H120 & H150 S & B Models

INSTALLATION AND OPERATING INSTRUCTIONS

Hurlcon Gas Fired

Hot Water Boiler

HURLCON Manufacturing & Sales Pty. Ltd. A.B.N. 97 007 284 504

48 Hanna Street, Noble Park, VICTORIA. 3174

Telephone: (03) 9554 2200 Facsimile: (03) 9554 2270

www.hurlcon.com.au email: service@hurlcon.com.au

Information and specifications subject to change without notice.

Rev 136-1105

INSTALLATION AND OPERATING INSTRUCTIONS ...........................................................1

1.0 INTRODUCTION ...............................................................................................................3

1.1 NOTICE TO INSTALLERS .....................................................................................3

2.0 MODELS AVAILABLE ....................................................................................................4

2.1 STANDARD EQUIPMENT......................................................................................4

3.0 INSTALLATION ...............................................................................................................5

3.1 SAFETY RULES......................................................................................................5

3.2 GUIDE TO INSTALLATION...................................................................................6

3.3 CLEARANCES ........................................................................................................7

3.4 ELECTRICAL CONNECTION ................................................................................7

3.5 BOILER DIMENSIONS...........................................................................................8

3.6 INDOOR INSTALLATION......................................................................................8

3.7 VENTILATION – AIR SUPPLY TO THE BOILER.................................................9

3.8 HEATING PIPE SIZE & LAYOUT........................................................................10

3.9 SIZING OF PRESSURE VESSEL .......................................................................... 10

4.0 COMMISSIONING ......................................................................................................... 11

4.1 STARTING BOILER..............................................................................................11

4.2 TESTING BURNER PRESSURE........................................................................... 11

4.3 FLOW SWITCH.....................................................................................................11

4.4 GENUS IV 3 BUTTON CONTROLLER…………………………………………...12

5.0 OPERATING INSTRUCTIONS .....................................................................................12

5.1 ENERGY SAVING TIPS........................................................................................13

5.2 MAINTENANCE ................................................................................................... 13

5.3 CONTROL SYSTEMS ...........................................................................................13

6.0 GAS CONVERSION........................................................................................................15

6.1 BURNER CONVERSION ......................................................................................15

6.2 GAS – COMPONENT INFORMATION ................................................................ 16

6.3 GAS PIPE SIZING TABLES..................................................................................16

7.0 TROUBLESHOOTING...................................................................................................17

8.0 H120 – H150 WIRING DIAGRAM................................................................................. 18

8.1 MODEL H120 – H150 WITH HEATSAVER ........................................................18

9.0 ONE YEAR LIMITED WARRANTY............................................................................. 19

H120 –H150 Hot Water Boilers page 2

1.0 INTRODUCTION

Congratulations on your purchase of a Hurlcon H120 - H150 Series Hot Water Boiler. Correct

installation and service of your new heating system and correct chemical maintenance of the water

will ensure years of service. The H120 - H150 Series Boiler is a compact lightweight and efficient

gas fired hot water boiler. It is equipped with features that take advantage of new technology

developed exclusively by Hurlcon.

The Hurlcon Boiler is a floor mounted atmospheric boiler with a built in balanced flue for outdoor

installation. The power output is controlled by an integrated electronic controller to maintain the set

point water temperature over a wide load range. In addition, the Hurlcon Boiler is equipped with

electronic ignition. The electronic display tells at a glance the operational status of the boiler.

1.1 NOTICE TO INSTALLERS

This is a Floor Mounted - External – Hot Water Boiler

For use with Natural Gas or LP Gas as per the attached data label.

The information below is given to assist the installer with the installation of this range of H120 –

H150 Boilers. Please read it carefully in order to make the installation as easy as possible and to

ensure the system works well and conforms to the necessary government regulations.

PLEASE READ THESE INSTRUCTIONS BEFORE STARTING THE INSTALLATION.

It is important that this boiler is installed and serviced as detailed in these instructions by an

AUTHORISED person.

This boiler is to be installed and serviced to the requirements of the

Local Building, Gas, Water and Electricity Authorities.

These instructions are to be held by the owner / user after installation.

This boiler must not be used as a SPA or POOL Heater

This appliance must be installed in accordance with the installation instructions, local gas fitting

regulations, the AGA Installation Code AG 601 and any other relevant statutory authorities.

Refer to data plate for details of gas type, gas consumption and burner pressure.

H120 –H150 Hot Water Boilers page 3

2.0 MODELS AVAILABLE

Details Model

Height 900 900

Length 510 640

Width 390

Gas input 105 MJ 144 MJ

Gas type Natural & L P Gas

Nom output 24 kW (82,000Btu) 35 kW (119,000Btu)

Ignition system Electronic Ignition

Heat exchanger/burner All copper/stainless steel

Boiler Thermostat digital Electronic Genus 1V

Pressure relief 300kPa (3 Bar)

Expansion vessel 7 litre diaphragm (~60lt system)*

Circulator In line Centrifugal Pump*

Hi limit Thermostat 100 oC manual reset

Run on timer Electronic temperature and time based.

