Hupfer SGR, SPV Operating Instructions Manual

Operating Instructions

Round Belt Conveyor System

SGR

4330054_A2

| SPV

Chapter 1 Introduction

Page 2 Appliance Information

1 Introduction

1.1 Appliance Information

Appliance designation Round Belt Conveyor System

Appliance type/ -s SGR | SPV

Manufacturer HUPFER® Metallwerke GmbH & Co KG

Dieselstraße 20

48653 Coesfeld

PO 1463

48634 Coesfeld

+49 2541 805-0

+49 2541 805-111

www.hupfer.de

inf

Round Belt Conveyor System

o@hupfer.de

SGR | SPV

Read these operating instructions thoroughly and attentively to ensure safe operation and avoid any damages! Ensure that sources of danger and possible faulty operations have been pointed out to the operating

staff.

Subject to modifications

The products covered by these operating instructions have been developed taking into consideration the requirements of the market and the latest technology.

appertaining technical documentation in so far as the modifications are in the name of technological progress. The data and weights as well as the description of performance and functions assured in the order

confirmation as binding are always decisive.

This manual is an original edition.

Manual edition

4330054_A2

Round Belt Conveyor System

SGR | SPV 4330054_A

HUPFER® reserves the right to modify the products and

2

Introduction Chapter 1

Table of Contents Page 3

1.2 Table of Contents

1 Introduction 2

1.1 Appliance Information 2

1.2 Table of Contents 3

1.3 List of Abbreviations 5

1.4 Definitions of Terms 6

1.5 Orientation Guide 6

1.6 Notes on Use of Manual 7

1.6.1 Notes on the manual structure 7

1.6.2 Notes and their illustrations used in the chapters 7

2 Safety Instructions 8

2.1 Introduction 8

2.2 Warning Symbols Used 8

2.3 Safety Instructions for Appliance Safety 8

2.3.1 Special safety instructions for mobile conveyor systems 9

2.4 Position of the Emergency Stop Button 9

2.5 Safety Instructions for Transport and Installation 10

2.6 Safety Instructions for Use and Operation 10

2.7 Safety Instructions for Maintenance and Care 10

2.8 Safety Instructions for Troubleshooting 11

2.9 Notes on Specific Hazards 11

3 Description and Technical Data 12

3.1 Performance Description 12

3.2 Intended Use 12

3.3 Improper Use 12

3.4 Appliance Description 13

