Hupfer BKW1/14 L-GN, BKW1/28 B-GN+10PK, BKW1/20 L-GN, BKW1/14 L-GN+5PK, BKW1/36 B-GN Operating Instructions Manual

...

Op

erating Instructions

BKW

Ba

nquet trolley heated | neutral

1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-

GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

91101983_A

1

Chapter 1 Introduction

Page 2 Appliance Information

1 Introduction

1.1 Appliance Information

Appliance designation Banquet trolley heated | neutral

Appliance type/ -s BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN |

BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23

L-GN

Manufacturer HUPFER® Metallwerke GmbH & Co. KG

Dieselstraße 20

48653 Coesfeld

PO 1463

48634 Coesfeld

+49 2541 805-0

+49 2541 805-111

www.hupfer.de

info@hupfer.de

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK |

BKW1/23 L-GN

Read these operating instructions thoroughly and attentively to ensure safe operation and avoid any damages!

Ensure that sources of danger and possible faulty operations have been pointed out to the operating staff.

Subject to modifications

The products covered by these operating instructions have been developed taking into consideration the requirements of the market and the latest technology. HUPFER® reserves the right to modify the products and

appertaining technical documentation in so far as the modifications are in the name of technological progress. The data and weights as well as the description of performance and functions assured in the order

confirmation as binding are always decisive.

Manual edition

91101983_A1

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Introduction Chapter 1

Table of Contents Page 3

1.2 Table of Contents

1 Introduction 2

1.1 Appliance Information 2

1.2 Table of Contents 3

1.3 List of Abbreviations 5

1.4 Definitions of Terms 6

1.5 Orientation Guide 7

1.6 Notes on Use of Manual 8

1.6.1 Notes on the manual structure 8

1.6.2 Notes and their illustrations used in the chapters 8

2 Safety Instructions 9

2.1 Introduction 9

2.2 Warning Symbols Used 9

2.3 Safety Instructions for Appliance Safety 10

2.3.1 Additional safety instructions for heated appliances 10

2.4 Safety Instructions for Transport 11

2.5 Safety Instructions for Cleaning and Care 11

2.6 Safety Instructions for Trouble Shooting 11

2.7 Notes on Specific Hazards 11

3 Description and Technical Data 12

3.1 Performance Description 12

3.2 Intended Use 12

3.3 Improper Use 12

3.4 Appliance Description 13

3.4.1 BKW1/14 L-GN | BKW1/20 L-GN | BKW 1/36 B-GN 13

3.4.2 BKW1/14 L-GN+5P | BKW1/28 B-GN+10PK 13

3.4.3 BKW1/23 L-GN 14

3.4.4 Appliance description 14

3.5 Technical Data 15

3.6 Rating Plate 17

4 Transport, Putting into Operation and Decommissioning 18

4.1 Transport 18

4.2 Putting into Operation 18

4.3 Storage and Recycling 19

5 Operation 20

5.1 Arrangement and Function of the Operating Elements 20

5.2 Operation 21

5.2.1 Heated banquet trolleys 21

5.2.2 Neutral banquet trolley 23

5.3 Measures at the End of Operation 23

5.3.1 Heated banquet trolleys 23

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 1 Introduction

Page 4 Table of Contents

5.3.2 Heated banquet trolleys 23

6 Fault Detection and Troubleshooting 24

6.1 Security Measures 24

6.2 Notes on Trouble Shooting 24

6.3 Fault and Action Table 24

7 Cleaning and Care 25

7.1 Security Measures 25

7.2 Hygiene Measures 25

7.3 Cleaning and Care 25

7.4 Special Care Instructions 26

8 Spare Parts and Accessories 28

8.1 Introduction 28

8.2 Spare Parts and Accessories List 28

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Introduction Chapter 1

List of Abbreviations Page 5

1.3 List of Abbreviations

Abbreviation Definition

BGR Rule of the Professional Association

BGV Regulation of the Professional Association

CE Communauté Européenee

European Community

DIN Deutsches Institut für Normung

German Institute for Standardisation, technical regulations and technical specifications

EC European Community

European Union

EN European Standard

Harmonised standard for the EU market

E/V Spare and wearing part

IP International Protection. The abbreviation IP and a further two-digit index specify the

LED Light Emitting Diode

protection class of a housing.

The first digit: Protection against ingress of solid foreign objects The second digit: Protection against ingress of

water

0 No protection against contact, no protec-

tion against ingress of solid foreign

objects

1 Protection against contact with any large

surface of the body such as the hand,

protection against ingress of foreign

objects >1.97'' (50 mm)

2 Protection against contact with the

fingers, protection against ingress of

foreign objects

>0.47'' (12 mm)

3 Protection against contact with tools,

thick wires or similar objects of >0.1''

(2.5 mm), protection against foreign

objects >0.1'' (2.5 mm)

4 Protection against contact with tools,

thick wires or similar objects of >0.04''

(1 mm), protection against foreign

objects >0.04'' (1 mm)

5 Protection against contact, protection

against dust deposits inside

6 Complete protection against contact,

protection against ingress of dust

7 Protection against ingress of water

8 Protection against pressurised water

0 No protection against ingress of water

1 Protection against vertically falling water

drops

2 Protection against dripping water (at any

angle up to 15° from the vertical)

3 Protection against water drips at any

angle up to 60° from the vertical

4 Protection against water splashing from

any direction

5 Protection against water jets (projected

by a nozzle) at any angle

6 Protection against rough sea or strong

water jets (flood protection)

during temporary immersion

during continuous immersion

Light diode

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 1 Introduction

Page 6 Definitions of Terms

1.4 Definitions of Terms

Term Definition

Authorised specialist An authorised specialist is a specialist that has been trained by the manufacturer, an

Cook&Chill-Kitchens "Cook and Chill": Kitchens where warm food after being cooked is chilled as quickly as

Cook&Serve-Kitchens "Cook and Serve": Kitchens where warm food is served immediately after being

Specialist A specialist is a person who can evaluate work assigned and can individually recog-

Gastronorm Gastronorm is a measurement system applied worldwide, for instance, in food proc-

Control Compare with certain conditions and/or characteristics such as damages, leaks, filling

Machine safety The term of machine safety means all the measures used to avert injury to persons.

Passive layer A non-metallic protective layer on a metallic material that prevents or slows down

Check Compare with certain values such as weight, torque, content, temperature.

Qualified person,

qualified staff

Schuko® The abbreviation of the German term "Protective contact" that indicates a system of

Instructed persons An instructed person is a person who has been instructed on the possible risks result-

authorised service dealer or a company assigned by the manufacturer.

possible.

cooked or kept warm until it is consumed.

nise any possible dangers due to the professional training, specialist knowledge and

experience as well as knowledge of the respective guidelines.

essing plants or large-scale kitchens and catering establishments. The use of standardised sizes makes possible to exchange food pans. The basic size of the gastronorm (GN) 1/1 is 12.8×20.9'' (325×530mm). Items are available in different depths.

levels, heat.

