Hupfer TE-2/V27-33, TE-2/VK19-26, TEH-2/V19-26, TEH-2/V27-33, TEUH-1/VS19-26 Operating Instructions Manual

...

Ope

rating Instructions

TE-2/V19-26

Plat

e dispenser

| TE-2/V27-33 | TE-2/VK19-26 | TEH-1/V19-26 |

TEH-1/V27-33 | TEH-2/V19-26 | TEH-2/V27-33 | TEUH-1/VS19-26

| TEUH-2/VS19-26| TEUH-2/VC19-26 | EBR/V19-26 | EBR/V27-

33 | EBRH/V19-26 | EBRH/V27-33 | EBRH-2/V19-26

4330000_A1

Ch

apter 1 Introduction

Page 2 Appliance Information

1 Intr

1.

1 Appliance Information

oduction

Ap

pliance designation Plate dispenser

Appliance type/ -s TE-2/V19-26 | TE-2/V27-33 | TE-2/VK19-26 | TEH-

Manufacturer HUPFER® Metallwerke GmbH & Co. KG

www.hupfer.de

info@hupfer.de

Plate dispenser

1/V19-26 | TEH-1/V27-33 | TEH-2/V19-26 | TEH-2/V2733 | TEUH-1/VS19-26 | TEUH-2/VS19-26| TEUH2/VC19-26 | EBR/V19-26 | EBR/V27-33 | EBRH/V19-26 |

EBRH/V27-33 | EBRH-2/V19-26

Dieselstraße 20

48653 Coesfeld

PO 1463

D-48634 Coesfeld

+49 2541 805-0

+49 2541 805-111

TE-2/V19-26 | TE-2/V27-33 | TE-2/VK19-26 | TEH-1/V19-26 | TEH-1/V27-33 | TEH-2/V19-26 |

TEH-2/V27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26| TEUH-2/VC19-26 | EBR/V19-26 |

EBR/V27-33 | EBRH/V19-26 | EBRH/V27-33 | EBRH-2/V19-26

Read these operating instructions carefully before the first operation of the appliance.

Ensure that sources of danger and possible faulty operations have been pointed out to the operating staff.

Subject to modifications

The products covered by these operating instructions have been developed taking into consideration the requirements of the market and the latest technology. HUPFER® reserves the right to modify the products and

appertaining technical documentation in so far as the modifications are in the name of technological progress. The data and weights as well as the description of performance and functions assured in the order

confirmation as binding are always decisive.

Manual edition

4330000_A1

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

In

troduction Chapter 1

Table of Contents Page 3

1.

