Huricon Heating HW130, HW160 Installation And Operating Instructions Manual

2/06/2010

INSTALLATION AND

OPERATING INSTRUCTIONS

(EXTERNAL MODELS)

Melbourne: 03 9554 2275 Gold Coast: 07 5552 2600 Perth: 08 9350 2600

Sydney: 02 9853 2100 Townsville: 07 4750 3100 sales@hurlconheating.com.au

Brisbane: 07 3308 5400 Adelaide: 08 8152 7600 www.hurlconheating.com.au

INSTALLATION AND OPERATING INSTRUCTIONS I INSTALLATION AND OPERATING INSTRUCTIONS

Hurlcon Gas Fired Hydronic

Heating Boiler HW130 & HW160

Modulating Models

HW130 & HW160 Modulating Boiler

2

INDEX

INTRODUCTION……………………………………………………………………………………… 3

NOTICE TO INSTALLERS…………………………………………………………………………... 3

MODELS AVAILABLE………………………………………………………………………………... 4

STANDARD EQUIPMENT…………………………………………………………………………… 4

INSTALLATION……………………………………………………………………………………….. 5

SAFETY RULES………………………………………………………………………………………. 5

GUIDE TO INSTALLATION………………………………………………………………………….. 6

CLEARANCES………………………………………………………………………………………… 7

ELECTRICAL CONNECTION……………………………………………………………………….. 7

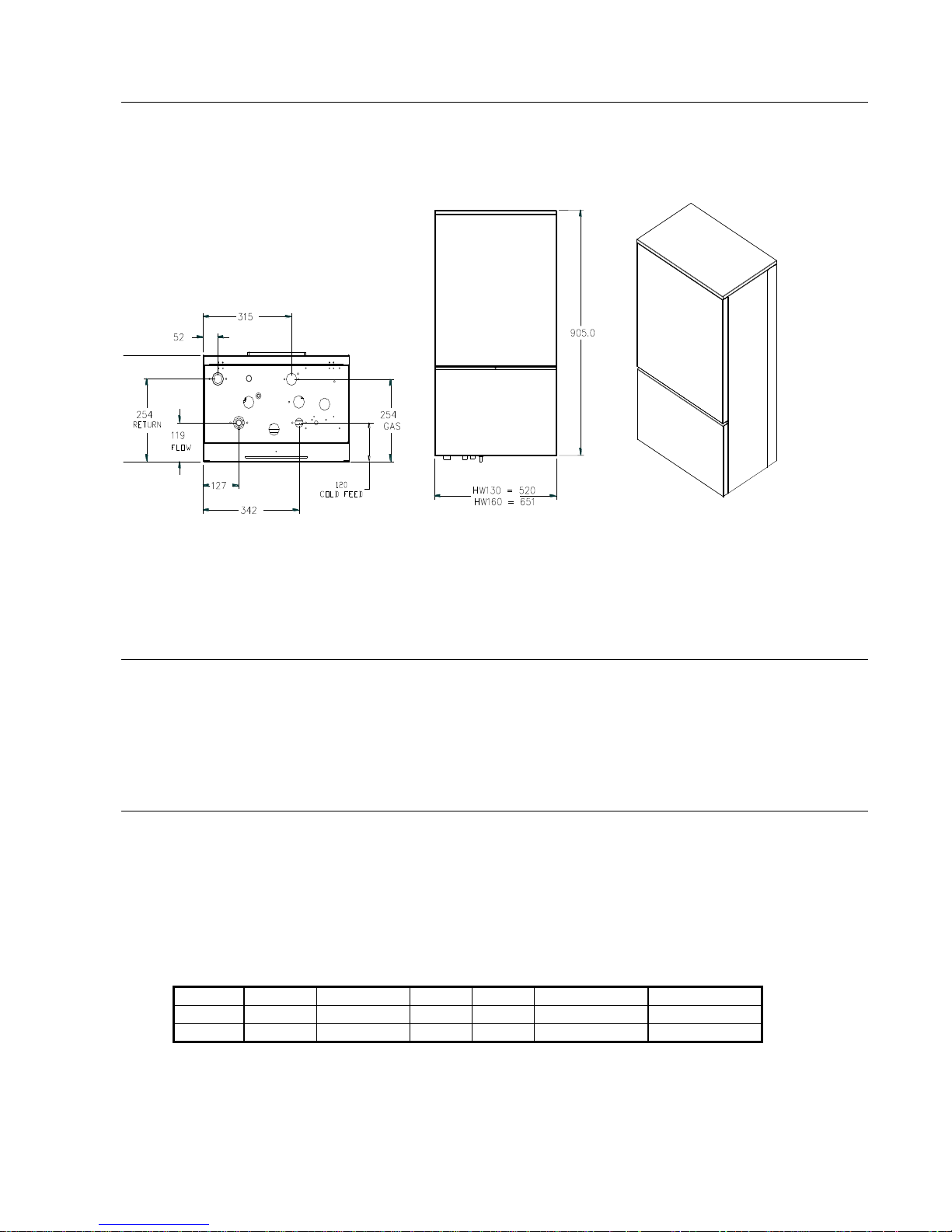

BOILER DIMENSIONS……………………………………………………………………………….. 8

INDOOR INSTALLATION……………………………………………………………………………. 8

HEATING PIPE SIZE & LAYOUT……………………………………………………………………. 8

SIZING OF PRESSURE VESSEL…………………………………………………………………… 9

COMMISSIONING…………………………………………………………………………………….. 9

STARTING BOILER…………………………………………………………………………………… 9

TESTING BURNER PRESSURE……………………………………………………………………. 10

FLOW SWITCH ……………………………………………………………………………………….. 11

CENTRAL HEATING CONTROLLER …………………………………….…………...……………. 12

OPERATING INSTRUCTIONS………………………………………………………………………. 12

ENERGY SAVING TIPS………………………………………………………………………………. 12

MAINTENANCE………………………………………………………………………………………... 13

CENTRAL HEATING THERMOSTAT INSTRUCTIONS . . …………….. . . . . . . . . .. . . . . . . 13

GAS CONVERSION……………………………………………………………………………………. 14

................................................................................................................................................... 15