The basis for this are national as well as EC-wide valid directives and laws for protecting users of technical devices and systems.

material corrosion.

Qualified personnel are persons who due to their professional training, experience and

instruction as well as their knowledge of the respective standards, guidelines, accident

prevention regulations and operating conditions have been authorised by a person

responsible for system safety to carry out required activities and can recognise and

prevent any possible danger (definition of specialists according to IEC 364).

domestic plugs and sockets equipped with protective earthed contacts used in most of

Europe.

ing from improper behaviour when carrying out the assigned task as well as on the

necessary protective equipment and protective measures and trained for this task if

necessary.

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Introduction Chapter 1

Orientation Guide Page 7

1.5 Orientation Guide

The front

"The front" means the side where the door and operating elements are arranged and at which the staff loads

the appliance.

The rear

The side named "the rear" means the opposite side of the front side (the front).

The right

The side named "the right" means the side at the right hand side of the front side (the front).

The left

The side named "the left" means the side at the left hand side of the front side (the front).

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 1 Introduction

Page 8 Notes on Use of Manual

1.6 Notes on Use of Manual

1.6.1 Notes on the manual structure

This manual is structured in functional and task orientated chapters.

1.6.2 Notes and their illustrations used in the chapters

The warnings and notes are separated from the other text and particularly marked by corresponding icons.

The icon cannot, however, replace the text of the safety instructions. Therefore, always read thoroughly the

full text of the safety instructions. The warnings and notes are separated in these operating instructions as

follows and categorised by the following danger levels by means of various symbols.

DANGER Brief description of danger

There is an imminent danger to life and limb of the user and / or third parties

when the instructions are not followed precisely or the circumstances described are not taken into account.

The type of danger is indicated by a symbol and explained in the accompanying text in more detail. In this example the general sign of danger is used.

WARNING Brief description of danger

There is an indirect danger to life and limb of the user and / or third parties

when the instructions are not followed precisely or the circumstances described are not taken into account.

The type of danger is indicated by a symbol and explained in the accompanying text in more detail. In this example the general sign of danger is used.

ATTENTION Brief description of danger

There is a potential risk of injury or damage to property when the instructions

are not followed precisely or the circumstances described are not taken into

account.

The type of danger is indicated by a general sign and explained in the accompanying text in more detail. In this example the general sign of danger is used.

NOTE Brief description of additional information

Attention is pointed to special conditions or additional important information on

the respective subject.

INFO Short title

Contains additional information on work assisting features or recommendations on the respective subject.

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Safety Instructions Chapter 2

Introduction Page 9

2 Safety Instructions

2.1 Introduction

The chapter on safety instructions describes the risks associated with the appliance in terms of product liability (according to the EU Low-Voltage Directive 2006/95/EC).

The safety instructions should warn of hazards and help to avoid damages to persons, the environment and

property. Please make sure that you have read and understood all the safety instructions given in this chapter.

You must comply with the respectively valid national and international Safety at Work Regulations. The

manager is responsible for the valid regulations he/she has to provide. He/she must acquaint himself/herself

and the operator with the new regulations.

In addition to these operating instructions, comply with the rules on health and safety at work issued by the

Main Association of the industrial Professional Associations, especially with those that concern the handling

of hot items and risks involved (BGR 110 "Protection of health and safety at work in restaurants" and BGR

111 "Protection of health and safety at work in large-scale kitchens").

2.2 Warning Symbols Used

Symbols are used in these operating instructions to point out the dangers that can occur while operating or

cleaning the appliance. In both cases, the symbol provides information on the type and circumstances of

danger.

The following symbols can be used:

General hazardous area

Hazardous electrical voltage

Risk of hand injuries

Risk of squashing

Risk of hot surfaces

Wear hand protection

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 2 Safety Instructions

Page 10 Safety Instructions for Appliance Safety

2.3 Safety Instructions for Appliance Safety

Safe operation of the appliance depends on appropriate and thorough use. Negligent handling of the appliance can lead to danger to life and limb of the user and / or third parties as well as hazards to the appliance

itself and the other operator's property.

The following points are to be observed to ensure the appliance safety:

The appliance may only be operated as intended, when it is in perfect condition with regards to tech-

nical standards, with awareness of safety and hazards and in accordance with the operating instructions.

All the operating and actuating elements must be in a perfect and functionally reliable condition with

regards to technical standards.

The appliance must be checked for external visible damages and defects whenever it is put into op-

eration. In case of damages, inform immediately the competent bodies and switch off the banquet

trolley.

Modifications or retrofits of the equipment are only permitted in consultation with the manufacturer

and on receipt of his written agreement.

The appliance is provided exclusively for manual transport. Mechanical transport is not permitted.

Risk of injury and damage.

Release both total brakes before commencing transporting. Moving the appliance with the total

brakes locked can damage the chassis

Transport should only be undertaken over level floors. Moving the appliance over very uneven floors

and stair steps can damage the chassis.

Do not stop the banquet trolley by applying the total brakes. The total brakes are designed to be able

to prevent the appliance from unintended moving. Do not stop the appliance on sloping floors. Secure

the appliance against rolling away by applying both total brakes when stopping it.

When approaching walls and moving round obstacles always pay attention to persons in the way.

Risk of injury.

When transporting the appliance, always hold push bars with both hands. Never let go the appliance

while moving it.

When transporting the appliance, do not move it faster than a walking pace. Heavily laden banquet

trolleys are difficult to brake and steer. If necessary, ask for assistance when transporting the appliance.

If the banquet trolley tips over due to outside influences or inattention, never catch it manually. Risk of

injury.

In the case of off-site transport in a vehicle such as a lorry, the appliances should be secured prop-

erly. The total brakes are not sufficient as a transport securing method.

2.3.1 Additional safety instructions for heated appliances

Before transporting, switch off the appliance, pull out the mains plug and insert it into the holder pro-

vided.

Never pull the mains plug out of the socket by the connecting lead.

Never move the appliance by pulling by the connecting lead.

If the mains plug has come into contact with water it must be dried before inserting it into the socket.

Danger to life.

Damaged mains plugs or connecting leads are to be replaced by authorised personnel before the ap-

pliance is reused.

Do not use any extension leads in wet and damp areas.

The crockery temperatures can exceed the permitted maximum temperatures of 149°F (65°C) for

touchable appliance surfaces. Always wear protective gloves when dispensing. Risk of burning.

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Safety Instructions Chapter 2

Safety Instructions for Transport Page 11

Plastic crockery, top and bottom parts of plastic insulated sets and plastic-coated items for keeping

food warm should not be stored or warmed up in heated banquet trolleys. Owing to the high temperatures in the interior of the appliance, the plastics can melt and catch fire.

