Abouts

Ontheroadoftheprogress,wekeeptotheguidelinesof"Prosperingwithquality,rooting

withscienceandtechnology"allalong,alsowecangraspanewdirectioninmarketdevelopment

accurately,innovatecontinuouslyandexploitbravely!

knightserviceandsatisfytheconsumers'needsfarthest!

Withanemphasisonsupremetechnology,theWenZhouHuaKongScienceandTechnology

CO.,LTDisamanufactureroftheintelligentelectricactuatorthatfocusesonresearch&

development,production,salesandcustomerservice.

advancedmanufacturetechnics,andperfectmachiningandtestequipment.Ourintelligent

actuatorsareprovidedwithexcellentquality,highcapability&lowpriceandsimplemanipulation.

Intheall-overworldactuatordomainourproductisintheone-upstatus.Itisintroducedintofrom

theforeigntechniques.Byourabstractionandameliorationourelectricactuatorisexcogitated.

isasupernal,pithyandtopendintelligentproductnowadays.

integration,so

ChineseorEnglishmenu.

intelligent,efficientandhumanperformance.

Ourcompanyhastheadvancedmachiningequipmentsanda

abilityinautomatization,instrumetation,machinedesign,motordesignandsoon.Theseoffer

powerfulsustainmentandguaranteeforthequalityandperformanceofthe"Hurko

actuator.Ourelectricactuatoriswidelyusedinthedomainofthepowerstation,petroleum,papermaking,chemicalplant,refinery,waterdisposalandsoon.Manyconsumershavealready

approbatedandlovedourelectricactuator.

Ourcompanyhasresearchanddevelopmentdepartment,technologydepartment,sales

department,examinationdepartment,productiondepartment,personneldepartment,logistics

departmentandsoon.Everydepartmenthasexecutedthequalitysystemcertificateof

ISO9001:2000.Inourcompany,everyworking-procedureisheldthepassstrictly.Ontheroadof

theprogress,weallalongmakegreatefforts!

Theexcellenceofourintelligentelectricactuatorsowingtoourhigh-precisionnumericalcontrolequipments,high-exactitudedetectioninstruments,high-tech,strictqualitymanagement

system,professionalpersons,andhigh-levelscienceandtechnologystrength!Ontheroadofthe

progress,weareallalongwithallourhearts!

Ifyouwanttoknowmoreaboutus,pleaseaccessourweb-siteHttp://www.hurko.cn.

us:

We

continuouslyhankerforthebetter

We

haveabundanttechnologystrength,

It

adoptsthesuperlarge-scale

it

haspowerfulfunctionsandsteadyperformance.OuractuatorhastheLCDofthe

It

isthemechanicalandelectricintegrativeproductassembledwith

lot

ofprofessionalpersonswith

®

"electrical

It

1

HK/HKE/HKM/HKC/HKJ/HKJM

HK/HKE/HKM/HKC/HKJ/HKJM

HK/HKE/HKM/HKC/HKJ/HKJM

Range

Range

Range

Intelligent Electric Actuator Selection

Installation and Debugging Instructions

2

CONTENTS

1:

S ummarizing ………………………………………………………………………………… .. …………… .

6662:M ain technique parameters ……………………………………………………………… . ……………

6663:F unction , performance and characteristic …………………… . ………………

666

4:

A ctuator data ……………………………………………………………………………………………… ..

1111115:A ctuator performance ………… .. ............................................ …………………………………… ..

141414

5.1Torque and turn range ............... … . ................ …………………………………… ..

14

5.2 C able entry and connection terminals ... … . ................ …………………………………… ..

14

5.3 Interface for machine installation .... …………………………………… ..

14

5.4 Additional gear-box .. …………………………………………… ..

15

5.5 Oscillation ............. … . ................ …………………………………… ..

15

5.6 Shielding and flameproof ............. … . ................ …………………………………… ..

15

5.7 Coupling interface .................... … . ................ ……………………………… .. …… ..

16

6:

Actuator control and wiring ..................................... …………………………………… ..

212121

7:

Order introduces ....................................................................................................................

278:Machining of the drive bush .....................................................................................................

299.Installation of the actuator .............................................

29

10.

Oprating your actuator.......................................................................................................

31

11.

Debugging your actuator...................................................................................................

32

12. Display of the alarm signal ..........................................................................................

46

13. Machine maintenance ..........................................................................................................

48

14. Changing battery......................................................................................................................

48

15. Important notices....................................................................................................................

48

CONTENTS

CONTENTS

Chapter one HKM range intelligent electrical actuator selection

installation and debugging instructions

3

Chapter two HK range intelligent electric actuator selection

1

Advanced design … ... ………………………………………………………… ………… . … ..

50

1.1 Technical parameters .......................... …………………………………………… ……

50

2

A pplications …… .. …………………………………………………………… ……………… .

52

2.1 Multi-turn control …………………… . …………………………… ………………………

52

2.2 Linear control ……………………………………………… . … ………………………… .

52

2.3 0~90 º Quarter Turn control ………………………………………………… ……………

52

3

Technical Data ………………… .. ................. … . ....................... ………………… …………

52

3.1 HK range Actuator Performance (220VAC/50Hz).. ………………………………… ..

52

3.2 HK range Actuator Performance (380VAC/50Hz).. ………………………………… ..

53

3.3 Technical Data of Worm Gearboxes combined with HK range Actuator

(220VAC/50Hz) … . …………………………………………… . ………………………… .

54

3.4 Technical Data of Worm Gearbox (380VAC/50Hz) ……… ……………………………

54

3.5 Valve/Actuator interface … . …………………………………… . ……………………… ..

55

3.6 Coupling Dimension …… .. …………………………………… . …………………………

55

4

Actuator Circuit Diagram … .. ……………………………………… . ……………………… ..

63

4.1 Basic HK range ………………………………………………………………… . … ..

63

4.2 Extended and enhanced HK range .................................................................. .

63

4.3 Control and Wiring …………………………………………………………………… ... …

63

5

Control Mode.. ……… .. ............................................ ……………………… …………… . …

65

5.1 Local Control …………………………………………………………………………… ....

65

5.2 Remote Control ……………………………………………………………………………

67

5.3 ESD Control ……………………………………………………………………………… .

67

5.4 Valve Position Feedback Signal …………………………………………………………

67

5.5 The analogue signal control ................................................................................

67

6

Model Designation ……………………………………………………………… …………… .

68

6.1 Actuator Model Number ………………………………………………………………… ..

68

6.2 Gear-box ………………………………………………………………………………… ...

68

installation and debugging instructions

7 Machining of the Drive Bush -------------------------------------------------------------------- 69

8 Installation of the Actuator ---------------------------------------------------------------------- 69

9 Operating your Actuator ------------------------------------------------------------------------- 70

10 Debugging your Actuator ------------------------------------------------------------------------

4

70

11 Alarm Message Display -----------------------------------------------------------------------------

74

12 Lubrication and Maintenance ----------------------------------------------------------------------- 76

13 Changing Battery ---------------------------------------------------------------------------------- 76

14 Important Notices ----------------------------------------------------------------------------------- 77

15 Fault is handled --------------------------------------------------------------------------------------- 77

Chapter three HKC range intelligent electric actuator selection

installation and debugging instructions

1 Summarizing .................................................... 80

2 Actuator specification ......................................... 80

3 Actuator features .............................................. 80

4 Technical Data ................................................. 81

5 Valve/Actuator interface ....................................... 81

6 Actuator Control and Wiring .................................... 82

7 Order Introduces................................................ 82

8 Machining of the Drive Bush .................................... 83

9 Installation of the actuator ................................... 83

10 Operating your actuator ........................................ 83

11 Debugging your actuator ........................................ 83

12 Display of the Alarm signal .................................... 83

13 Machine Maintenance ............................................. 83

14 Changing Battery ................................................ 83

15 Important Notices ............................................... 83

Chapter four HKE range intelligent electric actuator selection

installation and debugging instructions

1 Advanced design ................................................. 84

2 Applications .................................................... 84

3 Technical Data ........................................ 84

4 Coupling dimension .......................................... 86

5 Actuator electrical wiring diagram ............................... 86

6 Control mode ..................................... 87

7 Order ................................................... 87

8 Machining of the Drive Bush .................................... 88

9 Installation of the actuator ................................... 88

10 Operating your actuator ........................................ 88

11 Debugging your actuator ........................................ 88

12 Alarm Message Display .................... 88

13 Lubrication and Maintenance ........................ 88

14 Changing Battery ........................................... 89

15 Important Notices ............................................ 89

5

Chapter five HKJ/HKJM range intelligent electric actuator selection

installation and debugging instructions

1 Structure of HK J intelligent electrical angle travel actuator ……… ...............................

90

2 Production characteristics ………………………………………… .. … . .............................. 90

3 Type specification table ……………………………………………… .. 92

4 Technical specification and performances …………………………… .. 93

5 Optional item ………………………………………………………… .. 94

6 Wiring diagram ……………………………………………………… 94

7 Field bus control system ……………………………………………… .. 95

8 Dimension ……………………………………………………………… 96

9 Configuration table of actuator with vale ……………………………… 96

10 Method of configurating air-throttle valve …………………………… .. 97

11 Service promise s to customer ………………………………………… .. 97

6

Chapter one HKM range intelligent electrical actuator selection

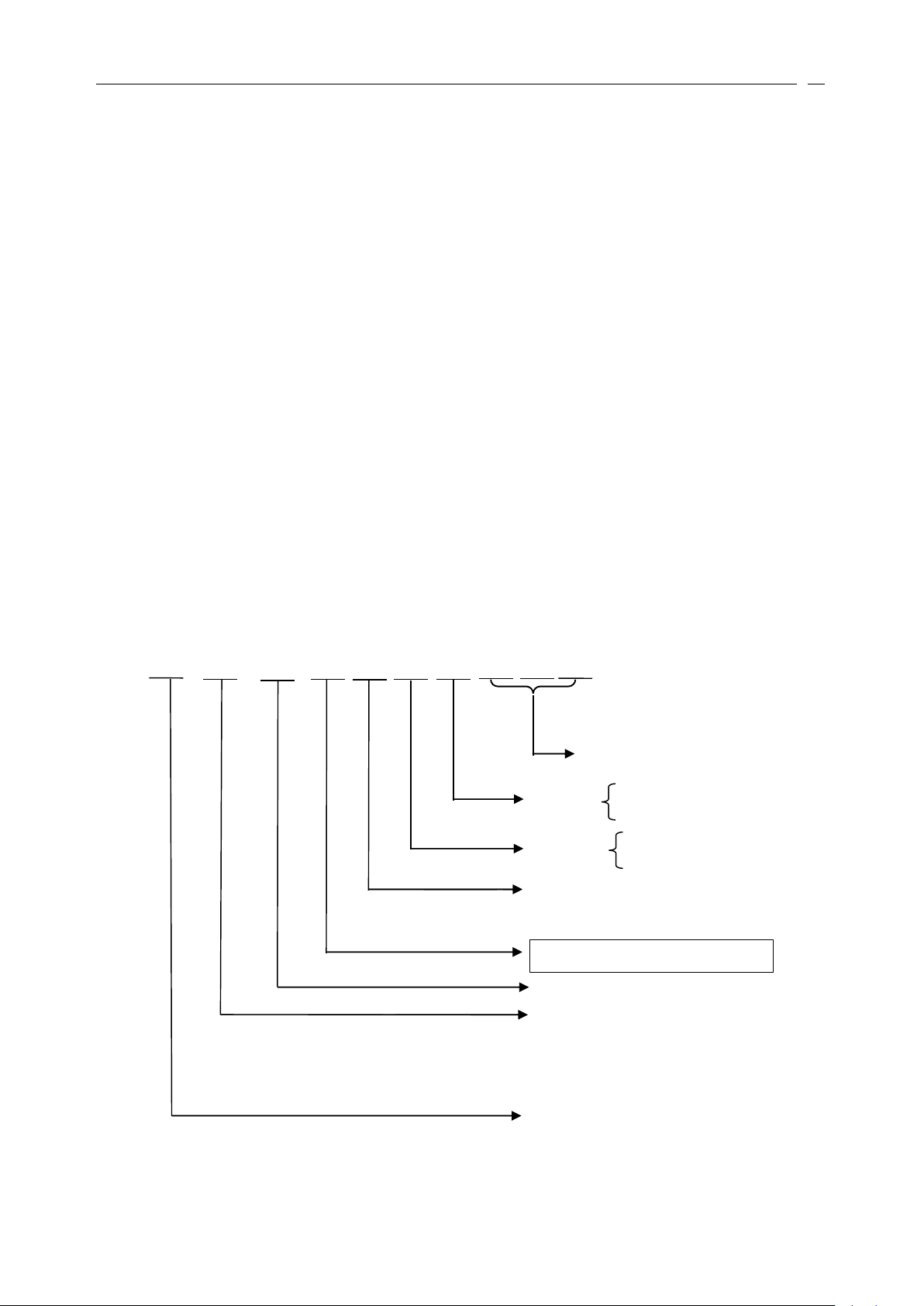

First sealed

Diagram 3-1

Humidity

Dust

Second sealed

installation and debugging instructions

Summarizing

1:1:1:

Summarizing

Summarizing

HKM actuator is the world leaderinthe field of electric al actuator products for the petroleum , gas, power,

water , waste treatment and so on industries. The series HKM actuator have two kinds of menu, one is the

Chinese menu, the other one is the English menu. Here we only explain the Chinese menu actuator, if you want

to know the English menu actuator, you can access our web-site: www.hurko.cn .

To

Hurko HKM actuator , we enjoy an unparalleled reputation for our imaginative and effective use of

advance technologies, and the quality and proven reliability of our products.

HKM actuator has the expertise to take on virtually any actuator challenge — including equipment for use

in

hazardous extreme cold and sub-sea conditions.

Customers choose HKM actuator for our ongoing commitment to:

Technological

Technological

Technological

through on-going research and development.

Flexibility:

Flexibility:

Flexibility:

to meet a vast range of specification quickly and efficiently.

Quality:

Quality:

Quality:

dispatch.

