Cordless Angle Grinder

Amoladora angular inalámbrica

Operating Instructions

Manual de instrucciones

Model No: HTP-AGR

IMPORTANT

This manual contains safety information. Read manual completely before rst using this product and save this

manual for future use.

IMPORTANTE

Este manual contiene información de seguridad. Lea completamente este manual antes de utilizar por primera

vez este producto, y guárdelo para poder consultarlo en el futuro.

Index/Index/Indice

English: Page 6

Español: Página

23

FUNCTIONAL DESCRIPTION

DESCRIPCIÓN FUNCIONAL

(O)

10.8 V ─ 28.8 V

(Q)

(Q)

(D)

(P)

(R)

(S)

(T)

(Q)

(E) (F)

(C)

(G)

(I)

(A)

(J)

(K)

(N)

(M)

(L)

(B)

(H)

(A)

Power switch

Interruptor de alimentación

(B)

Brush cap

Tapa de cepillo

(C)

Display panel

Panel de exhibición

(D)

Battery low warning lamp

Luz de aviso de baja carga de batería

(E)

On lock warning lamp

Luz de advertencia de bloqueo

(F)

Overheat warning lamp (battery)

Luz de advertencia de sobrecalentamiento

(batería)

(G)

Battery pack release button

Botón de liberación de batería

(H)

Alignment mark

Marca de alineación

(I)

Battery pack

Batería

(J)

Support handle

Mango de soporte

(K)

Support handle mounting hole

Oricio de montaje de mango de soporte

(L)

Grinding disc guard

Protección de disco de desbastado

(M)

Grinding disc guard xing screw

Tornillo de jación de protector de disco de

amoladora

(N)

Spindle

Eje

(O)

Spindle lock button

Botón de bloqueo de eje

(P)

Battery charger

Cargador de batería

(Q)

Battery pack cover

Cubierta de la batería

(R)

Clamp nut

Tuerca de abrazadera

(S)

Disc ange

Brida de disco

(T)

Disc wrench

Llave de disco

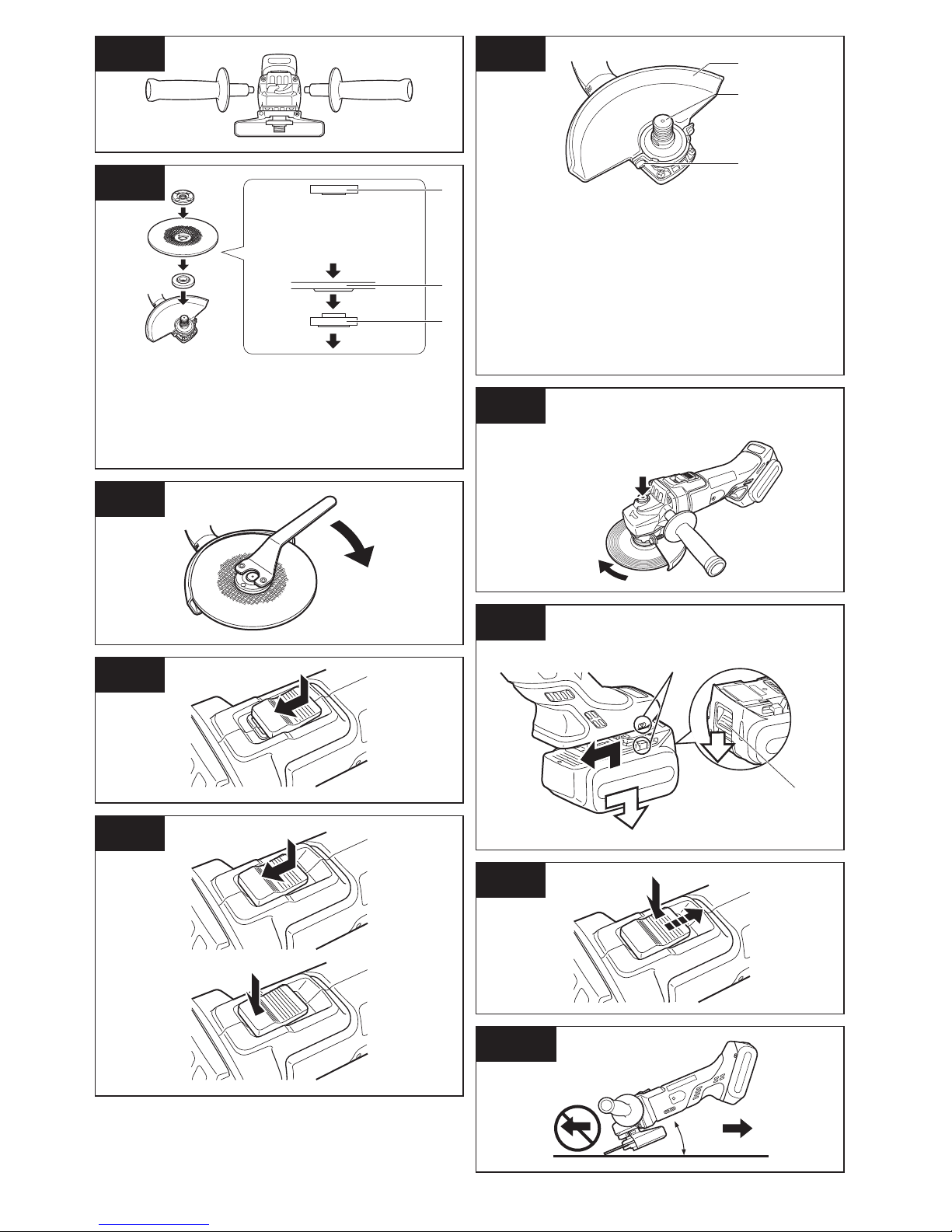

[Fig.6]

[Fig.2]

[Fig.3]

[Fig.4]

[Fig.5]

[Fig.7]

[Fig.9]

[Fig.8]

[Fig.1]

1. Grinding disc guard

Protección de disco de desbastado

2. Spindle

Eje

3. Grinding disc guard fixing screw

Tornillo de fijación de protector de disco de

amoladora

Spindle lock button

Botón de bloqueo de eje

Alignment marks

Marcas de alineación

Button

Botón

1

2

3

1. Clamp nut

Tuerca de abrazadera

2. Grinding disc

Disco de desbastado

3. Disc flange

Brida de disco

1

2

3

Make sure the side.

