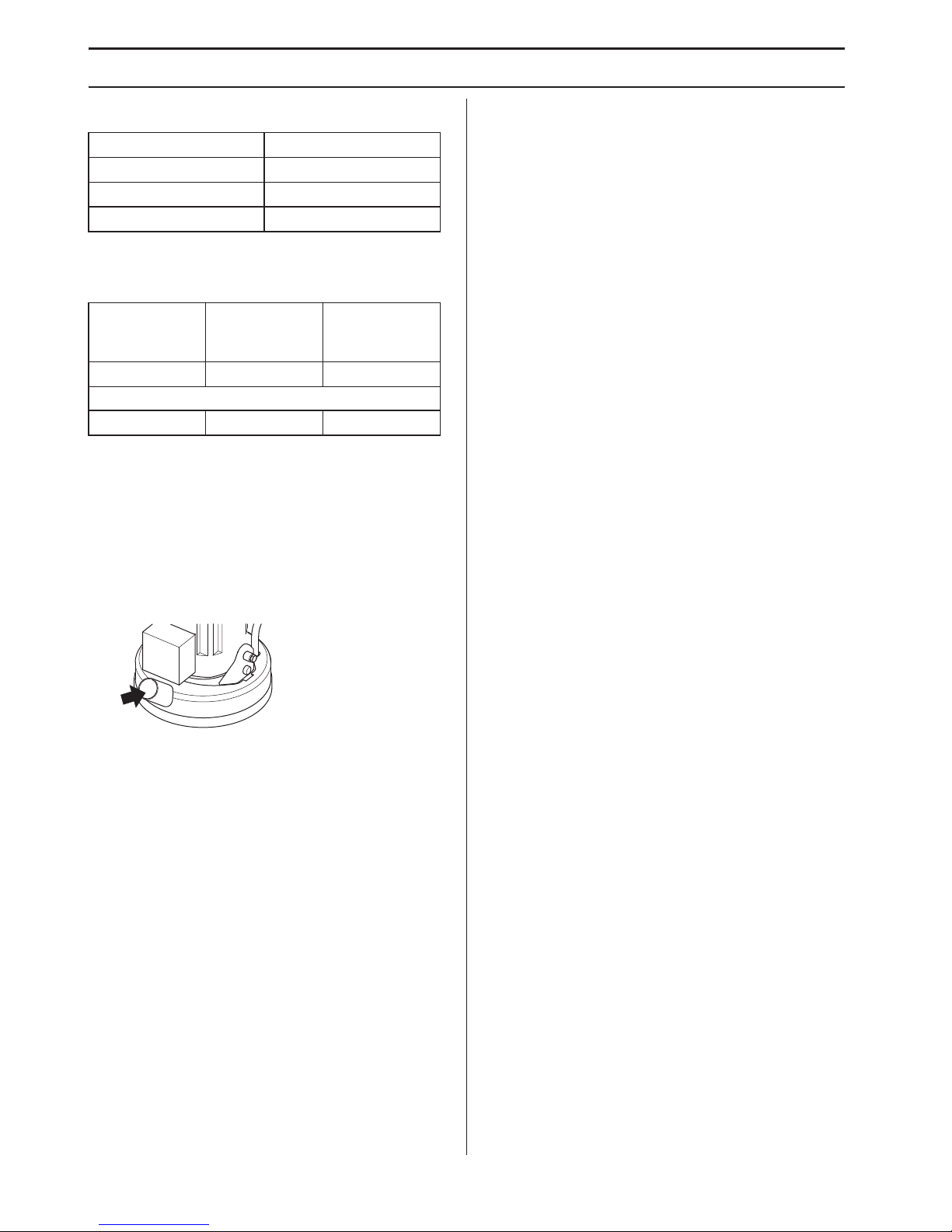

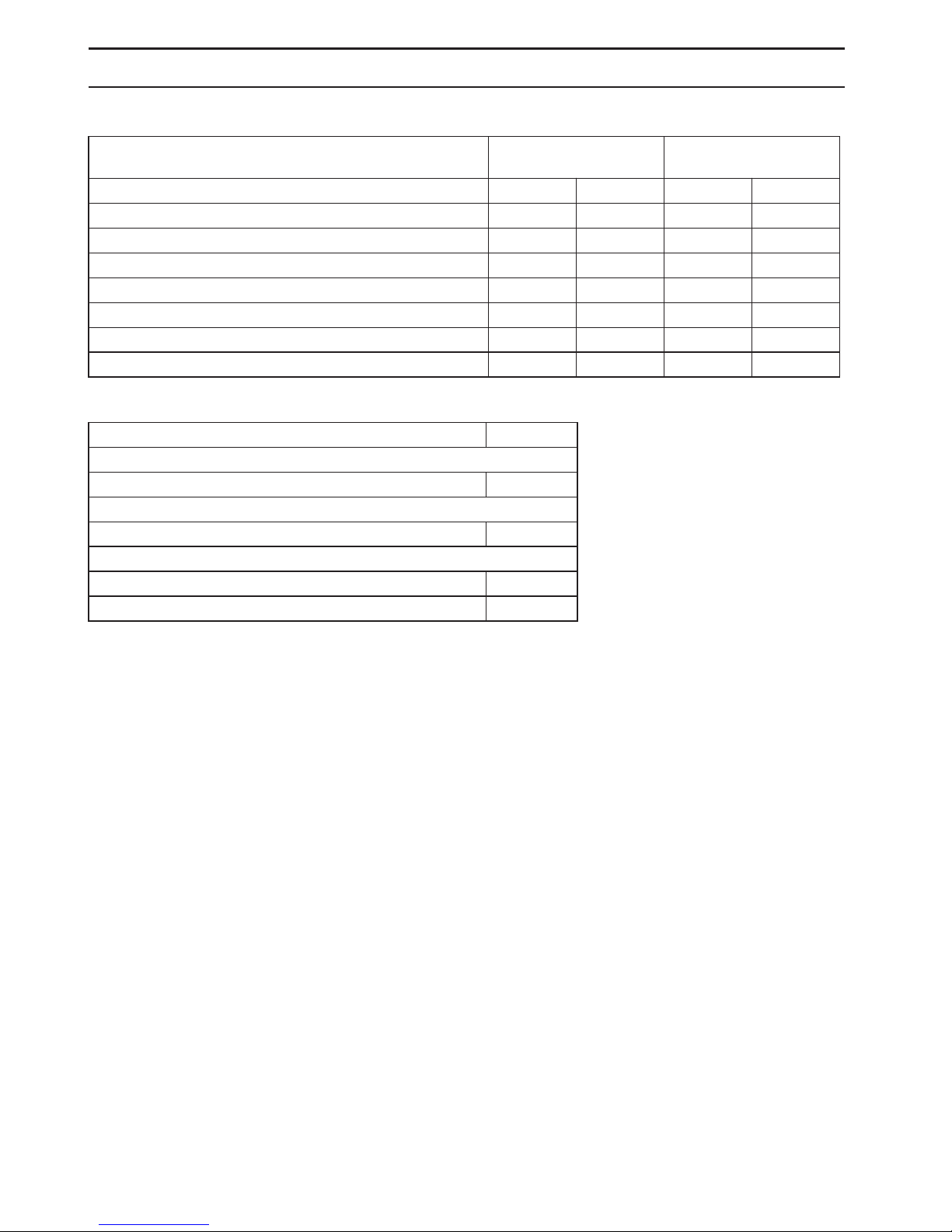

Handle heights

Grinding pressures

Below matrix shows grinding pressure for each height.

* Factory setting.

Connect the vacuum cleaner

Use a Husqvarna dust extraction system for complete

dust control.

• Connect the dust extractor to the machine. Use a 50

mm (2 inch) hose.

Make sure that the filters in the vacuum cleaner are intact

and clean. Pay attention to dust during operation.