Reliability:

Reliability:

Reliability:

virtually maintenance free.

innovation:

innovation:

innovation:

every HKM actuator is precision-built using pre-manufactured modules of the finest materials

every HKM actuators are hanging assembled and fully rig tested to stringent standards prior to

every HKM actuators us e advanced lubrication, electrical, and sealing techniques, to be

at Hurko we pride ourselves on developing leading-edge actuation solution

Main

2:2:2:

Technique

Main

Main

Technique

Technique

■ Input signals:

4mA ~ 20mA;1VDC ~ 5VDC;

2mA ~ 10mA;0.5VDC ~ 2.5VDC;

20V ~ 60VDC

■ Power supply:

380VAC/50Hz;220VAC/50Hz

■ Accuracy: ≤ 1%

■ Deadband: 0.1 ~ 9.9% of travel between open and close limit positions

■ Enclosure: IP68

■ Anti explosion nark: Exd Ⅱ C T4

Parameters

Parameters

Parameters

or

30V ~ 220

VAC

electricity signal;

7

■ Ambient temperature: - 4 0 ℃ ~ +70 ℃

Switch close

No switch stem

Switch open

■ Ambient humidity: ≤ 95%

Features

3:3:3:

Features

Features

Specification

Specification

Specification

3.1The working principle of actuator

Motor spin to pass unite axle organization directly drive worm turn , worm drives worm gear to turn , and

then drives output shaft through clutch to turn. When switch handle turns ,inthe location of by hand , on clutch ,

move , take off open worm gear an d handwheel coupling, turn handwheel drive output shaft turn. Electric

operation is prior always, unless operating handle has been locked ,inthe files of by hand. When output shaft

turns , drives a pair of bevel gear to turn , and changes through valve position sensor detection valve position.

3 .2The function characteristic of actuator

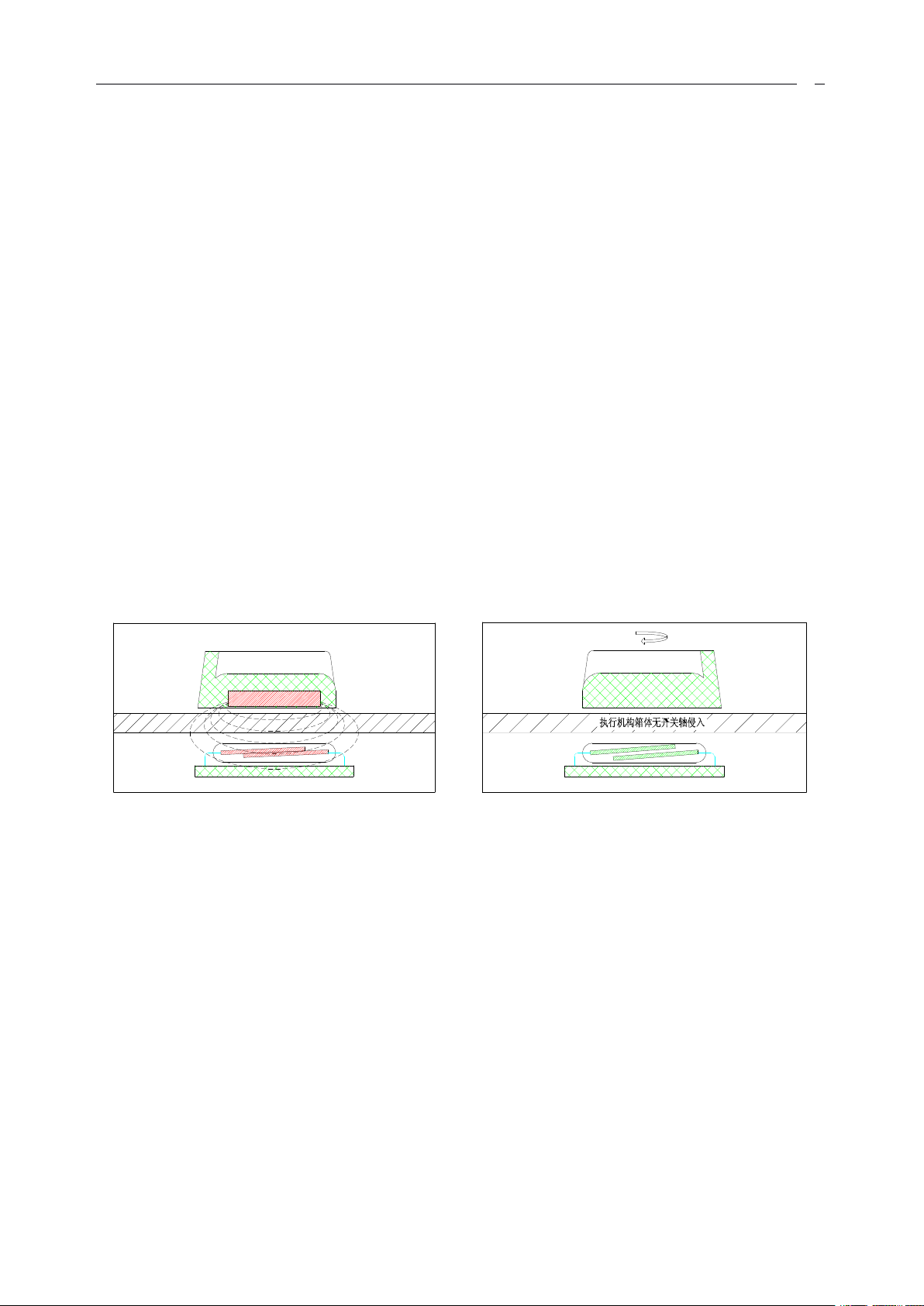

3.2.1 Double sealed

All HKM actuator are double sealed watertight enclosure to IP68 (3 meters — 48hours) and provide

complete protection on the internal equipment even if the cable gland are opened. Refer to Diagram 3-1.

3.2. 2 Non-intrusive design

Non-intrusive switching:

The HKM electric actuator employs magnetic induction mode switching

Non-intrusive setting:

Can be instantly set, checked and actuator non-intrusively using the hand held infra-red setting tool.

Refer to Diagram 3-2 and Diagram 3-3.

Diagram 3 Non-intrusive designs

3.2. 3 Protection features

3.2. 3.1

The torque protection values are independently configurable

T

orque protection

in

the range 40 ~ 120% of rated torque ,serve

as over-torque protection for the entire valve travel.

3.2.3.2 Limit protection

When the actuator runs to close limit position or opening limit position, it will

stop(if limit position protect setting is “ 有 ” ).

3.2.3.3 Automatically phase order adjustment

HKM actuator automaticlydetect the phase order of the three-phase power supply , encourages the switch

of which one through proper logic operation when deciding actuator 's operation in order to guarantee the correct

phase order of the motor. If no this function the motor may be damage the valve because of the phase order

mistake of wiring. With this function the actuator need not consider the phase order.

3.2.3.4

It

is instant to turn on the contrary to protect

When actuator accepts to the order of opposite direction movement, adds a time voluntarily to postpone ,

prevents producing the unnecessary abrasion for valve shaft and gearbox..

8

3.2.3.5 Power supply losing- phase protection

HKM actuator has the losing- phase protect ion function.

current, can detect the power supply loses phase

not when the motor is

in

the operation course, so, can prohibit the motor start the operation, avoid to execute the

or

not, also can detect that if the power supply loses phase

It

adopts to watch on the voltage and the electric

running instruction to the motor when losing phase .

3.2.3.6 Protection when valve is locked

Regardless of actuator to open direction

or

close direction movement still, sending the signal that

encourages motor after second s time from 5 s to 1 0 s , temporarily, prohibit torque to be protected ( if the

actuator

in

the above-mentioned second time of 5-10 have no movement, control circuit can cut off the

power supply of motor ).

3.2.3.7 Motor over temperature protection

Two thermostats are embedded

in

the motor stator end windings that will trip and de-energise the motor if

the temperature exceeds its rating. The thermostats can be overridden during an ESD operation.

3.2.4 Checking for valve position and torque

The actuator has a pair of bevel gear to pick up the turn of the output shaft , drives a circular magnetic flat

on the circumference has many N poles and S poles, makes its two environmental magnetic quick switches

produce pulse signal,

let

the pulse signal be sentenced and counted so as to calculate the valve position.

Valve

position detection resolulion capacity is 11.5 ° output shaft corner, output shaft revolution amount to value

upper limit reaches 2040 turns , this stroke scope signifies HKM actuator is great.

The detection of torque comes to get from the detection of the electric current and magnetic flux, this has

realized the continuous measure for output torque, makes adjustment of the torque protection value can be

accomplish ed with the setting-tool easily.

3.2.5 Solid state relay and function of inertia braking

With solid state relay, substitute AC contactor has raised the working frequency of regulation type , and

has prolonged service life.

To

satisfy the requirement of higher positional accuracy, HKM actuator has offered inertia braking

function. If client needs when ordering goods the function of inertia braking, we offer the product that has this

function. Whether use this function can pa ss

by

user to setting tool, select

in

scene. The function of inertia

braking takes effect under various electric mode of operations.

What needs pay attention is that have used the function of inertia braking and have increased motor

winding give out heat to measure. Therefore we suggest the condition

in

necessity to use the function of inertia

braking.

or

3.2.6 Intermittent timing operation

Intermittent timing operation means that actuator will execute a period of time opening and execute a

period of time closing and a period of time opening again, and so on. The motion time and stopping time

may be setting

prevent hydraulic shock (water hamm er) and flow surge

by

the infra-red setting. This effectively increases the valve stroke time and can be adjusted to

in

pipelines.

3.2.7 Network communication

HKM actuator provided full compatibility with proprietary remote supervisory control system as well as

all current network communication protocols, including Modbus, Profibus and Foundation Fieldbus.

3.2.8 Actuator’s setting and check

All HKM actuator functions can be rapidly set and checked without removing the actuator covers (even

in

wet

or

hazardous conditions) using the free, infra-red setting tool supplied. Intrinsically safe-certified and

watertight, this handy device can al so be used to control the actuator locally.Actuator setting such as the

following functions with infra-red setting tool.

9

■ the rotary orientation of output shaft during the close stroke

█

Valve position

Alarm area

■ protection function of open limit position and close limit position

■ protection values for torque during the open

■ setting open

■ push to run

or

close limit position

or

maintain for local control

or

close stroke

■ setting ESD Optional function

■ setting analogue control signal

■ setting interlocks function

■ setting the four state indication relay

3.2.9 Display of the actuator

A

back-lit liquid crystal display gives digital indication from fully open to

fully close

in

1% increments. Two LED’s colored red, green for indication of

close and open. The liquid crystal could display menu, alarm and valve

position in the same panel. A nd the alarm includes valve alarm, actuator alarm,

control system alarm and actuator battery status. The back-lit will lighting as

long as main power was supplied. The local display can be rotated to suit

actuator orientation. Refer to Diagram 3-5. Diagram 3-5

3.2.10 Operation of the actuator

The mode of operation of actuator divides into the electric operation and hand operation. Actuator has

handwheel used

in

operating

by

hand. Hand / electric switch handle is used to get actuator switch to hand

operation, when the motor of actuator operates , switches organization because of having designed electric prior

operation, actuator can return to electric mode of operation voluntarily.

HKM actuator standard handwheel is top pack handwheel,atthe same time, we can offer the side that can

be chosen to pack handwheel, lean to pack handwheel turn

make

by

hand operating and more economic al.

by

deceleration gear biography go to output shaft,

3.2.11 S tructure of the actuator (see diagram 3-7)

a. Even if opening terminal coverinscene, the alone sealed terminal case can also guarantee the integrity of

the electric equipment.

b. The control switch and working way of field work encourage way with the magnetism of isolation, have

avoided needing sealed link up axle.

c. Show window on the spot can alternate different position,

in

order to meet the installation position of

actuator. Additionally pass seal up show window, the infrared ware of the use for special purpose is set and

diagnosed for actuator , need not open electrical case

in

scene and expose built-in control circuit , this can

prevente the control circuit from dust and moisture’s corrode.

d. Low inertia high torque motor. After starting , motor can reach the torque of peak value promptly, if the

motor has no excitation

accurate temperature switches , these can avoid efficiently that motor is

,it

will not nearly exceed restricted transport move ,

in

overheat state.

in

motor coil, there are some

e. The torque detection circuit of special design has avoided to use lever and the spring switch of torque

control.

f.

Worm

drives worm gearinoil bath, this can raise the actuator

g.

Valve

position counter can measure and control the stroke of actuator accurately, even if the power supply

shuts off and electrifys the power supply again , the actuator can also guarantee the enumerated accuracy of

’

s life farthestinthe different environment s.

valve position.

h. Directly drive handwheel but

in

power source appearance fault , offer reliable urgent hand operation.

10

i. The hand/ electric clutch can also be operated safely even if the motor is running.

Notice: When motor turns , clutch will automatically switch to electric mode, unless handle is locked in the

location of hand intentionally .

j. To raise life and be easy to dismantle , the thrust of design that can be lubricated , can unload actuator

under not change the condition of valve position.

k.

To

be convenient for suiting with valve , detachable drive bushing can be compound processing with

valve rod.

l.

To

change the output speed of actuator easily, motor axle and worm axle are mutually independent.

m. Support the bus line on-the-spot of open:Modbus, CAN, Profibus and FF etc.

3.2.12 The organization of explosion proof of actuator designs

The structural design of explosion proof of actuator is basis: GB3836.1-2000 《 Electrical equipment for

explosive gas atmosphere use the first part general requirement 》 and GB3836.1-2000 《 Electrical

equipment for explosive gas atmosphere use the second part separating explode type 》

in

which the relevant

stipulation and requirement are used to design the separating explode products, separating explode sign is

ExdIIBT4.

It

applys to 1 ,2 environments of work area that contain II A, II B level and the T1- T4 level

explosive mixture, atmosphere force 86 Kpa-106 Kpa, environmental temperature - 30 ℃ + 70 ℃ .

3.2.12.1 Good sealing

The combination surface of main housing and coordinate element is long

,

has little gap, this is advantageous

to the separating explode,atthe same time, with the fine O model sealing circle and the skeleton revolving oil

sealing of import,it is satisfied with the sealing requirement.

3.2.12.2 E quipment for inducting the cable into actuator

E quipment for inducting the cable is designed according to GB 3836.2 and appendix D 《 the supplementary

requirement that equipment for inducting the cable of separating explode type and gasket 》

explode structure, detail is shown

in

Fig.3 - 8. Thread combines length and sealing ring with the combination

,itis the separating

width of cable is suitable to the requirement of separating explode standard.

3.2.12.3 The inducting link of the explosive proof type actuator

Wire lead into structure have adopted outside thread coordination, the method and organization that fills with

fluid sealant have ensured the equipment of the separating explode performance, details are shown

in

Fig.3-9.

3.2.12.4 The window structure of the explosion proof type actuator

Transparent window and housing have joined with O model weather strip and fluid sealant fill ( this place

must not open,otherwise can destroy to separating explode surface), double-deck transparent material presses

to surround the structural installat ion that compressed tightly,have satisfied the requirement of 5.4, 5.5 and 8.1

in

GB 3836.2, detail is shown

To

guarantee that the installation of actuator

in

Fig.3 - 10.

in

difference has normal liquid crystal on direction to show

direction, character shows normally that the liquid crystal of direction and actuator shows that screen has offered

4 kinds installation:

a. Actuator horizontal direction installation ( handwheel upturns

),

liquid crystal shows that screen is installed

according to normal location;

b. Under actuator dynasty lean direction installation ( handwheel adown), liquid crystal shows that screen is

installed according to normal location, can use setting tool to make the show way as show on the contrary;

c. The actuator direction of left side installation ( handwheel leftward

),

liquid crystal shows that screen is

installed near flange a side;

d. The actuator direction of right side installation ( handwheel rightward

),

liquid crystal shows that screen is

installed near flange a side, can use setting tool to make the show way as show on the contrary;

The installation direction that offers actuator more

by

user, we show the correctly installation supply of screen

according to liquid crystal. If user does not offer the installation of actuator direction easily, we can send the

11

staff to the spot to set the direction of the liquid crystal screen.