Pressure reduction valve 1 Bar pre-set *

Packed weight 50kg 60kg

2.1 STANDARD EQUIPMENT

120S & 120B

Model

150S & 150B

Electronic control including.

• Displays set and flow temperature.

• Electronic ignition

Safety devices

• Built in flow switch

• Built in run on timer

• Manual reset high limit

Built to last

• All copper double row heat exchanger

• Stainless steel burners

• Fully powder coated steel cabinet

• Powder coated flue terminal

Efficiency

• Hot surface ignition

• Highly efficient stainless steel burners

Ease of installation

• Fully plumbed ready to go, including circulator*, expansion tank*, pressure reduction valve*

& 1” flow – return isolation valves.

• All electrical pre wired including three pin power supply.

(* not supplied with ‘B’ model boiler)

H120 –H150 Hot Water Boilers page 4

3.0 INSTALLATION

THIS APPLIANCE MUST BE INSTALLED BY AN AUTHORISED PERSON.

Refer to boiler data plate for specifications of gas type, gas consumption, burner pressure and water

pressure.

This appliance must be installed in accordance with local regulations and A.G.A. Installation Code

AG 601.

The flow and return connections are located on the rear of the boiler. The flow and return

connections are clearly marked and the connections are 1” BSP FI.

The Hurlcon Boiler is fitted with a built in flow switch and will not start unless full of water and the

pump is operating.

The Hurlcon Boiler incorporates a balanced flue terminal and is suitable for outdoor installation. An

internal model is available on request.

3.1 SAFETY RULES

For your safety – read before lighting

This appliance is equipped with an ignition device, which automatically lights the burner. Do not

try to light the burner by hand.

BEFORE OPERATING smell all around the appliance area for gas. Be sure to smell next to the

floor because some gas is heavier than air and will settle on the floor.

Safety

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any gas appliance.

• Do not touch any electrical switch.

• Turn off the gas supply at the gas meter.

• Immediately call your gas supplier or licensed gas fitter.

NOTE. Some gases are heavier than air and it may be necessary to smell for leaks at

floor level.

House keeping

• Do not store or use flammable liquids or chemicals near this appliance.

• Do not use aerosols in the vicinity of this gas appliance.

• Keep this appliance free of debris.

WARNING:

Should overheating occur or the gas supply fail to shut off, turn off the manual gas control valve

to the appliance.

Do not use this boiler if any part has been under water.

H120 –H150 Hot Water Boilers page 5

M

Deleted:

Deleted:

Deleted:

Deleted:

Deleted:

Deleted:

Deleted:

3.2 GUIDE TO INSTALLATION

Location of Flue Terminals – An extract from AG 601

Minimum Clearances Required For Balanced Flue Terminals or The Terminals Of Outdoor

Appliances.

a

b

c

See note 3

g

T

f

n

T = Flue terminal

= Mechanical air inlet

I

j

or fuse box

h

T

h

h

T

ee

P

g

See note 2

Shading indicates prohibited

areas for flue terminals

d

d

j

opena ble

window

I

c

j

door

k

k

M = Gas meter

P = Electricity meter

MIN. CLEARANCE

(mm)

A Below eaves, balconies and other projections

Appliances up to 50 MJ/h input 300

Appliances over 50 MJ/h input 500

B From the ground, above a balcony or other surface 300

C From a return wall or external corner 500

D From a gas meter (M) 1000

E From an electricity meter or fuse box (P) 500

F From a drain pipe or soil pipe 150

G Horizontally from any building structure (unless appliance approved 500

for closer installation) or obstruction facing a terminal

H From any other flue terminal, cowl, or combustion air intake 500

I Horizontally from an openable window, door, non-mechanical air inlet, or any

other opening into a building with the exception of sub-floor ventilation

Appliances up to 150 MJ/h input 500

Appliances over 150 MJ/h input (natural draught) 1500

Appliances over 200 MJ/h input 1500

All fan-assisted flue appliances, in direction of discharge 1500

K From a mechanical air inlet, including a spa blower 1500

N Vertically below an openable window, non-mechanical air inlet, or any other

opening into a building with the exception of sub-floor ventilation

CLEARANCE ‘n’ (mm)

Space heaters All other appliances

Up to 50 MJ/h

input

Up to 50 MJ/h

input

Over 50 MJ/h &

up 150 MJ/h

150 500 1000 1500

NOTES:

1 All distances are measured to the nearest part of the terminal.

2 Prohibited area below electricity meter or fuse box extends to ground level.

3 See Clause 5.13.6.6 for restrictions on a flue terminal under a covered area.

4 See Appendix J, Figures J1(a) and J2(a), for clearances required from a flue terminal to an LP Gas cylinder.

A flue terminal is considered to be a source of ignition.

The above information is part of AG 601 FIGURE 5.3 as supplied by the AGA and is provided as an indication of the

correct clearances only. Please refer to the latest issue of AG 601.

500

See table

Over 150 MJ/h

input

H120 –H150 Hot Water Boilers page 6

3.3 CLEARANCES

The boiler must be installed at least 500mm from any combustible surface. Clearances must comply

with AG 601.