BURNER CONVERSION……………………………………………………………………………… 15

……………………………………………………………………………………………………………. 16

GAS PIPE SIZING TABLES…………………………………………………………………………… 17

TROUBLESHOOTING…………………………………………………………………………………. 18

HW130 – HW160 WIRING DIAGRAM……………………………………………………………….. 19

ONE YEAR LIMITED WARRANTY…………………………………………………………………… 20

MOUNTING INSTRUCTIONS ………………………………………………………...………...…... 21

HW130 & HW160 Modulating Boiler

3

INTRODUCTION

Congratulations on your purchase of a Hurlcon HW130 - HW160 Series Modulating Hot Water Boiler. Correct

installation and service of your new heating system and correct chemical maintenance of the water will ensure

years of service. The HW130 - HW160 Series Boiler is a compact lightweight and efficient gas fired hot water

boiler.

The Hurlcon HW Boiler is a wall mounted induced draught atmospheric boiler with inbuilt flue for outdoor

operation. The power output is controlled by an integrated electronic controller to maintain the set point water

temperature over a wide load range. In addition, the Hurlcon HW Boiler is equipped with electronic ignition. The

room thermostat display tells at a glance the operational status of the boiler. The boiler application (radiator or

floor coil) is selectable via jumper settings on the boiler controller.

Note:

The appliance is not intended for use by young children or infirm person without supervision. Please ensure that

young children are supervised to ensure that they do not play with the appliance.

NOTICE TO INSTALLERS

This is a Wall Mounted - External – Hot Water Heating Boiler

For use with Natural Gas or LP Gas as per the attached data label.

The information below is given to assist the installer with the installation of this range of HW130 – HW160 Boilers.

Please read it carefully in order to make the installation as easy as possible and to ensure the system works well

and conforms to the necessary government regulations.

PLEASE READ THESE INSTRUCTIONS BEFORE STARTING THE INSTALLATION.

THIS APPLIANCE MUST BE INSTALLED BY AN AUTHORISED PERSON ONLY.