Assurez-vous du côté.

Asegure el costado.

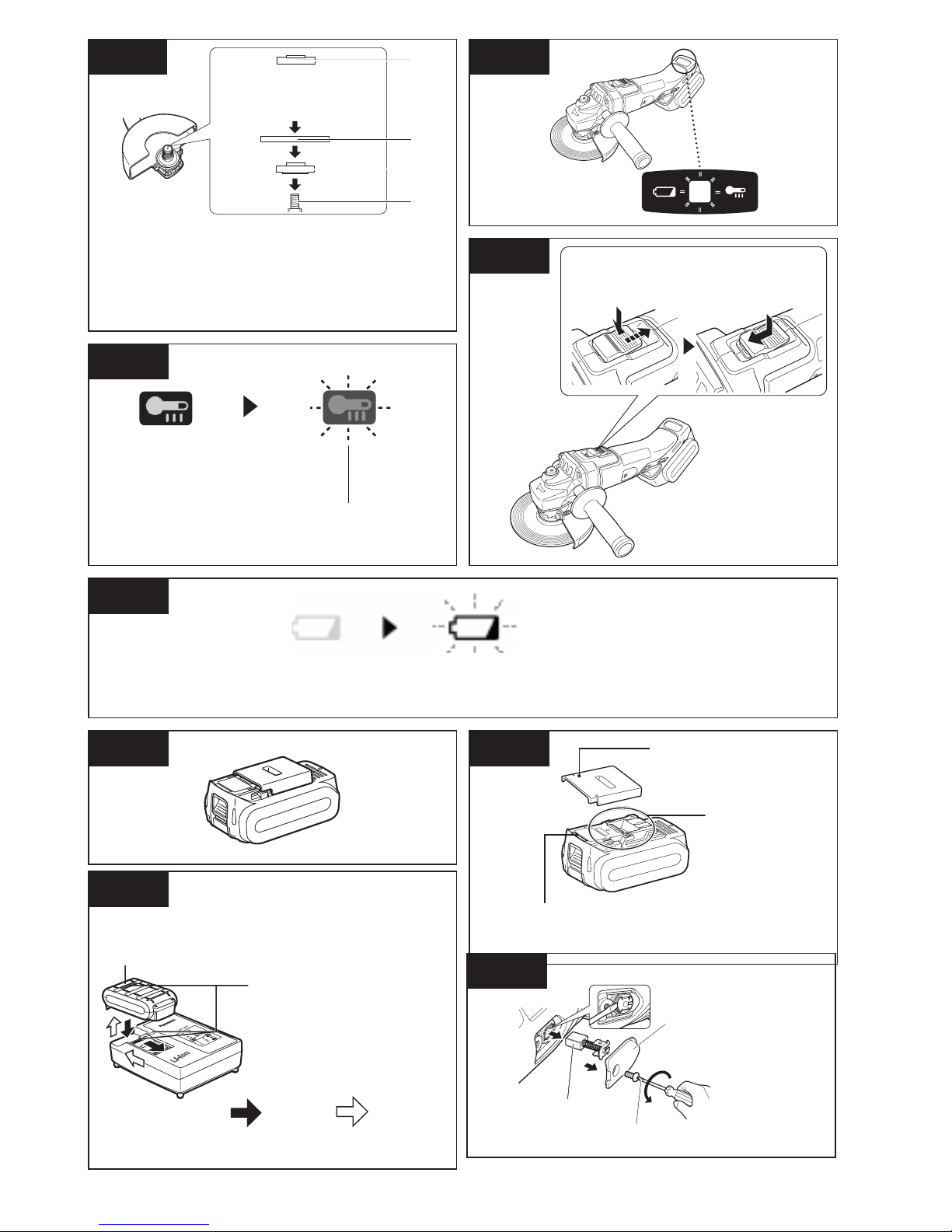

[Fig.10]

B

A

Carbon brush

Cepillo de carbón

Screw driver

Destornillador

Brush cap

Tapa de cepillo

[Fig.19]

[Fig.11] [Fig.12]

[Fig.14]

[Fig.16] [Fig.17]

[Fig.18]

[Fig.15]

[Fig.13]

1. Clamp nut

Tuerca de abrazadera

2. Cut-off disc

Disco de corte

3. Disc flange

Brida de disco

4. Spindle

Eje

ON→OFF

ON→OFF

OFF→ON

OFF→ON

Off (normal operation)

Apagado (funcionamiento normal)

Flashing (No charge) Battery protection feature active

Destella (Sin carga) Se activó la function de protección de la batería

Off (normal operation)

Apagado (funcionamiento normal)

Flashing: Overheat

Destella: Sobrecalentamiento

Make sure the side.

Asegure el costado.

1

2

3

4

Alignment marks

Marcas de alineación

Battery pack release button

Botón de liberación de batería

Pack cover

cudeksel

Terminals

Terminales

Label (red or yellow)

Etiqueta (roja o amarilla)

Attaching

Acoplamiento

Removing

Desacoplamiento

How to Use This Manual

• Please read this manual completely

before starting to use your grinder. If

you let someone else use the grinder,

make sure they either read this

manual or are fully instructed in the

proper use and all safety precautions

concerning the grinder.

• Please keep this manual for future

reference. It contains important safety

information that you must follow to

use the grinder safely.

• This manual and product use the

following signal words:

NOTE:

Notes provide additional information

that you should know about the grinder.

CAUTION

Caution indicates a potentially

hazardous situation, which could

result in minor or moderate injury if

not avoided. Cautions also alert you to

unsafe practices to be avoided.

WARNING

Warning indicates a potentially

hazardous situation, which could result

in serious injury or death if not avoided.

DANGER

Danger indicates an imminent hazard

which will result in serious injury or

death if not avoided.