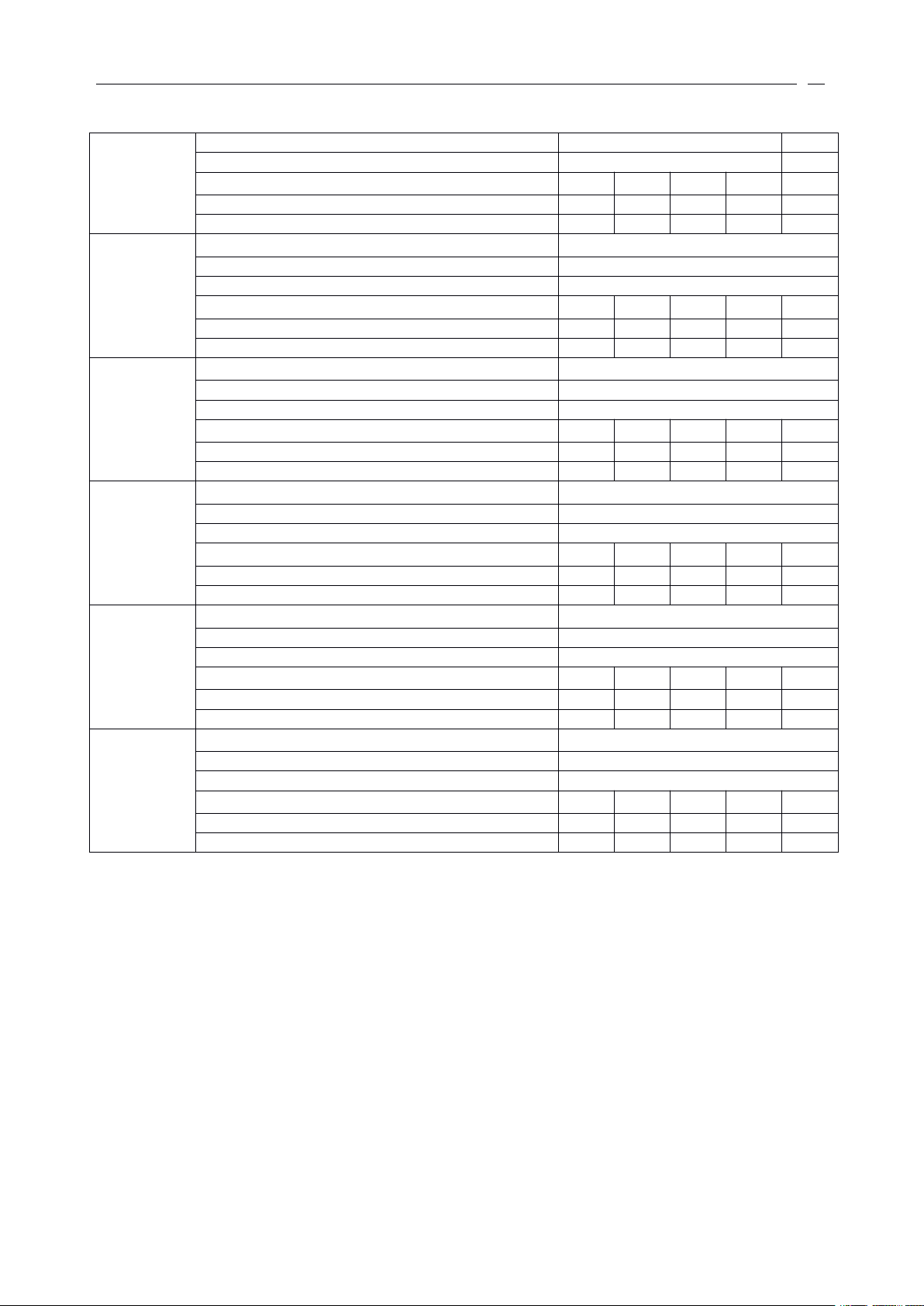

Actuator rpm

182436487296144

192

HKM

HKM

HKM

0 3

HKE03

Modulation torque N.m

171715.6

13.6

Max torque N . m

444439

35

Motor power kW

0.07

0.07

0.13

0.14

Rated currentAA

0.75

0.7511.1

Modulation thrust KN

7.14

7.14

6.55

5.71

Max thrust KN

14.2

14.2

12.6

8.4

Liner speed mm/s

1.5234HKM 0 5

HKE05

Modulation torque N.m

343430

27

Max torque N . m

807070

63

Motor power kW

0.12

0.13

0.19

0.23

Rated currentAA

0.8510.5

2.1

Modulation thrust KN

14.2

14.2

12.6

8.4

Max thrust KN

25.6

22.6

22.6

20.1

Liner speed mm/s

1.523

4

HKM10

HKE10

Modulation torque N.m

8181685447

Max torque N . m

159

142

1068971

Motor power kW

0.3

0.3

0.35

0.35

0.47

Rated currentAA

2.3

2.3

2.8

2.8

3.6

Liner speed mm/s

1.8

2.4

3.6

4.8

7.2

HKM 20

HKE20

Modulation torque N.m

152

152

129

102

102

Max torque N . m

266

266

212

177

177

Motor power kW

0.47

0.47

0.58

0.68

0.7

Rated currentAA

3.6

3.6

4.6

5.5

5.5

Modulation thrust KN

252521

16.7

14.5

Max thrust KN

33.7

33.72521

16.7

Liner speed mm/s

1.8

2.4

3.6

4.8

7.2

3.2.13 Electronic latch function

Actuator has arisen the phenomenon of over torque very easily when starting high inertia load.

start high inertia load successfully, HKM actuator prohibits torque temporarily

in

sending some seconds of

To

be able to

times after signal that encourage motor to protect function. This is electronic latch function. If have sent the

signal that encourages motor for some seconds actuator can not move, control circuit can break the power source

of motor. Electronic latch function for open the valve that is

in

clo sed position for a long time very effective.

3.2.14 P rotect data function when main power source falls

When main power source loses electricity, from battery, supplies power to valve position detection circuit,

and preserve valve position

in

EEPROM. Battery still supplies power to LCD ( but do not sustain to be shaded )

and supplies power to 4 state ins truction relaies, the service life of battery can reach 2 years. Suggest to change

battery when main power source has electricity.

3.2.15 Application range

HK M actuators are suitable for proportional control

in

automatic control loops

that the system rate of change is relatively high, and high accuracy continuous modulation

is necessary. When modulating applications require increased rates of starts per hour, the HKM actuator ranges

can be operated up to a rate of 1200 starts per hour providing the average torque required

by

the valve in mid

stroke does not exceed 50% of the rated torque of the selected actuator.

HKM actuator with W gear units could drive quarter turn modulating valve. And this combination output

rated torque from 470 to 51500 N • M. For more detail information about gearbox please send message to our

company.

4:4:4:

Actuator

Actuator

Actuator

Data

Data

Data

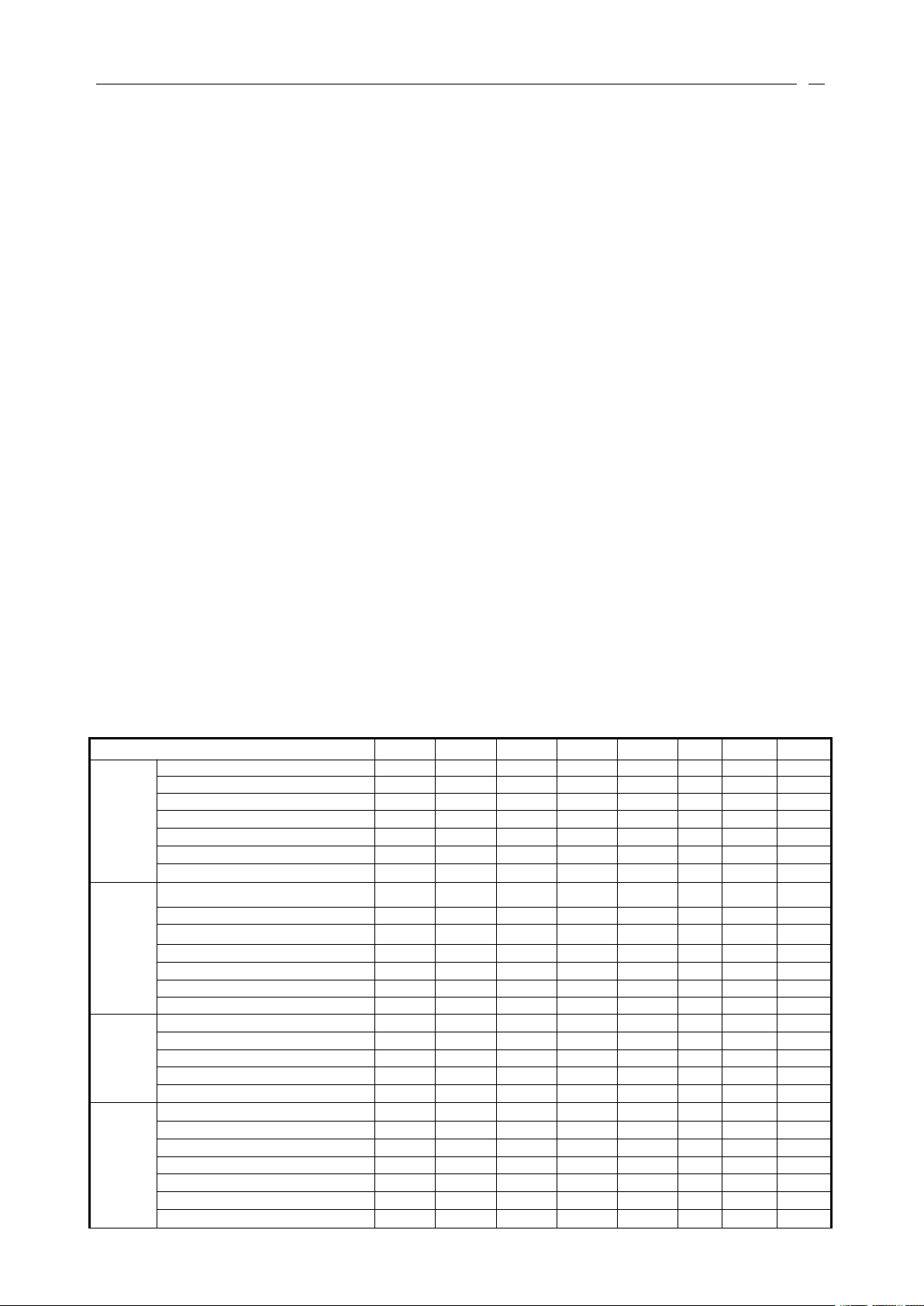

T he Table 4-1, Table 4-2,Table 4-3,Table4-4 and Table4-5 is also suitable for the HKE series actuator.

Table

Table

Table

444

–––

111

PPP

arameters of the multi-turn actuator ( 380V AC/50Hz

380V AC/50Hz

380V AC/50Hz

)