This boiler is to be installed and serviced to the requirements of the

Local Building, Gas, Water and Electricity Authorities.

These instructions are to be held by the owner / user after installation.

THIS APPLIANCE IS UNSUITABLE FOR USE AS A POOL HEATER

This appliance must be installed in accordance with the installation instructions, local gas fitting regulations, the

AGA Installation Code AS5601 / AG 601 and any other relevant statutory authorities.

Refer to data plate for details of gas type, gas consumption and burner pressure.

HW130 & HW160 Modulating Boiler

4

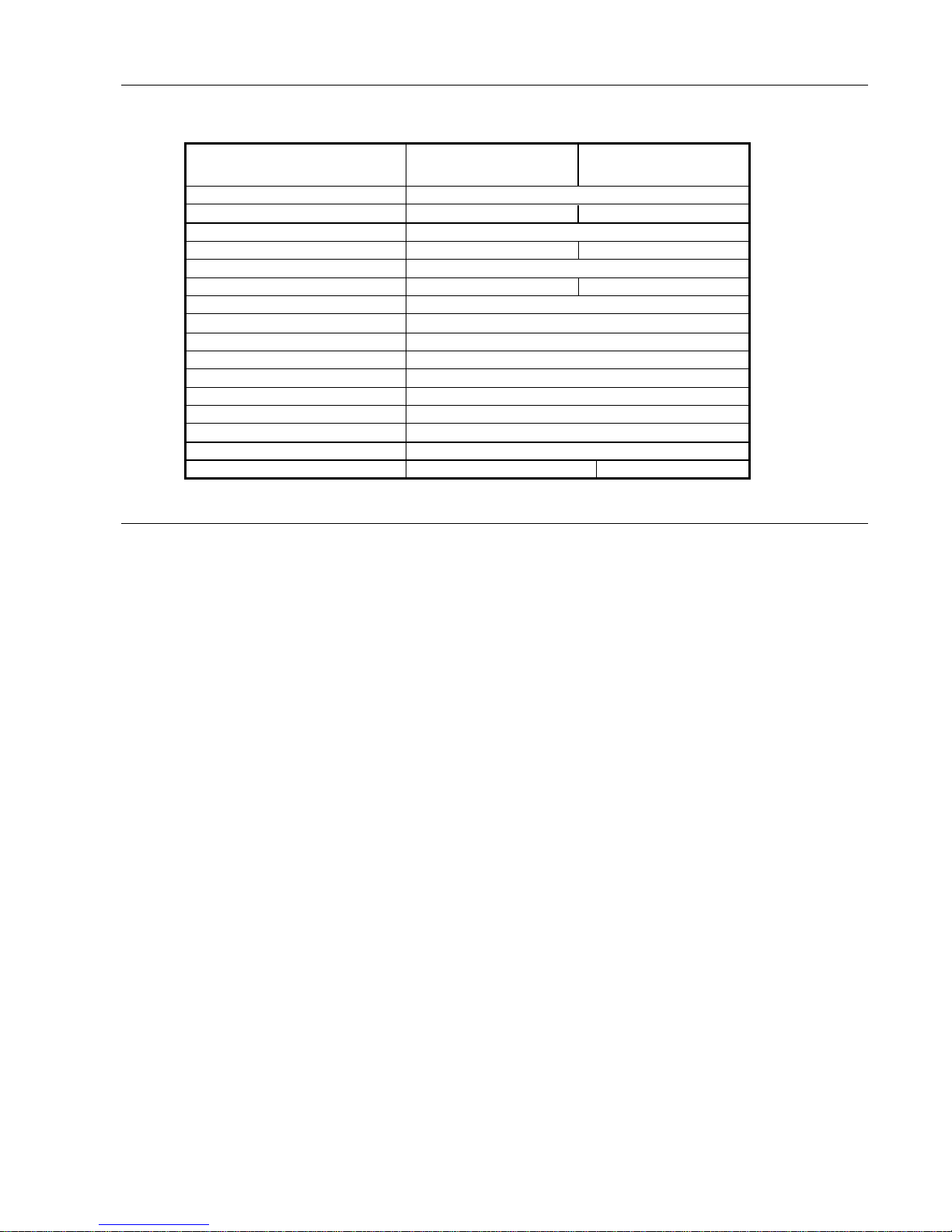

MODELS AVAILABLE

Details

Model

HW130 Modulating

Model

HW160 Modulating

Height

905

Width

520

651

Depth

325

Gas input

105.5 (95) MJ

145 (135) MJ

Gas type

Natural & (L P Gas)

