Hupfer TE-2/V27-33, TE-2/VK19-26, TEH-2/V19-26, TEH-2/V27-33, TEUH-1/VS19-26 Operating Instructions Manual

...

Ope

rating Instructions

TE-2/V19-26

Plat

e dispenser

| TE-2/V27-33 | TE-2/VK19-26 | TEH-1/V19-26 |

TEH-1/V27-33 | TEH-2/V19-26 | TEH-2/V27-33 | TEUH-1/VS19-26

| TEUH-2/VS19-26| TEUH-2/VC19-26 | EBR/V19-26 | EBR/V27-

33 | EBRH/V19-26 | EBRH/V27-33 | EBRH-2/V19-26

4330000_A1

Ch

apter 1 Introduction

Page 2 Appliance Information

1 Intr

1.

1 Appliance Information

oduction

Ap

pliance designation Plate dispenser

Appliance type/ -s TE-2/V19-26 | TE-2/V27-33 | TE-2/VK19-26 | TEH-

Manufacturer HUPFER® Metallwerke GmbH & Co. KG

www.hupfer.de

info@hupfer.de

Plate dispenser

1/V19-26 | TEH-1/V27-33 | TEH-2/V19-26 | TEH-2/V2733 | TEUH-1/VS19-26 | TEUH-2/VS19-26| TEUH2/VC19-26 | EBR/V19-26 | EBR/V27-33 | EBRH/V19-26 |

EBRH/V27-33 | EBRH-2/V19-26

Dieselstraße 20

48653 Coesfeld

PO 1463

D-48634 Coesfeld

+49 2541 805-0

+49 2541 805-111

TE-2/V19-26 | TE-2/V27-33 | TE-2/VK19-26 | TEH-1/V19-26 | TEH-1/V27-33 | TEH-2/V19-26 |

TEH-2/V27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26| TEUH-2/VC19-26 | EBR/V19-26 |

EBR/V27-33 | EBRH/V19-26 | EBRH/V27-33 | EBRH-2/V19-26

Read these operating instructions carefully before the first operation of the appliance.

Ensure that sources of danger and possible faulty operations have been pointed out to the operating staff.

Subject to modifications

The products covered by these operating instructions have been developed taking into consideration the requirements of the market and the latest technology. HUPFER® reserves the right to modify the products and

appertaining technical documentation in so far as the modifications are in the name of technological progress. The data and weights as well as the description of performance and functions assured in the order

confirmation as binding are always decisive.

Manual edition

4330000_A1

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

In

troduction Chapter 1

Table of Contents Page 3

1.

2 Table of Contents

1 Int

roduction 2

1.1 Appliance Information 2

1.2 Table of Contents 3

1.3 List of abbreviations 5

1.4 Definitions of Terms 6

1.5 Orientation Guide 7

1.6 Notes on Use of Manual 8

1.6.1 Notes on the manual structure 8

1.6.2 Notes and their illustrations used in the chapters 8

2 Safety Instructions 9

2.1 Introduction 9

2.2 Warning Symbols Used 9

2.3 Safety Instructions for Appliance Safety 9

2.3.1 Safety instructions for all appliances 9

2.3.2 Additional safety instructions for heated appliances 10

2.4 Safety Instructions for Cleaning and Care 11

2.5 Safety Instructions for Trouble Shooting 11

2.6 Notes on Specific Hazards 11

3 Description and Technical Data 12

3.1 Performance Description 12

3.2 Intended Use 12

3.3 Improper Use 12

3.4 Appliance Description 13

3.4.1 View of the appliance - Plate dispenser 13

3.4.2 View of the appliance - Built-in plate dispenser 13

3.4.3 Appliance Description 14

3.4.4 Optional accessories 14

3.5 Technical Data 15

3.6 Rating plate 19

4 Transport, Assembly, Putting into Operation and Decommissioning 20

4.1 Transport 20

4.2 Assembly (Built-in appliances only) 20

4.2.1 Unheated appliances (EBR/V19-26 | EBR/V27-33) 20

4.2.2 Heated appliances (EBRH/V19-26 | EBRH/V27-33 | EBRH-2/19-26) 22

4.3 Putting into Operation 26

4.4 Storage and Recycling 26

5 Operation 27

5.1 Arrangement and Function of the Operating Elements 27

5.2 Plate Dispenser Adjustment 27

5.2.1 Crockery guide adjustment 28

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 1 Introduction

Page 4 Table of Contents

5.2.2 Sp

ring adjustment 29

5.2.3 Calculating the plate dispenser capacity 30

5.3 Operation 31

5.3.1 Switching on the appliance 32

5.3.2 Loading the appliance 32

5.3.3 Moving the appliance 34

5.4 Measures at the End of the Operation 34

6 Fault Detection and Trouble Shooting 35

6.1 Security Measures 35

6.2 Notes on Trouble Shooting 35

6.3 Fault and Action Table 35

7 Cleaning and Care 36

7.1 Security Measures 36

7.2 Hygiene Measures 36

7.3 Cleaning and Care 36

7.4 Special Care Instructions 37

8 Replacement Parts and Accessories 38

8.1 Introduction 38

8.2 Spare Parts and Accessories List 38

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

In

troduction Chapter 1

List of abbreviations Page 5

1.

3 List of abbreviations

Ab

breviation

BG

R

BG

V

CE Co

DI

N

EC Eu

EN Eu

E/

V

IP In

LE

D

De

finition

Ru

le of the Professional Association

Re

gulation of the Professional Association

mmunauté Européenee

Eu

ropean Community

De

utsches Institut für Normung

Ge

rman Institute for Standardisation, technical regulations and technical specifications

ropean Community

Eu

ropean Union

ropean Standard

Ha

rmonised standard for the EU market

Sp

are and wearing part

ternational Protection. The abbreviation IP and a further two-digit index specify the

prot

ection class of a housing.

Th

e first digit: Protection against ingress of solid foreign objects The second digit: Protection against ingress of

wa

ter

0 No

protection against contact, no protec-

ti

on against ingress of solid foreign

obj

ects

1 Pr

otection against contact with any large

su

rface of the body such as the hand,

pr

otection against ingress of foreign

obj

ects >1.97 in

2 Pr

otection against contact with the

fi

ngers, protection against ingress of

fo

reign objects >0.47 in

3 Pr

otection against contact with tools,

th

ick wires or similar objects of >0.1

in

, protection against foreign objects

>0

.1 in

4 Pr

otection against contact with tools,

th

ick wires or similar objects of >0.04

in

, protection against foreign objects

>0

.04 in

5 Pr

otection against contact, protection

agai

nst dust deposits inside

6 Co

mplete protection against contact,

pr

otection against ingress of dust

7 Pr

8 Pr

Li

ght Emitting Diode

Li

ght diode

0 No

protection against ingress of water

1 Pr

otection against vertically falling water

dr

ops

2 Pr

otection against dripping water (at any

angl

e up to 15° from the vertical)

3 Pr

otection against water drips at any

angl

e up to 60° from the vertical

4 Pr

otection against water splashing from

an

y direction

5 Pr

otection against water jets (projected

by

a nozzle) at any angle

6 Pr

otection against temporary flooding

otection against ingress of water

dur

ing temporary immersion

otection against pressurised water

dur

ing continuous immersion

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 1 Introduction

Page 6 Definitions of Terms

1.

4 Definitions of Terms

Te

rm

Au

thorised specialist

Co

ver

Co

ok&Chill-Kitchens

Co

ok&Serve-Kitchens

El

ement formation

Sp

ecialist

Li

ft

Co

ntrol

Co

nvection

Co

rrosion

Ma

chine safety

Pa

ssive layer

Ch

eck

Qu

alified person,

qual

ified staff

Sc

huko®

In

structed persons

De

finition

An

authorised specialist is a specialist that has been trained by the manufacturer, an

aut

horised service dealer or a company assigned by the manufacturer.

A b

ell-shaped cover for keeping food warm on plates and dishes.

"C

ook and Chill": Kitchens where warm food after being cooked is chilled as quickly as

pos

sible.

"C

ook and Serve": Kitchens where warm food is served immediately after being coo-

ke

d or kept warm until it is consumed.

Al

so: contact corrosion. Occurs when different noble metals are in close contact with

eac

h other. This happens when a corrosive medium is between both metals, as for

ex

ample water or even air humidity.

A

specialist is a person who can evaluate work assigned and can individually recog-

ni

se any possible dangers due to the professional training, specialist knowledge and

ex

perience as well as knowledge of the respective guidelines.

A

movement, for example a vertical movement of the guide basket from bottom to top.

Co

mpare with certain conditions and/or characteristics such as damages, leaks, filling

le

vels, heat.

Ph

ysical properties or mass transfer (e.g. heat or cold) through currents in gases and

liq

uids.

Th

e chemical reaction of a metallic material with its surroundings, e.g. rust.

Th

e term of machine safety means all the measures used to avert injury to persons.

Th

e basis for this are national as well as EC-wide valid directives and laws for protect-

in

g users of technical devices and systems.

A n

on-metallic protective layer on a metallic material that prevents or slows down

ma

terial corrosion.