2 Table of Contents

1 Int

roduction 2

1.1 Appliance Information 2

1.2 Table of Contents 3

1.3 List of abbreviations 5

1.4 Definitions of Terms 6

1.5 Orientation Guide 7

1.6 Notes on Use of Manual 8

1.6.1 Notes on the manual structure 8

1.6.2 Notes and their illustrations used in the chapters 8

2 Safety Instructions 9

2.1 Introduction 9

2.2 Warning Symbols Used 9

2.3 Safety Instructions for Appliance Safety 9

2.3.1 Safety instructions for all appliances 9

2.3.2 Additional safety instructions for heated appliances 10

2.4 Safety Instructions for Cleaning and Care 11

2.5 Safety Instructions for Trouble Shooting 11

2.6 Notes on Specific Hazards 11

3 Description and Technical Data 12

3.1 Performance Description 12

3.2 Intended Use 12

3.3 Improper Use 12

3.4 Appliance Description 13

3.4.1 View of the appliance - Plate dispenser 13

3.4.2 View of the appliance - Built-in plate dispenser 13

3.4.3 Appliance Description 14

3.4.4 Optional accessories 14

3.5 Technical Data 15

3.6 Rating plate 19

4 Transport, Assembly, Putting into Operation and Decommissioning 20

4.1 Transport 20

4.2 Assembly (Built-in appliances only) 20

4.2.1 Unheated appliances (EBR/V19-26 | EBR/V27-33) 20

4.2.2 Heated appliances (EBRH/V19-26 | EBRH/V27-33 | EBRH-2/19-26) 22

4.3 Putting into Operation 26

4.4 Storage and Recycling 26

5 Operation 27

5.1 Arrangement and Function of the Operating Elements 27

5.2 Plate Dispenser Adjustment 27

5.2.1 Crockery guide adjustment 28

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 1 Introduction

Page 4 Table of Contents

5.2.2 Sp

ring adjustment 29

5.2.3 Calculating the plate dispenser capacity 30

5.3 Operation 31

5.3.1 Switching on the appliance 32

5.3.2 Loading the appliance 32

5.3.3 Moving the appliance 34

5.4 Measures at the End of the Operation 34

6 Fault Detection and Trouble Shooting 35

6.1 Security Measures 35

6.2 Notes on Trouble Shooting 35

6.3 Fault and Action Table 35

7 Cleaning and Care 36

7.1 Security Measures 36

7.2 Hygiene Measures 36

7.3 Cleaning and Care 36

7.4 Special Care Instructions 37

8 Replacement Parts and Accessories 38

8.1 Introduction 38

8.2 Spare Parts and Accessories List 38

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

In

troduction Chapter 1

List of abbreviations Page 5

1.