Nom output

24 (21) kW

35 (32) kW

Ignition system

Electronic Ignition

Heat exchanger/burner

All copper/stainless steel

Boiler Thermostat

SIT (modulating)

Pressure relief

300kPa (3 Bar)

Expansion vessel

7 litre diaphragm (~60lt system)

Circulator

In line Centrifugal Pump

Hi limit Thermostat

99 oC

Run on timer

Timed electronic

Pressure reduction valve

1 Bar pre-set

Packed weight

50kg

60kg

STANDARD EQUIPMENT

Electronic boiler control with linking room thermostat.

Set temperature display.

Electronic ignition

Safety devices

Built in flow switch

Manual reset high limit

Built in pressure relief valve

Built to last

Double row heat exchanger made from one piece extruded finned copper tube

Stainless steel burners

Fully powder coated steel cabinet

Stainless steel flue terminal

Efficiency

Hot surface ignition

Induced draught combustion

Highly efficient stainless steel burners

Modulating input gas burner

Ease of installation

Fully plumbed ready to go, including circulating pump, expansion tank, pressure reduction valve & 1” flow

and return isolation valves.

All electrical pre wired including three pin plug.

HW130 & HW160 Modulating Boiler

5

INSTALLATION

THIS APPLIANCE MUST BE INSTALLED BY AN AUTHORISED PERSON.

Refer to boiler data plate for specifications of gas type, gas consumption, burner pressure and water pressure.

This appliance must be installed in accordance with local regulations and A.G.A. Installation Code AS5601 / AG

601.

The flow and return connections are located on the bottom of the boiler. The flow and return connections are

clearly marked and the connections are 1” BSP FI.

The Hurlcon Boiler is fitted with a built in flow switch and will not start unless full of water and the pump is

operating.

The Hurlcon Boiler incorporates a powered flue terminal suitable for outdoor installation. An indoor room sealed

model combined with co-axial flue kit for internal installation is available on request.

SAFETY RULES

For your safety – read before lighting

This appliance is equipped with an ignition device, which automatically lights the burner. Do not try to light the

burner by hand.

BEFORE OPERATING smell all around the appliance area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

Safety

WHAT TO DO IF YOU SMELL GAS

Do not try to light any gas appliance.

Do not touch any electrical switch.

Turn off the gas supply at the gas meter.

Immediately call your gas supplier or licensed gas fitter.

NOTE. Some gases are heavier than air and it may be necessary to smell for leaks at floor level.

House keeping

Do not store or use flammable liquids or chemicals near this appliance.

Do not use aerosols in the vicinity of this gas appliance.

Keep this appliance free of debris.

WARNING:

Should overheating occur or the gas supply fail to shut off, turn off the manual gas control valve to the appliance.

Do not use this boiler if any part has been under water.