Co

mpare with certain values such as weight, torque, content, temperature.

Qu

alified personnel are persons who due to their professional training, experience and

in

struction as well as their knowledge of the respective standards, guidelines, accident

prev

ention regulations and operating conditions have been authorised by a person

res

ponsible for system safety to carry out required activities and can recognise and

prev

ent any possible danger (definition of specialists according to IEC 364).

Th

e abbreviation of the German term "Protective contact" that indicates a system of

dom

estic plugs and sockets equipped with protective earthed contacts used in most of

Eu

rope.

An

instructed person is a person who has been instructed on the possible risks result-

in

g from improper behaviour when carrying out the assigned task as well as on the

nec

essary protective equipment and protective measures and trained for this task if

nec

essary.

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

In

troduction Chapter 1

Orientation Guide Page 7

1.

5 Orientation Guide

The f

ront

"The front" means the side of the plate dispenser where the push bars are arranged. The operating staff

stays at this side to move the appliance.

The side of the built-in appliances named as "the front" means the side, at which the staff operates the plate

dispenser.

The rear

The side named "the rear" means the opposite side of the front side (the front).

The right

The side named "the right" means the side at the right hand side of the front side (the front).

The left

The side named "the left" means the side at the left hand side of the front side (the front).

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 1 Introduction

Page 8 Notes on Use of Manual

1.

6 Notes on Use of Manual

1.

6.1 Notes on the manual structure

This manual is structured in functional and task orientated chapters.

1.6.2 Notes and their illustrations used in the chapters

DANG

ER Brief description of danger

Th

ere is an imminent danger to life and limb of the user and / or third parties

when the instructions are not followed precisely or the circumstances described are not taken into account.

The type of danger is indicated by a symbol and explained in the accompanying text in more detail. In this example the general sign of danger is used.

WA

RNING Brief description of danger

Th

ere is an indirect danger to life and limb of the user and / or third parties

when the instructions are not followed precisely or the circumstances described are not taken into account.

The type of danger is indicated by a symbol and explained in the accompanying text in more detail. In this example the general sign of danger is used.

AT

TENTION Brief description of danger

Th

ere is a potential risk of injury or damage to property when the instructions

are not followed precisely or the circumstances described are not taken into

account.

The type of danger is indicated by a general sign and explained in the accompanying text in more detail. In this example the general sign of danger is used.

NO

TE Brief description of additional information

At

tention is pointed to special conditions or additional important information on

the respective subject.

IN

FO Short title

Co

ntains additional information on work assisting features or recommenda-

tions on the respective subject.

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Sa

fety Instructions Chapter 2

Introduction Page 9

2 Sa

2.

1 Introduction

fety Instructions

Th

e chapter on safety instructions describes the risks associated with the appliance in terms of product liabil-

ity (according to the EU Directive).

2.2 Warning Symbols Used

Sy

mbols are used in these operating instructions to point out the dangers that can occur while operating or

cleaning the appliance. In both cases, the symbol provides information on the type and circumstances of

danger.

The following symbols can be used:

Ge

neral hazardous area

Ha

zardous electrical voltage

Ri

sk of hand injuries

Ri

sk of squashing

Ri

2.

3 Safety Instructions for Appliance Safety

Sa

fe operation of the appliance depends on appropriate and thorough use. Negligent handling of the appliance can lead to danger to life and limb of the user and / or third parties as well as hazards to the appliance

itself and the other operator's property.

2.3.1 Safety instructions for all appliances

The following points are to be observed to ensure the appliance safety:

sk of hot surfaces

We

ar hand protection

The appliance may only be operated when it is in perfect condition with regards to technical stan-

dards.

All the operating and actuating elements must be in a perfect and functionally reliable condition with

regards to technical standards.

Modifications or retrofits of the equipment are only permitted in consultation with the manufacturer

and on receipt of his written agreement.

In no case may people sit or stand on the appliance. Transport of persons is not permitted.

Before loading, the crockery dispensing height must be adjusted to the kind of crockery used.

The crockery guides must be adjusted to the kind of crockery used before loading.

To avoid injuries to the hands, care should always be taken to ensure that the crockery dispensing

height does not fall below the upper rim of the housing.

Never push the guide basket down manually into the dispensing tube (e.g. for cleaning). There is a

risk of injury, if the guide basket is released.

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 2 Safety Instructions

Page 10 Safety Instructions for Appliance Safety

Th

e appliance is provided exclusively for manual transport. Mechanical transport is not permitted.

Risk of injury and damage.

If a stack of plates with the covers is too high, do not push it down forcibly. There is a risk of injury, if

the locking is released. Furthermore, the locking function of the covers can be damaged.

Release both total brakes before commencing transporting. Moving the appliance with the total bra-

kes locked can damage the chassis

Transport should only be undertaken over level floors. Moving the appliance over very uneven floors

can damage the chassis.

Transport over inclined planes or steps is not permitted.

When approaching walls and moving round obstacles always pay attention to persons in the way.

Risk of injury.

When transporting the appliance, always hold both bars with your hands. Never let go of the appli-

ance while moving it.

When transporting the appliance, do not move it faster than a walking pace. Heavily laden plate dis-

pensers are difficult to brake and steer. If necessary, ask for assistance when transporting the appliance.

If the plate dispenser tips over due to outside influences or inattention, never catch it manually. Risk

of injury.

Do not stop the appliance on sloping floors.

After stopping, the appliance should be secured against rolling away by means of both total brakes

being applied.

In the case of offsite transport in a vehicle such as a lorry, the appliances should be secured properly.

The total brakes are not sufficient as a transport securing method.

2.3.2 Additional safety instructions for heated appliances

The heated appliances can only be operated by instructed specialists and kitchen staff and under

continuous supervision.

Heated plate dispensers are intended for dispensing heated crockery. Their use for cooking food and

keeping it warm or for room heating is not permitted.

The crockery temperatures can exceed the permitted maximum temperatures of 149°F (65°C) for

touchable appliance surfaces. Always wear protective gloves when dispensing hot crockery. Risk of

burning.

During operation of the appliance, never reach into it and touch the heating element with the fingers.

Risk of burning.

Plastic crockery, top and bottom parts of plastic insulated sets and plastic-coated items for keeping

food warm should not be stored or warmed up in heated plate dispensers. Owing to the high temperatures of the heating elements, the plastics can melt and catch fire.

The base plate and used air from the base outlets can become very hot. The appliance should not be

operated on fibre-based floor coverings (e.g. carpets, mats).

Before transporting, switch off the appliance, pull out the mains plug and insert it into the plug park

provided.

Forceful straining of the connecting cable can lead to damage to the internal line. Risk of fire.

Never pull the mains plug out of the socket by the wire. The standard models of HUPFER

ances are equipped with a Schuko® angle plug. In contrast to a straight Schuko® plug this plug only

sticks insignificantly out of the socket and so cannot be damaged by being hit at the side. If the appliance is moved without pulling out the mains plug beforehand, the socket can be severely damaged or

even pulled out from the wall as a result of leverage arising from overstretching of the connecting cable.

Never move the appliance by pulling by the connecting cable.

If the mains plug has come into contact with water it must be dried before inserting it into the socket.

Danger to life.

®

appli-

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Sa

fety Instructions Chapter 2

Safety Instructions for Cleaning and Care Page 11

Da

maged mains plugs or connecting cables are to be replaced by authorised personnel before the

appliance is reused.

Do not use any extension cables in wet and damp areas.

Only insert mains plugs into suitable sockets. If the mains plug does not fit, the connecting cable of

the appliance is to be retrofitted by authorised specialist staff.

The use of socket adapters is not permitted. Risk of fire.

Do not clean the appliance with steam-jet or high-pressure washers. The appliance must be taken

out of operation and switched off at the mains beforehand in any area where steam-jet or highpressure washers are to be used.

2.4 Safety Instructions for Cleaning and Care

Th

e following points shall be observed when carrying out any cleaning and maintenance operations:

For reasons of hygiene the cleaning instructions shall be strictly observed.

Take the appliance out of operation before starting the cleaning process. Pull out the mains plug and

insert it into the plug park located on the appliance.

For cleaning, the appliance must be out of operation and cooled down sufficiently.

Do not clean the appliance with steam-jet or high-pressure washers. The appliance must be taken

out of operation and switched off at the mains beforehand in any area where steam-jet or highpressure washers are to be used.

Even appliances without an electrical connection should not be cleaned with running water or pres-

surised water.

2.5 Safety Instructions for Trouble Shooting

Th

e following points shall be observed when carrying out any maintenance and trouble shooting operations:

All trouble shooting work should only be carried out by authorised specialists.

When carrying out trouble shooting work, it must be ensured that the appliance is switched off. When

operating on the electrical installation, the appliance is to be switched off at the mains and secured

against reactivation.

The local applicable Accident Prevention Regulations must be observed.

Defective components should only be replaced with original parts.

2.6 Notes on Specific Hazards

El

ectrical energy

All work on the electrical installations should only be carried out by a certified electrician or by author-

ised specialists under supervision and monitoring of a certified electrician according to the certain electro-technical regulations.