II. GENERAL

SAFETY RULES

WARNING! Read all instructions

Failure to follow all instructions listed

below may result in electric shock, fire

and/or serious injury. The term “power

tool” in all of the warnings listed below

refers to your main operated (corded)

power tool and battery operated

(cordless) power tool.

This tool, as a complete unit with a battery

pack, satisfies appropriate IP Degrees of

Protection based on the IEC regulations.

Definition of IP code

IP5X: Ingress of dust is not totally

prevented, but dust shall not

penetrate in a quantity to interfere with

satisfactory operation of the tool or to

impair safety (In case that the talcum

powder under 75 μm intrudes inside the

tool)

IPX6: Water projected in powerful jets

against the tool from any direction

shall have no harmful effects (In case

that, with a nozzle of 12.5 mm inner

diameter, approximately 100 L/min of

normal temperature water is injected

to the tool for 3 minutes from 3 meter

distance)

LIMITED WARRANTY

The rating of IP56 qualifies this tool

for the minimum impact of water or

dust, but not for the assurance of

performance in such conditions. See

Safety and Operating Instructions for

further details for proper operation.

I. INTRODUCTION

Thank you for purchasing the

Huskie Tools Angle Grinder. The powerful grinding action of this tool, combined

with the convenience of its rechargeable battery pack, provides you with

great grinding performance.

This Angle Grinder is only to be used

for grinding and cutting-off.

DANGER

This product is a grinding tool, designed

to grind. It has a rotating disc which

is capable of cutting you deeply,

causing serious injury or death. As a

result, please read this manual and

the cautionary markings on the tool

carefully, and obey all of the Safety

Instructions to avoid such injury.

WARNING

To reduce the risk of injury, always use

proper guards when grinding.

SAVE THESE INSTRUCTIONS

Work Area Safety

1) Keep work area clean and well lit.

Cluttered or dark areas invite

accidents.

2) Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases or dust.

Power tools create sparks which may

ignite the dust or fumes.

3) Keep children and bystanders

away while operating a power tool.

Distractions can cause you to lose

control.

Electrical Safety

1) Power tool plugs must match the

outlet. Never modify the plug in

any way. Do not use any adapter

plugs with earthed (grounded)

power tools.

Unmodified plugs and matching

outlets will reduce risk of electric

shock.

2) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or

grounded.

3) Do not expose power tools to rain

or wet conditions.

Water entering a power tool will

increase the risk of electric shock.

4) Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp

edges or moving parts.

Damaged or entangled cords

increase the risk of electric shock.

5) When operating a power tool

outdoors, use an extension cord

suitable for outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

Personal Safety

1) Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use a power tool while you

are tired or under the influence of

drugs, alcohol or medication.

A moment of inattention while

operating power tools may result in

personal injury.

2) Use safety equipment. Always

wear eye protection.

Safety equipment such as dust

mask, non-skid safety shoes, hard

hat, or hearing protection used for

appropriate conditions will reduce

personal injuries.

3) Avoid accidental starting. Ensure

the switch is in the off position

before plugging in.

Carrying power tools with your finger

on the switch or plugging in the

power tools that have the switch on

invites accidents.

4) Remove any adjusting key or

wrench before turning the power

tool on.

A wrench or a key left attached to a

rotating part of the power tool may

result in personal injury.

5) Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the

power tool in unexpected situations.

6) Dress properly. Do not wear loose

clothing or jewelry. Keep your hair,

clothing and gloves away from

moving parts.

Loose clothes, jewelry or long hair

can be caught in moving parts.

7) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these

are connected and properly used.

Use of these devices can reduce dust

related hazards.

Power Tool Use and Care

1) Do not force the power tool. Use

the correct power tool for your

application.

The correct power tool will do the job

better and safer at the rate for which

it was designed.

2) Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be

controlled with the switch is

dangerous and must be repaired.

3) Disconnect the plug from the

power source and/or the battery

pack from the power tool before

making any adjustments, changing

accessories, or storing power

tools.

Such preventive safety measures

reduce the risk of starting the power

tool accidentally.

4) Store idle power tools out of

the reach of children and do not

allow persons unfamiliar with the

power tool or these instructions to

operate the power tool.

Power tools are dangerous in the

hands of untrained users.

5) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any

other condition that may affect the

power tools operation. If damaged,

have the power tool repaired

before use.

Many accidents are caused by poorly

maintained power tools.

6) Keep cutting tools sharp and

clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

7) Use the power tool, accessories

and tool bits etc. in accordance

with these instructions and in the

manner intended for the particular

type of power tool, taking into

account the working conditions

and the work to be performed.

Use of the power tool for operations

different from those intended could

result in a hazardous situation.

Battery Tool Use and Care

1) Ensure the switch is in the off

position before inserting battery

pack.

Inserting battery pack into power

tools that have the switch on invites

accidents.

2) Recharge only with the charger

specified by the manufacturer.

A charger that is suitable for one type

of battery pack may create a risk of

fire when used with another battery

pack.

3) Use power tools only with

specifically designated battery

packs.

Use of any other battery packs may

create a risk of injury and fire.

4) When battery pack is not in use,

keep it away from other metal

objects like paper clips, coins,

keys, nails, screws, or other small

metal objects that can make a

connection from one terminal to

another.

Shorting the battery terminals

together may cause burns, or a fire.

5) Under abusive conditions, liquid

may be ejected from battery; avoid

contact. If contact accidentally

occurs, flush with water. If liquid

contacts eyes, additionally seek

medical help.

Liquid ejected from the battery may

cause irritation or burns.

Service

1) Have your power tool serviced by

a qualified repair person using

only identical replacement parts.

This will ensure that the safety of

power tool is maintained.

7) Do not use a damaged accessory.

Before each use inspect the

accessory such as abrasive

wheels for chips and cracks.

If power tool or accessory is

dropped, inspect for damage or

install an undamaged accessory.

After inspecting and installing an

accessory, position yourself and

bystanders away from the plane of

the rotating accessory and run the

power tool at maximum no-load

speed for one minute. Damaged

accessories will normally break apart

during this test time.

8) Wear personal protective

equipment. Depending on

application, use face shield,

safety goggles or safety glasses.