HW130 & HW160 Modulating Boiler

6

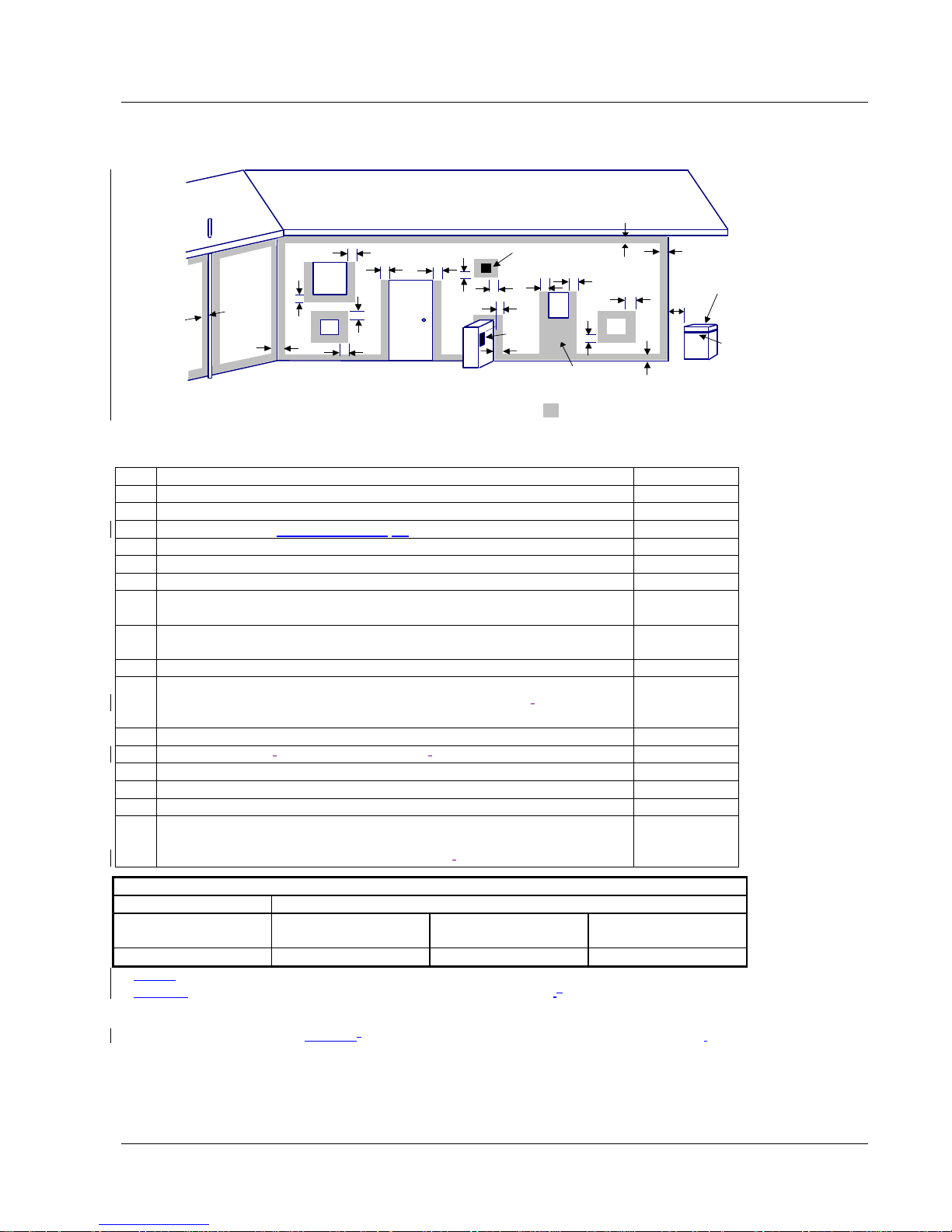

GUIDE TO INSTALLATION

Location of Flue Terminals – An extract from AG 601

Minimum Clearances Required For Powered Flue, Balanced Flue Terminals or the Terminals of Room Sealed

Appliances.

openable

window

door

M

P

g

See note 3

T

b

d

d

e

e

See note 2

h

h

a

g

h

j

jjn

k

kcc

f

T = Flue terminal

I = Mechanical air inlet

M = Gas meter

P = Electricity meter

or fuse box

Shading indicates prohibited

areas for flue terminals

T

T

I

MIN. CLEARANCE

(mm)

A

Below eaves, balconies and other projections

Appliances up to 50 MJ/h input

200

Appliances over 50 MJ/h input

300

B

From the ground, above a balcony or other surface

300

C

From a return wall or external corner

500

D

From a gas meter (M)

1000

E

From an electricity meter or fuse box (P)

