Page 1

Mold Base Technologies

Our Mold Technologies team supplies a wide range of mold

bases and mold accessories. From simple, strippable, closure

mold bases to complex 2- and 4-level stack systems, we offer

fully engineered and optimized mold base solutions featuring

mold technologies such as the patented Rotating Ratchet

Ring unscrewing system. With over 40 years of mold base

experience with expertise in high cavitation and stack systems for closure, medical, packaging and cutlery applications.

Each mold base includes:

• Precisely machined stainless steel plates

• Cooling channels sized for each application

• Balanced hydraulic and pneumatic functions for smooth

plate actuation

• Calculated insert stack compression to extend insert life

• Front-mounted cavity and core designs for easy maintenance

• All accessories, including lift bars, latches, water connection

kits and hardware

Each mold base is completely assembled and fully tested, making mold insert installation fast, simple and trouble-free.

Page 2

PRODUCTS

Husky’s mold technology is built upon years of design

experience paired with new product innovation.

Husky offers many technologies to increase cavitation,

reduce cycle times and produce better molded parts.

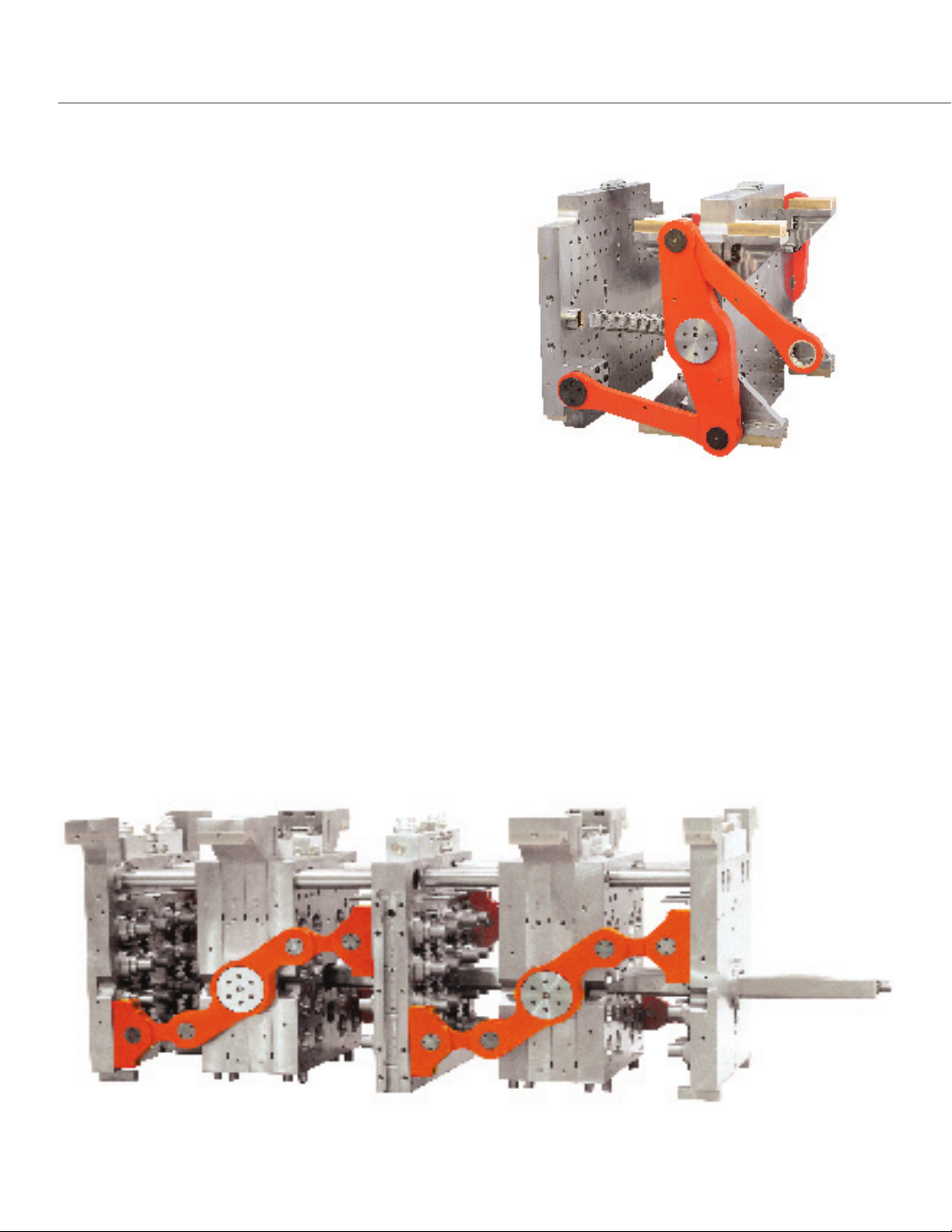

STACK MOLD BASES

We have pioneered stack technologies since the 1970s. Our

stack mold bases feature balanced hot runners, robust linkage systems and rugged mold supports. Mold base plate

actuation can be controlled through compact pneumatic or

hydraulic systems and/or rocker arms in order to meet part

ejection requirements. Husky’s stack mold bases substantially increase output while maintaining cycle times and part

quality. In addition to conventional 2-level stack mold bases,

Husky also offers the following stack technologies:

Stack platens convert similar individual molds into a single-stack mold.