Grinding guide Diamonds

Background

The diamond segment comprises usually of two

components:

• Diamonds (also called diamond crystals or corn).

Changing the size of the diamonds or corn will change

the coarseness or fineness of the scratches after the

grinding process.

• A bonding agent (metal or plastic). Powder is mixed

and suspended in a metal or plastic bonding agent. If

metal is used as a bonding agent, the finished product

is called metal-bonded or sintered diamond segment.

If plastic is used as a bonding agent, the finished

product is called plastic-bonded diamonds or

polishing disc. By changing the hardness of the

bonding agent, you can change how quickly or slowly

the diamond abrasive is worn down.

General Principles

General rules for using diamond tools when grinding

follow below. As with all rules, there are exceptions or

occasions when they do not apply.

Diamond grit size

Changing the size of the diamond grit to a smaller

particle/grit size will effect the performance of the

diamond tool in the following ways:

• Create a finer scratch pattern.

• Increased service life of diamond tools.

The opposite will occur when changing to a larger

particle/grit size.

Binding agent

Increasing hardness of bond will:

• Create a finer scratch pattern.

• Increased service life of diamond tools.

• Decrease production rate.

The opposite will occur when making the metal or resin

bond softer.

Number of diamond tools under the machine

An increased number of tools under the machine leads to:

• Reduce pressure on each individual diamond

segment - reduce wear rate on diamond segments.

• Reduce load

on the machine and cause the grinder to

draw less current.

• Create a smoother scratch pattern (particularly on soft

floors).

The reverse happens if you reduce the number of tools

under the machine.

Summary of diamond principles

The diamond tools must be worn in order to give a high

grinding efficiency. The wear on diamond tools can be

affected by the following factors:

• Pressure.

• Hardness of bond.

• Diamond grit size.

• Number of segments under the machine.

• Adding an additional abrasive (e.g. sand, silicone

carbide) on the floor will increase wear.

Generally, the faster a diamond segment wears, the faster

the productivity will be. By varying the above factors,

changes can also be made to effect the following:

• Scratch pattern.

• Current draw of machine.

• Flatness of floor (see next section).

• Ease of operation.

Hole position Handle height, mm/inch

Upper 835/33

Center 925/36

Lower 1000/39

Handle

position Low,

kg/lbs

Handle

position

Center, kg/lbs

Handle

position High,

kg/lbs

23/51 25/55* 27/60

With

accessory counterweight

17/37 20/44 23/51

OPERATING

English – 11

Determining the hardness of

concrete

All concretes are measured by their compressive strength

and depending on which part of the world you are from,

different compressive strength indices (e.g. PSi & MPa)

are used. Generally, the higher the compressive strength

rating, the harder the concrete and therefore, the harder it

will be to grind.

But there are also factors other than compression

strength that determine how hard a floor is and which

therefore affect the choice of diamond tool. As it is most

often only the top layer (5 mm) that we are talking about

from a grinding point of view, the surface treatment of the

concrete and the condition of the concrete surface have

many times a greater impact on the choice of diamond

segment than the compression strength.

Surface factors to consider when making a diamond

selection

Generally, if a concrete surface is very smooth (i.e. Most

likely it has been heavily trowelled/helicoptered), the

concrete will behave as if it has a high compressive

strength and therefore, require a soft bond segment.

Accordingly, if a concrete surface is coarse/aggressive

(e.g. rain-damaged, shot blasted, scarified, exposed

aggregate e.t.c.), the concrete will behave as if it has a

low compressive strength and therefore, require a hard

bond segment.

Surface coatings/contaminants (e.g. Epoxy coatings,

ceramic tile adhesives, levelling compounds/screeds) will

often have a larger bearing on what diamond to select,

than will the compressive strength of the concrete.

As a general rule, when grinding a concrete slab for the

first time and you are unsure about its hardness, always

begin with harder bond diamonds under the machine.

This will ensure the least amount of wear on the diamond

segments. If a hard diamond segment is not suited to the

application, all it has cost is a little amount of time without

wearing out the diamonds.

If performed the other way around (i.e. a soft segment is

used to begin with) and the concrete is soft or possesses

an abrasive surface or surface contaminant, it is quite

possible to wear-out a considerable amount of diamond in

very short period of time.

The motor’s direction of rotation

3-phase

The motor´s direction can be changed by reversing the

poles in the power plug.

1-phase

The arrow shows the direction of rotation of the motor.

NOTICE! The Piranha/PCD tools are designed to run in

only one direction.