Clearances from non combustible surfaces are:

Front 500mm

Both sides 500mm

Rear 80mm

Above 1500mm

Combustible Surfaces 500mm Minimum

Boiler must be installed on a fireproof base.

3.4 ELECTRICAL CONNECTION

The boiler is supplied with a standard 10 amp 3 pin plug for connection to a 240V 10 amp GPO.

The boiler incorporates a 240/24 VAC transformer which supplies power to the control circuit only

and must not be used for any additional equipment. All equipment connected to mains power

should be protected by an RCD circuit breaker. The boiler has a 240 volt power supply for the pump

electrical connection which incorporates the pump run on feature. A terminal strip is provided for a

24 volt room thermostat.

To enable temperature set-back, cut the blue wire loop at the 4 way connector attached to the control

board. Extend the blue wires to a remote switch or timer with volts free contacts. With contacts

closed, Set 1 is enabled. With contacts open, Set is enabled.

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person in order to avoid a hazard.

3.4.1 GAS CONNECTION

A ¾”BSP FI is provided for gas line connection. An approved manual shut off valve must be

installed in the gas fitting line before the boiler so that the gas can be turned off and the boiler

removed for servicing if required. The gas shut off valve should be sized the same as the gas fitting

line to prevent excessive pressure drop in the gas pipe.

The gas fitting line should be installed by an authorised person and comply with local regulations

and A.G.A. code AG 601. The gas line from the meter will usually be of a larger size than the gas

inlet connection. Therefore a reduction to the boiler connection fitting will be necessary. The

reduction should be as close to the boiler as possible.

Before using the boiler, test all connections for gas leaks using soapy water.

The boiler gas valve has a built in pressure regulator with a ⅛” pressure test point provided. On

starting the boiler, a manometer must be used and burner pressure checked against the boiler data

plate. The gas valve regulator may need adjustment to correct manifold pressure. Incorrect burner

pressure may void warranty.