12

Table

HK M5 5

HKE55

Modulation torque N.m

27

271

253

203

203

Max torque N . m

708

708

531

407

284

Motor power kW

0.9

1.05

1.27

1.2

1.35

Rated currentAA

679

7.8

8.2

Modulation thrust KN

27

271

253

203

203

Max thrust KN

708

708

531

407

284

Liner speed mm/s

2.4

3.2

4.8

6.4

9.6

Actuator rpm

182436487296144

192

HKHKHK

M 0 3

HKE03

Modulation torque N.m

121210

10

Max torque N . m

242421

20

Motor power kW

0.06

0.08

0.08

0.1

Rated currentAA

1.6

1.8

1.8

1.9

Modulation thrust KN

554.4

4.1

Max thrust KN

7.1

7.1

6.6

5.7

Liner speed mm/s

1.523

4

HK M0 5

HKE05

Modulation torque N.m

201815

13

Max torque N . m

423833

27

Motor power kW

0.12

0.12

0.12

0.12

Rated currentAA

2222Modulation thrust KN

8.4

7.6

6.3

5.5

Max thrust KN

12.6

11.3

9.7

8

Liner speed mm/s

1.523

4

HKM10

HKE10

Modulation torque N.m

4032262518

Max torque N . m

8577585538

Motor power kW

0.19

0.21

0.23

0.25

0.28

Rated currentAA

2.3

2.45

2.8

3.2

3.4

Modulation thrust KN

12.4

9.9

8.1

7.8

5.6

Max thrust KN

18.9

17.1

12.7

12.1

8.4

Liner speed mm/s

1.8

2.4

3.6

4.8

7.2

Actuator rpm

182436487296144

192

HKM

HKM

HKM20HKE20

Modulation torque N.m

7070554242

Max torque N . m

133

133

1078989

Motor power kW

0.28

0.35

0.32

0.35

0.37

Rated currentAA

3.4

3.75

3.6

3.75

3.9

Modulation thrust KN

21.7

21.7

17.11313

Max thrust KN

31.6

31.6

25.4

21.1

21.1

Liner speed mm/s

1.8

2.4

3.6

4.8

7.2

HKM55

HKE55

Modulation torque N.m

180

150

130

102

72

Max torque N . m

343

328

265

204

142

Motor power kW

0.8

0.8

0.75

0.8

0.8

Rated currentAA

2.4

3.2

4.8

6.4

9.6

Modulation thrust KN

57.64841.6

32.6

23

Max thrust KN

878165

50.2

34.9

Liner speed mm/s

57.64841.6

32.6

23

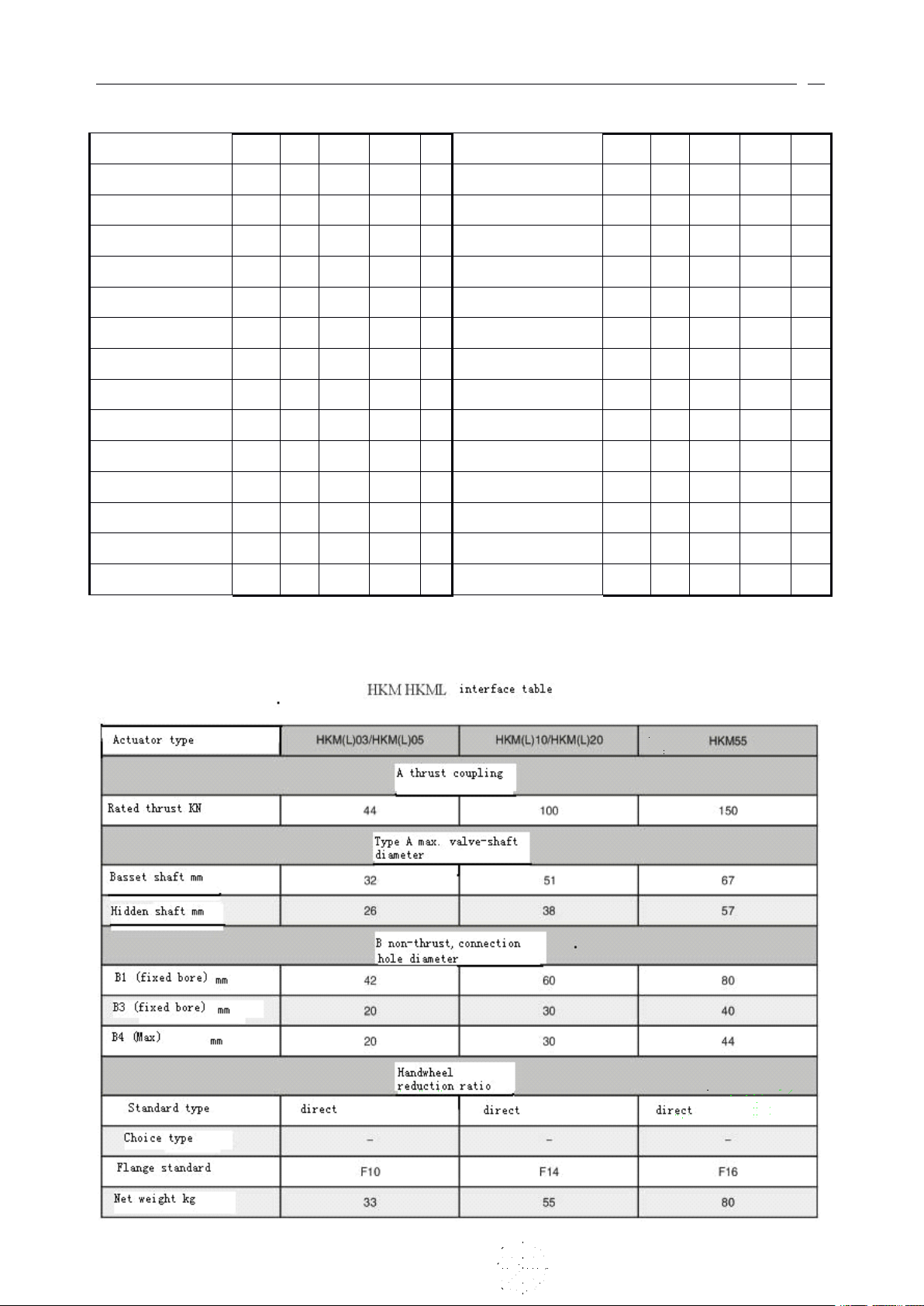

Actuator type

HK M 03 / HKM 0 5

HKM10 / HKM20

HKM55

Type A

Rated thrust KN44100

150

Max bore

Outside bore mm3251

67

Inside bore mm2638

57

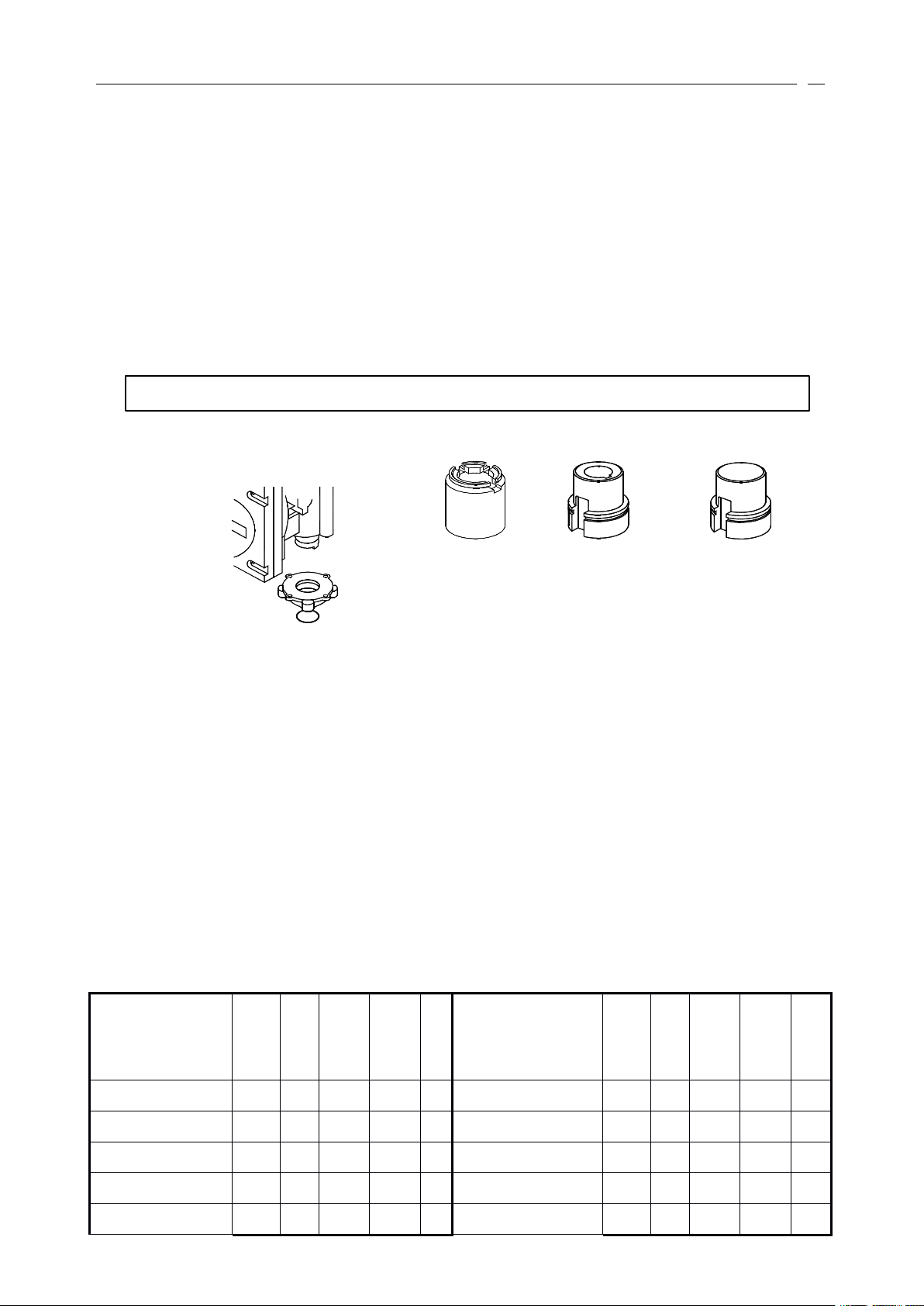

Table

Table

444

---

222

PPP

arameters of the multi-turn actuator ( 220V AC/50Hz

220V AC/50Hz

220V AC/50Hz

)

Table

Table

Table

Table

Table

Table

444

---

222

PPP

arameters of the multi-turn actuator ( 220V AC/50Hz

4-3

dimension

4-3

4-3

dimension

dimension

table

table

table

the

interface

ofofof

the

the

interface

interface

220V AC/50Hz

220V AC/50Hz

continu

)

(((

continu

continu

eee

)))

13

Table

Type B

B1 mm4260

80

B3 mm2030

40

B4 mm2030

44

Hand-wheel gearbox ratio

Standard

Directly

Directly

Directly

Extra option——

—

Flange size

F10

F14

F16

Net weight3355

80

Type

Output rev rpm

1824364872

HKML03

HKEL03

The diameter of drive screw rod

26/3

---

Max.liner stroke mm

115

---

Flange type(ISO 5210)

F10

---

Regulate thrust KN

9.20

9.20

8.45

7.37

Liner speed mm/sec

0.9

1.2

1.8

2.4

Rated close thrust KN

18.43

18.43

16.26

14.63

HKML05

HKEL05

The diameter of drive screw rod

26/3

Max.liner stroke mm

115

Flange type(ISO 5210)

F10

Regulate thrust KN

18.43

18.43

16.26

14.63

Liner speed mm/sec

0.9

1.2

1.8

2.4

Rated close thrust KN

33.06

29.27

29.27

26.02

HKML10

HKEL10

The diameter of drive screw rod

32/6

Max.liner stroke mm

115

Flange type(ISO 5210)

F14

Regulate thrust KN

31.15

31.15

26.12

20.74

18.06

Liner speed mm/sec

1.8

2.4

3.6

4.8

7.2

Rated close thrust KN

46.87

41.87

31.15

26.12

20.74

HKML10

HKEL10

The diameter of drive screw rod

38/14

Max.liner stroke mm

115

Flange type(ISO 5210)

F14

Regulate thrust KN

18.91

18.91

15.88

12.61

10.97

Liner speed mm/sec

4.2

5.6

8.4

11.2

16.8

Rated close thrust KN

28.49

25.45

18.91

15.88

12.61

HKML20

HKEL20

The diameter of drive screw rod

32/6

Max.liner stroke mm

115

Flange type(ISO 5210)

F14

Regulate thrust KN

58.39

58.39

49.56

39.18

39.18

Liner speed mm/sec

1.8

2.4

3.6

4.8

7.2

Rated close thrust KN

78.37

78.37

62.62

52.25

52.25

HKML20

HKEL20

The diameter of drive screw rod

38/14

Max.liner stroke mm

115

Flange type(ISO 5210)

F14

Regulate thrust KN

35.49

35.49

30.12

23.82

23.82

Liner speed mm/sec

4.2

5.6

8.4

11.2

16.8

Rated close thrust KN

47.64

47.64

38.06

31.76

31.76

Type

Output rev rpm

1824364872

HKML03

The diameter of drive screw rod

26/3

Table

Table

4-4

4-4

4-4

P arameters of the linear-travel actuator(380VAC/50Hz)

Table4-5

Table4-5

Table4-5

arameters

PPP

arameters

arameters

ofofof

the

liner

liner

liner

-travel

-travel

-travel

the

the

actuator(220V AC/50Hz)

actuator(220V AC/50Hz)

actuator(220V AC/50Hz)

14

ctuator

HKEL03

Max.liner stroke mm

115

Flange type(ISO 5210)

F10

Regulate thrust KN

6.50

6.50

5.42

5.42

Liner speed mm/sec

0.9

1.2

1.8

2.4

Rated close thrust KN

13.00

13.00

11.38

10.84

HKML05

HKEL05

The diameter of drive screw rod

26/3

Max.liner stroke mm

115

Flange type(ISO 5210)

F10

Regulate thrust KN

10.84

9.76

8.13

7.05

Liner speed mm/sec

0.9

1.2

1.8

2.4

Rated close thrust KN

22.76

20.60

17.89

14.63

HKML10

HKEL10

The diameter of drive screw rod

32/6

Max.liner stroke mm

115

Flange type(ISO 5210)

F14

Regulate thrust KN

15.37

12.29

9.99

9.60

6.91

Liner speed mm/sec

1.8

2.4

3.6

4.8

7.2

Rated close thrust KN

32.65

29.58

22.28

21.19

14.60

HKML10

HKEL10

The diameter of drive screw rod

38/14

Max.liner stroke mm

115

Flange type(ISO 5210)

F14

Regulate thrust KN

9.34

7.47

6.07

5.84

4.20

Liner speed mm/sec

4.2

5.6

8.4

11.2

16.8

Rated close thrust KN

19.85

17.98

13.54

12.84

8.87

HKML20

HKEL20

The diameter of drive screw rod

32/6

Max.liner stroke mm

115

Flange type(ISO 5210)

F14

Regulate thrust KN

26.89

26.89

21.13

16.13

16.13

Liner speed mm/sec

1.8

2.4

3.6

4.8

7.2

Rated close thrust KN

51.09

51.09

41.10

34.19

34.19

HKML20

HKEL20

The diameter of drive screw rod

38/14

Max.liner stroke mm

115

Flange type(ISO 5210)

F14

Regulate thrust KN

16.35

16.35

12.84

9.81

9.81

Liner speed mm/sec

4.2

5.6

8.4

11.2

16.8

Rated close thrust KN

31.06

31.06

24.99

20.78

20.78

555

:::

AAA

ctuator

ctuator

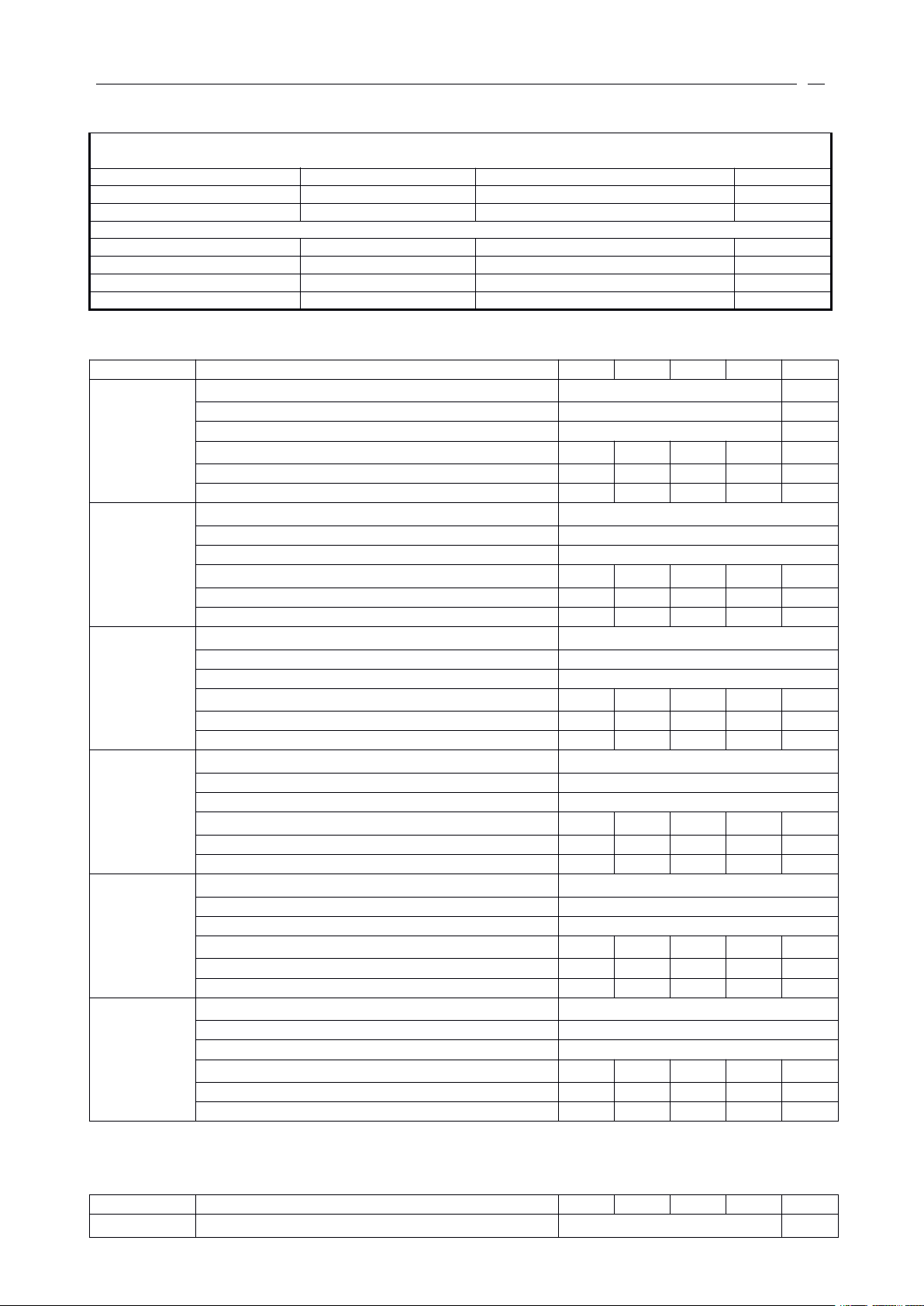

5.1 Torque and turning range

■ position setting range: 3.5 to 2040 turns, with a minimum angular resolution to 11.5 ° of actuator output

center column.