2.4 Safety Instructions for Transport

The following points are to be observed when transporting the banquet trolley:

When loading, use only hoists and load lifting devices approved for the weight of the parts to be lifted.

Use transport vehicles that are approved for the weight of the banquet trolley.

In no case put a defective appliance into operation and inform the supplier immediately.

2.5 Safety Instructions for Cleaning and Care

The following points shall be observed when carrying out any cleaning and maintenance operations:

Take the banquet trolley out of operation, switch it off, pull out the mains plug and secure against un-

authorised reactivation before performing cleaning and care measures.

For reasons of hygiene the cleaning instructions shall be strictly observed.

Heated appliances must be out of operation and sufficiently cooled before cleaning.

2.6 Safety Instructions for Trouble Shooting

The following points shall be observed when carrying out any trouble shooting operations:

The local applicable Accident Prevention Regulations must be observed.

Take the banquet trolley out of operation, switch it off, pull out the mains plug and secure against un-

authorised reactivation before performing maintaining or trouble shooting operations. When operating

on the electrical installation, the appliance is to be switched off at the mains and secured against reactivation. This work must only be carried out by a certified electrician.

Observe the valid product safety regulations when handling oils, greases and other chemical sub-

stances.

Wear suitable protective clothing when carrying out any maintaining or trouble shooting operations.

Carry out all the checks and inspections of the appliance on a regular basis. Remedy immediately de-

ficiencies, such as loose screw connections, melted or damaged leads.

All trouble shooting work should only be carried out by authorised specialists.

Defective components should only be replaced with original parts.

2.7 Notes on Specific Hazards

Electrical energy

All work on the electrical installations should only be carried out by a certified electrician or by author-

ised specialists under supervision and monitoring of a certified electrician according to the certain

electro-technical regulations.

The appliances that inspection, maintenance and trouble shooting work is performed on must be

switched voltage free on and secured against reactivation, when the voltage is not required for this

kind of work. This must only be carried out by a certified electrician.

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 3 Description and Technical Data

Page 12 Performance Description

3 Description and Technical Data

3.1 Performance Description

Banquet trolleys are intended for hygienic transportation of food in the food service industry and large-scale

catering establishments. Their main function is to transport for short distances and to keep food warm. They

hold up prepared meals in gastronorm containers or already portioned and covered meals on grids.

The unheated banquet trolley BKW1/23 L-GN is designed for transport of gastronorm containers, gastronorm

grids and prepared trays with warm or cold meals for short distances.

Heated banquet trolleys are designed to keep food warm and to transport hot food in gastronorm containers

or portioned meals.

The models BKW1/14 L-GN+5PK and BKW1/28 B-GN+10PK include an additional insulated compartment

that can be used together with a cold storage plate as a cooling compartment. So you can transport either

warm or chilled meals simultaneously.

3.2 Intended Use

Banquet trolleys are only intended to hold up gastronorm containers with prepared food or already portioned

meals on grids. They transport prepared food already portioned on crockery items ready for serving in the

food service industry and large-scale catering establishments.

The intended use means the predetermined procedures, compliance with the indicated specifications and

use of the delivered or additionally available original accessories.

Any other use of the appliance is considered as unintended use.

3.3 Improper Use

Any other use, especially loading of the banquet trolley with the other loads as given, is not permitted.

It is not permitted to cook food.

Transport of living beings, heavy and sharp-edged items, loose crockery items or stacks of crockery items is

not permitted.

Banquet trolleys are not intended to be used as a seating surface or as a storing surface for items. In no

case may people sit down or stand on or in to the appliance.

The manufacturer and suppliers are not liable for any consequential damages resulting from an unintended

use. No liability is assumed and no warranty claims can be submitted for damages caused by improper use.

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Description and Technical Data Chapter 3

Appliance Description Page 13

3.4 Appliance Description

3.4.1 BKW1/14 L-GN | BKW1/20 L-GN | BKW 1/36 B-GN

Figure 1 View of the heated banquet trolley

1 Temperature display 5 Heating panel

2 Push bar 6 Swivel caster with total brake

3 Holder for mains plug 7 Mains plug

4 Door opener 8 Fixed caster

3.4.2 BKW1/14 L-GN+5P | BKW1/28 B-GN+10PK

Figure 2 View of the heated banquet trolley with neutral compartment

1 Temperature display 7 Heated compartment

2 Insulated compartment 8 Door opener

3 Push bar 9 Heating panel

4 Door opener 10 Mains plug

5 Temperature display 11 Swivel caster with total brake

6 Holder for mains plug 12 Fixed caster

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 3 Description and Technical Data

Page 14 Appliance Description

3.4.3 BKW1/23 L-GN

Figure 3 View of the neutral banquet trolley

1 Push bar 3 Swivel caster with total brake

2 Door opener 4 Fixed caster

3.4.4 Appliance description

The banquet trolley is made of stainless steel and its surface is polished.

The appliance is equipped with a door on the front side. The removable support ledge frames are fitted on

the sides in the interior of the appliance to put the Gastronorm containers and/or grids.

The banquet trolley is equipped with two fixed and two lockable swivel casters with total brakes. The banquet

trolley is suitable for transport over carpets owing to a particular size of casters

fitted with special tyres.

The double-walled folding door is a thermal and sound insulation and you can swing it to an angle of 270°

and lock.

Two circumferential protective strips protect the appliance against damages when moving and transporting it.

The push bars of all the banquet trolleys (except BKW1/36 B-GN and BKW1/28 B-GN+10PK) move backwards with respect to the outer contour. This protects fingers sufficiently when holding the handles between

impact protection and push bars in such a way that there is no risk of injury when hitting, for instance, rough

walls.

The neutral banquet trolley BKW1/23 L-GN does not have a heating device.

Heated banquet trolleys (BKW1/14 L-GN, BKW1/20 L-GN and BKW1/36 B-GN) are equipped with a heating

unit with a circulating air blower and a water tank This generates a uniform circulating stream of moist hot air

in the interior of the trolley that prevents food from drying out. Water in the water tank (700 ml) is sufficient for

approx. 3,5 operating hours.

The operating temperature is to be set continuously by means of a rotary thermostat between 30 ℃ and 95

℃. The temperature will be displayed on the display arranged on the door of the banquet trolley. The circulating air blower runs independently of the heating during the complete operation.

The models BKW1/14 L-GN+5PK and BKW1/28 B-GN+10PK are equipped with an additional insulated

compartment above the heat area. This compartment can be equipped additionally with a cold storage plate

to be able to keep the temperature constant in the interior of the compartment for approx. 4 hours at approx.

4℃ when the ambient temperature is approx. 25°C.