H120 –H150 Hot Water Boilers page 7

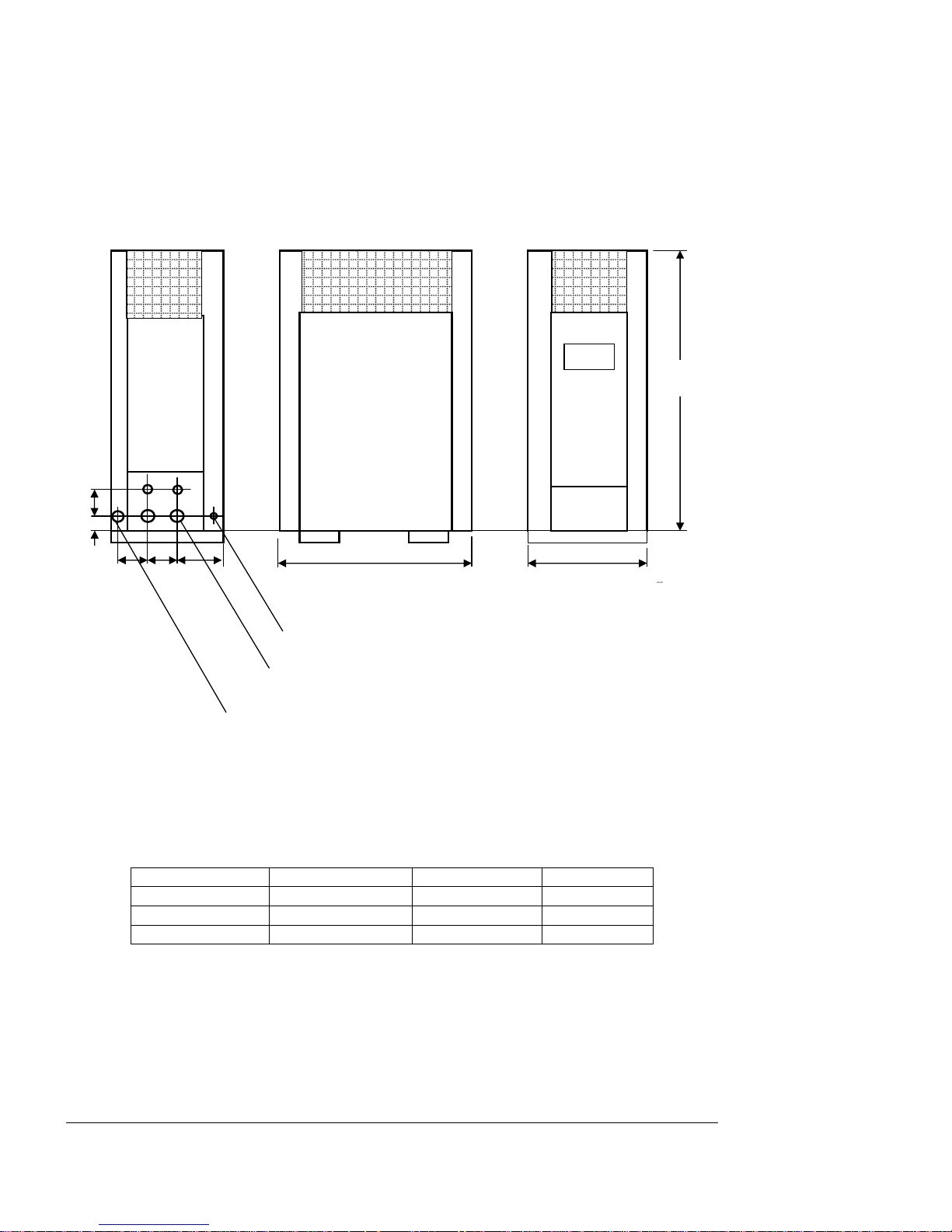

3.5 BOILER DIMENSIONS

60

70

Side Plumbing

105 130 130

Front

H120 – 510

H150 - 640

Cold feed ½” FI

Flow & Return 1” FI

Side Controls

900

390

Gas inlet ¾” FI

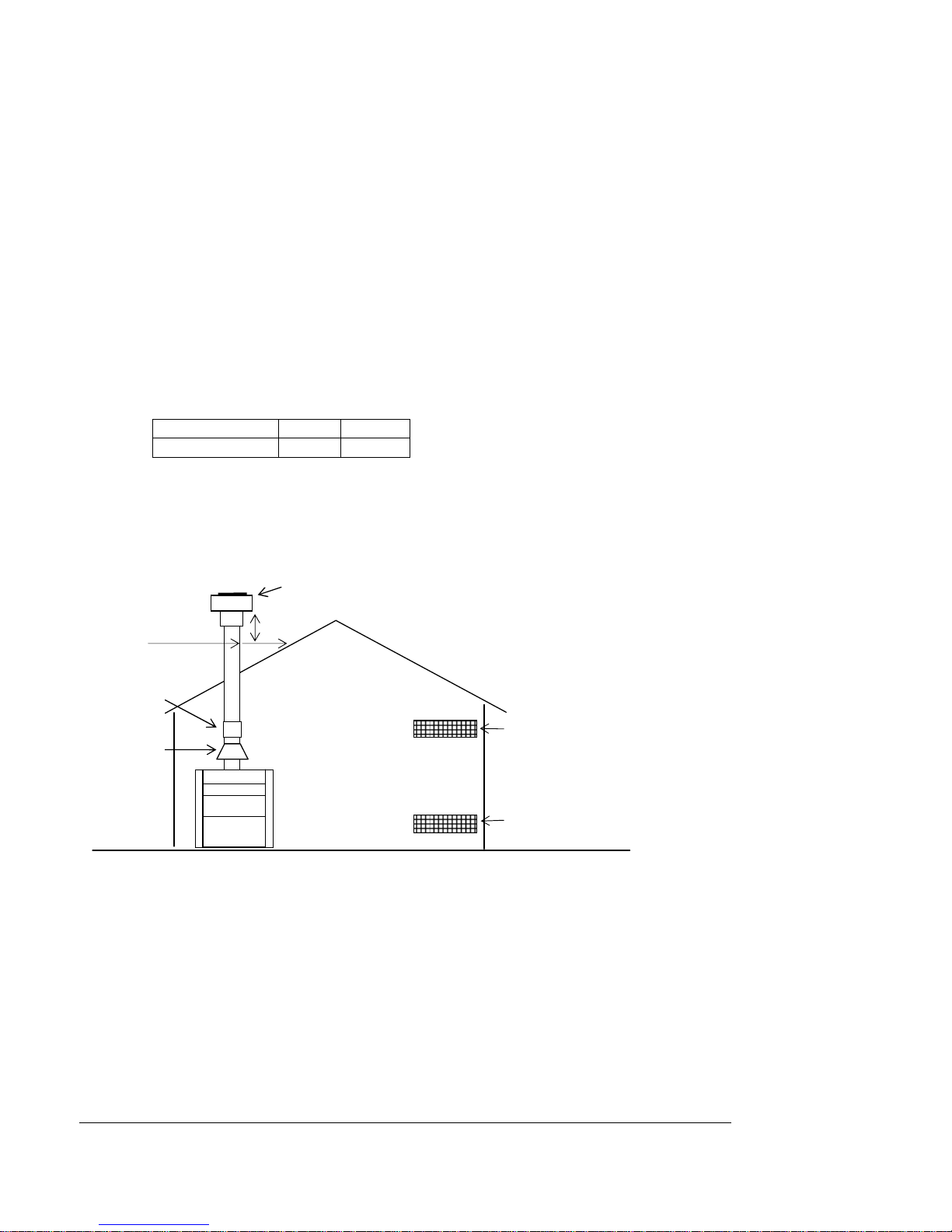

3.6 INDOOR INSTALLATION

If the H120 - 150 Boiler is to be installed indoors, an indoor draught hood kit must be purchased

from Hurlcon and installed on the Boiler to convert it to an indoor model.