As appropriate, wear dust mask,

hearing protectors, gloves

and workshop apron capable

of stopping small abrasive or

workpiece fragments. The eye

protection must be capable of

stopping flying debris generated

by various operations. The dust

mask or respirator must be capable

of filtrating particles generated by

your operation. Prolonged exposure

to high intensity noise may cause

hearing loss.

9) Keep bystanders a safe distance

away from work area. Anyone

entering the work area must wear

personal protective equipment.

Fragments of workpiece or of a

broken accessory may fly away and

cause injury beyond immediate area

of operation.

10) Hold the power tool by insulated

gripping surfaces only, when

performing an operation where the

cutting tool may contact hidden

wiring. Contact with a “live” wire

will also make exposed metal

parts of the power tool “live” and

could give the operator an electric

shock.

11) Position the cord clear of the

spinning accessory. If you lose

control, the cord may be cut or

snagged and your hand or arm may

be pulled into the spinning accessory.

Safety instructions for all

operations

Safety warning common for Grinding

or Abrasive Cutting-off operations:

1) This power tool is intended to

function as a grinder, or cut-off

tool. Read all safety warnings,

instructions, illustrations and

specifications provided with this

power tool. Failure to follow all

instructions listed below may result in

electric shock, fire and/or serious

injury.

2) Operations such as sanding, wire

brushing, polishing are not

recommended to be performed

with this power tool. Operations

for which the power tool was not

designed may create a hazard and

cause personal injury.

3) Do not use accessories which

are not specifically designed

and recommended by the tool

manufacturer. Just because the

accessory can be attached to your

power tool, it does not assure safe

operation.

4) The rated speed of the accessory

must be at least equal to the

maximum speed marked on the

power tool. Accessories running

faster than their RATED SPEED can

break and fly apart.

5) The outside diameter and the

thickness of your accessory must

be within the capacity rating of

your power tool. Incorrectly sized

accessories cannot be adequately

guarded or controlled.

6) Threaded mounting of accessories

must match the grinder spindle

thread. For accessories mounted

by flanges, the arbour hole of the

accessory must fit the locating

diameter of the flange. Accessories

that do not match the mounting

hardware of the power tool will run

out of balance, vibrate excessively

and may cause loss of control.

12) Never lay the power tool down

until the accessory has come

to a complete stop. The spinning

accessory may grab the surface and

pull the power tool out of your control.

13) Do not run the power tool while

carrying it at your side. Accidental

contact with the spinning accessory

could snag your clothing, pulling the

accessory into your body.

14) Regularly clean the power tool’s

air vents. The motor’s fan will draw

the dust inside the housing and

excessive accumulation of powdered

metal may cause electrical hazards.

15) Do not operate the power tool near

flammable materials. Sparks could

ignite these materials.

16) Do not use accessories that

require liquid coolants. Using water

or other liquid coolants may result in

electrocution or shock.

Further safety instructions for

all operations

Kickback and Related Warnings

Kickback is a sudden reaction to a

pinched or snagged rotating wheel,

backing pad, brush or any other

accessory. Pinching or snagging

causes rapid stalling of the rotating

accessory which in turn causes

the uncontrolled power tool to be

forced in the direction opposite of the

accessory’s rotation at the point of the

binding.

For example, if an abrasive wheel is

snagged or pinched by the workpiece,

the edge of the wheel that is entering

into the pinch point can dig into the

surface of the material causing the

wheel to climb out or kick out. The

wheel may either jump toward or

away from the operator, depending on

direction of the wheel’s movement at

the point of pinching. Abrasive wheels

may also break under these conditions.

Kickback is the result of power tool

misuse and/or incorrect operating

procedures or conditions and can be

avoided by taking proper precautions

as given below.

1) Maintain a firm grip on the power

tool and position your body

and arm to allow you to resist

kickback forces. Always use

auxiliary handle, if provided, for

maximum control over kickback

or torque reaction during start-up.

The operator can control torque

reactions or kickback forces, if proper

precautions are taken.

2) Never place your hand near the

rotating accessory. Accessory may

kickback over your hand.

3) Do not position your body in the

area where power tool will move

if kickback occurs. Kickback will

propel the tool in direction opposite to

the wheel’s movement at the point of

snagging.

4) Use special care when working

corners, sharp edges etc. Avoid

bouncing and snagging the

accessory. Corners, sharp edges or

bouncing have a tendency to snag

the rotating accessory and cause

loss of control or kickback.

5) Do not attach a saw chain

woodcarving blade or toothed saw

blade. Such blades create frequent

kickback and loss of control.

Additional safety instructions

for grinding and cutting-off

operations

Safety warnings specific for Grinding

and Abrasive Cutting-off operations:

1) Use only wheel types that are

recommended for your power tool

and the specific guard designed

for the selected wheel. Wheels

for which the power tool was not

designed cannot be adequately

guarded and are unsafe.

2) The grinding surface of centre

depressed wheels must be

mounted below the plane of the

guard lip. An improperly mounted

wheel that projects through the plane

of the guard lip cannot be adequately

protected.

3) The guard must be securely

attached to the power tool and

positioned for maximum safety,

so the least amount of wheel is

exposed towards the operator.

The guard helps to protect operator

from broken wheel fragments and

accidental contact with wheel and

sparks that could ignite clothing.

4) Wheels must be used only for

recommended applications. For

example: do not grind with the

side of cut-off wheel. Abrasive

cut-off wheels are intended for

peripheral grinding, side forces

applied to these wheels may cause

them to shatter.

5) Always use undamaged wheel

flanges that are of correct size and

shape for your selected wheel.

Proper wheel flanges support the

wheel thus reducing the possibility of

wheel breakage. Flanges for cut-off

wheels may be different from grinding

wheel flanges.

6) Do not use worn down wheels

from larger power tools. Wheel

intended for larger power tool is not

suitable for the higher speed of a

smaller tool and may burst.

Additional safety warnings

specific for abrasive cuttingoff operations:

1) Do not “jam” the cut-off wheel

or apply excessive pressure. Do

not attempt to make an excessive

depth of cut. Overstressing the

wheel increases the loading and

susceptibility to twisting or binding

of the wheel in the cut and the

possibility of kickback or wheel

breakage.