The appliances that inspection, maintenance and trouble shooting work is performed on must be

switched voltage free on and secured against reactivation, when the voltage is not required for this

kind of work. This must only be carried out by a certified electrician.

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 3 Description and Technical Data

Page 12 Performance Description

3 Des

3.

1 Performance Description

cription and Technical Data

Pl

ate dispensers are intended for storage of clean crockery items ready for use in the food service industry

and large-scale catering establishments. They are used mainly for storage of warmed crockery ready for use

on food distribution belts and storage of plates at normal temperature or chilled on self-service counters in

bistros or cafeterias.

There are various models available for selection. Depending upon the size and number of crockery items,

the plate dispensers are available in two sizes, 19-26 (for plates with a diameter of 7.48'' to 10.24'') and 2733 (for plates with a diameter of 10.63'' to 13'').

The unheated models with the enclosed side and front walls of the housing store crockery items ready for

use for serving portions of cold dishes.

The unheated models with cooling slots store crockery ready for serving portions of cold side dishes, e.g. salads and desserts.

The models heated by air circulation are intended for storage of crockery ready for serving portions of warm

components. The crockery can be heated up to 212°F (100°C).

Besides the mobile plate dispensers, there are plate dispensers intended for installation in worktops.

3.2 Intended Use

Pl

ate dispensers are intended exclusively for storage of clean plates with diameter of 7.48'' to 10.24'' or

10.63'' to 13'' ready for use. Depending on the model, the loaded plates can be cooled down or heated up.

The appliances are intended for transporting round china items or transport made of toughened glass.

Transport of other loads is not permitted.

The intended use means the predetermined procedures, compliance with the indicated specifications and

use of the delivered or additionally available original accessories.

Any other use of the appliance is considered as unintended use.

3.3 Improper Use

It i

s not permitted to load the plate dispenser with other loads as given.

In no case may people sit or stand on the appliance or be transported on it.

Moreover, it is not permitted to use the heated plate dispensers for cooking food or keeping it warm and for

room heating.

No flammable or outgasing objects, objects with plastic items or foodstuff should be stored under the plate

dispenser.

No liability is assumed and no warranty claims can be submitted for damages caused by improper use.

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

De

scription and Technical Data Chapter 3

Appliance Description Page 13

3.

4 Appliance Description

3.

4.1 View of the appliance - Plate dispenser

Fi

gure 1 View of the appliance

1 Push bar 7 Casters without total brakes

2 Thermostat for setting the temperature* 8 Corner bumpers

3 On / Off switch* 9 Guide basket

4 Plug park (dummy socket)* 10 Crockery guide

5 Connecting cable with mains plug* 11 Cover*

6 Casters with total brakes

* heated appliances only

3.4.2 View of the appliance - Built-in plate dispenser

Fi

gure 2 View of the appliance

1 Crockery guide 5 Locking positions for the crockery guide

2 Guide basket 6 Connecting socket for appliance plug*

3 Attachment bar with adjustable springs 7 Thermostat*

4 Guide rail 8 Cover*

* heated appliances only

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 3 Description and Technical Data

Page 14 Appliance Description

3.

4.3 Appliance Description

The plate dispensers accommodate clean chinaware and plates made of toughened glass in a adjustable,

spring-loaded guide basket. Owing to the use of special springs, crockery items are moved automatically

and constantly over the entire lift upwards to a uniform dispensing height.

If necessary, there are various models available. A plate dispenser model 19-26 is particularly suitable for

plates with diameter of 7.48'' to 10.24''. A plate dispenser model 27-33 is particularly suitable for plates with

diameter of 10.63'' to 13''.

All the plate dispensers are universally adjustable appliances suitable for the plate diameters, stack heights

and weights given above. The ergonomically favourable dispensing height can be adjusted within a limit to

persons of different height. Plate dispensers are available as one-tube and two-tube models.

Unheated appliances with enclosed side and front walls store crockery at normal temperature ready for use.

Unheated appliances with cooling slots are particularly suitable to be used in cold stores. When using in the

cold store, the cooling slots arranged on the side and front walls of the appliance housing ensure a rapid exchange of air and cause the cold air to be distributed uniformly inside.

The appliances with electric heating (static or circulating air) pre warm the plates or heat them up to a pre-set

temperature.

Besides the mobile plate dispensers, there are built-in plate dispensers intended for installation in worktops.

Depending on the purpose, the built-in appliances are available in different sizes, as one and two-tube models and heated or unheated.

The operating temperature can be continuously set on the heated plate dispensers. The controller is arranged on the front of the housing and can be adjusted as required when using built-in appliances.

The covers made of plastic protect the crockery against dust and condensed water even during relatively

long periods of temporary storage. Using a cover in the heated appliances lowers the heat loss upwards and

reduces the heating time of the inserted crockery or delays the cooling of pre-warmed crockery. The cover is

included in the scope of delivery of the heated models.

3.4.4 Optional accessories

The following parts can be applied as optional accessories for the plate dispenser:

Plastic cover 7.48''-10.24'' high for plate dispenser model 19-26

Plastic cover 7.48''-10.24'' flat for TEUH-2/VC 19-26 (not suitable for other models)

Plastic cover 10.63''-13' for plate dispenser model 27-33

Swivel casters made of stainless steel, Ø = 4.92'' with and without total brakes, plate attachment

The part numbers of the special accessories can be found in the spare parts catalogue a nd order lists available online.