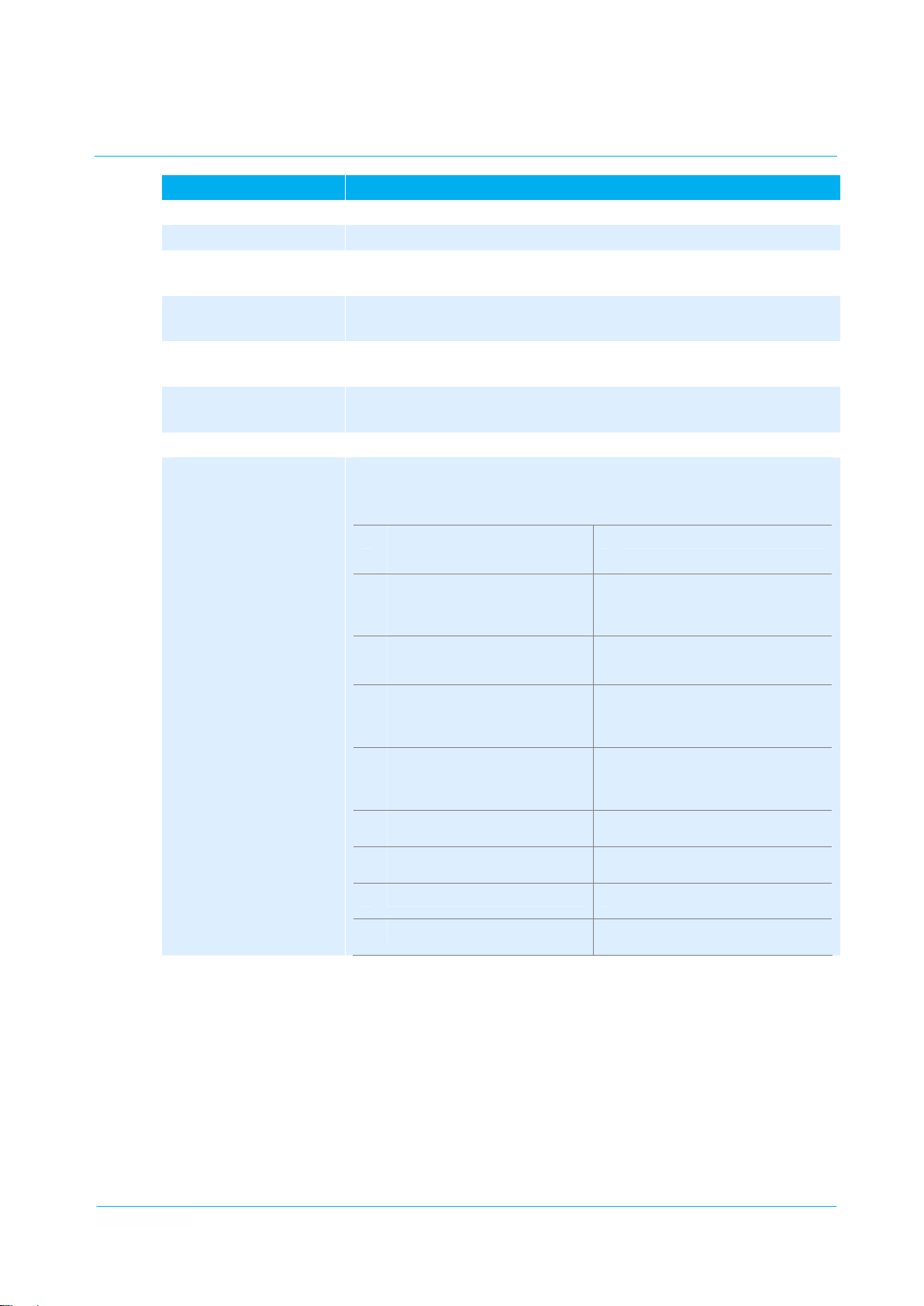

3 List of abbreviations

Ab

breviation

BG

R

BG

V

CE Co

DI

N

EC Eu

EN Eu

E/

V

IP In

LE

D

De

finition

Ru

le of the Professional Association

Re

gulation of the Professional Association

mmunauté Européenee

Eu

ropean Community

De

utsches Institut für Normung

Ge

rman Institute for Standardisation, technical regulations and technical specifications

ropean Community

Eu

ropean Union

ropean Standard

Ha

rmonised standard for the EU market

Sp

are and wearing part

ternational Protection. The abbreviation IP and a further two-digit index specify the

prot

ection class of a housing.

Th

e first digit: Protection against ingress of solid foreign objects The second digit: Protection against ingress of

wa

ter

0 No

protection against contact, no protec-

ti

on against ingress of solid foreign

obj

ects

1 Pr

otection against contact with any large

su

rface of the body such as the hand,

pr

otection against ingress of foreign

obj

ects >1.97 in

2 Pr

otection against contact with the

fi

ngers, protection against ingress of

fo

reign objects >0.47 in

3 Pr

otection against contact with tools,

th

ick wires or similar objects of >0.1

in

, protection against foreign objects

>0

.1 in

4 Pr

otection against contact with tools,

th

ick wires or similar objects of >0.04

in

, protection against foreign objects

>0

.04 in

5 Pr

otection against contact, protection

agai

nst dust deposits inside

6 Co

mplete protection against contact,

pr

otection against ingress of dust

7 Pr

8 Pr

Li

ght Emitting Diode

Li

ght diode

0 No

protection against ingress of water

1 Pr

otection against vertically falling water

dr

ops

2 Pr

otection against dripping water (at any

angl

e up to 15° from the vertical)

3 Pr

otection against water drips at any

angl

e up to 60° from the vertical

4 Pr

otection against water splashing from

an

y direction

5 Pr

otection against water jets (projected

by

a nozzle) at any angle

6 Pr

otection against temporary flooding

otection against ingress of water

dur

ing temporary immersion

otection against pressurised water

dur

ing continuous immersion

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 1 Introduction

Page 6 Definitions of Terms

1.