OPERATING

12 – English

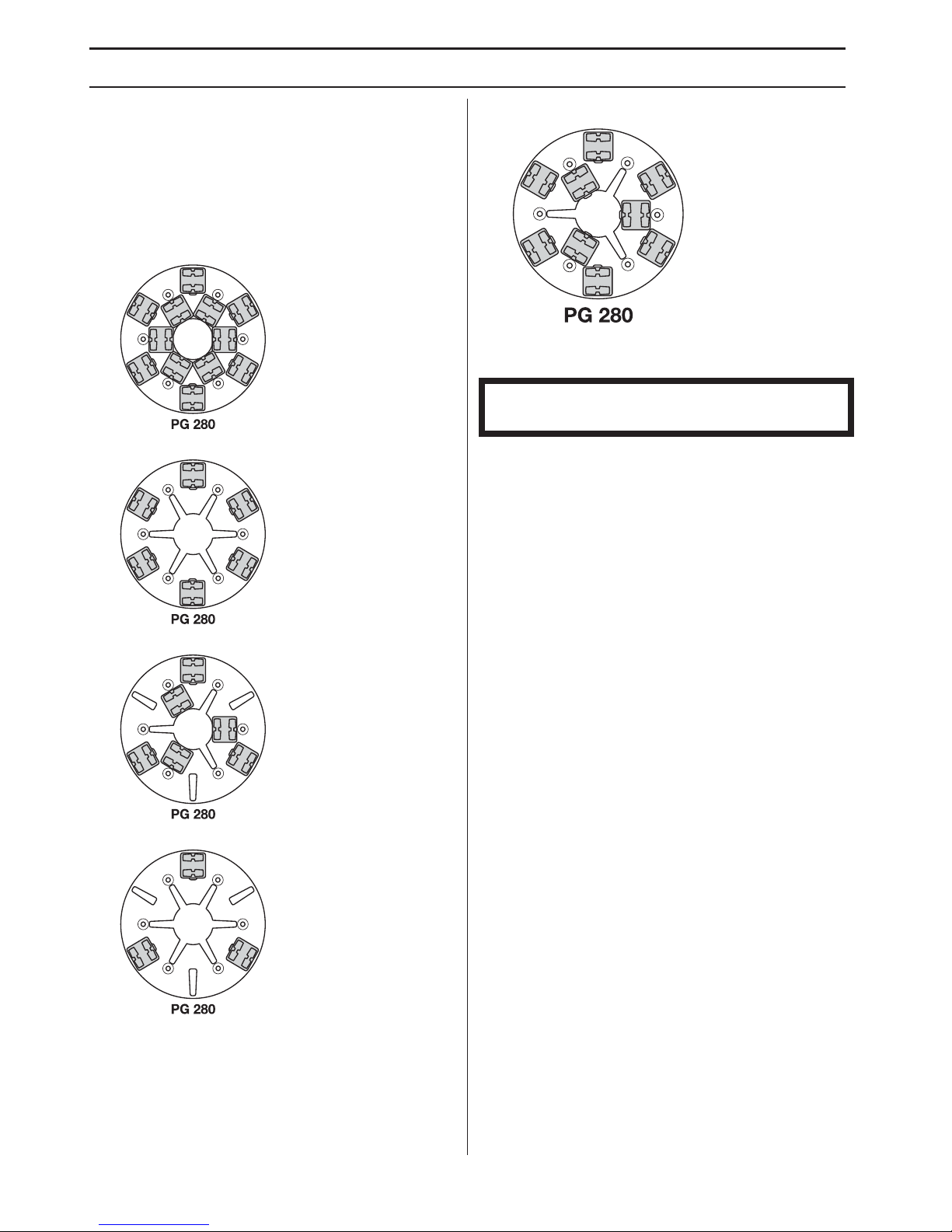

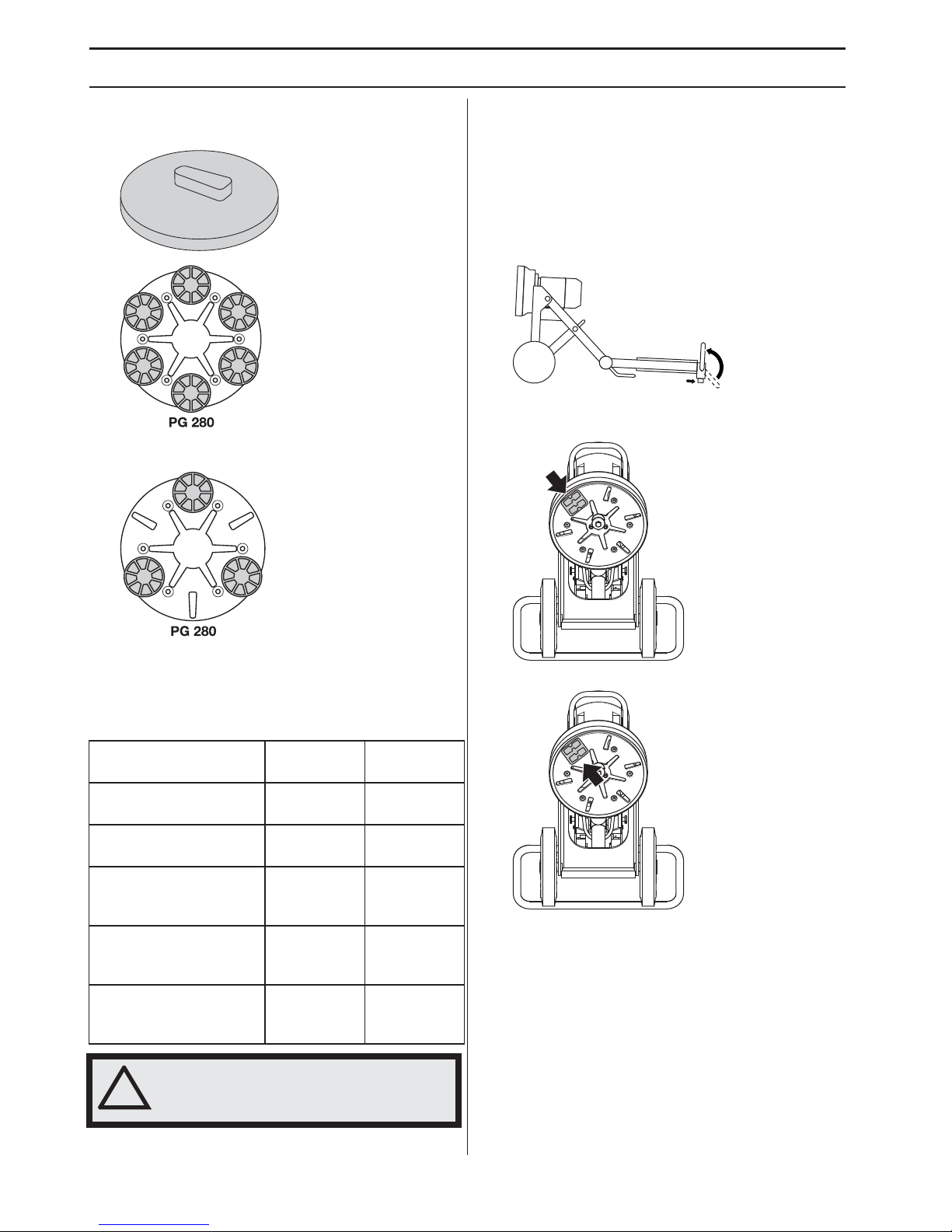

Diamond selection

They way diamond segments are set-up on the grinding

unit will greatly influence the performance of the machine,

the productivity levels and also the finished floor quality.

There are a number of different diamond configurations

that can be achieved on the PG 280.

Metal bond diamonds

Full set - inner and outer row

Full set - outer row

Half set - inner and outer row

Half set - outer row

For edge grinding PG280

Half set - inner row Full set - outer row

NOTICE! Husqvarna’s recommendation regarding

single disc grinders is two segments on each metal tool.

English – 13

OPERATING

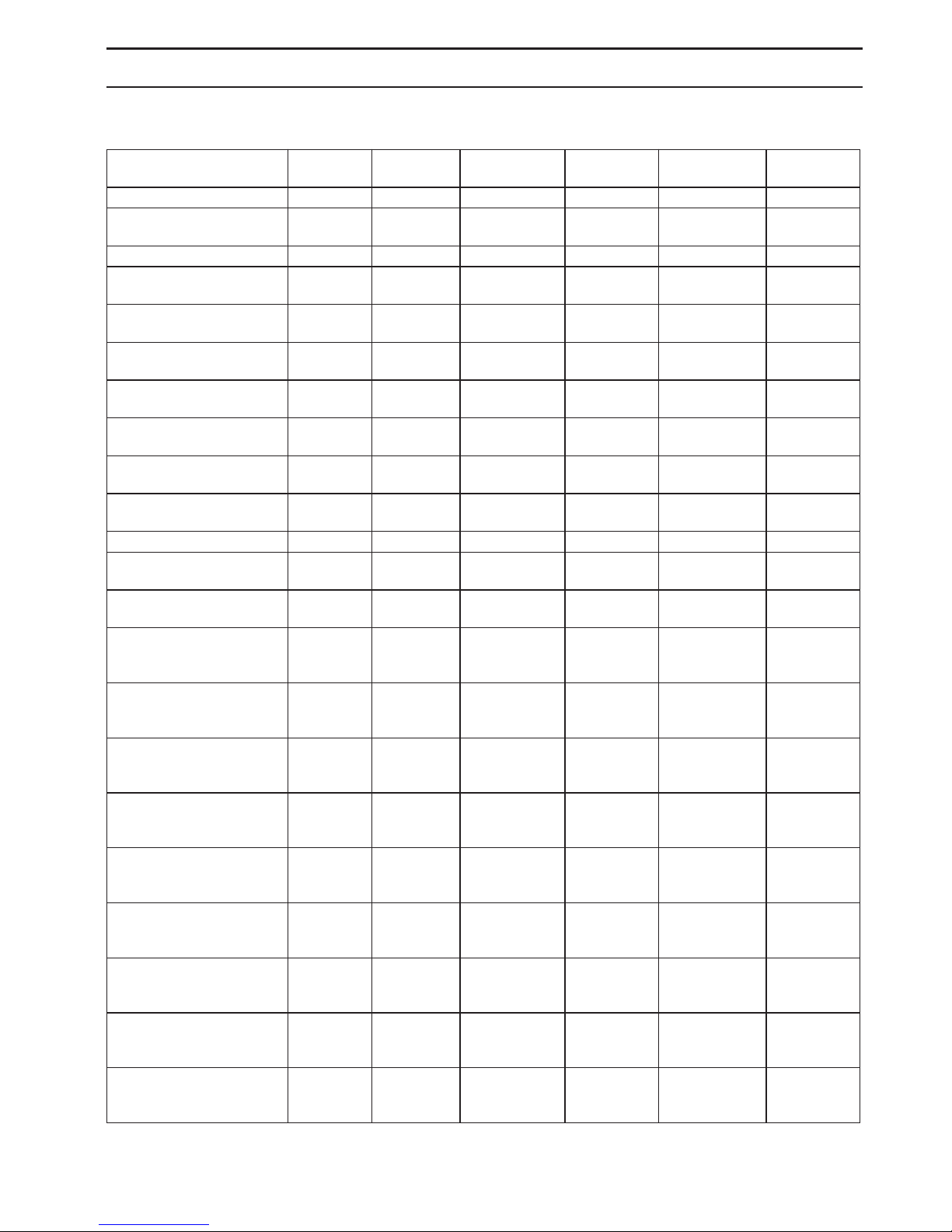

Select the correct metal bond diamonds for your application

The following suggestion cover the basic configurations for metal bonded diamond tools.