3.4.1 View of the crockery return belt system (SGR) 13

3.4.2 View of the food distribution belt system (SPV) 14

3.4.3 Equipment and optional accessories 14

3.5 Technical Data 16

3.6 Rating Plate 17

4 Transport, Assembly, Putting into Operation and Decommissioning 18

4.1 Transport 18

4.2 Assembly 18

4.2.1 Assembling the segment 19

4.2.2 Assembling the round belt 20

4.3 Putting into Operation 23

4.3.1 Connecting the conveyor system 24

4.3.2 Measures for putting the appliance into operation 24

4.4 Decommissioning, Storage and Recycling 24

Round Belt Conveyor System

4330054_A2 SGR

| SPV

Chapter 1 Introduction

Page 4 Table of Contents

5 Operation 26

5.1 Arrangement and Function of the Operating Elements 26

5.2 Operation 27

5.3 Measures at the End of Operation 27

6 Fault Detection and Troubleshooting 28

6.1 Security Measures 28

6.2 Notes on Troubleshooting 28

6.3 Fault and Action Table 28

7 Care and Maintenance 30

7.1 Security Measures 30

7.2 Hygiene Measures 30

7.3 Notes on Care and Maintenance Measures 30

7.3.1 Maintenance 31

7.3.2 Re-tension the round belt 32

7.4 Special Care Instructions 32

8 Spare Parts and Accessories 34

8.1 Introduction 34

8.2 Spare Parts and Accessories List 34

9 Annex 35

9.1 EC Declaration of Conformity 35

Round Belt Conveyor System

SGR | SPV 4330054_A

2

Introduction Chapter 1

List of Abbreviations Page 5

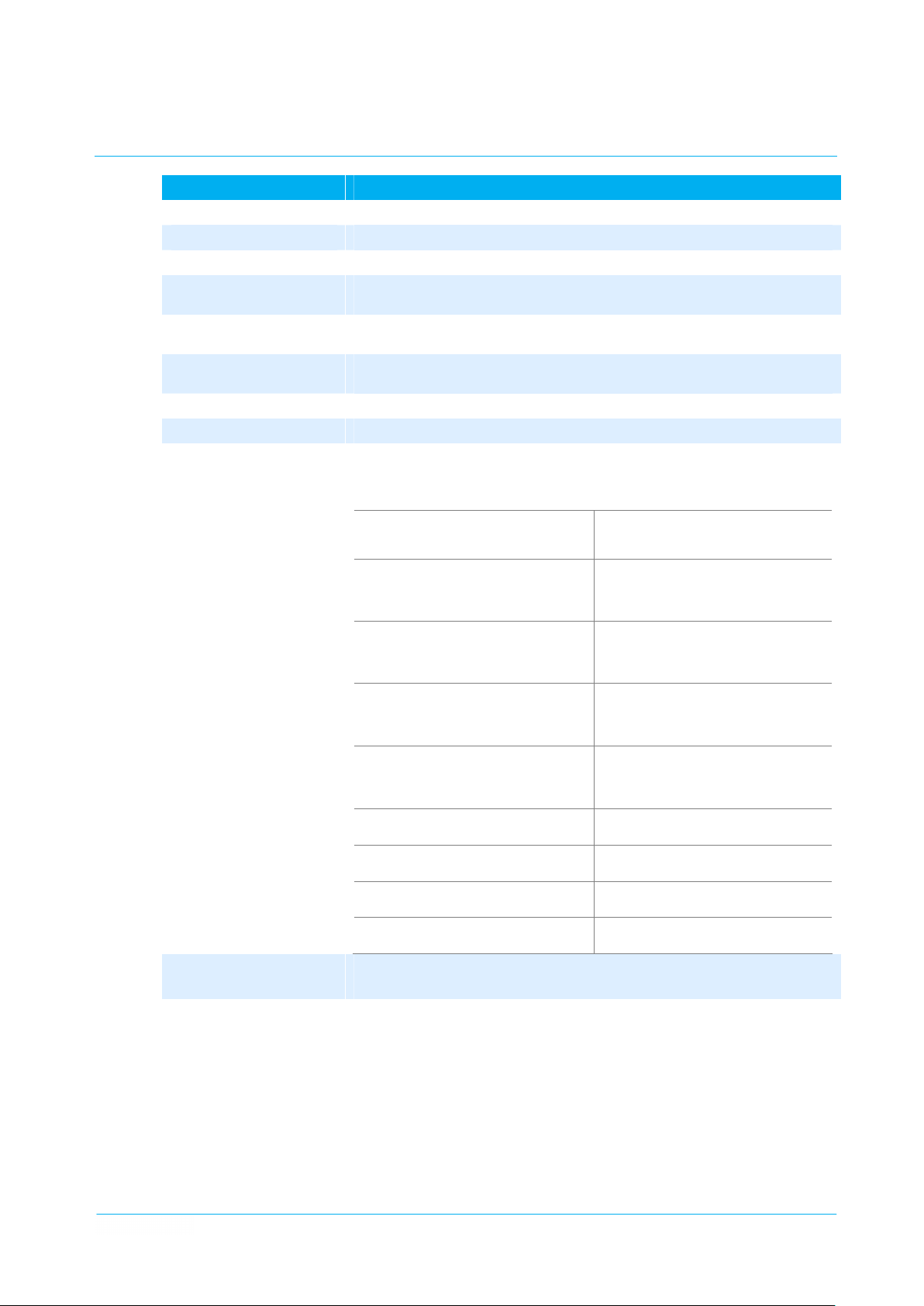

1.3 List of Abbreviations

Abbreviation Definition

BGR Rule of the Professional Association (Berufsgenossenschaftliche Regel)

BGV Regulation of the Professional Association (Berufsgenossenschaftliche Vorschrift)

CE Communauté EuropéenneEuropean Community

DIN German Institute for Standardisation (Deutsches Institut für Normung)German Institute

EC European Community

EN European Standard (Europäische Norm)

E/V Spare and wearing part (Ersatz- bzw. Verschleißteil)

EVU Power supply company (Energieversorgungsunternehmen)

IP International Protection. The abbreviation IP and a further two-digit index specify the

LED Light Emitting Diode

RCD Residual current device In the EU the English RCD (Residual Current Device) term is

for Standardisation, technical regulations and technical specifications

European Community

Harmonised standard for the EU market

protection class of a housing.