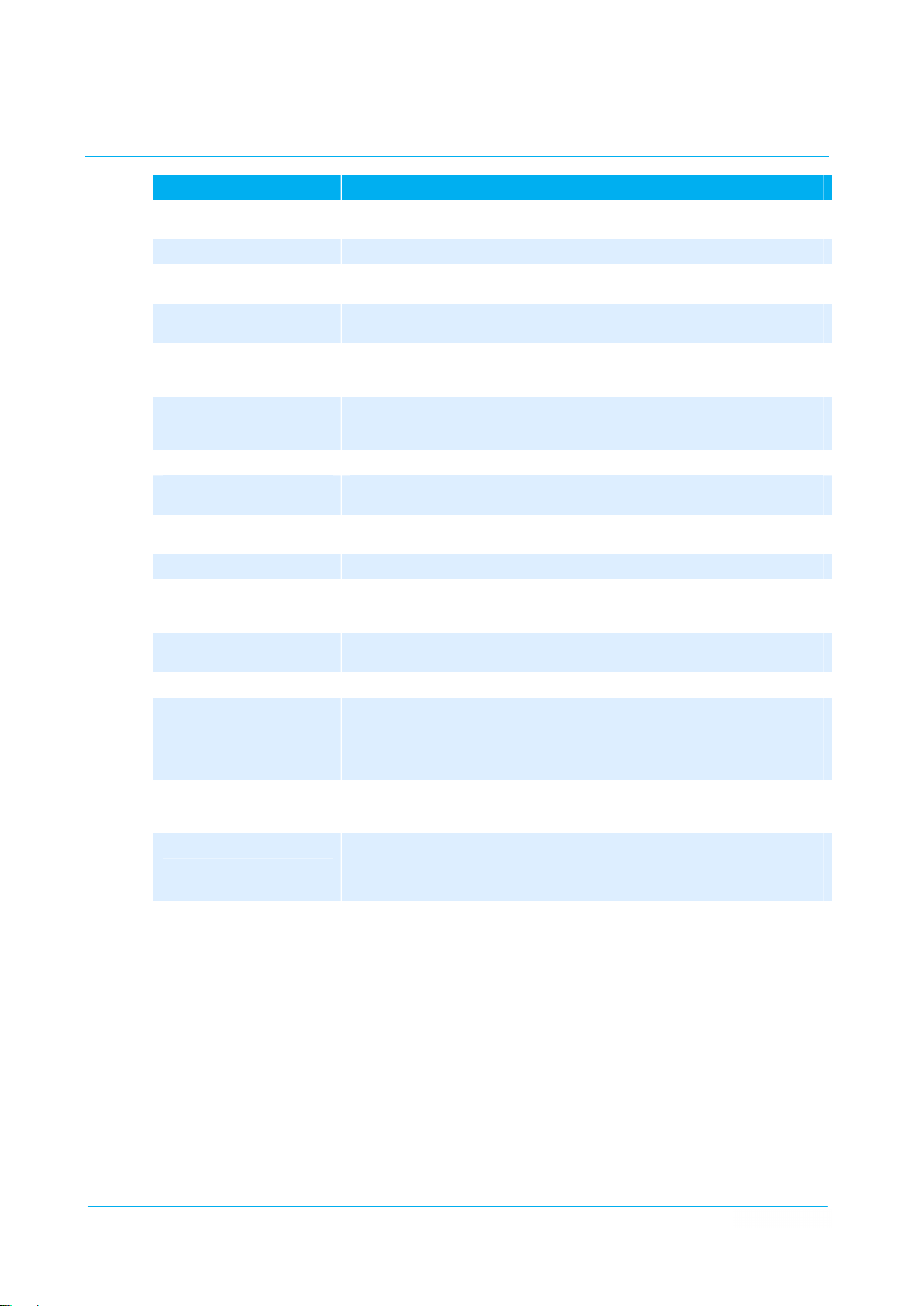

4 Definitions of Terms

Te

rm

Au

thorised specialist

Co

ver

Co

ok&Chill-Kitchens

Co

ok&Serve-Kitchens

El

ement formation

Sp

ecialist

Li

ft

Co

ntrol

Co

nvection

Co

rrosion

Ma

chine safety

Pa

ssive layer

Ch

eck

Qu

alified person,

qual

ified staff

Sc

huko®

In

structed persons

De

finition

An

authorised specialist is a specialist that has been trained by the manufacturer, an

aut

horised service dealer or a company assigned by the manufacturer.

A b

ell-shaped cover for keeping food warm on plates and dishes.

"C

ook and Chill": Kitchens where warm food after being cooked is chilled as quickly as

pos

sible.

"C

ook and Serve": Kitchens where warm food is served immediately after being coo-

ke

d or kept warm until it is consumed.

Al

so: contact corrosion. Occurs when different noble metals are in close contact with

eac

h other. This happens when a corrosive medium is between both metals, as for

ex

ample water or even air humidity.

A

specialist is a person who can evaluate work assigned and can individually recog-

ni

se any possible dangers due to the professional training, specialist knowledge and

ex

perience as well as knowledge of the respective guidelines.

A

movement, for example a vertical movement of the guide basket from bottom to top.

Co

mpare with certain conditions and/or characteristics such as damages, leaks, filling

le

vels, heat.

Ph

ysical properties or mass transfer (e.g. heat or cold) through currents in gases and

liq

uids.

Th

e chemical reaction of a metallic material with its surroundings, e.g. rust.

Th

e term of machine safety means all the measures used to avert injury to persons.

Th

e basis for this are national as well as EC-wide valid directives and laws for protect-

in

g users of technical devices and systems.

A n

on-metallic protective layer on a metallic material that prevents or slows down

ma

terial corrosion.