■ torque switch setting: 40% to 120% rated torque.

5.2 Cable entry and connecting terminals

The sizes of three cable entries are double M25 and M40.make cable entries appropriate to the cable type

and size. The sizes of four power terminals are M5. The sizes of control terminals are M4. Check that supply

voltage is the same as that, marked on th e actuator nameplate begin

5.3 Interface for machine installation

The actuator contains thrust type and non-thrust type. The thrust type is:A type, the non-thrust type is made

of B1,B3,B4. The drive bush’s shape for every link types please refer to diagram 5-1 and diagram 5-2.

5.3.1 Type

The type

5.3.2 Type B drive bush

erformance

PPP

erformance

erformance

A

drive bush

A

thrust bush suit the position of the valve-mounting flange.

by

connecting these cables.

15

Driving shaft bored and keyed to ISO 5210 standard. And the type B non-thrust bush has three basic form

Combination

Rated

Torque

(N.m)

Stroke

Time

(s)

Actuator

RPM

(rpm)

Gearbox

Ratio

Max

Bore

(mm)

Combination

Rated

Torque

(N.m)

Stroke

Time

(s)

Actuator

RPM

(rpm)

Gearbox

Ratio

Max

Bore

(mm)

HK M03B4/ W4

4102936

70 :164HK M1 0 B4/ W6

1 7 702936

70 :1

102

HK M03B4/ W4

2802524

40 :164HK M1 0 B4/ W6

2 0524424

70 :1

102

HK M03B4/ W4

2673318

40 :164HK M20B4/ W6

27342248

70 :1

102

HK M03B4/ W4

4184424

70 :164HK M1 0 B4/ W6R

25372972

140 :1102

HK M0 5 B4/ W4

5582524

40 :164HK M1 0 B4/ W6R

27504448

140 :1102

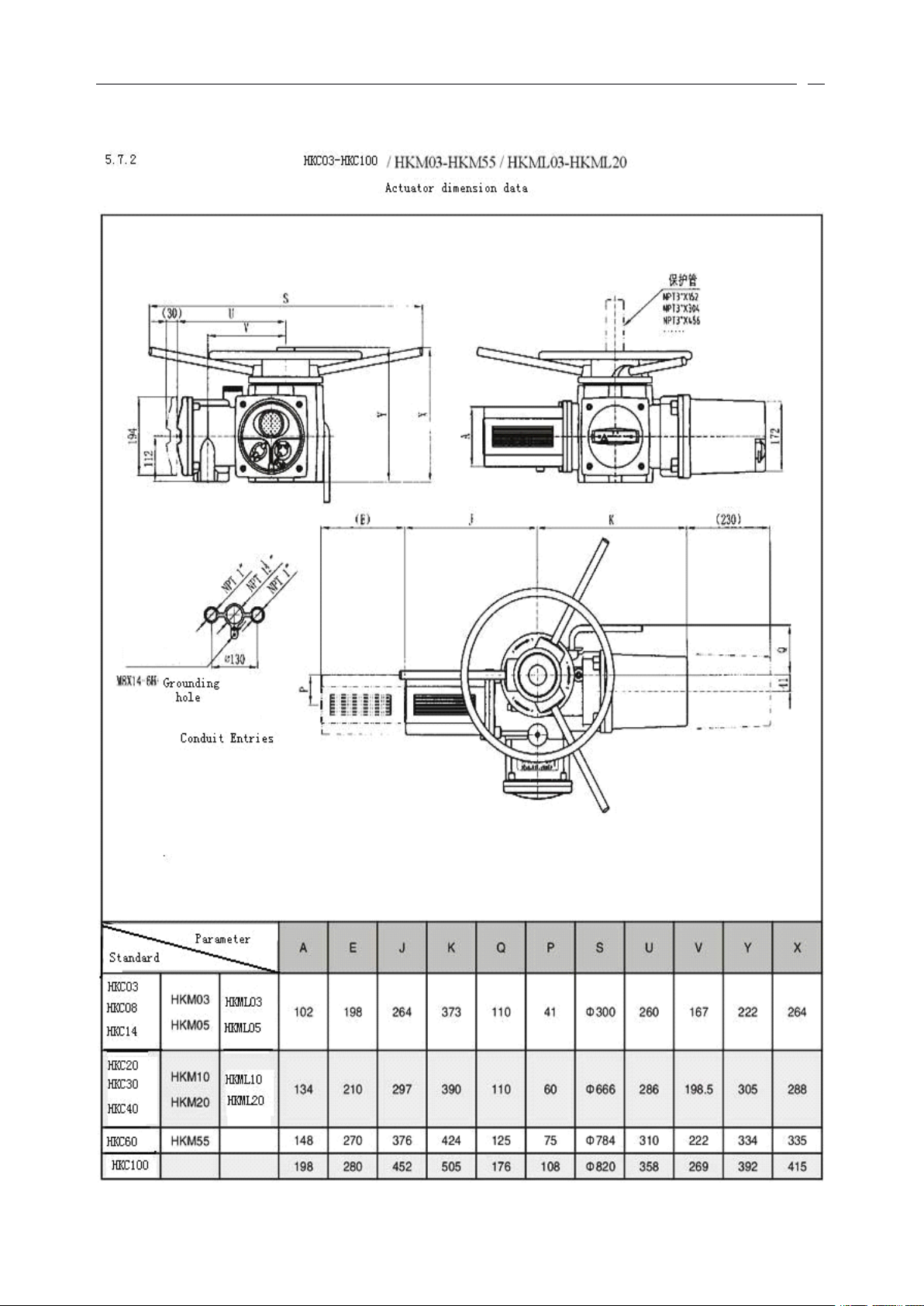

Diagram 5-1: Links of basic-base drive-bush for HKM03~HKM55 actuator

Type

Type

Type

B1B1B1

Used in

HKM03 ~ HKM55

Type

Type

Type

B4B4B4

Used

in

HKM03~HKM55

Type

Type

Type

B3B3B3

Used

in

HKM03~HKM55

Diagram 5-2: Links of non-thrust type drive-bush for type HKM03~HKM55

as follows B1, B3 and B4.

5.3.3 Type B1

The B1 is supplied a big key and shaft to drive the valve.

5.3.4 Type B3

The B3 is supplied a small key and shaft to drive the valve.

5.3.5 Type B4

B4 is supplied blank and must be machined to suit the input shaft of the gearbox

thatitwill drive.

a. Thrust type:

b. Non-thrust type:

or

valve

5.4 Additional gear-box

You

can use the gear-box to make the HKM linear stroke actuator as the angular stroke actuator, please see

table 5-2.

5.5 O scillation

The normal oscillation frequency and intensity for rang HKM is during the 10Hz ~ 200Hz and 0.5 times

acceleration of gravity .

5.6 Shielding and flameproof

Waterproof type: accord with <<GB4208-84>> IP68 proof grade

Flameproof type: accord with <<GB3836.1.2-2000>> d Ⅱ BT4 proof grade

Table 5-2 HK M actuator /W gearbox combination data

16

5.7

HK M0 5 B4/ W4

7232248

70 :164HK M1 0 B4/ W7

20163824

60 :1

127

HK M0 5 B4/ W4

5353318

40 :164HK M20B4/ W7

33282536

60 :1

127

HK M0 5 B4/ W4

7892936

70 :164HKM20B4/ W7

37843824

60 :1

127

HK M03B4/ W4R

4472548

80 :164HK M1 0 B4/ W7R

26903848

120 :

1

127

HK M03B4/ W4R

5033336

80 :164HK M1 0 B4/ W7R

36403872

180 :

1

127

HK M0 5 B4/ W5

4382524

40 :176HK M20B4/ W8

38003824

60 :1

153

HK M0 5 B4/ W5

8422248

70 :176HK M5 5 B4/ W8

63702536

60 :1

153

HKM 0 5 B4/ W5

4173318

40 :176HK M5 5 B4/ W8

68303824

60 :1

153

HK M0 5 B4/ W5

9152936

70 :176HK M20B4/ W8R

48803848

120 :1153

HK M0 5 B4/ W5

10144424

70 :176HKM20B4/ W8R

7 32 53872

180 :1153

HK M03B4/ W5R

5253848

120 :176HKM20B4/ W8R

60723836

60:1

153

HK M0 5 B4/ W5R

69525488076

HK M5 5 B4/ W9

62112524

60 :1

178

HK M0 5 B4/ W5R

76033368076

HK M5 5 B4/ W9

154123872

180:

1

178

HK M0 5 B4/ W5R

16184448

14076HK M5 5 B4/ W9R

170043824

60:1

203 .

2

HK M0 5 B4/ W6R

16184448

140

102

HK M5 5 B4/ W10

171483872

180:1203 .