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

De

scription and Technical Data Chapter 3

Technical Data Page 15

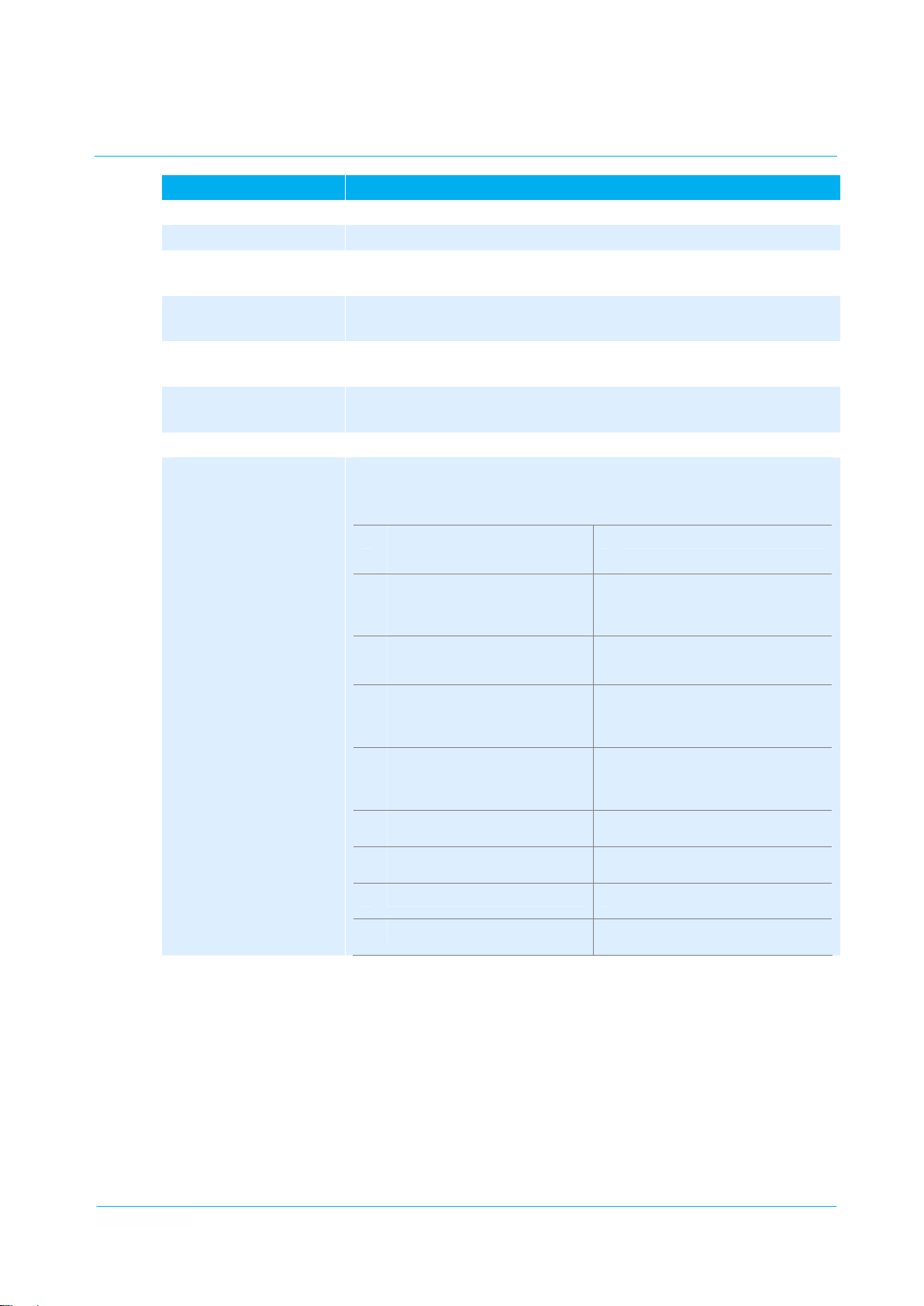

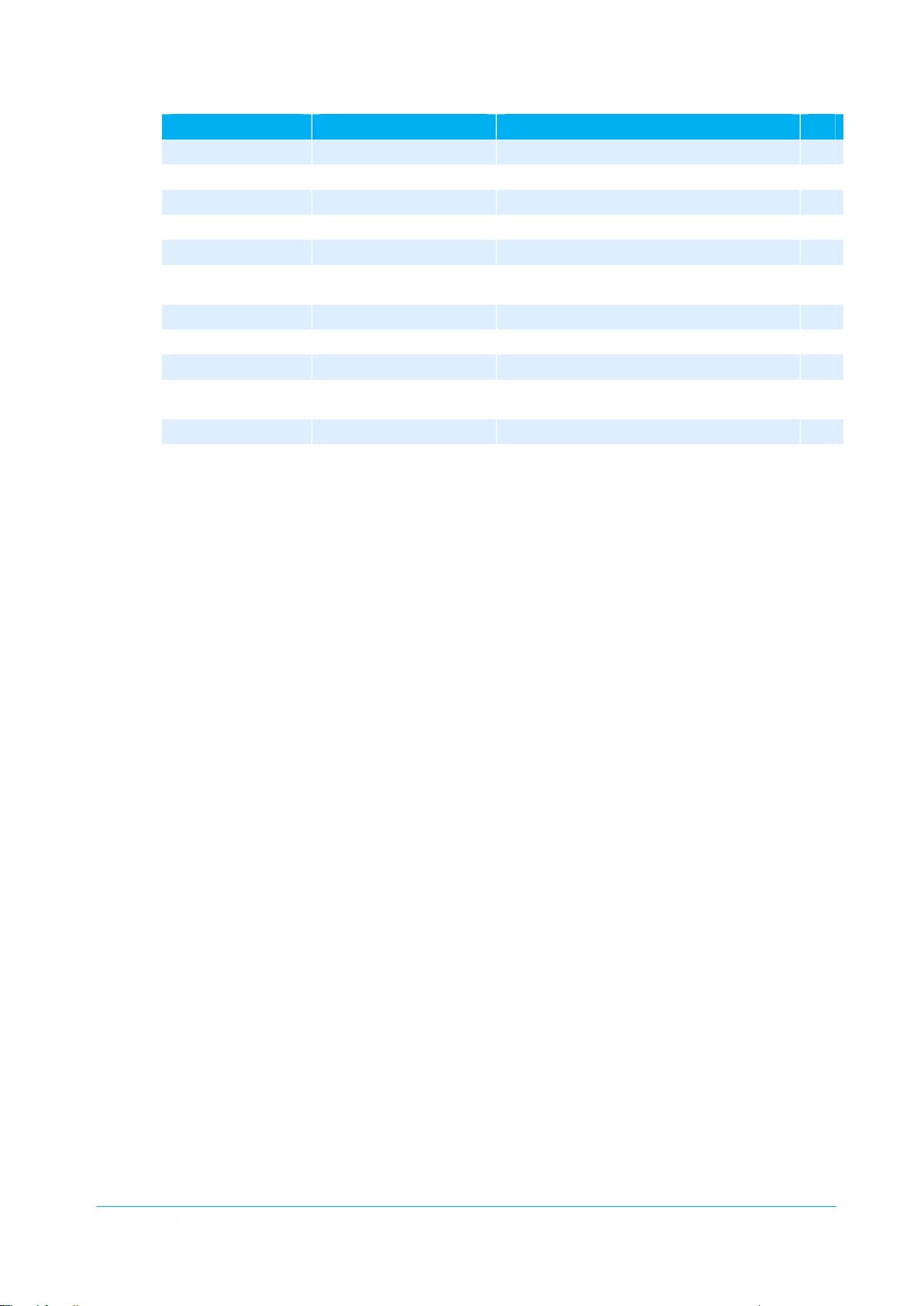

3.

5 Technical Data

Di

Vi

ew of the

appl

iance

Pl

Ow

n weight

Pa

yload

Pe

rmitted total

we

ight

Ov

erall dimen-

si

ons

w

x d x h

Op

erating and

am

bient condi-

ti

ons

Ch

assis

Cro

ckery guide

Gu

ide basket

Sta

ck height

wi

thout cover

Sta

ck height with

co

ver

Cro

ckery size

Ca

pacity given in

it

ems (depending

on

the stack

hei

ght)

Nu

mber of cro-

cke

ry stacks

m.

kg

(lbs)

kg

(lbs)

kg

(lbs)

mm

(i

n)

˚C

(˚F)

mm

(i

n)

3

mm

(i

n)

mm

(i

n)

mm

(i

n)

mm

(i

n)

up

2 2 2

TE-2/

V19-26

ate dispenser, unheated

and

without cooling device

31 (

68.3)

140 (

308.6)

171 (

377)

460

(18.11'') x 935 (36.81'')

x

900 (35.43'')

-20

(-4) to 50 (+122)

4

swivel casters, 2 of them

wi

th total brakes, Ø 125

mm

(5'')

adjustable guides per

tu

be, plastic-coated

Ro

d construction, plastic-

co

ated

670 (

26.37’’)

740 (

29.13’’)

190-260 (

and

7.48’’-10.24’’)

to 144 (without cover)

166 (with cover)

TE-2/

V27-33

Pl

ate dispenser, unheated

and

without cooling device

32 (

70.5)

140 (

308.6)

172 (

379)

530

(20.86'') x 1055

(41.

53'') x 900 (35.43'')

-20

(-4) to 50 (+122)

4

swivel casters, 2 of them

wi

th total brakes, Ø 125 mm

(5'

')

3

adjustable guides per

tu

be, plastic-coated

Ro

d construction, plastic-

co

ated

670 (

26.37’’)

740 (

29.13’’)

270-330 (

up

and

10.63’’-13’’)

to 106 (without cover)

122 (with cover)

TE

/-2/VK19-26

Pl

ate dispenser, unheated

wi

th cooling device

29 (

64)

140 (

308.6)

169 (

372.6)

460

(18.11'') x 935 (36.81'')

x

900 (35.43'')

-20

(-4) to 50 (+122)

4

swivel casters, 2 of them

wi

th total brakes, Ø 125 mm

(5'

')

3

adjustable guides per

tu

be, plastic-coated

Ro

d construction, plastic-

co

ated

670 (

26.37’’)

740 (

29.13’’)

190-260 (

up

and

7.48’’-10.24’’)

to 144 (without cover)

166 (with cover)

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 3 Description and Technical Data