Applications Metal bond Grit size

Full set - inner

and outer row

Full set outer row

Half set - inner

and outer row

Half set outer row

Flatten floor - Hard concrete Soft 16 or 30 X

Flatten floor - Medium

concrete

Medium 16 or 30 X

Flatten floor - Soft concrete Hard 16 or 30 X

Ceramic tile adhesive

removal

Medium

PIRANHA™

or 16-30

X

Vinyl or Carpet glue

removal - Hard concrete

Soft

PIRANHA™

or 16-30

X X

Vinyl or Carpet glue

removal - Medium concrete

Medium

PIRANHA™

or 16-30

X X

Vinyl or Carpet glue

removal - Soft concrete

Hard

PIRANHA™

or 16-30

X X

Epoxy paint removal - Hard

concrete

Soft

PIRANHA™

or 16-30

X X

Epoxy paint removal Medium concrete

Medium

PIRANHA™

or 16-30

X

Epoxy paint removal - Soft

concrete

Hard

PIRANHA™

or 16-30

X

Rain damaged concrete Hard 16-30 X X

Smoothen exposed

aggregate

Hard 16-30 X X

Lippage removal in

terrazzo/stone tiles

Soft 30 or 60 X

Surface polishing of

concrete floors - Hard

concrete

Soft 60 X X

Surface polishing of

concrete floors - Medium

concrete

Medium 60 X X

Surface polishing of

concrete floors - Soft

concrete

Hard 60 X X

Grinding to exposed

aggregate in concrete Hard concrete

Soft 16-30 X X X

Grinding to exposed

aggregate in concrete Medium concrete

Medium 16-30 X X X

Grinding to exposed

aggregate in concrete - Soft

concrete

Hard 16-30 X X

Flatten undulation in

concrete floors - Hard

concrete

Soft 16 or 30 X X X

Flatten undulation in

concrete floors - Medium

concrete

Medium 16 or 30 X X

Flatten undulation in

concrete floors - Soft

concrete

Hard 16 or 30 X X

OPERATING

14 – English

Resin bond diamonds

Redi Lock resin attachment adaptor

Full set - outer row

Half set - outer row

Selecting the correct resin bond diamond

configuration for your application

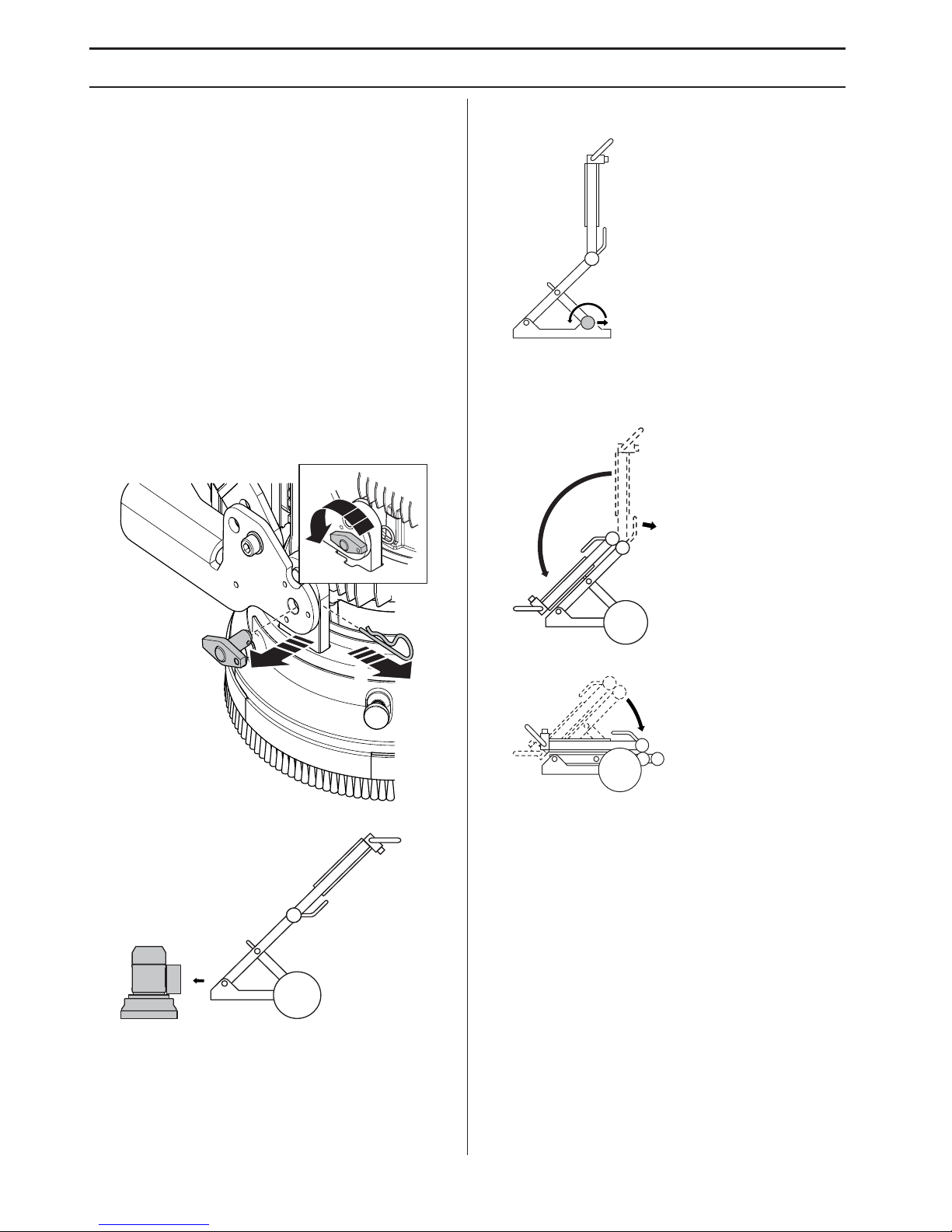

Changing the diamonds

Shut down the machine and disconnect the power plug.

Have a set of gloves ready, as diamond tools can get very

hot.

• Put the machine into service position.

• Pull back on handle to lift grinding head off the ground.

• Lay machine back on the ground.

• Put on gloves.

• Use a hammer to remove the diamond segments.

• Affix new diamond segments on the grinding disc.

• Once new diamond segments have been attached,

reverse procedure to lower machine to ground.

Applications

Full set outer row

Half set outer row

Polishing terrazzo/stone

tiles

X

Resurfacing terrazzo/

stone tiles

X

Surface polishing of

concrete floors - Hard

concrete

X

Surface polishing of

concrete floors - Medium

concrete

X

Surface polishing of

concrete floors - Soft

concrete

X

!

WARNING! CP1200 and P1100 must not

under any circumstances be used with a

Redi lock adapter.