Product code numbers for draught hoods are:

Boiler model Indoor top model Flue size Part number

H120 DH 12 125 mm 10134

H150 DH 15 150mm 10970

A flue no smaller than the draught diverter diameter must be installed and terminated with an

approved gas flue cowl (not a Chinaman’s hat) 600mm above any roofline that is within 1.5 metres

horizontally from the flue.

H120 –H150 Hot Water Boilers page 8

from Hurlcon

3.7 VENTILATION – AIR SUPPLY TO THE BOILER

When installing the boiler indoors, it is imperative that an adequate supply of fresh air is provided

for combustion. Failure to provide adequate ventilation voids all warranties and may be a danger to

persons or property. Please refer to AG 601 for full details.

Two permanent openings shall be provided directly to outside. The openings shall be located to

ensure the distance between the top of the upper opening and the ceiling of the room or enclosure,

and the distance between the bottom of the lower opening and the floor of the room or enclosure

does not exceed 5% of the height of the room or enclosure.

The minimum vertical dimension of any free ventilation opening shall be 6 mm.

The minimum free ventilation area provided by each opening shall be:

MODELS H120 H150

AREA mm

The following diagram is provided as a guide only. All fluing and installation work must be carried

out by an authorized person. Fluing must conform to local regulations and to A.G.A. installation

code AG 601. Care must be taken to provide the correct ventilation and correct fluing materials in

close proximity to combustible surfaces.

2

35,000 50,000

Approved gas

termination cowl

1500

Bolted

sleeve to

connect flue

Draft diverter

purchased

600

Upper grille for fresh

air ventilation

Lower grille for fresh

air ventilation

A Hurlcon indoor draught diverter must be fitted to unit in accordance with Hurlcon’s

Instructions and Installation Codes before the boiler can be enclosed.

Do not install spa blowers in the same room as a gas boiler. This is potentially dangerous to

spa users.

Do not store chemicals or fuel in the same room as the gas boiler. This may cause fire or

explosion.

When installing in a garage the H120 – 150 Boiler must be installed 450 mm above floor level.

H120 –H150 Hot Water Boilers page 9

Flow

Flow

Flow

3.8 HEATING PIPE SIZE & LAYOUT

• The flow & return connection sizes of 1”BSP on the boiler are not necessarily the correct

pipe sizes for the heating system. It is important that the pipe sizes are correctly calculated

before installation.

• Hurlcon recommend a two pipe system with the pipes sized according to the flow

requirements and length of runs with a maximum water velocity of 1.5 M/s.

• Reference The Institute of Plumbing Australia. - “SELECTION & SIZING OF COPPER

TUBES FOR PIPING SYSTEMS”.

Nominal flow capacities

Model Output Flow rates DT pd min Pipe dia F & R length

120 24 kW 0.38 l/s 15 °C 8 kPa 20 mm 6.0 m

150 35 kW 0.53 l/s 15 °C 14 kPa 25 mm 4.5 m

Typical two pipe system

Radiator/Heat emitter

Hydronic Boiler

Return

Notes

1. An automatic heating bypass valve should be fitted to maintain adequate flow rate through the

boiler when thermostatic valves are fitted and or when the majority of radiators are required to be

turned off for long periods of time.

2. Any pipe work that is in an unheated area such as under the floor or in the ceiling space should be

suitably insulated to prevent heat loss and possible freezing of the pipes.

3. The pipe work should be graded to facilitate the elimination of air at the highest point and the

draining of the system at the lowest point. Provide air bleeds and drains at these points.

Bypass valve

3.9 SIZING OF PRESSURE VESSEL

If the total water capacity of the heating

system is greater than 60 litres then an

additional pressure vessel should be fitted.

An approximate figure can be calculated

from the following table. An additional

tank can be fitted at a convenient location

on the system if required.

H120 –H150 Hot Water Boilers page 10

Item Capacity

litres

Therma rad Radiators 0.70 kW

Thermaboard single 0.22 metre

Thermaboard double 0.44 metre

Copper tube 25 mm 0.44 metre

Copper tube 20 mm 0.23 metre

Copper tube 15 mm 0.10 metre

per

4.0 COMMISSIONING

4.1 STARTING BOILER

• Fill system with water and purge all air from system and pump.

• Purge gas line of any air and wait five minutes for gas to clear.

• Plug three pin plug into a suitable power point and switch on. Digital controller should now

operate and indicate water temperature.

• Pump should start, the flow symbol should be displayed.

• Turn controller switch ON.

• After a few seconds, the burner should ignite. (Do not light by any other means.)

• If the burner fails to light, check flow indicator is on. Turn controller switch OFF for 5

seconds then ON to reset ignition system. (Trouble shooting page 19.)

• Allow boiler to run. Check there are no leaks and there is flow to all of system.

4.2 TESTING BURNER PRESSURE

• Set up manometer

• Turn boiler “OFF”.

• Remove screw from ⅛” brass test point located on outlet side of gas valve.

• Connect manometer tube to test point

• Turn boiler “ON” and wait for main burner to ignite.

• Once main burner has ignited, the manometer must indicate the nominal burner pressure

listed below.

• To adjust gas valve regulator, remove regulator adjustment cap and, using a screwdriver, turn

plastic bush clockwise to increase, anti-clockwise to decrease burner pressure.