If it is intended to transport the banquet trolley by lorry, a transport securing device available at HUPFER

can be used. This additional option must be indicated when ordering.

It is possible to fasten the appliance without causing any damages and transport it safely by lorry due to the

safety holders and reinforced side walls of the banquet trolley.

®

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Description and Technical Data Chapter 3

Technical Data Page 15

3.5 Technical Data

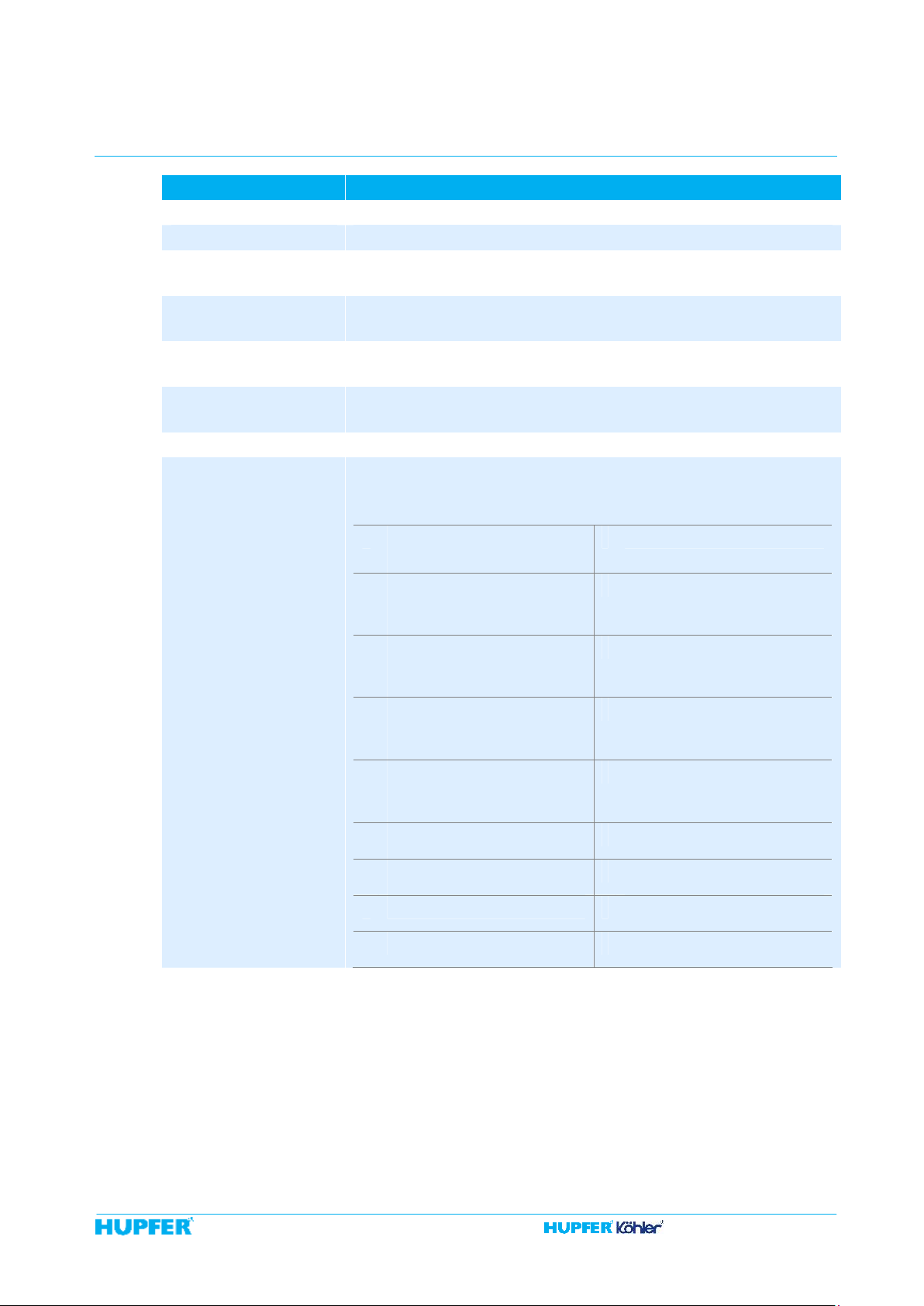

Dim. BKW 1/14 L-GN BKW 1/20 L-GN BKW 1/36 B-GN

Width in

Depth in

Height in

Own weight lbs

Payload lbs

Capacity

(related to grids with

the basic size GN1/1

325×530 mm, that of

the GN containers is

correspondingly

smaller)

Ledge spacing of the

support ledge frames

Operating and environmental conditions

of casters

Caster diameter in

Nominal current A 7 7 7

Nominal voltage V 230 230 230

Frequency Hz 50 50 50

Power requirement W 1600 1600 1600

Protection class IPX4 IPX4 IPX4

Thermostat setting ˚F

Temperature regulation

Maximum crockery

temperature

(mm)

(mm)

(mm)

(kg)

(kg)

14 grids 20 grids 36 grids

in

(mm)

˚F

(˚C)

(mm)

(˚C)

continuous continuous continuous

˚F

(˚C)

25.2’’

(640)

30.5’’

(775)

51.5’’

(1309)

218

(99)

154

(70)

2.3’’

(57.5)

- 4 to +122

(-20 to +50)

5’’

(125)

86-203

(30-95)

176

(80)

25.2’’

(640)

30.5’’

(775)

65’’

(1654)

258

(117)

220.5

(100)

2.3’’

(57.5)

- 4 to +122

(-20 to +50)

5’’

(125)

86-203

(30-95)

176

(80)

31.3’’

(795)

35.2’’

(895)

62’’

(1573)

308.5

(140)

397

(180)

2.3’’

(57.5)

- 4 to +122

(-20 to +50)

6.3’’

(160)

86-203

(30-95)

176

(80)

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 3 Description and Technical Data

