Page 1

Hot Runner Systems

English Metric 2005.

SP-Series

09

For use with DME/National standard mold bases

Information and specifications subject to change without notice. For latest product

information please refer to www.hotrunners.com

2005.09

or contact Husky

Page 2

PRONTO

PRONTO SP-Series Hot Runner Systems

• 4 week delivery

• Reduced cost

• 40 plate sizes matching DME/National mold base standards

• Variable nozzle length within allowable range

• Almost unlimited nozzle pitch flexibility

• 7 different manifold configurations

• 2 nozzle sizes

• 8 gating options

• Fully optimized melt channel sizing

• 3 year-leakproof warranty

HUSKY offers a full line of standard plate size hot runners which have all the fe atures of our custom systems but are

offered at lower cost and faster deliveries. SP-series plates have been designed to mate with D-M-E and National

industry-standard mold bases and the manifolds have been designed to provide a large degree of flexibility when laying

out cavities. Other series are also available for Hasco (KP) mold bases, Futaba (FP) mold bases and OMNI (MP) Mold

Systems mold bases.

Pronto hot runners are available in 2, 4, and 8 drop configurations with VG, VX, HT & TS Ultra 500 & Ultra 750 nozzles.

The plastic material to be processed should be reviewed with the material compatibility chart available on

www.hotrunners.com. This will determine if the application being considered is suitable for the Pronto manifold and nozzlegating combination. The appropriate melt channel sizes will be selected by Husky based on the resin and part information

provided.

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

2

SP-series 2005.09

Page 3

PRONTO

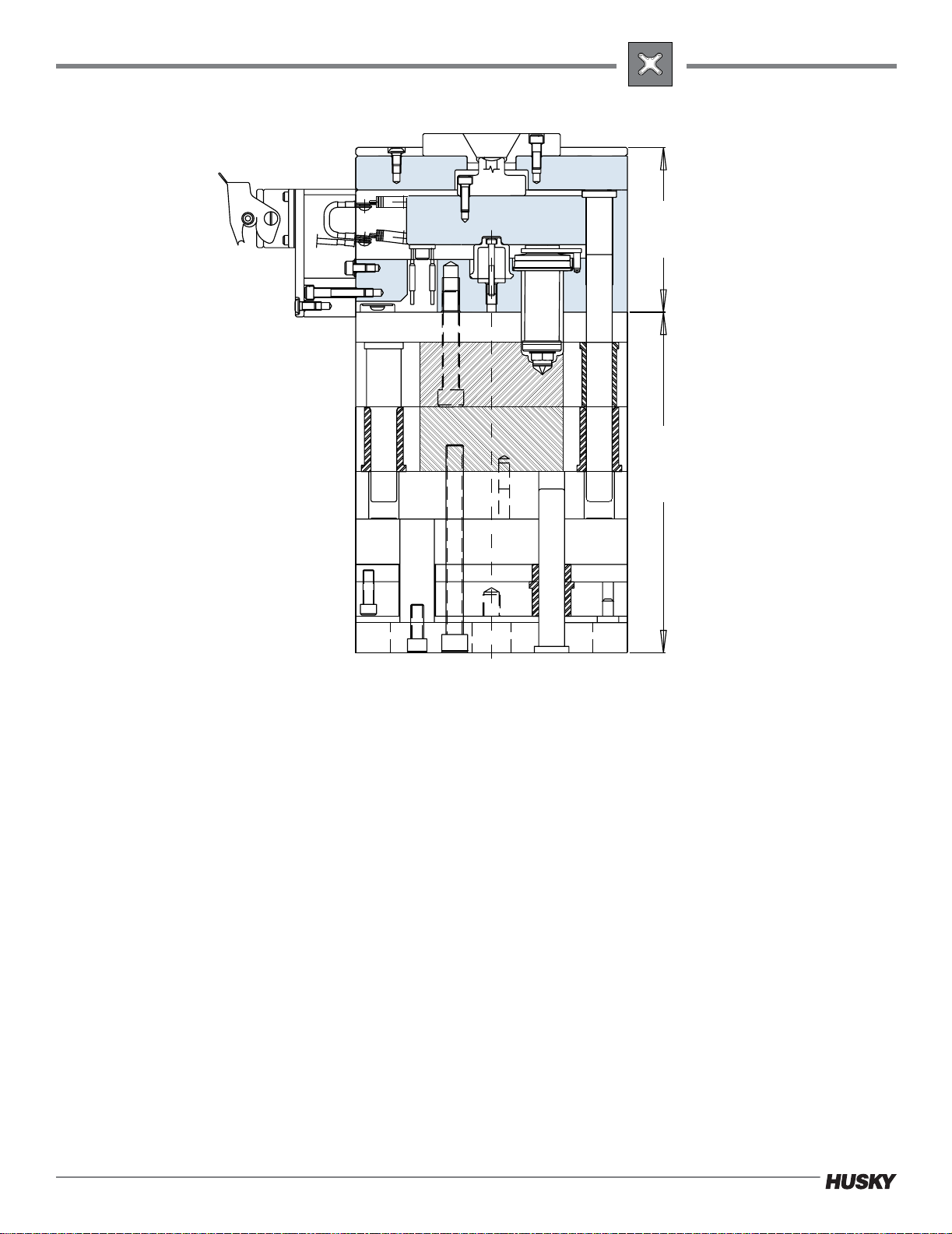

Pronto Hot Runner

System

Industry standard

mold base

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

3

Page 4

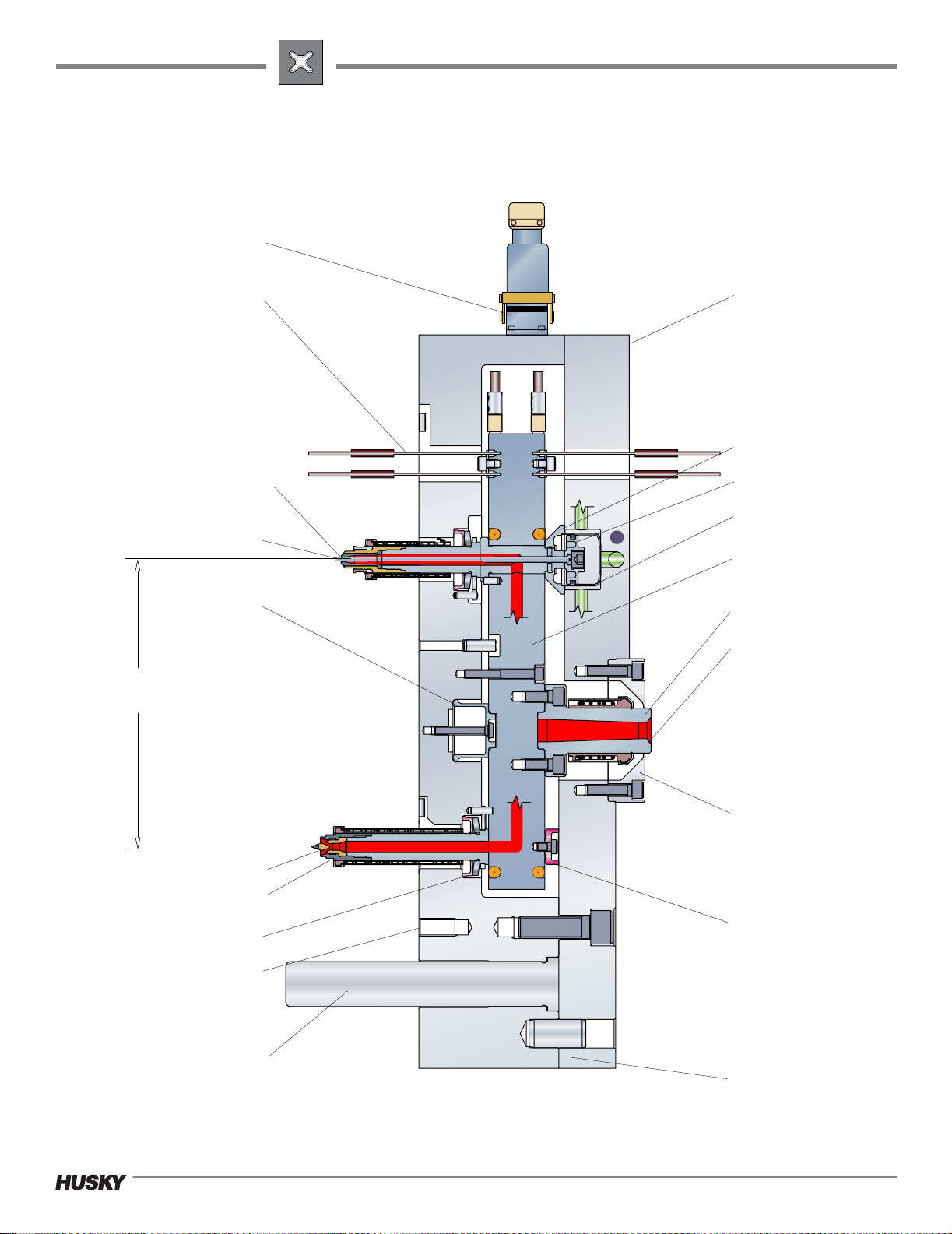

PRONTO Hot Runner System Design Guidelines

Electrical Connectors

Manifold Thermocouple

Ultra 750 Nozzle

VG Available With

1.0mm (0.039"), 1.8mm

(0.071"), or 2.5mm (0.098")

Gate Diameter

Ultra 500 VG/VX available with

1.0mm (0.039"), 1.2mm

(0.047"), 1.5mm (0.059") or

1.8mm (0.071")

Gate Diameter

Valve Stem

PRONTO

Optional 6.35mm

(1/4") platen

insulator board

available (not

shown)

Back-Up Pad

Piston

Piston Cylinder

Manifold

Center Insulator

Flexible

Pitch

Nozzle Ti p Insert

Tip Retainer

UltraSeal

1/2" - 13 UNC or M12

Cavity Plate Interface Taps

3/4" and 1" or

16mm and 20mm

Diameter Guide Pin

Sprue Bushing

Five Choices of Sprue

Bushing Interface

(Flat, 1/2", 3/4",

10.0mm, 15.5mm,

20.0mm & 40.0mm

Spherical Rad)

Six Choices of

Locating Ring Dia.

(3.99", 4.00"

100.0mm, 120.0mm,

125.0mm and

160.0mm)

Back-Up Insulator

Pad

Industry Standard Mold

Base Sizes

The top nozzle displays a valve gate (VG) system and the bottom nozzle displays a thermal gate (HT) system.

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

4

SP-series 2005.09

Page 5

PRONTO

PRONTO Hot Runner System Selection

Pronto Hot Runners are designed to mate directly with the most popular industry standard mold bases. Replacing the top

clamp plate of a standard mold set with a Husky hot runner will give you a complete runnerless mold solution. Pronto SPseries systems are available with 40 different sizes of plates which can be ordered in 2, 4, and 8-drop manifold

configurations. Flexible nozzle spacing and L-dimensions and 8 gating styles provide maximum flexibility.

Standard features and options of Pronto Hot Runner Systems include:

• Flexible nozzle spacing within allowable range for given plate size

• 4 guide pins located such that they will not interfere with mold leader pins or return pins. 3/4" or 16mm diameter on 17

7/8" x 23 1/2" and smaller plates, 1" or 20mm diameter on larger plates

• A large number of ½"-13 UNC or M12 cavity plate interface taps of which a minimum number must be incorporated into

the mold design

• Industry standard air fittings on the non-operator side of the mold and water fittings on the bottom of the mold

• For 2 and 4 drop systems a choice of: two 24-pin connectors, o ne 24-pin an d one 25-pin, on e 16-pin and one 25-pin or

two 16-pin electrical connectors located on top of the hot runner with a flexible wiring sequence

• For 8 drop systems a choice of: four 24-pin connectors, two 24-pin and two 25-pin, two 16-pin and two 25-pin or four

16-pin electrical connectors located on top of the ho t ru nn er w ith a flexib le wirin g se qu en ce

• Optional 6.35mm (

• Choice of 3.99", 4.00", 100mm, 120mm , 12 5m m or 16 0 mm loca tin g rin g diam eter

• Choice of flat, ½", ¾", 10.0mm, 15.5mm, 20.0mm or 40.0mm spherical radius sprue bushing interface

• Clamp slots (always on operator and non-operator plate sides)

• Plunger shut-off standard (Ultra 500 & Ultra 750 VG & VX). Ultr a 500 and Ultra 750 taper available upon request.

HUSKY recommends the use of a 25mm (1") spacer plate between the cavity plate and the hot runner plates if any mold

components require steel back-up. The orientation of the manifolds within the hot runner plates and the thickness of the

plates is pre-determined by Husky.

