Page 1

Flow Simulation Center

Optimize your mold performance with better part designs.

Injection molding and flow simulation specialists analyze and optimize part designs.

Detailed part analysis early in a product’s lifecycle can help

save time and money. By predicting filling behaviour and

improving part design up front, a product’s release to market

can be more successful.

Husky’s Flow Simulation Center (FSC) offers a complete

solutions approach to improving part productivity. Flow

simulation examines polymer flow behavior when injected

into the cavity (fill, pack, cool analysis) and once ejected

(warpage analysis).

Through its dedicated team of specialists located in

Luxembourg, Europe and Vermont, U.S.A., the FSC is able to

review, analyze, predict and support Husky’s customers in

their daily injection molding challenges.

The Flow Simulation Center focuses on all key aspects of the

injection molding process including:

Part design

• Determining the number of gates, gate location and size,

weld line location, fiber orientation and pressure levels

• Avoiding short shots and hesitation effects

Injection molding

• Defining optimum injection time

• Determining the table of sequence for sequential gating

Mold design

• Optimizing cooling efficiency

• Determining air trap location

FSC services can help customers in markets such as telecom,

packaging, automotive, medical, closures, housewares

and cosmetics.

Page 2

“The injection molding industry has become very

competitive. We need to get it right the first time.

Husky’s Flow Simulation Center allows us to predict

performance up-front and enhance our part and mold

designs. Their detailed filling analysis addresses issues

such as filling imbalance and hesitation effects. Husky

also helps us optimize wall thickness, gate size and

location and pressure levels. With Husky, we improve

our productivity, save money and get our parts to

market faster.”

Mr. Luca Mencarelii

SCS srl, Plastic Molds Services Group,

Italy

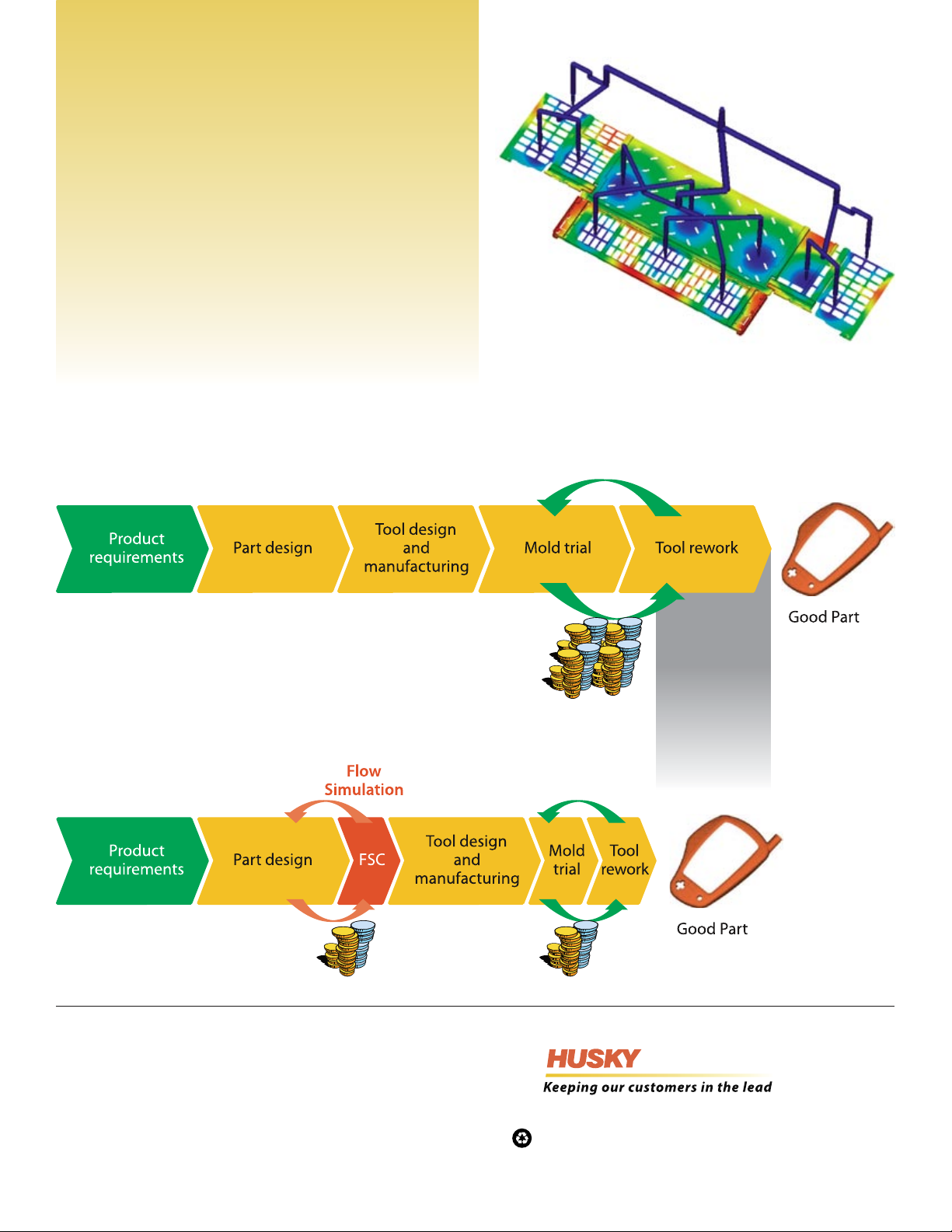

Traditional Part Development Process

Advanced Part Development Process

www.husky.ca

www.hotrunners.com

Europe

Zone Industrielle Riedgen

Technical Center, B.P. 93

L-3401 Dudelange

Luxembourg

Tel. (352) 52 11 51

Fax (352) 52 11 5 4458

Americas

288 North Road

Milton, Vermont

USA 05468

Toll Free (800) 516 9590

Tel. (802) 859 8000

Fax (802) 859 8322

Recycled paper, containing a minimum of 20% post consumer fiber.

®/© 2004 Husky Injection Molding Systems Ltd.

Printed in Canada. September 2004

Loading...

Loading...