2) Do not position your body in

line with and behind the rotating

wheel. When the wheel, at the point

of operation, is moving away from

your body, the possible kickback may

propel the spinning wheel and the

power tool directly at you.

3) When wheel is binding or when

interrupting a cut for any reason,

switch off the power tool and hold

the power tool motionless until

the wheel comes to a complete

stop. Never attempt to remove the

cut-off wheel from the cut while

the wheel is in motion otherwise

kickback may occur. Investigate

and take corrective action to

eliminate the cause of wheel binding.

4) Do not restart the cutting

operation in the workpiece. Let

the wheel reach full speed and

carefully reenter the cut. The

wheel may bind, walk up or kickback

if the power tool is restarted in the

workpiece.

5) Support panels or any oversized

workpiece to minimize the risk

of wheel pinching and kickback.

Large workpieces tend to sag under

their own weight. Supports must be

placed under the workpiece near the

line of cut and near the edge of the

workpiece on both sides of the wheel.

6) Use extra caution when making a

“pocket cut” into existing walls or

other blind areas. The protruding

wheel may cut gas or water pipes,

electrical wiring or objects that can

cause kickback.

Symbol Meaning

V Volts

Direct current

n Rated speed

… min

-1

Revolutions or

reciprocations per minutes

Ah

Electrical capacity of

battery pack

To reduce the risk of

injury, user must read and

understand instruction

manual.

For indoor use only.

Always wear eye

protection

WARNING

Some dust created by power sanding,

sawing, grinding, drilling, and other

construction activities contains

chemicals known to the State of

California to cause cancer, birth defects

or other reproductive harm. Some

examples of these chemicals are:

* Lead from lead-based paints

* Crystalline silica from bricks and

cement and other masonry products

* Arsenic and chromium from

chemically- treated lumber.

To reduce your exposure to these

chemicals: work in a well ventilated

area, and work with approved safety

equipment, such as dust masks that

are specially designed to filter the

microscopic particles.

WARNING

• Do not use other than the

Huskie Tools battery packs that

are designed for use with this

rechargeable tool.

• Huskie Tools is not responsible for

any damage or accident caused

by the use of the recycled battery

pack and the counterfeit battery

pack.

• Do not dispose of the battery pack

in a fire, or expose it to excessive

heat.

• Do not drive the likes of nails

into the battery pack, subject it to

shocks, dismantle it, or attempt to

modify it.

• Do not allow metal objects to

touch the battery pack terminals.

• Do not carry or store the battery

pack in the same container as nails

or similar metal objects.

• Do not charge the battery pack in a

high-temperature location, such as

next to a fire or in direct sunlight.

Otherwise, the battery may

overheat, catch fire, or explode.

• Never use other than the dedicated

charger to charge the battery pack.

Otherwise, the battery may leak,

overheat, or explode.

WARNING

• After removing the battery pack

from the tool or the charger,

always reattach the pack cover.

Otherwise, the battery contacts

could be shorted, leading to a risk

of fire.

• When the Battery Pack Has

Deteriorated, Replace It with a New

One. Continued use of a damaged

battery pack may result in heat

generation, ignition or battery

rupture.

III. FOR BATTERY

CHARGER &

BATTERY PACK

Important Safety Instructions

1) SAVE THESE IN STRUCTIONS

-This manual contains important

safety and operating instructions for

battery charger.

2) Before using battery charger, read all

instructions and cautionary markings

on (1) battery charger, (2) battery

pack.

3) CAUTION - To reduce the risk of

injury, charge only Huskie Tools

Battery Pack as shown in last page.

Other types of batteries may burst

causing personal injury and damage.

4) Do not expose charger to rain or

snow.

5) To reduce the risk of damaging the

electric plug and cord, pull by plug

rather than cord when disconnecting

charger.

6) Make sure cord is located so that it

will not be stepped on, tripped over,

or otherwise subjected to damage or

stress.

7) An extension cord should not be

used unless absolutely necessary.

Use of improper extension cord could

result in a risk of fire and electric

shock. If extension cord must be

used, make sure:

a. that pins on plug of extension cord

are the same number, size and

shape as those of plug on charger.

b. that extension cord is properly

wired and in good electrical

condition.

c. that wire size is large enough

for ampere rating of charger as

specified below.

RECOMMENDED MINIMUM AWG SIZE OF

EXTENSION CORDS FOR

BATTERY CHARGERS

AC Input Rating. Amperes AWG Size of Cord

Equal to or

greater than

But less

than

Length of Cord, Feet

25 50 100 150

0 2 18 18 18 16

8) Do not operate charger with

damaged cord or plug – replace them

immediately.

9) Do not operate charger if it has

received a sharp blow, been dropped,

or otherwise damaged in any way;

take it to a qualified serviceman.

10) Do not disassemble charger; take

it to a qualified serviceman when

service or repair is required. Incorrect

reassembly may result in a risk of

electric shock or fire.

11) To reduce the risk of electric shock,

unplug charger from outlet before

attempting any maintenance or

cleaning.

12) The charger and battery pack

are specifically designed to work

together.

Do not attempt to charge any other

cordless tool or battery pack with this

charger.

13) Do not attempt to charge the battery

pack with any other charger.

14) Do not attempt to disassemble the

battery pack housing.

15) Do not store the tool and battery pack

in locations where the tempera ture

may reach or exceed 50°C (122°F)

(such a metal tool shed, or a car

in the summer), which can lead to

deterioration of the storage battery.

16) Do not charge battery pack when the

temperature is BELOW 0°C (32°F)

or ABOVE 40°C (104°F). This is very

important.

17) Do not incinerate the battery pack. It

can explode in a fire.

18) Avoid dangerous environment. Do

not use charger in damp or wet

locations.

19) The charger is designed to operate

on standard household electrical

power only. Do not attempt to use it

on any other voltage!

20) Do not abuse cord. Never carry

charger by cord or yank it to

disconnect from outlet. Keep cord

away from heat, oil and sharp edges.

21) Charge the battery pack in a well

ventilated place, do not cover the

charger and battery pack with a cloth,

etc., while charging.