¼"’) platen insulator board

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

5

Page 6

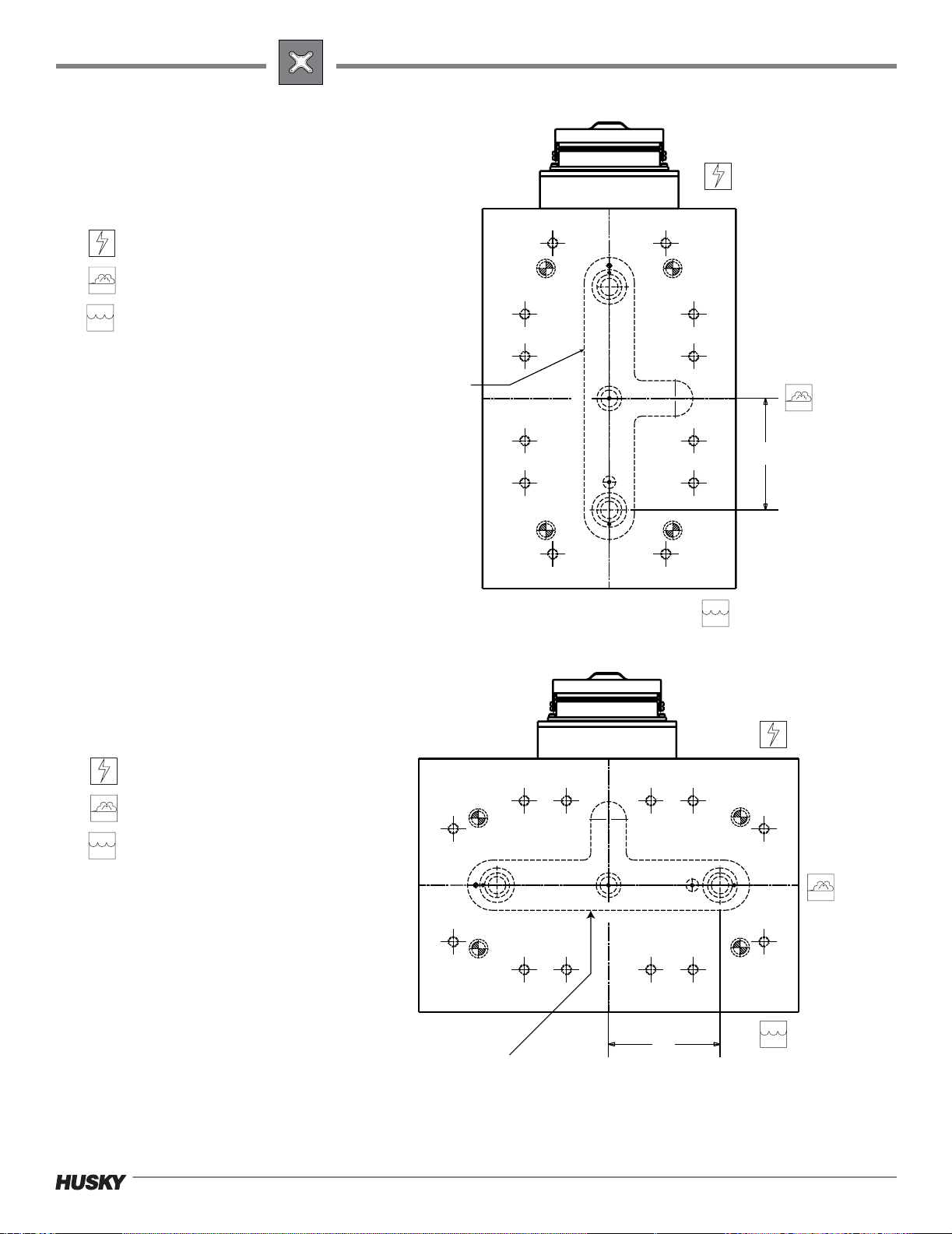

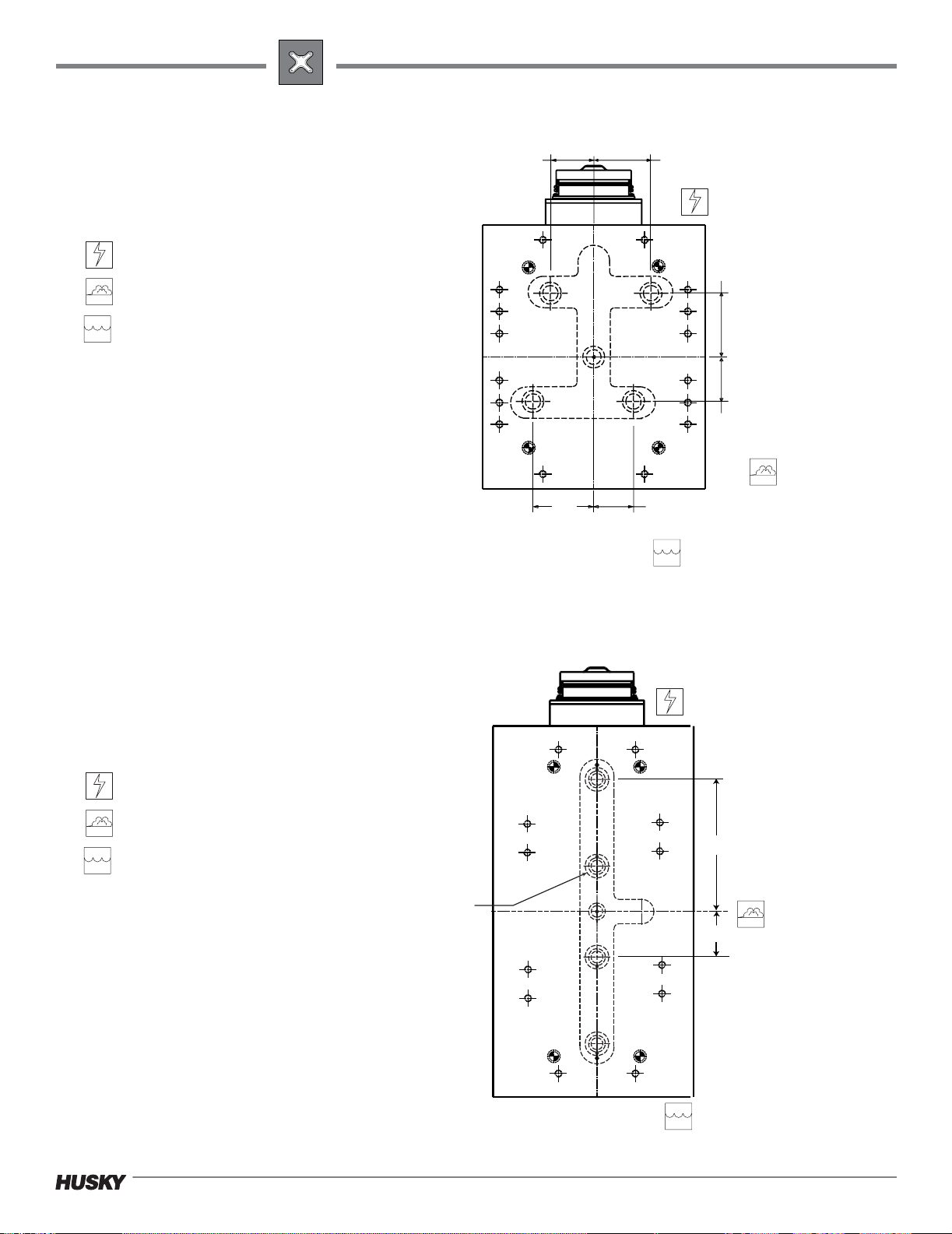

2 Drop A-Type

Orientation

Electrical

Air (Valve Gate)

Cooling water

PRONTO

TOP

OPERATOR

Drops Aligned

With Short Side

Of Plate

X

2 Drop B-Type

Orientation

Electrical

Air (Valve Gate)

Cooling water

TOP

OPERATOR

Drops Aligned

With Short Side

Of Plate

X

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

6

SP-series 2005.09

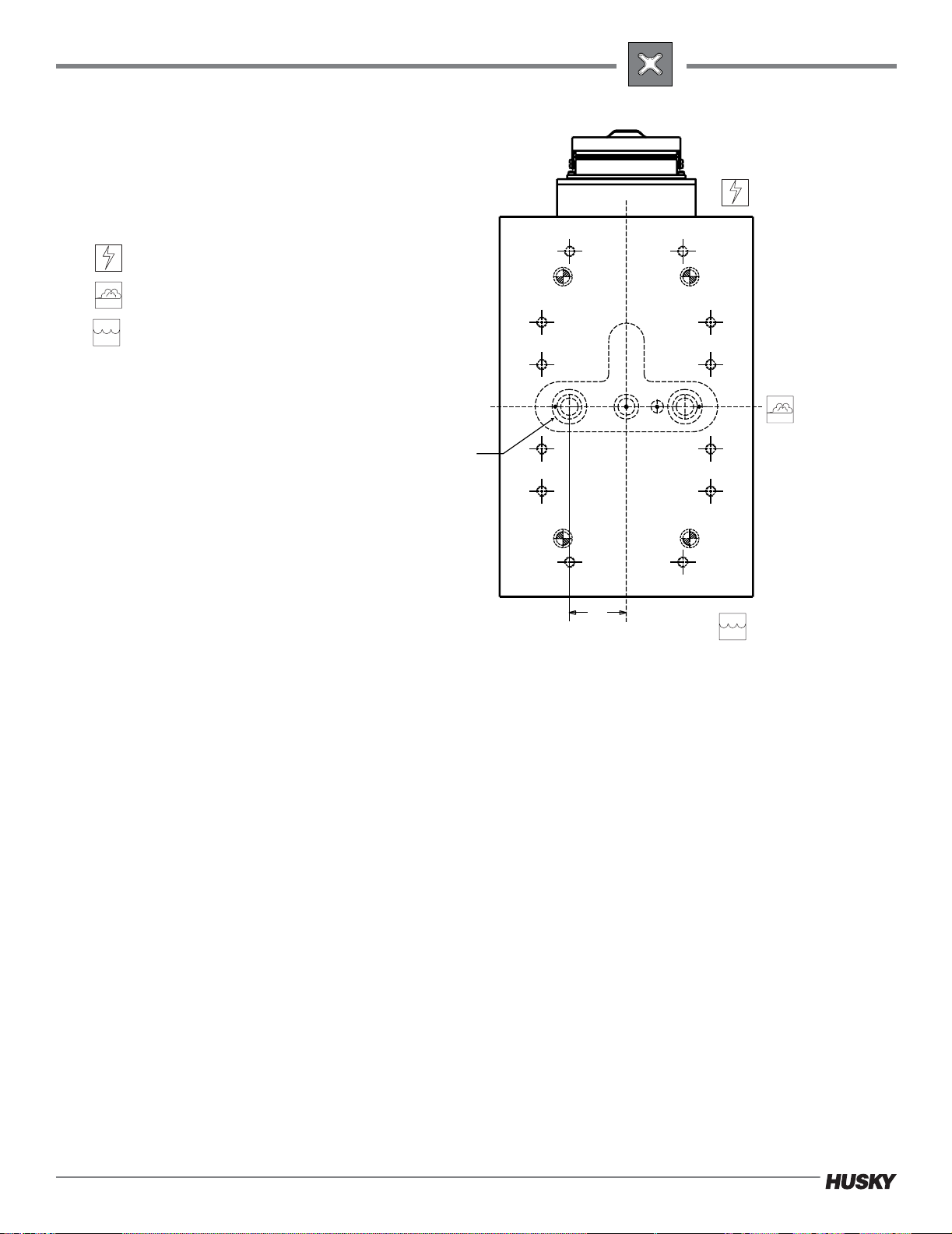

Page 7

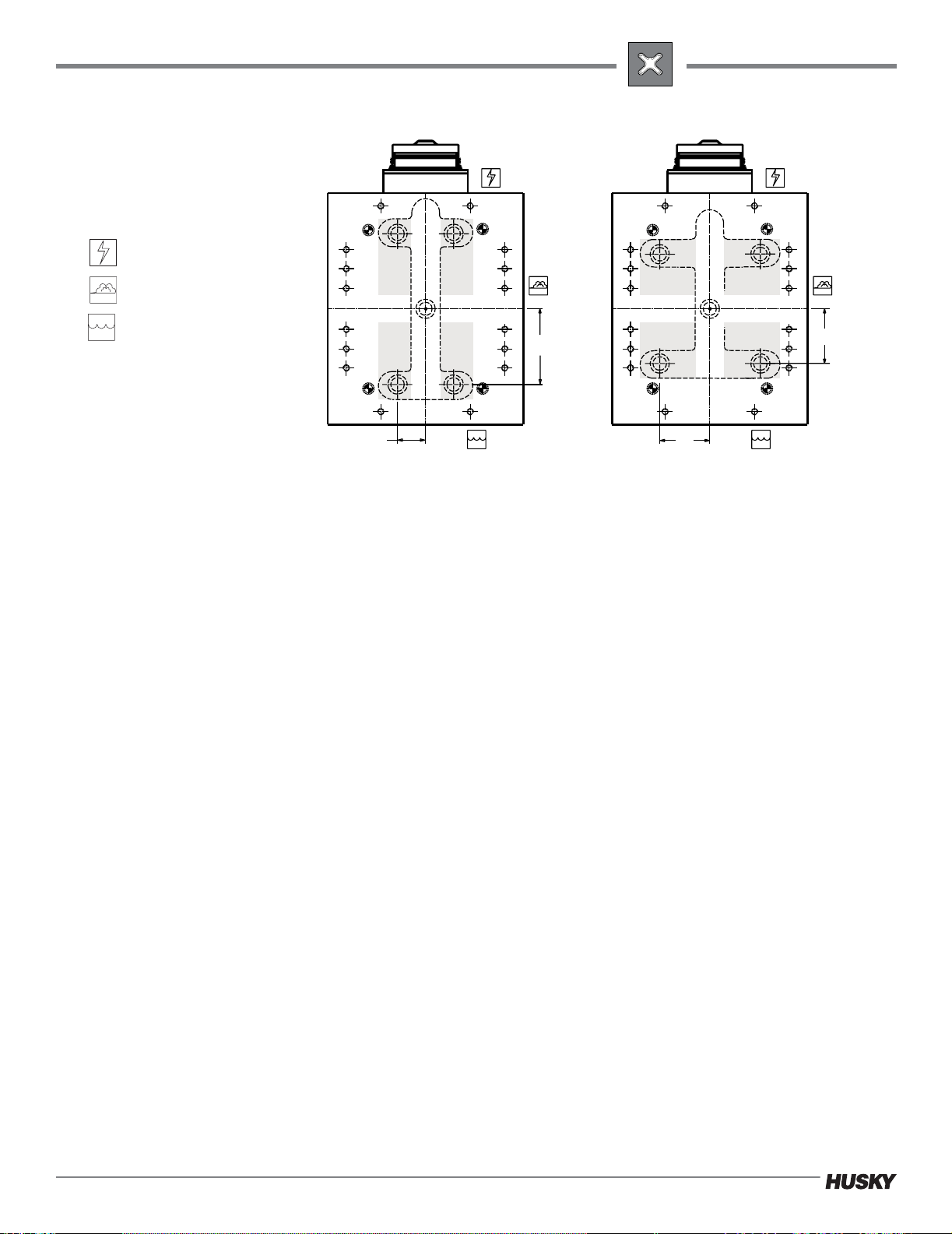

PRONTO

2 Drop C-Type

Orientation

TOP

OPERATOR

Electrical

Air (Valve Gate)

Cooling water

Drops Aligned

With Short Side

Of Plate

X

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

7

Page 8

X1 X2

4 Drop N-Type

Orientation

PRONTO

TOP

OPERATOR

Electrical

Air (Valve Gate)

Cooling water

4 Drop L-Type

Orientation

TOP

X3

Y1

Y2

X4

Electrical

Air (Valve Gate)

Cooling water

OPERATOR

Y

Drops Aligned

With Long Side

Of Plate

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

8

X

SP-series 2005.09

Page 9

PRONTO

4 Drop H-Type

Orientation

Electrical

Air (Valve Gate)

OPERATOR

TOP

TOP

OPERATOR

Cooling water

Y1

X1

LAYOUT 1

X2

LAYOUT 2

4 Drop H-Type Advantages:

The 4 drop H-Type provides increased flexibility concerning drop positioning (note- all drops are symmetrical to

one another). Determining which layout option to select, is dependent upon whether your drops are positioned

inside the guidepins vertically (Layout 1) or horizontally (Layout 2),

When determining drop locations, consider the following:

Y2

• If drop locations fall within the shaded region shown in Layout 1, X1/Y1 pitch maximums must be used.

• If drop locations fall within the shaded region shown in Layout 2, X2/Y2 pitch maximums must be used.

• There is a common region defined by X1/Y2. If your drops fall within these parameters, Layout 1 or Layout 2

can be used.

• Incompatible configurations are X2/Y1.

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

9

Page 10

2

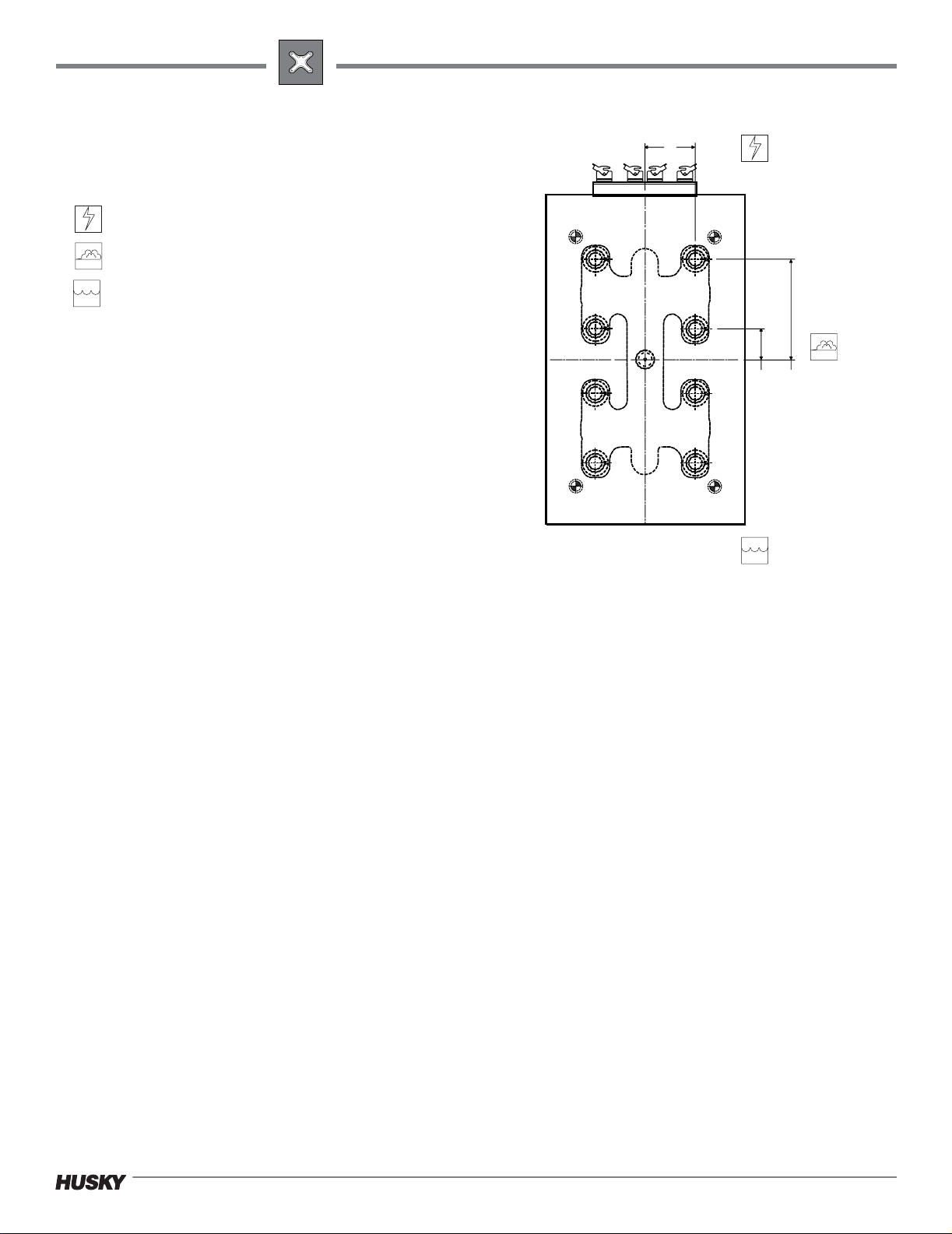

8 Drop H-Type

Orientation

Electrical

Air (Valve Gate)