2

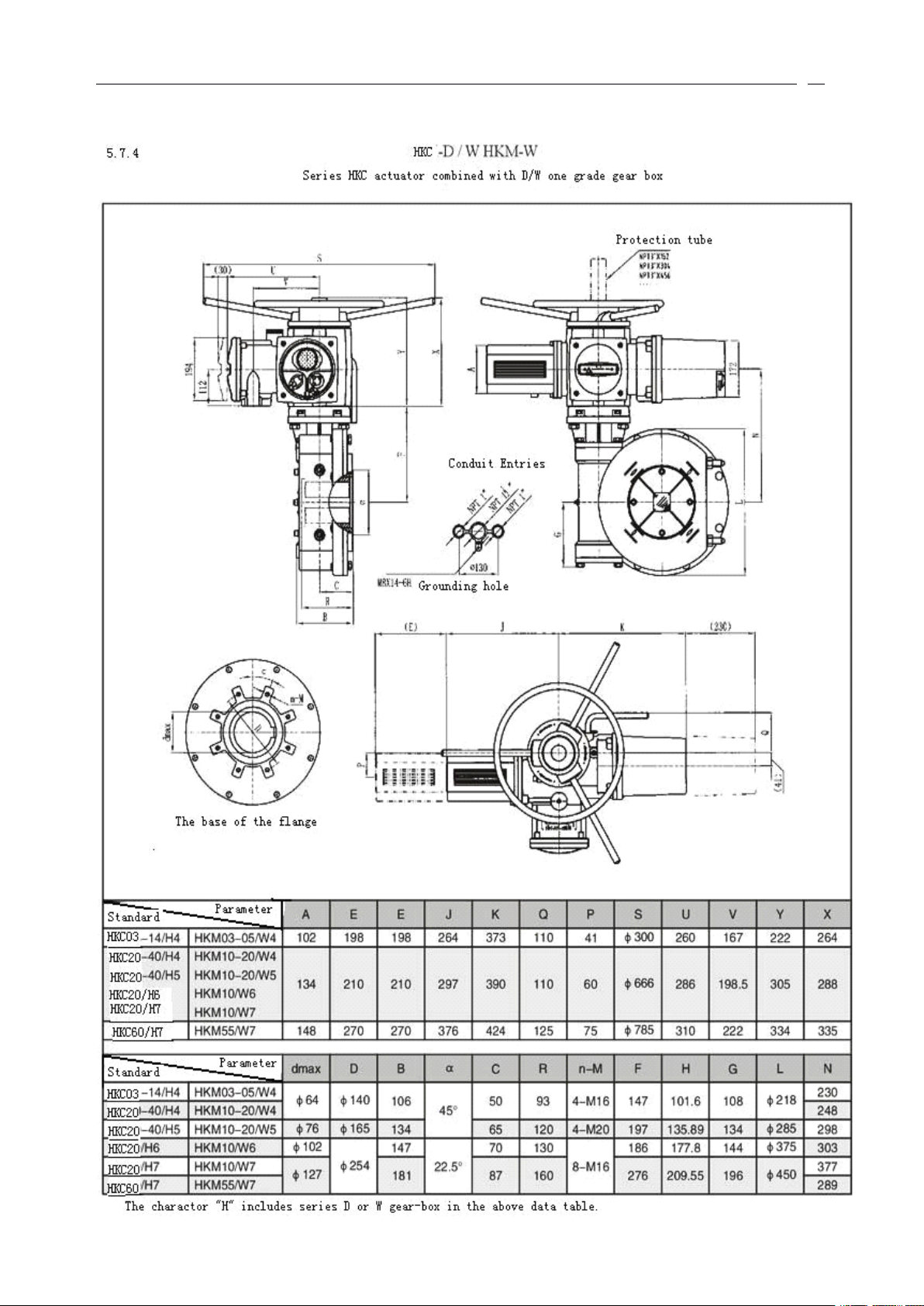

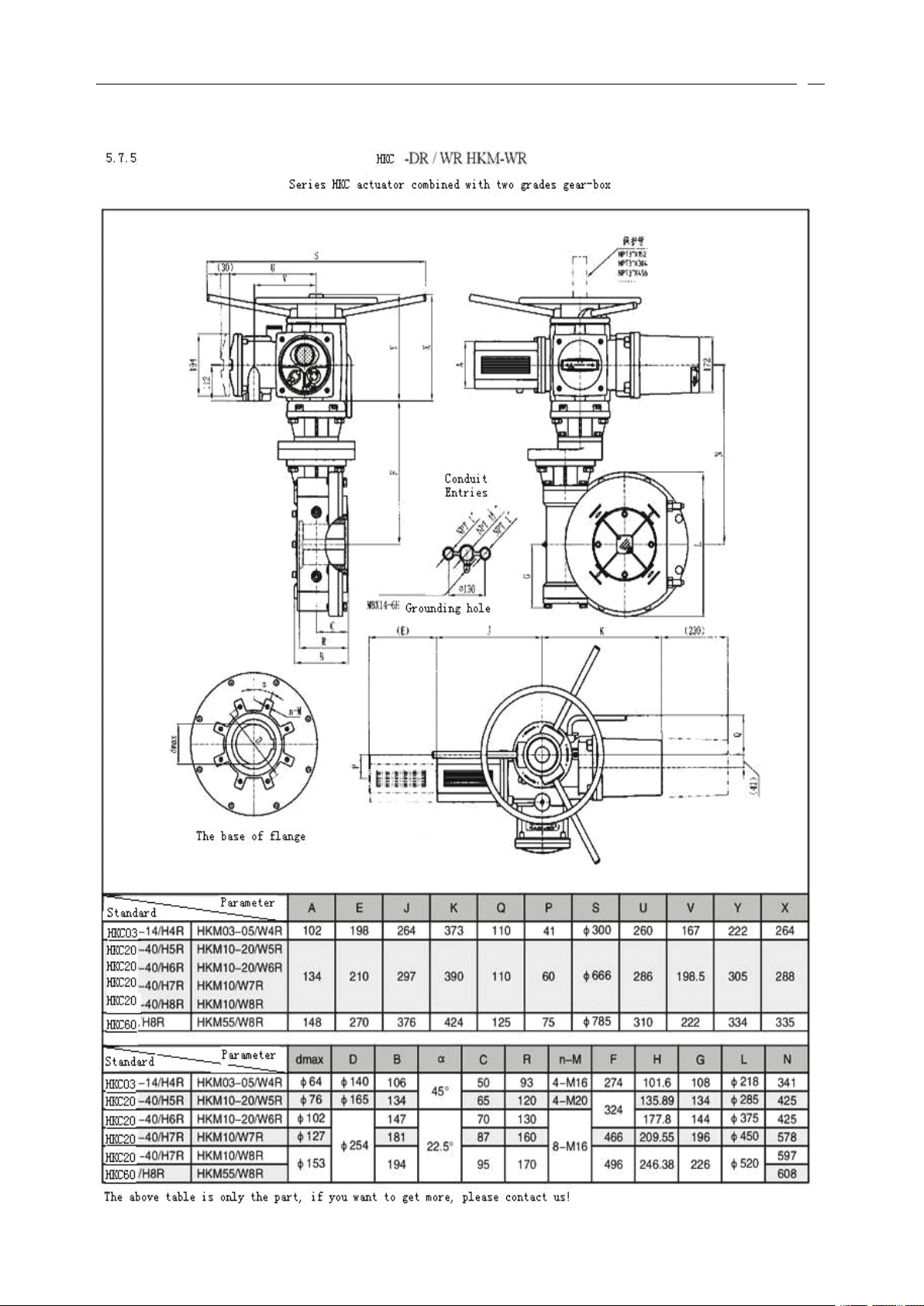

Coupling

5.7

5.7

Coupling

Coupling

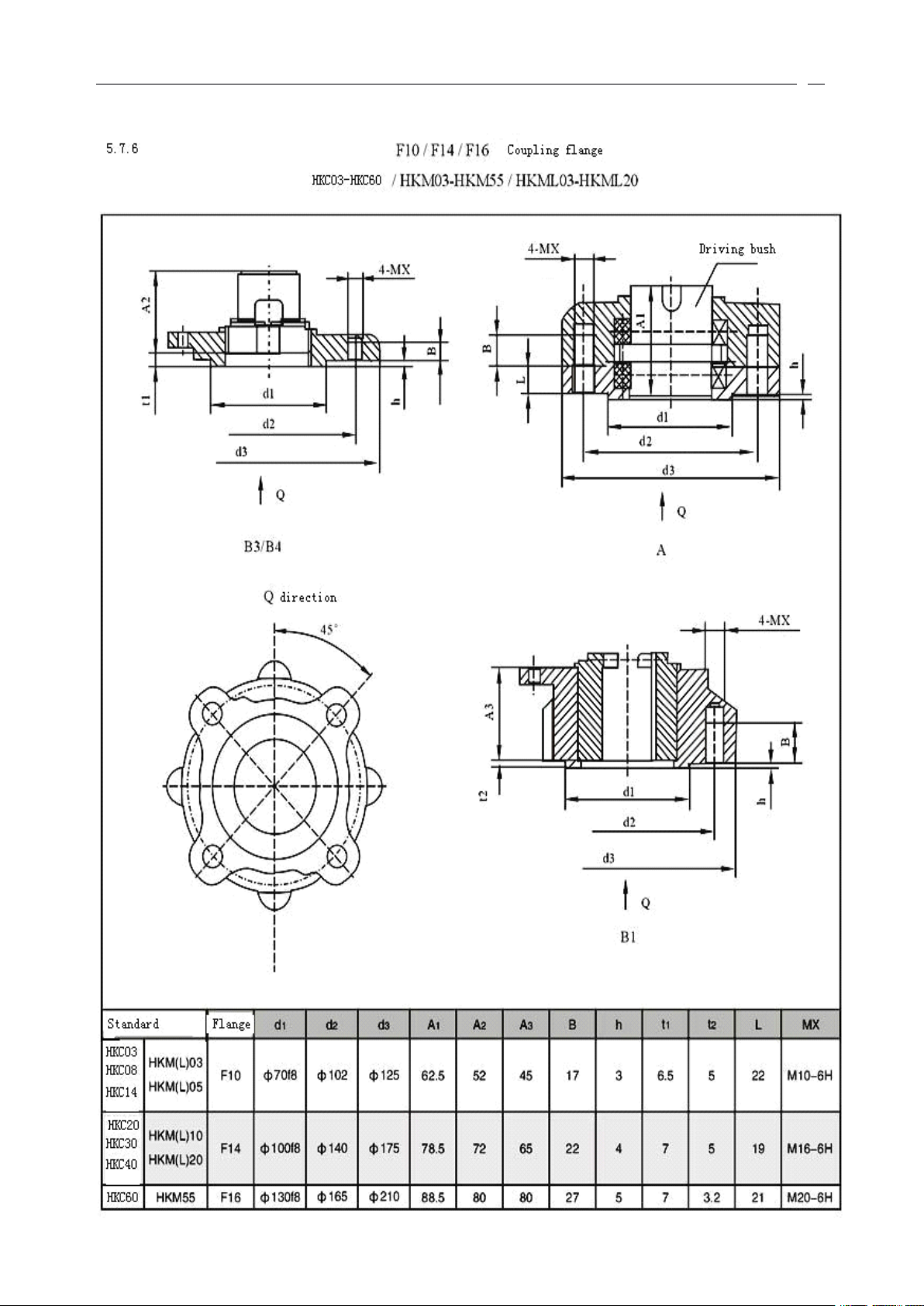

5.7.1

5.7.1

5.7.1

Coupling

Coupling

Coupling

interface

interface

interface

interface

interface

interface

for

HKM/HKML

for

for

HKM/HKML

HKM/HKML

17

you

***

change

IfIfIf

you

you

change

change

the

string

string

string

"HKM"

"HKM"

"HKM"

the

the

into

into

into

"HKE",

"HKE",

"HKE",

the

above

the

the

data

above

above

data

data

also

suitable

isisis

also

also

suitable

suitable

for

the

HKE

for

for

the

the

HKE

HKE

range.

range.

range.

18

you

***

change

IfIfIf

you

you

change

change

the

string

string

string

"HKM"

"HKM"

"HKM"

the

the

into

into

into

"HKE",

"HKE",

"HKE",

the

above

the

the

data

above

above

data

data

also

suitable

isisis

also

also

suitable

suitable

for

the

HKE

for

for

the

the

HKE

HKE

range.

range.

range.

19

you

***

change

IfIfIf

you

you

change

change

the

string

string

string

"HKM"

"HKM"

"HKM"

the

the

into

into

into

"HKE",

"HKE",

"HKE",

the

above

the

the

data

above

above

data

data

also

suitable

isisis

also

also

suitable

suitable

for

the

HKE

for

for

the

the

HKE

HKE

range.

range.

range.

20

you

***

change

IfIfIf

you

you

change

change

the

string

string

string

"HKM"

"HKM"

"HKM"

the

the

into

into

into

"HKE",

"HKE",

"HKE",

the

above

the

the

data

above

above

data

data

also

suitable

isisis

also

also

suitable

suitable

for

the

HKE

for

for

the

the

HKE

HKE

range.

range.

range.

21

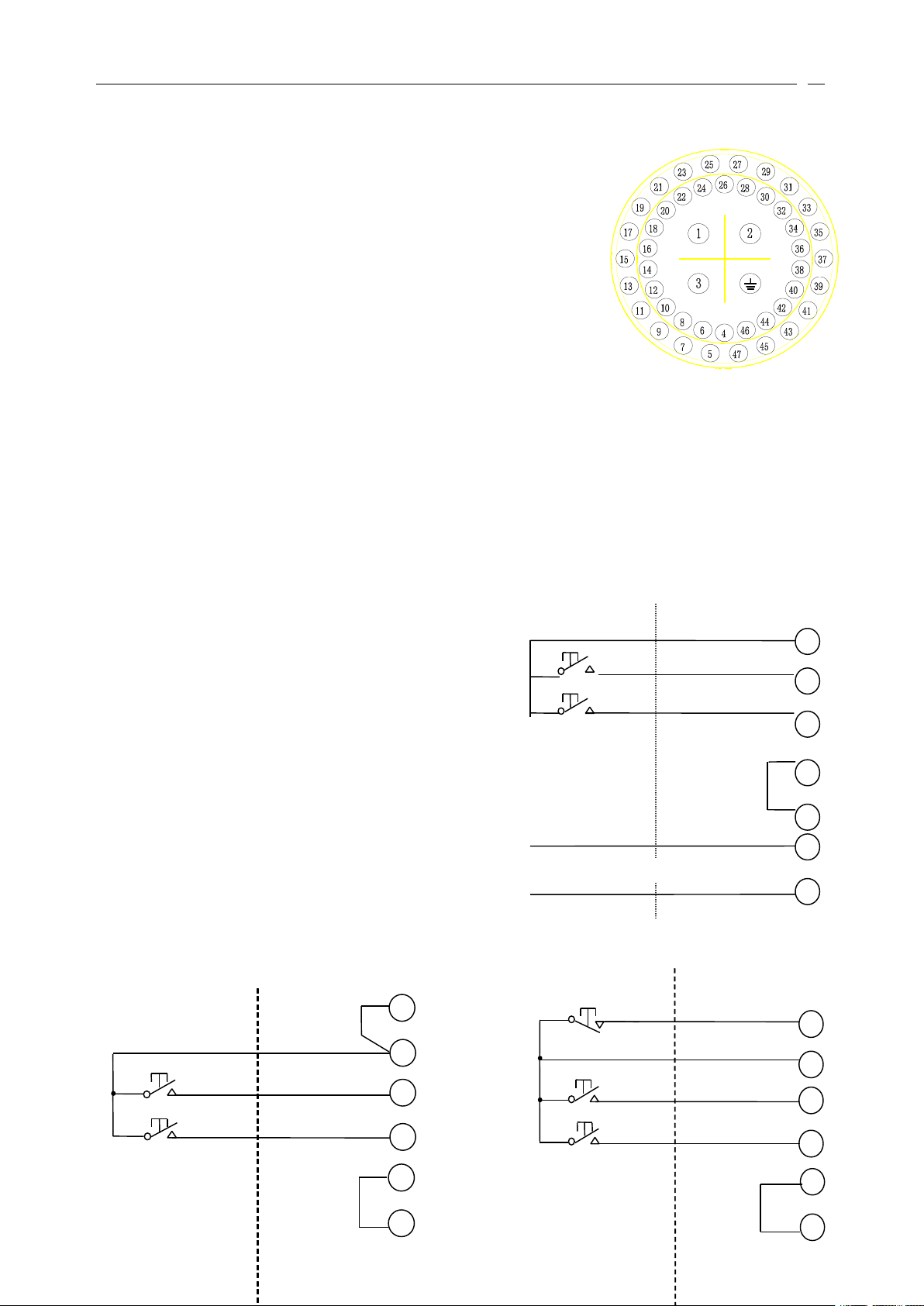

Stop

Close

Close

Open

Open

:Actuator

Diagram 6-1

Control

Actuator

5

353336

4

Close

Open

23

22

Valve

position feedback 4 ~ 20mA

Diagram 6-1 push to run open/close control

Control

Actuator

Control

Actuator

345333436

4355

33354

36

666

:Actuator

:Actuator

The wiring code card fixed

Control

Control

Control

and

wiring

and

and

wiring

wiring

(this

section

(this

(this

section

section

in

the terminal cover is particular to each

isisis

suitable

suitable

suitable

for

HKC

for

for

HKC

HKC

range)

range)

range)

actuator. The HKM actuator wiring code, please refer to diagram 7. The

means of each terminal refer to the diagram 6-1.

6.1 Local controls

Non-intrusive selectors are provided on the actuator electrical control

cover, one for local/stop/remote selection, pad-lockable

in

each position,

and the other open/close control. Local control may be configured for

maintained

or

push to run operation.

6.2 Remote manual controls

The power supply of remote control circuits can be provided as DC 24V

actuator internal supply

or

DC/AC 24V ~ 60V,AC 120 ~ 220V by external supply.