Page 16 Technical Data

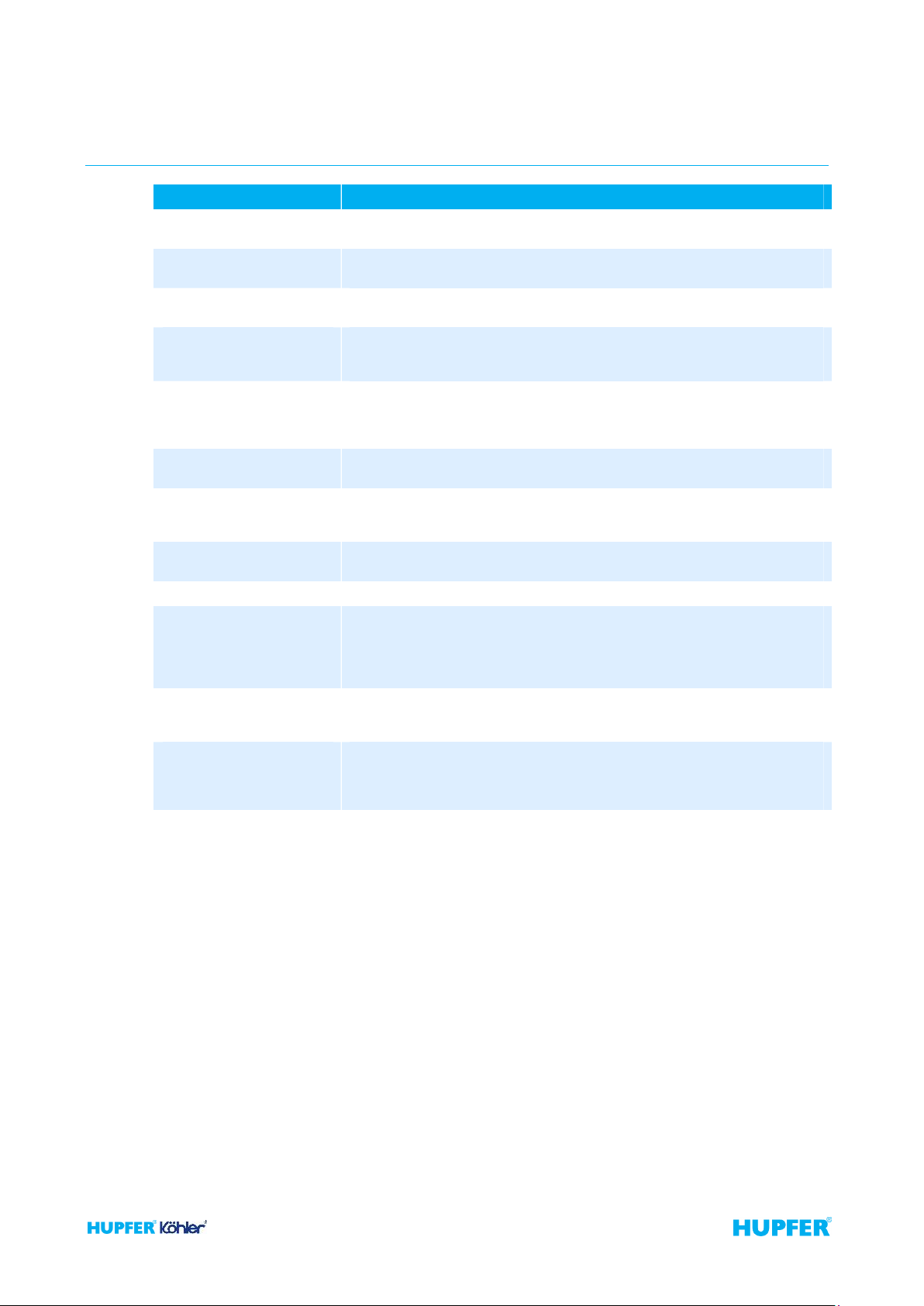

Dim. BKW 1/14 L-GN+5PK BKW1/28 B-GN+10PK BKW1/23 L-GN

Width in

Depth in

Height in

Own weight lbs

Payload lbs

Capacity

(related to grids with

the basic size GN1/1

12.8x20.8’’ (325×530)

mm, that of the GN

containers is correspondingly smaller)

Ledge spacing of the

support ledge frames

Operating and ambient conditions

Caster diameter in

Nominal current A 7 7 Nominal voltage V 230 230 Frequency Hz 50 50 Power requirement W 1600 1600 Protection class IPX4 IPX4 Thermostat setting ˚F

Temperature regulation

Maximum crockery

temperature

(mm)

(mm)

(mm)

(kg)

(kg)

heated: 14 grids

in

(mm)

˚F

(˚C)

(mm)

(˚C)

continuous continuous -

˚F

(˚C)

25.2’’

(640)

30.5’’

(775)

73.1’’

(1858)

328.5

(149)

154 (70) heated,

55 (25) neutral

neutral: 5 grids

heated: 2.3’’ (57,5)

neutral: 2.8’’ (72)

- 4 to +122

(-20 to +50)

5’’

(125)

86-203

(30-95)

176

(80)

31.3’’

(795)

35.2’’

(895)

74.5’’

(1892)

423

(192)

308.5 (140) heated,

110 (50) neutral

heated: 28 grids

neutral: 10 grids

heated: 2.3’’ (57,5)

neutral: 2.8’’ (72)

- 4 to +122

(-20 to +50)

6.3’’

(160)

86-203

(30-95)

176

(80)

25.2’’

(640)

30.5’’

(775)

65’’

(1654)

238

(108)

253.5 (115)

neutral: 23 grids

neutral: 2.3’’ (57,5)

- 4 to +122

(-20 to +50)

5’’

(125)

The corresponding test marks can be found on our home page at www.hupfer.de.

-

-

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Description and Technical Data Chapter 3

Rating Plate Page 17

3.6 Rating Plate

The rating plate is at the bottom right on the rear side of the banquet trolley.

Figure 4 Rating plate

1 Disposal of old appliances 9 Nominal current

2 Test mark 10 Frequency

3 Protection class 11 Nominal voltage

4 Chilling capacity 12 Payload

5 Coolant 13 Own weight

6 Induction frequency 14 Serial number/Order number

7 Current serial number 15 Item and brief description

8 Electric power 16 Manufacturer

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 4 Transport, Putting into Operation and Decommissioning

Page 18 Transport

4 Transport, Putting into Operation and Decommissioning

4.1 Transport

ATTENTION Appliance damages caused by improper transport

In the case of off-site transport in a vehicle such as a lorry, the appliances

should be secured properly. The total brakes are not sufficient as a transport

The banquet trolley is delivered as an assembled unit, i.e. it is completely assembled including the heating

elements.

When loading, use only hoists and load lifting devices approved for appliances 1,5 times heavier than the

banquet trolley to be lifted. Only the transport vehicles may be used that are approved for the weight of the

appliance.

According to the valid purchase contract, the scope of delivery is specified in the shipping documents attached to the delivery item.

securing method.

If the appliances are not secured properly, there is a risk of damage to prop-

erty and persons caused by squashing.

During transport, secure all the individually standing appliances using corre-

sponding transport securing devices. If it is possible, use the transport securing device available at HUPFER® to be able to fasten the banquet trolley in

the lorry without causing any damages.

4.2 Putting into Operation

DANGER Hazardous electrical voltage

The banquet trolley, especially the safety equipment, must be checked for external visible damages and defects whenever it is put into operation. In case of damages, inform immediately the competent bodies and do

not put the banquet trolley into operation.

Remove the original packing and check, whether the appliance is complete and undamaged. In no case put

a defective appliance into operation and inform the supplier immediately.