OPERATING

English – 15

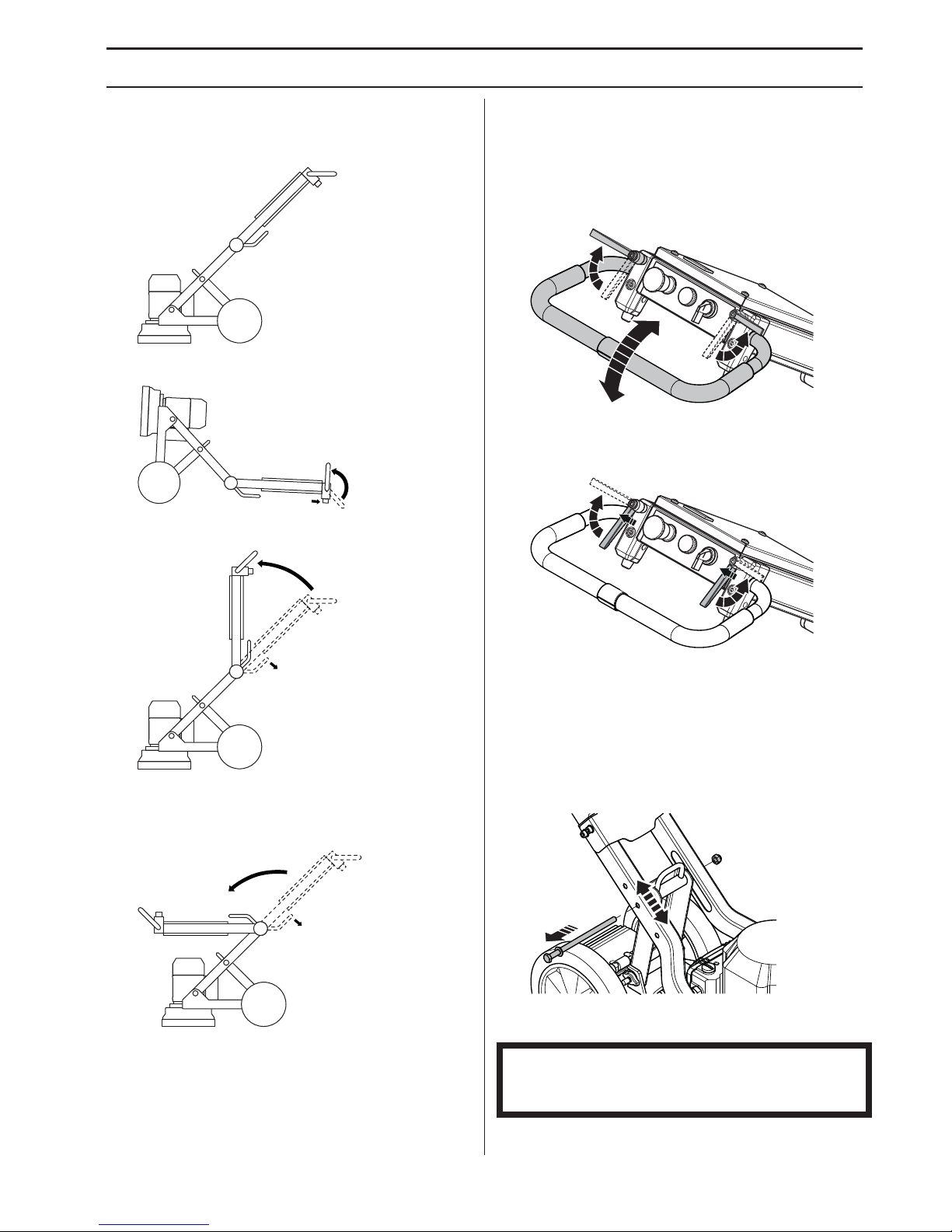

Edge grinding

This machine has edge grinding capabilities.

For edge grinding close to walls, the hatch on the right or

left side of the dust cover must be removed.

• Remove the screws (2) and the hatch. Fit the hatch on

to the holder.

• Under the hatch there is a removable guard to protect

the wall when grinding. The guard can be removed for

grinding closer next to the wall, 2 screws.

• Raise the foot pedal.

• Use your foot to give the wheels the right angle.

• For edge grinding on the right side, the wheels must

be directed left.

• For edge grinding on the left side, the wheels must be

directed right.

• When the red marking on the wheel axle (A) is in line

with the red marking on the frame (B), the direction is

again straight.

AB

OPERATING

16 – English

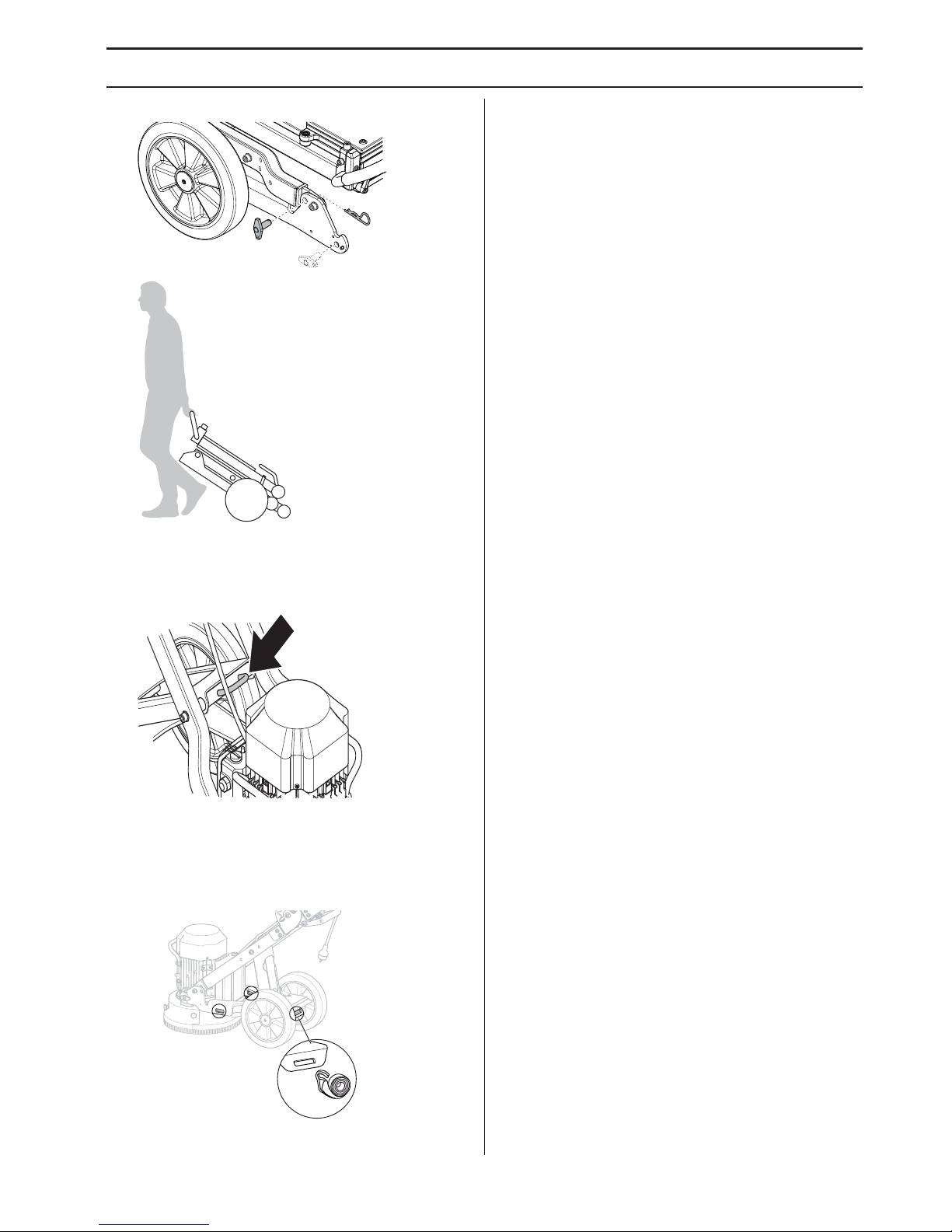

Transport and storage

• Secure the equipment during transportation in order

to avoid transport damage and accidents.