• Check all gas connections are tight and not leaking.

Maximum inlet gas pressure is:

Natural Gas 3.5 kPa Propane Gas 3.5 kPa ULPG 3.5 kPa

Nominal burner pressure is:

H120 H150

Natural Gas kPa 0.82 0.82

Propane Gas kPa 2.50 2.50

ULPG kPa 2.00 2.00

4.3 FLOW SWITCH

• The Hurlcon Boiler has an inbuilt flow switch which allows the burner to operate only when

the system is full of water and the circulating pump is operating. NOTE: The installed flow

switch has no user adjustments.

• Air in the system may stop the boiler from lighting.

H120 –H150 Hot Water Boilers page 11

4.4 GENUS IV 3 BUTTON CONTROLLER

• 90° or 55° operation. H series boilers are set factory default 90°. For floor heat

applications the boiler can be selected for 55° max setpoint by a jumper on the PCB. (See

page 18).

• Hurlcon Genus IV room thermostat. If a Hurlcon Genus IV room thermostat is fitted the

Genus boiler control will ‘learn’ automatically when powered up after approx 1 minute. If

the thermostat is disconnected or loses communication F5 fault will be displayed and the

boiler will shut down after 3 minutes. To change thermostat type see table below. The

thermostat selector switch will also need to be set, see page 18.

• Switching differential. The temperature switching differential can be adjusted to stop short

cycling. See table below for appropriate codes. (Default 5°.)

• °F or °C. The display can be toggled between Celsius and Fahrenheit. See table below for

Button presses

1 2 3 4

codes. (Default °C.)

With the unit switched off, press and hold the on/off button then press the following.

Degrees C U D D D

Degrees F U D D U

Genus IV thermostat U D U D

Standard thermostat U D U U

5 ° differential D D D U

10 ° differential D D U D

15 ° differential D D U U

20 ° differential D U D D

U = warm button D = cool button

5.0 OPERATING INSTRUCTIONS

• STOP! Read the safety rules on page 5 section 3.1.

• Turn off electric power to appliance.

• This appliance is equipped with an ignition device, which automatically lights the burner.

Do not try to light the burner by hand.

• Wait five minutes to clear out any gas. If you then smell gas, STOP! Refer to instructions

above.

• Turn on power to appliance.

• Set thermostat to desired setting and press ON/OFF switch to ON. The boiler will ignite in

around 10 seconds

• If the appliance will not operate, press ON/OFF switch to OFF then ON again. If the

appliance still does not ignite, check trouble shooting on page 19 or call your service

technician.

TO TURN GAS OFF TO APPLIANCE

• Turn off all electrical power to the appliance.

• Turn off gas tap in gas line prior to boiler.

H120 –H150 Hot Water Boilers page 12

5.1 ENERGY SAVING TIPS

>

ON/OFF WARM COOL

HURLCON

HURLCON

• During extended periods of non use, turn the boiler off.

• Set up a regular program of preventative maintenance for the boiler. Check heat exchanger,

controls, burner operation etc.

• For areas where there is a danger of freezing, water should circulate through your boiler even

if the heating is off.

5.2 MAINTENANCE

• It is recommended that the following items are professionally checked at least every six

months and at the beginning of every heating season.

• Examine the balanced flue or indoor draught diverter. Make sure there are no obstructions to

the flow of air to, or flue products from, the appliance.

• Visually check the main burner and pilot flames. If the flame appears yellow, the burner

should be cleaned by a qualified service technician.

• Keep the boiler area clear and free of combustibles and flammable liquids. Chlorine should

not be stored in the vicinity of the boiler. Chlorine vapours, when drawn through a boiler,

can rapidly cause corrosion of the heat exchanger.

• Keep the boiler area free from garden refuse and debris. This will help prevent insects

nesting in the unit and ensure extended life and reliability of your boiler.

5.3 CONTROL SYSTEMS

○

<

5.3.1 DESCRIPTION

The sophisticated digital thermostat provides temperature read out, set point temperature and

operating status of the boiler. The electronic display indicates the operational status of the boiler

and any fault conditions.

5.3.2 TEMPERATURE DISPLAY

• The temperature display indicates water temperature in the outlet (flow) of the boiler.

Therefore the pump must be operating for an accurate water temperature to be displayed.

• Water temperature can be set between 55˚C to 90˚C. (35˚C to 55˚C floor heat). To select

your desired water temperature press the up or down button repeatedly until the desired

temperature is reached.

• Fitting of an external switch allows temperature set-back via two adjustable set points. (See

section

H120 –H150 Hot Water Boilers page 13

• To prevent rapid cycling of the boiler, the thermostat has an inbuilt time delay which

prevents the boiler from turning on for two minutes after the set point has been reached. If

the time delay is activated, the symbol “L” will be displayed. This is part of normal

operation.

• The thermostat can be set to temperatures between 55˚C to 90˚C. (35˚C to 55˚C floor heat).