The first digit: Protection against ingress of solid foreign objects The second digit: Protection against ingress of

water

0 No protection against contact, no protec-

tion against ingress of solid foreign

objects

1 Protection against contact with any large

surface of the body such as the hand,

protection against ingress of foreign

objects >50 mm

2 Protection against contact with the

fingers, protection against ingress of

foreign objects

>12 mm

3 Protection against contact with tools,

thick wires or similar objects of >2.5

mm, protection against foreign objects

>2.5 mm

4 Protection against contact with tools,

thick wires or similar objects of >1

mm, protection against foreign objects

>1 mm

5 Protection against contact, protection

against dust deposits inside

6 Complete protection against contact,

protection against ingress of dust

7 Protection against ingress of water

8 Protection against pressurised water

0 No protection against ingress of water

1 Protection against vertically falling water

drops

2 Protection against dripping water (at any

angle up to 15° from the vertical)

3 Protection against water drips at any

angle up to 60° from the vertical

4 Protection against water splashing from

any direction

5 Protection against water jets (projected

by a nozzle) at any angle

6 Protection against rough sea or strong

water jets (flood protection)

during temporary immersion

during continuous immersion

Light diode

customary in standardisation matters.

Round Belt Conveyor System

4330054_A2 SGR

| SPV

Chapter 1 Introduction

Page 6 Definitions of Terms

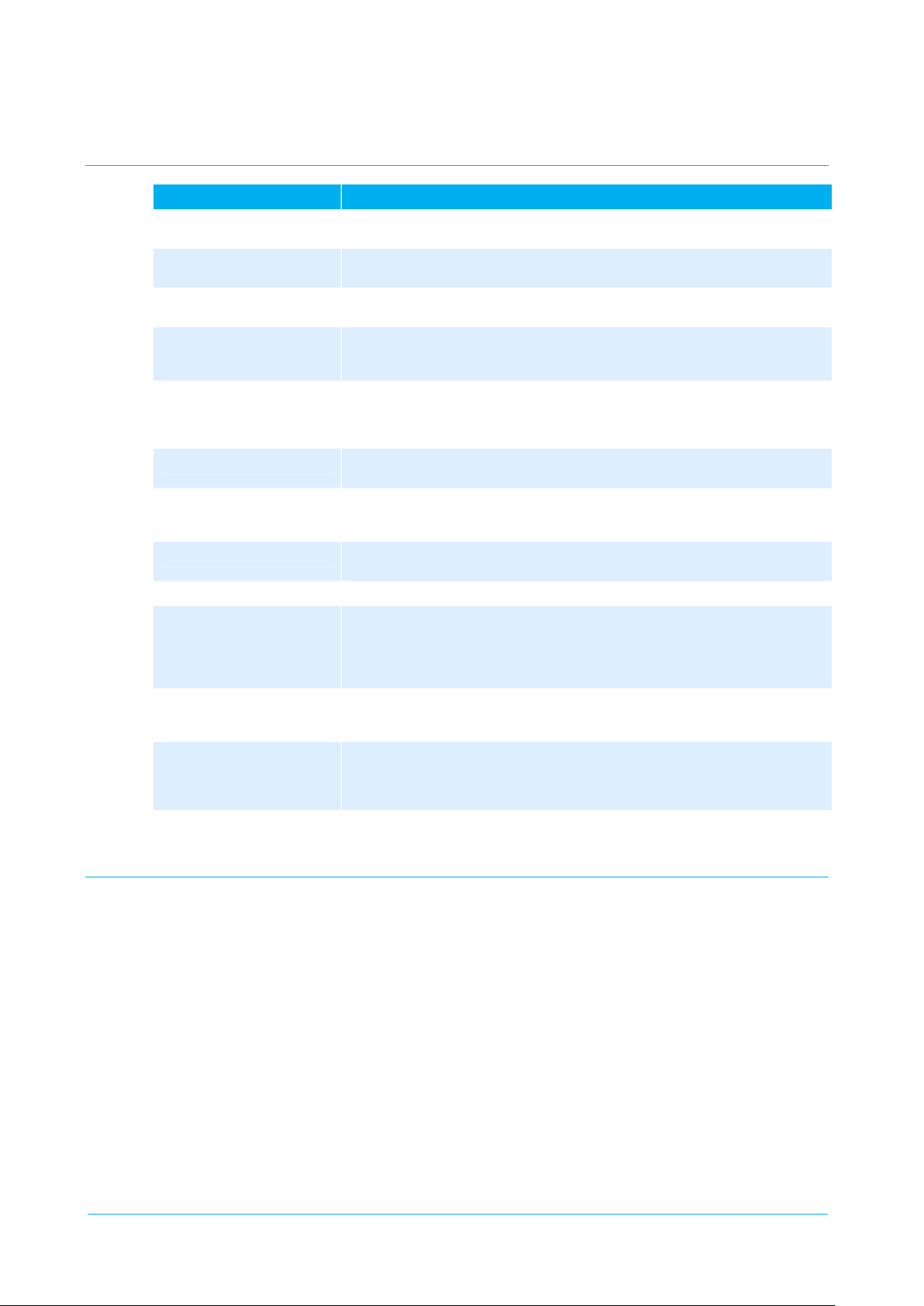

1.4 Definitions of Terms

Term Definition

Authorised specialist An authorised specialist is a specialist that has been trained by the manufacturer, an

Cook&Chill-Kitchens "Cook and Chill": Kitchens where warm food after being cooked is chilled as quickly as

Cook&Serve-Kitchens "Cook and Serve": Kitchens where warm food is served immediately after being

Specialist A specialist is a person who can evaluate work assigned and can individually recog-

Gastronorm Gastronorm is a measurement system applied worldwide, for instance, in food proc-

Control Compare with certain conditions and/or characteristics such as damages, leaks, filling

Machine safety The term of machine safety means all the measures used to avert injury to persons.

Passive layer A non-metallic protective layer on a metallic material that prevents or slows down