Refer to the circuit diagram 6-1 to 6-3.

by

22

Table 6-1 terminals description

NO

NAME

OPERATION

Connect with crust

Connect with grounding

1

Power supply terminal

380VAC(or 220VAC) input terminal

2

Power supply terminal

380VAC(or 220VAC) input terminal

3

Power supply terminal

380VAC(or void) input terminal

4

DC 0V

DC 24V “ - ” output

5

DC 24V

DC 24V “ + ” output

6

S1 relay terminal 1

Indication S1 relay terminal 1

7

S1 relay terminal 2

Indication S1 relay terminal 2

8

S 2 relay terminal 1

Indication S 2 relay terminal 1

9

S 2 relay terminal 2

Indication S 2 relay terminal 2

10

S 3 relay terminal 1

Indication S 3 relay terminal 1

11

S 3 relay terminal 1

Indication S 3 relay terminal 2

12

S 4 relay terminal 1

Indication S 4 relay terminal 1

13

S 4 relay terminal 2

Indication S 4 relay terminal 2

14

Battery relay terminal 1

Indicate battery power is too low ,the relay contact 1

15

Battery relay terminal2

Indicate battery power is too low , the relay contact 2

16

Temperature relay terminal 1

Indicate motor temperature is high, the relay contact 1

17

Temperature relay terminal 2

Indicate motor temperature is high , the relay contact 2

1819Remote relay terminal 1

Remote position indication relay , common terminal

20

Remote relay terminal 2

Remote position indication relay , normally close terminal

21

Remote relay terminal 3

Remote position indication relay , normally open terminal

22

Valve

position feedback signal +

Valve

position current analogue signal feedback terminal +

23

feedback signal common terminal

Valve

position current analogue signal feedback terminal +

24

Torque feedback signal +

Torque current analogue signal feedback terminal l

25

ESD

Emergent (ESD) active signal input terminal

26

Valve

position input signal +

Valve

position current analogue signal input terminal +

27

Valve

position input signal -

Valve

position current analogue signal input terminal -

2829Open position relay terminal 1

Valve

position fully open indication relay terminal 1

30

Open position relay terminal 2

Valve

position fully open indication relay terminal 2

31

Interlock low voltage terminal

Interlock low voltage common-terminal

32

Interlock high voltage terminal

Interlock high voltage common-terminal

33

Remote close

Remote close input terminal

34

Stop/maintain

Stop/maintain input terminal

35

Remote open

Remote open input terminal

36

Remote low voltage terminal

ESD, remote open/close, stop/maintain low voltage common-terminal

37

Open interlock

Open interlock input terminal

38

Close interlock

Close interlock input terminal

39

Manual/automatic terminal

Manual/automatic signal input terminal

40

Remote high voltage terminal

ESD, remote open/close, stop/maintain high voltage common-terminal

23

22

23

22

Valve

position feedback 4 ~ 20mA

Valve

position feedback 4 ~ 20mA

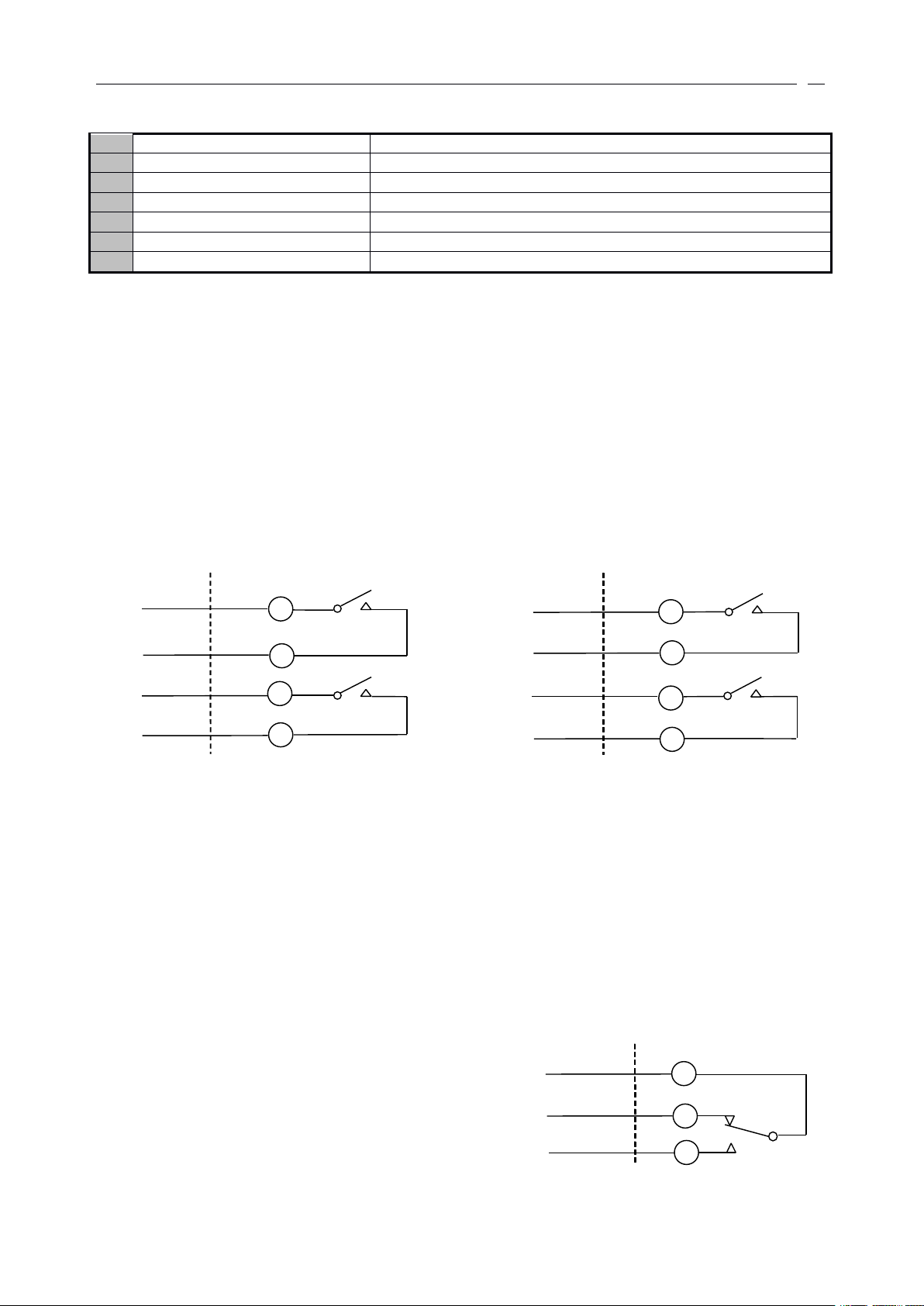

Diagram 6-2 maintain open/close control, support

reversion, intermediate position impossible

Diagram 6-3 maintain open/close/stop control

23

6.3 State indication relay

41

Manual/auto low voltage terminal

Manual/automatic low voltage common-terminal

42

Monitor relay terminal 1

Monitor relay common terminal

43

Monitor relay terminal 2

Monitor relay normally close terminal

44

Monitor relay terminal 3

Monitor relay normally open terminal

45

Manual/auto high voltage terminal

Manual/automatic high voltage input terminal

46

Close position relay terminal 1

Valve

position fully close indication relay terminal 1

47

Close position relay terminal 2

Valve

position fully close indication relay terminal 2

Actuator

Control

S1

6

7

S2

8

9

S3

10

11S412

13

Actuator

Control

Normally open

Normally open

Normally open

Normally open

Diagram 6-10 state indication relays

Diagram 6-11 monitor relay

wiring diagram

Actuator

Control

44

42

43

Normally close

Four state indication relay are provided, each one independently configurable using the HKM setting tool

to signal one of the following:

■ valve position

Fully open, fully close

or

any intermediate positions

■ status

Valve opening, closing, moving

valve alarms

■

Motor tripped on torque going open, going close, valve jammed

■ actuators alarms

Battery low

Each contact can be configured to either “ normally open ”

5A/250VAC

or

5A/30VAC.

Refer to diagram 6-5.

6.4 Monitor relay

An independent relay with a volt-free changeover contact

used for monitoring actuator electrical availability. Contact

rating 5A/250VAC

or

The relay will de-energise under a one,orcombination, of

the following conditions:

■ loss of one

or

more of the power supply phases

■ main control circuit is error

■ motor thermostat tripped

5A/30VAC.

or

“ normally close ” . Contacts are rated

at

24

■ mode switch is not

Item

Extra functions

Wiring

diagram

number

111

222

333

444

555

Base

Circuit

Battery low,

remote control select

and

thermostat tripped

alarm relay

Valve

position fully

open and

valve position fully

close

indication relay

Analogue

signal

input

Valve

position

signal

feedback

Torque

signal

output

√

—————

1 00-00√√

—

1 01-

√

—

√

1 02-

√

√

√

1 03- √

√

—

—

1 -01

√

—√—

1 -02

√

√√—

1 -03√

—

—

√

1 -04

√

√—√

1 -05

√

—√√

1 -06

√

√

√

√

1 -07

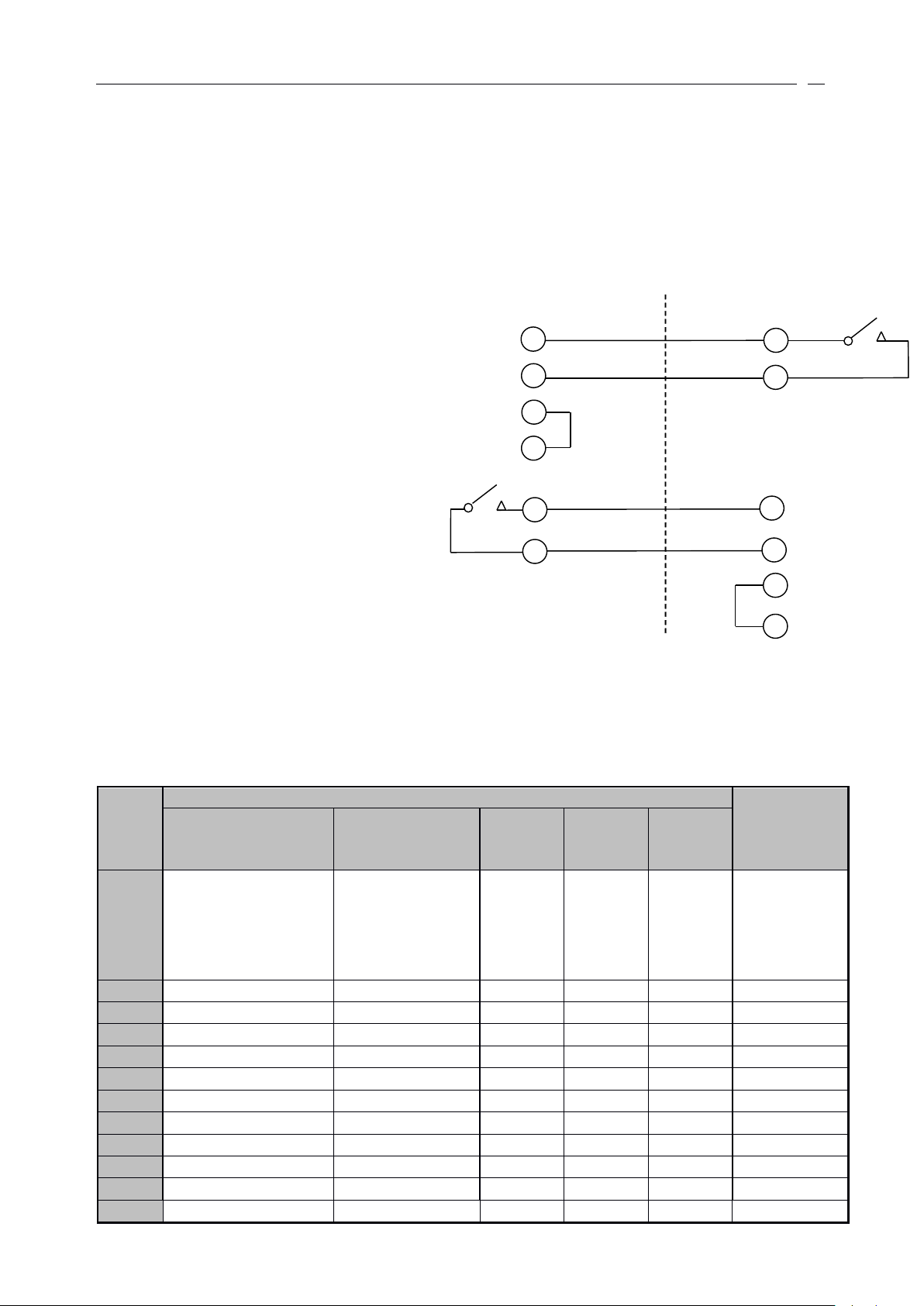

Diagram 6-12 interlock

3 853 7

3 148

9

453 176

24V DC +

24V DC +

24V DC -

24V DC

Contact close when valve fully close

Auxiliary actuator

Main actuator

Contact close when valve fully open

Close interlock

at

the remote position

Refer to diagram 6-11.

6.5 Emergency shut down - ESD

An active ESD signal will override any local

separate common to that used for open, close.

The following ESD options can be configured:

■ ESD signal

Active high, active low

■ ESD action

Close, open

■ ESD override

Motor thermostat

6.6 Interlocks

External hardwired interlocks for

opening, closing

or

both directions can be

configured to inhibit local and remote

operation until the external contacts are made.

Interlock circuits may be added with any of the

remote control circuits. The interlock inpu ts

operate from a separate common allowing for

isolation between the safety system and

operation control system.

Refer to Diagram 6-12.

or

remote control signal. The ESD input operates from a

6.7 HKM /HKC actuator extra functions option

Refer to Table 6-2.

Table 6-2 HKM /HKC actuator addition circuit and wiring diagram number

25

NOTE: “—” means you do not select ; “ √” means you already select ; “×” means you can select 。

6 × 10

4

32N

ms

> Pulse length >

18 × 10

4

32N

Example:If you selected 1,3,4 functions, the wiring diagram number is 101-03 。

6.7.1 Alarm relay

The extra alarm relay option provides five additional changeover relays. The extra alarm relay functions

are show below:

■ valve position fully open

■ valve position fully close

■ battery low

■ remote control select

■ thermostat tripped

6.7.2 Analogue signal input/output Module

The analogue signal input/output board provides a non-contacting internally fed 4 ~ 20mA analogue

signal prointerfaceional to valve position. Available

that may be connected to the signal is 500 ohms

at

terminals 22 and 23, the maximum external impedance

at

nominal supply voltage.

Analogue signal input impedance:

4mA ~ 20mA/250 ohm;1VDC ~ 5VDC/1M ohm;2mA ~ 10mA/250 ohm;0.5VDC ~ 2.5VDC/1M ohm

6.8 Analogue signal control

The HKM actuator analogue signal prointerfaceional controllers enable the actuator to automatically

position a valve

in

prointerfaceion to an analogue current

or

voltage.Asignal derived from the actuator noncontacting position sensor is electronicallycompared with a signal prointerfaceional to the input signal. The

difference between them triggers the open

position is therefore automatically adjusted

operation can be prevented

by

the adjustable deadband and the Motion inhibits Timer features.

or

close contactor

in

prointerfaceion to analogu e signal. Unnecessary frequent

in

the direction that will cancel the error.

■ Position corresponding to low input signal: close limitorpercentage open

■ Position corresponding to high input signal: open limitorpercentage open

■ deadband: 0.1 ~ 9.9% of travel between open and closed limit positions

■ motion inhibit time: 0.1 ~ 9.9 sec between actuator movements

■ action on loss of input signal: stay-put, move to high

or

low signal position. Response on loss of signal

will occur if signal falls below 50% of set “ low ” signal.