OPERATOR

TOP

PRONTO

X

Cooling water

Drops Aligned

With Long Side

Of Plate

Y1

Y

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

10

SP-series 2005.09

Page 11

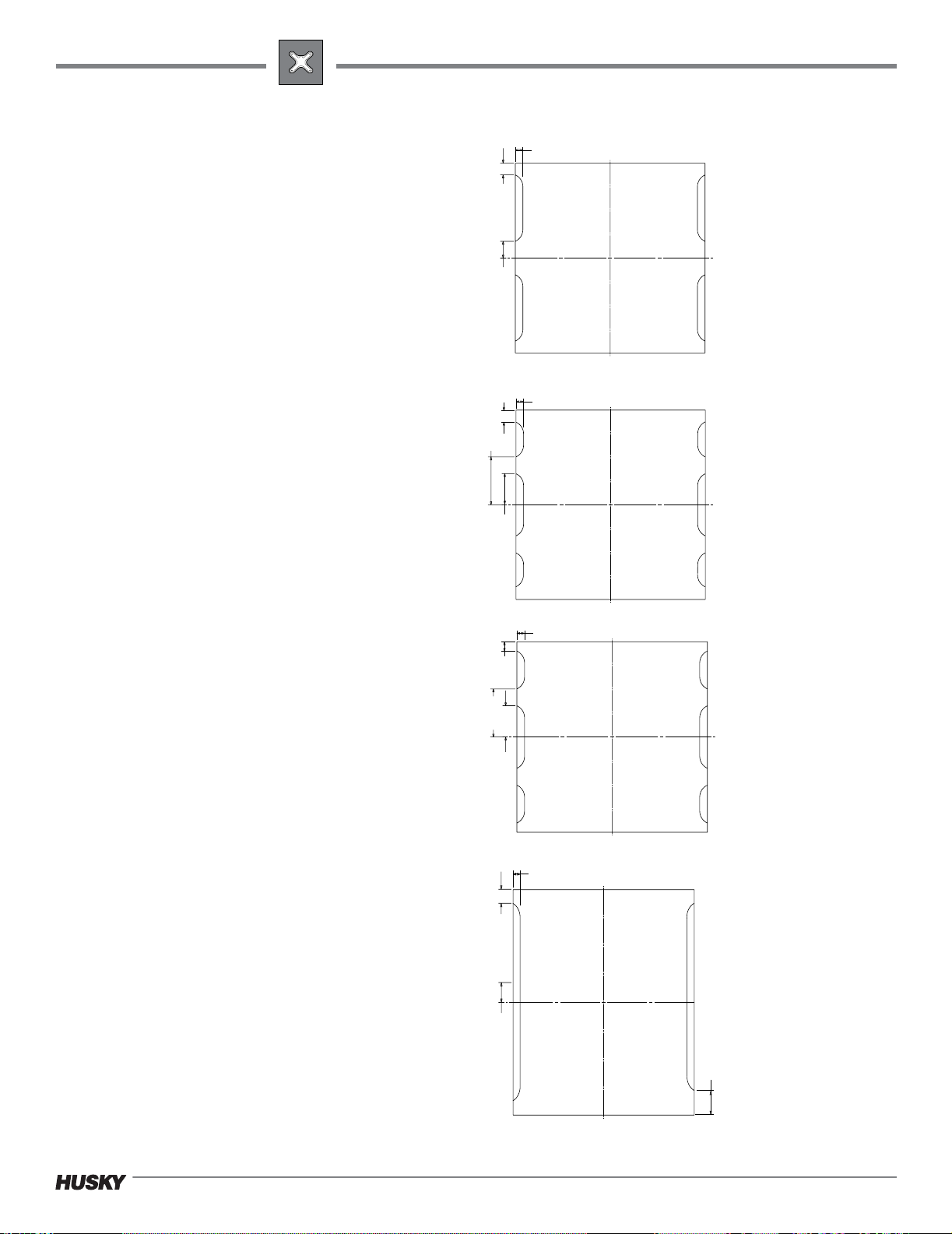

PRONTO Clamp Slot Configurations

16 mm

52mm (VG/VX)

Clamp slot configuration for 2A, 4N, 4H, and 4LType orientations.

Clamp slot configuration for 2B Type orientations.

28 mm

35 mm

Operator Side

28 mm

100 mm

16 mm

16 mm

PRONTO

Top

Top

Clamp slot configuration for 2C Type orientations.

Clamp slot configuration for 8H-Type orie ntations.

Operator Side

100mm

Operator Side

65 mm

28mm

60mm

28 mm

16 mm

Top

Top

28mm (HT/TS)

35 mm

Operator Side

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

11

SP-series 2005.09

Page 12

PRONTO

To configure Pronto hot runners follow the three simple steps below.

1 Determine the nozzle pitch required for the mold design and ensure that it is within the allowable range for the desired

size of plates.

2 Select the gating method suitable to your application

3 Select the desired nozzle length based on L-dimension range availab le for the selected gating style

For example, for a 9 7/8 x 20 hot runner, 2A-Type manifold, 750 nozzle size, 4.875" X-dimension, valve gated VG tips and

1.750" L-dimension order:

SP1020-7502A04.875I-VG-01.750

SP1020 7502A04.875/xx.xxxI VG 01.750

"I" for imperial

Manifold plate

length to nearest

Manifold plate width

to nearest inch

"SP" for SP-seires

with imperial

screws and

guidepins.

"SMP" for SP-

"M" for metric

SP and SMP-

series Pronto

Y-dimension (for 4H/4LTypes only center of

manifold to outer drop in

inches, three decimals)

X-dimension (center of

manifold to outer drop in

inches, three decimals)

A, B, C, H or L Type manifold

Number of drops

Nozzle size

Gate style

L- dimension

(in inches,

three

decimals)

STEP 1 - Ensure that the selected nozzle pitch is within the allowable guidelines of the plate model as shown in the charts

on the following pages.

• 2A, 2B and 2C manifolds have a minimum X-dimension of 60.0mm (2.362") for Ultra 500 & Ultra 750 thermal gates (HT

and TS) and 70.0mm (2.756") for Ultra 500 & Ultra 750 valve gates (VG and VX).

• 4L manifolds have a minimum X-dimension of 60.0mm (2.362") and a minimum Y-dimension of X + 45mm (1.772") for

Ultra 500 & Ultra 750 thermal gates (HT and TS). 4L mani folds have a minimum X-dimension of 70.0mm (2.756") and

a minimum Y-dimension of X + 57mm (2.244") for Ultra 500 & Ultra 750 valve gates (VG and VX).

• 4H and 4N manifolds have a minimum X-dimension of 50mm (1.969") and a minimum Y-dimension of 50mm (1.969")

for all nozzle series and gating options.

• 8H manifold minimum X & Y dimensions are as follows:

• HT 500 [Min ’X’ > 73mm (2.87") / Min ’Y1’ > 61.3mm (2.41") / Min ’Y2’>Y1+62mm (2.44")]

• HT 750 [Min ’X’ > 73mm (2.87") / Min ’Y1’ > 61.3mm (2.41") / Min ’Y2’ > Y1 + 62mm (2.44")],

• VG 500/750 [Min ’X’ > 73mm (2.87") / Min ’Y1’ > 61.3mm (2.41") / Min ’Y2’ > Y1 + 62mm (2.44")]

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

12

Page 13

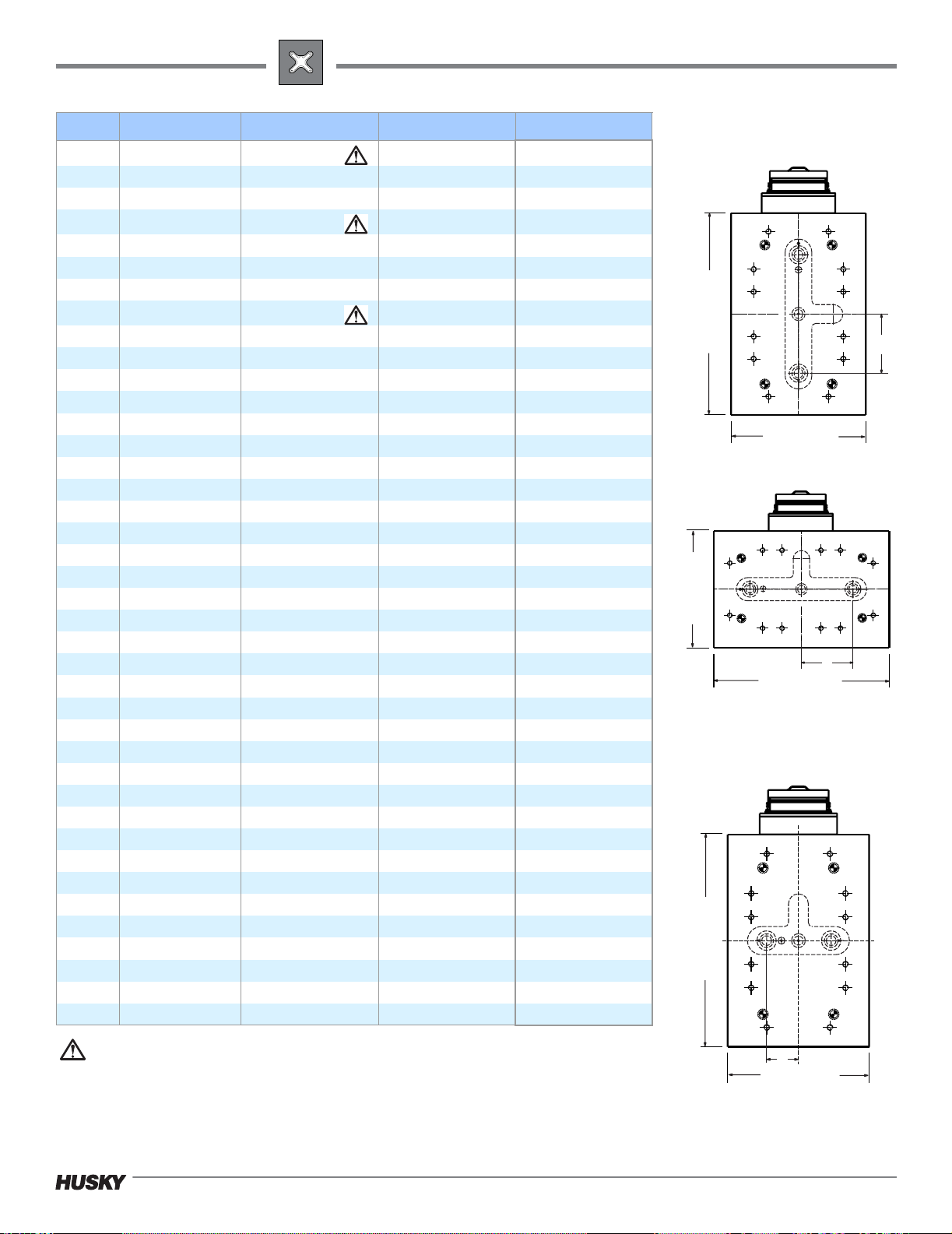

Part # Width x Length 2A-Type Max. "X" 2B-Type Max. "X" 2C-Type Max. "X"

PRONTO

SP1012 9.875 x 11.875

SP1016 9.875 x 16.000 119mm (4.685") 114mm (4.488") N/A

SP1020 9.875 x 20.000 169mm (6.654") 164mm (6.456") N/A

SP1112 10.875 x 12.000

SP1114 10.875 x 14.000 93mm (3.661") 72mm (2.834") N/A

SP1118 10.875 x 18.000 144mm (5.669") 139mm (5.472") N/A

SP1124 10.875 x 23.500 214mm (8.425") 209mm (8.228") N/A

SP1212 11.875 x 12.000

SP1215 11.875 x 15.000 106mm (4.173") 85mm (3.346") N/A

SP1220 11.875 x 20.000 169mm (6.653") 164mm (6.456") N/A

SP1224 11.875 x 23.500 214mm (8.425") 209mm (8.228") N/A

SP1315 13.375 x 15.000 106mm (4.173") 85mm (3.346") N/A

SP1318 13.375x18.000 144mm (5.669") 139mm (5.472") N/A

SP1321 13.375 x 20.750 179mm (7.047") 174mm (6.850") N/A

SP1324 13.375 x 23.500 214mm (8.425") 209mm (8.228") N/A

SP1326 13.375 x 26.000 246mm (9.685") 241mm (9.488") N/A

SP1330 13.375 x 29.500 290mm (11.417") 285mm (11.220") N/A

SP1518 14.875 x 17.875 143mm (5.629") 138mm (5.433") N/A

SP1524 14.875 x 23.750 217mm (8.543") 212mm (8.346") N/A

SP1530 14.875 x 29.500 290mm (11.417") 285mm (11.220") N/A

SP1616 15.875 x 16.000 119mm (4.685") 114mm (4.488")

SP1620 15.875 x 20.000 169mm (6.653") 164mm (6.456")

SP1624 15.875 x 23.500 214mm (8.425") 209mm (8.228")

SP1626 15.875 x 26.000 246mm (9.685") 241mm (9.488")

SP1630 15.875 x 29.500 290mm (11.417") 285mm (11.220")

SP1636 15.875 x 35.500 366mm (14.409") 361mm (14.213")

SP1724 16.500 x 23.750 217mm (8.543") 212mm (8.346")

SP1730 16.500 x 29.500 290mm (11.417") 285mm (11.220")

SP1818 17.875 x 18.000 144mm (5.669") 139mm (5.472’)

SP1820 17.875 x 20.000 169mm (6.653") 164mm (6.456")

SP1824 17.875 x 23.500 214mm (8.425") 209mm (8.228")

SP1826 17.875 x 26.000 246mm (9.685") 241mm (9.488")

SP1830 17.875 x 29.500 290mm (11.417") 285mm (11.220")

SP1836 17.875 x 35.500 366mm (14.409") 361mm (14.212")

SP2024 19.500 x 23.750 217mm (8.543") 212mm (8.346")

SP2030 19.500 x 29.500 290mm (11.417") 285mm (11.220")

SP2036 19.500 x 35.500 366mm (14.409") 361mm (14.212")

SP2424 23.750 x 23.750 217mm (8.543") 212mm (8.346")

SP2430 23.750 x 29.500 290mm (11.417") 285mm (11.220")

SP2436 23.750 x 35.500 366mm (14.409") 361mm (14.212’)

66mm (2.598")

68mm (2.677")

68mm (2.677")

N/A N/A

N/A N/A

N/A N/A

114mm (4.488")

114mm (4.488")

114mm (4.488")

114mm (4.488")

114mm (4.488")

114mm (4.488")

121mm (4.763")

121mm (4.763")

139mm (5.472")

139mm (5.472")

139mm (5.472")

139mm (5.472")

139mm (5.472")

139mm (5.472")

159mm (6.259")

159mm (6.259")

159mm (6.259")

212mm (8.346")

212mm (8.346")

212mm (8.346")