22) Use of an attachment not

recommended may result in a risk

of fire, electric shock, or injury to

persons.

23) Do not short the battery pack. A

battery short can cause a large

current flow, over heating and burns.

24) NOTE: If the supply cord of this

appliance is damaged, it must only be

replaced by a repair shop appointed

by the manufacturer, because special

purpose tools are required.

25) TO REDUCE THE RISK OF

ELECTRIC SHOCK, THIS

APPLIANCE HAS A POLARIZED

PLUG (ONE BLADE IS WIDER

THAN THE OTHER).

This plug will fit in a polarized outlet

only one way. If the plug does not fit

fully in the outlet, reverse the plug. If

it still does not fit, contact a qualified

electrician to install the proper outlet.

Do not change the plug in any way.

IV. ASSEMBLY

NOTE:

When attaching or removing a support

handle, disconnect battery pack from

tool.

CAUTION

Always be sure that the support handle

is installed securely before operation.

Screw the side handle securely as shown

in the figure. [Fig.1]

Never actuate the lock pin when the

spindle is rotating. The tool may be

damaged.

Press the lock button to prevent spindle

rotation when installing or removing

parts, such as grinding disc, disc guard,

etc.

Installing or removing disc

[Fig.2-5]

Inspection before use

• Has the correct grinding disc been

mounted for the object to be ground?

• Has the proper diameter of the

grinding disc been mounted for the

tool rating?

• Has the correct disc been fitted in

compliance safety standards listed

below?

U.S.A, Canada - ANSI

CAUTION

• When using, the Grinding disc guard

must be installed on the tool so that

the closed side of the guard always

faces toward the operator.

• Ensure that blotters are used when

they are provided with the bonded

abrasive product and when they are

required;

WARNING

Always use supplied guard when using

tool. Grinding disc can shatter during

use and Grinding disc guard helps to

reduce chances of personal injury.

1. Install the Grinding disc guard, and then

securely tighten the screw.

2. Install the disc flange and the disc to the

spindle in order as shown in the figure.

3. Tighten the clamp nut onto the spindle

so that hollow side faces opposite

direction to the disc.

4. Push the Spindle lock button to secure

the spindle in place, and then use the

clamp nut wrench to tighten the clamp

nut securely.

5. To remove the grinding disc, follow the

installation procedure in reverse.

Attaching or Removing

Battery Pack

CAUTION

Before inserting battery pack, check that

the power switch on the tool actuates

properly and returns to the “OFF”

position when released.

1. To connect the battery pack [Fig.6 ]:

Align the highlighted marker points

and attach battery pack.

• Slide the battery pack until it locks

into position.

2. To remove the battery pack [Fig.6 ]:

Push down the button and slide the

battery pack forward.

CAUTION

After operation, always switch off the

tool and wait until the wheel has come

to a complete stop before putting the

tool down.

Visual inspection and

workout test on disc

1. Always make sure that the disc has no

cracks before use.

2. Always give workout test on the blade

as follows.

3. Always make sure the disc is firmly

fixed.

Work out time

Brand new disc more than 3 min.

Before use on

current disc

more than 1 min.

Grinding operation [Fig.10]

ALWAYS hold the tool firmly with one

hand on grip and the other on the

support handle. Turn on the tool and

then apply the wheel or disc to the

workpiece.

In general, keep the edge of the wheel

or grinding disc at an angle of about

15º-30º to the workpiece surface.

When using a new grinding disc, do

not work the grinder in the B direction

or it will cut into the workpiece. Once

the edge of the grinding disc has

been rounded off by use, the grinding

disc may be worked in both A and B

direction.

Using a cut-off disc guard

(Available as an accessory,

not included) [Fig.11]

WARNING

• When using an abrasive cut-off disc,

be sure to use only the cut-off disc

guard designed for this use with

cut-off disc.

• NEVER use cut-off disc for grinding.

V. OPERATION

NOTE:

Be aware that this tool is always in an

operating condition, since it does not

have to be plugged into an electrical

outlet.

Power switch operation

CAUTION

• Before inserting the battery pack

into the tool, always make sure that

the power switch operates properly

and returns to the “OFF” position

when the rear of the power switch is

depressed.

• Power switch can be locked in “ON”

position. Stay alert when locking

tool in “ON” position and grasp the

tool firmly using support handle and

grip.

To start operation, press and slide the

power switch toward the “ON” position.

[Fig.7]

For continuous operation, press the

front of the power switch to lock it.

[Fig.8]

To stop the tool, press the rear of the

power switch, then it returns to the

“OFF” position. [Fig.9]

WARNING

• It should never be necessary to

force the tool. The weight of the tool

applies adequate pressure. Forcing

and excessive pressure could cause

dangerous grinding disc breakage.

• ALWAYS replace grinding disc if tool

is dropped while grinding.

• NEVER bang or hit grinding disc.

• Avoid bouncing and snagging the

grinding disc, especially when

working corners, sharp edges etc.

This can cause loss of control and

kickback.

• Do not jam the Disc or apply excessive

pressure. Do not attempt to make an

excessive depth of cut. Overstressing

the cut-off disc increases the loading

and susceptibility to twisting or

binding of the cut-off disc in the cut

and the possibility of kickback, cut-off

disc breakage and overheating of the

motor may occur.

• Do not start when disc is in the

workpiece. To do so causes the cut-off

disc binding or kickback. Let the

cut-off disc reach full speed and then

carefully cut the workpiece.

• During cutting operations, never

change the angle of the disc. Placing

side pressure on the cut-off disc (as in

grinding) will cause the disc to crack

and break, causing serious personal

injury.

CAUTION

• To prevent excessive temperature

increase of the tool surface, do not

operate the tool continuously using

two or more battery packs. The tool

needs cool-off time before switching

to another pack.

• Do not close up ventilation slots

on the sides of the body during

operation. Otherwise, the machine

function is adversely affected to

cause a failure.

• Do not strain the tool (motor). This

may cause damage to the unit.

• Use the tool in such a way as to

prevent the air from the ventilation

slots from blowing directly onto

your skin. Otherwise, you may get

burned.

Indicator lamp for On lock

start prevention function

The grinder will not start when the

battery pack is inserted with the switch

at the ON position (switch lever at ON).