Check Compare with certain values such as weight, torque, content, temperature.

Qualified person,

qualified staff

Schuko® The abbreviation of the German term "Protective contact" that indicates a system of

Instructed persons An instructed person is a person who has been instructed on the possible risks result-

authorised service dealer or a company assigned by the manufacturer.

possible.

cooked or kept warm until it is consumed.

nise any possible dangers due to the professional training, specialist knowledge and

experience as well as knowledge of the respective guidelines.

essing plants or large-scale kitchens and catering establishments. The use of standardised sizes makes possible to exchange food pans. The basic size of the gastronorm (GN) 1/1 is 12.8×20.9'' (325×530mm). Items are available in different depths.

levels, heat.

The basis for this are national as well as EC-wide valid directives and laws for protecting users of technical devices and systems.

material corrosion.

Qualified personnel are persons who due to their professional training, experience and

instruction as well as their knowledge of the respective standards, guidelines, accident

prevention regulations and operating conditions have been authorised by a person

responsible for system safety to carry out required activities and can recognise and

prevent any possible danger (definition of specialists according to IEC 364).

domestic plugs and sockets equipped with protective earthed contacts used in most of

Europe.

ing from improper behaviour when carrying out the assigned task as well as on the

necessary protective equipment and protective measures and trained for this task if

necessary.

1.5 Orientation Guide

The front

"The front" means the side where members of the staff place trays (beginning of the belt).

The rear

"The rear" means the side where members of the staff remove trays from the belt. The operating elements of

the conveyor system are fitted here (end of the belt).

The right

The side named "the right" means the right side of the conveyor system in relation to the conveying direction.

The left

The side named "the left" means the left side of the conveyor system in relation to the conveying direction.

Round Belt Conveyor System

SGR | SPV 4330054_A

2

Introduction Chapter 1

Notes on Use of Manual Page 7

1.6 Notes on Use of Manual

1.6.1 Notes on the manual structure

This manual is structured in functional and task orientated chapters.