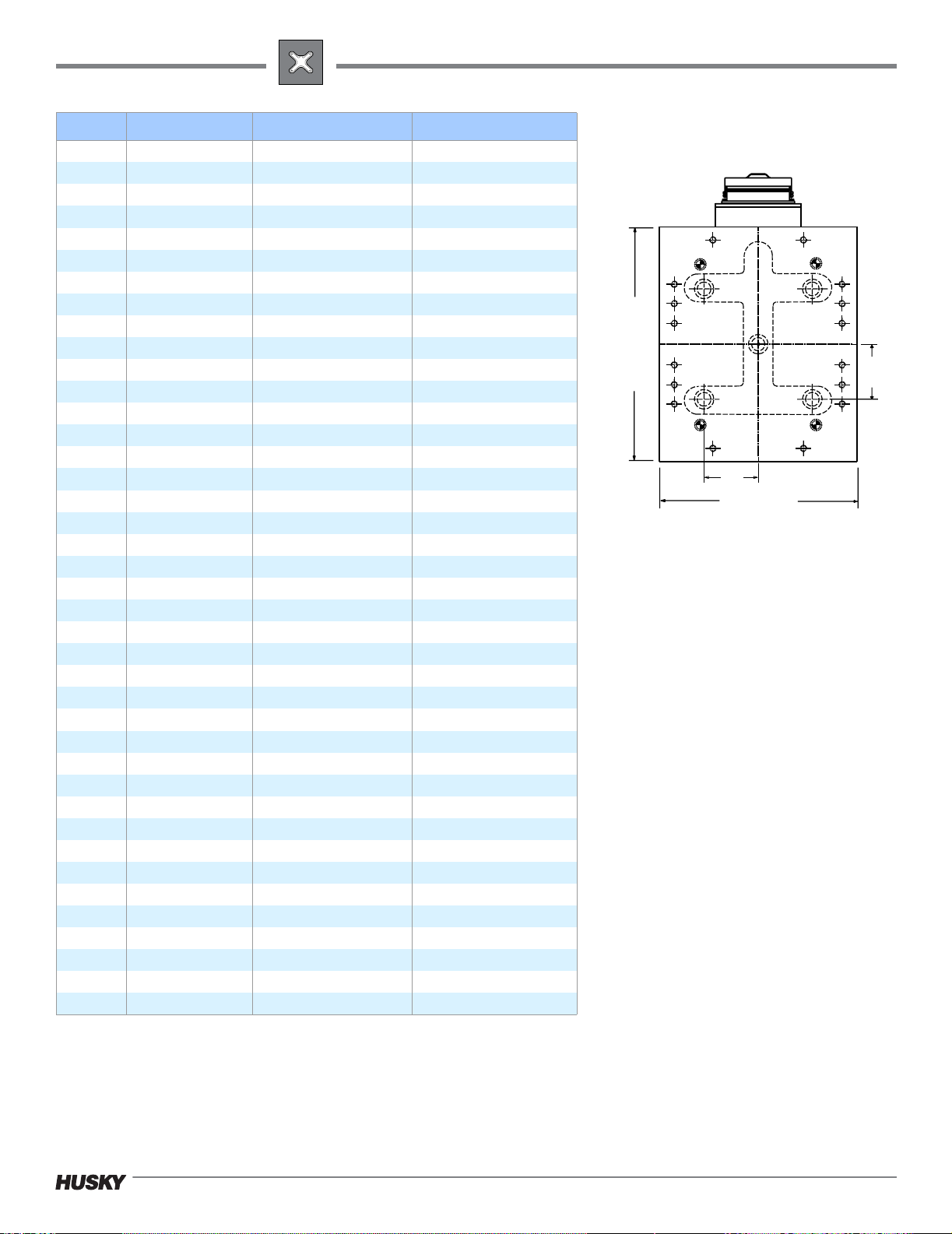

2A-Type

Length

Operator

2B-Type

Length

Operator

2C-Type

Length

Operator

Top

X

Width

Top

X

Width

Top

- HT or TS nozzle only

Minimum ’X’ for 2A, 2B & 2C-Type:

For thermal gates (HT & TS) X = 60mm (2.363")

For valve gates (VG & VX) X = 70mm (2.756")

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

13

X

Width

SP-series 2005.09

Page 14

PRONTO

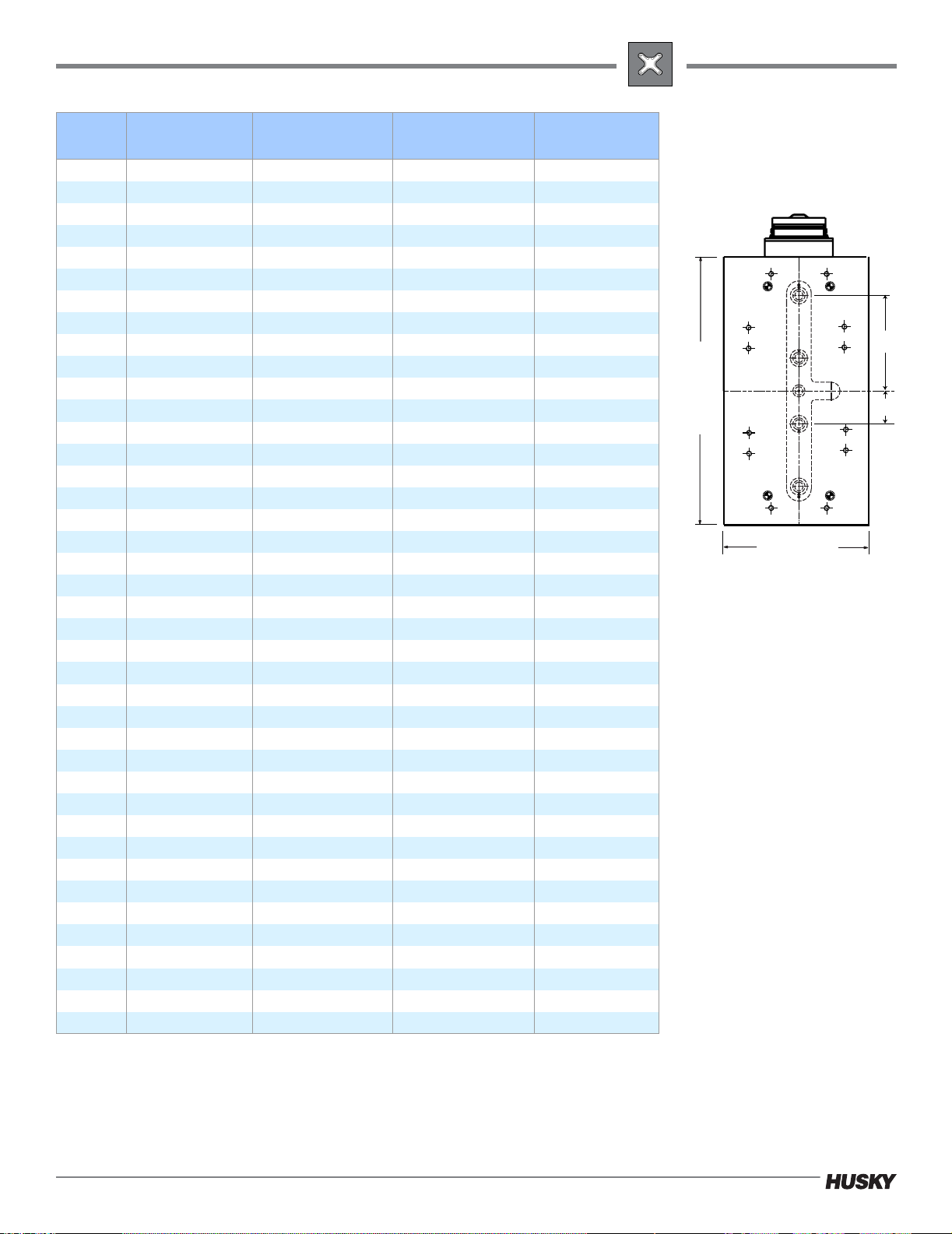

Part # Width x Length

SP1012 9.875 x 11.875 N/A N/A N/A

SP1016 9.875 x 16.000 N/A N/A N/A

SP1020 9.875 x 20.000 N/A N/A N/A

SP1112 10.875 x 12.000 N/A N/A N/A

SP1114 10.875 x 14.000 N/A N/A N/A

SP1118 10.875 x 18.000 Y - 45mm (1.772") Y - 57mm (2.244")

SP1124 10.875 x 23.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1212 11.875 x 12.000 N/A N/A N/A

SP1215 11.875 x 15.000 N/A N/A N/A

SP1220 11.875 x 20.000 Y - 45mm (1.772") Y - 57mm (2.244")

SP1224 11.875 x 23.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1315 13.375 x 15.000 N/A N/A N/A

SP1318 13.375 x 18.000 Y - 45mm (1.772") Y - 57mm (2.244")

SP1321 13.375 x 20.750 Y - 45mm (1.772") Y - 57mm (2.244")

SP1324 13.375 x 23.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1326 13.375 x 26.000 Y - 45mm (1.772") Y - 57mm (2.244")

SP1330 13.375 x 29.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1518 14.875 x 17.875 Y - 45mm (1.772") Y - 57mm (2.244")

SP1524 14.875 x 23.750 Y - 45mm (1.772") Y - 57mm (2.244")

SP1530 14.875 x 29.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1616 15.875 x 16.000 N/A N/A N/A

SP1620 15.875 x 20.000 Y - 45mm (1.772") Y - 57mm (2.244")

SP1624 15.875 x 23.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1626 15.875 x 26.000 Y - 45mm (1.772") Y - 57mm (2.244")

SP1630 15.875 x 29.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1636 15.875 x 35.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1724 16.500 x 23.750 Y - 45mm (1.772") Y - 57mm (2.244")

SP1730 16.500 x 29.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1818 17.875 x 18.000 Y - 45mm (1.772") Y - 57mm (2.244")

SP1820 17.875 x 20.000 Y - 45mm (1.772") Y - 57mm (2.244")

SP1824 17.875 x 23.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1826 17.875 x 26.000 Y - 45mm (1.772") Y - 57mm (2.244")

SP1830 17.875 x 29.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP1836 17.875 x 35.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP2024 19.500 x 23.750 Y - 45mm (1.772") Y - 57mm (2.244")

SP2030 19.500 x 29.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP2036 19.500 x 35.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP2424 23.750 x 23.750 Y - 45mm (1.772") Y - 57mm (2.244")

SP2430 23.750 x 29.500 Y - 45mm (1.772") Y - 57mm (2.244")

SP2436 23.750 x 35.500 Y - 45mm (1.772") Y - 57mm (2.244")

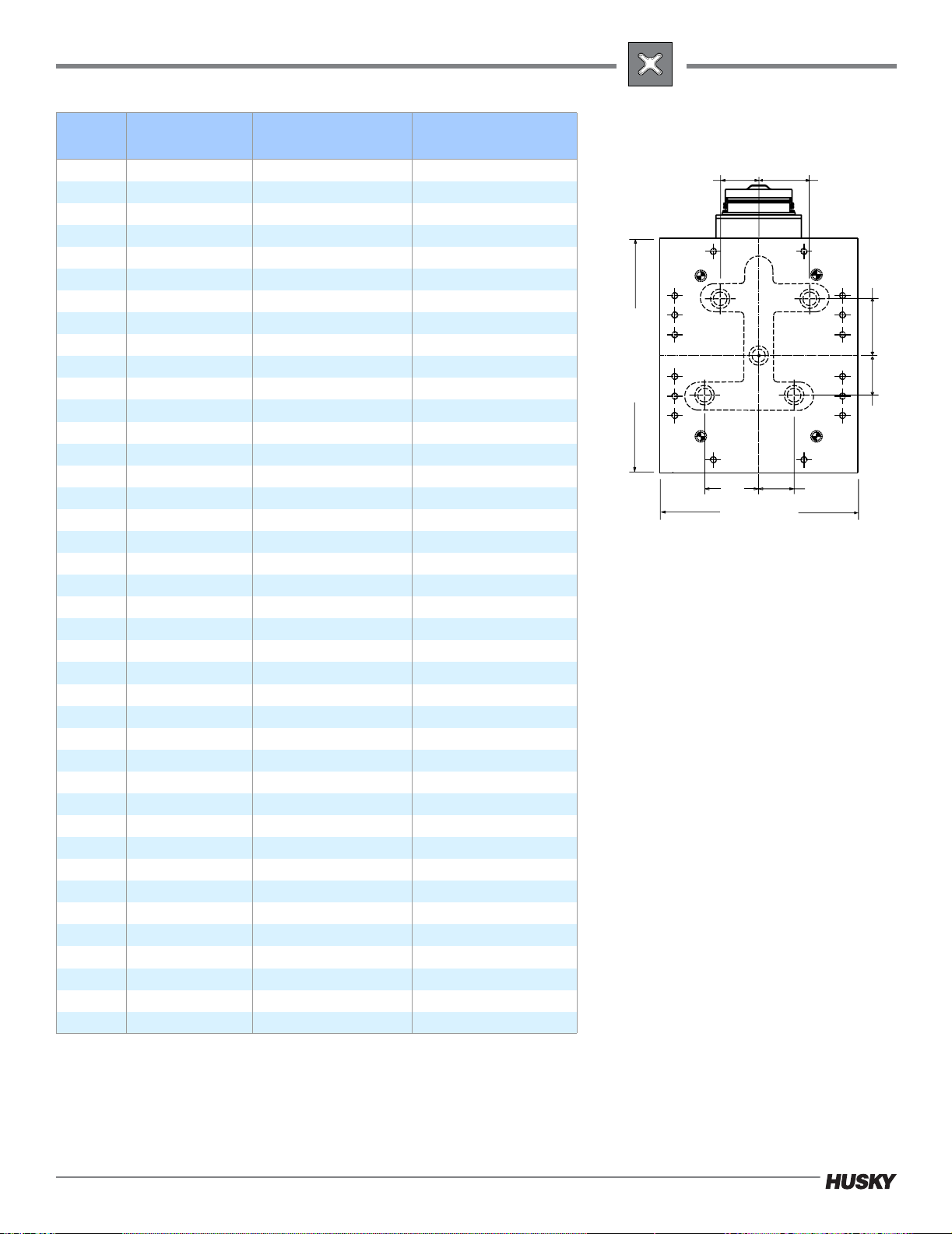

4L-Type Max. ’X’

(HT/TS)

4L-Type Max. ’X’

(VG/VX)

4L-Type Max.