• The machine should be transported under cover

where possible, limiting the exposed to natural

elements – in particular rain and snow.

• Store the equipment in a lockable area so that it is out

of reach of children and unauthorized persons.

• The machine should always be stored in a dry place

when not in use.

Transport

The machine can be taken apart and folded to give a

smaller size when transporting.

• Disconnect the motor cable from the electrical box.

• Loosen the nuts a few turns to release any pressure,

pull out the locking pins and remove the bolts on each

side.

• Loosen the grinding head from the wheel chassis.

• Put the machine in inclined transport position. Loosen

the locking knobs on the support foot.

• Fold forward the support foot.

• Hold down the handle on the angle joint while

simultaneously angling the upper part of the frame

carefully forward.

• Fold up the machine carefully.

1

3

2

1

2

OPERATING

English – 17

• Secure the machine with locking pin and bolt.

Lifting eye

• Always use the machine mounted lifting eye when

lifting. To ensure a balanced lift, use a spotter as

support when lifting.

Secure the machine

The machine is equipped with holes for strapping down

the machine to the vehicle during transport. Attach the

strapping hook into the hole in the chassis and tighten it

firmly downwards.

3X

STARTING AND STOPPING

18 – English

Before starting

• Perform daily maintenance.

• Position grinder on the working area.

• Make sure there are diamonds beneath the machine

and that they are firmly attached.

• Connect the dust extractor to the machine.

• Use locking knobs for handlebar adjustment to set

most comfortable working height.

• Make sure the motor cable is connected to the

electrical box before the machine is plugged into an

electric socket.

• Plug the machine into an electric socket.

• Check that the emergency stop button is not pressed

by turning it clockwise.

• Check the motor’s direction of rotation

Starting

• Reduce the pressure between grinding disc and floor

by pushing down the handle without lifting the grinding

unit from the floor when starting.

• To start the machine. Start the machine by turning the

0/1 knob to position 1 (drive). The machine will then

start smoothly and accelerate to the set speed within

5 seconds.

Stopping

• Turn off the machine with the start/stop knob, turn it to

'0' (stop).

• Keep grinding segments in contact with the floor when

stopping. This will help bring the machine to a

complete stop quickly. Do not lift the grinding head off

the floor when stopping as this can create a significant

amount of dust in the air.

• Pull out the plug.

!

WARNING! Please read the operator’s

manual carefully and make sure you

understand the instructions before using

the machine.

Wear personal protective equipment. See

instructions under the ”Personal

protective equipment” heading.

Make sure no unauthorised persons are

in the working area, otherwise there is a

risk of serious personal injury.

Check that the machine is assembled

correctly and do not show any signs of

damage.

~1 mm

1

2

MAINTENANCE

English – 19

Faults and trouble shooting

The machine does not start

• Check the power supply and the power cables to

make sure they are not damaged.

• Check that the emergency stop button is not pressed

by turning it clockwise.

• Check the overload lamp. If the overload lamp is on,

allow the motor to cool down for a few minutes until the

machine is automatically reset.

Machine is hard to hold onto

• Too few diamonds under the machine or the wrong

type of tool for the application (stiff adhesive or soft

floor coverings result in high stress to the machine

and the user if there are too few diamonds under the

machine). Usually also accompanied by high current

draw by motor.

Use the number of diamonds recommended by

Husqvarna to reduce the stress on the grinder and the

user.

Machine is jumping around

• Diamonds may not be fitted correctly or have different

heights. Check to ensure all diamonds are fitted

correctly and are the same height.

The machine stops after just a while

• The machine is overloaded and the overload

protection has been released. Reduce load. The

machine will reboot after about a minute when the

motor has cooled off.

• Ensure any extension cables are not under

dimensioned.

The machine stops during start-up

• The electric motor has overloaded and the overload

lamp is on. Give the machine one or two minutes to

reset and try again. When this does not help, contact

an authorised service workshop.

• Ensure any extension cables are not under

dimensioned.

Maintenance

Used correctly, the machine is an extremely lowmaintenance and reliable product.

Daily maintenance

• Cleaning

• Electrical Feed

• Brush list

Cleaning

Always pull out the plug from the outlet socket before

cleaning, maintenance or assembly.

Always clean all the equipment at the end of the working

day. Do not use a high pressure washer to clean the

machine.

In order for the machine to always be cooled sufficiently

the cooling air openings must be kept clear and clean.

Electrical Feed

Check that the cord and extension cord are intact and in

good condition.

Never use the machine if the cord is damaged, hand it in

to an authorized service workshop for repair.

Brush list

Make sure the brush strip is whole and reaches down to

the floor.

Service

NOTICE! The lower hole for a higher handlebar and

greater grinding pressure. The upper hole for a lower

handlebar and less grinding pressure.

NOTICE! Good motor performance depends on proper

voltage. Extension cables that are too long and/or which

have a gage that is too small, reduce power to the motor

under load.

IMPORTANT! Inspection and/or maintenance should be

carried out with the motor switched off and the plug

disconnected.

!

WARNING! Never use damaged cables.

They can cause serious, even fatal,

personal injuries.

IMPORTANT! All types of repairs may only be carried

out by authorised repairmen. This is so that the

operators are not exposed to great risks.

20 – English

TECHNICAL DATA

Technical data

Noise emissions

Note 1: Noise emission in the environment measured as sound power according to EN 60335-2-72. Expected

measurement uncertainty 2,5 dB(A).

Note 2: Sound pressure level according to EN 60335-2-72. Expected measurement uncertainty 4 dB(A).

Note 3: Vibration level according to EN 60335-2-72. Reported data for vibration level has a typical statistical dispersion

(standard deviation) of 1 m/s

2

PG280 (Single-phase,

220-240V)

PG280 (Single-phase,

100-120V)

50 Hz 60 Hz 50 Hz 60 Hz

Motor Power, kW/hp 2,2/3,0 2,2/3,0 1,5/2,0 1,5/2,0

Rated current, A 13 13 20 19

Rated voltage, V 220-240 220-240 100-120 100-120

Weight, kg/lbs 72/158 72/158 72/158 72/158

Grinding width, mm/inch 280/11 280/11 280/11 280/11

Grinding pressure, kg/lbs 25/55 25/55 25/55 25/55

Rotation speed - grinding disc, rpm 1410 1730 940 1150

PG280

Noise emissions (see note 1)

Sound power level, measured dB(A) 90

Sound levels (see note 2)

Sound pressure level at the operators ear, dB(A) 74,1

Vibration levels (see note 3)

Handle right, m/s

2

4,0

Handle left, m/s

2

3,8

English – 21

TECHNICAL DATA

EC Declaration of Conformity

(Applies to Europe only)

Husqvarna AB, SE–561 82 Huskvarna, Sweden, tel: +46–36–146500, declares under sole responsibility that the floor

grinder

Husqvarna PG280 dating from 2014 serial numbers and onward (the year is clearly stated on the type plate,

followed by the serial number), complies with the requirements of the COUNCIL’S DIRECTIVE:

• of May 17, 2006 ”relating to machinery” 2006/42/EC.

• of February 26, 2014 ”relating to electromagnetic compatibility” 2014/30/EU.

• of February 26, 2014 ”relating to electrical equipment designed for use within certain voltage limits” 2014/35/EU.

• of June 8, 2011 on the ”restriction of use of certain hazardous substances” 2011/65/EU.

The following standards have been applied: EN ISO 12100:2010, EN 55014-1:2006+A1:2009+A2:2011, EN 55014-

2:1997+A1:2001+A2:2008, EN 61000-3-11, EN 60335-2-72:2012, EN 60335-1:2010.