Always place the banquet trolley on firm and level floors when unpacking and operating it. Apply the total

brakes on both swivel casters to secure the appliance against rolling away.

INFO Disposal of packing material

The electrical voltage may be considerably dangerous to limb and life of persons and lead to injuries.

Before putting the appliance into operation check, whether the power supply

indicated on the rating plate (230V / 50 Hz) corresponds to the local power

supply. Otherwise, do not put the appliance into operation.

Do not use any extension leads in wet areas.

The packing consists of recyclable materials and can be disposed of appropriately. Thereby, the different m aterials are to be separated and disposed in

an environmentally compatible manner. In any case, the local bodies responsible for disposal are to be involved for this purpose.

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Transport, Putting into Operation and Decommissioning Chapter 4

Storage and Recycling Page 19

The interior and exterior of the banquet trolley should be thoroughly cleaned with a soft cloth before putting it

into operation for the first time.

Finally, it is necessary to check whether the appliance functions properly.

The following functions are to be checked separately:

In all the appliances: the function of the total brake.

In the heated appliances: the function of the operating elements and heating.

Before the appliance is put into operation it must be clean and dry.

4.3 Storage and Recycling

Temporary storage must take place in a dry and frost-free environment. The banquet trolley must be kept

covered with a suitable covering material to be protected against dust ingress.

The appliance kept in the storage location must be checked for damages and corrosion every 6 months.

NOTE Condensed water formation

Before the appliance is taken back into operation it must be clean and dry.

If the banquet trolley is required to be recycled, all the operating and auxiliary materials must be disposed in

an environmentally compatible manner. The recyclable materials must be properly separated and disposed

in an environmentally compatible manner according to the local Waste Disposal Regulations. In any case,

the local bodies responsible for disposal are to be involved for this purpose. Separate the reusable materials

of the appliance (casters and plastic parts) before disposing or send the appliance to a recycling centre. Dispose the electronics at corresponding collection centres.

We offer our customers to dispose their waste appliances. Please contact us or one of our distribution partners.

Packaging and packing material can be sent to the recycling centre by indicating the waste disposal contract

number. If you do not have the valid waste disposal contract number, you can ask for it at HUPFER® Service.

Ensure that there is sufficient ventilation and no large temperature fluctuations

in the storage location to avoid condensed water formation.

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 5 Operation

Page 20 Arrangement and Function of the Operating Elements

5 Operation

ATTENTION Appliance damages

Fully loaded banquet trolleys on very uneven floors and steep slopes can lose

their balance and tip over.

The banquet trolley, especially the safety equipment, must be checked for external visible damages and defects whenever it is put into operation. In case of damages, inform immediately the competent bodies and do

not put the banquet trolley into operation.

5.1 Arrangement and Function of the Operating Elements

The operating elements of the heated banquet trolley are arranged under the door on the panel of the heating unit.

Only move the banquet trolley over even floors.

If the banquet trolley tips over due to outside influences or inattention, never

catch it manually.

Figure 5 Heating unit with operating elements

1 Button of the safety thermostat

2 Thermostat knob

3 Control lamp

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Operation Chapter 5

Operation Page 21

Position digit Operating element Function

1 Button of the safety thermostat Springs out, if the safety thermostat has been

2 Thermostat knob Controls heating and maintains the selected

3 Control lamp Light is on, if the heating runs and functions prop-

triggered.

temperature.

The levels of the thermostat knob correspond to

the following temperatures:

0 off

1 approx. 77°F (25°C)

2 approx. 122°F (50°C)

3 approx. 167°F (75°C)

4 approx. 203°F (95°C).

erly. If the temperature has been achieved, the

control lamp goes off.

5.2 Operation

5.2.1 Heated banquet trolleys

WARNING Risk of hot surfaces

If the thermostat is set to the level 3 and higher, the permitted maximum temperature of 149°F (65°C) for touchable appliance surfaces can be exceeded.

This can cause burns.

The appliance set to the level 4 may only be operated by an instructed staff.

Wear suitable protective clothing.

WARNING Danger of escaping steam

Hot steam can escape when opening the door. Risk of burning.

Please stay at a safe distance and wait until the steam has volatilised.

Step 1: Filling the thermal module

The thermal module of the heating unit must be filled with water before each operation.

Pull the mains plug out.

Lift the panel of the heating unit by handles of the module and pull it out.

Alternatively, you can unscrew the water tank.

Fill the thermal module with 25 oz (700 ml) cold water.

Insert the panel of the heating unit back or screw tight the thermal module.

INFO Water supply

The amount of water in the thermal module is sufficient to supply the banquet

trolley with moist hot air for approx. 3,5 operating hours.

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 5 Operation

Page 22 Operation

Step 2: Set temperature

There are the thermostat knob, red button of the safety thermostat, control lamp and the connecting lead arranged on the panel of the removable heating unit.

Connect the banquet trolley to the mains.

Set the desired temperature using the thermostat knob.

WARNING Risk of hot surfaces

If the thermostat is set to the level 3 and higher, the permitted maximum temperature of 149°F (65°C) for touchable appliance surfaces can be exceeded.

INFO Operating temperature

This can cause burns.

The appliance set to the level 4 may only be operated by an instructed staff.

Wear suitable protective clothing.

A temperature of approx. 203°F (95°C) is recommended for a normal operation. If the interior of the banquet trolley is empty, the operating temperature

will be reached in approx. 25 minutes.

Step 3: Loading

After the operating temperature has been reached, the banquet trolley can be loaded with hot food in the

gastronorm containers or meals already portioned on the grids.

WARNING Danger of escaping steam

Hot steam can escape when opening the door. Risk of burning.

NOTE Inserting the gastronorm containers

Please stay at a safe distance and wait until the steam has volatilised.

Leave a space of at least 45 mm between the bottommost gastronorm container and the upper edge of the th ermal module to avoid heat accumulation.

Load the banquet trolley quickly. Ensure that the door does not remain open unnecessarily to keep

heat loss as low as possible during the loading.

Leave the appliance connected to the mains after it has been loaded until the operating tem perature

is reached again. The control lamp on the switch panel switches off when the temperature is reached.

Step 4: Moving

Switch off the banquet trolley using the thermostat knob.

Pull out the mains plug and insert it into the plug park provided on the banquet trolley.

Release the total brakes.

Push or pull the banquet trolley to the destination place.

Apply both total brakes and make sure they are locked and the banquet trolley cannot be moved.

Connect the banquet trolley to the mains.

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Operation Chapter 5

Measures at the End of Operation Page 23

Step 5: Unloading

WARNING Danger of escaping steam

Hot steam can escape when opening the door. Risk of burning.

Please stay at a safe distance and wait until the steam has volatilised.

Select the temperature range using the thermostat knob and switch again the heating on.