500

F

From a drain pipe or soil pipe

75

G

Horizontally from any building structure (unless appliance approved

500

for closer installation) or obstruction facing a terminal

H

From any other flue terminal, cowl, or combustion air intake

300

I

Horizontally from an openable window, door, non-mechanical air inlet,

or any other opening into a building with the exception of sub-floor

ventilation

Appliances up to 150 MJ/h input

300

Appliances over 150 MJ/h but less than 200 MJ/h input

500

Appliances over 200 MJ/h input

1500

All fan-assisted flue appliances, in direction of discharge

1500

K

From a mechanical air inlet, including a spa blower

1000

N

Vertically below an openable window, non-mechanical air inlet, or any

other

opening into a building with the exception of sub-floor ventilation

See table

CLEARANCE „n‟ (mm)

Space heaters

All other appliances

Up to 50 MJ/h

input

Up to 50 MJ/h

input

Over 50 MJ/h &

up 150 MJ/h

Over 150 MJ/h

input

150

500

1000

1500

NOTES: 1 All distances are measured to the nearest part of the terminal.

2 Prohibited area below electricity meter or fuse box extends to ground level.

3 See Clause 5.13.6.6 for restrictions on a flue terminal under a covered area.

4 See Appendix J, Figures J1(a) and J2(a), for clearances required from a flue terminal to an LP Gas

cylinder. A flue terminal is considered to be a source of ignition.

The above information is part of AG 601 FIGURE 5.3 as supplied by the AGA and is provided as an indication of

the correct clearances only. Please refer to the latest issue of AG 601.

HW130 & HW160 Modulating Boiler

7

CLEARANCES

The boiler must not be installed against any combustible surface.

Clearances must comply with AS5601 / AG 601.

Clearances from surfaces are:

Front

500mm

Both sides

50mm

Above

300mm

Below

900mm

ELECTRICAL CONNECTION

The boiler is supplied with a standard 10 amp 3 pin plug for connection to a 240V 10 amp earthed GPO. The

boiler incorporates a 240/24 VAC transformer which supplies power to the central heating thermostat only and

must not be used for any additional equipment. All equipment connected to mains power should be protected by

an RCD circuit breaker. The boiler has a 240 volt power supply for the pump, fan and gas valve control. A terminal

strip is provided for connection to the central heating thermostat.

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a suitably qualified

person in order to avoid a hazard.

GAS CONNECTION

A ¾”BSP FI is provided for gas line connection. An approved manual shut off valve must be installed in the gas

fitting line before the boiler so that the gas can be turned off and the boiler removed for servicing if required. The

gas shut off valve should be sized the same as the gas fitting line to prevent excessive pressure drop in the gas

pipe.

The gas fitting line should be installed by an authorised person and comply with local regulations and A.G.A. code

AGS5601. The gas line from the meter will usually be of a larger size than the gas inlet connection. Therefore a

reduction to the boiler connection fitting will be necessary. The reduction should be as close to the boiler as

possible.

Before using the boiler, test all connections for gas leaks using soapy water.

The boiler gas valve has a built in pressure regulator with a ⅛” pressure test point provided. On starting the boiler,

a manometer must be used and burner pressure checked against the boiler data plate. The gas valve regulator

may need adjustment to correct manifold pressure. Incorrect burner pressure may void warranty.

HW130 & HW160 Modulating Boiler

8

BOILER DIMENSIONS

INDOOR INSTALLATION

This boiler is designed for outdoor use only. If the HW130 - 160 Boiler is to be installed indoors, a dedicated

indoor model with special flue kit is available.

HEATING PIPE SIZE & LAYOUT

The flow & return connection sizes of 1”BSP on the boiler are not necessarily the correct pipe sizes for the

heating system. It is important that the pipe sizes are correctly calculated before installation.

Hurlcon recommend a two pipe system with the pipes sized according to the flow requirements and length

of runs with a maximum water velocity of 1.5 M/s.

Reference The Institute of Plumbing Australia. - “SELECTION & SIZING OF COPPER TUBES FOR

PIPING SYSTEMS”.

Nominal flow capacities

Model

Output

Flow rates

DT

pd

min Pipe dia

F & R length

130

24 kW

0.38 l/s

15 oC

8 kPa

20 mm

6.0 m

160

35 kW

0.53 l/s

15 oC

14 kPa

25 mm

4.5 m

Loading...

Loading...