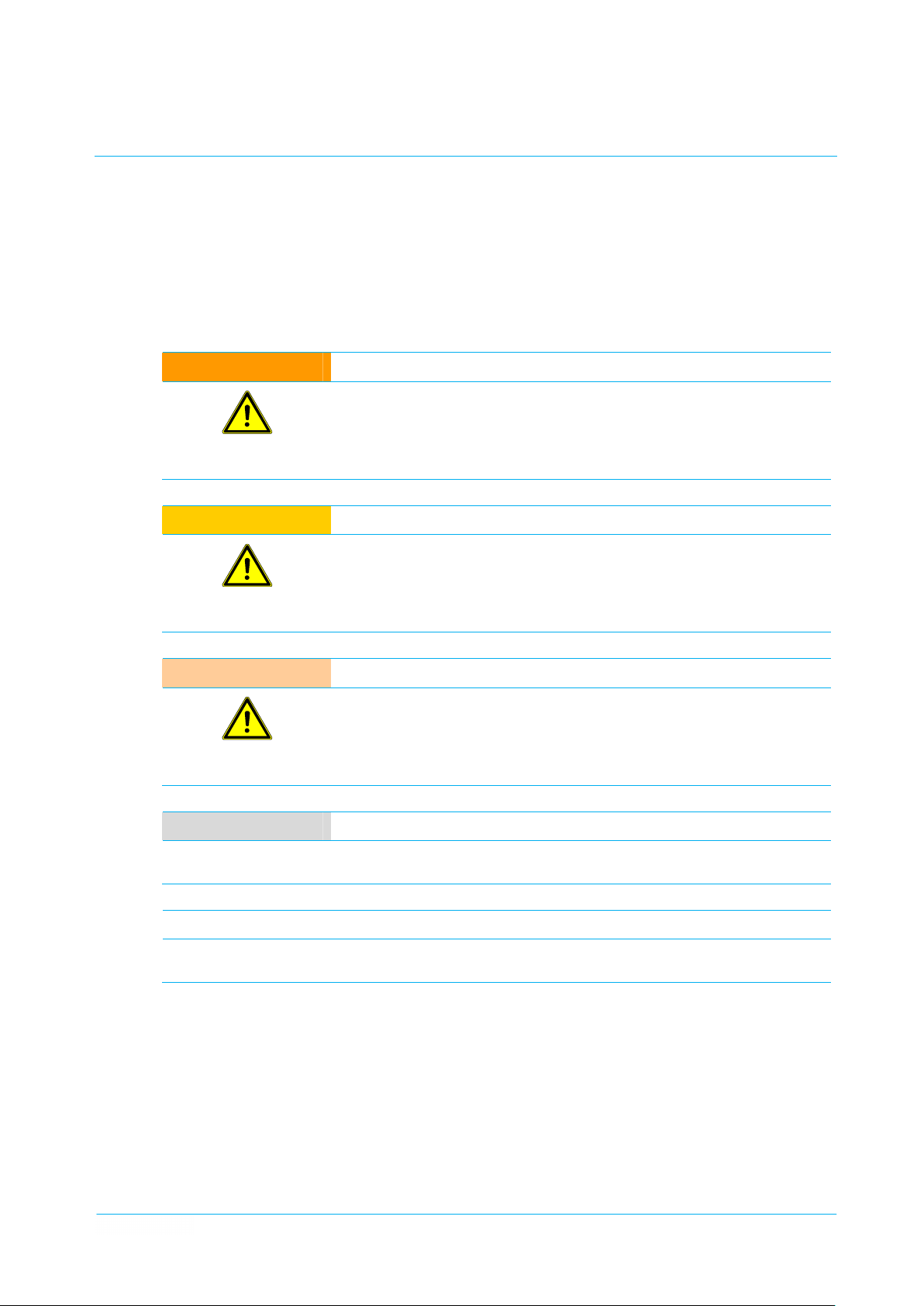

1.6.2 Notes and their illustrations used in the chapters

The warnings and notes are separated from the other text and particularly marked by corresponding icons.

The icon cannot, however, replace the text of the safety instructions. Therefore, always read thoroughly the

full text of the safety instructions. The warnings and notes are separated in these operating instructions as

follows and categorised by the following danger levels by means of various symbols.

DANGER Brief description of danger

There is an imminent danger to life and limb of the user and / or third parties

when the instructions are not followed precisely or the circumstances described are not taken into account.

The type of danger is indicated by a symbol and explained in the accompanying text in more detail. In this example the general sign of danger is used.