Page 16 Technical Data

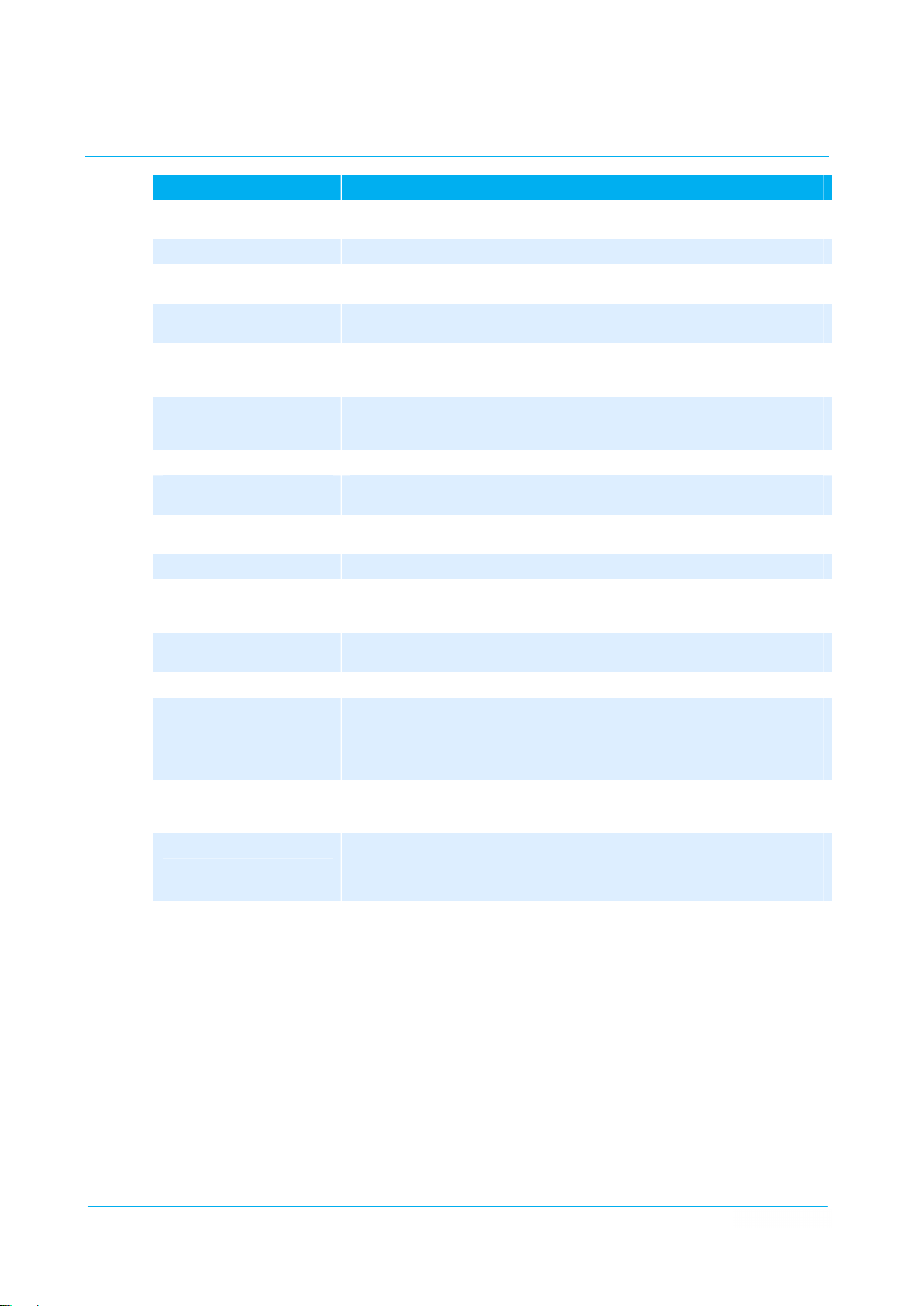

Di

Vi

ew of the appliance

m. TEH-1/V19-26

TE

H-1/V27-33

TE

H-2/V19-26

TE

H-2/V27-33

Pl

Ow

n weight

Pa

yload

Pe

rmitted total weight kg

Ov

erall dimensions

w

x d x h

Op

erating and ambi-

ent

conditions

Ch

assis

Cro

ckery guide

Gu

ide basket

Sta

ck height without

co

ver

Sta

ck height with

co

ver

Cro

ckery size

Ca

pacity given in

it

ems (depending on

th

e stack height)

Nu

mber of crockery

sta

cks

He

ating

Th

ermostat setting

Ma

ximum crockery

te

mperature

Te

mperature regula-

ti

on

He

at insulation

El

ectrical connection

Po

wer requirement

Pr

otection class

kg

(l

bs)

kg

(l

bs)

(l

bs)

mm

(i

n)

˚C

(˚F

)

mm

(i

n)

3

mm

(i

n)

mm

(i

n)

mm

(i

n)

mm

(i

n)

up

1 1 2 2

Sta

˚C

(˚F

)

˚C

(˚F

)

co

ce

230

kW 0,

IPX

ate dispenser,

heat

ed

30 (

66.13)

70 (

154.32)

100 (

220.46)

460

(18.11'') x 610

(24'

') x 900

(35.

43'')

-20

(-4) to 50

(+

122)

4

swivel casters, 2

of

them with total

brak

es, Ø 125 mm

(5'

')

adjustable guides

per

tube, plastic-

co

ated

Ro

d construction,

pl

astic-coated

670 (26.

37’’)

740 (

29.13’’)

190-260 (

10.

24’’)

7.48’’-

to 72 (without

co

ver) and 83 (with

co

ver)

inless steel

tu

bular heating

el

ement

30-115 (

86-239)

70 (

158)

ntinuous

ramic mat

V 1N AC 50

Hz

9

5

Pl

ate dispenser,

heat

ed

35 (

77.16)

80 (

176.36)

115 (

253.53)

530

(20.86'') x 710

(28.

'') x 900

(35.

43'')

-20

(-4) to 50

(+

122)

4

swivel casters, 2

of

them with total

brak

es, Ø 125 mm

(5'

')

3

adjustable guides

per

tube, plastic-

co

ated

Ro

d construction,

pl

astic-coated

670 (26.

37’’)

740 (

29.13’’)

270-330 (

13’

’)

up

co

ver) and 61 (with

co

ver)

Sta

tu

bular heating

el

ement

30-115 (

70 (

co

ntinuous

ce

ramic mat

230

Hz

0,

9

IPX

10.63’’-

to 53 (without

inless steel

86-239)

158)

V 1N AC 50

5

Pl

ate dispenser,

heat

ed

41 (

90.38)

140 (

308.64)

181 (

399)

460

(18.11'') x 935

(36.

81'') x 900

(35.

43'')

-20

(-4) to 50

(+

122)

4

swivel casters, 2

of

them with total

brak

es, Ø 125 mm

(5'

')

3

adjustable guides

per

tube, plastic-

co

ated

Ro

d construction,

pl

astic-coated

670 (26.

37’’)

740 (

29.13’’)

190-260 (

10.

up

co

ver) and 166

(w

ith cover)

Sta

tu

bular heating

el

ement

30-115 (

80 (

co

ntinuous

ce

ramic mat

230

7.48’’-

24’’)

to 144 (without

inless steel

86-239)

176)

V 1N AC 50

Hz

0,

9

IPX

5

Pl

ate dispenser,

heat

ed

51 (

112.43)

140 (

308.64)

191 (

421)

530

(20.86'') x

1055

(41.53'') x

900

(35.43'')

-20

(-4) to 50

(+

122)

4

swivel casters, 2

of

them with total

brak

es, Ø 125 mm

(5'

')

3

adjustable guides

per

tube, plastic-

co

ated

Ro

d construction,

pl

astic-coated

670 (26.

37’’)

740 (

29.13’’)

270-330 (

13’

’)

up

co

ver) and 122

(w

ith cover)

Po

wer module

30-115 (

80 (

co

ntinuous

ce

ramic mat

230

Hz

1,

5

IPX

10.63’’-

to 106 (without

86-239)

176)

V 1N AC 50

5

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

De

scription and Technical Data Chapter 3

Technical Data Page 17

Di

Vi

ew of the appliance

Pl

Ow

n weight

Pa

yload

Pe

rmitted total weight kg

Ov

erall dimensions

w

x d x h

Op

erating and ambi-

ent

conditions

Ch

assis

Cro

ckery guide

Gu

ide basket

Sta

ck height without

co

ver

Sta

ck height with

co

ver

Cro

ckery size

Ca

pacity given in

it

ems (depending on

th

e stack height)

Nu

mber of crockery

sta

cks

He

ating

Th

ermostat setting

Ma

ximum crockery

te

mperature

Te

mperature regula-

ti

on

He

at insulation

El

ectrical connection

Po

wer requirement

Pr

otection class

m. TEUH-1/VS19-26

kg

(l

bs)

kg

(l

bs)

(l

bs)

mm

(i

n)

˚C

(˚F

)

mm

(i

n)

3

mm

(i

n)

mm

(i

n)

mm

(i

n)

mm

(i

n)

up

1 2 2 2

Po

˚C

(˚F

)

˚C

(˚F

)

co

sp

230

kW 1,

IPX

ate dispenser,

heat

ed

39 (

86)

70 (

154.32)

109 (

240.3)

510

(20'') x 610

(24'

') x 900

(35.

43'')

-20

(-4) to 50

(+

122)

4

swivel casters, 2

of

them with total

brak

es, Ø 125 mm

(5'

')

adjustable guides

per

tube, plastic-

co

ated

Ro

d construction,

pl

astic-coated

670 (26.

37’’)

740 (

29.13’’)

190-260 (

10.

24’’)

to 72 (without

co

ver) and 83 (with

co

ver)

wer module

20-110 (

80 (

176)

ntinuous

ecial insulation

V 1N AC 50

Hz

5

5

7.48’’-

68-230)

TE

UH-2/VS19-26

Pl

ate dispenser,

heat

ed

55 (

121.25)

140 (308.

195 (

510

(37.

(35.

-20

(+

4

of

brak

(5'

3

per

co

Ro

pl

670 (

740 (

190-260 (

10.

up

co

(w

Po

20-110 (

80 (

co

sp

230

Hz

1,

IPX

64)

430)

(20'') x 960

8'') x 900

43'')

(-4) to 50

122)

swivel casters, 2

them with total

es, Ø 125 mm

')

adjustable guides

tube, plastic-

ated

d construction,

astic-coated

26.37’’)

29.13’’)

7.48’’-

24’’)

to 144 (without

ver) and 166

ith cover)

wer module

68-230)

176)

ntinuous

ecial insulation

V 1N AC 50

5

5

TE

UH-2/VC19-26

Pl

ate dispenser,

heat

ed

55 (

121.25)

140 (

308.64)

195 (

430)

510

(20'') x 960

(37.

8'') x 900

(35.

43'')

-20

(-4) to 50

(+

122)

4

swivel casters, 2

of

them with total

brak

es, Ø 125 mm

(5'

')

3

adjustable guides

per

tube, electro-

pol

ished

Ro

d construction,

el

ectropolished

585 (

23’’)

615 (

24.21’’)

190-260 (

10.