Co

mpare with certain values such as weight, torque, content, temperature.

Qu

alified personnel are persons who due to their professional training, experience and

in

struction as well as their knowledge of the respective standards, guidelines, accident

prev

ention regulations and operating conditions have been authorised by a person

res

ponsible for system safety to carry out required activities and can recognise and

prev

ent any possible danger (definition of specialists according to IEC 364).

Th

e abbreviation of the German term "Protective contact" that indicates a system of

dom

estic plugs and sockets equipped with protective earthed contacts used in most of

Eu

rope.

An

instructed person is a person who has been instructed on the possible risks result-

in

g from improper behaviour when carrying out the assigned task as well as on the

nec

essary protective equipment and protective measures and trained for this task if

nec

essary.

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

In

troduction Chapter 1

Orientation Guide Page 7

1.

5 Orientation Guide

The f

ront

"The front" means the side of the plate dispenser where the push bars are arranged. The operating staff

stays at this side to move the appliance.

The side of the built-in appliances named as "the front" means the side, at which the staff operates the plate

dispenser.

The rear

The side named "the rear" means the opposite side of the front side (the front).

The right

The side named "the right" means the side at the right hand side of the front side (the front).

The left

The side named "the left" means the side at the left hand side of the front side (the front).

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 1 Introduction

Page 8 Notes on Use of Manual

1.

6 Notes on Use of Manual

1.

6.1 Notes on the manual structure

This manual is structured in functional and task orientated chapters.

1.6.2 Notes and their illustrations used in the chapters

DANG

ER Brief description of danger

Th

ere is an imminent danger to life and limb of the user and / or third parties

when the instructions are not followed precisely or the circumstances described are not taken into account.

The type of danger is indicated by a symbol and explained in the accompanying text in more detail. In this example the general sign of danger is used.

WA

RNING Brief description of danger

Th

ere is an indirect danger to life and limb of the user and / or third parties

when the instructions are not followed precisely or the circumstances described are not taken into account.

The type of danger is indicated by a symbol and explained in the accompanying text in more detail. In this example the general sign of danger is used.

AT

TENTION Brief description of danger

Th

ere is a potential risk of injury or damage to property when the instructions

are not followed precisely or the circumstances described are not taken into

account.

The type of danger is indicated by a general sign and explained in the accompanying text in more detail. In this example the general sign of danger is used.

NO

TE Brief description of additional information

At

tention is pointed to special conditions or additional important information on

the respective subject.

IN

FO Short title

Co

ntains additional information on work assisting features or recommenda-

tions on the respective subject.

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Sa

fety Instructions Chapter 2

Introduction Page 9

2 Sa

2.

1 Introduction

fety Instructions

Th

e chapter on safety instructions describes the risks associated with the appliance in terms of product liabil-

ity (according to the EU Directive).

2.2 Warning Symbols Used

Sy

mbols are used in these operating instructions to point out the dangers that can occur while operating or

cleaning the appliance. In both cases, the symbol provides information on the type and circumstances of

danger.

The following symbols can be used:

Ge

neral hazardous area

Ha

zardous electrical voltage

Ri

sk of hand injuries

Ri

sk of squashing

Ri

2.

3 Safety Instructions for Appliance Safety

Sa

fe operation of the appliance depends on appropriate and thorough use. Negligent handling of the appliance can lead to danger to life and limb of the user and / or third parties as well as hazards to the appliance

itself and the other operator's property.

2.3.1 Safety instructions for all appliances

The following points are to be observed to ensure the appliance safety:

sk of hot surfaces

We

ar hand protection

The appliance may only be operated when it is in perfect condition with regards to technical stan-

dards.

All the operating and actuating elements must be in a perfect and functionally reliable condition with

regards to technical standards.

Modifications or retrofits of the equipment are only permitted in consultation with the manufacturer

and on receipt of his written agreement.

In no case may people sit or stand on the appliance. Transport of persons is not permitted.

Before loading, the crockery dispensing height must be adjusted to the kind of crockery used.

The crockery guides must be adjusted to the kind of crockery used before loading.

To avoid injuries to the hands, care should always be taken to ensure that the crockery dispensing

height does not fall below the upper rim of the housing.

Never push the guide basket down manually into the dispensing tube (e.g. for cleaning). There is a

risk of injury, if the guide basket is released.