It also incorporates several safety features including a 100˚C high limit function to prevent

overheating. On simultaneous shut down of the circulating pump and boiler, the water within

the boiler may exceed the set temperature for a short period. If the pump and boiler are

restarted during this period, the thermostat will go into a standby mode and prevent the boiler

from relighting until the temperature within the boiler has dropped below the set

temperature.

• If the optional set-back function is used, both set points (Set, Set 1) need to be adjusted

independently. These are each adjustable over the full thermostat range.

• Should the thermostat fail to stop the boiler at the set point or at 100˚C, there is a manual

reset temperature limiting safety device designed to lock the boiler out and prevent further

heating. Plus a lock out condition is indicated by the symbols F1 or F2. To reset a lock out

condition, turn the controller off for five seconds. An F2 condition will first require the

mechanical safety device to be reset. To do this, remove the rear access panel and press the

red button. If the boiler has cooled sufficiently, a positive “click” should be heard and felt.

5.3.3 FAULT INDICATION

Under fault conditions the thermostat display will indicate a set of alpha numeric symbols to

indicate the status of the boiler. The meaning of each symbol and action to be taken are listed as

follows:

SYMBOL MEANING ACTION

Temp

Display

F0 Boiler locked off, thermistor wire is

F1 Thermostat reads greater than

F2 Mechanical Hi Limit greater than

F5 Thermostat communication fault Check connections. Check thermostat ‘type’

L Boiler locked out on time delay No action. Boiler will delay for 2 minutes

Unit has power. No action

If water temperature reads greater than 0°C, turn

disconnected or water at 0°C

off/on if problem persists phone for service.

(freeze conditions).

Allow water to cool, turn boiler off then on

100°C or thermistor short circuited.

again.

Allow water to cool, reset Hi Limit, turn boiler

100°C.

off then on again.

setting is correct.

Automatically reset after time delay. Or switch

off then on again for immediate ignition.

Pump operating & sufficient water

flow to operate boiler

Thermostat calling for heat

operating.

Burner system has ignited and is

No action.

No action, boiler electronic ignition should

ignite in a few seconds.

No action.

operating.

H120 –H150 Hot Water Boilers page 14

5.3.4 OPERATION

Sequence of events once the boiler has been correctly installed with the room thermostat and burner

turned off.

Event Result

Turn on electrical power to the boiler Controller powers up and completes test procedure.

Pump starts up. Flow indicator on.

Turn on room thermostat

Turn controller on.

Water flow reaches set temperature. Burner turns off.

Water flow temperature falls 5°C

below set temperature.

Water flow temperature reaches 100°C

Controller turned off Burner shuts down, pump continues to run.

Room thermostat switches off Burner shuts down, pump continues to run till water

Room thermostat switches on Pump restarts, burner ignites.

Water flow stopped by external control Flow switch de-activates, burner turns off and pump

Water flow is reinstated Flow switch reactivates, burner re ignites.

Ignition sequence begins; checks water flow, high limit

and flow temperature against set temperature.

Burner lights.

Burner indicator on.

Burner relights.

Burner indicator on.

High limit switch opens, burner shuts down. Pump

continues to run.

temperature drops to 40˚C.

continues to run.

Flow indicator off.

Flow indicator on.

6.0 GAS CONVERSION

6.1 BURNER CONVERSION

Gas type burner conversion

• Turn off the gas at the external gas valve and turn off the power.

• Remove the access panels from all available sides.

• Disconnect internal gas pipe from inlet side of gas valve.

• Remove the four screws holding the burner assembly in position.

• Disassemble burner tray and remove ribbon burners to expose burner injectors.

• Remove burner injectors and replace with the correct sized injectors for the gas.

• Remove regulator screw cap from top of gas valve.

• Turn plastic plug anti-clockwise until fully removed and withdraw spring.

• Insert spring for desired gas type and re-install plastic plug.

• Re-install burner assembly and reconnect gas supply make sure all gas joints are tight

and the earth screw is replaced.

• Check gas system for leaks.

• Commence lighting procedure as described above.

• Adjust burner pressure as described above.

H120 –H150 Hot Water Boilers page 15

6.2 GAS – COMPONENT INFORMATION

Natural Gas Propane Gas ULPG Gas

Injector Burner Injector Burner Injector Burner

Model size pressure size pressure size pressure

H120 1.25mm 0.90 kPa 0.75mm 2.50 kPa 0.75mm 2.00 kPa

H150 1.25mm 0.90 kPa 0.75mm 2.50 kPa 0.75mm 2.00 kPa

6.3 GAS PIPE SIZING TABLES

Natural gas at 1.13 kPa gas meter pressure

VICTORIA

Maximum run of copper pipe with average number of fittings

Model 20 mm 25 mm 32 mm 40 mm 50 mm

H120 4 m 25 m 90 m 260 m 320 m

H150 2 m 14 m 50 m 140 m 320m

1.25 kPa gas meter pressure

S.A., W.A., some areas N.S.W.

Maximum run of copper pipe with average number of fittings

Model 20 mm 25 mm 32 mm 40 mm 50 mm

H120 18 m 85 m 300 m 320 m H150 10 m 45 m 160 m 320 m -

2.75 kPa gas meter pressure

N.S.W. some areas, some new areas of Victoria.