WARNING Brief description of danger

There is an indirect danger to life and limb of the user and / or third parties

when the instructions are not followed precisely or the circumstances described are not taken into account.

The type of danger is indicated by a symbol and explained in the accompanying text in more detail. In this example the general sign of danger is used.

ATTENTION Brief description of danger

There is a potential risk of injury or damage to property when the instructions

are not followed precisely or the circumstances described are not taken into

account.

The type of danger is indicated by a general sign and explained in the accompanying text in more detail. In this example the general sign of danger is used.

NOTE Brief description of additional information

Attention is pointed to special conditions or additional important information on

the respective subject.

INFO Short title

Contains additional information on work assisting features or recommendations on the respective subject.

Round Belt Conveyor System

4330054_A2 SGR

| SPV

Chapter 2 Safety Instructions

Page 8 Introduction

2 Safety Instructions

2.1 Introduction

The chapter on safety instructions describes the risks associated with the appliance in terms of product liability (according to the EU Machinery Directive).

The safety instructions should warn of hazards and help to avoid damages to persons, the environment and

property. Please make sure that you have read and understood all the safety instructions given in this chapter.

You must comply with the respectively valid national and international Safety at Work Regulations. The

manager is responsible for the valid regulations he/she has to provide. He/she must acquaint himself/herself

and the operator with the new regulations.

2.2 W

Symbols are used in these operating instructions to point out the dangers that can occur while operating or

cleaning the appliance. In both cases, the symbol provides information on the type and circumstances of

danger.

The following symbols can be used:

arning Symbols Used

General hazardous area

Hazardous electrical voltage

Risk of pulling in

Risk of hand injuries

Risk of crushing

Risk of hot surfaces

Wear hand protection

2.3 Safety Instructions for Appliance Safety

Safe operation of the appliance depends on appropriate and thorough use. Negligent handling of the appliance can lead to danger to life and limb of the user and / or third parties as well as hazards to the appliance

itself and the other operator's property.

The following points are to be observed to ensure the appliance safety:

The appliance may only be operated as intended, when it is in perfect condition with regards to tech-

nical standards, with awareness of safety and hazards and in accordance with the operating instructions.

All the operating and actuating elements must be in a

regards to technical standards.

Only operate the conveyor system when all the safety devices or emergency stop devices are avail-

able and function properly. There should be easy access to the emergency stop button. Do not remove safety devices.

Round Belt Conveyor System

SGR | SPV 4330054_A

perfect and functionally reliable condition with

2

Safety Instructions Chapter 2

Position of the Emergency Stop Button Page 9

Comply with the safety instructions and hazard warnings on the conveyor system and make sure they

are easy-to-read.

The appliance must be checked for external visible damages and defects whenever it is put into op-

eration. In case of damages, inform immediately the competent bodies and switch off the conveyor

system.

Setting up, assembly, dismantling, startup, operating, maintenance and overhaul are only to be car-

ried out by trained operating staff.

Modifications or retrofits of the equipment are only permitted in consultation with the manufacturer

and on receipt of his written agreement.

Stationary conveyor systems are designed for permanent installation.

2.3.1 Special safety instructions for mobile conveyor systems

The conveyor systems are designed only for manual transport. Transport using any kind of devices is

not permitted.

Conveyor systems can start moving on their own and randomly if the casters are not applied.

Switch off the conveyor system, pull out the mains plug and put it on the belt before transporting it.

Never pull the mains plug out of the socket by the lead.

Before moving the conveyor system release the locking brakes. Moving the appliance with the applied

locking brakes can damage the chassis!

Do not move the appliance over inclined surfaces or stairs. When approaching walls and moving

round obstacles always pay attention to persons in the way.

When transporting the conveyor system, do not move it faster than a walking pace. It is difficult to

brake and steer heavily laden appliances. If necessary, ask for assistance when transporting the appliance.

When moving the conveyor system make sure that the appliance will not tip over due to outside influ-

ences or inattention. If, nevertheless, it tips over never try to catch the conveyor system.

Secure the conveyor system against rolling away before putting it into operation.

Do not stop the appliance on sloping floors. Before placing the appliance in position make sure that

the floors are level and even and the conveyor system is level.