We recommend a temperature of approx. 203°F (95 °C). Set to the maximum level about 10 minutes

prior to serving meal and keep this setting until the end of serving.

Proceed with serving as quickly as possible.

If you are supposed to interrupt the serving procedure, close the door immediately!

5.2.2 Neutral banquet trolley

Step 1: Loading

Put gastronorm containers or portioned meals on grids into the banquet trolley. When doing this, en-

sure that the door does not remain open unnecessarily to keep heat loss as low as possible during

the loading.

Step 2: Moving

Release the total brakes.

Push or pull the banquet trolley to the destination place.

Apply both total brakes and make sure they are locked and the banquet trolley cannot be moved.

Step 3: Unloading

Proceed with serving.

If you are supposed to interrupt the serving procedure, close the door.

5.3 Measures at the End of Operation

5.3.1 Heated banquet trolleys

To switch off the heated banquet trolley, proceed as follows:

Switch off the heating using the thermostat knob.

Pull out the mains plug and insert it into the plug park provided on the banquet trolley.

Apply both total brakes in order to secure the appliance against unintended movement.

Allow the thermal module of the banquet trolley to cool down and drain it.

5.3.2 Heated banquet trolleys

To bring the neutral banquet trolley to a standstill, apply both total brakes in order to secure the appli-

ance against movement.

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 6 Fault Detection and Troubleshooting

Page 24 Security Measures

6 Fault Detection and Troubleshooting

6.1 Security Measures

DANGER Hazardous electrical voltage

The electrical voltage may be considerably dangerous to limb and life of persons and lead to injuries.

6.2 Notes on Trouble Shooting

Please contact our service partners in case of malfunctions and complaints within the warranty period. Even

after the warranty period is expired you can have necessary repair work done by our service partners and

certified electricians.

Service work should only be carried out by authorised specialist staff.

Defective components should only be replaced with HUPFER

the replacement of individual components.

In the event of after-sales service and when ordering spare parts specify always the data and corresponding

part number given in the rating plate.

Regular inspection and maintenance of the appliance prevent disruptions to operation and ensure safety.

Before looking for faults, switch off the appliance at the mains. Pull out the

mains plug and insert it into the plug park provided on the banquet trolley.

®

original parts. The modular design simplifies

6.3 Fault and Action Table

Fault Possible cause Action

Safety thermostat gets triggered the

heating switches off, the control lamp

goes off and the small red button of

the safety thermostat on the heating

panel springs out.

Defective caster bearings Replace the casters. Running noise of casters

Sticky surface of the casters Clean the casters with water.

Temperature sensor is damaged or

broken

Overheating of the banquet trolley Allow the appliance to cool down.

Inform service partners and certified

electricians.

Press in the red button to switch

again the heating on. Observe the

temperature display and control by

means of the control lamp, whether

the heating will switch off when the

set temperature is achieved. If this

does not happen or the safety thermostat triggers again, there is a fault.

Inform service partners and certified

electricians.

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Cleaning and Care Chapter 7

Security Measures Page 25

7 Cleaning and Care

7.1 Security Measures

DANGER Hazardous electrical voltage

The electrical voltage may be considerably dangerous to limb and life of persons and lead to injuries.

WARNING Risk of hot surfaces

WARNING Danger of escaping steam

Before cleaning, switch off the appliance at the mains. Pull out the mains plug

and insert it into the plug park provided on the banquet trolley.

The heated appliances can become hot during operation and only cool down

slowly in the air.

For cleaning, open the door of the appliance and let it cool down sufficiently.

7.2 Hygiene Measures

The correct behaviour of the operating staff is decisive for optimal hygiene.

All persons must be informed about the locally valid hygiene regulations, observe them and comply with

them.

Stick a waterproof plaster to cover wounds on the hands and arms.

Never sneeze or cough on clean crockery or meals.

7.3 Cleaning and Care

If the banquet trolleys are handled with care, cleaned and maintained on a regular basis are not exposed to

excess moisture, they do not require any additional care measures.

The interior of the trolley should be cleaned regularly, at the latest every 25 operating hours, to ensure a hygienically perfect operation.

To clean thoroughly and quickly, wipe the interior of the banquet trolley with a soft cloth. Use for cleaning a

soft cleaning cloth or an uncoated sponge. Use degreasing liquid cleansers that are approved for food industry.

To clean the heated banquet trolley, proceed as follows:

Switch off the appliance. Pull out the mains plug and insert it into the holder located on the banquet

trolley.

Open the door.

Let the interior to cool down.

Lift up the support ledge frames and take out from the holders.

Wipe the interior and exterior panelling, heating unit and grids.

The heating unit shall not be splashed with water in any case. This is applied especially to the area with the

electrical components.

Hot steam can escape when opening the door. Risk of burning.

Please stay at a safe distance and wait until the steam has volatilised.

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 7 Cleaning and Care

Page 26 Special Care Instructions

Never use high-pressure cleaner, chloride-containing cleaning agents, abrasive cleaning powder or other dry

cleaning agents, steel wool, steel sponges and/or sharp-edged items.

The neutral banquet trolley

Table of care measures

Cleaning and care measures

Interior of the banquet trolley clean

ball bearing mounted casters pivoted on the axle lubricate

Connecting lead: mechanical damages and obsolescence check

Mains plug: mechanical damages and obsolescence check

x1 = if necessary, every 25 operating hours at the latest

x2 = every 2 months

x3 = every 6 months

7.4 Special Care Instructions

The resistance to corrosion of stainless steels is based on a passive layer which is formed on the surface

when oxygen is admitted. The oxygen in the air is sufficient for the formation of the passive layer, so that

faults or damage to the passive layer can be remedied agai n automatically by mechanical action.

The passive layer develops or reforms more quickly when the steel comes into contact with flowing water

containing oxygen. The passive layer can be chemically damaged or disrupted by agents having a reducing

(oxygen-consuming) action when the steel comes into contact with them in concentrated form or at high

temperatures.

Such aggressive substances are for example:

substances containing salt and sulphur

chlorides (salts)

seasoning concentrates (e.g. mustard, vinegar essence, seasoning cubes, saline solutions)

Further damages can occur due to:

extraneous rust (e.g. from other components, tools or rust film)

iron particles (e.g. grinding dust)

contact with non-ferrous metals (element formation)

lack of oxygen (e.g. no admission of air, low-oxygen water).

General working principles for the handling of appliances made of "refined stainless steel":

Always keep the surface of appliances made from stainless steel clean and accessible to the air.

Use cleaning agents suitable for stainless steel. No bleaching and chloride-containing cleaning

agents should be used.

Remove layers of lime scale, grease, starch and egg-white daily by cleaning. Corrosion can occur

underneath these layers due to lack of air admission.

After each cleaning operation remove all cleaning agent residues by wiping thoroughly. Afterwards,

the surface should be thoroughly dried.