The supplied machine conforms to the example that underwent EC type examination.

Partille, August 21, 2017

Joakim Ed

Global R & D Director

Construction Equipment Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

SYMBOLERKLÄRUNG

22 – German

Symbole am Gerät:

WARNUNG! Das Gerät kann falsch

oder nachlässig angewendet gefährlich

sein und zu schweren oder gar

lebensgefährlichen Verletzungen des

Benutzers oder anderer Personen

führen.

Lesen Sie die Bedienungsanweisung

sorgfältig durch und machen Sie sich

mit dem Inhalt vertraut, bevor Sie das

Gerät benutzen.

Tragen Sie persönliche

Schutzausrüstung. Siehe die

Anweisungen unter der Überschrift

”Persönliche Schutzausrüstung”.

WARNUNG! Bei der Arbeit mit dem

Schleifer bildet sich Staub, der beim

Einatmen gesundheitsschädlich sein

kann. Verwenden Sie einen

zugelassenen Atemschutz. Sorgen Sie

stets für gute Belüftung.

Dieses Produkt stimmt mit den

geltenden CE-Richtlinien überein.

Umweltkennzeichnung. Das

Symbol auf dem Produkt oder der

Verpackung gibt an, dass dieses

Produkt nicht im Hausmüll entsorgt

werden darf.

Durch eine korrekte Entsorgung dieses

Produkts tragen Sie dazu bei, mögliche

negative Auswirkungen auf Ihre

Umwelt und Mitmenschen zu

verhindern. Durch eine unsachgemäße Entsorgung

dieses Produkts können Schäden entstehen.

Ausführliche Recyclinginformationen zu diesem Produkt

erhalten Sie von Ihrer Kommune,

Entsorgungsunternehmen für Hausmüll oder dem

Geschäft, in dem Sie das Produkt erworben haben.

Sonstige Symbole/Aufkleber am Gerät beziehen sich

auf spezielle Zertifizierungsanforderungen, die in

bestimmten Ländern gelten.

Erläuterung der Warnstufen

Es bestehen drei unterschiedliche Warnstufen.

WARNUNG!

ACHTUNG!

HINWEIS!

!

WARNUNG! Zeigt eine Gefahrensituation

an, deren Nichtvermeidung zum Tod oder

zu schweren Verletzungen führen kann.

!

ACHTUNG! Zeigt eine Gefahrensituation

an, deren Nichtvermeidung zu leichten

oder mittleren Verletzungen führen kann.

HINWEIS! Weist auf Handlungen hin, die nicht zu

Verletzungen führen.

INHALT

German – 23

Inhalt

SYMBOLERKLÄRUNG

Symbole am Gerät: ............................................... 22

Erläuterung der Warnstufen ................................. 22

INHALT

Inhalt ..................................................................... 23

VORSTELLUNG

Sehr geehrter Kunde! ........................................... 24

Konstruktion und Funktionen ................................ 24

PG280 .................................................................. 24

WAS IST WAS?

Was ist was am Schleifer? .................................... 25

SICHERHEITSAUSRÜSTUNG DES GERÄTES

Allgemeines .......................................................... 26

Stopp-/Anlassschalter .......................................... 26

Nothalt .................................................................. 26

BETRIEB

Allgemeine Sicherheitsvorschriften ...................... 27

Persönliche Sicherheit .......................................... 28

Verschiedene Maschinenmodi ............................. 30

Handgriffverstellung ............................................. 30

Einstellung der Rahmenhöhe ............................... 30

Schleifdrücke ........................................................ 31

Anschließen des Unterdrucksaugers ................... 31

Anleitung zum Schleifen ....................................... 31

Bestimmung des Härtegrads von Beton ............... 32

Motordrehrichtung ................................................ 32

Auswahl der Diamanten ....................................... 33

Auswechseln der Diamanten ................................ 35

Kantenschleifen ................................................... 36

Transport und Aufbewahrung ............................... 37

STARTEN UND STOPPEN

Vor dem Start ....................................................... 39

Starten .................................................................. 39

Stoppen ................................................................ 39

WARTUNG

Störungsbeseitigung ............................................. 40

Wartung ................................................................ 40

Service ................................................................. 40

TECHNISCHE DATEN

Technische Daten ................................................. 41

EG-Konformitätserklärung .................................... 42

VORSTELLUNG

24 – German

Sehr geehrter Kunde!

Vielen Dank, dass Sie sich für ein Produkt von Husqvarna

entschieden haben.

Wir hoffen, dass Sie mit Ihrer Maschine über lange Jahre

zufrieden sein werden. Mit dem Erwerb unserer Produkte

erhalten Sie professionelle Hilfe bei Reparaturen und

Service. Haben Sie das Gerät nicht bei einem unserer

Vertragshändler gekauft, fragen Sie dort nach der

nächsten Servicewerkstatt.

Diese Bedienungsanweisung ist ein wertvolles

Dokument. Halten Sie die Bedienungsanweisung stets

griffbereit. Die genaue Befolgung ihres Inhalts

(Verwendung, Service, Wartung usw.) verlängert die

Lebensdauer der Maschine erheblich und erhöht zudem

ihren Wiederverkaufswert.Sollten Sie Ihre Maschine

verkaufen, händigen Sie dem neuen Besitzer bitte auch

die Bedienungsanleitung aus.

Über 300 Jahre Innovationsgeschichte

Husqvarna ist ein schwedisches Unternehmen, dessen

Geschichte bis ins Jahr 1689 zurückreicht, als König Karl

XI eine Fabrik errichten ließ, in der Musketen gefertigt

werden sollten. Damit wurden die Grundlagen einer

erfolgreichen Firmengeschichte gelegt, in deren Verlauf

bahnbrechende technische Neuerungen in Bereichen wie

Waffensysteme, Fahr- und Motorräder, Haushaltsgeräte,

Nähmaschinen und Gartenprodukte auf den Markt

gebracht werden konnten.

Husqvarna gilt als führender Anbieter von Geräten zur

Garten- und Waldpflege sowie von Schneidausrüstungen

und Diamantwerkzeugen für die Bau- und Steinindustrie.

Pflichten des Betreibers

Der Betreiber ist verpflichtet, nur entsprechend

ausgebildete Personen mit der Bedienung der Maschine

zu betrauen. Aufsichtspersonen und Bediener haben

sämtliche Anweisungen in diesem Handbuch zur

Kenntnis zu nehmen. Insbesondere ist auf Folgendes zu

achten:

• Sicherheitshinweise

• Vorgesehene Anwendungsbereiche

• Nutzungs- und Wartungshinweise

Die Benutzung dieser Maschine könnte durch eine

nationales Gesetz geregelt sein. Finden Sie heraus,

welche Gesetze Anwendung finden, bevor Sie mit der

Benutzung der Maschine beginnen.

Vorbehaltsbestimmungen des Herstellers

Es ist möglich, dass Husqvarna nach der Veröffentlichung

dieses Handbuchs weitere Informationen zum sicheren

Betrieb dieses Produkts herausgibt. Der Betreiber ist

verpflichtet, stets über die sichersten Betriebsverfahren

informiert zu sein.

Die Husqvarna AB arbeitet ständig an der

Weiterentwicklung ihrer Produkte und behält sich daher

das Recht auf Änderungen ohne vorherige Ankündigung,

z. B. von Form und Aussehen, vor.

Informationen und Hilfe für unsere Kunden bietet unsere

Website: www.husqvarna.com

Konstruktion und Funktionen

Die Entwicklung von zuverlässigen und innovativen

Hochleistungstechnologien und eine umweltfreundliche

Produktfertigung sind die erklärten Ziele von Husqvarna.

Ein sicherer Betrieb dieses Produkts setzt voraus, dass

der Betreiber dieses Handbuch aufmerksam durchliest.