24’’)

up

to 130 (without

co

ver) and 138

(w

ith cover)

Po

wer module

20-130 (

100 (

co

ntinuous

sp

ecial insulation

230

Hz

2,

0

IPX

7.48’’-

68-266)

212)

V 1N AC 50

5

EBR

H-2/V19-26

Bu

ilt-in plate dis-

pens

er, heated

27 (

59.5)

140 (

308.64)

157 (

346)

626

(36.45'') x 435

(17.

12'') x 650

(25.

6'')

-20

(-4) to 50

(+

122)

-

3

adjustable guides

per

tube, plastic-

co

ated

Ro

d construction,

pl

astic-coated

455 (

17.9’’)

555 (

21.85’’)

190-260 (

10.

up

co

ver) and 140

(w

ith cover)

Sta

tu

bular heating

el

ement

30-115 (

70 (

co

ntinuous

ce

ramic mat

230

Hz

1,

0

IPX

7.48’’-

24’’)

to 120 (without

inless steel

86-239)

158)

V 1N AC 50

4

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 3 Description and Technical Data

Page 18 Technical Data

Di

Vi

ew of the appliance

Bu

Ow

n weight

Pa

yload

Pe

rmitted total weight kg

Ov

erall dimensions

Ø

x h

Op

erating and ambi-

ent

conditions

Cro

ckery guide

Gu

ide basket

Sta

ck height without

co

ver

Sta

ck height with

co

ver

Cro

ckery size

Ca

pacity given in

it

ems

(dependi

sta

Nu

sta

He

Th

Ma

te

Te

ti

He

El

Po

Pr

ng on the

ck height)

mber of crockery

cks

ating

ermostat setting

ximum crockery

mperature

mperature regula-

on

at insulation

ectrical connection

wer requirement

otection class

EBR

m.

kg

(l

bs)

kg

(l

bs)

(l

bs)

mm

(i

n)

˚C

(˚F

)

3

mm

(i

n)

mm

(i

n)

mm

(i

n)

mm

(i

n)

up

2 2 2 2

- - Sta

˚C

(˚F

)

˚C

(˚F

)

- - co

- - ce

- - 230

kW - - 0,

- - IPX

/V19-26

ilt-in plate dis-

pens

er, unheated

6 (

13.22)

55 (

121.25)

61 (

134.48)

400

(15.74'') x 650

(25.

6'')

-20

(-4) to 50

(+

122)

adjustable guides

per

tube, plastic-

co

ated

Ro

d construction,

pl

astic-coated

495 (19.

49’’)

630 (

24.8’’)

190-260 (

10.

24’’)

to 72 (without

co

ver) and 83 (with

co

ver)

7.48’’-

- - 20-85 (

- - 80 (

EBR

/V27-33

Bu

ilt-in plate dis-

pens

er, unheated

7 (

15.43)

60 (

132.28)

67 (

147.7)

470

(18.5'') x 650

(25.

6'')

-20

(-4) to 50

(+

122)

3

adjustable guides

per

tube, plastic-

co

ated

Ro

d construction,

pl

astic-coated

495 (19.

49’’)

630 (

24.8’’)

270-330 (

13’

’)

up

co

ver) and 52 (with

co

ver)

10.63’’-

to 44 (without

EBRH/

Bu

ilt-in plate dis-

pens

14 (

30.86)

55 (

121.25)

69 (

152.11)

400

(15.74'') x 650

(25.

6'')

-20

(-4) to 50

(+

122)

3

adjustable guides

per

tube, plastic-

co

ated

Ro

d construction,

pl

astic-coated

495 (19.

630 (

190-260 (

10.

24’’)

up

to 144 (without

co

ver) and 166

(w

ith cover)

inless steel

tu

bular heating

el

ement

176)

ntinuous

ramic mat

V 1N AC 50

Hz

6

4

Th

e corresponding test marks can be found on our home page at www.hupfer.de.

V19-26

er, heated

49’’)

24.8’’)

7.48’’-

68-185)

EBR

H/V27-33

Bu

ilt-in plate dis-

pens

er, heated

17 (

37.47)

60 (

132.28)

77

(169.75)

470

(18.5'') x 650

(25.

6'')

-20

(-4) to 50

(+

122)

3

adjustable guides

per

tube, plastic-

co

ated

Ro

d construction,

pl

astic-coated

495 (19.

49’’)

630 (

24.8’’)

270-330 (

13’

’)

up

co

ver) and 122

(w

ith cover)

Sta

tu

bular heating

el

ement

20-85 (

80 (

co

ntinuous

ce

ramic mat

230

Hz

0,

6

IPX

10.63’’-

to 106 (without

inless steel

68-185)

176)

V 1N AC 50

4

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

De

scription and Technical Data Chapter 3

Rating plate Page 19

3.

6 Rating plate

Fi

gure 3 Rating plate

1 Disposal of old appliances 9 Nominal current

2 Certificate/Label 10 Frequency

3 Protection class 11 Nominal voltage

4 Chilling capacity 12 Payload

5 Refrigerant 13 Own weight

6 Induction frequency 14 Serial number/Order number

7 Current serial number 15 Item and brief description

8 Electric power 16 Manufacturer

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 4 Transport, Assembly, Putting into Operation and Decommissioning

Page 20 Transport

4 Trans

sio

ning

4.

1 Transport

4.

2 Assembly (Built-in appliances only)

Th

e following section describes the assembly of the built-in plate dispenser.

Primarily, the unheated appliances EBR/V19-26 and EBR/V27-33 are described that do not require any electrical installations after the assembly.

Subsequently, there follows the assembly description of the heated appliances EBRH/V19-26, EBRH/V27-33

and EBRH-2/19-26 that must be connected to the power supply after the assembly.

port, Assembly, Putting into Operation and Decommis-

AT

TENTION Appliance damages caused by improper transport

In

the case of offsite transport in a vehicle such as a lorry, the appliances

should be secured properly. The total brakes are not sufficient as a transport

securing method.

If the appliances are not secured properly, there is a risk of damage to property and persons caused by squashing.

During transport, secure all the individually standing appliances using corresponding transport securing devices.

4.2.1 Unheated appliances (EBR/V19-26 | EBR/V27-33)

NO

TE Appliance location

Figur

e 4 Worktop cut-out EBR/V19-26

Bu

ilt-in appliances may only be used after being retrofitted or built-in (e.g. in a

cabinet).

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Tr

ansport, Assembly, Putting into Operation and Decommissioning Chapter 4

Assembly (Built-in appliances only) Page 21

Figur

e 5 Worktop cut-out EBR/V27-33

Step 1: Preparation

Prepare cut-outs in the worktop corresponding to the indicated dimensions.

The worktop cut-out dimensions are given in mm as shown in the drawing.

Remove the protective plastic film from the metal plates.

Step 2: Installation

EBR/V19-26

Insert the appliance into the worktop cut-out from above and fasten it.

Figur

e 6 Assembly instructions EBR/V19-26

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 4 Transport, Assembly, Putting into Operation and Decommissioning

Page 22 Assembly (Built-in appliances only)

EB

R/V27-33

Insert the appliance EBR/V27-33 into the worktop cut-out from above and fasten it.

Figur

e 7 Assembly instructions EBR/V27-33

4.2.2 Heated appliances (EBRH/V19-26 | EBRH/V27-33 | EBRH-2/19-26)

DANG

ER Hazardous electrical voltage

Th

e electrical voltage may be considerably dangerous to limb and life of per-

sons and lead to injuries.

All work on the electrical installations should only be carried out by a certified

electrician or by authorised specialists under supervision and monitoring of a

certified electrician according to the certain electro-technical regulations.

AT

TENTION Risk of hot surfaces

Th

e internal surfaces and base plates of the heated appliances can become

hot during and/or after the operation. The heated appliances should not come

into contact with light inflammable materials.

Ensure that there is enough space between the housing and cladding required for air circulation.

NO

TE Appliance location

Th

e built-in appliances may only be put into operation after being retrofitted or

built-in (e.g. in a cabinet).

Th

ere is a connecting cable set with a wiring diagram attached to the built-in heated appliances.

The set consists of a connecting cable with a Schuko® plug and a connecting cable with an appliance plug

arranged on the appliance. The connecting cables are wired up via the on/off switch with an integrated indicator light.

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Tr

ansport, Assembly, Putting into Operation and Decommissioning Chapter 4

Assembly (Built-in appliances only) Page 23

Figur

e 8 Worktop cut-out EBRH/V19-26

Figur

e 9 Worktop cut-out EBRH/V27-33

Figur

e 10 Worktop cut-out EBRH-2/V19-26

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 4 Transport, Assembly, Putting into Operation and Decommissioning

Page 24 Assembly (Built-in appliances only)

Ste

p 1: Preparation

Prepare cut-outs in the worktop and the front cladding corresponding to the indicated dimensions.

The worktop cut-out dimensions are given in mm as shown in the corresponding drawing of the builtin appliance.

The cut-out dimension for the switch is 1.18'' x 0.87''.

Remove the protective plastic film from the metal plates.

Step 2: Installation

NO

TE Presetting the operating temperature

Ins

ert the appliance into the worktop cut-out and fasten it.

In

contrast to the mobile appliances with the switch and controller arranged

next to each other, the switch of the built-in appliance can be placed anywhere on the front side.