’Y’

139mm (5.472")

209mm (8.228")

164mm (6.456")

209mm (8.228")

139mm (5.472")

174mm (6.850")

209mm (8.228")

241mm (9.488")

285mm (11.22")

138mm (5.433")

212mm (8.346")

285mm (11.22")

164mm (6.456")

209mm (8.228")

241mm (9.488")

285mm (11.22")

361mm(14.212")

212mm (8.346")

285mm (11.22")

139mm (5.472")

164mm (6.456")

209mm (8.228")

241mm (9.488")

285mm (11.22")

361mm(14.212")

212mm (8.346")

285mm (11.22")

361mm(14.212")

212mm (8.346")

285mm (11.22")

361mm(14.212")

4L-Type

Length

Operator

Top

Y

X

Width

Minimum ’X’ and ’Y’ for 4L-Type:

For both thermal gates (HT & TS) X = 60mm (2.362") Y = X + 45 mm (1.772")

For both valve gates (VG & VX) X = 70mm (2.756") Y = X + 57mm (2.244")

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

14

Page 15

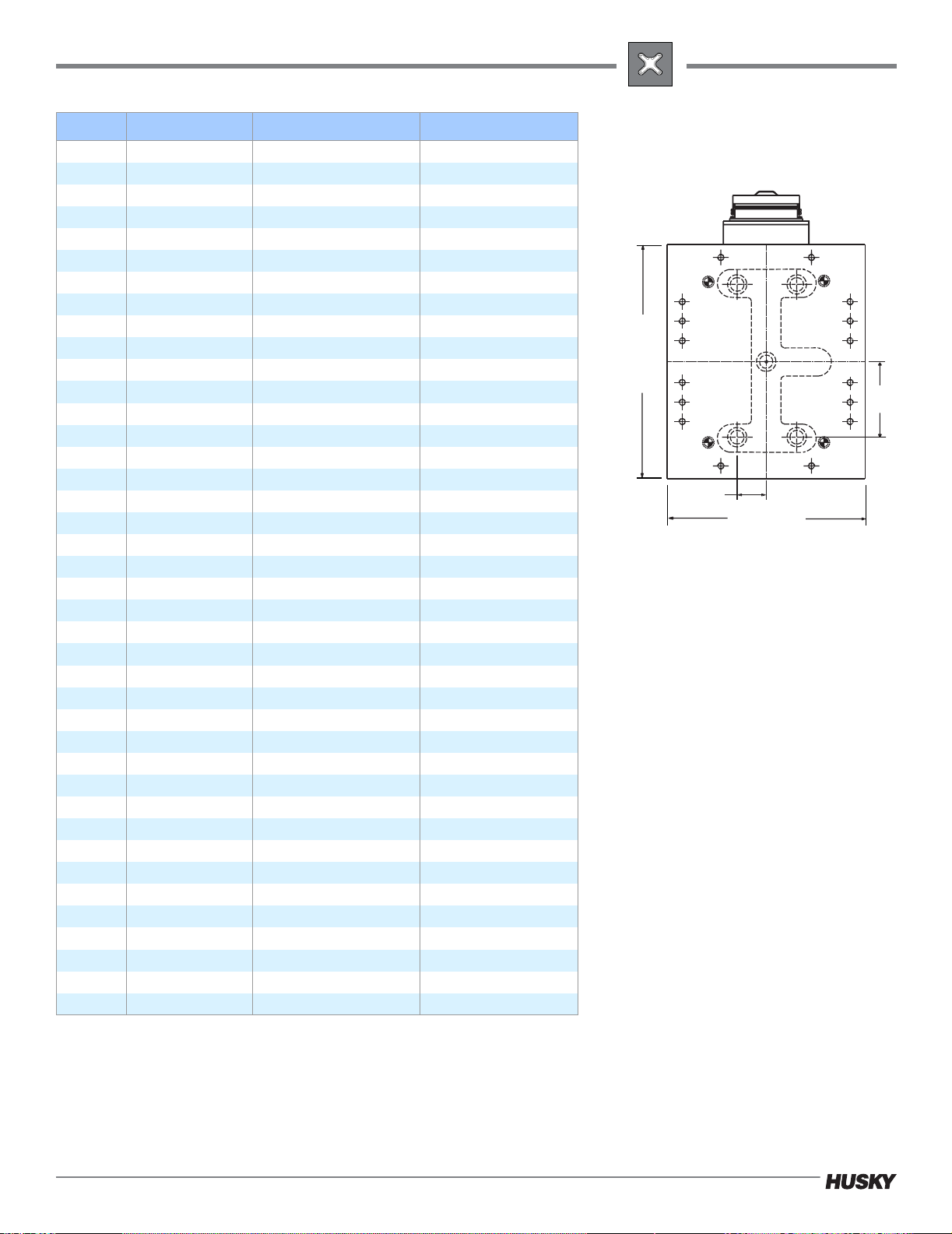

PRONTO

Part # Width x Length 4H-Type Max. ’X1’ 4H-Type Max. ’Y1’

SP1012 9.875 x 11.875 N/A N/A

SP1016 9.875 x 16.000 N/A N/A

SP1020 9.875 x 20.000 N/A N/A

SP1112 10.875 x 12.000 N/A N/A

SP1114 10.875 x 14.000 N/A N/A

SP1118 10.875 x 18.000 N/A N/A

SP1124 10.875 x 23.500 N/A N/A

SP1212 11.875 x 12.000 N/A N/A

SP1215 11.875 x 15.000 60mm (2.362") 71mm (2.795")

SP1220 11.875 x 20.000 60mm (2.362") 135mm (5.315")

SP1224 11.875 x 23.500 60mm (2.362") 179mm (7.047")

SP1315 13.375 x 15.000 79mm (3.110") 71mm (2.795")

SP1318 13.375 x 18.000 57mm (2.244") 109mm (4.291")

SP1321 13.375 x 20.750 57mm (2.244") 144mm (5.669")

SP1324 13.375 x 23.500 57mm (2.244") 179mm (7.047")

SP1326 13.375 x 26.000 57mm (2.244") 211mm (8.307")

SP1330 13.375 x 29.500 57mm (2.244") 255mm (10.039")

SP1518 14.875 x 17.875 73mm (2.874") 108mm (4.252")

SP1524 14.875 x 23.750 73mm (2.874") 182mm (7.165")

SP1530 14.875 x 29.500 73mm (2.874") 255mm (10.039")

SP1616 15.875 x 16.000 79mm (3.110") 84mm (3.307")

SP1620 15.875 x 20.000 79mm (3.110") 135mm (5.315")

SP1624 15.875 x 23.500 79mm (3.110") 179mm (7.047")

SP1626 15.875 x 26.000 79mm (3.110") 211mm (8.307")

SP1630 15.875 x 29.500 79mm (3.110") 255mm (10.039")

SP1636 15.875 x 35.500 79mm (3.110") 331mm (13.032")

SP1724 16.500 x 23.750 93mm (3.661") 182mm (7.165")

SP1730 16.500 x 29.500 93mm (3.661") 255mm (10.039")

SP1818 17.875 x 18.000 111mm (4.370") 109mm (4.291")

SP1820 17.875 x 20.000 111mm (4.370") 135mm (5.315")

SP1824 17.875 x 23.500 105mm (4.134") 179mm (7.047")

SP1826 17.875 x 26.000 105mm (4.134") 211mm (8.307")

SP1830 17.875 x 29.500 105mm (4.134") 255mm (10.039")

SP1836 17.875 x 35.500 105mm (4.134") 331mm (13.032")

SP2024 19.500 x 23.750 125mm (4.921") 182mm (7.165")

SP2030 19.500 x 29.500 125mm (4.921") 255mm (10.039")

SP2036 19.500 x 35.500 125mm (4.921") 331mm (13.032")

SP2424 23.750 x 23.750 178mm (7.008") 182mm (7.165")

SP2430 23.750 x 29.500 178mm (7.008") 255mm (10.039")

SP2436 23.750 x 35.500 178mm (7.008") 331mm (13.032")

4H-Type

Length

Operator

Top

Y1

X1

Width

Minimum ’X’ and ’Y’ for 4H-Type:

For all gating styles and nozzle series X1 = 50.0 mm, Y1 = 50.0 mm

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

15

Page 16

Part # Width x Length 4H-Type Max. "X2 4H-Type Max. "Y2"

SP1012 9.875 x 11.875 N/A N/A

SP1016 9.875 x 16.000 N/A N/A

SP1020 9.875 x 20.000 N/A N/A

SP1112 10.875 x 12.000 N/A N/A

SP1114 10.875 x 14.000 N/A N/A

SP1118 10.875 x 18.000 N/A N/A

SP1124 10.875 x 23.500 N/A N/A

SP1212 11.875 x 12.000 N/A N/A

SP1215 11.875 x 15.000 60mm (2.362") 71mm (2.795")

SP1220 11.875 x 20.000 60mm (2.362") 135mm (5.315")

SP1224 11.875 x 23.500 60mm (2.362") 179mm (7.047")

SP1315 13.375 x 15.000 79mm (3.110") 71mm (2.795")

SP1318 13.375 x 18.000 79mm (3.110") 105mm (4.134")

SP1321 13.375 x 20.750 79mm (3.110") 139mm (5.472")

SP1324 13.375 x 23.500 79mm (3.110") 174mm (6.850")

SP1326 13.375 x 26.000 79mm (3.110") 206mm (8.110")

SP1330 13.375 x 29.500 79mm (3.110") 247mm (9.724")

SP1518 14.875 x 17.875 98mm (3.858") 93mm (3.661")

SP1524 14.875 x 23.750 98mm (3.858") 168mm (6.614")

SP1530 14.875 x 29.500 98mm (3.858") 241mm (9.488")

SP1616 15.875 x 16.000 111mm (4.370") 73mm (2.874")

SP1620 15.875 x 20.000 111mm (4.370") 124mm (4.882")

SP1624 15.875 x 23.500 111mm (4.370") 168mm (6.614")

SP1626 15.875 x 26.000 111mm (4.370") 200mm (7.874")

SP1630 15.875 x 29.500 111mm (4.370") 244mm (9.606")

SP1636 15.875 x 35.500 111mm (4.370") 320mm (12.598")

SP1724 16.500 x 23.750 118mm (4.646") 166mm (6.535")

SP1730 16.500 x 29.500 118mm (4.646") 239mm (9.409")

SP1818 17.875 x 18.000 136mm (5.354") 93mm (3.661")

SP1820 17.875 x 20.000 136mm (5.354") 119mm (4.685")

SP1824 17.875 x 23.500 136mm (5.354") 147mm (5.787")

SP1826 17.875 x 26.000 136mm (5.354") 179mm (7.047")

SP1830 17.875 x 29.500 136mm (5.354") 224mm (8.819")

SP1836 17.875 x 35.500 136mm (5.354") 306mm (12.047")

SP2024 19.500 x 23.750 157mm (6.181") 151mm (5.945")

SP2030 19.500 x 29.500 157mm (6.181") 224mm (8.819")

SP2036 19.500 x 35.500 157mm (6.181") 300mm (1 1.811")

SP2424 23.750 x 23.750 211mm (8.307") 151mm (5.945")

SP2430 23.750 x 29.500 211mm (8.307") 224mm (8.819")

SP2436 23.750 x 35.500 211mm (8.307") 301mm (11.850")

4H-Type

Length

Operator

PRONTO

Top

Y2

X2

Width

Minimum ’X’ and ’Y’ for 4H-Type:

For all gating styles and nozzle series X2 = 50.0 mm, Y2 = 50.0 mm

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

16

SP-series 2005.09

Page 17

PRONTO

X1 X2

Part # Width x Length

SP1012 9.875 x 11.875 N/A N/A

SP1016 9.875 x 16.000 N/A N/A

SP1020 9.875 x 20.000 N/A N/A

SP1112 10.875 x 12.000 N/A N/A

SP1114 10.875 x 14.000 N/A N/A

SP1118 10.875 x 18.000 N/A N/A

SP1124 10.875 x 23.500 N/A N/A

SP1212 11.875 x 12.000 N/A N/A

SP1215 11.875 x 15.000 60mm (2.362") 71mm (2.795")

SP1220 11.875 x 20.000 60mm (2.362") 135mm (5.315")

SP1224 11.875 x 23.500 60mm (2.362") 179mm (7.047")

SP1315 13.375 x 15.000 79mm (3.110") 71mm (2.795")

SP1318 13.375 x 18.000 79mm (3.110") 105mm (4.134")

SP1321 13.375 x 20.750 79mm (3.110") 139mm (5.472")

SP1324 13.375 x 23.500 79mm (3.110") 174mm (6.850")

SP1326 13.375 x 26.000 79mm (3.110") 206mm (8.110")

SP1330 13.375 x 29.500 79mm (3.110") 247mm (9.724")

SP1518 14.875 x 17.875 98mm (3.858") 93mm (3.661")

SP1524 14.875 x 23.750 98mm (3.858") 168mm (6.614")

SP1530 14.875 x 29.500 98mm (3.858") 241mm (9.488")

SP1616 15.875 x 16.000 111mm (4.370") 73mm (2.874")

SP1620 15.875 x 20.000 111mm (4.370") 124mm (4.882")

SP1624 15.875 x 23.500 111mm (4.370") 168mm (6.614")

SP1626 15.875 x 26.000 111mm (4.370") 200mm (7.874")

SP1630 15.875 x 29.500 111mm (4.370") 244mm (9.606")

SP1636 15.875 x 35.500 111mm (4.370") 320mm (12.598")

SP1724 16.500 x 23.750 118mm (4.646") 166mm (6.535")

SP1730 16.500 x 29.500 118mm (4.646") 239mm (9.409")

SP1818 17.875 x 18.000 136mm (5.354") 93mm (3.661")

SP1820 17.875 x 20.000 136mm (5.354") 119mm (4.685")

SP1824 17.875 x 23.500 136mm (5.354") 147mm (5.787")

SP1826 17.875 x 26.000 136mm (5.354") 179mm (7.047")

SP1830 17.875 x 29.500 136mm (5.354") 224mm (8.819")

SP1836 17.875 x 35.500 136mm (5.354") 306mm (12.047")

SP2024 19.500 x 23.750 157mm (6.181") 151mm (5.945")

SP2030 19.500 x 29.500 157mm (6.181") 224mm (8.819")

SP2036 19.500 x 35.500 157mm (6.181") 300mm (1 1.811")

SP2424 23.750 x 23.750 211mm (8.307") 151mm (5.945")

SP2430 23.750 x 29.500 211mm (8.307") 224mm (8.819")

SP2436 23.750 x 35.500 211mm (8.307") 301mm (11.850")

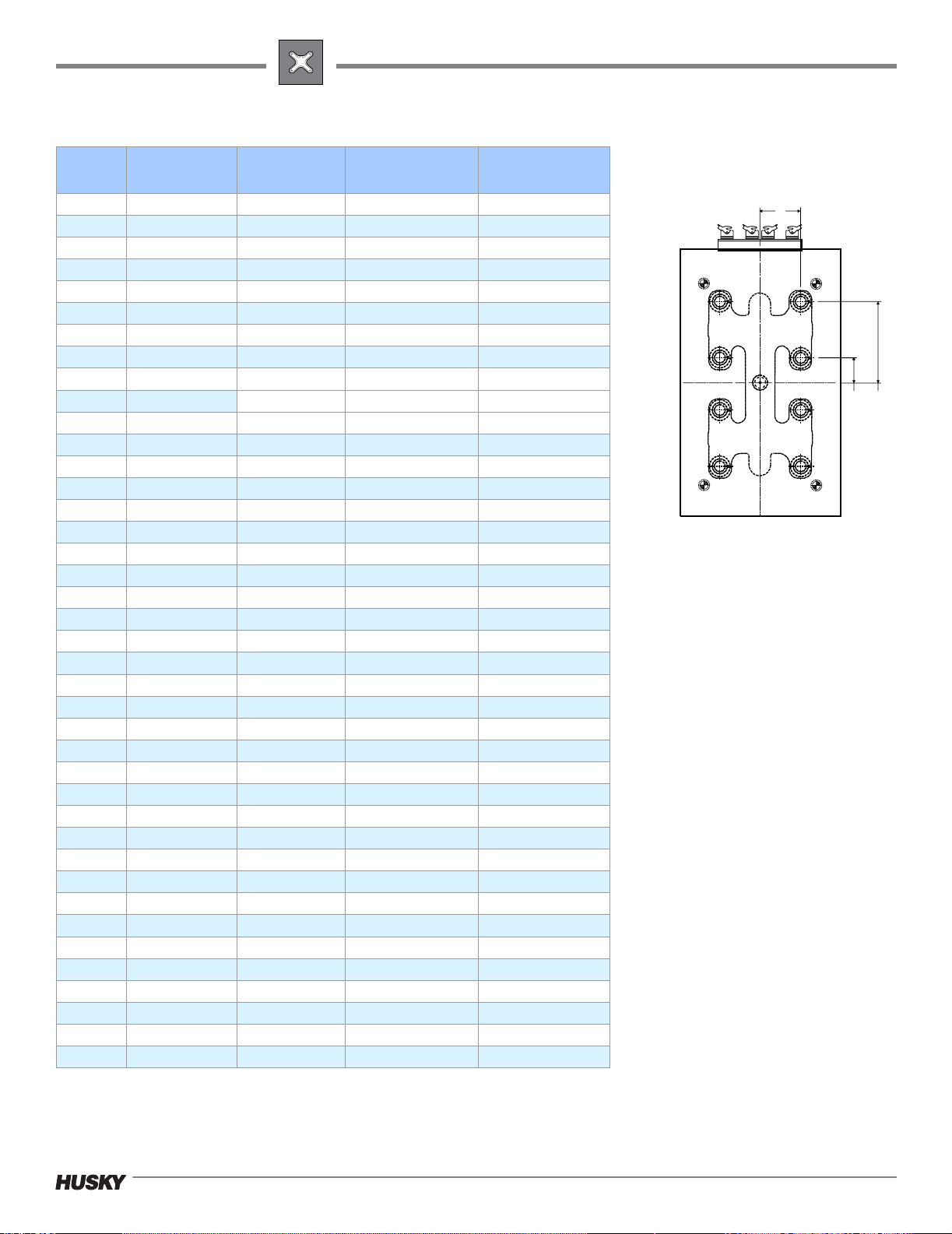

4N-Type Max. "X1,

X2, X3, and X4"

4N-Type Max. "Y1/2"

Minimum ’X’ and ’Y’ for 4N-Type:

4N-Type

Length

Operator

X3

Top

Y1

Y2

X4

Width

For all gating styles and nozzle series X1/2/3/4 = 50.0 mm (1.969"),

For all gating styles and nozzle series Y1/2 = 50.0 mm (1.969").