The warning lamp will flash at this

time to indicate that the ‘On lock start

prevention function’ has operated.

[Fig.12]

Press the switch to the OFF position

(switch lever at OFF) and then press it

back to the ON position (switch lever at

ON) to start the grinder. [Fig.13]

Overheat warning lamp

[Fig.14]

Indicates operation has been halted due

to motor or battery overheating.

To protect the battery, be sure to note

the following when carrying out this

operation.

• If the battery becomes hot, the

protection function will be activated

and the motor or battery will stop

operating. The overheat warning lamp

on the control panel illuminates or

flashes when this feature is active.

• If the overheating protection feature

activates, allow the tool to cool

thoroughly (at least 30 minutes).

The tool is ready for use when the

overheat warning lamp goes out.

• Avoid using the tool in a way that

causes the overheating protection

feature to activate repeatedly.

• If the tool is operated continuously

under high-load conditions or if it is

used in hot-temperature conditions

(such as during summer), the

overheating protection feature may

activate frequently.

• If the tool is used in cold-temperature

conditions (such as during winter) or

if it is frequently stopped during use,

the overheating protection feature

may not activate.

• The ambient temperature range

is between 0°C (32°F) and 40°C

(104°F). If the battery pack is used

when the battery temperature is

below 0°C (32°F), the tool may fail to

function properly.

• When charging a cool battery pack

(below 0°C (32°F)) in a warm place,

leave the battery pack at the place

and wait for more than one hour to

warm up the battery to the level of the

ambient temperature.

Battery low warning lamp

[Fig.15]

Excessive (complete) discharging of

lithium ion batteries shortens their

service life dramatically. The tool

includes a battery protection feature

designed to prevent excessive

discharging of the battery pack.

• The battery protection feature

activates immediately before the

battery loses its charge, causing the

battery low warning lamp to flash.

• If you notice the battery low warning

lamp flashing, charge the battery

pack immediately.

• If it is started with too little battery

power remaining, the tool may stop

operating without the battery low

warning lamp flashing first. This

indicates that there is too little battery

power remaining to use the tool, and

the battery pack should be charged

before further use.

• If the tool is subject to a sudden load

during use that causes the motor to

lock up, the overdischarge prevention

sensor may be triggered, and the

battery low warning lamp may flash.

The lamp will stop flashing once you

address the cause of the motor’s

locking up and cycle the trigger.

[Battery Pack]

For Appropriate Use of

Battery pack [Fig.16]

Li-ion Battery pack

• For optimum battery life, store the

Li-ion battery pack following use

without charging it.

• When charging the battery pack,

confirm that the terminals on the

battery charger are free of foreign

substances such as dust and water

etc. Clean the terminals before

charging the battery pack if any

foreign substances are found on the

terminals.

The life of the battery pack

terminals may be affected by foreign

substances such as dust and water

etc. during operation.

• When battery pack is not in use,

keep it away from other metal objects

like: paper clips, coins, keys, nails,

screws, or other small metal objects

that can make a connection from one

terminal to another.

Shorting the battery terminals

together may cause sparks, burns or

a fire.

• When operating the battery pack,

make sure the work place is well

ventilated.

• When the battery pack is removed

from the main body of the tool,

replace the battery pack cover

immediately in order to prevent dust

or dirt from contaminating the battery

terminals and causing a short circuit.

Battery Pack Life

The rechargeable batteries have

a limited life. If the operation time

becomes extremely short after

recharging, replace the battery pack

with a new one.

Battery Recycling

ATTENTION:

FOR Li-ion Battery Pack

A Li-ion battery that is recyclable

powers the product you have

purchased. Please call 1-800-8BATTERY for information on how to

recycle this battery.

Recommendations for use

[Fig.17]

Be sure to use the Pack cover

• When the battery pack is not being used,

store the battery in a way that foreign

substances such as dust and water etc.

do not contaminate the terminals. Be

sure to attach the battery pack cover to

protect the battery terminals.

• When charging the battery pack, confirm

that the terminals on the battery charger

are free of foreign substances such as

dust and water etc. Clean the terminals

before charging the battery pack if any

foreign substances are found on the

terminals. The life of the battery pack

terminals may be affected by foreign

substances such as dust and water etc.

during operation.

CAUTION

To protect the motor or battery, be sure

to note the following when carrying out

operation.

• If the battery becomes hot, the

protection function will be activated

and the battery will stop operating. The

overheat warning lamp on the control

panel illuminates or flashes when this

feature is active.

For safe use

• The battery pack is designed to be

installed by proceeding two steps for

safety. Make sure the battery pack is

installed properly to the main unit before

use.

• If the battery pack is not connected firmly

when the switch is switched on, the

overheat warning lamp and the battery

low warning lamp will flash to indicate

that safe operation is not possible, and

the main unit will not rotate normally.

Connect the battery pack into the unit

of the tool until the red or yellow label

disappears.

[Battery Charger]

Charging

CAUTION

• The charger is designed to operate

on standard domestic electrical

power only as stated in the rating

plate. Charge only on the voltage

indicated on the rating plate of unit.

e.g.120V / 60Hz.

• Do not attempt to use it on any other

voltage or frequency rating.

• The ambient temperature range

is between 0°C (32°F) and 40°C

(104°F).

• If the battery pack is used when the

battery temperature is below 0°C

(32°F), the tool may fail to function

properly.

• If the temperature of the battery pack

falls approximately below 0°C ( 32°F),

charging will automatically stop to

prevent degradation of the battery.

• Use the charger at temperatures

between 0°C and 40°C, and charge

the battery at a temperature similar

to that of the battery itself. (There

should be no more than a 15°C

difference between the temperatures

of the battery and the charging

location.)

• When charging a cool battery pack

(below 0°C (32°F) in a warm place,

leave the battery pack at the place

and wait for more than one hour to

warm up the battery to the level of

the ambient temperature.

• Cool down the charger when

charging more than two battery

packs consecutively.

• Do not insert your fingers into

contact hole, when holding charger

or any other occasions.

• To prevent the risk of fire or damage

to the battery charger.