Do not bring parts made from stainless steel into contact with concentrated acids, seasonings, salts

etc. for longer than is absolutely necessary. Acid fumes which generate during cleaning of tiles also

promote the corrosion of "refined stainless steel".

Action

daily

wweekly

monthly

x1

x2

x3

x3

Interval

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Cleaning and Care Chapter 7

Special Care Instructions Page 27

Avoid damaging the surface of the stainless steel, particularly by metals other than stainless steel.

Residues of extraneous metals produce extremely small amounts of chemical elements which can

cause corrosion. In any case, contact with iron and steel should be avoided because that leads to extraneous rust. If stainless steel comes into contact with iron (steel wool, steel particles from pipes, water containing iron), this can be a trigger for corrosion. Therefore, for mechanical cleaning use exclusively refined steel wool or brushes with natural, plastics or refined steel bristles. Steel wool or

brushes with unalloyed steel lead to extraneous rust due to abrasion.

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 8 Spare Parts and Accessories

Page 28 Introduction

8 Spare Parts and Accessories

8.1 Introduction

Service work should only be carried out by authorised specialist staff.

Defective components should only be replaced with HUPFER® original parts. That is the only way to guaran-

tee a safe operation and long service life together with a high transport capacity.

In the event of after-sales service and when ordering spare parts specify always the data and corresponding

part number given in the rating plate.

Always give the order number and corresponding part number when ordering replacement parts. The order

number is given on the rating plate of the banquet trolley.

Always stockpile a full set of replacement parts as a reserve or make a maintenance contract with a specialised dealer to avoid standstill times.

8.2 Spare Parts and Accessories List

BKW1/23 L-GN

Spare part, part number Item designation Type Q-ty

4164026 Closing element PA6 182/35/28 black 1

014164029 Pin for closing element 1

91157180 Extension for drain plug spring-loaded PA6 Ø29/28 sw 1

4002973 Silicone profile Lip seal, yard goods 1

4000400 Fixed caster Polymer P3/125 2

4000402 Swivel caster Polymer P3/125 m.F. 2

BKW1/14 L-GN | BKW1/20 L-GN

Spare part, part number Item designation Type Q-ty

4164026 Closing element PA6 182/35/28 black 1

014164029 Pin for closing element 1

91157180 Extension for drain plug spring-loaded PA6 Ø29/28 sw 1

4002973 Silicone profile Lip seal, yard goods 1

4000400 Fixed caster Polymer P3/125 2

4000402 Swivel caster Polymer P3/125 m.F. 2

91089438 Thermometer 0-120°C (68-230°F) 1

91177229 Safety temperature limiter 180°C 1Ö Kl.1500 1

91090164 Indicator lamp 230V AC green 1

4001203 Thermostat 30-115°C 1S / switch 2S UL 1

4001507 Lead Wend H07BQ-F 3G1,5/2500 WS-DEFH 1

4001401 Fan Axial 80/80/38 230VAC 50Hz 12,5W 1

91024188 Heating element 4404 Ø6,4/2307 230V 1600W 1

4001400 Fan Radial 230VAC 50Hz 32W 1

91093679 Switch with double break 1

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Spare Parts and Accessories Chapter 8

Spare Parts and Accessories List Page 29

BKW1/36 B-GN

Spare part, part number Item designation Type Q-ty

4164026 Closing element PA6 182/35/28 black 1

014164029 Pin for closing element 1

91157180 Extension for drain plug spring-loaded PA6 Ø29/28 sw 1

4002973 Silicone profile Lip seal 1

4000152 Fixed caster St galv. T1/160 2

4000151 Swivel caster St galv. T1/160 m.F. 2

91089438 Thermometer 0-120°C (68-230°F) 1

91177229 Safety temperature limiter 180°C 1Ö Kl.1500 1

91090164 Indicator lamp 230V AC green 1

4001203 Thermostat 30-115°C 1S / switch 2S UL 1

4001507 Lead Wend H07BQ-F 3G1,5/2500 WS-DEFH 1

4001401 Fan Axial 80/80/38 230VAC 50Hz 12,5W 1

91024188 Heating element 4404 Ø6,4/2307 230V 1600W 1

4001400 Fan Radial 230VAC 50Hz 32W 1

91093679 Switch with double break 1

BKW 1/28 B-GN+10PK

Spare part, part number Item designation Type Q-ty

4164026 Closing element PA6 182/35/28 black 2

014164029 Pin for closing element 1

91157180 Extension for drain plug spring-loaded PA6 Ø29/28 sw 2

4002973 Silicone profile Lip seal 2

4000152 Fixed caster St galv. T1/160 2

4000151 Swivel caster St galv. T1/160 m.F. 2

91089438 Thermometer 0-120°C (68-230°F) 2

91177229 Safety temperature limiter 180°C 1Ö Kl.1500 1

91090164 Indicator lamp 230V AC green 1

4001203 Thermostat 30-115°C 1S / switch 2S UL 1

4001507 Lead Wend H07BQ-F 3G1,5/2500 WS-DEFH 1

4001401 Fan Axial 80/80/38 230VAC 50Hz 12,5W 1

91024188 Heating element 4404 Ø6,4/2307 230V 1600W 1

4001400 Fan Radial 230VAC 50Hz 32W 1

91093679 Switch with double break 1

Banquet trolley heated | neutral

91101983_A1 BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN

Chapter 8 Spare Parts and Accessories

Page 30 Spare Parts and Accessories List

BKW1/14 L-GN+5PK

Spare part, part number Item designation Type Q-ty

4164026 Closing element PA6 182/35/28 black 2

014164029 Pin for closing element 1

91157180 Extension for drain plug spring-loaded PA6 Ø29/28 sw 2

4002973 Silicone profile Lip seal, yard goods 2

4000400 Fixed caster Polymer P3/125 2

4000402 Swivel caster Polymer P3/125 m.F. 2

91089438 Thermometer 0-120°C (68-230°F) 2

91177229 Safety temperature limiter 180°C 1Ö Kl.1500 1

91090164 Indicator lamp 230V AC green 1

4001203 Thermostat 30-115°C 1S / switch 2S UL 1

4001507 Lead Wend H07BQ-F 3G1,5/2500 WS-DEFH 1

4001401 Fan Axial 80/80/38 230VAC 50Hz 12,5W 1

91024188 Heating element 4404 Ø6,4/2307 230V 1600W 1

4001400 Fan Radial 230VAC 50Hz 32W 1

91093679 Switch with double break 1

Banquet trolley heated | neutral

BKW1/14 L-GN | BKW1/20 L-GN | BKW1/36 B-GN | BKW1/14 L-GN+5PK | BKW1/28 B-GN+10PK | BKW1/23 L-GN 91101983_A1

Loading...

Loading...