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

17

Page 18

ULTRA 500 HT

2

PRONTO

Part #

SP1012 9.875 x 11.875 N/A N/A N/A

SP1016 9.875 x 16.000 N/A N/A N/A

SP1020 9.875 x 20.000 N/A N/A N/A

SP1112 10.875 x 12.000 N/A N/A N/A

SP1114 10.875 x 14.000 N/A N/A N/A

SP1118 10.875 x 18.000 N/A N/A N/A

SP1124 10.875 x 23.500 N/A N/A N/A

SP1212 11.875 x 12.000 N/A N/A N/A

SP1215 11.875 x 15.000 N/A N/A N/A

SP1220 11.875 x 20.000 N/A N/A N/A

SP1224 11.875 x 23.500 N/A N/A N/A

SP1315 13.375 x 15.000 N/A N/A N/A

SP1318 13.375 x 18.000 N/A N/A N/A

SP1321 13.375 x 20.750 79mm (3.11") Y2-62mm (1.00") 139mm (5.47")

SP1324 13.375 x 23.500 79mm (3.11") Y2-62mm (1.00") 174mm (6.85")

SP1326 13.375 x 26.000 79mm (3.11") Y2-62mm (1.00") 206mm (8.11")

SP1330 13.375 x 29.500 79mm (3.11") Y2-62mm (1.00") 247mm (9.72")

SP1518 14.875 x 17.875 N/A N/A N/A

SP1524 14.875 x 23.750 98mm (0.71") Y2-62mm (1.00") 168mm (6.61")

SP1530 14.875 x 29.500 98mm (0.71") Y2-62mm (1.00") 241mm (9.49mm)

SP1616 15.875 x 16.000 N/A N/A N/A

SP1620 15.875 x 20.000 111mm (4.37") Y2-62mm (1.00") 124mm (4.88")

SP1624 15.875 x 23.500 111mm (4.37")

SP1626 15.875 x 26.000 111mm (4.37")

SP1630 15.875 x 29.500 111mm (4.37")

SP1636 15.875 x 35.500 111mm (4.37") Y2-62mm (1.00") 320mm (12.60")

SP1724 16.500 x 23.750 118mm (4.64") Y2-62mm (1.00") 166mm (6.54")

SP1730 16.500 x 29.500 118mm (4.64") Y2-62mm (1.00") 239mm (9.41")

SP1818 17.875 x 18.000 N/A N/A N/A

SP1820 17.875 x 20.000 N/A N/A N/A

SP1824 17.875 x 23.500 136mm (5.35") Y2-62mm (1.00") 147mm (5.79")

SP1826 17.875 x 26.000 136mm (5.35") Y2-62mm (1.00") 179mm (7.05")

SP1830 17.875 x 29.500 136mm (5.35") Y2-62mm (1.00") 224mm (8.82")

SP1836 17.875 x 35.500 136mm (5.35") Y2-62mm (1.00") 306mm (12.05")

SP2024 19.500 x 23.750 157mm (6.18") Y2-62mm (1.00") 151mm (5.94")

SP2030 19.500 x 29.500 157mm (6.18") Y2-62mm (1.00") 224mm (8.82")

SP2036 19.500 x 35.500 157mm (6.18") Y2-62mm (1.00") 300mm (11.81")

SP2424 23.750 x 23.750 211mm (8.30") Y2-62mm (1.00") 151mm (5.94")

SP2430 23.750 x 29.500 211mm (8.30") Y2-62mm (1.00") 224mm (8.82")

SP2436 23.750 x 35.500 211mm (8.30") Y2-62mm (1.00") 301mm (11.85")

Width x

Length

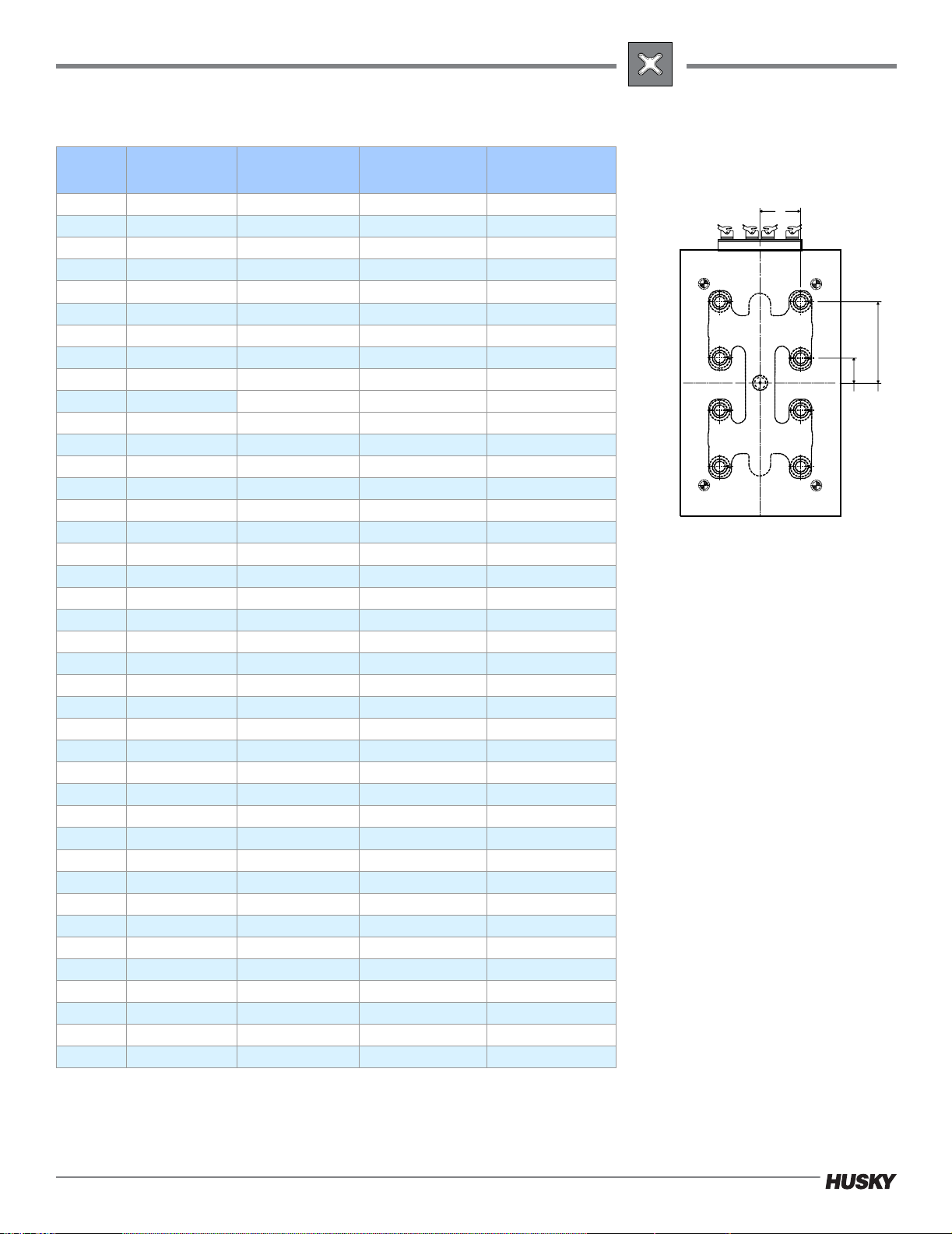

8H-T ype Max.

’X’

8H-Type Max.

’Y1’

Y2-62mm (1.00") 168mm (6.61")

Y2-62mm (1.00") 200mm (7.87")

Y2-62mm (1.00") 244mm (9.61")

8H-Type Max.

’Y2’

Operator

8H-Type

Length

Width

X

Top

Y1

Y

Min ’X’ > 73mm (2.87") / Min ’Y1’ > 61.3mm (2.41") / Min ’Y2’>Y1+62mm (2.44")

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

18

SP-series 2005.09

Page 19

PRONTO

2

ULTRA 750 HT

Part #

SP1012 9.875 x 11.875 N/A N/A N/A

SP1016 9.875 x 16.000 N/A N/A N/A

SP1020 9.875 x 20.000 N/A N/A N/A

SP1112 10.875 x 12.000 N/A N/A N/A

SP1114 10.875 x 14.000 N/A N/A N/A

SP1118 10.875 x 18.000 N/A N/A N/A

SP1124 10.875 x 23.500 N/A N/A N/A

SP1212 11.875 x 12.000 N/A N/A N/A

SP1215 11.875 x 15.000 N/A N/A N/A

SP1220 11.875 x 20.000 N/A N/A N/A

SP1224 11.875 x 23.500 N/A N/A N/A

SP1315 13.375 x 15.000 N/A N/A N/A

SP1318 13.375 x 18.000 N/A N/A N/A

SP1321 13.375 x 20.750 79mm (3.11") Y2-62mm (1.77") 139mm (5.47")

SP1324 13.375 x 23.500 79mm (3.11") Y2-62mm (1.77") 174mm (6.85")

SP1326 13.375 x 26.000 79mm (3.11") Y2-62mm (1.77") 206mm (8.11")

SP1330 13.375 x 29.500 79mm (3.11") Y2-62mm (1.77") 247mm (9.72")

SP1518 14.875 x 17.875 N/A N/A N/A

SP1524 14.875 x 23.750 98mm (3.86") Y2-62mm (1.77") 168mm (6.61")

SP1530 14.875 x 29.500 98mm (3.86") Y2-62mm (1.77") 241mm (9.49")

SP1616 15.875 x 16.000 N/A N/A N/A

SP1620 15.875 x 20.000 111mm (4.37") Y2-62mm (1.77") 124mm (4.88")

SP1624 15.875 x 23.500 111mm (4.37") Y2-62mm (1.77") 168mm (6.61")

SP1626 15.875 x 26.000 111mm (4.37") Y2-62mm (1.77") 200mm (7.87")

SP1630 15.875 x 29.500 111mm (4.37") Y2-62mm (1.77") 244mm (9.60")

SP1636 15.875 x 35.500 111mm (4.37") Y2-62mm (1.77") 320mm (12.59")

SP1724 16.500 x 23.750 118mm (4.64") Y2-62mm (1.77") 166mm (6.53")

SP1730 16.500 x 29.500 118mm (4.64") Y2-62mm (1.77") 239mm (9.40")

SP1818 17.875 x 18.000 N/A N/A N/A

SP1820 17.875 x 20.000 N/A N/A N/A

SP1824 17.875 x 23.500 136mm (5.35") Y2-62mm (1.77") 147mm (5.78")

SP1826 17.875 x 26.000 136mm (5.35") Y2-62mm (1.77") 179mm (7.04")

SP1830 17.875 x 29.500 136mm (5.35") Y2-62mm (1.77") 224mm (8.81")

SP1836 17.875 x 35.500 136mm (5.35") Y2-62mm (1.77") 306mm (12.04")

SP2024 19.500 x 23.750 157mm (6.18") Y2-62mm (1.77") 151mm (5.94")

SP2030 19.500 x 29.500 157mm (6.18") Y2-62mm (1.77") 224mm (8.81")

SP2036 19.500 x 35.500 157mm (6.18") Y2-62mm (1.77") 300mm (11.81")

SP2424 23.750 x 23.750 211mm (8.30") Y2-62mm (1.77") 151mm (5.94")

SP2430 23.750 x 29.500 211mm (8.30") Y2-62mm (1.77") 224mm (8.81")

SP2436 23.750 x 35.500 211mm (8.30") Y2-62mm (1.77") 301mm (11.85")

Width x

Length

8H-Type Max.

’X’

8H-Type Max.

’Y1’

8H-Type Max.

’Y2’

Min ’X’ > 73mm (2.87") / Min ’Y1’ > 61.3mm (2.41") / Min ’Y2’>Y1+62mm (2.44")

Operator

8H-Type

Length

Width

X

Top

Y1

Y

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

19

Page 20

ULTRA 500/750 VG

2

PRONTO

Part #

SP1012 9.875 x 11.875 N/A N/A N/A

SP1016 9.875 x 16.000 N/A N/A N/A

SP1020 9.875 x 20.000 N/A N/A N/A

SP1112 10.875 x 12.000 N/A N/A N/A

SP1114 10.875 x 14.000 N/A N/A N/A

SP1118 10.875 x 18.000 N/A N/A N/A

SP1124 10.875 x 23.500 N/A N/A N/A

SP1212 11.875 x 12.000 N/A N/A N/A

SP1215 11.875 x 15.000 N/A N/A N/A

SP1220 11.875 x 20.000 N/A N/A N/A

SP1224 11.875 x 23.500 N/A N/A N/A

SP1315 13.375 x 15.000 N/A N/A N/A

SP1318 13.375 x 18.000 N/A N/A N/A

SP1321 13.375 x 20.750 79mm (3.11") Y2-62mm (1.96") 139mm (5.47")

SP1324 13.375 x 23.500 79mm (3.11" Y2-62mm (1.96") 174mm (6.85")

SP1326 13.375 x 26.000 79mm (3.11" Y2-62mm (1.96") 206mm (8.11")

SP1330 13.375 x 29.500 79mm (3.11" Y2-62mm (1.96") 247mm (9.72")

SP1518 14.875 x 17.875 N/A N/A N/A

SP1524 14.875 x 23.750 98mm (3.85") Y2-62mm (1.96") 168mm (6.61")

SP1530 14.875 x 29.500 98mm (3.85") Y2-62mm (1.96") 241mm (9.48")

SP1616 15.875 x 16.000 N/A N/A N/A

SP1620 15.875 x 20.000 111mm (4.37") Y2-62mm (1.96") 124mm (4.88")

SP1624 15.875 x 23.500 111mm (4.37") Y2-62mm (1.96") 168mm (6.61")

SP1626 15.875 x 26.000 111mm (4.37") Y2-62mm (1.96") 200mm (7.87")

SP1630 15.875 x 29.500 111mm (4.37") Y2-62mm (1.96") 244mm (9.60")

SP1636 15.875 x 35.500 111mm (4.37") Y2-62mm (1.96") 320mm (12.59")

SP1724 16.500 x 23.750 118mm (4.64")( Y2-62mm (1.96") 166mm (6.53")

SP1730 16.500 x 29.500 118mm (4.64")( Y2-62mm (1.96") 239mm (9.40")

SP1818 17.875 x 18.000 N/A N/A N/A

SP1820 17.875 x 20.000 N/A N/A N/A

SP1824 17.875 x 23.500 136mm (5.35") Y2-62mm (1.96") 147mm (5.78")

SP1826 17.875 x 26.000 136mm (5.35") Y2-62mm (1.96") 179mm (7.04")

SP1830 17.875 x 29.500 136mm (5.35") Y2-62mm (1.96") 224mm (8.81")

SP1836 17.875 x 35.500 136mm (5.35") Y2-62mm (1.96") 306mm (12.04")

SP2024 19.500 x 23.750 157mm (6.18") Y2-62mm (1.96") 151mm (5.94")

SP2030 19.500 x 29.500 157mm (6.18") Y2-62mm (1.96") 224mm (8.81")

SP2036 19.500 x 35.500 157mm (6.18") Y2-62mm (1.96") 300mm (11.81")

SP2424 23.750 x 23.750 211mm (8.30")( Y2-62mm (1.96") 151mm (5.94")

SP2430 23.750 x 29.500 211mm (8.30")( Y2-62mm (1.96") 224mm (8.81")

SP2436 23.750 x 29.500 211mm (8.30")( Y2-62mm (1.96") 301mm (11.85")

Width x

Length

8H-T ype Max.