1. Do not use power source from an

engine generator.

2. Unplug the charger when not in

use.

NOTE:

Your battery pack is not fully charged

at the time of purchase. Be sure to

charge the battery before use.

How to charge

1. Plug the charger into the AC outlet.

NOTE:

Sparks may be produced when the

plug is inserted into the AC power

supply, but this is not a problem in

terms of safety.

2. Connect the battery pack firmly into the

charger.

1. Line up the alignment marks and

place the battery onto the dock on

the charger.

2. Slide forward in the direction of the

arrow. [Fig.18 ]

3. During charging, the charging lamp

will be illuminated. When charging is

completed, an internal electronic switch

will automatically be triggered to prevent

overcharging.

• Charging will not start if the

battery pack is warm (for example,

immediately after heavy-duty

operation).The orange standby

lamp will be flashing until the battery

cools down.Charging will then begin

automatically.

4. The charge lamp (green) will flash

slowly once the battery is approximately

80% charged.

5. When charging is completed, the

charging lamp in green color will turn off.

6. If the temperature of the battery pack

is 0°C or less, charging takes longer to

fully charge the battery pack than the

standard charging time.

Even when the battery is fully charged,

it will have approximately 50% of the

power of a fully charged battery at

normal operating temperature.

7. Consult an authorized dealer if the

charging lamp (green) does not turn off.

8. If a fully charged battery pack is inserted

into the charger again, the charging

lamp lights up. After several minutes,

the charging lamp in green color will turn

off.

9. Remove the battery pack while the

battery pack release button is held up.

[Fig.18

]

LAMP INDICATIONS

Charging is completed. (Full charge.)

Battery is approximately 80% charged.

Now charging.

Charger is plugged into the AC outlet. Ready to charge.

Charging Status Lamp.

Left: green Right: orange will be displayed.

Battery pack is cool.

The battery pack is being charged slowly to reduce the load on the battery.

Battery pack is warm.

Charging will begin when temperature of battery pack drops. If the temperature of the

battery pack is -10° or less, the charging status lamp (orange) will also start flashing.

Charging will begin when the temperature of the battery pack goes up.

Charging is not possible. Clogged with dust or malfunction of the battery pack.

Turn off Illuminated Flashing

(Green)(Orange)

Replacing carbon brushes

[Fig.19]

Keep the carbon brushes clean and

free to slip in the holders. When it is

less than 5mm (3/16”) shorter both

carbon brushes should be replaced

at the same time. Use only identical

carbon brushes.

Use a screwdriver to remove the caps.

Take out the worn carbon brushes,

insert the new ones and secure the

brush caps.

To maintain product SAFETY and

RELIABILITY, repairs, any other

maintenance or adjustment should be

performed by Huskie Tools Authorized

or Factory Service Centers, always

using Huskie Tools replacement parts.

VI. MAINTENANCE

• Use only a dry, soft cloth for wiping the

unit. Do not use a damp cloth, thinner,

benzine, or other volatile solvents for

cleaning.

• In the event that the inside of the tool or

battery pack is exposed to water, drain

and allow to dry as soon as possible.

Carefully remove any dust or iron

filings that collect inside the tool. If you

experience any problems operating the

tool, consult with a repair shop.

VII. ACCESSORIES

CAUTION

• The use of any accessories not

specified in this manual may

result in fire, electric shock, or

personal injury. Use recommended

accessories only.

• Your tool is supplied with a guard

for use with a grinding disc. A cut-off

disc can also be used with a cut-off

disc guard.

Grinding Disc

• Rated speed: greater than or equal

to (2834 - 21/32” inch/min)

• Max. wheel diameter:

Φ125mm (4 - 29/32”)

• Hole diameter: Φ22mm (7/8”)

• Max. thickness: 6mm (1/4”)

Grinding Disc Guard

• WHTP-AG

Cut-off Disc

• Rated speed: greater than or equal

to (2834 - 21/32” inch/min)

• Max. wheel diameter:

Φ125mm (4 - 29/32”)

• Hole diameter: Φ22mm (7/8”)

• Flat disc only

Cut-off Disc Guard (For cut-off disc)

• WHTP-AG

Disc Flange

• EY4640K1168

Clamp Nut

• WEY4640K1178

VIII. SPECIFICATIONS

MAIN UNIT

Mounting wheel diameter Φ125mm (4 -29/32)

Spindle thread size M14

Mounting wheel hole diameter 22mm (7/8)

Weight 1.65kg (3.63lbs) (main unit only)

Overall length 300mm (11- 13/16) (main unit only)

Motor voltage DC 18 V

Rated speed

10000min-1 (rpm)

BATTERY PACK

Model No.

BP-185

Storage battery Li-ion battery

Battery voltage

18 V DC

(3.6 V × 10 cells)

BATTERY CHARGER

Model No. CH-185

Electrical rating See the rating plate on the bottom of charger

Weight 0.93 kg (2 lbs)

Charging

time

Model No.

BP-185

Full 80 min.

NOTE: This chart may include models that are not available in your area.

Please refer to the latest general catalogue.

Federal Communication Commission Interference Statement

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

FCC Caution: To assure continued compliance, install and use in accordance with provided

instructions. Use only the battery pack specified in the instructions. Any changes or

modifications not expressly approved by the party responsible for compliance could void

the user’s authority to operate this equipment.

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

This Class B digital apparatus complies with Canadian ICES-003.

IX. APPENDIX

WARRANTY SUPPLEMENT

• The breakdown and damage caused by usage consistent for a long time (e.g.:

factory work on the assembly line, etc.) is out of warranty.

• Damage or failure caused by use of accessories that are not specified in this

manual will not be covered by warranty.

HARMONIZED STANDARDS

MAIN UNIT

Conforms to UL Std. 60745-1 & 60745-2-3

Certified to CSA Std.C22.2 No. 60745-1 & 60745-2-3

BATTERY CHARGER

Conforms to UL Std.1310

Certified to CSA Std.C22.2 No. 223-M91

195 Internationale Blvd

Glendale Heights, IL 60139

Phone 800-860-6170

Fax 800-345-3767

www.huskietools.com

Loading...

Loading...