Maximum run of copper pipe with average number of fittings

Model 15 mm 20 mm 25 mm 32 mm

H120 12 m 100 m 320 +m H150 8 m 65 m 260 m 320 +m

NO allowance has been made for other appliances connected to the gas main. This

information is supplied as an indication of the capacities only. Refer to the latest issue of

AG601 for full details.

H120 –H150 Hot Water Boilers page 16

7.0 TROUBLESHOOTING

BOILER WILL NOT LIGHT

Possible cause Remedy

Automatic ignition system fails Check water flow light indicator.

Pump not running Check pump and flow switch

Pump air locked Air bleed system & pump bearing

Flow switch open Check continuity

Defective gas control Shut off gas supply and call for service

Thermostat turned off Turn on

Set temperature lower than water temperature Increase set temperature

Water too hot-fault condition displayed Refer to fault indication table

High Limit Thermostat open Reset

Insufficient water flow Check for too many valves turned off

BOILER MAKING KNOCKING NOISES

Possible cause Remedy

Boiler operating after pump has shut off Shut off gas supply and call for service

Heat exchanger scaled Shut off gas supply and call for service

If the boiler cannot be made to perform correctly, please contact the Hurlcon Service Office closest

to you.

For VICTORIA: Phone (03) 9765 9765

NEW SOUTH WALES: Phone (02) 9674 8544

QUEENSLAND: Phone (07) 3393 3233

SOUTH AUSTRALIA Phone (08) 8345 5755

WESTERN AUSTRALIA Phone (08) 9258 9322

For all other areas, please contact our Victorian office.

H120 –H150 Hot Water Boilers page 17

8.0 H120 – H150 WIRING DIAGRAM

8.1 MODEL H120 – H150 WITH HEATSAVER

8.2 55 – 90 DEGREE SETTING & THERMOSTAT SELECTION

By changing the jumper position the boiler

maximum setpoint can be altered from 90° to

55°. This should be done prior to start up,

however if this is done after power has been

applied to the boiler un- plugging and

reconnecting power will ensure the correct

setting. This is located on the rear of the

Genus control board at the front of the Boiler.

If the optional Hurlcon Genus room

thermostat is used the thermostat selector

switch is required to be set to the correct

position. This switch is located at the rear of

the electrical panel within the boiler cabinet as

shown.

H120 –H150 Hot Water Boilers page 18

9.0 ONE YEAR LIMITED WARRANTY

GENERAL CONDITIONS

Hurlcon cover your boiler with a limited 1 year warranty against defective materials and

workmanship from the date of purchase (plus 30 days to allow for installation). The heat

exchanger, burner and cabinet are covered by a five year limited warranty (plus 30 days to allow for

installation). Proof of purchase date must be provided in order to substantiate warranty claim.

The warranty includes in field labour costs where the boiler is installed in a capital city metropolitan

area. Labour charges apply to boilers installed outside of these areas. Any costs for transport of

faulty or replacement parts, removal or reinstallation are the owner’s responsibility.

Hurlcon assumes no liability for consequential damages of any kind.

Like your motor vehicle, your new boiler requires periodic service and maintenance to keep it

operating in top condition and at maximum efficiency. An annual service by one of our qualified

service technicians is highly recommended.

LIMITATIONS

All warranties only apply if the boiler is installed and operated in complete compliance with the

installation and operating instructions. The warranty shall not apply to any boilers or parts that

have been subject to accident, negligence, alteration, abuse or misuse.

ADDITIONAL WARRANTY EXCLUSIONS:

This warranty does not cover failures or malfunctions resulting from:

• Failure to properly install, operate or maintain the boiler in accordance with our printed

instructions provided.

• Abuse, alteration, accident, fire, flood and the like. Examples of misuse or neglect include,

but are not limited to, physical damage from external force, not following installation

instructions, leaving door off for extended periods of time, inappropriate application of the

boiler, etc.

• Scaling, freezing, or other conditions causing an inadequate water circulation.

• Incorrect gas pressure or gas supply.

• Incorrect or excessive flow rate of water.

• Failing to correctly bleed water system of air.

• Chemical contamination of combustion air or use of chemical additives to the water.

• Printed Circuit Boards: This item is warranted against all claims except for power surges,

lightening strikes, wilful damage or water damage

No person is authorised to make any warranties on Hurlcon’s behalf. To place a service call,

contact your nearest Hurlcon office.

Hurlcon Manufacturing & Sales Pty. Limited

Victoria:

Ph: (03) 9554 2275

Fax: (03) 9554 2272

Website: www.hurlcon.com.au

Email: service@hurlcon.com.au

New South Wales:

Ph: (02) 9674 8544

Fax: (02) 9674 8522

Queensland:

Ph: (07) 3393 3233

Fax: (07) 3393 3255

South Australia:

Ph: (08) 8345 5755

Fax: (08) 8345 5211

Western Australia:

Ph: (08) 9258 9322

Fax: (08) 9258 9344

H120 –H150 Hot Water Boilers page 19

Loading...

Loading...