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 2 Safety Instructions

Page 10 Safety Instructions for Appliance Safety

Th

e appliance is provided exclusively for manual transport. Mechanical transport is not permitted.

Risk of injury and damage.

If a stack of plates with the covers is too high, do not push it down forcibly. There is a risk of injury, if

the locking is released. Furthermore, the locking function of the covers can be damaged.

Release both total brakes before commencing transporting. Moving the appliance with the total bra-

kes locked can damage the chassis

Transport should only be undertaken over level floors. Moving the appliance over very uneven floors

can damage the chassis.

Transport over inclined planes or steps is not permitted.

When approaching walls and moving round obstacles always pay attention to persons in the way.

Risk of injury.

When transporting the appliance, always hold both bars with your hands. Never let go of the appli-

ance while moving it.

When transporting the appliance, do not move it faster than a walking pace. Heavily laden plate dis-

pensers are difficult to brake and steer. If necessary, ask for assistance when transporting the appliance.

If the plate dispenser tips over due to outside influences or inattention, never catch it manually. Risk

of injury.

Do not stop the appliance on sloping floors.

After stopping, the appliance should be secured against rolling away by means of both total brakes

being applied.

In the case of offsite transport in a vehicle such as a lorry, the appliances should be secured properly.

The total brakes are not sufficient as a transport securing method.

2.3.2 Additional safety instructions for heated appliances

The heated appliances can only be operated by instructed specialists and kitchen staff and under

continuous supervision.

Heated plate dispensers are intended for dispensing heated crockery. Their use for cooking food and

keeping it warm or for room heating is not permitted.

The crockery temperatures can exceed the permitted maximum temperatures of 149°F (65°C) for

touchable appliance surfaces. Always wear protective gloves when dispensing hot crockery. Risk of

burning.

During operation of the appliance, never reach into it and touch the heating element with the fingers.

Risk of burning.

Plastic crockery, top and bottom parts of plastic insulated sets and plastic-coated items for keeping

food warm should not be stored or warmed up in heated plate dispensers. Owing to the high temperatures of the heating elements, the plastics can melt and catch fire.

The base plate and used air from the base outlets can become very hot. The appliance should not be

operated on fibre-based floor coverings (e.g. carpets, mats).

Before transporting, switch off the appliance, pull out the mains plug and insert it into the plug park

provided.

Forceful straining of the connecting cable can lead to damage to the internal line. Risk of fire.

Never pull the mains plug out of the socket by the wire. The standard models of HUPFER

ances are equipped with a Schuko® angle plug. In contrast to a straight Schuko® plug this plug only

sticks insignificantly out of the socket and so cannot be damaged by being hit at the side. If the appliance is moved without pulling out the mains plug beforehand, the socket can be severely damaged or

even pulled out from the wall as a result of leverage arising from overstretching of the connecting cable.

Never move the appliance by pulling by the connecting cable.

If the mains plug has come into contact with water it must be dried before inserting it into the socket.

Danger to life.

®

appli-

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

Sa

fety Instructions Chapter 2

Safety Instructions for Cleaning and Care Page 11

Da

maged mains plugs or connecting cables are to be replaced by authorised personnel before the

appliance is reused.

Do not use any extension cables in wet and damp areas.

Only insert mains plugs into suitable sockets. If the mains plug does not fit, the connecting cable of

the appliance is to be retrofitted by authorised specialist staff.

The use of socket adapters is not permitted. Risk of fire.

Do not clean the appliance with steam-jet or high-pressure washers. The appliance must be taken

out of operation and switched off at the mains beforehand in any area where steam-jet or highpressure washers are to be used.

2.4 Safety Instructions for Cleaning and Care

Th

e following points shall be observed when carrying out any cleaning and maintenance operations:

For reasons of hygiene the cleaning instructions shall be strictly observed.

Take the appliance out of operation before starting the cleaning process. Pull out the mains plug and

insert it into the plug park located on the appliance.

For cleaning, the appliance must be out of operation and cooled down sufficiently.

Do not clean the appliance with steam-jet or high-pressure washers. The appliance must be taken

out of operation and switched off at the mains beforehand in any area where steam-jet or highpressure washers are to be used.