Four-Level Stack Mold Bases — four-level stack molds virtually

quadruple the output of an injection molding machine, with

minimal increase in clamp tonnage relative to a single-face

mold. Husky’s 4-level systems utilize dual sprue bars controlling melt flow to both hot runners as well as a primary and

secondary harmonic linkage system for advanced mold opening. Four-level systems are effective for parts with compatible

part heights and shot sizes requiring simple ejection systems.

Stack Platens – The stack platen permits the consolidation

of two single-face molds in one injection molding machine.

This system delivers melt to a center platen via an offset

sprue bar. The center platen is configured with a Euromap or

SPI interface and transports melt to either side of the platen.

This allows two similar individual molds to function as a single-stack mold, increasing machine output, reducing floor

space requirements and utilizing existing tooling.

4-level stack molds quadruple output, without significant increase in clamp tonnage.

Page 3

UNSCREWING MOLD BASES – ROTATING RATCHET RING

For parts that are unscrewed during ejection, Husky’s Rotating

Ratchet Ring (RRR) mold bases provide a superior alternative

to conventional unscrewing molds. The patented RRR

design uses teeth in the ratchet ring to unscrew the molded

part from a stationary core. The primary benefits of using

a stationary core are larger cooling channels and no rotary

seals. Additionally, the RRR design incorporates a unique

unidirectional clutch on the drive gear. The clutch permits

the ratchet ring to rotate in one direction to eject the part

and allows the ring to idle during rack reset.

Larger cooling channels, no rotary seals and the unique clutch design of the

Rotating Ratchet Ring provide faster cycles with less maintenance.

Integrated servo swingchutes for fastest possible cycle times.

SWINGCHUTES

Husky’s patented swingchutes replace costly robotics for

product handling. Swingchutes are actuated by cams or

servo motors and are integrated directly into the mold base.

Suction cups at the end of the swingchute arms grip the

parts, remove them from the mold and place them into a

stationary chute next to the mold.

GATE INSERTS

Properly designed gate inserts improve cycle time and gate

quality. Correctly positioned and sized gate insert cooling

lines provide the widest possible processing window without compromising gate quality. Accurate insert manufacturing and finishing ensures correct nozzle and cavity seal off,

eliminating detrimental resin hang-up spots. Husky provides

standard and custom gate inserts manufactured from

hardened tool steel and designed for easy maintenance and

optimal heat extraction.

Page 4

WORKING WITH HUSKY

Ordering a mold base from Husky means one-stop shopping,

full project management and single-source responsibility.

We provide:

• Extensive mold base engineering expertise, including

experience with closures, unscrewing systems, thinwall

parts and cutlery

• Stack mold experience with 2- and 4-level stack mold

bases, stack platens and offset stack systems to maximize

machine output

• Rotating Ratchet Ring technology for unscrewing closures,

providing faster cycles and reduced maintenance

• Manufacturing capacity to handle multi-mold orders and

large plate production

Automated manufacturing cells provide capacity for large and multi-mold

projects.

Incorporating Husky mold bases into the mold is easy:

• You provide Husky with part drawing, including cavitation,

machine tie bar and shutheight specifications

• Husky recommends mold base size and ejection system

• Husky furnishes a core/cavity stack installation drawing

specific to the mold base

• Husky designs and manufactures a complete mold base

with all necessary accessories

The moldmaker simply designs and manufactures the core/

cavity stacks, supplying only the fasteners and seals to install

these components into the mold base.

Accurate bore alignment ensures extended mold insert life.

www.husky.ca

www.hotrunners.com

Americas & Asia

288 North Road

Milton, Vermont, USA 05468

Toll Free (800) 516 9590

Tel. (802) 859 8000

Fax (802) 859 8321

Europe

Hot Runner Mold Building

B.P. 231, L-3403 Dudelange,

Luxembourg

Tel. (352) 52 11 51

Fax (352) 52 11 5 4458

Our Mold Technology Team delivers in depth product knowledge, manufacturing resources and project management.

Rec ycled pape r, contai ning a mi nimum of 2 0% po st co nsume r fib er.

®/©2 003 H usky Inje ction Mold ing S ystem s Ltd. Printe d in Canad a. Apr il 20 03

Husk y ac tively prot ects its techni cal and d esign innov ations thro ugh a glo bal i ntelle ctual prop erty

stra tegy. Hu sky c urren tly h as mo re th an 90 0 pat ents and p atent appl icatio ns wo rldwi de.

The equip ment shown in t his p ublic ation may be co vered by o ne or more of these paten ts.

“Husky” is a trademark owned by Husky Injection Molding Systems Ltd.

Oth er co mpany, pr oduct , and servi ce na mes m ay be trad emark s of their resp ectiv e own ers.

Loading...

Loading...