Under these circumstances, the controller is no longer accessible for operating after the installation. Ensure that the desired temperature is set on the

thermostat before the installation.

Figur

e 11 Assembly instructions EBRH/V19-26

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Tr

ansport, Assembly, Putting into Operation and Decommissioning Chapter 4

Assembly (Built-in appliances only) Page 25

Figur

e 12 Assembly instructions EBRH/V27-33

Figur

e 13 Assembly instructions EBRH-2/V19-26

Step 3: Connect

Connect the appliance according to the wiring diagram: Insert the appliance plug of the connecting

cable set into the socket of the plate dispenser and the mains plug of the connecting cable set into the

on-site existing power supply socket.

Put thermally insulating plates around the appliance.

The appliance is ready to be put into operation.

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 4 Transport, Assembly, Putting into Operation and Decommissioning

Page 26 Putting into Operation

4.

3 Putting into Operation

Be

fore the appliance is put into operation it must be clean and dry. Before the first use of the appliance, re-

move the protective plastic film from the metal plates.

The following appliance functions must be checked before putting it into operation:

In the mobile appliances: the function of the total brake.

In the heated appliances: the function of the operating elements and heating.

IN

FO Disposal of packing material

4.

4 Storage and Recycling

Te

mporary storage must take place in a dry and frost-free environment. The plate dispenser must be kept

covered with a suitable covering material to be protected against dust ingress.

The plate dispenser kept in the storage location must be checked for damages and corrosion every 6

months.

Th

e packing consists of recyclable materials and can be disposed of appropriately. Thereby, the different materials are to be separated and disposed in

an environmentally compatible manner. In any case, the local bodies responsible for disposal are to be involved for this purpose.

NO

TE Condensed water formation

Be

fore the appliance is taken back into operation it must be clean and dry.

If the plate dispenser is required to be recycled, all the heating devices (if available) must be removed safely

and completely, the recyclable materials must be separated properly and disposed in an environmentally

compatible manner according to the Waste Disposal regulations.

In any case, the local bodies responsible for disposal are to be involved for this purpose.

En

sure that there is sufficient ventilation and no l arge temperature fluctuations

in the storage location to avoid condensed water formation.

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Op

eration Chapter 5

Arrangement and Function of the Operating Elements Page 27

5 Op

5.

1 Arrangement and Function of the Operating Elements

eration

Th

e operating elements are located on the front of the housing of the heated plate dispensers.

Figur

e 14 Operating elements

The desired temperature can be set on the thermostat. A continuous adjustment is possible within the 4 power ranges. The On / Off switch of the appliance is arranged next to it. An indicator light integrated into the

switch shows, whether the appliance is ready to be operated.

5.2 Plate Dispenser Adjustment

WA

Th

e adjustments should only be carried out on the appliances which are switched off, disconnected from the

power supply and cooled down (room temperature).

Before work starts, it is always necessary to check whether the plate dispenser to be operated is correctly

set for the crockery to be used.

The following functions are to be checked separately:

The vertical guide of the plates, in order to prevent any risk of injury to the operating staff if the crock-

The dispensing height, so that the staff cannot suffer injury or become trapped and no breakage of

Basically, the appliance must be adjusted if at least one of the following crockery parameters alters:

Diameter

Height

Stack height

Weight.

RNING Risk of hot surfaces

Th

e internal surfaces of the heated appliances and the base plates can be-

come hot during operation and only cool down slowly in the air.

ery guides are set too far apart or too close together.

crockery can occur.

To adjust the guide basket, allow the appliance to cool down sufficiently with

the cover removed.

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 5 Operation

Page 28 Plate Dispenser Adjustment

5.

2.1 Crockery guide adjustment

Before loading, the crockery guides must be adjusted to the diameter of the crockery items and fixed in the

locking positions provided.

If the crockery guides are set too far apart from each other, the crockery stack can become wedged under

the upper plate due to the possible high tilt angles, and can injure the operating staff when released.

If the crockery guides are set too close, the plates can become jammed and can injure people when released suddenly.

Too small crockery items cannot be guided properly and, therefore, should not be used.

Adjustment of crockery guides

Figur

e 15 Crockery guides

Release the crockery guides (A) out of the locking position by lifting them and put them on the outer-

most position.

Load a stack of 10 to 12 plates on the guide basket.

Turn the crockery guides (A) and fix them in the corresponding locking position with respect to the

crockery diameter. Check by pressing slightly the crockery stack, whether it can move easily on its

guide without rocking.

All three crockery guides must be fixed in the same locking positions to ensure uniform loading of the

guide basket.

After the appliance is loaded and before transport begins, the guide rails must be checked again

manually to ensure that they are fixed.

Adjust retaining bolts

Figur

e 16 Retaining bolts

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Op

eration Chapter 5

Plate Dispenser Adjustment Page 29

If i

t is necessary to alternate between the rows of holes in the plate dispenser model 27-33 (except

TEUH-2VC27-33), the upper holders of the crockery guides must also be inserted into the available

holes. When using TEUH-2VC, the holders of the crockery guide will be fitted respectively on to the

other retaining bolts (B).

Remove the crockery guides in the area of the retaining bolts (B) by pressing them down slightly and

fit them onto the other retaining bolts (B).

NO

TE Crockery diameters

5.

2.2 Spring adjustment

AT

TENTION Damage to persons and property due to improper adjustment

Th

e following crockery diameters can be set with the locking positions pro-

vided:

Plate dispenser Type 19-26: 7.48'' / 8.46'' / 9.25'' / 10.24'' (the first row of

holes)

Plate dispenser Type 27-33: 10.63'' / 11.81'' / 13'' (the first row of holes)

11.02'' / 12.6'' (the second row of holes)

Wh

en the dispensing height is exceeded, there is a risk of accident or injury

due to tipping of the crockery stack and breakage of dishes. If the level falls

below the dispensing height, injuries to the fingers due to squashing can occur when removing dishes.

Adjust appropriately the dispensing height by hooking or unhooking the

springs. When adjusting springs on sharp edges, pay particular attention to

the ends of the tension springs. Act carefully.

NO

TE Guide basket

It i

s not necessary to dismantle the guide basket in order to adjust the springs.

It

should only be dismantled by specialist staff and, moreover, it is not possi-

ble do this from above without a tool.

Be

fore loading the appliance, the dispensing height must be adjusted to the kind of crockery used. The dispensing height is adjusted by hooking or unhook ing tension springs. So long as the same kind of plates is

always used, the dispensing height only needs to be set once.

The dispensing height must be adjusted so that over the entire lift the uppermost item of crockery is constantly moved upwards to a uniform dispensing height between 1.57'' and 2.36'' above the upper rim of the

housing.

Step 1 - Checking the spring adjustment

Load a stack of 15 to 20 items on the guide basket to test the dispensing height.

Wait for a reaction.

If the dispensing height of the crockery stack is about 1.97’’ above the upper rim of the appliance, the spring

system is adjusted correctly.

If the crockery stack drops down only a little or not at all, the dispensing height must be altered by adjusting

the springs.

Step 2 - Altering the spring adjustment

The dispensing height is adjusted by hooking or unhooking tens ion springs on two attachment bars. The

springs are arranged in groups of 5, where 1 to 2 are base springs with higher tension (1) and 4 are adjustable springs (2) with lower tension.

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

1-n

apter 5 Operation

Page 30 Plate Dispenser Adjustment

Figur

e 17 Attachment bar with tension springs

If the dispensing height is too high, adjustable springs must be unhooked.

If the dispensing height is too low, adjustable springs must be added.

Procedure for setting the springs:

Take the inserted crockery items out of the plate dispenser (if available).

Hook or unhook adjustable springs uniformly in all groups of springs.

Preferably unhook the adjustable springs. Always leave the base springs inserted, if possible. Always

unhook the springs on the lower attachment bar.

Both steps must be repeated as often as possible, until the dispensing height is in the range from 1.57'' to

2.36''. So long as the same kind of crockery is always used, the dispensing height only needs to be set once.

NO

TE Arrangement of the springs

For

guiding the guide basket uniformly and without friction, a symmetrical

arrangement of springs between the attachment bars is necessary.

A slightly asymmetrical arrangement of springs within an attachment bar does

not pose any problem.

NO

TE Spring system

Si

nce all the plate dispensers are designed for a maximum crockery load, the

available spring system of the appliances is entirely sufficient for all usual

market plates.

Owing to the base springs with higher tension, the unheated plate dispensers

are also unsuitable for plastic items.

5.