Weitere Informationen erhalten Sie von Ihrem Händler

oder Husqvarna.

Hier werden einige der Funktionen aufgeführt, die

unseren Produkten das entscheidende Plus an Qualität

verleihen.

PG280

• Die Maschine ist für das Schleifen von BetonOberflächen unterschiedlicher Härtegrade ausgelegt.

• PG280 Sie ist robust und benutzerfreundlich

• Die Maschine kann zum einfacheren Transportieren

zusammengeklappt werden.

• Die Maschine ist mit einer Schwimmabdeckung

ausgerüstet.

• Die Maschine ist eine Kantenschleifmaschine.

• 1-phasig

• 280 mm Schleiffläche

German – 25

WAS IST WAS?

Was ist was am Schleifer?

2

1

4

24

3

4

5

6

7

8

9

10

11

12

13

15

16

17

18

19

20

21

22

23

24

25

14

1 Betriebsstundenzähler

2 Schaltkasten

3 Griff/Führungsholm

4 Verriegelungshebel für die Lenkereinstellung

5 Nothalt

6 Überlastlampe

7 Stopp-/Anlassschalter

8 Anschluss, Schnellanschluss für Motorkabel

9 Handgriff für Winkelanschluss

10 Stecker

11 Fußpedal

12 Verriegelungsknopf

13 Gummiräder

14 Verbindung, Vakuumschlauch

15 Sperrfunktion

16 Befestigung für Motor/Schleifkopf

17 Schrauben für Luke zum Kantenschleifen

18 Luke, Kantenschleifen

19 Lifting eye

20 Elektromotor

21 Hubhebel, Motor

22 Schwimmabdeckung

23 Werkzeugplatte

24 Bürstenrasterung

25 Bedienungsanweisung

SICHERHEITSAUSRÜSTUNG DES GERÄTES

26 – German

Allgemeines

In diesem Abschnitt werden einzelnen Teile der

Sicherheitsausrüstung des Gerätes beschrieben, welche

Funktion sie haben und wie ihre Kontrolle und Wartung

ausgeführt werden sollen, um sicherzustellen, dass sie

funktionsfähig sind.

Stopp-/Anlassschalter

Der Start/Stopp-Knopf wird zum Starten und Abstellen

des Gerätes verwendet.

Überprüfen des Stopp-/Anlassschalters

Stellen Sie sicher, dass die Not-Aus- oder die MaschinenStopp-Taste nicht betätigt wird, indem Sie sie im

Uhrzeigersinn drehen.

• Senken Sie den Druck zwischen der Schleifscheibe

und dem Boden durch Herunterdrücken des

Handgriffs, ohne dass das Schleifgerät beim Start

vom Boden angehoben wird.

• Starten Sie die Maschine durch Drehen des Start/

Stopp-Knopfs in Position 1 (Antrieb). Die Maschine

startet dann reibungslos und beschleunigt innerhalb

von 5 Sekunden auf die eingestellte Geschwindigkeit.

• Drehen Sie den Start/Stopp-Knopf auf 0 (Stopp), um

die Maschine anzuhalten.

Nothalt

Mit dem Notschalter kann die Maschine schnell

abgeschaltet werden. Mit dem Notschalter der Maschine

können Sie die Stromzufuhr zur Maschine unterbrechen.

Testen des Notschalters

• Drücken Sie den Notschalter (STOP). Prüfen Sie, ob

der Motor stoppt.

• Not-Aus-Taster freigeben (im Uhrzeigersinn drehen).

!

WARNUNG! Benutzen Sie nie ein Gerät

mit defekter Sicherheitsausrüstung. Die

Sicherheitsausrüstung des Gerätes

muss so kontrolliert und gewartet

werden, wie dies in diesem Abschnitt

beschrieben wird. Wenn Ihr Gerät den

Kontrollanforderungen nicht entspricht,

muss eine Servicewerkstatt aufgesucht

werden.

ACHTUNG! Schließen Sie das Motorkabel an den

Schaltkasten an, bevor der Stecker angeschlossen

wird.

~1 mm

1

2

1

2

BETRIEB

German – 27

Allgemeine

Sicherheitsvorschriften

• Lesen Sie vor der Inbetriebnahme der Maschine

diese Bedienungsanleitung aufmerksam durch und

machen Sie sich mit dem Inhalt vertraut.

Bewahren

Sie alle Warnhinweise und Anweisungen für

spätere Referenzzwecke auf.

Sicherheit im Arbeitsbereich

• Sorgen Sie für einen sauberen und gut

ausgeleuchteten Arbeitsbereich.

Durch zugestellte

oder dunkle Arbeitsbereiche steigt die Unfallgefahr

stark an.

• Kein Betrieb der Maschine in feuer- und

explosionsgefährdeten Bereichen.

Elektrische Sicherheit

• Kontrollieren, ob die Netzspannung mit der auf dem

Geräteschild angegebenen übereinstimmt.

• Kontrollen und/oder Wartungsarbeiten sind bei

abgeschaltetem Motor und abgezogenem Stecker

durchzuführen.

• Schalten sie das Gerät aus, bevor Sie den

Stromstecker ziehen.

• Maschine nicht am Netzkabel ziehen und Stecker

nicht am Kabel aus der Steckdose ziehen. Ziehen Sie

direkt am Stecker, nicht am Kabel.

• Das Gerät nicht benutzen, wenn ein Kabel oder

Stecker beschädigt ist, sondern zur Reparatur in eine

autorisierte Servicewerkstatt geben.

• Beim Betrieb unter Wasser darf die Maschine nicht so

weit getaucht werden, dass die Gerätschaften

dadurch beschädigt werden. Bei spannungsführender

Maschine können außerdem Verletzungen die Folge

sein.

• Achten Sie stets darauf, dass das Stromkabel nicht

angeschlossen ist, wenn Sie den Kontakt zwischen

Motor und Schaltkasten herstellen oder trennen.

!

WARNUNG! In diesem Abschnitt werden

grundlegende Sicherheitsregeln

vorgestellt. Die folgenden Informationen

sind kein Ersatz für das Wissen, das ein

professioneller Anwender durch seine

Ausbildung und praktische Erfahrung

erworben hat. Lassen Sie sich bei

Unsicherheiten von einer Fachkraft

beraten. Fragen Sie Ihren Fachhändler,

Ihre Servicewerkstatt oder einen

erfahrenen Anwender. Führen Sie keine

Arbeiten aus, wenn Unsicherheiten

bezüglich der richtigen Vorgehensweise

bestehen.

!

WARNUNG! An elektrisch betriebenen

Geräten besteht stets die Gefahr von

elektrischen Schlägen. Ungünstige

Witterungsbedingungen sowie einen

Körperkontakt mit Blitzableiter und

metallischen Gegenständen vermeiden.

Stets die Vorgaben in der

Bedienungsanleitung befolgen, um

Schäden auszuschließen.

Schließen Sie das Gerät niemals an eine

Steckdose an, wenn Stecker oder Kabel

beschädigt sind.

!

ACHTUNG! Das Gerät erfüllt die

Anforderungen nach EN

61000-3-11 und

kann unter bestimmten Bedingungen an

das Netz angeschlossen werden. Es

kann in Absprache mit dem

Energieversorgungsunternehmen

angeschlossen werden.

Das Gerät kann nur an das Stromnetz

angeschlossen werden, wenn die

Impedanz weniger als 0,28

Ohm beträgt.

Die Systemimpedanz am

Anschlusspunkt kann beim

Energieversorgungsunternehmen erfragt

werden.

Wenn das Stromnetz über eine höhere

Impedanz verfügt, können beim Start des

Geräts kurze Spannungseinbrüche

auftreten. Dies kann Einfluss auf den

Betrieb anderer Produkte haben, z.

B.

Flackern von Lampen.

Loading...

Loading...