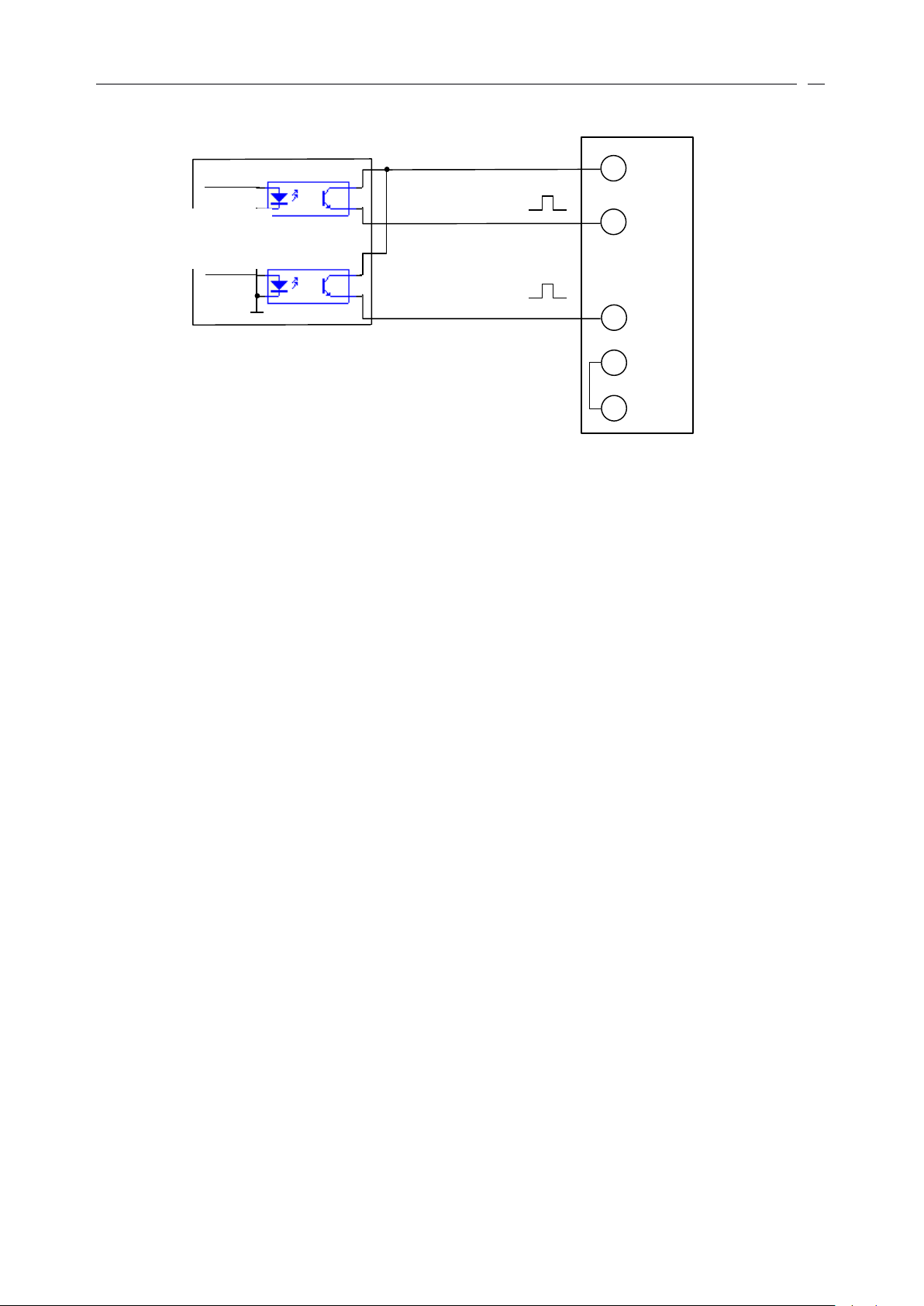

6.9 Pulse control

In the omputercontrol system, the user may be used the pulse control the actuator. HKM actuator are

fitted this control mode.

Please refer to diagram 6-14

Valve

■ the interval of pulse must according to maximum 1200 starts per hour and 50% working time.

■ Pulse width according to the output rpm N

26

Actuator

53543633

#1 output (close control)

Control system

output module

#2 output (open control)

Diagram 6-14 pulses control sketch map

6.11 Field bus control

6.11.1 Modbus communication

Signal

or

dual MODBUS modules may be included

in

the HKM actuator to provide remote serial

communication to the control functions and for status feedback data. The field network uses an RS485 data

highway, either 2

or

4 wires, and can be duplicated where redundancy is required. The communication is half

duplex and the protocol used is Modbus RTU with data rates up to 38 K baud. The actuator variables necessary

to set up the system are programmable over the infra-red data link.

Modbus module advantages:

■ cable cost reduction

■ installation cost reduction

■ simple to configure

■ simple to use

■ widespread open standard protocol

■ many compatible devices available

■ redundant configuration available

6.11.2 CAN bus communication

The CAN bus uses CAN2.0B protocol

,itis based on ISO/OSI. The signal transmission medium is the

twisted-pair,the great communication speed is 1Mbit/s, the great distance of the communication is 10Km

(5kbps), the bus can link 110 actuators maximal

ly.

6.11.3 Profibus communication

Profibus connectivity is possible

by

fitting the DP interface module within the HKM actuator, this allows

the HKM actuator to be integrated into a standard Profibus network. Full compatibility with the fieldbus

standard EN 50170 is provided and the module carries Profibus certification for inter-operability. The network

allows full control of the actuator and feedback of status data to the host. The HKM actuator Profibus module

has two communication interfaces to facilitate redundant fieldbus wiring where reliability is paramount, data

rates up to 1.5 M baud are supinterfaceed.

Profibus module advantage

■ cable cost reduction

■ installation cost reduction

■ simple to configure and use

■ devices independently approved

■ widespread open standard protocol

27

■ large number of compatible devices available

HK M □ □ □ - □ - □ - □ - □ - □ - □

Wiring diagram number (refer to table 6-2)

E: explosion proof, Exd Ⅱ BT4

W: water tight, IP68

Enclosure

S: 380ACV, 3 phase

D: 220ACV, single phase

Power supply

Output speed (rpm): 18; 24; 36; 48; 72; 96; 144; 192

Con n ect mode:A;B1;B3;B4

Flange type: F10; F14; F16

Type: HK M03; HK M0 5 ; HK M12; HK M20;

HK M5 5 . According to torque, thrust, output

speed and valve stem dimension, to refer table 41,table 4-2 and table 4-3.

HK M series

■ redundant configuration available

6.11.4 Foundation Fieldbus communication

HKM actuator may be connected to a Foundation Fieldbus network

by

the inclusion of a HKM actuator FF

module. The device complies with fieldbus standard IEC 61158-2, using a 2 wire electrical connection to the

highway and has been certified for inter-opera bility. The foundation highway exchanges data and control

between devices and full actuator functionality is available. Each actuator has full link scheduler capability and

function blocks for analogue and digital inputs and outputs as well as PID and the standard transducer block.

Foundation Fieldbus networks are capable of operating without a host system as a supervisor, the field devices

communicating directly between themselves.

Foundation fieldbus module advantages:

■ open standard protocol

■ cable cost reduction

■ installation cost reduction

■ simple to configure and use

■ access to the transducer block provides comprehensive diagnostic data

■ simple communications on plug and play basis

777

Order

Order

Order

ntroduce

III

ntroduce

ntroduce

sss

Model designation must be noted the each item, for example the wiring diagram number means the

actuators versions, and if you require order a gearbox, you need to fill upon its model number.

■ Actuator model number

Example: HK M20F14A-24- S -W- 1 01-03

Means: actuator modulating torque: 152N.M; flange type: F14; drive bush type: A; output speed: 24; Power

supply: 380ACV; enclosure: IP68 water tight; appending analogue signal input, valve position signal feedback,

28

battery low alarm

Gearbox ratio

Gearbox dimension number

Gearbox series

relay,

remote control select alarm relay and thermostat tripped alarm relay.

■ Gearbox

□ □ □

Detail information can be found on the corresponding technical data sheets.

Example: W5- 40: 1

Means: W series; dimension number: 5;gearbox ratio: 40:1.

Even if the actuator and gearbox are provided all together, the model of the gearbox is not marked on the

identification plate of the actuator. There is an individual identification plate on the gearbox; on

model of the gearbox and so on.

it

marked with

por

ImImIm

por

por

ttt

exorbitant

exorbitant

exorbitant

ant

notice:

ant

ant

notice:

notice:

output

output

output

ininin

rotate

rotate

rotate

order

order

order

tototo

speed.

speed.

speed.

advance

advance

advance

Here

Here

Here

the

orientation

the

the

orientation

orientation

advice

’’’

sss

aaa

advice

advice

the

:::

the

the

stroke

stroke

stroke

precision

precision

precision

time

time

time

popularly

,,,

popularly

popularly

not

isisis

not

not

you

you

you

less

than

less

less

than

than

dododo

252525

not

not

not

seconds.

seconds.

seconds.

select

select

select

the

the

the

29

8 、 Machining of the Drive Bush

888

.1.1.1

Thrust

Thrust

Thrust

Base

Base

Base

Type

Type

Type

:

1) Turn actuator onto its side, remove the two cap-headed screws holding base plate onto thrust base, pull

out the drive bush complete with its bearing assembly. Remove the thrust bearing of the drive bush’s double end

(The two thrust bearing stop ring ne

ar

the mid bulgy – shoulder of the drive bush may not be removed.) (Refer

to diagram1-1 ,1-2).

2) According to the thread dimension of the valve stem, machine the internal screw thread of the drive

bush.

3) Remove all swarf from the drive bush and others that removed, ensuring that they are

in

good

condition, clean and greased. According to the above steps, with adverse steps we can refit the drive bush and

base assembly on the actuator, ensuring that the sl ots

in

the drive bush are located into the drive dogs of the

hollow output shaft. (The bearing modules must be topped up lubricating oil).

8 .2 Non-Thrust Base Type (Refer to diagram 1-3).

1) Turn actuator onto its side, remove the base, the retaining clip on top of the drive bush can be seen now.

2) Turn the retaining clip slots until reach the drive dogs of the output shaft,orwith the screwdriver seek out the

retaining clip, we can remove the drive bush. According to the connection mode of the configured value, we can

machine the hole of the dr ive bush shaft, key seatorcombinative-dogs, and refit them assembly on the actuator.

Then

fit

on the retaining clip and base . Before fitting on the base, must daub between base and drive bush with

any lubricating – oil.

999

、 III

nstallation

nstallation

nstallation

ofofof

the

the

the

actuator

actuator

actuator

9.1

9.1

9.1

Installation

Installation

Installation

with

with

with

the

the

the

visible

visible

visible

stem

stem

stem

valves:

valves:

valves:

9.1.1

9.1.1

9.1.1

Install

Install

Install

the

the

the

Thrust

Thrust

Thrust

Base

Base

Base

Type

Type

Type

:

1). When leaving factory, according to the requests of the clients the screw thread inside the drive bush has

been machined well. As a combination of actuator and drive bush,

it

is assembled with valve.

Firstly

let

the hand – operating step available, then place the actuator onto valve, put the screw thread of

the actuator and the valve stem

in

order, wind the handwheel

in

the opening direction to engage the drive bush

diagram 1-1 diagram 1-2 diagram 1-3

30

onto the stem. Continue winding until the actuator is firmly down on the valve flange. Wind two further turns,

fit

securing bolts and tighten fully.

2). If the clients machine the internal screws of the drive bush, according to above 1.1, machine and

fit in

the drive bush. According to the above “ a ”,fit

them assembly.

9.1.2

9.1.2

9.1.2

Installing

Installing

Installing

the

the

the

Non

Non

Non

–––

thrust

thrust

thrust

Base

Base

Base

Type

Type

Type

Ensuring that the drive bushes of the non- thrust type have been machined, then

fit

the actuator and valve

as a combined unit.

Firstly

let

the hand – operating step of the actuator available, then place the actuator onto the valve,

let

the valve stem into the hole of the drive bush,

or

the combinative – dog of the drive bush is secured to the

combinative – dog of the valve, wind the handwheel

in

opening direction until the actuator is firmly down on

the valve flange. Wind two further turns,

fit

securing bolts and tighten fully.

9.2

9.2

9.2

Installation

Installation

Installation

with

with

with

the

the

the

valve

valve

valve

with

with

with

gear

gear

gear

case

case

case

Firstly checking that the drive bush, input shaft, key and key seat are all appropriate

or

not,

fit

the base

and drive bush assembly on the actuator firstly, then place the actuator onto the flange of the gear case correctly,

let

the input shaft of the ge

ar

case into the hole of the drive bush shaft, wind the handwheel, ensuring that the

key is located into the key – seat of the drive bush, then

fit

securing bolts and tighten fully.

9.3

9.3

9.3

Installation

Installation

Installation

with

with

with

the

the

the

hidden

hidden

hidden

–––

stem

stem

stem

valve

valve

valve

Popularly according to the 2.1.2, use the same way to assembly. But if the actuator will support thrust, we

should use the thrust – type connection with thrust bearing.

9.4

9.4

9.4

Handwheel

Handwheel

Handwheel

Sealing

Sealing

Sealing

Ensuring that sealing plug

in

center of handwheel is sealed with PTFE tape and fully tightened, ensuring

that moisture does not pass down the output shaft of the actuator.

9.5

9.5

9.5

Connecting

Connecting

Connecting

tototo

Terminals

Terminals

Terminals

and

and

and

Cable

Cable

Cable

Entry

Entry

Entry

1. According to the control orders, connect the power wires and signal wires.

2. The actuator has expert earth terminals,

in

order to ensure that persons and equipments are safe, the

actuator should be earthed credibly.

3. Only appropriate certified Explosion – Proof entry reduces, glands

or

conduit may be used

in

hazardous

locations. Ensure that threaded adaptors, Seal unused cable entries with a steel

or

brass threaded plug. In

hazardous areas an appropriately cert ified threaded blanking plug must be used.

9.6

9.6

9.6

Mounting

Mounting

Mounting

the

the

the

LCD

LCD

LCD

Screen

Screen

Screen

Correctly

Correctly

Correctly

When the actuator is located on the different orientations,inorder to make the actuator have the natural

direction of the LCD display, that is to say the charactors have natural display direction, the LCD screen of the

actuator provides four sorts of settings:

1. Installing the actuator

in

the horizontal direction (operating handwheel is upturned), the LCD screen is

mounted with a natural position.

31

2. The actuator is installed conversely (operating handwheel is gadarene

),

the charactors are displayed

reversely.

3. Installing the actuator

in

the leftward direction (operating handwheel is leftward

),

the LCD screen is

mounted near

by

the side of the flange.

4 Installing the actuator

in

the rightward direction (operating handwheel is rightward

),

the LCD screen

is mounted near

by

the side of the flange. The charactors are displayed reversely.

10 . Operating your Actuator

10.1 Operation

by

hand

The actuator provides operating handwheel and Electrical/Handwheel lever, when the actuator is

in

the

special instance, e.g. main power failed

or

the control circuit failed and so on, we can operate the actuator

by

hand. Before operating the handwheel, fi rstly

let

the mode selection switch be

in

the “ stop ”