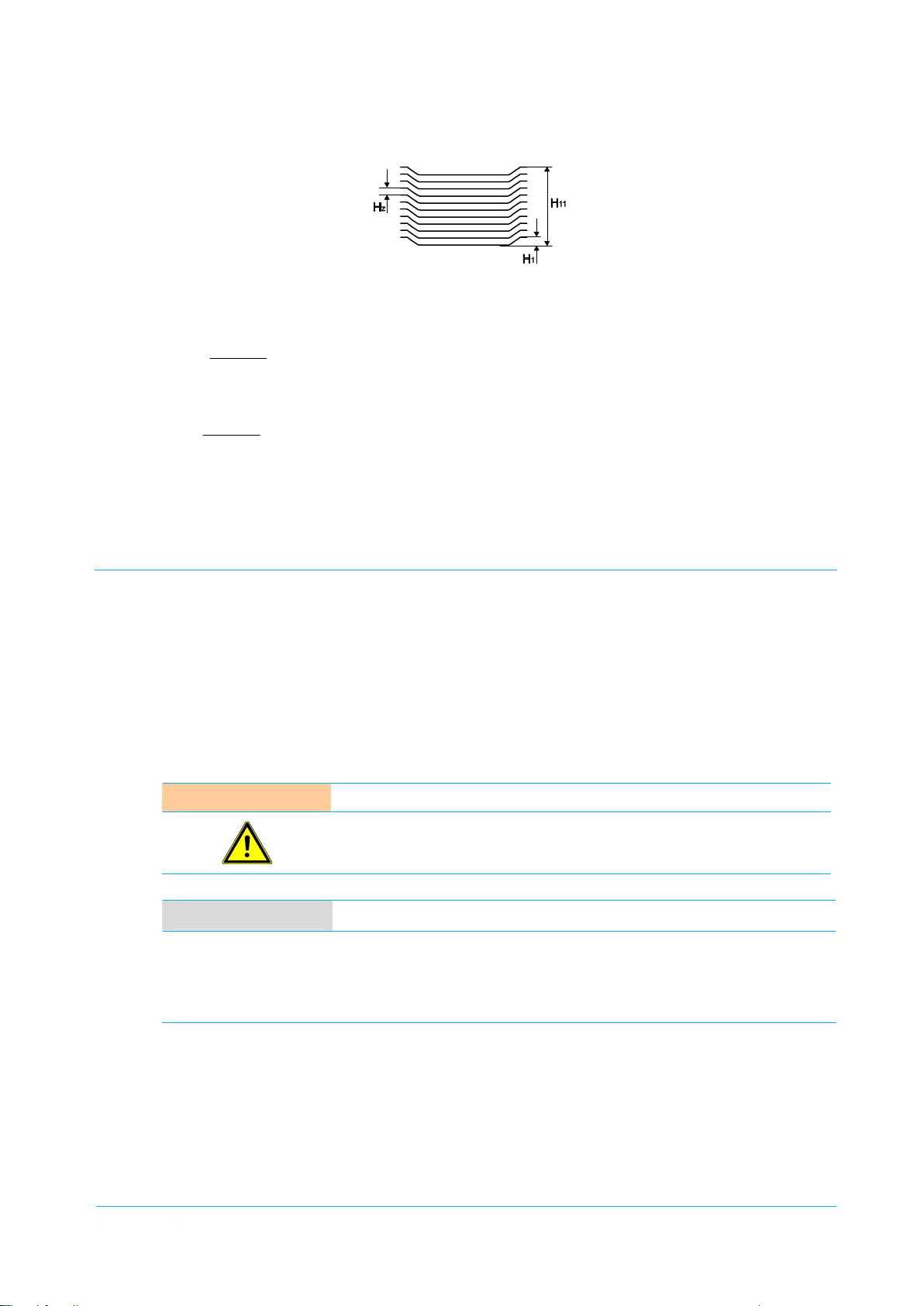

2.3 Calculating the plate dispenser capacity

The total capacity of a plate dispenser depends on the kinds of crockery loaded and the number of dispensing tubes.

All leading manufacturers give the necessary data for calculating the intermediate stack height in the following manner:

T

H

Z

=

o

)H - (H

1n

g

e

t

h

e

The capacity per crockery stack can be calculated together with the stack height Hs of the plate dispenser:

HZ:

In

termediate stack height

H1:

He

ight of the first crockery item

Hn:

He

ight of n crockery items

n:

Nu

mber of crockery items

K

(

H

H

1

s

=

+1

H

z

K:

HS:

Ite

ms per crockery stack

Sta

ck height of the plate dispenser

)

-

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Op

eration Chapter 5

Operation Page 31

Figur

e 18 Intermediate stack height Hz of 11 crockery items

Example:

HZ =

K =

10

44.0

1.

1 - 5.51

= 0.44

1.16.24

+1 = 54

items

H1

=

1.1 in: Height of the first crockery item

H11

=

5.51 in: Height of 11 crockery items

t

=

11: Number of crockery items

HS

=

24.6 in: Stack height

So, 54 crockery items can be stacked into this dispensing tube.

5.3 Operation

Be

fore the appliance is put into operation it must be clean and dry.

Before work starts, it is always necessary to check whether the plate dispenser to be operated is correctly

set for the crockery to be used.

The vertical guide of the plates must be ensured, in order to prevent any risk of injury to the operating

staff if the crockery guides are set too far apart or too close together.

The correct dispensing height must be ensured, so that the staff cannot suffer injury or become trap-

ped and no breakage of crockery can occur.

Use of the cover

AT

TENTION Risk of injury

NO

Al

l the covers are provided with a 3-point locking mechanism.

Place the cover on to the dispensing tube and lock it by turning it clockwise.

Open the cover again by turning it anti-clockwise.

When using the plate dispenser with two dispensing tubes, a cover that have been removed previously can

be placed on to the second cover of the dispensing tube next to it.

If a

stack of plates with the covers is too high, do not push it down forcibly.

There is a risk of injury, if the locking is released.

TE Use of the cover

Th

e cover ensures effective protection against ingress of dust and condensed

water even during relatively long periods of temporary storage. Using the

cover in the heated appliances lowers the heat loss upwards and reduces the

heating time of the inserted crockery or delays the cooling of pre warmed

crockery.

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 5 Operation

Page 32 Operation

5.

3.1 Switching on the appliance

CAUT

ION Hazardous electrical voltage

Th

e electrical voltage may be considerably dangerous to limb and life of per-

sons and lead to injuries.

Only use the plug connection provided for this. The appliance should not be

operated with a damaged connecting line or other visible damages.

All work on the electrical installations should only be carried out by a certified

electrician or by authorised specialists under supervision and monitoring of a

certified electrician according to the electro-technical regulations.

NO

TE Heated appliances

So

me parts of this section relate exclusively to the heated appliances and do

not apply to the unheated models.

Co

ver all the dispensing tubes with the covers to avoid heat loss.

Insert the mains plug into a suitable socket.

Switch on the appliance with the On / Off switch. The indicator integrated in the switch will light up to

show that the appliance is ready for operation.

Set the desired temperature using the thermostat. A continuous adjustment is possible within the 4

power ranges.

NO

TE Crockery temperature

5.

3.2 Loading the appliance

NO

TE Loading

NO

TE Warm-keeping items

De

pending upon the number and arrangement of the crockery stacks, the

required temperature of the crockery with the cover on and an initial crockery

temperature of at least 59 °F will be reached after 2 to 3 hours.

Be

fore the crockery items are inserted, the crockery guide and the stack

height must be set correctly.

Insert the items individually or in small safely manageable stacks.

Me

tal-coated warm-keeping items filled with wax can also be heated up wrong

in the most powerful plate dispenser.

The plate dispenser's performance is not sufficient to melt the wax within the

metallic sheath. As a result, liquid-to-solid phase transition cannot take place

during heat emission, so that the warm-keeping function of the warm-keeping

items is drastically reduced.

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Op

eration Chapter 5

Operation Page 33

Loading

crockery

AT

TENTION Breakage of crockery

Th

e maximum loading height of the crockery baskets must be about 0.12'' to

0.20'' below the upper rim, otherwise this can cause breakage of crockery.

Do not stack the crockery items into the crockery baskets up to the upper

edge of the crockery basket.

Pl

ace the first plates on the centre of the guide basket and lower them slowly.

Place the further plates precisely onto the plates already positioned in the appliance.

The maximum filling level is achieved, when the guide basket does not lower anymore while loading

further plates.

If no cover is used, the uppermost plate should not protrude more than 2.36'' above the upper rim of

the housing.

NO

TE Filling level

A h

igher filling level is possible in the appliances used with the covers. Depending on the inherent stability of the items, they can be stacked up to the

lower edge of the cover. However, in the heated models the crockery items

resting above the upper rim of the appliance cannot be heated to the required

temperature.

The crockery with the cover should not protrude more than 5.12''. Even when

stationary, the plate dispenser must never be loaded beyond the permitted

maximum value of 5.12''.

Un

loading crockery

WA

RNING Risk of burning

Re

move the cover and put it down.

Take out the plates.

Put the cover back on.

NO

TE Appliances with cooling slots

In the hea

ted appliances the crockery temperatures can exceed the permitted

maximum temperatures of 149°F for touchable appliance surfaces.

Never reach into the appliance or touch the heating element with the fingers

during the operation.

Always wear protective gloves when dispensing hot crockery.

Th

e appliances are intended to provide cooled crockery. For this purpose, the

loaded appliances must remain in cold stores for several hours. The duration

of cooling depends on the initial crockery temperature, the temperature of the

cold store and the desired crockery temperature. The appliances must always

be free-standing in the room so that optimum air circulation is ensured by free

convection within and around the appliances.

Plate dispenser