’X’

8H-Type Max.

’Y1’

8H-Type Max.

’Y2’

Min ’X’ > 73mm (2.87") / Min ’Y1’ > 61.3mm (2.41") / Min ’Y2’>Y1+62mm (2.44")

Operator

8H-Type

Length

Width

X

Top

Y1

Y

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

20

SP-series 2005.09

Page 21

PRONTO

m

(1.57”)

(4.53” - 4.97”)

L

STEP 2 - Select the gating method

Pronto hot runners are available with the Ultra 500 or Ultra 750 nozzles in HT, TS, VG, or VX gating styles. Please refer to

www.hotrunners.com or the Hot Runner Design Center for details about each nozzle/gating style.

STEP 3 - Determine the L-dimension required for your mold. This is the distance from th e face of the hot runner manifold

plate to the molding surface. The L-dimension must fall within the maximum and minimum available for the gating style you

have chosen.

Available L-Dimensions (Ultra 500)

HT-D/HT-T/HT-U HT-X VG VX

Minimum 17mm (0.67") 27mm (1.06") 17mm (0.67") 17mm (0.67")

Maximum 124mm (4.88") 134mm (5.28") 124mm (4.88") 124mm (4.88")

.

Thermal Gate (HT & TS)

Valve Gate (VG & VX)

VG available with 1.0mm (0.039"),

1.2mm (0.047"), 1.5mm (0.059"), or 1.8

mm (0.071")gate diameter as standard

Plate Thickness

For 2 and 4 Drop Configurations

32mm

(1.26”)

(3.74” - 4.13”)

95mm-105mm

L-dimension

(2.36”)

60mm

Plate Thickness

For 8 Drop Configurations

L-dimension

40m

115mm - 125mm

60mm

(2.36”)

-dimension

(3.74” - 4.13”)

95mm-105mm

L-dimension

(4.53” - 4.97”)

115mm - 125mm

The hot runner Guide Pin (4) will protrude from the manifold plate up to 15mm more than the selected Ldimension. Be sure that enough clearance has been left in the mold plates for the full length of this Guide Pin (4).

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

21

Page 22

Available L-Dimensions (Ultra 750)

m

7”)

L

HT-D/HT-T/HT-U VG VX TS

Minimum 27.4mm (1.08") 27.4mm (1.08") 27.4mm (1.08") 27.4mm (1.08")

Maximum 134.3mm (5.29" ) 134.3mm (5.29") 124.3mm (4.89") 134.3mm (5.29")

.

PRONTO

Thermal Gate (HT & TS)

Valve Gate (VG & VX)

Plate Thickness

For 2 and 4 Drop Configurations

32mm

(1.26”)

(3.74” - 4.13”)

95mm - 105mm

L-dimension

60mm

(2.36”)

Plate Thickness

For 8 Drop Configurations

40m

115mm - 125mm

L-dimension

(1.5

(4.53” - 4.97”)

60mm

(2.36”)

VG available with 1.00 (0.039"),

1.80mm (0.071"), or 2.50mm

(0.098") gate diameters

standard.

-dimension

(3. 74” - 4 .13 ”)

95mm - 105mm

L-dimension

(4. 53” - 4 .97 ”)

115mm - 125mm

The hot runner Guide Pin (4) will protrude from the manifold plate up to 15mm more than the selected Ldimension. Be sure that enough clearance has been left in the mold pla tes for the full length of this Guide Pin (4).

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

22

SP-series 2005.09

Page 23

PRONTO

9 7/8 x 11 7/8

SP1012

9 7/8

Top

Operator

1/2-13 UNC

OR M12

Select at least 4

Offset (1)

3

15

/16

11

7

/8

1

/16

3

5

3/4" or 16mm

1

3 15/16

Diameter

Guide Pin (4)

2 13/16 3 1/16

4

1

/8

2A Only

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A 60mm (2.362") 66mm (2.598")

2B N/A N/A

2C N/A N/A

4N N/A N/A N/A N/A N/A N/A

4L N/A N/A N/A N/A N/A N/A

4H N/A N/A N/A N/A N/A N/A

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

23

Page 24

SP1016

O

9 7/8 x 16

PRONTO

9 7/8

16

6

Top

perator

Offset (1)

/8

7

9

1/2-13 UNC

OR M12

Select at least 4

6

3/4" or 16mm

Guide Pin (4)

1

3

3

/16

Diameter

7 1/4

/16

1

3

/16

13

2

/16

15

3

/4

1

7

Top

Operator

1/2-13 UNC

OR M12

Select at least 4

3

1

3/4" or 16mm

Diameter

Guide Pin (4)

Offset (1)

6

16

6

3

/16

2B Only

2 13/16

3 15/16

3 1/16

2A Only

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

2C N/A N/A

4N N/A N/A N/A N/A N/A N/A

4L N/A N/A N/A N/A N/A N/A

4H-Type N/A N/A N/A N/A N/A N/A

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

119mm (4.685")

114mm (4.488")

24

SP-series 2005.09

Page 25

PRONTO

9 7/

9 7/8 x 20

Top

Offset (1)

Operator

/8

7

9

1/2-13 UNC

OR M12

Select at least 4

SP1020

8

Top

20

7

7

/8

2B Only

1 3/8

3

4

/8

8

3/4" or 16mm

Diameter

Guide Pin (4)

1

9 1/4

Operator

/16

1

3

/16

13

/16

2

15

3

/8

3

4

/8

3

1

/4

1

9

1/2-13 UNC

OR M12

Select at least 4

1

3/4" or 16mm

Diameter

Guide Pin (4)

Offset (1)

7

7

/8

20

8

2 13/16

3 15/16

3 1/16

2A Only

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

2C N/A N/A

4N N/A N/A N/A N/A N/A N/A

4L N/A N/A N/A N/A N/A N/A

4H-Type N/A N/A N/A N/A N/A N/A

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

169mm (6.654")

164mm (6.456")

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

25

Page 26

SP1112

10 7/8 x 12

PRONTO

10 7/8

Top

Operator

1/2-13 UNC

OR M12

Select at least 4

Offset (1)

3

7

/8

12

1

3 5/16

3/4" or 16mm

Diameter

Guide Pin (4)

3 7/16

/4

1

5

1

4 7/16

4

1

/16

2A Only

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A 60mm (2.362") 68mm (2.677")

2B N/A N/A

2C N/A N/A

4N N/A N/A N/A N/A N/A N/A

4L N/A N/A N/A N/A N/A N/A

4H-Type N/A N/A N/A N/A N/A N/A

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

26

SP-series 2005.09

Page 27

PRONTO

10 7/8 x 14

4 7/8

Top

SP1114

14

5 1/16

Top

10 7/8

Operator

Operator

/8

7

10

Offset (1)

1/2-13 UNC

OR M12

Select at least 4

3/4" or 16mm

Guide Pin (4)

1 1/8

4 1/8

Diameter

2 1/8

6 1/4

/16

7

3

/8

/16

5

3

/16

7

4

/4

1

6

1

1

/8

1

4

/8

1

2

2B Only

1/2-13 UNC

OR M12

Select at least 4

3/4" or 16mm

Diameter

Guide Pin (4)

3 5/16

4 7/16

2A Only

Offset (1)

3 7/16

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

2C N/A N/A

4N N/A N/A N/A N/A N/A N/A

4L N/A N/A N/A N/A N/A N/A

4H-Type N/A N/A N/A N/A N/A N/A

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

93mm (3.661")

72mm (2.834")

4

7

/8

14

5

1

/16

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

27

Page 28

SP1118

10 7/8 x 18

PRONTO

10 7/8

Top

6 7/8

18

7 1/16

Operator

Top

Operator

Offset (1)

/8

7

10

1/2-13 UNC

OR M12

Select at least 4

3/4" or 16mm

Diameter

Guide Pin (4)

1

/16

7

3

/16

5

3

/16

7

4

1

/8

7

3

/4

1

8

1/2-13 UNC

OR M12

Select at least 4

1

3/4" or 16mm

Guide Pin (4)

1

7

3

/8

8 1/4

2B Only

3 5/16

4 7/16

Diameter

3 7/16

Offset (1)

6

7

/8

18

7

1

/16

2A & 4L Only

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

2C N/A N/A

4N N/A N/A N/A N/A N/A N/A

4L-Type

60mm (2.362") HT/TS

70mm (2.756") VG/VX

4H-Type N/A N/A N/A N/A N/A N/A

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

144mm (5.669")

139mm (5.472")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

139mm (5.472") N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

28

SP-series 2005.09

Page 29

PRONTO

10 7/8 x 23 1/2

SP1124

10 7/8

TOP

TOP

OPERATOR

/8

7

10

OFFSET (1)

1

/2 - 13 UNC

or M12

Select at least 8

N/A = Not Available

Available manifold sizes

5

/8

9

23 1/2

4 1/8

1 1/8

9 13/16

3

/4" or 16mm Dia.

Guide Pin (4)

1

5

/8

6

11

/16

7

3

/16

5

/16

3

7

4

/8

1

4

1

/8

5

6

11

OPERATOR

/8

1

1

/2 - 13 UNC

or M12

Select at least 8

1

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

9

5

/8

23

1

/2

9

13

/16

2B ONLY

3 5/16

4 7/16

3 7/16

2A & 4L ONLY

Minimum X Maximum X Minimum Y/Y1 Maximum Y/Y1 Minimum Y2 Maximum Y2

2A

2B

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

214mm (8.425")

209mm (8.228")

2C N/A N/A

4N N/A N/A N/A N/A N/A N/A

4L

60mm (2.362") HT/TS

70mm (2.756") VG/VX

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

209mm (8.228") N/A N/A

4H-Type N/A N/A N/A N/A N/A N/A

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

29

Page 30

SP1212

11 7/8 x 12

PRONTO

11 7/8

TOP

OPERATOR

/8

/4

7

1

1

5

1

/2 - 13 UNC

or M12

Select at least 4

2 13/16

3 13/16

4 15/16

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

3 15/16

3

3

/4

12

3

15

/16

2A ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A 60mm (2.362") 68mm (2.677")

2B N/A N/A

2C N/A N/A

4N N/A N/A N/A N/A N/A N/A

4L N/A N/A N/A N/A N/A N/A

4H N/A N/A N/A N/A N/A N/A

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

30

SP-series 2005.09

Page 31

PRONTO

11 7/8 x 15

SP1215

1

3 13/16

11 7/8

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

3 15/16

5

1

/4

15

5

7

/16

15

1

/4

5

TOP

OPERATOR

/8

7

11

OFFSET (1)

1/2 - 13 UNC

or M12

Select at least 4

2B ONLY

2 3/8

5 7/16

3

/4" or 16mm Dia.

Guide Pin (4)

1

6 3/4

TOP

OPERATOR

/16

15

3

/8

3

/16

1

13

3

2

/16

15

4

/4

3

6

1/2 - 13 UNC

or M12

Select at least 4

1

4 15/16

2A, & 4H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

2C N/A N/A

4N 50mm (1.969") 60mm (2.362") 50mm (1.969") 71mm (2.795") N/A N/A

4L N/A N/A N/A N/A N/A N/A

4H-Type

X1 = 50mm (1.969")

X2 = 50mm (1.969")

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

106mm (4.173")

85mm (3.346")

X1 = 60mm (2.362")

X2 = 60mm (2.362")

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

Y1 = 71mm (2.795")

Y2 = 71mm (2.795")

N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

31

Page 32

SP1220

11 7/8 x 20

PRONTO

11 7/8

20

3

/4

7

TOP

OPERATOR

/8

7

11

OFFSET (1)

1/2 - 13 UNC

or M12

Select at least 6

2

7 15/16

3

/4" or 16mm Dia.

Guide Pin (4)

1

3

/8

4 3/8

9 1/4

/16

15

3

/16

13

1

/16

3

15

4

1

2B ONLY

TOP

OPERATOR

/8

3

2

/8

3

4

/4

9

1/2 - 13 UNC

or M12

Select at least 6

1

1

3 13/16

4 15/16

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

3 15/16

7

3

/4

20

7

15

/16

2A, 4L, 4H, & 8H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

2C N/A N/A

4N 50mm (1.969") 60mm (2.362") 50mm (1.969") 135mm (5.315") N/A N/A

4L

4H-Type

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

169mm (6.653")

164mm (6.456")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X1 = 60mm (2.362")

X2 = 60mm (2.362")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

164mm (6.456") N/A N/A

Y1 = 135mm (5.315")

Y2 = 135mm (5.315")

N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

32

SP-series 2005.09

Page 33

PRONTO

11 7/8 x 23 1/2

SP1224

11 7/8

TOP

1

/2

9

TOP

OPERATOR

/8

7

11

OFFSET (1)

1/2 - 13 UNC

or M12

Select at least 8

23 1/2

9 11/16

1/2 - 13 UNC

OPERATOR

or M12

Select at least 8

3

/4" or 16mm Dia.

Guide Pin (4)

1

2

1

4

/8

6 1/8

11

/16

15

3

/16

13

1

/16

3

15

4

2

/8

1

4

/8

1

6

11

1

1

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

9

1

/2

23

1

/2

9

11

/16

2B ONLY

3 13/16

4 15/16

3 15/16

2A, 4L, 4H, & 8H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

2C N/A N/A

4N 50mm (1.969") 60mm (2.362") 50mm (1.969") 179mm (7.047") N/A N/A

4L

4H-Type

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

214mm (8.425")

209mm (8.228")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X1 = 60mm (2.362")

X2 = 60mm (2.362")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

33

209mm (8.228") N/A N/A

Y1 = 179mm (7.047")

Y2 = 179mm (7.047")

N/A N/A

Page 34

SP1315

13 3/8 x 15

PRONTO

15

1

/4

5

TOP

OPERATOR

/8

3

13

OFFSET (1)

1/2 - 13 UNC

or M12

Select at least 4

2B ONLY

5 7/16

3

Guide Pin (4)

1

/4" or 16mm Dia.

2

6 3/4

TOP

OPERATOR

/8

5

4

/16

9

3

1

2

/16

11

/4

5

3

6

1/2 - 13 UNC

or M12

Select at least 4

1

1

5 11/16

3 9/16

13 3/8

3

/4" or 16mm Dia.

Guide Pin (4)

4 5/8

OFFSET (1)

5

1

/4

15

5

7

/16

2A & 4H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

2C N/A N/A

4N 50mm (1.969") 79mm (3.110") 50mm (1.969") 71mm (2.795") N/A N/A

4L N/A N/A N/A N/A N/A N/A

4H-Type

8H 500 HT N/A N/A N/A N/A N/A N/A

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

106mm (4.173")

85mm (3.346")

X1 = 79mm (3.110")

X2 = 79mm (3.110")

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

Y1 = 71mm (2.795")

Y2 = 71mm (2.795")

N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

34

SP-series 2005.09

Page 35

PRONTO

13 3/8 x 18

1

/2

6

SP1318

13 3/8

18

6 11/16

TOP

TOP

OPERATOR

/8

3

13

OFFSET (1)

1/2 - 13 UNC

or M12

Select at least 6

N/A = Not Available

Available manifold sizes

2B ONLY

OPERATOR

3

/4" or 16mm Dia.