2.4 Position of the Emergency Stop Button

Figure 1 Position of the Emergency Stop button (option)

Round Belt Conveyor System

4330054_A2 SGR

| SPV

Chapter 2 Safety Instructions

Page 10 Safety Instructions for Transport and Installation

2.5 Safety Instructions for Transport and Installation

The following points are to be observed when transporting the conveyor system:

When loading, use only hoists and load lifting devices approved for the weight of the parts to be lifted.

On replacing heavy single components and major assemblies they are to be fixed and secured at

hoists in such a way as to rule out any hazards from them.

Securing sling gear at the lifting lugs of the conveyor system must be done in such a way as to rule

out the risk of any falling loads.

Use transport vehicles that are approved for the weight of the conveyor system.

Parts that have possibly been dismantled prior transport must be fitted back and fastened before put-

ting the appliance into operation.

Even in case of a minor relocation switch off the conveyor system at the mains or disconnect it from

any power supply.

In no case put a defective appliance into operation and inform the supplier immediately.

2.6 Safety Instructions for Use and Operation

The following points shall be observed when using and operating the appliance:

Staff are to be instructed in the use and operation of the conveyor system before it is started.

Loose items of clothing (e.g. scarf or tie) and jewellery are not to be worn when working on the con-

veyor system. Otherwise there is the risk of being pulling in by rotating machinery parts.

Unimpeded access to the EMERGENCY STOP button must be on hand at all times.

Make sure that no-one is at risk from a startup up of the conveyor system before switching it on.

2.7 Safety Instructions for Maintenance and Care

The following points shall be observed when carrying out any maintenance operations:

Take the conveyor system out of operation, switch it off and secure against unauthorised reactivation

before performing maintaining or troubleshooting operations. When operating on the electrical installation, the appliance is to be switched off at the mains and secured against reactivation.

Only persons with qualifications and knowledge of electrical engineering may perform maintenance

and repair work on electrical devices.

If it is required to maintain or repair live parts, you should in any case call in a second person.

You have to meet the deadlines for maintenance and care specified in the operating instructions.

Before proceeding with maintenance and repair work close the maintenance area and the access to

the working area for unauthorised persons. If necessary place an indication sign that draws attention

to the running maintenance and repair work.

Observe the valid product safety regulations when handling oils, greases and other chemical sub-

stances.

Lubricants must be compatible with foodstuffs (e.g. edible oil).

Carry out all the checks and inspections of the appliance on a regular basis. Remedy immediately de-

ficiencies, such as loose screw connections, melted or damaged leads.

Fit the dismantled safety devices back to the appliance and check them for proper functionality after

completing maintenance and repair work.

For reasons of hygiene the cleaning instructions shall be strictly observed.

Never clean the running conveyor system.

Do not clean the conveyor system with steam-jet or high-pressure washers.

Round Belt Conveyor System

SGR | SPV 4330054_A

2

Safety Instructions Chapter 2

Safety Instructions for Troubleshooting Page 11

Take the conveyor system out of operation and switch it off at the mains in any area where steam-jet

or high-pressure washers are to be used.

2.8 Safety Instructions for Troubleshooting

The following points shall be observed when carrying out any trouble shooting operations:

The local applicable Accident Prevention Regulations must be observed.

Take the conveyor system out of operation, switch it off and secure against unauthorised reactivation

before performing maintaining or troubleshooting operations. When operating on the electrical installation, the appliance is to be switched off at the mains and secured against reactivation.

Observe the valid product safety regulations when handling oils, greases and other chemical sub-

stances.

Wear suitable protective clothing when carrying out any repair work.

Only authorised specialists may perform all repair work.

Tighten the loosen screw connections and fit the safety devices back to the appliance if dismantled

and check them for proper functionality after completing the repair work.

Defective components should only be replaced with original parts.

2.9 Notes on Specific Hazards

Electrical energy

All work on the electrical installations should only be carried out by a certified electrician or by author-

ised specialists under supervision and monitoring of a certified electrician according to the certain

electro-technical regulations.

The appliances that inspection, maintenance and troubleshooting work is performed on must be

switched voltage free on and secured against reactivation, when the voltage is not required for this

kind of work. This must only be carried out by a certified electrician.

Round Belt Conveyor System

4330054_A2 SGR

| SPV

Loading...

Loading...