Even appliances without an electrical connection should not be cleaned with running water or pres-

surised water.

2.5 Safety Instructions for Trouble Shooting

Th

e following points shall be observed when carrying out any maintenance and trouble shooting operations:

All trouble shooting work should only be carried out by authorised specialists.

When carrying out trouble shooting work, it must be ensured that the appliance is switched off. When

operating on the electrical installation, the appliance is to be switched off at the mains and secured

against reactivation.

The local applicable Accident Prevention Regulations must be observed.

Defective components should only be replaced with original parts.

2.6 Notes on Specific Hazards

El

ectrical energy

All work on the electrical installations should only be carried out by a certified electrician or by author-

ised specialists under supervision and monitoring of a certified electrician according to the certain electro-technical regulations.

The appliances that inspection, maintenance and trouble shooting work is performed on must be

switched voltage free on and secured against reactivation, when the voltage is not required for this

kind of work. This must only be carried out by a certified electrician.

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Ch

apter 3 Description and Technical Data

Page 12 Performance Description

3 Des

3.

1 Performance Description

cription and Technical Data

Pl

ate dispensers are intended for storage of clean crockery items ready for use in the food service industry

and large-scale catering establishments. They are used mainly for storage of warmed crockery ready for use

on food distribution belts and storage of plates at normal temperature or chilled on self-service counters in

bistros or cafeterias.

There are various models available for selection. Depending upon the size and number of crockery items,

the plate dispensers are available in two sizes, 19-26 (for plates with a diameter of 7.48'' to 10.24'') and 2733 (for plates with a diameter of 10.63'' to 13'').

The unheated models with the enclosed side and front walls of the housing store crockery items ready for

use for serving portions of cold dishes.

The unheated models with cooling slots store crockery ready for serving portions of cold side dishes, e.g. salads and desserts.

The models heated by air circulation are intended for storage of crockery ready for serving portions of warm

components. The crockery can be heated up to 212°F (100°C).

Besides the mobile plate dispensers, there are plate dispensers intended for installation in worktops.

3.2 Intended Use

Pl

ate dispensers are intended exclusively for storage of clean plates with diameter of 7.48'' to 10.24'' or

10.63'' to 13'' ready for use. Depending on the model, the loaded plates can be cooled down or heated up.

The appliances are intended for transporting round china items or transport made of toughened glass.

Transport of other loads is not permitted.

The intended use means the predetermined procedures, compliance with the indicated specifications and

use of the delivered or additionally available original accessories.

Any other use of the appliance is considered as unintended use.

3.3 Improper Use

It i

s not permitted to load the plate dispenser with other loads as given.

In no case may people sit or stand on the appliance or be transported on it.

Moreover, it is not permitted to use the heated plate dispensers for cooking food or keeping it warm and for

room heating.

No flammable or outgasing objects, objects with plastic items or foodstuff should be stored under the plate

dispenser.

No liability is assumed and no warranty claims can be submitted for damages caused by improper use.

Plate dispenser

TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26 4330000_A1

De

scription and Technical Data Chapter 3

Appliance Description Page 13

3.

4 Appliance Description

3.

4.1 View of the appliance - Plate dispenser

Fi

gure 1 View of the appliance

1 Push bar 7 Casters without total brakes

2 Thermostat for setting the temperature* 8 Corner bumpers

3 On / Off switch* 9 Guide basket

4 Plug park (dummy socket)* 10 Crockery guide

5 Connecting cable with mains plug* 11 Cover*

6 Casters with total brakes

* heated appliances only

3.4.2 View of the appliance - Built-in plate dispenser

Fi

gure 2 View of the appliance

1 Crockery guide 5 Locking positions for the crockery guide

2 Guide basket 6 Connecting socket for appliance plug*

3 Attachment bar with adjustable springs 7 Thermostat*

4 Guide rail 8 Cover*

* heated appliances only

Plate dispenser

4330000_A1 TE-2/V19-26, 27-33 | TE-2/VK19-26 | TEH-1/V19-26, 27-33 | TEH-2/V19-26, 27-33 | TEUH-1/VS19-26 | TEUH-2/VS19-26, 27-33 | TEUH-2/VC19-26

EBR/V19-26, 27-33 | EBRH/V19-26, 27-33 | EBRH-2/V19-26

Loading...

Loading...