Guide Pin (4)

1

1

2

1

3

/2

8 1/4

/8

5

4

2

/16

9

3

/2

1

3

/16

11

5

/4

1

8

1/2 - 13 UNC

or M12

Select at least 6

1

1

5 11/16

3 9/16

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

4 5/8

6

1

/2

18

6

11

/16

2A, 4L 4H, & 8H ONLY

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

60mm (2.362") HT/TS

70mm (2.756") VG/

144mm (5.669")

VX

60mm (2.362") HT/TS

2B

70mm (2.756") VG/

VX

139mm (5.472")

2C N/A N/A

4N 50mm (1.969") 79mm (3.110") 50mm (1.969") 105mm (4.134") N/A N/A

4L

4H-Type

60mm (2.362") HT/TS

70mm (2.756") VG/

VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X1 = 57mm (2.244")

X2 = 79mm (3.110")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

139mm (5.472") N/A N/A

Y1 = 109mm (4.291")

Y2 = 105mm (4.134")

N/A N/A

8H 500 HT X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-25.4mm (1.00") Y2 > Y1+ 62mm (2.44") 105mm (4.13")

8H 750 HT X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-45mm (1.77") Y2 > Y1+ 62mm (2.44") 105mm (4.13")

8H 500/750 VG X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-50mm (1.96") Y2 > Y1+ 62mm (2.44" ) 105mm (4.13")

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

35

Page 36

SP1321

13 3/8 x 20 3/4

PRONTO

13 3/8

7

/8

7

TOP

OPERATOR

/8

3

13

OFFSET (1)

1/2 - 13 UNC

or M12

Select at least 8

20 3/4

8 1/16

3

/4" or 16mm Dia.

Guide Pin (4)

1

1

1

2

/4

3

4

/4

9 5/8

/8

5

4

/16

9

3

/16

1

11

5

5

TOP

OPERATOR

/4

3

4

/4

1

2

/8

9

1/2 - 13 UNC

or M12

Select at least 8

1

1

1

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

7

7

/8

20

3

/4

8

1

/16

2B ONLY

3 9/16

5 11/16

4 5/8

2A, 4L, 4H & 8H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

2C N/A N/A

4N 50mm (1.969") 79mm (3.110") 50mm (1.969") 139mm (5.472") N/A N/A

4L

4H-Type

8H 500 HT X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-25.4mm (1.00") Y2 > Y1+ 62mm (2.44") 139mm (5.47")

8H 750 HT X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-45mm (1.77") Y2 > Y1+ 62mm (2.44") 139mm (5.47")

8H 500/750 VG X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-50mm (1. 96") Y2 > Y1+ 62mm (2.44") 139mm (5.47")

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

179mm (7.047")

174mm (6.850")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X1 = 57mm (2.244")

X2 = 79mm (3.110")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

174mm (6.850") N/A N/A

Y1 = 144mm (5.669")

Y2 = 139mm (5.472")

N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

36

SP-series 2005.09

Page 37

PRONTO

13 3/8 x 23 1/2

SP1324

13 3/8

1

/4

9

TOP

OFFSET (1)

OPERATOR

/8

3

13

1/2 - 13 UNC

or M12

Select at least 8

23 1/2

9 7/16

3

/4" or 16mm Dia.

Guide Pin (4)

1

1

1 3/4

3

3

/4

6 1/8

11

/8

5

4

/16

9

3

/16

1

11

5

11

TOP

OPERATOR

/4

3

3

/4

3

1

/8

1

6

1/2 - 13 UNC

or M12

Select at least 8

1

1

1

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

9

1

/4

23

1

/2

9

7

/16

2B ONLY

3 9/16

5 11/16

4 5/8

2A, 4L, 4H, & 8H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

2C N/A N/A

4N 50mm (1.969") 79mm (3.110") 50mm (1.969") 174mm (6.850") N/A N/A

4L

4H-Type

8H 500 HT X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-25.4mm (1.00") Y2 > Y1+ 62mm (2.44") 174mm (6.85")

8H 750 HT X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-45mm (1.77") Y2 > Y1+ 62mm (2.44") 174mm (6.85")

8H 500/750 VG X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-50mm (1.96") Y2 > Y1+ 62mm (2.44") 174mm (6.85")

SP-series 2005.09

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

214mm (8.425")

209mm (8.228")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X1 = 57mm (2.244")

X2 = 79mm (3.110")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

209mm (8.228") N/A N/A

Y1 = 179mm (7.047")

Y2 = 174mm (6.850")

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

37

N/A N/A

Page 38

SP1326

13 3/8 x 26

TOP

OFFSET (1)

OPERATOR

/8

3

13

1/2 - 13 UNC

or M12

Select at least 10

PRONTO

13 3/8

TOP

1 1/4

26

1

2

/4

3

5

/8

10 11/16

3

/4" or 16mm Dia.

Guide Pin (4)

11

12 1/4

1/2 - 13 UNC

OPERATOR

or M12

Select at least 10

/8

5

4

/16

9

3

1

1

/16

11

5

/4

1

1

/8

3

5

/4

1

2

1

/4

1

12

1

1

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

10

1

/2

26

10

11

/16

1

/2

10

2B ONLY

1

5 11/16

3 9/16

4 5/8

2A, 4L, 4H, & 8H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

2C N/A N/A

4N 50mm (1.969") 79mm (3.110") 50mm (1.969") 206mm (8.110") N/A N/A

4L

4H-Type

8H 500 HT X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-25.4mm (1.00") Y2 > Y1+ 62mm (2.44") 206mm (8.11")

8H 750 HT X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-45mm (1.77") Y2 > Y1+ 62mm (2.44") 206mm (8.11")

8H 500/750 VG X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-50mm (1.96") Y2 > Y1+ 62mm (2.44") 206mm (8.11")

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

246mm (9.685")

241mm (9.488")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X1 = 57mm (2.244")

X2 =79mm (3.110")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

241mm (9.488") N/A N/A

Y1 = 211mm (8.307")

Y2 = 206mm (8.110")

N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

38

SP-series 2005.09

Page 39

PRONTO

13 3/8 29 1/2

SP1330

13 3/8

TOP

TOP

OFFSET (1)

OPERATOR

/8

3

13

1/2 - 13 UNC

or M12

Select at least 10

N/A = Not Available

Available manifold sizes

1 1/4

29 1/2

5 1/4

12 5/16

3

/4" or 16mm Dia.

Guide Pin (4)

11

1

/4

2

9

14

/8

5

4

/16

9

3

1

/16

11

5

9

14

/4

1

5

1/2 - 13 UNC

OPERATOR

or M12

Select at least 10

/4

1

1

/4

1

2

11

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

12

1

/8

29

1

/2

12

5

/16

1

/8

12

2B ONLY

1

3 9/16

5 11/16

4 5/8

2A, 4L, 4H, & 8H ONLY

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

290mm (11.417")

285mm (11.220")

2C N/A N/A

4N 50mm (1.969") 79mm (3.110") 50mm (1.969") 247mm (9.724") N/A N/A

4L

4H-Type

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X1 = 57mm (2.244")

X2 = 79mm (3.110")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

285mm (11.22") N/A N/A

Y1 = 255mm (10.039")

Y2 = 247mm (9.724")

N/A N/A

8H 500 HT X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-25.4mm (1.00") Y2 > Y1+ 62mm (2.44") 247mm (9.72")

8H 750 HT X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-45mm (1.77") Y2 > Y1+ 62mm (2.44") 247mm (9.72")

8H 500/750 VG X > 73mm (2.87") 79mm (3.11") Y1 > 61.3mm (2.41") Y2-50mm (1.96") Y2 > Y1+ 62mm (2.44") 247mm (9.72")

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

39

Page 40

SP1518

14 7/8 x 17 7/8

PRONTO

3 9/16

14 7/8

3

/4" or 16mm Dia.

Guide Pin (4)

5 1/4

OFFSET (1)

6

1

/16

17

7

/8

6

1

/4

/16

2B ONLY

17 7/8

1

2

/4

3

Guide Pin (4)

1

6 1/4

/4" or 16mm Dia.

1

8 3/16

TOP

OPERATOR

/4

1

5

/4

1

/16

9

1

3

2

/16

7

6

/16

3

8

1/2 - 13 UNC

or M12

Select at least 6

1

1

6 7/16

1

1

6

TOP

OPERATOR

/8

7

14

OFFSET (1)

1/2 - 13 UNC

or M12

Select at least 6

2A, 4L & 8H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

2C N/A N/A

4N 50mm (1.969") 98mm (3.858") 50mm (1.969") 93mm (3.661") N/A N/A

4L

4H-Type

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

8H 500 HT X > 73mm (2.87") 98mm (3.85") Y1 > 61.3mm (2.41") Y2-25.4mm (1.00")

8H 750 HT X >73mm (2.87") 98mm (3.85") Y1 > 61.3mm (2.41") Y2-45mm (1.77")

8H 500/750 VG N/A N/A N/A N/A N/A N/A

143mm (5.629")

138mm (5.433")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X1 = 73mm (2.874")

X2 = 98mm (3.858")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

138mm (5.433") N/A N/A

Y1 = 108mm (4.252")

Y2 = 93mm (3.661")

N/A N/A

Y2 > Y1 + 62 mm

(2.44")

Y2 > Y1 + 62mm

(2.44")

93mm (3.66")

93mm (3.66")

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

40

SP-series 2005.09

Page 41

PRONTO

14 7/8 x 23 3/4

9

SP1524

14 7/8

3

/4

23

3

/16

9

TOP

1/2 - 13 UNC

OPERATOR

TOP

OFFSET (1)

1

/4

1

1 5/8

3

/4" or 16mm Dia.

Guide Pin (4)

8 3/4

11 1/8

/4

1

5

/16

9

3

1

1

/16

7

6

/4

1

4

/8

5

1

/4

3

8

/8

1

11

OPERATOR

/8

7

14

1/2 - 13 UNC

or M12

Select at least 8

4

2B ONLY

or M12

Select at least 8

1

1

1

3 9/16

6 7/16

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

5 1/4

9

23

3

/4

9

3

/16

2A, 4L, 4H, & 8H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

2C N/A N/A

4N 50mm (1.969") 98mm (3.858") 50mm (1.969") 168mm (6.614") N/A N/A

4L

4H-Type

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

8H 500 HT X > 73mm (2.87") 98mm (3.85") Y1 > 61.3mm (2.41") Y2-25.4mm (1.00") Y2 > Y1 + 62 mm (2.44") 168mm (6.61")

8H 750 HT X >73mm (2.87") 98mm (3.85") Y1 > 61.3mm (2.41") Y2-45mm (1.77") Y2 > Y1 + 62mm (2.44") 168mm (6.61")

8H 500/750 VG X > 73mm (2.87") 98mm (3.85") Y1 > 61.3mm (2.41") Y2-50mm (1.96") Y2 > Y1 + 62 mm (2.44") 168mm (6.61")

217mm (8.543")

212mm (8.346")

Y - 45mm (1.77") HT/

TS

Y - 57mm (2.24") VG/

VX

X1 = 73mm (2.874")

X2 = 98mm (3.858")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

212mm (8.346") N/A N/A

Y1 = 182mm (7.165")

Y2 = 168mm (6.614")

N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

41

Page 42

SP1530

14 7/8 x 29 1/2

7

/8

11

TOP

OFFSET (1)

OPERATOR

/8

7

14

1/2 - 13 UNC

or M12

Select at least 10

2B ONLY

1 1/4

29 1/2

PRONTO

14 7/8

TOP

12 1/16

1/2 - 13 UNC

OPERATOR

or M12

Select at least 10

3

/4" or 16mm Dia.

Guide Pin (4)

11

2 1/4

5

8 1/2

5

/8

11

14

/4

1

5

/16

9

3

1

/16

7

6

14

/4

1

1

5

/4

1

/2

2

1

8

/8

5

11

11

1

3 9/16

6 7/16

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

5 1/4

11

7

/8

29

1

/2

12

1

/16

2A, 4L, 4H, & 8H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/ Y1 Min Y2 Max Y2

2A

2B

2C N/A N/A

4N 50mm (1.969") 98mm (3.858") 50mm (1.969") 241mm (9.488") N/A N/A

4L

4H-Type

8H 500 HT X > 73mm (2.87") 98mm (3.85") Y1 > 61.3mm (2.41") Y2-25.4mm (1.00") Y2 > Y1 + 62 mm (2.44") 241mm (9.48")

8H 750 HT X >73mm (2.87") 98mm (3.85") Y1 > 61.3mm (2.41") Y2-45mm (1.77") Y2 > Y1 + 62mm (2.44") 241mm (9.48")

8H 500/750 VG X > 73mm (2.87") 98mm (3.85") Y1 > 61.3mm (2.41") Y2-50mm (1.96") Y2 > Y1 + 62 mm (2.44") 241mm (9.48")

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

290mm (11.417")

285mm (11.220")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X1 = 73mm (2.874")

X2 = 98mm (3.858")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

285mm (11.22") N/A N/A

Y1 = 255mm (10.039")

Y2 = 241mm (9.488")

N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

42

SP-series 2005.09

Page 43

PRONTO

15 7/8 x 16

SP1616

16

1

/4

5

5 3/8

15 7/8

TOP

OFFSET (1)

OPERATOR

/8

7

15

1/2 - 13 UNC

or M12

Select at least 6

3

/4" or 16mm Dia.

Guide Pin (4)

1

2

7 1/4

/2

1

5

/16

1

3

1

1

/16

15

6

TOP

1/2 - 13 UNC

OPERATOR

2

/4

1

7

or M12

Select at least 6

1

1

1

3 1/16

6 15/16

OFFSET (1)

3

/4" or 16mm Dia.

Guide Pin (4)

5 1/2

5

1

/4

16

5

3

/8

2A, 2C, 4H & 8H ONLY2B ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

2C

4N 50mm (1.969") 111mm (4.370") 50mm (1.969") 73mm (2.874") N/A N/A

4L N/A N/A N/A N/A N/A N/A

4H-Type

8H 500 HT X > 73mm (2.87") 111mm (4.37") Y1 > 61.3mm (2.41") Y2-25.4mm (1.00") Y2 > Y1 + 62mm (2.44") 73mm (2.87")

8H 750 HT N/A N/A N/A N/A N/A N/A

8H 500/750 VG N/A N/A N/A N/A N/A N/A

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

119mm (4.685")

114mm (4.488")

114mm (4.488")

X1 = 79mm (3.110")

X2 = 111mm (4.370")

Y1 = 50mm (1.969")

Y2 = 50mm (1.969")

Y1 = 84mm (3.307")

Y2 = 73mm (2.874")

N/A N/A

Please confirm all dimensions and nozzle suitability by referring to www.hotrunners.com or by calling Husky.

SP-series 2005.09

43

Page 44

SP1620

15 7/8 x 20

TOP

OFFSET (1)

OPERATOR

PRONTO

15 7/8

1

7

20

/4

7 3/8

3

/4" or 16mm Dia.

Guide Pin (4)

TOP

OPERATOR

/2

1

5

1/2 - 13 UNC

or M12

Select at least 8

OFFSET (1)

7

1

/4

/8

7

15

1/2 - 13 UNC

or M12

Select at least 8

1

2

4

9 1/4

/16

1

3

1

1

/16

15

6

2B ONLY

2

4

/4

1

9

1

1

1

6 15/16

3 1/16

3

/4" or 16mm Dia.

Guide Pin (4)

5 1/2

20

7

3

/8

2A, 2C, 4L, 4H, & 8H ONLY

N/A = Not Available

Available manifold sizes

Min X Max X Min Y/Y1 Max Y/Y1 Min Y2 Max Y2

2A

2B

2C

4N 50mm (1.969") 111mm (4.370") 50mm (1.969") 124mm (4.882") N/A N/A

4L

4H-Type

8H 500 HT X > 73mm (2.87") 111mm (4.37") Y1 > 61.3mm (2.41") Y2-25.4mm (1.00") Y2 > Y1 + 62mm (2.44") 124mm (4.88")

8H 750 HT X > 73mm (2.87") 111mm (4.37") Y1 > 61.3mm (2.41") Y2-45mm (1.77") Y2 > Y1 + 62mm (2.44") 124mm (4.88")

8H 500/750 VG X > 73mm (2.87") 111mm (4.37") Y1 > 61.3mm (2.41") Y2-50mm (1.96") Y2 > Y1 + 62mm (2.44") 124mm (4.88")

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

60mm (2.362") HT/TS

70mm (2.756") VG/VX

X1 = 50mm (1.969")

X2 = 50mm (1.969")

169mm (6.653")

164mm (6.456")

114mm (4.488")

Y - 45mm (1.77") HT/TS

Y - 57mm (2.24") VG/VX

X1 = 79mm (3.110")

X2 = 111mm (4.370")

X + 45mm (1.77") HT/TS

X + 57mm (2.24") VG/VX